Wall protection method in construction of bored piles of bridges in highway engineering

A technology of bored piles and construction, which is applied in the direction of drilling equipment and methods, infrastructure engineering, drilling equipment, etc. It can solve the problems of delaying the construction progress and not allowing the drilling speed to be too fast, so as to save the amount of consumption and reduce the number of boreholes. Bottom sediment thickness, effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

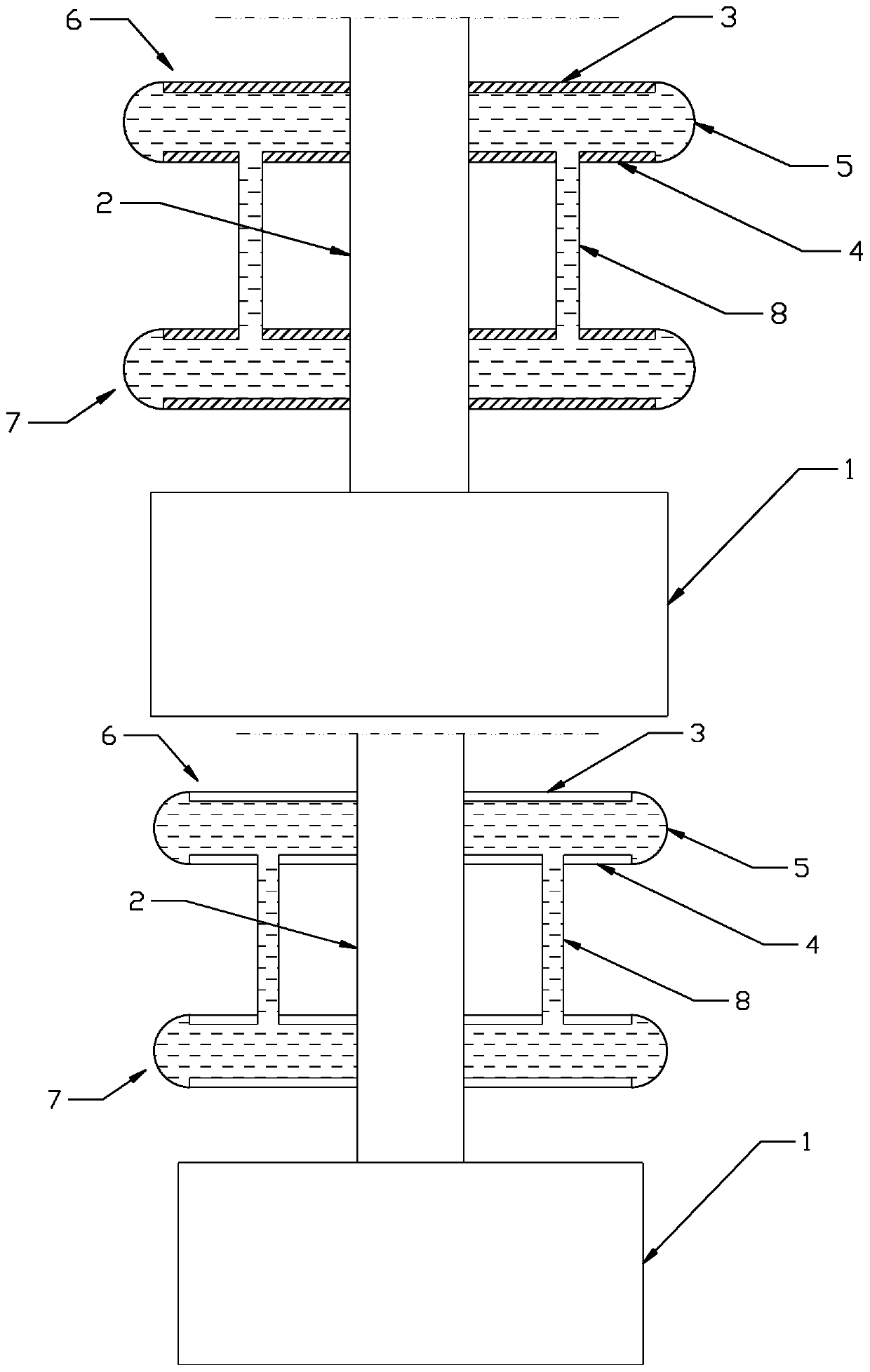

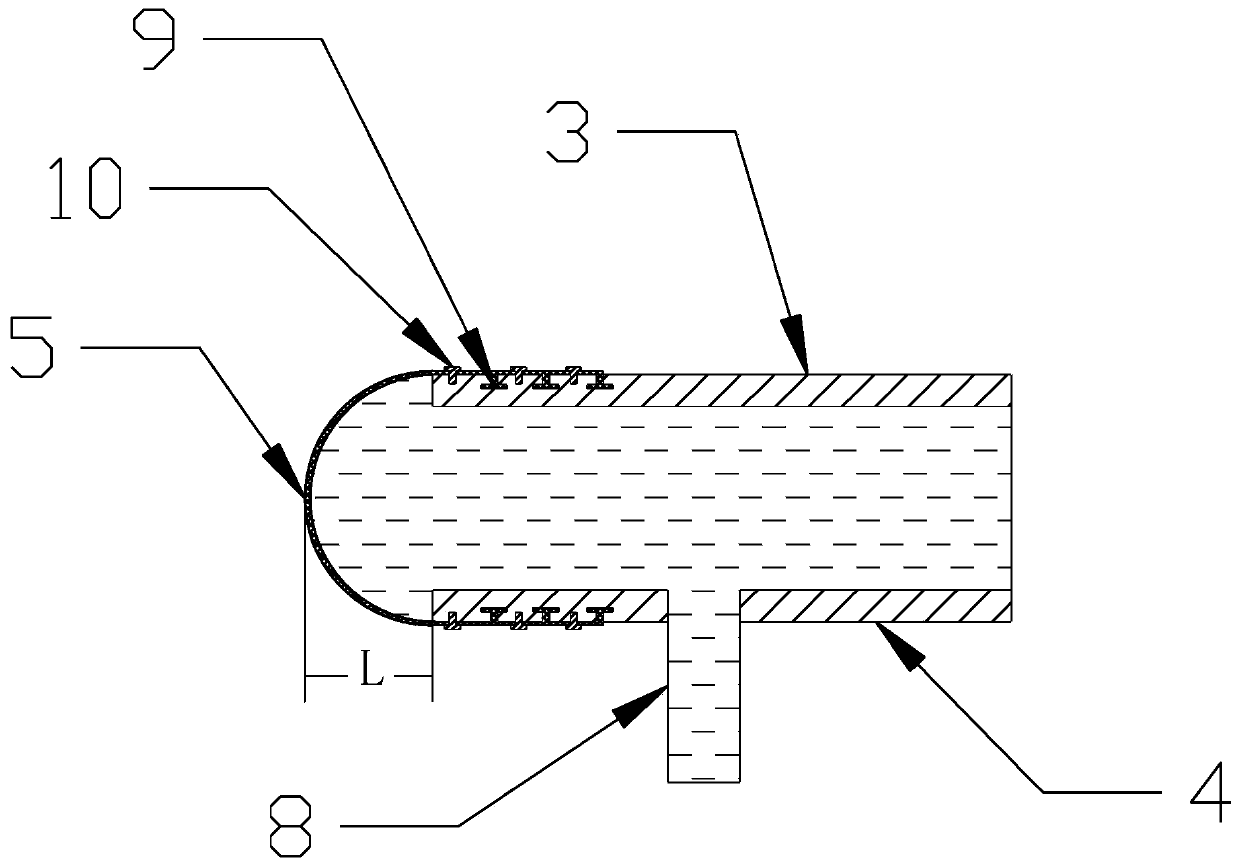

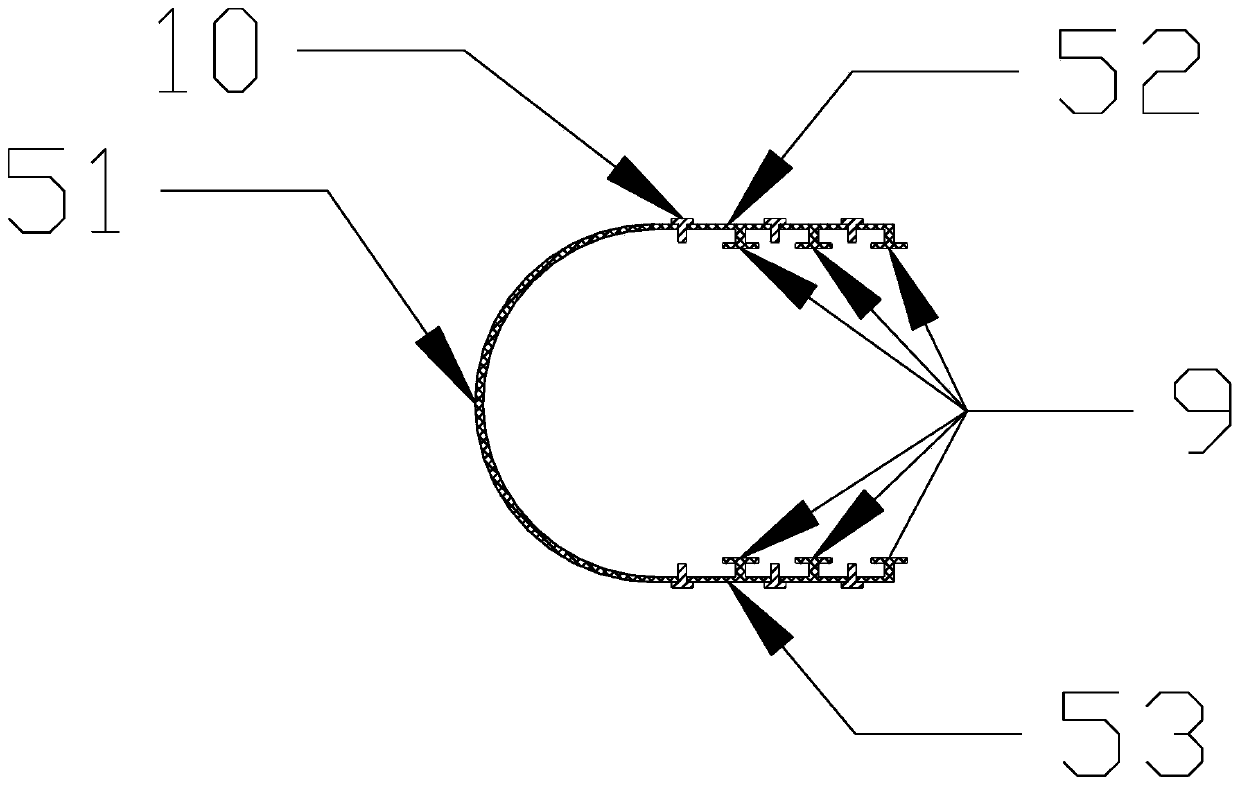

[0035] The wall protection method in the construction of bored piles for highway engineering bridges includes the following steps:

[0036] (1) Set up a mud pool near the borehole, inject clean water into the mud pool, and add wall protection mud powder into the mud pool together with the clean water, and install a mud circulation pump next to the mud pool.

[0037] The wall retaining mud powder is composed of drilling cuttings adsorbent, sand fixing agent, wall protecting agent, penetrating agent and plugging agent. The mass ratio of leakage agent is 1:0.6:0.4:0.2:0.5. The drill cuttings adsorbent is fatty alcohol polyoxyethylene ether sodium sulfate RO-(CH2 CH 2 O) 2 -SO 3 Na, R is dodecyl. The preparation method of the sand-fixing agent is as follows: disperse hydroxypropyl methylcellulose and starch in water, then add sodium dodecylbenzenesulfonate, heat and stir at 65°C; then add N,N-methylenebispropylene Amide and ammonium persulfate, heat and stir at 65°C; finally ...

Embodiment 2

[0047] The wall protection method in the construction of bored piles for highway engineering bridges includes the following steps:

[0048] (1) Set up a mud pool near the borehole, inject clean water into the mud pool, and add wall protection mud powder into the mud pool together with the clean water, and install a mud circulation pump next to the mud pool.

[0049] Composed of drilling cuttings adsorbent, sand fixing agent, wall protecting agent, penetrating agent and lost circulation agent, the mass of the drilling cuttings adsorbent, sand fixing agent, wall protecting agent, penetrating agent and the lost circulation agent The ratio is 1:0.8:0.3:0.3:0.6. The drill cuttings adsorbent is fatty alcohol polyoxyethylene ether sodium sulfate RO-(CH 2 CH 2 O) 3 -SO 3 Na, R is pentadecyl. The preparation method of the sand-fixing agent is as follows: disperse hydroxypropyl methylcellulose and starch in water, then add sodium dodecylbenzenesulfonate, heat and stir at 70°C; then...

Embodiment 3

[0059] The wall protection method in the construction of bored piles for highway engineering bridges includes the following steps:

[0060] (1) Set up a mud pool near the borehole, inject clean water into the mud pool, and add wall protection mud powder into the mud pool together with the clean water, and install a mud circulation pump next to the mud pool.

[0061] Composed of drilling cuttings adsorbent, sand fixing agent, wall protecting agent, penetrating agent and lost circulation agent, the mass of the drilling cuttings adsorbent, sand fixing agent, wall protecting agent, penetrating agent and the lost circulation agent The ratio is 1:0.5:0.5:0.15:0.8. The drill cuttings adsorbent is fatty alcohol polyoxyethylene ether sodium sulfate RO-(CH 2 CH 2 O) 2 -SO 3 Na, R is n-tetradecyl. The preparation method of the sand-fixing agent is as follows: disperse hydroxypropyl methylcellulose and starch in water, then add sodium dodecylbenzenesulfonate, heat and stir at 60°C; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com