Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Process is easy to adjust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-melt strength polypropylene foam material and preparation method thereof

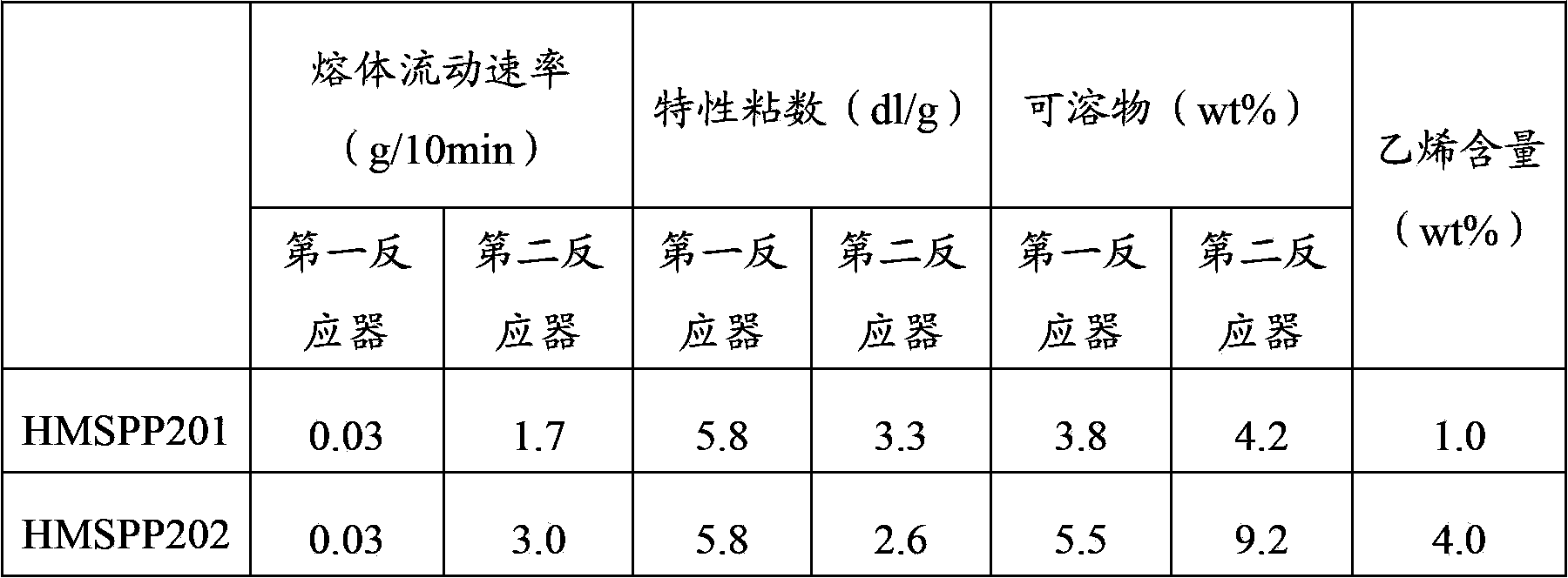

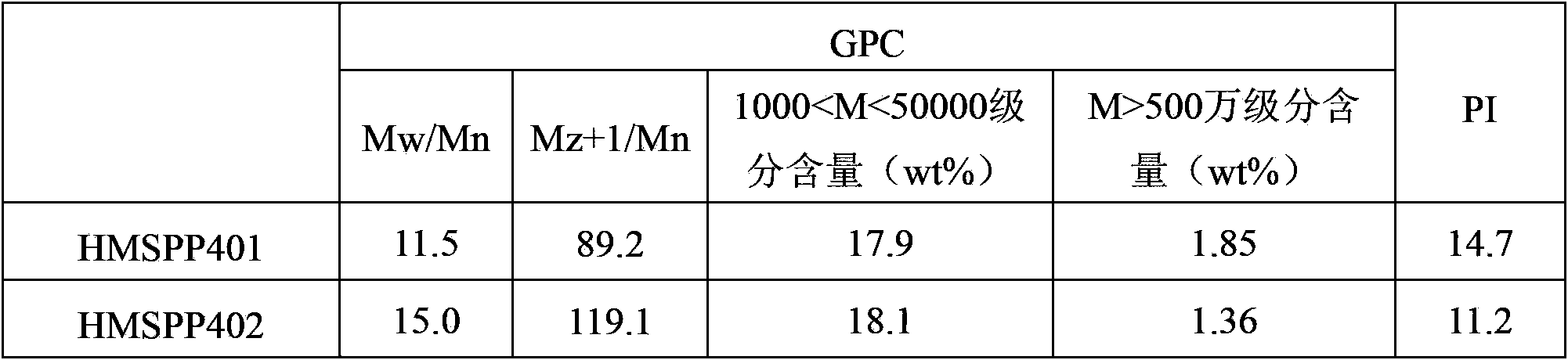

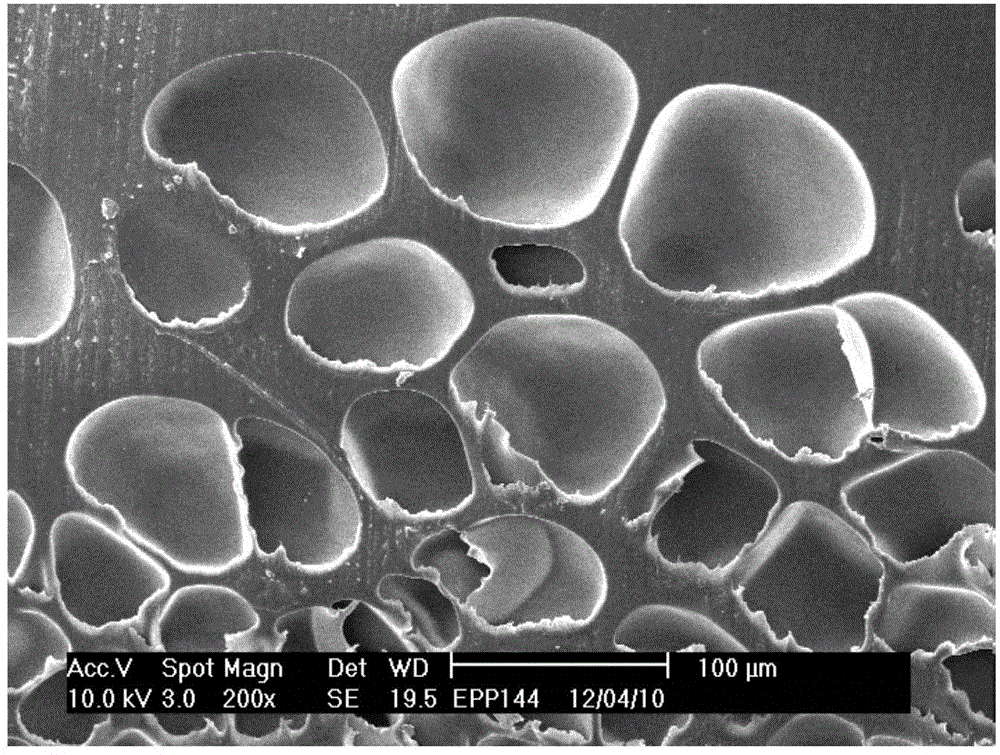

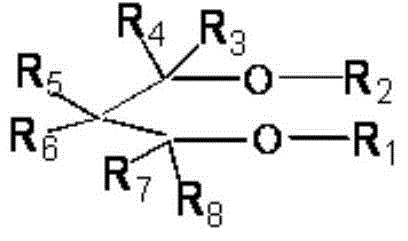

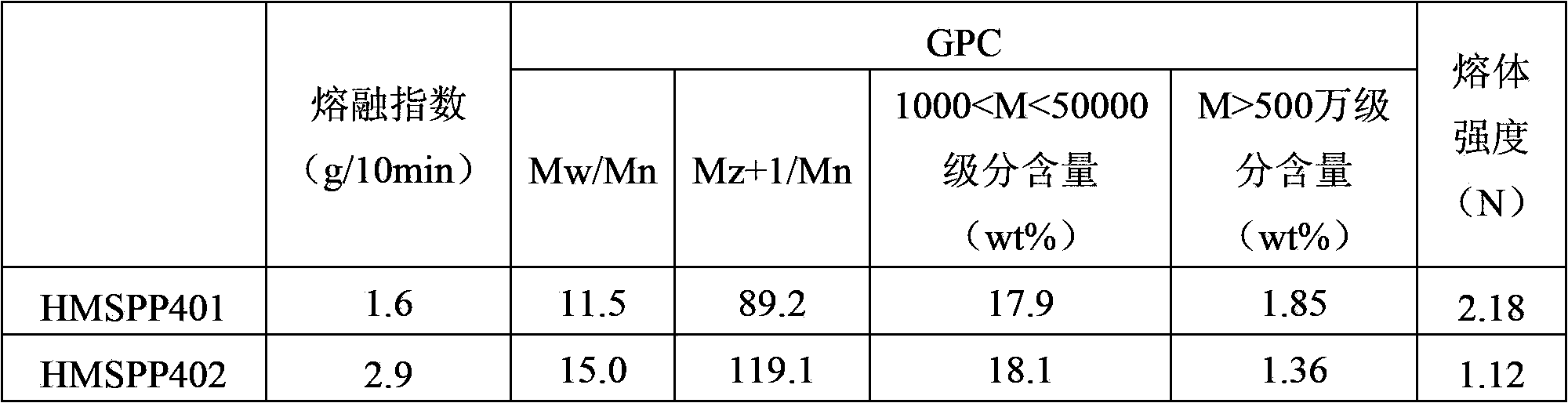

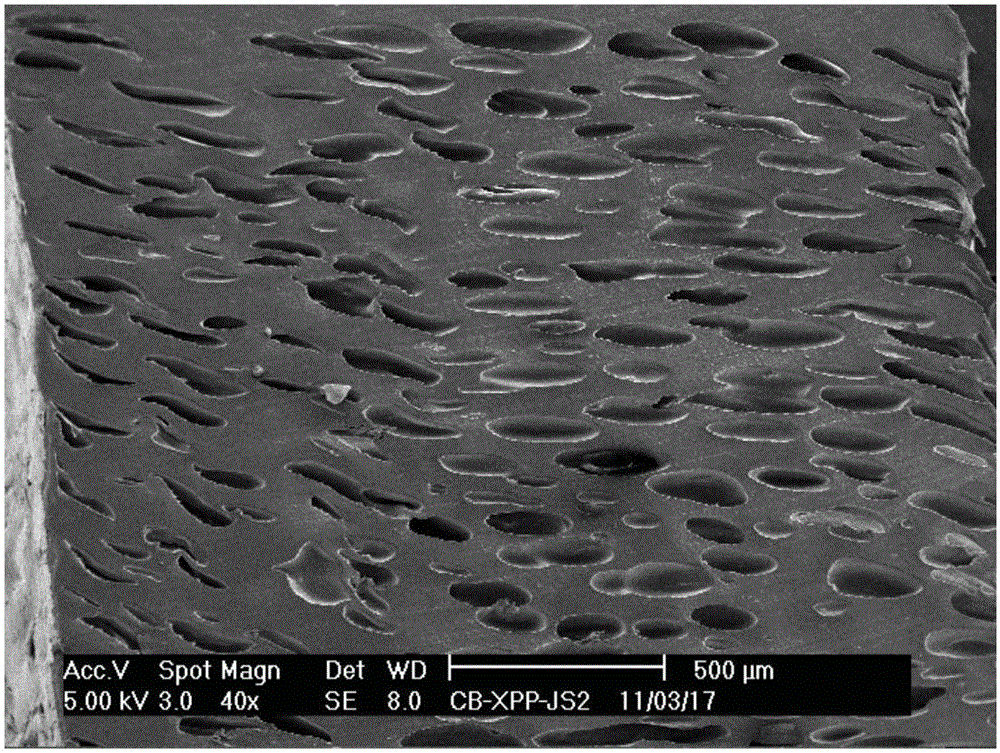

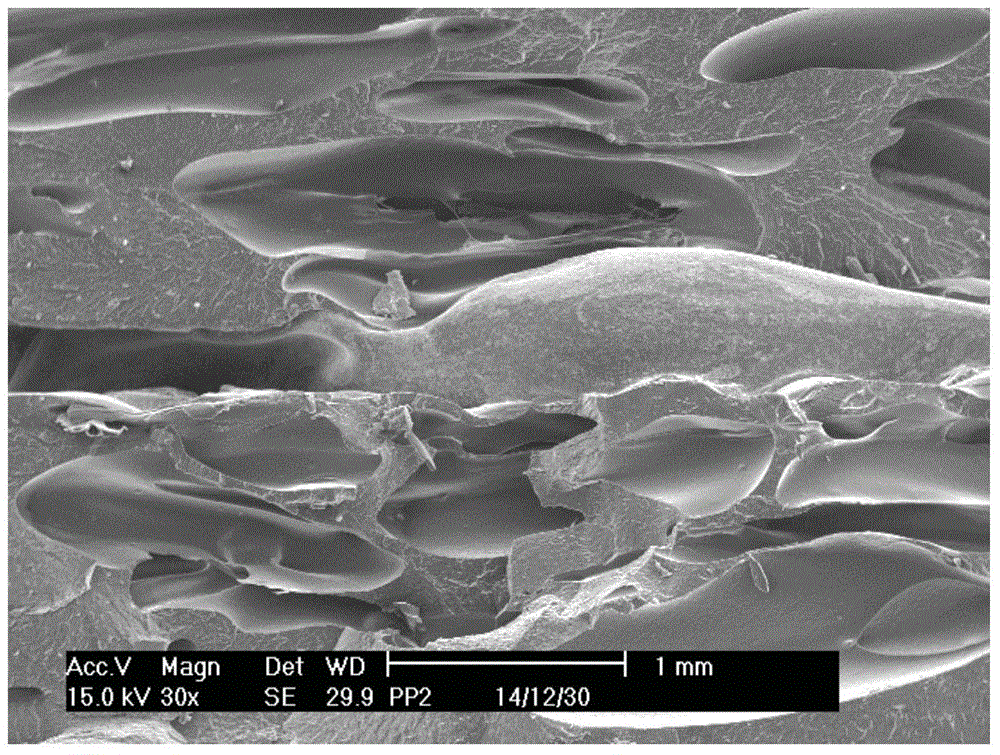

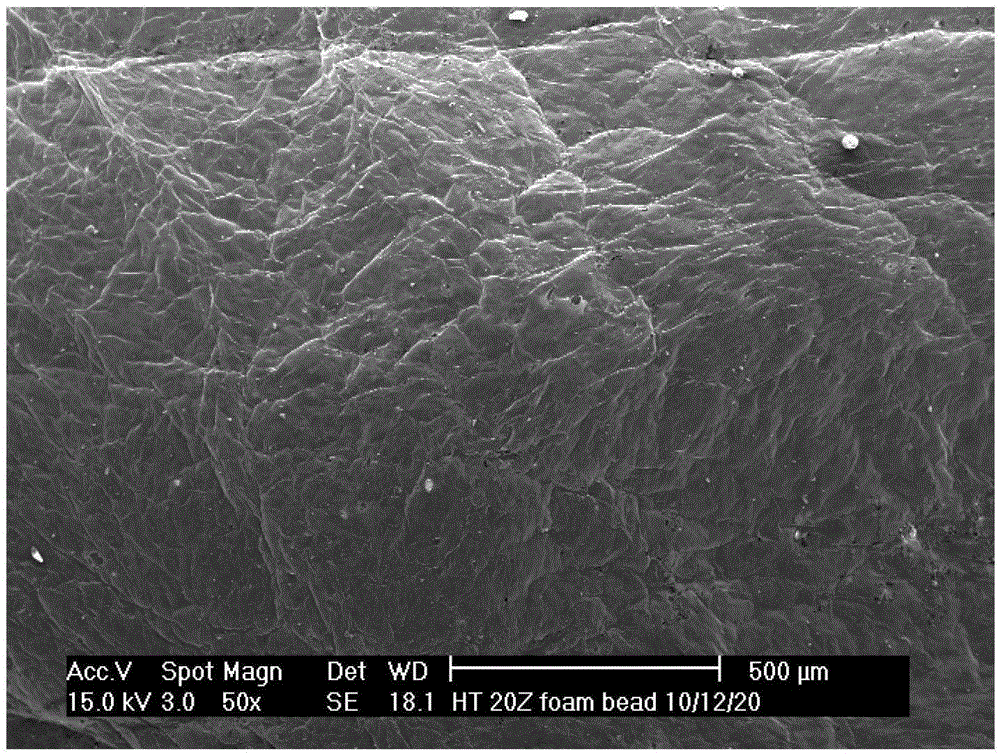

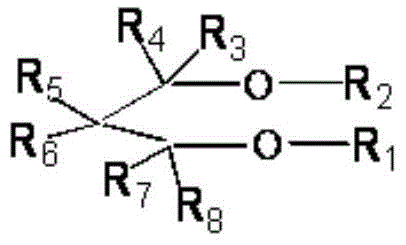

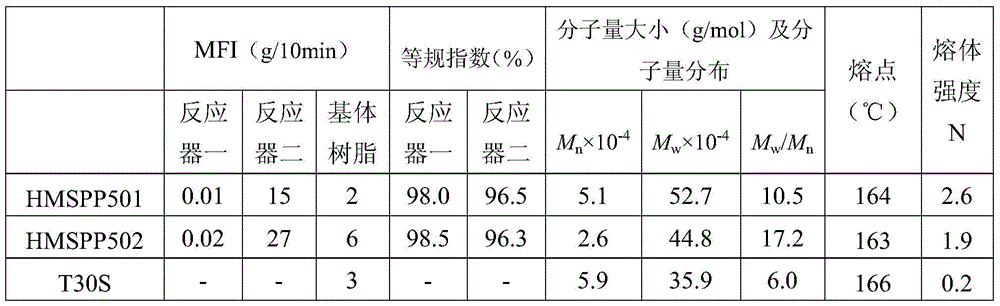

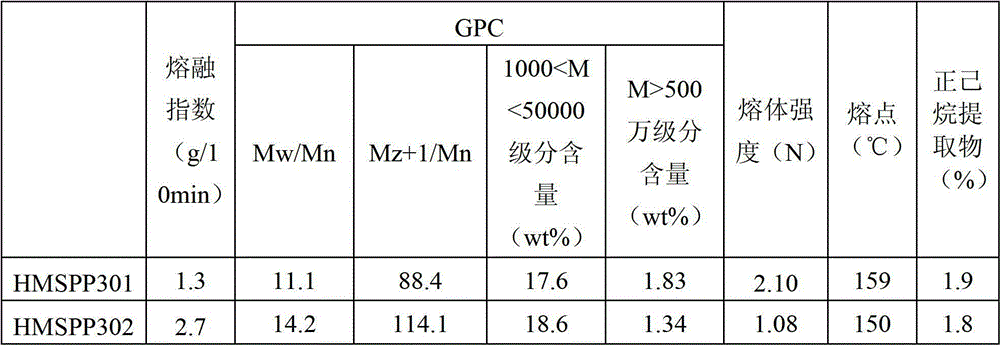

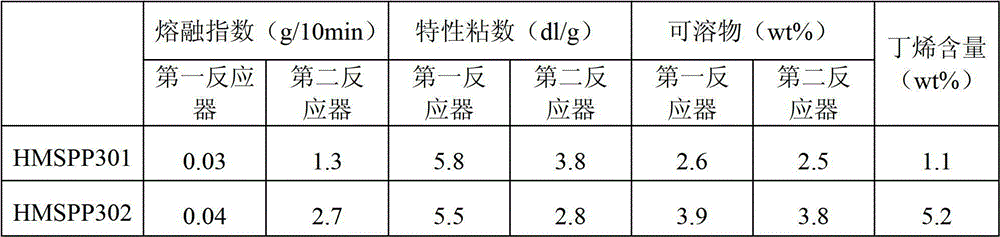

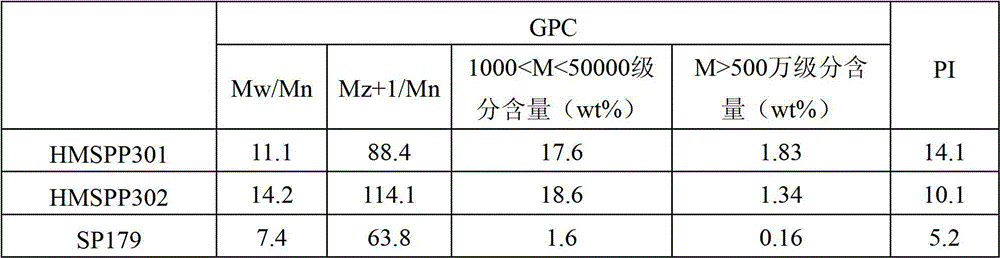

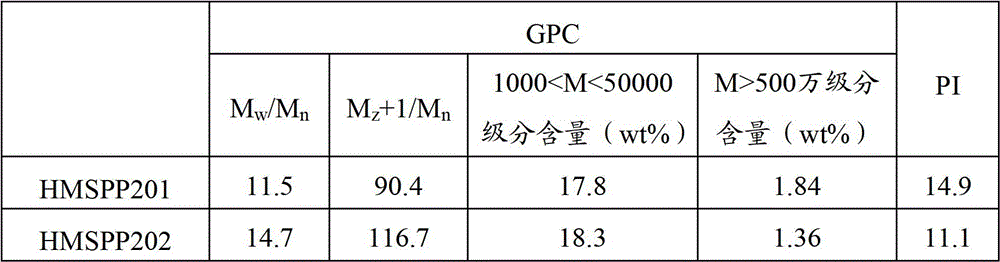

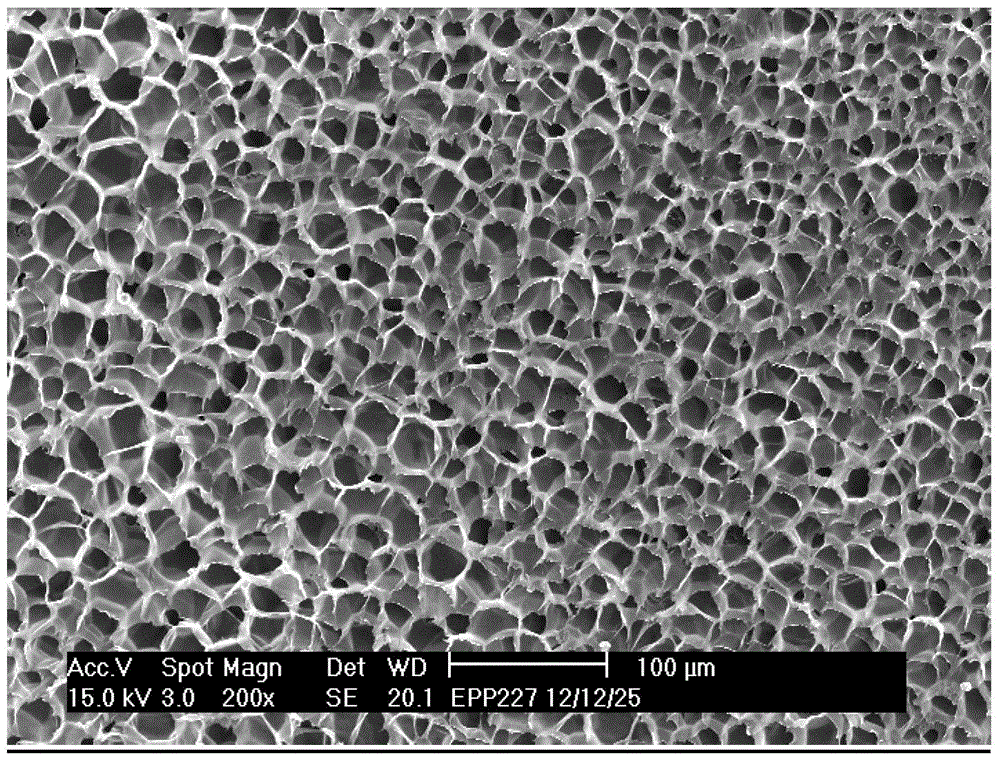

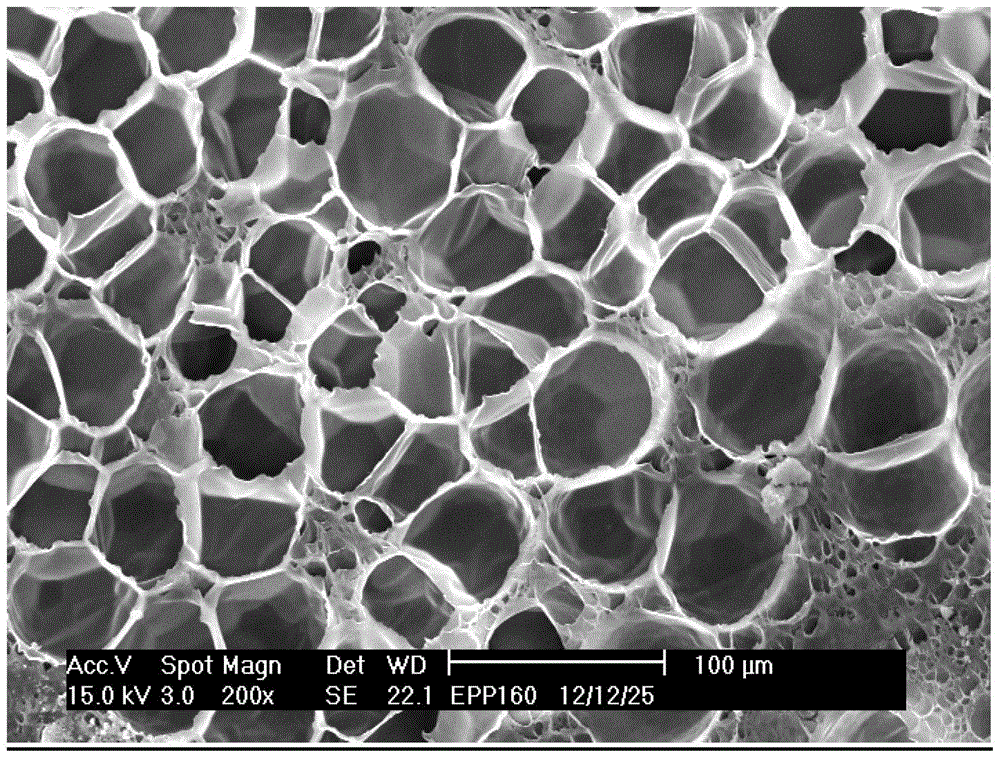

The invention discloses a high-melt strength polypropylene foam material and a preparation method thereof. The matrix resin of the foam material is high-melt strength polypropylene. The high-melt strength polypropylene foam material has the following characteristics: (1) the melt index (190 DEGC / 2.16kg) is 1.0-10g / min; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the molecules with molecular weight over 5 million is greater than or equal to 0.8% by weight; and (4) (Mz+1) / Mn is greater than or equal to 70. The foam material is prepared by premix melting, blending and foaming of the following components in parts by weight: 100 parts of high-melt strength polypropylene and 1-15 parts of foaming agent. The obtained foam material meets the environmental protection requirements of degradability, uniform cell, high physical heat resistance, low production cost and smooth surface, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

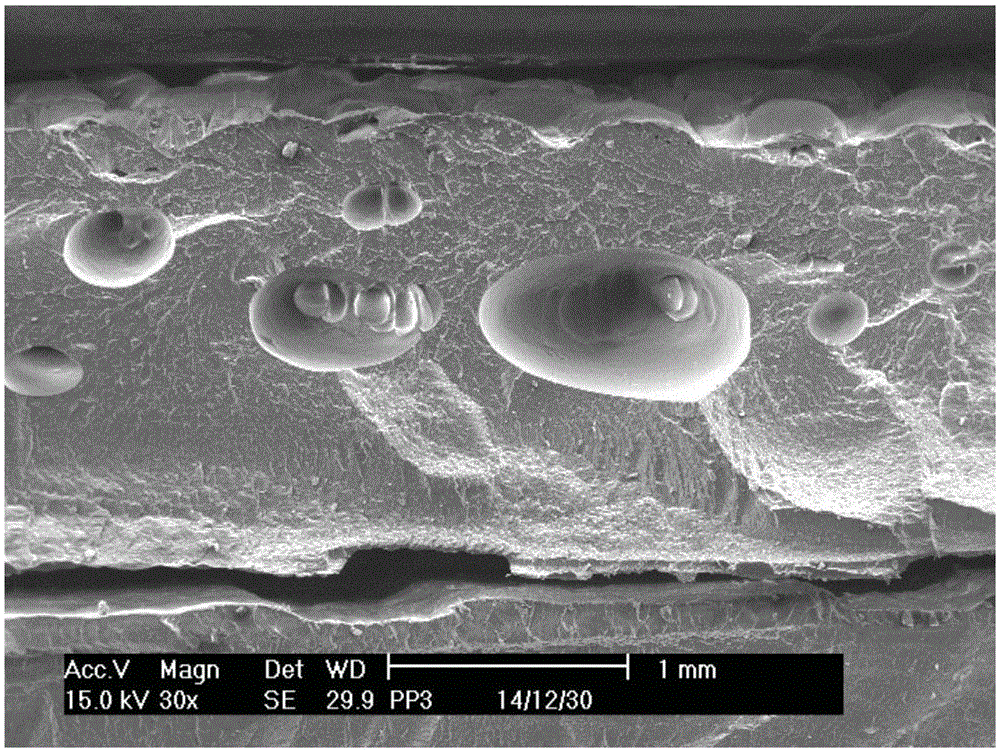

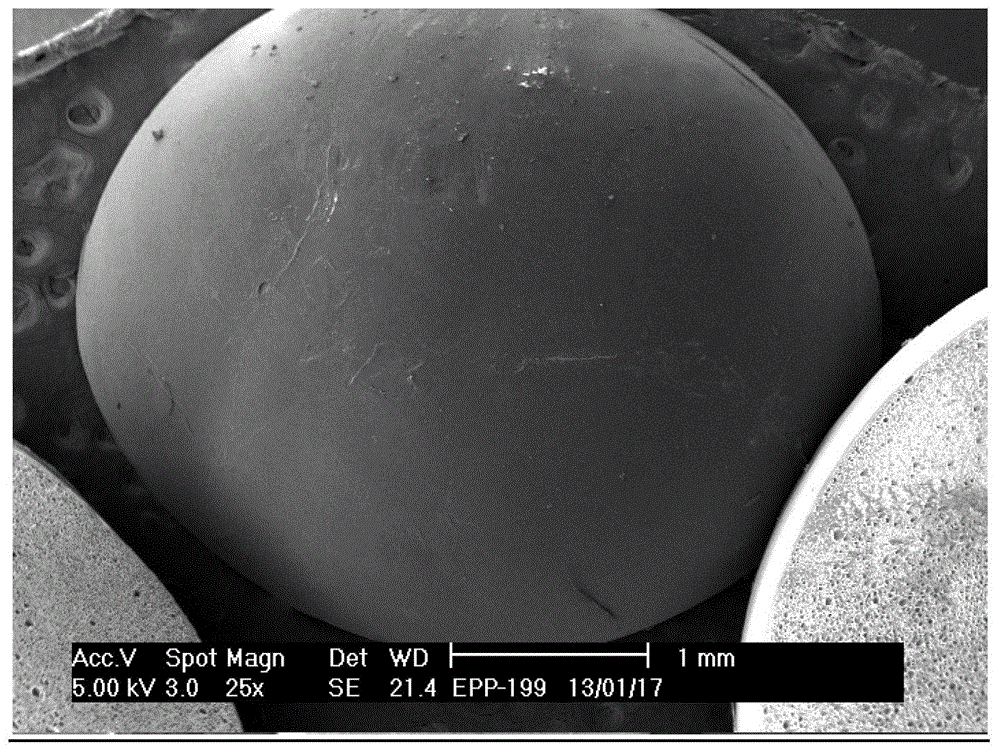

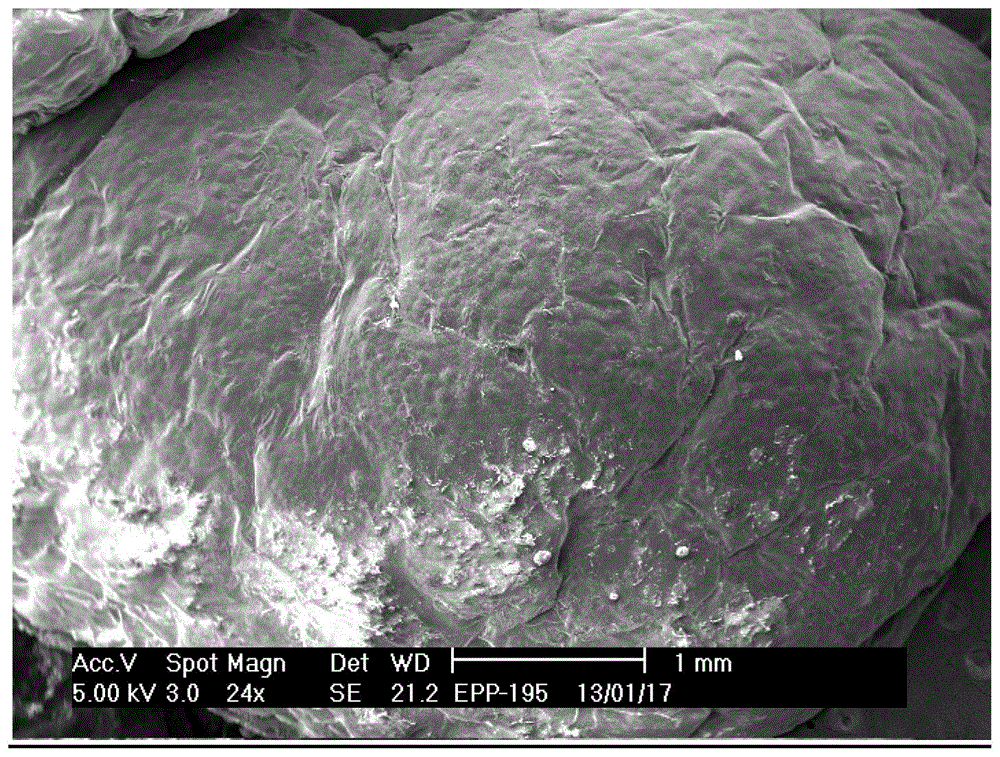

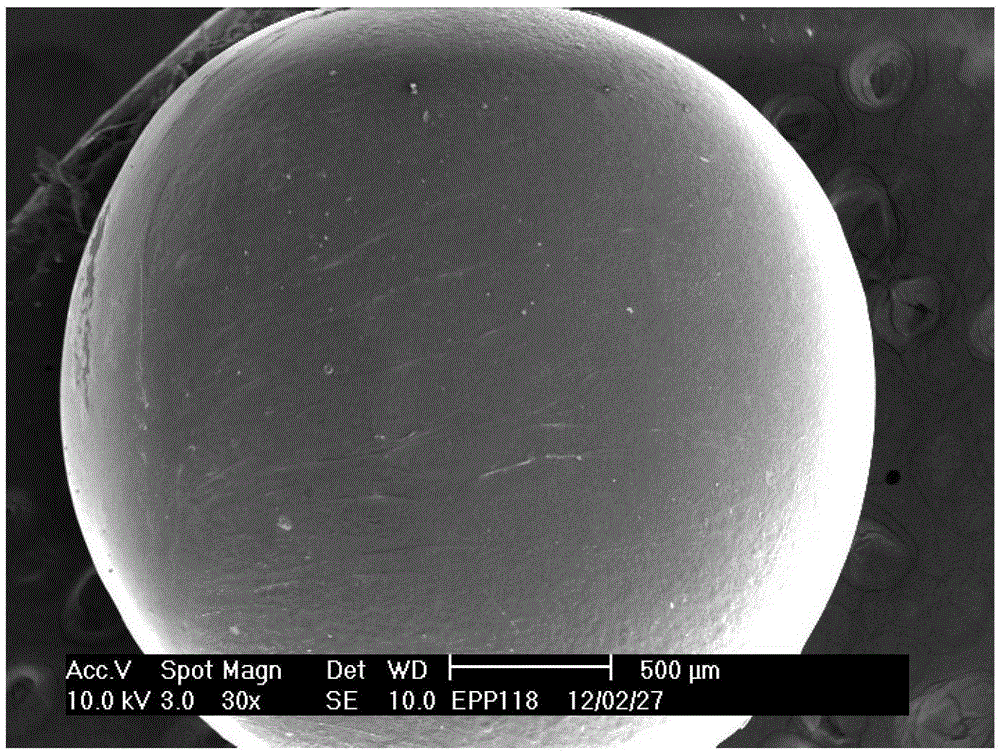

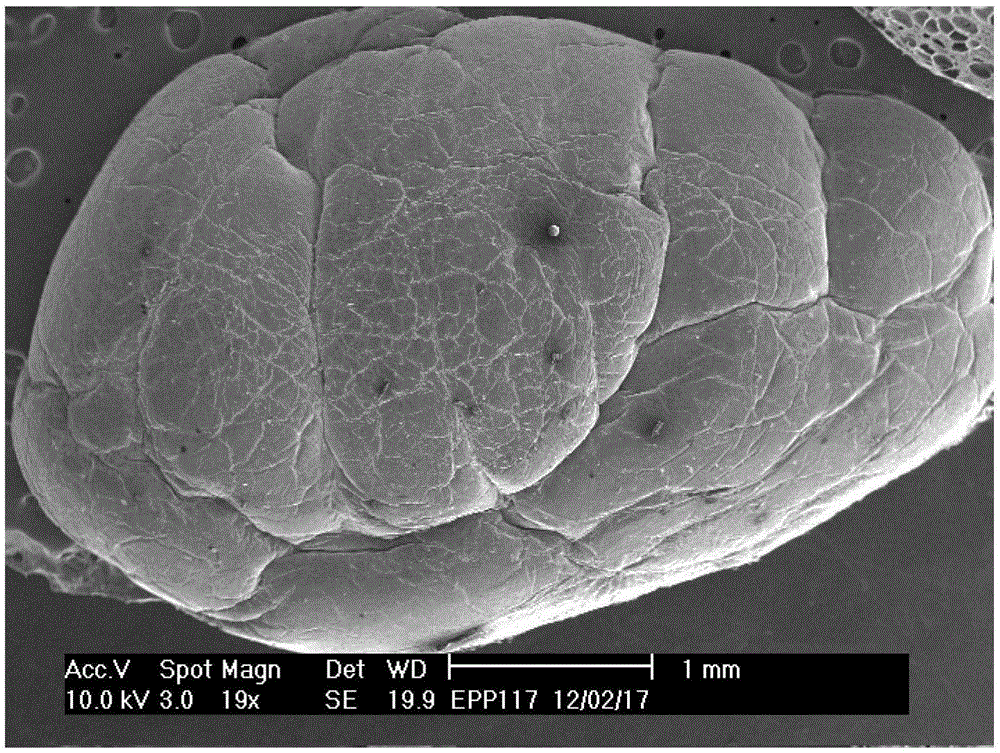

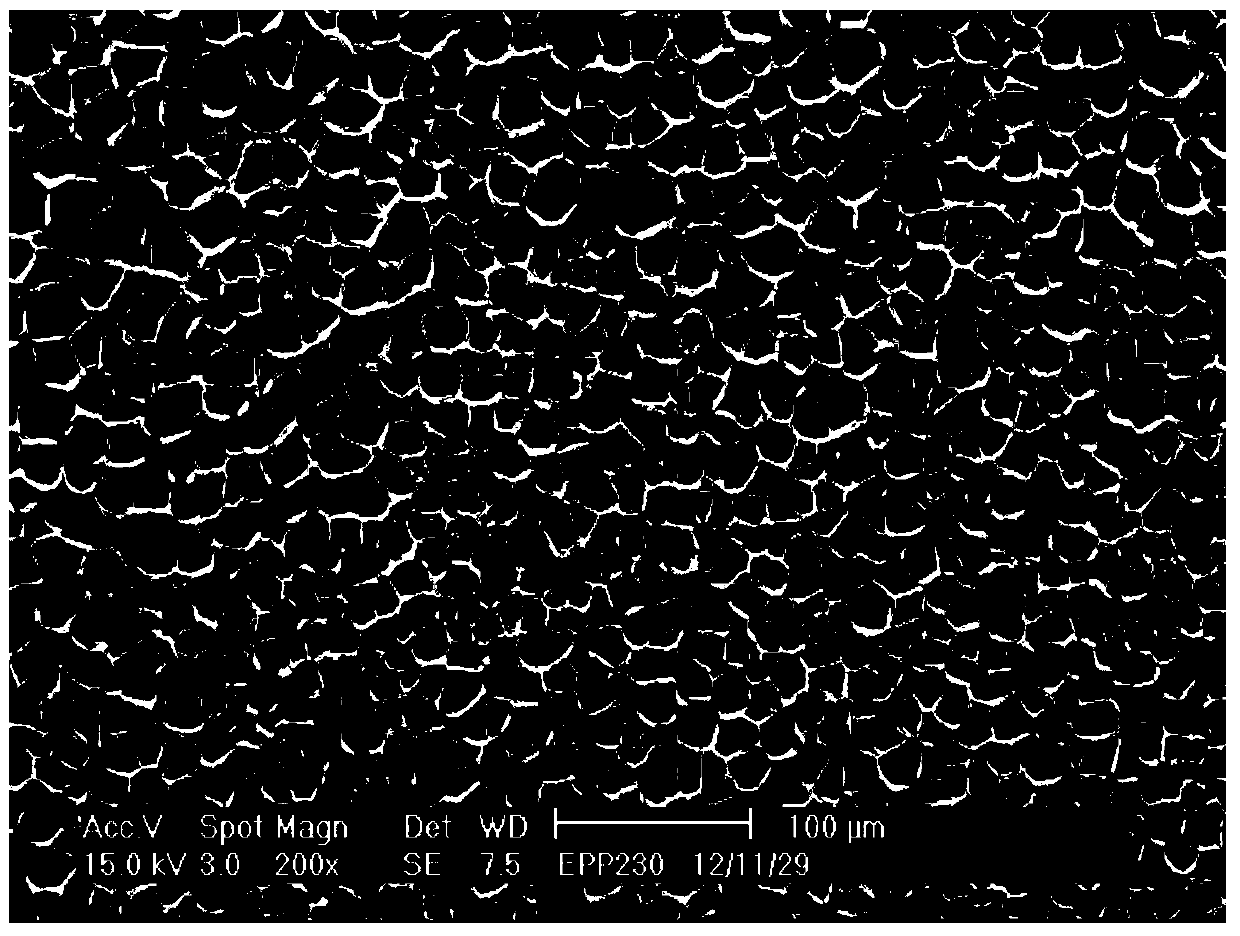

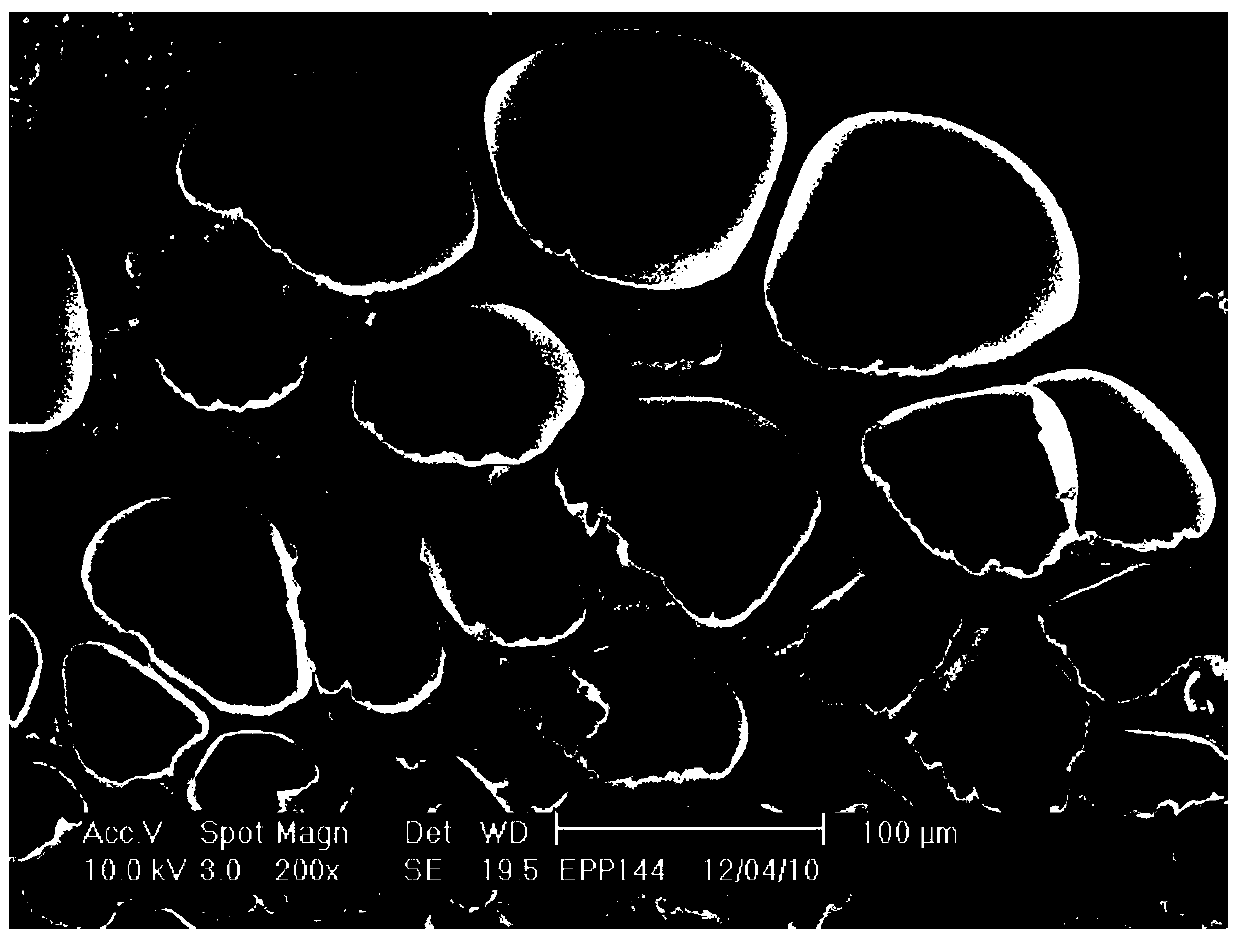

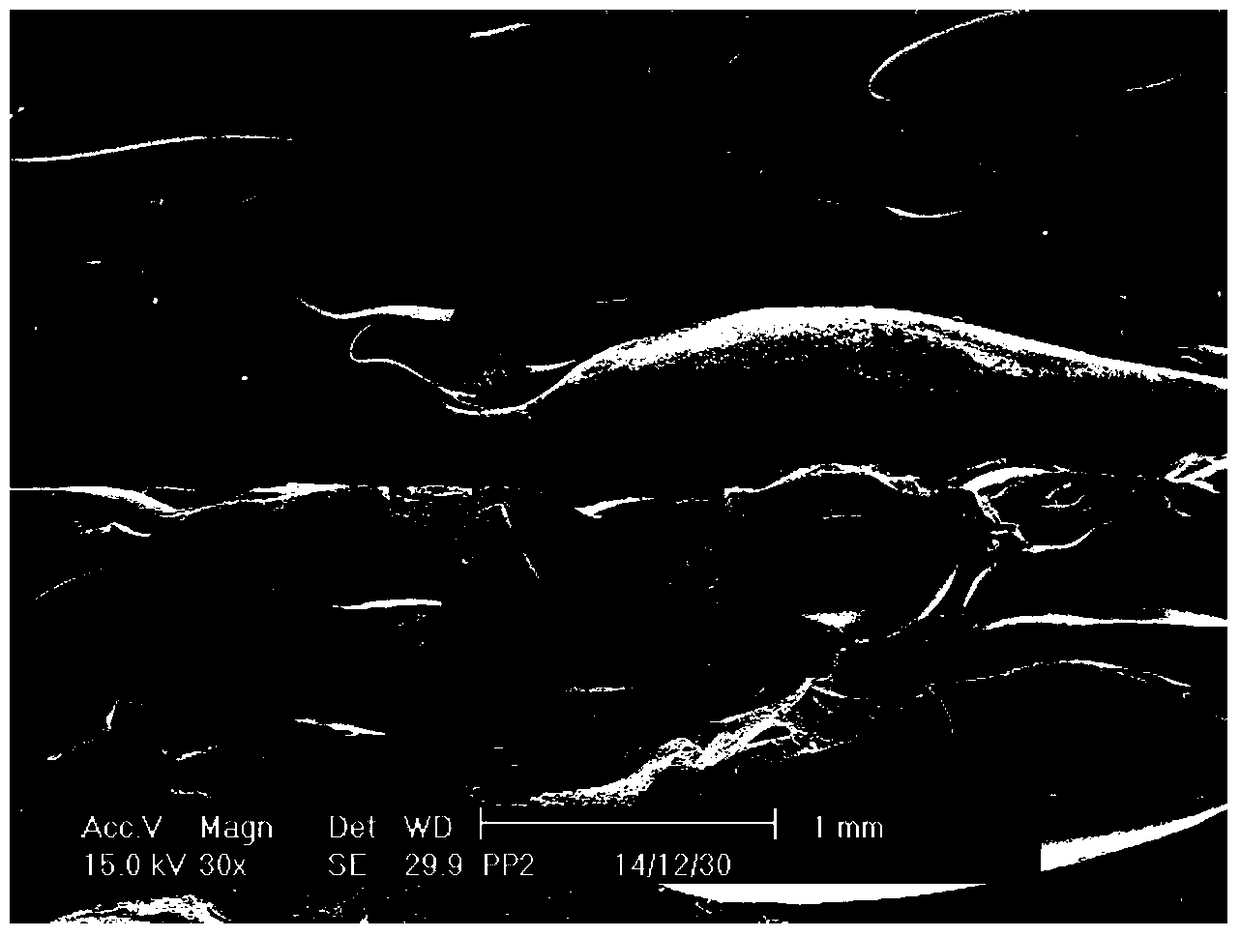

Polypropylene foaming bead formed body and preparation method thereof

The invention provides a polypropylene foaming bead formed body and a preparation method thereof. The preparation method comprises the following steps: mixing polypropylene foaming beads having different foaming rates and prepared by using wide-molecular-weight-distribution high-melt-strength polypropylene as a raw material in proportion, and carrying out thermal molding of the above obtained mixed foaming beads to obtain the foamed body with good surface flatness and tight adhesion. The formed body can be widely applied to the heat insulation tableware field, the automobile interior decorative part field, the finishing material interlayer field, the product damping packaging field and the like. Additionally, the molded body can be recycled, causes no secondary pollution, and accords with circular economy requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

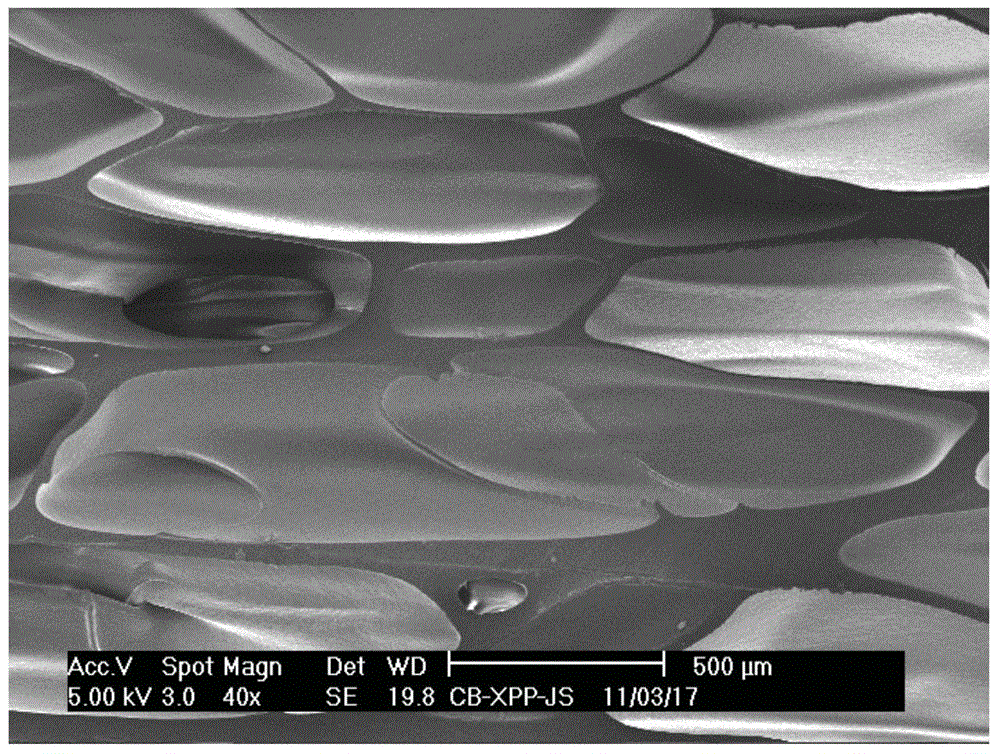

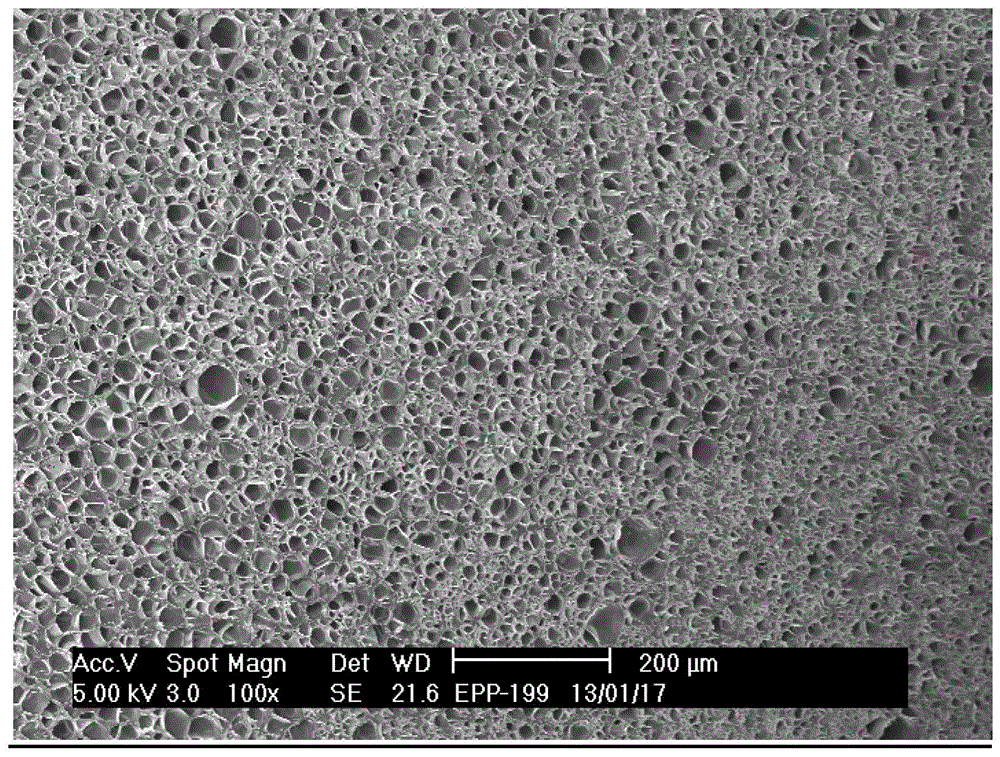

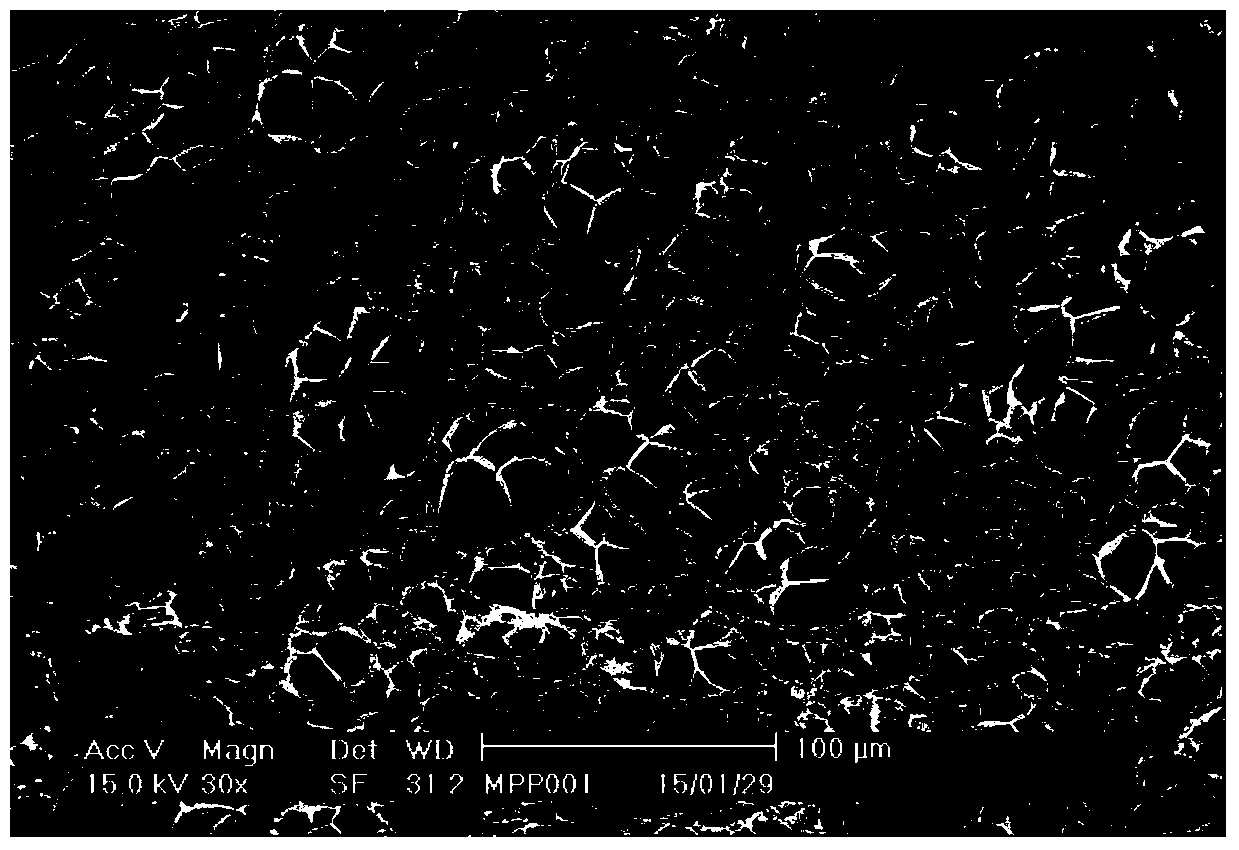

Propylene-ethylene-butylene high-melt-strength polypropylene foamed bead and preparation method thereof

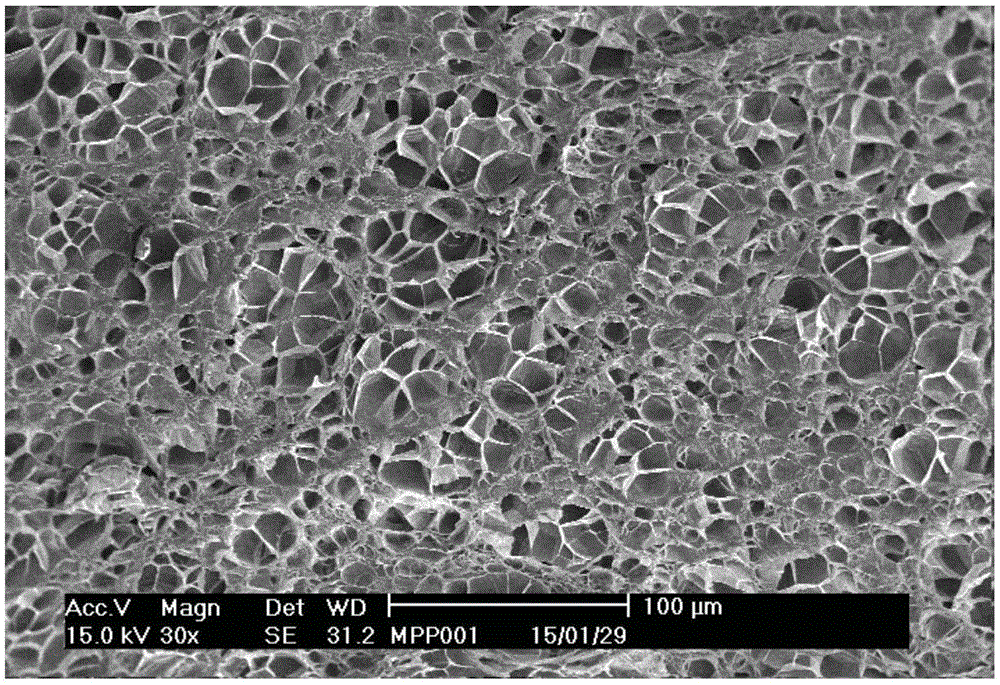

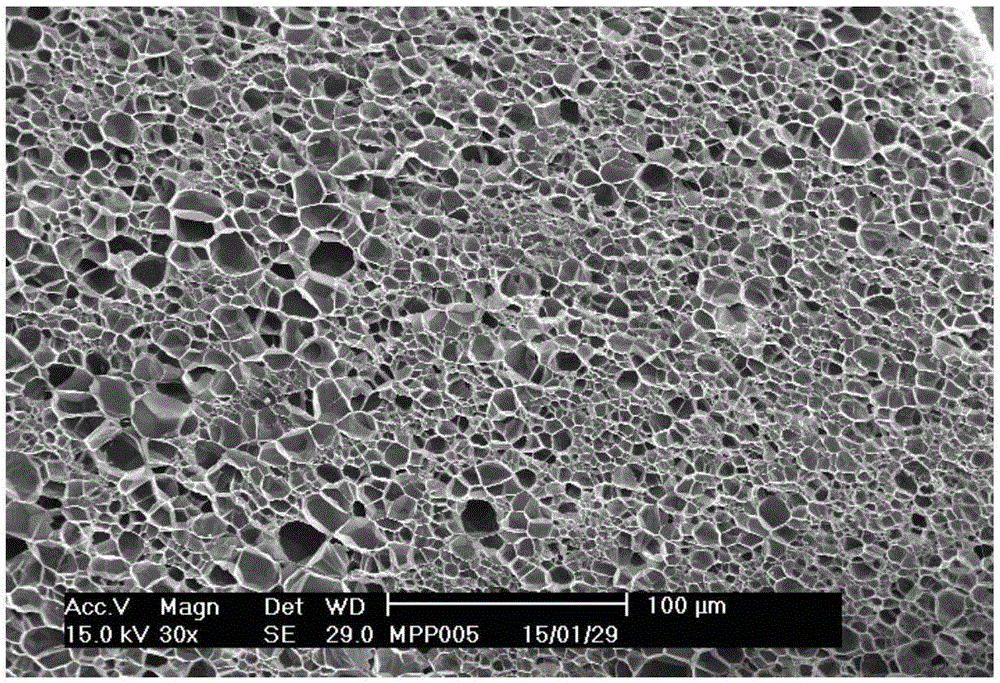

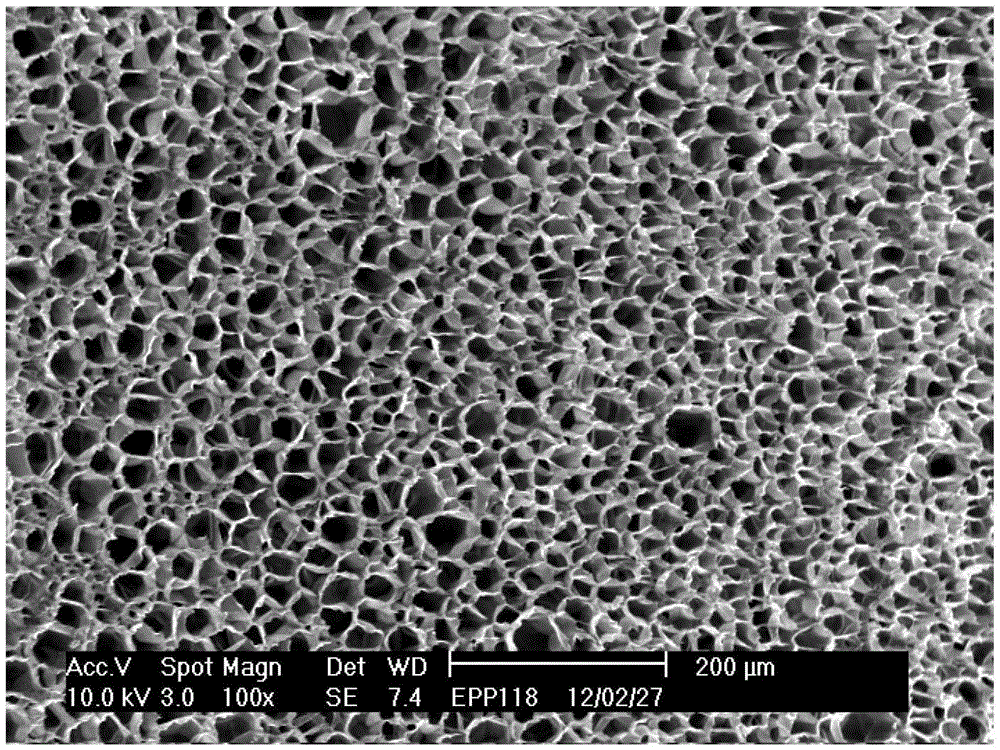

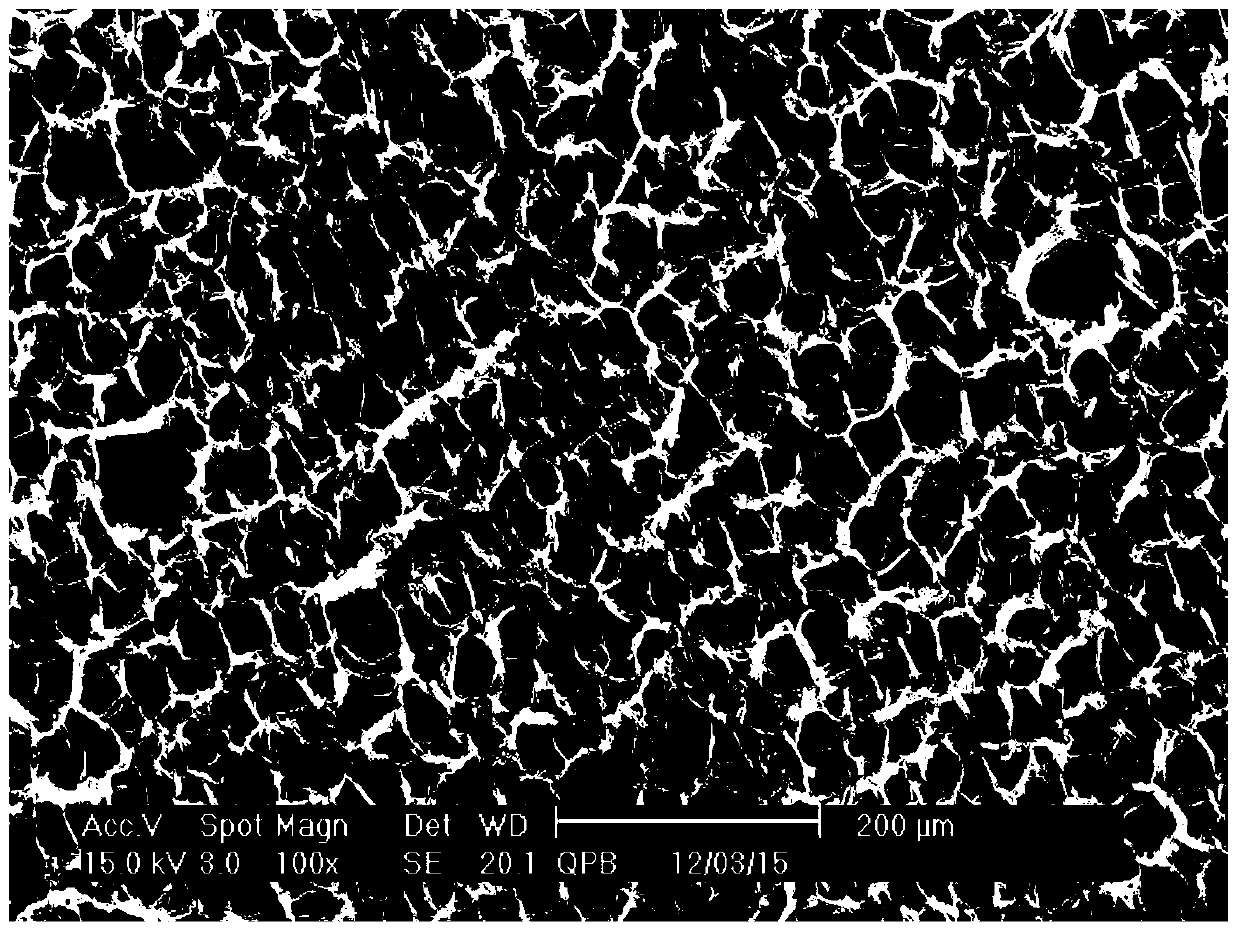

The invention provides a polypropylene foamed bead. The foamed bead is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, the ethylene content is 0.1-15 wt%, and the butylene content is 0.1-15 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, the technique is easy to adjust, and the cost is low; the method can be used for preparing the polypropylene foamed bead with the density of 0.02-0.3 g / cm<3>, which has the advantages of uniform pore diameter, compact pores, uniform pore size distribution and close-pore structure; and the polypropylene foamed bead can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

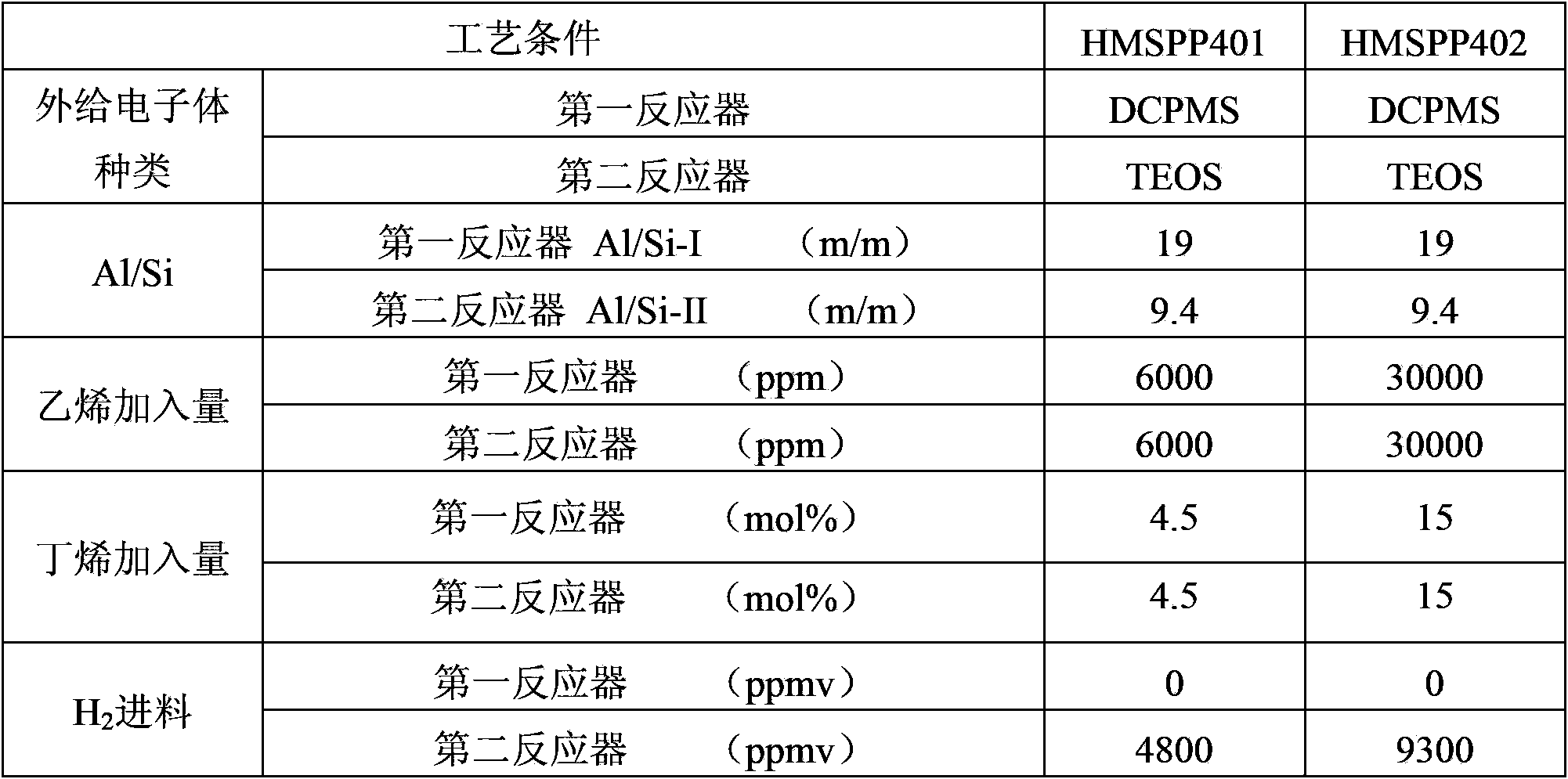

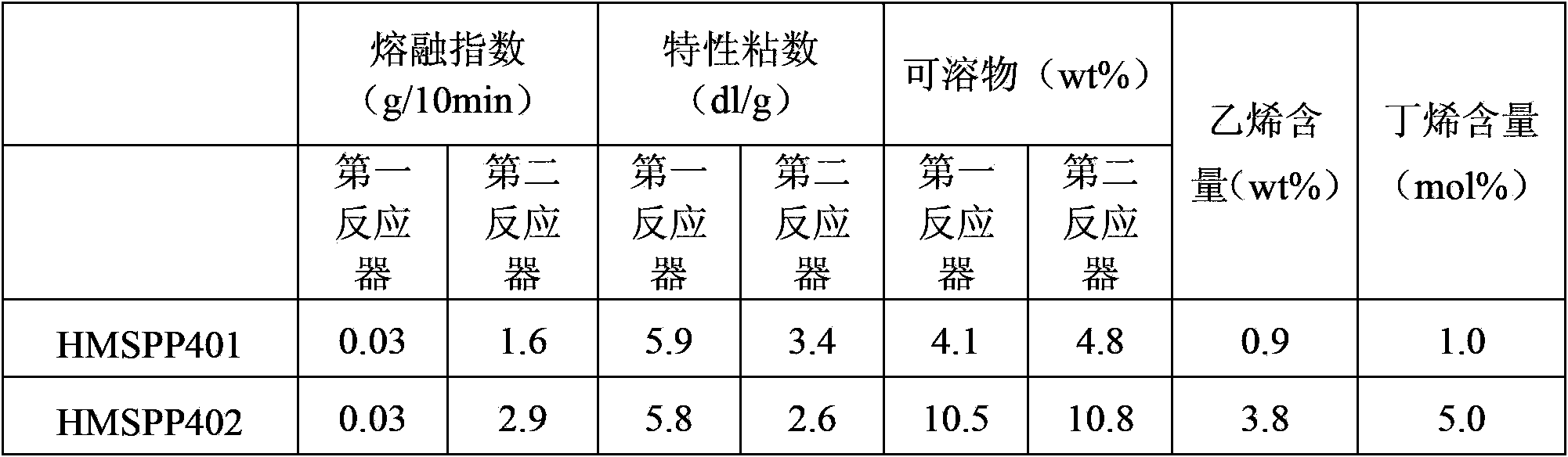

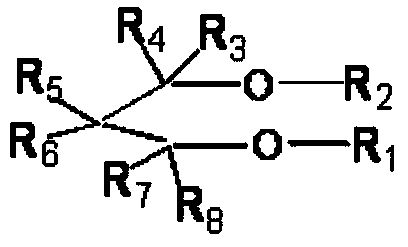

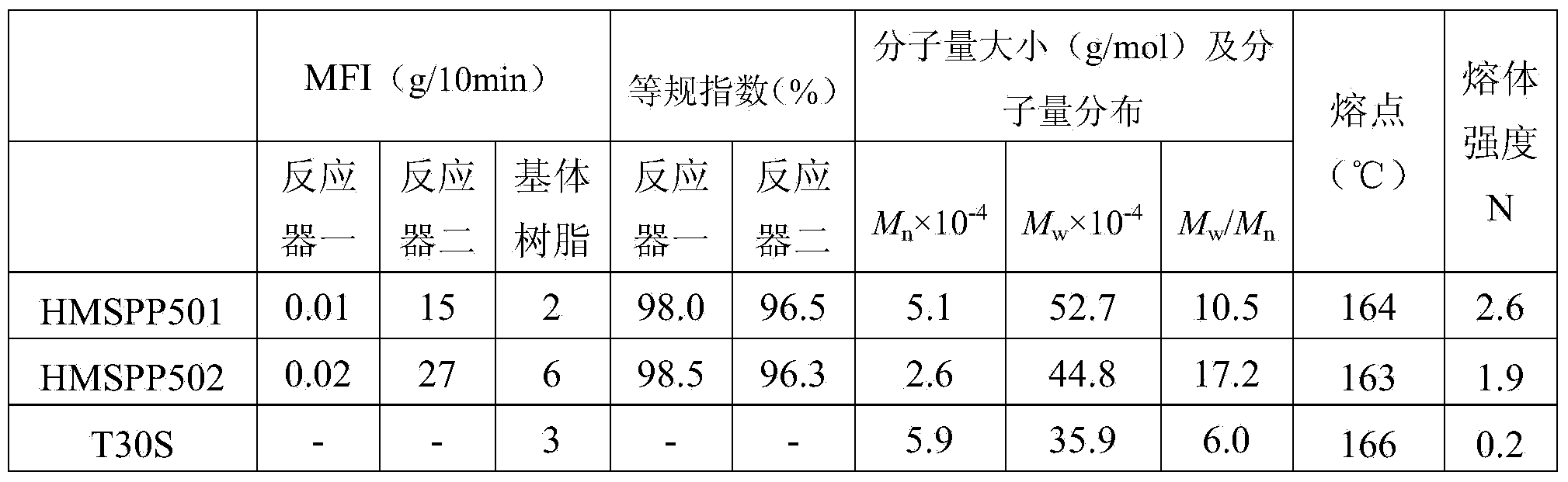

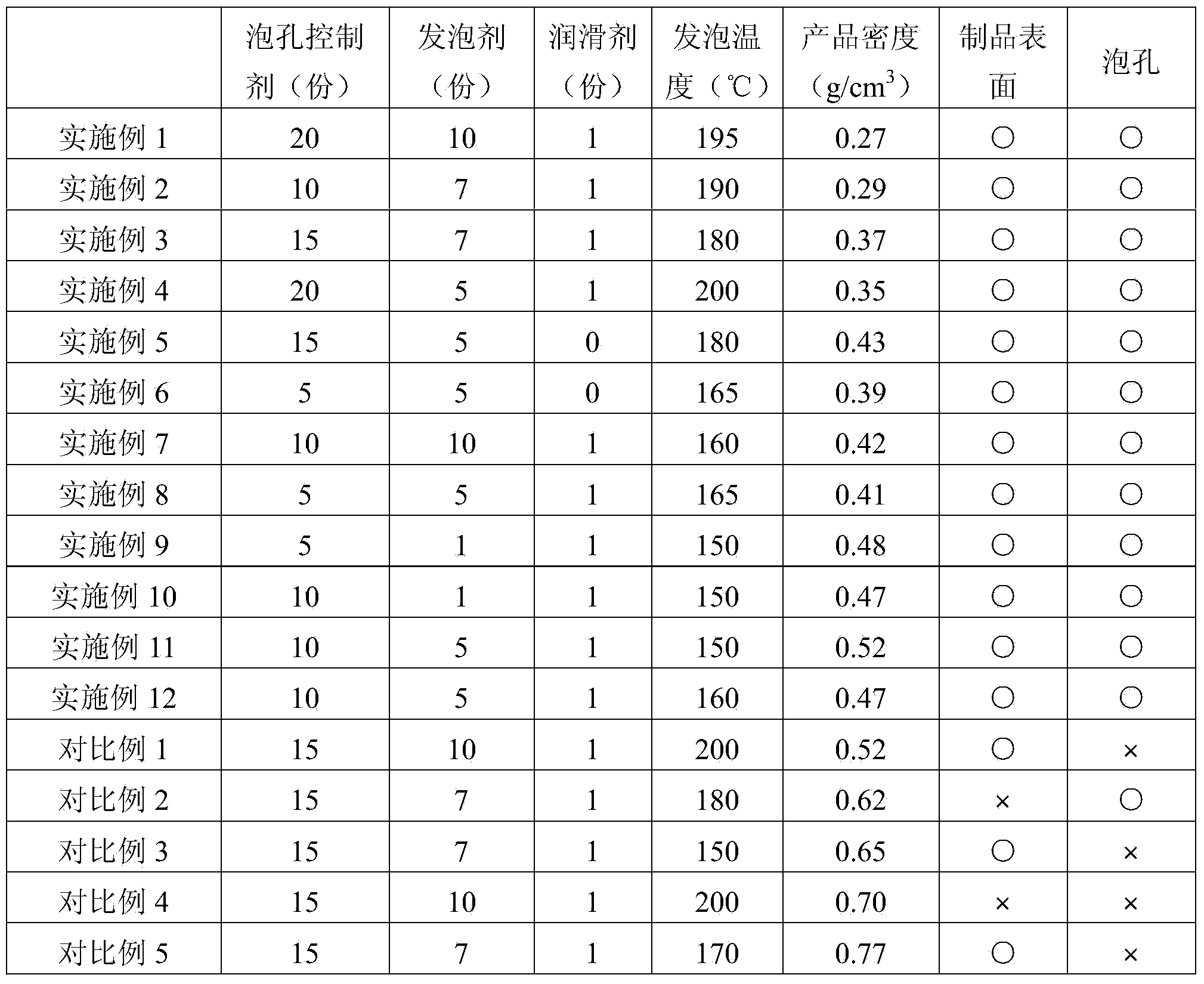

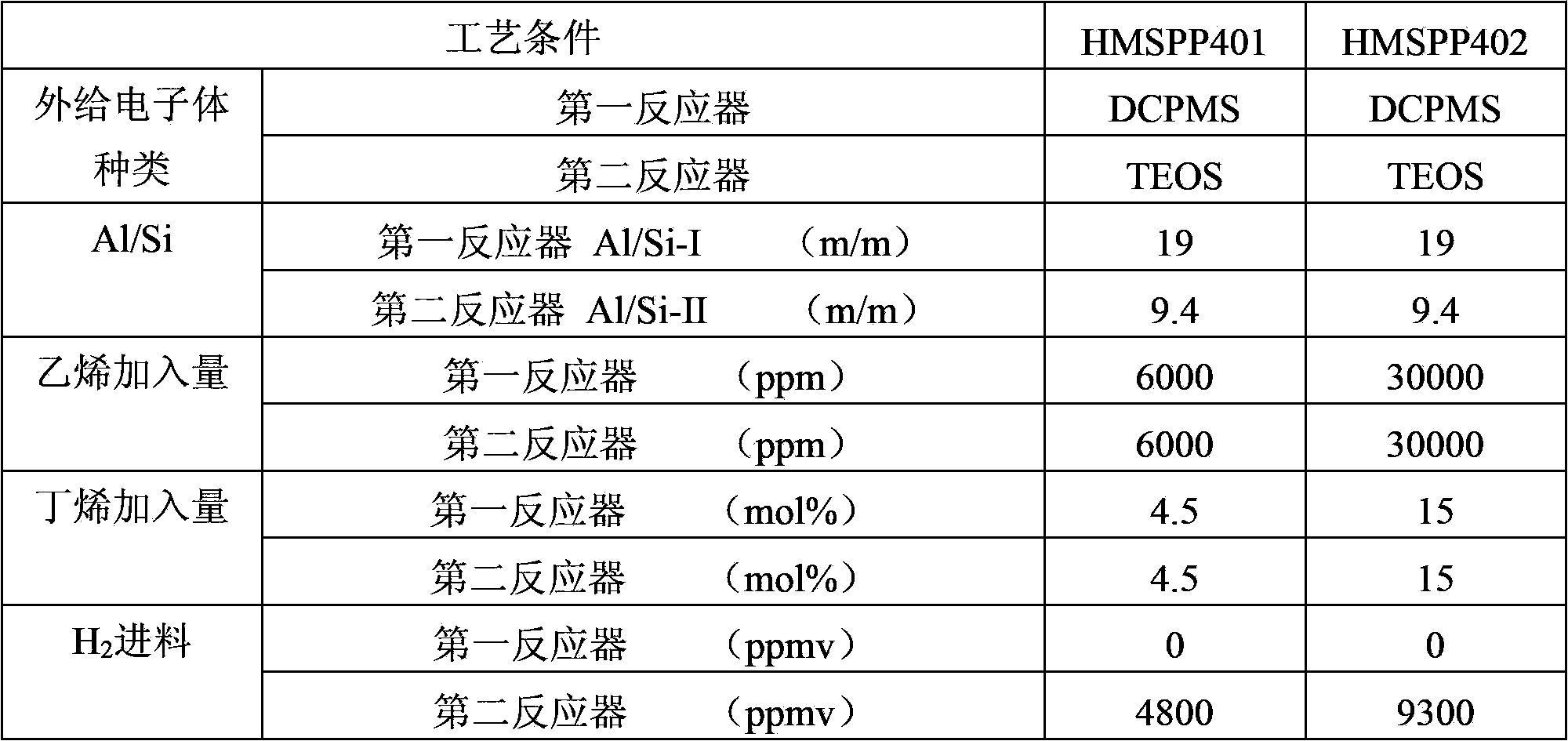

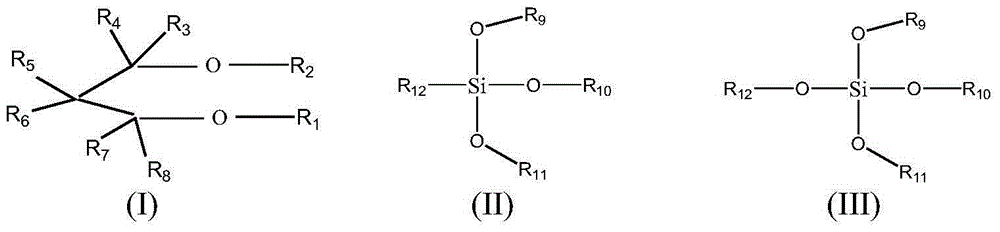

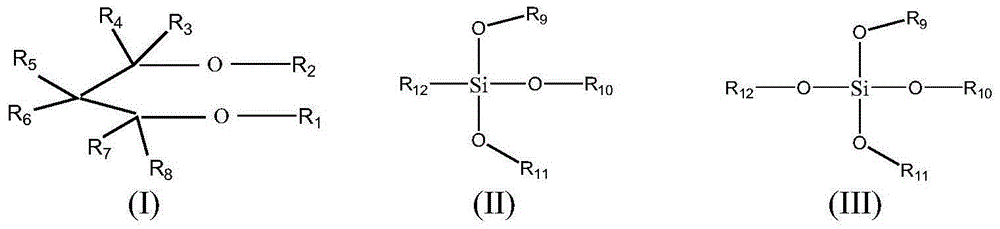

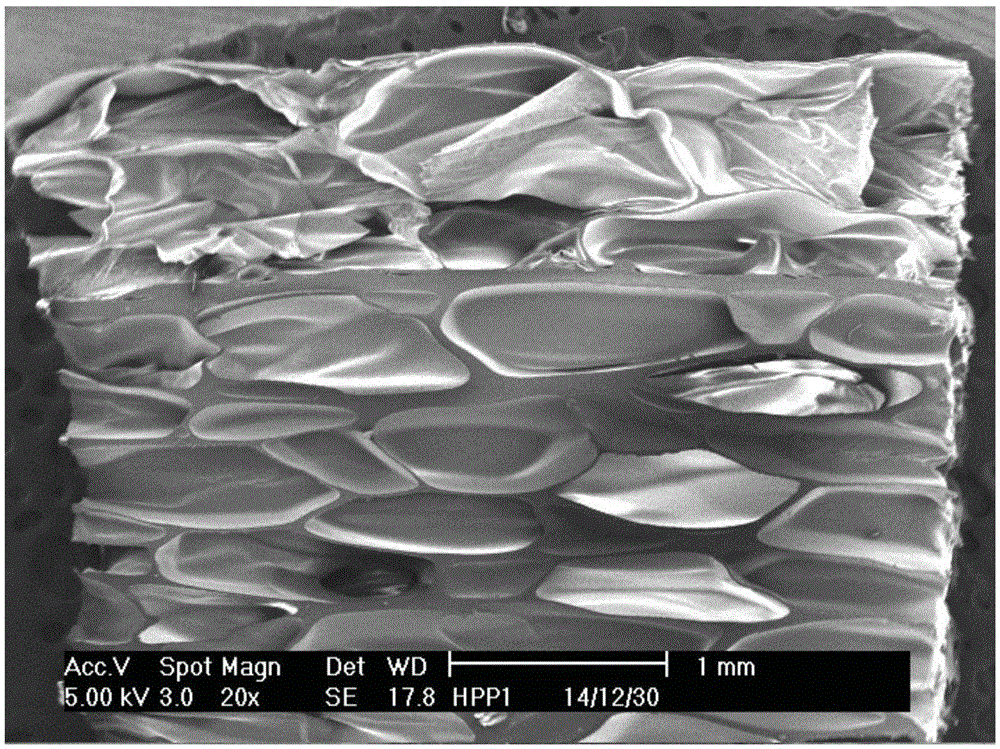

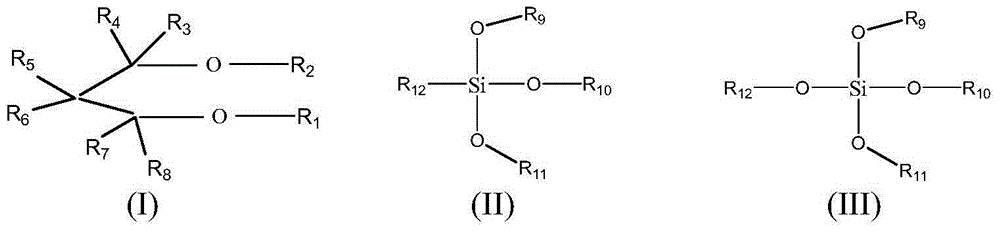

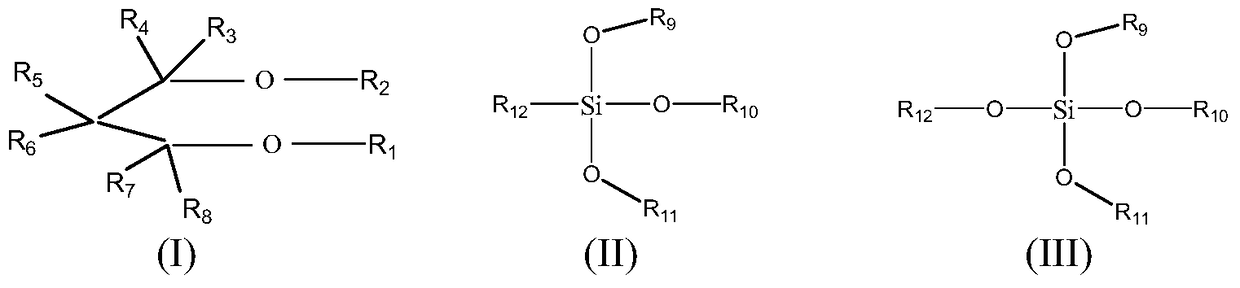

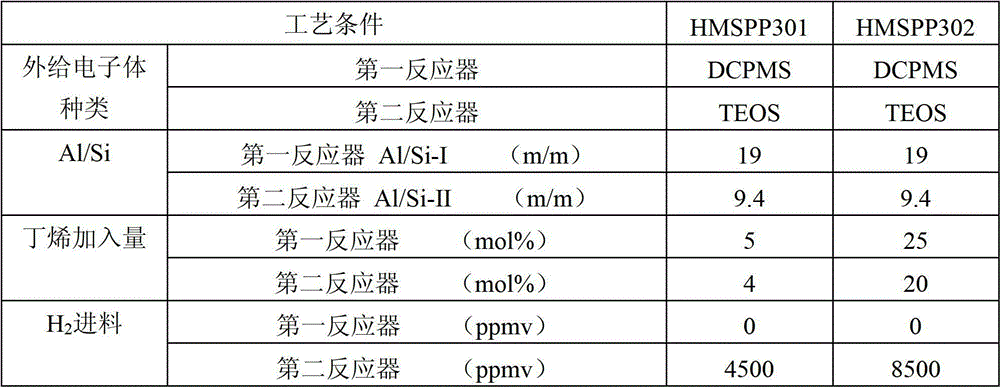

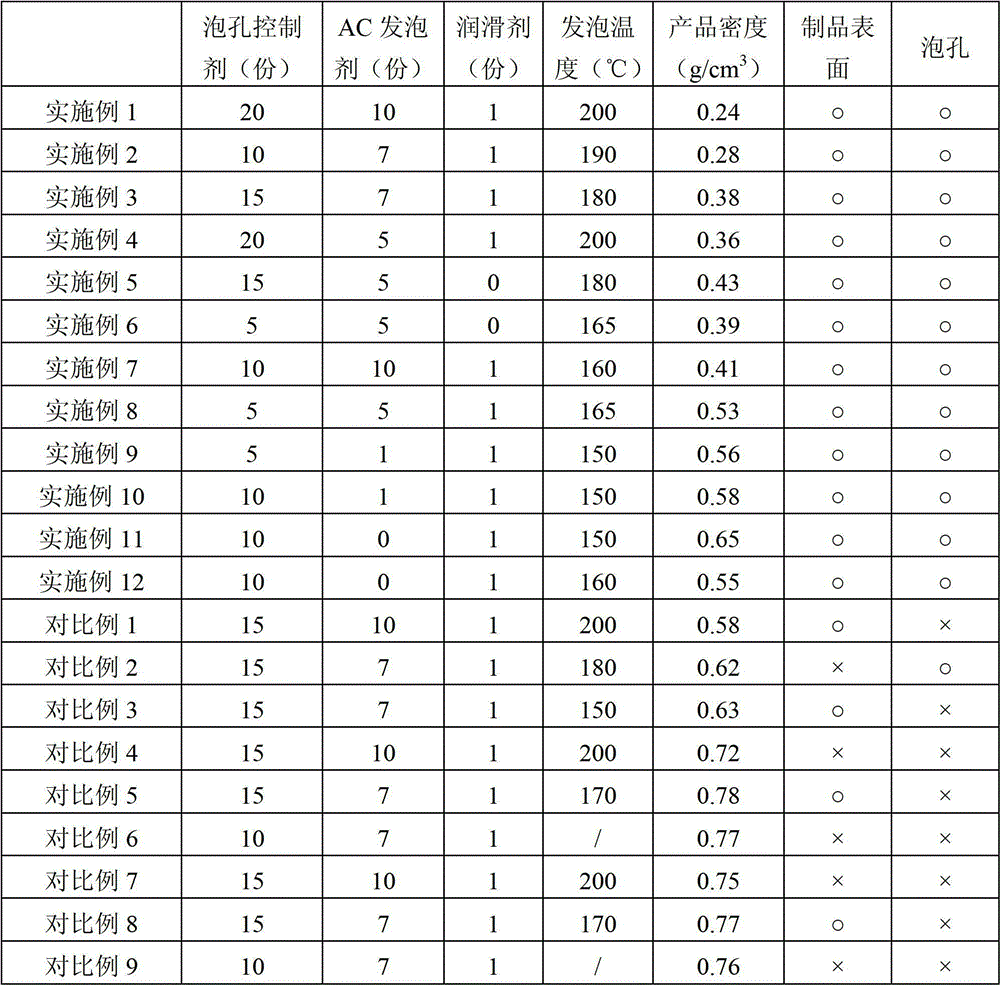

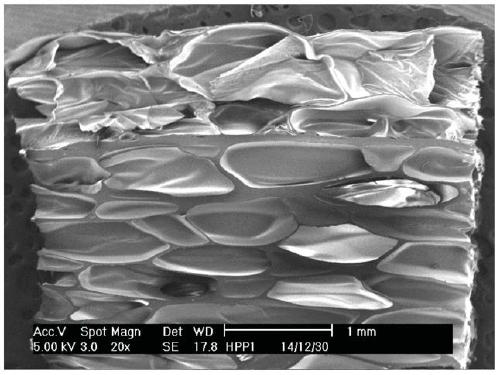

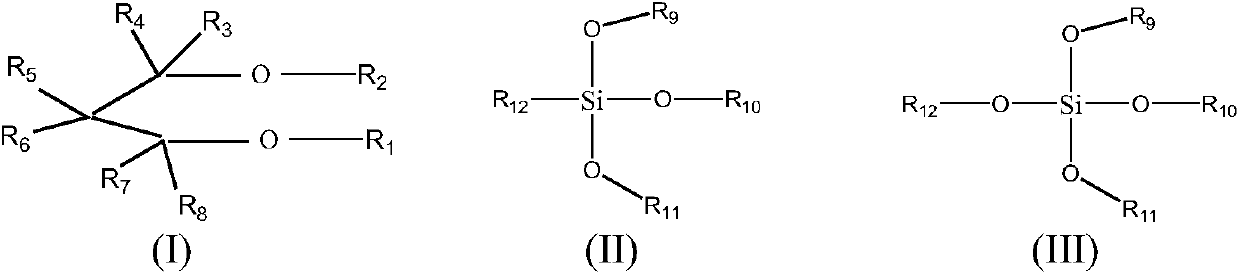

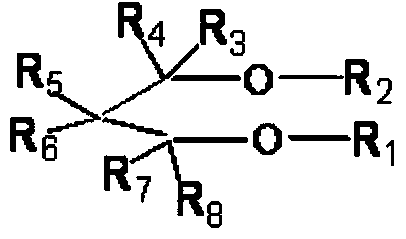

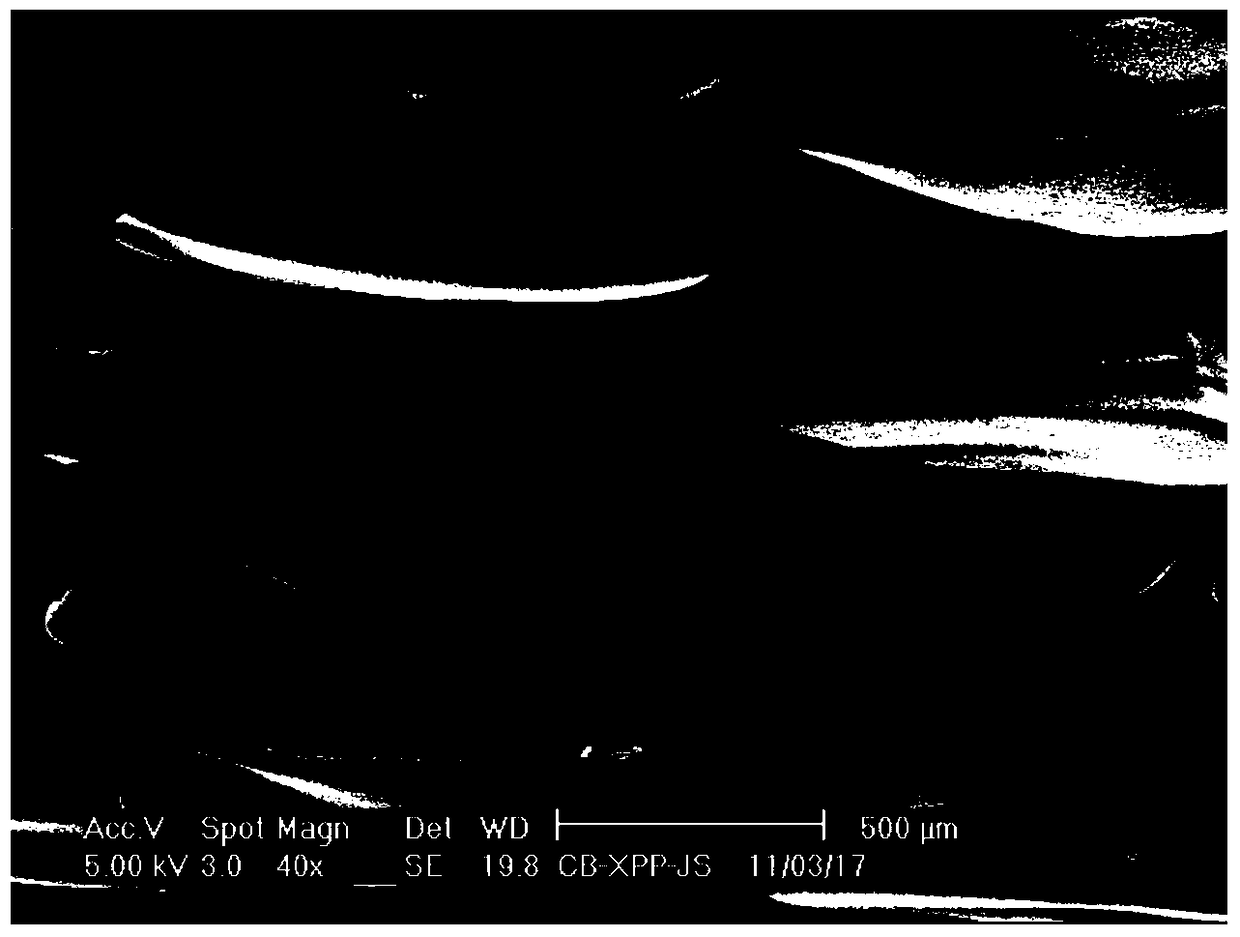

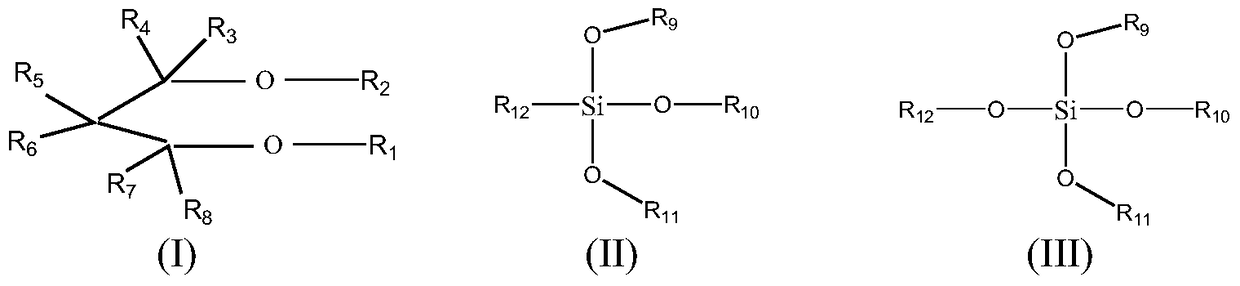

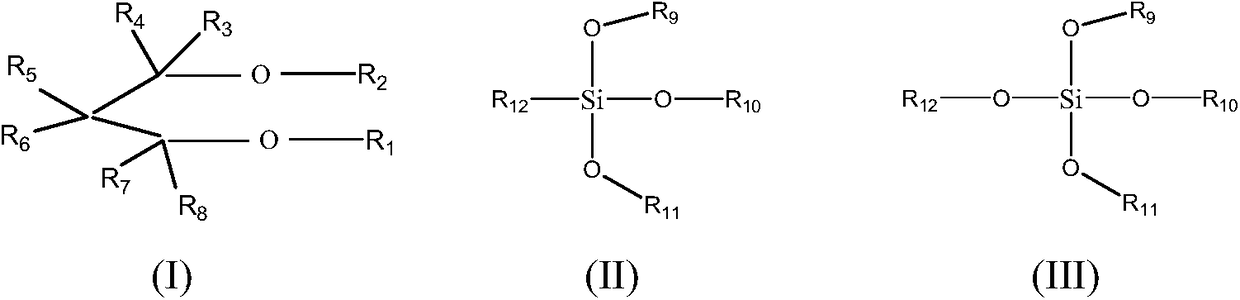

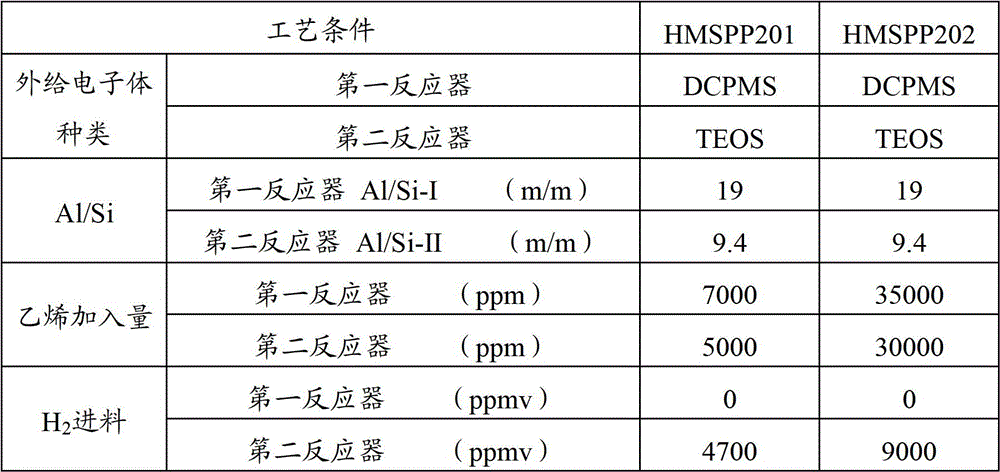

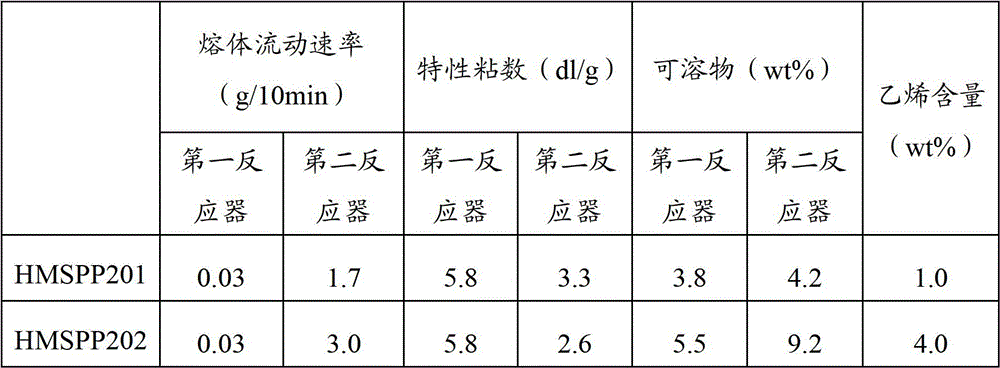

Preparation method of polypropylene foaming plate or sheet

The present invention provides a preparation method of a polypropylene foaming plate or sheet. According to the preparation method, high melt strength homopolymerization polypropylene is adopted as a matrix resin and a foaming agent is adopted to foam to prepare the polypropylene foaming plate or sheet, wherein the homopolymerization polypropylene preparation method comprises: in two or more than two reactors having the series connection operation, carrying out a two-stage or multi-stage propylene homopolymerization reaction, wherein the external electron donors used in the two-stage reaction are respectively a silane compound and a diether compound. According to the present invention, the high melt strength polypropylene having the wide molecular weight distribution is adopted as the raw material to achieve the stabilization of the polypropylene raw material, such that the foaming window is effectively expanded, the process is easy to adjust, the polypropylene foaming plate or sheet having the smooth self-skinning, the uniform foam hole diameter, the closed hole rigid structure, the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400 mm can be prepared, and the polypropylene foaming plate or sheet can be widely used in the fields of heat-insulation tableware, automotive interiors, building templates, camping supplies, decoration material sandwiches, product vibration reduction packaging and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

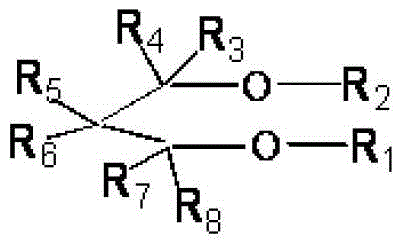

Composite foaming agent and polypropylene foam material prepared from same

The invention discloses a composite foaming agent and a polypropylene foam material prepared from the same. The foaming agent comprises the following components in parts by weight: 100 parts of azodicarbonamide, 10-20 parts of N,N'-dimethyl-N,N-dinitrosoterephthalamide, 10-30 parts of zinc oxide and 10-30 parts of sodium citrate. The polypropylene foam material comprises the following blended components in parts by weight: 100 parts of high-melt strength polypropylene and 3-15 parts of composite foaming agent. The composite foaming agent disclosed by the invention has controllable foaming temperature, uniform foam cell, smooth surface and high physical heat resistance; and the polypropylene foam material prepared from the composite foaming agent meets the environmental protection requirement, is degradable and low in production cost, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polypropylene foamed beads

ActiveCN104974369AImprove performanceMeet the requirements of weight reduction and light weightPolymer scienceElectron donor

The invention provides a preparation method of polypropylene foamed beads. The preparation method comprises the steps of preparing polypropylene according to a following method, adding organic peroxides into obtained polypropylene serving as matrix resin, and foaming by virtue of a physical foaming agent, so as to obtain the polypropylene foamed beads, wherein the method of polypropylene comprises the step of carrying out propylene polymerization reaction including two or more stages in two or more reactors which are connected in series for operation, wherein external electron donors used in the two stages are respectively alkane compounds and diether compounds. According to the preparation method, high-melt-strength polypropylene with wide molecular weight distribution is taken as a raw material, the organic peroxides are taken as a surface modifier of EPP beads, and the closed-hole-structured polypropylene foamed beads having the advantages that the diameters of foamed holes are uniform, the foamed holes are compact and the hole distribution is uniform can be prepared; the polypropylene foamed beads can be applied to the fields such as automobile manufacturing, packaging, building insulation, sport equipment, living goods, aerospace and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene-ethylene-butylene high-melt-strength polypropylene foamed board or sheet and preparation method thereof

The invention provides a polypropylene foamed board or sheet. The foamed board or sheet is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, the ethylene content is 0.1-15 wt%, and the butylene content is 0.1-15 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, and the technique is easy to adjust; the method can be used for preparing the polypropylene foamed board or sheet with the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400mm, which has the advantages of smooth surface crust, uniform pore diameter and close cell hard structure; and the polypropylene foamed board or sheet can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

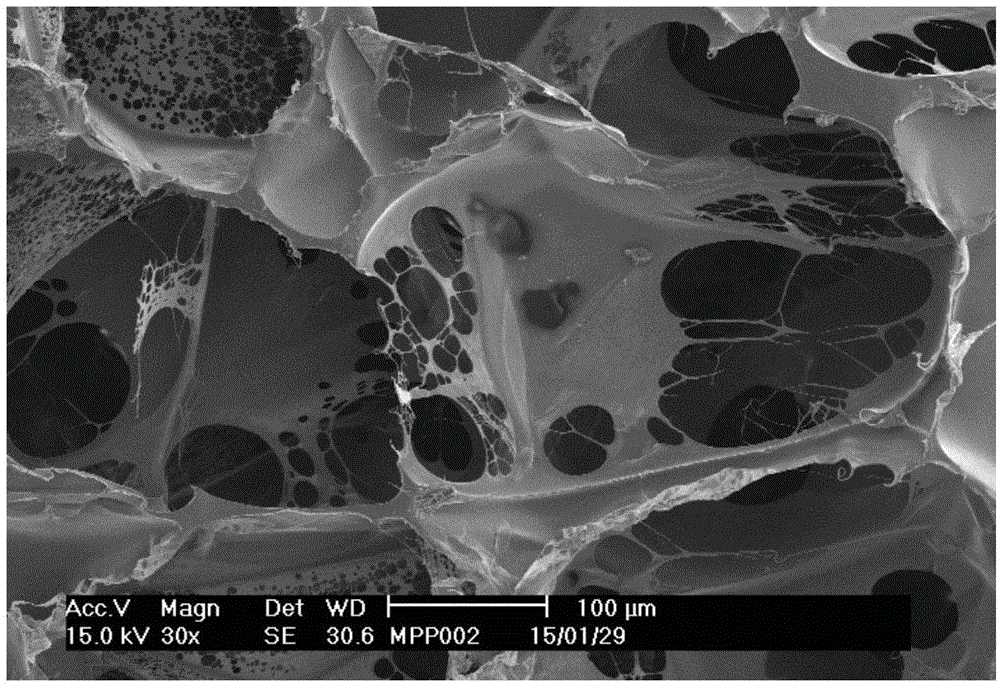

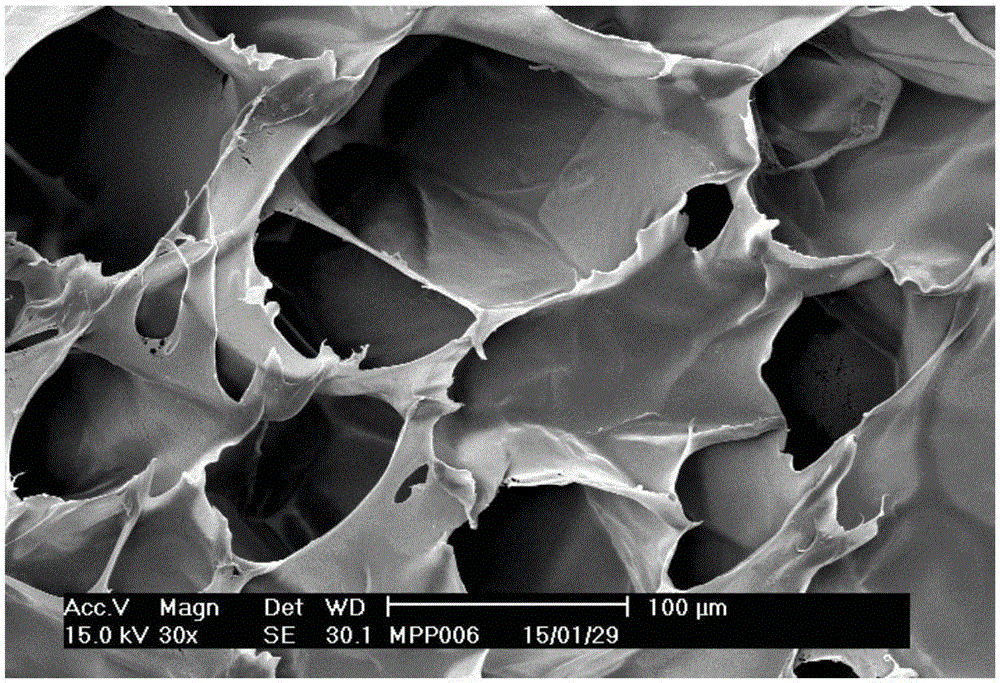

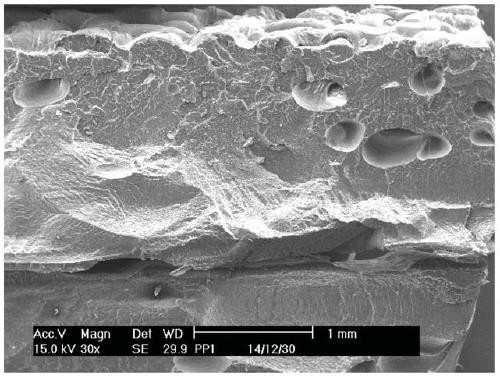

Impact polypropylene foam plate with high melt strength and method for preparing impact polypropylene foam plate

The invention provides a polypropylene foam plate and a method for preparing the same. Impact polypropylene with high melt strength is used as basic resin for the polypropylene foam plate and is foamed and rolled to obtain the polypropylene foam plate. The impact polypropylene with the high melt strength comprises random copolymerization polypropylene continuous phases and propylene-ethylene copolymer rubber dispersion phases, the content of room-temperature dimethylbenzene soluble matters in the impact polypropylene is higher than or equal to 10% and is lower than or equal to 35% by weight, a proportion of the Mw (molecular weight) of room-temperature trichlorobenzene soluble matters in the impact polypropylene to the Mw of room-temperature trichlorobenzene insoluble matters in the impact polypropylene is higher than 0.4 and is lower than or equal to 1. The polypropylene foam plate and the method have the advantages that the polypropylene foam plate has smooth surfaces and bubbles, is uniform in pore diameter distribution, good in high-temperature and low-temperature impact resistance and high in melt strength and can be widely applied to the fields of automobile components, food and electronic packaging, building decoration and the like; the method is simple and is easy to implement and low in cost, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impact-resistant polypropylene foamed sheet with high melt strength and preparation method therefor

The invention provides a polypropylene foamed sheet and a preparation method therefor. The foamed sheet is prepared by taking impact-resistant polypropylene with high melt strength as base resin and carrying out foaming and rolling, wherein the impact-resistant polypropylene with high melt strength contains a propylene homopolymer ingredient and an ethylene-1-butylene copolymer ingredient, and the ratio of Mw of room-temperature trichlorobenzene soluble matters of the impact-resistant polypropylene with high melt strength to Mw of room-temperature trichlorobenzene insoluble matters of the impact-resistant polypropylene with high melt strength is greater than 0.5 and smaller than or equal to 1; and the content of room-temperature dimethylbenzene soluble matters in the impact-resistant polypropylene with high melt strength is higher than 10wt% and lower than 30wt%. The polypropylene foamed sheet provided by the invention has the advantages of smooth surface, uniform bubble and pore size distribution, good high- / low-temperature impact resistance, high melt strength and the like and can be extensively applied to the field of automotive parts, food and electronic packages, architectural decoration and the like; and the preparation method for the polypropylene foamed sheet is simple and is easy in operation and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition used for preparing polypropylene foaming material and prepared foaming formed body

The invention provides a composition used for preparing a polypropylene foaming material. The composition comprises high melt-strength anti-punching polypropylene as a base resin, the high melt-strength anti-punching polypropylene comprises a propylene homopolymer ingredient and a propylene-ethylene copolymer ingredient, and is characterized in that the molecular weight distribution Mw / Mn is less or equal to 10, and is greater or equal to 4; Mz+1 / Mw is greater than 10 and less than 20; the content of a room-temperature xylene soluble substance is greater than 10 wt% and less than 30 wt%; and the ratio of a room-temperature trichloro-benzenes soluble substance Mw to a room-temperature trichloro-benzenes insoluble substance is greater than 0.4 and less than 1. The invention also provides a polypropylene injection foaming formed body produced by the composition through injection foaming and a preparation method thereof, and the formed body is suitable for the fields with special requirements on the part shapes such as automobile, aircraft, and high-speed rail internal and external decoration.

Owner:CHINA PETROLEUM & CHEM CORP +1

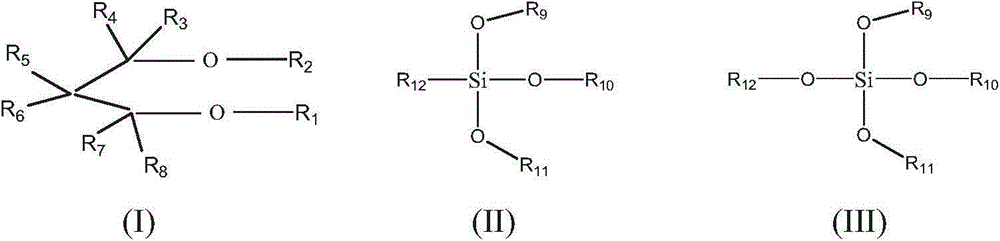

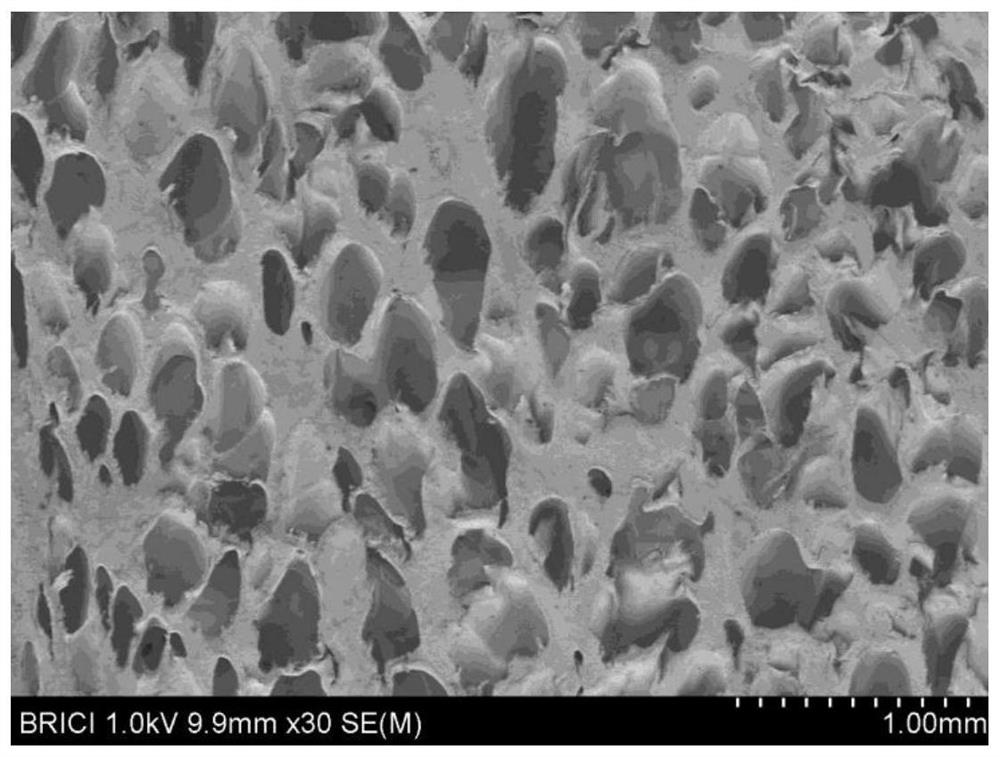

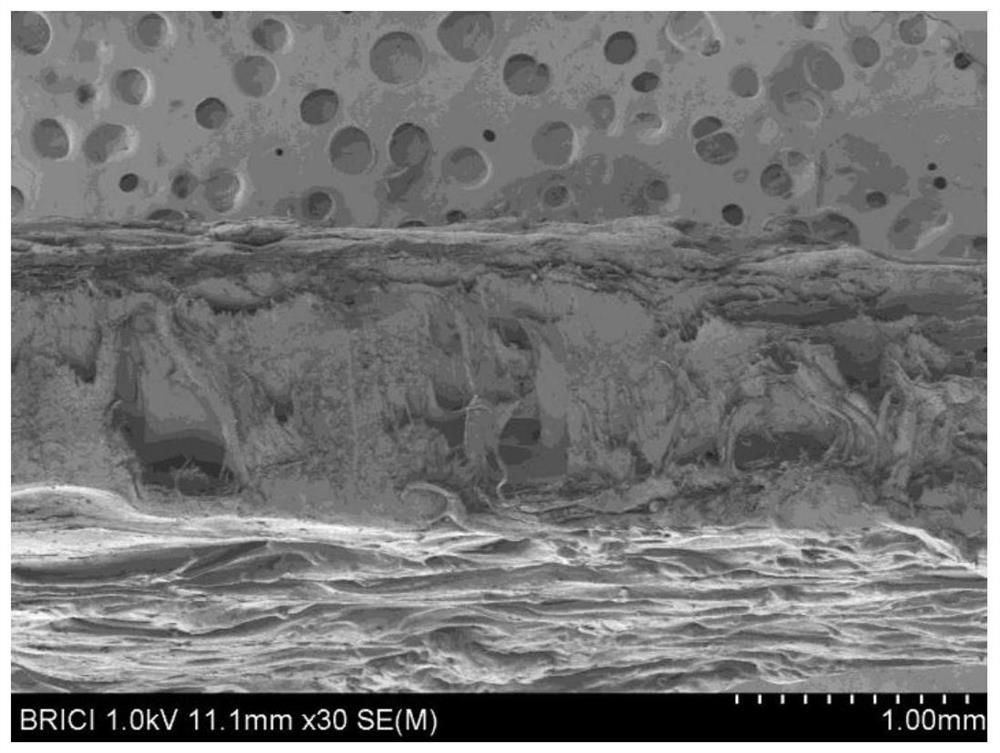

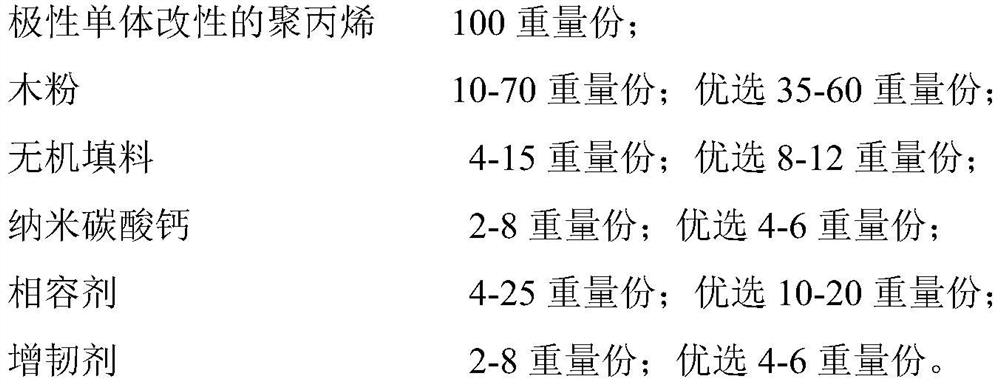

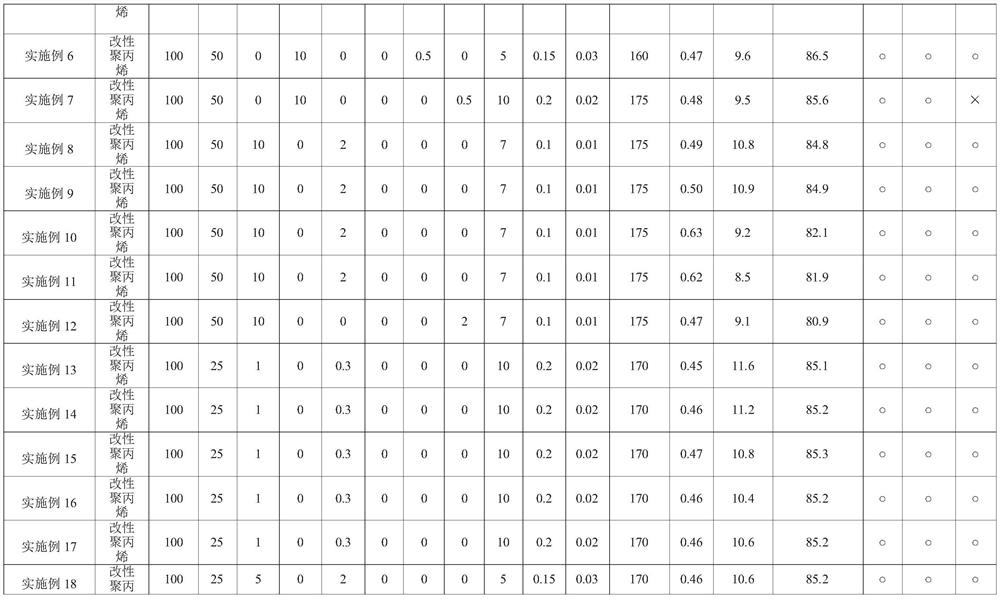

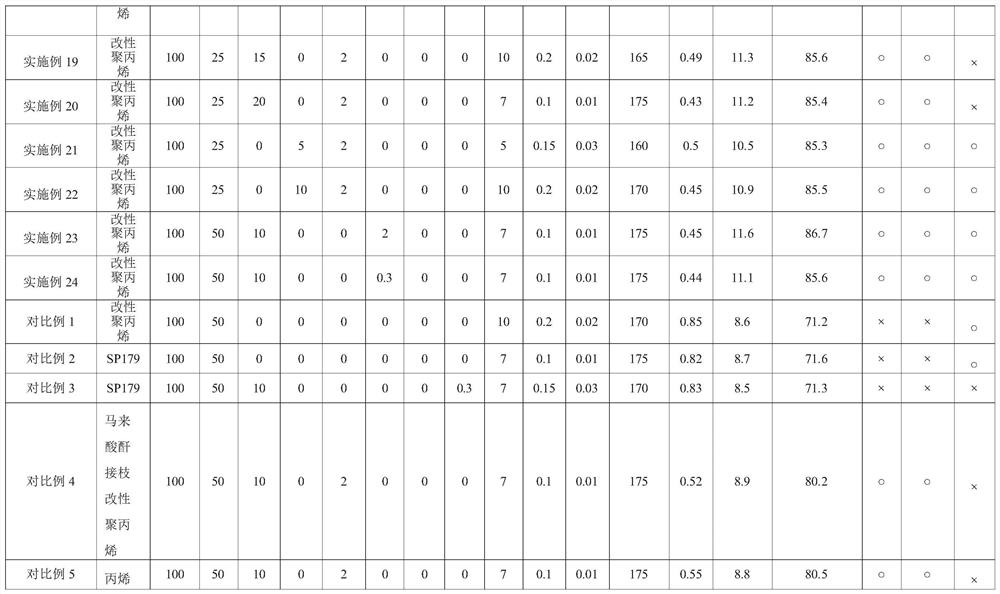

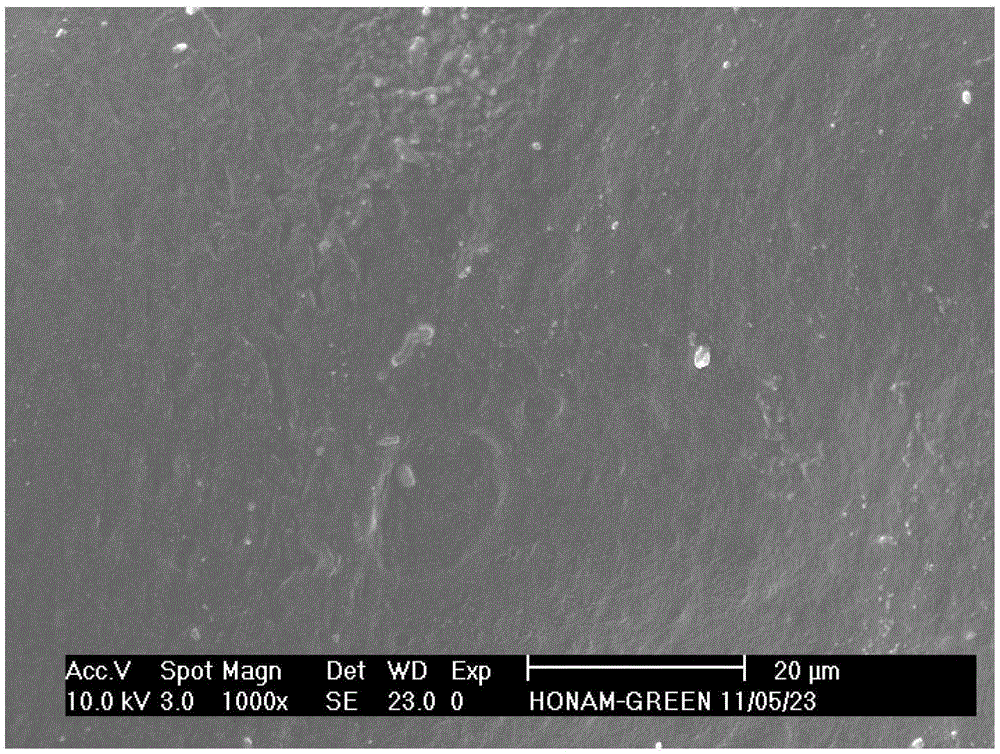

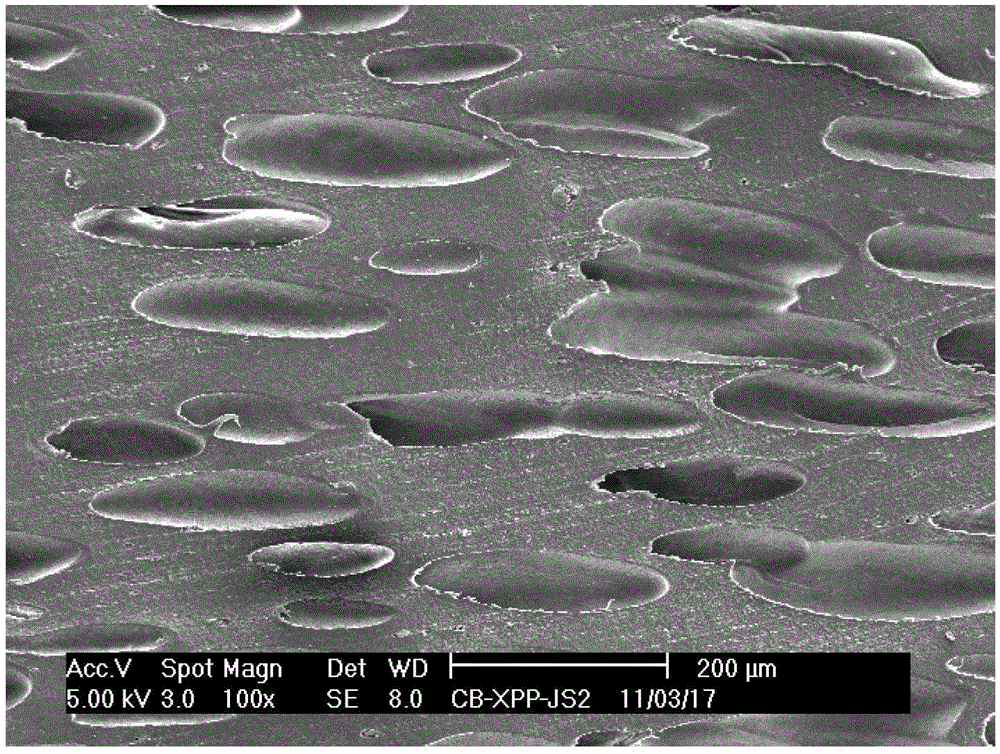

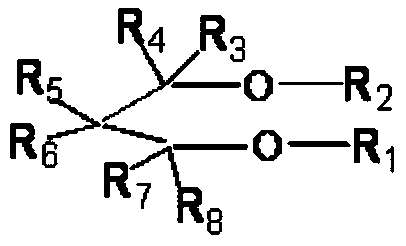

Composition for preparing polypropylene plastic-wood composite material, composite material prepared from composition and application of composite material

The invention provides a composition for preparing a polypropylene plastic-wood composite material. The composition comprises the following components in parts by weight: 100 parts of polar monomer modified polypropylene; 10-70 parts of wood flour, 4-15 parts by weight of an inorganic filler; 2-8 parts by weight of nano calcium carbonate; 4-25 parts by weight of a compatilizer; and 2-8 parts by weight of a flexibilizer. The foamed sheet prepared by foaming the plastic-wood composite material prepared from the composition has the characteristics of flat surface, compact cells, uniform cell diameter, low and controllable foaming ratio, closed-cell hard structure, good impact and bending properties and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

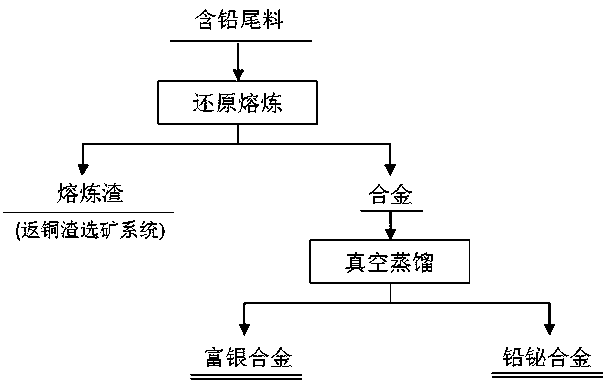

Smelting method for recycling lead, bismuth and precious metal from lead-containing tailings in acid making

InactiveCN107557588AHigh recovery rateHigh recycling valueProcess efficiency improvementLead bismuthSlag

The invention discloses a smelting method for recycling lead, bismuth and precious metal from lead-containing tailings in acid making. The method comprises the steps that smelting slag is separated after high-temperature reduction and smelting treatment of the lead-containing tailings generated by the acid-making technology, and high-lead alloy is produced; then, through a vacuum distillation technology, lead-bismuth alloy and silver-rich alloy are obtained, wherein the obtained lead-bismuth alloy meets the lead and bismuth content requirements of lead-bismuth products, and refining and impurity removal procedures are reduced; at the same time, the lead and bismuth losses are also reduced; thus, with the method disclosed by the invention, the production cost is reduced, and the recovery rate of the precious metal is improved; the lead and bismuth recovery cycles are shortened, and the lead and bismuth recovery values are improved; manufactured products are high in quality; at the sametime, according to the method disclosed by the invention, the metal recycling separation can be achieved completely, and the comprehensive recovery rate of the metal is high; and no waste residue, dust or waste gas is generated, and the method facilitates full realizing of the value of raw materials, and is environmentally friendly. In addition, the method disclosed by the invention has the advantages of high adaptation to the raw materials, easiness in adjustment of the technology, and easiness in control of production process.

Owner:JINCHUAN GROUP LIMITED

High-melt-strength anti-impact polypropylene foamed board and preparation method thereof

The invention provides a high-melt-strength anti-impact polypropylene foamed board and a preparation method thereof. The foamed board is prepared with high-melt-strength anti-impact polypropylene serves as matrix resin through foaming and rolling. The high-melt-strength anti-impact polypropylene is composed of a propylene homopolymer component and a propylene-ethylene copolymer component and has the characteristics that molecular weight distribution Mw / Mn is smaller than or equal to 10 and larger than or equal to 4, Mz+1 / Mw is larger than 10 and smaller than 20, the room temperature dimethylbenzene soluble component content is larger than 10 wt% and smaller than 30 wt%, and the ratio of Mw of room temperature trichlorobenzene soluble components to Mw of room temperature trichlorobenzene insoluble components is larger than 0.4 and smaller than 1. The polypropylene foamed board has the advantages of being flat in surface, uniform in foam pore and aperture size distribution, good in high-and-low-temperature anti-impact performance, high in melt strength and the like, can be widely used in the fields of vehicle parts, food and electronic packaging, building decoration and the like, and is simple in preparation method, easy to operate and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

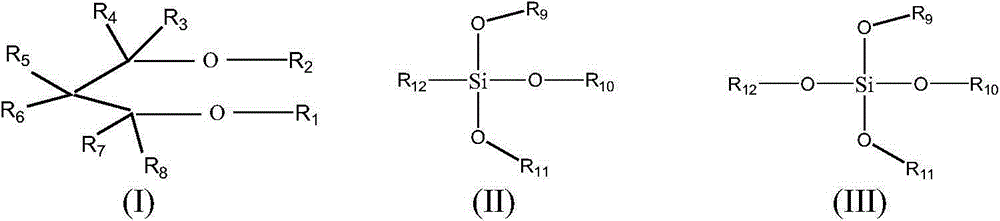

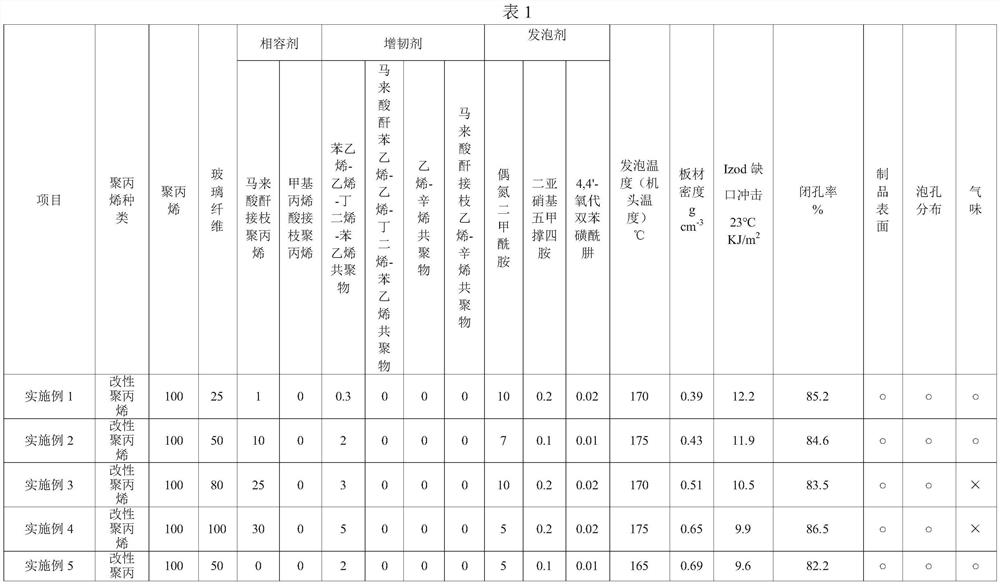

Composition for preparing glass fiber reinforced polypropylene material, material prepared from composition and application

PendingCN112442250AUniform and dense cellsGood mechanical and heat resistancePolypropyleneGlass fiber

The invention provides a composition for preparing a glass fiber reinforced polypropylene material. The composition comprises the following components in parts by weight: 100 parts of polar monomer modified polypropylene; 1-30 parts of a compatilizer; 0.3-5 part of a toughening agent; and 25-100 parts of glass fiber. A foamed plate prepared by foaming the glass fiber reinforced polypropylene material prepared from the composition has the characteristics of smooth surface, compact cells, uniform cell diameter, closed-cell hard structure, good impact property and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene ethylene high melt strength polypropylene foam board or sheet and preparation method thereof

The invention provides a polypropylene foamed board or sheet. The foamed board or sheet is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, and the ethylene content is 0.1-20 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, and the technique is easy to adjust; the method can be used for preparing the polypropylene foamed board or sheet with the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400mm, which has the advantages of smooth surface crust, uniform pore diameter and close-pore hard structure; and the polypropylene foamed board or sheet can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition for preparing polypropylene foaming material and foaming forming body prepared from same

The invention provides a composition for preparing a polypropylene foaming material. The composition comprises high melt strength impact polypropylene, and the high melt strength impact polypropylene comprises a random copolymerization polypropylene continuous phase and a propylene-ethylene copolymer rubber dispersion phase. The content of room temperature dimethylbenzene solvend is larger than or equal to 10 wt%, and smaller than or equal to 35 wt%. The ratio of room temperature Mw of trichlorobenzene solvend to Mw of room temperature trichlorobenzene insoluble is larger than 0.4 and smaller than or equal to 1. The invention further provides a polypropylene injection foaming forming body made of the composition by injection foaming and a preparation method thereof. The forming body is suitable for the fields having special requirements for shapes, such as automobile, aircraft and high-speed rail inside and outside decoration components and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

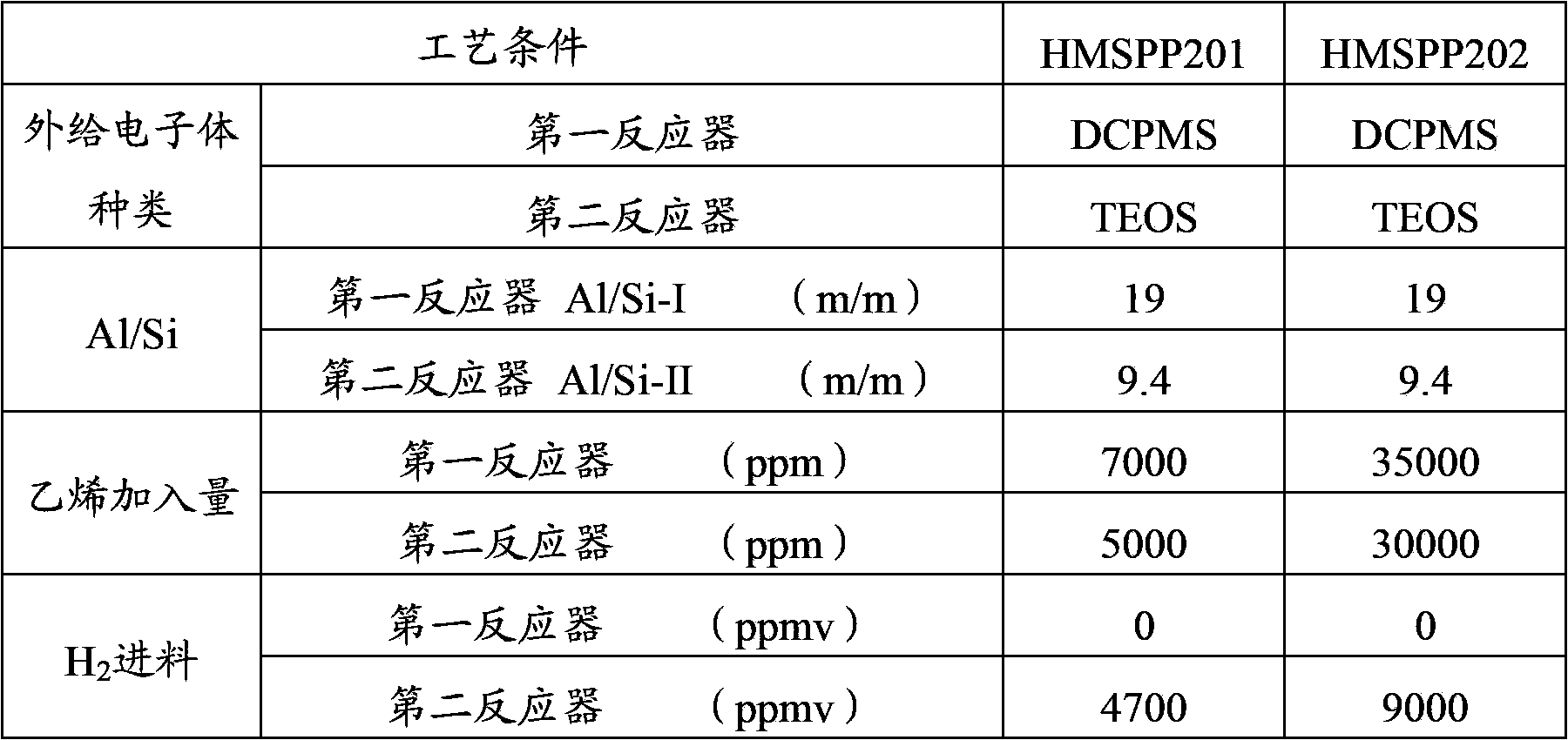

A kind of preparation method of polypropylene foam board or sheet

The present invention provides a preparation method of a polypropylene foaming plate or sheet. According to the preparation method, high melt strength homopolymerization polypropylene is adopted as a matrix resin and a foaming agent is adopted to foam to prepare the polypropylene foaming plate or sheet, wherein the homopolymerization polypropylene preparation method comprises: in two or more than two reactors having the series connection operation, carrying out a two-stage or multi-stage propylene homopolymerization reaction, wherein the external electron donors used in the two-stage reaction are respectively a silane compound and a diether compound. According to the present invention, the high melt strength polypropylene having the wide molecular weight distribution is adopted as the raw material to achieve the stabilization of the polypropylene raw material, such that the foaming window is effectively expanded, the process is easy to adjust, the polypropylene foaming plate or sheet having the smooth self-skinning, the uniform foam hole diameter, the closed hole rigid structure, the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400 mm can be prepared, and the polypropylene foaming plate or sheet can be widely used in the fields of heat-insulation tableware, automotive interiors, building templates, camping supplies, decoration material sandwiches, product vibration reduction packaging and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of polypropylene expanded beads

The invention provides a preparation method of polypropylene foaming beads. High-melt strength homo-polypropylene as base resin and a physical foaming agent undergo foaming so that the polypropylene foaming beads are prepared. The preparation method comprises that two or more stages of propylene homopolymerization reactions occur in two or more reactors connected in series, wherein external electron donors used in the two or more stages of reactions respectively comprise silane and diether compounds. The preparation method utilizes the wide-molecular weight distribution high-melt strength polypropylene as a raw material, realizes polypropylene raw material stabilization, effectively enlarges a foaming window, has easily adjustable processes and a low cost, can prepare the polypropylene foaming beads having uniform foam pore diameters, compact foam pores, uniform pore size distribution, a closed pore structure and density of 0.03-0.4g / cm<3> and can be widely used in fields of thermal insulation tableware, automobile interior decorative parts, building templates, camping articles, decorative material interlayers and product damping packages.

Owner:CHINA PETROLEUM & CHEM CORP +1

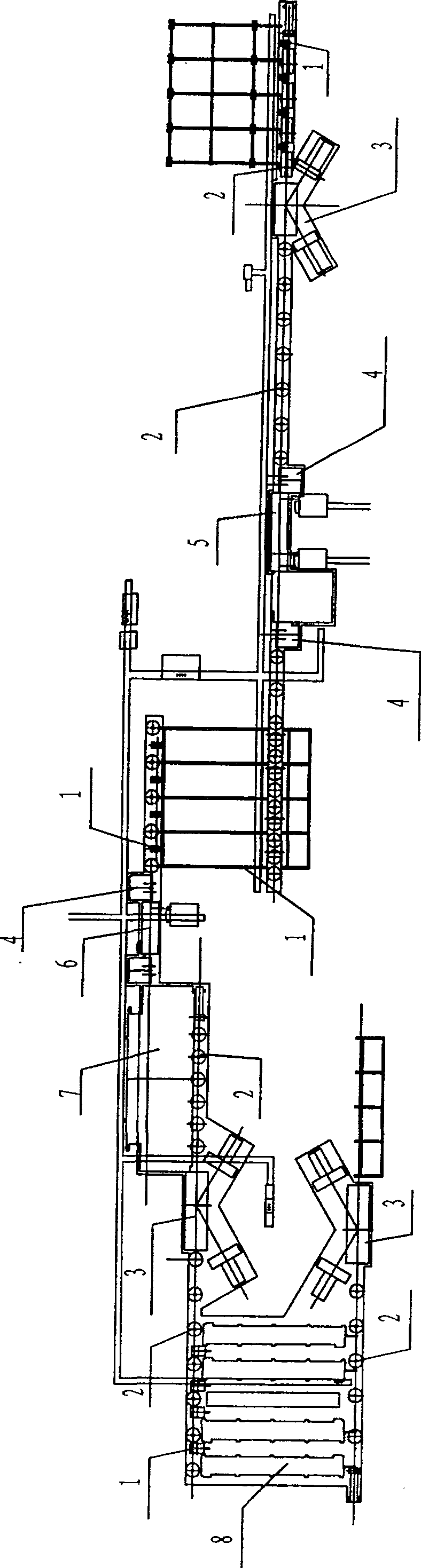

Technique for induction heating steel rod tempering heat treatment

InactiveCN100537792CSimple structureStrong process controllabilityFurnace typesHeat treatment furnacesProduction lineInduction hardening

The invention relates to a process method for quenching and tempering heat treatment of steel rods by induction heating. Process, the specific process is: straightening, quenching, tempering, cooling and straightening, blanking inspection, and storage. Beneficial effects of the invention: use the thermal effect of induction eddy current to carry out quenching and tempering heat treatment on steel, so that the core structure is a uniform tempered sorbite structure; no pre-heating heating is required, and the temperature rises rapidly; length-length material processing can be performed.

Owner:TIANJIN JINNENG POWER ELECTRONICS

Composition for preparing polypropylene foam material and foamed molded body thereof

The invention provides a composition for preparing a polypropylene foaming material. The composition comprises high melt strength impact polypropylene, and the high melt strength impact polypropylene comprises a random copolymerization polypropylene continuous phase and a propylene-ethylene copolymer rubber dispersion phase. The content of room temperature dimethylbenzene solvend is larger than or equal to 10 wt%, and smaller than or equal to 35 wt%. The ratio of room temperature Mw of trichlorobenzene solvend to Mw of room temperature trichlorobenzene insoluble is larger than 0.4 and smaller than or equal to 1. The invention further provides a polypropylene injection foaming forming body made of the composition by injection foaming and a preparation method thereof. The forming body is suitable for the fields having special requirements for shapes, such as automobile, aircraft and high-speed rail inside and outside decoration components and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene butene high melt strength polypropylene foam board or sheet and preparation method thereof

The invention provides a polypropylene foamed board or sheet. The foamed board or sheet is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, and the butylene content is 0.1-15 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, and the technique is easy to adjust; the method can be used for preparing the polypropylene foamed board or sheet with the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400mm, which has the advantages of smooth surface crust, uniform pore diameter and close-pore hard structure; and the polypropylene foamed board or sheet can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene ethylene high melt strength polypropylene foam beads and preparation method thereof

The invention provides a polypropylene foamed bead. The foamed bead is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, and the ethylene content is 0.1-20 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, the technique is easy to adjust, and the cost is low; the method can be used for preparing the polypropylene foamed bead with the density of 0.02-0.3 g / cm<3>, which has the advantages of uniform pore diameter, compact pores, uniform pore size distribution and close-pore structure; and the polypropylene foamed bead can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of antistatic polypropylene foam beads

The invention provides a preparation method of antistatic polypropylene foam beads, comprising firstly obtaining polypropylene according to the following method, then using the obtained polypropylene as a matrix resin, adding carbon nanotubes as an antistatic agent, and using a physical foaming agent The polypropylene foamed beads are obtained by foaming; wherein, the preparation method of the polypropylene is: two or more stages of propylene polymerization are carried out in two or more reactors operated in series, and the two-stage reaction The external electron donors used are silane compounds and diether compounds respectively. The invention uses high-melt-strength polypropylene with wide molecular weight distribution as raw material and carbon nanotubes as antistatic agent to realize the stabilization of polypropylene raw material, effectively expand the foaming window, easy to adjust the process, and can prepare excellent performance Antistatic polypropylene foam beads are widely used in fields with high antistatic requirements, including aerospace, precision instruments, and electronic product packaging.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene butene copolymer foamed beads and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

A high-melt strength impact-resistant polypropylene foam board and its preparation method

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of polypropylene foam beads

The invention provides a preparation method of polypropylene foamed beads, which comprises the following steps: firstly obtaining polypropylene according to the following method, then using the obtained polypropylene as matrix resin, adding organic peroxide and foaming with a physical foaming agent to prepare The polypropylene foamed beads; wherein, the preparation method of the polypropylene is: in two or more reactors operated in series, two or more stages of propylene polymerization are carried out, and an external electron donor used in the two-stage reaction is carried out. The compounds are silane compounds and diether compounds, respectively. The invention uses high melt strength polypropylene with wide molecular weight distribution as raw material and organic peroxide as the surface modifier of EPP beads, and can prepare uniform cell diameter, dense cell, uniform cell distribution and closed cell structure. The polypropylene expanded beads are widely used in automobile manufacturing, packaging, building insulation, sports equipment, daily necessities and aerospace and other fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

A high-melt strength impact-resistant polypropylene foam board and its preparation method

The invention provides a polypropylene foamed sheet and a preparation method therefor. The foamed sheet is prepared by taking impact-resistant polypropylene with high melt strength as base resin and carrying out foaming and rolling, wherein the impact-resistant polypropylene with high melt strength contains a propylene homopolymer ingredient and an ethylene-1-butylene copolymer ingredient, and the ratio of Mw of room-temperature trichlorobenzene soluble matters of the impact-resistant polypropylene with high melt strength to Mw of room-temperature trichlorobenzene insoluble matters of the impact-resistant polypropylene with high melt strength is greater than 0.5 and smaller than or equal to 1; and the content of room-temperature dimethylbenzene soluble matters in the impact-resistant polypropylene with high melt strength is higher than 10wt% and lower than 30wt%. The polypropylene foamed sheet provided by the invention has the advantages of smooth surface, uniform bubble and pore size distribution, good high- / low-temperature impact resistance, high melt strength and the like and can be extensively applied to the field of automotive parts, food and electronic packages, architectural decoration and the like; and the preparation method for the polypropylene foamed sheet is simple and is easy in operation and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition for preparing polypropylene foam material and foamed molded body thereof

The invention provides a composition used for preparing a polypropylene foaming material. The composition comprises high melt-strength anti-punching polypropylene as a base resin, the high melt-strength anti-punching polypropylene comprises a propylene homopolymer ingredient and a propylene-ethylene copolymer ingredient, and is characterized in that the molecular weight distribution Mw / Mn is less or equal to 10, and is greater or equal to 4; Mz+1 / Mw is greater than 10 and less than 20; the content of a room-temperature xylene soluble substance is greater than 10 wt% and less than 30 wt%; and the ratio of a room-temperature trichloro-benzenes soluble substance Mw to a room-temperature trichloro-benzenes insoluble substance is greater than 0.4 and less than 1. The invention also provides a polypropylene injection foaming formed body produced by the composition through injection foaming and a preparation method thereof, and the formed body is suitable for the fields with special requirements on the part shapes such as automobile, aircraft, and high-speed rail internal and external decoration.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of polypropylene expanded bead molded body and preparation method thereof

The invention provides a polypropylene foaming bead formed body and a preparation method thereof. The preparation method comprises the following steps: mixing polypropylene foaming beads having different foaming rates and prepared by using wide-molecular-weight-distribution high-melt-strength polypropylene as a raw material in proportion, and carrying out thermal molding of the above obtained mixed foaming beads to obtain the foamed body with good surface flatness and tight adhesion. The formed body can be widely applied to the heat insulation tableware field, the automobile interior decorative part field, the finishing material interlayer field, the product damping packaging field and the like. Additionally, the molded body can be recycled, causes no secondary pollution, and accords with circular economy requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of polypropylene expanded beads

The invention provides a preparation method of polypropylene foaming beads. High-melt strength homo-polypropylene as base resin and a supercutical fluid as a foaming agent undergo foaming so that the polypropylene foaming beads are prepared. The preparation method comprises that two or more stages of propylene homopolymerization reactions occur in two or more reactors connected in series, wherein external electron donors used in the two or more stages of reactions respectively comprise silane and diether compounds. The preparation method utilizes the wide-molecular weight distribution high-melt strength polypropylene as a raw material, realizes polypropylene raw material stabilization, effectively enlarges a foaming window, has easily adjustable processes and a low cost, can prepare the polypropylene foaming beads having uniform foam pore diameters, compact foam pores, uniform pore diameter distribution, a closed pore structure and density of 0.017-0.036g / cm<3> and can be widely used in occasions of automobile parts, foods, electronic packaging and building decoration having high flame-retardation requirements on plastic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com