Stirring device and method for stirring sea mud

A mixing device and sea mud technology, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of uneven mixing, slow pile forming speed, and poor spraying efficiency, so as to improve mixing efficiency and uniformity, reduce Obstruction and shock, effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

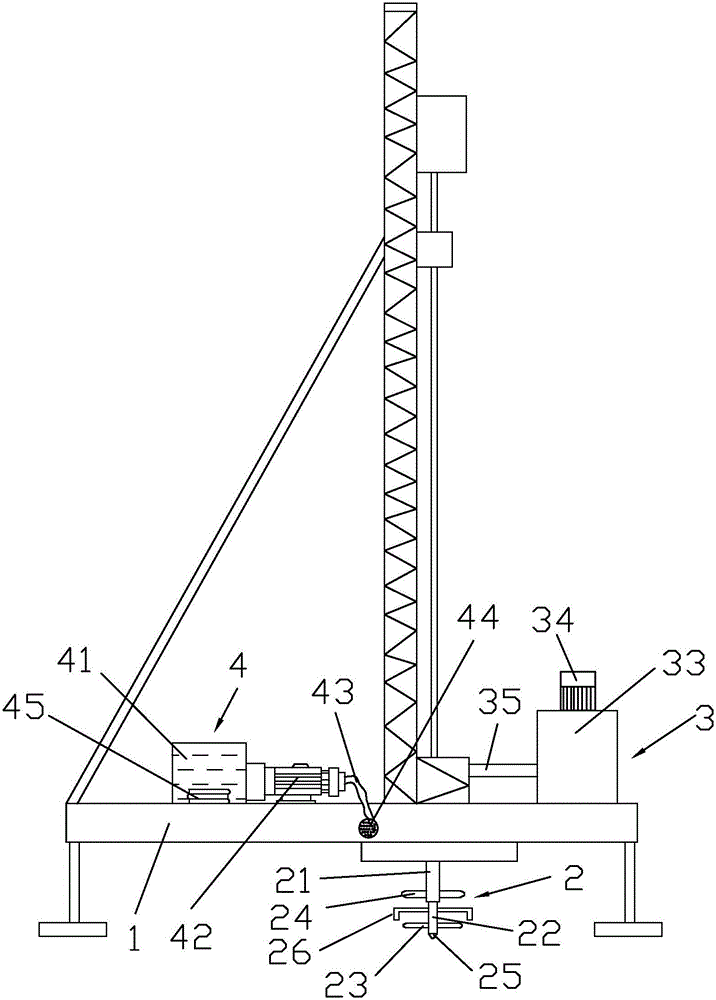

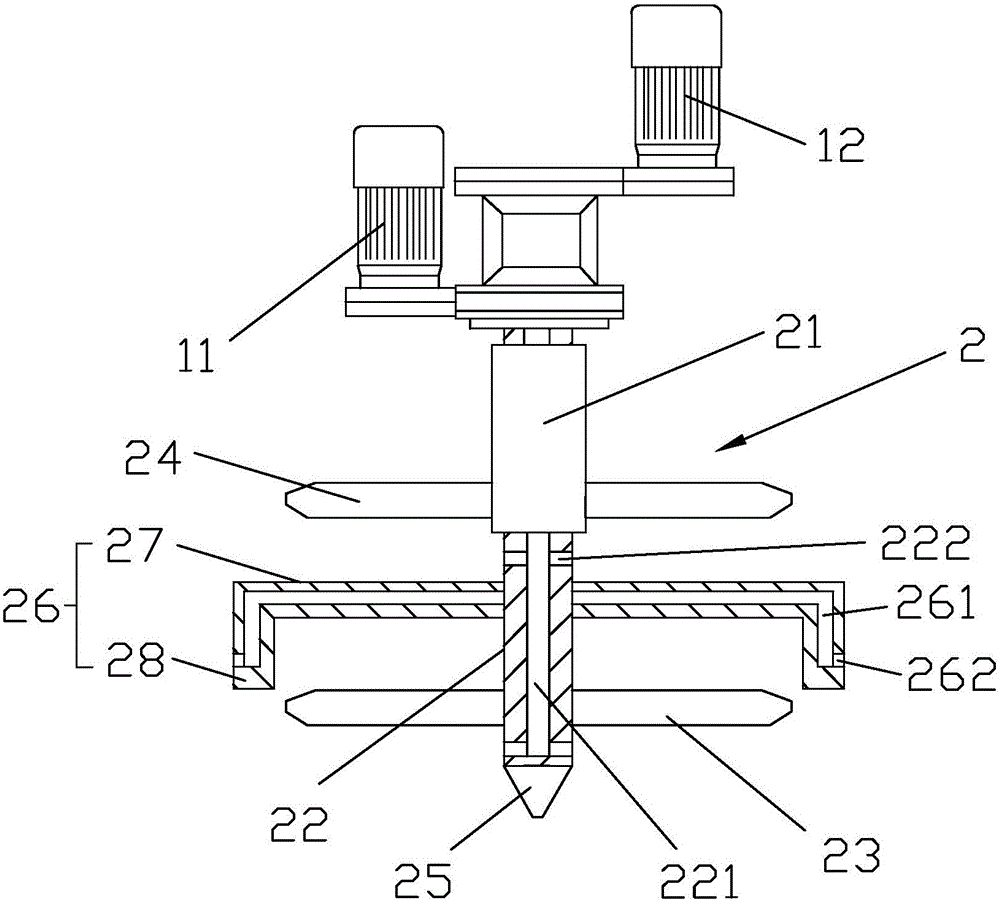

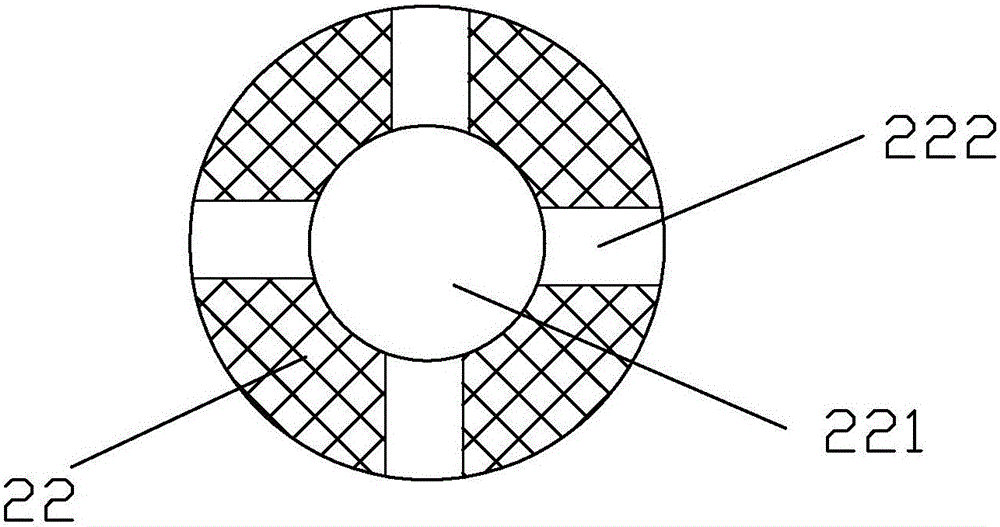

[0043] Such as Figure 1-4 Shown here is a mixing device for mixing sea mud of the present invention, which includes a chassis 1, a first motor 11, a second motor 12, a mixer head 2 and a conveying device 3. The mixer head 2 includes an outer drill rod 21, The inner drill rod 22, the first mixing blade 23 and the second mixing blade 24, the outer drill rod 21 is sleeved on the inner drill rod 22, the output shaft of the first motor 11 is connected with the outer drill rod 21 through the outer rotating sleeve, and the second The output shaft of the motor 12 is connected to the inner drill rod 22 through an inner rotating sleeve. The first motor 11 and the second motor 12 drive the outer drill rod 21 and the inner drill rod 22 to rotate in opposite directions, respectively. The outer drill rod 21 and the inner drill rod 22 are respectively driven by two motors, so that the outer drill rod 21 and the inner drill rod 22 can work independently of each other, with high working stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com