Water photovoltaic pile driver

A photovoltaic piling machine and piling ship technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of large wind and waves on the water surface, high construction cost, difficulty in ensuring the accuracy of the pile down position, etc., and achieves fast piling speed. , High work efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

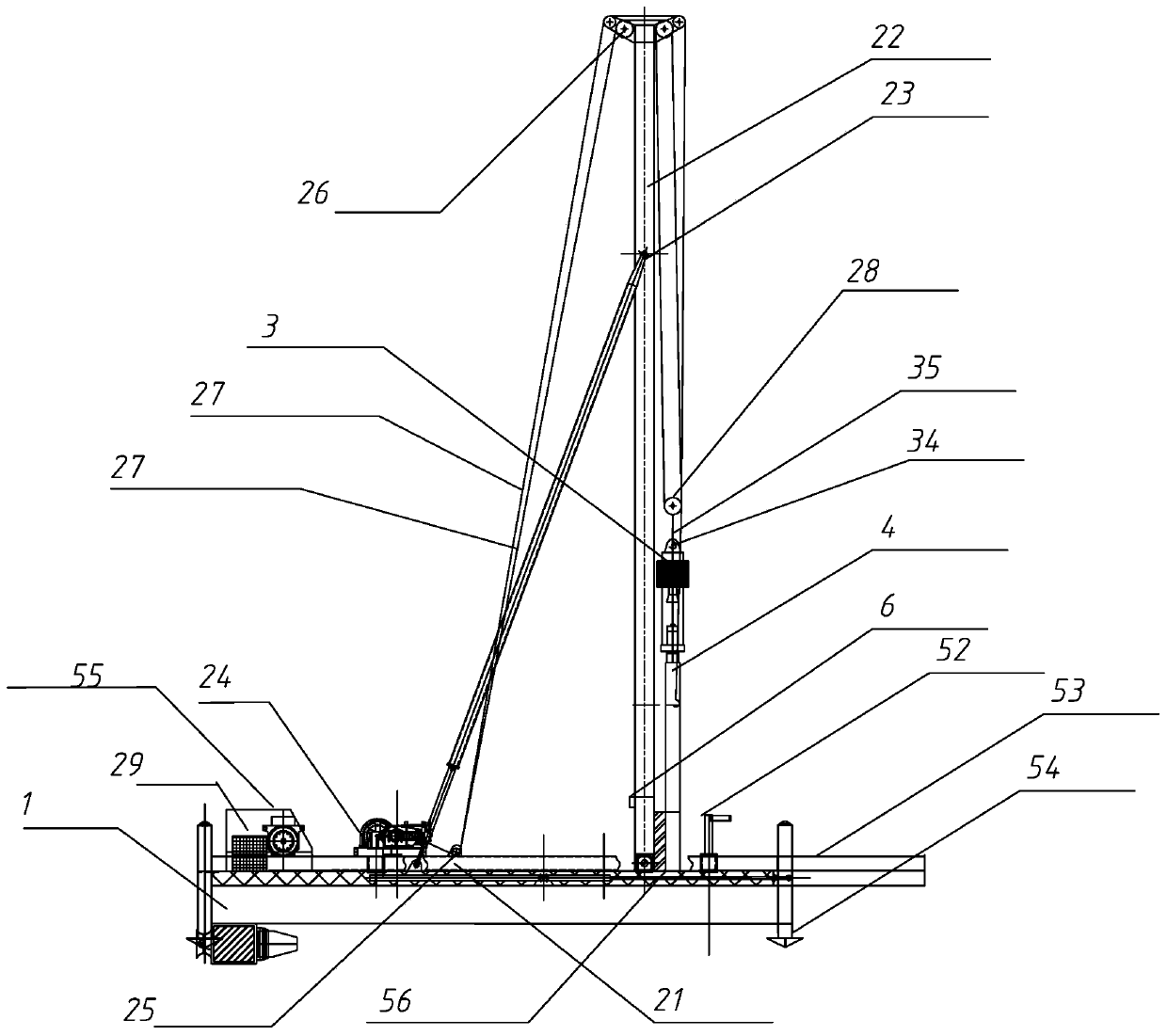

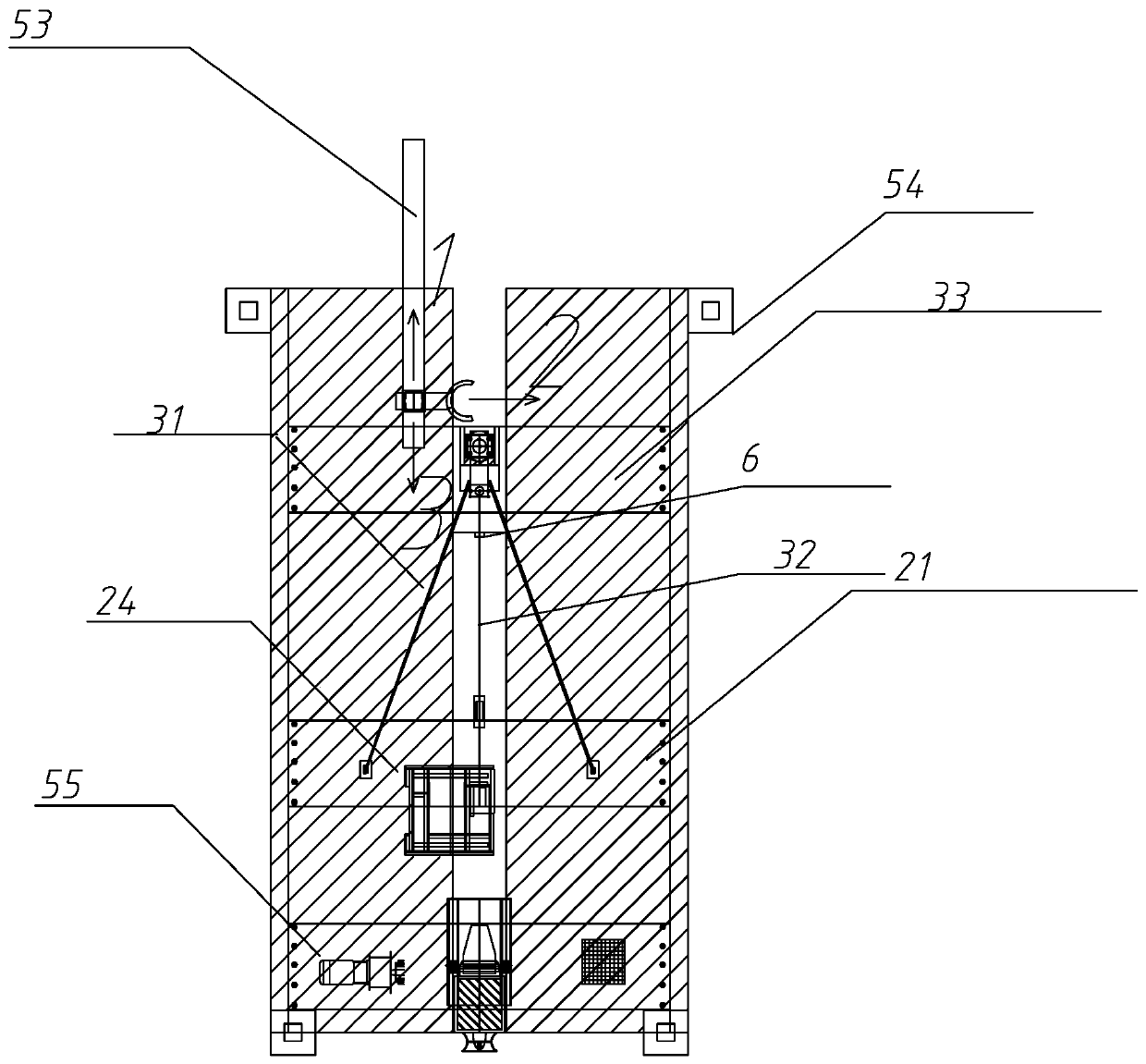

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

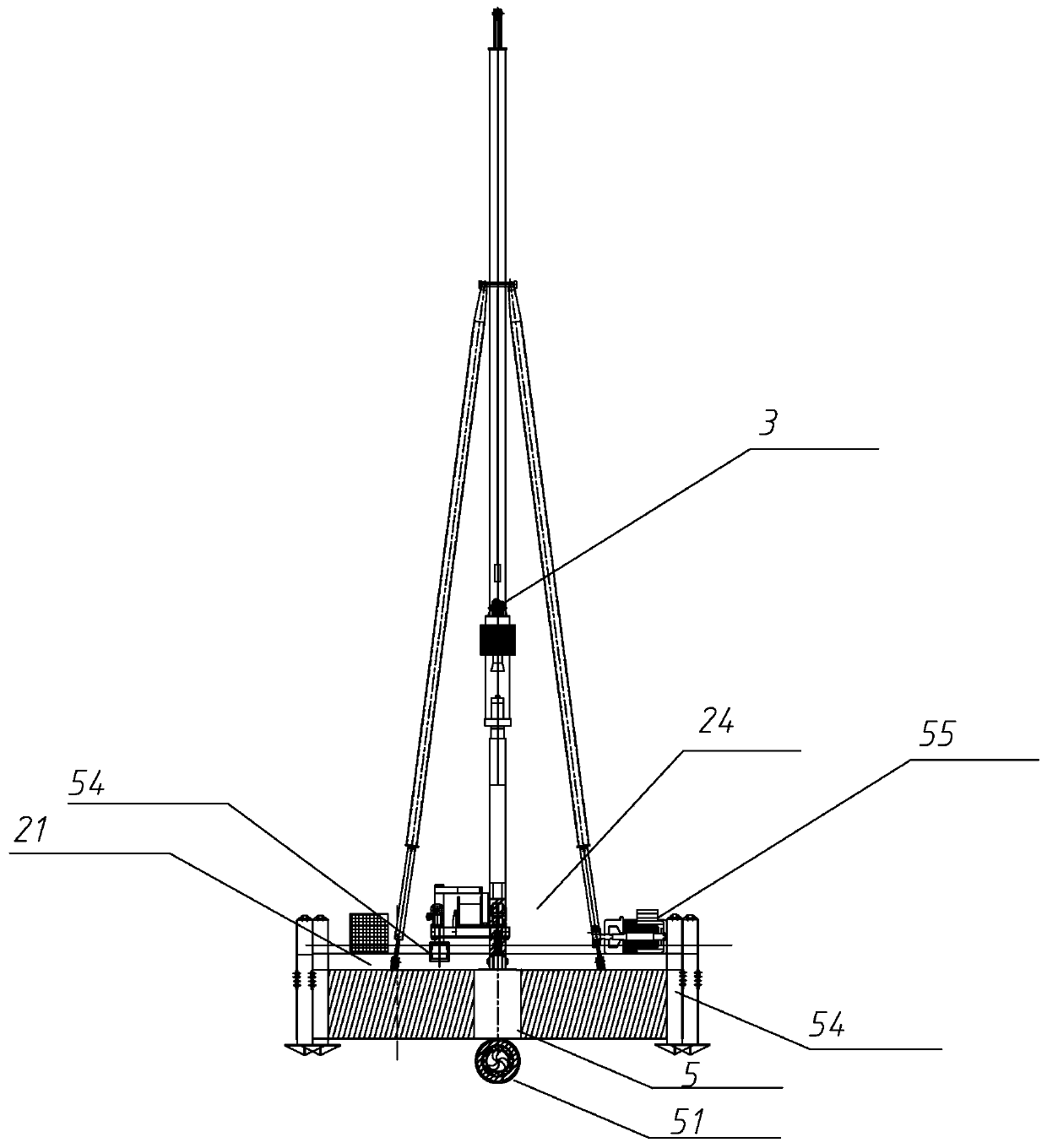

[0024] Such as Figure 1-4 As shown, a photovoltaic piling machine on water includes a piling ship hull 1, a piling pile frame 2 set on the piling ship platform, a driving mechanism 5 for controlling the displacement of the piling ship, and a measuring mechanism for measuring the piling point of the piling mechanism, The hull 1 of the piling ship is composed of two buoyant tank structures 11 floating side by side on the water surface and a walking steel plate 12 connecting and fixing the two buoyant tank structures 11. The running steel plate 12 is installed above the two buoyant tank structures 11 and along the The longitudinal direction of the structure 11 is equid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com