Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Realize continuous cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

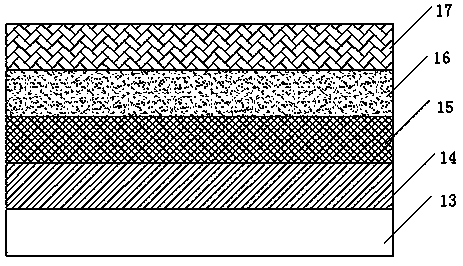

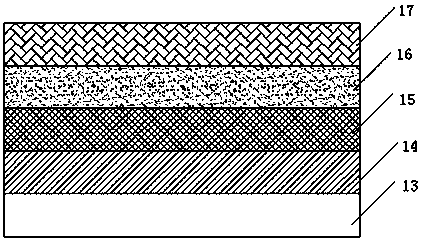

Ceramic filter film of rare-earth modified attapulgite with nano coating and preparation method thereof

InactiveCN102614782AUniform pore size distributionLight in massSemi-permeable membranesCeramicwareRare earthPore diameter

Owner:SHANGHAI MARITIME UNIVERSITY

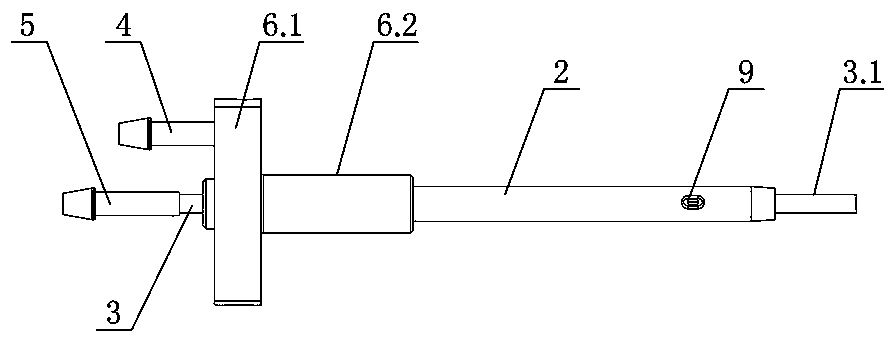

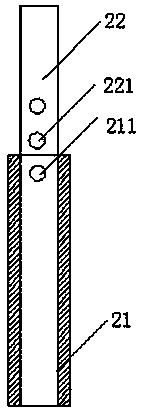

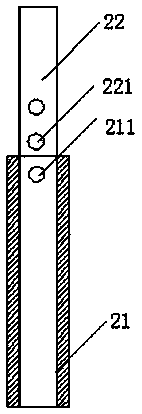

Sleeve needle suitable for magnetic bead washing system

PendingCN109877120AWith self-cleaning functionImprove accuracyHollow article cleaningMaterial analysisMagnetic beadBiomedical engineering

The invention discloses a sleeve needle suitable for a magnetic bead washing system. The sleeve needle comprises a connecting base. An outer washing needle extending outwards is installed in an installing groove of the connecting base in an inserted manner. An inner liquid suction needle is connected into the outer washing needle through a fixing assembly. The outer end of the inner liquid suctionneedle extends out of the outer end of the outer washing needle to form an inserting section. The inner end of the inner liquid suction needle penetrates out of the inner end of the outer washing needle and is fixedly connected to the bottom wall of the installing groove. The connecting base or the outer washing needle is provided with an outer pipeline connector communicating with the outer washing needle. The connecting base or the outer washing needle is provided with an inner pipeline connector communicating with the inner liquid suction needle. The sleeve needle has the advantages that the structure is simple, the sleeve needle has a self-cleaning function, it can be ensured that the inner wall and the outer wall of the inner liquid suction needle are washed cleanly, the washing effect is good, and the situation that cross contamination among different samples occurs, and accuracy and reliability of sample detecting results are influenced can be prevented.

Owner:AUTOBIO LABTEC INSTR CO LTD

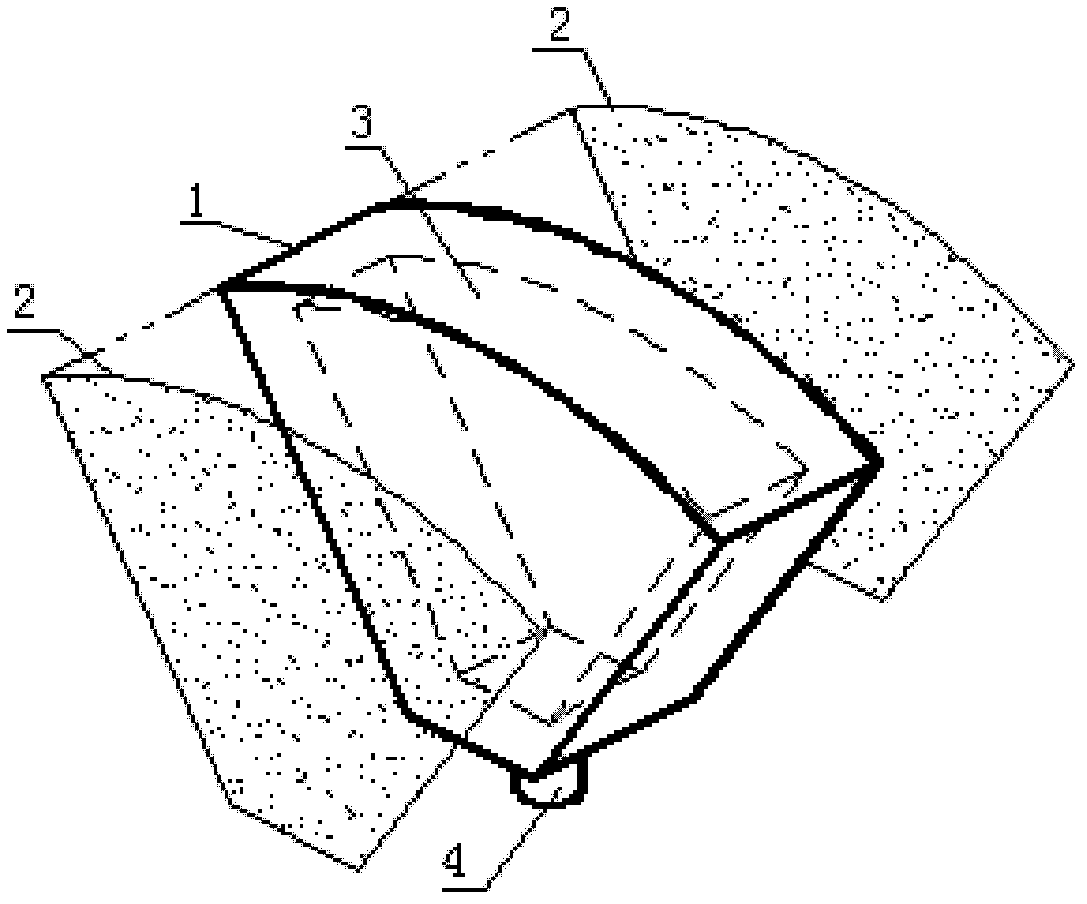

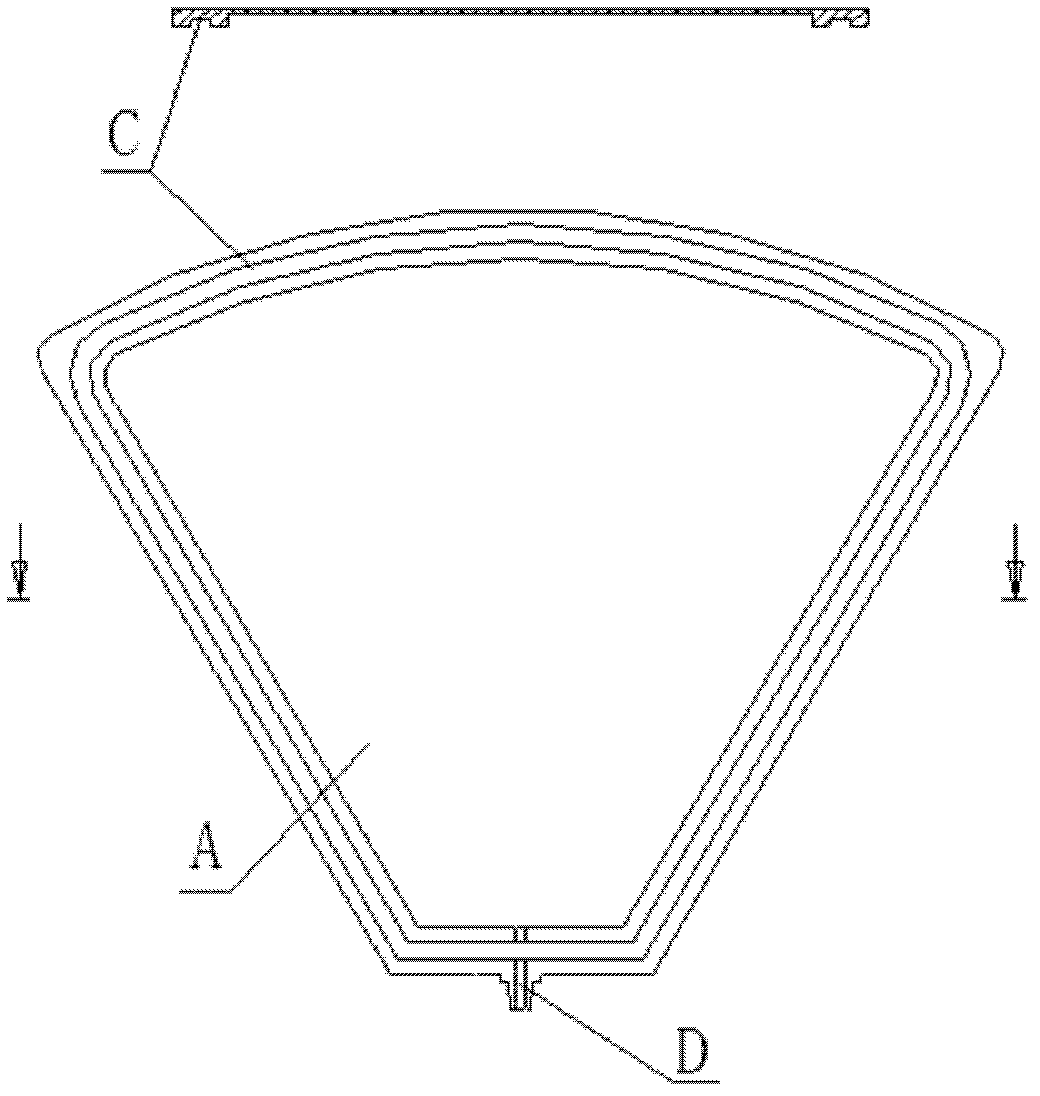

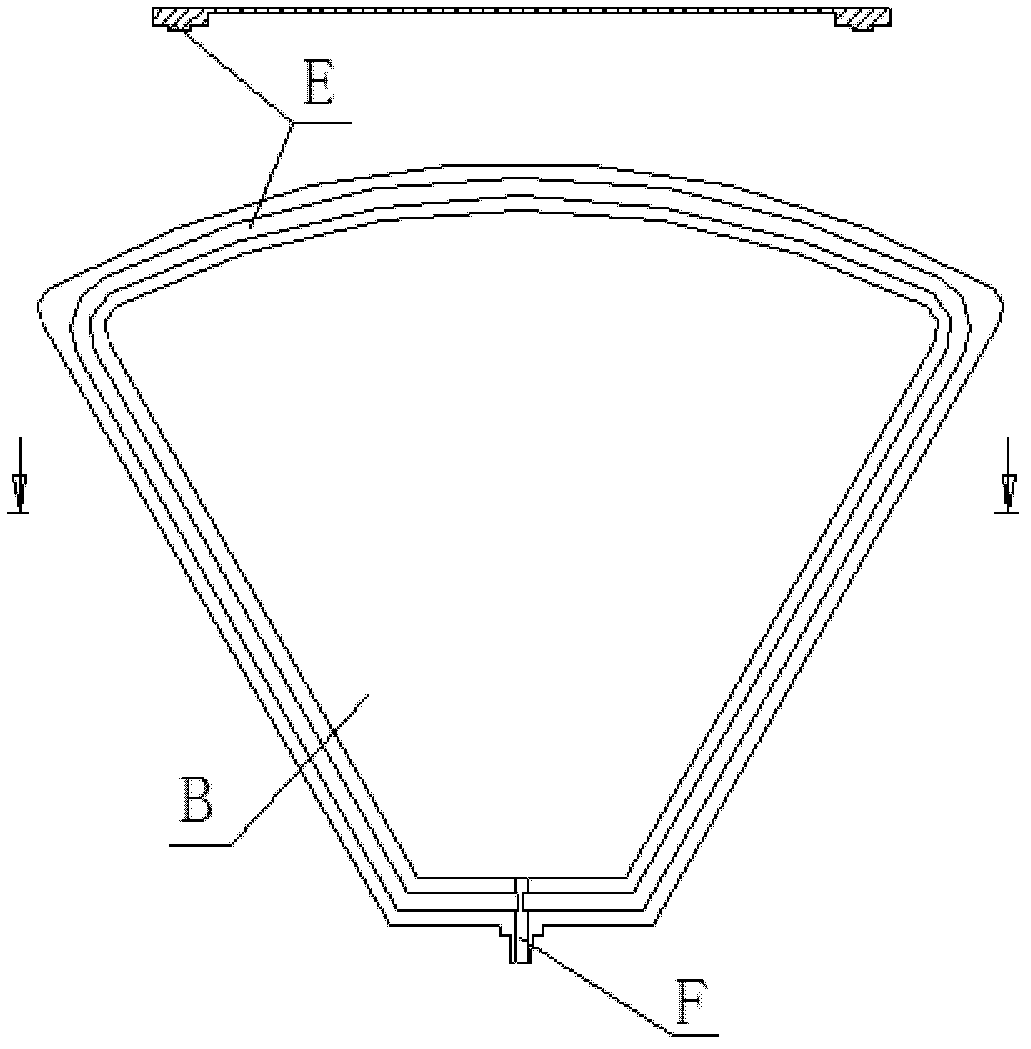

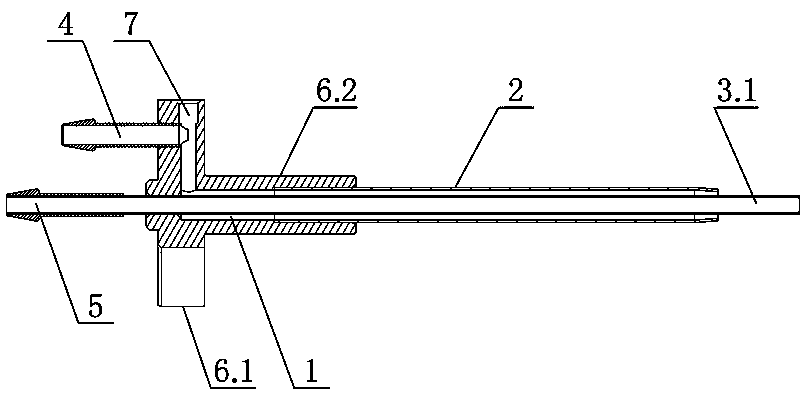

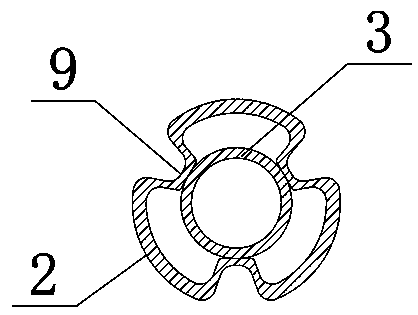

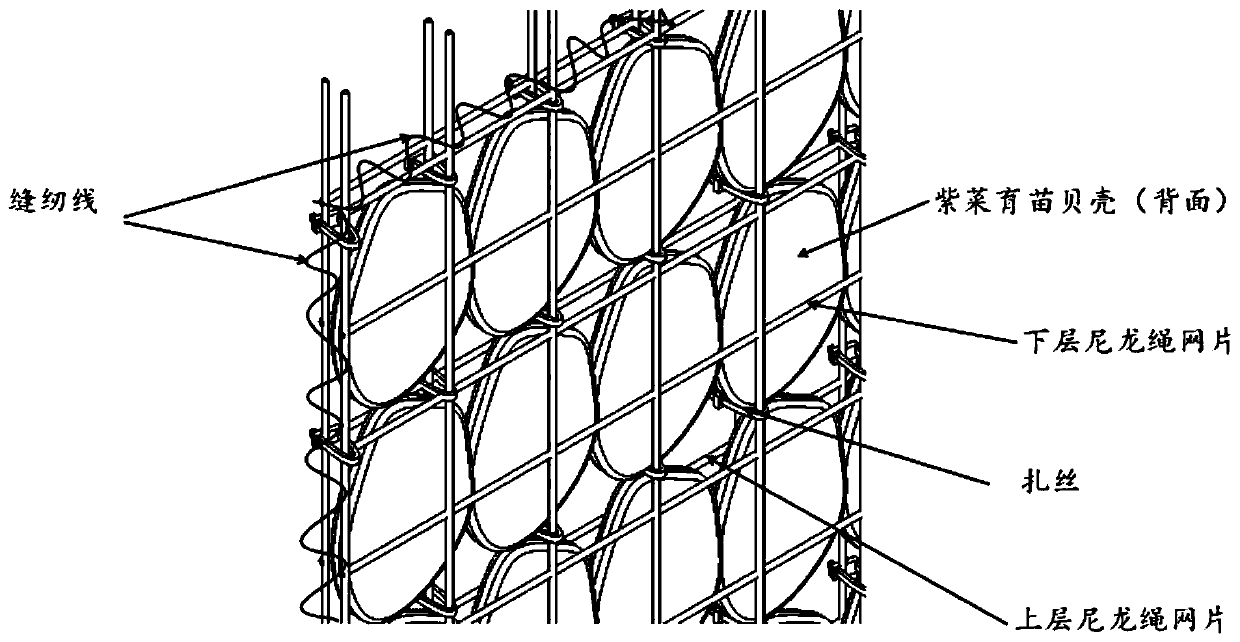

Laver seedling culturing shell net screen and arraying and seaming device thereof

ActiveCN111316908AEasy to cleanSmall sizeCultivating equipmentsCleaning using liquidsBiotechnologyEngineering

That the strength is high and the efficiency is low; and during cleaning the walls and the bottoms of the seedling culturing ponds, the laver seedling culturing shells need to be repeatedly piled, andafter cleaning is completed, the laver seedling culturing shells are realigned in the bottom of each seedling culturing pond are solved; and the arraying and seaming device special for the laver seedling culturing shell net screen is designed and manufactured for the arraying and seaming of the laver seedling culturing shell net screen, so that the manual seaming difficulty of the laver seedlingculturing shell net screen is reduced, and the seaming quality is improved.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG

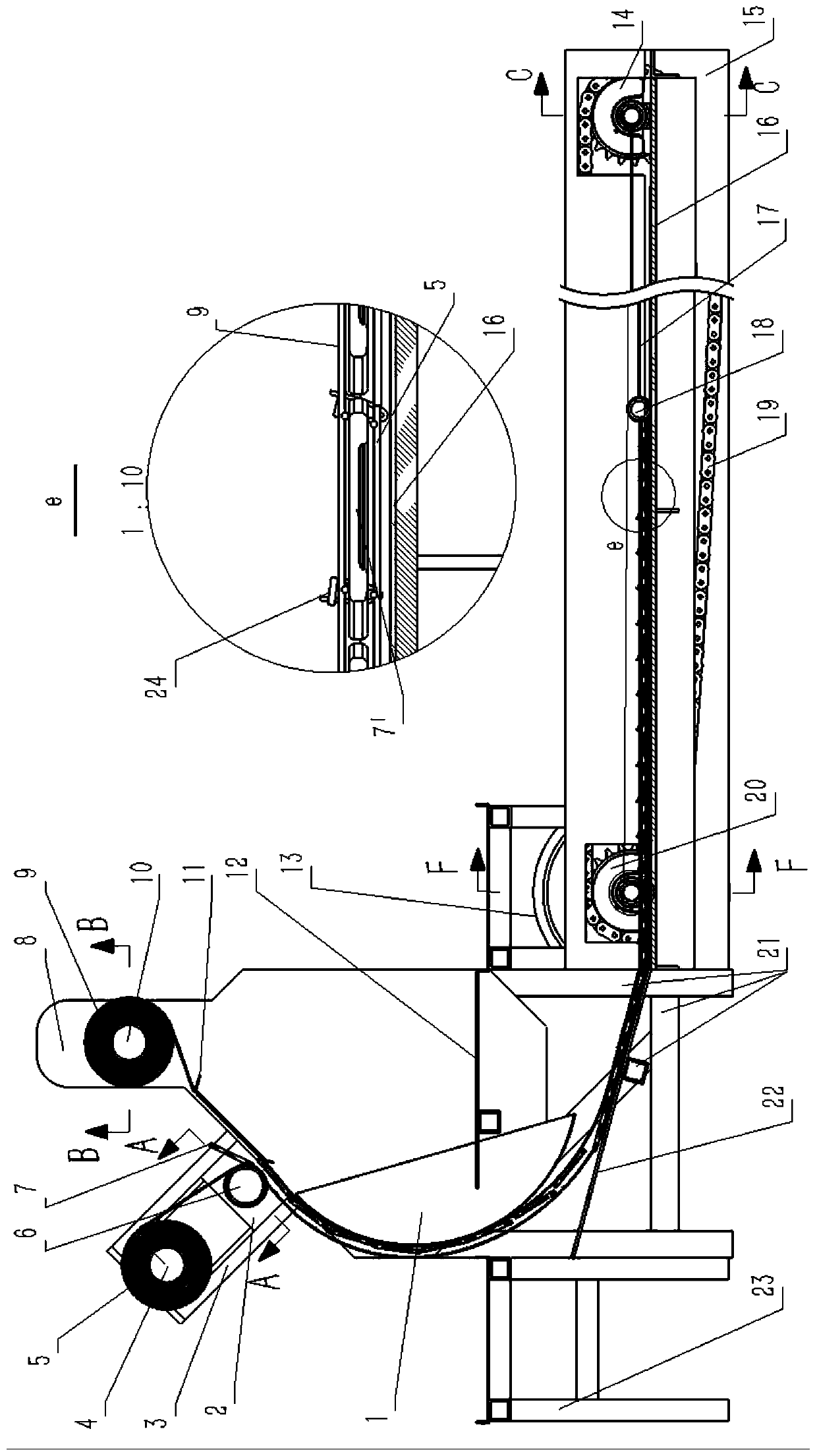

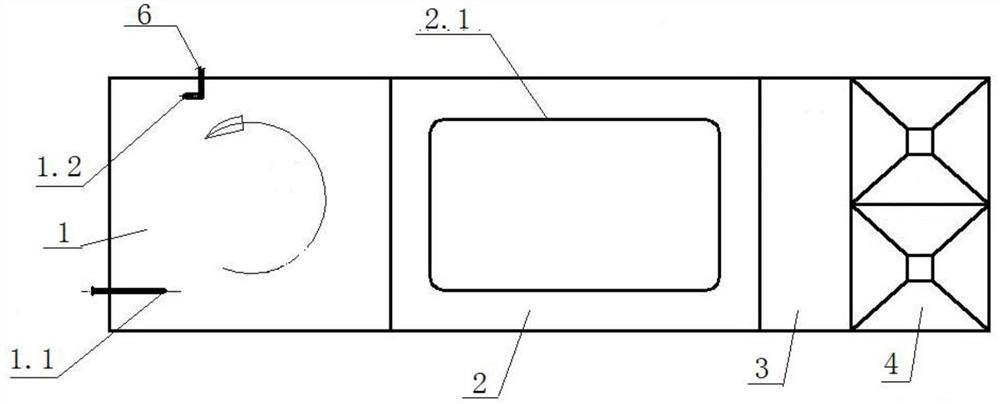

Absorbent charcoal cleaning machine

The invention discloses an active-carbon cleaner. A discharge outlet is arranged at either side of the machine frame; a conveying device is arranged on the machine frame; a grille box, a deviation rectifying device, a sprinkling rinsing device, a blowing and material-flapping device are arranged on the conveying device from the left to the right. The grille box is arranged on the horizontal segment on the left of the conveying device; a bubble cleaning and hydraulic flushing device is arranged on the grille box; the grille box is overlapped over the middle inclined segment of the conveying device, and the deviation rectifying device is arranged in the area with which the grille box and the middle inclined segment are connected; the sprinkling rinsing device is arranged above the middle inclined segment of the conveying device; the blowing and material-flapping device is arranged above the horizontal segment on the right of the conveying device; a silo is arranged under the blowing and material-flapping device; and a micro-vibration draining device is arranged on the corresponding ground under the silo. The invention is capable to sufficiently remove the impurities on the surface of active carbon, the dirt in the capillary porosity, the intercrystal reductive composition, and is capable to produce cleaning granular active coal applied to drinking water engineering and water purifier.

Owner:宜兴市乔阳电器有限公司

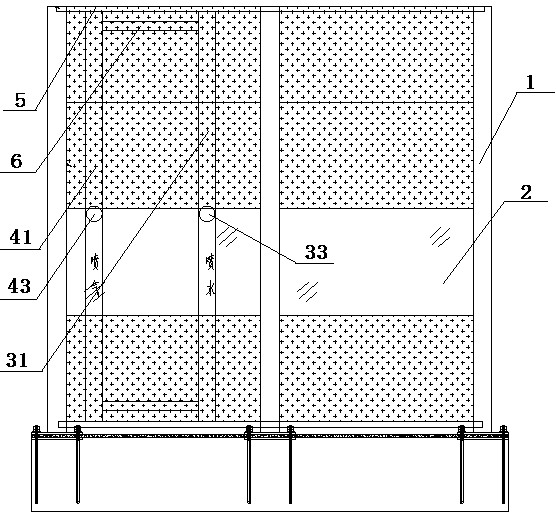

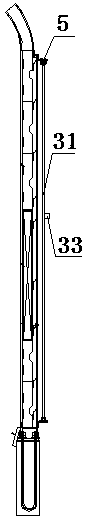

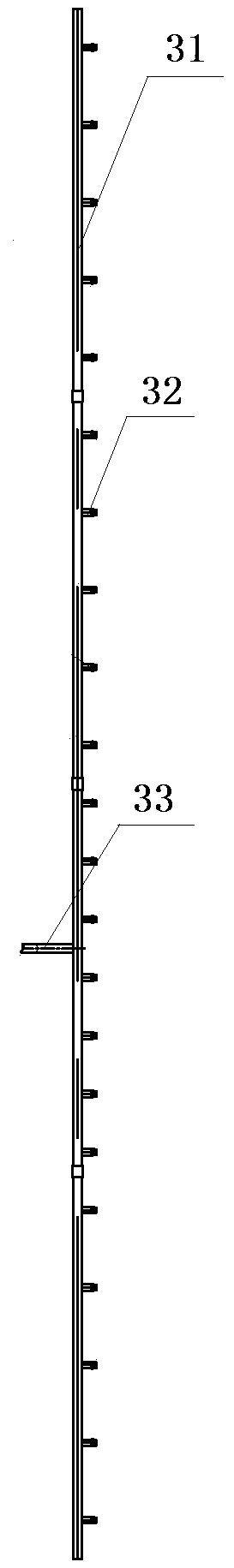

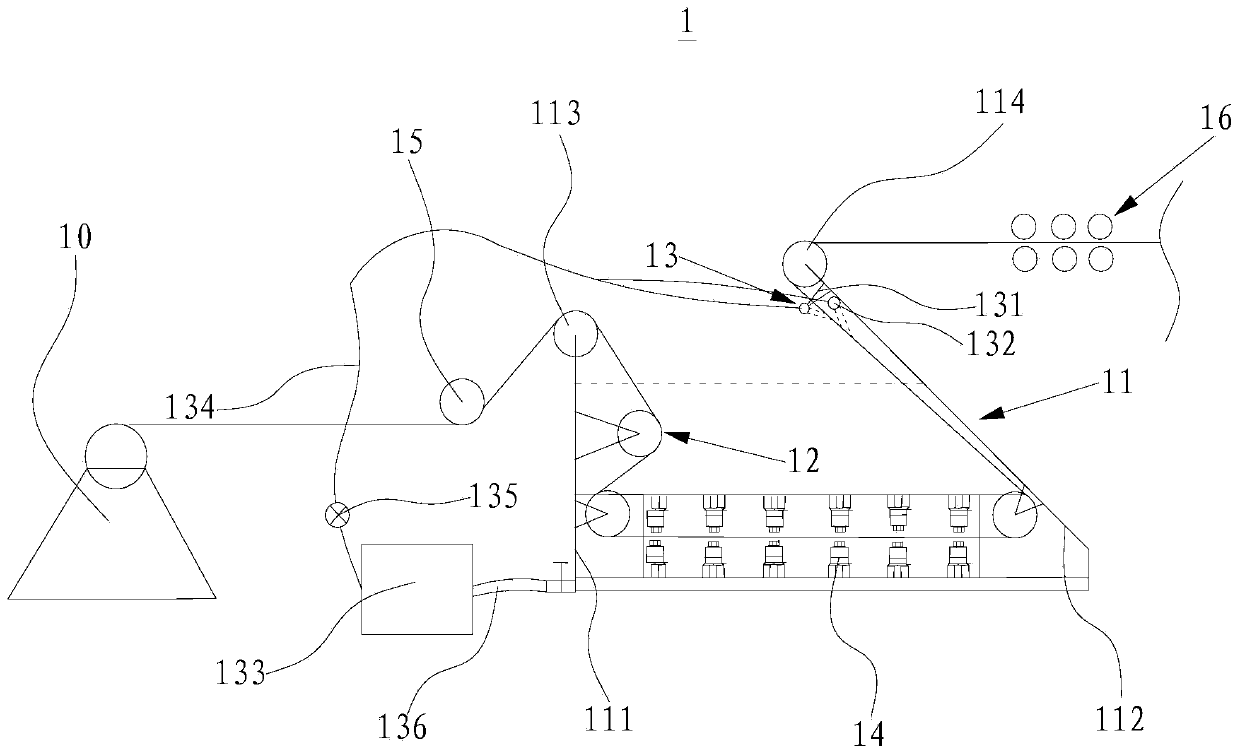

Cleaning system for sound barrier

PendingCN110219257ARealize intelligenceContinuous cleaningNoise reduction constructionCleaning using liquidsEngineeringWater supply

The invention discloses a cleaning system for a sound barrier. The sound barrier comprises stand columns and sound barrier unit plates arranged between every two adjacent stand columns. The device further comprises a cleaning system, the cleaning system comprises a water spraying system and a water supply system, a flushing device is additionally arranged on an existing sound barrier, and continuous cleaning of the sound barrier is achieved without manual wiping. When the dirt degree of the surface of the sound barrier is different, proper cleaning pressure can be selected according to the actual situation, and automatic cleaning is achieved. A drying system is additionally arranged, the cleaned sound barrier is rapidly dried in a blow-drying mode, and water spots left in a natural dryingmode are avoided. According to the device, manual consumption is avoided, potential safety hazards are reduced to the minimum, normal traffic is not affected, and the system has wide application prospects.

Owner:SHAZC GRP CORP LTD

Novel spinning head washing technology

The invention belongs to the spinning detection field, and particularly relates to a novel spinning head washing technology. The novel spinning head washing technology includes the concrete steps of: 1, alkaline liquid spray washing; 2, hot water spray washing; 3, hot water spray washing; 4, air spray washing; 5, acid pickling; 6, alkaline liquid spray washing; 7, hot water spray washing; 8, hot water spray washing; 9, air spray washing; and 10, drying. The above technical processes realize automation except the beginning manual material-loading and the final manual material-discharging and assembling. At the same time, a process of supersonic wave washing is not needed. Two-stage filtration is adopted in a reservoir, so that clean washing is guaranteed and a nozzle is prevented from being blocked. The continuous washing is realized. Unclean matters on the outer surface of a spinning head are removed, and the spinning head is not damaged.

Owner:YIBIN GRACE

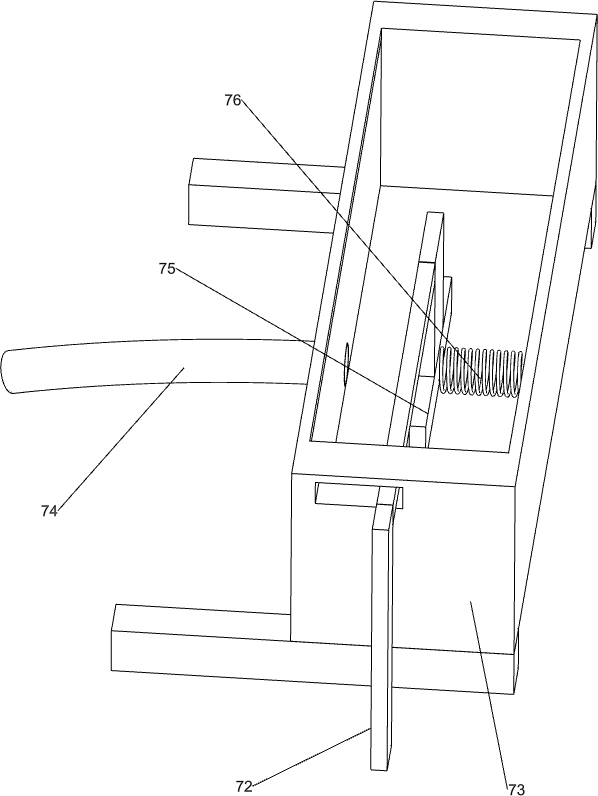

Dustbin cleaning device

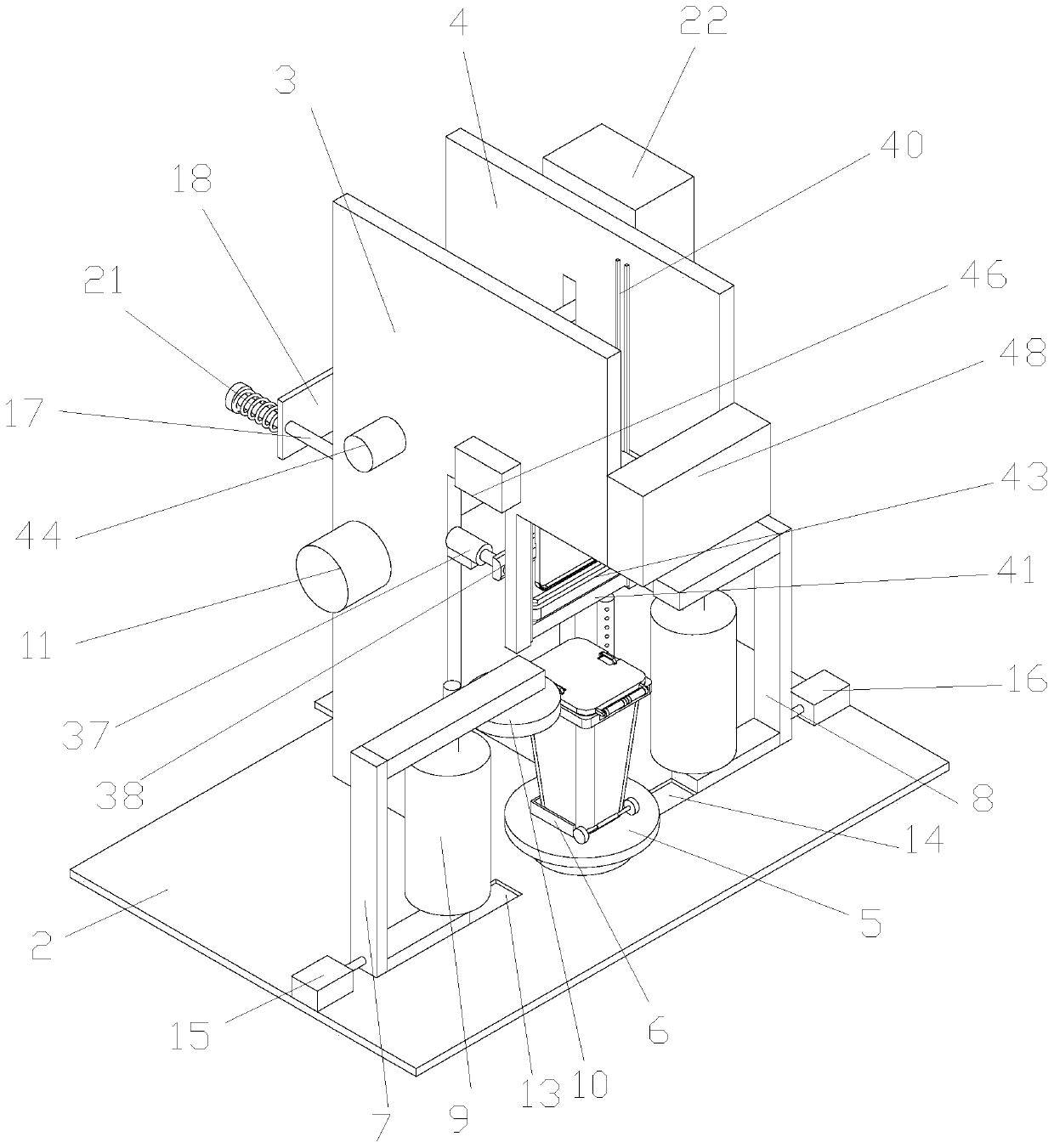

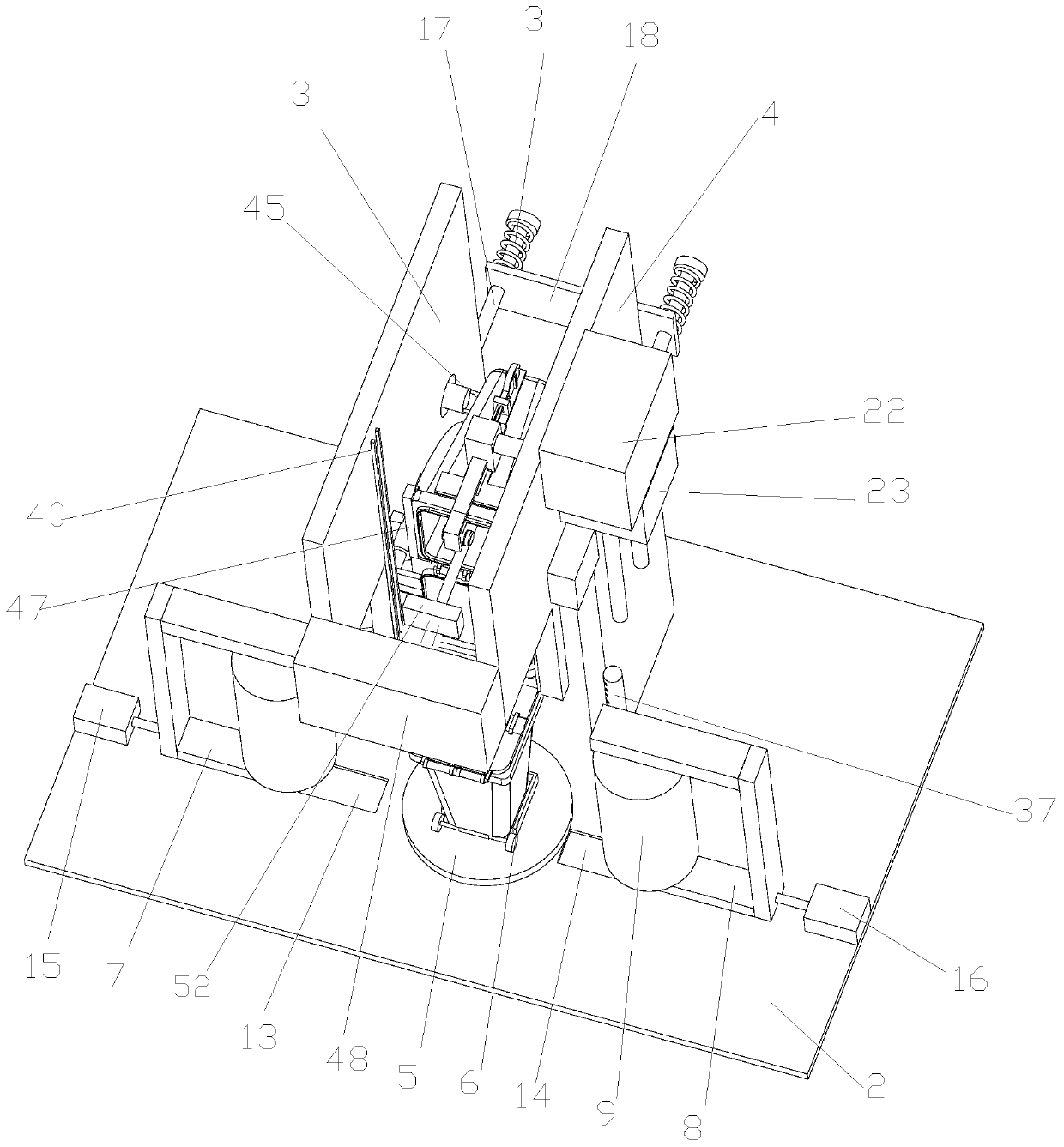

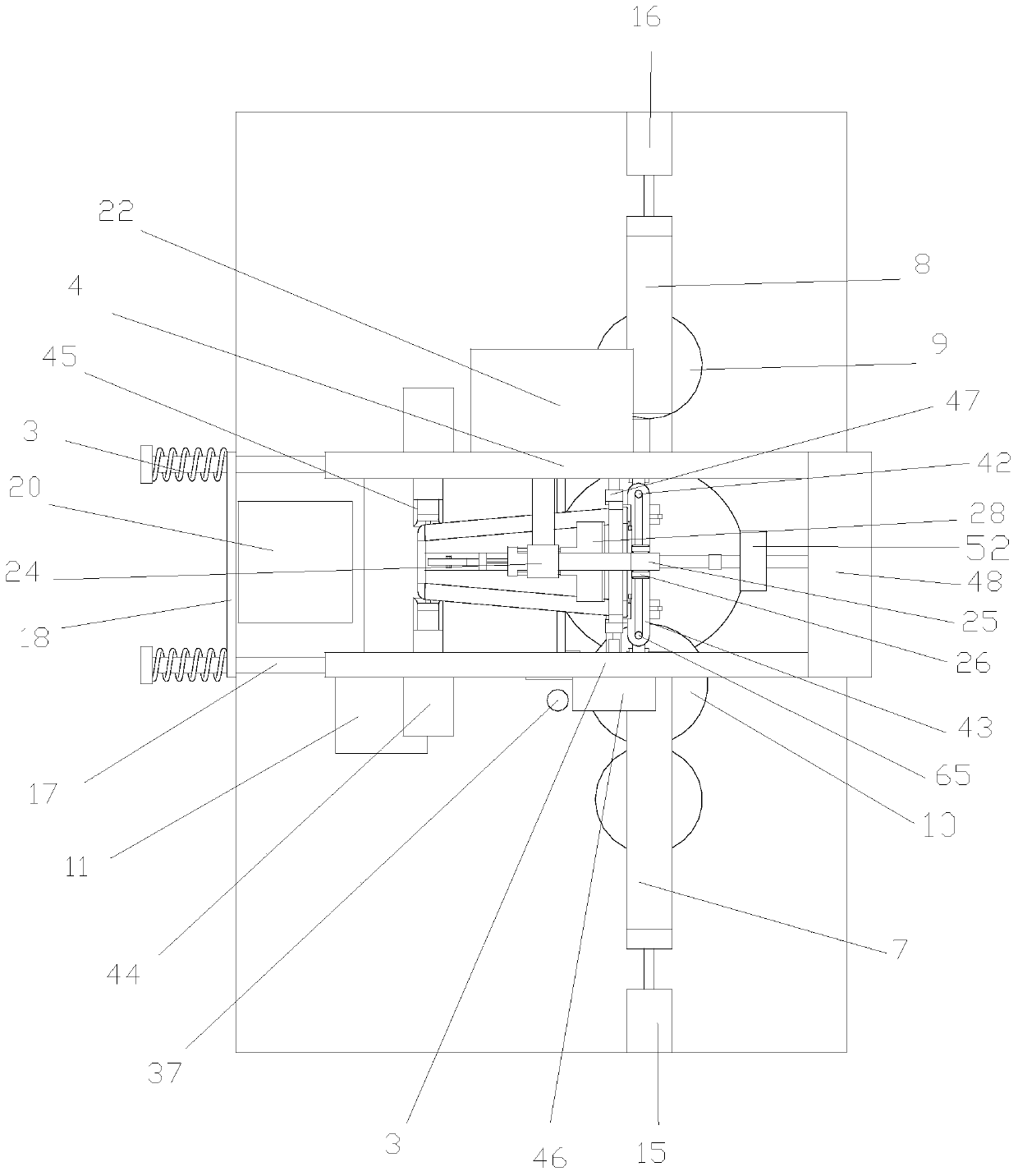

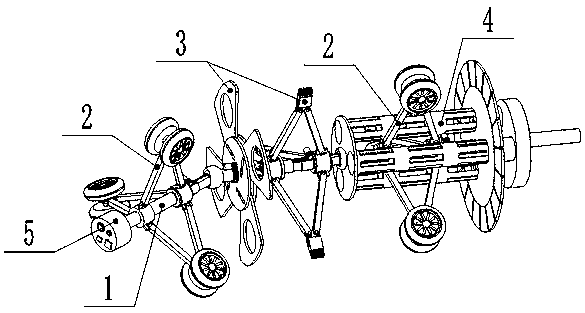

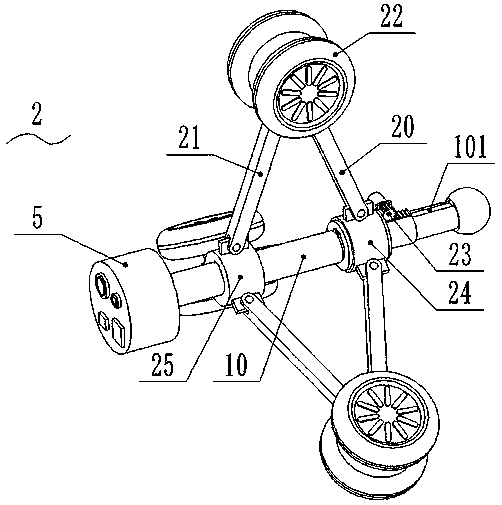

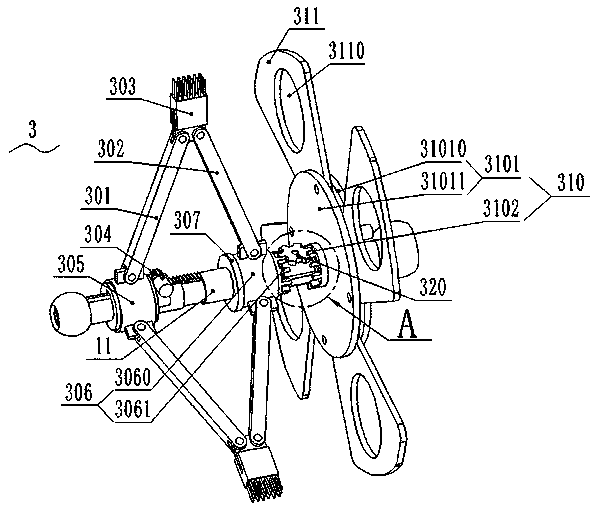

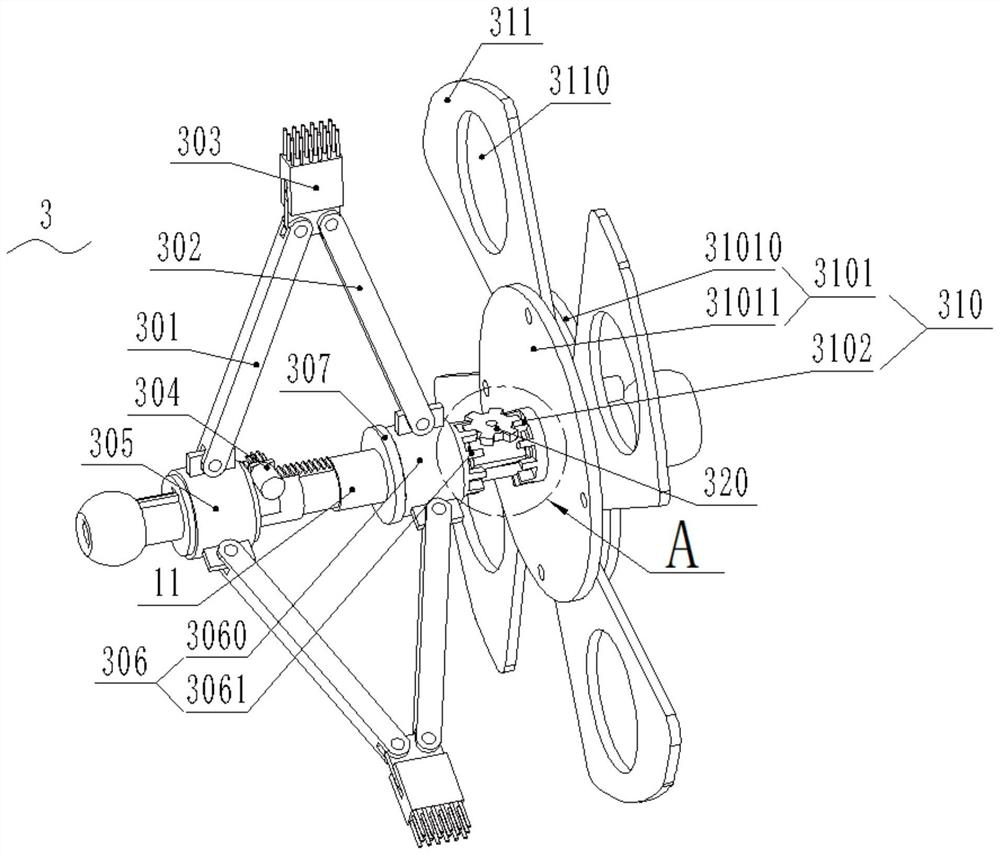

ActiveCN110788098ARealize continuous cleaningImprove cleaning efficiencyHollow article cleaningEngineeringMechanical engineering

A dustbin cleaning device comprises a rack, a cleaning mechanism arranged on the rack, a hoisting mechanism used for obliquely placing a dustbin, and a fixing mechanism arranged on the rack. The cleaning mechanism comprises a first cleaning device, a second cleaning device and a third cleaning device. The dustbin cleaning device is characterized in that the hoisting mechanism comprises a rotatablefixing frame, a dumping driving part used for driving the fixing frame to rotate, a lifting driving part used for driving the dumping driving part to move up and down, and a clamping component arranged on the fixing frame; and the second cleaning device comprises a brush and a stretchable component used for driving the brush to be attached to the inner wall of the dustbin. The dustbin cleaning device has the following advantages that the second cleaning device can brush the inner-diameter portion of the dustbin, so that the cleaning efficiency is high, and thorough cleaning is achieved; and through the arrangement of the hoisting mechanism and a dustbin lowering mechanism, the dustbin does not need to be manually carried when cleaned, continuous cleaning of the dustbin can be achieved, and the cleaning efficiency is further improved.

Owner:杨宁

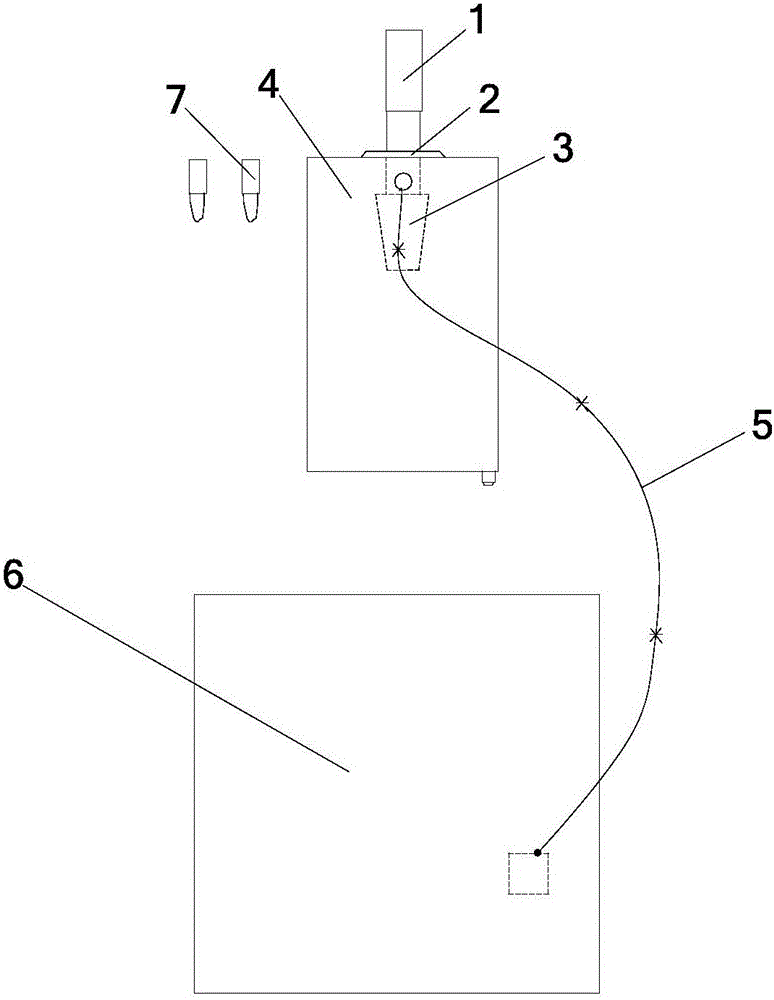

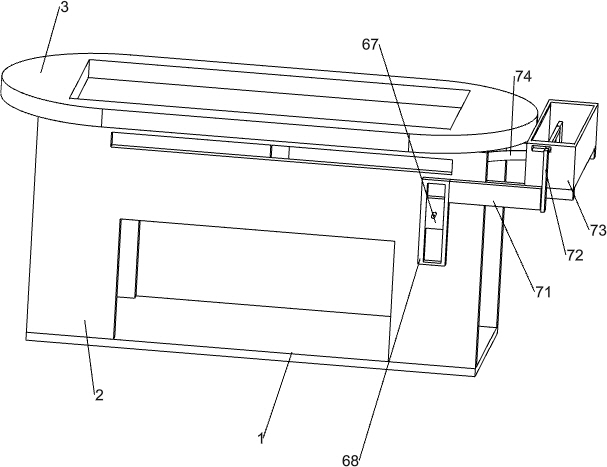

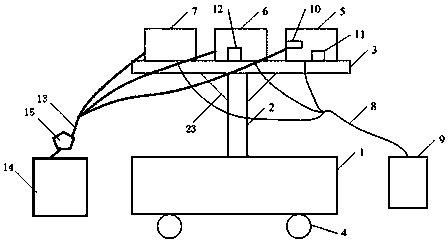

A solar panel cleaning device

ActiveCN107824498BComprehensive cleaningImprove work efficiencyCleaning using toolsCleaning using liquidsDrive wheelElectric machine

Owner:海盐派特普科技有限公司

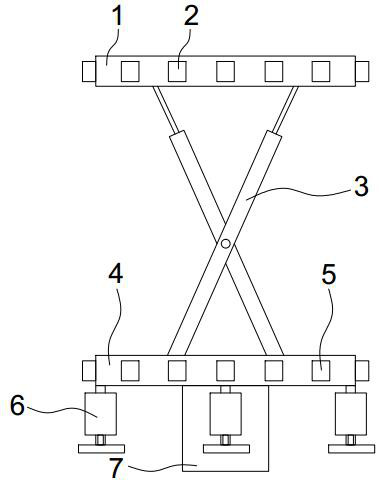

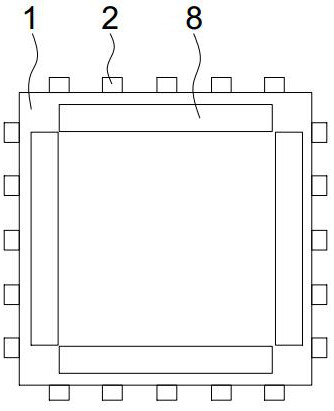

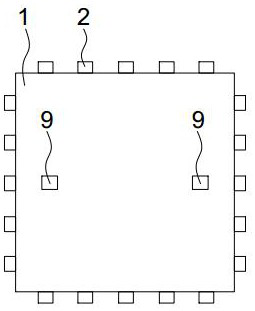

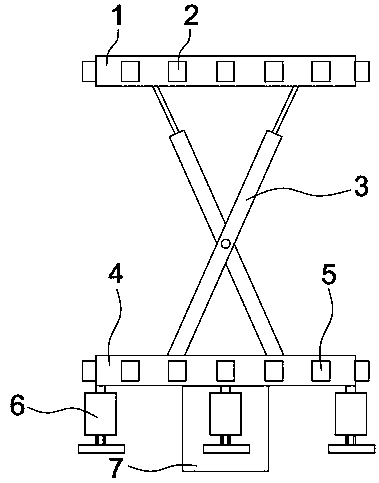

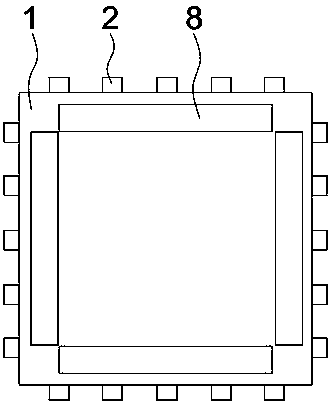

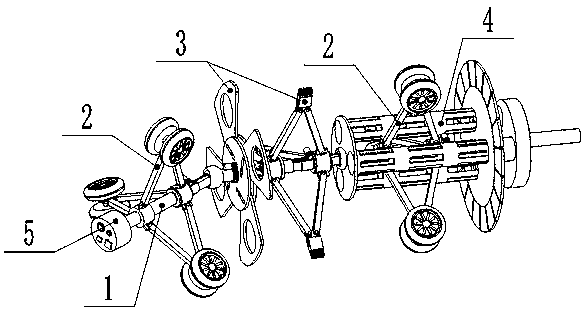

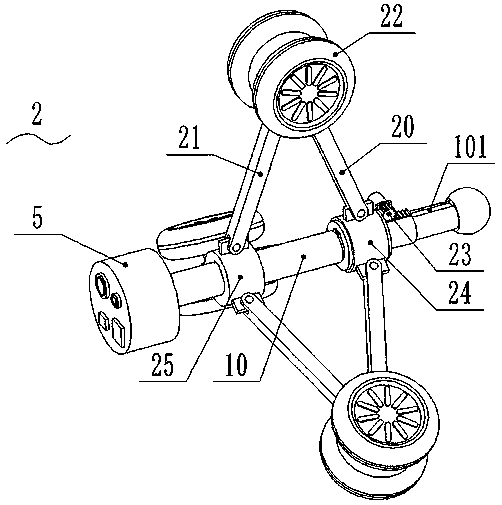

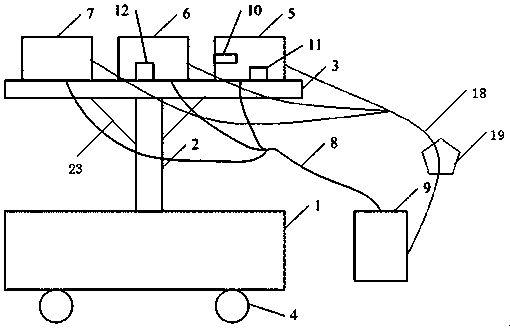

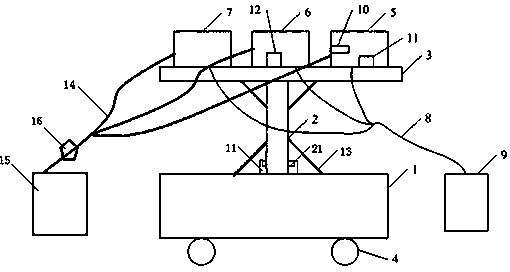

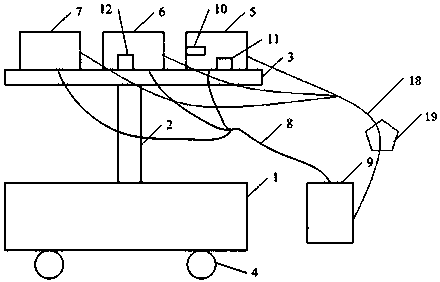

Solar panel cleaning device

ActiveCN107824498AComprehensive cleaningImprove work efficiencyCleaning using toolsCleaning using liquidsDrive wheelSupport plane

The invention provides a solar panel cleaning device and belongs to the technical field of solar cleaning. The solar panel cleaning device comprises an upper panel and a lower panel connected with theupper panel through support frames, wherein driven wheels are connected to the periphery of the upper panel; the two support frames are crossed; driving wheels are connected to the periphery of the lower panel; a motor is arranged in the center of the bottom surface of the lower panel; cleaning mechanisms are connected to the periphery of the bottom surface of the lower panel; the crossed supportframes can be driven to rotate by the motor to realize continuous cleaning of a solar panel; and the cleaning mechanisms can move up and down, and left and right to perform all-sided cleaning, and are controlled by a control box to perform accurate and quick cleaning, so that the cleaning time is remarkably saved, and cleaning loss of solar energy is reduced. The solar panel cleaning device is simple in structure and low in cleaning cost, and can realize continuous cleaning of the solar panel.

Owner:海盐派特普科技有限公司

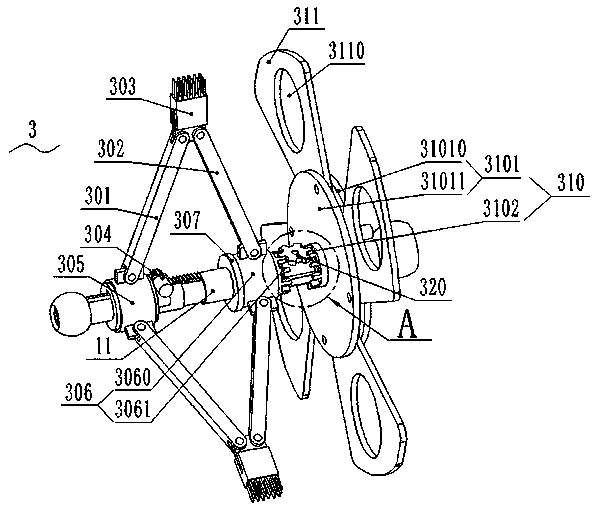

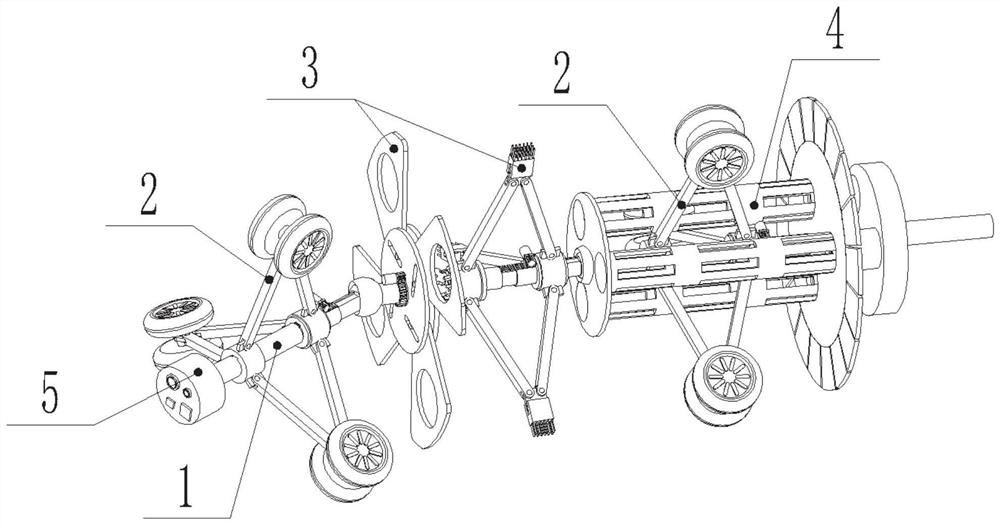

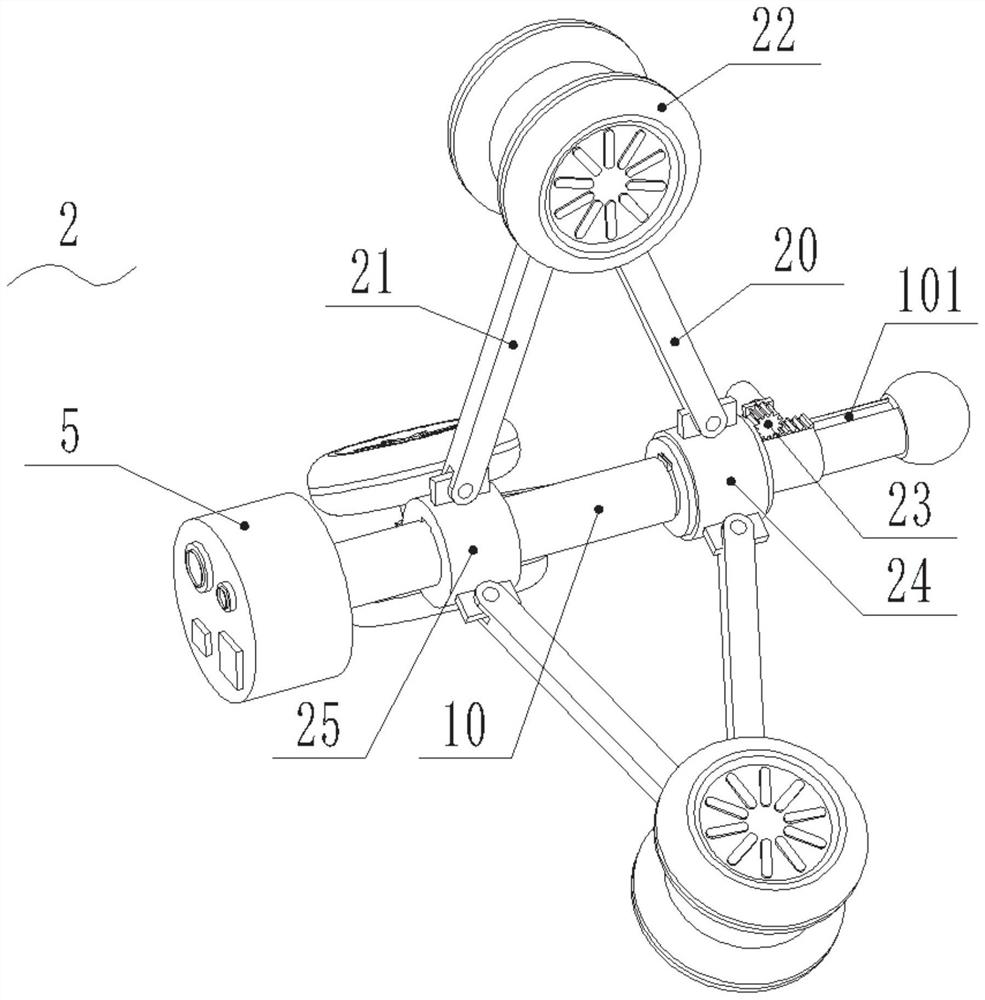

Pipeline cleaning robot

ActiveCN111282929AClean up thoroughlyEasy to cleanHollow article cleaningDirt cleaningStraight tubeSimulation

The invention discloses a pipeline cleaning robot. The pipeline cleaning robot comprises traveling driving mechanisms, a sweeping mechanism, an impurity recovery mechanism and a trunk body. The two ends of the trunk body are both provided with the traveling driving mechanisms. The impurity recovery mechanism is mounted at one end of the trunk body. The sweeping mechanism is mounted in the middle of the trunk body. The sweeping mechanism comprises a rotation driving assembly and a plurality of first sweeping assemblies. Each first sweeping assembly comprises a sweeping brush, a first sweeping arm and a second sweeping arm. The pipeline cleaning robot achieves the automatic cleaning effect of pipelines without manual operation, greatly saves manpower, and is suitable for cleaning of both straight pipelines and curved pipelines, wide in application range, economical and practical.

Owner:湖南翰坤实业有限公司

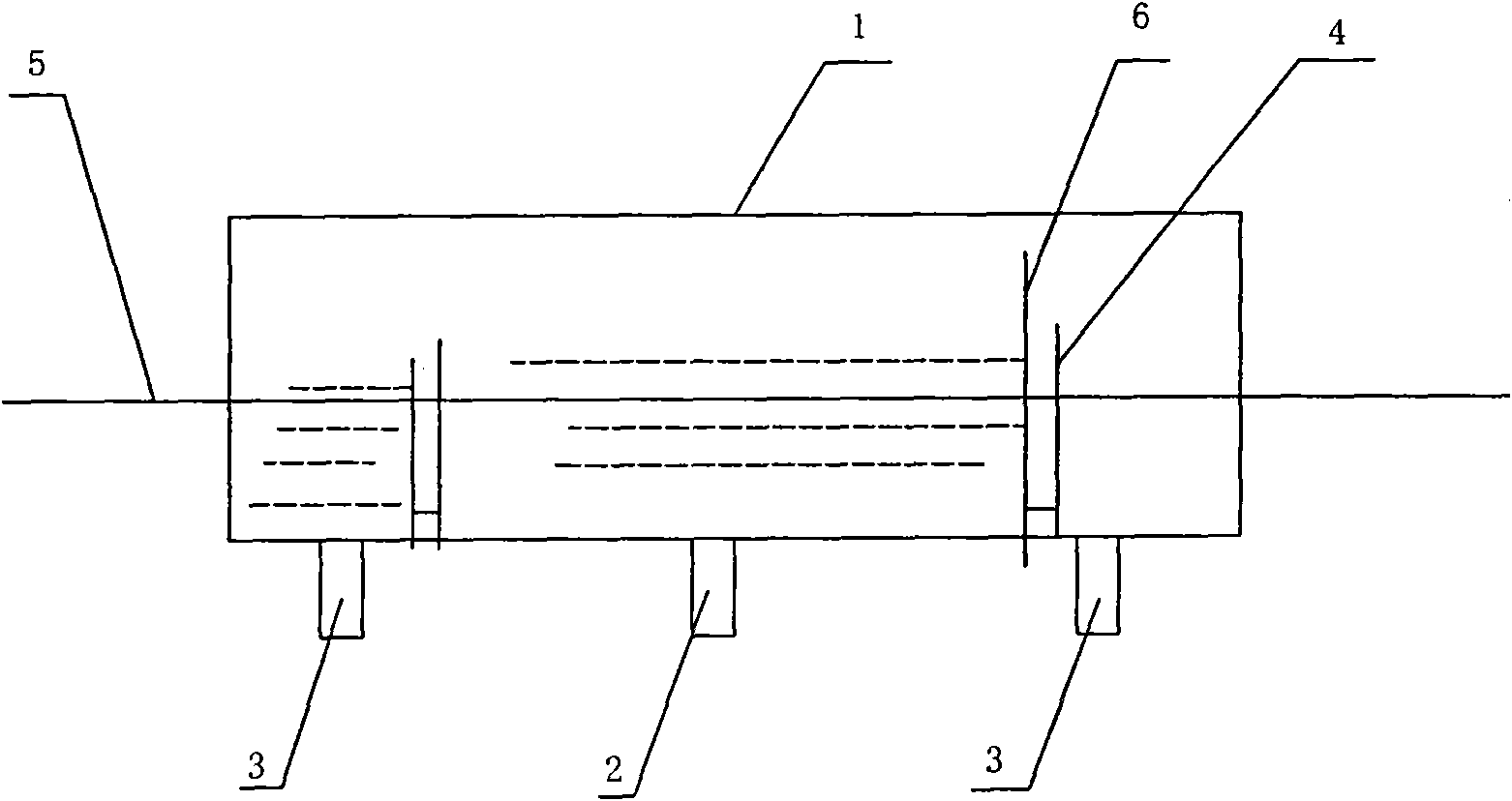

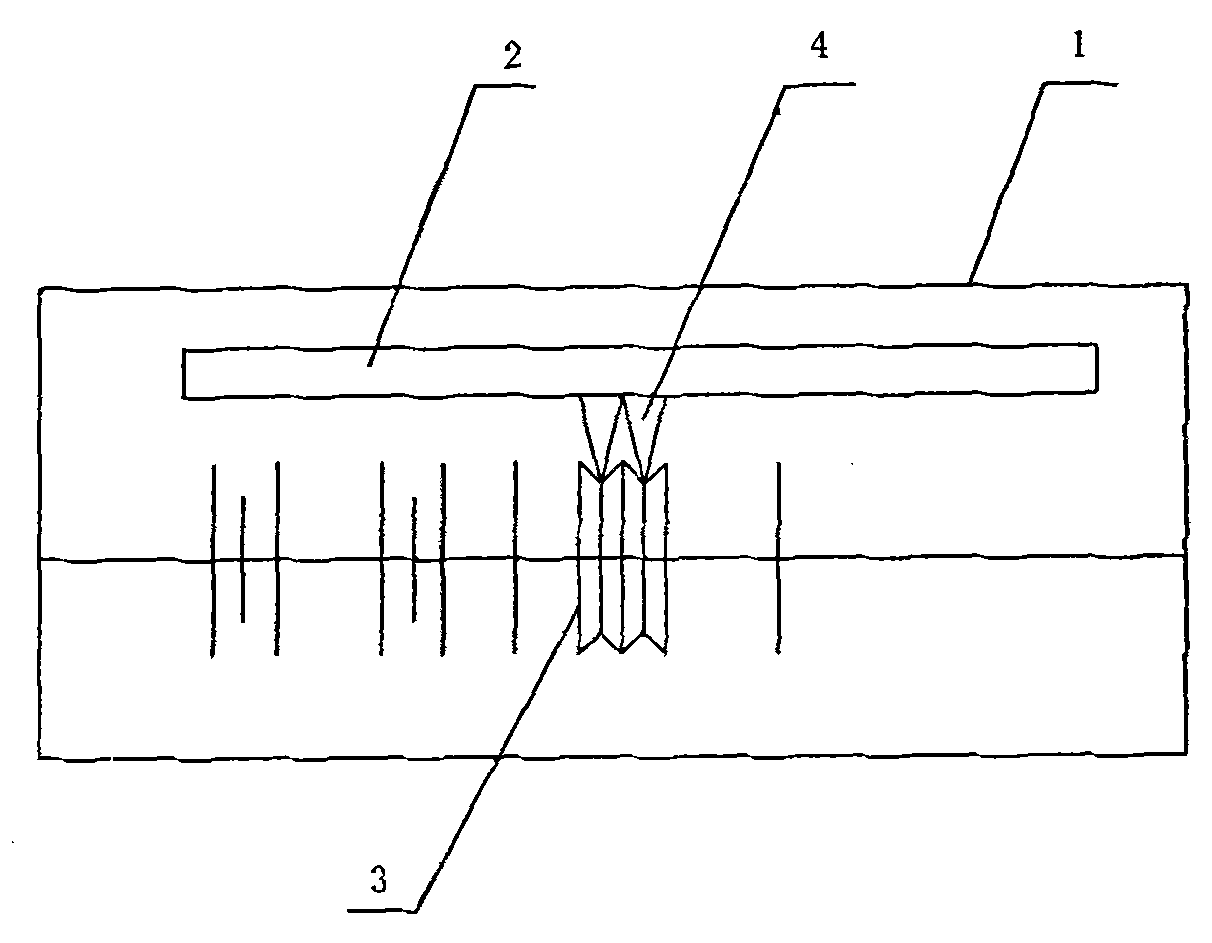

Copper wire cleaning device

InactiveCN101879538ARealize continuous cleaningSimple structureExtrusion cleaning devicesCopper wireEngineering

The invention discloses a copper wire cleaning device which is characterized by comprising a water tank (1), wherein a water inlet pipe (2) and a water outlet pipe (3) are arranged on the water tank (1); a hair felt pressing plate (4) is arranged in the water tank (1); a hair felt is pressed under the hair felt pressing plate (4); and a copper wire (5) penetrates through the hair felt under the hair felt pressing plate (4). The invention has simple and practical structure and low cost, and can realize continuous cleaning of the copper wire.

Owner:江苏茂达电磁线有限公司

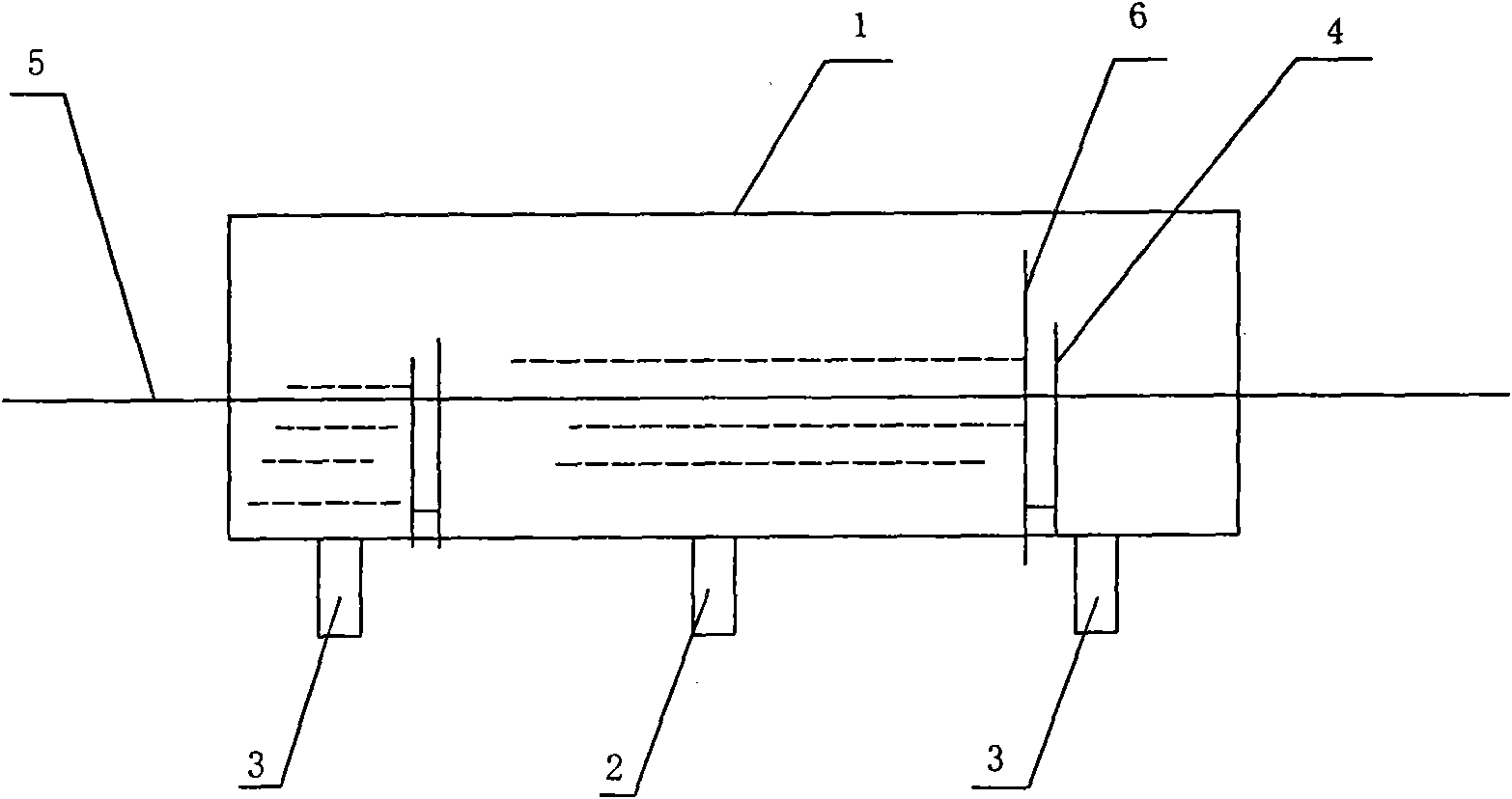

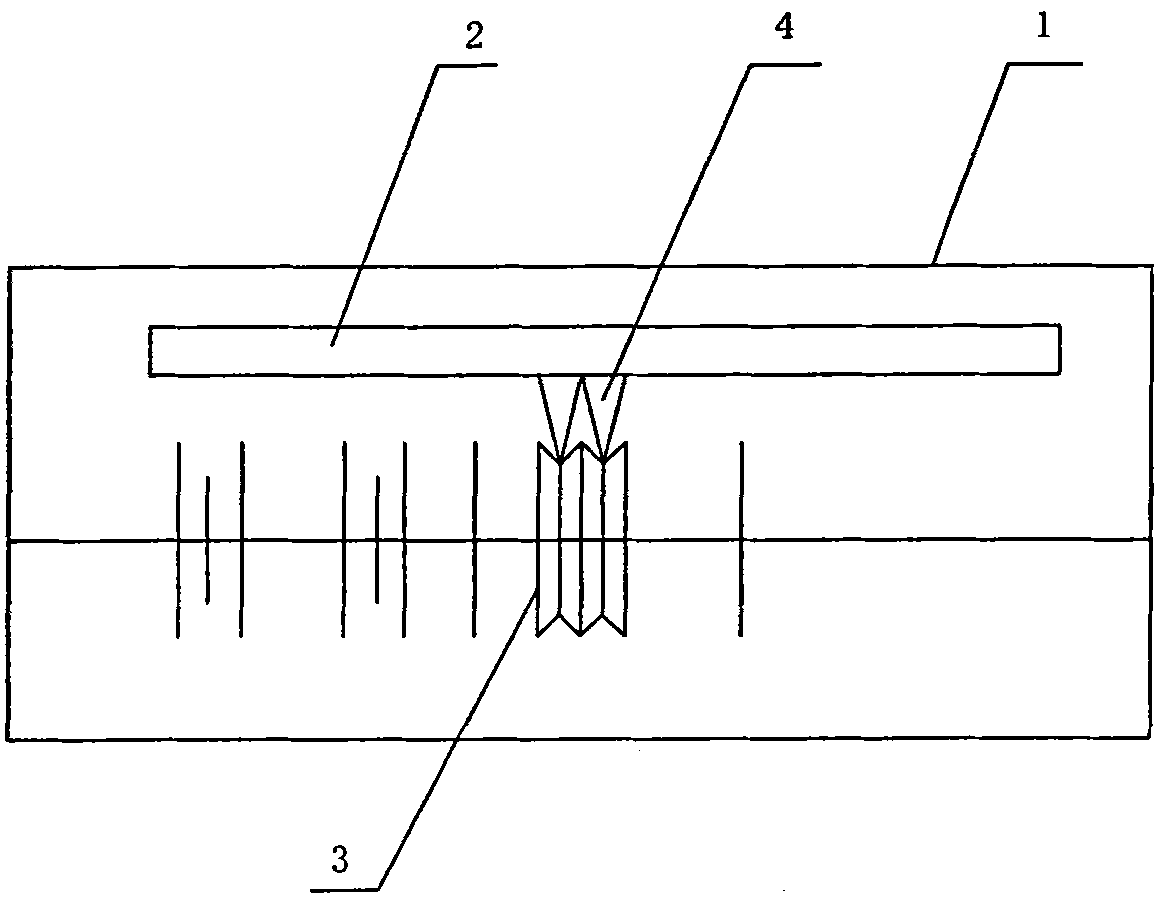

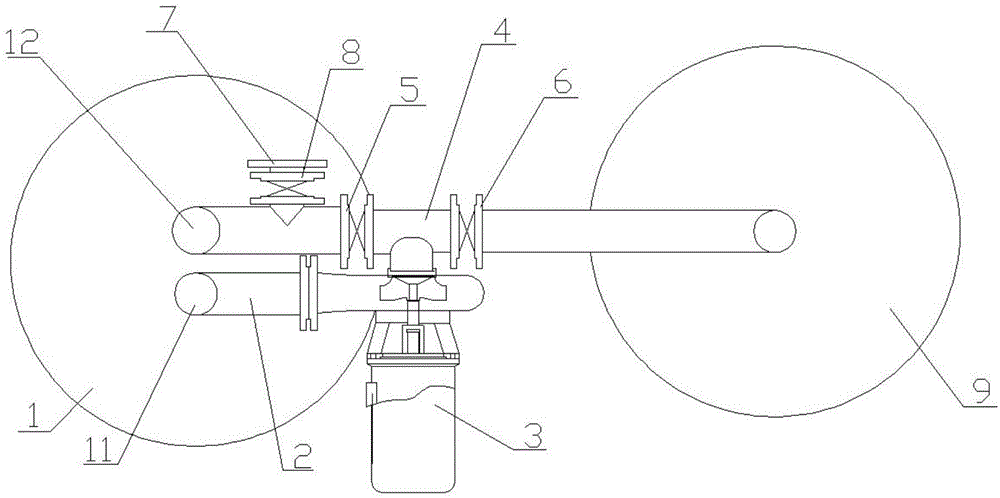

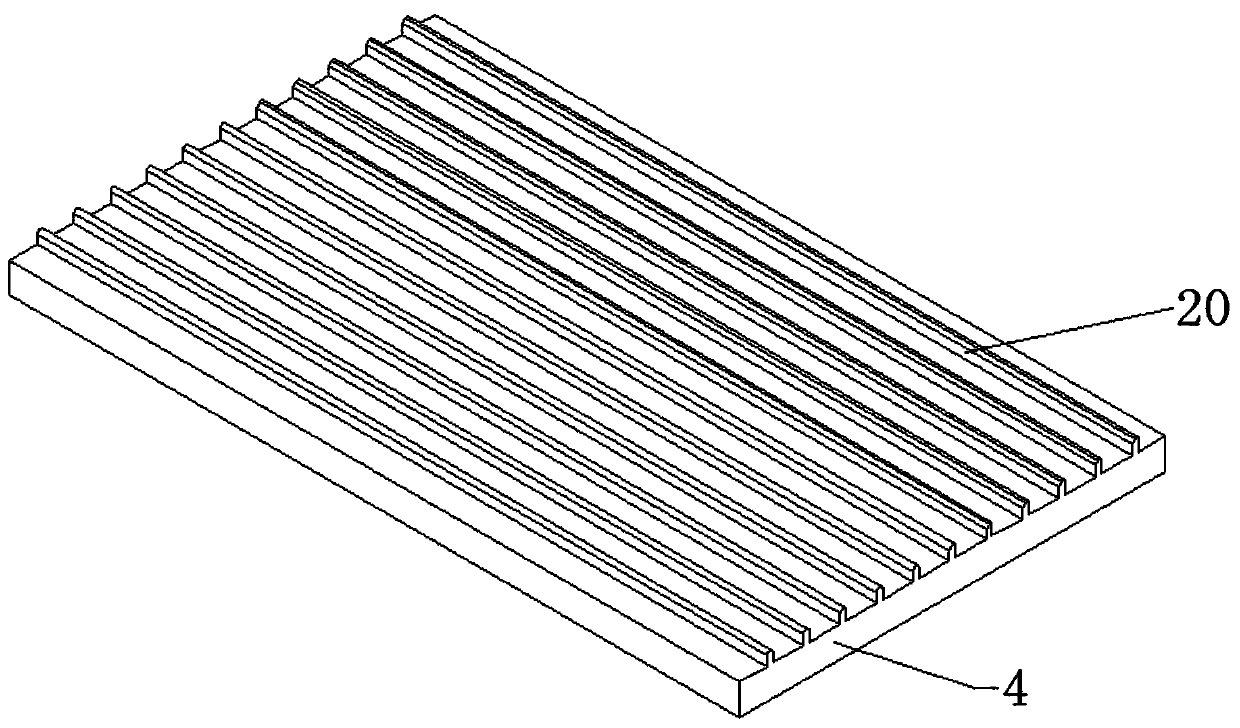

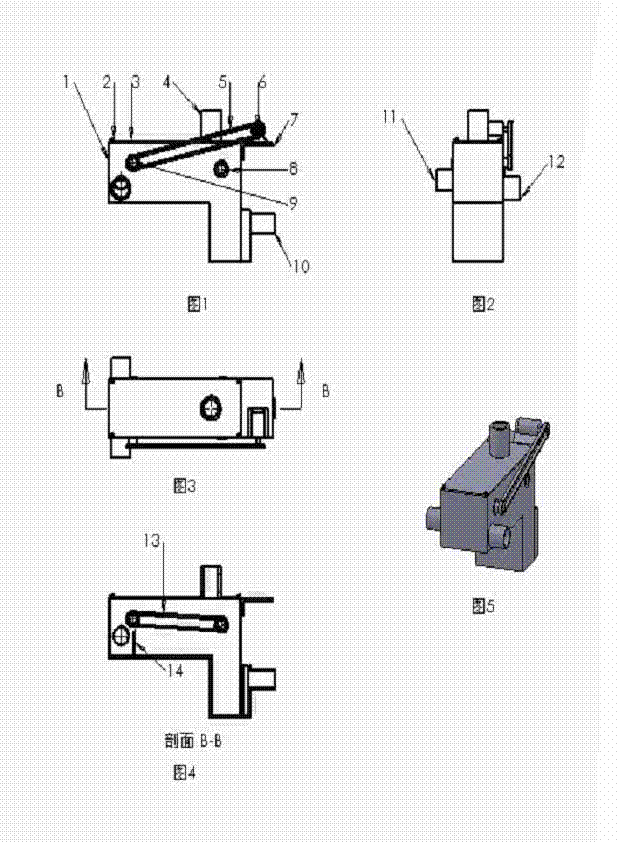

Automatic cleaning device for water tank guide pulleys of enameling machine

InactiveCN101894634ARealize continuous cleaningSimple structureInsulating conductors/cablesPulleyWaste management

The invention discloses an automatic cleaning device for water tank guide pulleys of an enameling machine, which is characterized by comprising a water tank (1), wherein a felt splint (2) and guide pulleys (3) are arranged in the water tank (1), the felt splint (2) is provided with felt strips (4), and the felt strips (4) are positioned in and are in contact with the pulley grooves of the guide pulleys (3). The automatic cleaning device has the advantages of simplicity, practicality and low cost, and can realize continuous cleaning of the guide pulleys of the enameling machine, raise the working efficiency and improve the product quality.

Owner:江苏茂达电磁线有限公司

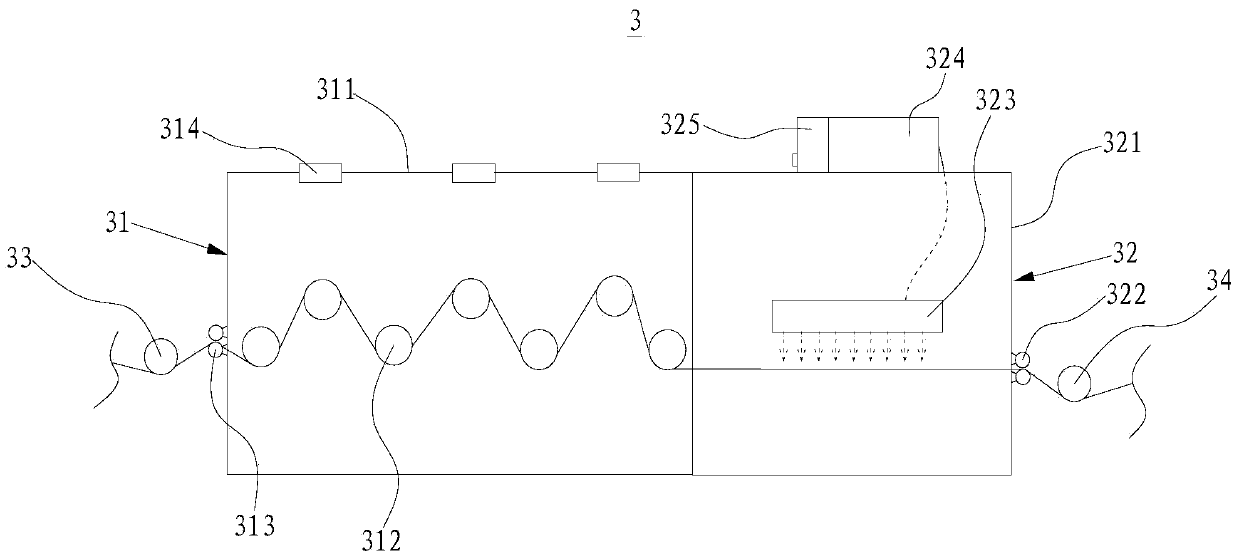

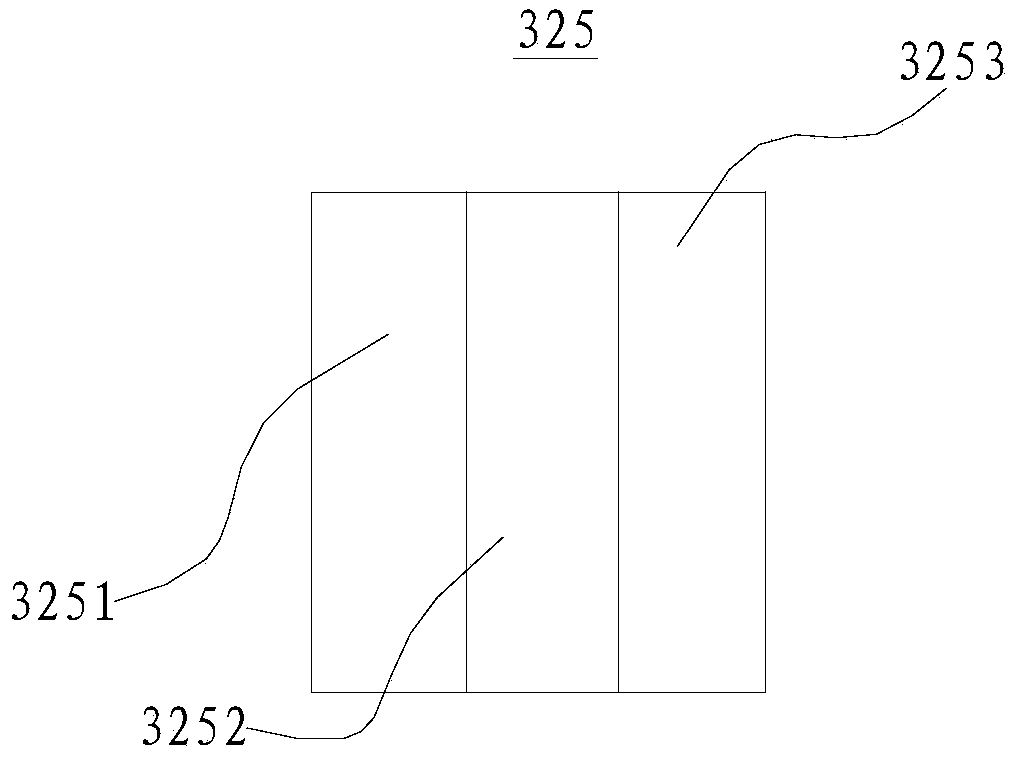

Flexible ultrathin material treatment system

PendingCN111188138ARealize continuous cleaningHigh degree of automationSevering textilesTextile treatment machine arrangementsEngineeringTreatment system

The invention discloses a flexible ultrathin material treatment system. The system comprises a cleaning component; a drying component; a cutting device, wherein the cutting device is arranged at one side of the drying component and comprises a supporting component, an action component and a cutting component; the supporting component comprises a supporting frame body, at least one sixth cloth guide roller arranged in the supporting frame body and a limiting baffle plate which is arranged in the supporting frame body and is vertically arranged below the sixth cloth guide roller; the action component comprises a rotating mechanism and a telescopic material sucking mechanism which are matched with each other. Therefore, the continuous cleaning, drying, static electricity removing, cutting andstacking treatment of the flexible ultrathin materials can be realized, and the automatic degree and the production efficiency are higher.

Owner:苏州市仓嘉超净科技有限公司

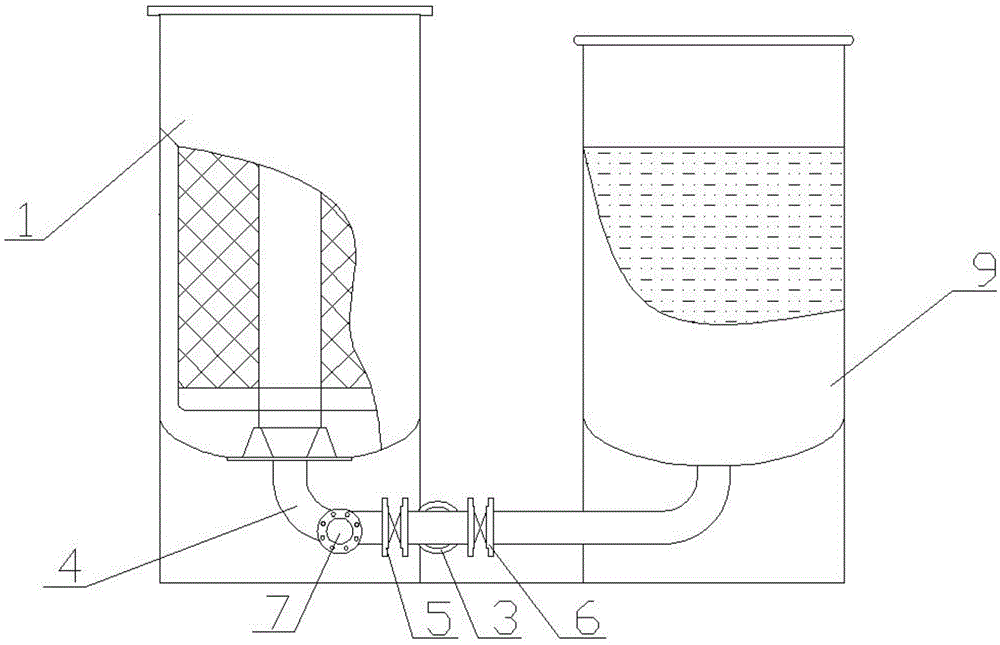

Loose wool fiber dyeing/washing integrated machine and cleaning method of loose wool fiber

InactiveCN105483957AGuaranteed dyeing effectRealize continuous cleaningTextile treatment machine arrangementsLiquid/gas/vapor fibres/slivers/rovings treatmentWater sourceEngineering

The present invention provides a loose wool fiber dyeing / washing integrated machine which comprises a dyeing / washing cylinder; the bottom of the dyeing / washing cylinder is provided with a water inlet and a water outlet; the water inlet is connected with a water pump through a first water transmission pipe; the water outlet is connected with a water source through a second water transmission pipe; the connecting end of the second water transmission pipe and the water outlet is used as a leading-out end; the connecting end of the second water transmission pipe and the water source is used as an introducing end; the second water transmission pipe is provided with a communicating port connected with the water pump; a first valve body is disposed between the leading-out end and the communicating port; a second valve body is disposed between the introducing end and the communicating port; a drainage exit is disposed between the leading-out end and the first valve body; and the drainage exit is provided with a third valve body. The present invention also provides a cleaning method of loose wool fiber in the dyeing / washing integrated machine. According to the loose wool fiber dyeing / washing integrated machine and the cleaning method of the loose wool fiber, water inlet and outlet structure are changed, continuous cleaning is achieved when dyeing speed and effect are ensured, cleaning speed is accelerated, water consumption is saved, and resource waste is avoided.

Owner:高国庆

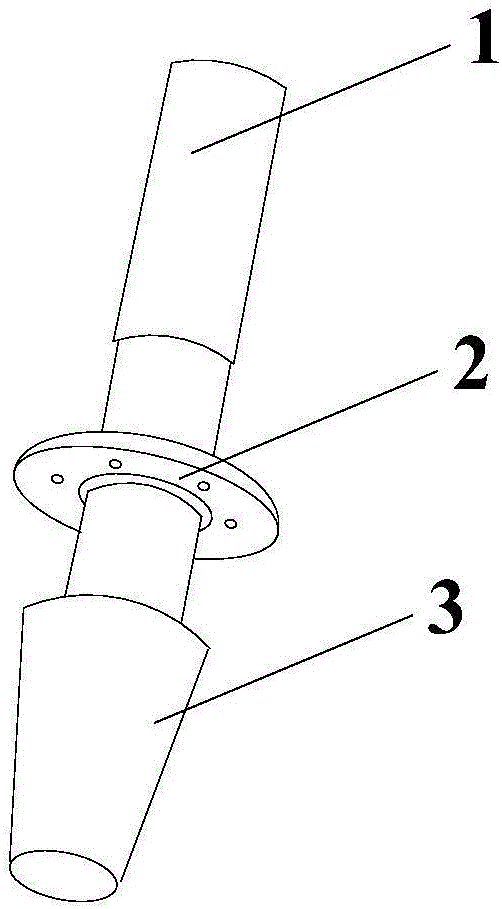

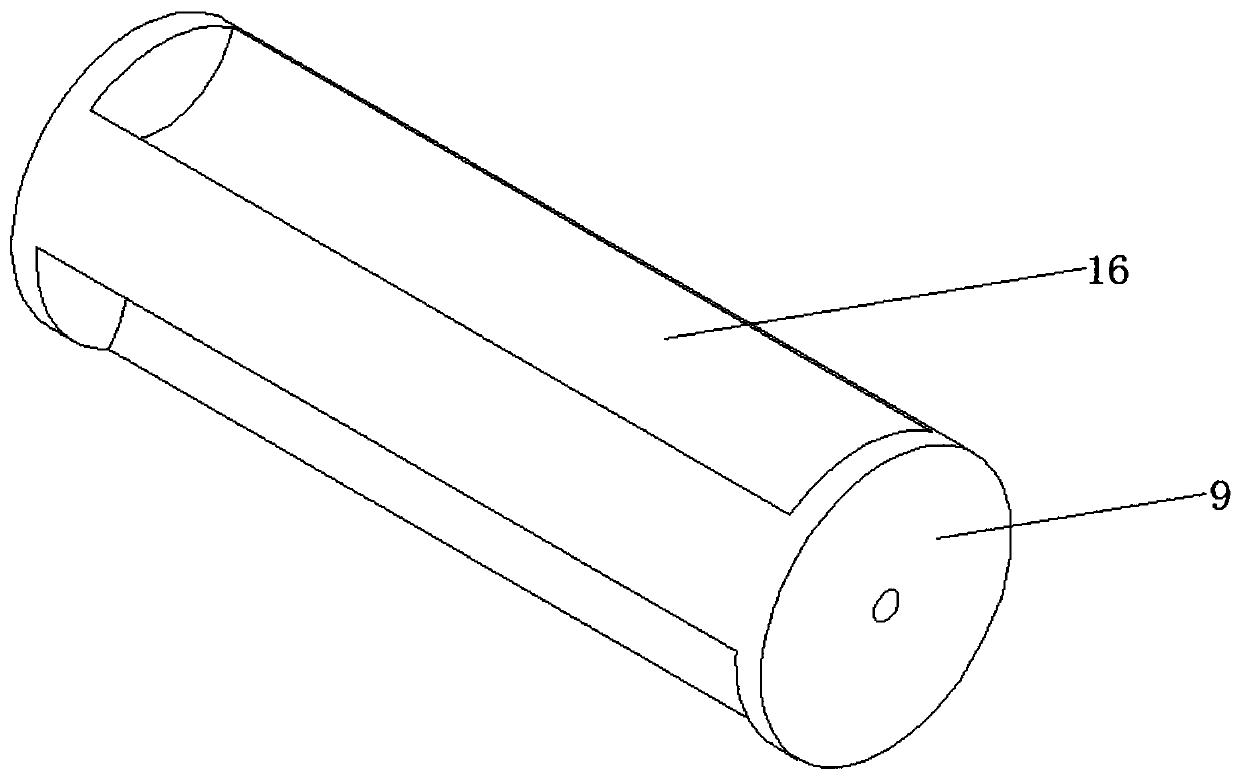

Rotation-pipe-shaped object cleaning device

InactiveCN105127143ARealize complete cleaning without dead endsNo chemical corrosionDrying gas arrangementsCleaning using gasesChemical agentPollution

The invention discloses a rotation-pipe-shaped object cleaning device which comprises a reactor, a water containing tank for containing clean water, and a centralization type ultrasonic wave system, wherein a rotation-pipe-shaped object to be cleaned is inserted in the reactor; the centralization type ultrasonic wave system is matched with the water containing tank to perform ultrasonic cleaning on a part, inserted in the reactor, of the rotation-pipe-shaped object to be cleaned; the centralization type ultrasonic wave system is inserted into the reactor; the water containing tank is communicated with the water inlet of the reactor by a hose; the water outlet of the reactor is formed above the water containing tank; and a water pump connected with the hose is arranged in the water containing tank. According to the rotation-pipe-shaped object cleaning device, the clean water is used as a detergent; after the matching of the ultrasonic wave system, the rotation-pipe-shaped object is cleaned in a continuous sectional type ultrasonic cleaning manner; no chemical agent is used in the cleaning process, so that the rotation-pipe-shaped object cleaning device has the advantages of being free of pollution and discharging, and capable of achieving all-around cleaning without dead corners; and simultaneously the cleaning can be integrated with a processing procedure of the rotation-pipe-shaped object in one step, so that the carrying and damage of the rotation-pipe-shaped object are reduced.

Owner:SICHUAN WUHUAN PETROCHEM EQUIP CO LTD

A pipe cleaning robot

ActiveCN111282929BClean up thoroughlyEasy to cleanHollow article cleaningDirt cleaningStraight tubeEngineering

The invention discloses a pipeline cleaning robot, which comprises a walking driving mechanism, a cleaning mechanism, an impurity recovery mechanism and a body. Both ends of the body are equipped with the walking driving mechanism, and one end of the body is equipped with the impurity recovery mechanism. mechanism; the cleaning mechanism is installed in the middle of the body; the cleaning mechanism includes a rotary drive assembly and a plurality of first cleaning assemblies, and the first cleaning assembly includes a cleaning brush, a first cleaning arm and a second cleaning arm. The invention realizes the automatic cleaning of pipelines without manual operation and greatly saves manpower. At the same time, it is not only suitable for cleaning straight pipelines, but also suitable for cleaning curved pipelines. It has a wide range of applications and is economical and practical.

Owner:湖南翰坤实业有限公司

Blowing type cleaning device for agricultural potato harvesting

InactiveCN110367555AEasy to cleanRealize continuous cleaningFood treatmentAgricultural engineeringBlow out

The invention relates to the field of agriculture, and particularly discloses a blowing type cleaning device for agricultural potato harvesting. The device comprises a shell, a potato filling port, adischarge hole and a base; the shell is internally provided with an inclined first screen board, the left end of the first screen board is higher than the right end of the first screen board, an opening is formed in the shell side wall corresponding to the lower end of the first screen board, a spraying and blowing shell located on the outer side of the shell is communicated with the opening, a horizontal rotating guide roller is coaxially and rotationally installed in the spraying and blowing shell, multiple rotating grooves concaved inwards are formed in the arc-shaped side wall of the rotating guide roller, a horizontal spraying and blowing tube is communicated with the side wall of the spraying and blowing shell, and the spraying and blowing tube is communicated with an air compressorthrough an air duct. Accordingly, potatoes move in the rotating grooves, in the moving process, the potatoes make contact with air blown out by the spraying and blowing tube, wet soil on the surfacesof the potatoes is blown away, soil at the hollow positions of the surfaces of the potatoes can be cleaned away, the cleaning effect on the potatoes is greatly improved, and soil residues are reduced.

Owner:曲昭硕

Gecko type efficient air ash removal system of rotary air pre-heater

PendingCN114857987ARealize continuous cleaningAccurate and efficient dust removalCombustion processIndirect carbon-dioxide mitigationControl systemProcess engineering

The invention discloses a rotary air pre-heater gecko-type efficient air ash removal system which comprises an air compressor set, an air storage tank and a gecko-type power spray pipe, the air compressor set is connected with the air storage tank through a pipeline, the gecko-type power spray pipe is connected with the air storage tank, and the gecko-type power spray pipe is located in a boiler rotary air pre-heater. The boiler rotary air pre-heater is of a multi-layer structure, and the number of the air storage tanks and the number of the gecko type power spray pipes are the same as the number of layers of the boiler rotary air pre-heater. Furthermore, the gas storage tank boiler rotary air pre-heater is provided with three layers. In the implementation process, air with proper pressure is provided as power energy through the air compressor unit, the air source pressure of the gecko power spray pipe is controlled through the control system, continuous cleaning in the rotating working process of the air pre-heater is achieved along with rotation of the air pre-heater, adjustment is conducted according to the dust deposition condition, accurate and efficient dust cleaning of the air pre-heater is achieved, and the cleaning efficiency of the air pre-heater is improved. And the flue gas temperature is reduced, the boiler efficiency is improved, and the safety and economical efficiency of boiler operation are achieved.

Owner:北京胜源科技有限公司

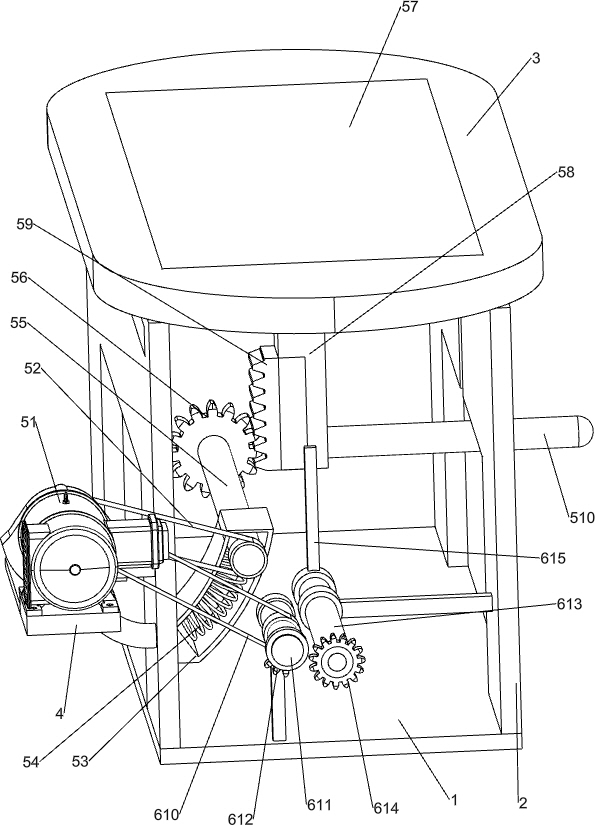

Rapid cleaning device for dining table

ActiveCN112056762ARealize continuous cleaningEasy to cleanCarpet cleanersFloor cleanersEngineeringMechanical engineering

Owner:南京智慧阳光科技有限公司

Cleaning device special for PDC drill bits

InactiveCN107671065AGuaranteed cleaning effectGuarantee the amount of waterCleaning using toolsCleaning using liquidsCircular discMegasonic cleaning

The invention relates to a cleaning device special for PDC drill bits. The cleaning device special for the PDV drill bits comprises a base, a rotary shaft and a disk. The base is provided with brake trundles. One end of the rotary shaft is connected with the middle of the upper surface of the base, and the other end of the rotary shaft is fixedly connected with the middle of the disk. A first cleaning tank, a second cleaning tank and a third cleaning tank are arranged on the upper surface of the disk, and the upper surface of the first cleaning tank, the upper surface of the second cleaning tank and the upper surface of the third cleaning tank are open. Drain holes are formed in the bottom surfaces of the cleaning tanks, and water inlets are further formed in the side faces of the cleaningtanks. Drain pipes are connected to the drain holes and connected with a water collection tank. Water inlet pipes are connected to the water inlets and connected with a water supply tank, and water inlet pumps are further connected to the water inlet pipes in series. A water gun and an electric cleaning bush are arranged in the first cleaning tank, an ultrasonic cleaning machine is arranged in the second cleaning tank, and cleaning liquid is contained in the third cleaning tank. The cleaning device special for the PDV drill bits has the advantages that water can be effectively supplied in thecleaning process, continuous cleaning is ensured, and thus the cleaning efficiency is improved.

Owner:QIDONG TIANSHAN TOOLS CO LTD

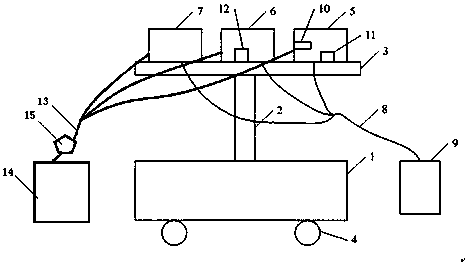

A low-concentration organic sewage treatment system

ActiveCN108793599BAvoid pollutionStrong impact resistanceWater contaminantsTreatment involving filtrationBiofilmMicroorganism

The invention discloses a low-concentration organic wastewater treatment system, which comprises an anoxic pool, an aerobic pool, a packing separation pool, a sand filter and an equipment room connected in sequence. It is connected with the water supply inlet pipe; the anoxic pool is connected with the aerobic pool through the overflow port A; the aerobic pool is provided with an aeration area, and the aerobic pool is covered with porous biological fillers, and the biological fillers are attached with Microbes; the filler separation tank is located outside the outlet of the aerobic tank, and is separated from the aerobic tank by a scum baffle, and there is a gap between the scum baffle and the bottom of the filler separation tank. The beneficial effect of the present invention is: the anoxic pool, the aerobic pool, the filler separation pool and the sand filter are integrated, the biofilm technology and the dynamic sand filter technology are combined, and the PLC control system is used to control the whole sewage treatment process , This kind of sewage treatment configuration has strong impact resistance, ensures the quality of effluent water, reduces operating costs, and can treat various low-concentration organic wastewater.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD +1

Water-sealing feeder

InactiveCN103245180ARealize continuous cleaningImprove cleaning efficiencyDrying gas arrangementsChain typeEngineering

The invention discloses a water-sealing feeder used in the process of grain processing cleaning. The water-sealing feeder mainly solves the problems of conveying for intermediate links from cleaning to drying, water-material separation and sealing and connection of a drying device, so that cleaning and drying are conducted automatically and continuously. Cleaned grains are driven by water to enter the feeder, water-material separation is achieved on a chain type conveying belt, grains are conveyed through a connected closed drying system, and the water which is discharged continuously seals one end of the feeder. The water-sealing feeder can be widely used in the automatic grain cleaning industry.

Owner:河南百安粮油有限公司

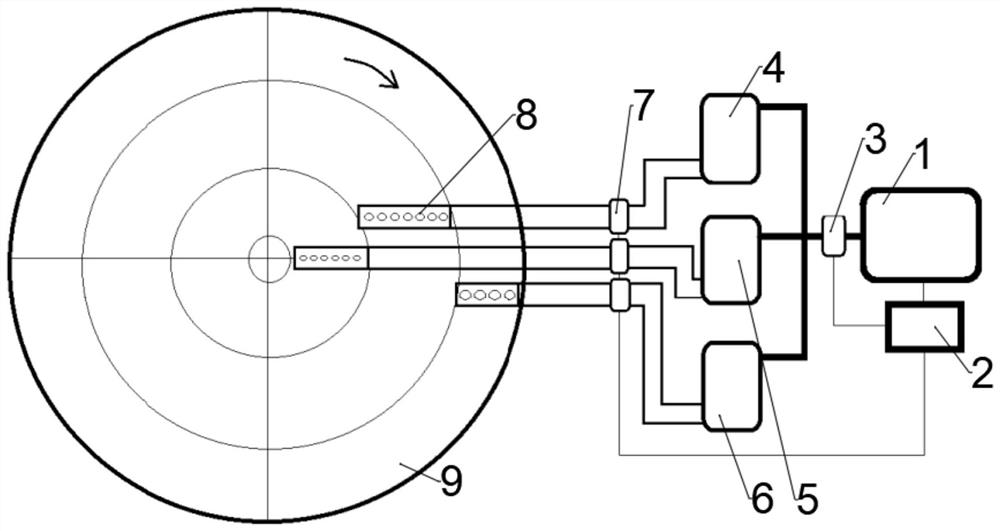

Cleaning system for PDC drill bit

InactiveCN107716402ACleaning consistentGuaranteed cleaning effectCleaning using toolsCleaning using liquidsCircular discRotational axis

The invention relates to a cleaning system for a PDC drill bit. The cleaning system comprises a base, a rotation shaft and a disc. The rotation shaft comprises a fixed shaft and a telescopic shaft. Apair of pin shaft holes are formed in the upper end of the fixed shaft, a plurality of pairs of positioning holes are formed in the lower end of the telescopic shaft, and the fixed shaft and the telescopic shaft are inserted in the pin shaft holes and the positioning holes through bearing pins. The lower end of the fixed shaft and the middle portion of the upper surface of the base are connected,and the upper end of the telescopic shaft is located in a circular groove. A supporting frame is further symmetrically hinged to the two sides of the upper end of the telescopic shaft, and the other end of the supporting frame and the bottom face of the disc are fixedly connected through a lock pin. Three cleaning boxes with the upper surfaces opened are arranged on the upper surface of the disc,water outlet holes are formed in the bottom faces of the cleaning boxes, and water inlet holes are formed in the side faces of the cleaning boxes. The water outlet holes are connected with a water collecting box through a water outlet pipe, and the water inlet holes are connected with a water supply box through a water inlet pipe. The cleaning system has the beneficial effects that the cleaning system can be applicable to cleaning of drill bits different in height, stability of the disc and the rotation shaft is improved, effective water supply can be achieved in the cleaning process, cleaningcontinuity is guaranteed, and accordingly the cleaning efficiency is improved.

Owner:QIDONG TIANSHAN TOOLS CO LTD

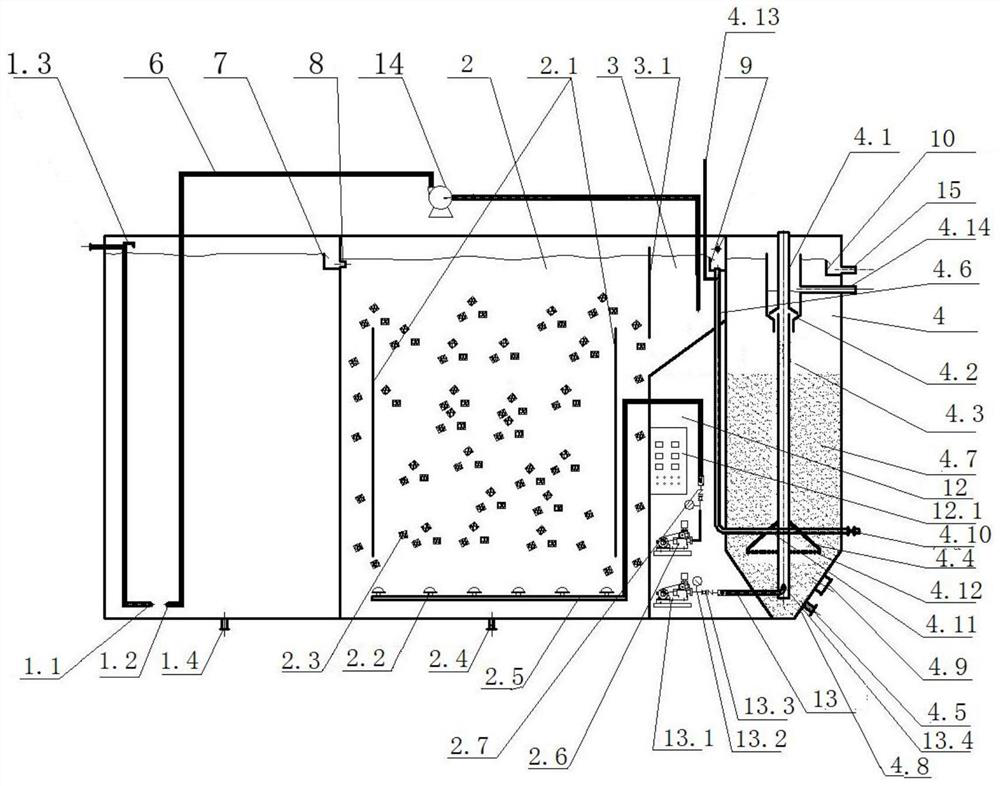

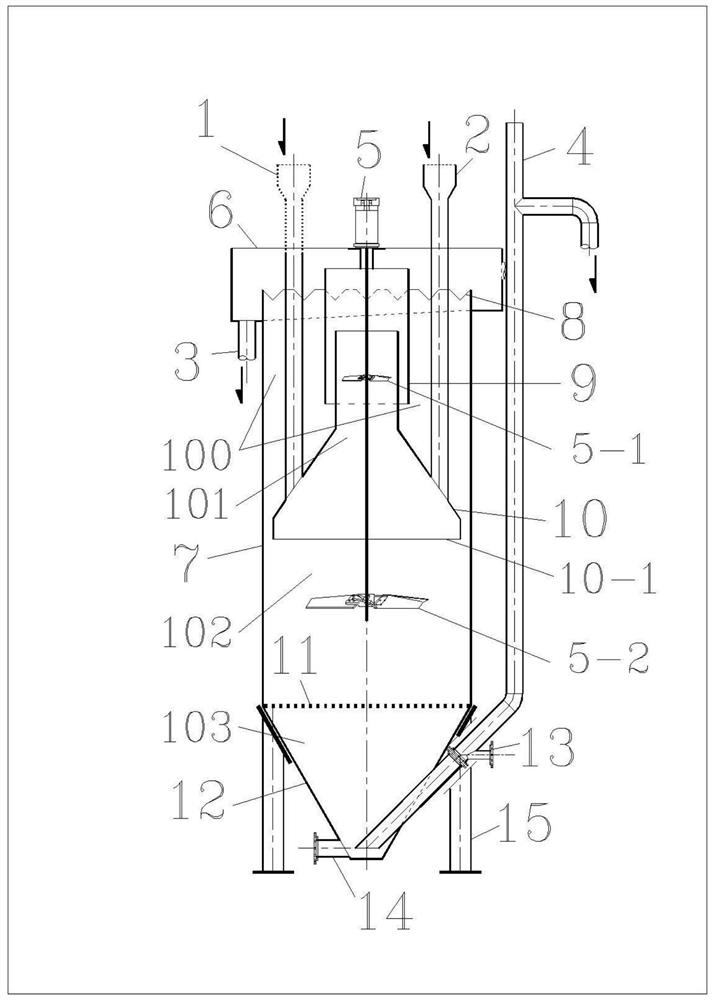

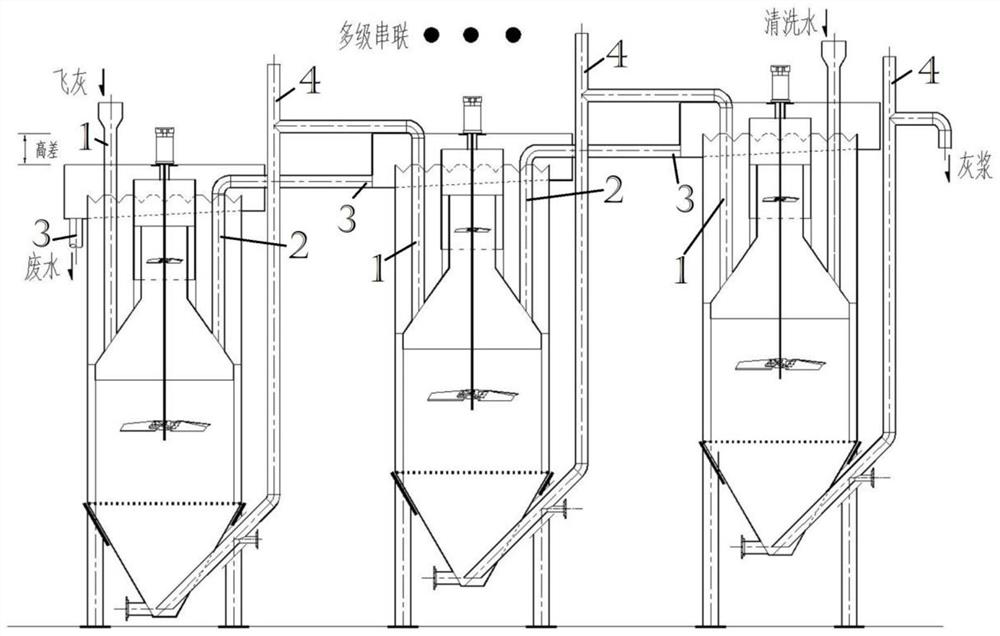

A continuous water washing and dechlorination device for waste incineration fly ash

ActiveCN113003964BRealize continuous cleaningImprove cleaning efficiencyCement productionWater flowAgitator

The invention provides a continuous water washing and dechlorination device for waste incineration fly ash. The device includes a dechlorination device unit, and the device unit includes a main body, a sleeve, a mixing zone partition, a water outlet weir, an agitator, a fly ash feeding pipe, a cleaning Liquid inlet pipe, mortar riser pipe, the device includes vertical flow grey water precipitation area, grey water rising area, grey water mixing dechlorination area and mortar concentration area from top to bottom, which realizes continuous fly ash cleaning in one cleaning device , Fly ash and ash water separation and transportation of mortar and waste water. The device provided by the invention can be used alone or in series. When used in series, the cleaning water flows from the cleaning device with the highest elevation of the outlet weir to the cleaning device with the lowest elevation of the outlet weir in turn, and the fly ash is sequentially lifted from the cleaning device with the lowest elevation of the outlet weir to the water. The cleaning device with the highest weir elevation. The cleaning device of the invention realizes the continuous and high-efficiency water washing of the fly ash, can be used alone or in series, and has simple and convenient operation and regulation.

Owner:上海波赛统环境科技有限公司

An automatic pipe cleaning device

ActiveCN111530863BClean up thoroughlyEasy to cleanHollow article cleaningDirt cleaningStraight tubeProcess engineering

The invention discloses an automatic pipeline scale removing device. The automatic pipeline scale removing device comprises walking driving mechanisms, a cleaning mechanism, an impurity recycling mechanism and a body, wherein the walking driving mechanisms are arranged at the two ends of the body; the impurity recycling mechanism is arranged at one end of the body; the cleaning mechanism is arranged in the middle of the body; the cleaning mechanism comprises a rotary driving assembly, a plurality of cleaning assemblies and a second cleaning assembly; and the first cleaning assemblies comprisefirst cleaning brushes, first cleaning arms and second cleaning arms. Through the adoption of the automatic pipeline scale removing device, a pipeline can be automatically cleaned without manual operation, so that labor force is saved greatly. Meanwhile, the automatic pipeline scale removing device can not only be suitable for cleaning straight pipelines, but also suitable for cleaning bent pipelines, and is wide in application range, economical and practical.

Owner:湖南翰坤实业有限公司

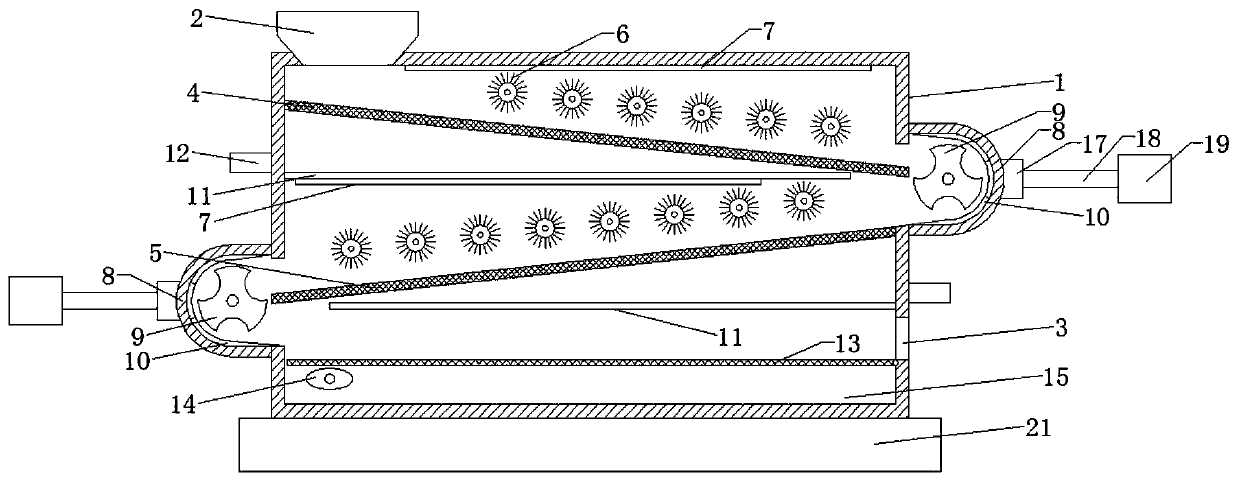

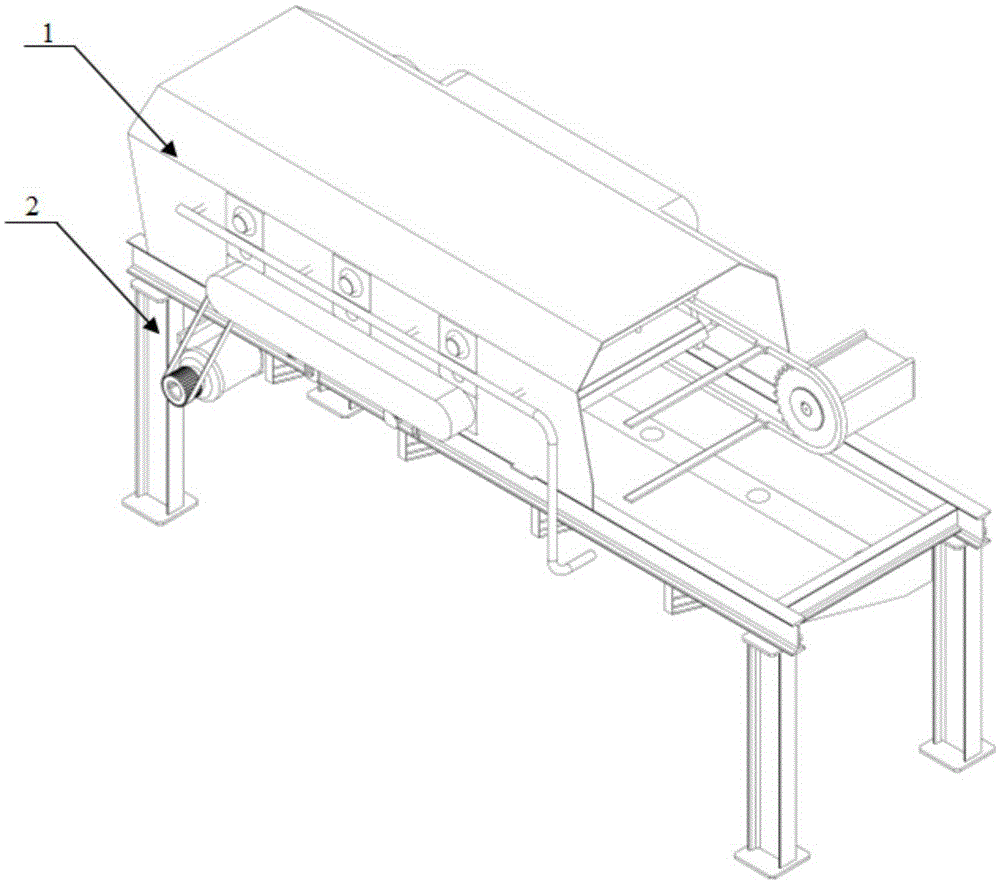

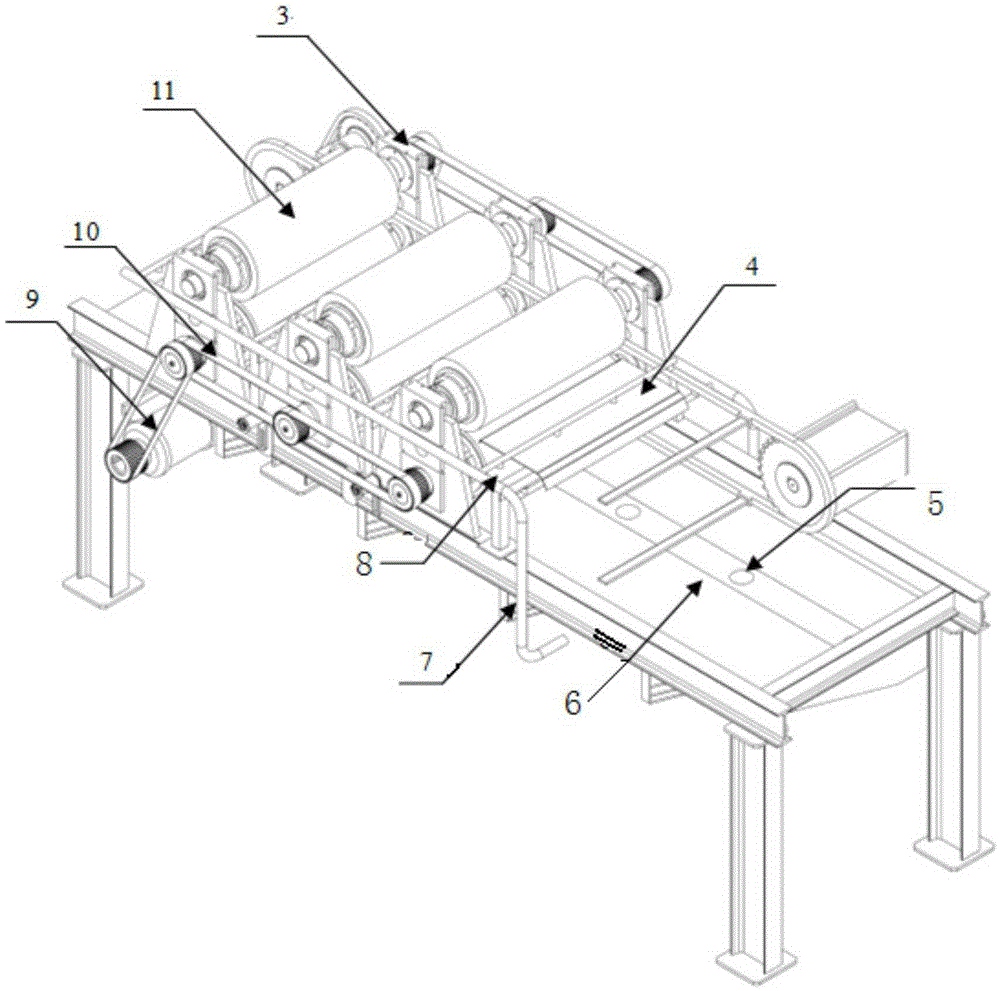

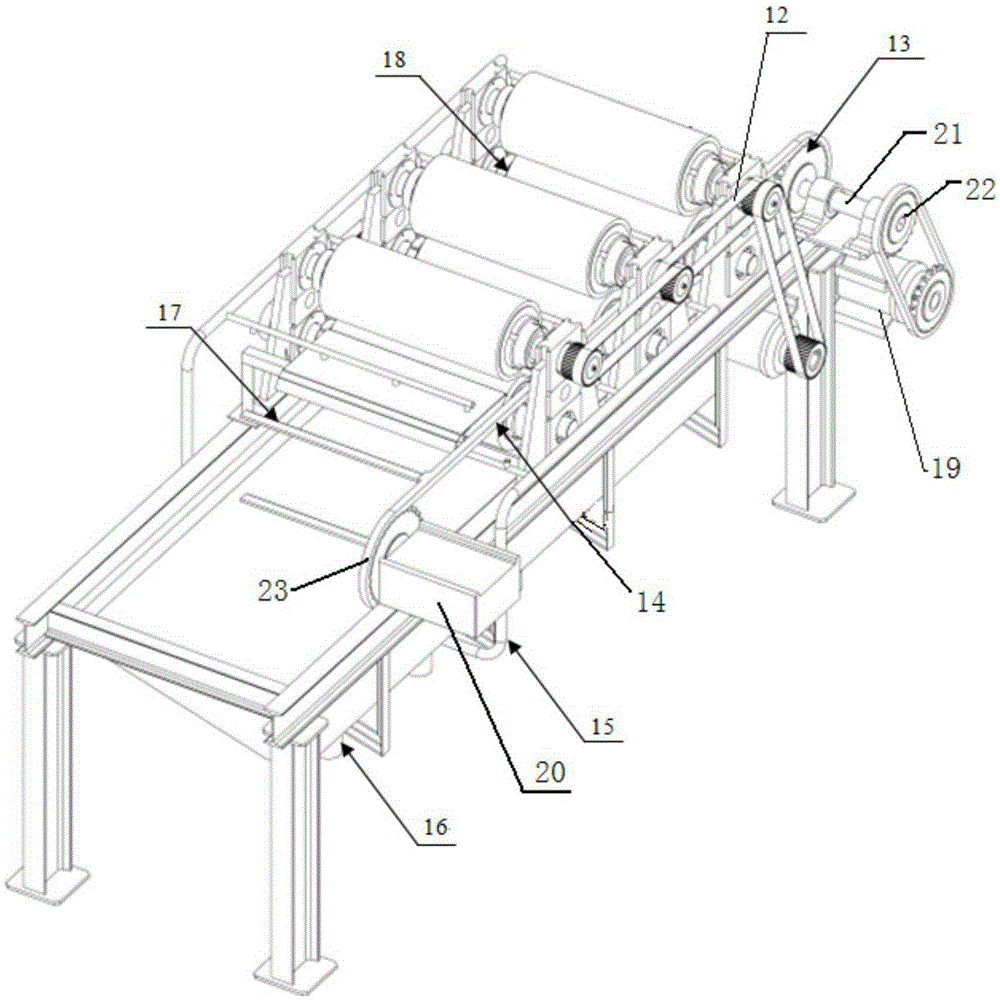

Continuous washing device for polyester-nylon barrel

InactiveCN105381970ARealize continuous cleaningImprove work efficiencyCleaning using toolsCleaning using liquidsPolyesterEngineering

The invention relates to a continuous washing device for a polyester-nylon barrel. The device is characterized by comprising a rack, a protecting hood, a front plate, a washing mechanism, a conveying mechanism, a collecting mechanism and a power mechanism, wherein the protecting hood, the front plate, the washing mechanism, the conveying mechanism, the collecting mechanism and the power mechanism are mounted on the rack; the protecting hood covers the washing mechanism, and the washing mechanism is driven through the power mechanism; the front plate is mounted at one side, used for inputting the polyester-nylon barrel, of the washing mechanism; the collecting mechanism is positioned at the bottom part of the washing mechanism. The continuous washing device has the advantages that the polyester-nylon barrel can be continuously washed, and the operation can be performed by only one person, so that the working efficiency can be improved, and the labor cost can be reduced; in addition, a manner of washing through three groups of reverse rotating brush rollers is adopted and the washing quality superior to that of a manual washing manner is achieved, and the rate of rework is low.

Owner:TAISHAN FIBERGLASS INC

A New Spinneret Washing Process

The invention belongs to the spinning detection field, and particularly relates to a novel spinning head washing technology. The novel spinning head washing technology includes the concrete steps of: 1, alkaline liquid spray washing; 2, hot water spray washing; 3, hot water spray washing; 4, air spray washing; 5, acid pickling; 6, alkaline liquid spray washing; 7, hot water spray washing; 8, hot water spray washing; 9, air spray washing; and 10, drying. The above technical processes realize automation except the beginning manual material-loading and the final manual material-discharging and assembling. At the same time, a process of supersonic wave washing is not needed. Two-stage filtration is adopted in a reservoir, so that clean washing is guaranteed and a nozzle is prevented from being blocked. The continuous washing is realized. Unclean matters on the outer surface of a spinning head are removed, and the spinning head is not damaged.

Owner:YIBIN GRACE

Special cleaning system for PDC drill bit

InactiveCN107716404ACleaning consistentGuaranteed cleaning effectCleaning using toolsCleaning using liquidsEngineeringDrill bit

The invention relates to a special cleaning system for a PDC drill bit. The special cleaning system for the PDC drill bit comprises a base, a rotating shaft and a disk; the rotating shaft comprises afixed shaft and a telescopic shaft; a pair of pin shaft holes are formed in the upper end of the fixed shaft; a plurality of pairs of positioning holes are formed in the lower end of the telescopic shaft; the lower end of the fixed shaft is connected with the middle portion of the upper surface of the base; the upper end of the telescopic shaft is located in a round groove; a supporting frame is further symmetrically hinged to the two sides of the upper end of the telescopic shaft; the other end of the supporting frame is fixedly connected with the bottom face of the disk through a lock pin; three cleaning boxes with openings in the upper surfaces are arranged on the upper surface of the disk; the bottom face of each cleaning box is provided with a water draining hole, and the position ofeach water draining hole is provided with a filter screen; the side face of each cleaning box is further provided with a water inflow hole; the water draining holes are connected with a water collecting box through water draining pipes; and the water inflow holes are connected with a water supply box through water inflow pipes. The special cleaning system for the PDC drill bit has the beneficial effects that the special cleaning system for the PDC drill bit can adapt to cleaning of drill bits at different heights, the stability of the disk and the rotating shaft is improved, water can be effectively supplied in the cleaning process, continuous cleaning is guaranteed, and therefore the cleaning efficiency is improved.

Owner:QIDONG TIANSHAN TOOLS CO LTD

Novel special cleaning device for drill bit

InactiveCN107838090ASmall footprintEasy to transportCleaning using toolsCleaning using liquidsDrill bitEngineering

The invention relates to a novel special cleaning device for a drill bit. The novel special cleaning device comprises a base, a rotary shaft and a disc; one end of the rotary shaft is inserted and fixed to the middle of the upper surface of the base, and the other end of the rotary shaft is fixedly connected with the middle of the disc; the upper surface of the disc is provided with three cleaningboxes of which the upper surfaces are open, the bottom face and the side face of each cleaning box are provided with a water outlet hole and a water inlet hole, a water outlet pipe is connected to each water outlet hole, the water outlet pipes are connected with a water collecting box, a water inlet pipe is connected to each water inlet hole, and the water inlet pipes are connected with a water supply box; and one ends of supporting frames are symmetrically hinged to the two sides of the upper end of the rotary shaft correspondingly as well as the two sides of the lower end of the rotary shaft correspondingly, the other ends of the upper-end supporting frames are fixedly connected with the bottom face of the disc through lock pins, and the other ends of the lower-end supporting frames arefixedly connected with the upper surface of the base through lock pins. The novel special cleaning device of the drill pit has the advantages that the occupied space can be decreased, transport is convenient, the stability between the disc and the rotary shaft as well as the stability between the base and the rotary shaft can be improved, water can be effectively supplied in the cleaning process,continuous cleaning is ensured, and accordingly, the cleaning efficiency is improved.

Owner:QIDONG TIANSHAN TOOLS CO LTD

Cleaning device for PDC drill bits

InactiveCN107838087AGuaranteed cleaning effectEfficient removalCleaning using toolsCleaning using liquidsEarly effectWater resources

The invention relates to a cleaning device for PDC drill bits. The cleaning device comprises a base, a rotary shaft and a disc. The base is provided with brake trundles. One end of the rotary shaft isconnected with the middle of the upper surface of the base, and the other end of the rotary shaft is fixedly connected with the middle of the disc. A first cleaning box, a second cleaning box and a third cleaning box are arranged on the upper surface of the disc, wherein openings are formed in the upper surface of the first cleaning box, the upper surface of the second cleaning box and the uppersurface of the third cleaning box. A drainage hole is formed in the bottom face of each cleaning box, and a filter screen is arranged at each drainage hole and comprises a rough filter layer, a primary-efficiency layer, an intermediate-efficiency layer, a high-efficiency layer and a purification layer which are sequentially arranged from the water inlet side to the water outlet side. A water inlethole is further formed in the side face of each cleaning box. Each drainage hole is connected with a drainage pipe. The drainage pipes are connected with a water collection box. Each water inlet holeis connected with a water inlet pipe. The water inlet pipes are connected with a water supply box. A water inlet pump is further connected to the water inlet pipes in series. The cleaning device hasthe beneficial effects that water can be effectively supplied in the cleaning process, cleaning continuity can be guaranteed, then the cleaning efficiency is improved, and cyclic utilization of waterresources can be achieved.

Owner:QIDONG TIANSHAN TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com