Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Pile fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

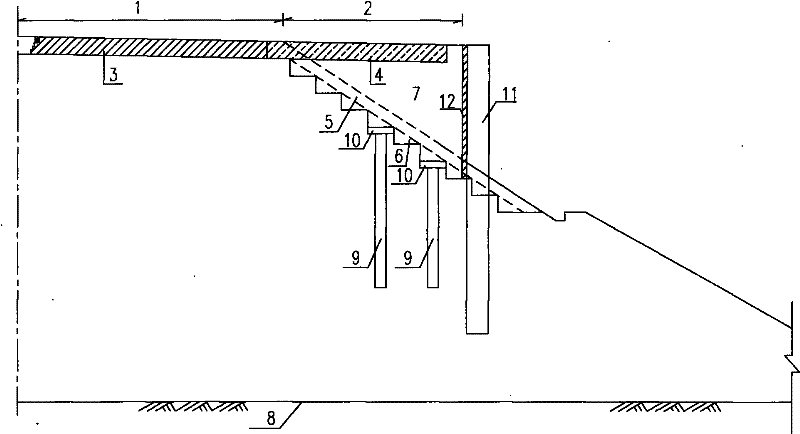

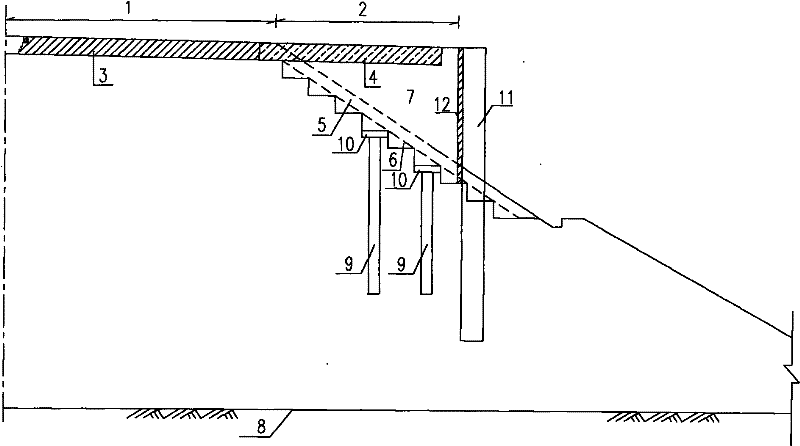

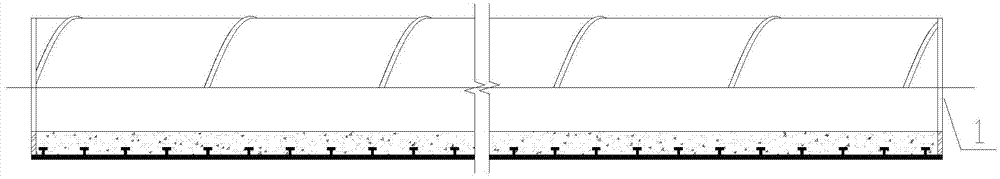

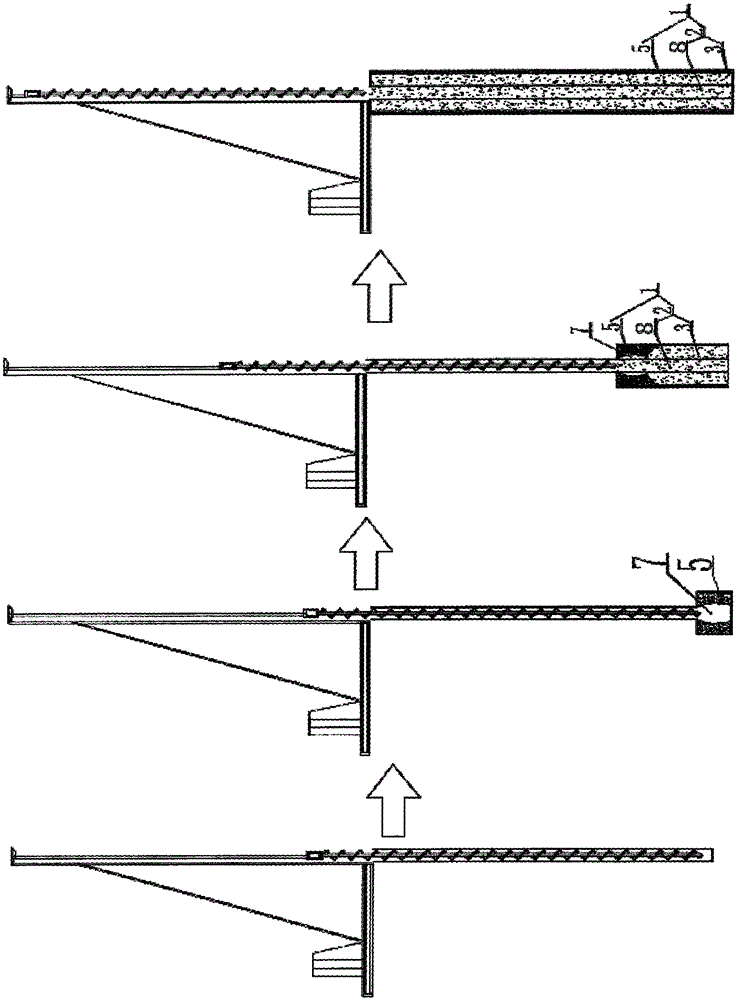

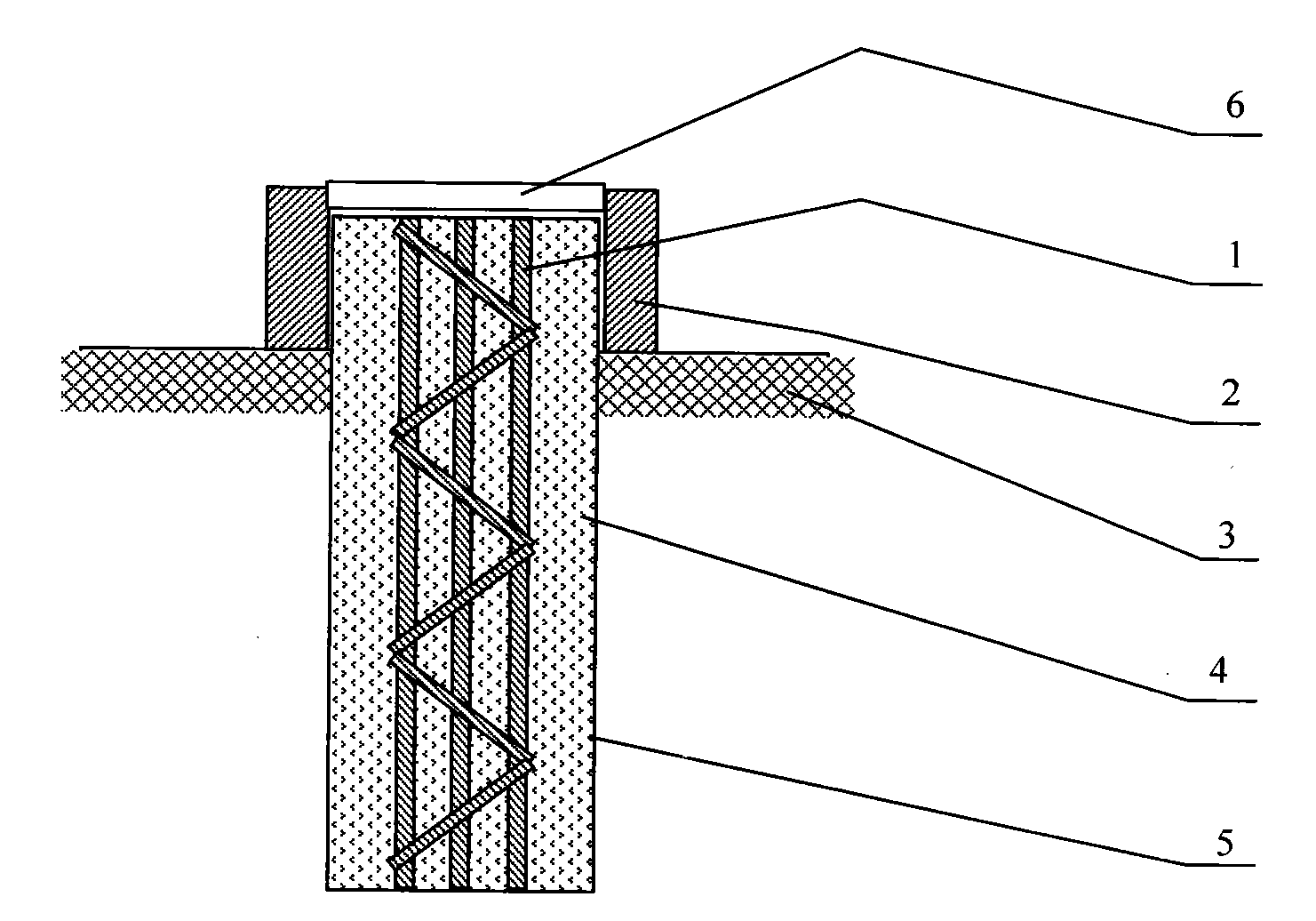

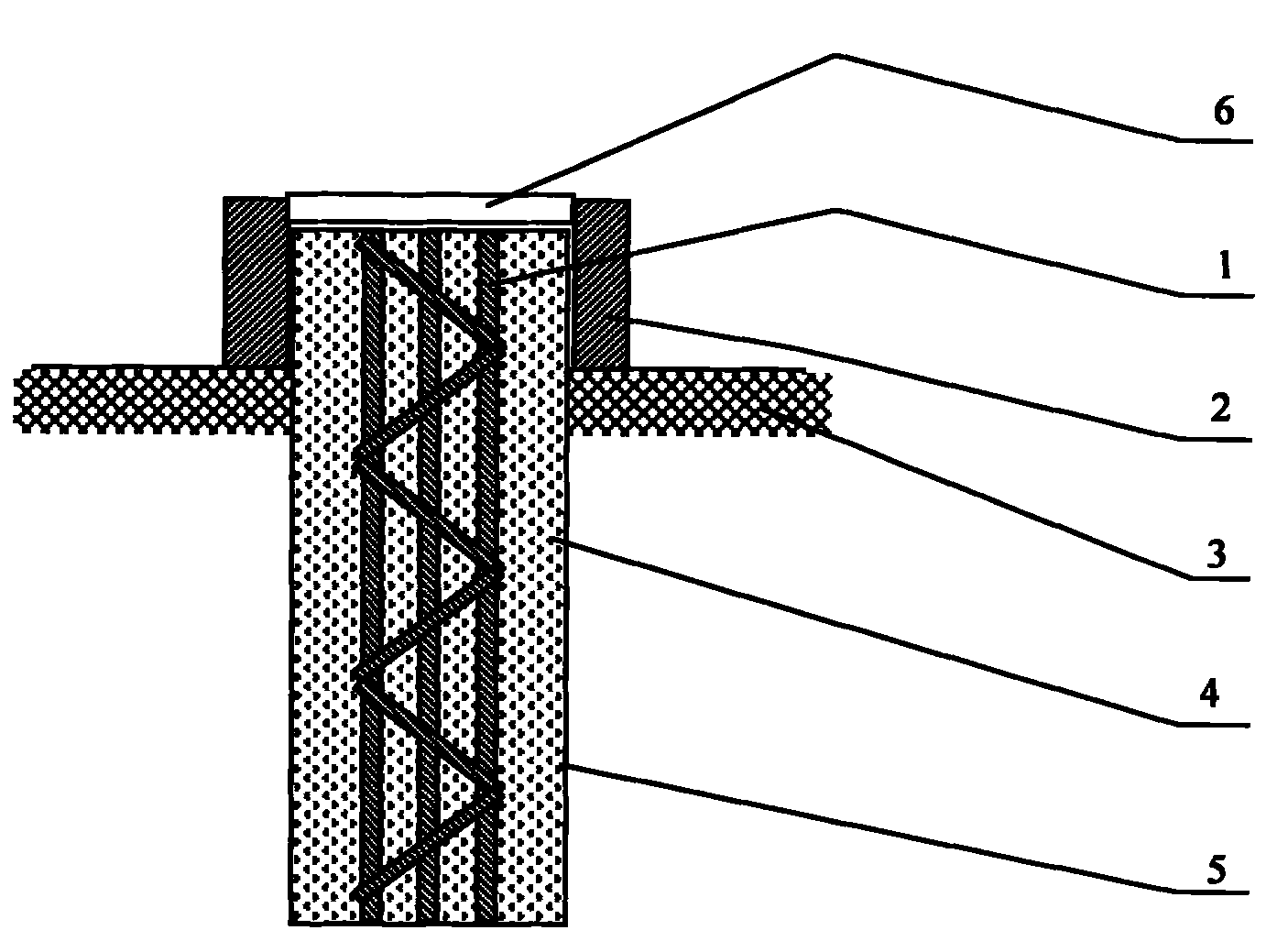

Method for splicing highfill roadbed by adopting pile-sheet retaining wall

ActiveCN102352590AReduce disturbanceReduce land occupationArtificial islandsRoadwaysReinforced concreteEngineering

The invention discloses a method for splicing a highfill roadbed by adopting a pile-sheet retaining wall, comprising the following steps of: forming an operation platform by using an old roadbed (1), a cutting slope (5) and an excavation step (6); longitudinally constructing an excavation filling pile (11); hoisting the cutting slope (5) and the excavation step (6) layer by layer from bottom to top during construction; installing a reinforced concrete soil retaining plate (12) so that the reinforced concrete soil blocking plate (12) is in overlap joint with the excavation filling pile (11); constructing an excavation C10-C12 element concrete pile (9) and a C20 reinforced concrete pile follower (10) step by step; and filling and compacting filler (7) layer by layer to realize seamless overlap joint of an old road surface (3) and a new road surface (4). The method has the advantages of no increase of occupied land, simple and convenient construction machines, short construction period, low cost and simplicity in maintaining traffic moving, thereby being extremely suitable for road sections widened by using highfill.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

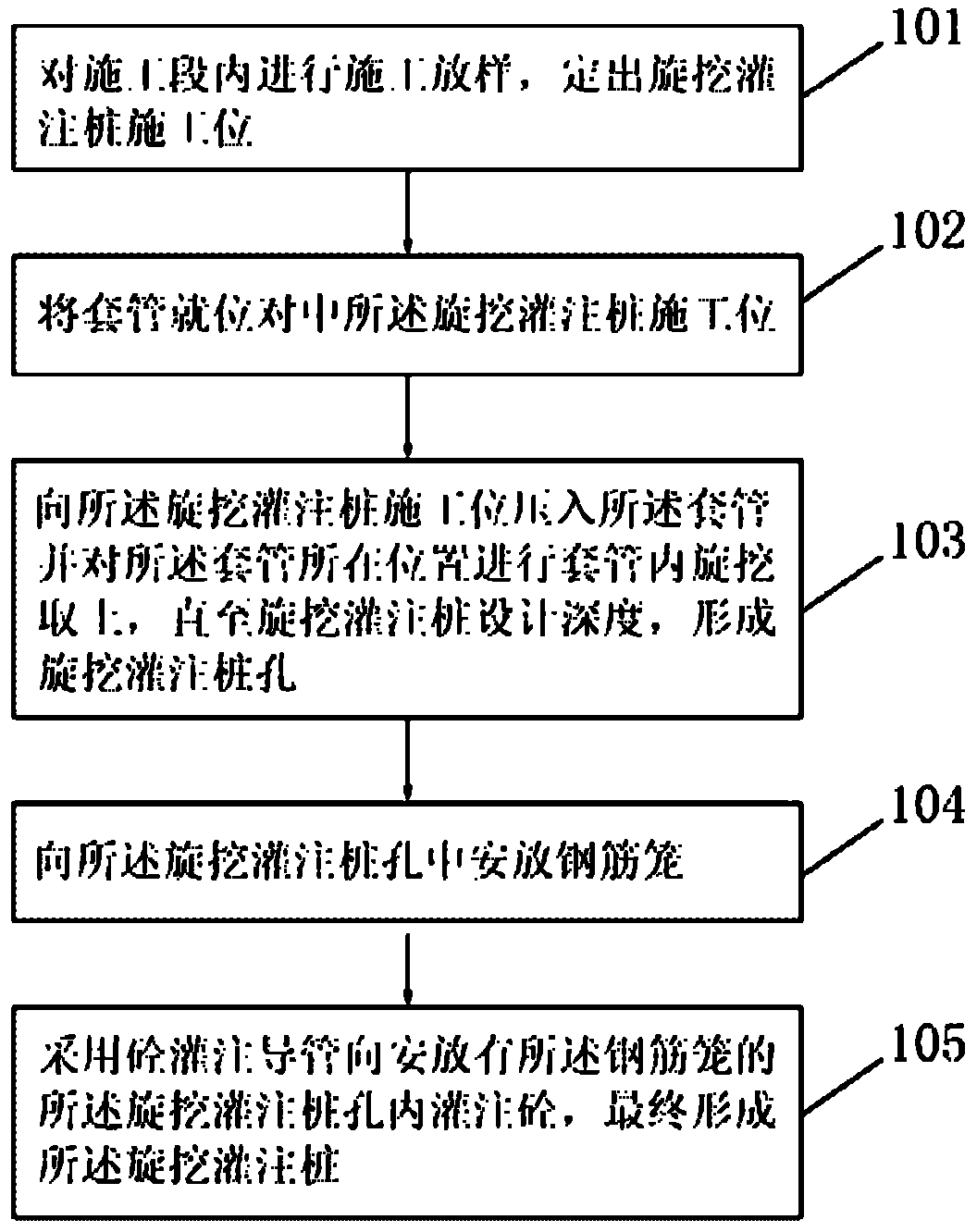

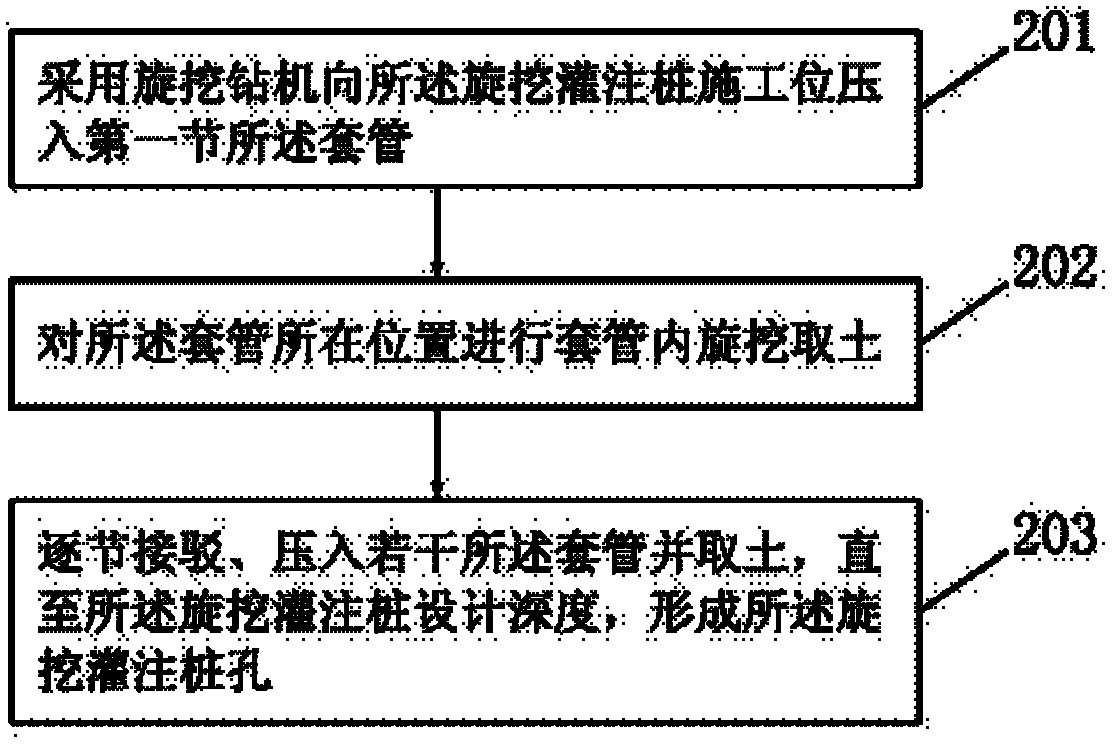

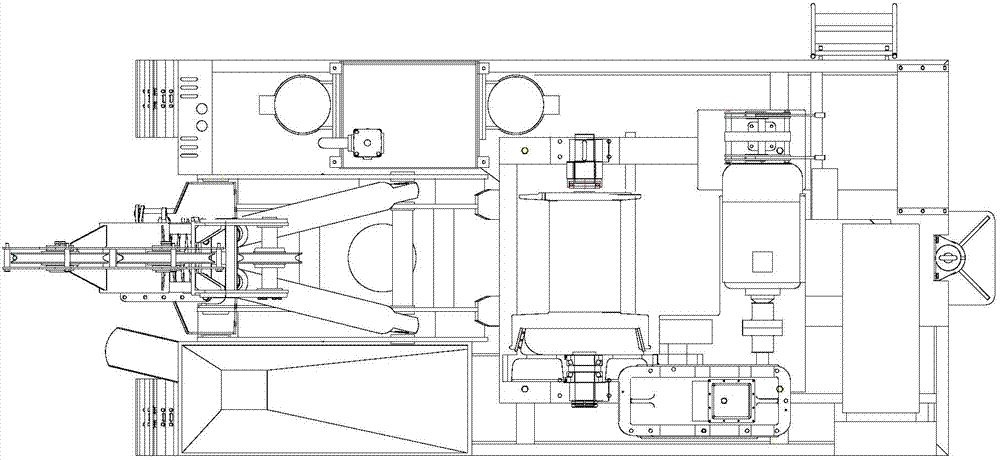

Construction method for revolving digging cast-in-place pile

An embodiment of the invention discloses a construction method for a revolving digging cast-in-place pile. A case pile is used for holing and protecting a wall, a revolving digging machine is used for taking soil and holing from the inside of the case pile, soil excavated volume of the construction method is lower as compared with a traditional wall protecting method by the aid of mud, a peripheral soil structure cannot be damaged, influences to surrounding environments and pollution due to construction are low, the speed for removing slag in end holes is fast, quality is high, and the problem that the mud skin on a side of a mud wall protecting and holing technical pile reduces bearing capacity of the engineering pile is avoided effectively. The construction method effectively stops common quality drawbacks of other types of punched and bored cast-in-place piles, such as hole collapse, necking and the like. Operation is safe, pile forming speed is faster, cost is lower, and construction efficiency and construction quality are greatly improved.

Owner:深圳市润信建设工程有限公司 +1

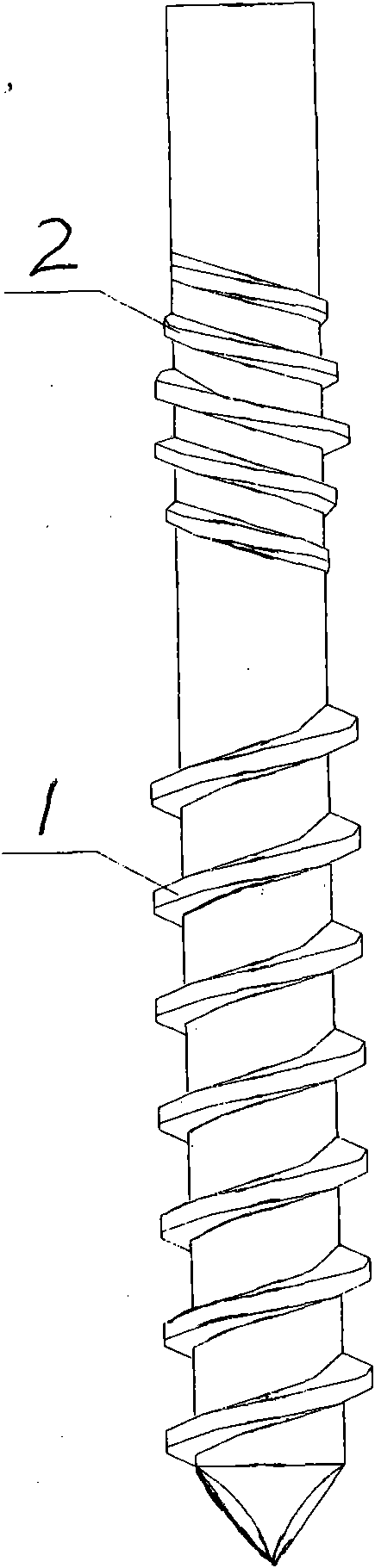

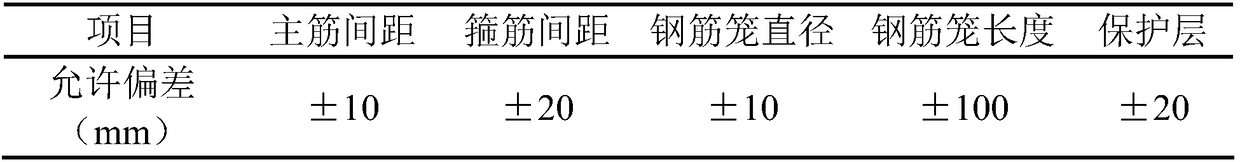

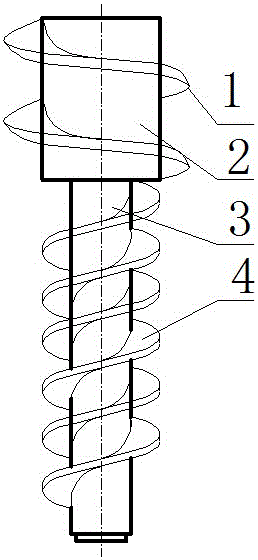

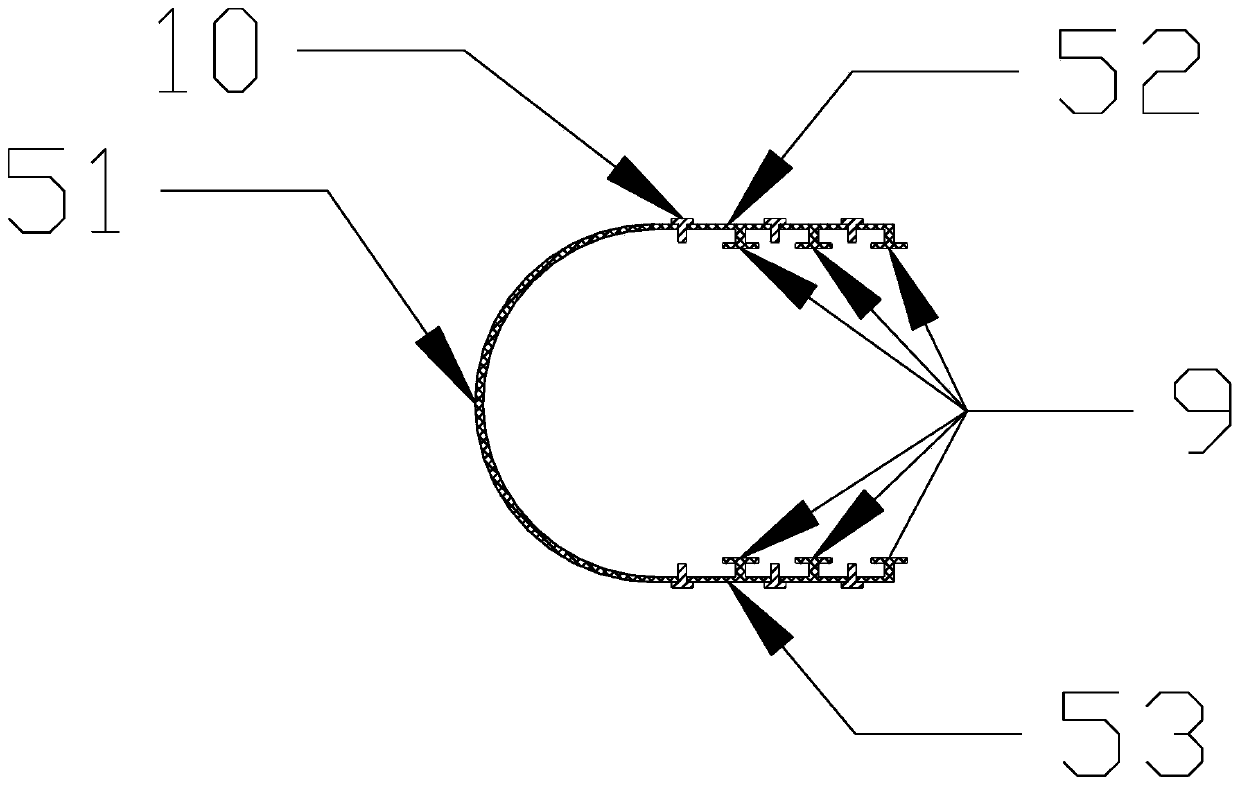

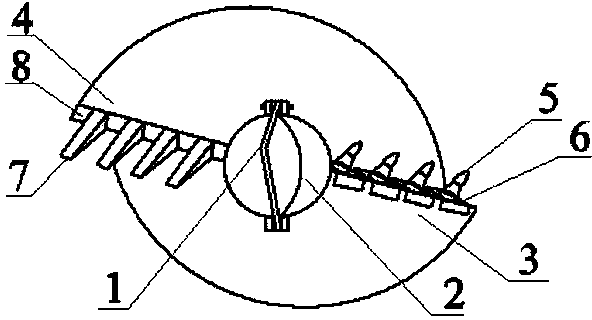

Pile-forming drilling tool for screw pile and pile-forming construction method thereof

InactiveCN101864768ASimplify the construction processSimple and fast operationDrill bitsDrilling rodsReinforced concreteRebar

The invention relates to a pile-forming drilling tool for a screw pile and a pile-forming construction method thereof, wherein forward drilling threads are arranged at the lower part of the pile-forming drilling tool, and backward sweeping threads are detachably arranged on the upper part thereof. The pile-forming construction method comprises the following steps: adopting special screw pile equipment to be assorted with the drilling tool to align with a pile position; utilizing the drilling tool to drill downwards so as to form threaded soil holes to reach the design depth of the pile, and meanwhile utilizing the sweeping threads at the upper part of the drilling tool to extrude and sweep the soil threads to form straight holes which reach the design depth of a straight lever section; lifting up the drilling tool in a rotating mode, and simultaneously concreting to form the thread section and the straight lever section of the pile; and after concreting is completed, placing a reinforcing cage to form the reinforced concrete screw pile. The drilling tool provided by the invention can effectively eliminate part of a threaded soil mass to form the straight holes by adopting forward threads and backward threads, thus achieving the effect of forming screw pile holes by boring at a time and realizing hole-forming and pile-forming of the screw pile at a time; and the pile-forming construction method has simple working procedures, faster speed, reduced construction resistance and no need of taking soil.

Owner:彭桂皎

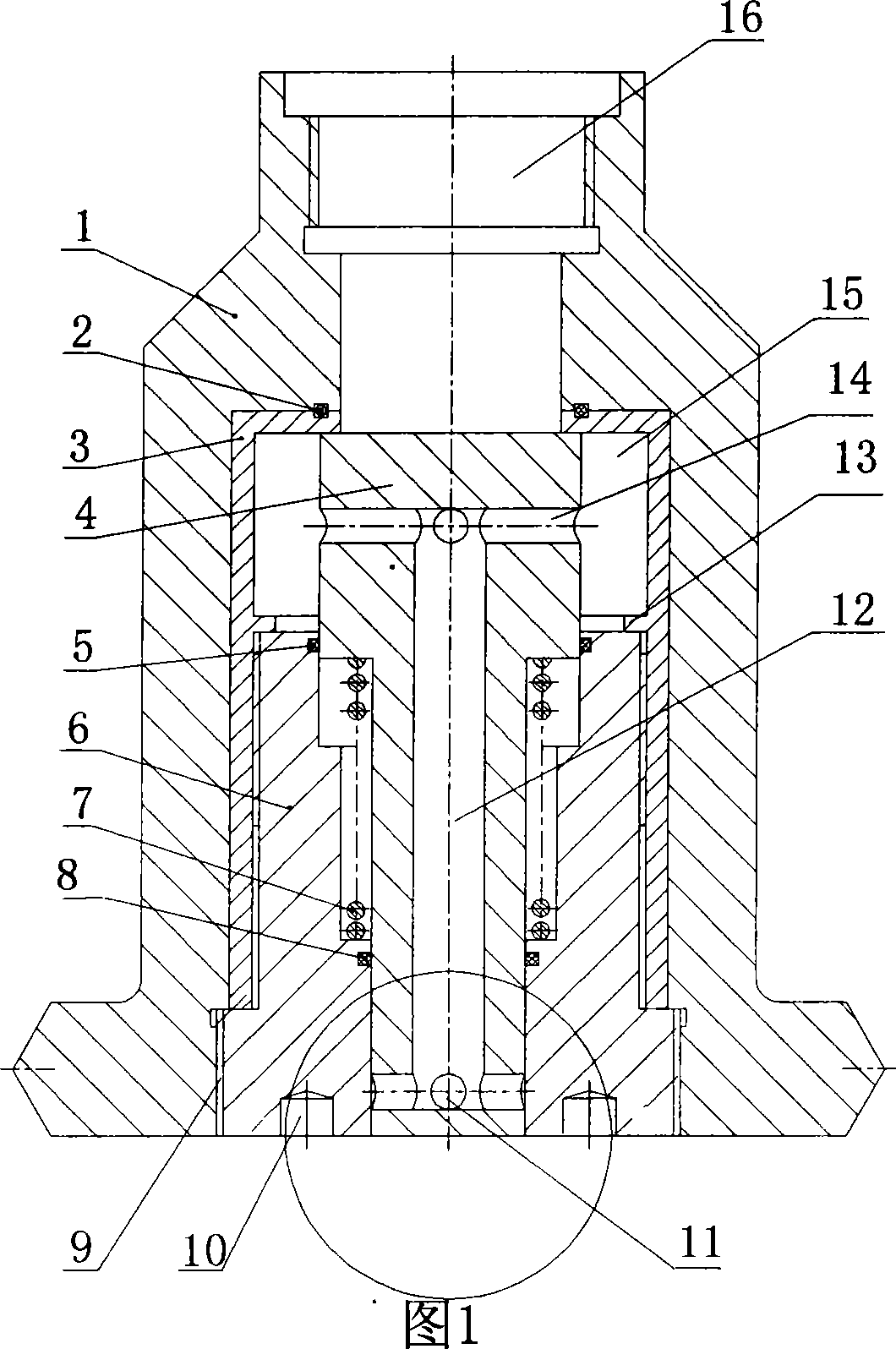

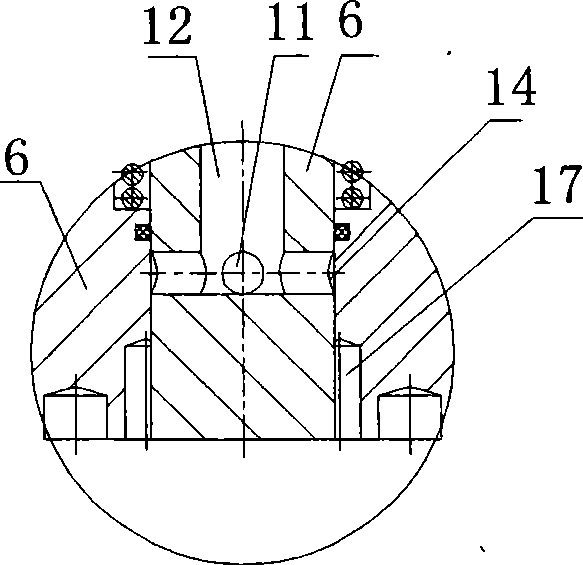

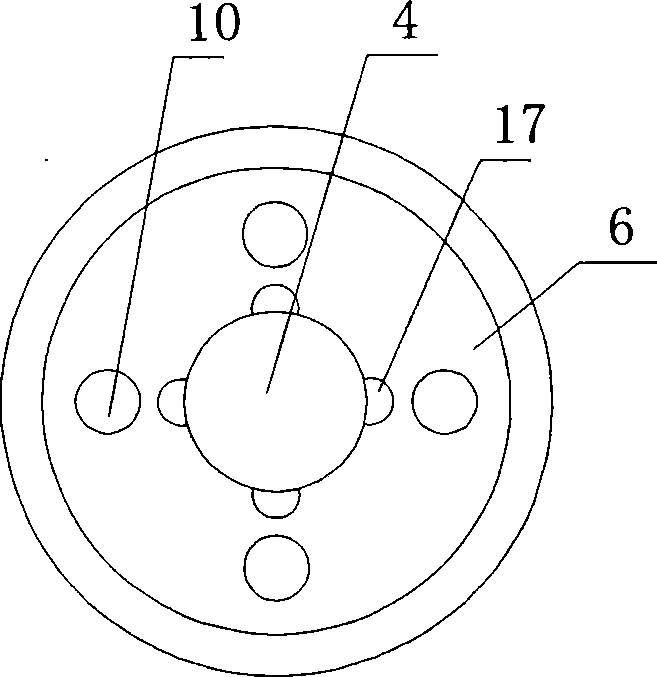

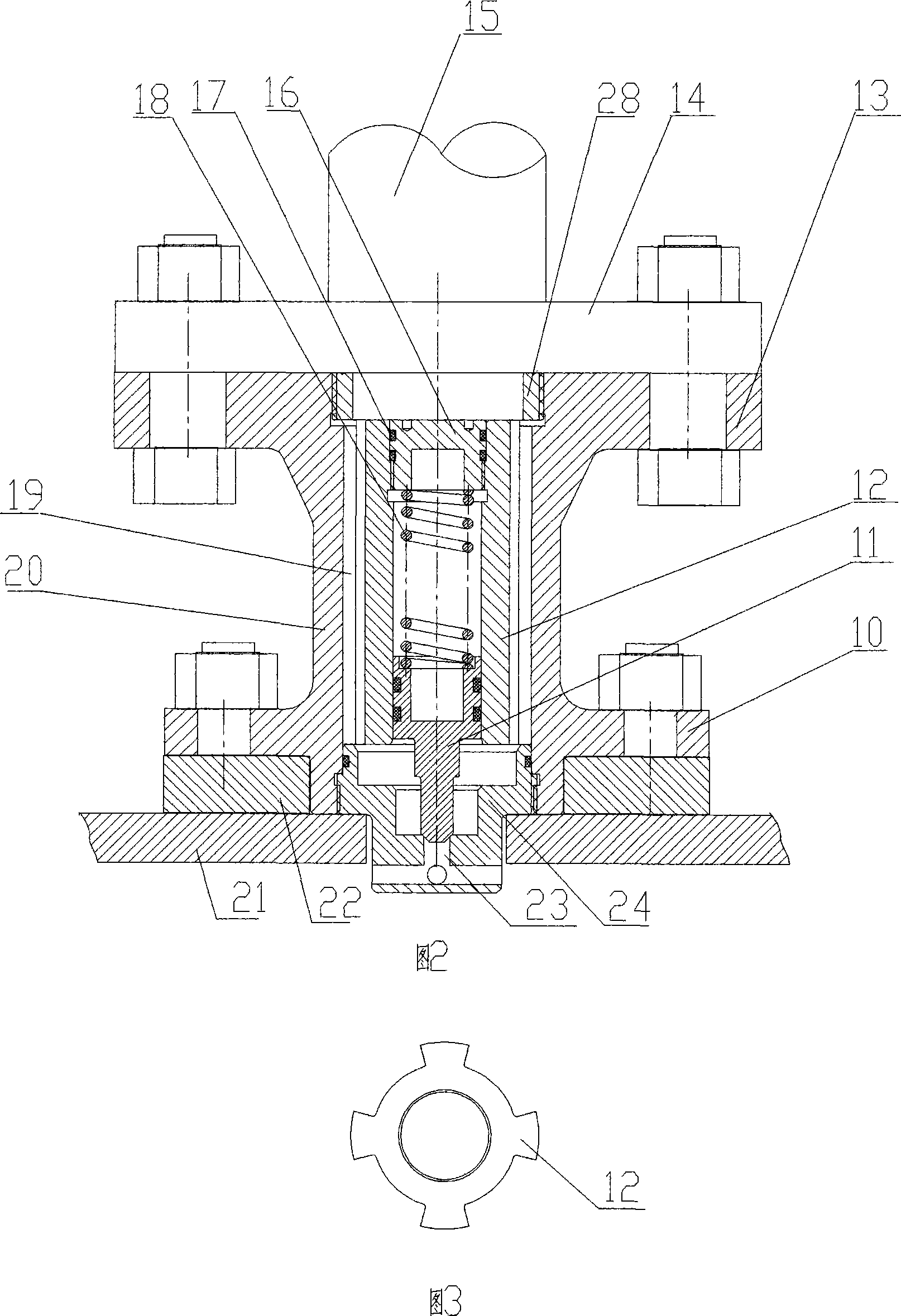

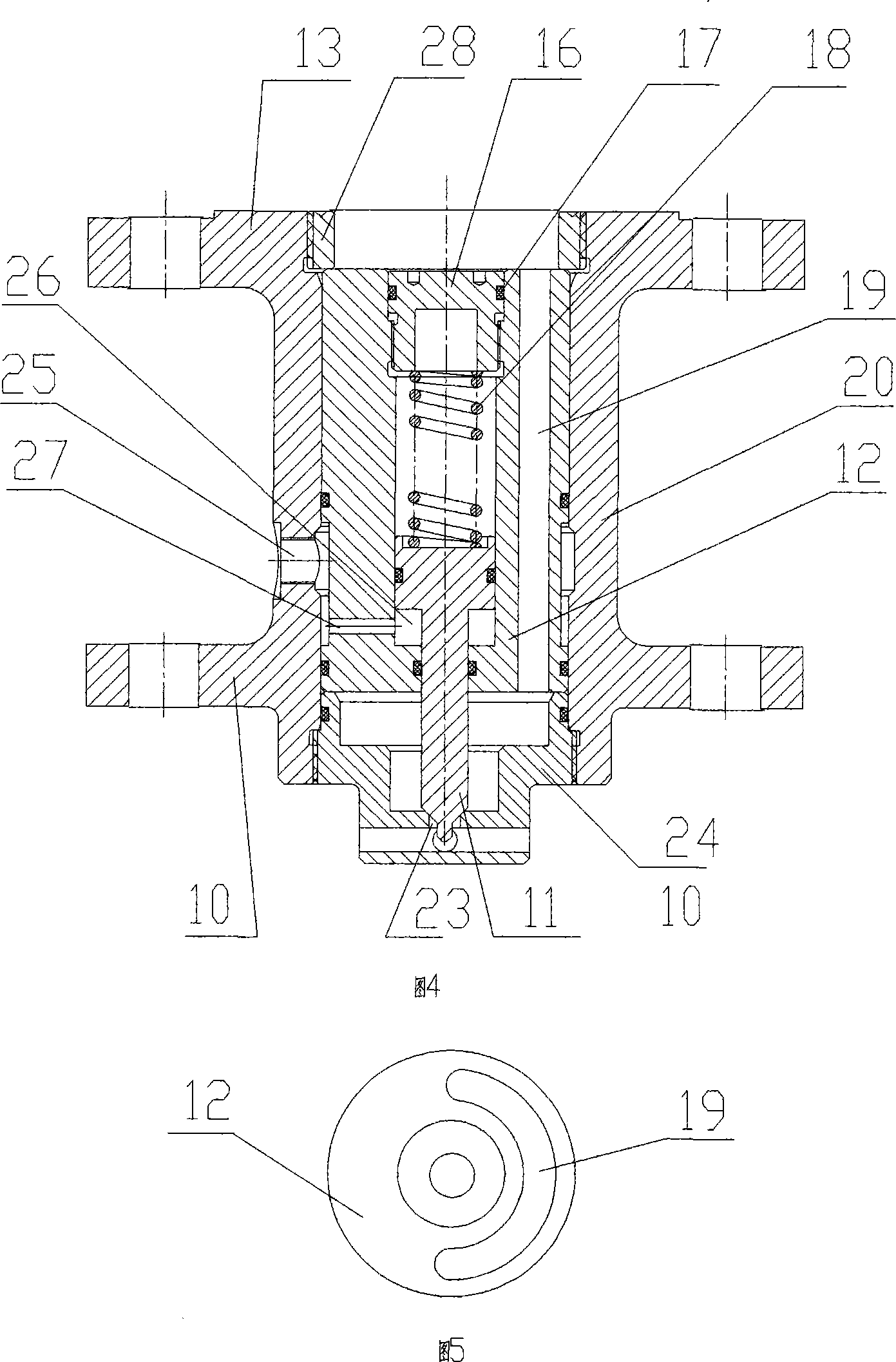

Block-resistant spraying device

ActiveCN101429769AImprove the efficiency of migration constructionImprove stabilityArtificial islandsUnderwater structuresEngineeringHigh pressure water

The invention provides an anti-clogging jetting machine, which consists of a shell, a piston sleeve, a composite piston and an anticorrosive inner sleeve, wherein the shell is provided with a cavity, and the top of the shell is provided with a high-pressure water pipe joint; the high-pressure water pipe joint and a lower cavity are arranged downwards; the bottom of the piston sleeve is provided with a threaded convex ring, and the threaded convex ring at the bottom of the piston sleeve is rotatably connected with the bottom of the shell; the middle of the piston sleeve is provided with a trapezoidal hole with large upper part and small lower part; the lower end of the composite piston is provided with a small piston which is glidingly connected with a small hole at the bottom of the trapezoidal hole in the middle of the piston sleeve, and the upper end of the composite piston is provided with a large piston which is glidingly connected with the upper part of the trapezoidal hole; a spring is sleeved on an excircle of the small piston; the lower end of the spring is connected with the middle of the trapezoidal hole; the upper part of the composite piston is provided with a water inlet hole, and the lower part of the composite piston is provided with a blowhole; and the water inlet hole and the blowhole are connected with each other through a channel in the center of the composite piston. Compared with the prior art, the jetting machine has the characteristics of reasonable design, simple structure, safety and reliability, convenient use, easy maintenance and so on, and has good popularization value and use value.

Owner:ZHEJIANG BETHEL TECH CO LTD

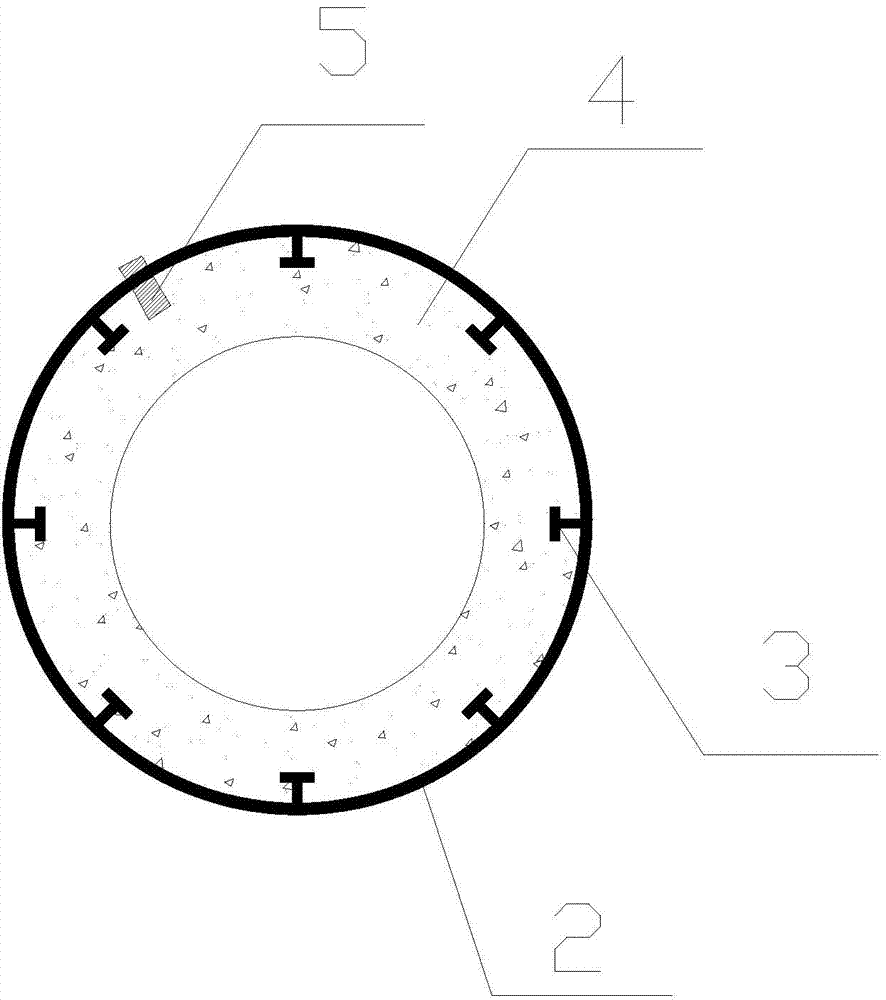

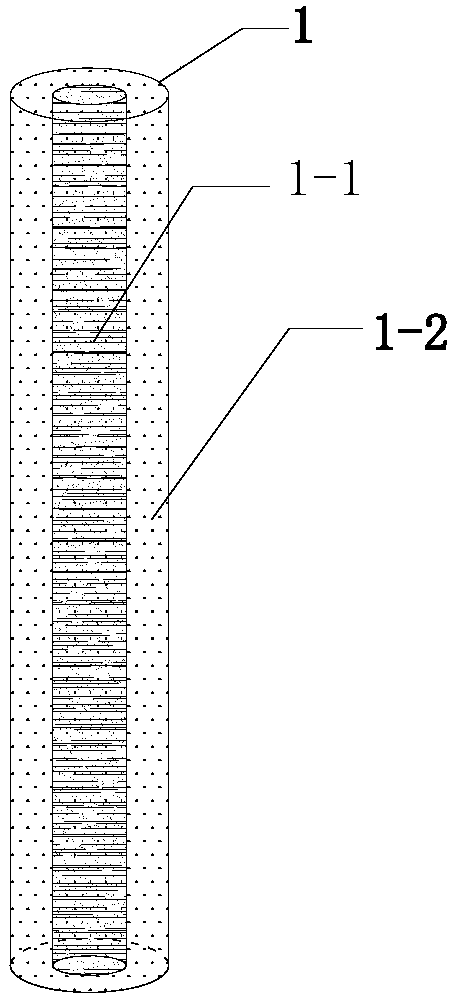

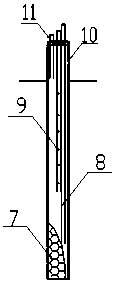

Steel pipe concrete pile

InactiveCN104762954AImprove bending resistanceImprove adhesionSurface layering apparatusCeramic shaping mandrelsBiting forceBinding force

The invention provides a steel pipe concrete pile. The steel pipe concrete pile comprises an outer-layer steel pipe; a spiral rib is fixed on the inner wall of the outer-layer steel pipe; a plurality of circles of rivets are fixed at the circumference of the inner wall of the outer-layer steel pipe; the outer-layer steel pipe is lined with a concrete inner layer, and an end plate is arranged at the end portion of the outer-layer steel pipe; according to the structural design, the biting force of the steel pipe and the concrete comprises three parts, namely the biting force of the spiral rib and the concrete, the anchoring force of the rivet and the concrete and the binding force of the inner wall of the steel pipe and the concrete; the added spiral rib rivet is capable of improving the binding of the concrete and the steel pipe to a large extent, so that the concrete and the steel pipe can be bound firmly and the impact resistance can be enhanced, and in the striking process, the concrete and the steel pipe are not separated from each other. According to experimental verification, after the spiral rib is added and the rivet is arranged, the bending resistance and the shear-bearing capacity of the novel pipe pile are improved by 50%.

Owner:建华建材(蚌埠)有限公司

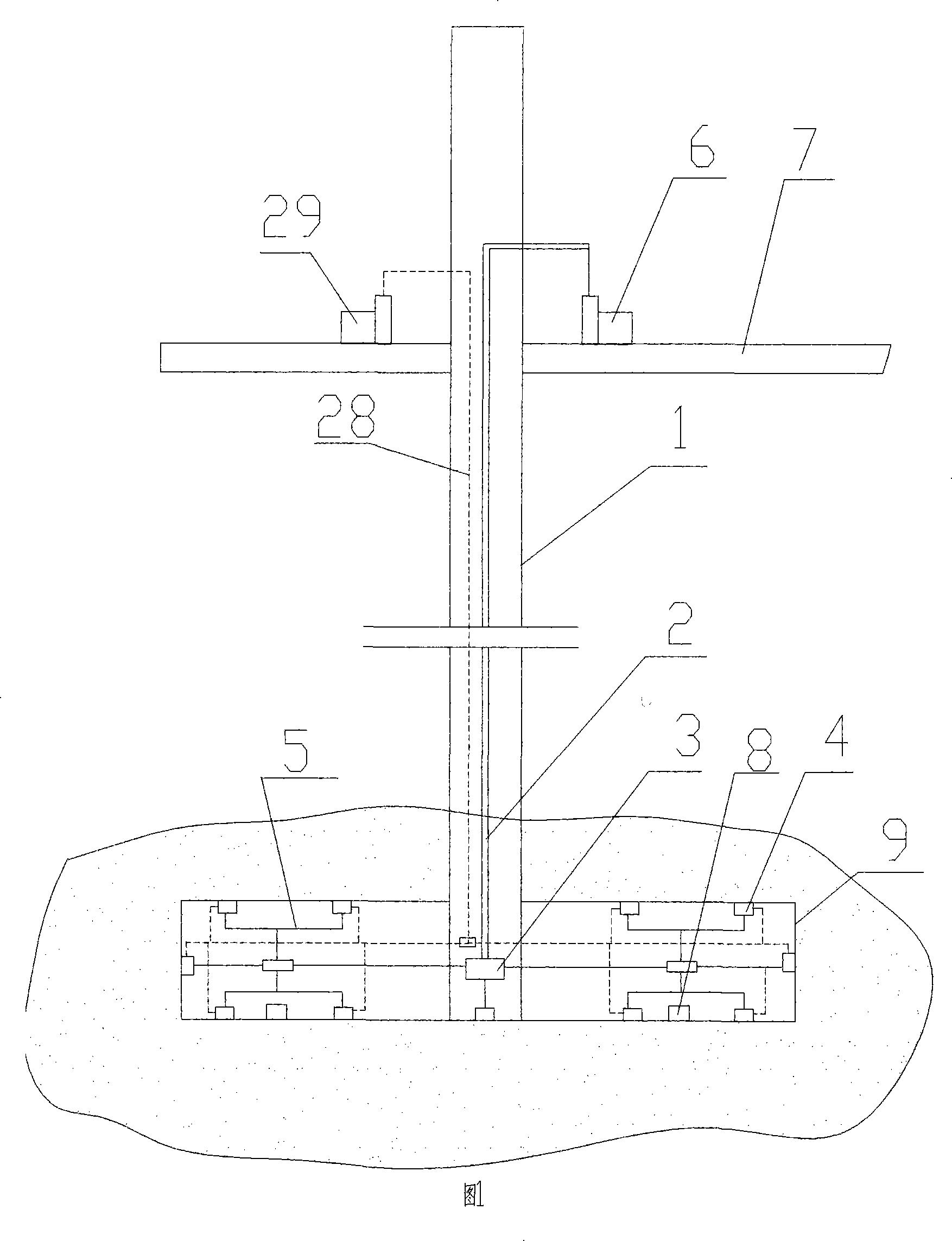

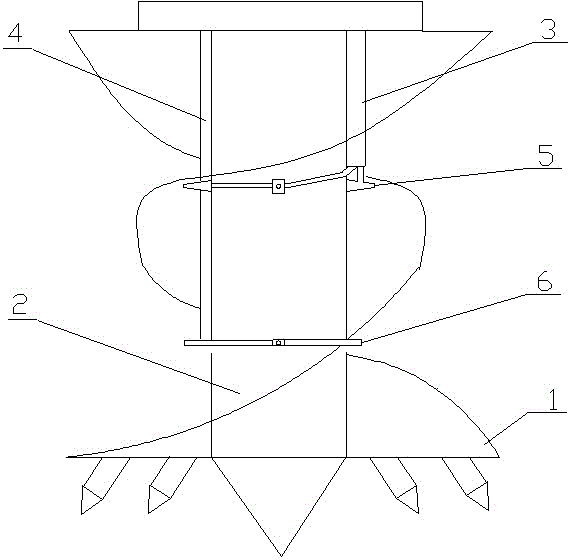

Petroleum platform pile shoe lifting auxiliary system

ActiveCN101126235AImprove the efficiency of migration constructionImprove stabilityArtificial islandsUnderwater structuresEconomic benefitsWater flow

The invention provides a system to assist to lift the pile shoe of the petroleum platform, which is to arrange a high pressure pump on the petroleum platform, a feed water pipe of the high pressure pump passes through the central tubular cavity of the pile and is connected with an anti-blockage injector arranged in the pile shoe at the lower end of the pile, the anti-blockage injector is arranged in the upper side, the lower side and the periphery of the inner wall of the pile shoe, the high-pressure water flow injected from the anti-blockage injector is utilized to cut the silt adhered on the outer surface of the pile shoe; a pulsator is additionally arranged in the pile shoe, the silt adhered on the outer surface of the pile shoe is made loose and flow like the porridge through the vibration of the pulsator and thus, the resistance is reduced and the lifting speed of the pile shoe is improved. The invention has the advantages that the invention needs less investment, is easy to be operated and the lifting speed of the pile is high, which can improve the operating efficiency in the transfer of the petroleum platform and shorten the construction period. In addition, when the pile of the petroleum platform is lowered in a new site, the pulsator arranged in the pile shoe can be utilized to expedite the sinking speed of the pile shoe to improve the stability of the pile shoe and thus, the invention has huge economic benefit.

Owner:ZHEJIANG BETHEL TECH CO LTD

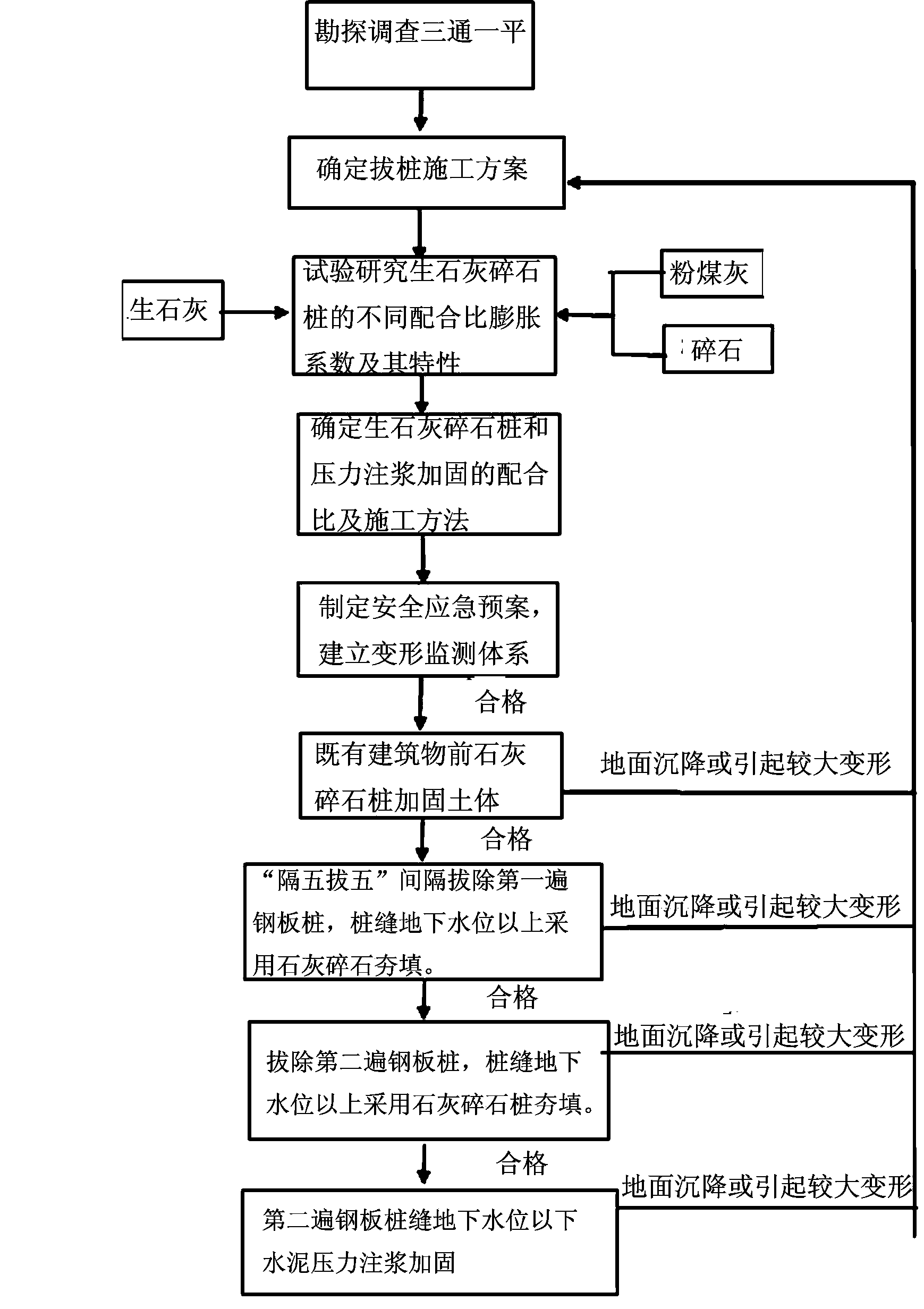

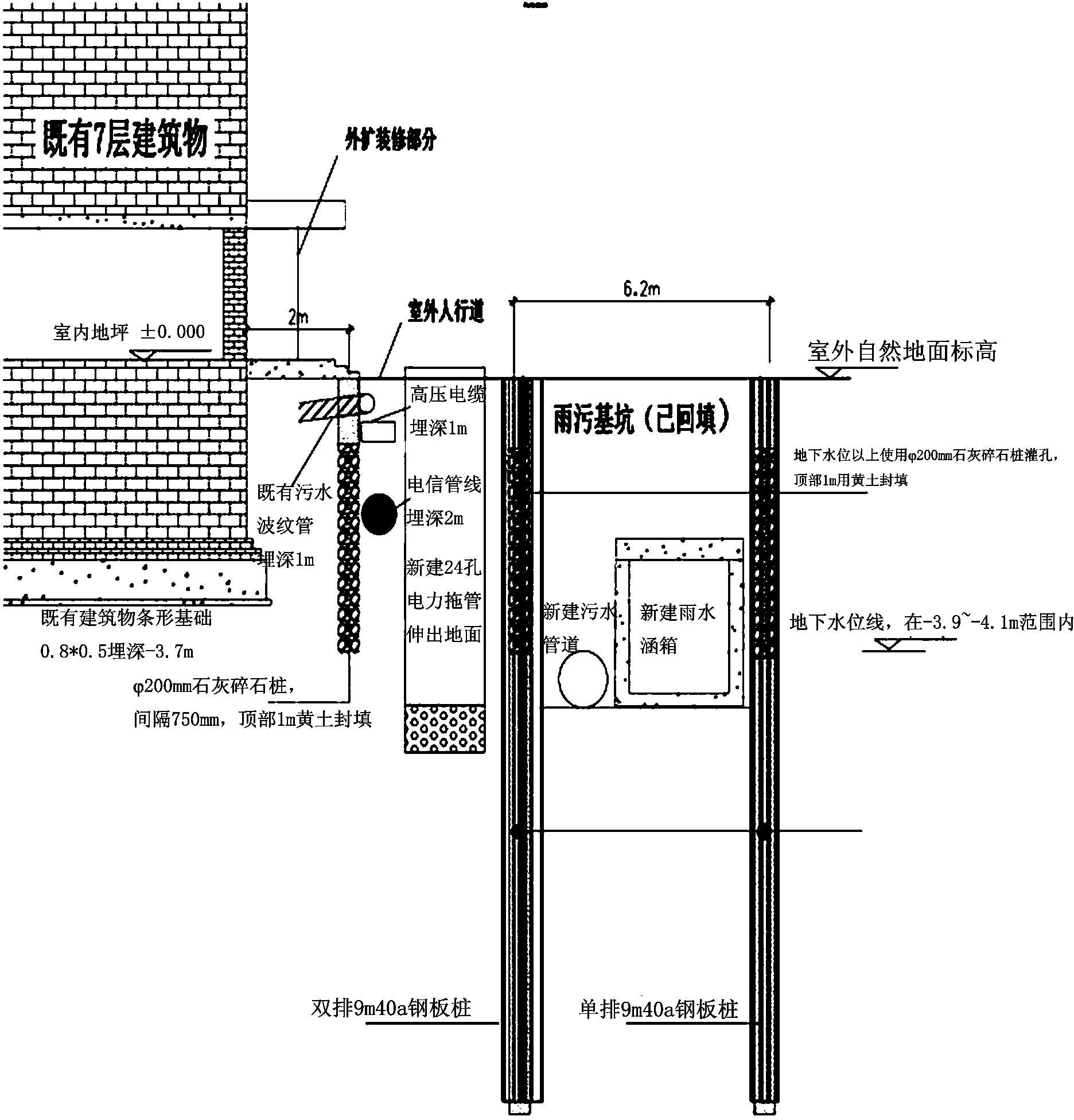

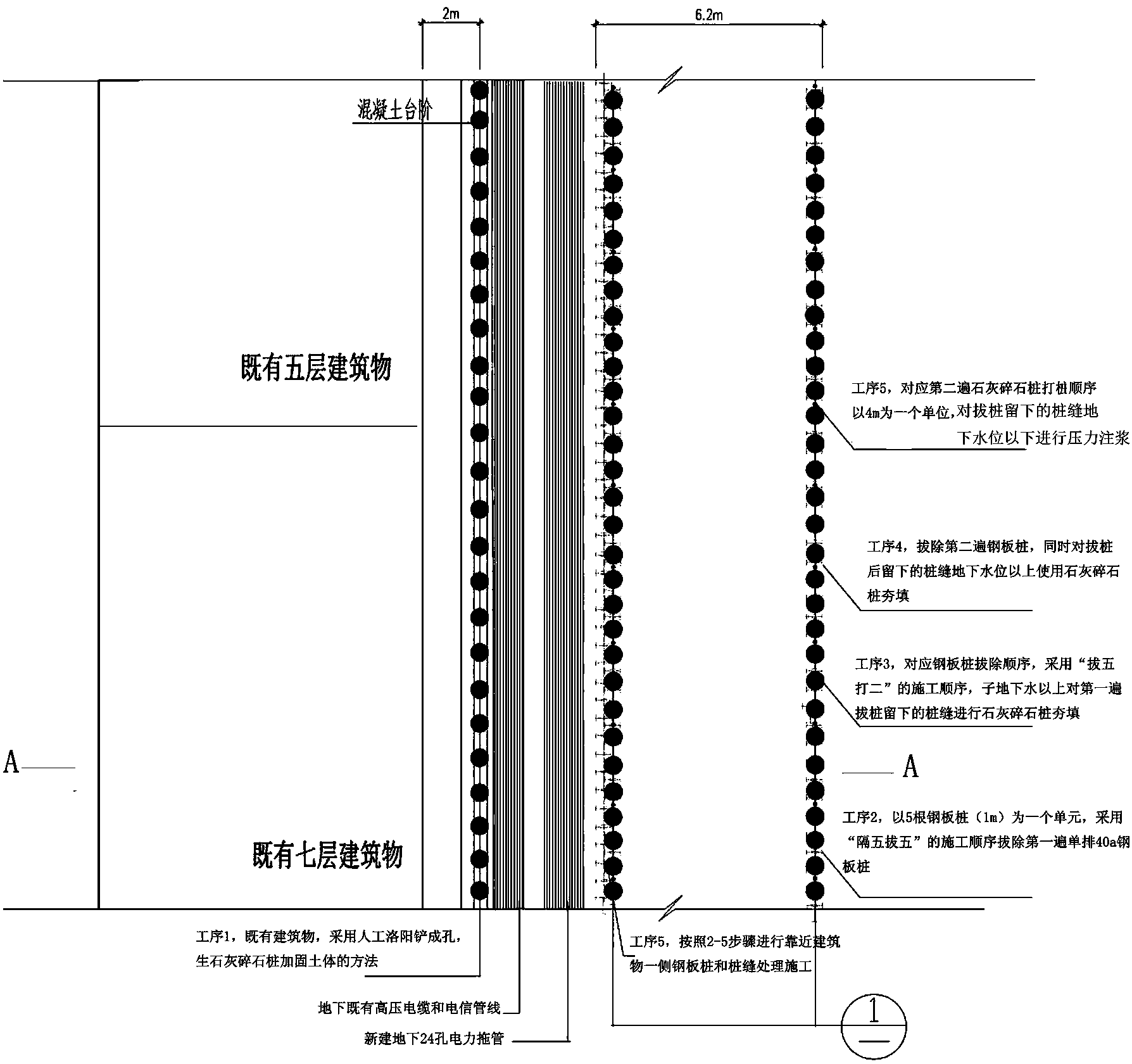

Construction method for pulling out steel sheet piles close to existing buildings

The invention relates to steel sheet pile pulling out technique, in particular to a construction method for pulling out steel sheet piles close to existing buildings, and solves the technical problem that at present, foundations of the existing buildings are prone to influences so as to influence safety of buildings when the steel sheet piles are pulled out in construction of road pipe networks close to the buildings. The construction method for pulling out the steel sheet piles close to the existing buildings is characterized by including the steps: (1) taking five steel sheet piles as a unit to pull out the steel sheet piles; (2) using a 'pulling out five and piling two' construction method, namely piling two lime gravel piles when every five steel sheet piles are pulled out, for punning and filling pile seams, above underground water level, left after first-time pulling out; (3) pulling out remnant steel sheet piles for the second time, and using the 'pulling out five and piling two' construction method for treatment of the pile seams left after second-time pulling out of the steel sheet piles. The method is safe, reliable, simple in construction operation, quick in construction, effective in reinforcement, low in manufacturing cost, low in environmental constraint and low in influences on the existing buildings and pipelines.

Owner:CHINA RAILWAY SIXTH GROUP +1

CFG core gravel composite pile, composite foundation formed by CFG core gravel composite pile and construction method

InactiveCN108677912AImprove stabilityShorten the construction periodSoil preservationSoil strengthIndustrial waste

The invention discloses a CFG core gravel composite pile, a composite foundation formed by the CFG core gravel composite pile and a construction method. The CFG core gravel composite pile comprises aCFG core and a gravel shell wrapping the CFG core, wherein the gravel shell is formed by sand and macadam according to the volume ratio being (1-2):1. The composite foundation formed by the CFG core gravel composite pile is characterized by comprising a soft soil foundation, the CFG core gravel composite pile driven into the soft soil foundation and a mattress layer filled into the position abovethe CFG core gravel composite pile and the soft soil foundation, and a geogrid is arranged on the mattress layer. The invention further discloses a construction method. The CFG core gravel composite pile, the composite foundation formed by the CFG core gravel composite pile and the construction method have the beneficial effects that the construction is easy and convenient, the pile forming speedis high, super-static pore water pressure in soil between piles in the construction period is quickly scattered, the soil strength is quickly restored, the working period is shortened, the post-construction settlement is small, and the industrial waste is used for reducing the building cost of projects; and the economic benefit and the social benefit are obvious.

Owner:JIANGSU UNIV OF SCI & TECH

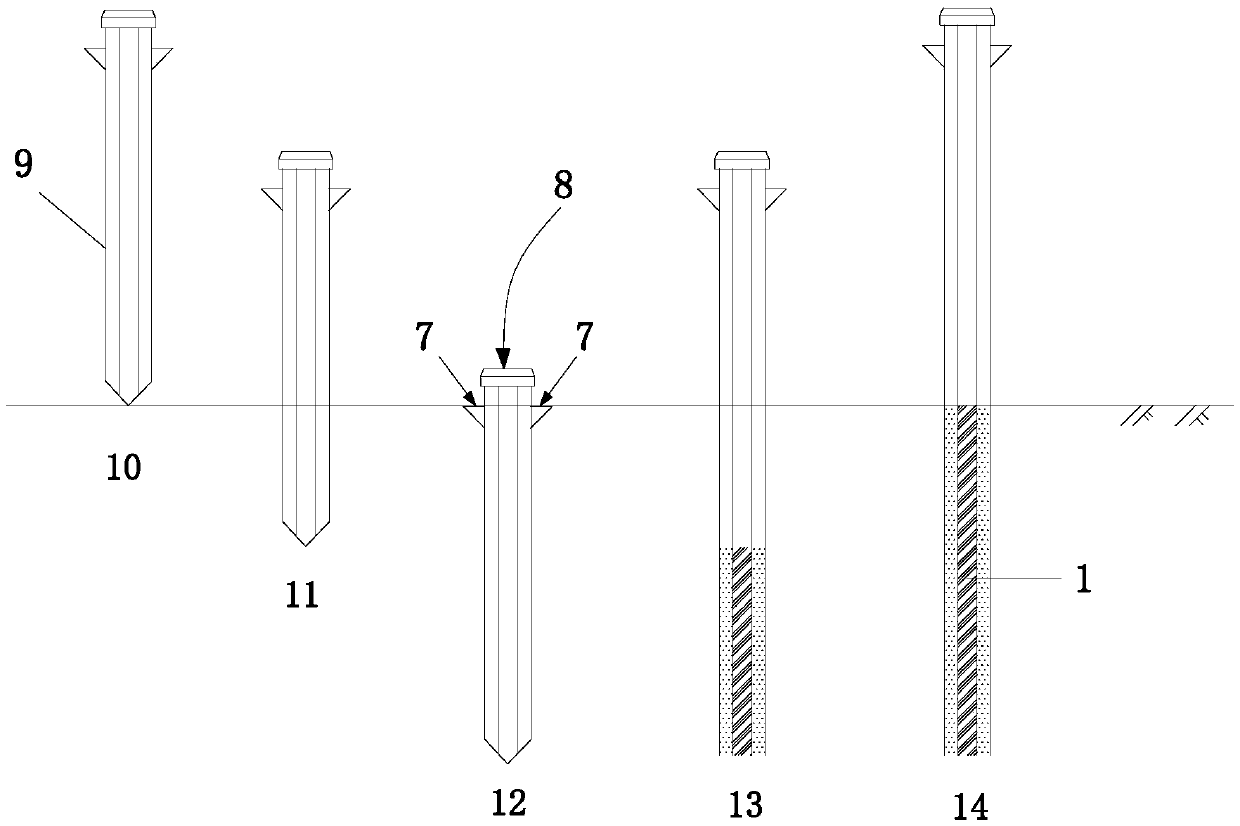

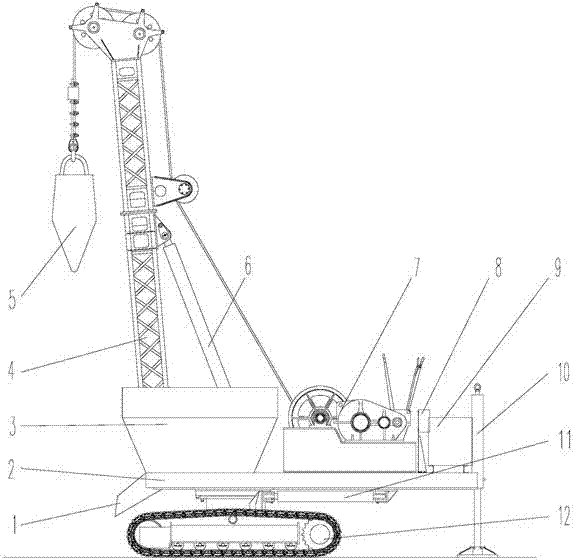

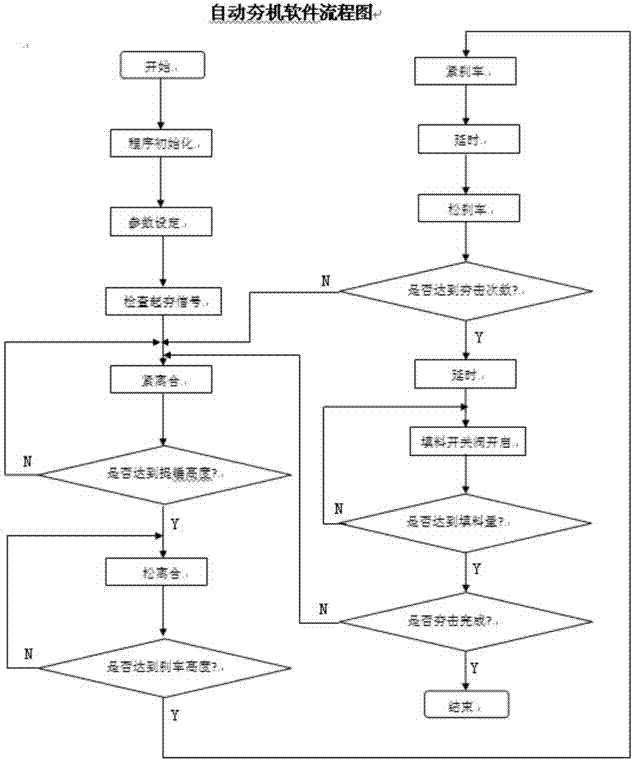

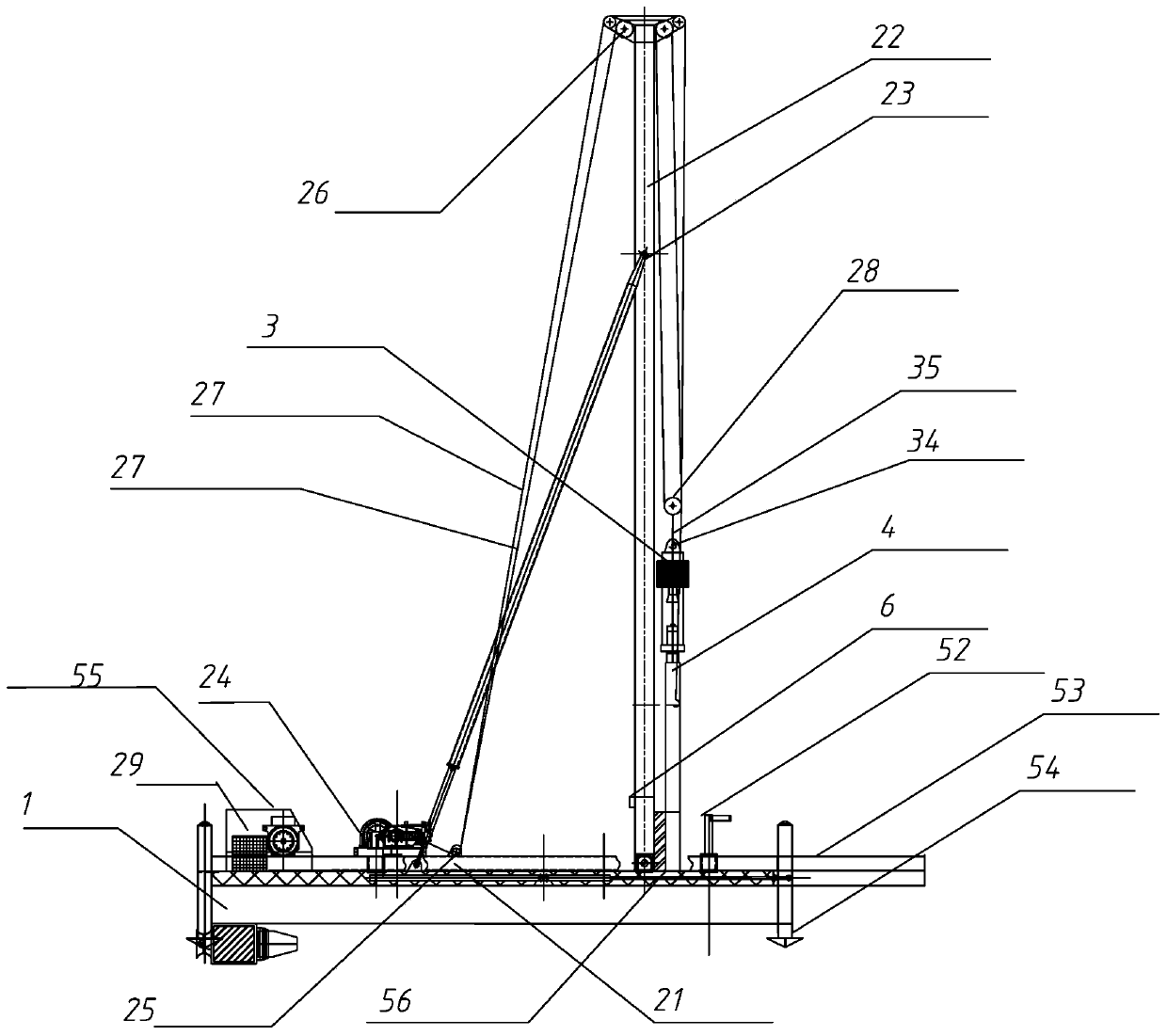

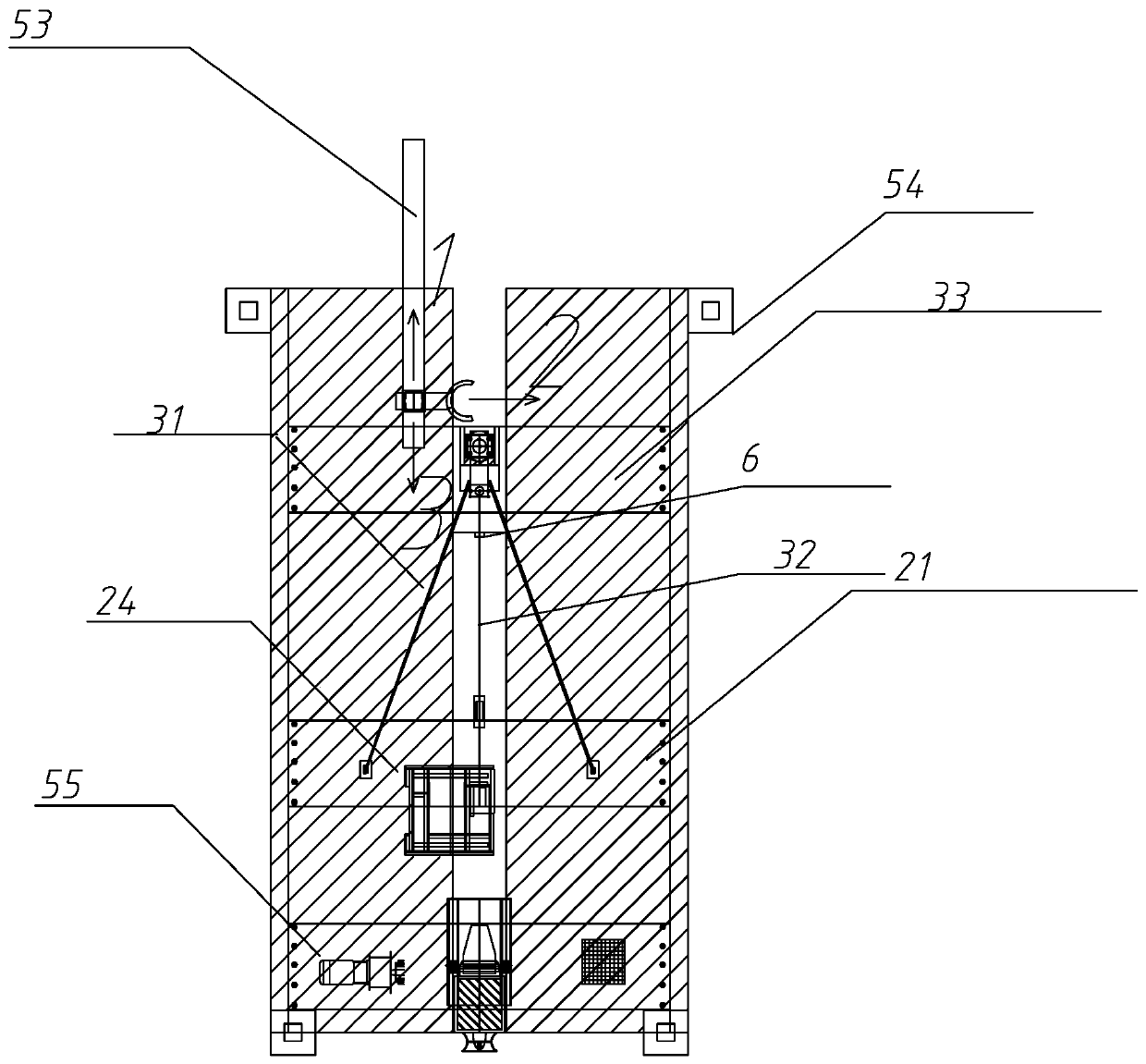

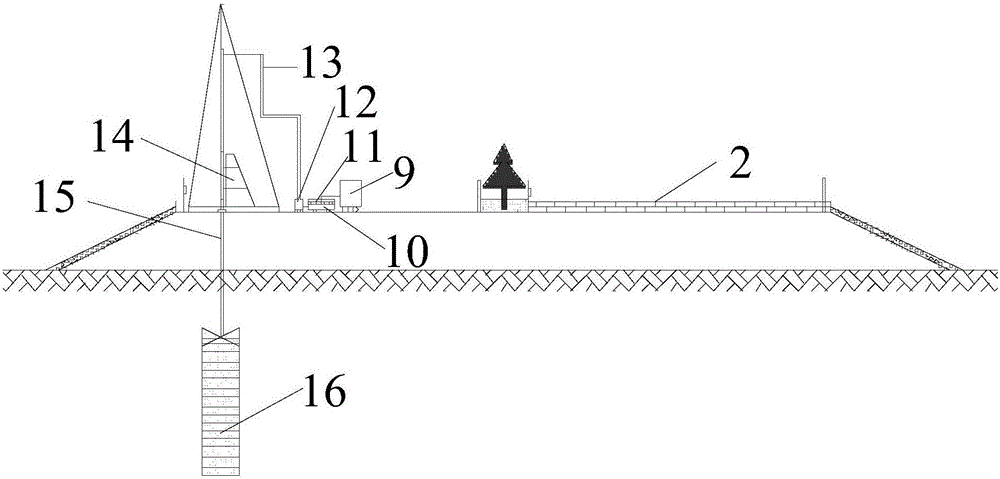

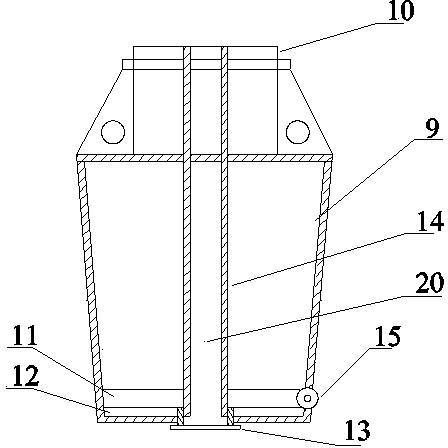

Down-hole deep dynamic compactor

InactiveCN103758107AEasy to fillRealize automatic cycle scalingSoil preservationControl systemPulley

The invention discloses a down-hole deep dynamic compactor. The down-hole deep dynamic compactor comprises a base plate (12), a platform (2), a mast (4), an operation table (8), a hydraulic system, a control system (9), a hoist (7) and a pounder (5), wherein the lower end of the mast (4) is hinged on the platform (2), a mast oil cylinder (6) is arranged between the platform (2) and the mast (4) in hinge mode, a steel wire rope on the hoist (7) is wound around a dynamic hip pulley on the mast (4) and then fixedly connected with the pounder (5), the platform (2) is connected with the base plate (12) through a rotary device, a hopper (3) and a material tongue (1) are arranged on the platform (2), an outlet of the hopper (3) is provided with a hopper door which is butted with the material tongue (1), and the control system (9) is communicated with an operation system of the hoist (7) and an operation system of the hopper door. According to the down-hole deep dynamic compactor, pile butting is facilitated, the pounder of the down-hole deep dynamic compactor does not comprise a hook, and padding quantity of pile holes is convenient to control. Furthermore, the down-hole deep dynamic compactor is simple and reliable to operate, high in pile forming quality, and high in pile forming speed.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

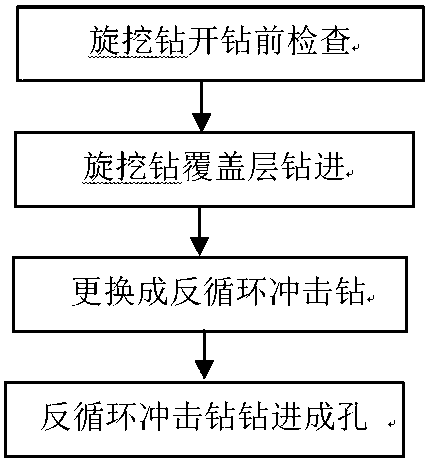

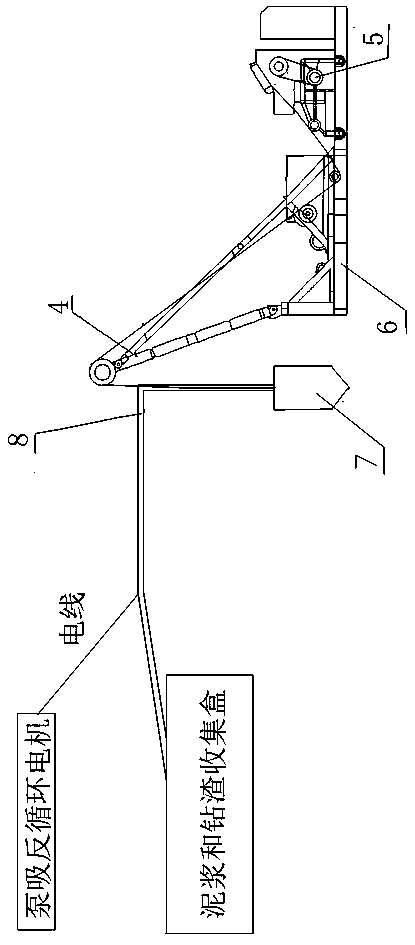

Rapid hole-forming construction method of large-diameter deep hole pile foundation under karst geology

InactiveCN111594041AEasy to moveAvoid drilling difficulties, low efficiency and other problemsDrilling drivesFlushingKarstEconomic benefits

The invention discloses a rapid hole-forming construction method for a large-diameter deep hole pile foundation under karst geology. 'Rotary drill and reverse circulation impact drill' combined relaydrilling is performed, a rotary drill rapidly performs drilling construction of a covering layer, and a reverse circulation impact drill is used for relay construction when a karst geological layer isdrilled. The combined construction process gives full play to the advantages of the two kinds of drills under the situations of different geological conditions and hole depths, the advantages are complemented with each other, and the construction efficiency and economic benefits of the large-diameter deep hole pile foundation under the karst geology are improved. Drilling of single drilling equipment is converted into combined drilling of the two different kinds of drilling equipment, the construction progress of the pile foundation is greatly accelerated under the condition of ensuring the hole-forming quality of the pile foundation, meanwhile, environmental friendliness is better achieved, civilized construction is facilitated, input of personnel and mechanical equipment is reduced, andthe good economic benefits are generated.

Owner:THE 5TH ENG MBEC

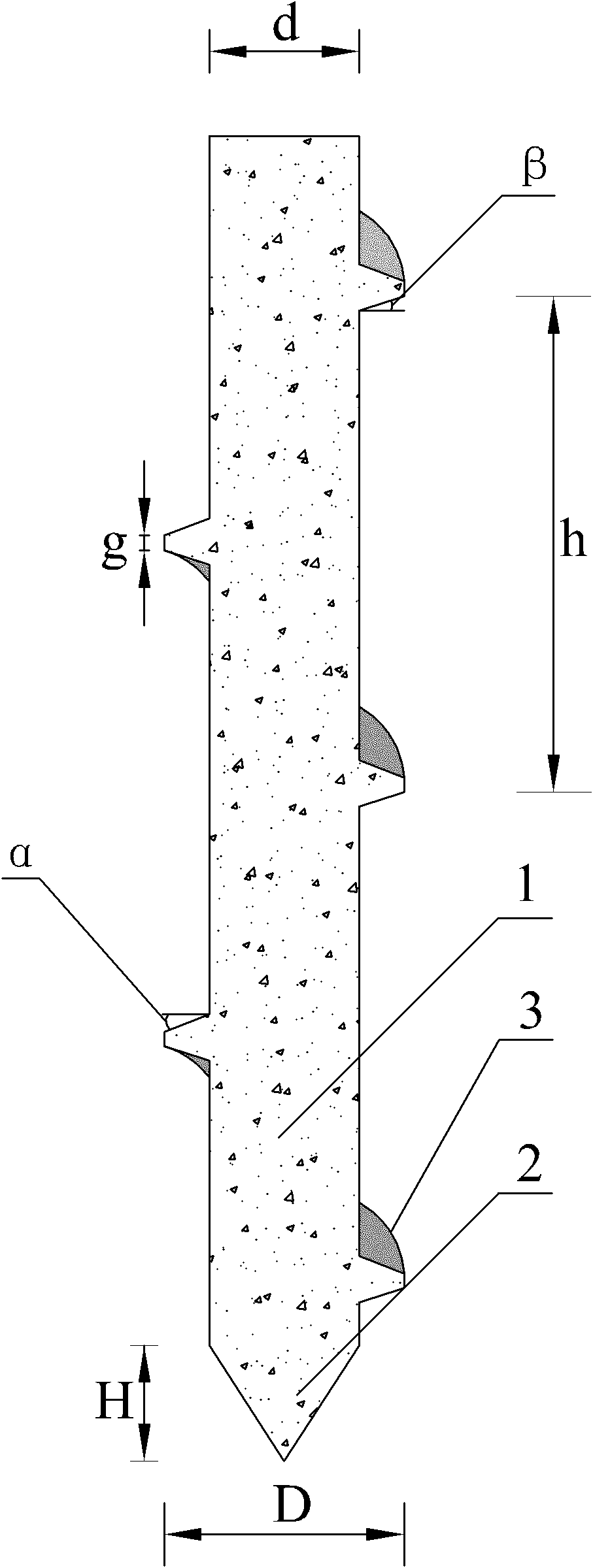

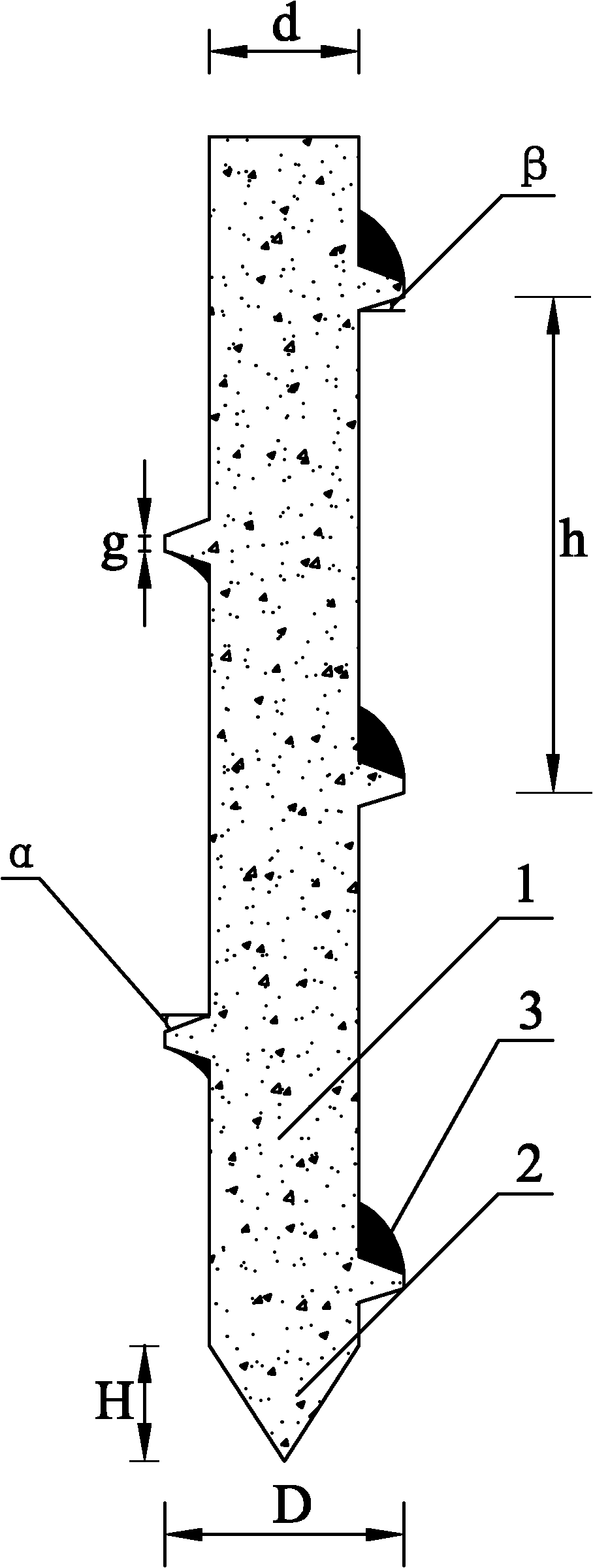

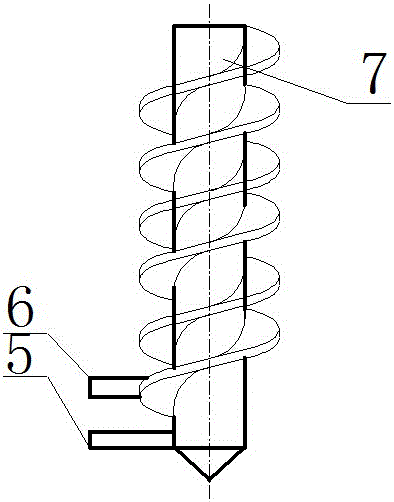

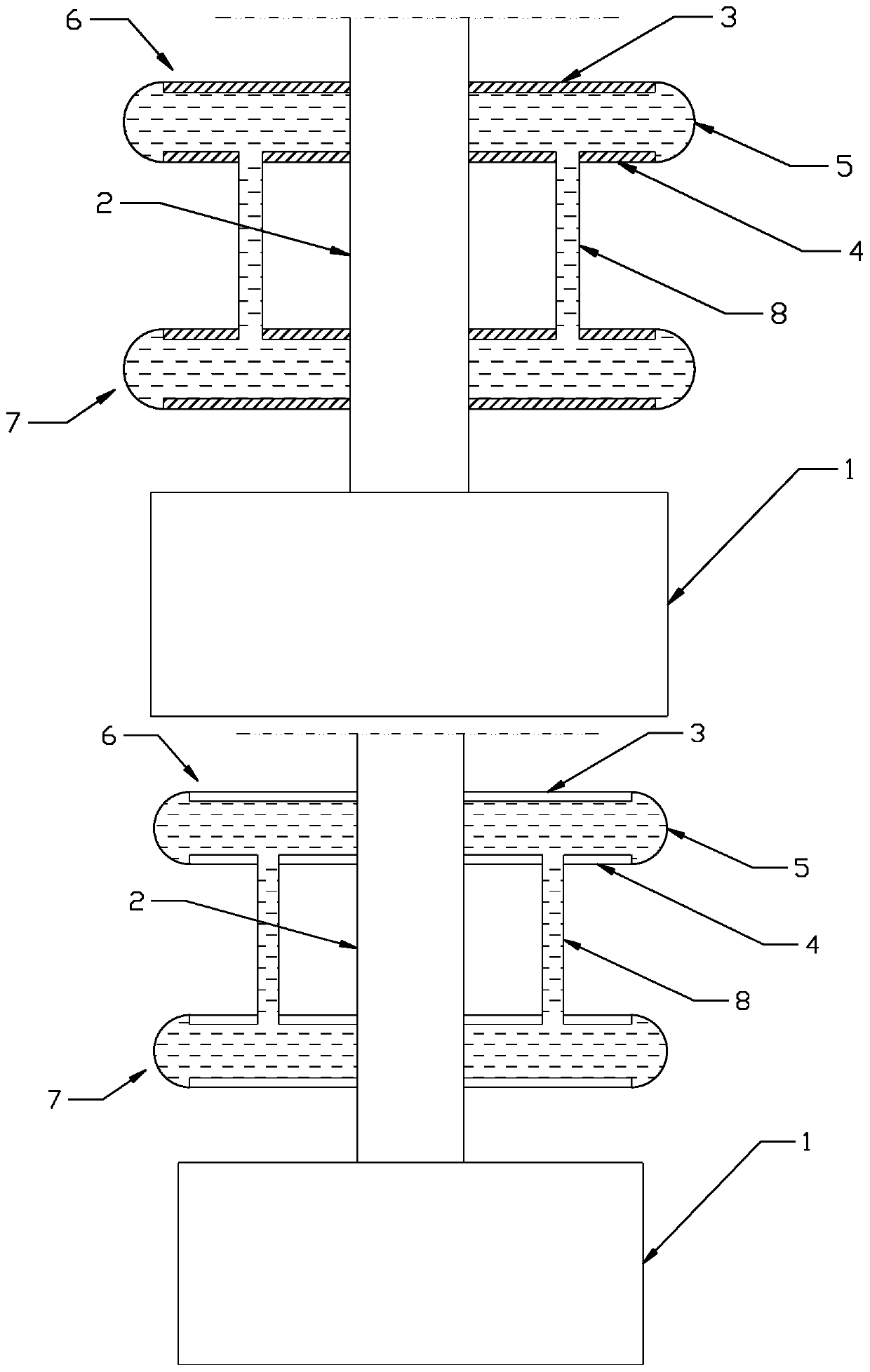

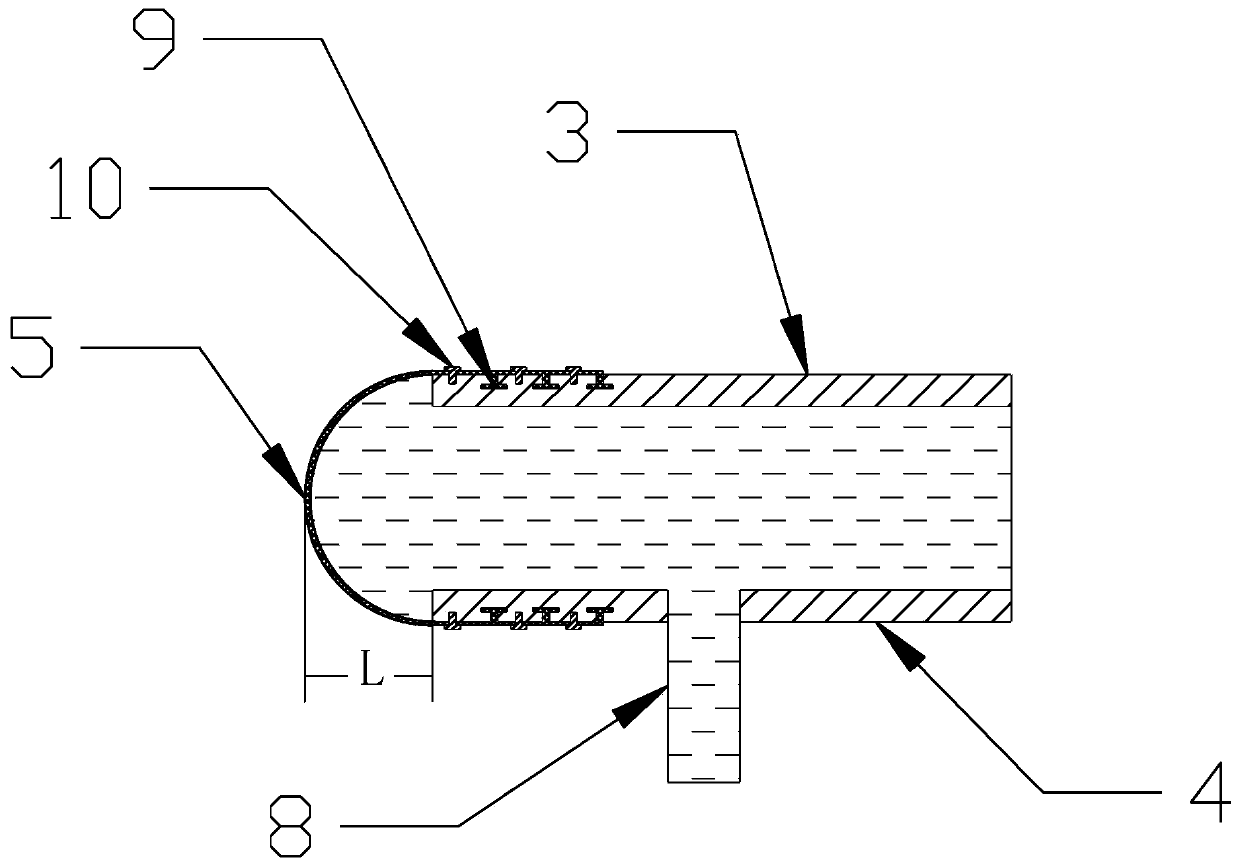

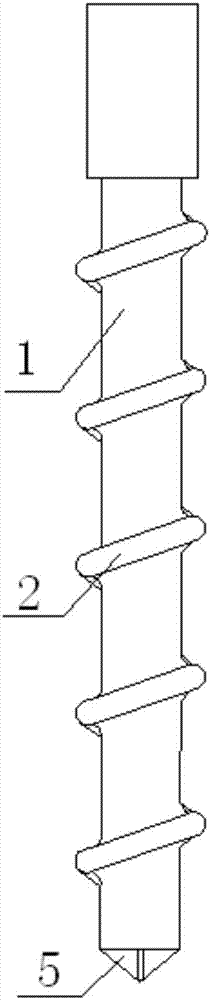

Screw pile used for seasonally frozen ground zone

InactiveCN102031778AWith continuous compactnessWith denseBulkheads/pilesStructural engineeringEngineering

The invention relates to a screw pile used for a seasonally frozen ground zone, belonging to a screw pile and aiming at solving the problems of a certain limit of application range, easy breaking, no guarantee of pile body quality and high engineering cost of the traditional linear pile in the seasonally frozen ground zone at present. The screw pile comprises a concrete pile body, a concrete pile head and a concrete screw blade, wherein the concrete pile body is cylindrical, the concrete pile head is shaped as a cone, the bottom end face of the concrete pile body and the upper end face of the concrete pile head are fixedly connected and made into a whole, the concrete screw blade is arranged on the outer wall of the concrete pile body, the concrete screw blade and the concrete pile body are made into a whole, the upper inclination of the concrete screw blade is 15-45 DEG, the pitch of the concrete screw blade is 800-1,000mm, and the ratio of the diameter of the concrete pile body to the outer diameter of the concrete screw blade is 0.5-0.7. The invention is used for the pile foundation of the seasonally frozen ground zone.

Owner:HARBIN INST OF TECH

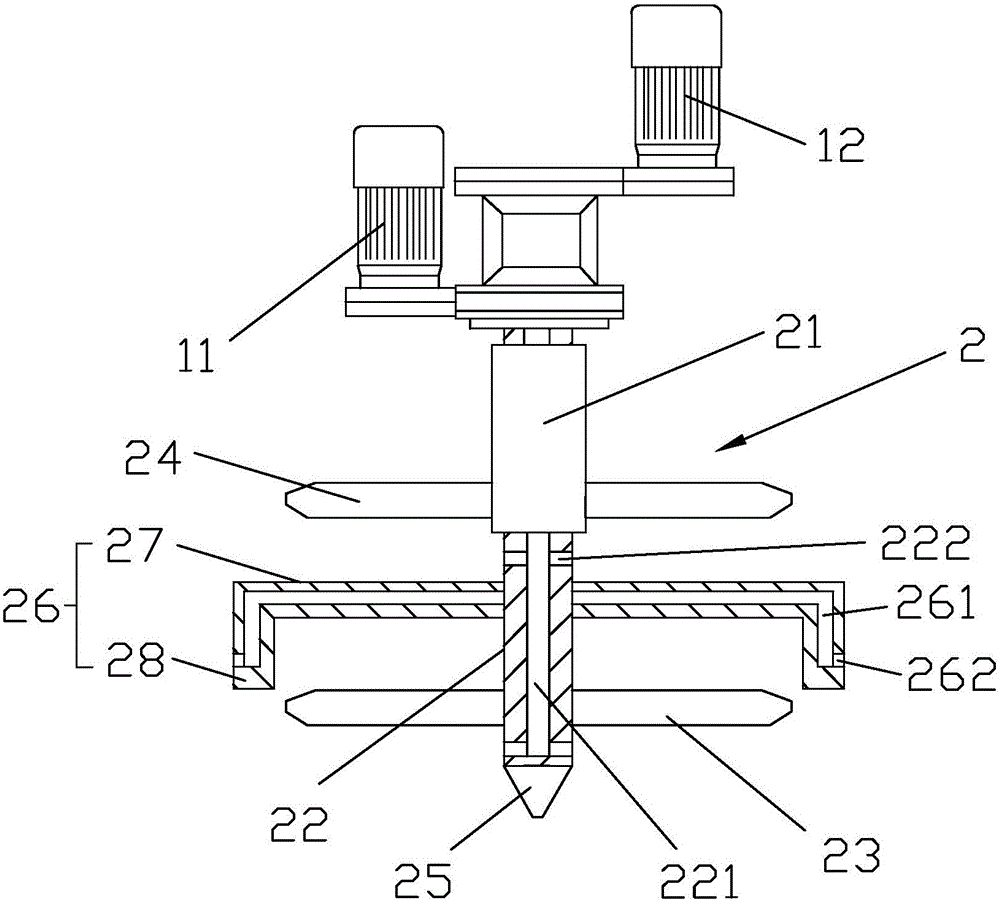

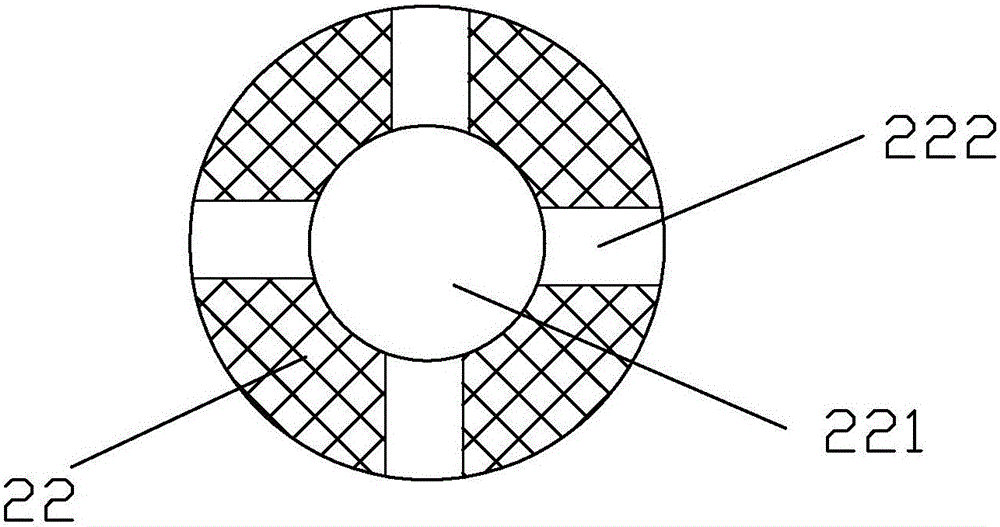

Stirring device and method for stirring sea mud

The invention mainly discloses a stirring device and method for stirring sea mud. According to the technical scheme, the stirring device comprises a chassis, a first motor, a second motor, a stirring machine head and a conveying device; the stirring machine head comprises an outer drill pipe, an inner drill pipe, first stirring blades and second stirring blades; the inner drill pipe is provided with a drill bit and third stirring blades; the drill bit is located at the bottom end of the inner drill pipe, and the third stirring blades are located between the first stirring blades and the second stirring blades; the inner drill pipe is provided with a first conveying channel and two first discharging sections; and the third stirring blades are provided with a second conveying channel and a second discharging section. The method comprises the steps of primary stone crushing, grout spraying, stirring and sinking, in-situ stirring, detecting, grout spraying, stirring and ascending, secondary detecting and stirring machine head cleaning. According to the stirring device and method, the multiple stirring blades are adopted, stirring is uniform, and the stirring efficiency and the stirring mixing effect are improved; and the multiple discharging sections are arranged, the one-time grout spraying amount is large, the pile forming speed is high, the pile forming quality is good, and the construction cost is saved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

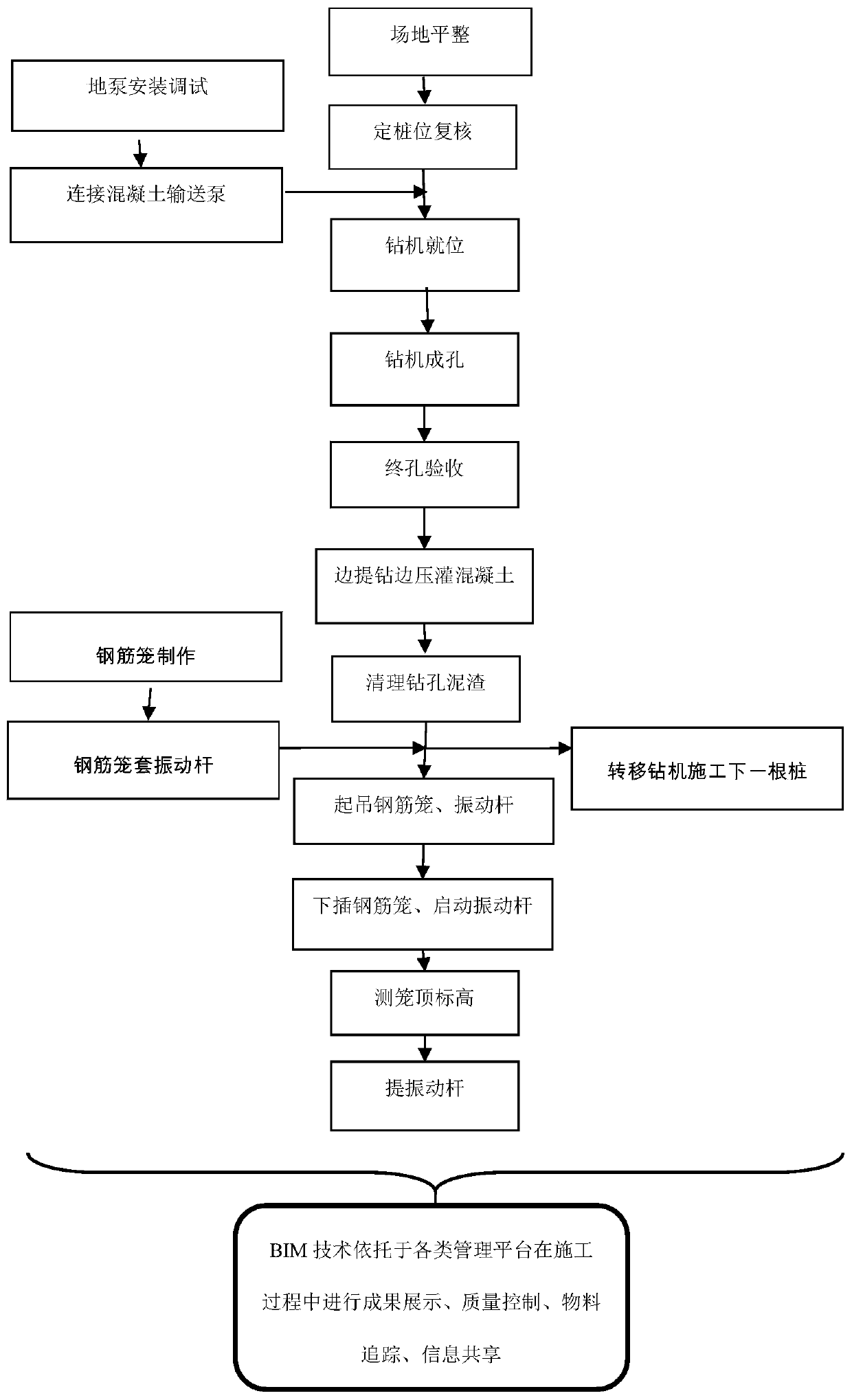

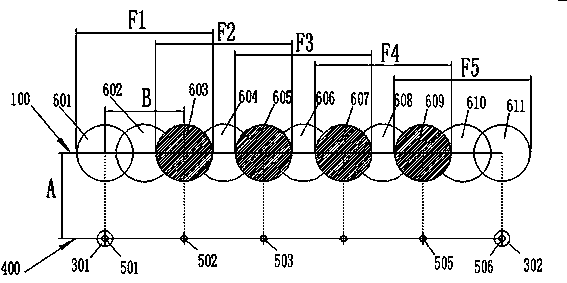

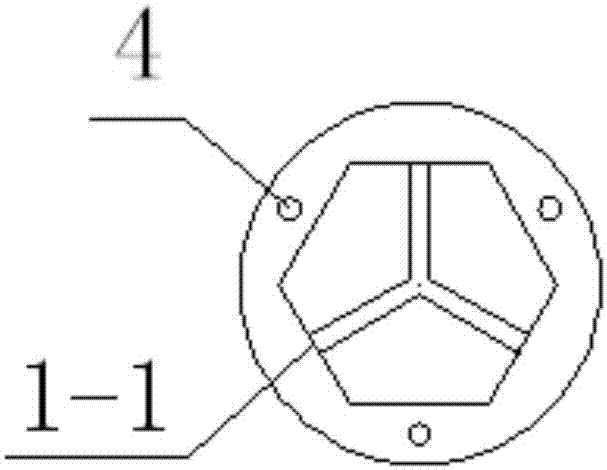

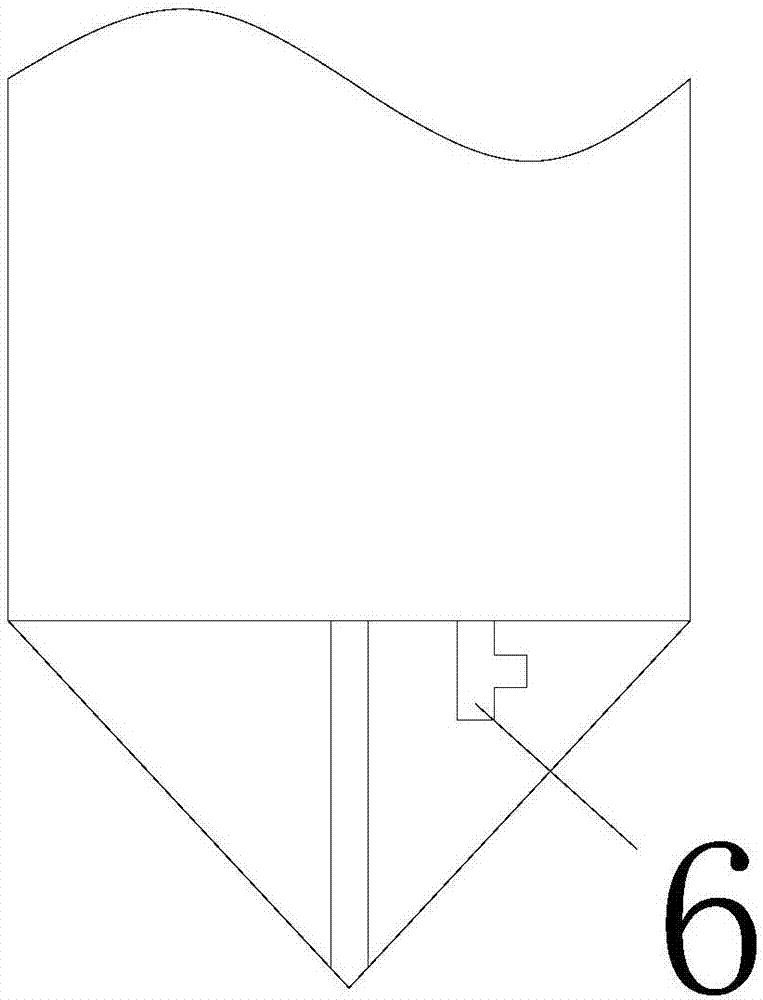

Forming construction method of long-spiral pore-forming pile-slab-pile supporting and anti-seepage continuous wall

PendingCN105464079AReduce investmentShear resistantArtificial islandsUnderwater structuresHigh pressureCement paste

The invention discloses a forming construction method of a long-spiral pore-forming pile-slab-pile supporting and anti-seepage continuous wall. The continuous wall is formed in a manner that a long-spiral drilling high-pressure jetting cemented soil composite concrete pile slab composite pile is taken as a construction main body and pile-slab-pile crossed construction and combination in different sequences is carried out. The forming construction method comprises the following steps that Step one, construction preparation is carried out; Step two, pile foundation construction and pore-forming are carried out, high-pressure jetting cement paste slab forming hole construction, and press grouting pile slab concrete construction are carried out, concrete is subjected to press grouting to reach the elevation of a pile top, then first plain concrete pile slab construction is accomplished; Step three, a second plain concrete pile slab is coaxially connected and constructed according to a designed pile space, and after second plain concrete pile slab construction is accomplished, the construction of a pile-slab-pile supporting and anti-seepage continuous wall structural unit is accomplished; and Step four, the pile slab construction of the next unit is carried out according to the operational procedures above, then the complete pile-slab-pile supporting and anti-seepage continuous wall is formed. According to the forming construction method of the long-spiral pore-forming pile-slab-pile supporting and anti-seepage continuous wall, stand-alone construction is realized, the equipment investment is low, the energy consumption is low, and the cost is saved.

Owner:李金良

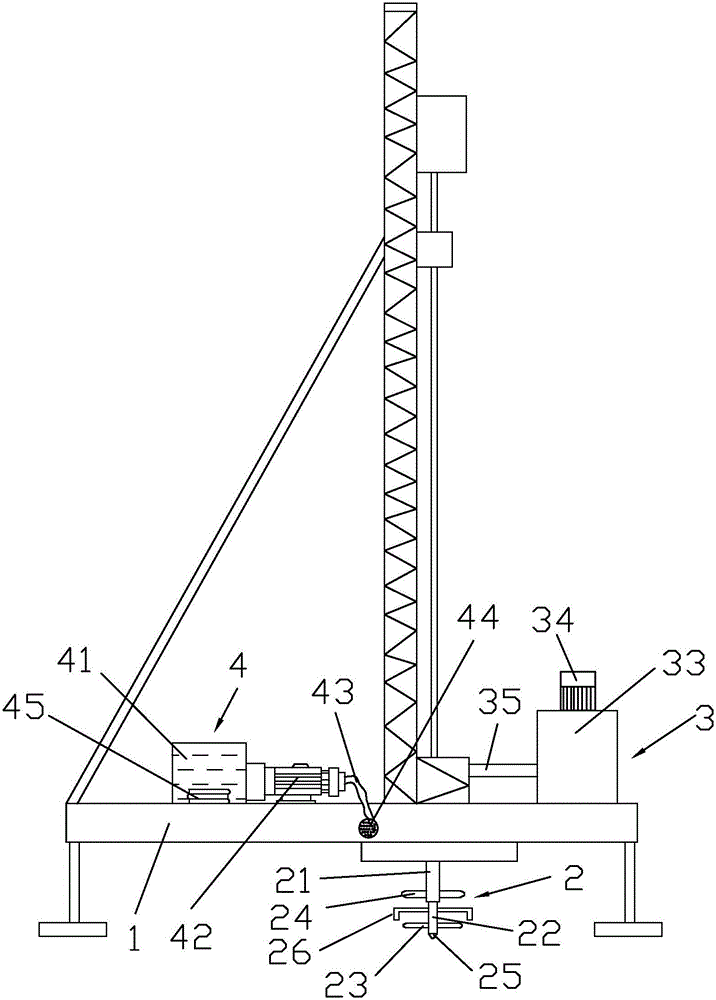

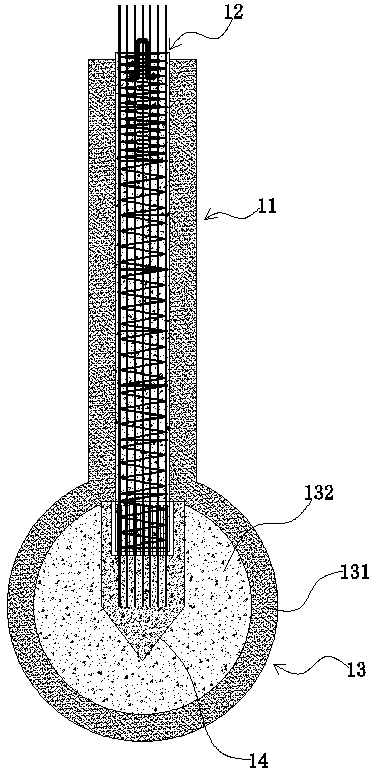

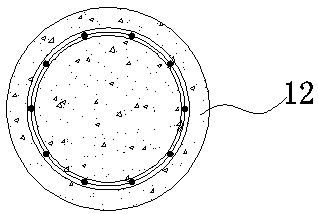

Spiral high-pressure jetting wing-enlarged stirring bottom-expanded stiff composite pile, construction method thereof and drilling machine

PendingCN108729440AImprove bearing capacityIncrease side frictionBulkheads/pilesThree stageHigh pressure

The invention discloses a spiral high-pressure jetting wing-enlarged stirring bottom-expanded stiff composite pile, a construction method thereof and a drilling machine. According to the stiff composite pile, the construction method thereof and the drilling machine, the technical problems of relatively low bearing capacity, high cost, certain quality defects and the like of an existing stiff composite pile are solved. The spiral high-pressure jetting wing-enlarged stirring bottom-expanded stiff composite pile comprises an outer pile body, an inner core pile body and a bottom-expanded base, wherein the outer pile body, the inner core pile body and the bottom-expanded base are combined into a whole, the strength composite pile further comprises a prefabricated pile tip installed at the lowerend of the inner core pile body, and the inner core pile body and the prefabricated pile tip are planted into the center of the outer pile body. According to the stiff composite pile, the construction method thereof and the drilling machine, firstly, the outer pile body is subjected to high-pressure grouting injection to carry out first-stage extrusion and compaction on pile periphery soil, whenguncreting is carried out on center concrete through the bottom-expanded base, second-stage extrusion and compaction are carried out on the outer pile body, third-stage extrusion and compaction are carried out on the outer pile body in the process of planting the inner core pile body, and the outer pile body which are formed through the three stages of extrusion and compaction is extruded and compacted with the surrounding soil layer, and the resistance of the side of the pile is greatly improved; and secondly, the three stages of extrusion and compaction are carried out on the bottom-expandedconcrete through high-pressure grouting bottom expanding, concrete guncreting bottom expanding and the prefabricated pile tip, so that the resistance of a pile end is further improved.

Owner:中航旭日(北京)岩土工程技术有限公司 +2

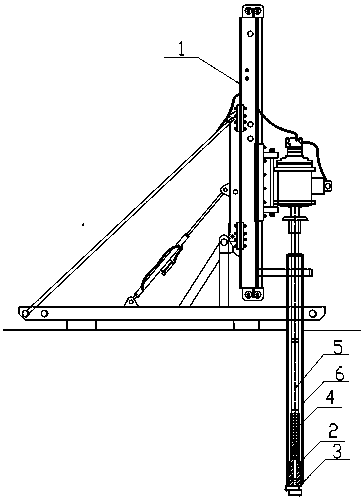

Pile foundation manufacturing method

InactiveCN101892663ALow costReduce the number of processesBulkheads/pilesRebarUltimate tensile strength

The invention discloses a pile foundation manufacturing method, which comprises the following steps of: downwards drilling the ground 3 to form a vertical drill hole 5; pouring concrete into the drill hole 5; lowering a small-aperture pile formed by a reinforcement cage; and directly constructing the mounting of an upper structure after a concrete pile body 4 has certain strength. A pile foundation is manufactured by pouring the concrete into the drill hole formed by downwards drilling the ground, so the method has the advantages of no ground works generated in the construction, reduced work stages (from conventional six work stages to three work stages), remarkably-reduced concrete consumption, remarkably-shortened construction period which is entirely two-thirds shorter than that of a conventional foundation, remarkably-reduced foundation construction cost which is reduced by 75 percent compared with that of the conventional foundation, simplicity, high piling speed, hole-forming process free from the limitation of geological conditions, pile length which can be flexibly adjusted according to the geological conditions, and applicability to foundation design under various reservoir conditions.

Owner:XINJIANG ELECTRIC POWER DESIGN INST

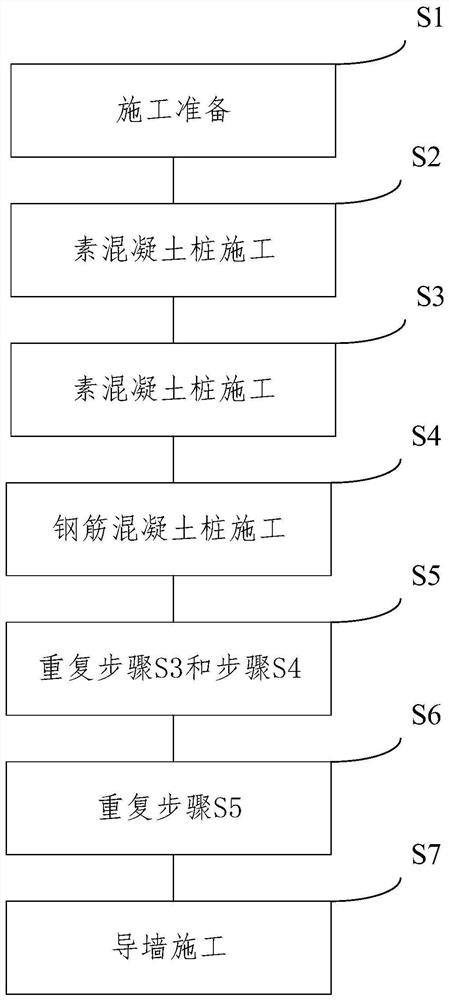

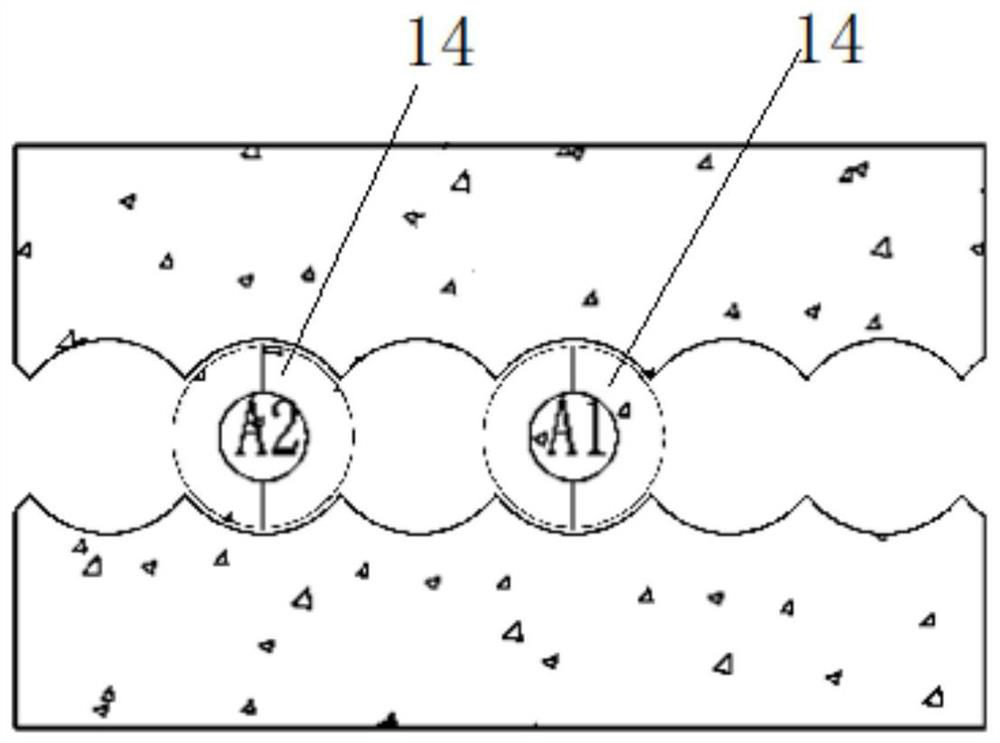

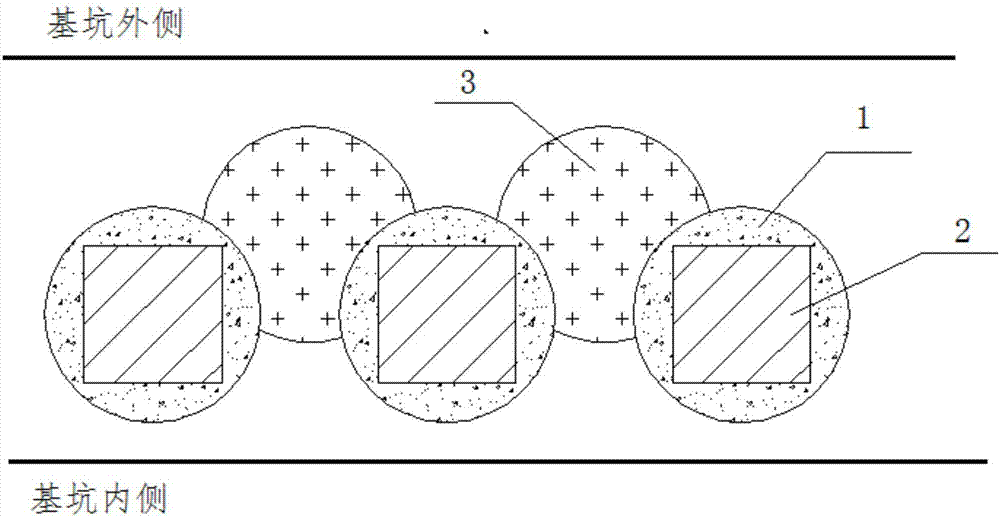

Secant pile construction method and reinforcing structure

The invention relates to the technical field of building construction, in particular to a secant pile construction method and a reinforcing structure. The secant pile construction method comprises the following steps that S1, construction preparation is conducted; S2, a first plain concrete pile is constructed to form an A1 pile; S3, a second plain concrete pile is constructed to form an A2 pile; S4, a first reinforced concrete pile is constructed to form a B1 pile, and the B1 pile is arranged in a secant mode with the A1 pile and the A2 pile; S5, the step S3 is repeated to form a pile A3, the step S4 is repeated to form a pile B2, and the pile B2 is arranged in a secant mode with the pile A2 and the pile A3; S6, the step S5 is repeated, and the construction sequence of all the piles is A1-A2-B1-A3-B2-A4-B3-A5-B4-... An-Bn till secant pile construction is completed; and S7, guide wall construction is conducted. The secant pile construction method is suitable for geology such as moderately-weathered siltstone, strongly-weathered siltstone, cohesive soil, silty soil, sandy soil and artificial filling soil.

Owner:CHINA RAILWAY 19TH BUREAU GRP 3RD +1

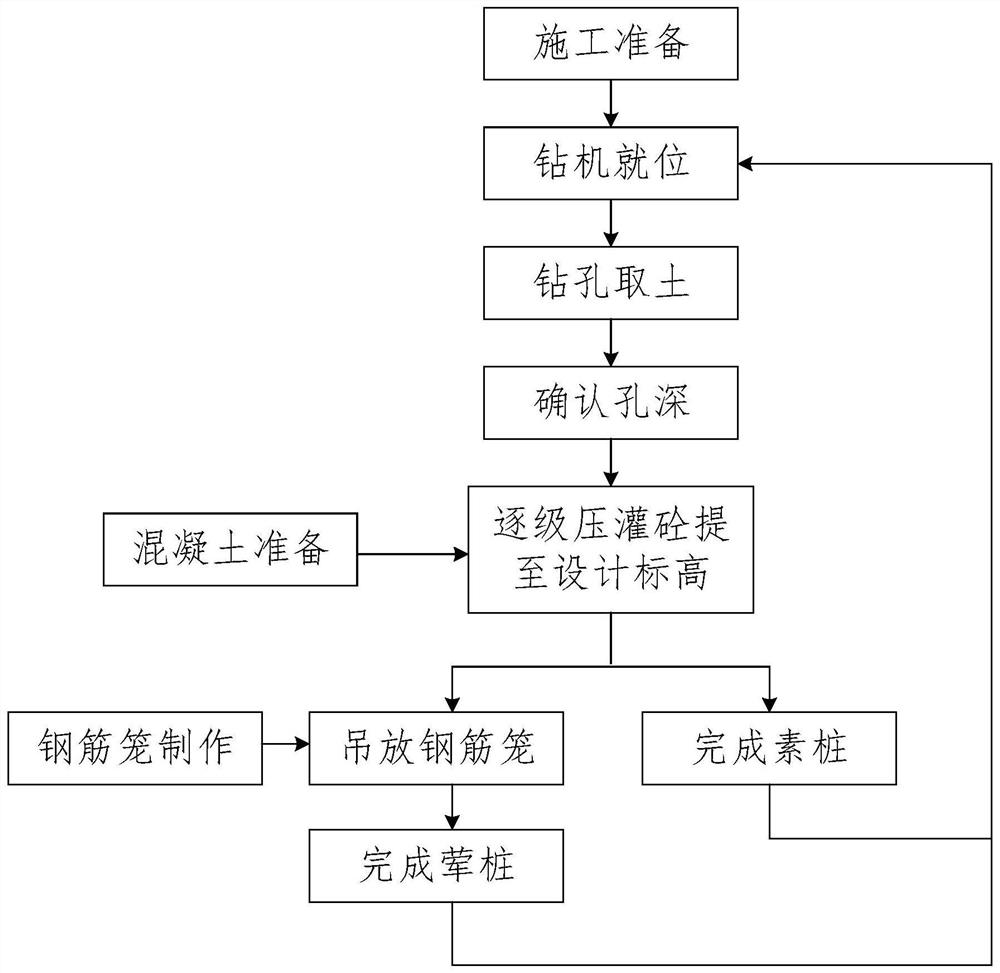

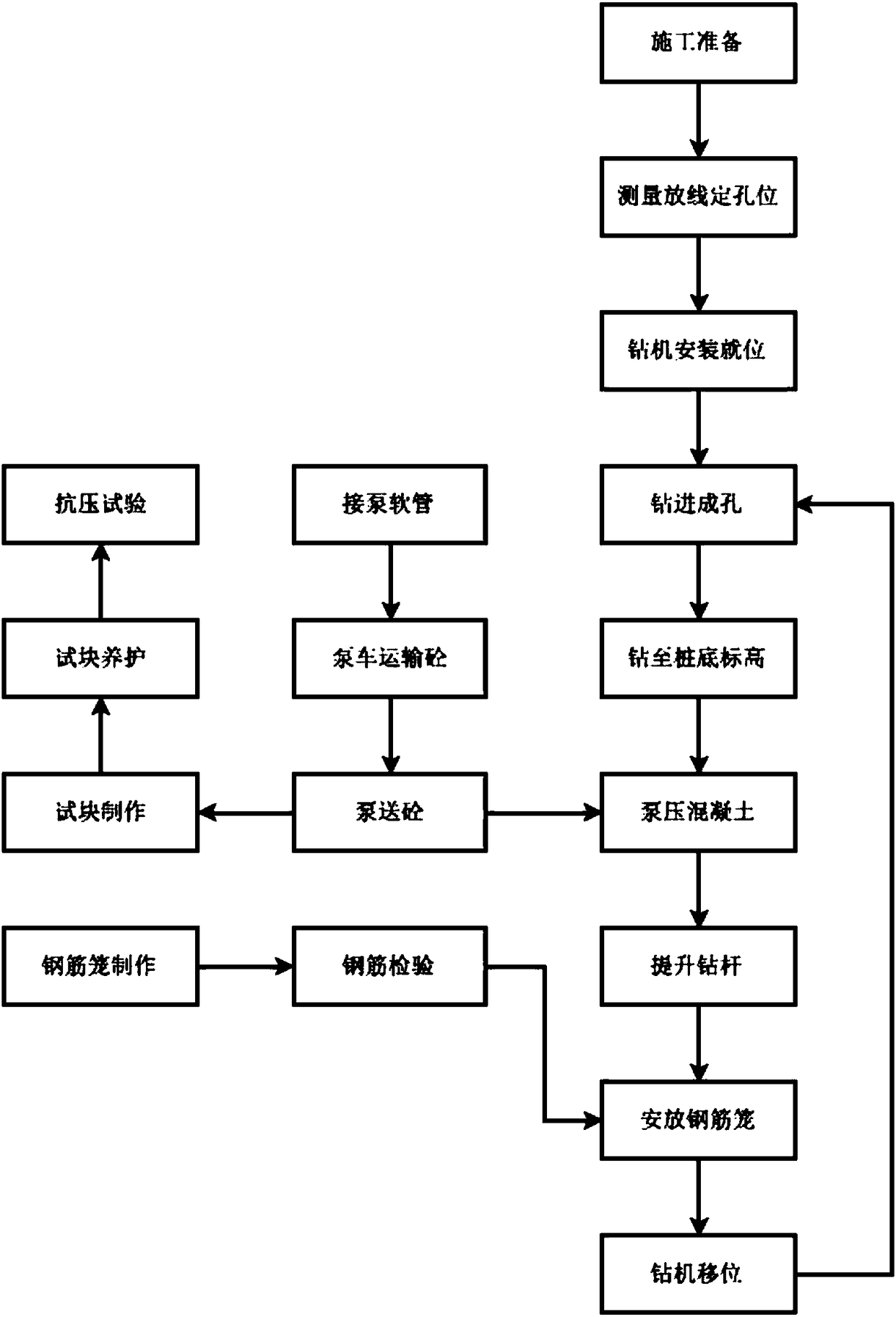

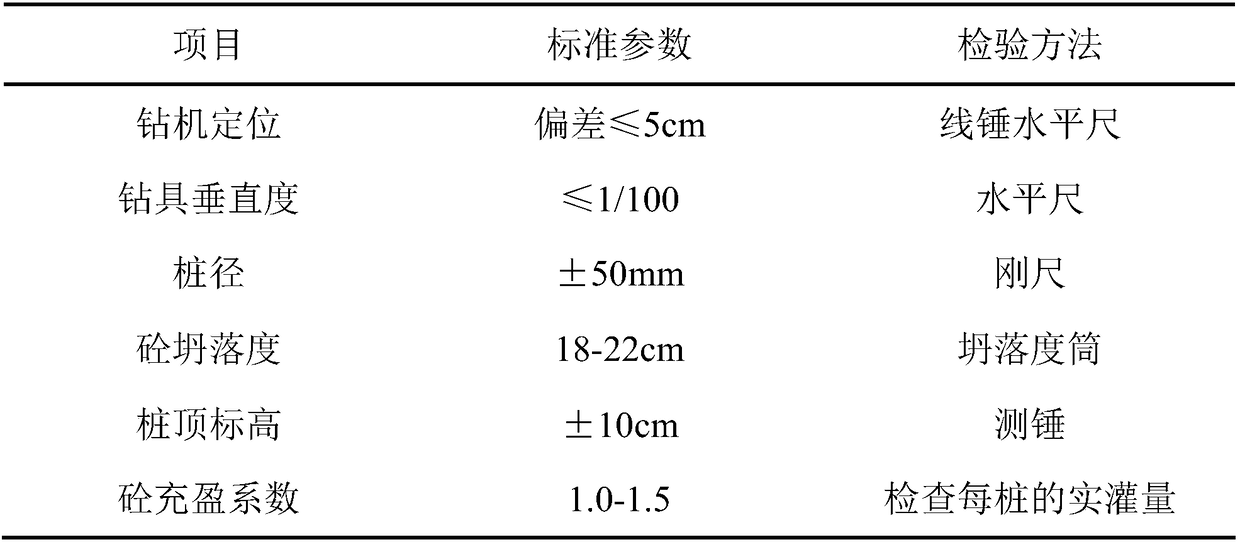

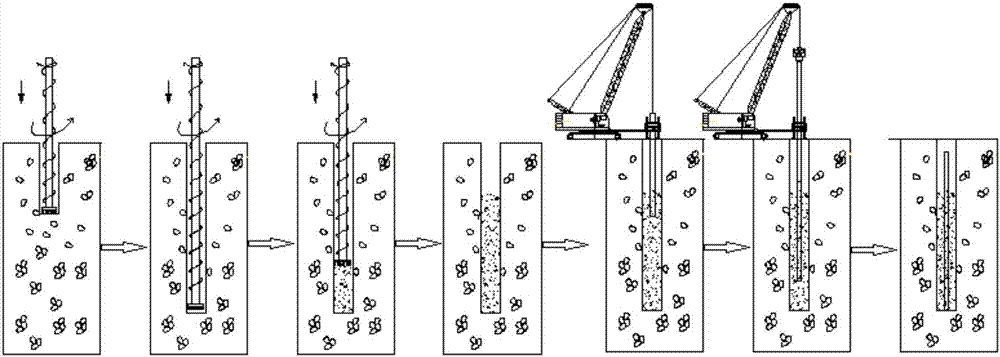

Method for cast-in-place pile bar inserting after concrete pressure irrigation of long auger drilling hole

The invention discloses a method for cast-in-place pile bar inserting after concrete pressure irrigation of a long auger drilling hole. The method includes the following steps that (1) a long spiral drilling machine drills a hole until the designed depth is obtained; (2) pressure irrigation of concrete into the hole with a certain pressure is carried out by using a high-pressure concrete pump through a drill stem center channel while a long spiral drill is lifted, and concrete irrigation is carried out until the set elevation is obtained; and (3) in virtue of the dead load of steel cage and / orspecial vibration equipment, a steel cage is inserted into the concrete to reach the designed elevation to form a reinforced concrete cast-in-place pile. The method has the beneficial effects that the quality of a pile body is easy to ensure, the concrete compactness is good, strength is high, soil is in close contact with a surrounding soil body, and the friction force of the pile body is increased; and the pile tip has no virtual soil, pile breaking, diameter reducing, hole collapse and other common quality problems are prevented.

Owner:瑞森新建筑有限公司

Construction method of cast-in-place pile

The invention provides a construction method of a cast-in-place pile. The construction method includes: using a full screw earth auger to drill a construction site; performing bottom cleaning after apreset depth is reached; lifting a drill pipe, and using a concrete pump to grout concrete to the bottom of the hole through the inner cavity of the drill pipe and the discharge outlets of a drill bit; taking out the drill pipe, and placing into a reinforcement cage. The construction method is free of slurry pollution, fast in construction, high in construction efficiency and low in cost.

Owner:BEIJING NO 5 CONSTR ENG GRP

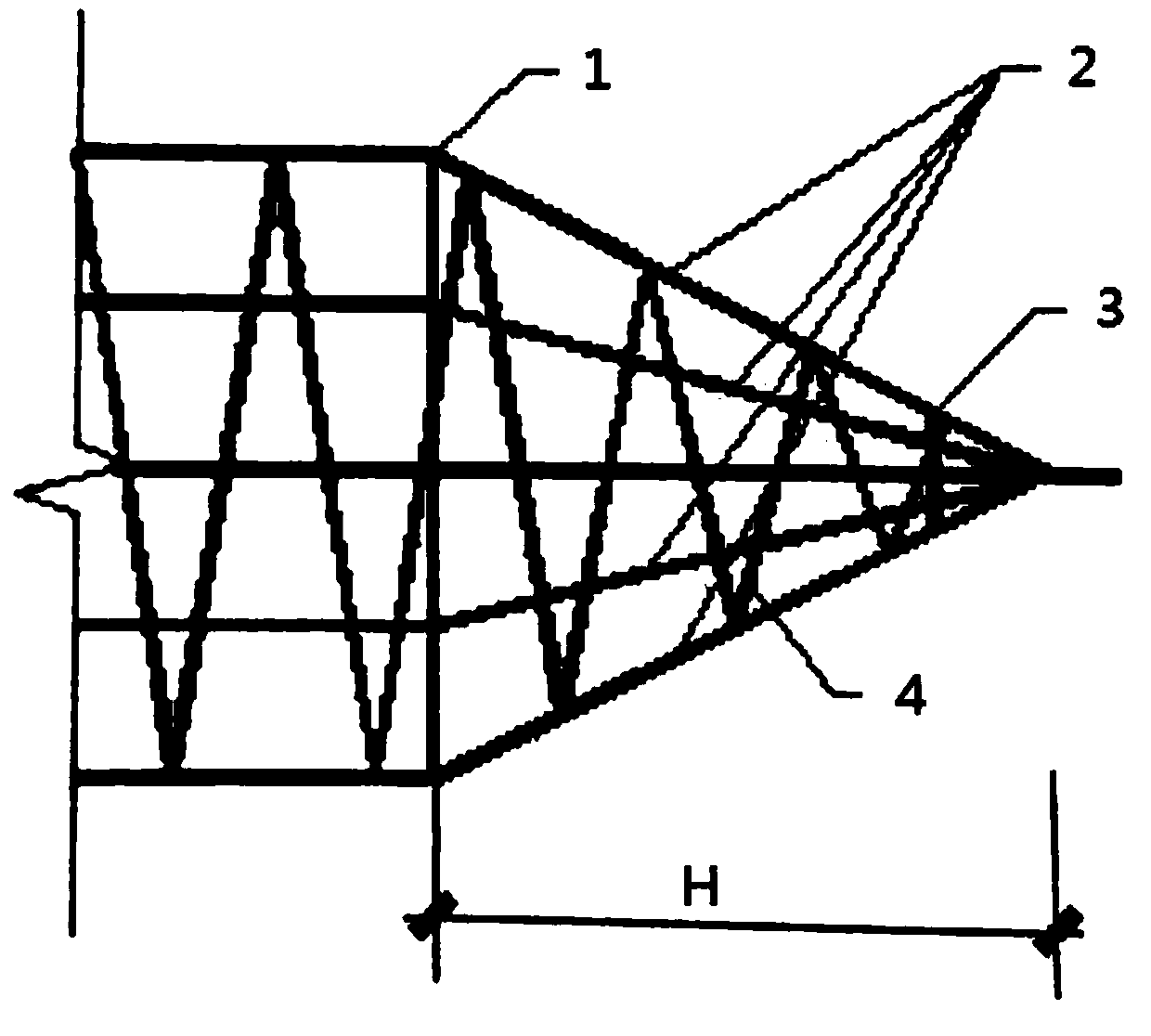

A variable-diameter fully threaded pile and its construction method

The invention discloses a variable diameter all-thread pile and a pile forming method thereof. The variable diameter all-thread pile comprises an upper-part pile core (2), wherein one end of the upper-part pile core is connected to a lower-part pile core; an upper-part thread pile thread (1) is integrally formed on the upper-part pile core, and a lower-part thread pile thread (4) is integrally formed on the lower-part pile core; the upper-part thread pile thread and the upper-part pile core constitute an upper-part pile body; the lower-part pile core and the lower-part thread pile thread constitute a lower-part pile body; the diameter of the lower-part pile body is not less than that of the upper-part pile body. According to the variable diameter all-thread pile and the pile forming method, the pile cores with different diameters are fixed together, outer threads are integrally formed on the pile cores, so that bearing capacity of a cast-in-place pile is improved to the maximum, the pile forming technology simple and quick in pile forming speed; the variable diameter all-thread pile and the pile forming method are less in soil that is pressed out while pressing soil to form the pile, low in cost, energy-saving and environment-friendly, and applicable to popularizing in the field of constructional engineering.

Owner:刘淼

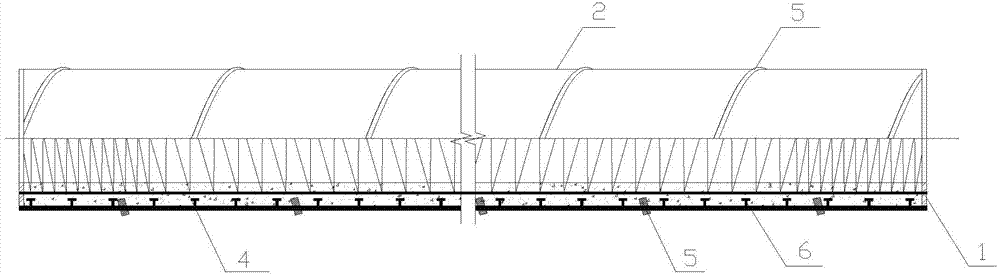

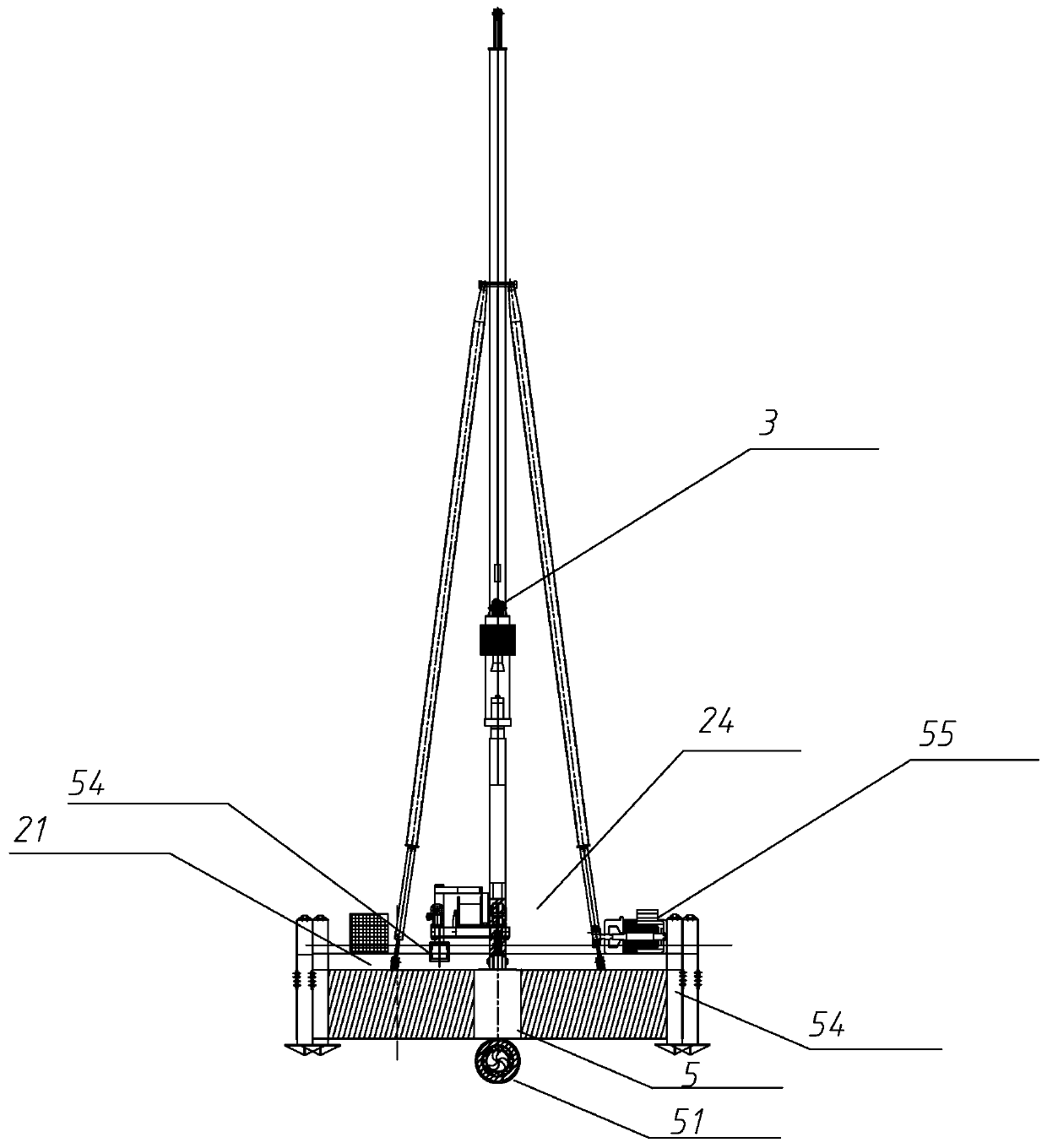

Water photovoltaic pile driver

InactiveCN110644486AGuaranteed accuracyReduce labor intensityBulkheads/pilesMarine engineeringArchitectural engineering

The invention discloses a water photovoltaic pile driver. The water photovoltaic pile driver comprises a pile driving barge body, a pile driving frame arranged on a pile driving barge platform, a driving mechanism for controlling a pile driving barge to displace, and a measuring mechanism used for measuring the pile driving point of a pile driving mechanism. The pile driving barge body is composedof two buoyancy tank structures floating on the water side by side and walking steel plates fixedly connected with the buoyancy tank structures, and the walking steel plates are mounted above the twobuoyancy tank structures, and are fixed to the barge top face at equal distances in the length direction of the buoyancy tank structures. The free falling body motion of a diesel hammer is used for beating a pipe pile, equipment is simple, the pile forming speed is high, the work efficiency is high, meanwhile, combination of GPS real-time positioning and an electric anchor tool is adopted, precision of the pile lowering position is ensured, finally, a fixed clamp and a guide rail thereof are in mutual effect to rapidly and accurately achieve positioning and moving in the continuous pile driving process, the work efficiency is greatly improved, and the labor intensity of an operation worker is reduced.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Wall protection method in construction of bored piles of bridges in highway engineering

The invention discloses a wall protection method in construction of bored piles of bridges in highway engineering. The method includes the steps of (1) placing a mud pool near a borehole, injecting clean water into the mud pool, adding wall protection mud powder into the mud pool along with the clean water, and installing a mud circulation pump beside the mud pool; (2) burying a protection barrelwith an inner diameter of 20-40 cm larger than that of a bored pile and a height of 30-50 cm higher than that of the ground, and the buried depth of protection barrel is 150-200 cm; (3) applying a rotary drilling rig for hole drilling construction, applying the mud circulating pump for mud circulation, meanwhile filtering the mud; (4) injecting clean water to replace mud for cleaning the hole. A secondary hole clearing after hole formation is unnecessary in the wall protection method, and concrete is directly poured, thereby greatly improving the speed of pile formation and improving the working efficiency by 30%. The mud can be reused to save cost, the cost can be saved by 50% or more than 50% per meter comparing with the traditional wall protection method of traditional red clay or bentonite.

Owner:包头市公路工程股份有限公司

Pore-forming construction method by mixing high pressure water with air in long screw pile in high clay layer

InactiveCN104453723AReduce side dragReduce viscosityDrill bitsBulkheads/pilesWater flowHigh pressure water

The invention relates to a pore-forming construction method by mixing high pressure water with air in a long screw pile in a high clay layer, and the pore-forming construction method comprises the following steps: first step, mounting a plurality of paths of central shunts beneath the power head of a long screw pile machine, and mounting a high pressure water conveying pipe with a spray head and an air conveying pipe on the outer side of a long spiral drill pipe; second step, when a drill bit drills to the clay layer, injecting high pressure water into the high pressure water conveying pipe through a high pressure water injection pump, wherein the water flow injected at a high pressure cuts clay between spiral pieces into broken blocks; third step, pressing air into the air conveying pipe through an air compressor; fourth step, forming a water-air-soil mixture at the pile bottom, and the water-air-soil mixture moves upwards to a pile orifice under the rotary thrust of the drill pipe. The construction method provided by the invention is simple and convenient to operate, wide in rock stratum application range, high in pile forming speed and capable of greatly improving the construction speed and efficiency and filling a blank in the pile foundation industry of our country.

Owner:江西中恒地下空间科技有限公司

Pile position alignment device and pile position alignment process applying pile position alignment device

The invention relates to a pile position alignment device and a pile position alignment process applying the pile position alignment device. The pile position alignment device comprises two inclined support rods arranged at the front end of a support frame of a three-axle piling machine, two outward moving positioning rods and two connecting modules; the two outward moving positioning rods are horizontally arranged in parallel; the back ends of the two outward moving positioning rods are fixed at the lower part of the front end surface of the support frame; the center lines of the two outwardmoving positioning rods are perpendicular to the drill rod center line on two sides of a three-axle drill rod; the center lines of the outward moving positioning rod and the drill rod on the same sideare positioned in the same vertical surface; the front ends of the two outward moving positioning rods are fixedly connected with the lower ends of the two inclined support rods; the upper ends of the two inclined support rods are fixed at the upper part of the front end surface of a support frame; the connecting modules comprise connecting ropes, and fixed pieces bound at the lower ends of the connecting ropes; the upper ends of the connecting ropes of the two connecting modules are fixed on the two outward moving positioning rods; and the distances from the two fixed places to the center lines of the drill rods on the same sides are equal. The pile position alignment device is convenient to operate and suitable for large-batch pile formation.

Owner:CSCEC STRAIT CONSTR & DEV

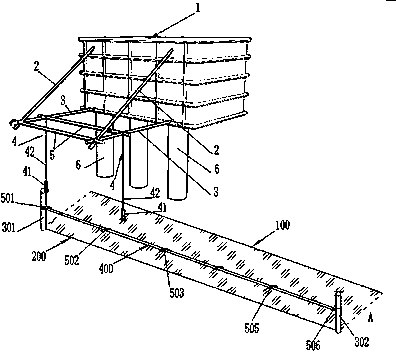

Method for treating open-to-traffic soft soil foundation bridgehead settlement through high-pressure jet grouting piles by means of embankment hole drilling

InactiveCN106522072ASmooth handlingDoes not affect trafficExcavationsRoads maintainenceAfter treatmentRoad surface

The invention relates to a method for treating open-to-traffic soft soil foundation bridgehead settlement through high-pressure jet grouting piles by means of embankment hole drilling. The method comprises the following steps that (1) the treatment lengths of settlement highway sections on the two sides of an open-to-traffic highway bridge are determined, the treatment sections are divided into four subsections of the subsection I, the subsection II, the subsection III and the subsection IV, the subsection I and the subsection III are located on the left highway section, and the subsection II and the subsection IV are located on the right highway section; (2) the left highway section is closed, asphalt running pavements or concrete running pavements of the subsection I and the subsection II of the left highway section are cleaned, pavement bed courses and embankment filling which are located under the pavements are exposed, the part, from the shoulder to the slope toe, of the left highway section is kept in the original state, and passage of the right highway section is ensured; (3) running pavement subgrades are treated through the single-tube high-pressure jet grouting pile; and (4) after treatment of the running pavement subgrades is completed, the triple-tube high-pressure jet grouting pile is adopted for treating embankment slopes. The method has the advantages that the method is suitable for treatment of excessive settlement of bridgehead highway sections and also suitable for treatment of excessive settlement of any other highway sections of open-to-traffic highways.

Owner:NINGBO UNIV

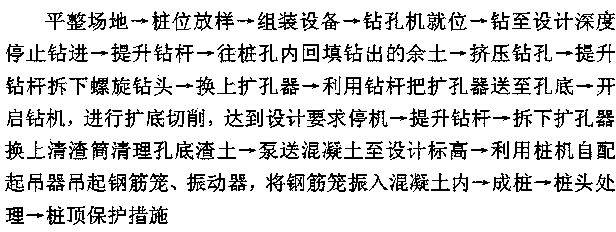

Construction method for bottom-expanded pile casting by long-spiral drilling and compacted half soil sampling

The invention relates to a construction method for bottom-expanded pile casting by long-spiral drilling and compacted half soil sampling. The construction method comprises the following steps: adopting a long-spiral drilling machine provided with a special in-rock drilling bit for construction to a preset pole-hole depth; backfilling rock soil discharged by the long-spiral drilling machine into a pole hole, and adopting the long-spiral drilling machine provided with a special in-rock drilling bit for extruded drilling to the preset depth; installing a reamer at the bottom part of a drilling rod by replacement, and putting into the bottom part of the pile hole for reaming construction; after reaming, taking out the long-spiral drilling machine, installing a multifunctional slag removing drum at the bottom part of the drilling rod by replacement, and putting into the pile hole for slag removing construction; after the residual slag at the bottom part of the pile hole is removed completely, opening a concrete output valve at the bottom part of the multifunctional slag removing drum, and concreting into the expanded bottom of the pile hole by a concrete pump; and lifting into a steel bar cage, and vibrating for positioning the steel bar cage by utilizing a vibrator and the self weight of the steel bar cage. The cast hole pile has the advantages of large force bearing area at the pile bottom, high load bearing force for single pile and strong vibration resistance at the bottom part of the single pile.

Owner:江西省欣峰地基基础工程有限公司

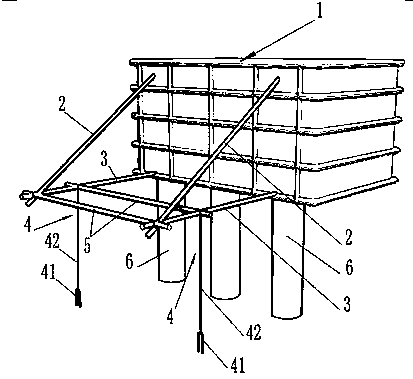

A Construction Method for Reinforcement Treatment of Soft Foundation Steel Pipe Pile in Confined Space

ActiveCN105951749BSimple structureEasy to moveBulkheads/pilesDrilling machines and methodsConfined spaceEngineering

The invention discloses a construction method for reinforcement treatment of a soft foundation steel pipe pile in a confined space. By means of the construction method for reinforcement treatment of the soft foundation steel pipe pile in the confined space, construction is easy, convenient and fast. The construction method comprises the following steps of (1) assembly of drilling equipment, (2) drilling operation, (3) cleaning of the steel pipe pile, (4) grouting preparation, (5) grouting operation and (6) forming of the steel pipe pile. By means of the construction method, spatial constraints are avoided, operation is easy and convenient, and secondary disturbance to existing buildings is prevented.

Owner:SINOHYDRO BUREAU 14 CO LTD

Prefabricated screw pile construction method

InactiveCN107012868ATo achieve common workTo achieve a compact effectBulkheads/pilesLine tubingHigh pressure

The invention discloses a prefabricated screw pile construction method, relates to a pile construction method, and aims to solve such problems as small adaption range, difficult pile plantation, lower side friction of piles, low strength of pile bodies, lower bearing capacity of the pile bodies, and easiness in necking, pile breakage phenomenon and low construction efficiency in the pile forming process to different extents in a traditional pile forming method by cast-in-place piles and prefabricated piles. The method comprises the following steps: (1) prefabricated screw piles and connecting pipelines are mounted; (2) the prefabricated screw piles are directly screwed into soil by the rotating power of a slewing drilling machine for pile plantation, or the spraying hole expansion pile plantation is performed by a high-pressure jet grouting mode; and (3) the post-grouting is performed for pile ends. As the method adopts the high-pressure spraying in through holes in pipe walls, the scene pulp discharge quantity is greatly reduced, no soil is discarded, no water falls, residents are not disturbed, the construction scene is tidy, the single-pile bearing capacity is high, the number and the length of the piles can be reduced, the raw materials are saved, and the effects of low carbon and energy conservation are achieved. The method is suitable for prefabricated screw pile construction.

Owner:王景军

Piling method

InactiveCN1974940AImprove bearing capacityImprove strength utilizationBulkheads/pilesReinforced concreteRebar

The present invention discloses a construction method of building pile foundation engineering, in particular, it relates to a pile-forming method of pipe-sinking belled pile. Said pile-forming method includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out the metal pile head, utilizing belling equipment to enlarge base and make said base portion be formed into a base hollow cavity; borrowing; placing the radial steel bars into the base hollow cavity and nailing said radial steel bars into the hard soil layer, pouring the prepared concrete into the base hollow cavity to obtain concrete base; downwards placing the prefabricated reinforced concrete pile body and making said prefabricated reinforced concrete pile body and cast-in-situ concrete base be butt-connected together by means of inserted bars of base portion and anchored into one body; drawing out said sinking pipe so as to obtain the invented pile.

Owner:王茂华

Large-scale prefabricated enclosure structure and construction method for deep foundation pit

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Construction foundation working method

InactiveCN1974939AImprove bearing capacityImprove strength utilizationBulkheads/pilesReinforced concreteEngineering

The present invention discloses a construction method of building pile foundation engineering, in particular, it relates to a building foundation construction process of pipe-sinking belled pile. Said construction process includes the following steps: pressing the sinking pipe with metal pile head to the hard soil layer with designed level; taking out said metal pile head, utilizing belling equipment to enlarge base and make the base portion be formed into base hollow cavity; borrowing; placing the radial steel bars into said base hollow cavity and nailing said radial steel bars into the hard soil layer; then pouring the prepared concrete into the base hollow cavity to obtain concrete base, and downwards placing the prefabricated reinforced concrete pile body and making said prefabricated reinforced concrete pile body and cast-in-situ concrete base be butt-connected and anchored into one body by means of inserted steel bars of base portion; drawing out sinking pipe and injecting cement slurry so as to obtain the invented belled pile.

Owner:王茂华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com