Detectable attachment joint for carbon fiber composite material pipes and application method of detectable attachment joint

A composite material pipe and detachable connection technology, which is applied in the direction of rod connection, material gluing, and connection components, can solve the problems of easy loosening of prestressed cable connections, stress concentration at the edge of mechanical connection holes, and difficult positioning dimensions. To achieve the effect of facilitating segmented production and transportation, ensuring integrity, and ensuring firm reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

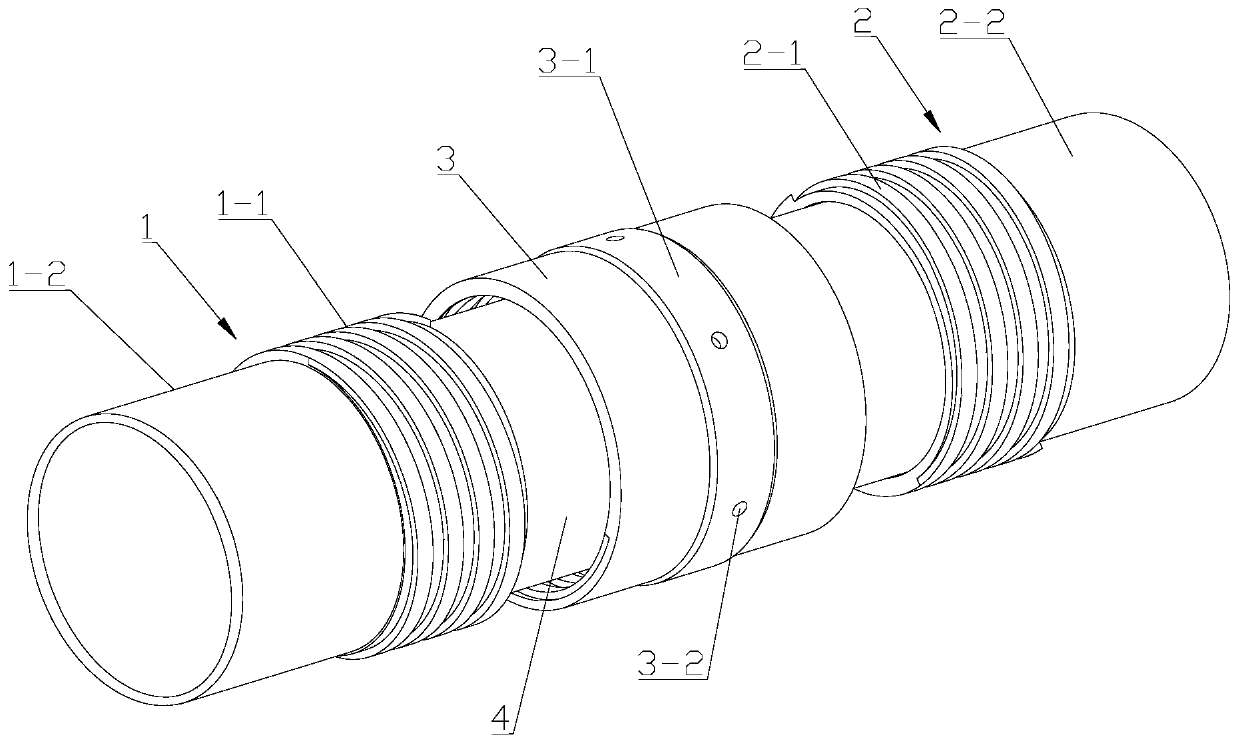

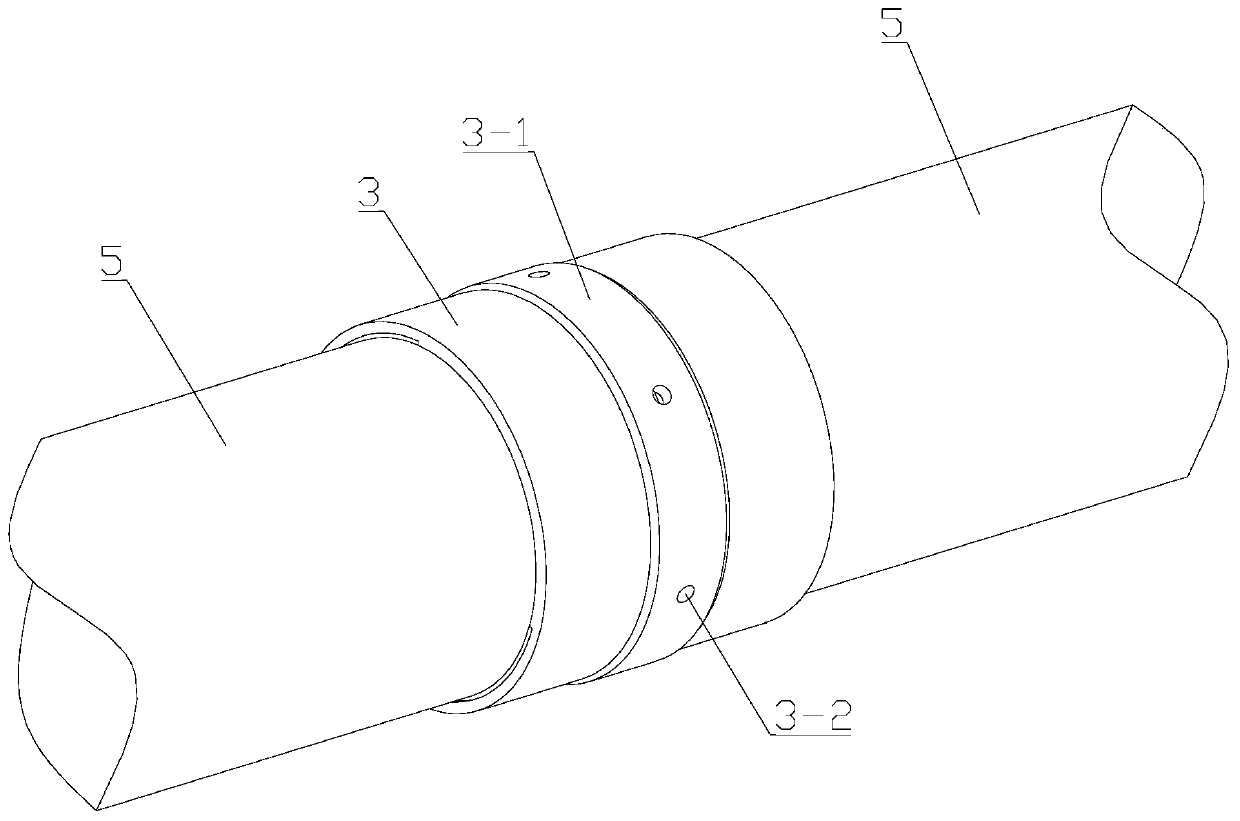

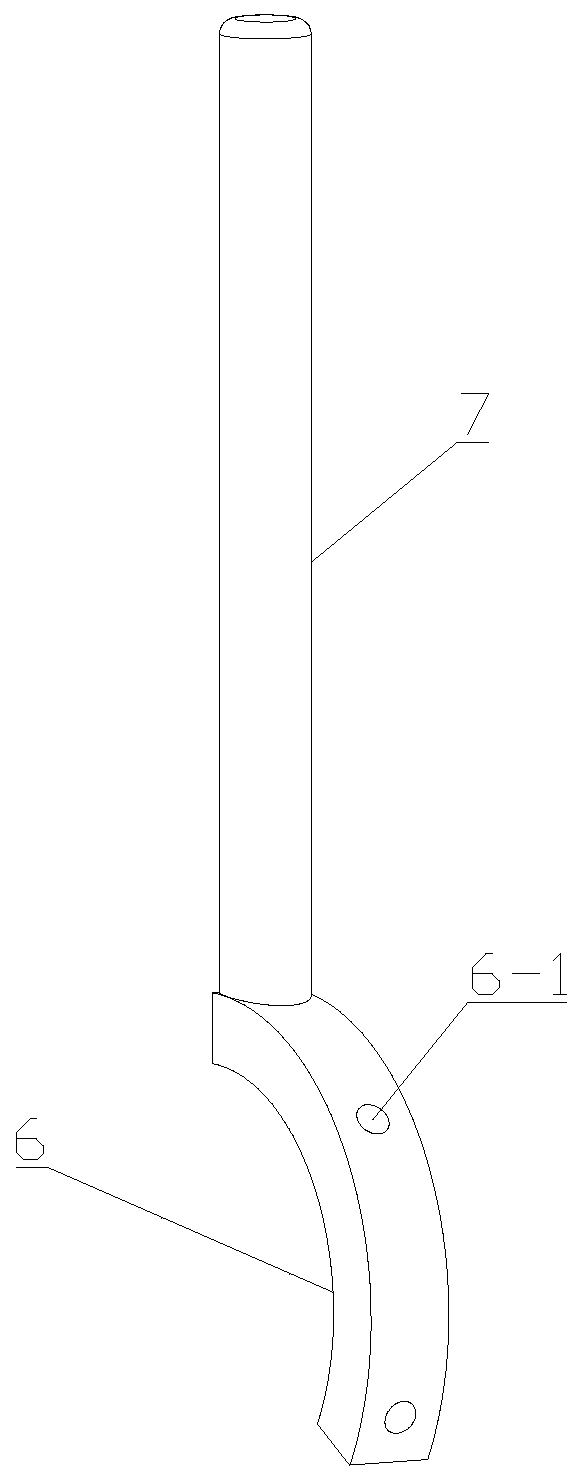

[0042] Such as figure 1 and figure 2 As shown, the present invention comprises a left joint 1 connected at the end of one carbon fiber composite pipe 5 and a right joint 2 connected at the end of another carbon fiber composite pipe 5, and the outside of the left joint 1 and the right joint 2 pass through the external The ferrule joint 3 is tightly connected, and the inner side of the left joint 1 and the right joint 2 are tightly connected by the internal insertion pipe 4, between the left joint 1 and the external ferrule joint 3, and between the right joint 2 and the external ferrule The joints 3 are threaded connections, the left joint 1, the right joint 2 and the external ferrule joint 3 are all cylindrical joints, the internal insertion pipe 4 and the carbon fiber composite pipe 5 are round pipes, and the left The right end of the joint 1 is provided with a left-handed external thread 1-1, the left end of the right joint 2 is provided with a right-handed external thread ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com