Block-resistant spraying device

A jet-flushing and anti-blocking technology, applied in water conservancy projects, artificial islands, sheet pile walls, etc., can solve the problems of difficult construction, affecting the safe construction of oil platforms, and high costs, shortening the construction period and improving the migration construction. Efficiency and quick pile up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

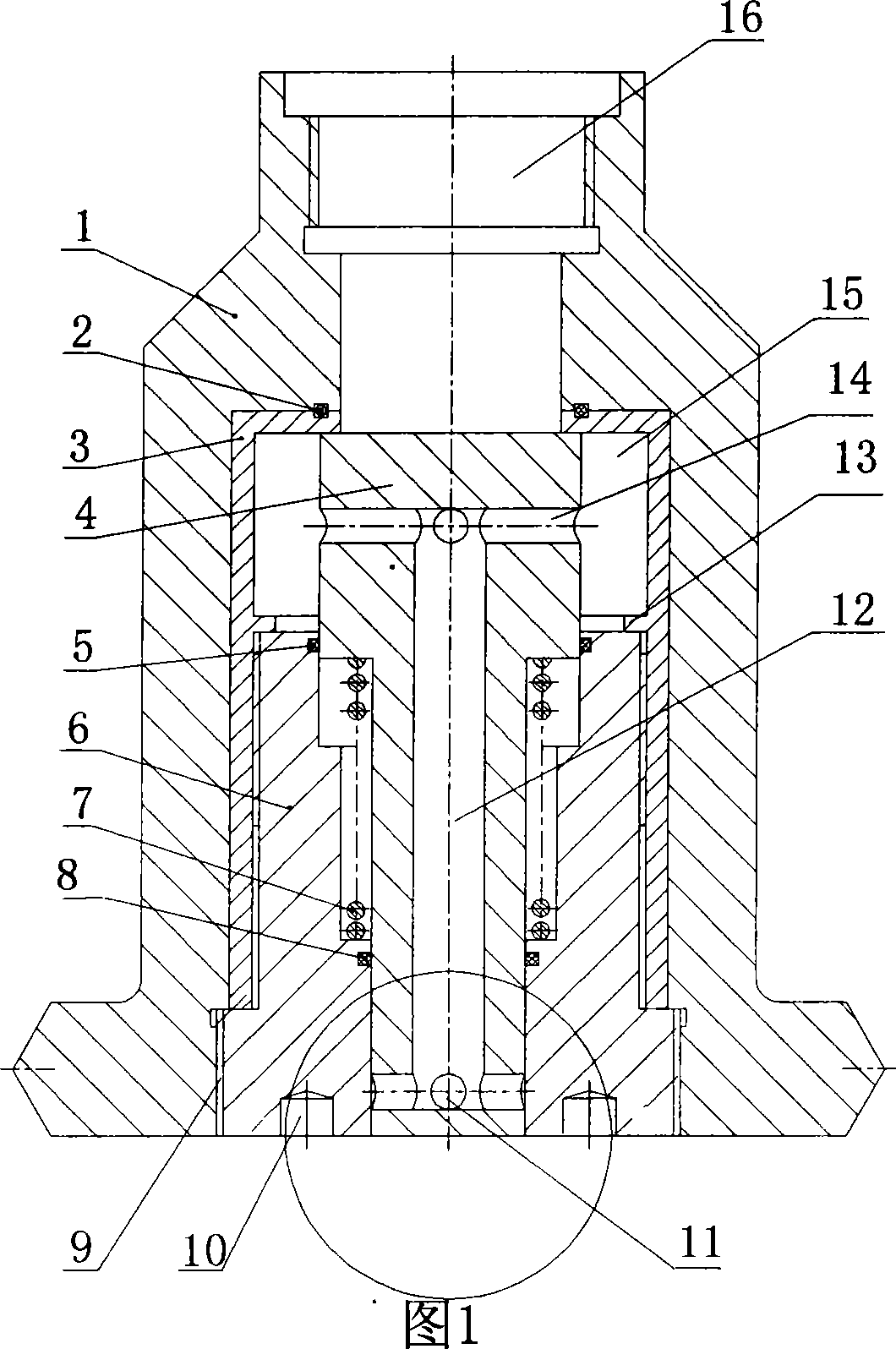

[0019] Embodiment 1, the working principle of the anti-blocking automatic flushing device of the present invention is as follows: when the high-pressure water from the high-pressure pipeline enters the upper part of the housing through the interface, the water pressure pushes the composite piston to move down, and the high-pressure water enters the upper part of the composite piston through the water separation chamber In the water inlet hole, when the compound piston moves down, the water spray port at the lower end protrudes from the lower end of the piston sleeve, and the water spray hole opens to spray around. When the water pressure decreases to less than the spring pressure, the compound piston moves up, The water spray port is retracted into the piston sleeve to close the water spray hole to prevent sediment from entering the valve body.

Embodiment 2

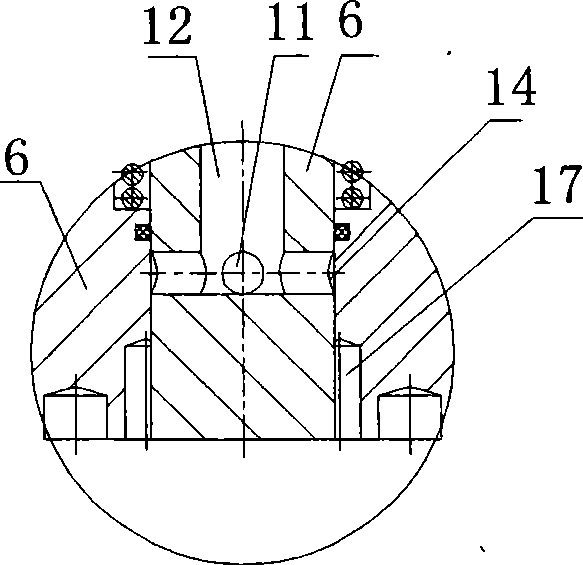

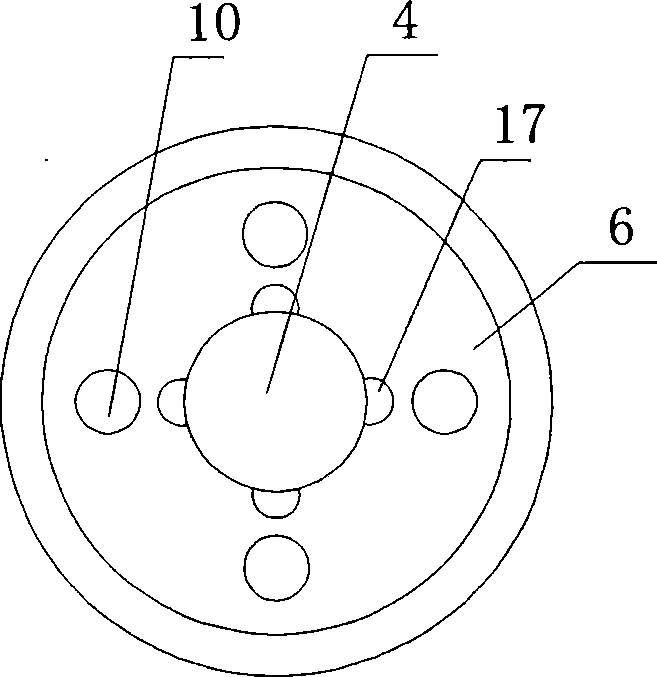

[0020] Embodiment 2, if the water spraying of design is sprayed in the downward direction, as attached figure 2 - As shown in 3, a vertical groove is set at the lower opening of the piston sleeve, and when the water spray port at the bottom of the piston communicates with the vertical groove, the water flow is sprayed downwards through the vertical groove. There is an annular groove on the outer circle of the large and small piston of the compound piston, and the water inlet hole and the water spray hole are opened on the annular groove. The purpose is that even if the water nozzle is not aligned with the vertical groove, the water flow can enter the vertical groove through the annular groove Spray down.

[0021] The processing can be made according to the traditional machining process.

[0022] Compared with the prior art, the anti-blocking automatic flushing device of the present invention has the characteristics of reasonable design, simple structure, easy processing, smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com