Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce broken rice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rice process

The invention discloses a rice process in the technical field of rice processing. The rice process comprises the steps of: impurity removal; dehumidification: paddies are paved in a drying room for drying by a hot air drying method to reach the paddy water content of 12-14%, and the hot air temperature is 35-45 DEG C; primary rice milling: the unshelling rate reaches 60-80%; attachment of water mist on the surfaces of semi-finished products by an atomization method; drying of the semi-finished products by cold air to reach the semi-finished product water content of 12-14%; secondary rice milling; polishing; and color sorting and classification. The paddies are cooled before being suffered from a mechanical effect in each link; compared with traditional airing and direct once high-temperature drying, the dehumdification process alleviates the effect of taking away water in the paddies, and is uniform in heating; compared with a traditional process, the rice process combines wetting and drying procedures, adds the wetting and drying, after wetting, steps, and uses secondary rice milling for largely reducing the rice milling rate; and the same one batch of paddies machined by the method reaches the rice milling rate of below 8%.

Owner:双峰县雷打石生态农业农民专业合作社

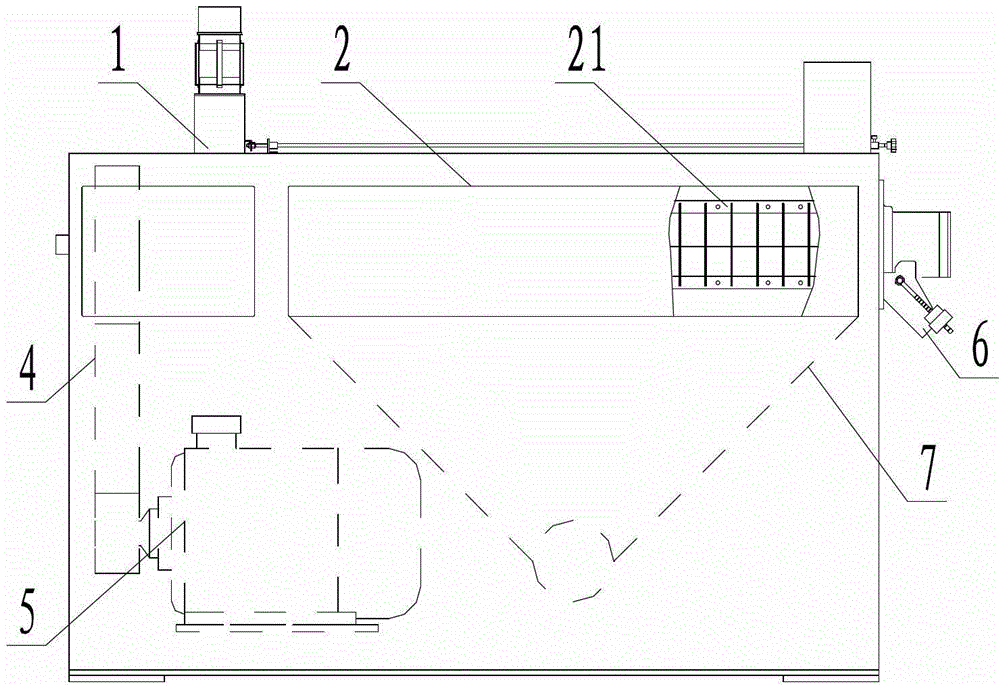

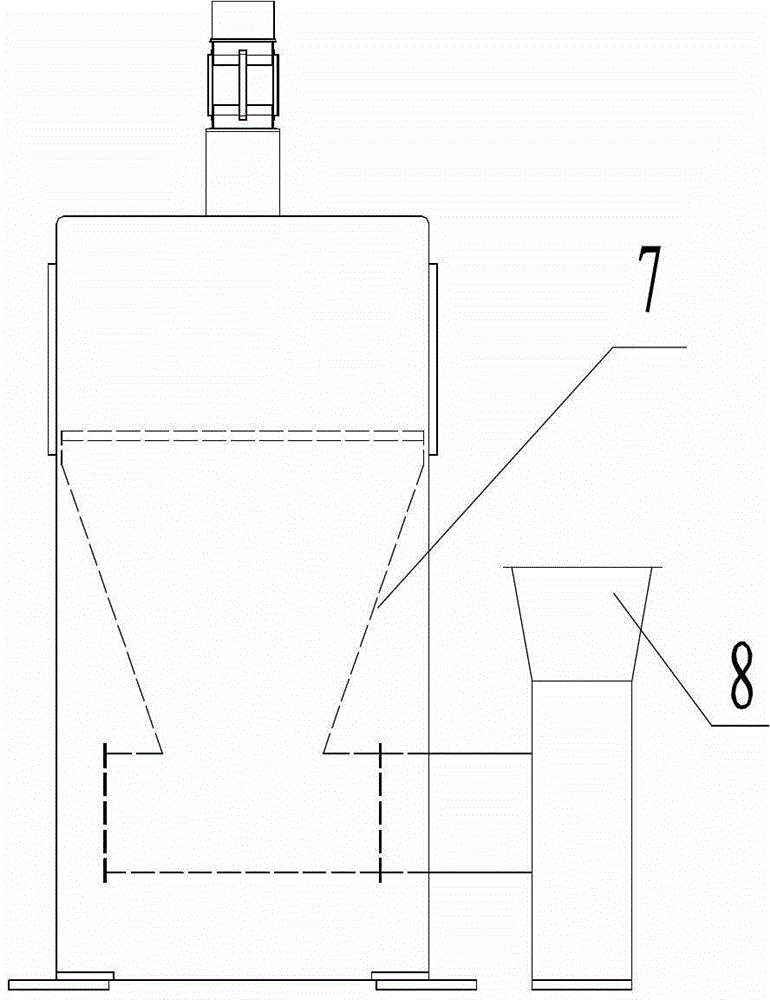

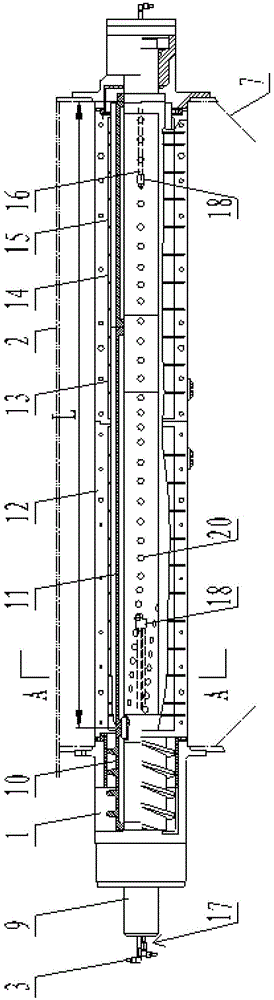

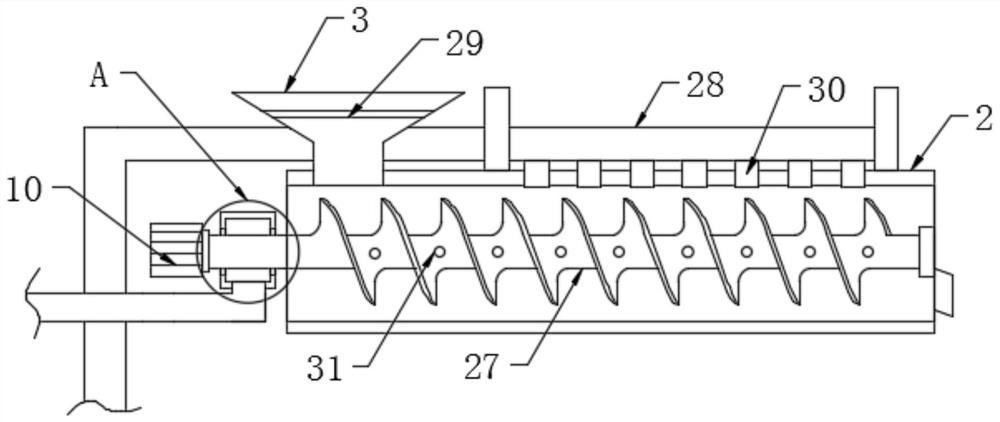

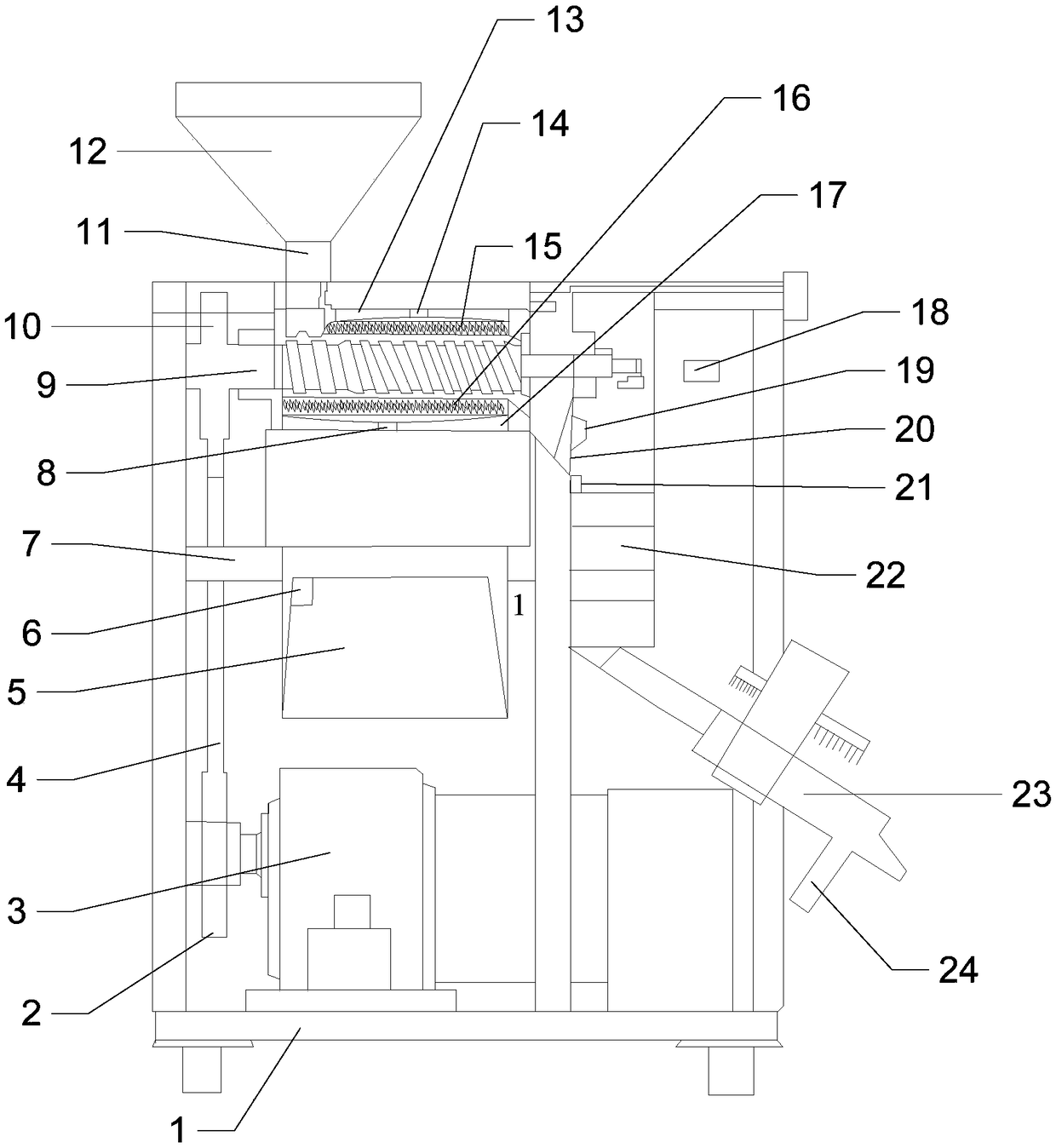

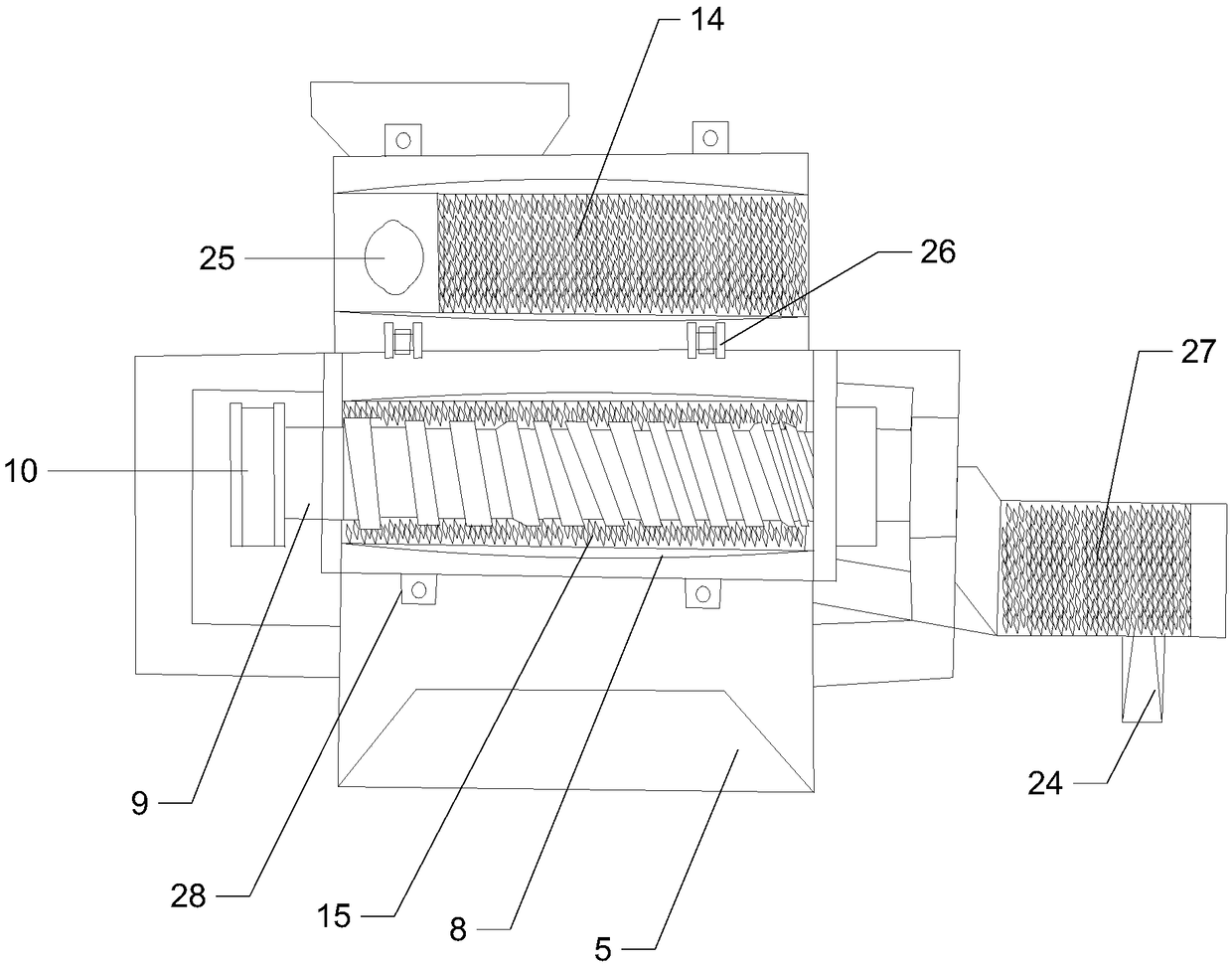

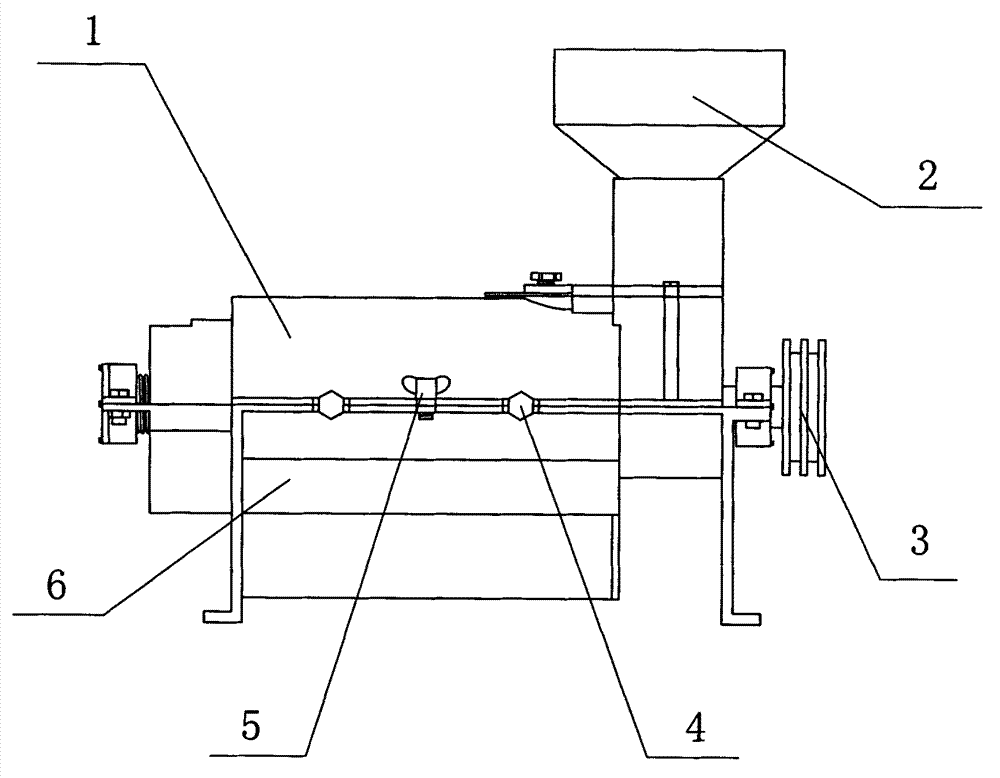

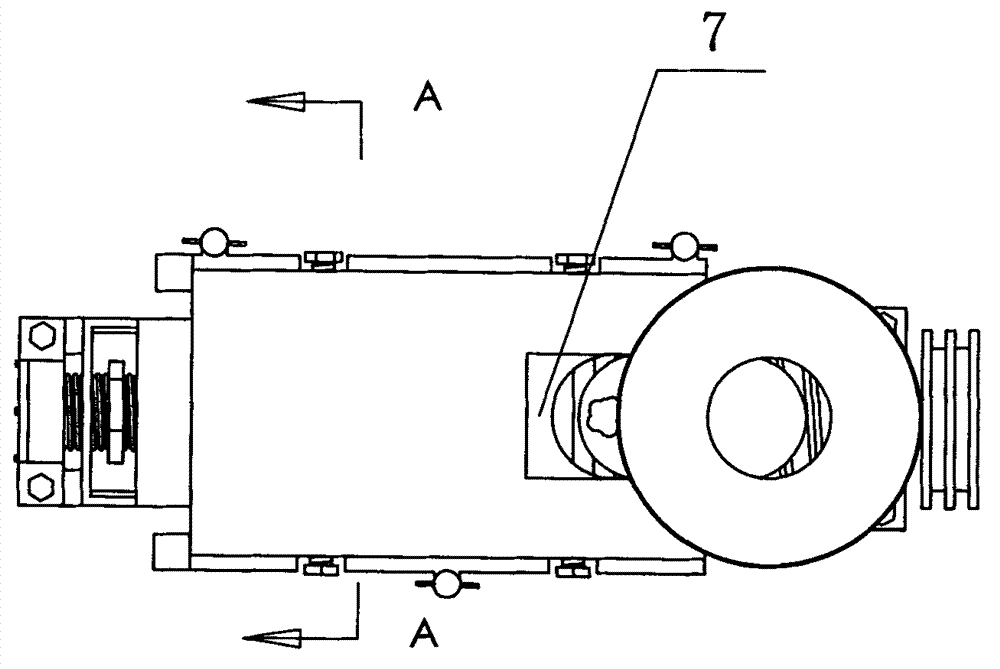

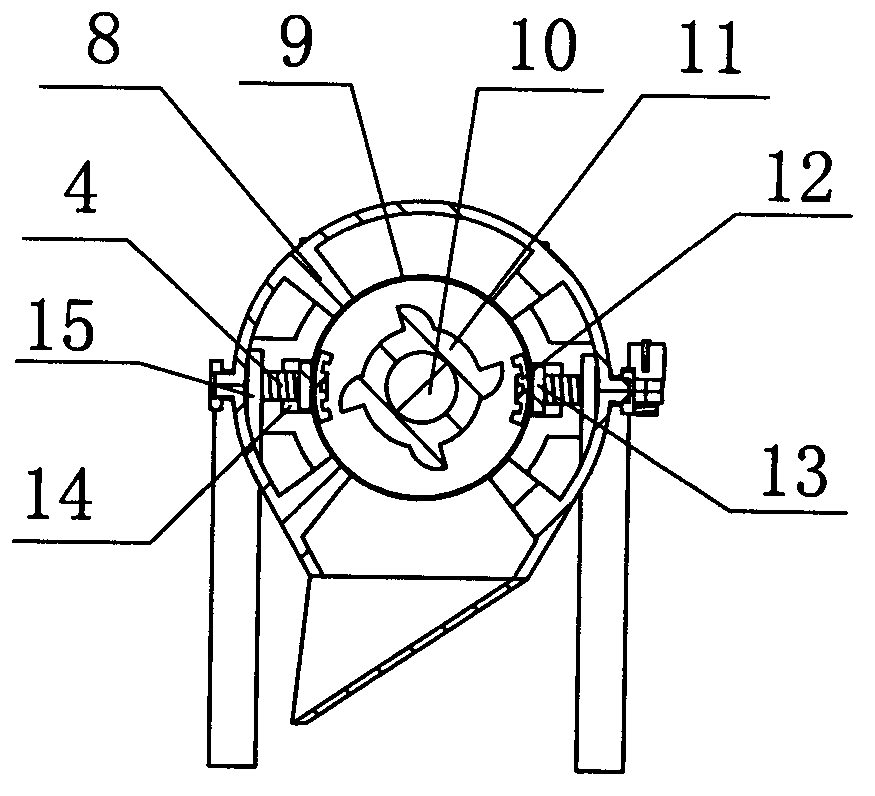

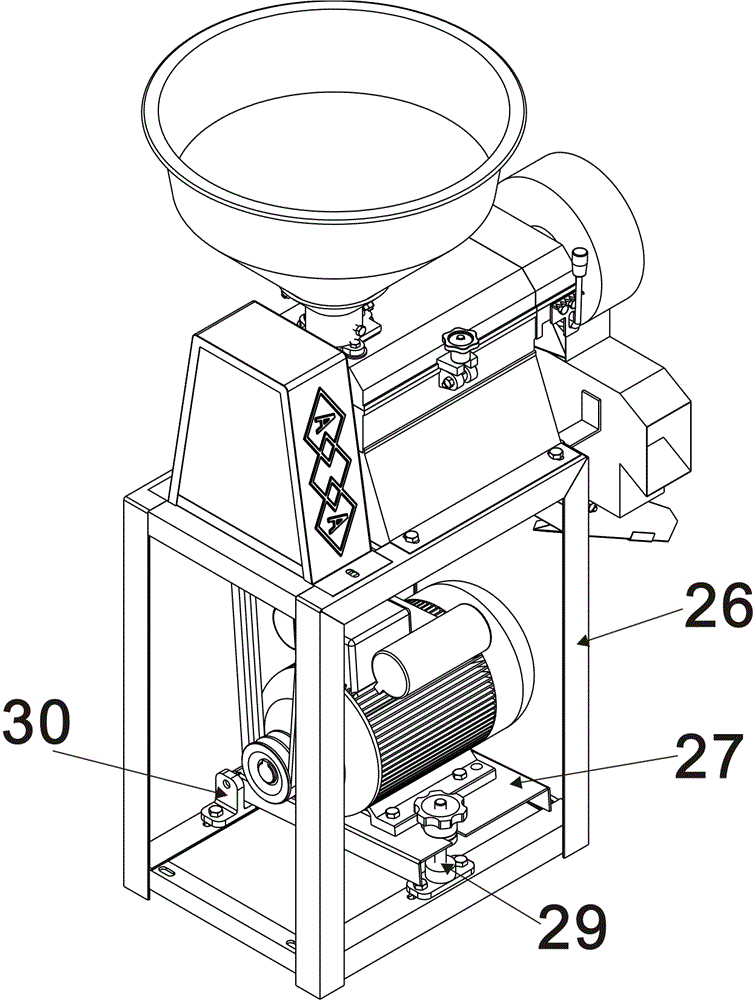

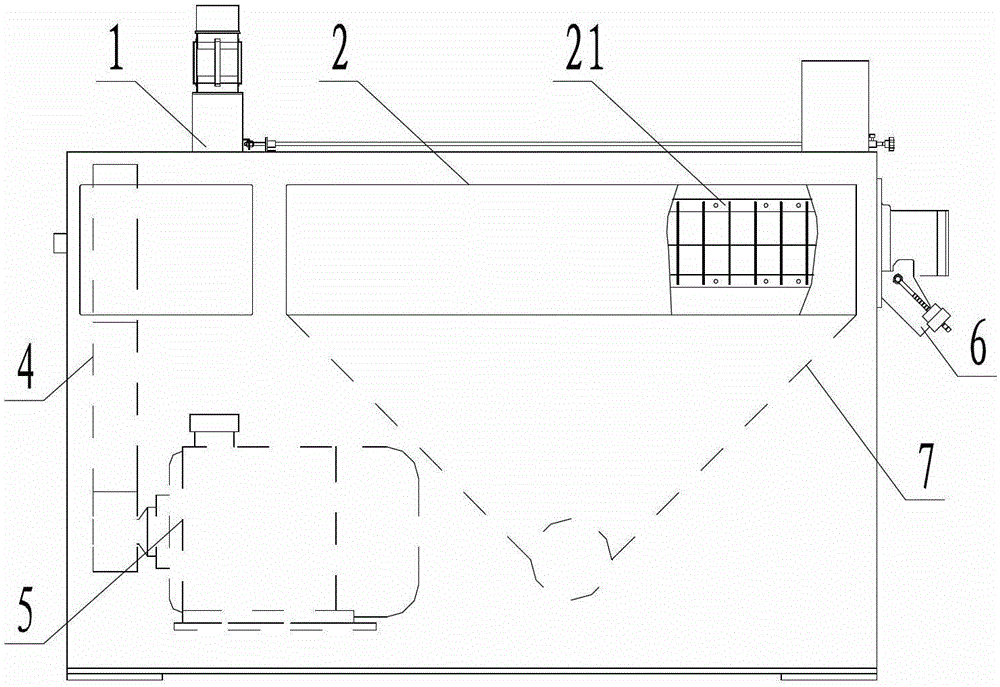

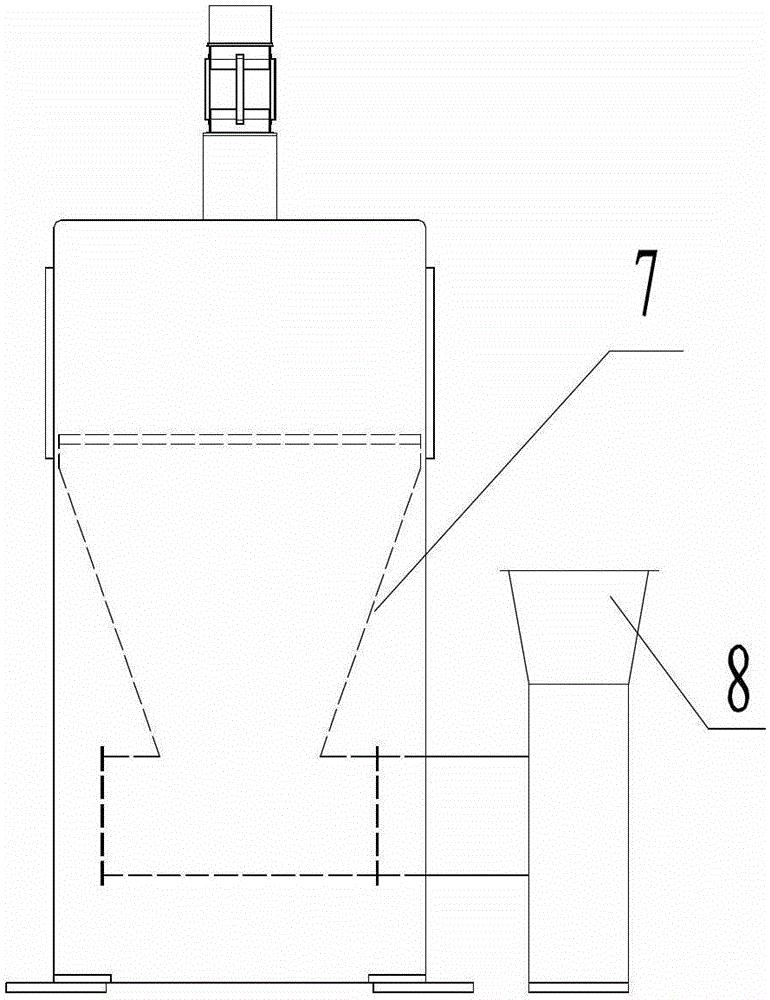

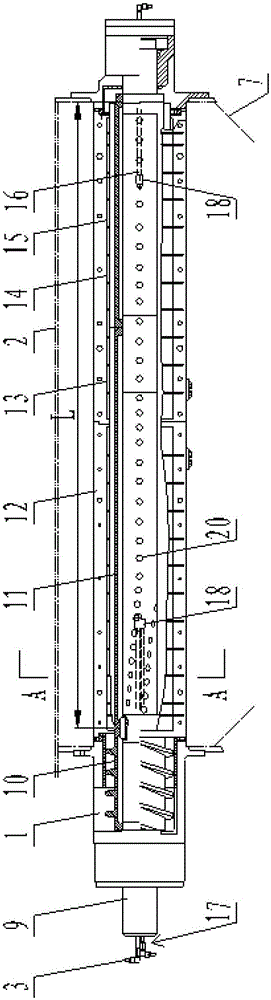

Rice polishing machine

ActiveCN103143409AImprove polishing rateImprove the finishGrain huskingGrain polishingSpray nozzleEngineering

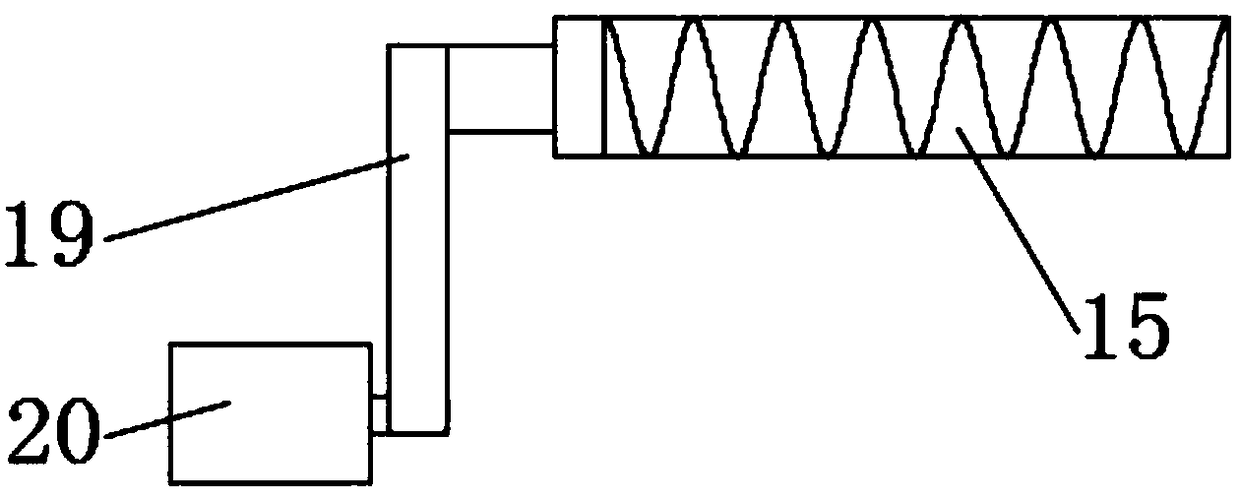

The invention provides a rice polishing machine which comprises a fan (8); a backing strip (15) is fixedly arranged on a crossbeam (14); a feed opening (1) is fed into a first end above a thruster (10); a discharge port (6) is positioned on the tail end below a polishing chamber (21); spray nozzles (18) are connected onto the ends of a pressure air pipe (3) and a water injection pipe (26); the spray nozzles (18) penetrate through an upper crossbeam (14) and the backing strip (15) and are fed into the polishing chamber (21); and the length of a polishing roll (11) is 1000mm to 2000mm, and the outer diameter of the polishing roll (11) is 150mm to 190mm. The rice polishing machine overcomes the defects that an existing rice polishing machine has a non-uniform dampening method and small output and the rice is easily crushed, and has the advantages of uniform dampening method, low rice crushing rate and large output.

Owner:WUHAN KINHE FOOD MACHINERY

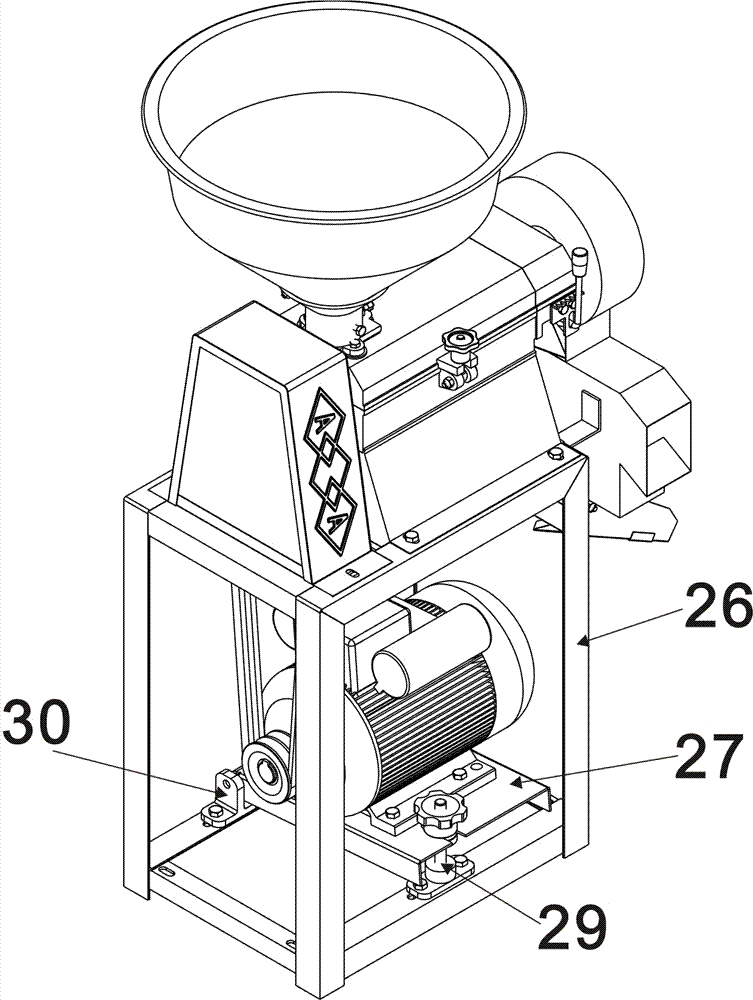

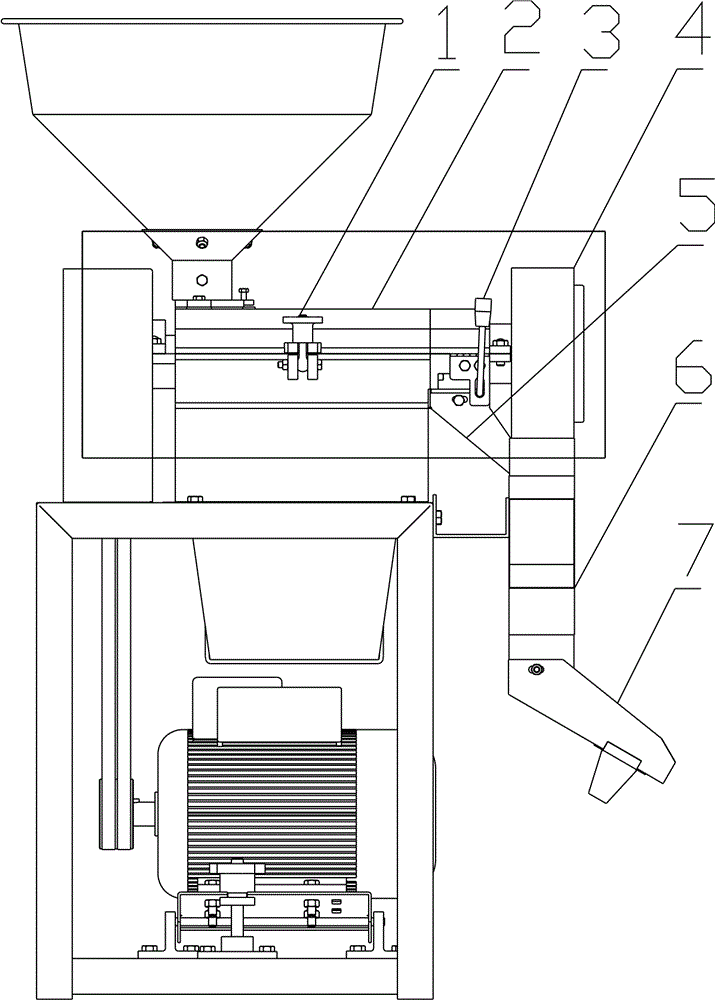

Rice polisher

The invention discloses a rice polisher which is characterized in that a shell can be locked or unlocked by a plum blossom hand wheel, a hopper seat is arranged on the shell, a feeding hopper and the hopper seat are fixed, a rice roller is arranged inside the shell, one end of the rice roller and a belt wheel are fixed, the belt wheel is connected with a motor through a belt, a safety protection cover is arranged at the belt wheel, a screw pushing end corresponding to the rice roller corresponds to the lower portion of the hopper seat, a body portion of the rice roller is made of high abrasion resistant arc-shaped rice milling ribs and positioned in an equilateral polygonal rice sieve to form a rice milling chamber, the right side of the rice roller penetrates a rear bearing block, the right end of the rice roller is arranged inside a fan shell and is fixedly provided with a wind wheel, a rice baffle and a spring are arranged on the right side of the rice roller and adjusted by a shifting fork, and the shifting fork is connected with an accuracy adjusting handle. The rice polisher is simple in structure, convenient to operate, safe and fine in rice milling quality and more importantly solves the problems of more broken rice and low milled rice rate of an existing rice milling device, and energy is saved.

Owner:四川省旭东机械制造有限公司

Rice grain production and processing technology

The invention provides a rice grain production and processing technology, and relates to the technical field of rice processing. The rice grain production and processing technology comprises the following steps that after acceptance of unhusked rice, the unhusked rice is stacked in a warehouse, the unhusked rice is screened in sunny days and impurities such as weeds, rice stems and stones are removed, then the unhusked rice is placed in a magnetic separator for iron removal, then the unhusked rice is dried for 1-3d and then transferred to a drying room, and a hot-air blower is used for hot-airdrying of the unhusked rice; the unhusked rice is transported by a belt conveyor to a rice huller for husking; brown rice is transported to a rice mill for three times of rice milling treatment in sequence, the brown rice is atomized between the first and second times of rice milling treatment, and the brown rice is dried by 1-5 DEG C drying air between the second and third times of rice millingtreatment; and the rice cooled to the room temperature is polished and then placed in a color sorting machine for color sorting, and then rice finished products can be sterilized and packaged. Compared with a general rice grain production and processing technology, the broken rice rate is greatly reduced, the quality of rice grains is greatly improved, and the added value of the products is increased.

Owner:乐山惠田米业有限公司

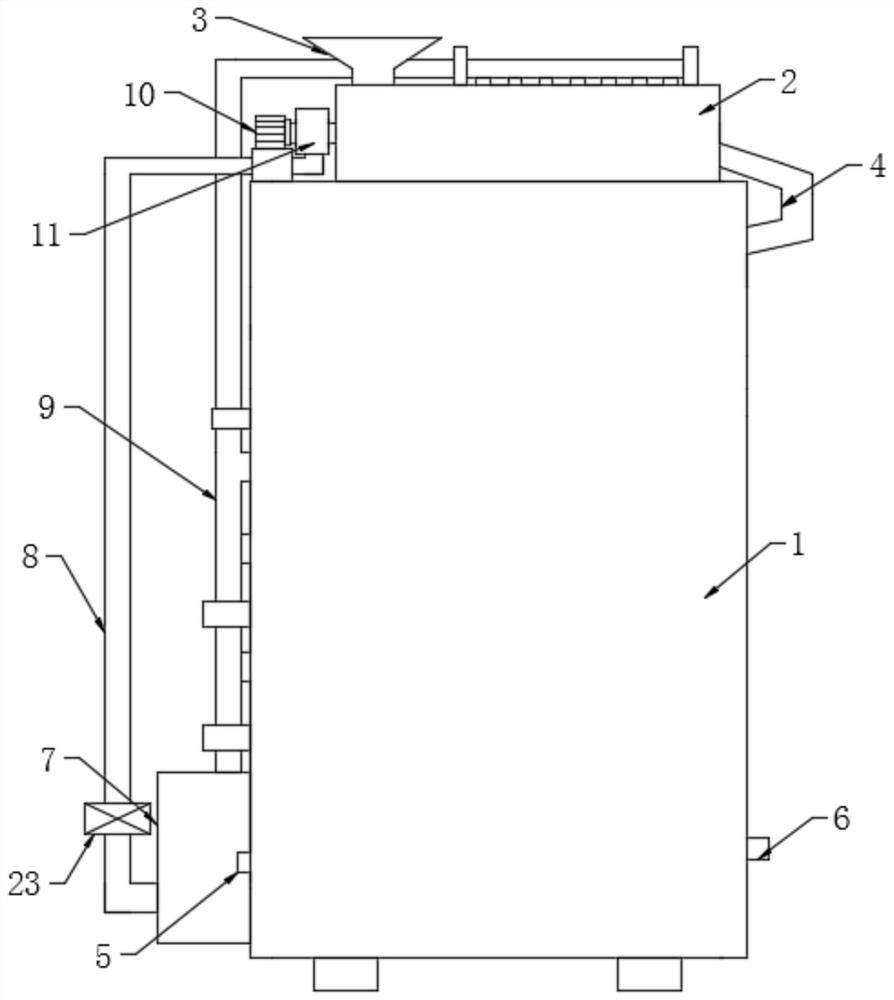

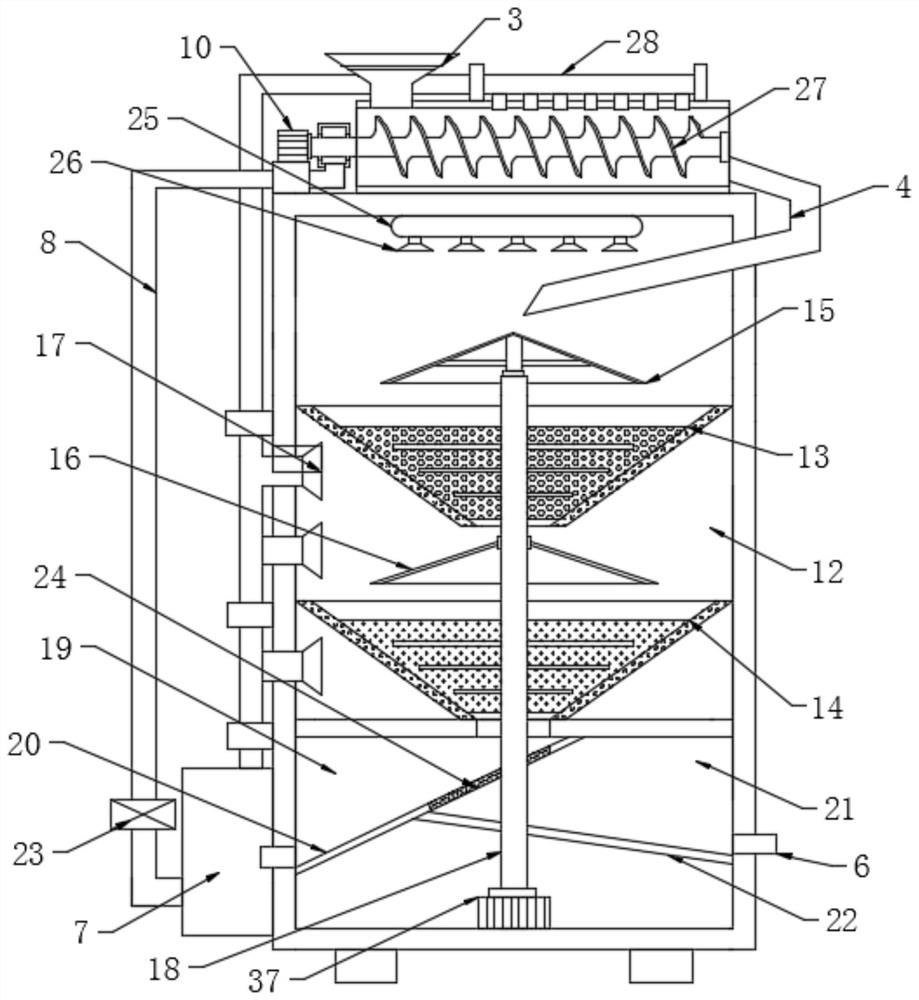

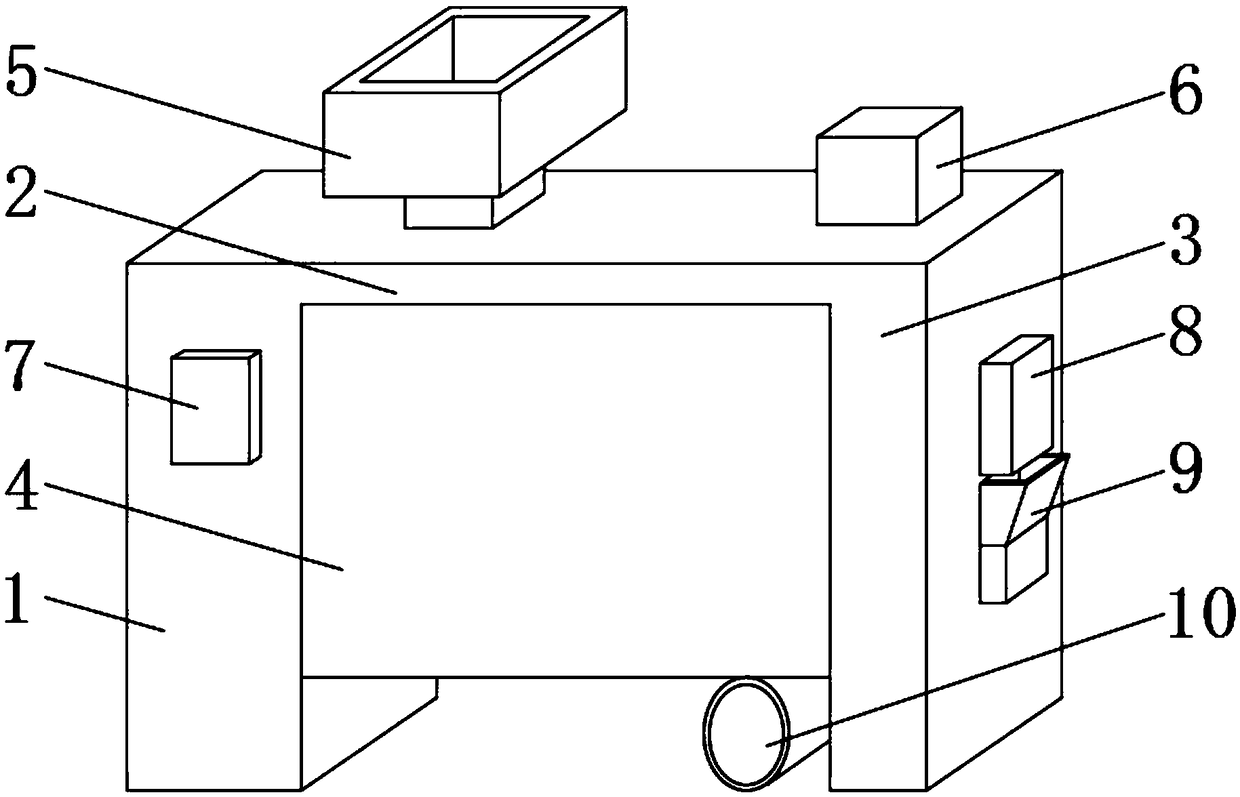

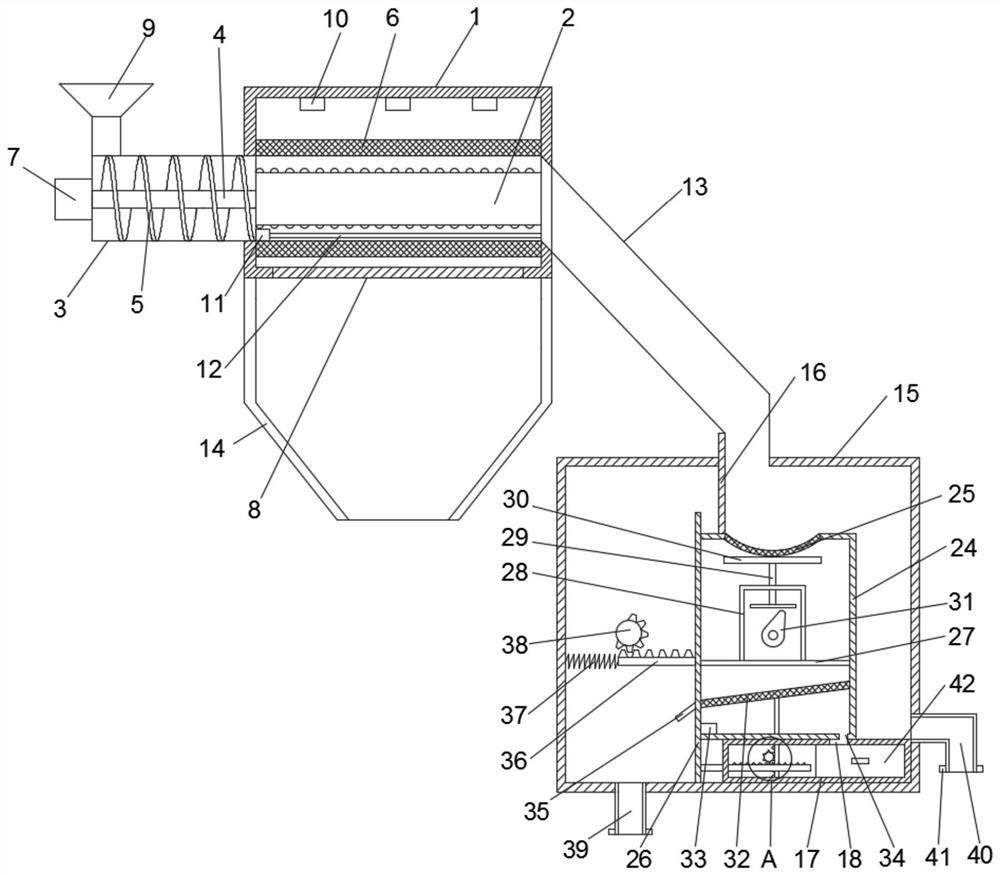

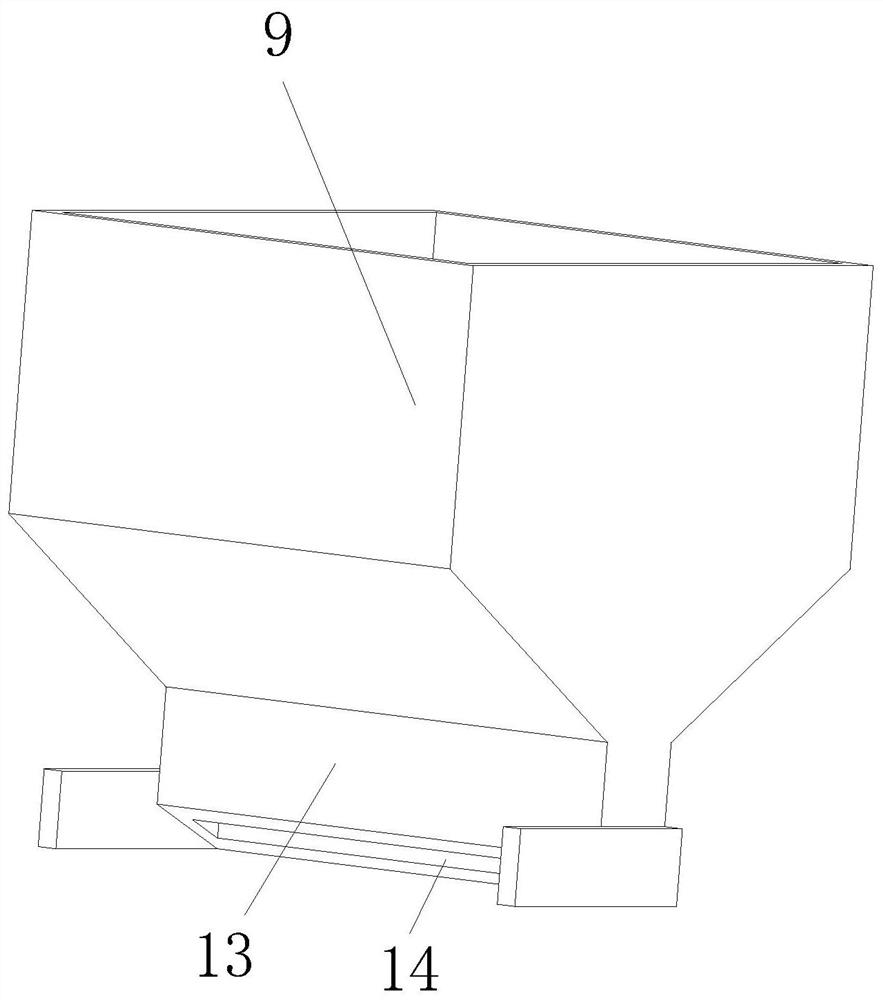

Full-automatic rice polisher

InactiveCN111686841AImprove polishing effectAvoid crushing pressureGrain huskingGrain polishingElectric machinePolishing

The invention discloses a full-automatic rice polisher. The full-automatic rice polisher comprises a box, a screening mechanism, a polishing mechanism and a separating mechanism; the screening mechanism is positioned on the top of the box; the polishing mechanism and the separating mechanism are positioned in the box; the polishing mechanism comprises a polishing chamber, a first polishing groove,a second polishing groove and a rotating shaft; both the first polishing groove and the second polishing groove are fixedly installed in the polishing chamber; a second motor is arranged at the bottom in the box; and the output shaft of the second motor is fixedly connected with the rotating shaft. According to the full-automatic rice polisher in the invention, due to arrangement of the first polishing groove and the second polishing groove, rice can be polished for the first time by utilization of the first polishing groove; furthermore, the rice polished for the first time fall into the second polishing groove to be polished again; due to two-time polishing, the good polishing effect can be ensured; furthermore, polishing is carried out by adoption of polishing grains; the grinding force generated by polishing through a polishing roller can be avoided; and broken rice while polishing can be effectively reduced.

Owner:JIANGXI DONGJIAN AGRI DEV CO LTD

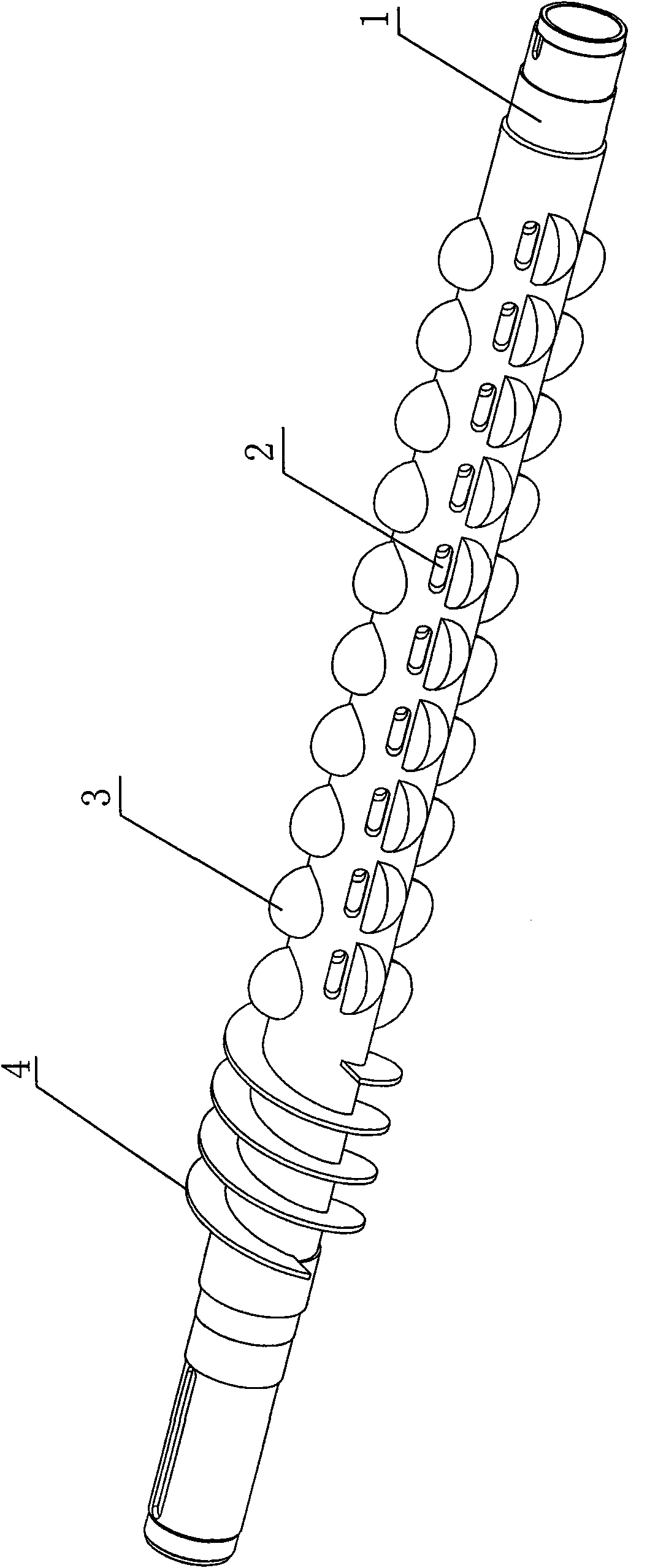

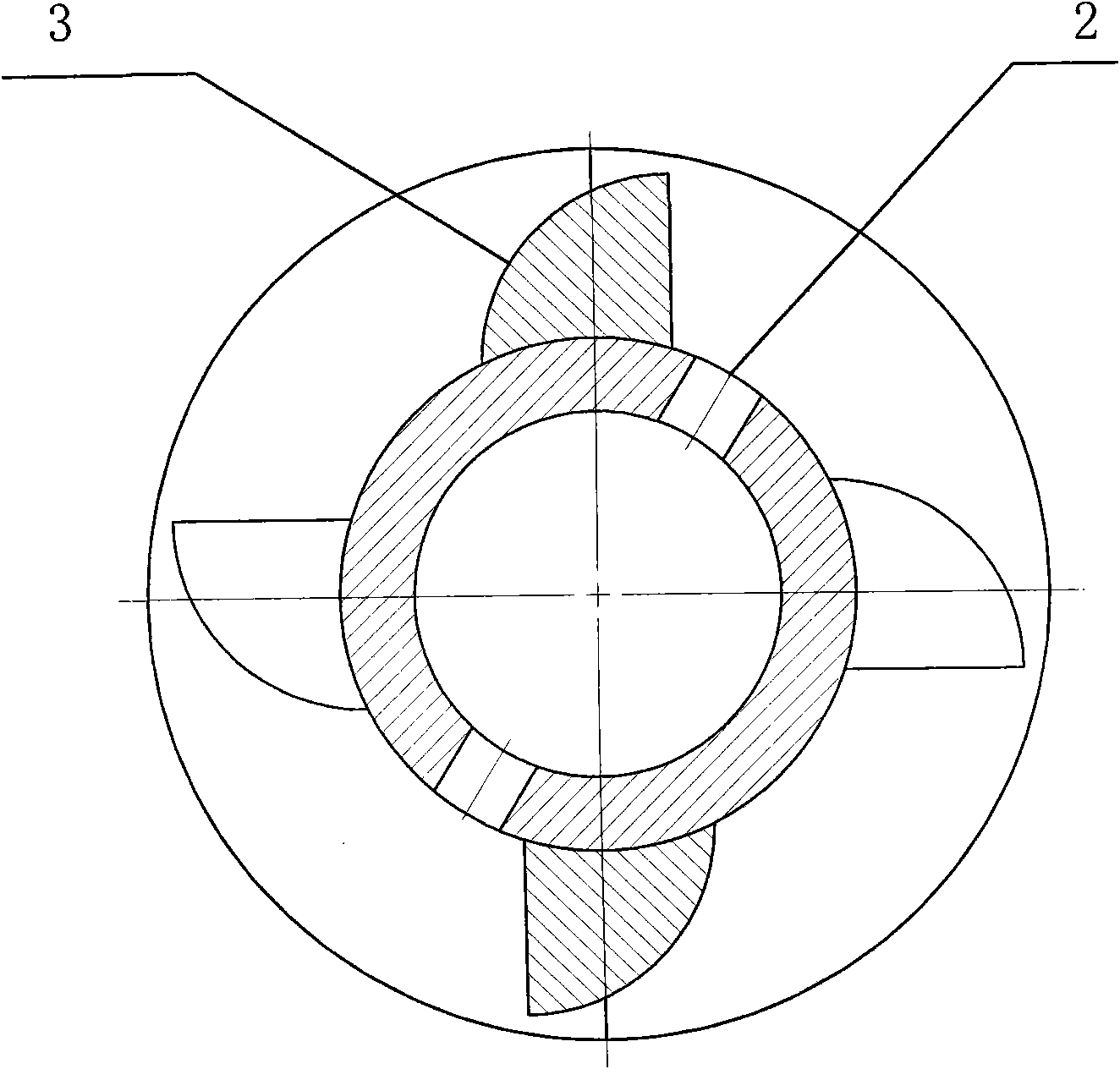

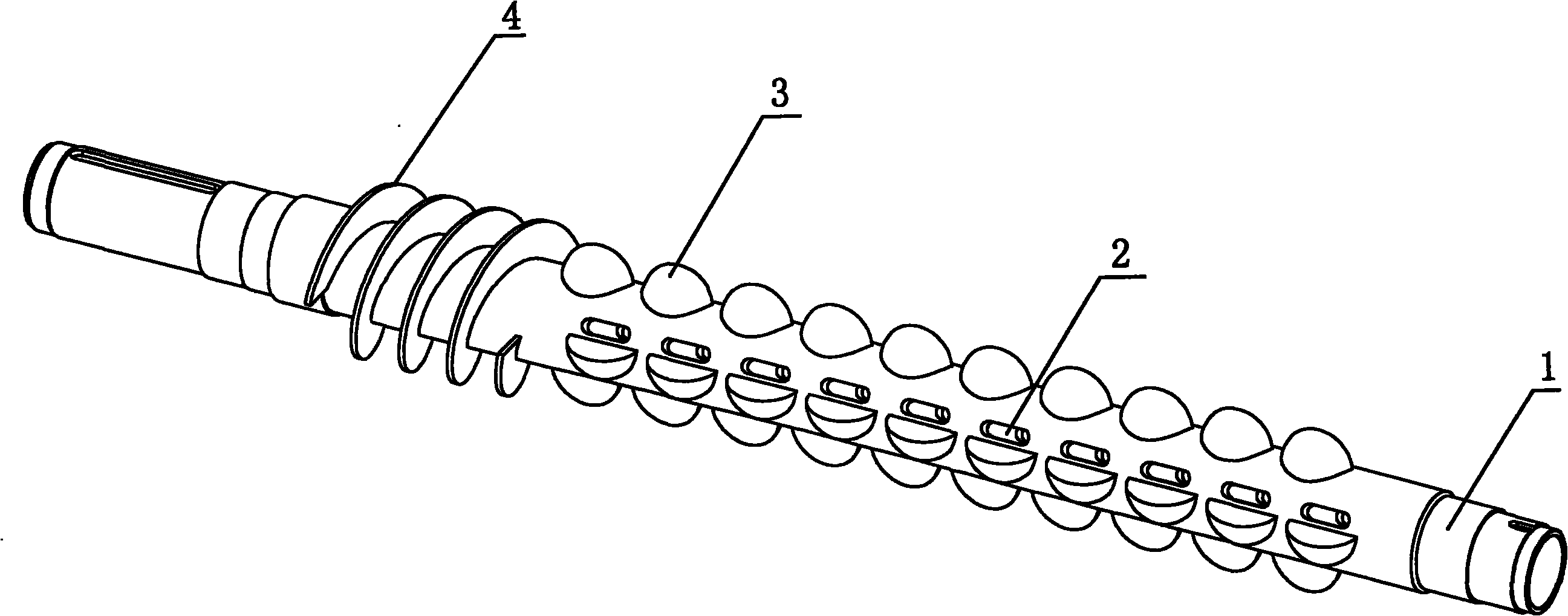

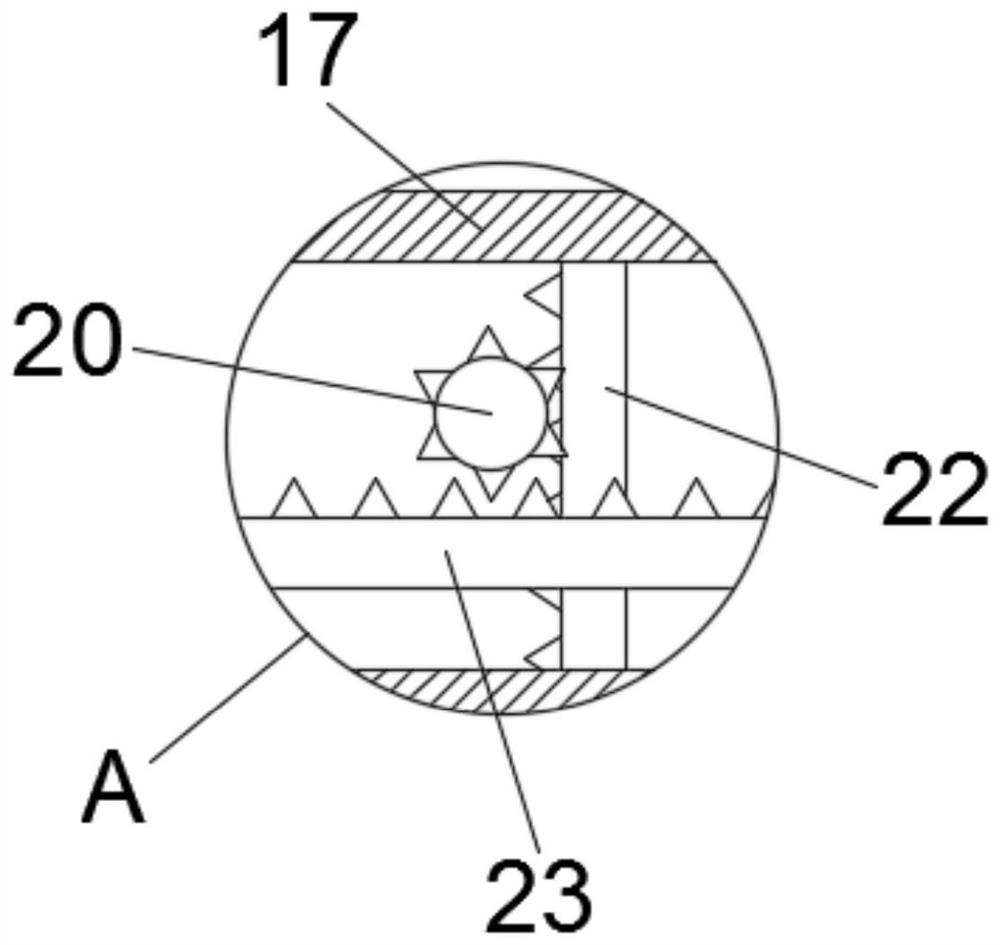

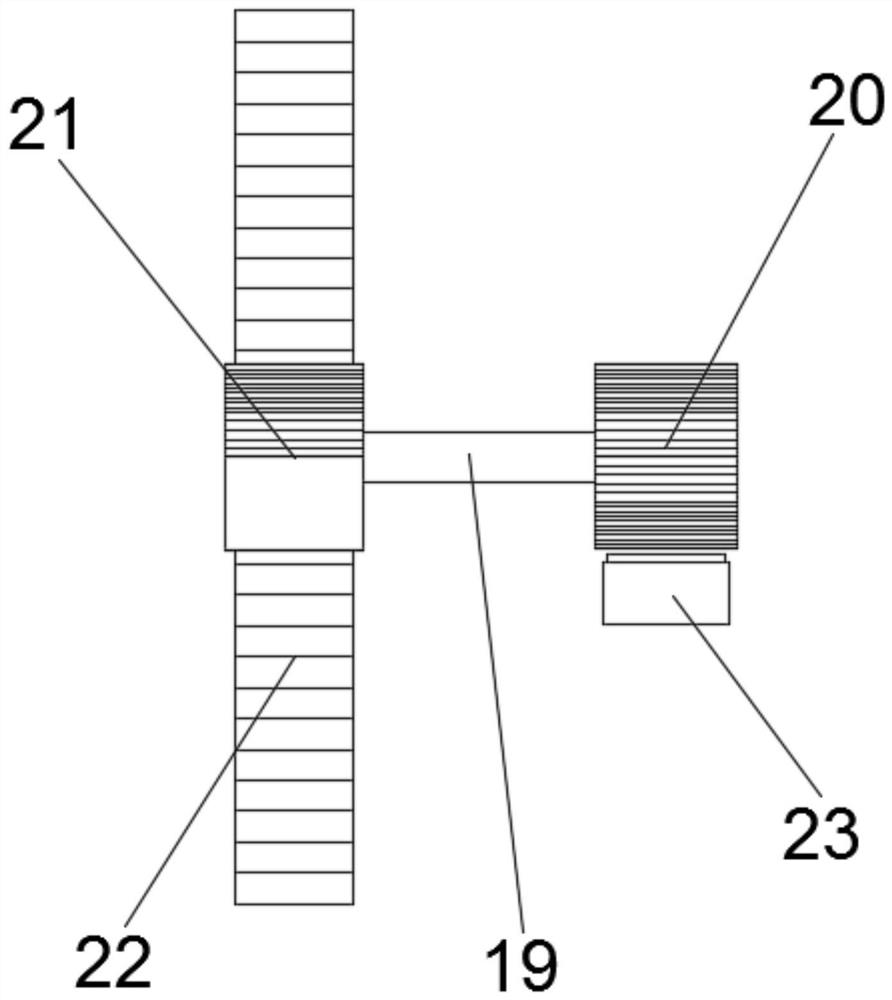

Novel siamesed roller for processing rice

InactiveCN102029204AImprove polishing effectReduce broken riceGrain huskingGrain polishingHelical bladeBroken rice

The invention discloses a novel siamesed roller for processing rice, which comprises a roller body, wherein the roller body is hollow and is provided with a ventilation slot; the surface of the roller body is provided with working ribs for processing in a certain mode; the working ribs are fixed on the roller body in a welding or any other mode; and helical blades for feeding are welded on the surface of the roller body. The invention has the advantages of high processing efficiency, less broken rice and favorable polishing effect; and the main shaft and the working roller for processing are integrated into the siamesed roller.

Owner:谢泽良

Intelligent rice milling machine

InactiveCN109174256AHigh grinding rateSolve the low germination rateGrain huskingGrain polishingEmbryo preservationDrivetrain

The invention discloses an intelligent rice milling machine. The intelligent rice milling machine comprises a support, a power transmission system, a pounding and refining system, a detection device,a control center, a grain inlet mechanism and a grain outlet mechanism, wherein the power transmission system and the pounding and refining system are arranged on the support; the detection device isarranged on the pounding and refining system; the control center is in signal connection with the detection device; the grain inlet mechanism is arranged at an inlet of the pounding and refining system; and the grain outlet mechanism is arranged at an outlet of the pounding and refining system. By means of the intelligent rice milling machine, the milling force of the rice milling machine can be intelligently controlled according to the rice bran milling rate and the embryo preservation rate of milled rice with embryos; the control process is implemented automatically, and manual control is not needed; and the problems that manual adjustment is not precise, so that rice grains are not milled properly, and the milling rate is low are avoided. The embryo preservation rate of the milled ricewith the embryos is high; and the rice grains are refine and white, a small number of broken rice grains are generated, and the rice quality is improved.

Owner:深圳威琳懋生物科技有限公司

Refining method for processing of rice

The invention relates to the technical field of rice processing, and discloses a refining method for processing of rice. The refining method comprises the following steps of removing impurities from unhulled rice, screening the unhulled rice without impurities, removing husks of the screened unhulled rice, separating husked rice, performing careful selection, performing rice milling and polishing,performing color sorting and classifying, performing sterilization and performing packing. The weight of the unhulled rice is weighed, early stage experiment can be performed, and the results show that the weight of the unhulled rice is the same as that of water. An appropriate amount of water is added to an atomization plant, and is uniformly sprayed for wetting the unhulled rice, so that the brown rice moisture in the unhulled rice is maintained to 13.5%15.0%. The brown rice is atomized, sprayed with water and moisturized for some time, so that the friction coefficient of the surface of thebrown rice is increased, grinding, cutting, applying and separating of the cortex of the brown rice are facilitated, the milling pressure can be reduced, the brown rice in the rice milling process can be reduced, and the milled rice rate is increased. The refining method for processing of rice can solve the problem that the moisture of the brown rice in the unhulled rice is low to cause more broken rice during processing.

Owner:湖南溢香园粮油有限公司

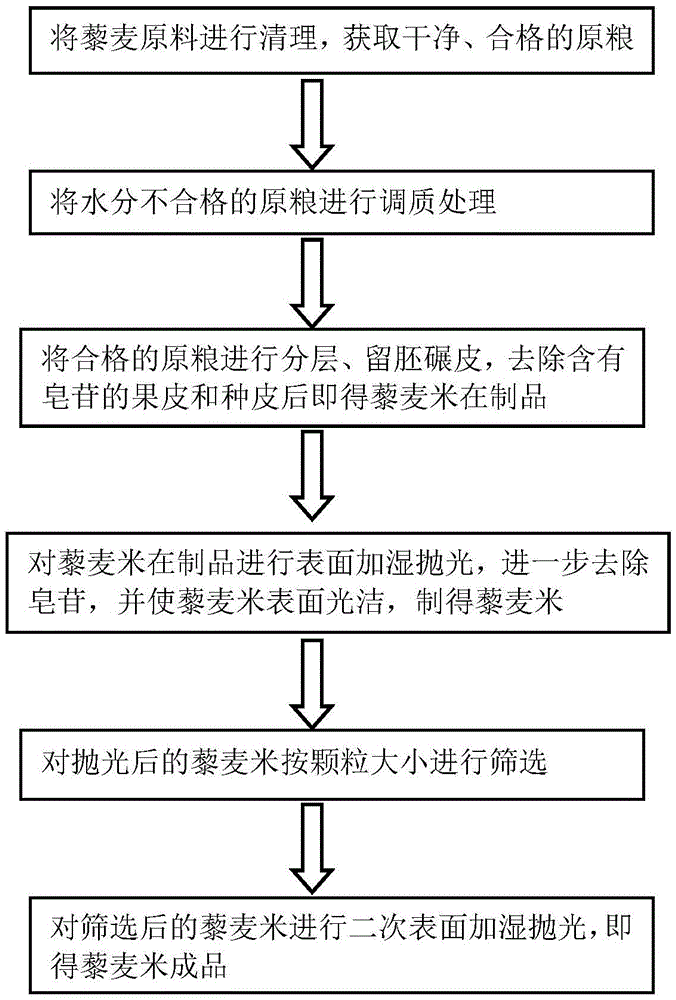

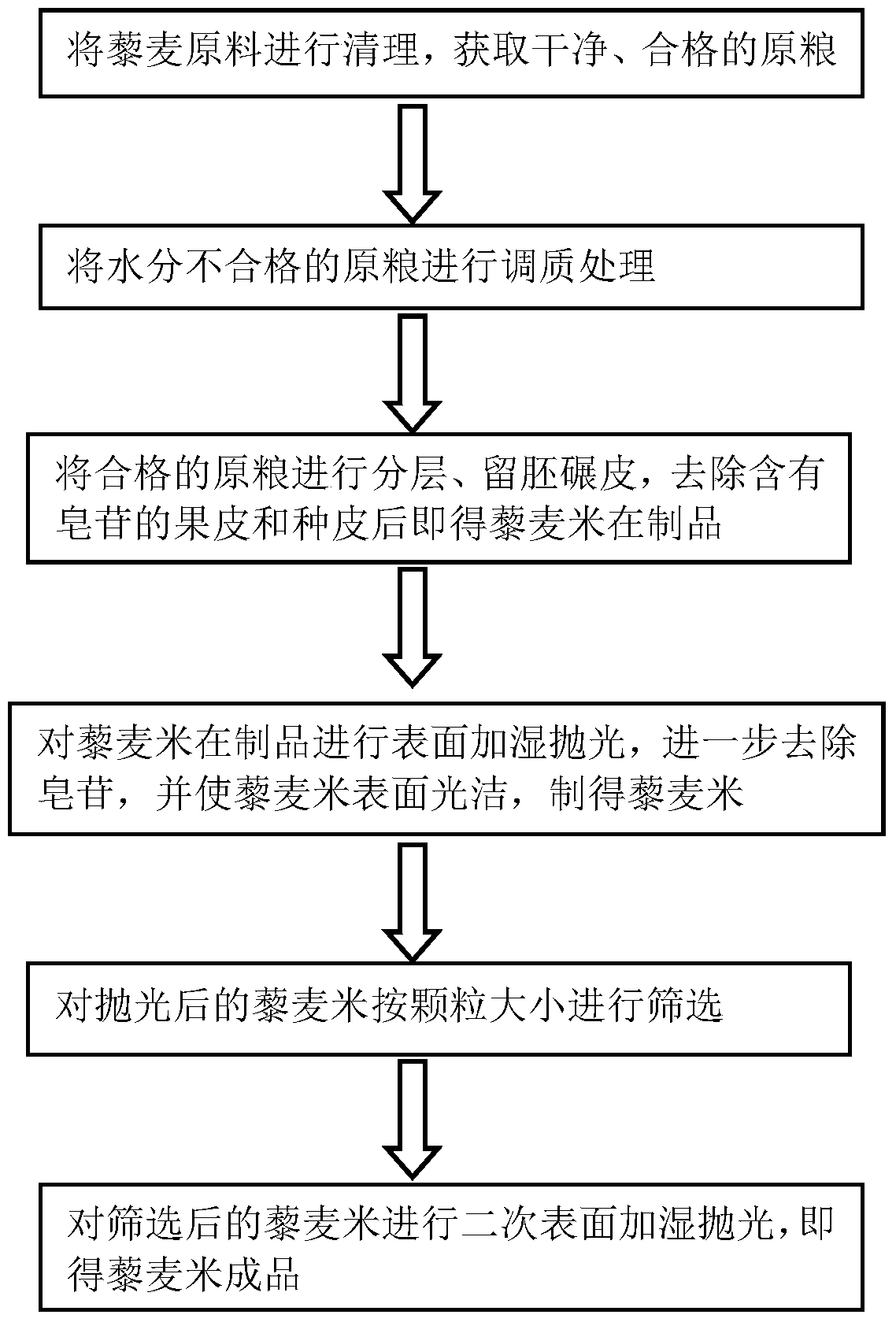

Quinoa rice dry processing technique

ActiveCN105536914AEasy to processAvoid mildew and spoilageGrain huskingGrain polishingHuskBroken rice

The invention discloses a quinoa rice dry processing technique. The quinoa rice dry processing technique comprises the steps that quinoa raw materials are cleaned, so that clean and qualified rough grain is obtained; thermal refining is conducted on the rough grain with the unqualified moisture content, so that the moisture content of the rough grain reaches 10%-14%; layering, gearm reserving and husk removing are conducted on the qualified rough grain, and quinoa pulp husks containing saponin and quinoa seed husks containing saponin are removed, so that processed quinoa rice is obtained; and surface wetting and air-jetting polishing are conducted on the processed quinoa rice, so that saponin residues are further removed, the surface of the quinoa rice is made smooth and clean, and finished quinoa rice is obtained. The quinoa germs are reserved while the pulp husks containing saponin and the seed husks containing saponin are removed, the surface of the atomized and humidified quinoa rice is polished through a polishing roller, rice bran powder which is generated during polishing and contains saponin is separated out under the action of high-pressure airflow, and then grading and color sorting are conducted, so that the finished quinoa rice is obtained. By the adoption of the quinoa rice dry processing technique, water resource waste and environmental pollution caused by washing are avoided, and energy consumption is reduced due to the fact that secondary drying is not needed; the yield of quinoa rice can be remarkably increased, the quantity of reserved germs is improved, and the quantity of broken rice is reduced; processing is moderate, nutrients are maintained, and the product quality is improved.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

Rice processing technology

A rice processing technology comprises the following steps that rice is aired under the sun till the water content of the rice is 18-20%; the temperature in a container is adjusted to be 28-30 DEG C,the pressure of the container is adjusted to be 120-125 kpa, the humidity of the container is adjusted to be 60-65%, the time is 30-35 minutes, then the temperature in the rice hulling container is adjusted to be 24-26 DEG C, the pressure is adjusted to be 90-105 kpa, the humidity is adjusted to be 65-70%, and the time is 25-30 minutes, so that the water content of the rice is 13-15%; the rice isput into a rice milling machine for rice milling; the rice obtained after the rice milling process is graded and sorted, and broken rice which exceeds the requirement is extracted; special-color particles is removed by a color sorter; the rice is polished through a polishing machine. The rice processing technology well starts from characteristics of the rice, and appropriate conditions are provided in the rice processing process so that rice husks can easily fall off, and the broken rice is greatly reduced.

Owner:贵州大娄山稻香来食品有限公司

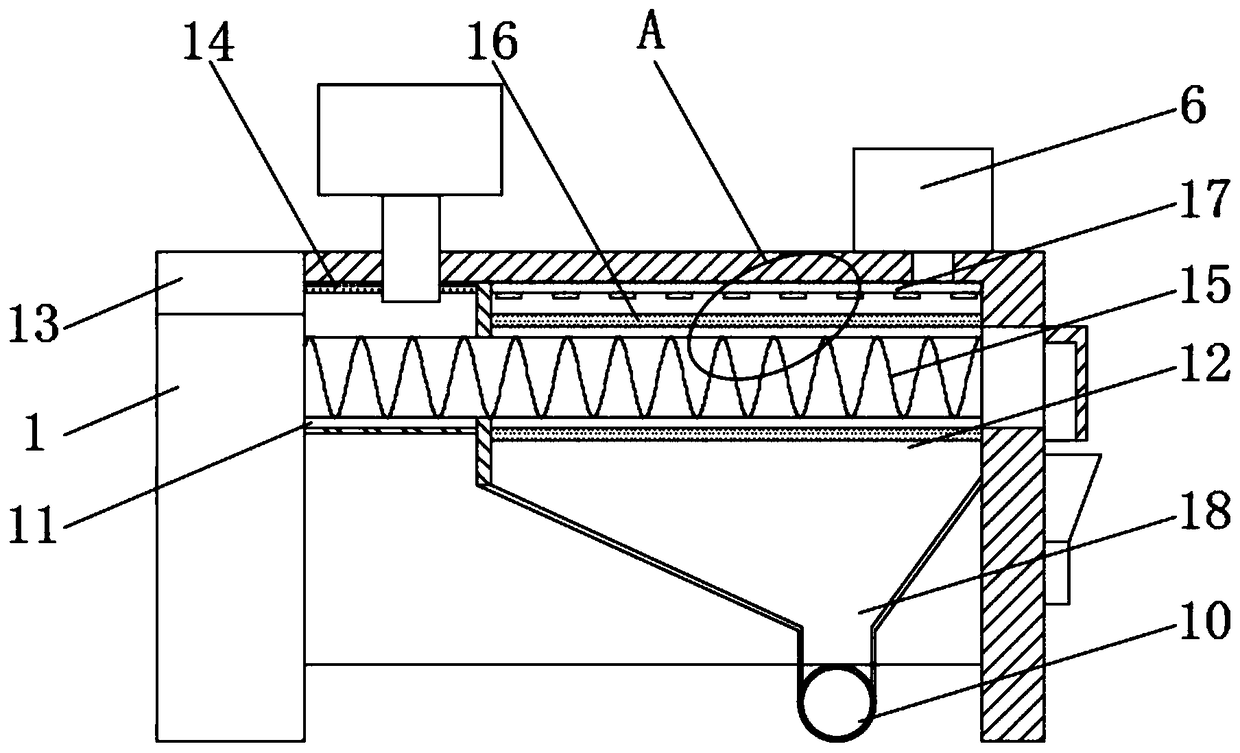

Slab abrasive belt rice mill

InactiveCN108405030AEffective contactEasy to shellGrain huskingGrain polishingMilling cutterElectric machinery

The invention discloses a slab abrasive belt rice mill. The slab abrasive belt rice mill comprises a hopper, an abrasive belt is arranged below the hopper, a cover body is arranged on the abrasive belt and provided with a plurality of cutting blade brackets, and a rice milling cutter is slidably arranged on each cutting blade bracket; the distance between the rice milling cutters and the abrasivebelt is gradually increased from the hopper to the discharging direction of the abrasive belt; the middle of the abrasive belt is provided with a supporting plate, and convex and concave blocks are arranged on the supporting plate; a cam shaft which is driven by a motor to rotate is arranged above the cover body; one end of the abrasive belt is provided with a winnowing box; one side of the winnowing box is provided with a bran discharging pipeline, and the other side of the winnowing box is provided with an air exhaust pipeline connected with an air blower; and the lower end of the winnowingbox is provided with a discharging outlet. The slab abrasive belt rice mill can effectively complete the rice milling procedure, the temperature of rice in the rice milling procedure is not high, thefollow-up polishing work is not influenced, in addition, the hulling speed is high, and the smashed rice amount is small.

Owner:常州市武进双湖粮油机械股份有限公司

Rice polishing device

InactiveCN109482258APromote wettingImprove the finishGrain huskingGrain polishingAgricultural engineeringBran

The invention discloses a rice polishing device. The rice polishing device comprises a body box and a top plate fixedly arranged at the upper end of the body box. A bottom box is fixedly arranged at one end of the bottom of the top plate. A feeding chamber and a polishing chamber are fixedly arranged at the bottom end of the top plate. According to the rice polishing device, water can be evenly sprayed to rice entering the feeding chamber, rice wetting is convenient, rice bran can be better thoroughly removed through grinding, the smooth finish and polishing uniformity of rice are improved, crushed rice is reduced, uniform exhausting can be conducted on the polishing chamber, bran powder generated due to polishing can be blown out of a polishing pipe, falls into a material receiving chamber and is discharged through a bran powder discharging pipe. Meanwhile, the rice obtained after polishing is dried, a front cover arranged at the front end can be convenient to mount and dismount, detection and maintenance can be conducted on the inner feeding chamber and the polishing chamber, the material receiving chamber can be conveniently cleaned, inner cleanliness is kept, pipeline blockageis avoided, and better usage prospects are brought.

Owner:颍上县皖润米业有限公司

Processing technology for lowering rice breaking rate

The invention relates to the technical field of rice processing, in particular to a processing technology for lowering rice breaking rate. The processing technology for lowering the rice breaking ratecomprises the following steps of one, impurity-removing, wherein unhusked rice harvested is put into an impurity remover, and impurities are removed; two, one-time drying, wherein microwave drying equipment is adopted, the unhusked rice is dried under nitrogen condition until moisture content of the unhusked rice reaches 16-18%, and the unhusked rice is cooled to room temperature; and three, one-time rice-milling, wherein the unhusked rice cooled to the room temperature is put into a rice husking machine so that rice husks are removed, the husking rate reaches 60-80%, and a semi-finished product is obtained. The processing technology for lowering the rice breaking rate has the beneficial effects that by means of a microwave drying manner, drying is conducted through generation of heat byvibration of holistic water molecules rather than through thermal transmission from the outside to the inside; in this way, drying is uniform; the situation that surface of rice grains becomes brittlerapidly because of excessively high temperature, while excessive internal moisture is still reserved is avoided; the surface of the rice grains does not become brittle, and then the probability thatphenomenon of broken rice appears is lowered; moreover, stirring is not needed; the phenomena of broken rice caused by machinery are reduced; and germination of unhusked rice under a microwave condition is guaranteed by the nitrogen atmosphere.

Owner:汉寿县德穗米业有限公司

Processing technology for rice with long storage life and low broken rice rate

InactiveCN107583711AReduce broken rice rateReduce moisture contentDrying solid materials without heatDrying gas arrangementsWater contentBroken rice

The invention discloses a processing technology for rice with the long storage life and the low broken rice rate. The technology comprises the steps that impurities in picked unhusked rice are removed, indoor temperature air drying is performed, hot air drying is performed under the stirring state, and preprocessed rice is obtained; Arabic gum and water are mixed, stirred and added into a single-walled nanotube for ultrasonic concussion, vacuum drying is performed, the preprocessed rice is added and mixed to be uniform, the stirring temperature is 5-10 DEG C, the mixture is fed into steam to be heated and fed into a rice husking machine to be husked, husked rice separation is performed, and husked rice is obtained; the husked rice is cooled to the indoor temperature, polishing, color sorting and classification are performed to obtain the rice with the long storage life and the low broken rice rate. The rice is low in broken rice rate, low in water content, long in storage life and quite high in economic benefit.

Owner:安徽省明光市中富粮油食品贸易有限公司

Rice milling device for rice processing

ActiveCN112169868BAvoid residueBig impactGrain huskingGrain polishingAgricultural engineeringBroken rice

The invention discloses a rice milling device for rice processing, which comprises a rice milling box, a rolling roller is installed in the middle of the rice milling box, several groups of first air blowers are arranged on the top of the rice milling box, and the rice milling box A delivery box is fixedly installed on the left side, a transmission shaft is fixedly installed in the middle of the delivery box, and a spiral blade is fixedly installed on the outside of the transmission shaft; A bran screen is fixedly installed, an outlet is provided at the right end of the rice milling box, a channel is fixedly installed outside the outlet, a distribution box is fixedly installed at the bottom of the channel, and a fixed box is fixedly installed at the bottom of the distribution box. The top of the fixed box is slidingly connected with the mobile box. The invention relates to the field of rice processing devices, which can classify and collect rice while reducing the generation of broken rice.

Owner:和县金城米业有限责任公司

Rice processing method capable of reducing impurities

InactiveCN107149958AImprove water absorptionFacilitated DiffusionGrain huskingGrain polishingBroken riceEngineering

The invention discloses a rice processing method for reducing impurities, which comprises the following steps: adding fly ash, gelatin and silane coupling agent to the pretreated clay, sending it into a ball mill, adding water, grinding, filtering, washing, drying, Add fresh rice and stir to separate and obtain pretreated rice; send the pretreated rice to the rice huller to remove the husk to obtain rice paddy; send the rice paddy to the paddy separator for separation of paddy paddy to obtain brown rice; pass the brown rice through the classification processor in turn to screen Grading, multi-pass rice milling, rice polishing, and ventilation to obtain cold rice; the cold rice is successively whitened, polished, and rice color sorted, followed by fine processing and sterilization to obtain rice. The steps of the invention are clear and reasonable, the taste of the rice is excellent, and the structure of the rice is not damaged, the subsequent impurity removal process can be omitted, and under the premise of ensuring extremely low impurity content, there is very little broken rice.

Owner:全椒县崇明米业有限公司

Rice Processing Technology

The invention discloses a rice process in the technical field of rice processing. The rice process comprises the steps of: impurity removal; dehumidification: paddies are paved in a drying room for drying by a hot air drying method to reach the paddy water content of 12-14%, and the hot air temperature is 35-45 DEG C; primary rice milling: the unshelling rate reaches 60-80%; attachment of water mist on the surfaces of semi-finished products by an atomization method; drying of the semi-finished products by cold air to reach the semi-finished product water content of 12-14%; secondary rice milling; polishing; and color sorting and classification. The paddies are cooled before being suffered from a mechanical effect in each link; compared with traditional airing and direct once high-temperature drying, the dehumdification process alleviates the effect of taking away water in the paddies, and is uniform in heating; compared with a traditional process, the rice process combines wetting and drying procedures, adds the wetting and drying, after wetting, steps, and uses secondary rice milling for largely reducing the rice milling rate; and the same one batch of paddies machined by the method reaches the rice milling rate of below 8%.

Owner:湖南省水府庙农林科技开发有限公司

Vertical rice tool device of rice milling machine

InactiveCN102773127AIncrease frictionReduce broken riceGrain huskingGrain polishingEngineeringCushion

The invention discloses a vertical rice tool device of a rice milling machine. The vertical rice tool device comprises an upper machine shell, a lower rack, a rice tool board, a rice tool adhesion board, a rice sieve and a grain inlet hopper, and is characterized in that 3-8 bead rice tools and rice tool grooves are arranged at the inner side of the rice tool board; the rice tool board is fixedly arranged on the rice tool adhesion board after passing through an elastic cushion by using bolts; the upper-lower rice sieve is inserted into a gap between the rice tool board and the rice tool adhesion board, so as to form a round rice milling outdoor chamber; the both ends of the rice tool adhesion board are placed on a walking groove on the center horizontal line of a shell of the rice milling machine; supports are arranged in inner cavities of the upper machine shell and the lower rack for placing the rice sieve; an adjusting screw post is erected on the lower rack for adjusting the rice tool board; and a grain inlet adjustment inserting board is arranged on the grain inlet hopper. The vertical rice tool device provided by the invention has the advantages as follows: friction is increased, so that rice can be sufficiently ground to un-shelling and white-milling; the vertical rice tool device has the characteristics of rice striping, less crushed rice, compact structure, small volume, and reduced cost; and the rice tool is adjusted outside the shell, so that the convenience and the rapidness can be achieved.

Owner:刘力成

Low temperature increase rice milling device

ActiveCN111359699AImprove drop-out efficiencyReduce broken riceSievingGrain huskingPistonAgricultural engineering

The invention relates to the field of rice processing and in particular discloses a low temperature increase rice milling device which comprises a driving part, an outer cylinder and an inner cylinder, wherein the inner cylinder is positioned in the outer cylinder; a sealable feeding hole is formed in the outer cylinder; a separation bucket which is opened towards the outer cylinder is fixed on the side wall of the outer cylinder; separation cavities are formed in the separation bucket; a plurality of separation holes for communicating the separation cavities with the inner cavity of the outercylinder are formed in the side wall of the outer cylinder; pistons are sealed in the separation cavities in a sliding manner; a plurality of sealing columns are fixed at one ends, facing to the inner cylinder, of the pistons; the plurality of the sealing columns are in one to one correspondence to the plurality of the separation holes and are connected with the separation holes in a sliding manner; push rods are fixed at one ends, far away from the inner cylinder, of the pistons; the push rods penetrate through the side wall of the separation bucket and are connected with the side wall of the separation bucket in a sliding manner; a husk outlet hole communicating with the separation cavities is formed in the outer wall of the separation bucket; and the husk outlet hole is positioned in one sides, far away from the inner cylinder, of the pistons. By adopting the rice milling device provided by the invention, separated husks can be separated while being separated, so that obstruction caused by friction of an outer shell with rice husks and other rice husks or a rice miller can be avoided.

Owner:重庆穗花食为天粮油有限公司

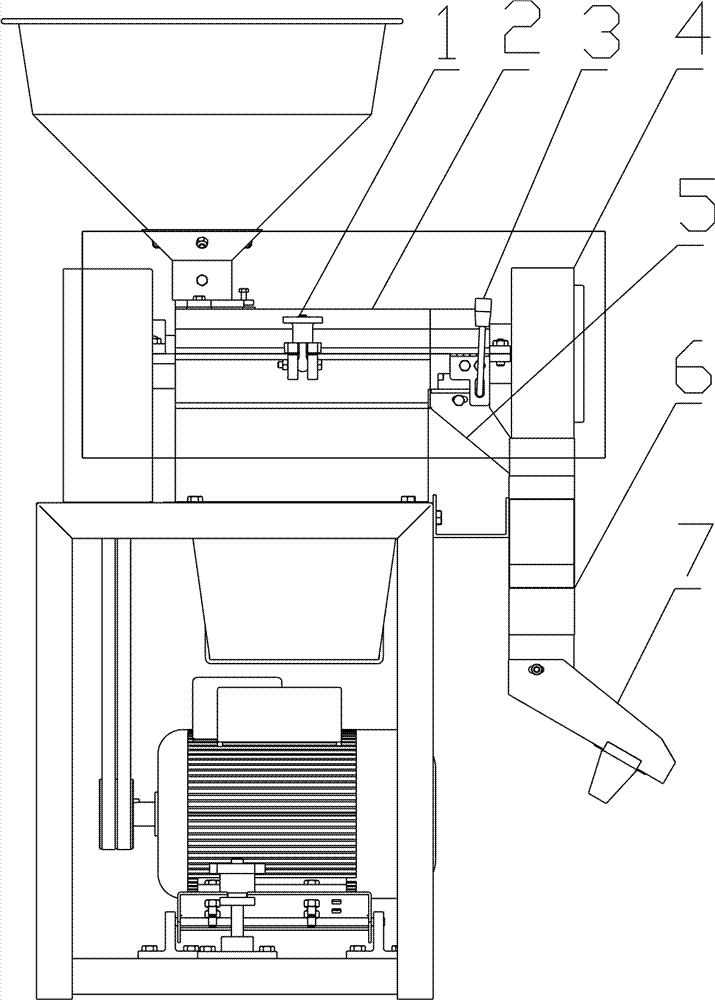

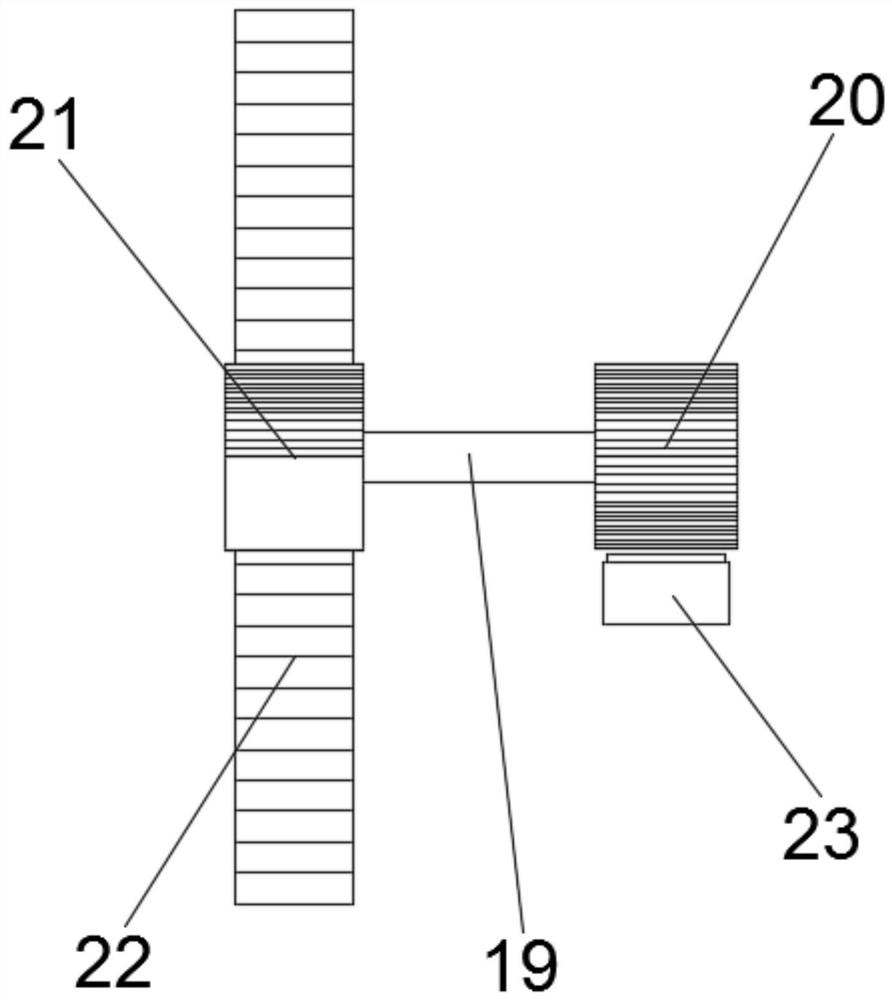

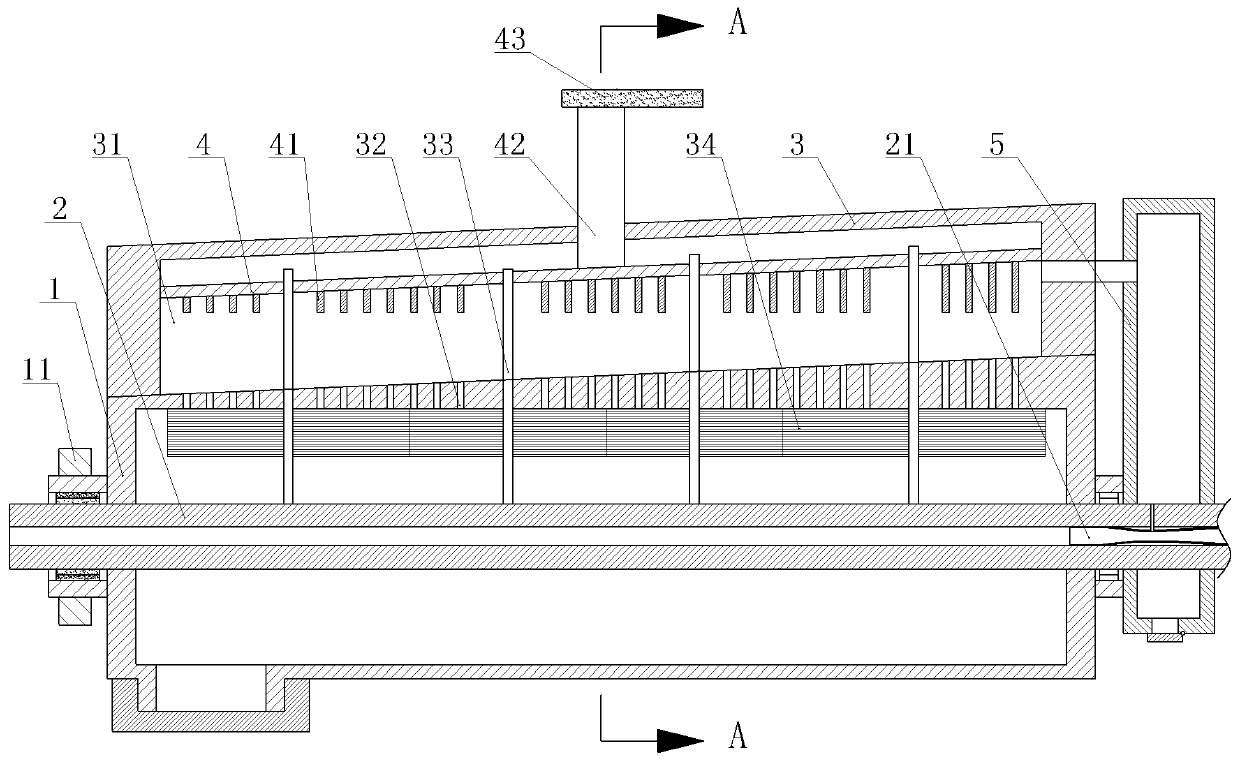

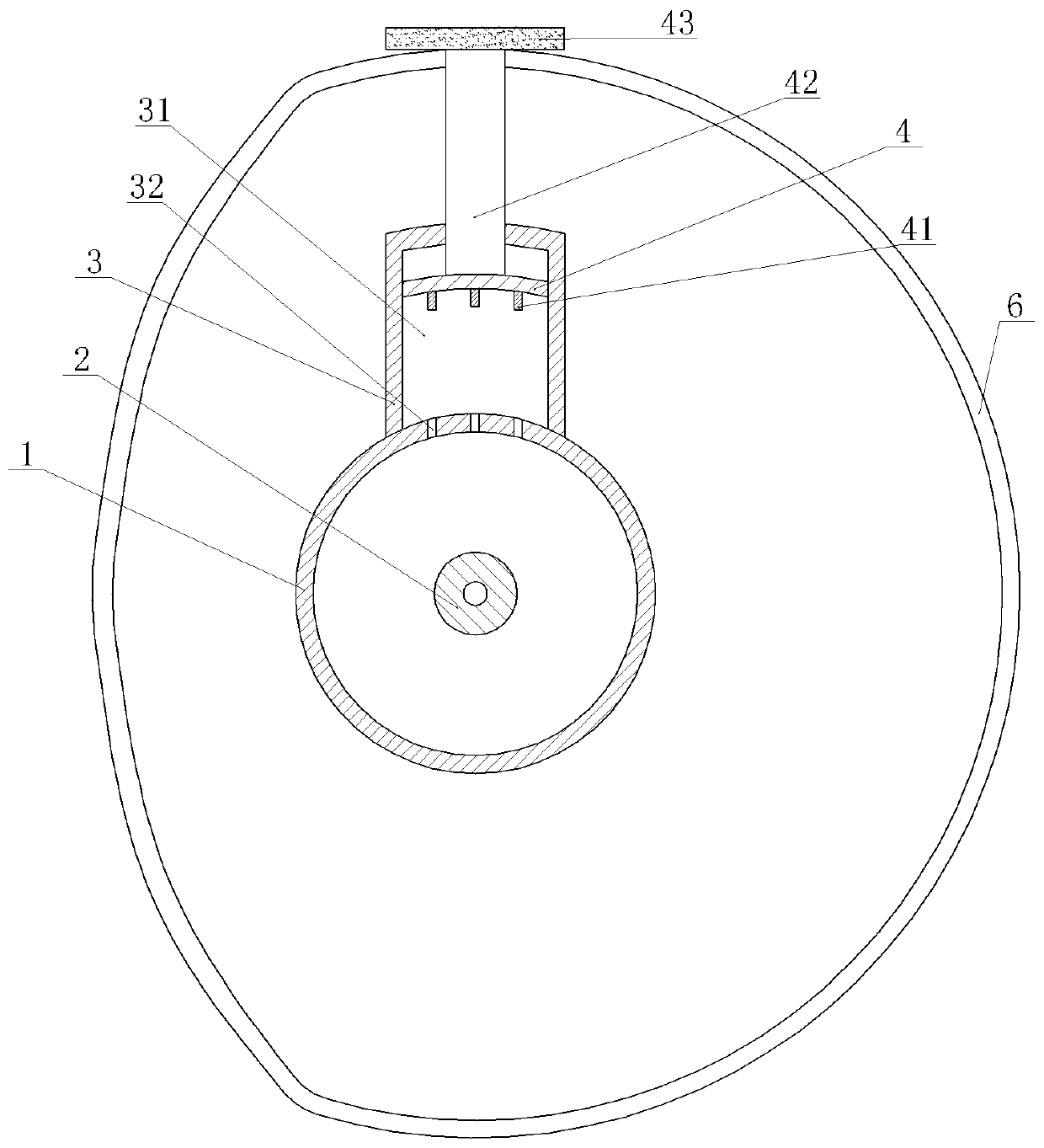

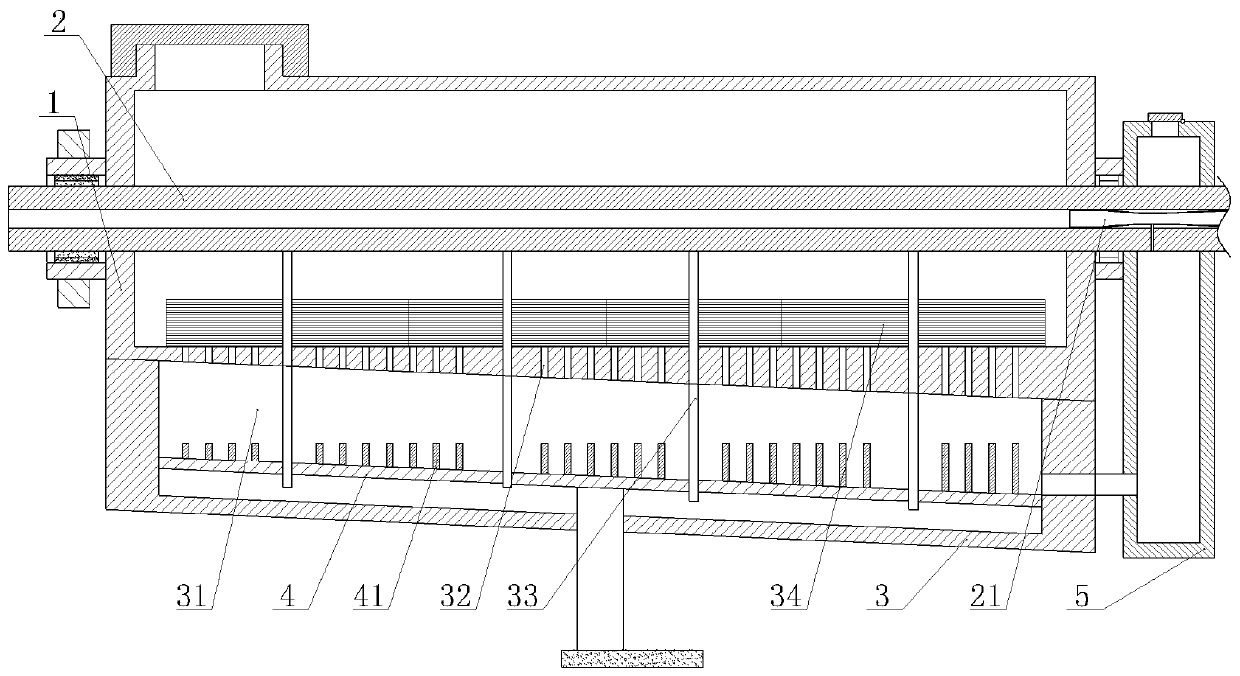

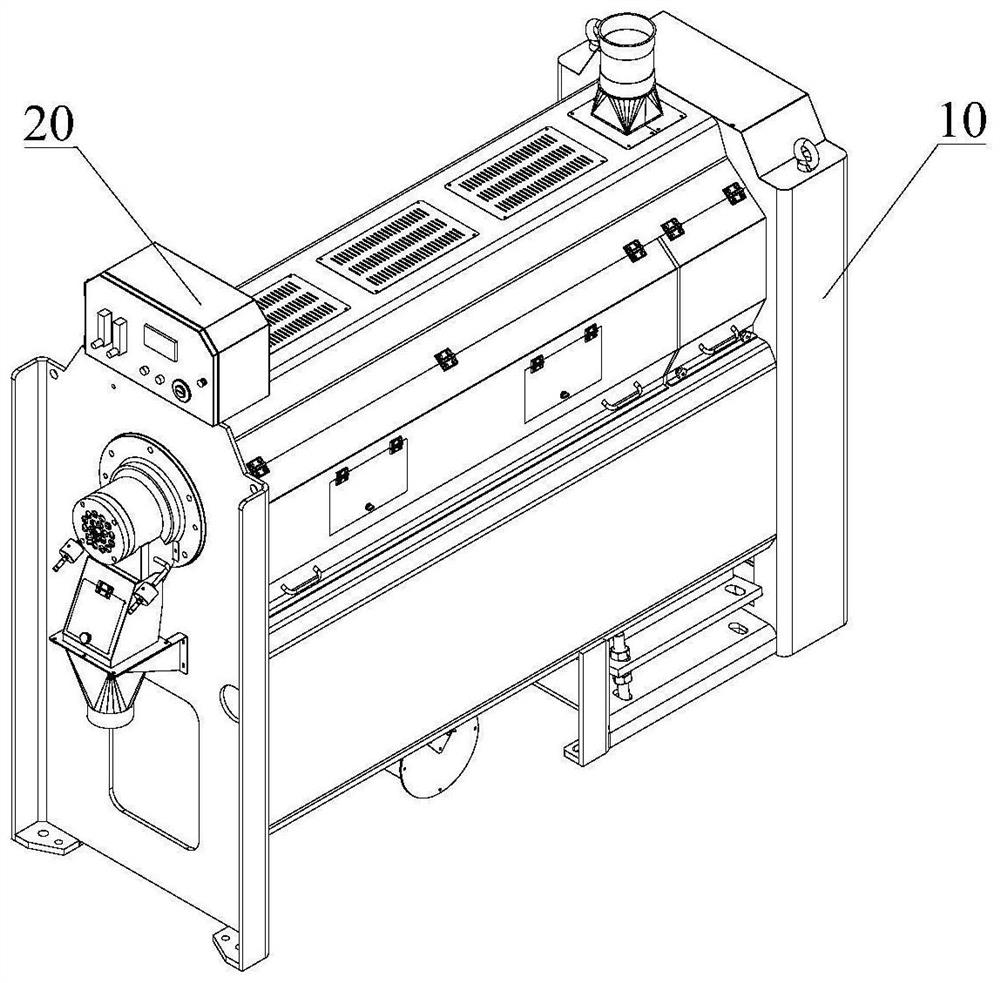

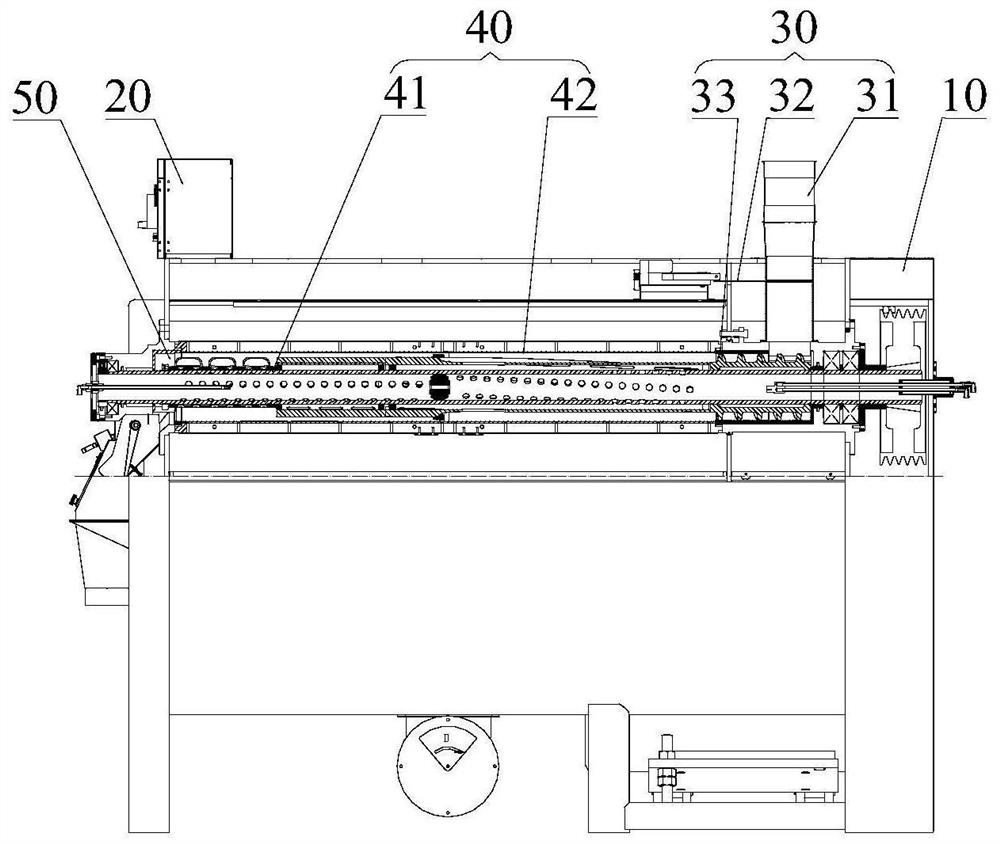

Double-roller polisher

InactiveCN106622445ASmooth feedingIncrease productionGrain huskingGrain polishingEngineeringReplacement procedure

The invention aims at providing a double-roller polisher. Two polishing rollers are arranged in a polishing chamber of the double-roller polisher and can operate simultaneously, and the purpose of yield increase is achieved. In addition, a rotary cross beam support seat component is installed, and thus disassembly and replacement procedures of a screen frame, a screen piece, a polishing ball and other inner parts are convenient.

Owner:汪成亮

Fruit-flavored rice processing technology

The invention discloses a fruit-flavored rice processing technology. The processing technology comprises the following steps of first impurity removal; drying; quick freezing; soaking; refrigeration;drying and dehumidification; rice milling; secondary impurity removal; post treatment. The technology has the following advantages that after two times of impurity removal treatment, aspecific gravityseparation method is adopted, and rice basically does not contain any impurities which affect the quality and taste of the rice; the soaking treatment with a concentrated juice makes is adopted, therice has a fruity flavor, and the rice cooked tastes refreshing; the refrigerationtreatment is adopted to ensure that the fruityflavor can penetrate into the rice, and be long-lasting and fragrant; anintermittent hot air is used for dehumidifying the rice, the moisture inrice grains wrapped in chaffs and the chaffs can be slowly and uniformly taken, the temperature control is appropriate, it is avoided that an excessive temperaturecauses that the surfaces of the rice grains become brittle and the internal moisture remains too much, and the surfaces of the rice grainsdo not become brittle, whichreduces the probability of broken rice; after cooling to the room temperature, the rice is milled to remove the chaffs, and the rice is prevented from being excessively dried andbeing fragile when pressed.

Owner:怀化金泥农业种植农民专业合作社

A kind of quinoa rice dry processing technology

ActiveCN105536914BEasy to processAvoid mildew and spoilageGrain huskingGrain polishingBroken riceWater resources

The invention discloses a quinoa rice dry processing technique. The quinoa rice dry processing technique comprises the steps that quinoa raw materials are cleaned, so that clean and qualified rough grain is obtained; thermal refining is conducted on the rough grain with the unqualified moisture content, so that the moisture content of the rough grain reaches 10%-14%; layering, gearm reserving and husk removing are conducted on the qualified rough grain, and quinoa pulp husks containing saponin and quinoa seed husks containing saponin are removed, so that processed quinoa rice is obtained; and surface wetting and air-jetting polishing are conducted on the processed quinoa rice, so that saponin residues are further removed, the surface of the quinoa rice is made smooth and clean, and finished quinoa rice is obtained. The quinoa germs are reserved while the pulp husks containing saponin and the seed husks containing saponin are removed, the surface of the atomized and humidified quinoa rice is polished through a polishing roller, rice bran powder which is generated during polishing and contains saponin is separated out under the action of high-pressure airflow, and then grading and color sorting are conducted, so that the finished quinoa rice is obtained. By the adoption of the quinoa rice dry processing technique, water resource waste and environmental pollution caused by washing are avoided, and energy consumption is reduced due to the fact that secondary drying is not needed; the yield of quinoa rice can be remarkably increased, the quantity of reserved germs is improved, and the quantity of broken rice is reduced; processing is moderate, nutrients are maintained, and the product quality is improved.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

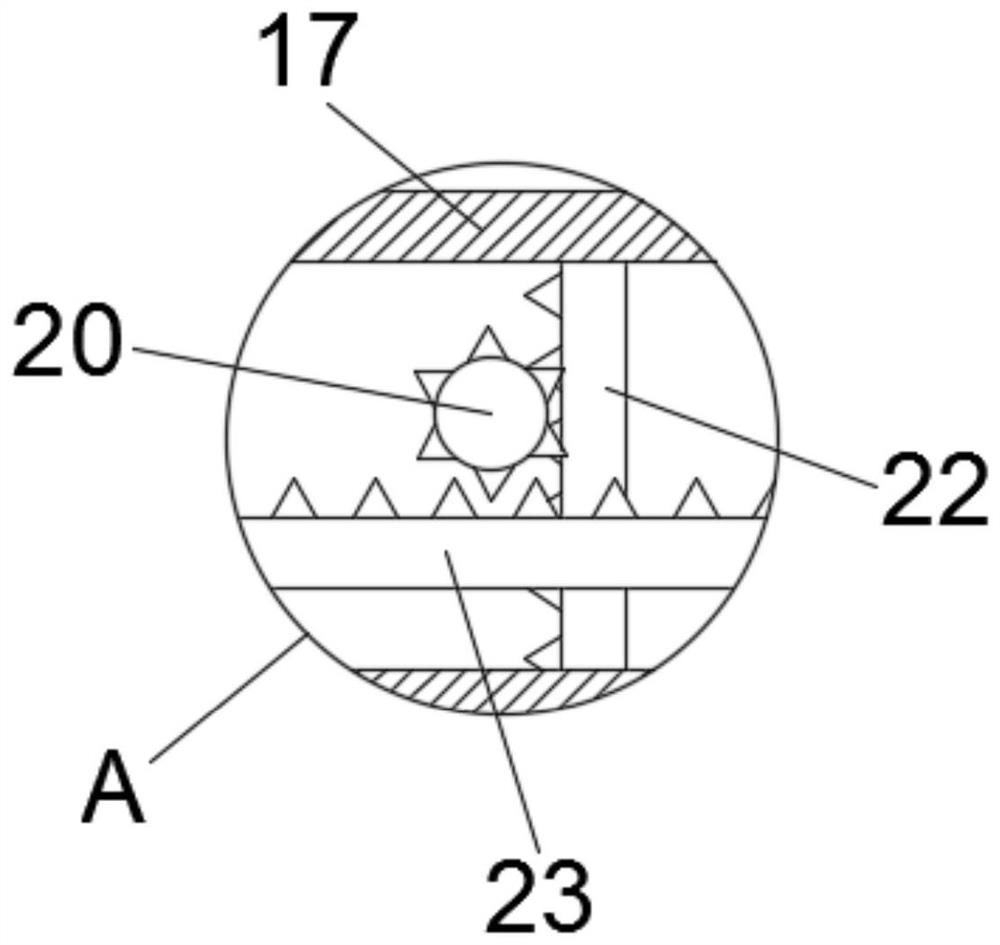

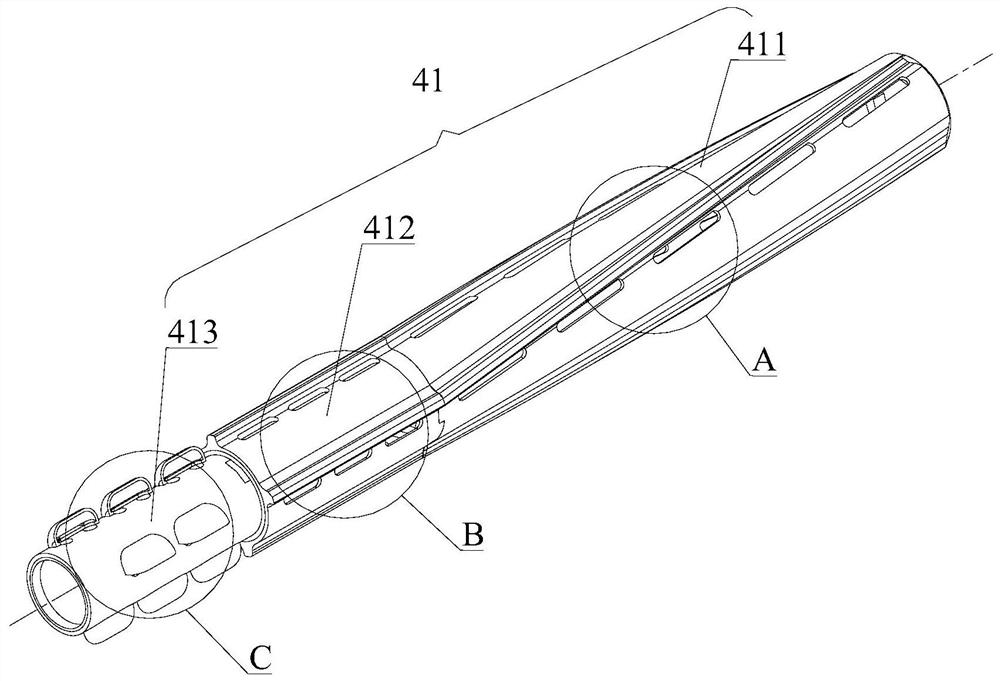

rice polisher

ActiveCN106925369BEliminate resistanceReduce broken riceGrain huskingGrain polishingBroken riceEngineering

The invention discloses a rice polishing machine, which includes a frame, an electric control box, a feeding assembly, a polishing chamber and a discharging assembly; the polishing roller includes a water mixing section, a pre-polishing section and a fine polishing section arranged in sequence along the axis The water mixing section includes the first roller body and inclined ribs. The cross section of the inclined ribs perpendicular to the axis is trapezoidal, and the inclined ribs form a helical angle with the axis; the pre-polishing section includes the second roller body and straight ribs. The section is trapezoidal, and the straight ribs are parallel to the axis; the fine polishing section includes the third roller body and a polishing block, and the section of the outer surface of the polishing block perpendicular to the axis is involute; the discharge assembly includes a discharge port set at the end of the screen The bushing, the bushing at the discharge port includes a screen interface that is docked with the tail end of the screen, and the shape of the inner wall of the screen interface matches the shape of the outer shape of the screen. In the rice polishing machine of the present invention, the outer surface of the polishing block of the fine polishing section of the polishing roller is an involute curved surface, and the interface of the sieve is in the same shape as the sieve, thereby reducing broken rice and energy consumption.

Owner:湖北五丰粮食机械有限公司

a rice milling machine

InactiveCN103691506BImprove the rice yieldRice milling is convenientGrain huskingGrain polishingEngineeringSieve

The invention discloses a rice polisher which is characterized in that a shell can be locked or unlocked by a plum blossom hand wheel, a hopper seat is arranged on the shell, a feeding hopper and the hopper seat are fixed, a rice roller is arranged inside the shell, one end of the rice roller and a belt wheel are fixed, the belt wheel is connected with a motor through a belt, a safety protection cover is arranged at the belt wheel, a screw pushing end corresponding to the rice roller corresponds to the lower portion of the hopper seat, a body portion of the rice roller is made of high abrasion resistant arc-shaped rice milling ribs and positioned in an equilateral polygonal rice sieve to form a rice milling chamber, the right side of the rice roller penetrates a rear bearing block, the right end of the rice roller is arranged inside a fan shell and is fixedly provided with a wind wheel, a rice baffle and a spring are arranged on the right side of the rice roller and adjusted by a shifting fork, and the shifting fork is connected with an accuracy adjusting handle. The rice polisher is simple in structure, convenient to operate, safe and fine in rice milling quality and more importantly solves the problems of more broken rice and low milled rice rate of an existing rice milling device, and energy is saved.

Owner:四川省旭东机械制造有限公司

Improved germ remaining rice husking machine huller blade set

ActiveCN106622440AAvoid being unable to move up and downReasonable structureGrain huskingGrain polishingBroken riceEngineering

The invention discloses an improved germ remaining rice husking machine huller blade set which comprises a knife rest. A fixing groove is formed in the knife rest. An elastic gasket and a spring steel gasket are arranged at the bottom of the fixing groove. A huller blade set body is connected to the interior of the fixing groove. The improved germ remaining rice husking machine huller blade set is reasonable in structure, the groove formed in a partition component has no dead angle, and rice bran powder can be removed thoroughly; the thickness of the partition component is increased, and the height of the partition component is decreased, so that the volume of contained rice bran powder is increased, and the maintenance frequency is decreased; the top of the partition component is lower than the top of a blade, the height direction of the partition component is shorter than that of the blade, a certain gap is formed between the bottom and the partition component, the huller blade set body does not need to be take out from the knife rest when rice bran powder is removed, only light knocking is needed to pour out rice bran powder or blow out the rice bran powder through an air gun, and time and labor are saved; the thickness of the partition component is increased, and the whitening efficiency in the rice machining process is greatly improved; due to a fixed-distance protruding hole boss, the phenomenon that a blade cannot move up and down due to extrusion of partition components on the two sides in the rice machining process is avoided, the amount of broken rice is reduced, the maintenance frequency is greatly decreased, and the maintenance cost is lowered.

Owner:福州天兵环保科技有限公司

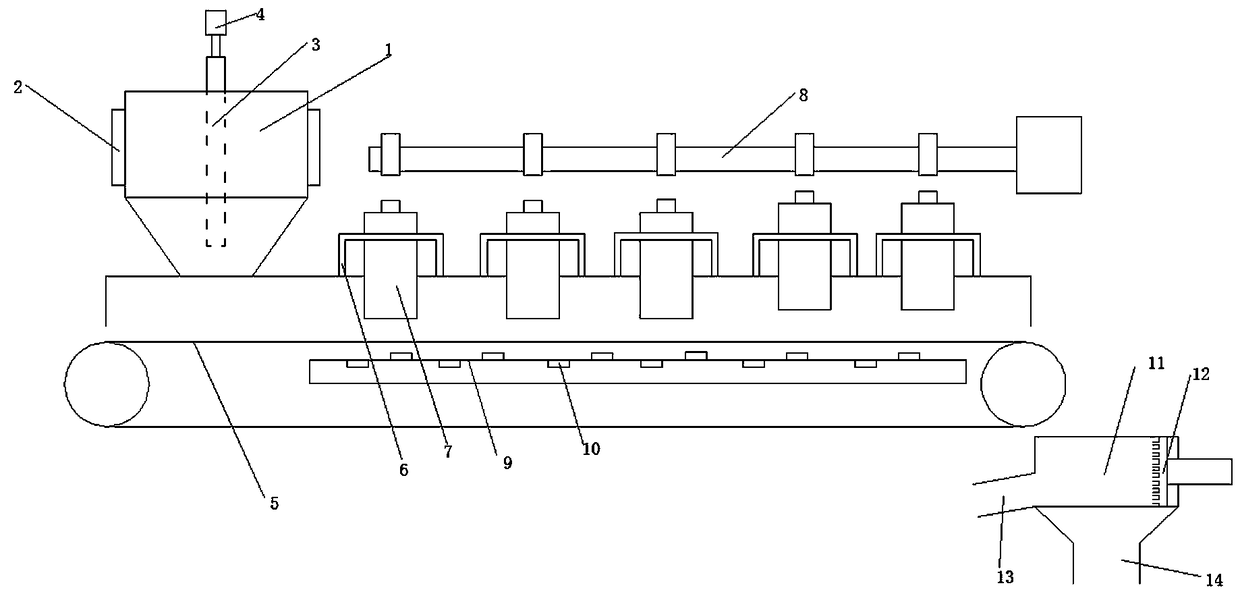

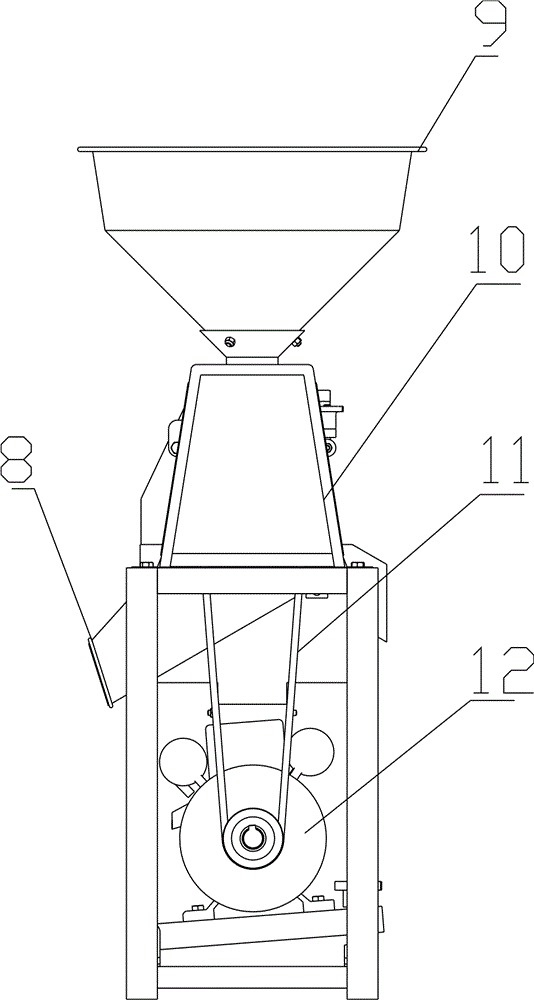

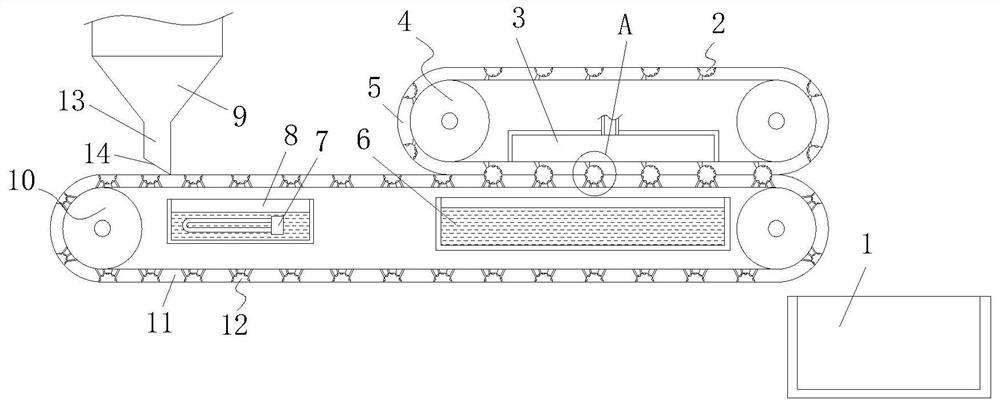

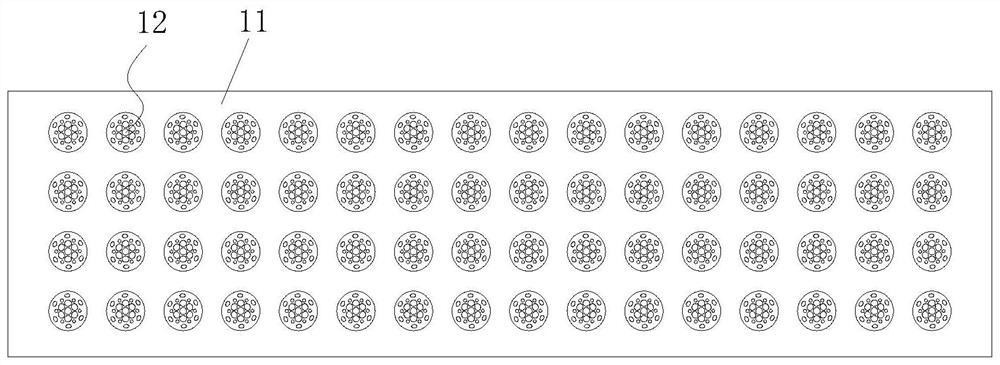

A rice grain rapid polishing device

ActiveCN109759171BQuality assurancePrevent being squeezedGrain huskingGrain polishingBroken riceEngineering

The invention relates to the technical field of grain polishing, in particular to a rapid polishing device for rice grains. The rapid polishing device comprises a first belt conveying device and a second belt conveying device, wherein the second belt conveying device is longer than the first belt conveying device; a leaking device is arranged above the front end of the second belt conveying device; the first belt conveying device is located at the rear end above the second belt conveying device; polishing balls are arranged on the inner walls of first polishing cavities and the inner walls ofsecond polishing cavities; an air outlet box is arranged in the middle of the first belt conveying device; the first polishing cavities are communicated with the air outlet box through an air outlet hole formed in a first conveyor belt; the second polishing cavities are communicated with the outside through residue discharge holes formed in a second conveyor belt. Rice is polished in independent spherical cavities, so that rice polishing quality is good, and polished rice is better; the rice is driven by airflow to be polished and prevented from being extruded, and broken rice is effectively reduced.

Owner:安徽宏虎粮油股份有限公司

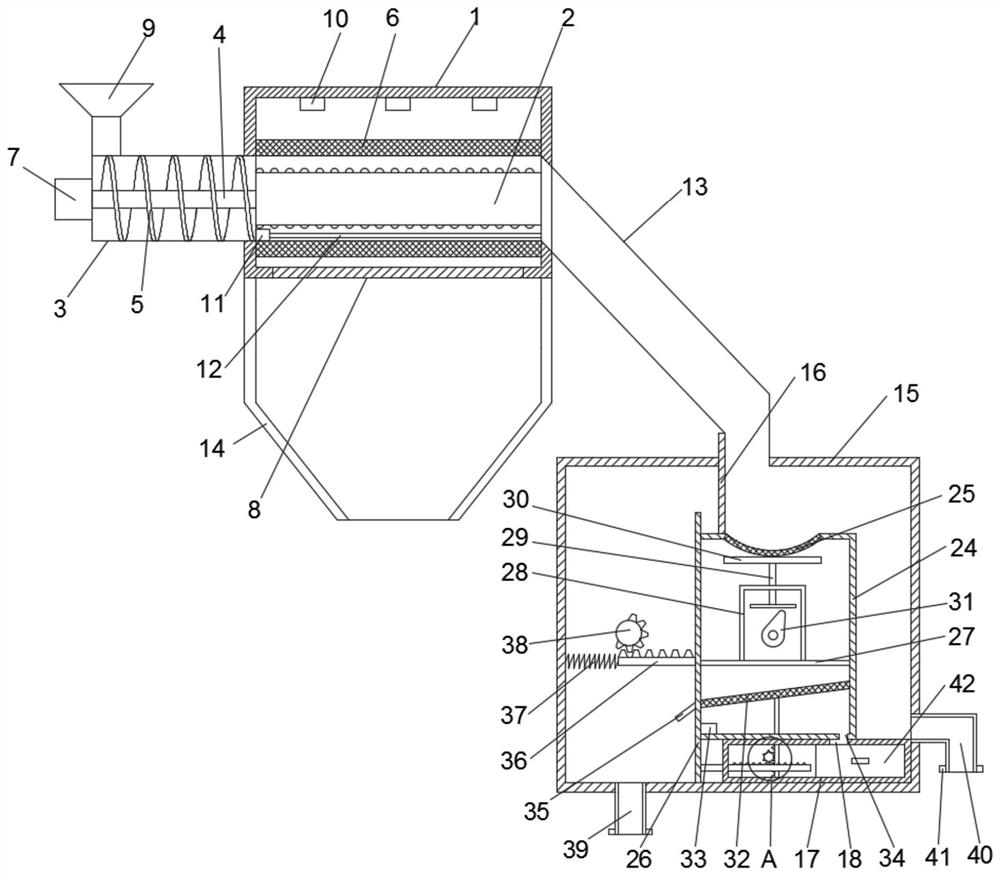

Rice milling device for rice processing

ActiveCN112169868AAvoid residueBig impactGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention discloses a rice milling device for rice processing. The device comprises a rice milling box; a milling roller is rotationally installed in the middle of the rice milling box; a plurality of sets of first air blowers are arranged at the top of the rice milling box; a conveying box is fixedly installed at the left side of the rice milling box; a transmission shaft is fixedly installedin the middle of the conveying box; a spiral blade is fixedly mounted at the outer side of the transmission shaft; a rice feeding hopper is fixedly mounted at the top of the left side of the conveying box; a bran screening net is fixedly mounted inside the rice milling box; an outlet is formed in the right end of the rice milling box; a channel is fixedly mounted at the outer side of the outlet;a material distribution box is fixedly mounted at the bottom end of the channel; a fixed box is fixedly mounted at the bottom of the material distribution box; and a movable box is slidably connectedwith the top of the fixed box. The rice milling device for rice processing relates to the field of rice processing devices, and can classify and collect rice while reducing broken rice.

Owner:和县金城米业有限责任公司

Processing technology of good-quality rice

The invention discloses a processing technology of good-quality rice. The processing technology is characterized by comprising the following steps of impurity removal, drying, one-time rice milling, wetting, drying, two-time rice milling, polishing and color sorting and grading. The processing technology of the good-quality rice has the advantages that in each step, rice is cooled before the rice is about to be subjected to a mechanical effect; compared with traditional airing and direct one-time high-temperature drying for the rice, through a process of drying the rice, the effect of removing moisture in the rice is relieved, and heating is even; in combination with wetting and drying processes, through two-time rice milling, compared with a traditional technology, the wetting step and drying step after wetting are added, the rice milling rate is greatly reduced, and for the rice, processed through the method, in the same batch, the rice milling rate reaches 8% or below.

Owner:王文斌

An improved rice cutter group for rice mill with embryos

ActiveCN106622440BAvoid being unable to move up and downReasonable structureGrain huskingGrain polishingAgricultural engineeringBroken rice

The present invention disclosed an improved type of embryo -stayed rice knife set, including the blade frame, with a fixed groove on the blade frame; the bottom of the fixed slot is elastic pads and spring steel pads;The knife group, the structure of the present invention is reasonable, the grooves on the partition parts have no dead ends, which is conducive to cleaning the bran powder; the increase in the thickness of the partition parts and the reduction of the height greatly increases the volume of the bran powder, which is conducive to reducing the number of maintenance;The top of the component is lower than the top of the blade, and the height is shorter than the blade. There is a certain gap with the bottom. When cleaning the bran powder, there is no need to move out of the knife set from the blade rack.Save time and effort; increase the thickness of the partition parts, which greatly improves the whitening efficiency of the rice processing process; the fixed -distance convex bumps avoid the phenomenon of the blade of the blade being squeezed by the partition parts on both sides during the rice processing process.It is not only conducive to reducing broken rice, but also greatly reduces the number of maintenance and reduces maintenance costs.

Owner:福州天兵环保科技有限公司

rice polisher

ActiveCN103143409BImprove polishing rateImprove the finishGrain huskingGrain polishingSpray nozzleEngineering

The invention provides a rice polishing machine which comprises a fan (8); a backing strip (15) is fixedly arranged on a crossbeam (14); a feed opening (1) is fed into a first end above a thruster (10); a discharge port (6) is positioned on the tail end below a polishing chamber (21); spray nozzles (18) are connected onto the ends of a pressure air pipe (3) and a water injection pipe (26); the spray nozzles (18) penetrate through an upper crossbeam (14) and the backing strip (15) and are fed into the polishing chamber (21); and the length of a polishing roll (11) is 1000mm to 2000mm, and the outer diameter of the polishing roll (11) is 150mm to 190mm. The rice polishing machine overcomes the defects that an existing rice polishing machine has a non-uniform dampening method and small output and the rice is easily crushed, and has the advantages of uniform dampening method, low rice crushing rate and large output.

Owner:WUHAN KINHE FOOD MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com