A kind of biological polyurethane and its preparation method and application

A polyurethane, bio-based technology, applied in the field of polyurethane, can solve the problems of difficult to control the degradation time, the comprehensive performance of porous sponge materials is not ideal, the degradability and biocompatible sponge properties are difficult to take into account, etc., and achieve good degradability. , ideal biocompatibility, ideal mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

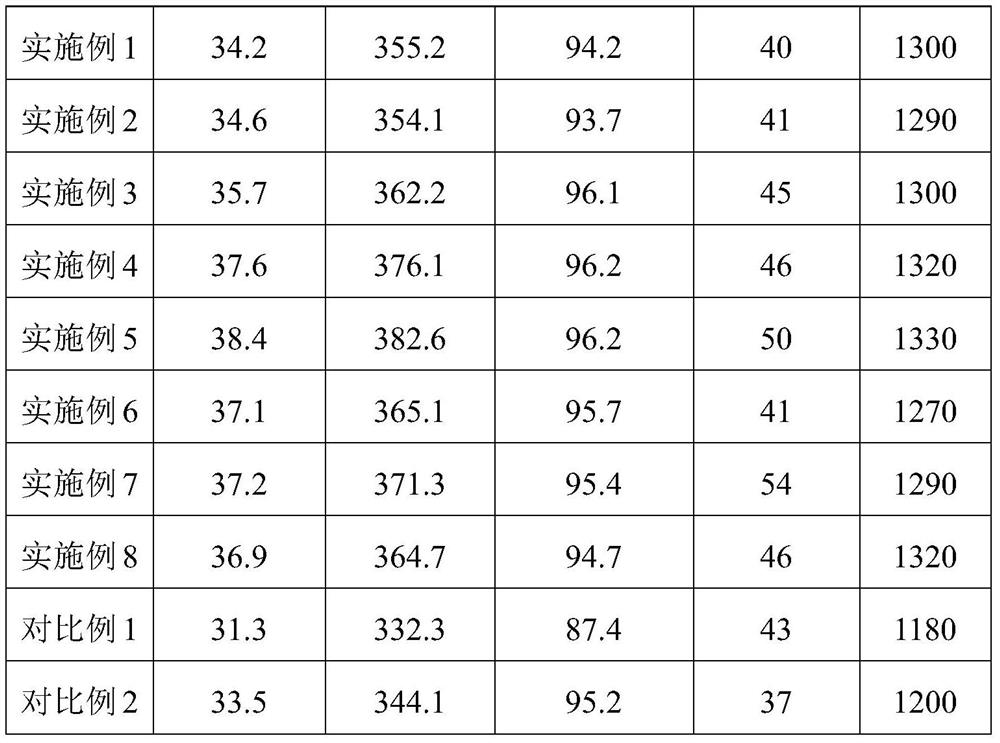

Examples

preparation example 1

[0032] S1. The reaction raw materials are placed in a vacuum drying box, vacuum dried at 80°C for 12 hours, and then stored in a glove box under nitrogen atmosphere, during which the entry of moisture in the air is strictly prevented;

[0033] S2. Place 1 mol of 1,3,5-benzenetrimethanol and 3.1 mol of p-phenylenediisocyanate in an appropriate amount of anhydrous toluene solvent, in 1,3,5-benzenetrimethanol 1wt% dibutyltin dilaurate Under the system of , heating to 70 ℃ for reaction, the reaction time is 1h, and the prepolymer is obtained;

[0034] S3. Add 1.8 mol of threonine and 0.21 mol of polyethylene glycol monomethyl ether to the above prepolymer, heat to 70 ° C for reaction, the reaction time is 1 h, after evaporating the solvent to dryness, the product bio-based polyurethane 1 is obtained, Its number average molecular weight is about 17200 g / mol.

preparation example 2

[0036] S1. The reaction raw materials are placed in a vacuum drying box, vacuum dried at 80°C for 12 hours, and then stored in a glove box under nitrogen atmosphere, during which the entry of moisture in the air is strictly prevented;

[0037] S2. Place 1 mol of 1,3,5-benzenetrimethanol and 3.08 mol of methylcyclohexyl diisocyanate in an appropriate amount of anhydrous toluene solvent, in 1,3,5-benzenetrimethanol 1wt% dilauric acid Under the system of dibutyltin, the reaction is heated to 70 °C, and the reaction time is 1 h to obtain a prepolymer;

[0038] S3. Add 2.1 mol of serine and 0.15 mol of polyethylene glycol monomethyl ether to the above prepolymer, heat to 90 ° C for reaction, the reaction time is 3 h, after evaporating the solvent to dryness, the product bio-type polyurethane 2 is obtained. The average molecular weight is about 17000 g / mol.

preparation example 3

[0040] S1. The reaction raw materials are placed in a vacuum drying box, vacuum dried at 80°C for 12 hours, and then stored in a glove box under nitrogen atmosphere, during which the entry of moisture in the air is strictly prevented;

[0041] S2. Place 1 mol of 1,3,5-benzenetrimethanol and 2.10 mol of methylcyclohexyl diisocyanate in an appropriate amount of anhydrous toluene solvent, in 1,3,5-benzenetrimethanol 1wt% diacetic acid diacetate Under the system of butyl tin, the reaction is heated to 80 °C, and the reaction time is 2 h to obtain a prepolymer;

[0042] S3. Add 1.9 mol of tyrosine, 0.19 mol of polyethylene glycol monomethyl ether, and 1.0 mol of methylcyclohexyl diisocyanate to the above prepolymer, heat to 80 ° C for reaction, the reaction time is 2 h, steam After drying the solvent, the product biotype polyurethane 3 was obtained, and its number average molecular weight was about 18300 g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com