Technique for induction heating steel rod tempering heat treatment

A quenching and tempering heat treatment and induction heating technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as poor steel bar structure, small batch production, poor process controllability, etc., to achieve convenient process and save The effect of materials and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

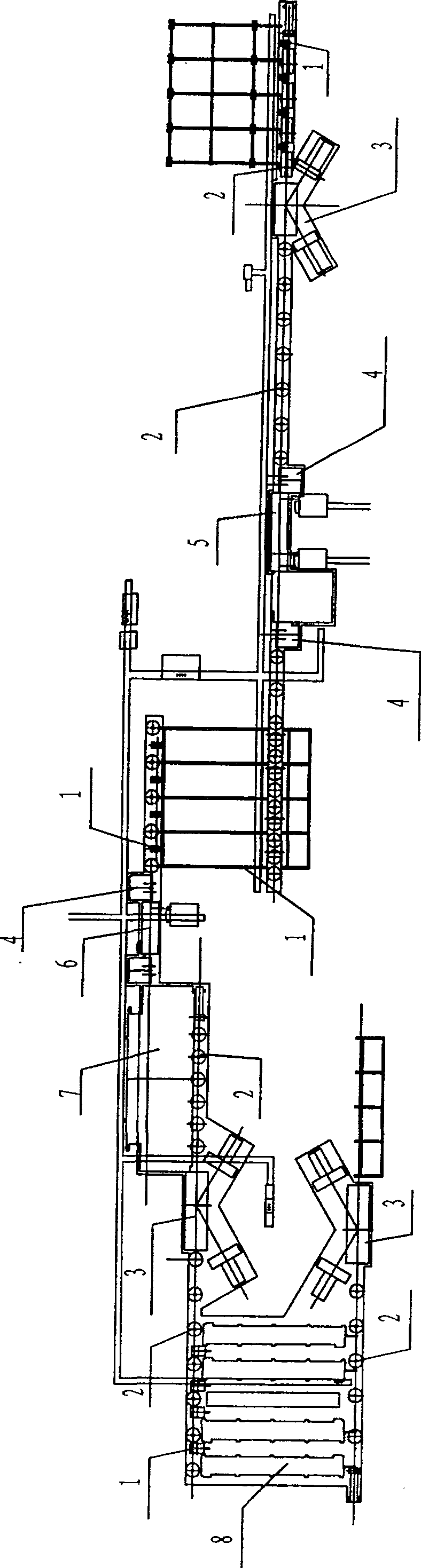

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] As shown in the figure, a process method of quenching and tempering heat treatment of steel rods by induction heating, the quenching and tempering process of steel rods through straightening-induction quenching-induction tempering-insulation tempering-rolling cooling and completed on a continuous production line, The specific process is:

[0014] A. Straightening: Put the steel rods on the feeding platform manually, and after they are leveled, they are sent to the parallel roller table 2 in a stepwise manner through the feeding machine 1, and are straightened by the seven-roller straightening machine 3 before entering the heat treatment. Through the parallel roller table 2, it is sent to the mechanical tractor 4 before the sensor;

[0015] B. Quenching: Through the steady speed operation of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com