Rice polishing machine

A polishing machine and rice technology, applied in grain finishing, grain degerming, grain processing, etc., can solve problems affecting rice quality, wet rice bran, poor bran discharge, etc., to improve the finish and brightness, and increase the outer diameter and length, the effect of reducing the weight of a single piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

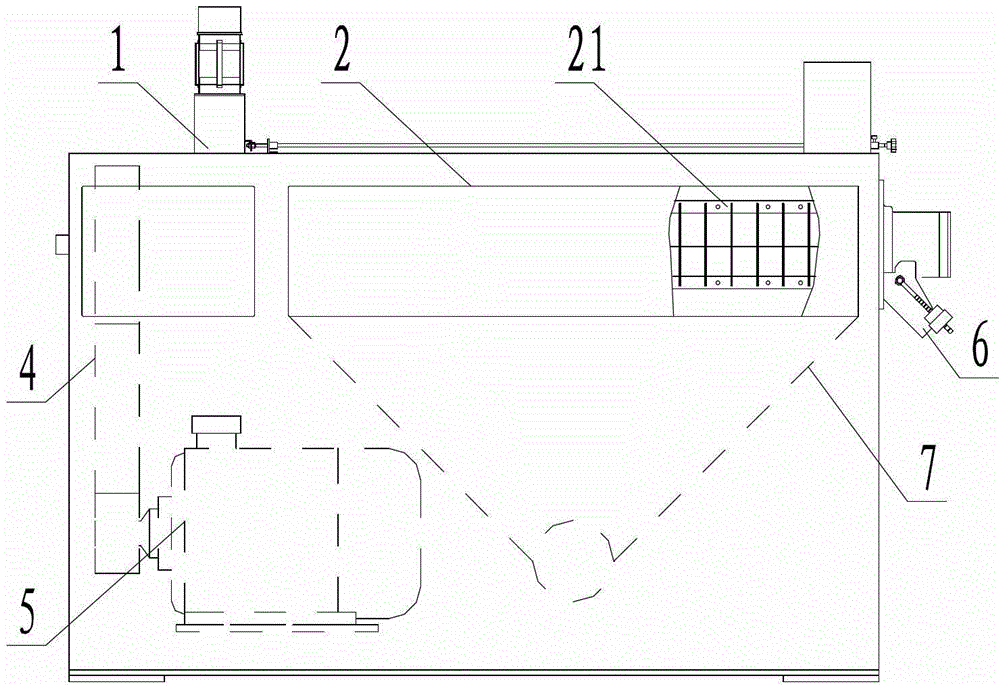

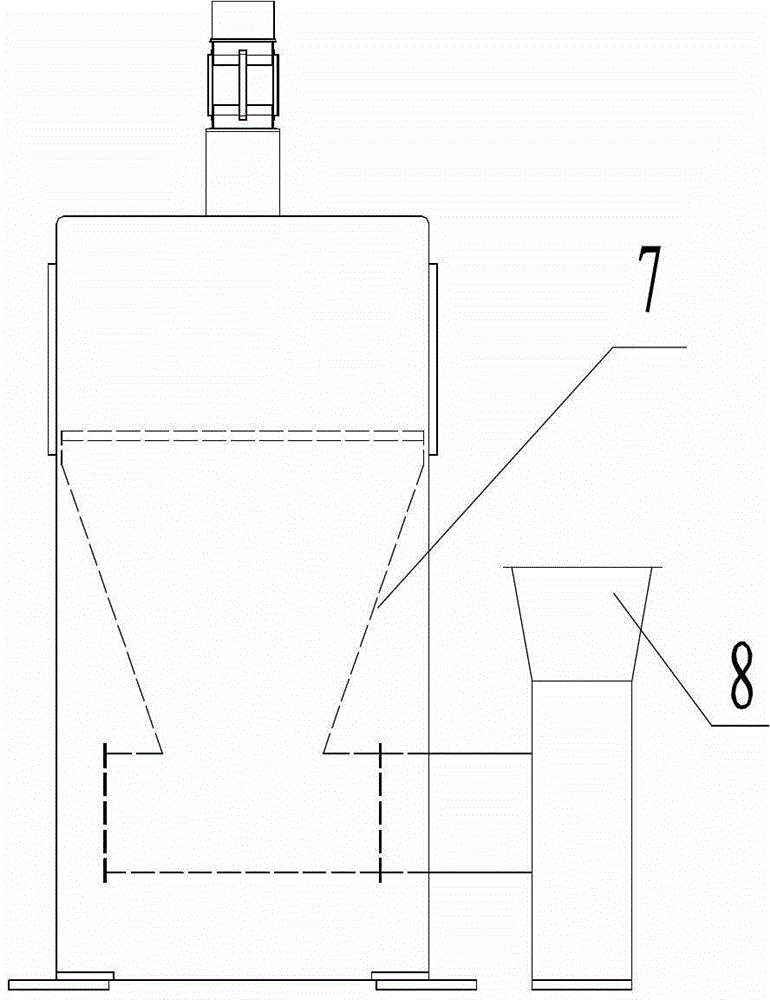

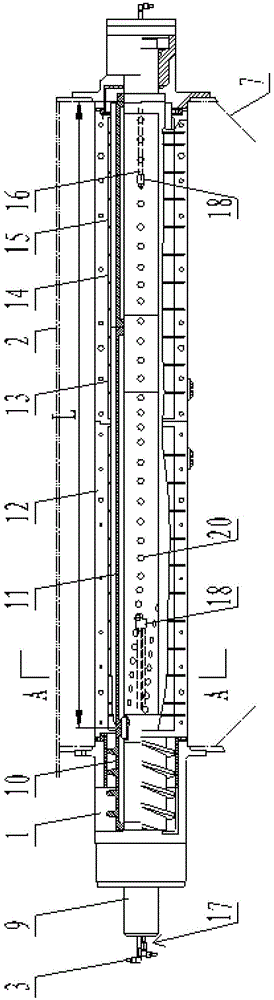

[0023] Referring to the accompanying drawings, it can be seen that the rice polishing machine of the present invention includes a fan 8, the fan 8 communicates with the chaff bucket 7, and the motor 5 is placed in the frame 2, the main shaft 9 is arranged laterally along the frame 2, and the motor 5 passes through The belt pulley 4 is connected with the main shaft 9, the main shaft 9 is a hollow tubular structure, the main shaft 9 is covered with a propeller 10 and a polishing roller 11, and a ventilation groove 19 is opened on the polishing roller 11, between the polishing roller 11 and the sieve plate 13 The space is the polishing chamber 21, the sieve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com