A continuous water washing and dechlorination device for waste incineration fly ash

A waste incineration fly ash and ash water technology, applied in the field of fly ash treatment, can solve the problems of cumbersome regulation and operation, inconvenient operation and management, etc., and achieve the effects of preventing external contact, high cleaning efficiency, and simple and convenient operation and regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

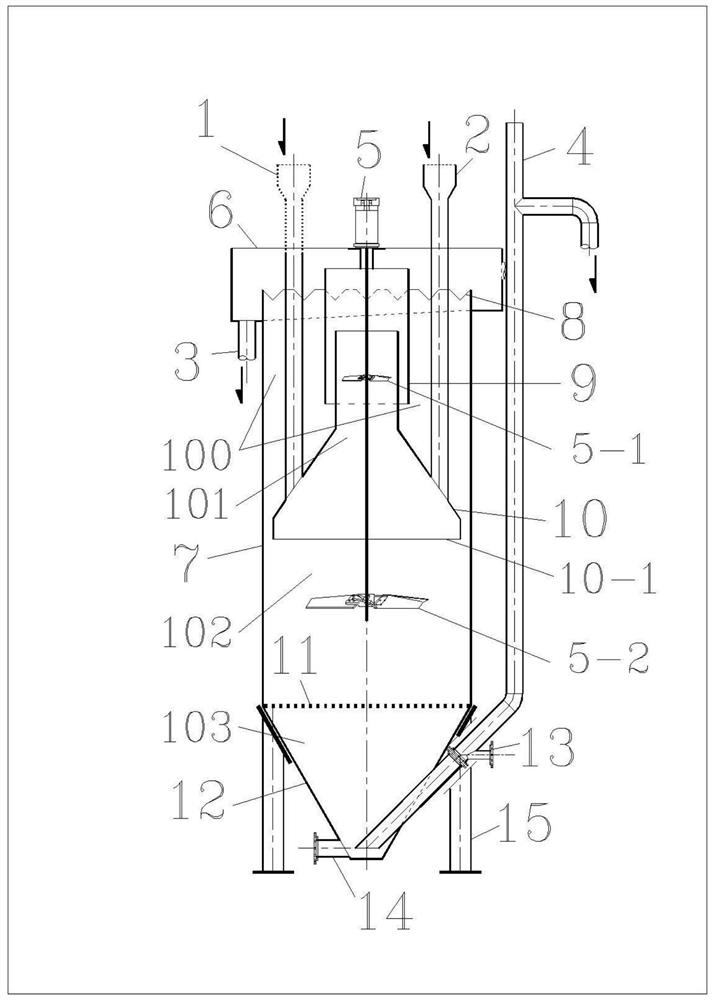

[0026] Such as figure 1 As shown, it is a schematic diagram of the waste incineration fly ash continuous washing dechlorination device provided by the present invention. The device provided in this embodiment has only one device unit, and the device unit includes a fly ash feed pipe 1, a cleaning liquid inlet pipe 2, and a waste water outlet pipe. 3. Mortar riser 4, mixing system 5, top cover 6, main body 7, outlet weir 8, sleeve 9, mixing zone partition 10, orifice plate 11, ash hopper 12, air inlet pipe 13, emptying pipe 14, bracket 15;

[0027] The device unit includes vertical gray water sedimentation area 100, gray water ascending area 101, gray water mixing dechlorination area 102 and mortar concentration area 103 from top to bottom. The gray water rising zone 101 is from the lower part of the partition plate 10 in the mixing zone to the horizontal line 10-1 at its end, and the gray water mixing dechlorination zone 102 is between the horizontal line 10-1 at the end of t...

Embodiment 2

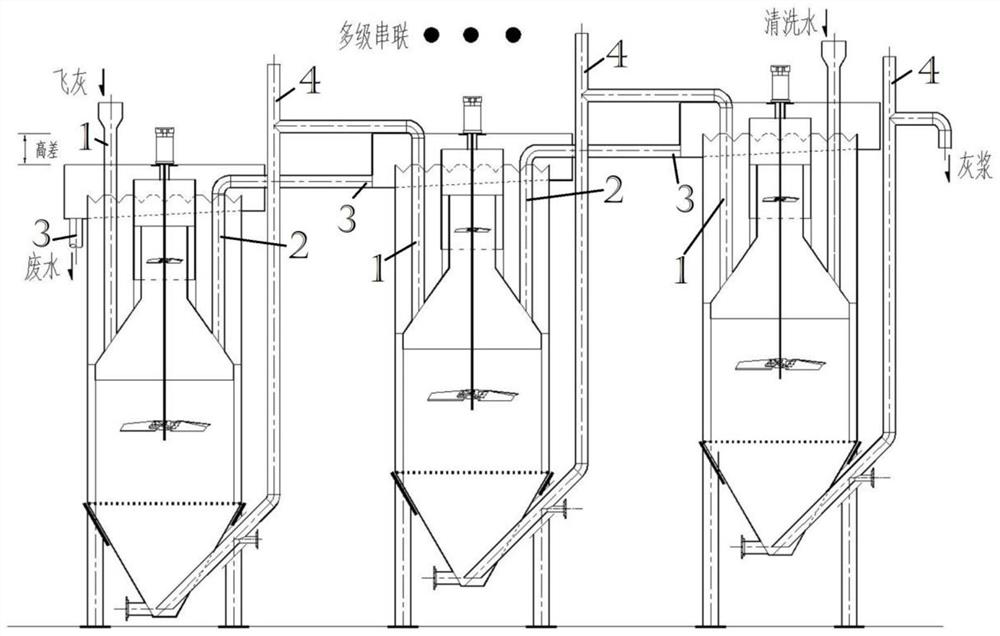

[0039] Such as figure 2 As shown, it is a schematic diagram of a multi-stage serial waste incineration fly ash continuous washing dechlorination device provided by the present invention. The difference between the device provided in this embodiment and Embodiment 1 is that the device includes a plurality of device units, and the plurality of device units are connected in series through the upper The waste water outlet pipe 3 of one device unit is connected with the cleaning liquid inlet pipe 2 of the next device unit, and the fly ash feed pipe 1 of the previous device unit is connected with the mortar riser pipe 4 of the next device unit, realizing serial use The cleaning water flows from the cleaning device with the highest weir elevation to the cleaning device with the lowest weir elevation, and the fly ash is lifted from the cleaning device with the lowest weir elevation to the cleaning device with the highest weir elevation.

[0040] When multi-stage series cleaning is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com