Overhead conductor with thin insulation layer

An overhead wire and insulating layer technology, applied to insulated conductors, insulated cables, insulating conductors/cables, etc., can solve problems such as difficulty in power transmission, leaving hidden dangers of accidents, and sag, avoiding rain or salt fog. The effect of entering the inside of the wire, not easy to accumulate ice or snow, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

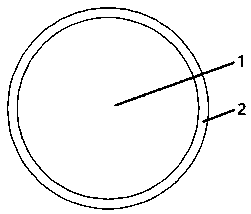

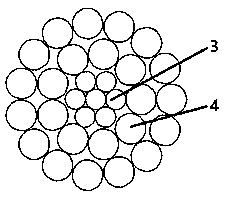

[0016] The overhead wire core 1 is made first, and then a thin insulating layer 2 is extruded outside the overhead wire core 1 . The center of the overhead wire core 1 is the twisted layer 1 3, which can be made of one or more galvanized steel wires, or aluminum-clad steel wires, or high-strength aluminum alloy wires, and the outside is twisted. One layer of twisted layer 2 4 is twisted, and the twisted layer 2 4 can be formed by twisting one or more layers of aluminum wires or aluminum alloy wires. The center of the conductive wire core mainly bears the role of tensile force, and the outer twisted aluminum wire or aluminum alloy wire bears the role of conduction and part of the role of tensile force. The requirements for overhead wire core 1 meet the standards for corresponding overhead wires. The thin insulating layer 2 is composed of a layer of weather-resistant cross-linked or non-cross-linked thin insulating plastic with a thickness of 0.3-1.0 mm.

[0017] The thin insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com