Composition for preparing polypropylene plastic-wood composite material, composite material prepared from composition and application of composite material

A technology for wood-plastic composite material and polypropylene, which is applied in the field of preparing the composition of polypropylene-plastic wood-plastic composite material, can solve the problems of affecting service life and use effect, low mechanical properties and impact resistance, fracture failure of wood-plastic materials, and the like. Achieve the effect of closed-cell hard structure impact and bending performance, excellent performance, and low foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

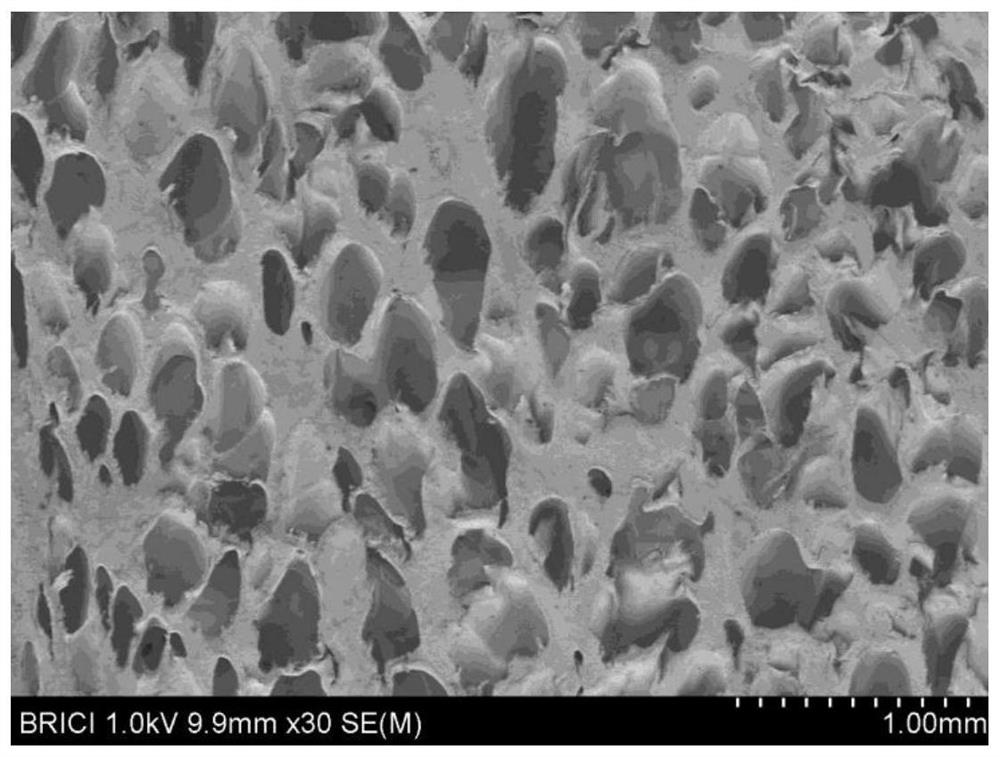

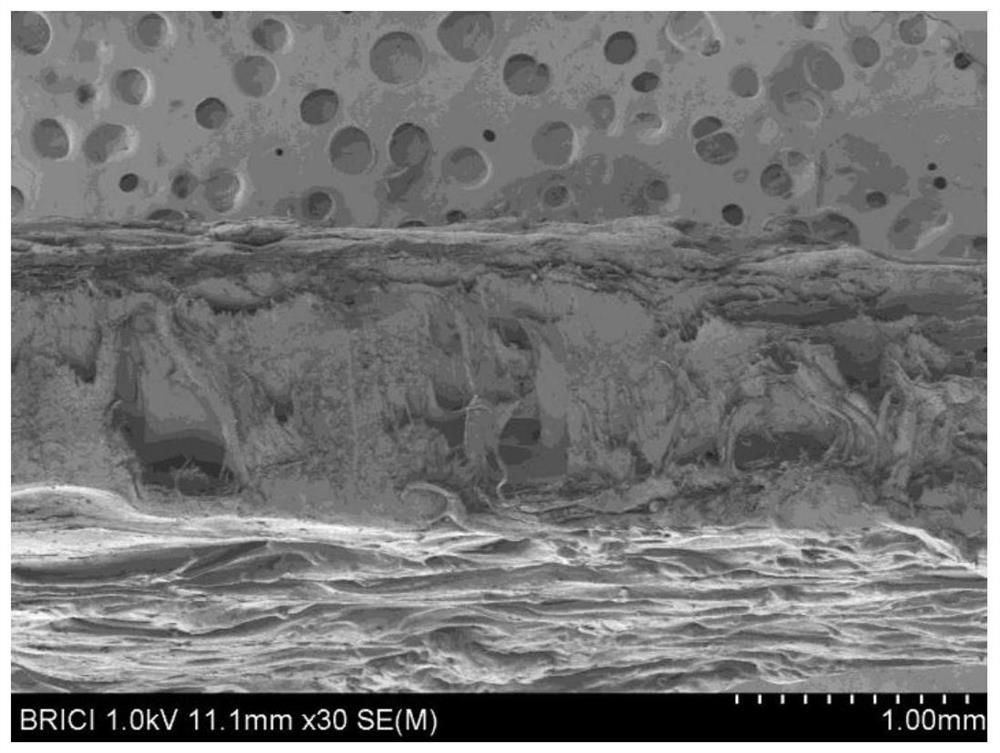

Image

Examples

Embodiment 1

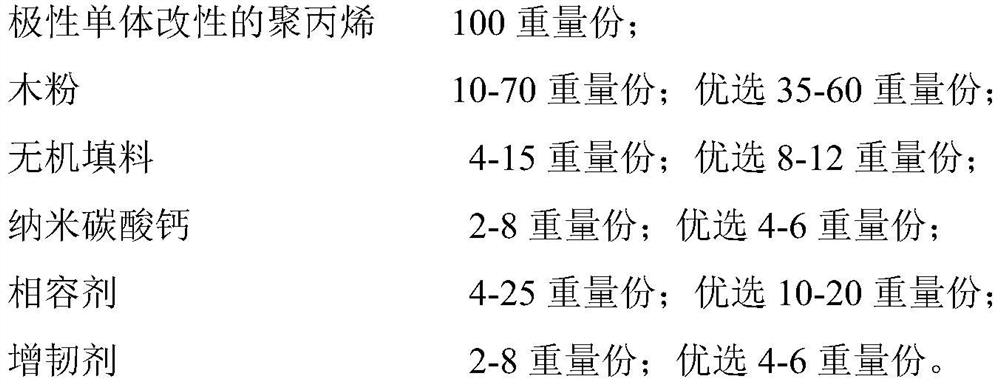

[0086] 10 parts by weight of wood powder with a particle size of 100 mesh was dried at 70°C for 6 hours, and then 100 parts by weight of glycidyl methacrylate graft-modified SP179, dried wood powder, 4 parts by weight of talc powder, 2 The nano-calcium carbonate of weight part, 4 weight parts compatibilizer, 2 weight parts toughening agent, 0.5 weight part antioxidant, 0.2 weight part lubricant are mixed uniformly and then add twin-screw extruder, through melt blending, extrusion and granulating to obtain a polypropylene wood-plastic composite material. The processing temperature of the twin-screw extruder is 190-210°C.

[0087] Using a high-speed stirrer to mix the above-mentioned polypropylene wood-plastic composite material, foaming agent and lubricant to obtain a premixed material for polypropylene foam boards;

[0088] Put the premix into the hopper of the single-screw extruder, and raise the temperature of the extruder to the foaming temperature shown in Table 2 to melt...

Embodiment 2-6 and comparative example 1-5

[0090] The difference between Examples 2-6 and Comparative Examples 1-5 and Example 1 is only that the amount of each component used to prepare the polypropylene wood-plastic composite material is different, and the amount of each component in Examples 2-6 and Comparative Examples 1-5 See Table 1 for dosage.

Embodiment 7-10

[0092] The only difference between Examples 7-10 and Example 1 lies in the grafting ratio of glycidyl methacrylate in the glycidyl methacrylate grafted polypropylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com