Pile-forming drilling tool for screw pile and pile-forming construction method thereof

A screw pile and drilling tool technology, which is applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve the problems of pile body mud inclusion, pile body quality impact, high construction requirements, etc., to achieve faster pile formation, higher pile quality, The effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

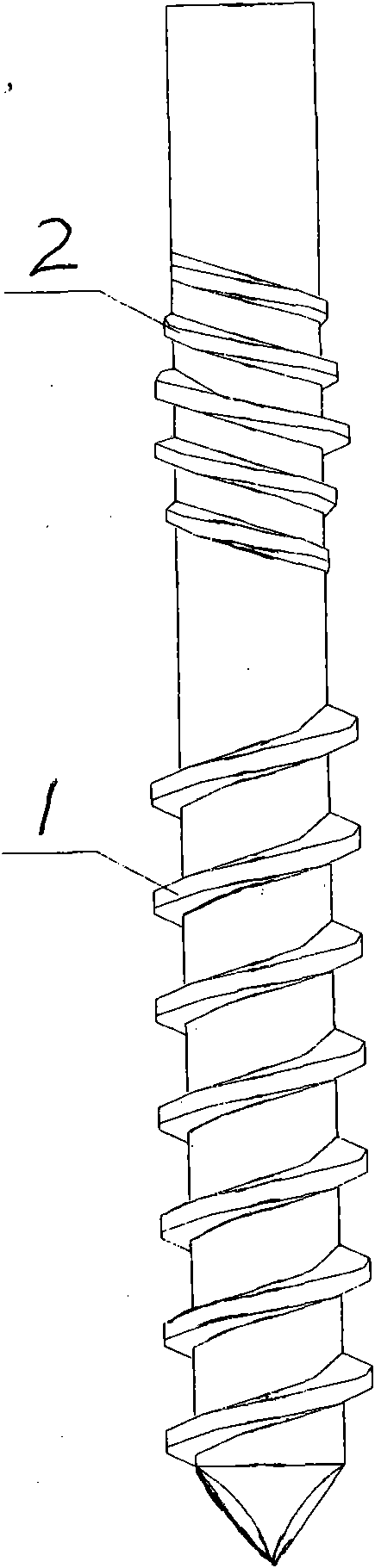

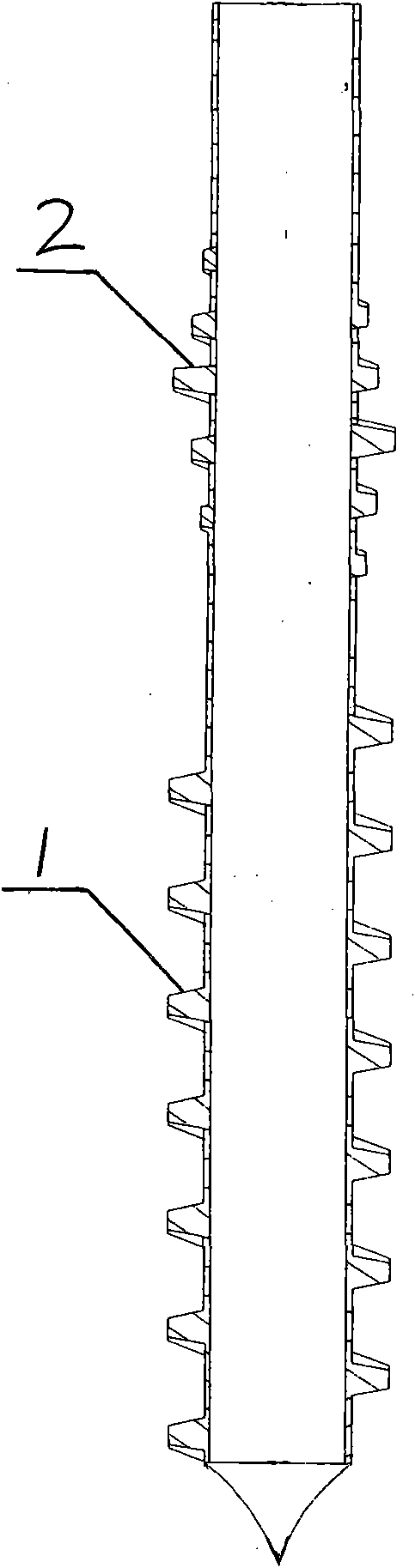

[0032] exist figure 1 , figure 2 In the shown structure, the lower part of the screw pile pile-forming drilling tool designed by the present invention is provided with a forward (clockwise) drilling thread 1 with equal cross-section and equal pitch, and a reverse (counterclockwise) screw thread can be installed and disassembled on the upper part of the drilling tool. ) equal-pitch sweeping thread 2, and the sweeping thread 2 is fixed on the drill pipe with a fixture according to the design requirements of the straight rod section of the pile body before construction.

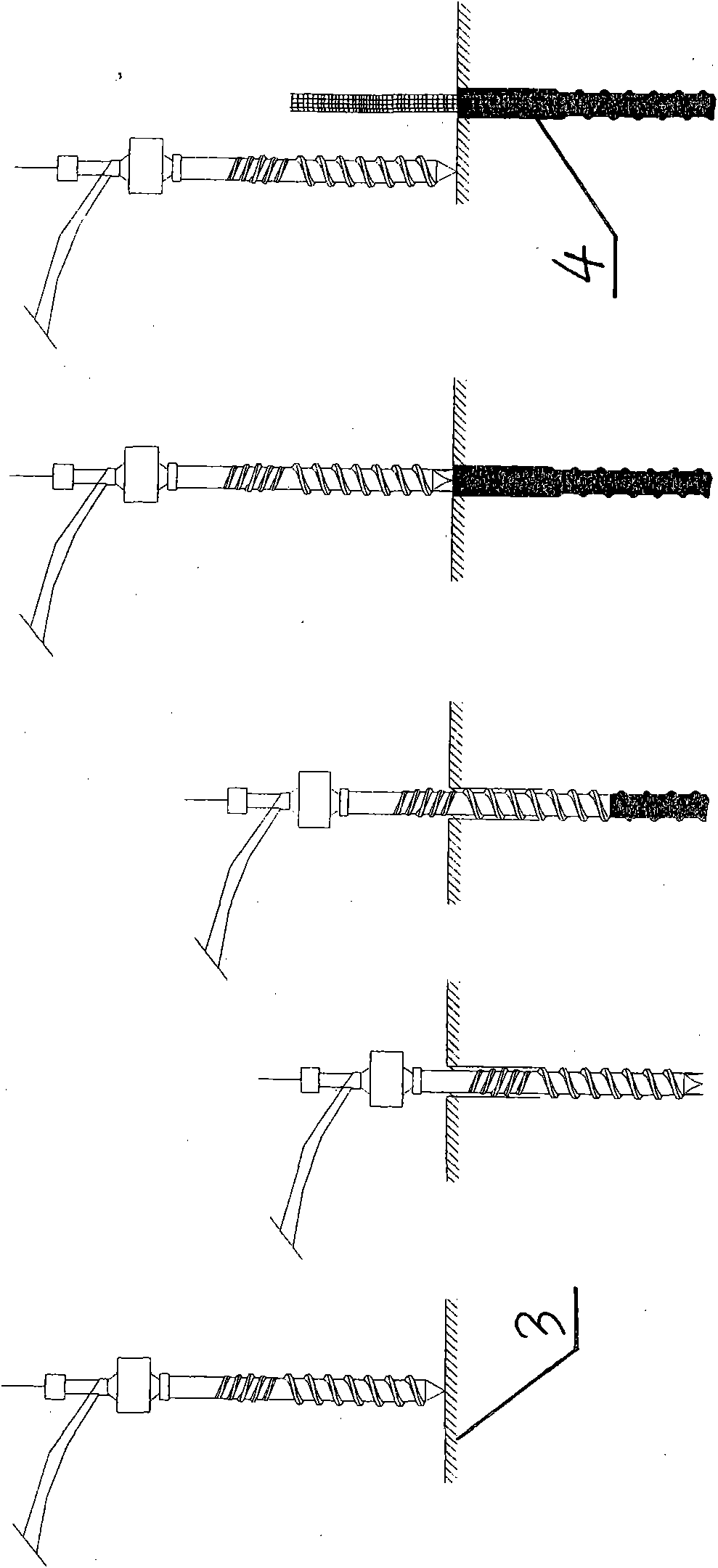

[0033] Such as image 3 Shown, the screw pile pile-forming method provided by the present invention comprises the following steps:

[0034] Step 1: Use special equipment for screw piles to match the above drill pipes to align the piles;

[0035] Step 2: The pile-forming drilling tool adopts forward synchronous technology within the pile length range to rotate the drilling thread 1 of the lower part of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com