Polishing powder, polishing liquid for glass and preparation method thereof, glass and electronic product

A technology of polishing powder and polishing liquid, applied in polishing compositions containing abrasives, telephone communication, electrical components, etc., can solve the problems of poor glass surface quality, low polishing liquid processing efficiency, glass surface scratches, etc. Improve polished surface quality, stock removal rate and scratch performance index balance, good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

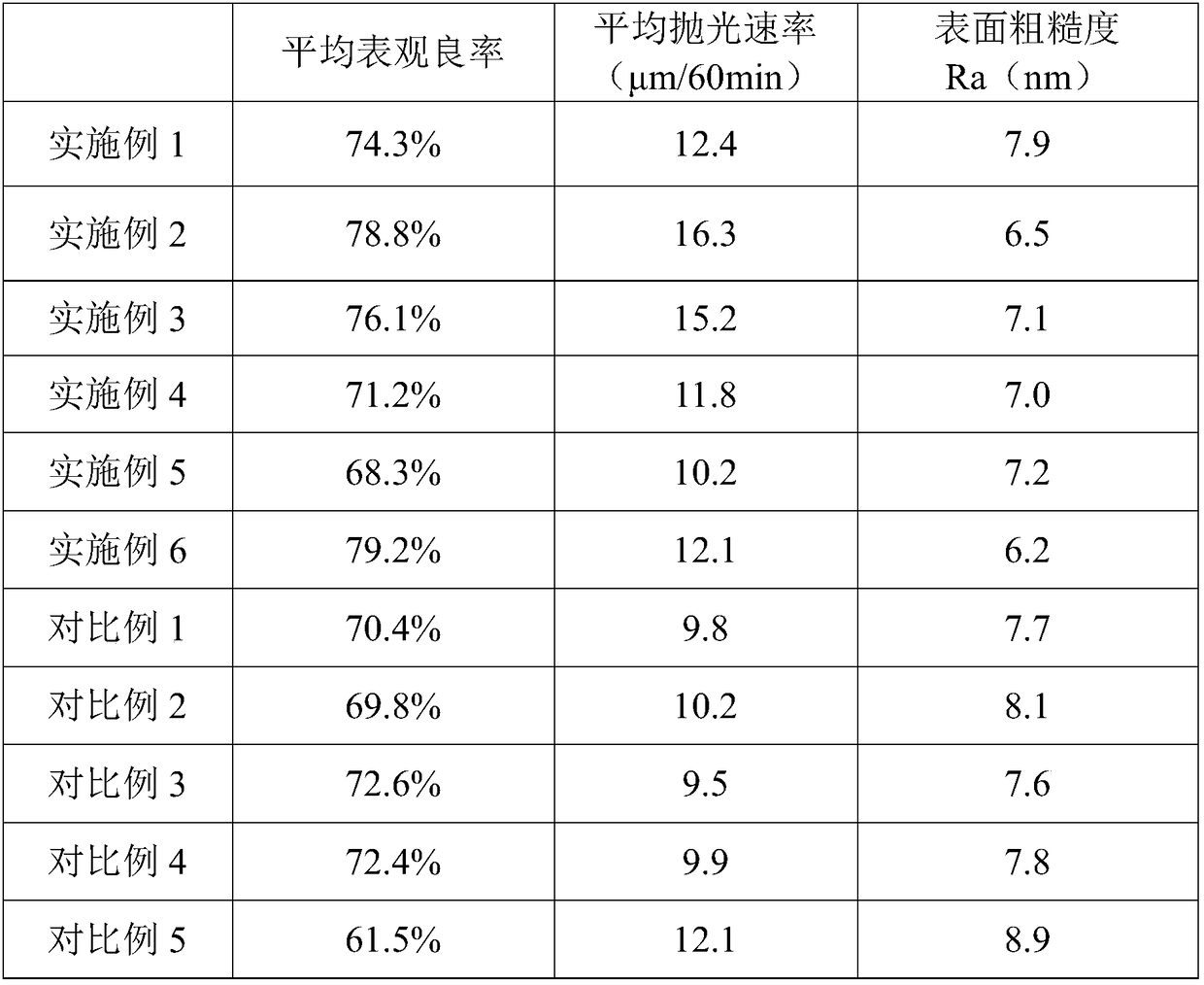

Examples

preparation example Construction

[0052] The preparation process of polishing powder can be carried out by conventional solid phase reaction method or calcination precipitation method.

[0053] Preferably, the preparation method of polishing powder, comprises the steps:

[0054] (1) synthesizing the precursor of lanthanum cerium rare earth polishing powder;

[0055] (2) Carry out fluorination to the above-mentioned precursor, control the addition of fluorine to account for 10-20% of the total amount, and mix uniformly;

[0056] (3) After drying and burning, the semi-finished polishing powder is obtained, and then post-processed.

[0057] Preferably, the precursor of the lanthanum-cerium rare earth polishing powder is a mixture of lanthanum and cerium chlorides, sulfates, nitrates, carbonates or oxides.

[0058] Preferably, the fluoride added to the precursor is one or more of fluorosilicic acid, hydrofluoric acid, ammonium bifluoride, ammonium fluoride, sodium fluoride or potassium fluoride.

[0059] Prefer...

Embodiment 1

[0112] A polishing powder for glass, comprising the following components in mass percentage: 50% of cerium oxide, 30% of lanthanum oxide and 20% of fluorine. Among them, the D50 of the polishing powder for glass is 1.04 μm, the D90 is 2.4 μm, and the Mohs hardness is 7. The number of particles with spherical shape in the polishing powder for glass accounts for 50% of the total number of polishing powder particles.

Embodiment 2

[0114] A polishing powder for glass, comprising the following components in mass percentage: 55% of cerium oxide, 25% of lanthanum oxide and 20% of fluorine. Among them, the D50 of the polishing powder for glass is 1.5 μm, the D90 is 2.4 μm, and the Mohs hardness is 7. The number of particles with spherical shape in the polishing powder for glass accounts for 50% of the total number of polishing powder particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com