Rotation-pipe-shaped object cleaning device

A technology for cleaning devices and tubular objects, which is applied in the directions of drying gas arrangement, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve the problems of ultrasonic energy blocking, poor energy efficiency conversion, large energy consumption, etc. Ensure safety and health and save waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

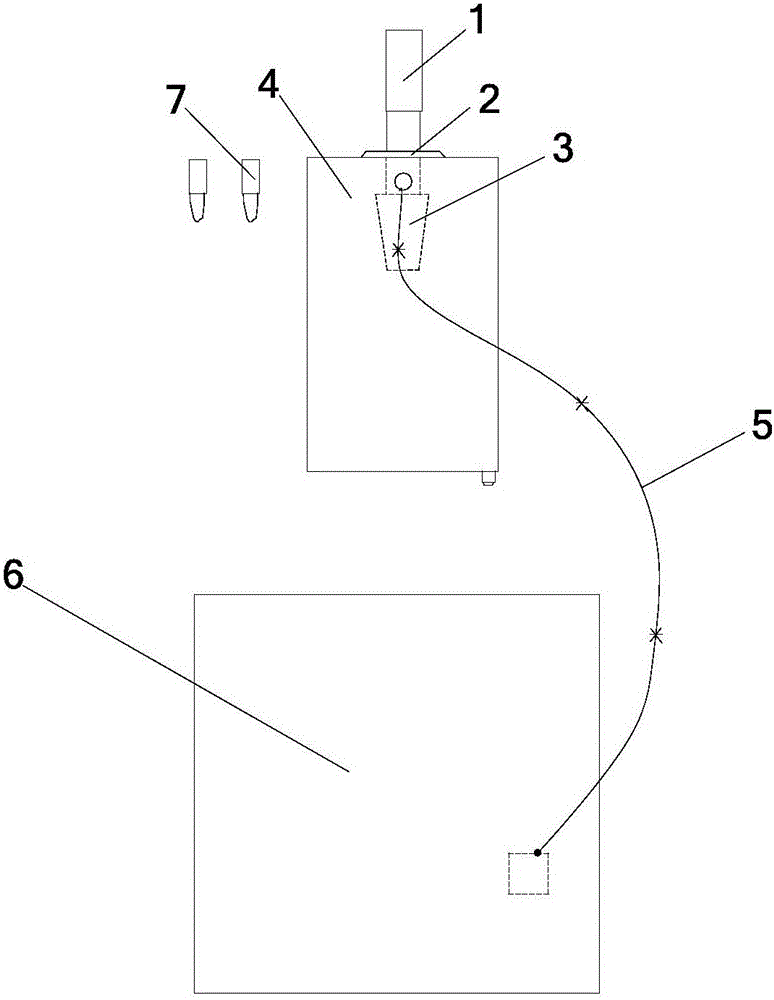

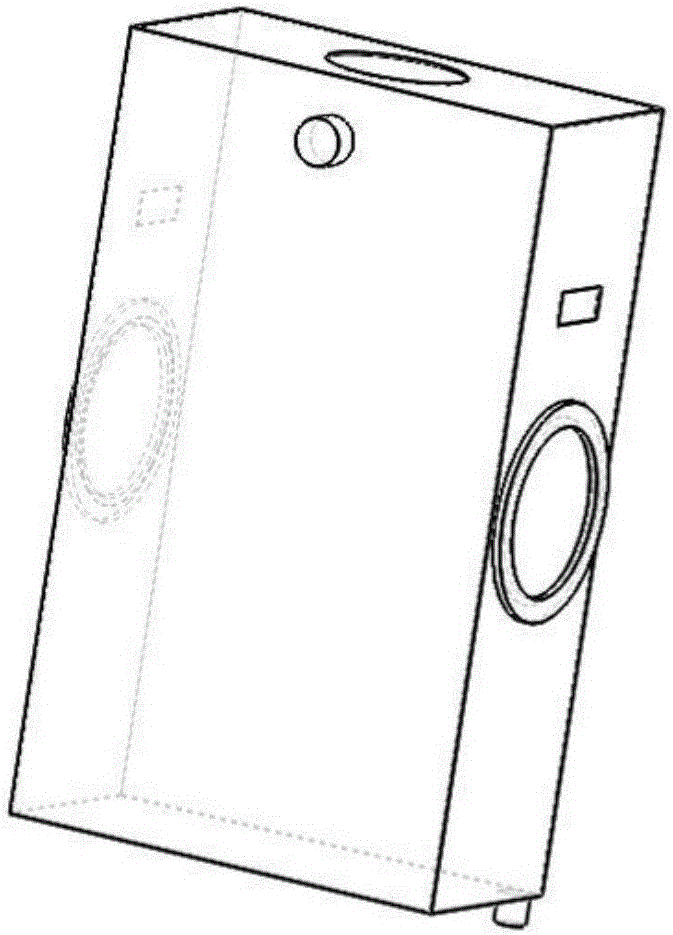

[0027] like figure 1 As shown, the present invention provides a device for cleaning rotating tubular objects, which includes a centralized ultrasonic system, a reactor 4 , a water tank 6 and an air nozzle 7 . like figure 2 As shown, the reactor 4 is used to run through the rotating tubular object, so as to continuously advance the rotating tubular object and continuously clean the part where the rotating tubular object is located after cooperating with the centralized ultrasonic system and the water tank 6 .

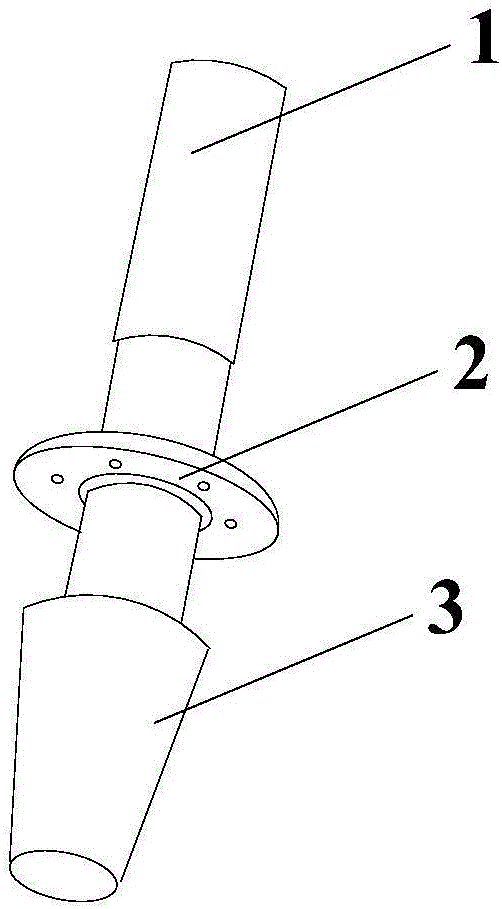

[0028] The centralized ultrasonic system includes a transducer 1, an amplifier 2 and a sonic pole 3, wherein the transducer 1 is located outside the reactor 4; one side of the amplifier 2 is connected to the transducer 4 ; The sonic pole 3 is connected to the other side of the amplifier 2, and extends into the reactor 4. like image 3 or Figure 4 As shown, the sonic pole 3 in the present invention can be located above, below or on the side of the rotating tubular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com