Smelting method for recycling lead, bismuth and precious metal from lead-containing tailings in acid making

A smelting method and precious metal technology, applied in the fields of smelting bismuth and precious metals and recovering lead, can solve problems such as serious environmental pollution, loss of valuable metals, and difficulty in mutual separation, and achieve high comprehensive recovery rate, high product quality, and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

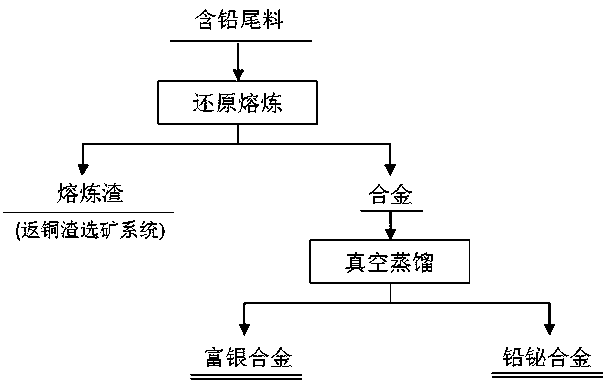

[0016] Lead-containing tailings of wet acid production in a smelter (the main average composition is: Pb 48.85%, Bi 2.58%, Au 3.41%, Cu0.72%, Se 0.35%, As 0.16%, Ag 383g / t), the Put the lead tailings into the reduction smelting equipment, add a reducing agent containing 15% of the weight of the tailings containing lead, and a flux containing 25% of the weight of the tailings containing lead. Finally, separate the alloy from the smelting slag; put the alloy obtained by reduction smelting into the vacuum distillation equipment, control the vacuum degree <30Pa, and keep it at 1100°C for 1 hour to obtain a silver-rich alloy (Cu 19.76%, Ag 1.96%, Pb0.014 %, Bi 0.0069%) and lead-bismuth alloy (Pb 95.52%, Bi 3.84%), the silver-rich alloy returns to the precious metal smelting system to produce silver products, and the lead-bismuth alloy can be sold directly.

Embodiment 2

[0018] The lead-containing tailings of wet acid production in a smelter (the main average components are: Pb 50.56%, Bi 4.25%, Au 2.48%, Se0.46%, As 0.71%, Ag 313 g / t), the lead-containing tailings Put it into the reduction smelting equipment, add a reducing agent containing 20% of the weight of the tailings containing lead, and a flux containing 20% of the weight of the tailings containing lead. Separated from the smelting slag; put the alloy obtained by reduction smelting into the vacuum distillation equipment, control the vacuum degree <30Pa, and keep it at 1200°C for 1 hour to obtain a silver-rich alloy (Cu 22.78%, Ag 1.58%, Pb 0.17%, Bi 0.02 %) and lead-bismuth alloy (Pb 95.62%, Bi 4.25%), the silver-rich alloy returns to the precious metal smelting system to produce silver products, and the lead-bismuth alloy can be sold directly.

Embodiment 3

[0020] Lead-containing tailings of wet acid production in a smelter (the main average components are: Pb 58.13%, Bi 2.73%, Au 3.07%, Cu0.54%, As 1.03%, Ag 203 g / t), the lead-containing tailings Put it into the reduction smelting equipment, add a reducing agent with 15% of the weight of the lead-containing tailings, and a flux with 30% of the weight of the lead-containing tailings. The reducing agent is pulverized coal, and the flux is quartz, and heated to 1250 ° C. Separation of alloy and smelting slag; put the alloy obtained by reduction smelting into vacuum distillation equipment, control the vacuum degree <30Pa, and keep it at 1150°C for 1 hour to obtain a silver-rich alloy (Cu 20.14%, Ag 1.78%, Pb 0.065%, Bi 0.011%) and lead-bismuth alloy (Pb 95.38%, Bi 4.13%), the silver-rich alloy is returned to the precious metal smelting system to produce silver products, and the lead-bismuth alloy can be sold directly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com