Pillow structure of A-shaped glass bracket

An A-shaped, glass technology, applied to external frames, containers to prevent mechanical damage, packaging of vulnerable items, etc., can solve the problems of slipping and breaking, and the lower part of the glass cannot be fixed by the slot, so as to ensure the beauty and prevent wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

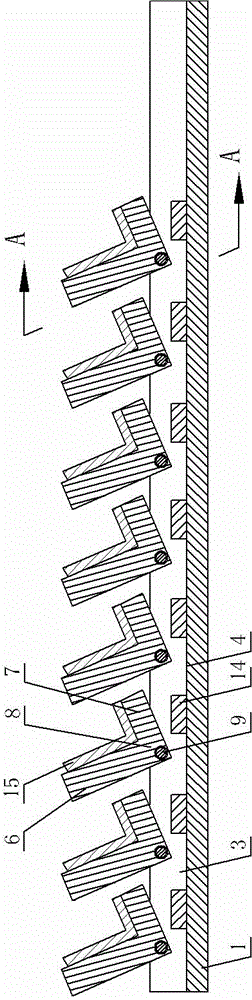

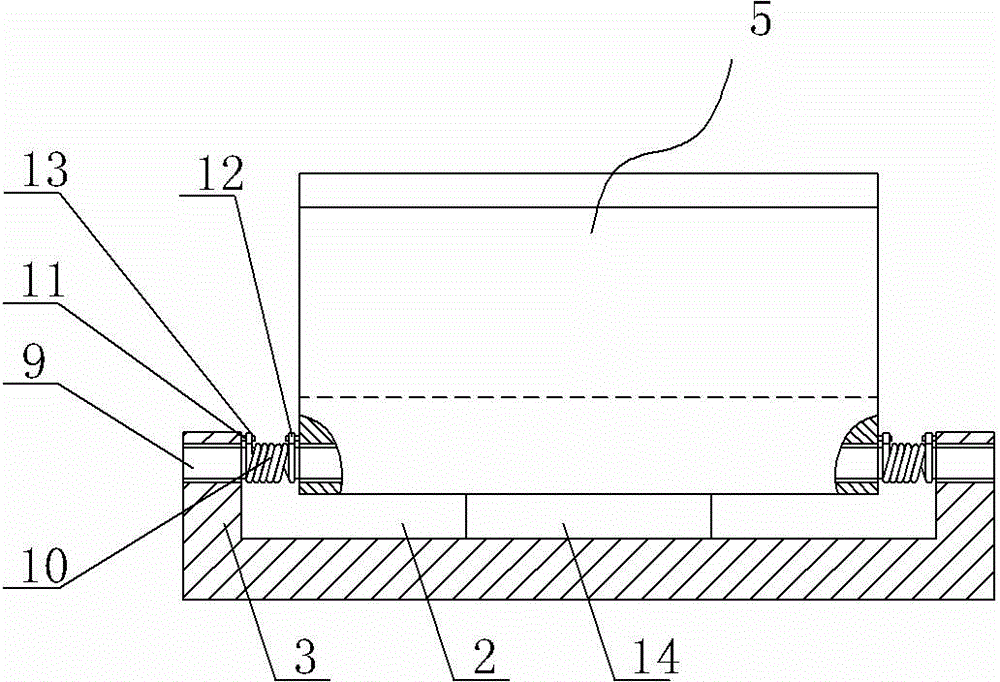

[0011] Such as Figure 1 to Figure 2 As shown, including the pillow bar 1, the upper middle position of the pillow bar 1 is provided with a U-shaped groove 2 arranged along the length direction, and a plurality of L-shaped clamping plates 5 are arranged in the U-shaped groove 2, and the L-shaped clamping plates 5 include an upper clamping plate 6 and the lower clamping plate 7 vertically fixed on the lower end of the upper clamping plate 6, the rotating shaft 9 runs through the connecting part 8 where the upper clamping plate 6 and the lower clamping plate 7 intersect and is supported on the two side walls 3 of the U-shaped groove 2, and is located on the L-shaped clamping plate. Between the connecting portion 8 of the plate 5 and the two side walls 3 of the U-shaped groove 2, a torsion spring 10 is sleeved on the rotating shaft 9, and the side walls at both ends of the connecting portion 8 and the side walls 3 of the U-shaped groove 2 are symmetrically arranged respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com