Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Prevent slipping and breaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

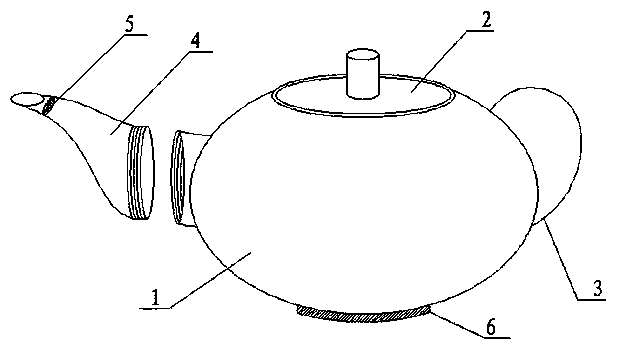

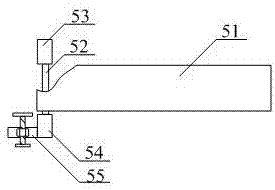

Teapot convenient to clean

The invention discloses a teapot convenient to clean. The teapot comprises a teapot body, a teapot cap, a handle and a spout. The spout is in threaded connection with the teapot body, external threads are arranged on the spout, and the teapot body is provided with internal threads matched with the external threads. When the teapot needs to be cleaned, a user only needs to rotate and disassemble the spout, and then the user can clean the inner wall of the spout easily. After cleaning, the user needs to rotate and install the spout to the teapot body, and then the teapot can be normally used again. The teapot is simple in structure, convenient to use and high in practicality.

Owner:WUXI JUNDA TESTING TECH SERVICES

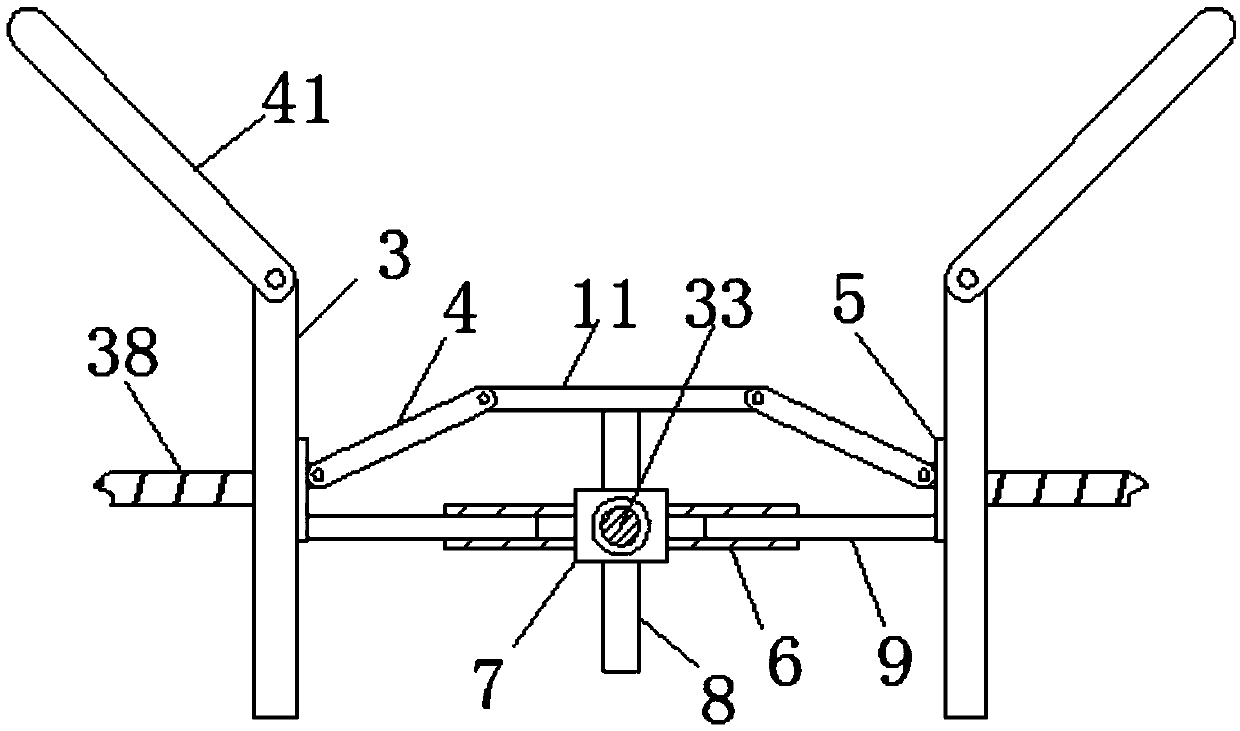

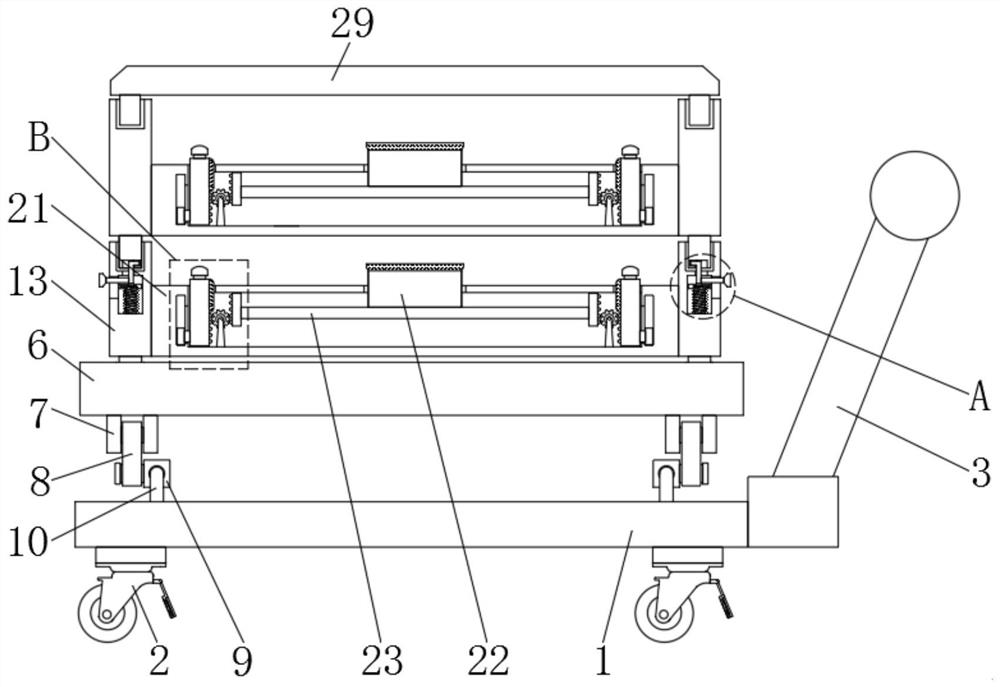

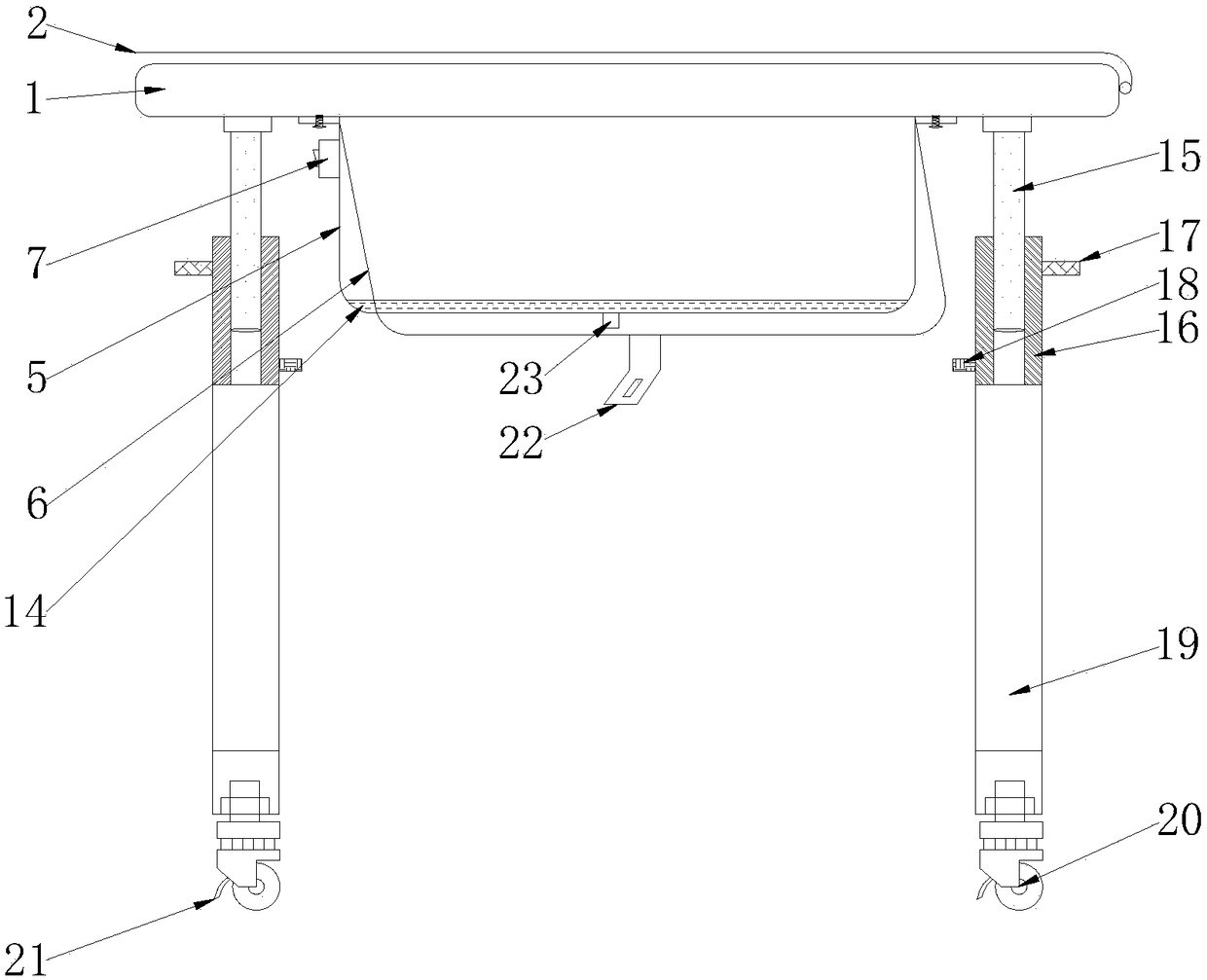

Conveying adjusting device for LED lamp machining and using method thereof

ActiveCN109592362ASimple structureEasy to operateMechanical apparatusSpace heating and ventilation safety systemsLED lampPortal frame

The invention relates to the field of lamp feeding, in particular to a conveying adjusting device for LED lamp machining and a using method thereof. The conveying adjusting device for LED lamp machining comprises a portal frame, the portal frame stretches across the two sides of a conveyer belt, and the two lower ends of the portal frame are fixedly connected to the portions, on the two sides of the conveyer belt, of a rack through clamping mechanisms separately; two vertical frames of the portal frame are each provided with a second sliding groove, an adjustable width limiting portion is connected to the interior of each second sliding groove, each width limiting portion comprises a sleeve slidably connected to the interior of the corresponding second sliding groove, a width limiting plate is connected to the interior of each sleeve through a width adjusting mechanism, and the two width limiting plates are located on the inner side of the portal frame and oppositely arranged; and eachwidth limiting portion further comprises a narrowness adjusting mechanism, and an adjustable height limiting mechanism is connected between the two width limiting plates. According to the conveying adjusting device for LED lamp machining, width and narrowness adjusting is conducted on the width limiting plates through the width adjusting mechanisms and the narrowness adjusting mechanism, height adjusting is conducted on a height limiting plate through the height limiting mechanism, operation is easy and convenient, the portal frame is assembled and disassembled through the clamping mechanisms, the structure is simple, and operation is convenient.

Owner:孔含之

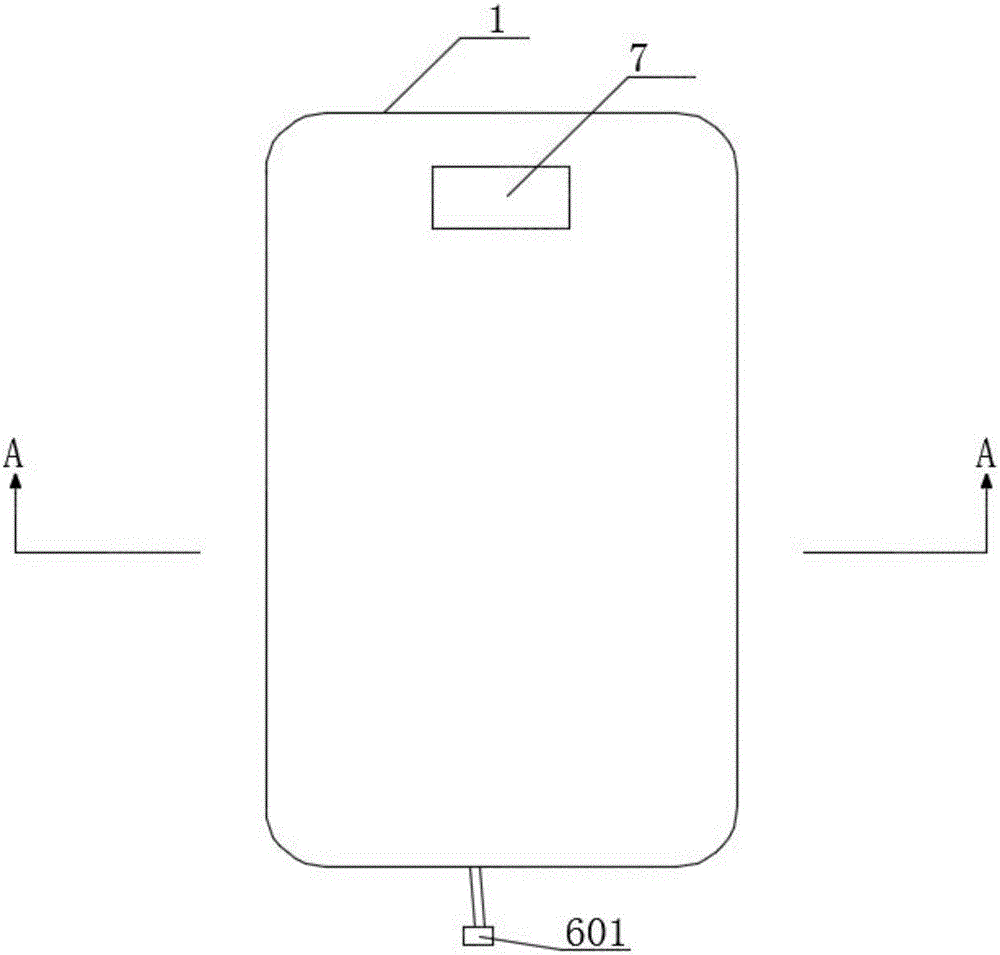

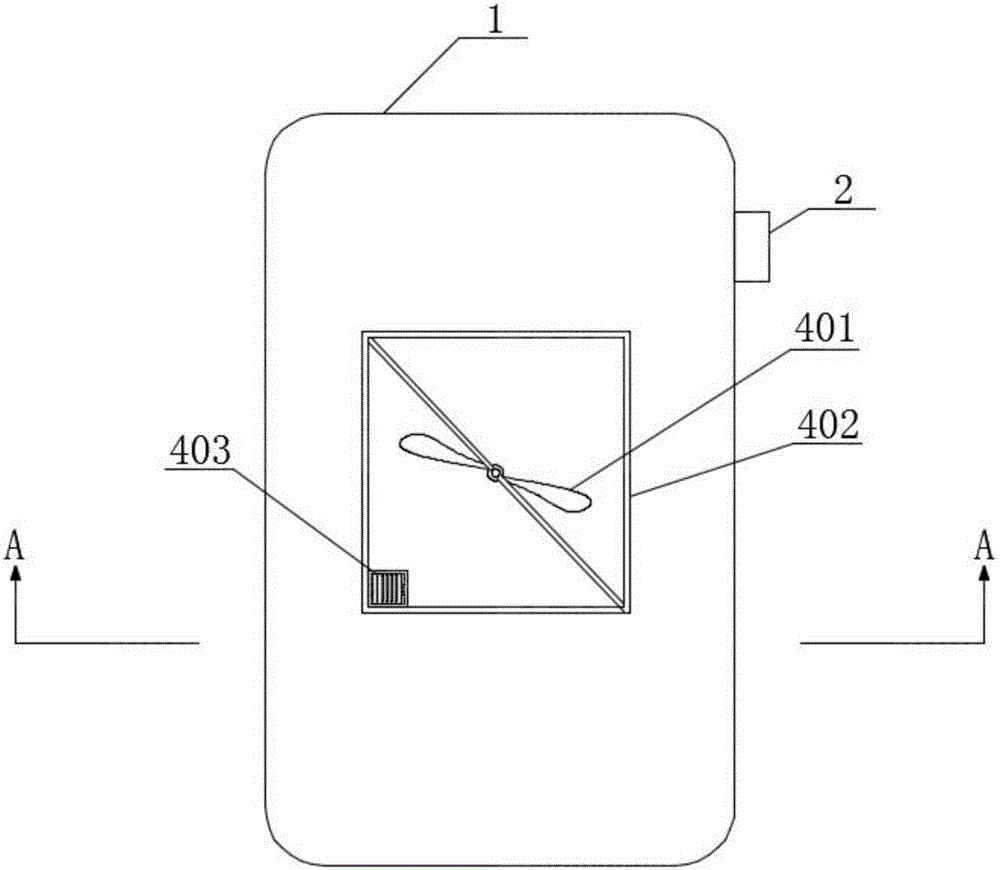

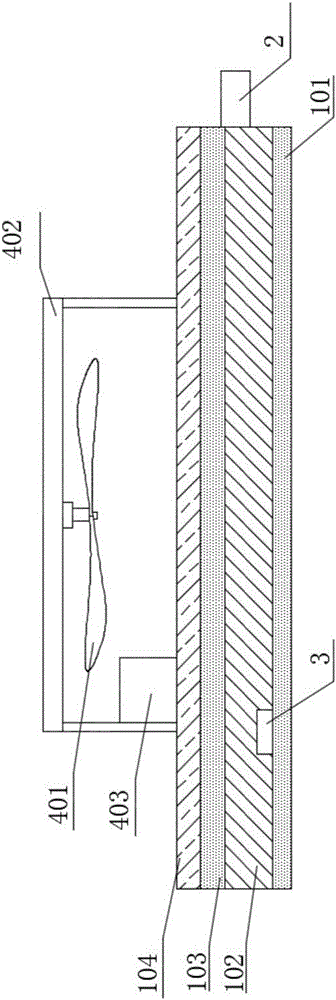

Mobile phone shell with thermal insulation and heating functions

InactiveCN106790866AReduce heat exchangeIncrease the ambient temperatureTelephone set constructionsElectricityUSB adapter

The invention relates to a mobile phone shell, in particular to a mobile phone shell with thermal insulation and heating functions. The mobile phone shell comprises a shell body, wherein the shell body comprises a waterproof layer, a heat transfer layer, a vacuum insulation layer and a protecting layer which are overlapped and laid from interior to exterior in sequence; a resistance wire mesh is arranged between the heat transfer layer and the vacuum insulation layer and is electrically connected to a mobile phone battery through a USB adapter; the vacuum insulation layer comprises a thermal insulation wall and a vacuum insulation cavity encircled by the thermal insulation wall; a sound playing port is arranged on the shell body; the heat transfer layer comprises a heat transfer wall and a heat transfer cavity encircled by the heat transfer wall, and water is filled in the heat transfer cavity; thermal insulation is carried out through the vacuum insulation layer and heating is carried out through the resistance wire mesh, so that a problem that the power source of the existing mobile phone cannot supply the electricity to the mobile phone in the low-temperature environment is solved.

Owner:怀宁佳瑞包装有限公司

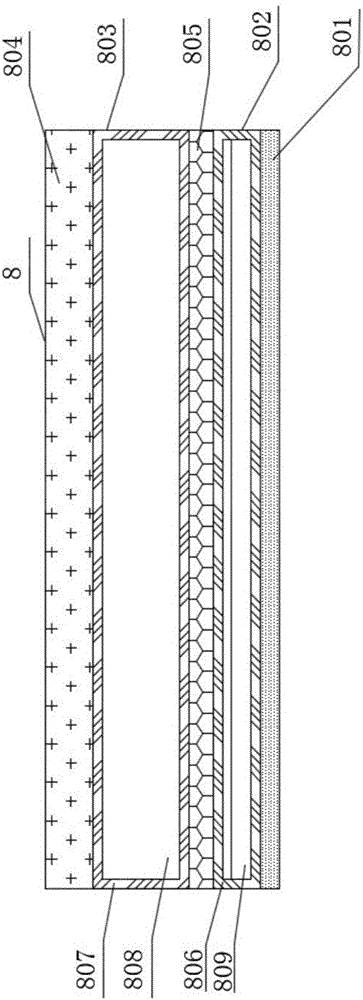

Push rod buckle for baby carriage

PendingCN108082263AEasy to adjust the angleEasy to pushCarriage/perambulator accessoriesLinear bearingsEngineering

Owner:嘉兴市优贝童车有限公司

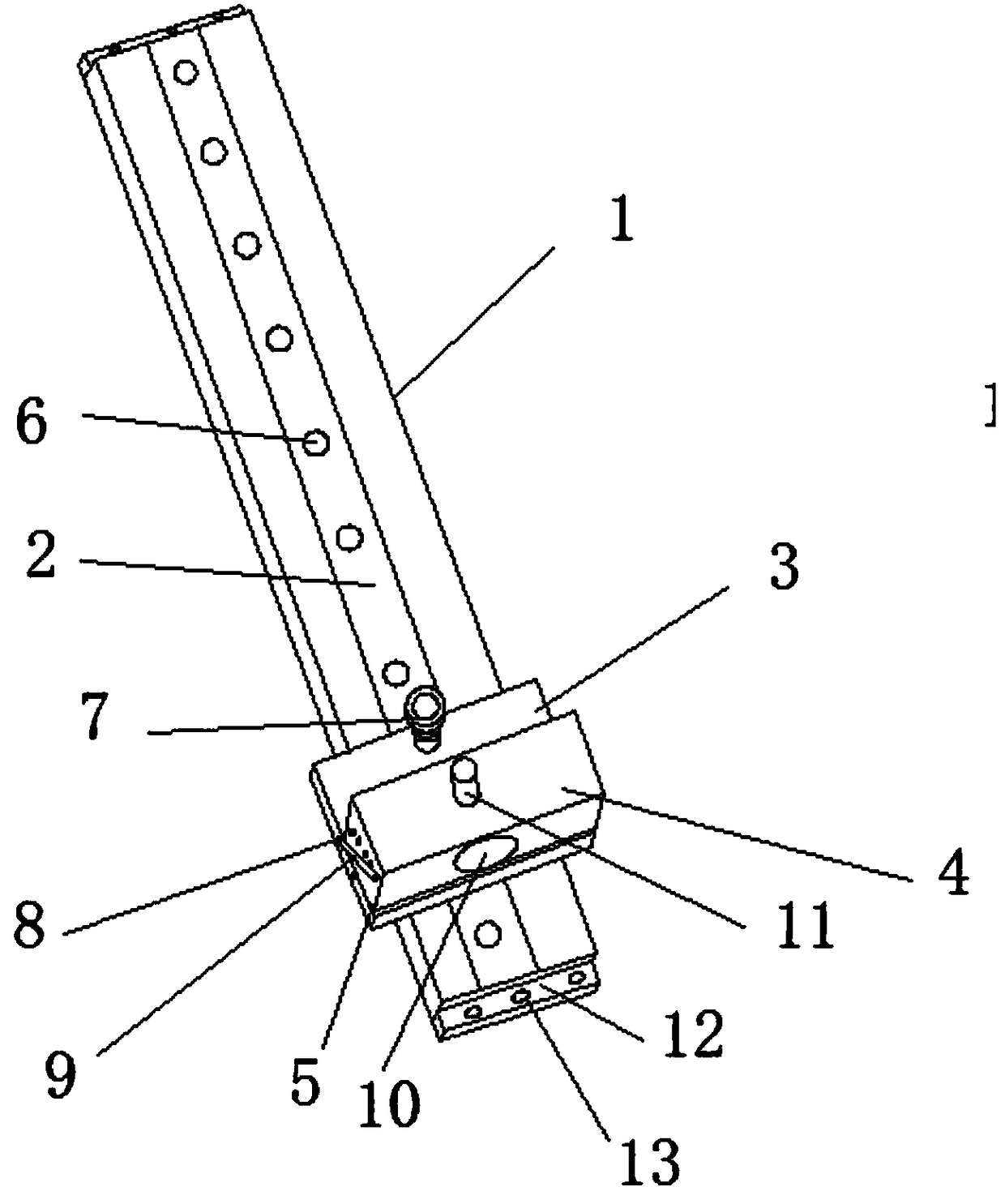

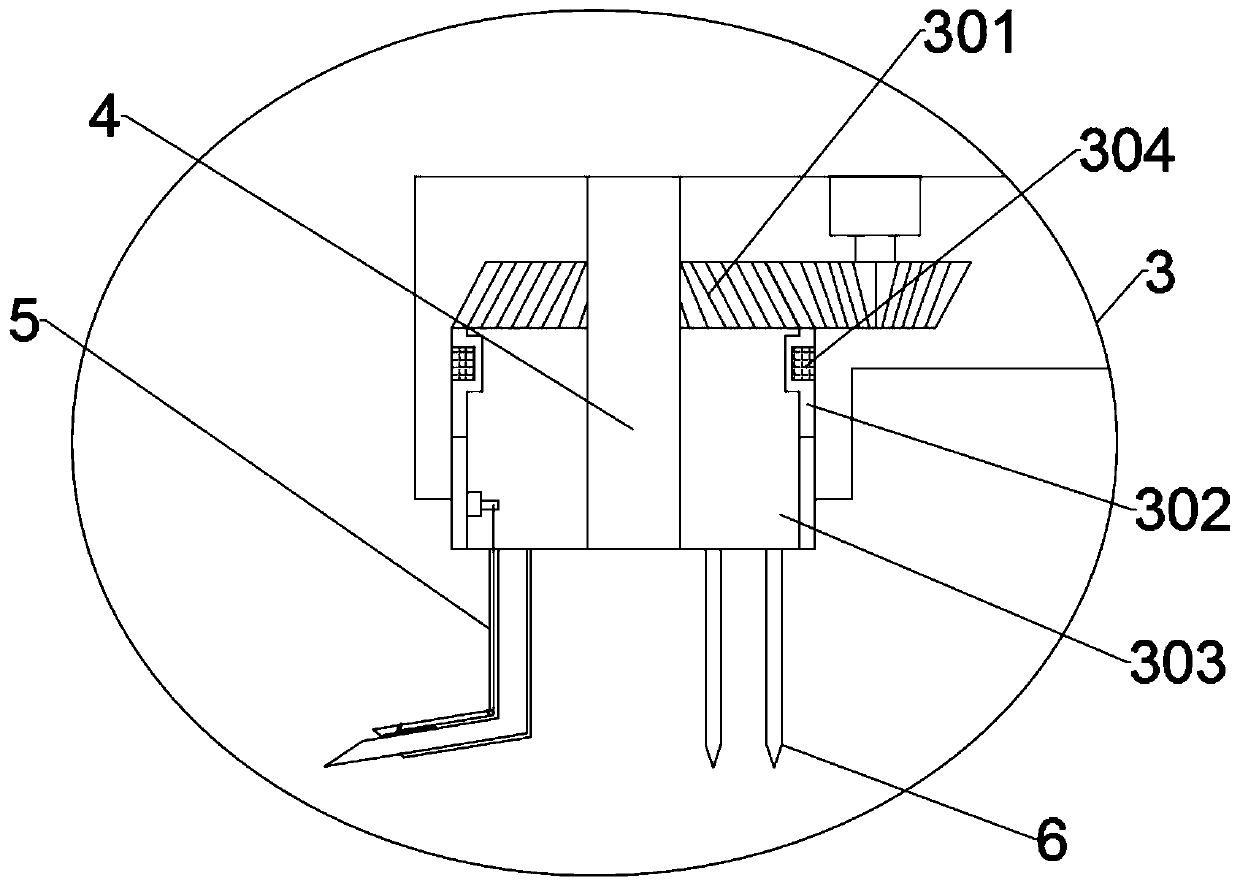

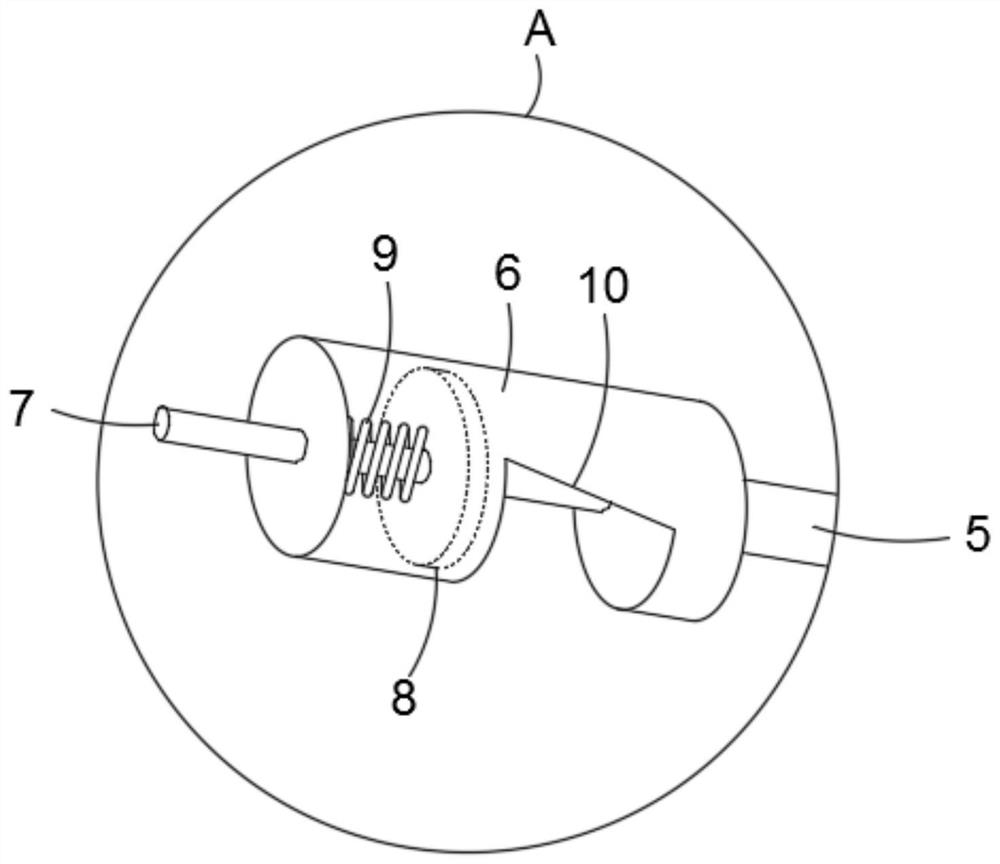

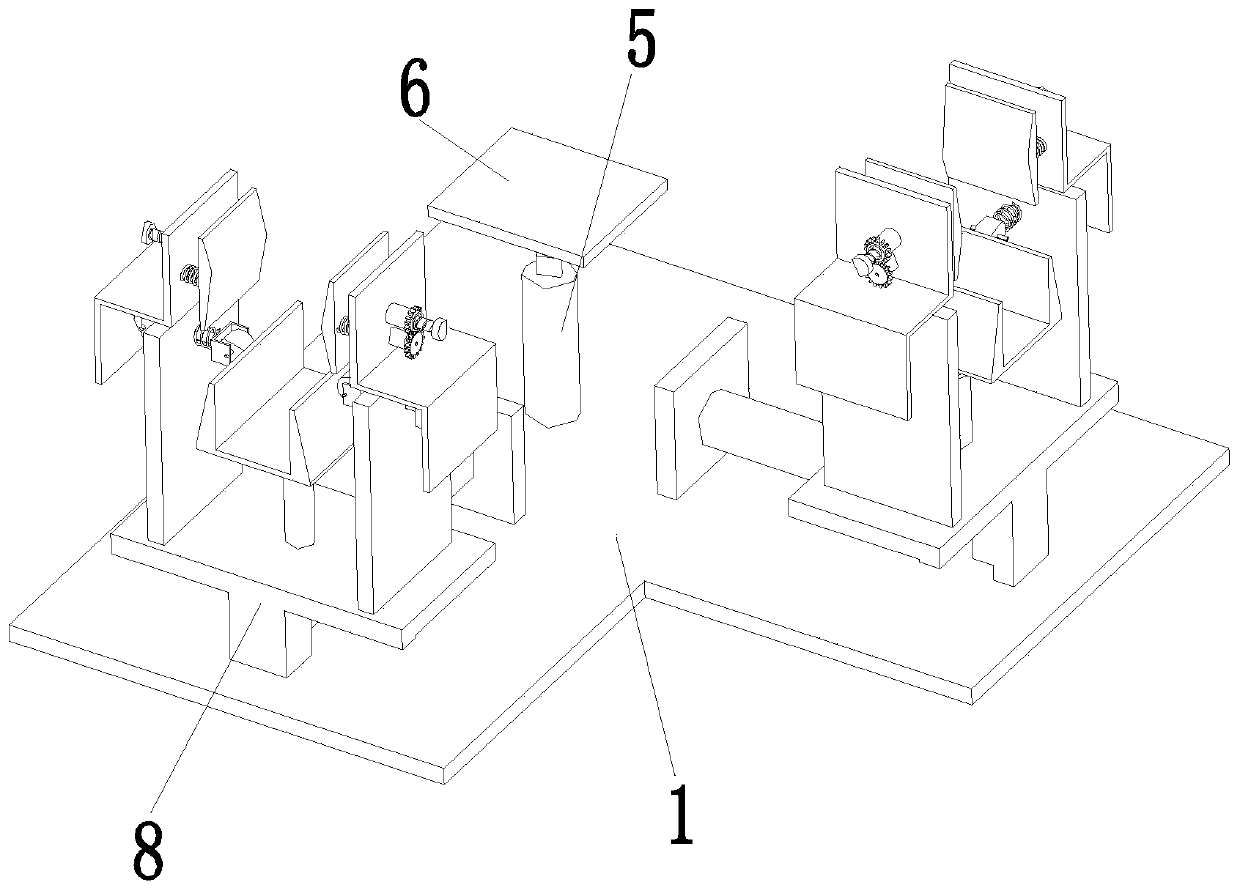

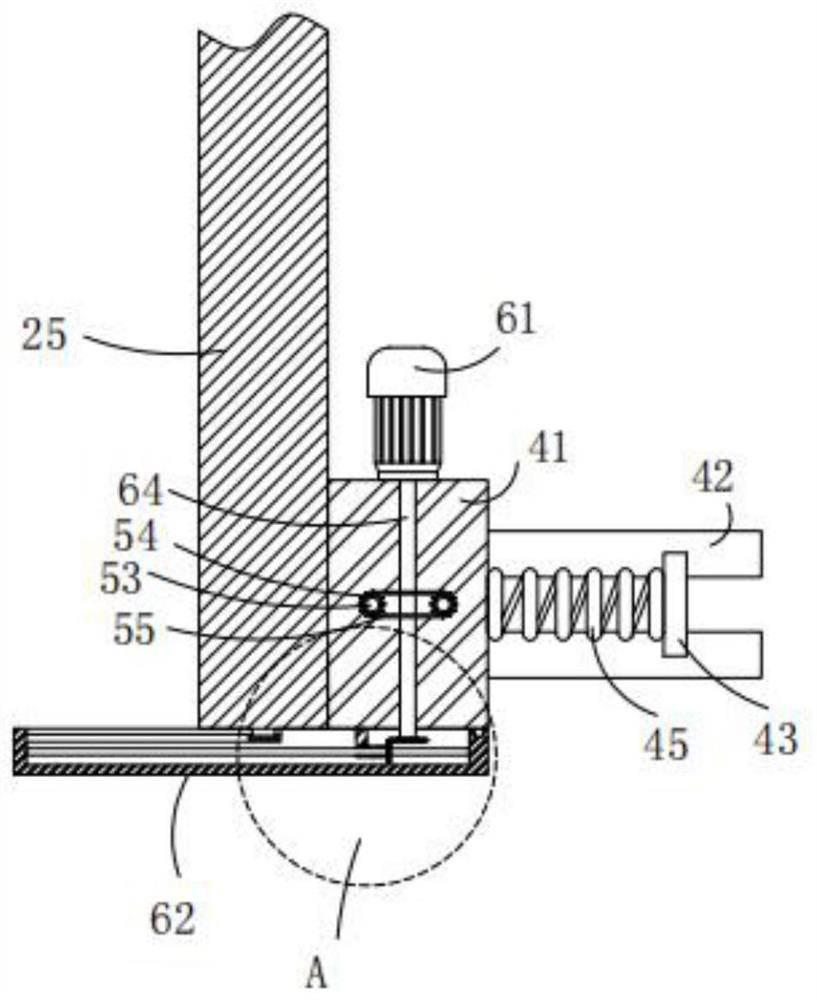

Apparatus for fixing a power bus slot

ActiveCN108767785APrevent slipping and breakingGuaranteed installation angleBus-bar installationEngineeringUltimate tensile strength

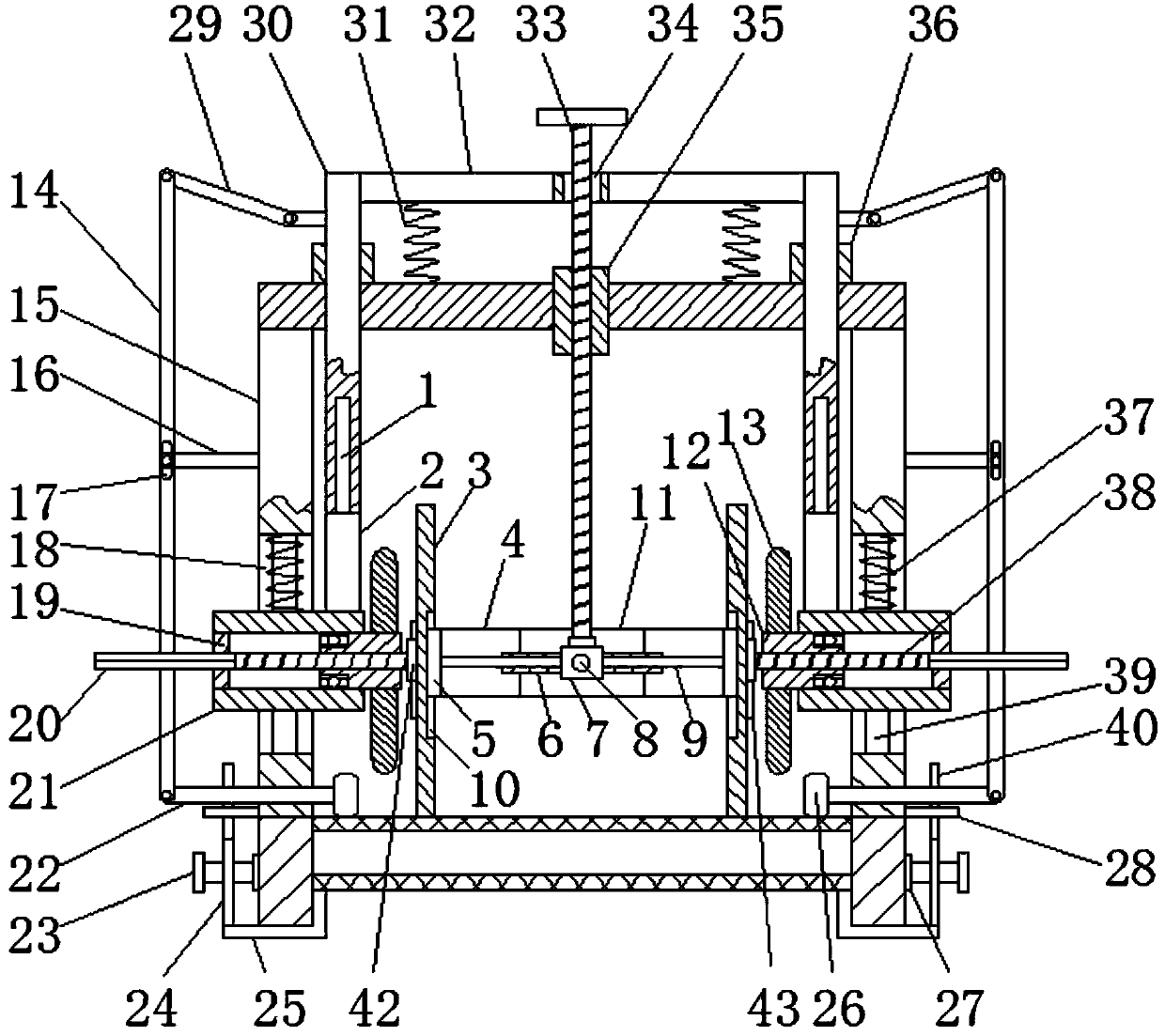

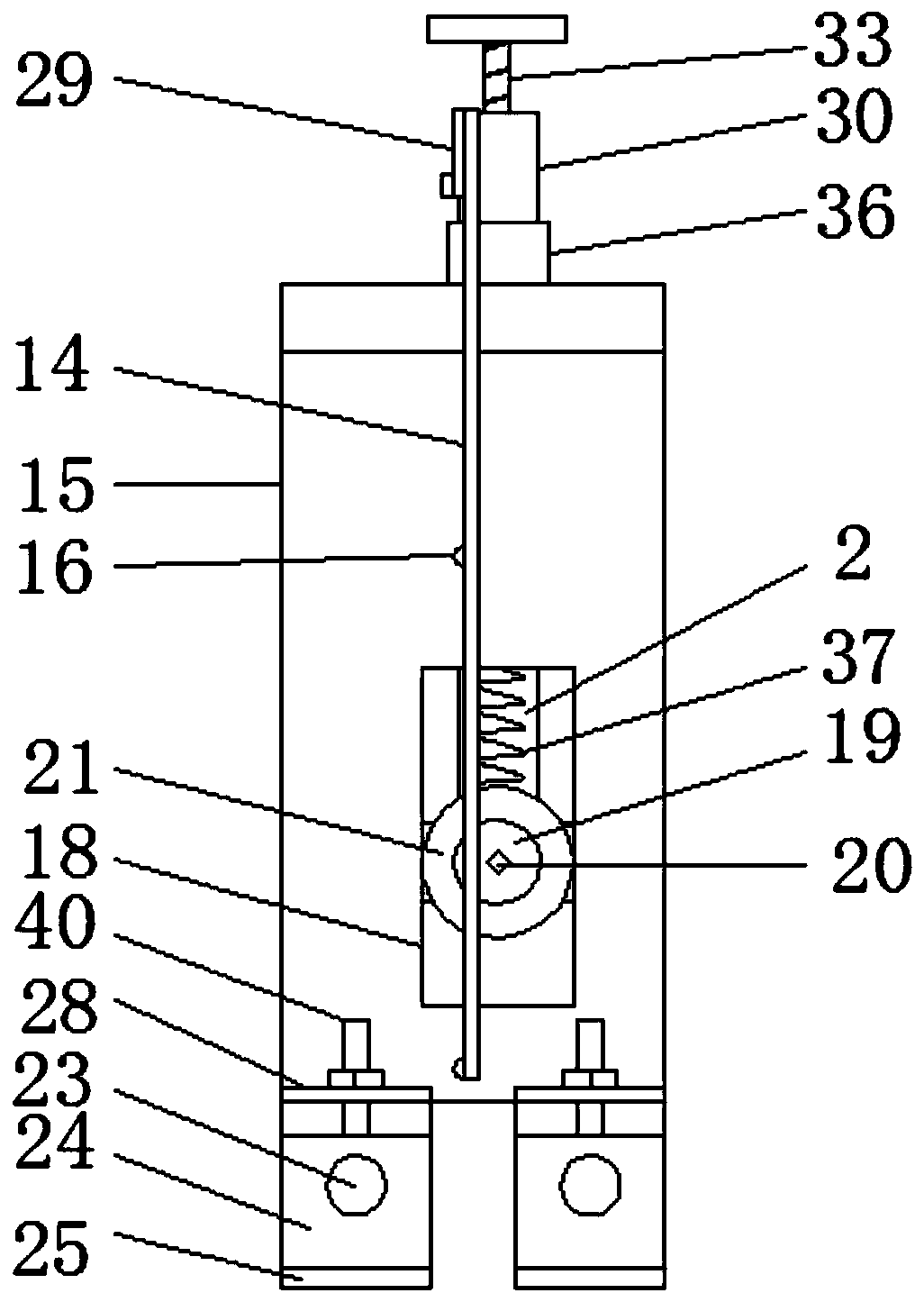

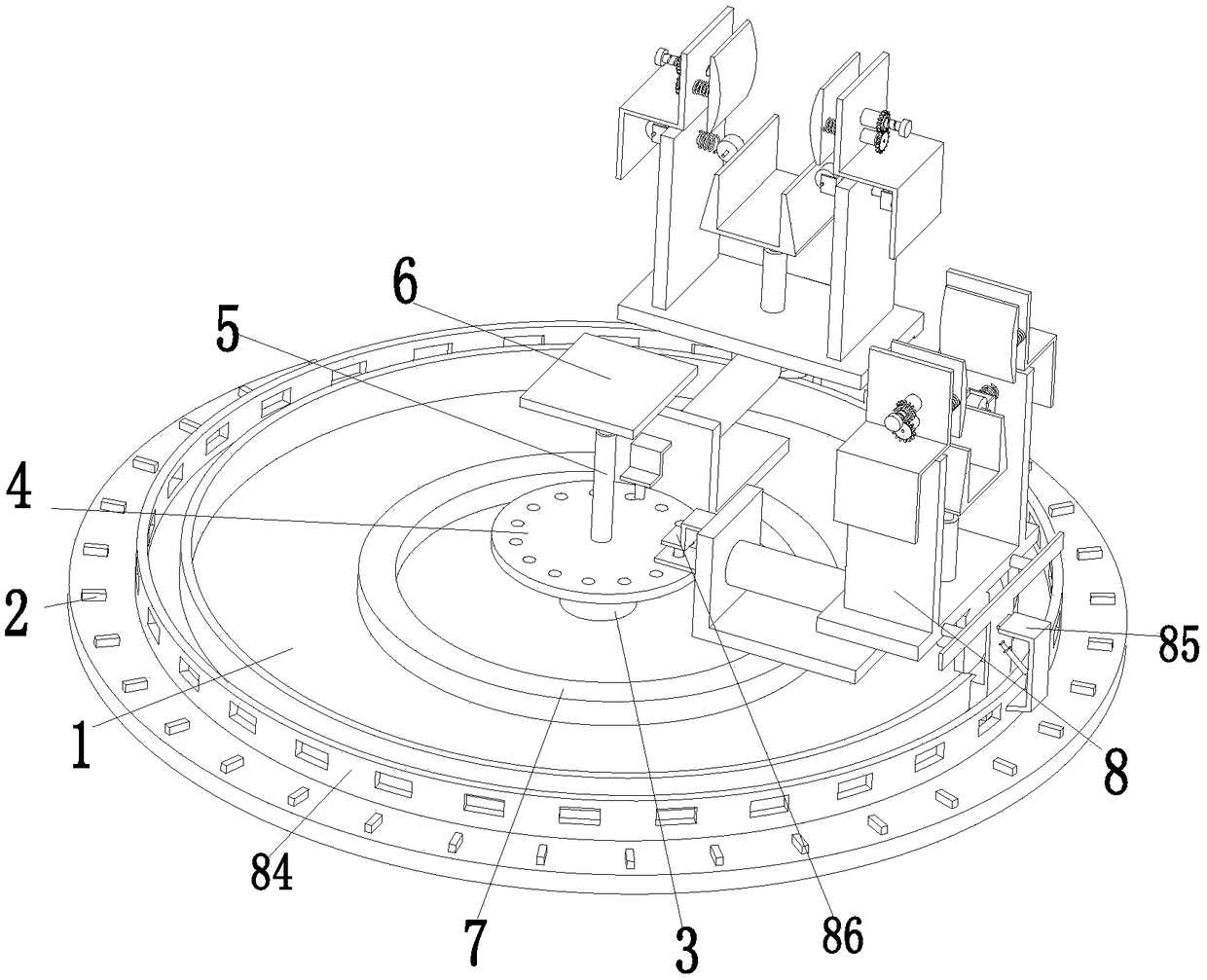

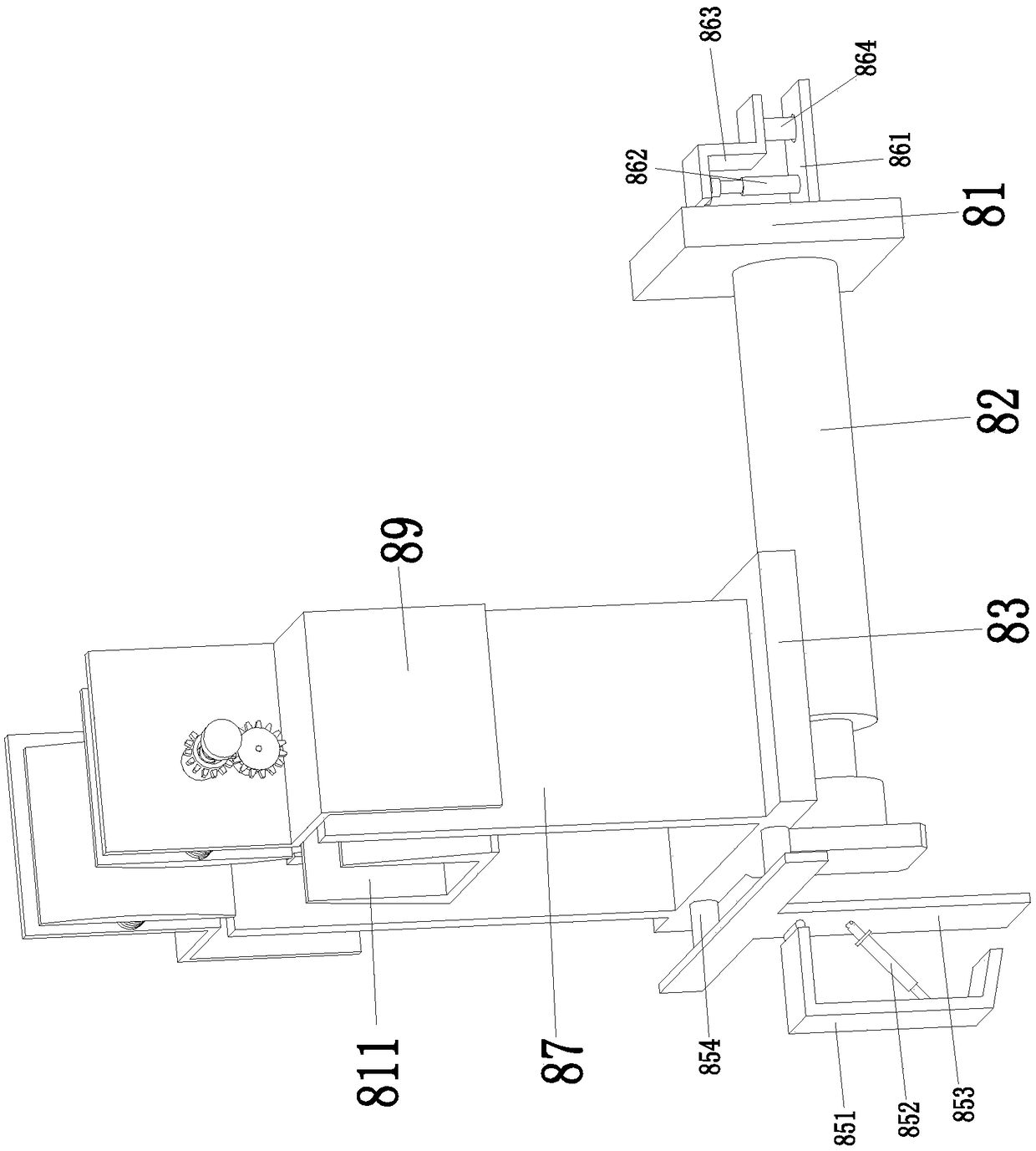

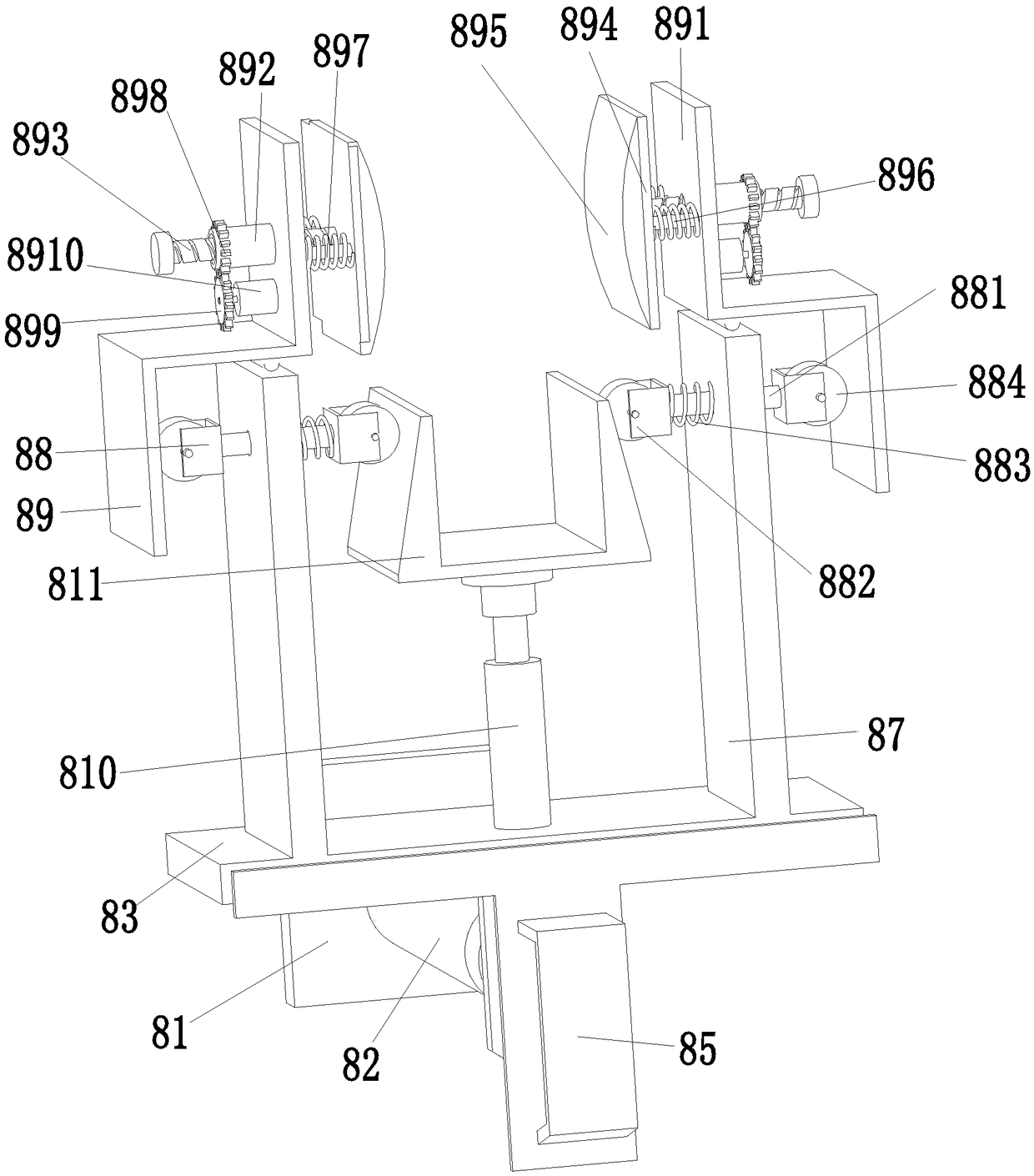

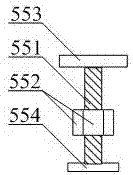

An apparatus for fixing a power bus slot comprises a bottom plate, a rotary supporting motor is installed at the upper end and the middle part of the bottom plate through a motor seat, a rotary supporting plate is installed on the output shaft of the rotary supporting motor, a position limit adjusting holes are uniformly arranged in the rotary supporting plate along the circumferential direction thereof, an annular slider is installed on the bottom plate, and two adjusting fixing devices are installed on the annular slider. The invention can solve the problem that the L-shaped wooden bus slotin the prior L-shaped wooden bus slot installation process needs manual fixation of the L-shaped structure bus slot by means of a clamping tool, there are differences in center of gravity, bus slot lengths of different specifications, etc. The clamping tools need to be adjusted manually, and there are errors in the manual adjustment, which cannot ensure the stability of the bus slot in the conveying process, easily make the bus slot slip and break in the conveying process, cannot ensure the installation angle of the bus slot, need to be corrected manually, the operation is complex, the labor intensity is high and the work efficiency is low, and other problems also exist.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO YUCHENG POWER SUPPLY CO

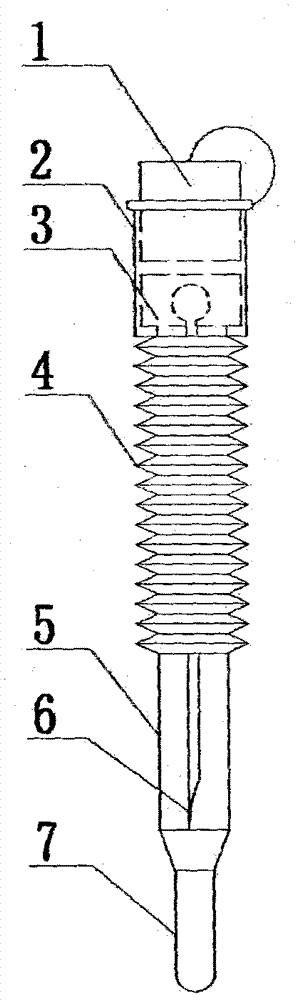

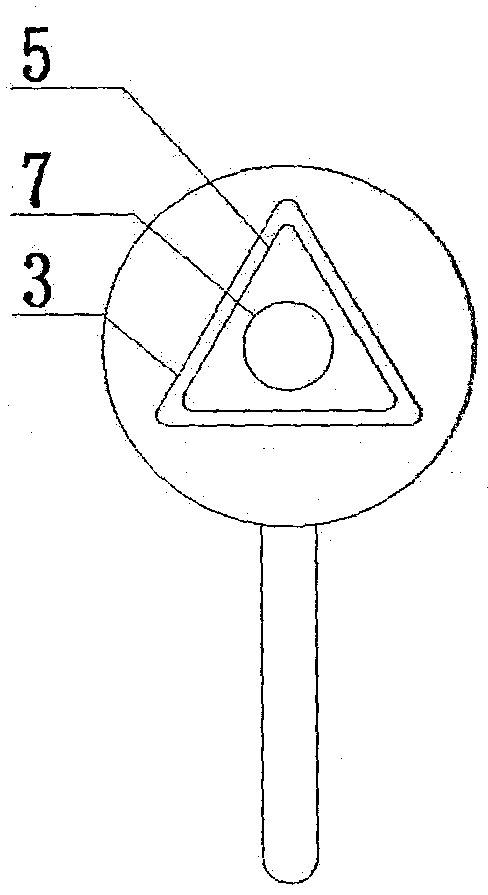

Pump type automatic chamber protection type swing-falling-easy safe thermometer convenient to disinfect

InactiveCN107212862APrevent slipping and breakingPrevent burstThermometer detailsThermometers using material expansion/contactionMedical institutionMechanical engineering

The invention discloses a pump type automatic chamber protection type swing-falling-easy safe thermometer convenient to disinfect. The pump type automatic chamber protection type swing-falling-easy safe thermometer convenient to disinfect comprises a mercury chamber and a capillary value display tube, and is characterized in that a safe chamber thicker than the capillary value display tube is communicated to the end, opposite to the mercury chamber, of the capillary value display tube; a telescopic extending type corrugated casing which is obviously longer than an inner cavity of the thermometer and is matched with the appearance of the thermometer is movably arranged on the outer wall of the thermometer in a sleeving mode. The thermometer can stretch into a cavity of the extending type corrugated casing from a wide opening in the upper portion of the extending type corrugated casing, and a wide opening cover can be clamped in the wide opening of the extending type corrugated casing. The body temperature can be detected as long as the extending type corrugated casing is pulled to the other end with the safety chamber to expose the mercury chamber. When the thermometer slides, the extending type corrugated casing can stretch instantly to cover the mercury chamber, and it can be avoided that the thermometer is damaged due to falling. The thermometer can slide out after the wide opening cover is removed, and a nurse can conveniently read the body temperature value and carry out concentrated disinfection and concentrated swing falling. The extending type corrugated casing can be a consumable item, and cross infection can be avoided. The pump type automatic chamber protection type swing-falling-easy safe thermometer convenient to disinfect is suitable for family standby and body temperature detection of medical institutions.

Owner:李思宇 +1

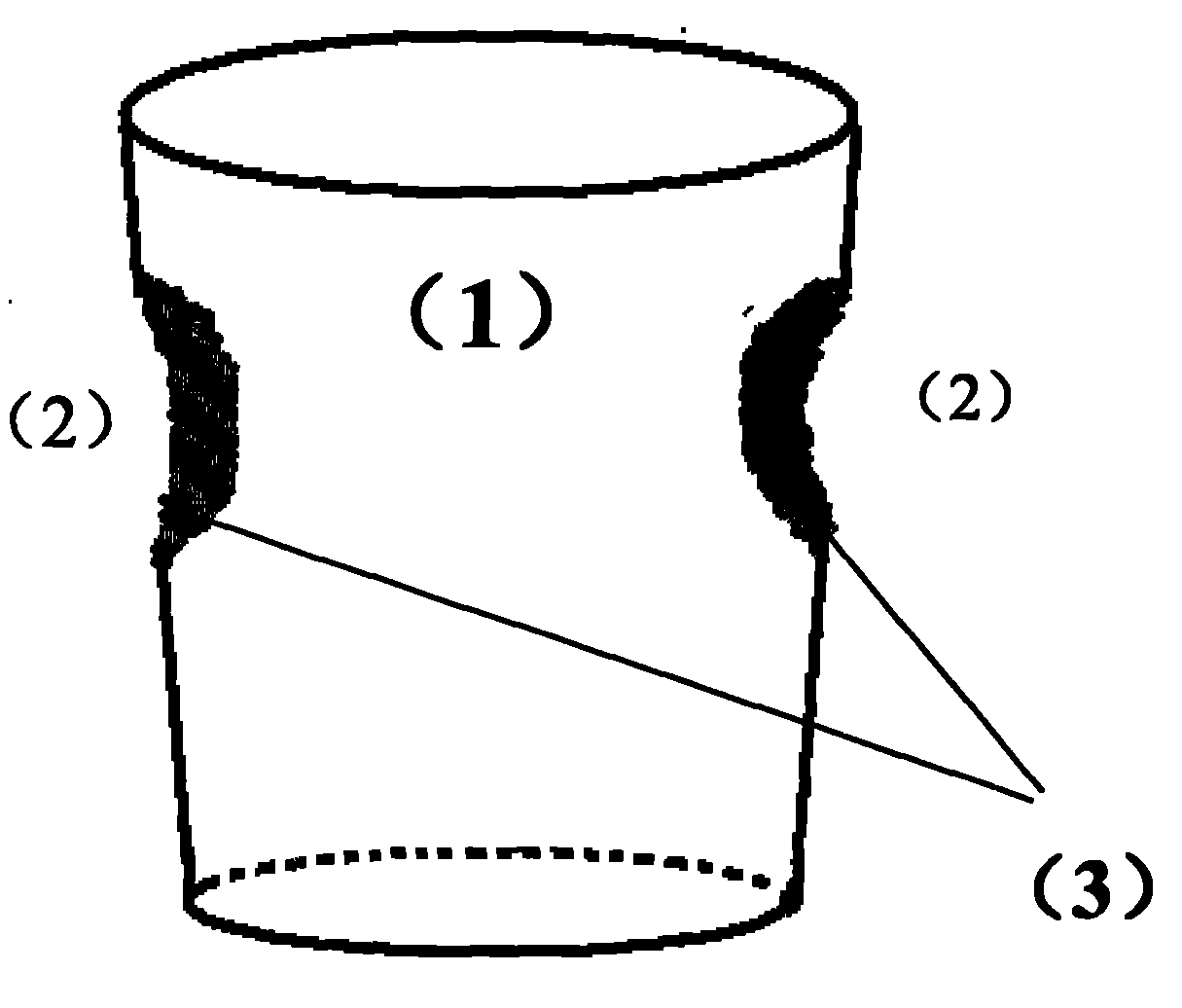

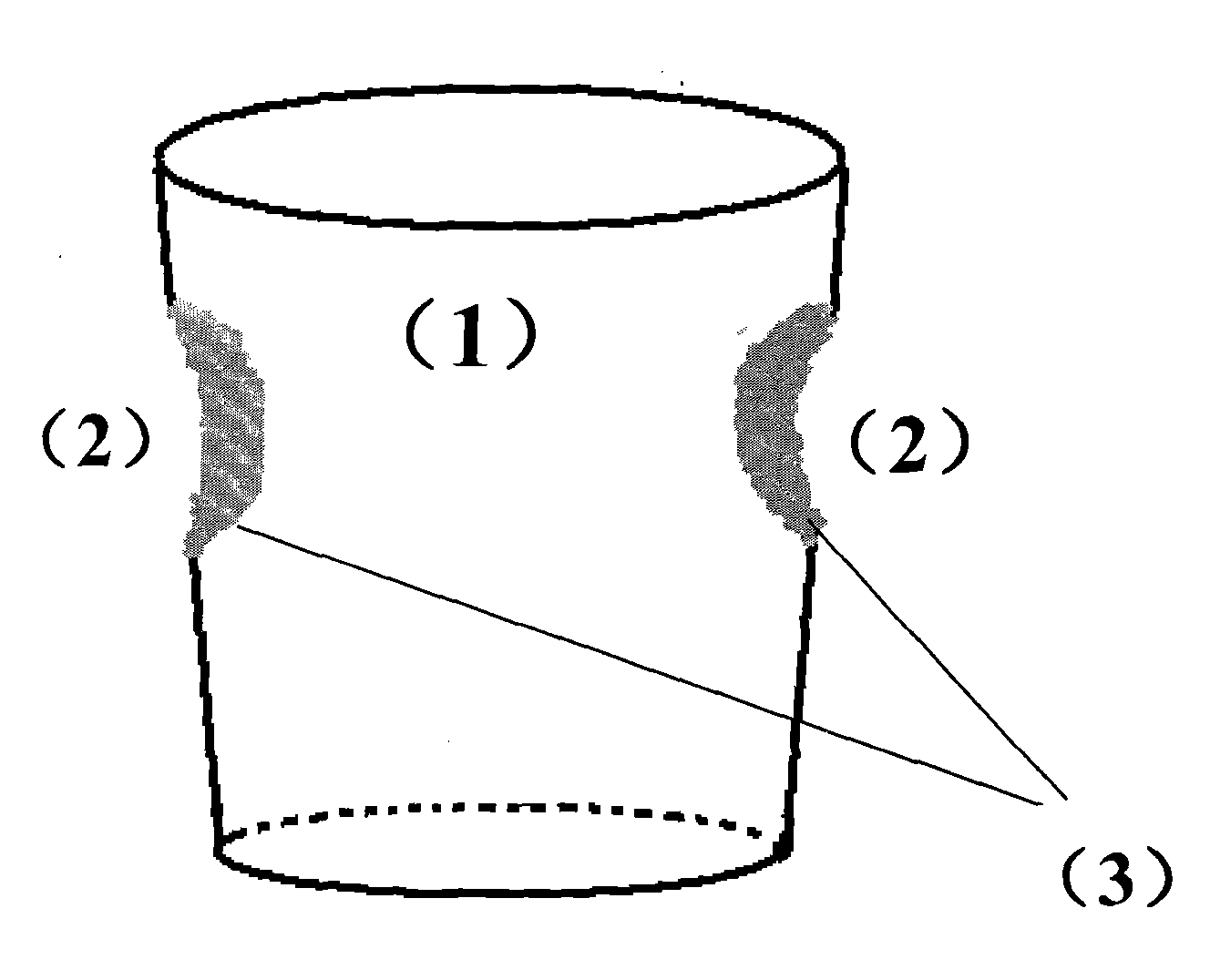

Skid-proof and burn-proof glass cup

InactiveCN102078117APrevent slipping and breakingPrevent scaldingDrinking vesselsBurned handsBurning hand

Owner:吕尚格

A-shaped storage bracket

InactiveCN105775386AAvoid wear and tearGuaranteed aestheticsExternal framesDamagable goods packagingEngineeringChassis

The invention provides an A-shaped storage bracket which can effectively fix glass to protect the glass against sliding and surface abrasion. The A-shaped storage bracket comprises an underframe and an A-shaped support fixed to the upper portion of the underframe. A pair of sleepers are arranged on the underframe and located on the two sides of the A-shaped support correspondingly. The A-shaped storage bracket is characterized in that a U-shaped groove is formed in the middle of the upper portion of each sleeper in the length direction; a plurality of L-shaped clamping plates are arranged in each U-shaped groove; supporting shafts penetrate through the junctions where upper clamping plates and lower clamping plates of the corresponding L-shaped clamping plates intersect and are supported on the two sidewalls of the U-shaped grooves; the parts, located between the junctions and the two sidewalls of the U-shaped grooves, of the supporting shafts are sleeved with torsional springs; two spring legs of each torsional spring are connected to the corresponding junctions and corresponding stand columns arranged on the sidewalls of the U-shaped grooves in an inwards protruding mode correspondingly; lateral pressing mechanisms are arranged on the underframe and located on the outer sides of the sleepers; each lateral pressing mechanism comprises a pressing shaft, a connecting rod, a rotary shaft and a gas spring; and the rotary shafts are supported on the underframe through shaft seats, the two ends of the pressing shafts are connected with the corresponding rotary shafts through the corresponding connecting rods, and the pressing shafts can turn over towards the inner sides of the sleepers.

Owner:WUXI CITY NEW DISTRICT WEICHUANGLI MOLD FACTORY

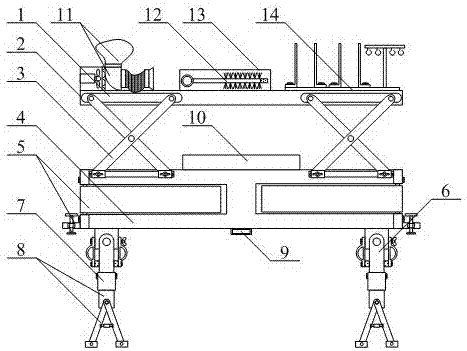

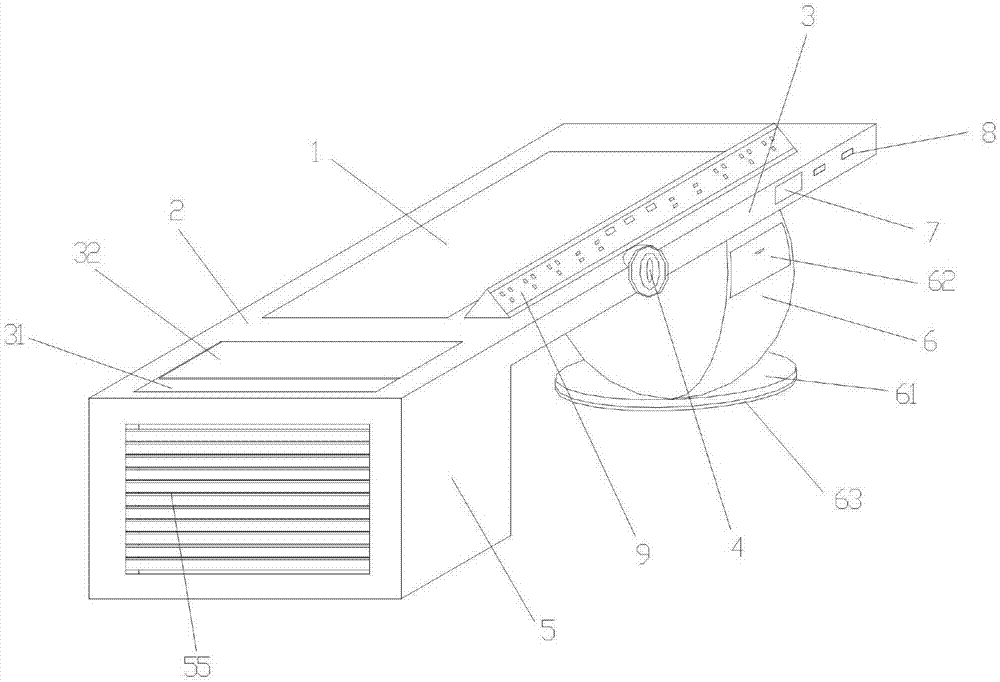

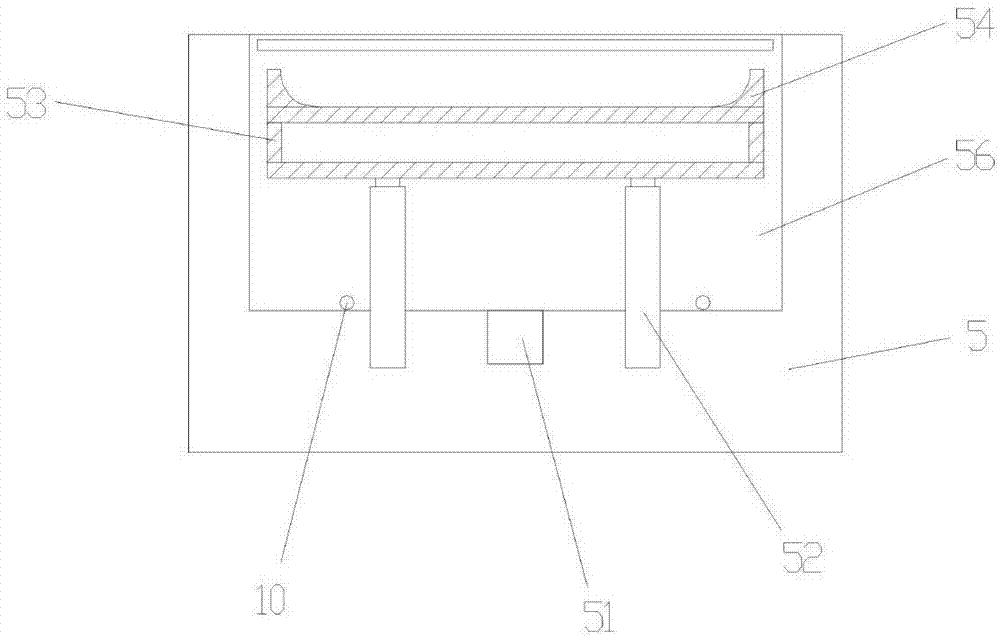

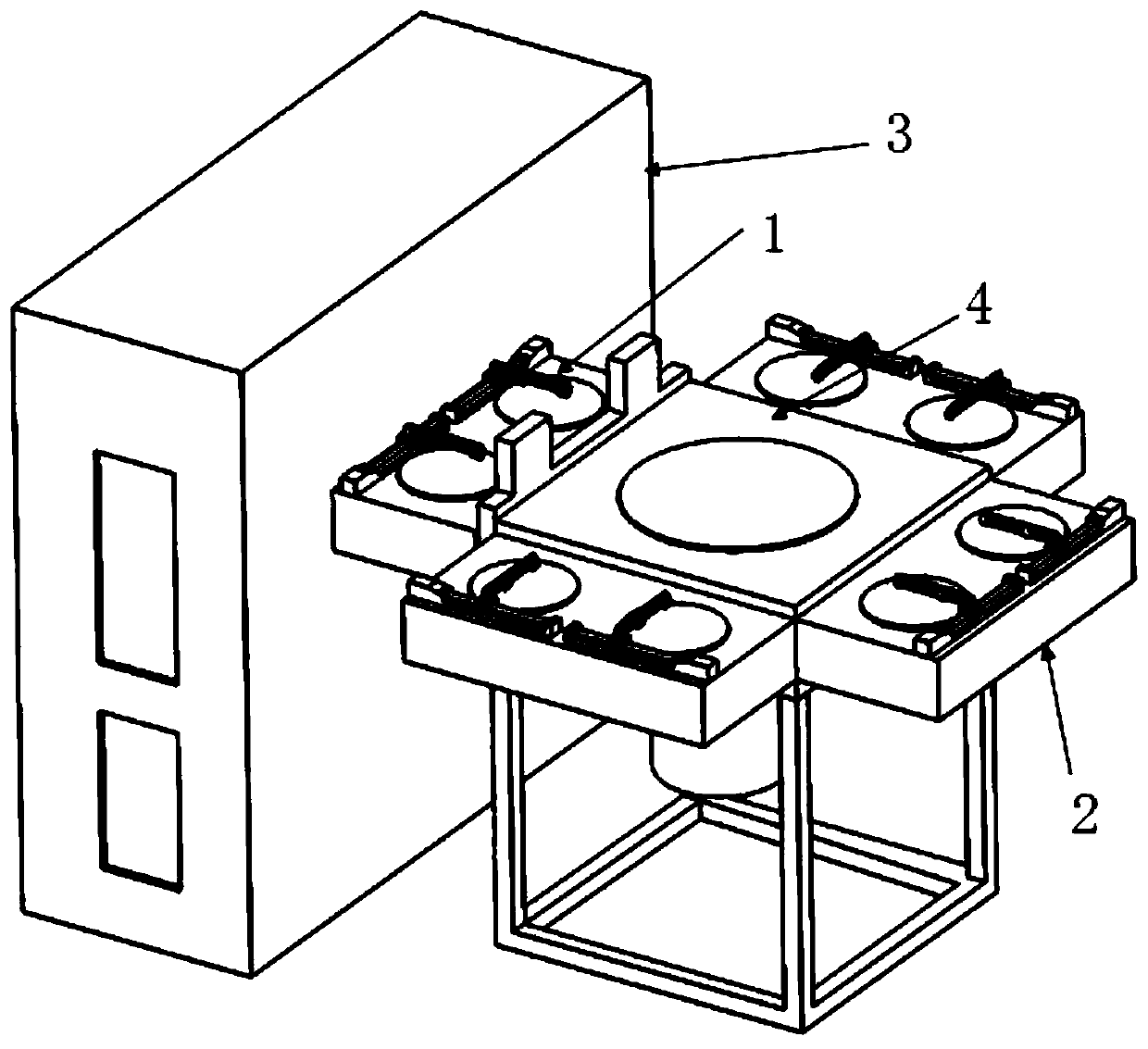

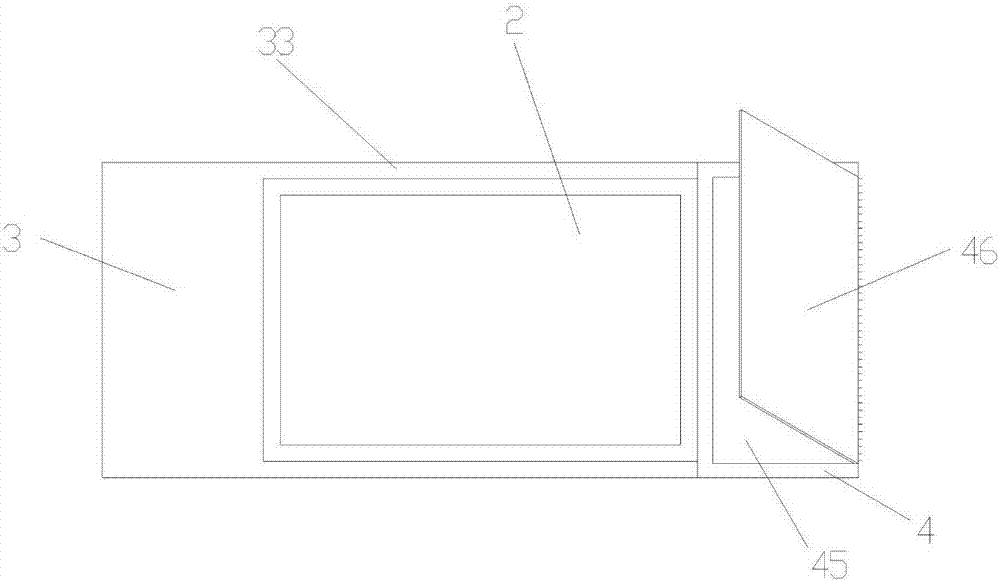

Multifunctional teaching robot matched practical training platform

The invention provides a multifunctional teaching robot matched practical training platform, and the platform comprises a chute, a display stand, a liftable adjustment rail device, an I-shaped platform, a variable angle plate device, a desk frame folding device, a rectangular connecting pipe, a height adjustment foot stool, a hanging buckle, a computer placing seat, a foreign matter absorbing dust-removing device, a desk cleaning device, a placement box, and a classification teaching board device. According to the invention, the setting of a rotating plate, a rotating shaft, a first-stage fixed block, a second-stage fixed block and a locking block facilitates the extending of the platform, so as to enable the application and operation to be more convenient. The setting of a locking screw, a locking nut, a jack disc and a rotating handle facilitates the supporting, tightening and locking of the rotating plate. The setting of a lifting plate, a movable shaft, a sliding block, a sliding rail and a fastening bolt facilitates the adjustment of the height of the display stand at any time according to the display and teaching demands, so as to enable the use to be more convenient.

Owner:陕西舜洋电子科技有限公司

New intelligent tea table

PendingCN107224115AFunction increasePrevent slipping and breakingOffice tablesServing tablesComputer engineering

The invention discloses a novel intelligent coffee table, which includes a touch screen, a tea set lifting structure, an air humidifying device, a power strip, an ARM processor, a coffee table table, a projector, a support body, a support column, a signal transceiver and a main circuit switch; The supporting body and the supporting column are respectively arranged on both sides of the bottom of the coffee table for supporting the coffee table; the supporting column is spherical, and a foot pad is provided below it; the supporting body is a cuboid structure, and the ARM processing The device, tea set lifting structure and air humidifying device are all set in the support body; a rectangular groove is arranged in the middle of the upper part of the coffee table, and a touch screen connected to the ARM processor is installed in the groove, and the touch screen is connected with the upper surface of the coffee table. flush, one side of the coffee table is provided with a signal transceiver and a main circuit switch which are both connected to the processor, and a projector is installed in the middle of one side of the coffee table. The tea table has complete functions, is convenient to use, has a high degree of intelligence, and has a beautiful and harmonious shape, which can greatly facilitate people's life.

Owner:成都方寸家居有限公司

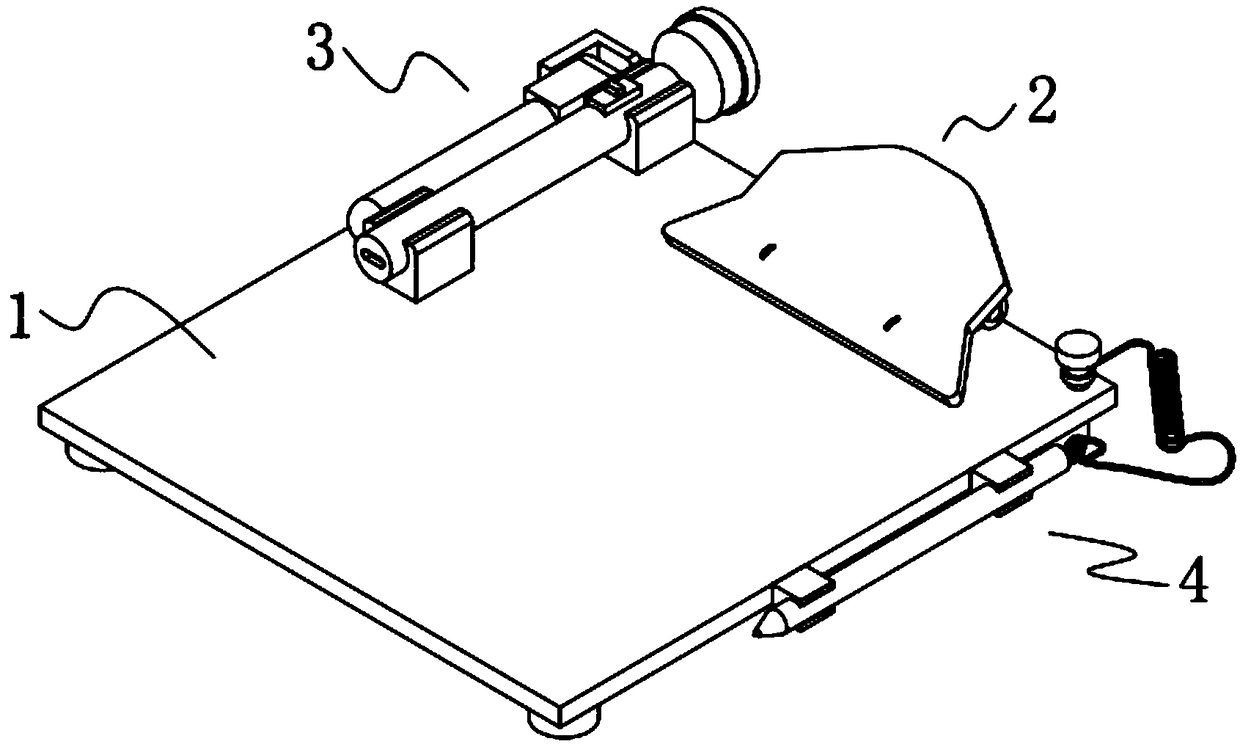

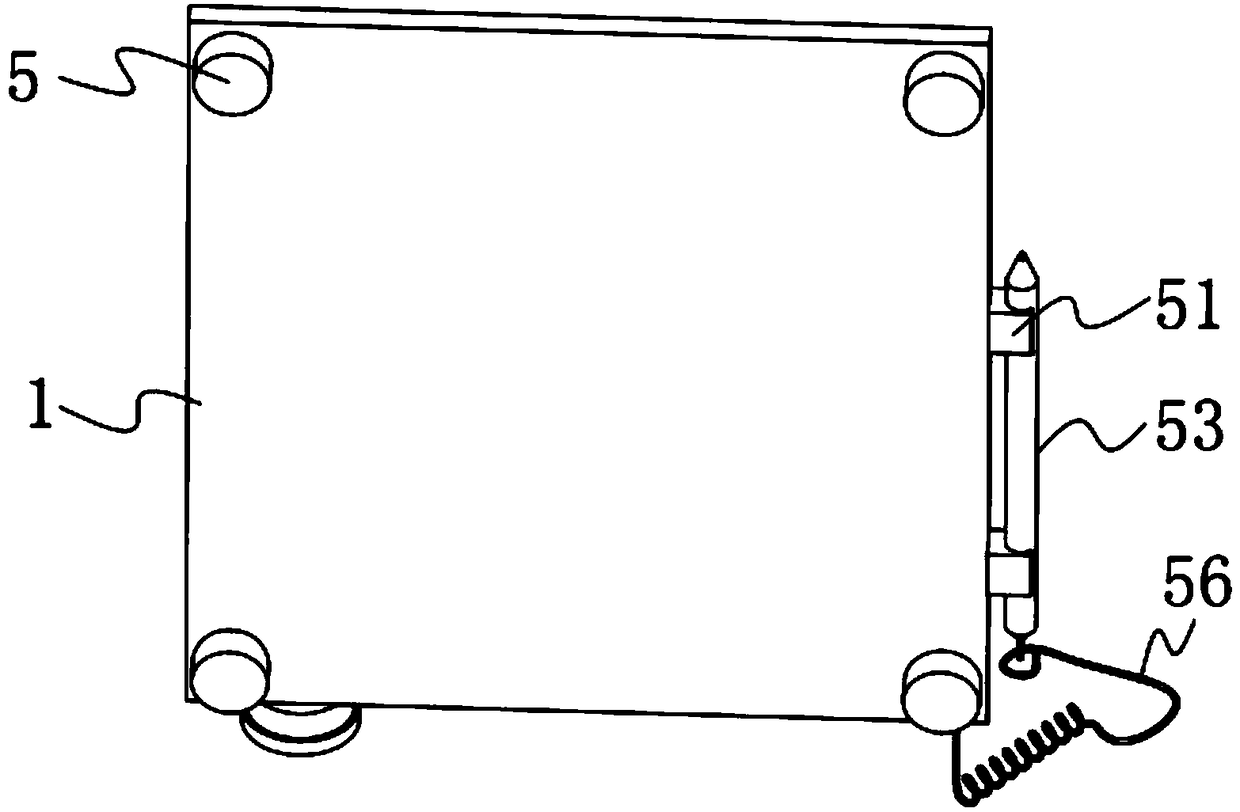

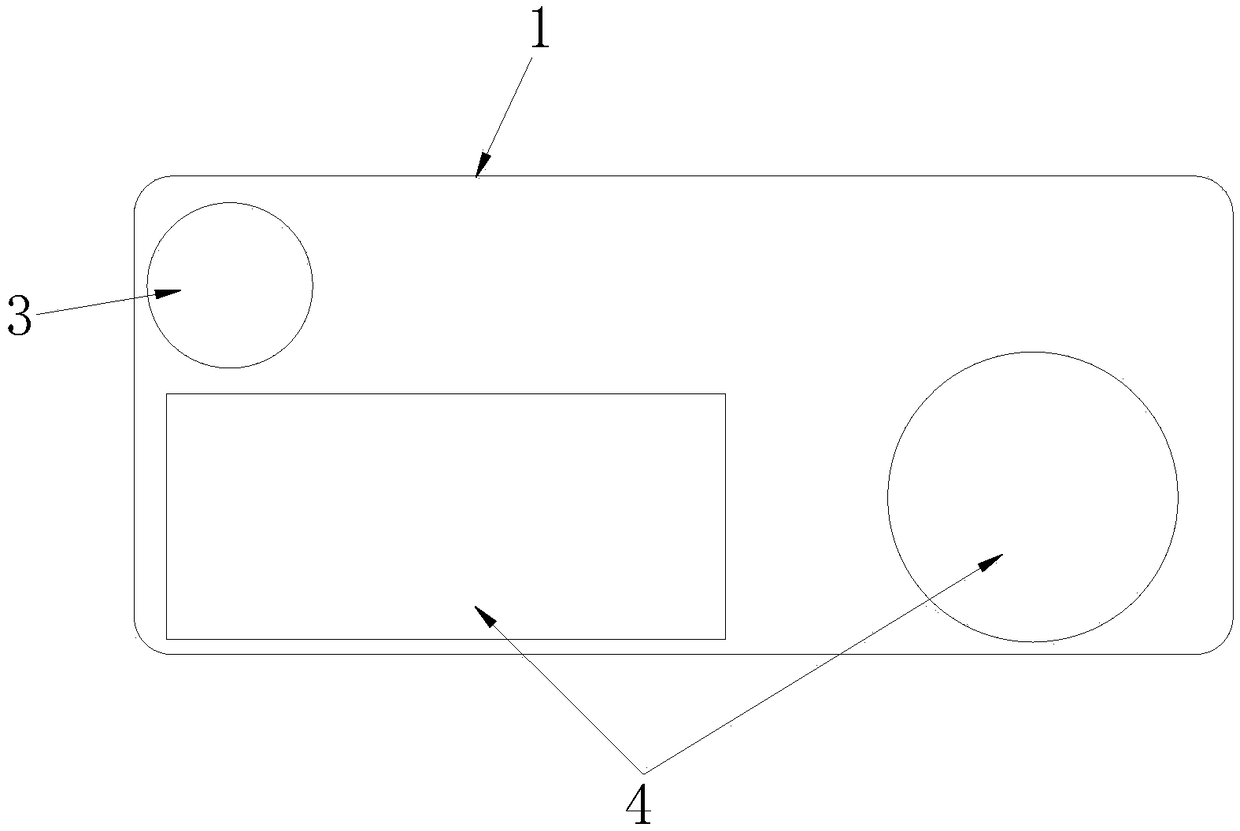

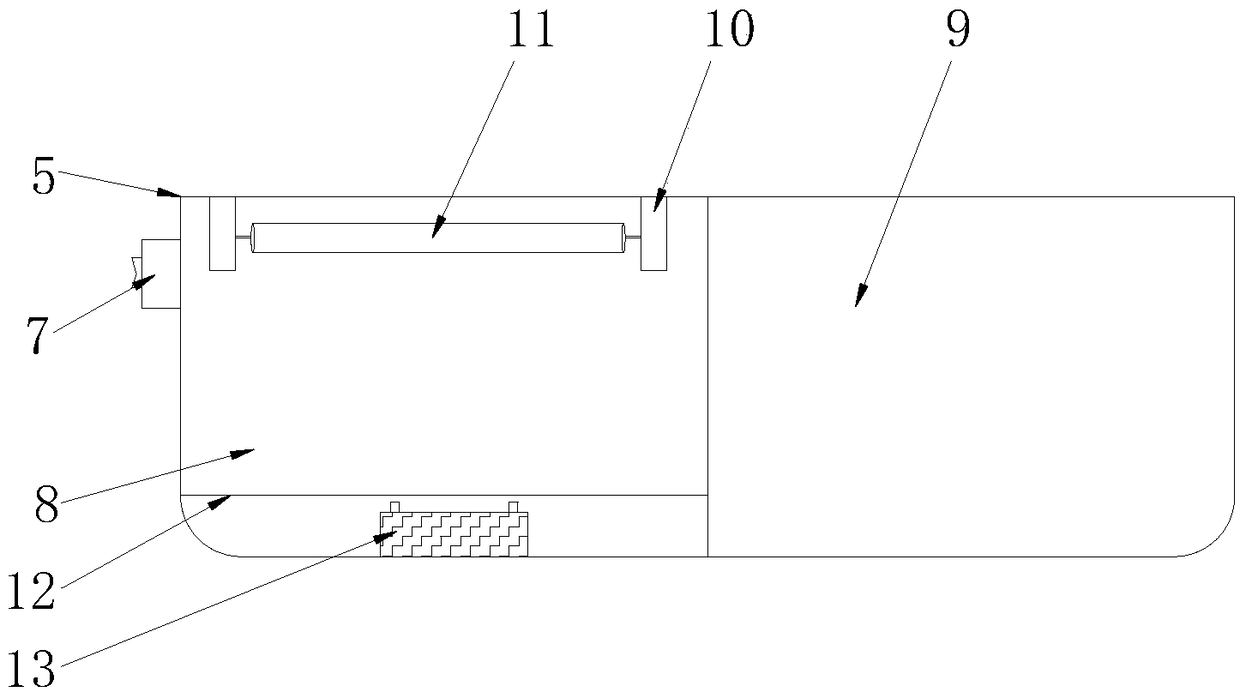

Energy-saving recording tool for night ward round of nurse

The invention discloses an energy-saving recording tool for the night ward round of a nurse. The energy-saving recording tool for the night ward round of the nurse comprises a base plate. The base plate is a square base plate. The upper portion of the base plate is provided with a clamping unit which is close to one edge of the base plate. A lighting unit is arranged on the upper portion of the base plate and is close to one corner of the base plate. The energy-saving recording tool for the night ward round of the nurse can effectively prevent a recording book or a recording table from falling, the nurse can conveniently use the energy-saving recording tool, and it is avoided that when a lighting lamp in a ward is switched on, rest of a patient is influenced; in addition, in the process ofeffectively reducing the switching-on frequency of the lighting lamp in the ward, the electricity saving effect is achieved, and the energy-saving recording tool is convenient to use and good in practicability; a sign pen can be effectively prevented from being lost, a manufactured protective layer can effectively improve the corrosion resistance, wear resistance, skid resistance and aging resistance of the base plate, and therefore the energy-saving recording tool is long in service life; and importantly, the recording book or recording table placed on the base plate can be prevented from sliding off, and meanwhile the energy-saving recording tool can be effectively prevented from sliding off from the hand of the nurse and being broken.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

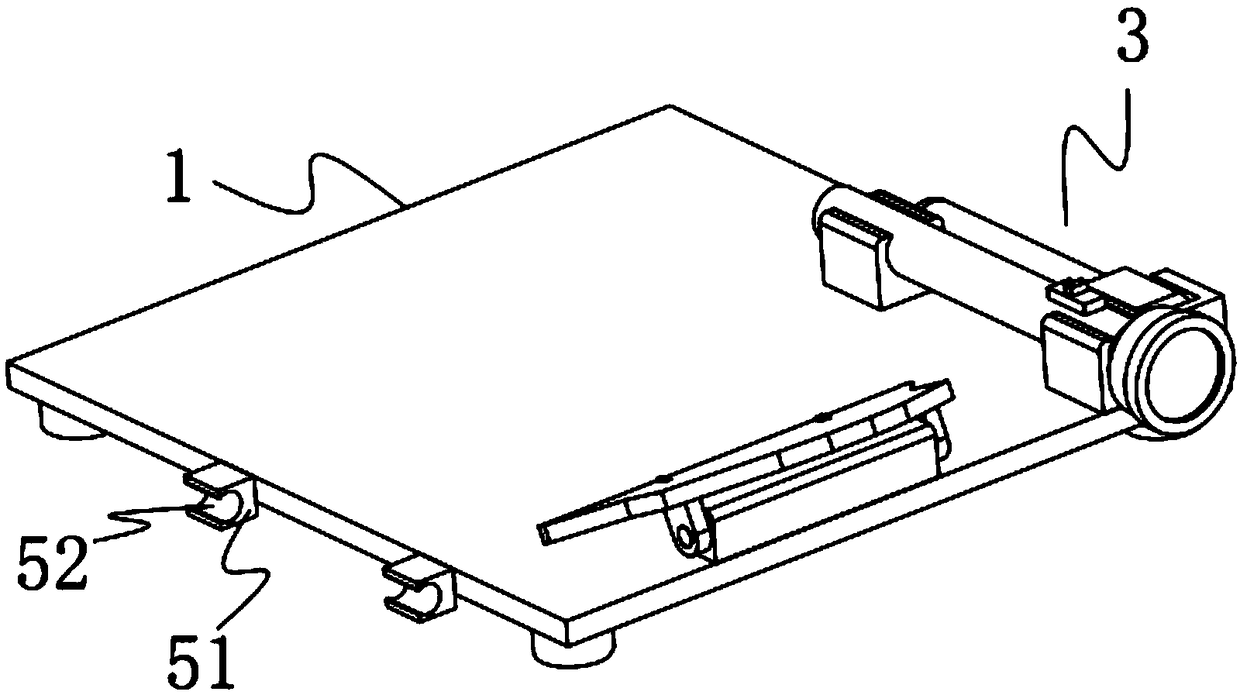

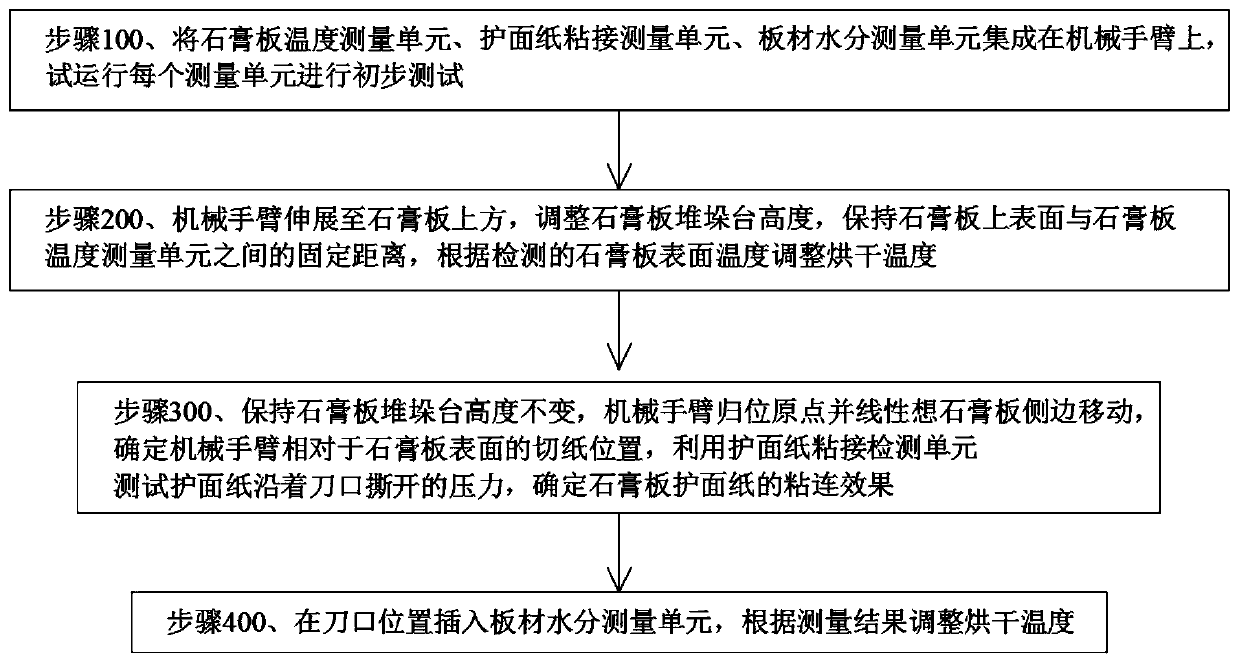

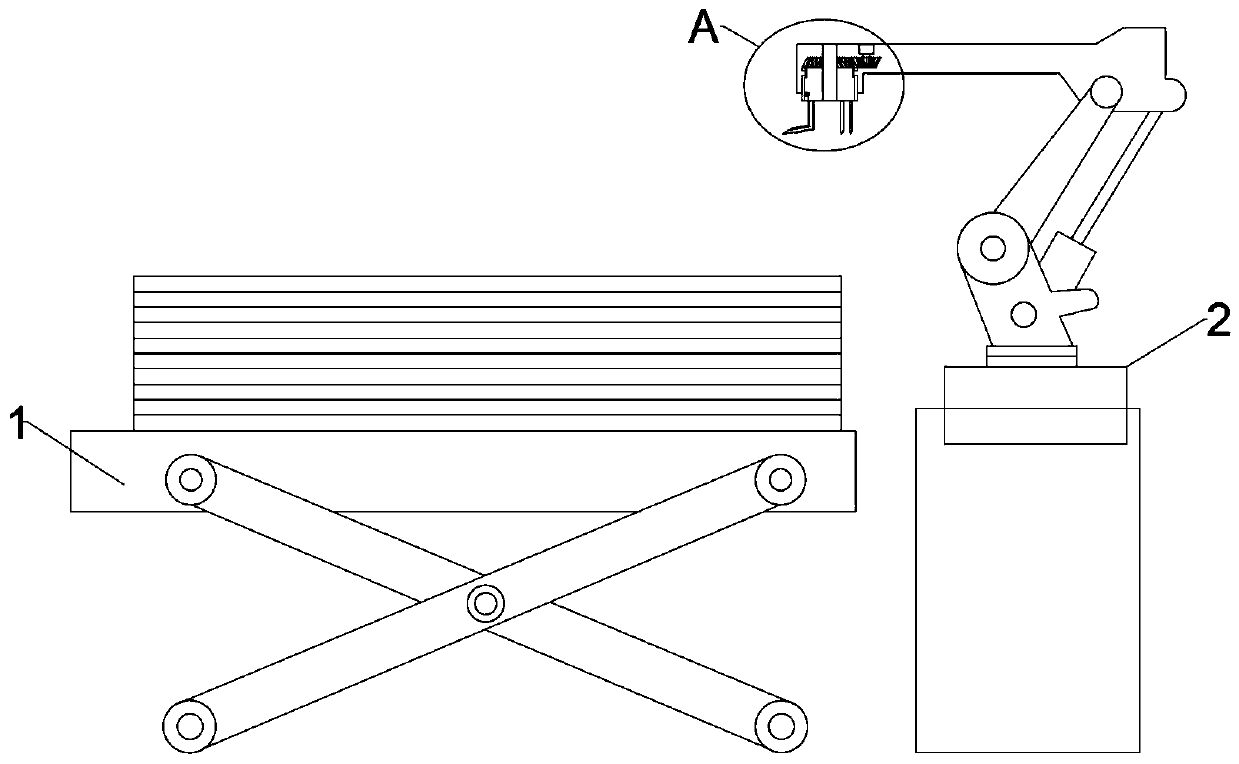

Method and device for intelligently detecting panel

ActiveCN110887785AEfficient and fast detectionLabor savingRadiation pyrometryUsing mechanical meansRobotic armStructural engineering

The embodiment of the invention discloses a method and device for intelligently detecting a panel. The method comprises the following steps: enabling a gypsum board temperature measurement unit, a surface protection paper bonding measurement unit and a panel moisture measurement unit to be integrated on a mechanical arm, and carrying out the trial operation of each measurement unit for preliminarytesting; extending the mechanical arm to be above a gypsum board, adjusting the height of a gypsum board stacking table, and adjusting a drying temperature according to the detected gypsum board surface temperature; keeping the height of the gypsum board stacking table to be unchanged, returning the mechanical arm to the original point and linearly moving the side edge of the gypsum board, determining a paper cutting position of the mechanical arm relative to the surface of the gypsum board, and testing the tearing pressure of the surface protection paper along the knife edge through the surface protection paper bonding measurement unit; and inserting the panel moisture measurement unit into the knife edge position and adjusting the drying temperature. According to the invention, the temperature measurement of the dried gypsum board, the adhesion degree of gypsum board surface protection paper and the humidity parameter of the gypsum board can be detected intelligently and automatically; the detection process is rapid and efficient; and the time and labor are saved and the manual labor is saved.

Owner:湖北北新建材有限公司 +1

Pillow structure of A-shaped glass bracket

InactiveCN105775440AEasy to insertEffectively fixedExternal framesContainers to prevent mechanical damageEngineering

Owner:WUXI CITY NEW DISTRICT WEICHUANGLI MOLD FACTORY

Liftable ceramic flower pot

InactiveCN108781873ALow costPrevent slipping and breakingFlower holdersReceptacle cultivationDrive motorEngineering

The invention discloses a liftable ceramic flower pot. The pot comprises universal self-locking wheels, a first bottom plate and first top plates, one side of the bottom of the first bottom plate is symmetrically fixedly provided with four universal self-locking wheels, standing columns are fixedly disposed at the tops of the two ends of the first bottom plate, the first top plates are fixedly connected to the tops of the standing columns, second bottom plates are disposed on the sides of the standing columns, support columns are fixedly disposed at the top ends of the two ends of the second bottom plates, second top plates are fixedly connected to the tops of the support columns, the first bottom plate is of a hollow structure, a driving motor is disposed in the first bottom plate, the driving motor is rotatably connected with a screw rod through a self-contained motor shaft, the top of the screw rod is fixedly provided with a connecting rod, the connecting rod is rotatably connectedto the middles of the first top plates, the screw rod is rotatably connected with a nut, a motor controller and the driving motor are arranged to drive the screw rod and the nut to rotate, and a useradjusts the height of the flower pot according to the needed height, which is convenient and quick.

Owner:JIANGSU TIANBAO CERAMICS CO LTD

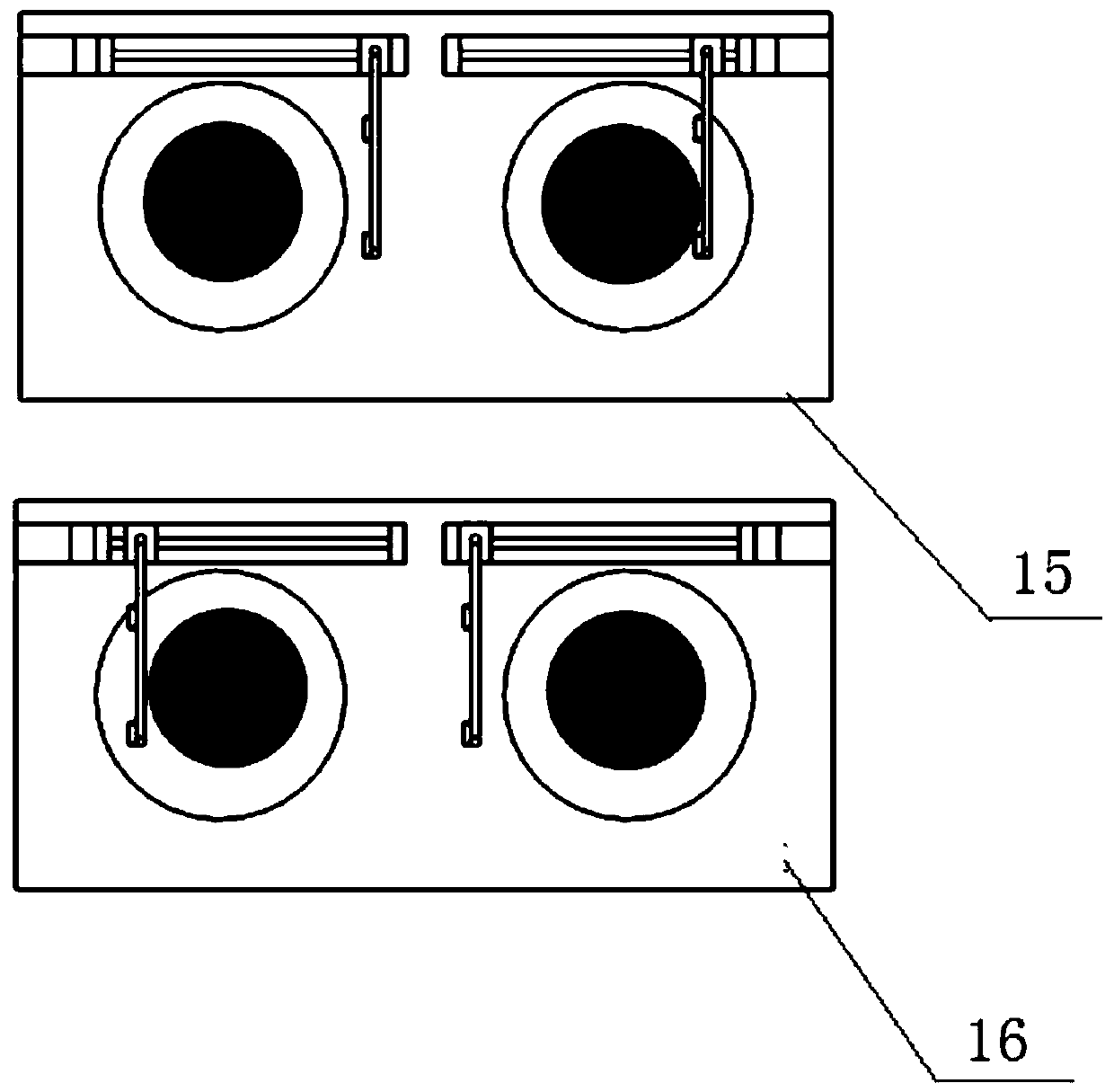

Wafer transfer and measurement system

ActiveCN109904101AGuaranteed treatment effectAvoid processing failuresSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringTransmission equipment

The invention relates to the technical field of transmission equipment, and relates to a wafer transfer device and a measurement method. The wafer transfer device comprises an atmospheric transmissiondevice, a wafer loading chamber, a vacuum transmission device and a wafer processing chamber, wherein each of the wafer loading chamber and the wafer processing chamber comprise a chamber main body,a transparent window, a transmission device and a wafer position detection device; and the system is used for detecting the wafers when the wafers are placed in the wafer loading chamber and the waferprocessing chamber. According to the system, the wafers are placed in the loading chamber and the processing chamber for detection, so that the detection result is more real and accurate, and the deviation caused by relative sliding of the wafer and a support in the placing process is avoided.

Owner:PIOTECH CO LTD

Intelligent household dust removal type router

PendingCN112808642ARealize dust scraping movementMovement while pumpingCleaning using toolsCleaning using gasesDust controlStructural engineering

The invention discloses an intelligent household dust removal type router. The intelligent household dust removal type router comprises a shell, wherein a groove is formed in the upper side wall of the shell, sliding grooves are formed in the inner walls of the two sides of the groove, a scraper blade is arranged between the two sliding grooves in a sliding mode, a collecting box is inserted into the shell in a sliding mode, an end of the collecting box is connected with a suction pipe, an end of the suction pipe is fixedly connected with a connecting rod, a cavity is formed in an end of the connecting rod, a piston is arranged in the cavity in a sliding mode, and a pull rod is fixedly connected to the middle of the piston. According to the intelligent household dust removal type router, swinging of the shell is realized when the temperature of the shell is too high, the scraper blade slides to remove accumulated dust on the upper side wall of the shell, meanwhile, the piston moves downwards to achieve suction type movement in the suction pipe, the scraped accumulated dust is sucked into the collecting box to be collected, so that the heat dissipation capability of the router is restored, and the stable and efficient work of the router is guaranteed.

Owner:艾安萍

Multifunctional tea table

PendingCN107149297AVersatileBeautiful and harmonious shapeServing tablesFeetAir purificationFish tank

The invention discloses a multifunctional tea table, which comprises a rectangular parallelepiped base, a left support seat and a right support seat arranged on both sides above the base, a fish tank arranged above the base and between the left support seat and the right support seat, and The coffee table table above the left support seat and the fish tank; the upper surface of the coffee table table is flush with the upper surface of the right support seat; the inside of the left support seat is provided with an air purification device, and the air outlet of the air purification device is in line with the fish tank Connected; the inside of the right support seat is provided with a tea set lifting structure. The tea table has complete functions, both ornamental and practical features, beautiful and harmonious shape, and can be widely popularized.

Owner:成都方寸家居有限公司

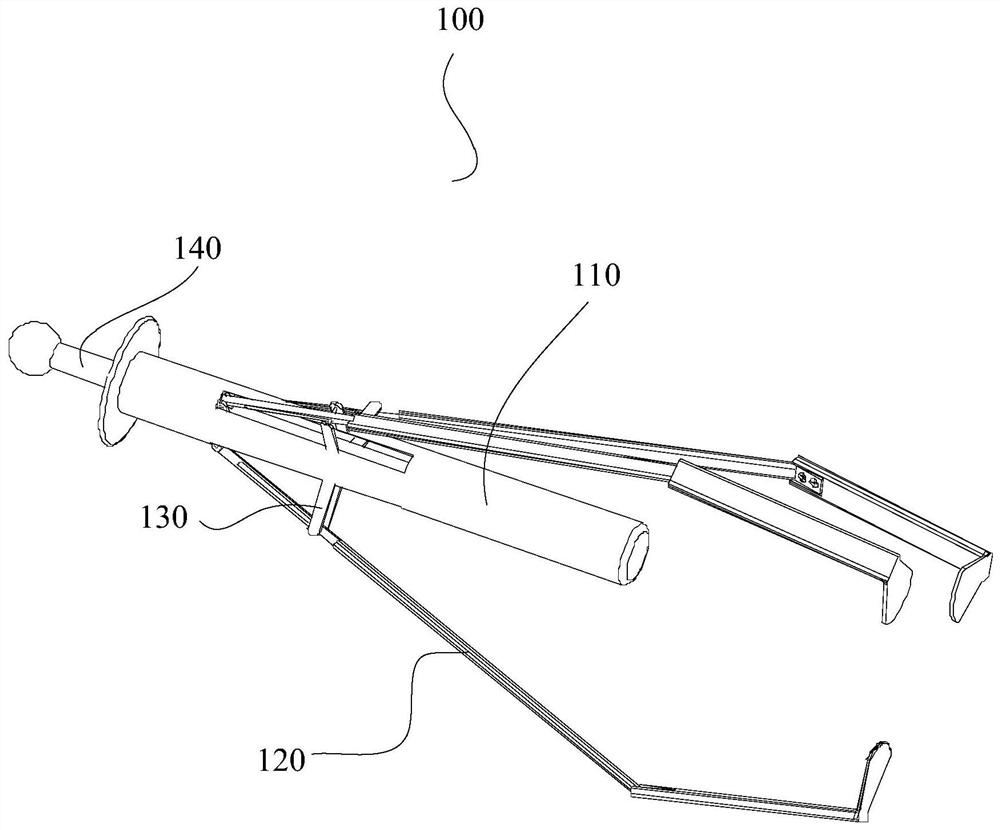

Toughened glass transportation device with anti-fragmentation structure

PendingCN113501041AReduce turbulenceAvoid damageSupporting partsHand carts with multiple axesGear wheelBar pressing

The invention relates to the technical field of tempered glass transportation, in particular to a tempered glass transportation device with an anti-fragmentation structure, which comprises a bottom plate, universal wheels are mounted on the periphery of the lower end of the bottom plate, a towing rod is mounted on the right side of the bottom plate, sleeve plates are fixedly mounted on the left and right groups of the bottom plate, and a gear is connected to one side, away from a pressing rod, of a second connecting plate. A clamping plate is connected to the side, away from the second connecting plate, of the gear, a sliding block is fixedly mounted on the side, away from the gear, of the clamping plate, a button is arranged at the top end of the clamping plate, and a cover plate is mounted at the top end of the mounting frame. According to the transportation device, first springs and a buffer plate are arranged, when a vehicle bumps, the first springs and the buffer plate generate elastic deformation, a certain buffer space can be provided between the bottom plate and the bearing plate through mutual cooperation of a connecting sleeve, a connecting rod and a bearing rod, and therefore the bump amplitude of the transport device is effectively reduced, and the toughened glass is buffered and protected.

Owner:吴艳霞

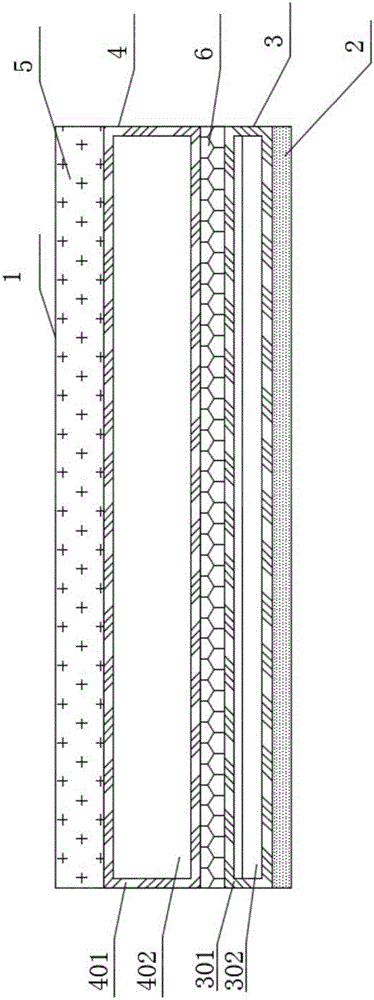

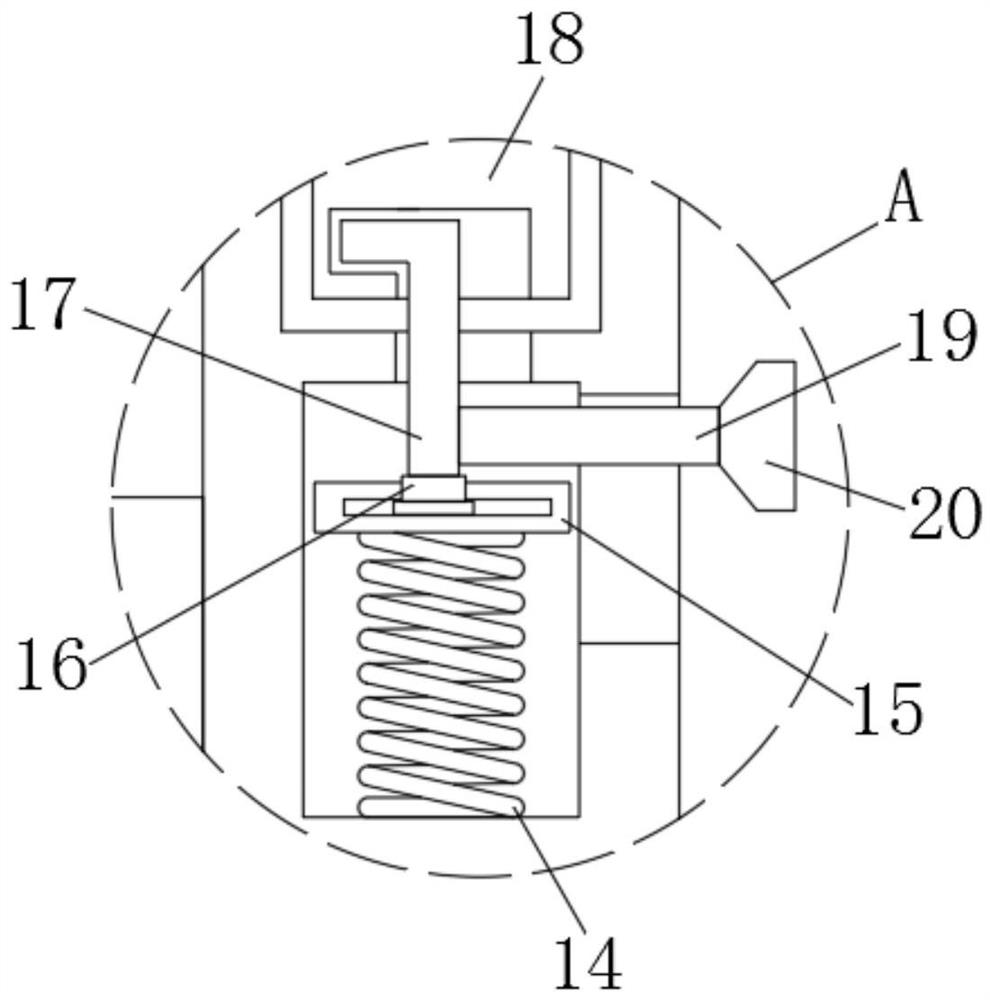

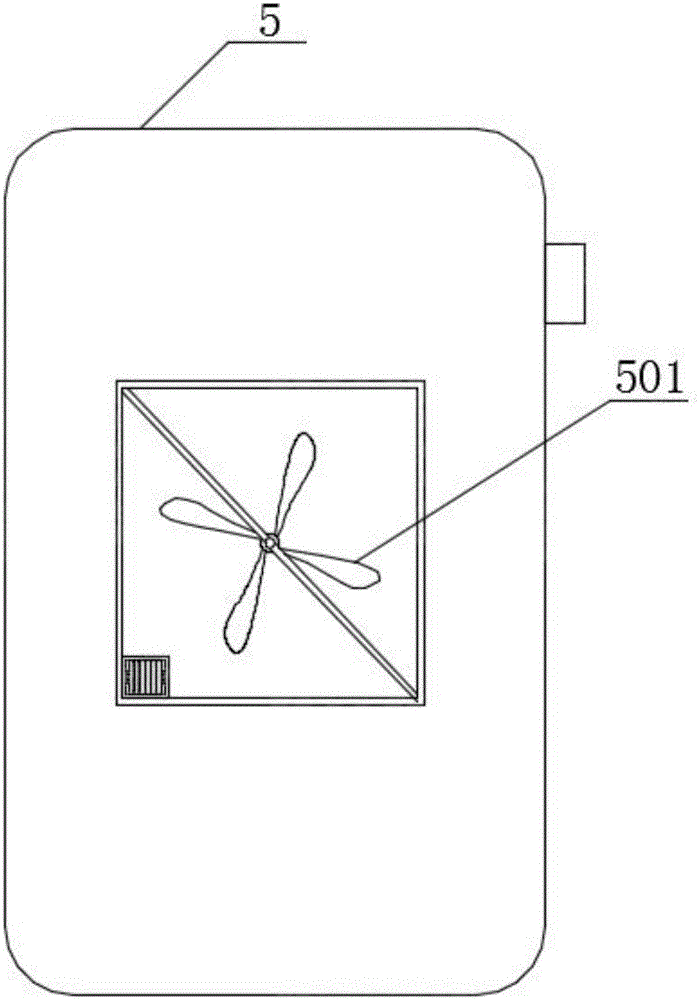

Mobile phone shell possessing high temperature alarm and cooling functions

InactiveCN106506747AImprove thermal conductivityPrevent slipping and breakingAlarmsTelephone set constructionsElectricityImpeller

The invention relates to a mobile phone shell and especially relates to a mobile phone shell possessing high temperature alarm and cooling functions. The mobile phone shell comprises a shell and an alarm lamp installed on a side edge of the shell. The shell comprises a first anti-oxidation layer, a silver heat conduction layer, a second anti-oxidation layer and a protective layer which are successively overlaid and arranged from inside to outside. The silver heat conduction layer is provided with a temperature-sensitive sensor. The temperature-sensitive sensor is electrically connected to the alarm lamp. The shell is provided with a cooling fan. A rotary impeller of the cooling fan is arranged towards a shell surface. The temperature-sensitive sensor is used to sense heat of a back portion of a mobile phone and carries out alarm. The cooling fan is used to accelerate emission of the heat of the mobile phone so as to solve a problem that heat dissipation of an existing mobile phone is slow.

Owner:怀宁佳瑞包装有限公司

Wine box easy to output wine for medicinal wine production

InactiveCN106167129AHigh reuse rateEasy to drinkDischarging meansDamagable goods packagingWine bottleAgricultural engineering

A wine box for the production of medicated wine, which is convenient for wine delivery, comprising a box body, a base is installed at the bottom end of the box body, a wine bottle placement area is installed at the middle end of the box body, and a wine output device is installed at the upper end of the box body; The front of the base is equipped with the first drawing plate, the second drawing plate and the third drawing plate in sequence from left to right; the left side of the wine bottle placement area is equipped with the first placement area, and the wine bottle placement area The end device is the second placement area, the right side of the wine bottle placement area is the third placement area; the left side of the wine dispensing device is the first wine dispensing device, and the middle end of the wine dispensing device is the second wine dispensing device device, the third wine outlet is installed on the right side of the wine outlet device; the top of the first placement area, the second placement area, and the third placement area are respectively connected to the first wine outlet, the second wine outlet, The third wine dispenser. The wine box for the production of medicated wine of the present invention has the advantages of wide application range, simple operation, convenient use, compact and reasonable structure, high reuse rate, rich functions and strong practicability.

Owner:HARBIN SHANBAO LIQUOR IND

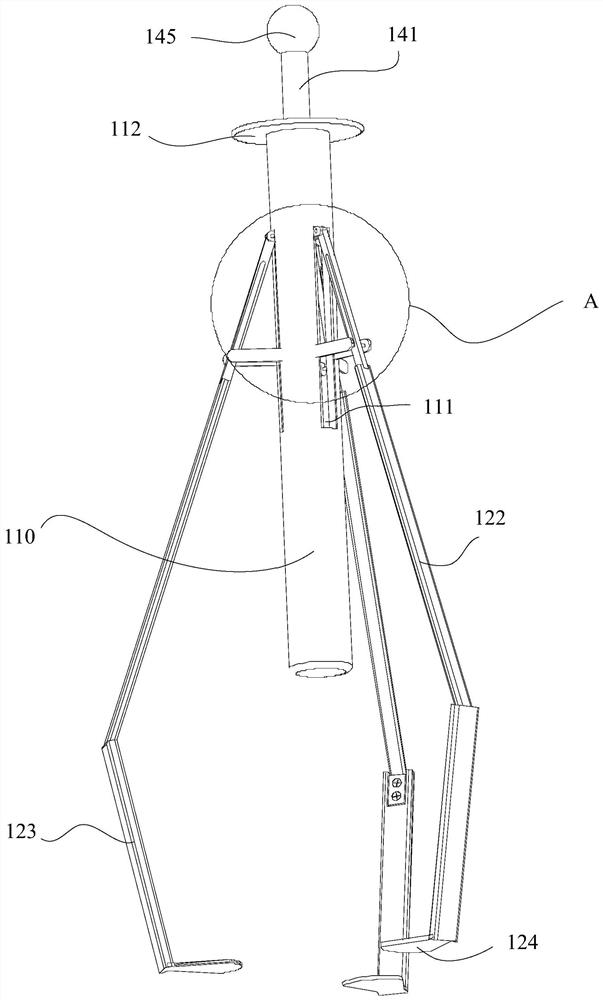

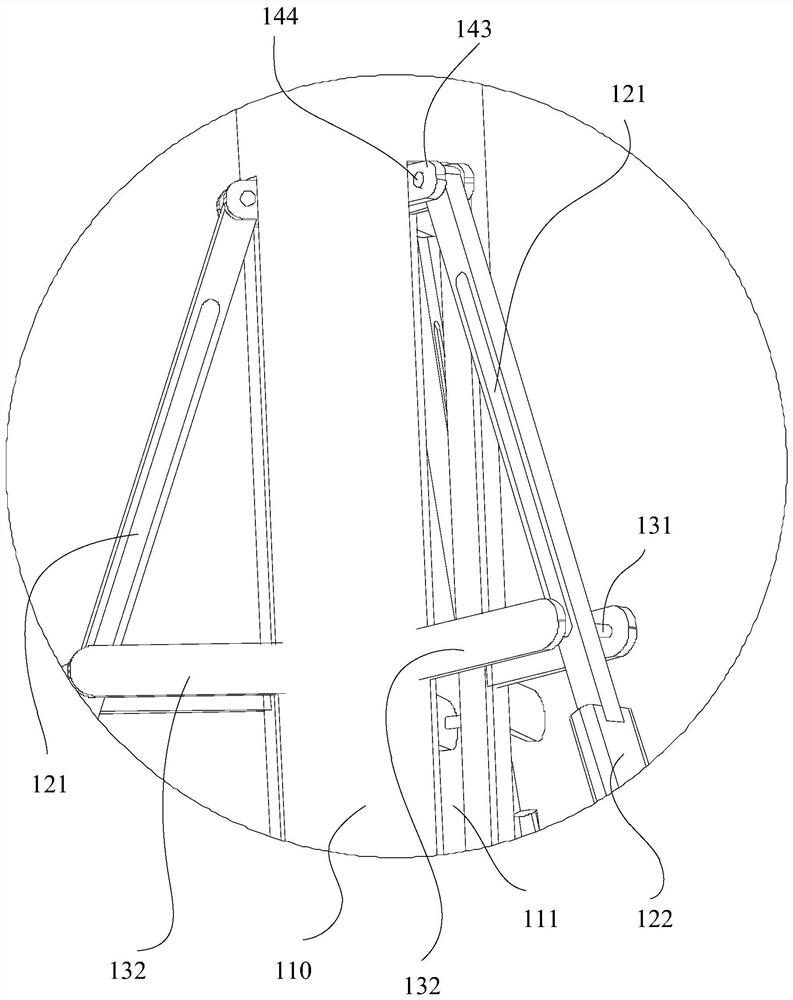

Wafer clamping fixture

PendingCN113808992AImprove processing efficiencyAddress non-standardizationSemiconductor/solid-state device manufacturingWaferEngineering

The invention relates to the technical field of mechanical jigs, and discloses a wafer clamping fixture which comprises a barrel, at least three clamping jaws, at least three supporting assemblies and a driving assembly. A sliding groove is formed in each clamping jaw; each supporting assembly is fixedly connected with the barrel, the supporting assembly and the clamping jaw are arranged correspondingly, the supporting assembly comprises a supporting shaft, and part of the supporting shaft is arranged in the sliding groove; and one end of the clamping jaw is rotationally connected with the driving assembly. According to the technical scheme, the barrel, the at least three clamping jaws, the at least three supporting assemblies and the driving assembly are adopted, so that the function of rapidly transferring wafers is achieved; the problems of nonstandardization and safety in wafer transfer after de-bonding are solved; and the safety of operators is protected, the wafers are prevented from slipping off and being broken, the working efficiency of wafer production is improved, and wafer pollution caused by operation is reduced.

Owner:威科赛乐微电子股份有限公司

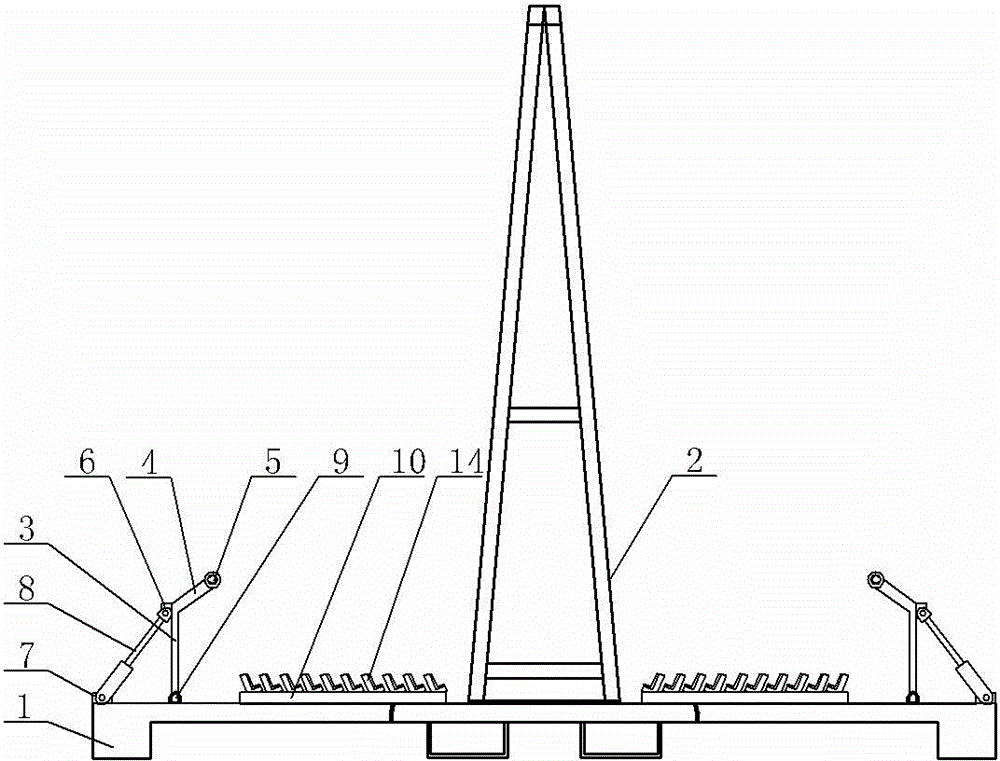

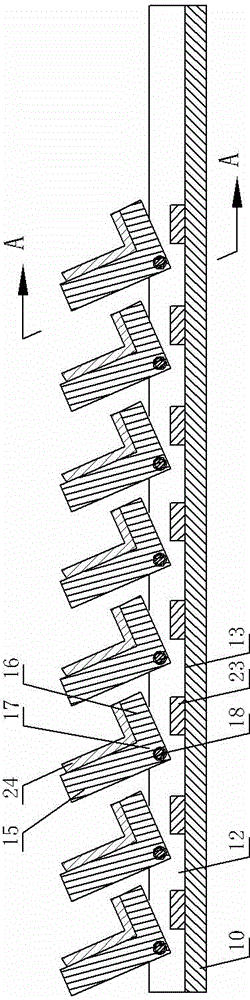

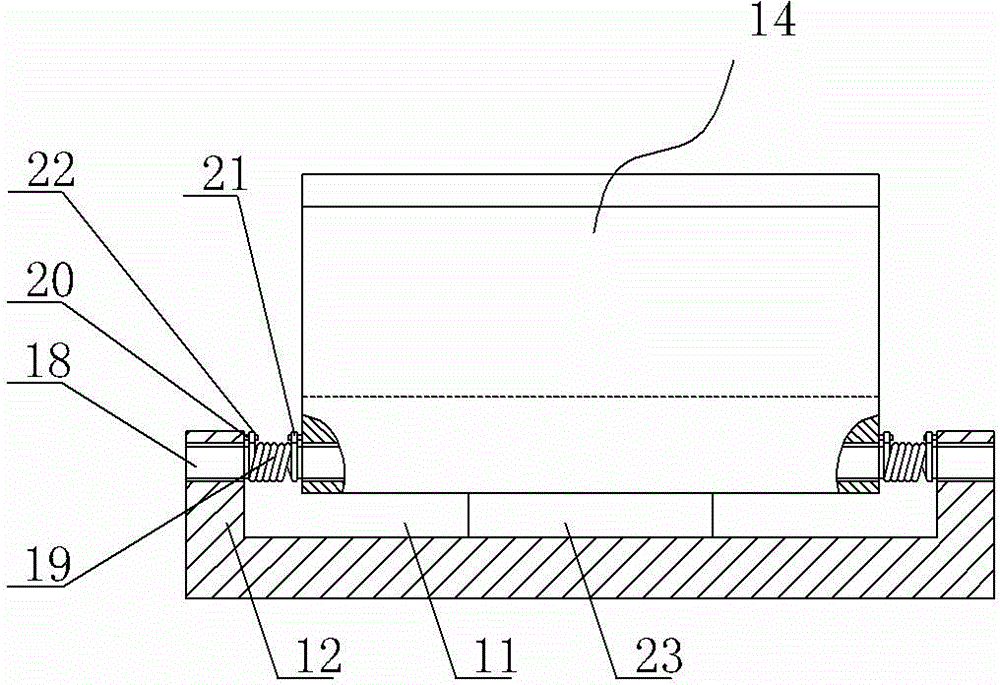

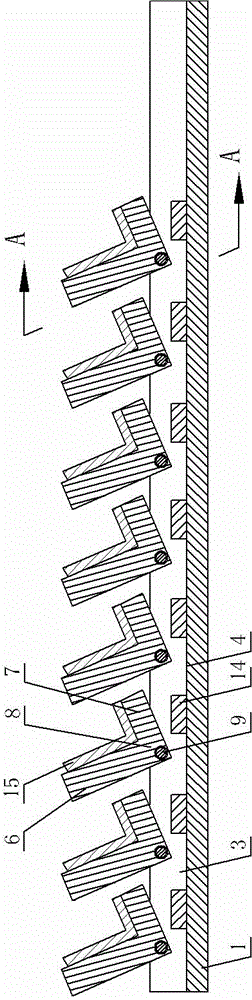

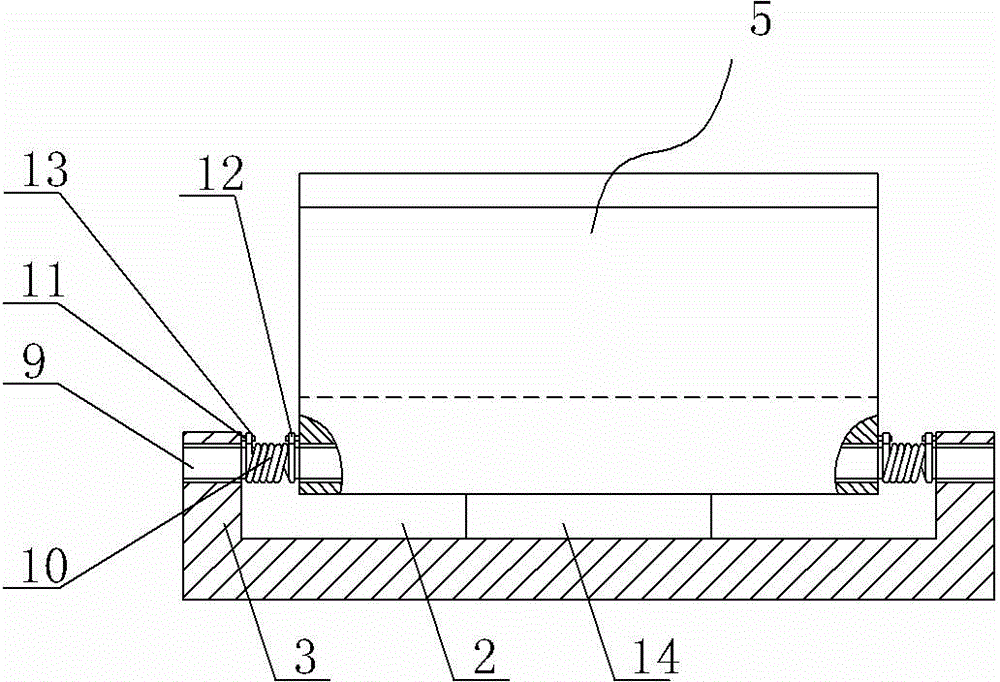

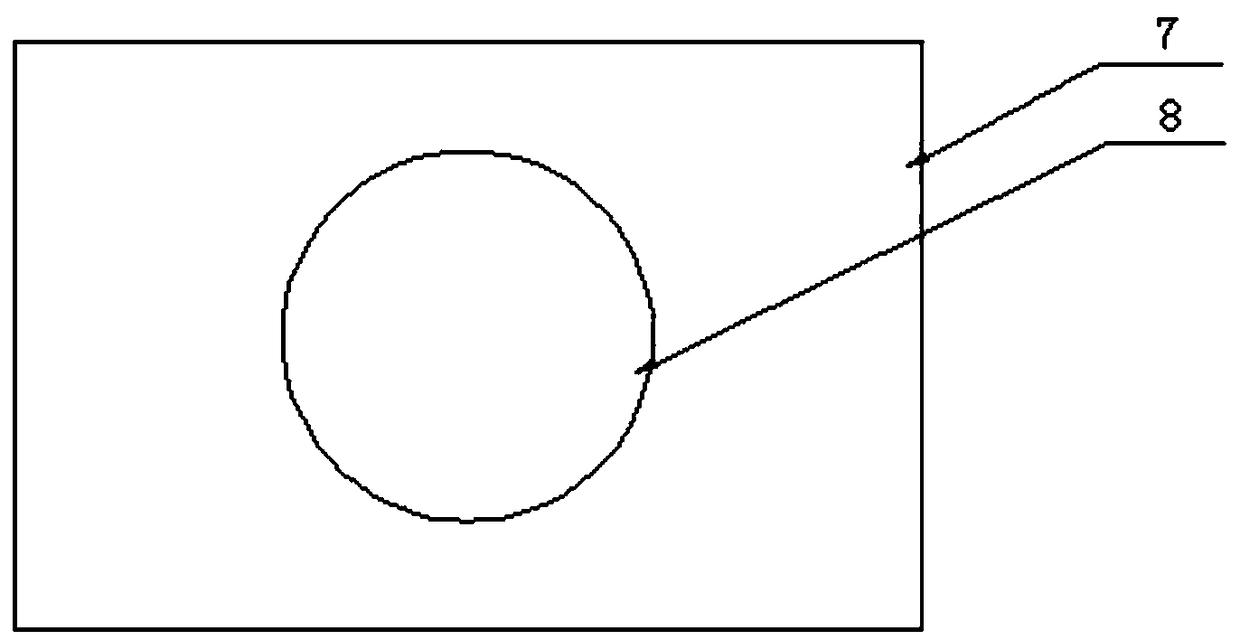

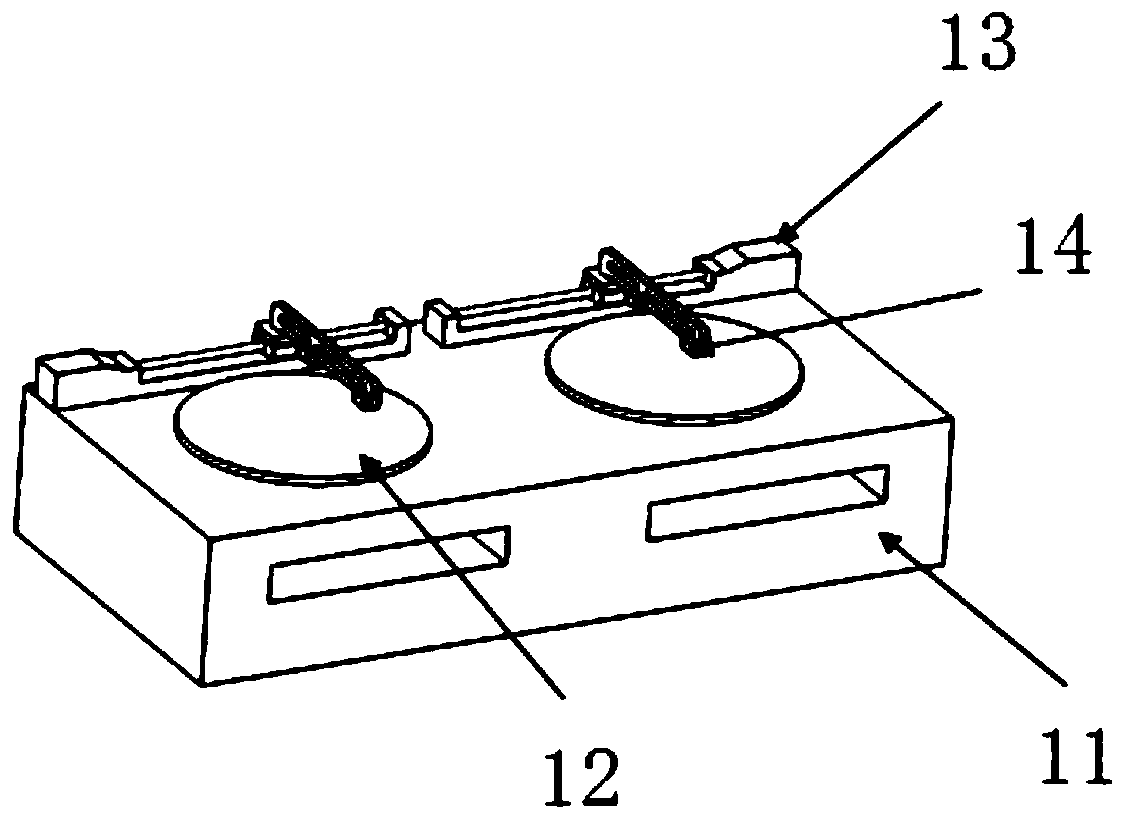

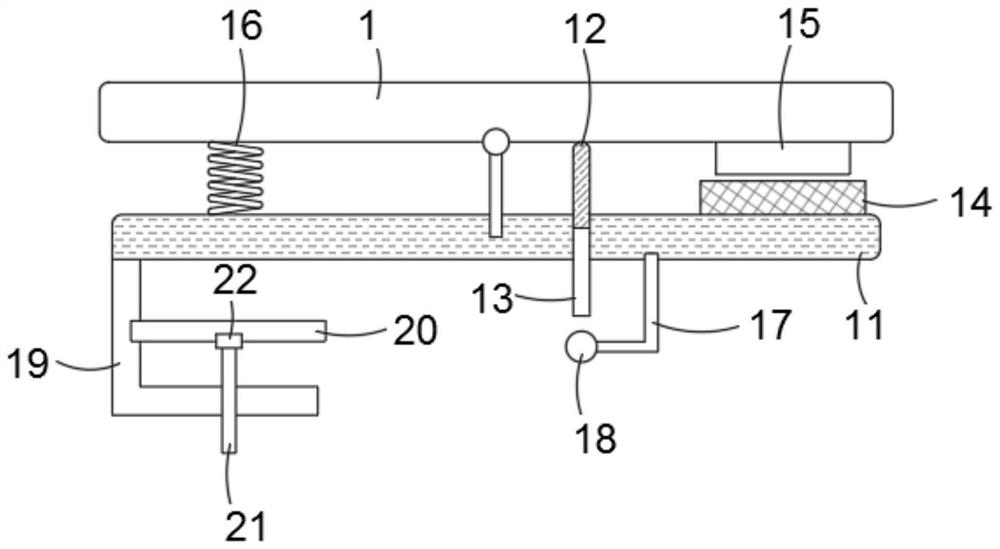

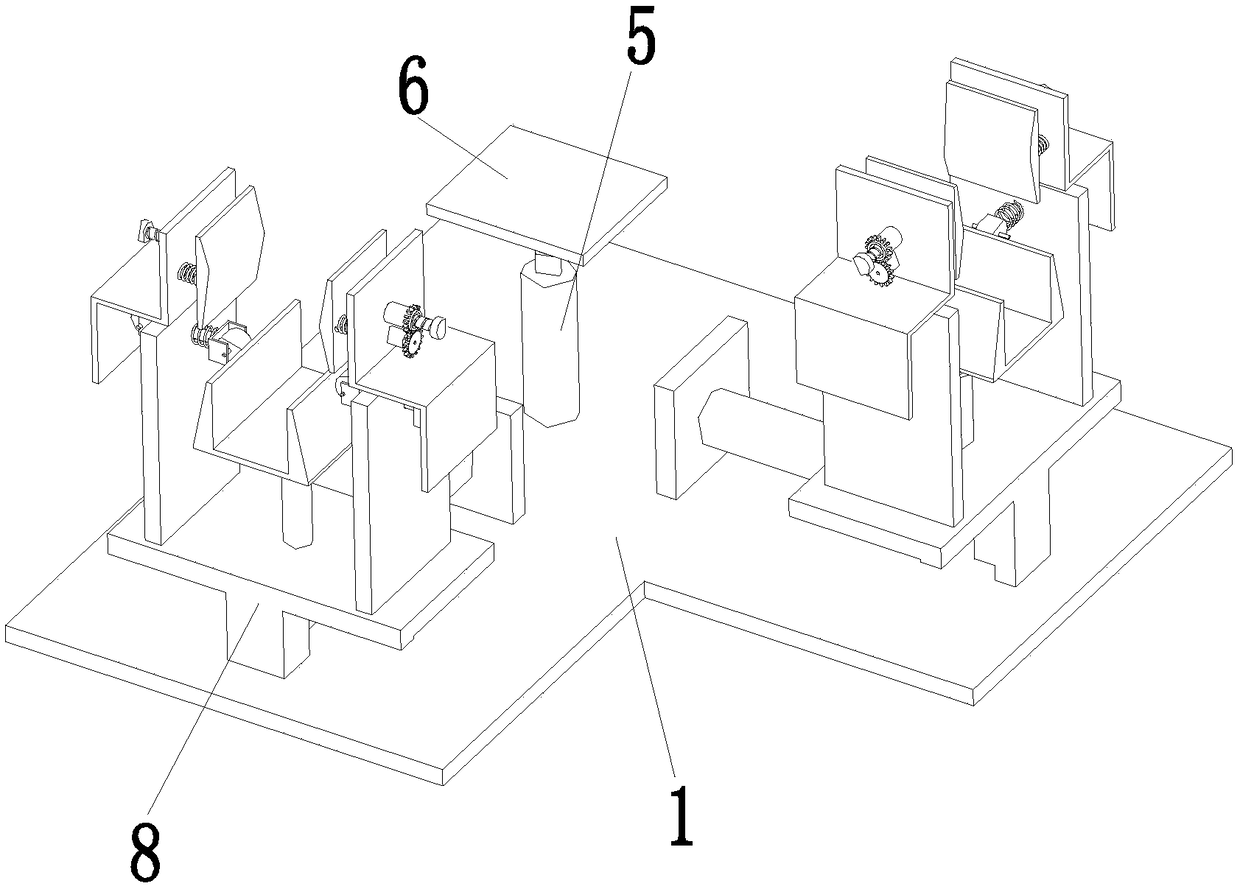

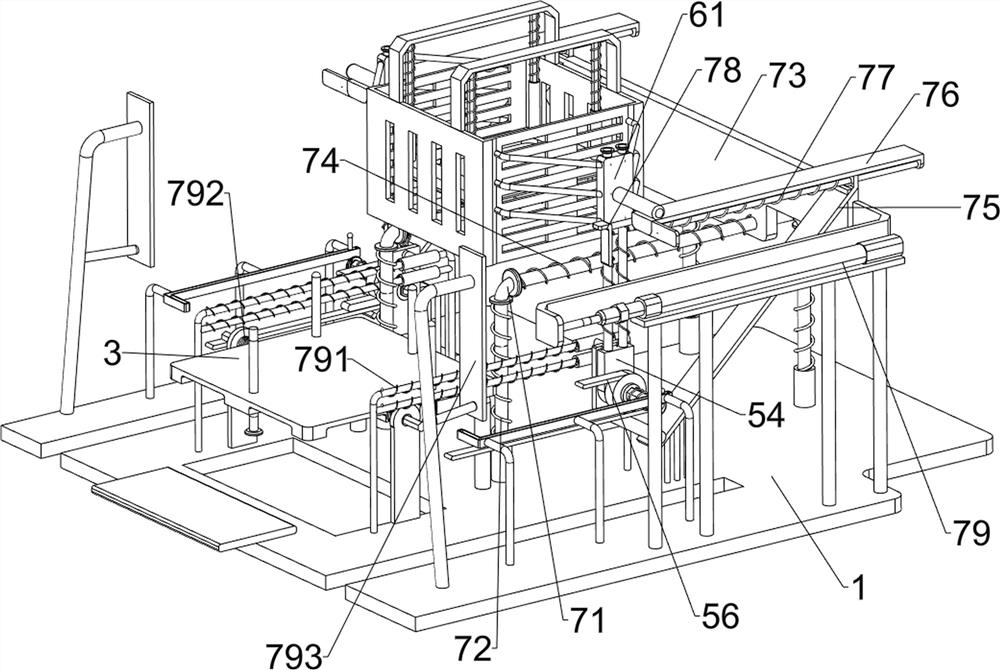

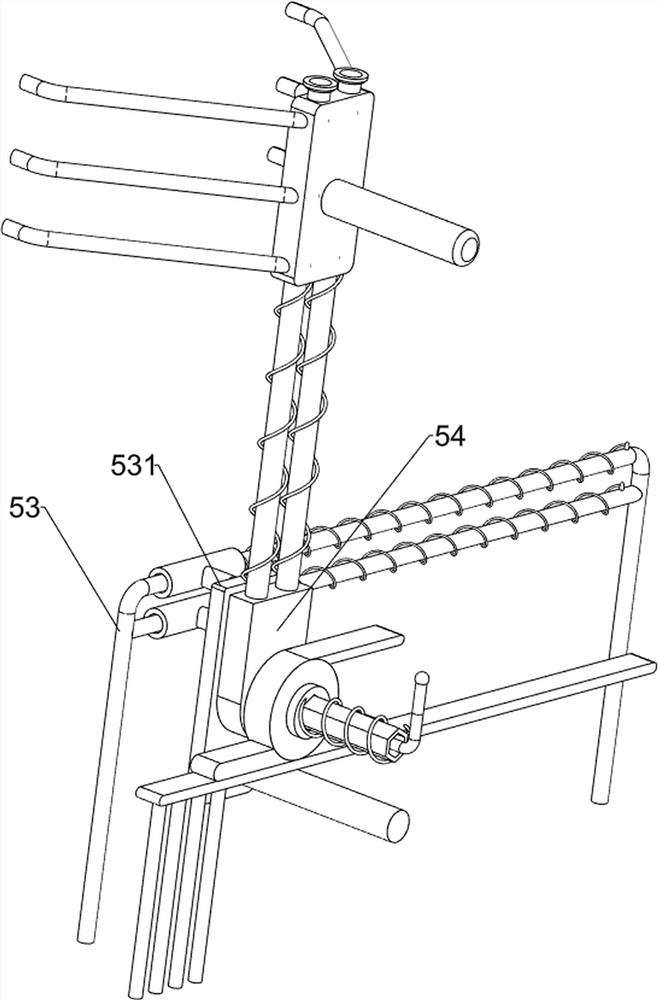

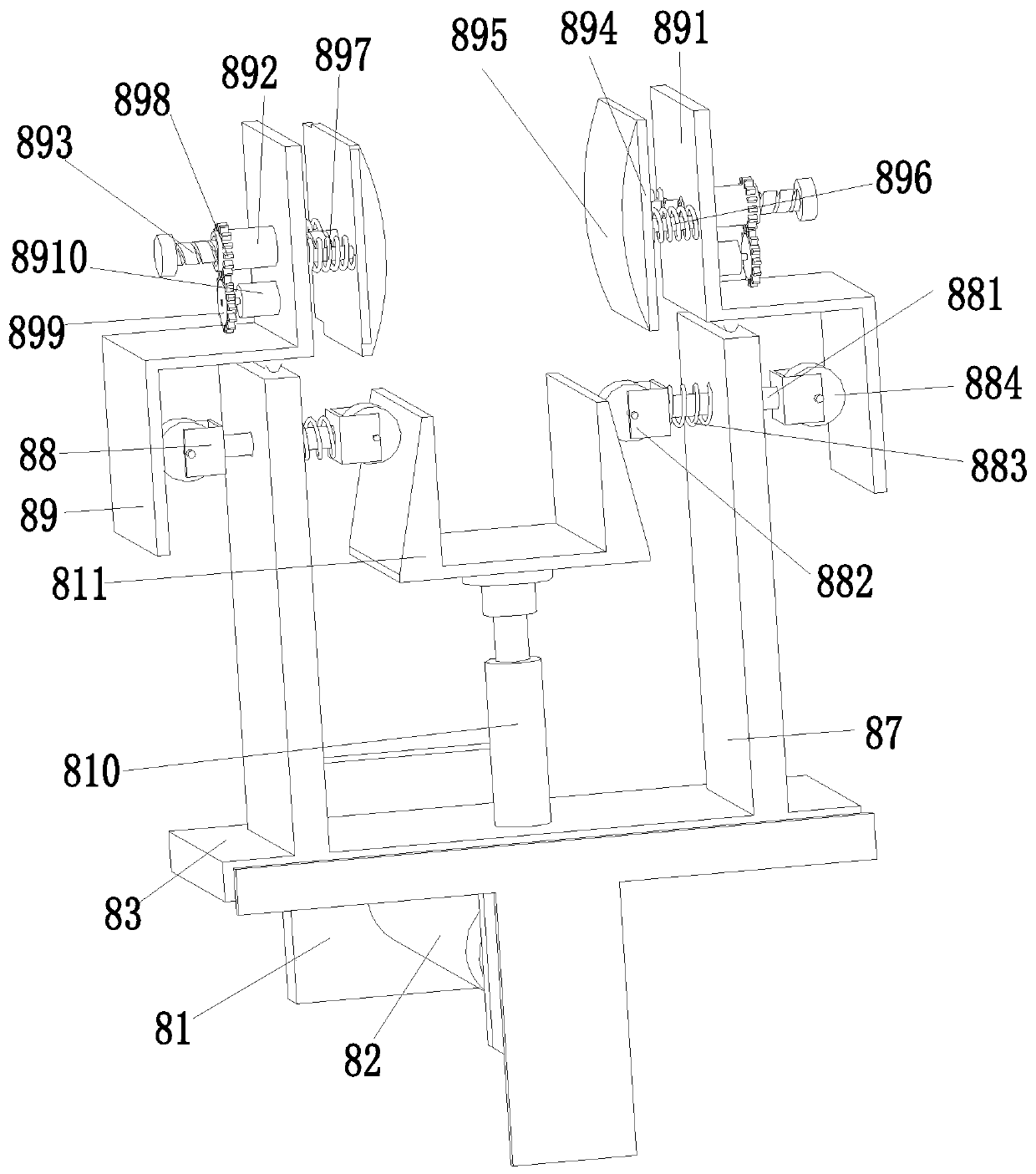

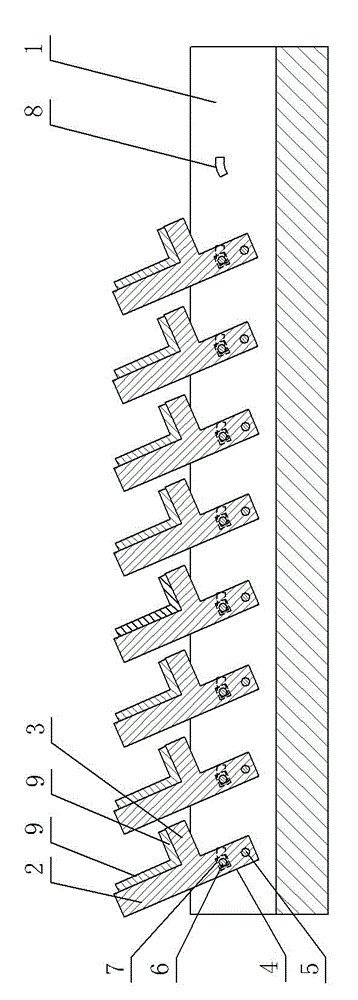

Power busway installation equipment

ActiveCN108861061APrevent slipping and breakingRealize the function of intelligent fixed clampingExternal framesSoftware engineeringFlange

The invention relates to power busway installation equipment comprising a baseplate. The baseplate is provided with two regulation fixing devices, and each regulation fixing device comprises a fixed support frame installed on the baseplate; the outside wall of each fixed support frame is provided with a fixed telescopic cylinder of which the top end is installed on a fixed driven frame through a flange, and the fixed driven frame is provided with two fixed support plates; and each fixed support plate is provided with a fixed working trough which is internally provided with a fixed driving mechanism, and the upper end of each fixed support plate is provided with a fixed clamping mechanism through a hinge pin. The power busway installation equipment has the capability of solving the problemsthat an existing L-shaped busway needs to be manually fixed with a clamping tool in the installation process, the clamping tool needs to be regulated manually; and errors exist in manual regulation;the stability of the busway in the conveying process can not be ensured, and consequently the busway is liable to slide and damage in the conveying process, and needs to be corrected manually.

Owner:清远市长丰电力科技有限公司

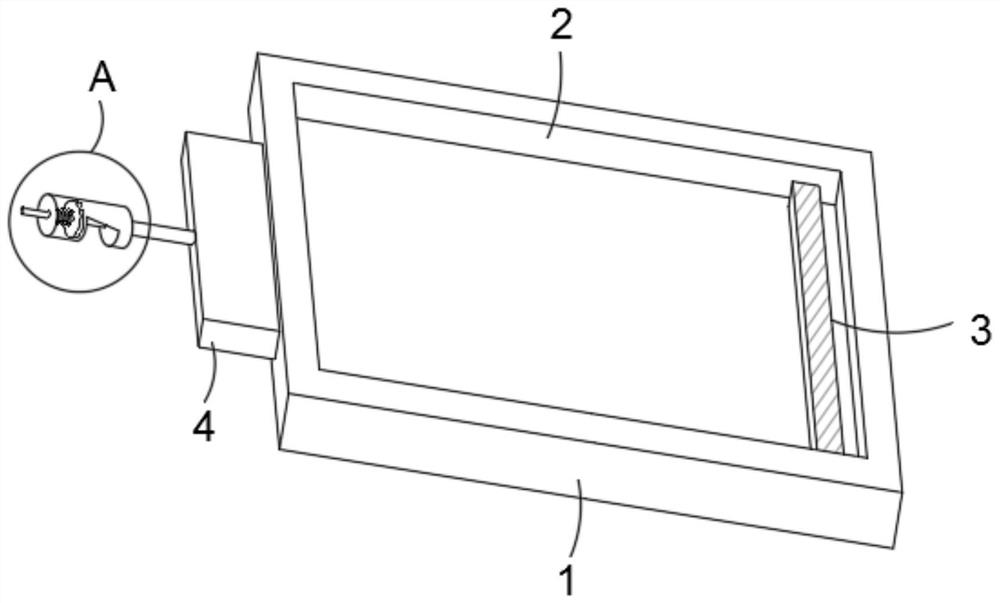

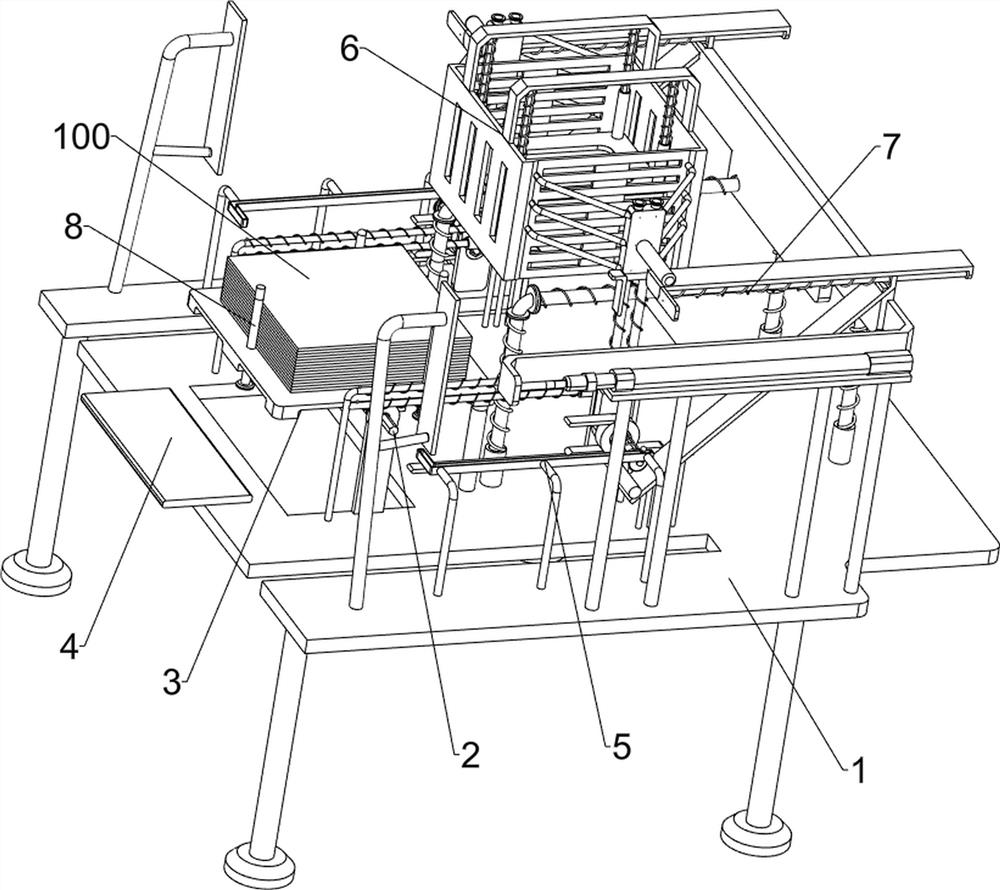

Auxiliary transportation equipment for glass production

ActiveCN112124966ASave human effortPrevent glass from slipping and breakingCharge manipulationConveyor partsEngineeringManufacturing engineering

The invention relates to transportation equipment, in particular to auxiliary transportation equipment for glass production. The technical problem to be solved by the invention is how to design the auxiliary transportation equipment for glass production, which can fix and erect glass during operation so as to avoid damage caused by falling of the glass. In order to solve the technical problem, theinvention provides the auxiliary transportation equipment for glass production which comprises a support, a placing plate and a fixing plate. One side of the top of the support is rotatably connectedwith a rhombus rod; the placing plate is connected onto the rhombus rod; the part, located on one side of the rhombus rod, of the placing plate is longer than the part, located on the other side of the rhombus rod, of the placing plate; the longer side of the placing plate is supported by the support; and the fixing plate is connected to the side, close to the placing plate, of the top of the support. The auxiliary transportation equipment for glass production provided by the invention achieves the effect of assisting in glass transportation through the matched operation of a moving assemblyand a framing assembly.

Owner:佛山市南海斯维雅玻璃有限公司

A power bus duct installation device

ActiveCN108861061BPrevent slipping and breakingRealize the function of intelligent fixed clampingExternal framesSoftware engineeringFlange

The invention relates to power busway installation equipment comprising a baseplate. The baseplate is provided with two regulation fixing devices, and each regulation fixing device comprises a fixed support frame installed on the baseplate; the outside wall of each fixed support frame is provided with a fixed telescopic cylinder of which the top end is installed on a fixed driven frame through a flange, and the fixed driven frame is provided with two fixed support plates; and each fixed support plate is provided with a fixed working trough which is internally provided with a fixed driving mechanism, and the upper end of each fixed support plate is provided with a fixed clamping mechanism through a hinge pin. The power busway installation equipment has the capability of solving the problemsthat an existing L-shaped busway needs to be manually fixed with a clamping tool in the installation process, the clamping tool needs to be regulated manually; and errors exist in manual regulation;the stability of the busway in the conveying process can not be ensured, and consequently the busway is liable to slide and damage in the conveying process, and needs to be corrected manually.

Owner:清远市长丰电力科技有限公司

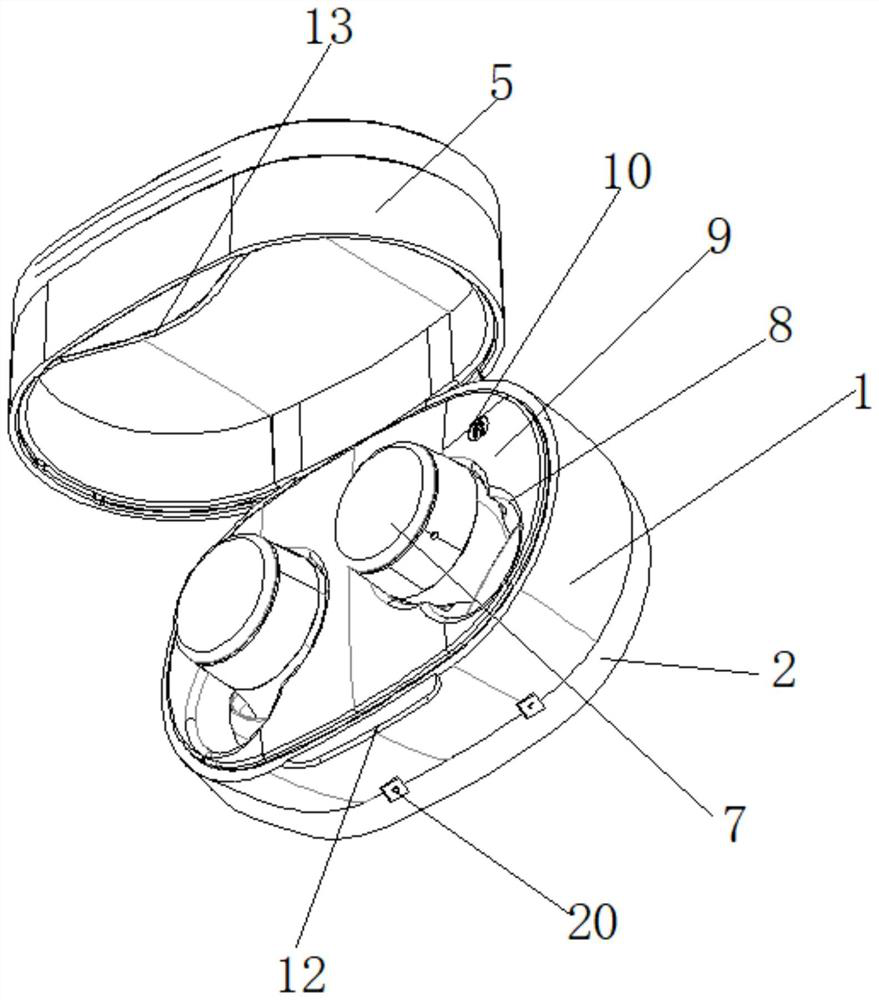

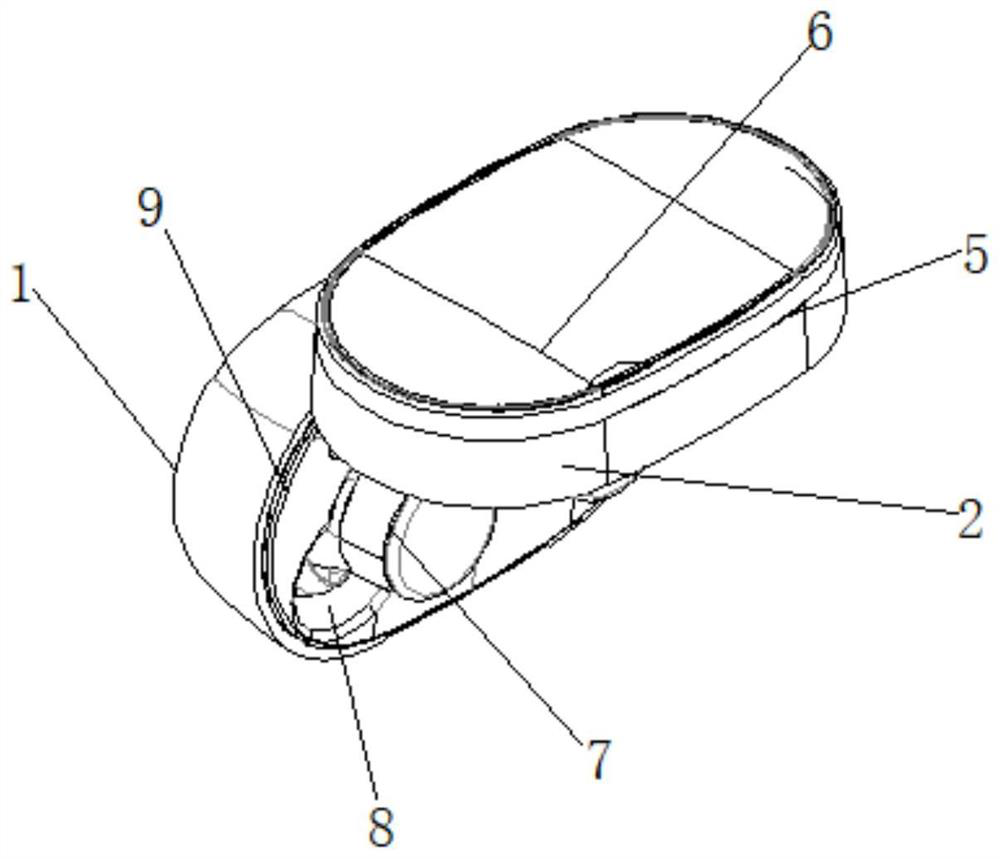

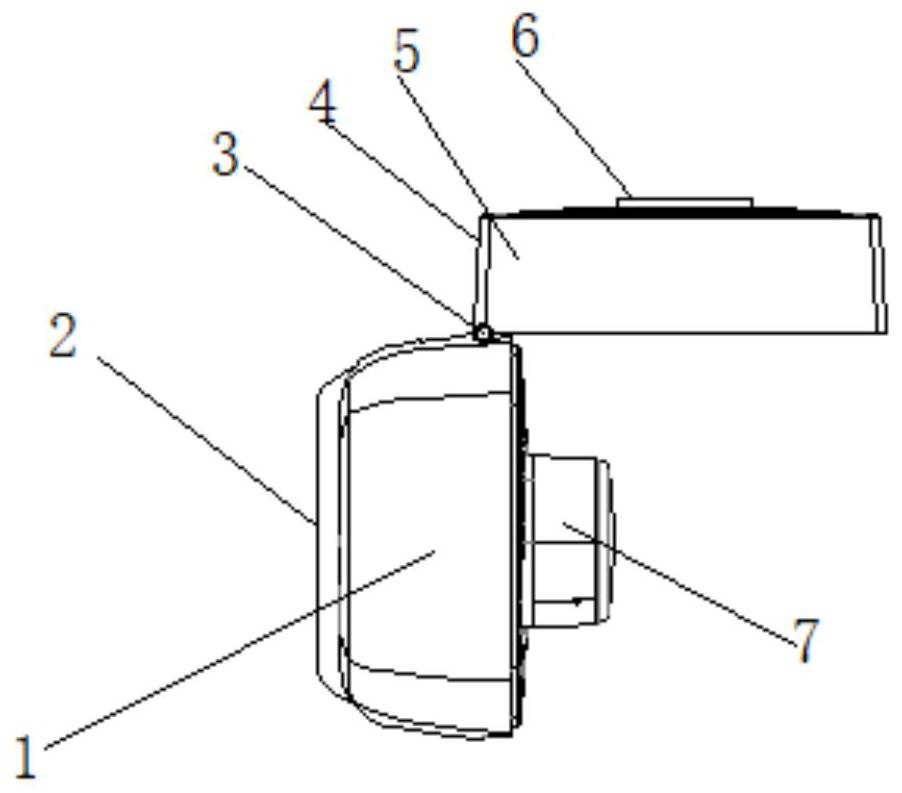

Anti-slip true wireless Bluetooth earphone

InactiveCN111757208ADifferent feelComfortable gripCharging attachments/accumulatorsEngineeringHeadphones

The invention discloses an anti-slip true wireless Bluetooth earphone. In the present invention, the earphone comprises an earphone bottom shell and an upper top cover; a top cover fixing groove is fixedly formed in the edge of the front side of the earphone bottom shell; a top cover fixing clamping block is fixedly connected to the position, right opposite to the top cover fixing groove, of the upper surface of the upper top cover. The interior of the upper top cover is provided with an upper fixing groove which is matched with the size of the wireless earphone body. Mounting grooves are formed in the two ends of the bottom of the earphone bottom shell. A clamping spring is fixedly mounted in the groove; one end, far away from the earphone bottom shell, of the clamping spring is bonded and fixed; the mounting plate is matched with the holding block for use, so people can obtain different hand feelings when holding the earphone; the bottom antiskid plate can increase the dynamic friction factor of the earphone and the contact surface, so the friction force is increased, the earphone is prevented from slipping off and being broken in the daily use process, the protection of the earphone is improved, and the service life of the earphone is prolonged.

Owner:DONGGUAN UIISII ELECTRONICS CO LTD

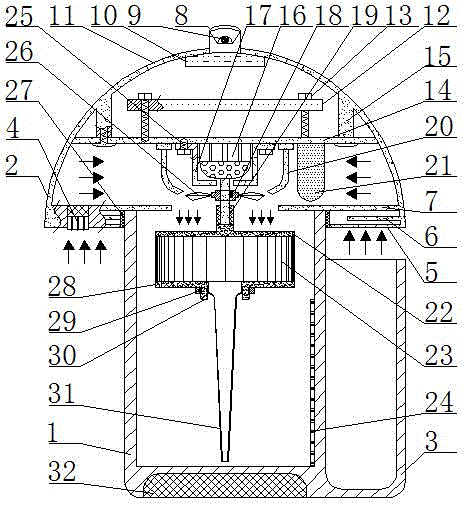

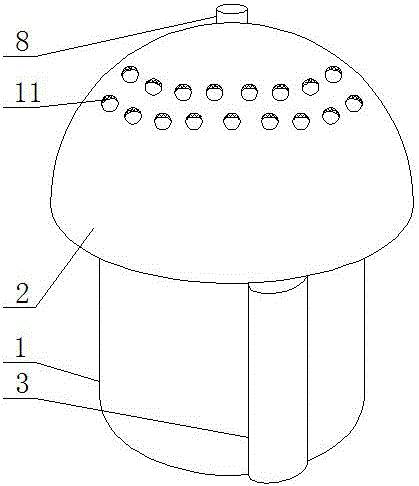

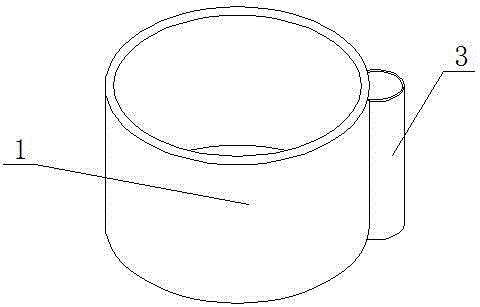

Negative ion adsorption type aromatherapy humidifier for eliminating particulate matters (pm) 2.5

InactiveCN105823156APrevent backflowEnhanced diversionMechanical apparatusLighting and heating apparatusAromatherapyImpeller

The invention relates to the technical field of air purifying equipment, in particular to a negative ion adsorption type aromatherapy humidifier for eliminating particulate matters (pm) 2.5. The negative ion adsorption type aromatherapy humidifier for eliminating pm 2.5 comprises a cup, a centrifugal impeller and a mushroom-shaped upper cover; an aromatherapy bottle placing tank is arranged on the right side of the cup; a mounting transverse plate is arranged in the middle of the mushroom-shaped upper cover; a driving motor is arranged in the middle of the lower side of the mounting transverse plate; a negative ion generator is arranged on a side of the driving motor; a driving rotating shaft is connected with an upper clamp plate through a threaded groove; a lower clamp plate is arranged on the lower side of the upper clamp plate; the centrifugal impeller is sandwiched between the upper clamp plate and the lower clamp plate; a hollow rotating shaft is arranged below the lower clamp plate; an air inlet slot is formed in a brim of the mushroom-shaped upper cover; a baffle plate is mounted in the slot; a guide plate is arranged above the baffle plate; and a power interface is formed in a gap of the air inlet slot of the mushroom-shaped upper cover. By the negative ion adsorption type aromatherapy humidifier, the shortcomings of existing air purifying equipment can be overcome, the air purifying rate is increased, the structure of an air purifier is improved, the aromatherapy function is added, health of human bodies is improved, fatigue is relieved, and the like.

Owner:SUZHOU YANBO ENVIRONMENTAL PROTECTION ENERGY SAVING TECH CO LTD

Coated glass processing technology

The invention discloses a coated glass processing technology. The technology is characterized by comprising the following steps of preparation work, wherein coated glass, a coating roller, coating liquid and a scraping plate are prepared; glass cutting, edging and cleaning are conducted, wherein to-be-coated glass is put in a cutting machine and cut according to the actual conditions, after cutting, corners are quite angular, the cut glass is subjected to edging, and after processing, the glass is conveyed into a glass cleaning machine for cleaning; glass drying, wherein the cleaned glass is conveyed into a dyer for drying through a conveying device. According to the technology, waste of the coating liquid can be reduced to avoid that after the coating liquid is pulled out, the waiting time is long, and meanwhile, the coating liquid on the surface of the glass can be levelled. The coating liquid is added to the surface of the glass through a coating liquid adding device, therefore thecoating liquid is directly added to the surface of the glass, the operation is simple and convenient, it is not necessary to put the whole glass into the coating liquid, it is avoided that the glass slips down and is broken, and the stability is improved.

Owner:中山市华达诚钢化玻璃有限公司

Multifunctional dining table for medical treatment sickbed

InactiveCN108903292ASolve the fallPerformance is not affectedServing tablesVariable height tablesHydraulic cylinderEngineering

The invention discloses a multifunctional dining table for a medical treatment sickbed. The multifunctional dining table comprises a table board; a turning plate is hinged to the right side of the table board and covers the surface of the table board; a cup groove and bowl grooves are formed in the surface of the table board; a table belly is fixedly mounted in the middle of the lower portion of the table board; a turning cover is hinged to the exterior of the table belly, and a switch is mounted on the outer wall of the left side of the table belly; the interior of the table belly is dividedinto two areas including the disinfection area and the storage area correspondingly; lamp holders are mounted at the top of the disinfection area, and an ultraviolet lamp tube is mounted on the lamp holders; a partition plate is mounted below the ultraviolet lamp tube; a storage battery is pasted between the partition plate and the bottom end of the table belly; a bent baffle is fixedly mounted atthe bottom end in the table belly; hydraulic rods are mounted on the lower portions of the two sides of the table board; hydraulic cylinders are mounted at the lower ends of the hydraulic rods; pressing plates and pressure release valves are mounted on the two sides of the hydraulic cylinders correspondingly; table legs are mounted at the bottoms of the hydraulic cylinders; universal wheels are mounted on the lower portions of the table legs through screws; and brake pads are arranged on the universal wheels.

Owner:芜湖碧水谣医疗设备科技有限公司

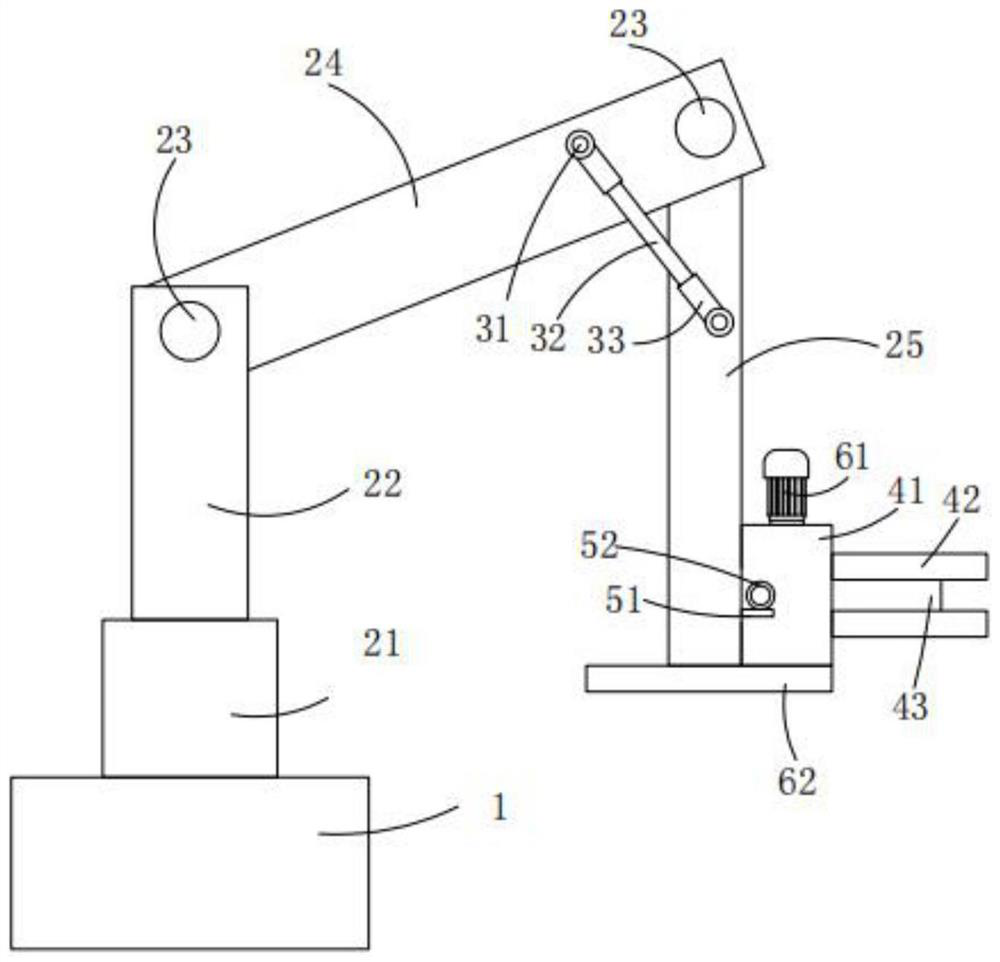

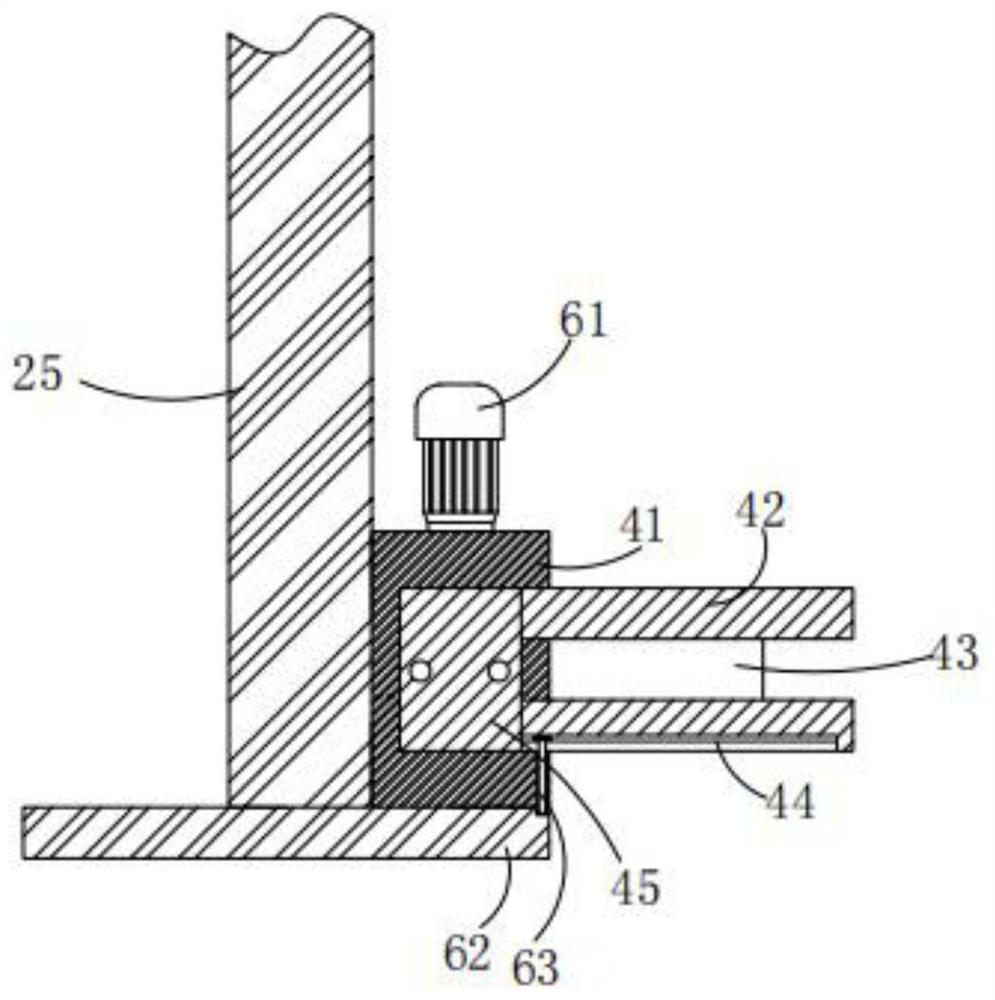

Intelligent mechanical arm with grabbing structure

InactiveCN114043467APlay a supporting rolePrevent slipping and breakingProgramme-controlled manipulatorGripping headsStructural engineeringControl table

The invention provides an intelligent mechanical arm with a grabbing structure. The intelligent mechanical arm with the grabbing structure comprises a base; a control structure installed on the top face of the base, wherein the control structure comprises a control table, a supporting rod, a connecting piece, a force arm rod, a driving rod and a connecting block, wherein the control table is installed on the top face of the base, the supporting rod is vertically installed on the top face of the control table, and one end of the force arm rod is installed at the top end of the supporting rod; a hydraulic rod structure mounted on the side wall of the force arm rod and the side wall of the driving rod; a clamping arm structure fixed on the side wall of the driving rod; and a supporting plate structure mounted at the bottom end of the driving rod. The intelligent mechanical arm with the grabbing structure has the advantage that when the mechanical arm carries heavy objects, the objects are prevented from sliding off and being broken.

Owner:湖南五子塑业有限责任公司

A pillow base for an A-shaped glass support

InactiveCN105800078AAvoid wear and tearEffectively fixedExternal framesDamagable goods packagingEngineeringMechanical engineering

Owner:WUXI FORMEN TECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com