Novel siamesed roller for processing rice

A rice processing and conjoined technology, which is applied in grain processing, application, grain pod removal, etc., can solve the problems that the thickness of the polishing roller should not be too thin, the cost is high, and the output of rice processing is affected, and the polishing effect is good and the production efficiency is high. , the effect of less broken rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

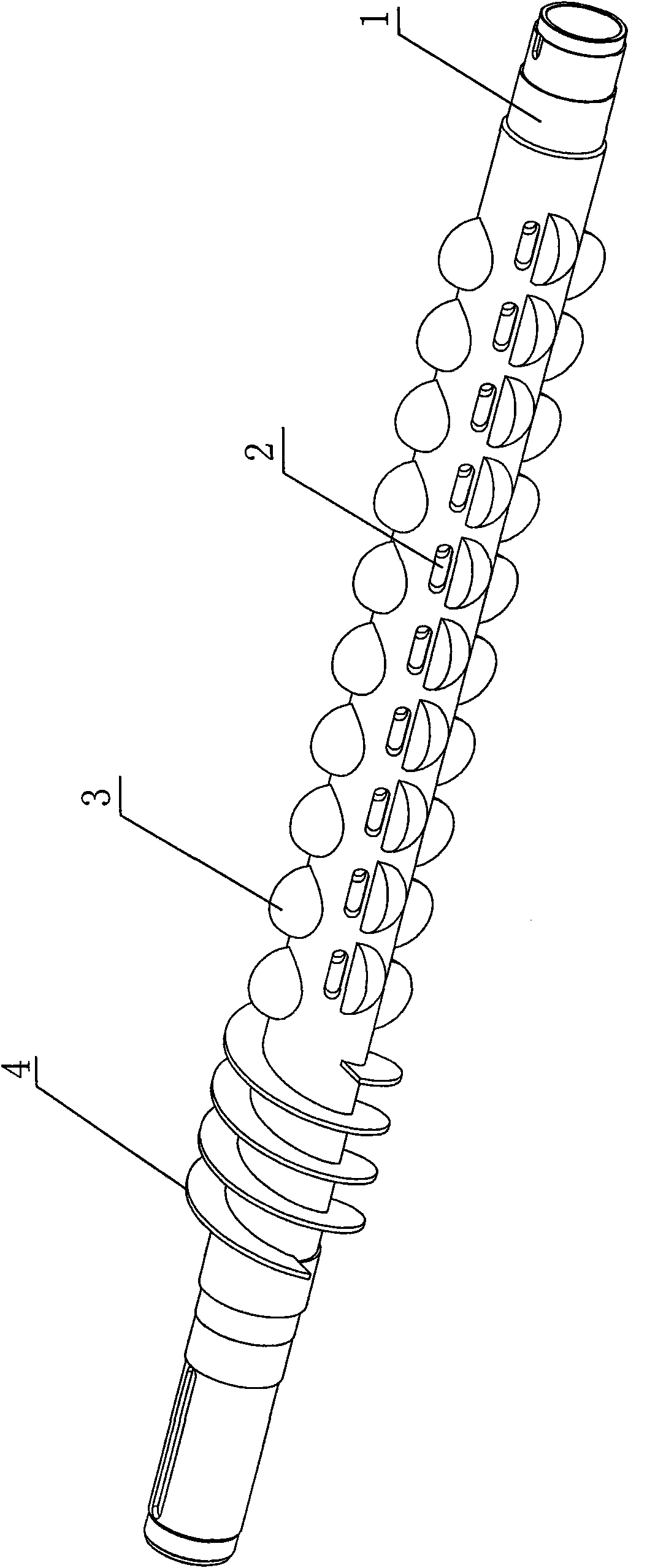

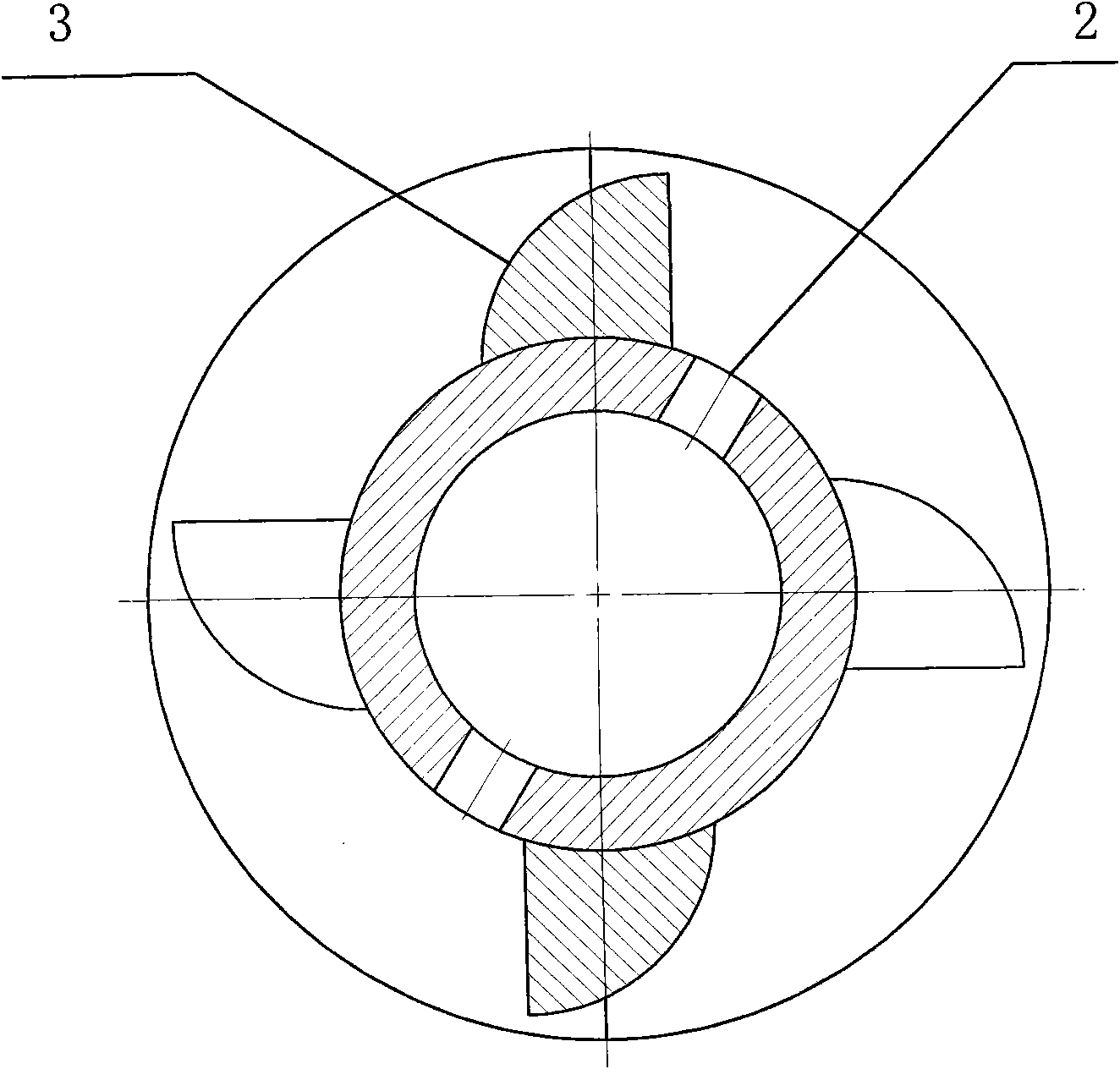

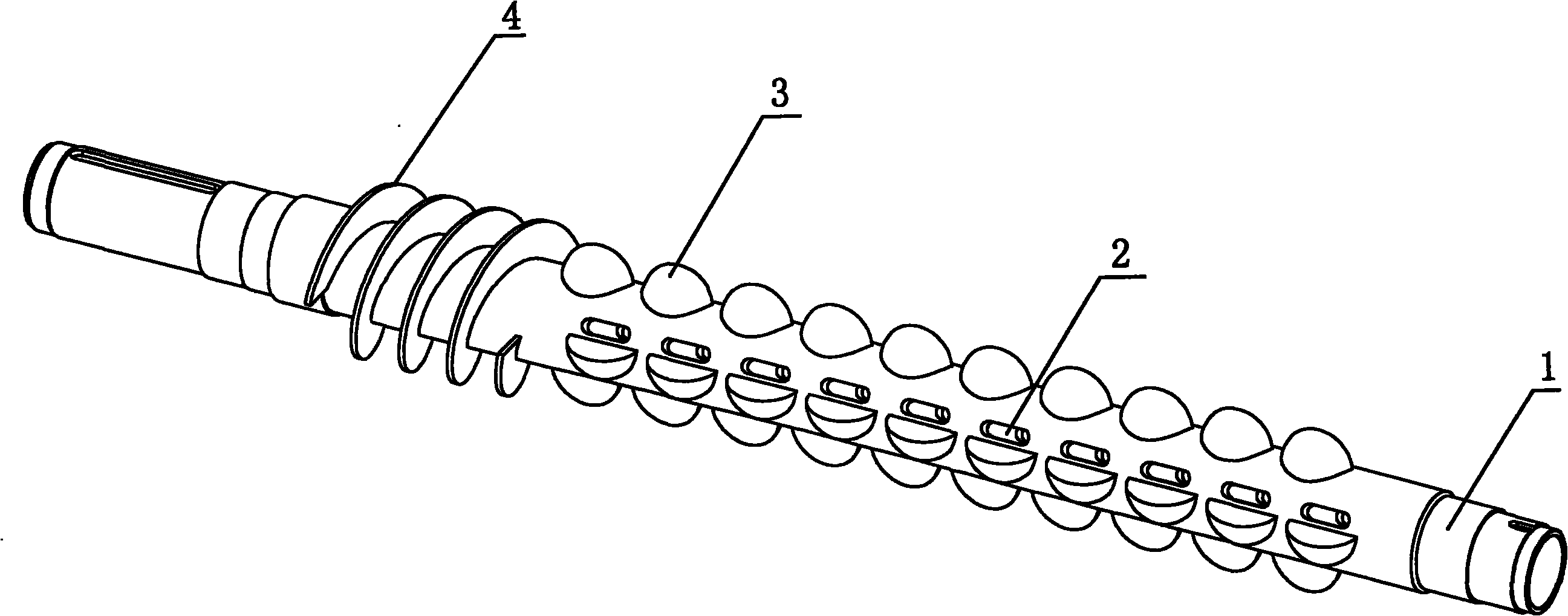

[0012] like figure 1 , figure 2 As shown, a novel rice processing conjoined roller includes a roller body 1, which is characterized in that: the roller body 1 is hollow, and the roller body 1 is provided with ventilation grooves 2, and the roller body 1 surface is pressed by a certain amount. There are working ribs 3 for processing, and the working ribs 3 are fixed on the roller body 1 by welding.

[0013] The working rib 3 is 1 / 4 hemispherical.

[0014] The screw blade 4 for feeding is welded on the surface of the roller body 1 .

[0015] The polishing ribs 3 and the polishing roller body 1 are arranged in a certain way in the axial direction, so that when the polishing roller body 1 is rolling, the rice enters the roller body 1 with the spiral blade 4 to roll and rub. , so that the polishing pressure is soft, and the excessive pressure in a local area can be relieved by the gap between the surface of the polishing rib 3 ball itself and the polishing ribs, thereby greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com