Composition for preparing glass fiber reinforced polypropylene material, material prepared from composition and application

A polypropylene material and composition technology, applied in the field of glass fiber reinforced polypropylene, can solve the problems of inability to strengthen and toughen, and achieve the effects of good mechanical and heat resistance, smooth surface, and dense and uniform cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

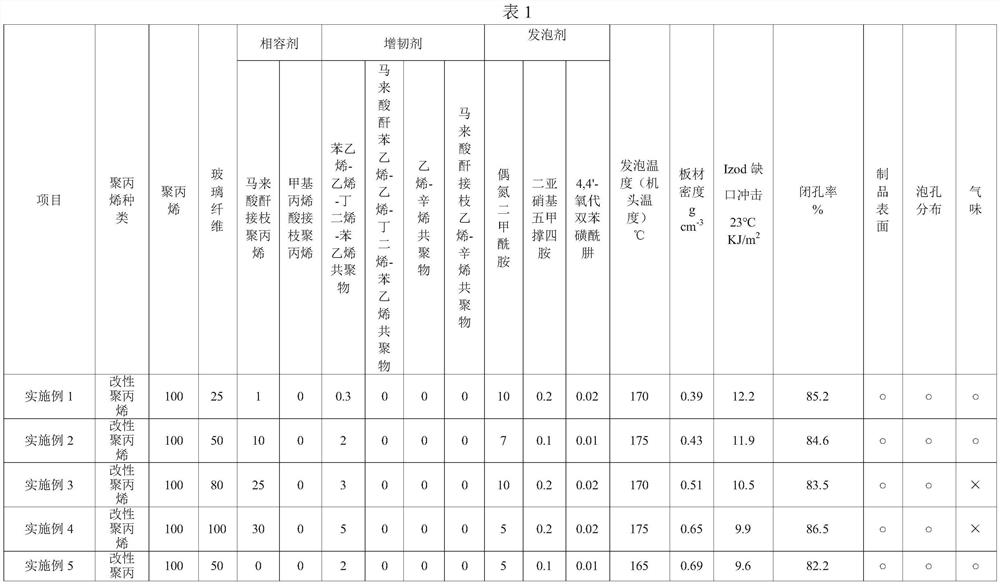

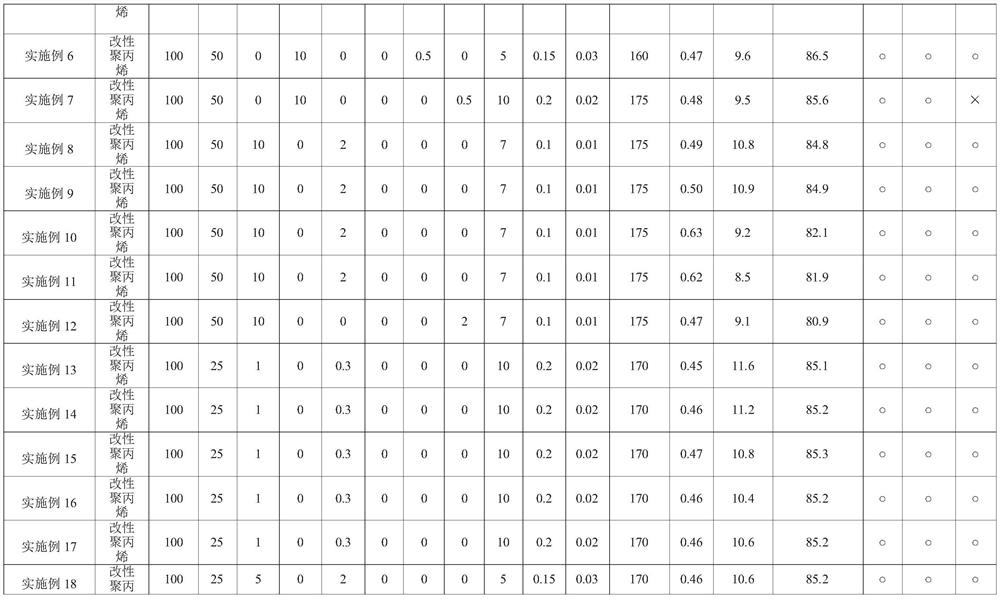

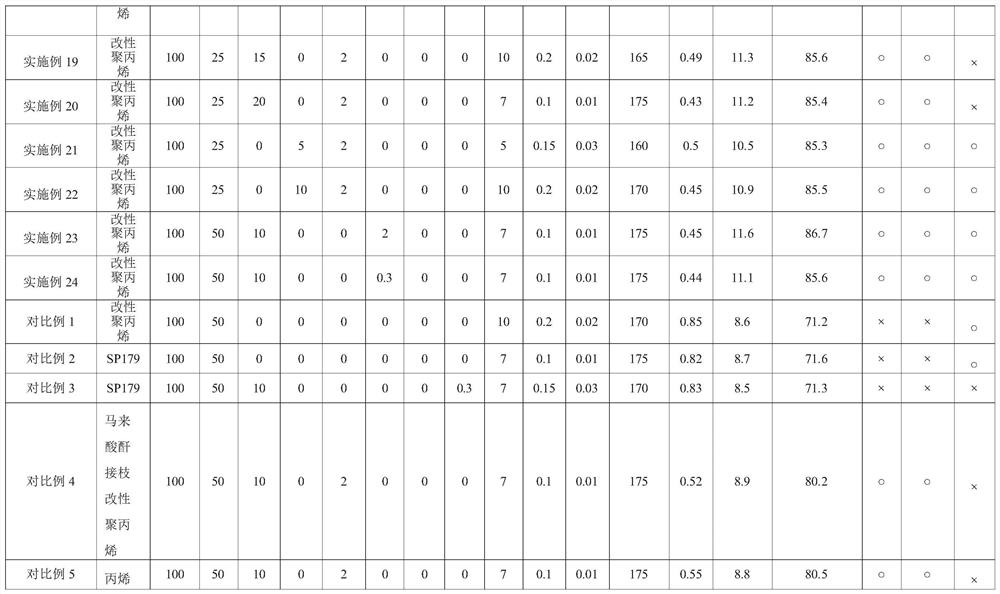

[0057] According to the addition of each material in Table 1, take by weighing dry polar monomer modified polypropylene (grafting rate 4wt%), glass fiber, compatibilizer, toughening agent and antioxidant, each component After mixing evenly, put it into a twin-screw extruder, and go through melt blending, extrusion and granulation to obtain a glass fiber reinforced polypropylene material. The processing temperature of the twin-screw extruder is: the temperature of the first zone is 150°C, the temperature of the second zone is 160°C, the temperature of the third zone is 165°C, the temperature of the fourth zone is 170°C, the temperature of the fifth zone is 170°C, the temperature of the sixth zone is 170°C, Head temperature 165°C.

[0058] Foaming and rolling process:

[0059] Add the above-mentioned glass fiber reinforced polypropylene material, foaming agent and processing aid according to the formula shown in Table 1 into a high-speed stirrer and mix at high speed for 1 minu...

Embodiment 2-7 and comparative example 1-3

[0064] The difference between Examples 2-7 and Comparative Examples 1-3 and Example 1 is only that the amount of each component used to prepare the glass fiber reinforced polypropylene material is different, wherein the polypropylene used in Comparative Examples 2 and 3 is unmodified polypropylene The grade of propylene is SP179; see Table 1 for the consumption of each component in Examples 2-7 and Comparative Examples 1-3.

Embodiment 8-11

[0066] The difference between Examples 8-11 and Example 2 lies in the grafting ratio of glycidyl methacrylate in polypropylene grafted with glycidyl methacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com