Construction method for bottom-expanded pile casting by long-spiral drilling and compacted half soil sampling

A technology of long helical drilling and bottom-expanding cast-in-place piles is used in sheet pile walls, infrastructure engineering, construction, etc., which can solve the problem of reducing the bearing capacity and shear resistance of the pile body, restricting the development of the pile foundation industry, and high maintenance costs. problems, to achieve the effect of good bottom expansion, improve the bearing capacity of the pile, and achieve the effect of fast pile formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The construction method of the long auger bored compacted half-borrowed soil and bottom-expanded cast-in-place pile comprises the following steps:

[0030] Step 1: Use a long auger drill equipped with a special rock drill bit to construct to the predetermined depth of the pile hole, and then put out the long auger drill;

[0031] Step 2: Backfill the rock and soil discharged by the long auger drill into the pile hole, squeeze the hole to the predetermined depth again with the long auger drill equipped with a special rock drilling bit, and finally lift out the long auger drill;

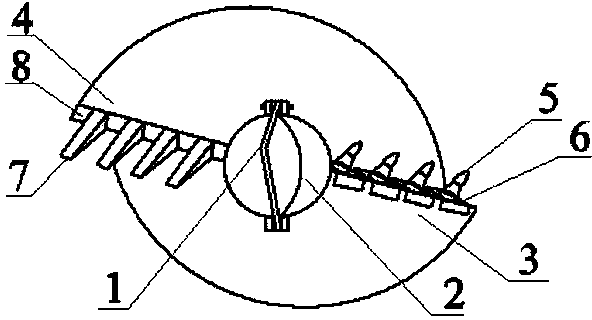

[0032] Step 3: Replace the upper reamer at the bottom of the drill pipe, put it into the bottom of the pile hole for reaming construction;

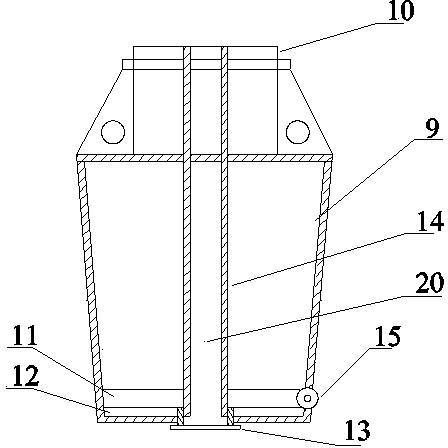

[0033] Step 4: After reaming, put out the long auger drilling rig, replace the multi-functional slag cleaning tube at the bottom of the drill pipe, and put it into the bottom of the pile hole for slag cleaning construction;

[0034] Step 5: After the resid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com