A kind of preparation method of antistatic polypropylene foam beads

A technology for foaming beads and polypropylene, applied in the field of polymers, can solve problems such as affecting conductivity, poor dispersibility, affecting carbon nanotubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation of matrix resin HMSPP501

[0047] The polymerization reaction was carried out on a polypropylene pilot plant. Its main equipment includes prepolymerization reactor, first loop reactor and second loop reactor.

[0048] Pre-polymerization reaction: the main catalyst (DQ-III catalyst, provided by Beijing Aoda Branch of Sinopec Catalyst Company) with a flow rate of about 0.5g / hr, the co-catalyst (triethylaluminum) with a flow rate of 6.33g / hr, and a flow rate of 0.63 g / hr of the first external electron donor (dicyclopentyldimethoxysilane, DCPMS) was pre-contacted at 6°C for 20 minutes, and then continuously added to the continuous stirred tank prepolymerization reactor for prepolymerization reaction. Prepolymerization It is carried out under the environment of the propylene liquid phase body, the temperature is 15°C, and the residence time is about 4 minutes. Under these conditions, the prepolymerization ratio of the catalyst is about 120 to 150 times. The mol...

Embodiment 1~10

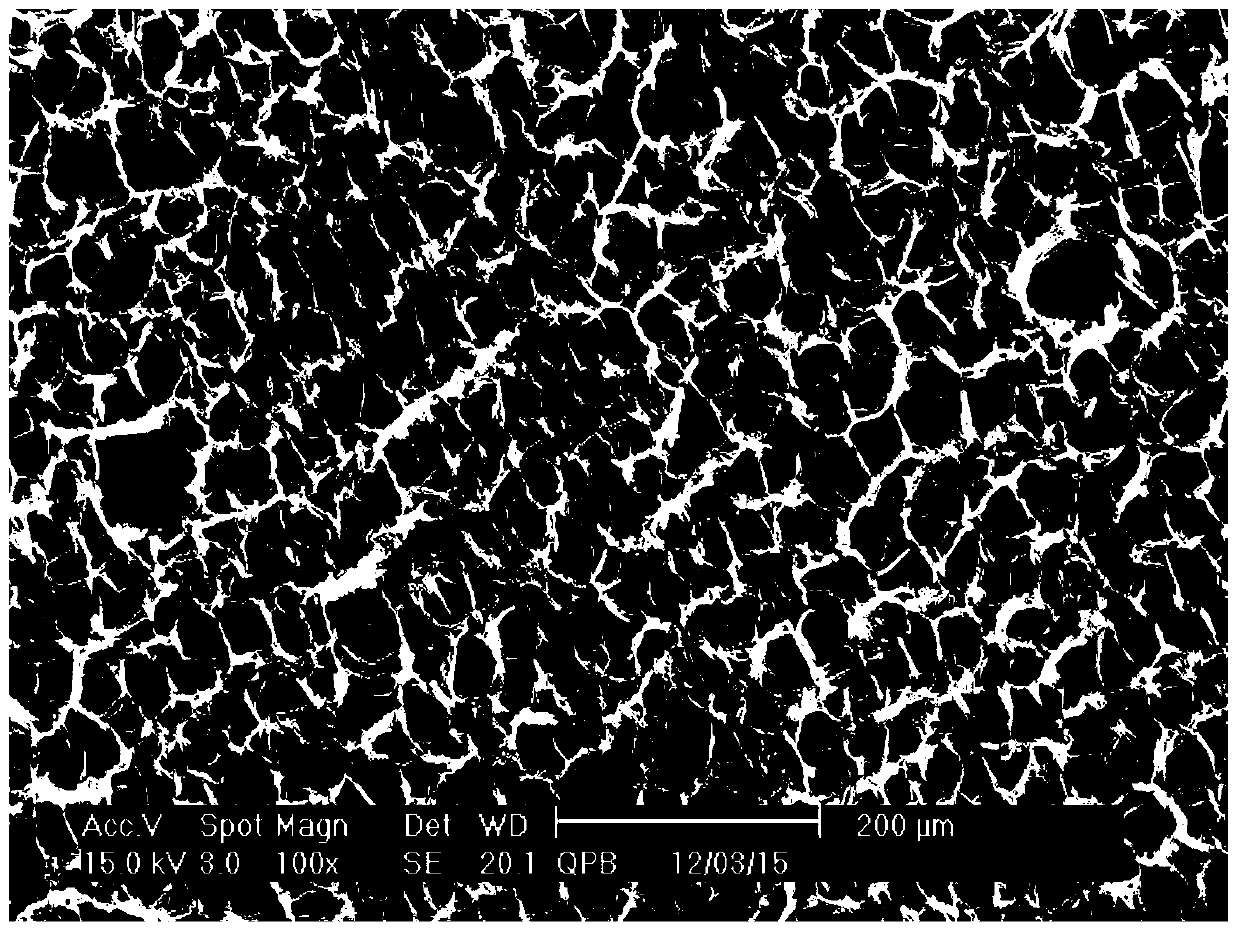

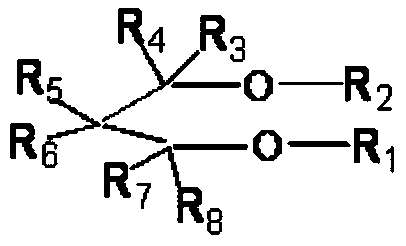

[0059] 1) Preparation of modified carbon nanotubes: Weigh 0.5g of carbon nanotubes (multi-walled carbon nanotubes, diameter 15-30nm), mix them with 125g of agate balls, place them in an agate ball mill, and place them in a planetary ball mill to express Ball mill at the rotational speed listed in 2 for a period of one hour to obtain dispersed carbon nanotubes. Weigh 5.0g of the dispersed carbon nanotubes obtained by the above-mentioned ball milling and add it into 500ml of nitric acid / hydrogen peroxide mixed solution (the concentration of nitric acid is 65wt%, the concentration of hydrogen peroxide is 45wt%, and the volume ratio H 2 o 2 : HNO 3 =1:3), the solution was magnetically stirred at room temperature for 30 minutes, and then subjected to 40 kHz ultrasonic treatment for 30 minutes, and then the solution was connected to the reflux reaction device, and refluxed and stirred at 120 ° C for 2 hours. The obtained product was suction-filtered with a 0.22-micron microporous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com