Loose wool fiber dyeing/washing integrated machine and cleaning method of loose wool fiber

A wool fiber and integrated machine technology, applied in the field of dyeing machines, can solve the problems of clean water becoming dirty water, insufficient cleaning, large water consumption, etc., achieve continuous cleaning, ensure dyeing speed and effect, and save water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

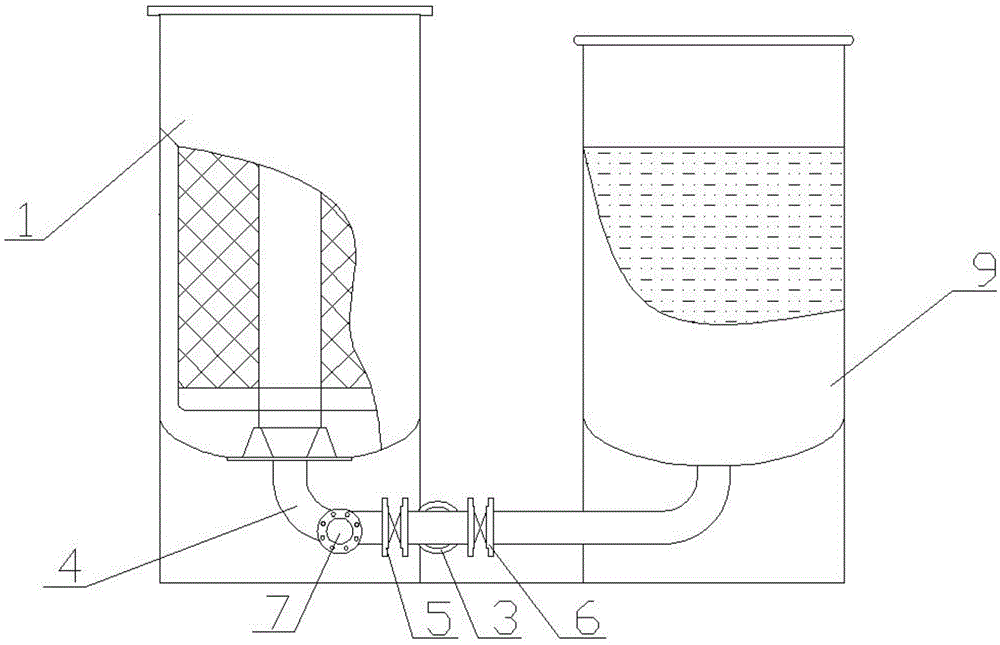

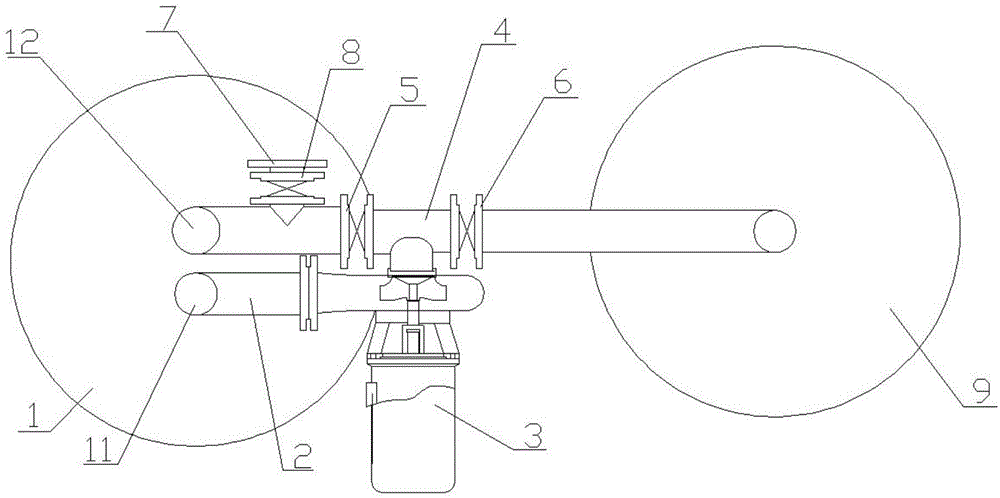

[0015] Such as figure 1 , 2 As shown, a loose wool fiber dyeing and washing machine includes a dyeing and washing tank 1, the bottom of the dyeing and washing tank 1 is provided with a water inlet 11 and a water outlet 12, and the water inlet 11 is connected to one end of the first water delivery pipe 2, the first The other end of the water delivery pipe 2 is connected with the water pump 3; the water outlet 12 is connected with one end of the second water delivery pipe 4, and the other end of the second water delivery pipe 4 is used to connect the water source, and the connecting end of the second water delivery pipe 4 and the water outlet 12 serves as The lead-out end, the connection end of the second water delivery pipe 4 and the water source is used as the lead-in end; the second water delivery pipe 4 is provided with a communication port, and the communication port is connected to the water pump 3; a first valve body 5 is arranged between the lead-out end and the communic...

Embodiment 2

[0019] The difference between embodiment 2 and embodiment 1 is that the setting position of the drain port is replaced to the bottom of the dyeing and washing tank, and other operations are the same. The advantage is that the size of the drain port is not limited by the size of the second water delivery pipe, and can be It needs to be bigger to speed up the drainage.

[0020] The invention provides a loose wool fiber dyeing and washing machine and its cleaning method, which changes the structure of the water inlet and outlet, ensures the dyeing speed and effect, realizes continuous cleaning, accelerates the cleaning speed, saves water consumption, and avoids waste of resources .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com