CFG core gravel composite pile, composite foundation formed by CFG core gravel composite pile and construction method

A composite foundation and composite pile technology, which is applied in basic structural engineering, soil protection, construction, etc., can solve the problems of slow dissipation of excess static pore water pressure, pile fracture, and large post-construction settlement. and the effect of settlement during operation, accelerated consolidation settlement, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

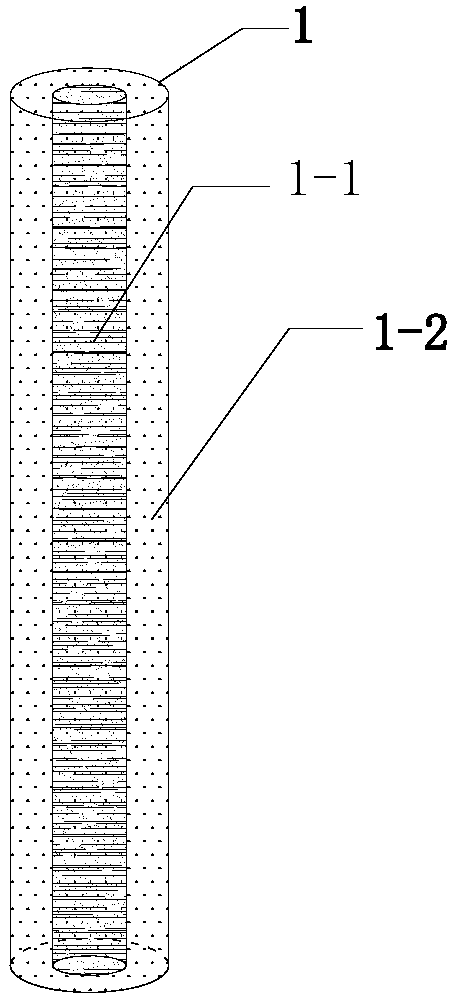

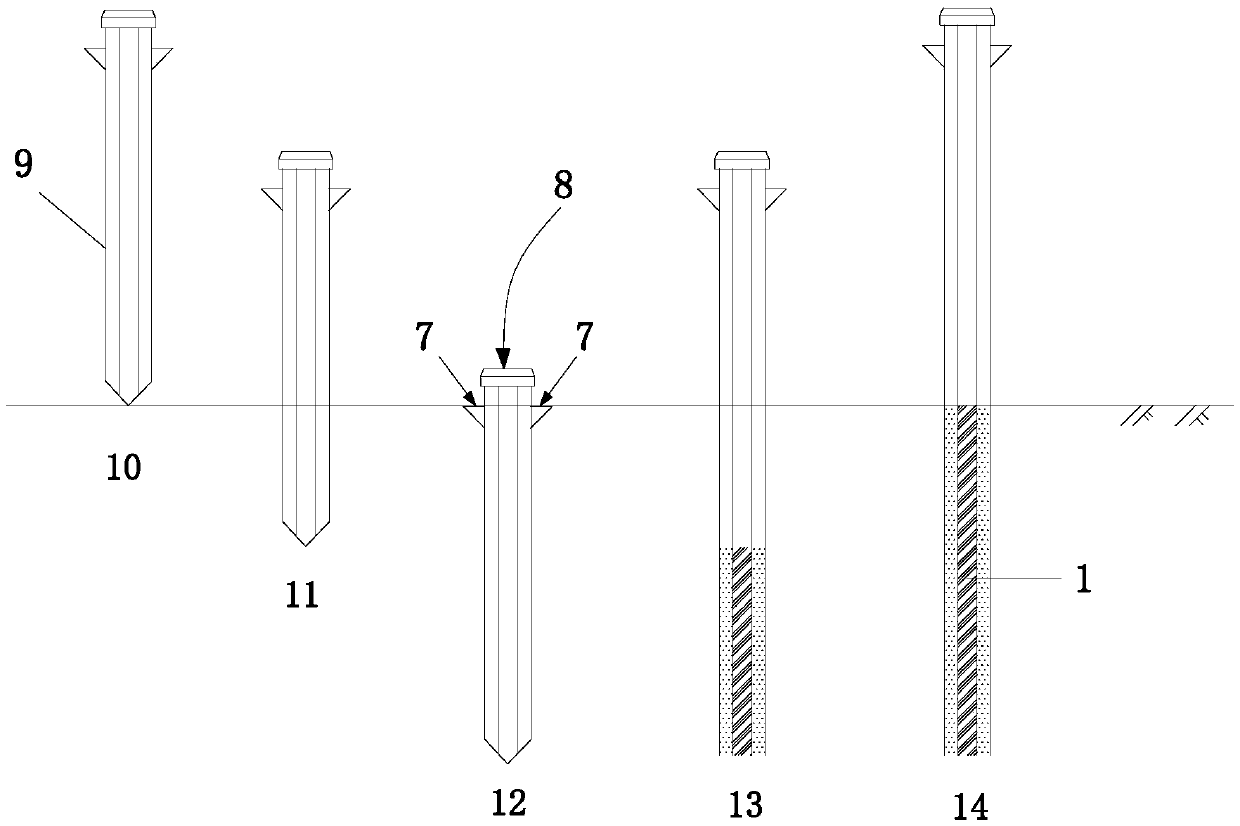

[0039] Such as figure 1 , the CFG core sand-stone composite pile composite foundation of the present invention includes a CFG core sand-stone composite pile 1, a geogrid 2, a cushion layer 3 and a soft soil foundation 5. The CFG core sand-stone composite pile 1 is driven into the soft soil foundation 5, and the bottom end extends into the hard soil layer 6 at the pile end.

[0040] Such as figure 2 , the CFG core sand and gravel composite pile 1 is composed of a CFG core 1-1 and a sand and gravel shell 1-2 that wraps the CFG core. The cross-section is circular and arranged concentrically with the CFG core, and the thickness of the sandstone shell is 5-10cm.

[0041] The CFG core is obtained by infusing the CFG mixture. The final setting strength grade of the CFG mixture is not lower than C15, the sand is medium sand or coarse sand, the particle size of the crushed stone is 5-20mm, and the cement is 42.5 ordinary Portland cement , The slump of the mixture is 30-50mm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com