Cleaning system for PDC drill bit

A cleaning system and drill bit technology, applied to the cleaning method using tools, cleaning methods using liquid, cleaning methods and utensils, etc., can solve the problems of lack of stability, trouble, water reduction, etc., to achieve continuous cleaning and improve Cleaning efficiency and cleaning cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

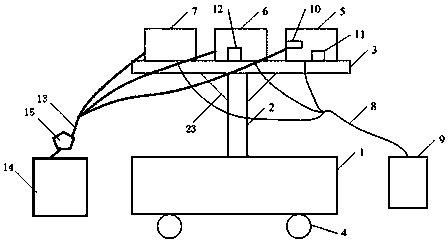

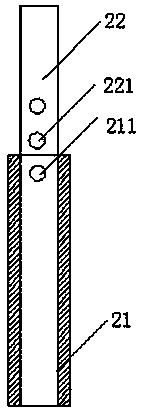

[0025] This embodiment is used for the cleaning system of PDC drill bit, as figure 1 As shown, it includes a base 1, a rotating shaft 2, and a disc 3. The base 1 is provided with brake casters 4, and the bottom of the disc 3 is provided with a circular groove, such as figure 2 As shown, the rotating shaft 2 includes a fixed shaft 21 and a telescopic shaft 22, and a pair of pin holes 211 are provided at the upper end of the fixed shaft 21, and several pairs of positioning holes 221 are provided at the lower end of the telescopic shaft 22, which are inserted into the In pin hole 211 and positioning hole 221, fixed shaft 21 and telescopic shaft 22 are fixed; The middle part of the upper surface is connected, and the upper end of the telescopic shaft 22 is located in the circular groove; a support frame 23 is hinged symmetrically on both sides of the upper end of the telescopic shaft 22, and the other end of the support frame 23 is fixedly connected with the bottom surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com