N(2)-L-alanyl-L-glutamine preparation for injection and preparation method thereof

A technology of glutamine and alanyl, which is applied in the field of N-L-alanyl-L-glutamine preparation for injection and its preparation, can solve the problems of poor stability and rehydration, auxiliary materials affecting product content, and product freezing type. Not good and other problems, to achieve high stability, avoid moisture absorption and slow oxidation, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

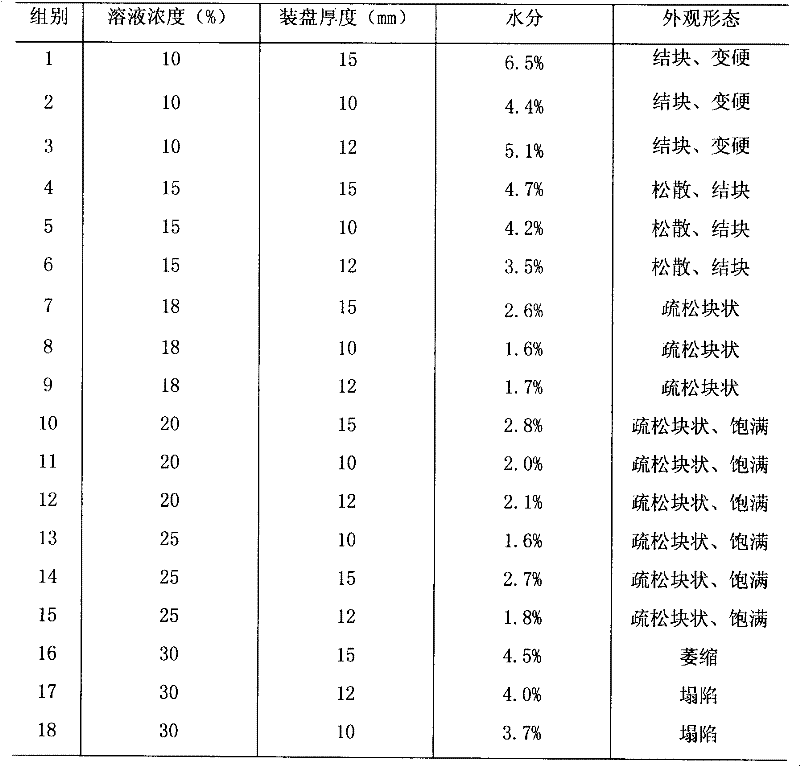

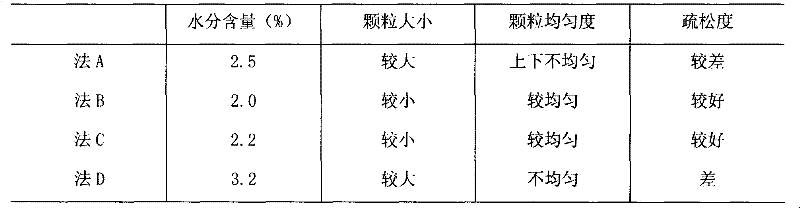

Method used

Image

Examples

Embodiment 1

[0083] (1) Get 1000g of N(2)-L-alanyl-L-glutamine raw material, add the water for injection of the total amount of the prepared drug solution, the total amount of the prepared drug solution is 5000ml, fully stir to make it completely dissolve to a concentration of 20% solution;

[0084] (2) Add activated carbon for needles with a total amount of 0.3% of the dosing solution, stir and dissolve for 10 minutes, filter and decarbonize, and then perform sterilizing filtration through a 0.2 μm filter;

[0085] (3) Take the filtrate and put it in a sterilized freeze-drying tray, each tray has a thickness of 12 mm, put it into the freezer of a freeze dryer, and pre-freeze it. The pre-freezing temperature is -40 ° C, and keep it for 3.5 hours after reaching the temperature. , vacuuming, the vacuum degree is: 10-25Pa, heating, the temperature rises to -20°C, maintains for 1 hour, rises to -10°C, maintains for 4 hours, heats up to -5°C, maintains for 1 hour, rises to 0°C, and waits Keep ...

Embodiment 2

[0088](1) Get 1250g of N(2)-L-alanyl-L-glutamine raw material, add the water for injection of the total amount of the prepared drug solution, the total amount of the prepared drug solution is 5000ml, fully stir to make it completely dissolve to a concentration of 25% solution;

[0089] (2) Add activated carbon for needles with a total amount of 0.1% of the solution, stir and dissolve for 20 minutes, filter for decarbonization, and then perform sterilizing filtration through a 0.2 μm filter;

[0090] (3) Take the filtrate and place it in a sterilized freeze-drying tray. The thickness of each tray is 10 mm. Put it into the freezer of the freeze dryer for pre-freezing. The pre-freezing temperature is -50 ° C, and keep it for 5 hours after reaching the temperature. , vacuuming, the vacuum degree is: 10-25Pa, heating, the temperature rises to -20°C, keeps for 2 hours, rises to -10°C, keeps for 3 hours, heats up to -5°C, keeps for 2 hours, rises to 0°C, and waits Keep warm for 1 ho...

Embodiment 3

[0093] (1) Get 1100g of N(2)-L-alanyl-L-glutamine raw material, add the water for injection of the total amount of the prepared medicinal liquid, the total amount of the prepared medicinal liquid is 5000ml, fully stir to make it completely dissolve to a concentration of 22% solution;

[0094] (2) Add activated carbon for needles with a total amount of 0.4% of the dosing solution, stir and dissolve for 5 minutes, filter and decarbonize, and then perform sterilizing filtration through a 0.2 μm filter;

[0095] (3) Take the filtrate and place it in sterilized freeze-drying trays. The thickness of each tray is 15 mm. Put it into the freezer of the freeze dryer for pre-freezing. The pre-freezing temperature is -45 ° C and keep for 2 hours after reaching the temperature. , vacuuming, the vacuum degree is: 10-25Pa, heating, the temperature rises to -20°C, maintains for 0.5 hours, rises to -10°C and maintains for 6 hours, heats up to -5°C, maintains for 0.5 hours, rises to 0°C, and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com