Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Minimized installation space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

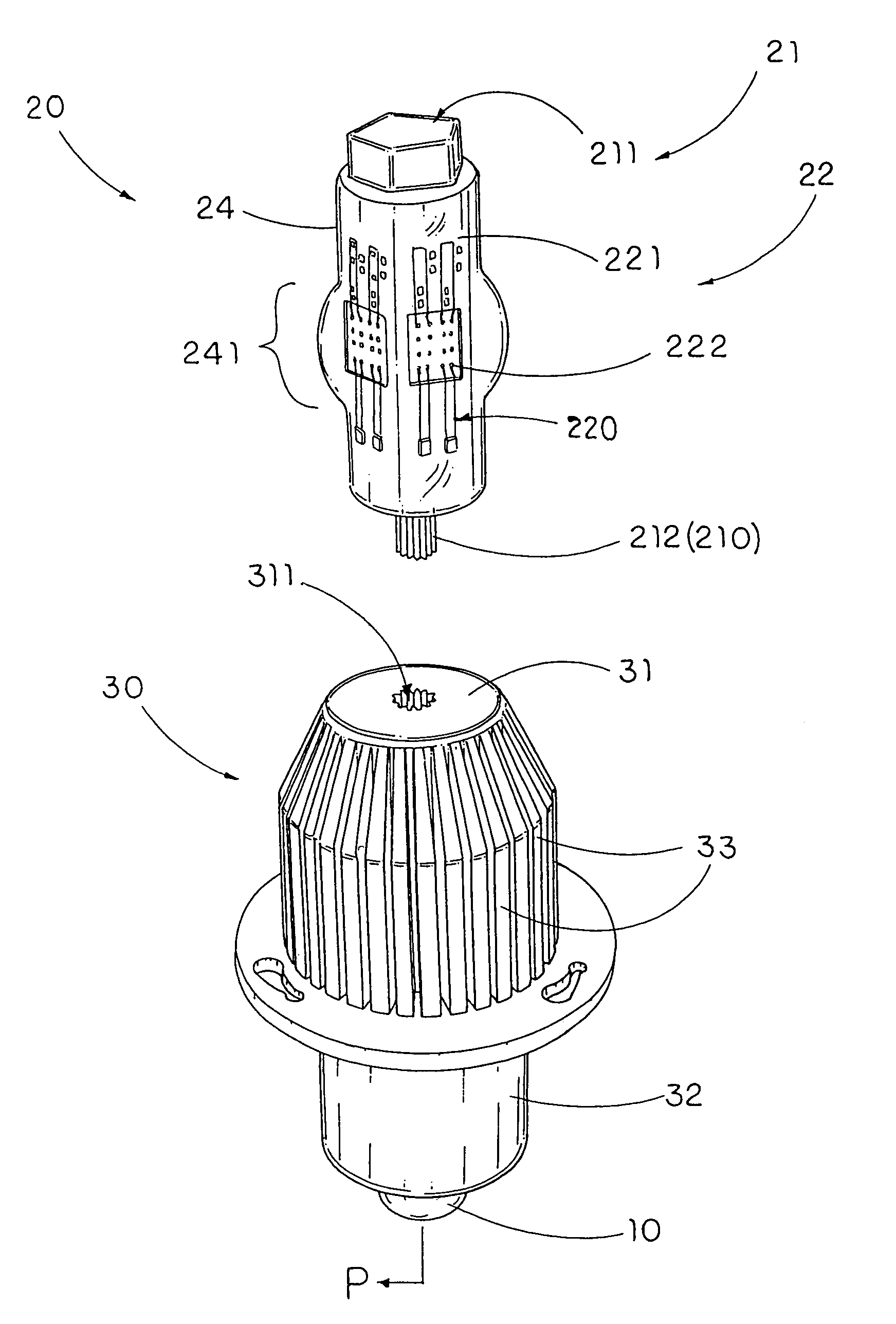

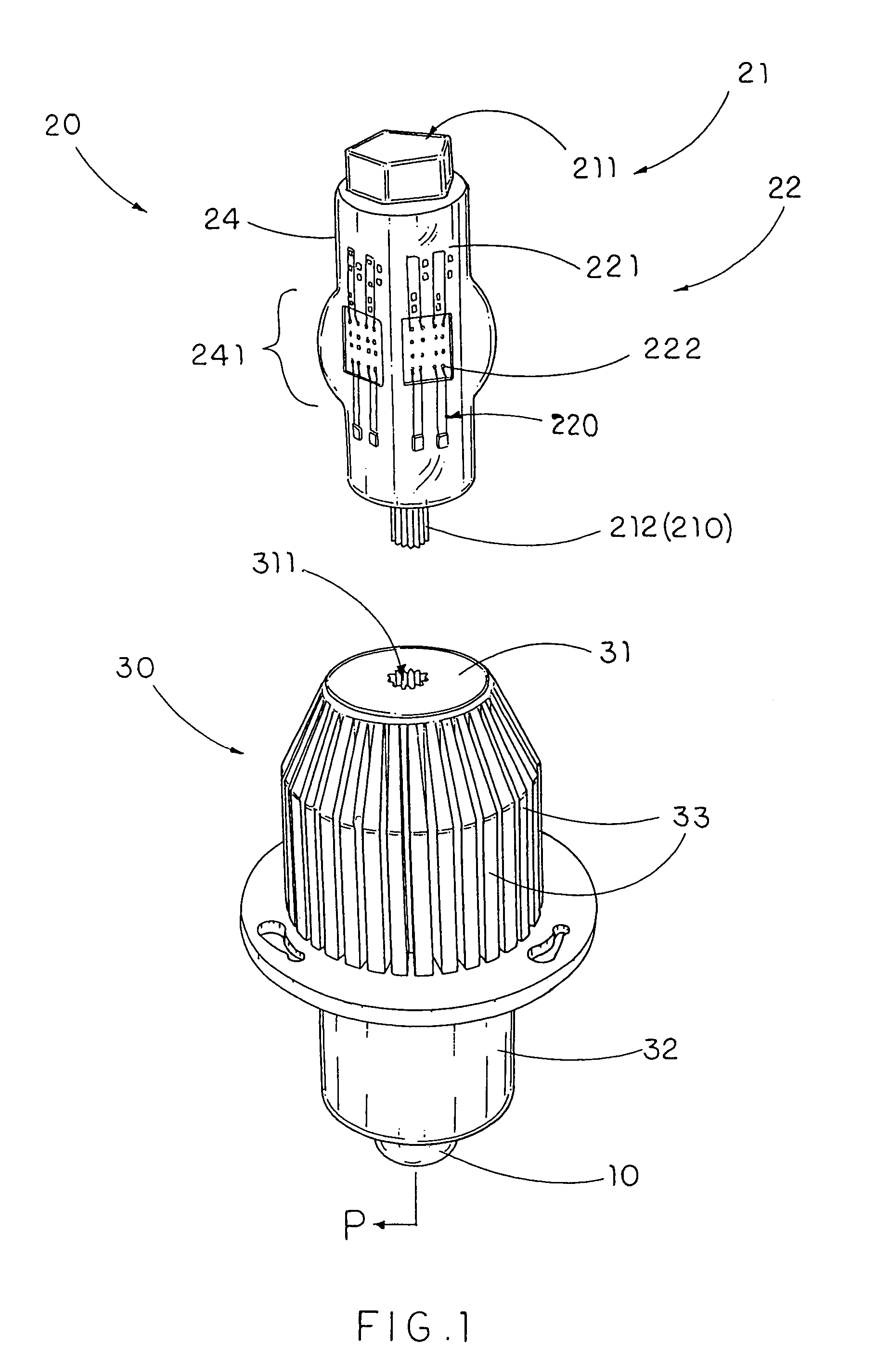

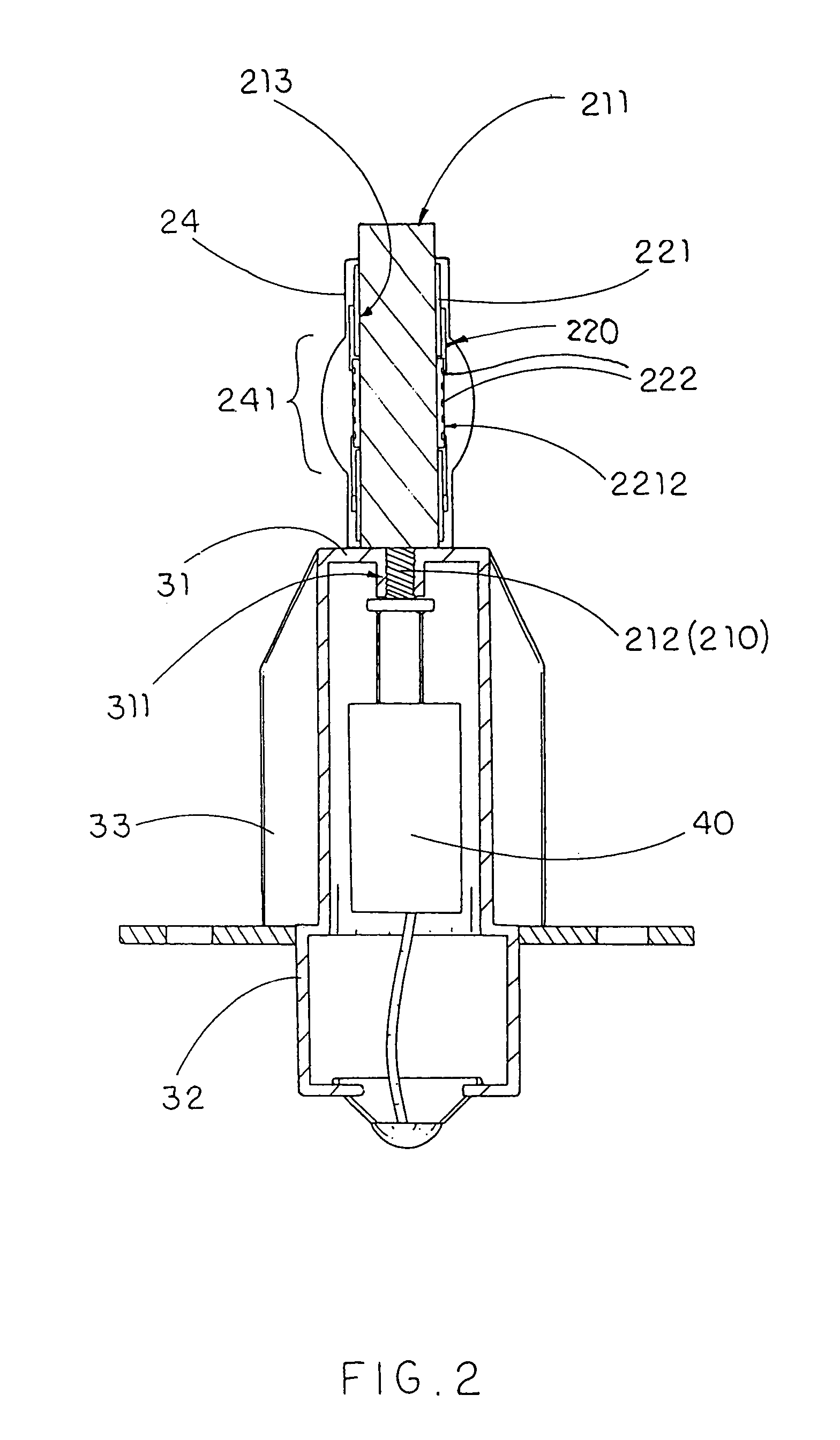

Light source arrangement

InactiveUS7401945B2Increase brightnessImprove cooling effectLighting support devicesPoint-like light sourceElectricityLight head

A light source arrangement includes an electric input adapter for electrically connecting with a power source and a light head including a supporting frame and a luminary unit. The supporting frame has a dissipating end and a peripheral surface provided thereon. The luminary unit includes a circuit board provided on the peripheral surface of the supporting frame and electrically connected with the electric input adapter, and at least a luminary element, having two terminal electrodes, which is supported by the supporting frame and electrically connected to the circuit board for emitting light when the terminal electrodes are electrified. Therefore, the heat generated by the luminary element directly dissipates at the dissipating end of the supporting frame so as to prevent the light head from overheating.

Owner:CHEN AMY YUN

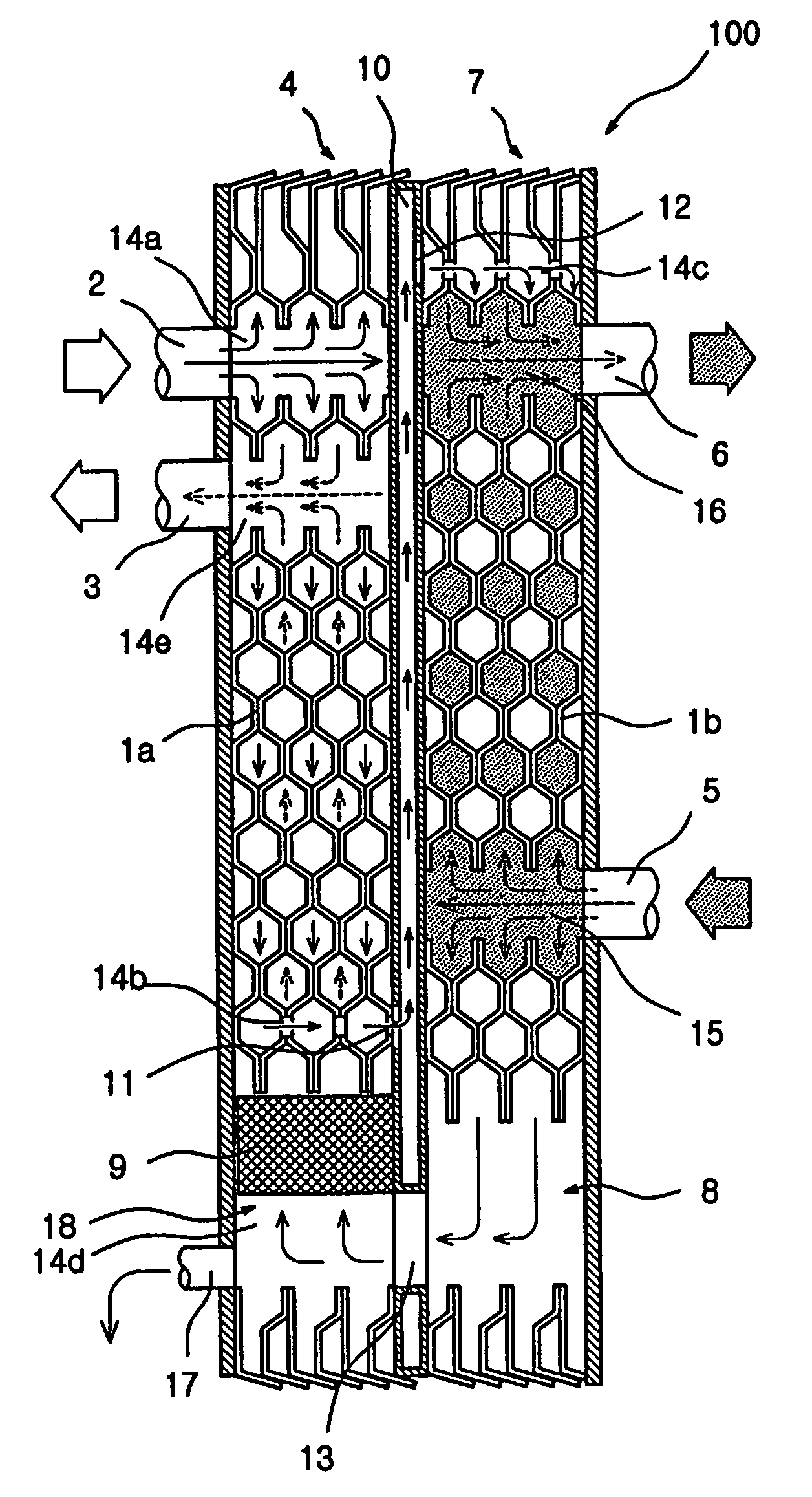

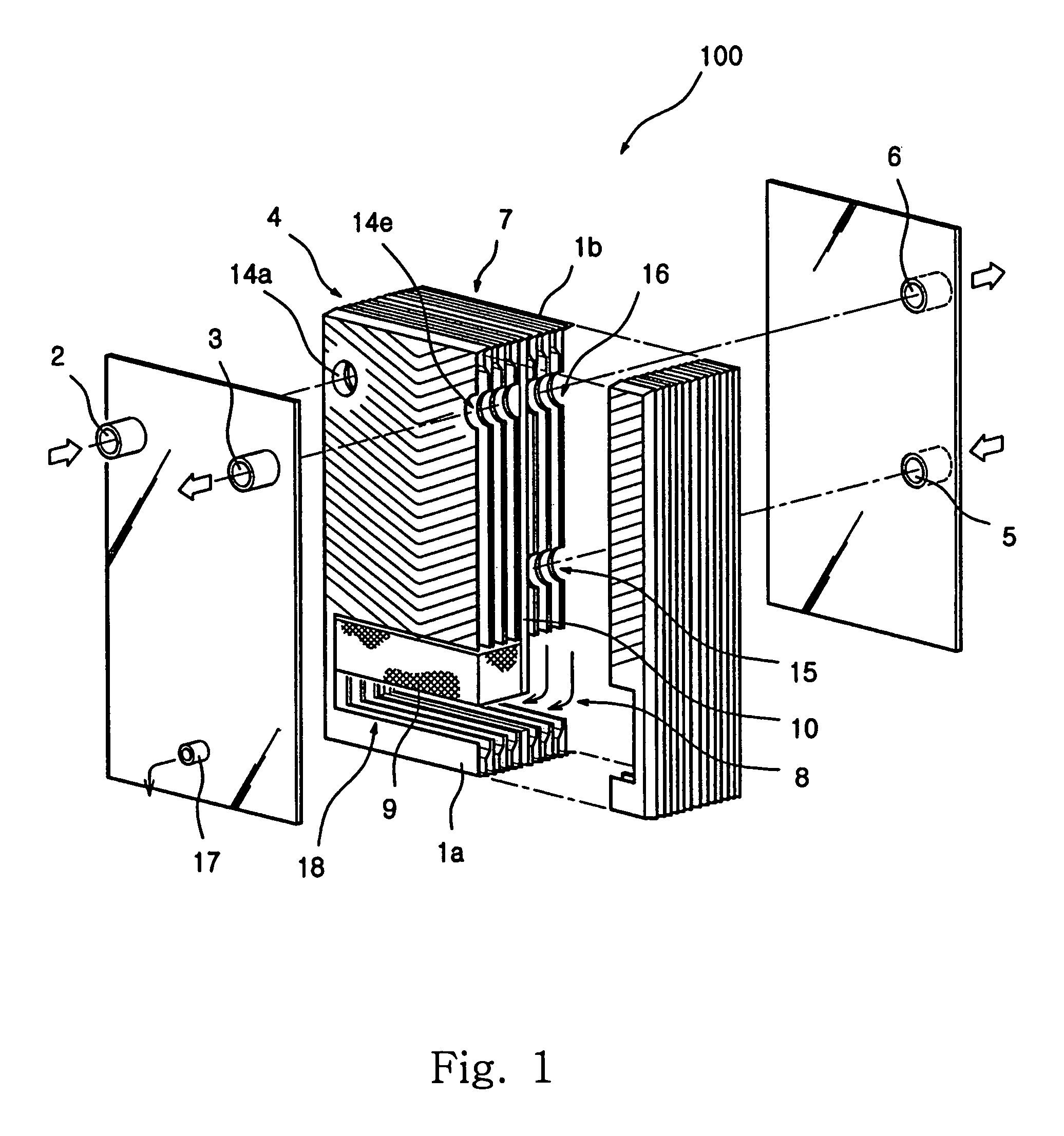

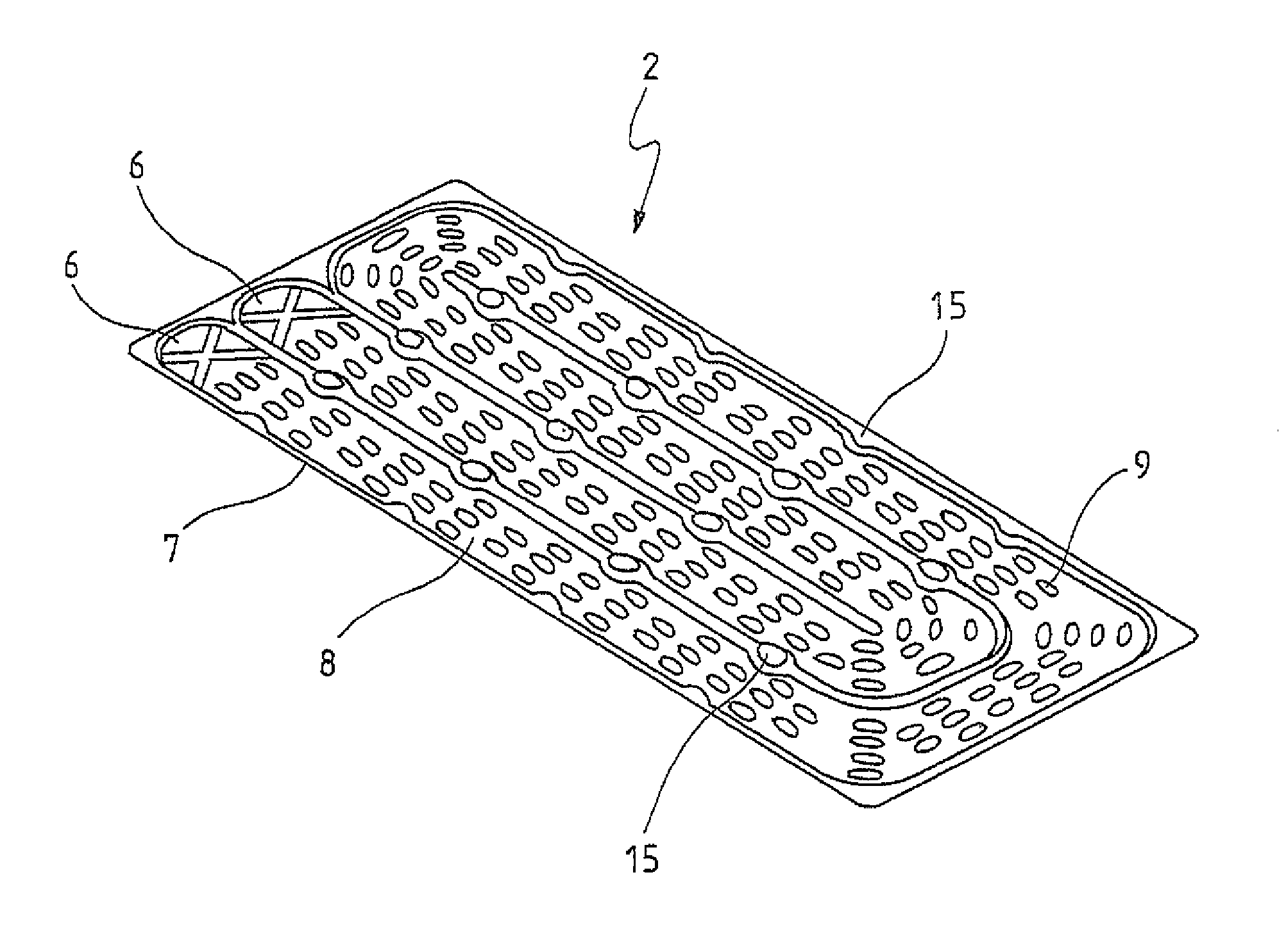

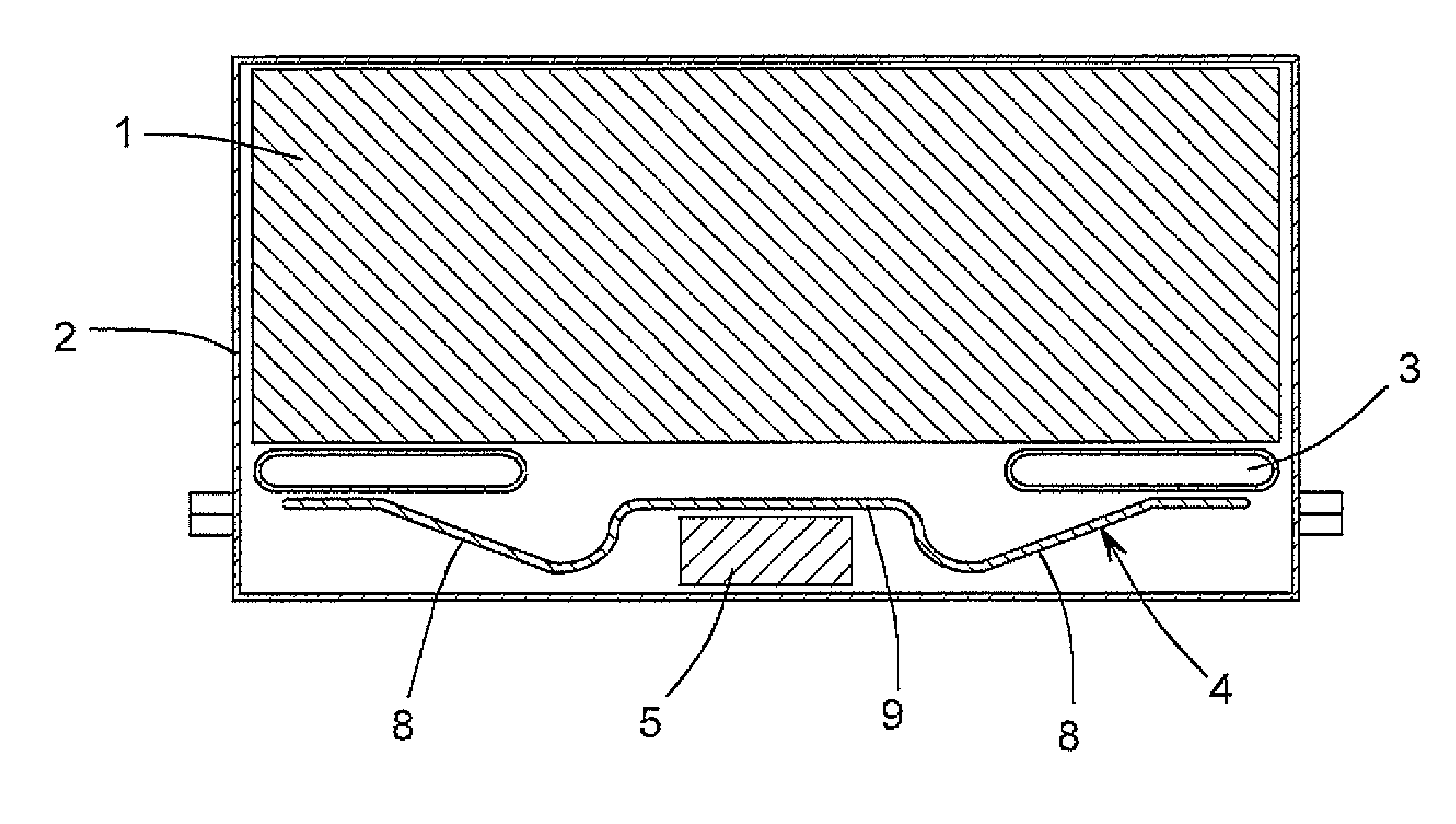

Plate heat exchanger with condensed fluid separating functions

ActiveUS7762090B2Minimized installation spaceReduce manufacturing costVapor condensationSteam/vapor condensersWorking fluidEngineering

A plate heat exchanger with a condensed fluid separating function, which includes a reheater having plural laminated wrinkled plates and introduction and discharge holes connected to different compressed air channels therein; a chiller having plural laminated wrinkled plates, working fluid inlet and outlet holes connected to a working fluid channel therein, and compressed air channels formed therein; and a wall-shaped pipe configured for partitioning the reheater and the chiller with providing a flow line to communicate a compressed air with he reheater and the chiller. An adiabatic expansion chamber is formed in a lower portion of the chiller on a flow line for the compressed air cooled in the chiller to move toward the reheater. A condensation chamber is formed in a lower portion of the reheater connected to the adiabatic expansion chamber. A condensation mesh sieve and a drainage hole are formed in the condensation hole.

Owner:IND TECH & SERVICES KOREA CO LTD

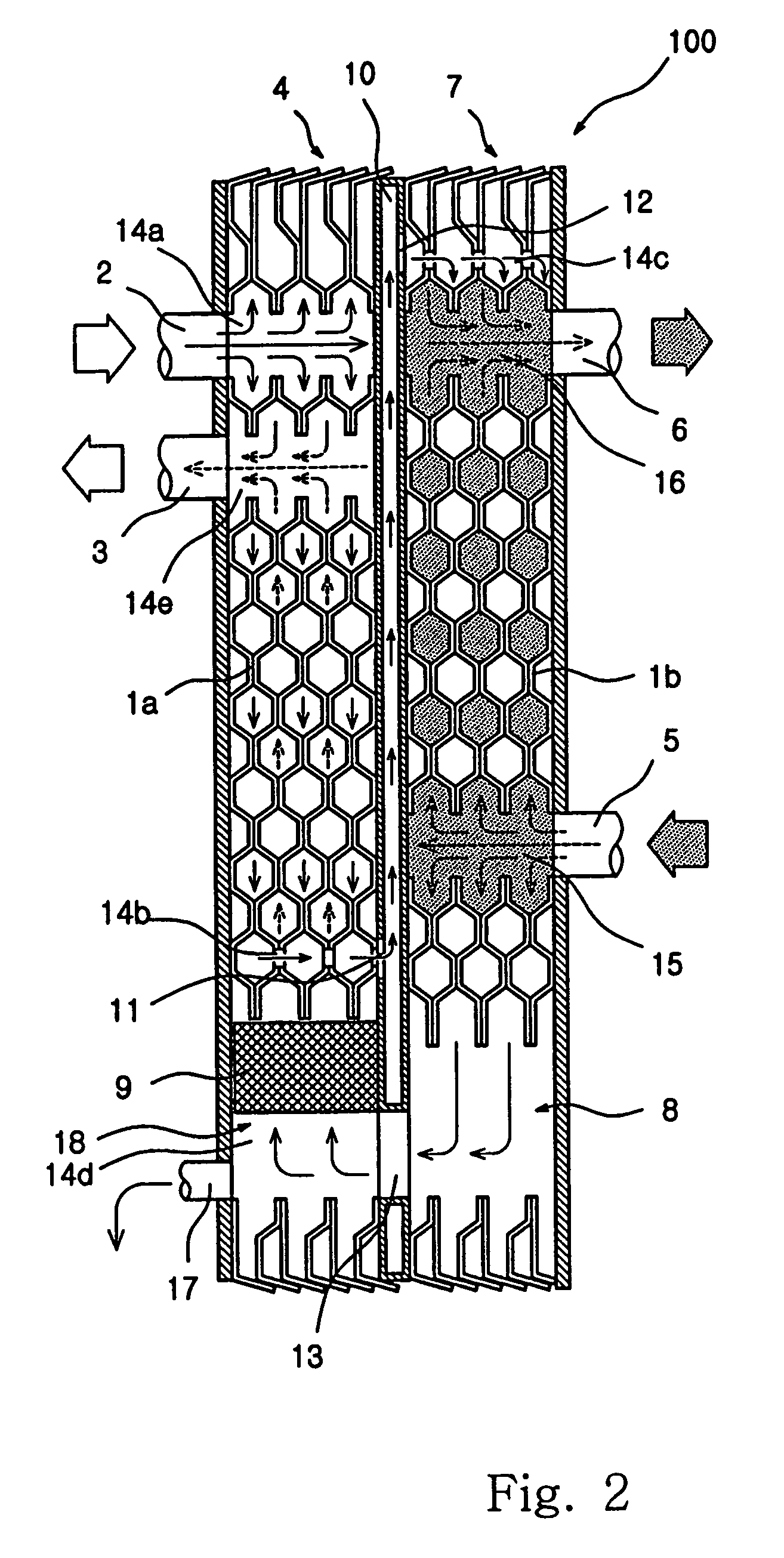

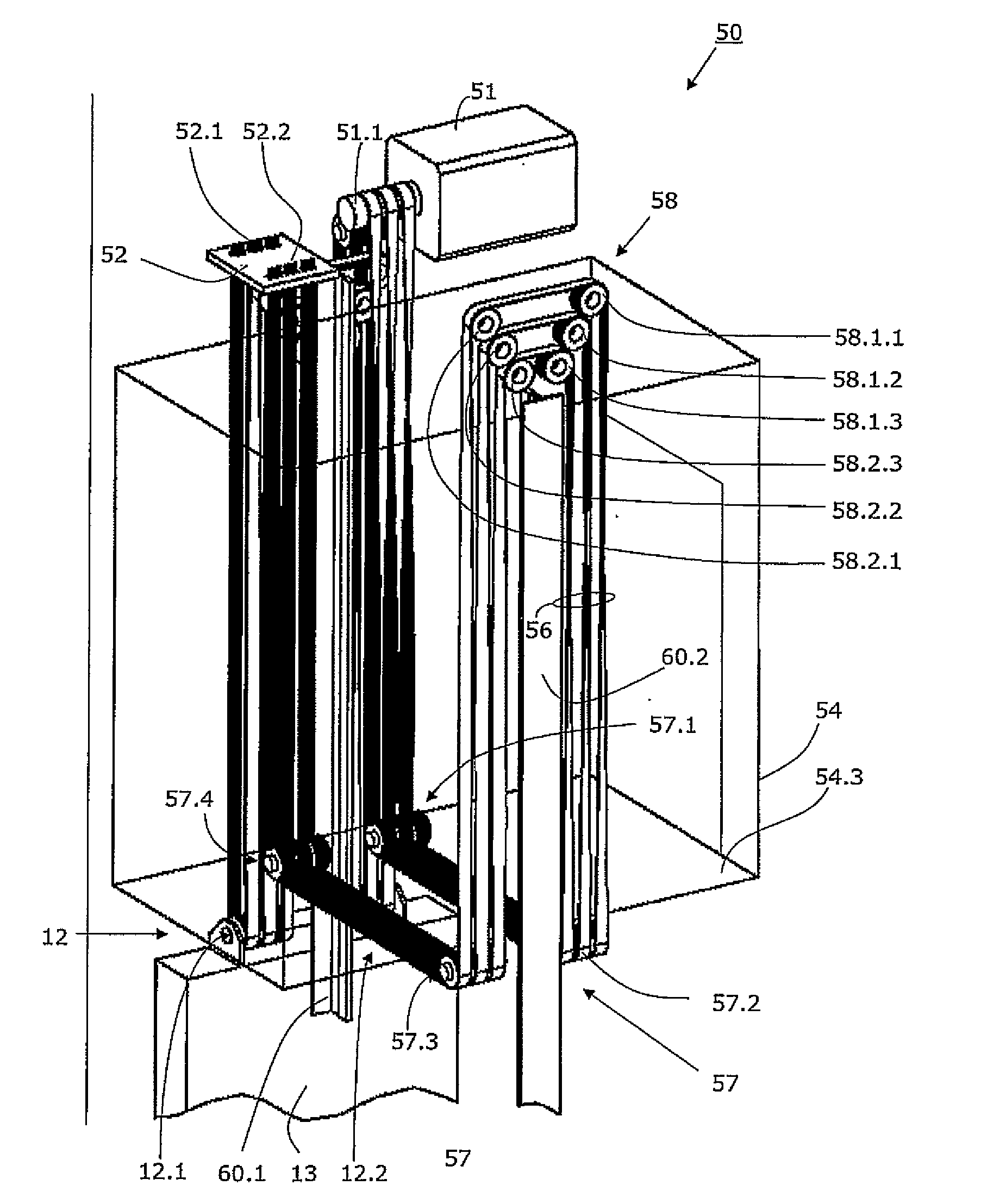

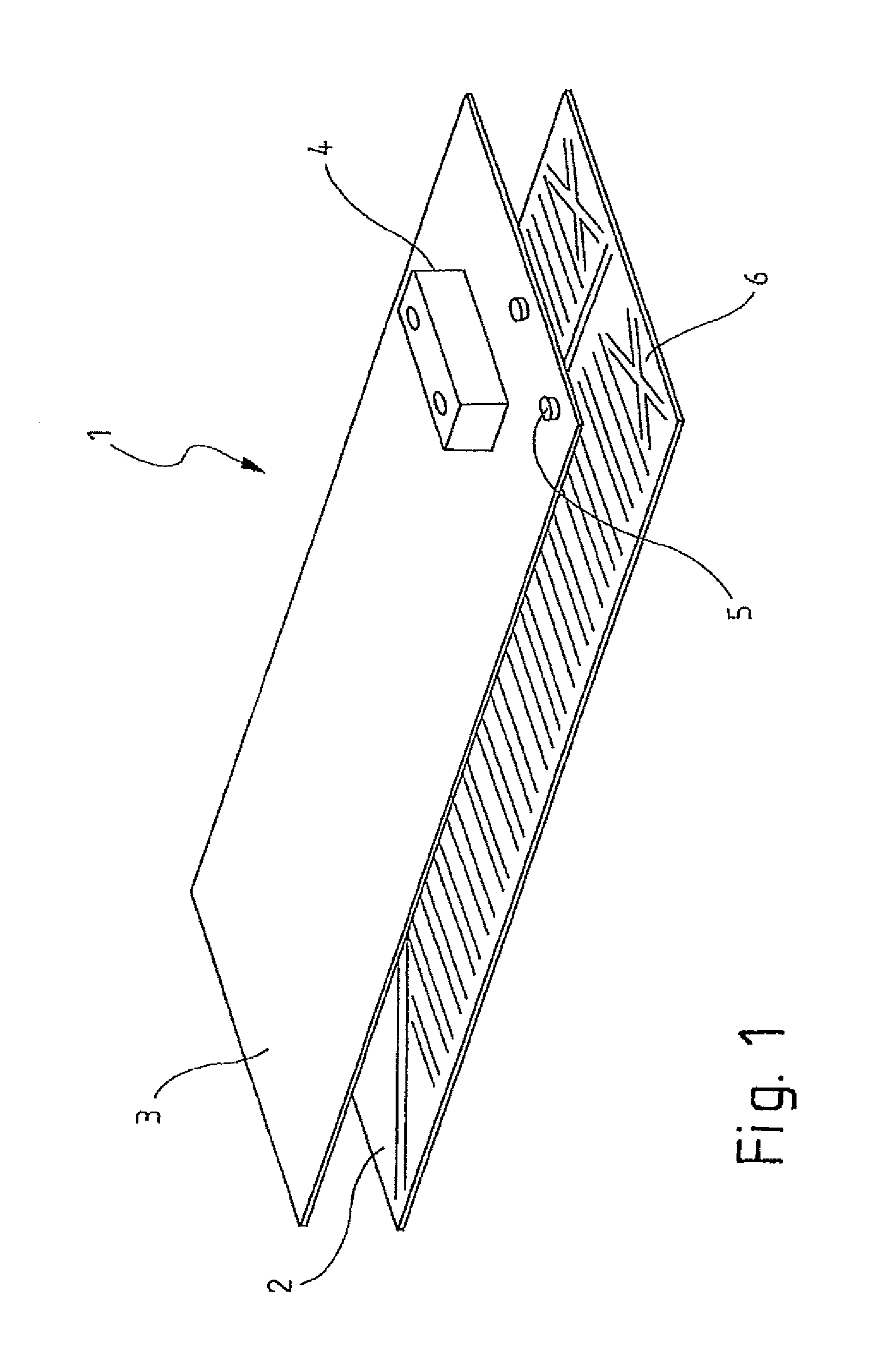

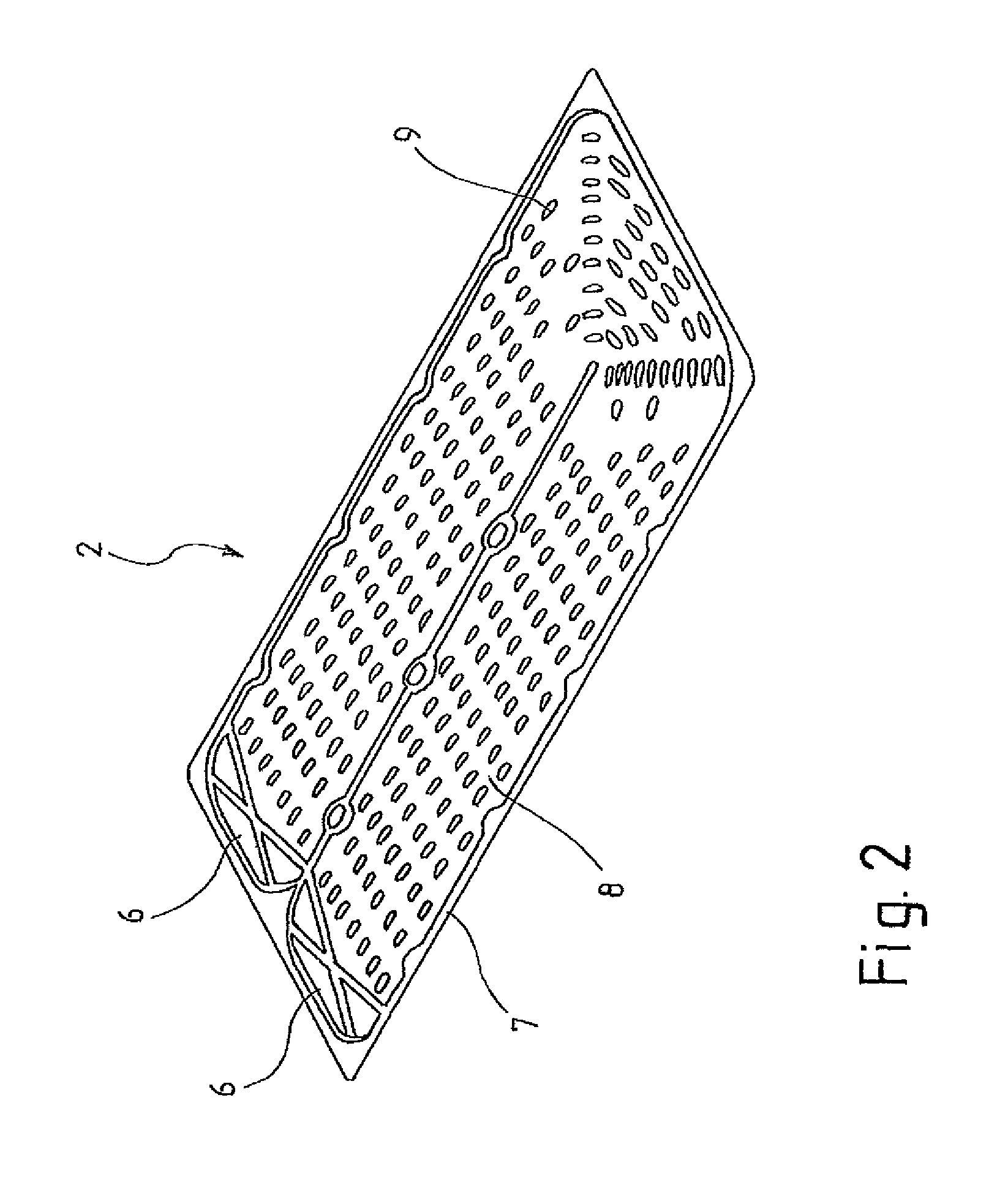

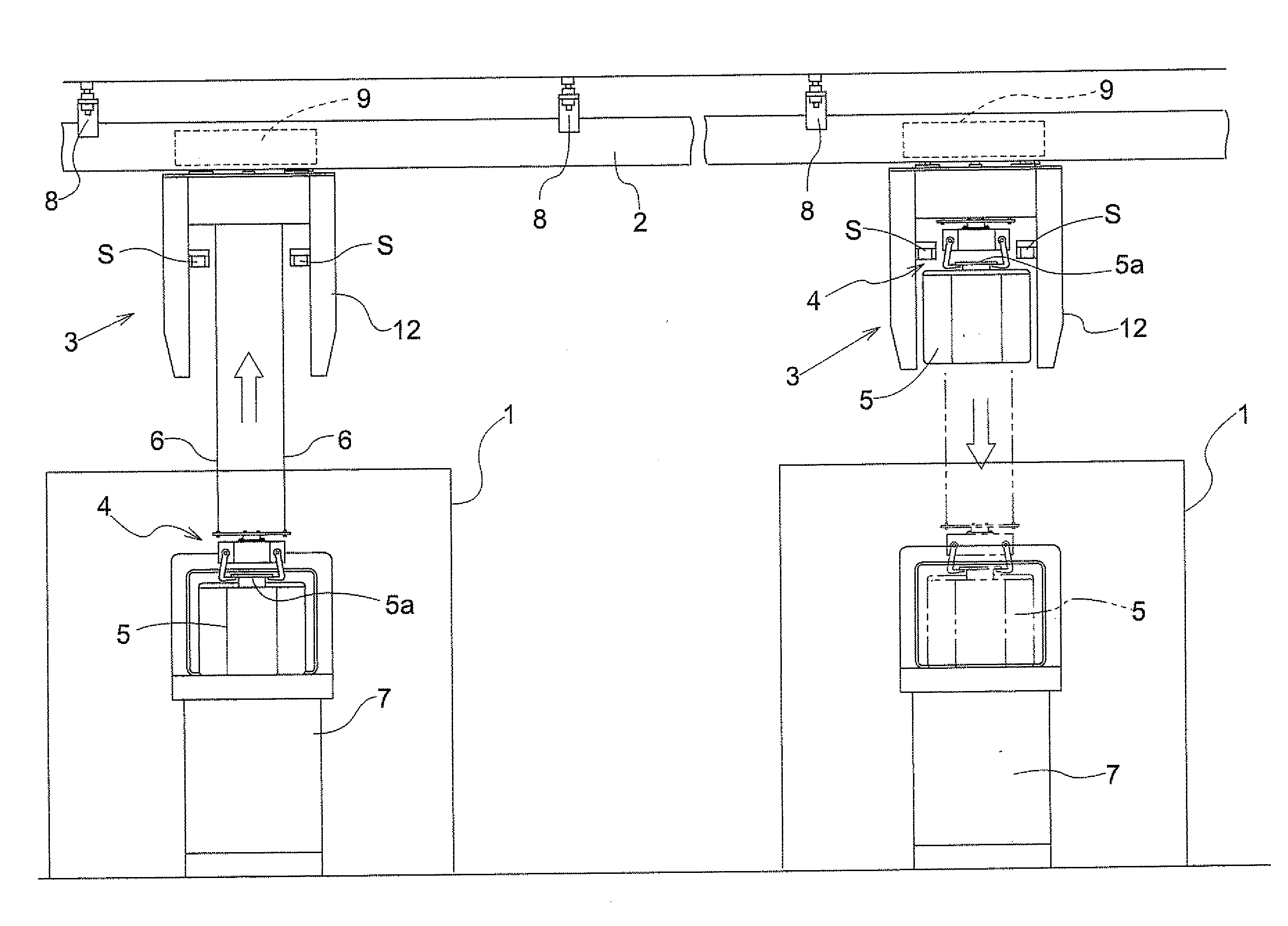

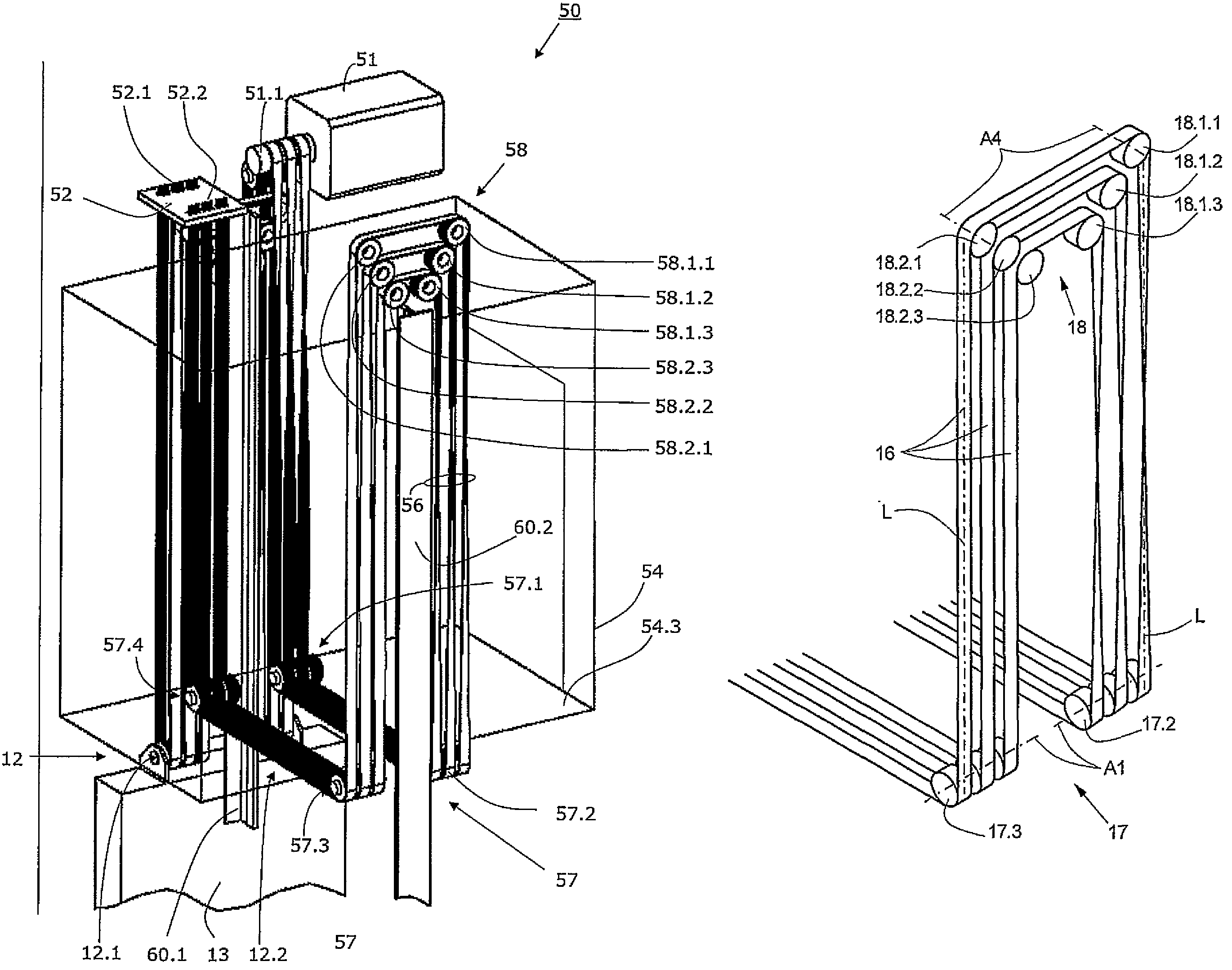

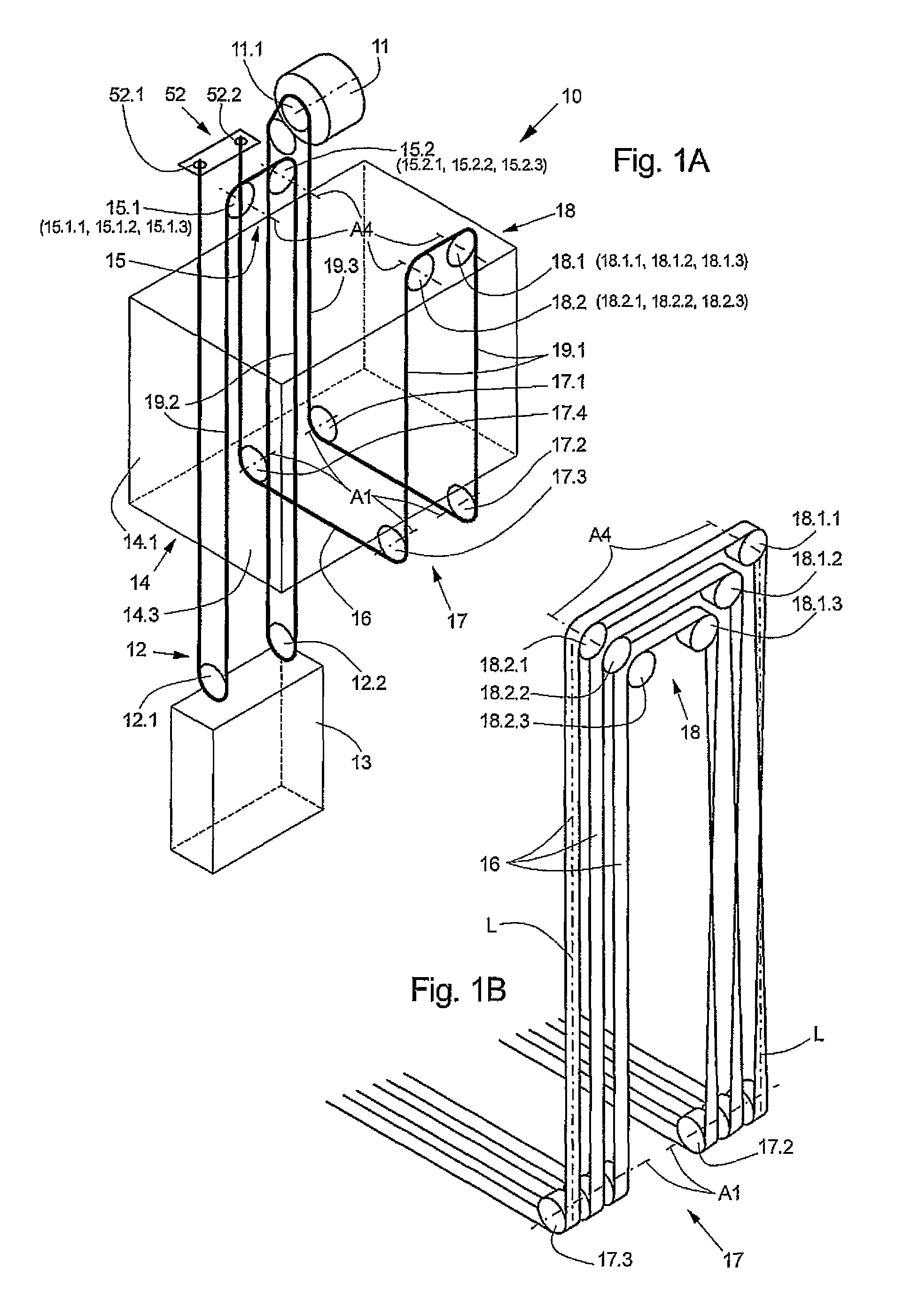

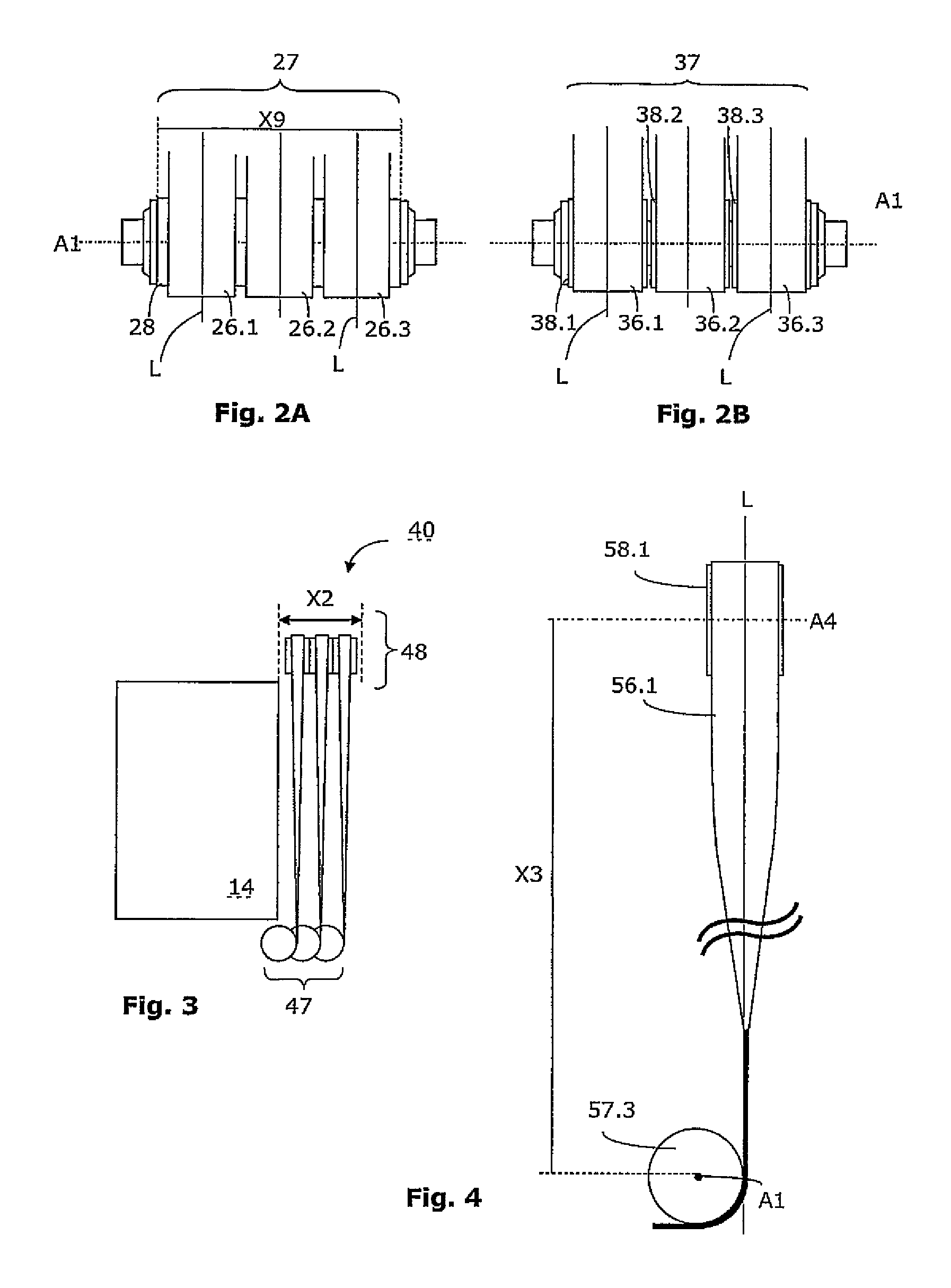

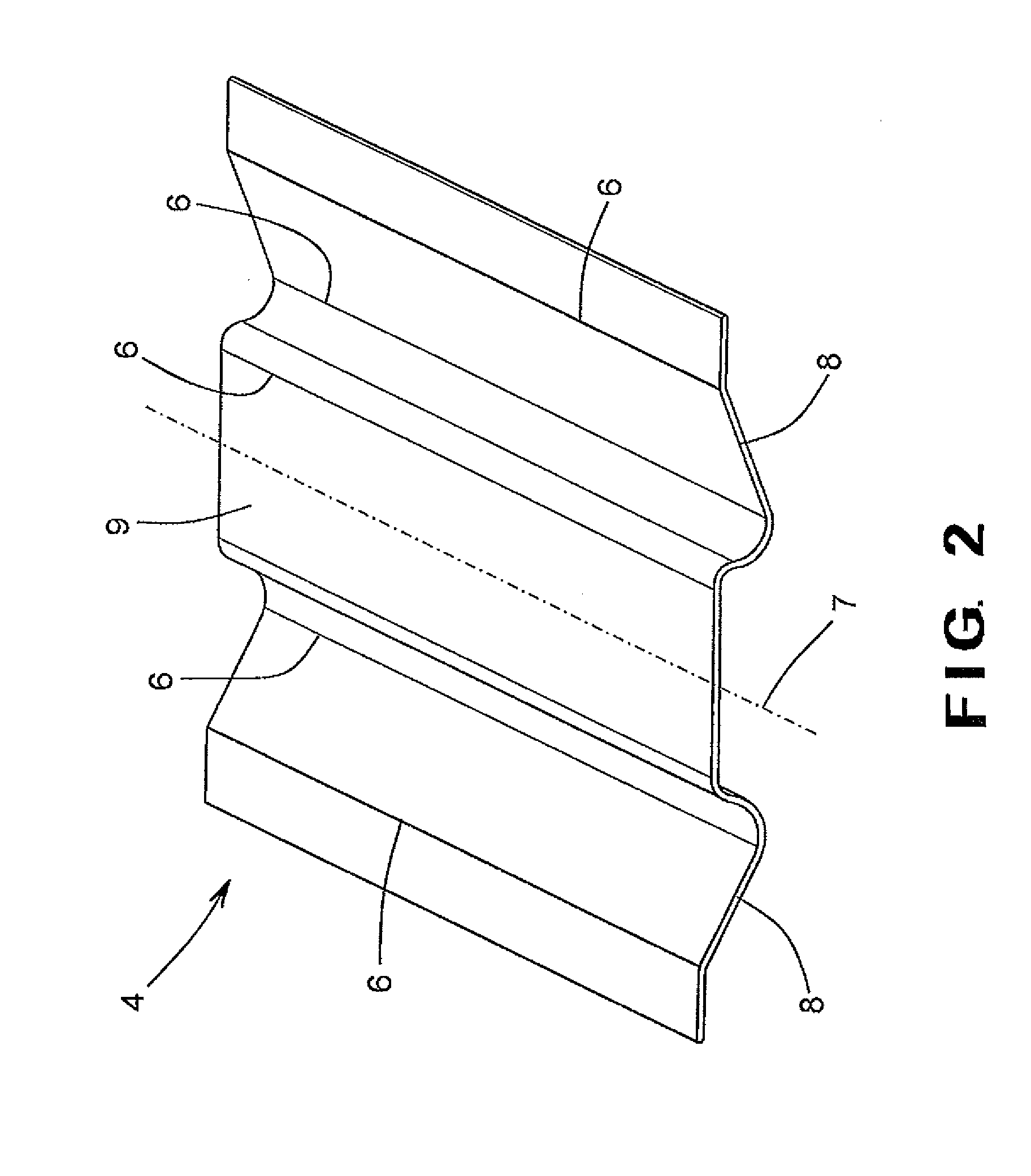

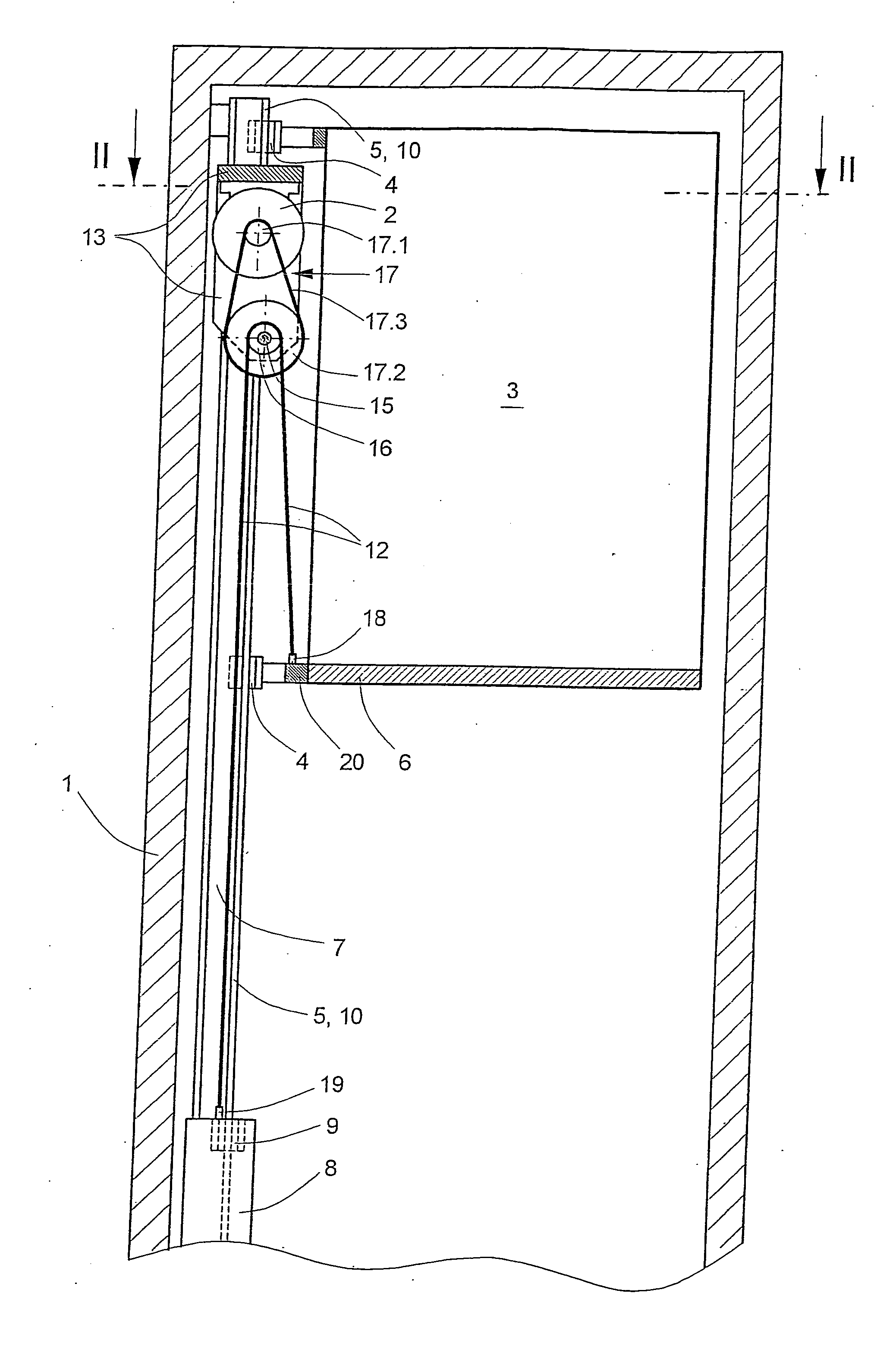

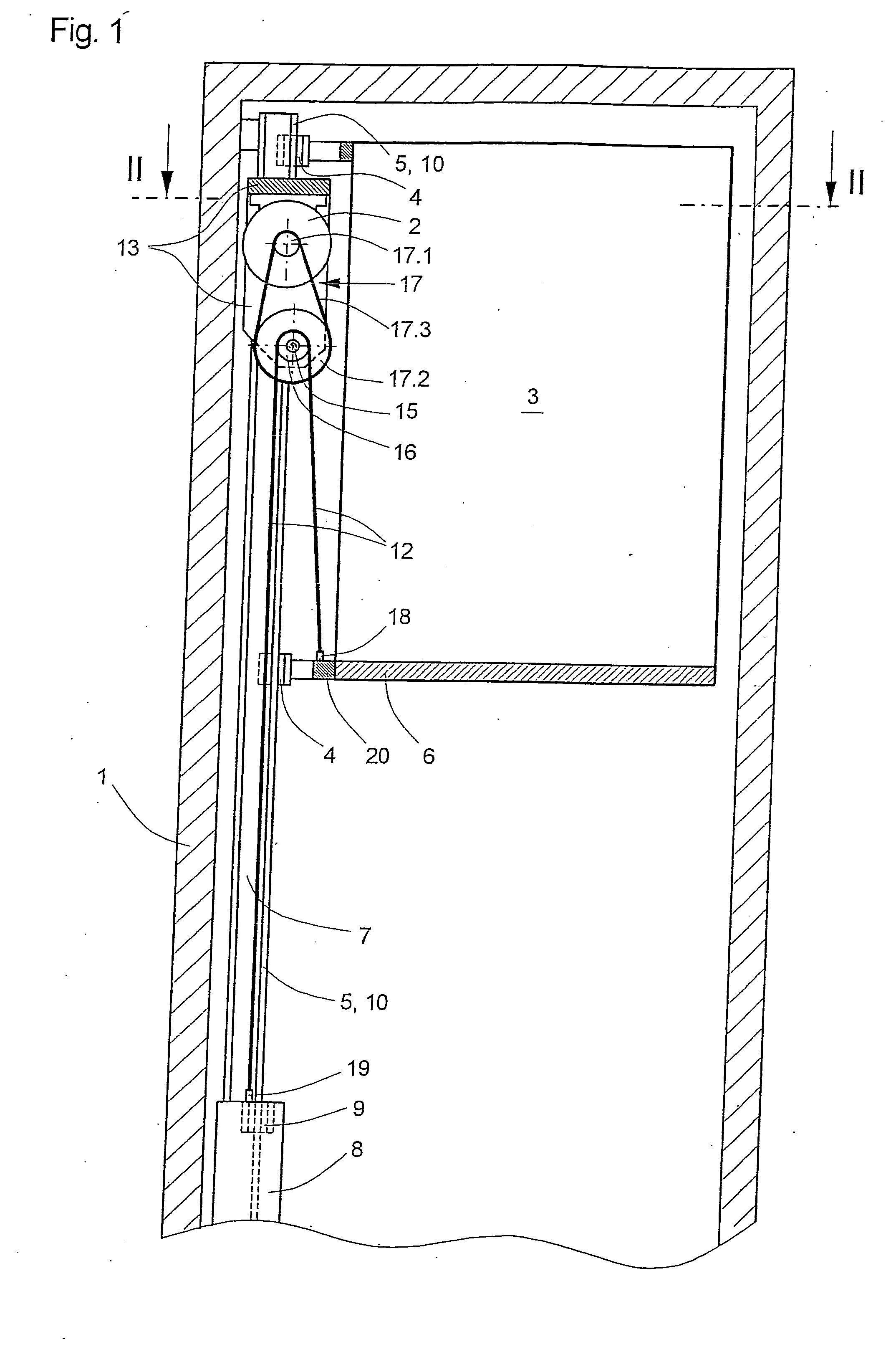

Elevator and Pulley Assembly for Use in an Elevator

InactiveUS20080121468A1Simple roller framesSmall constructionElevatorsBuilding liftsSupport beltEngineering

An elevator comprises an elevator car and support belts that form a 4:1 suspension for the elevator cabin and that are looped several times beneath the elevator car. Several parallel, flat belts are used and the rollers of at least one fixed roller group that diverts the belts are positioned in such a way that the belt sections of the parallel belts lie vertically above one another in the vicinity of the belt diversion.

Owner:INVENTIO AG

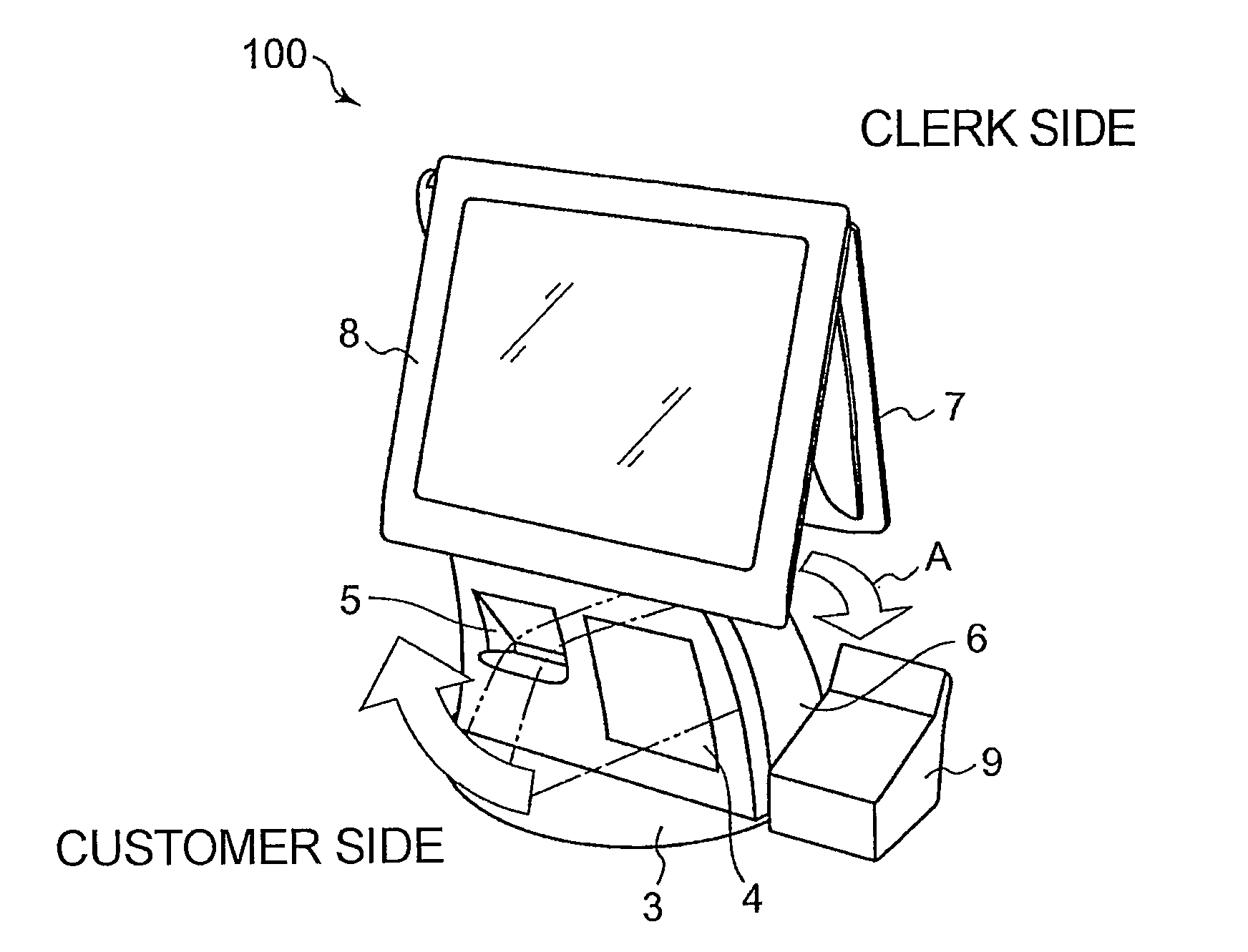

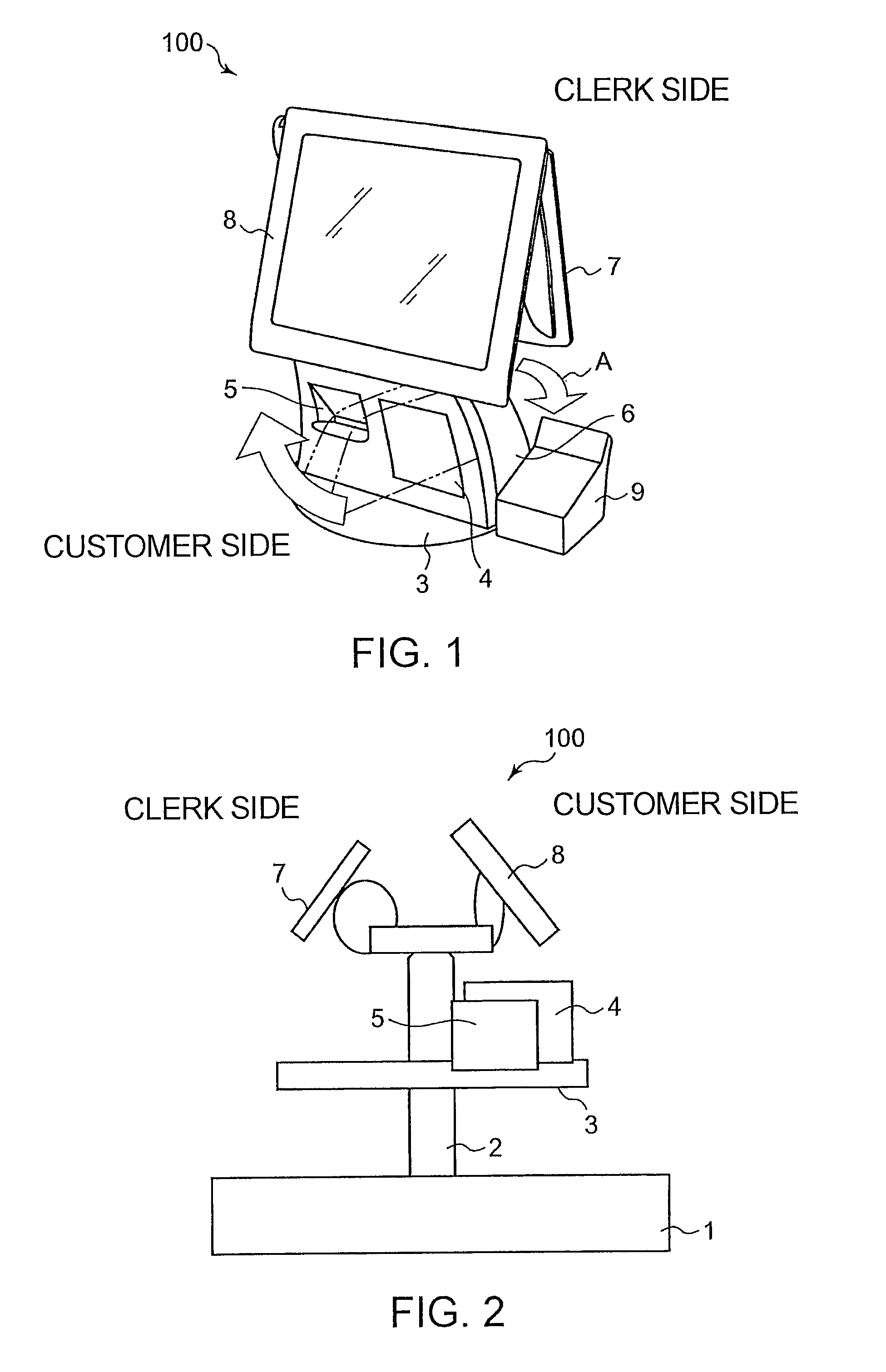

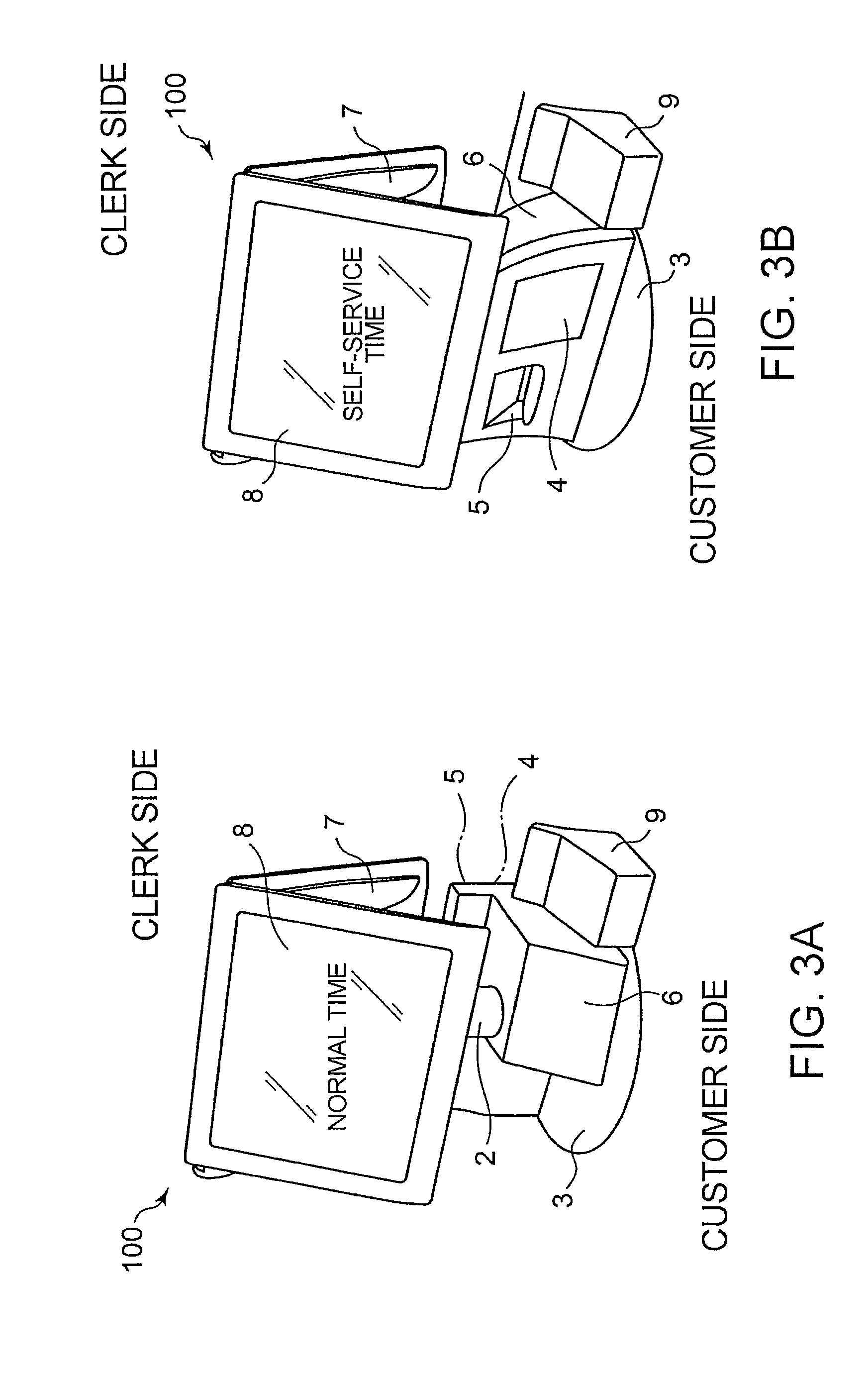

POS device

ActiveUS7970650B2Simple structureEasy to operateDigital data processing detailsCash registersBarcodeDisplay device

A POS device includes a rotation shaft vertically fixed, a rotary plate provided so as to be rotatable about the rotation shaft, a rotating portion placed on the rotary plate and having at least a barcode scanner and a receipt printer, and a display device for clerk and a display device for customer both provided at the top end of the rotation shaft.

Owner:NEC PLATFORMS LTD

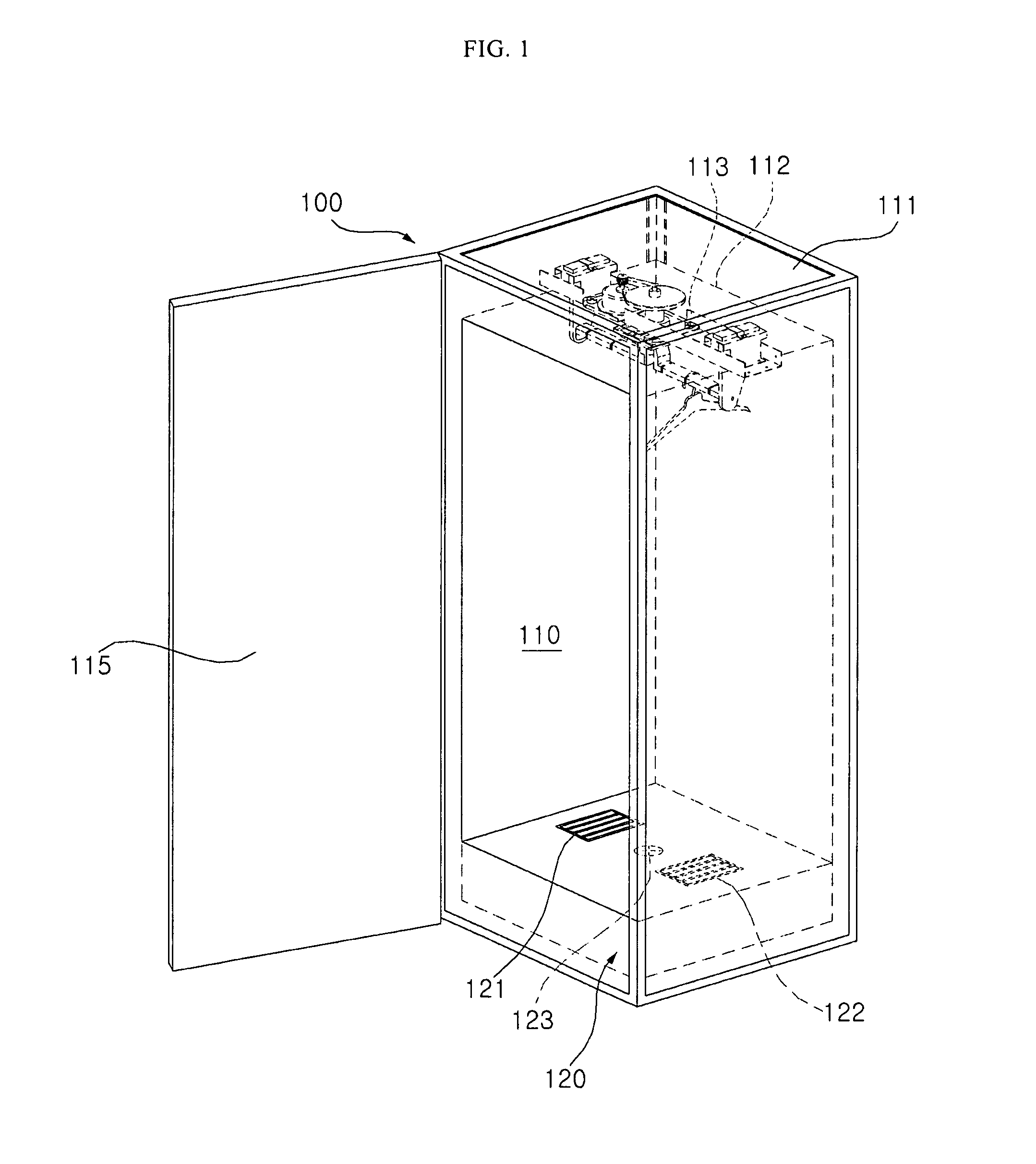

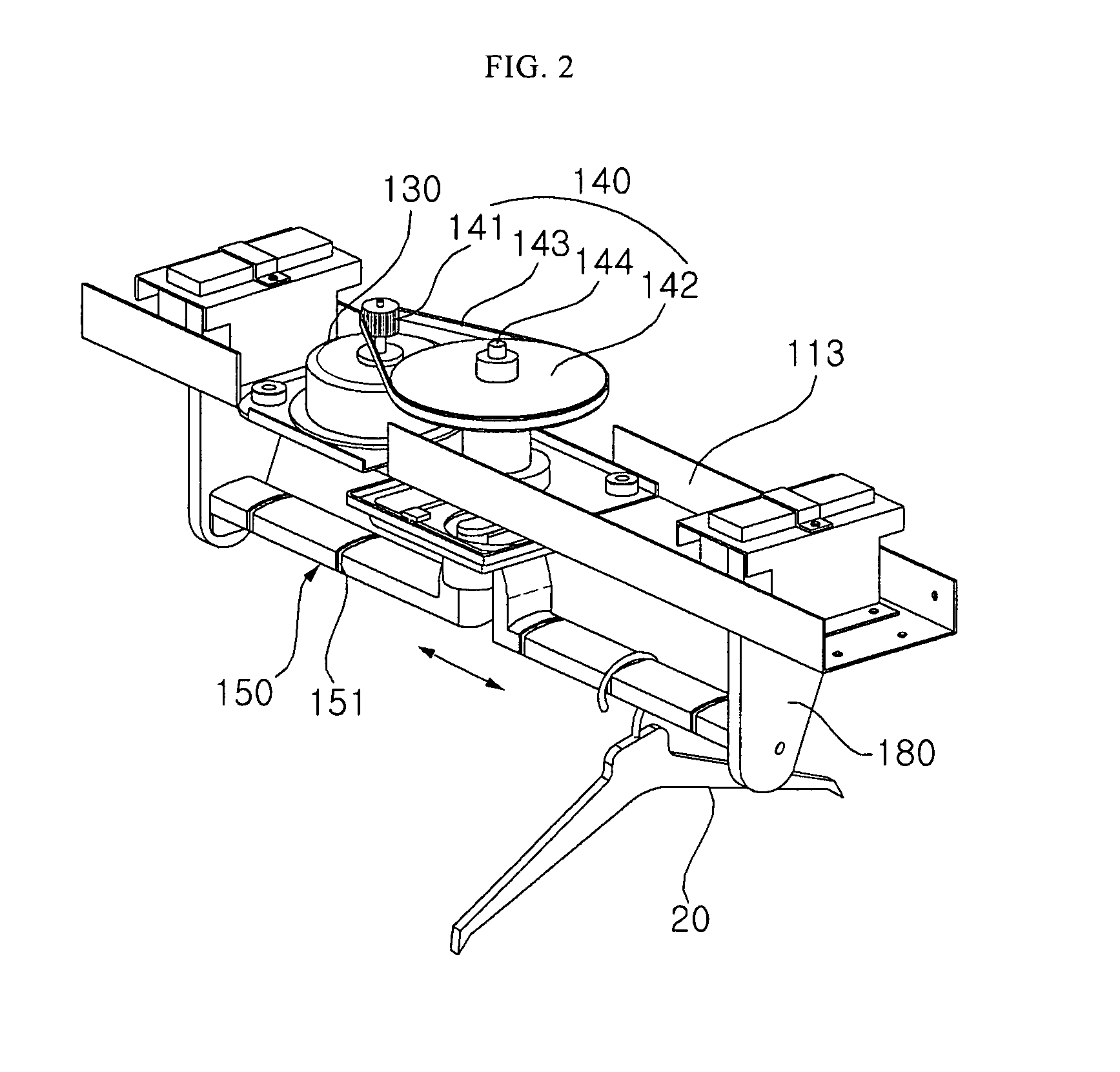

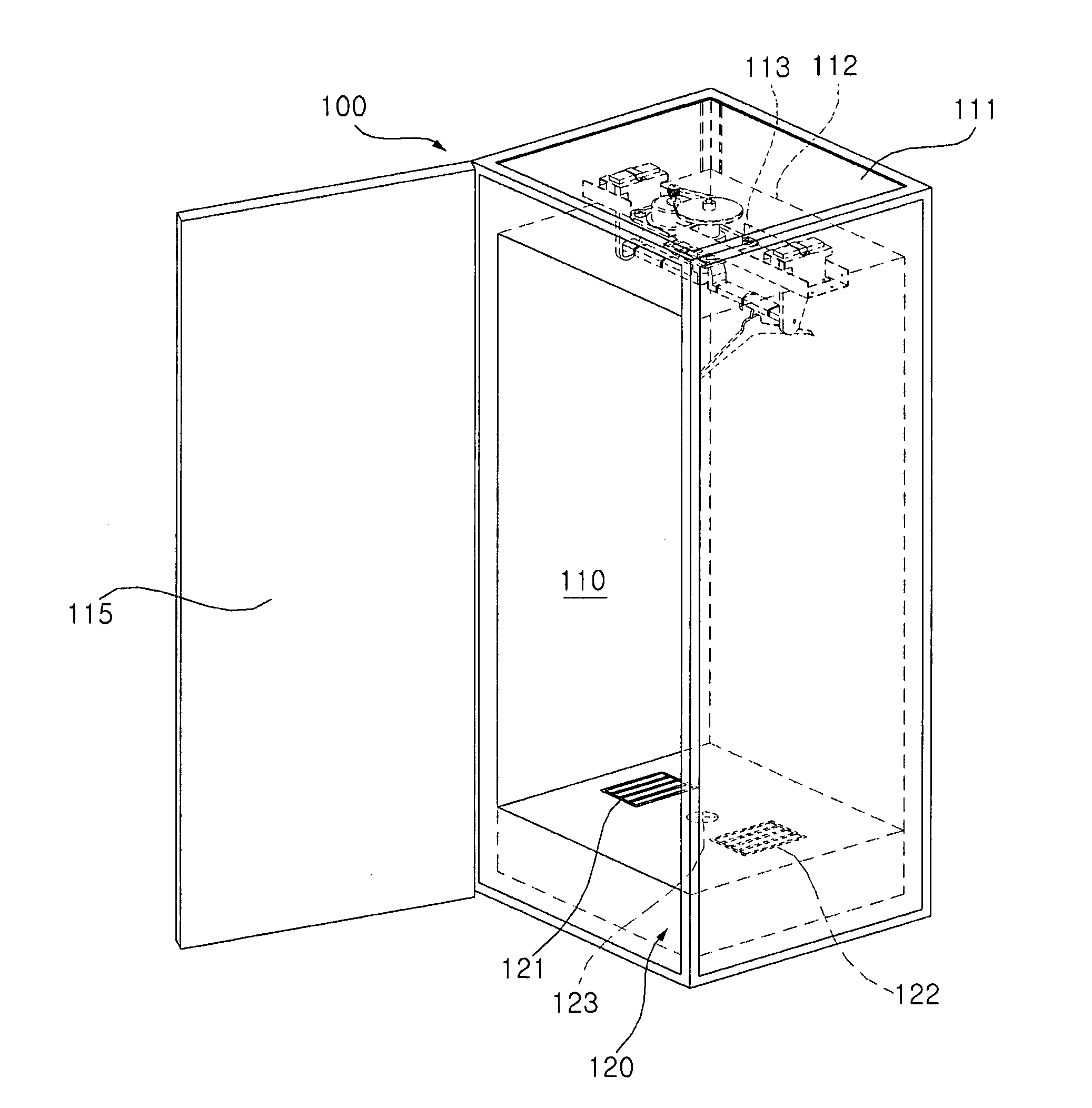

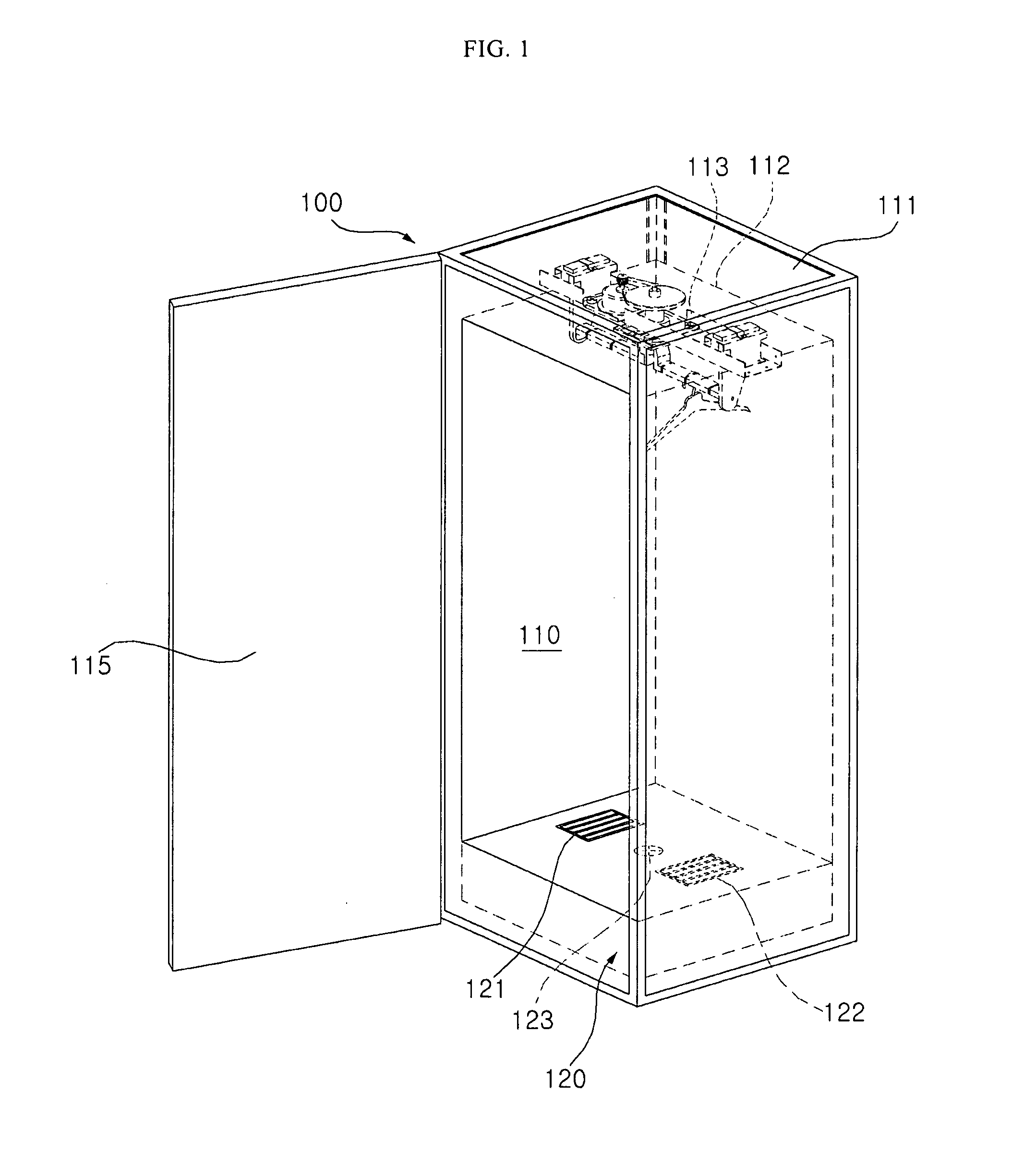

Fabric treating apparatus

ActiveUS8296967B2Improve space efficiencyMinimized installation spaceTextile treatment machine partsOther washing machinesMechanical engineeringEngineering

Owner:LG ELECTRONICS INC

Fabric treating apparatus

ActiveUS20100146805A1Improve space efficiencyMinimized installation spaceDrying chambers/containersIroning apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

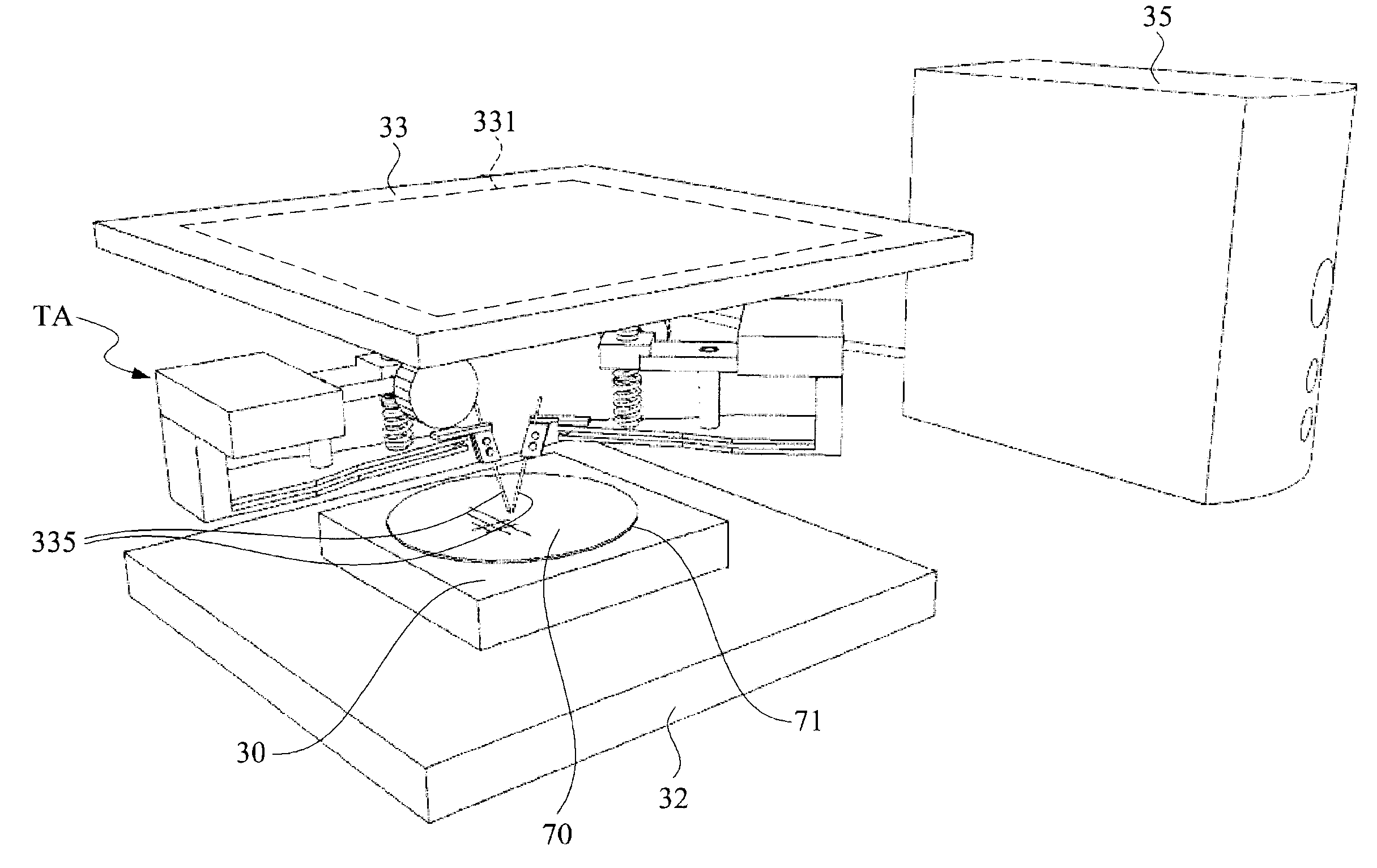

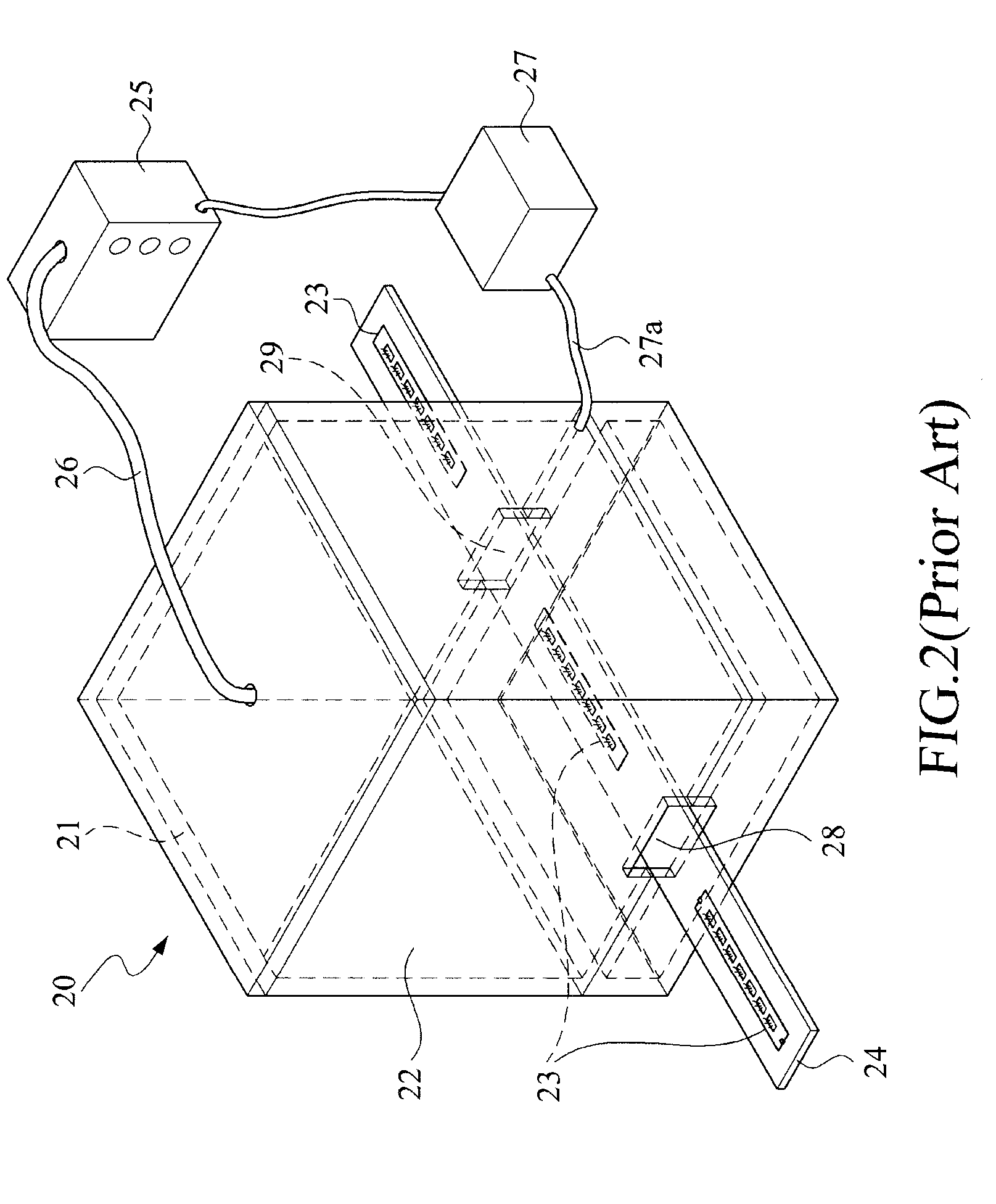

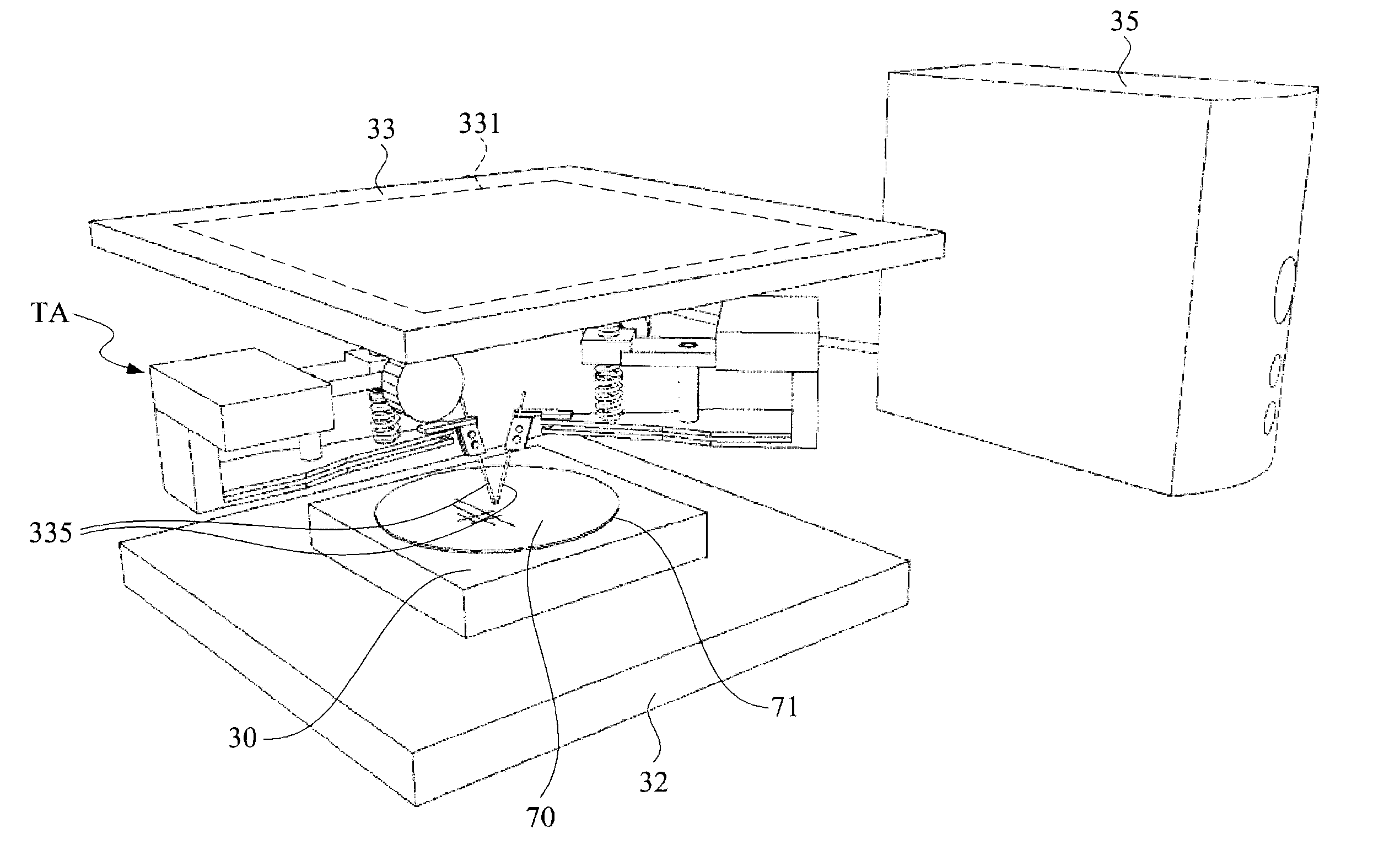

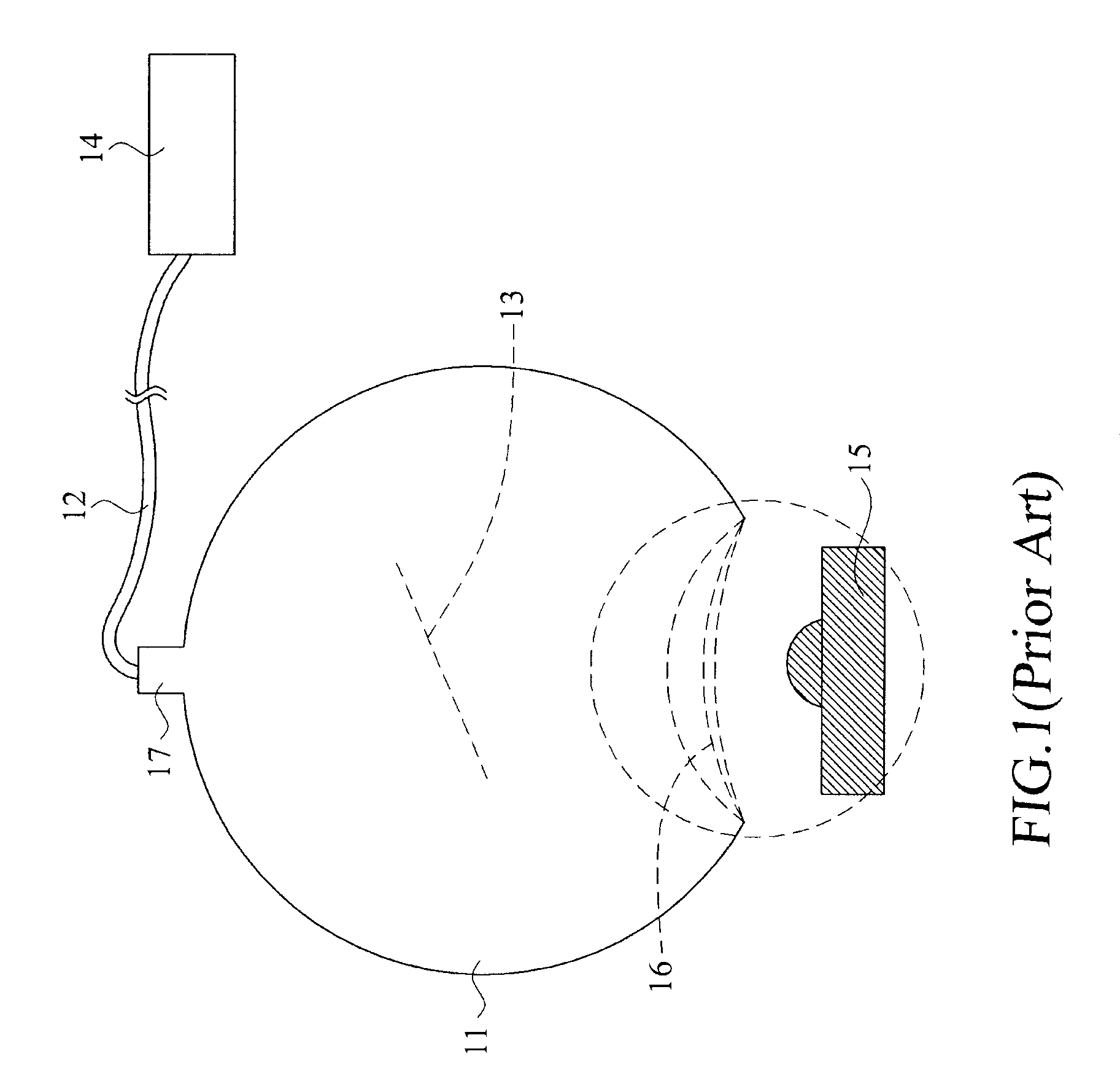

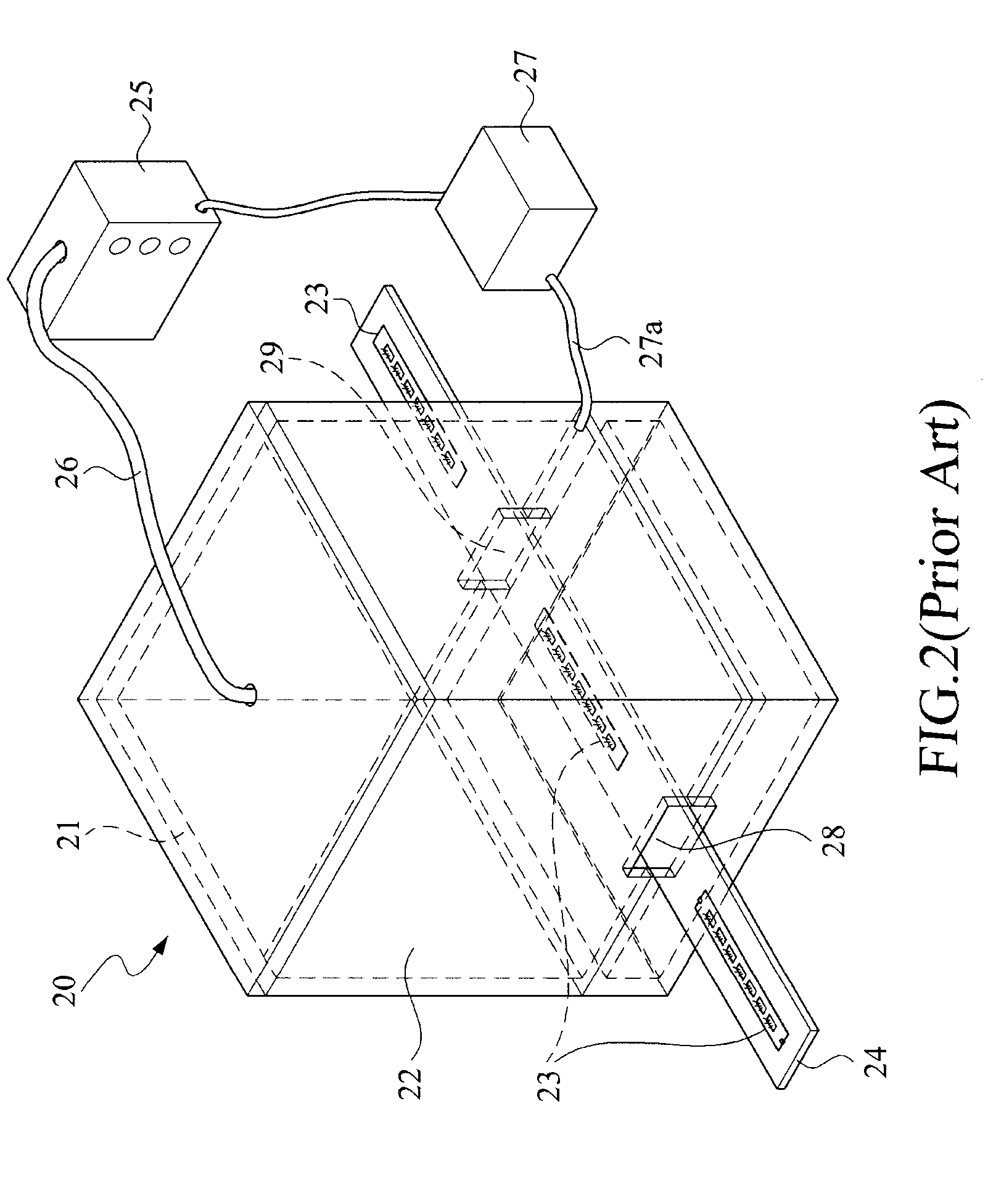

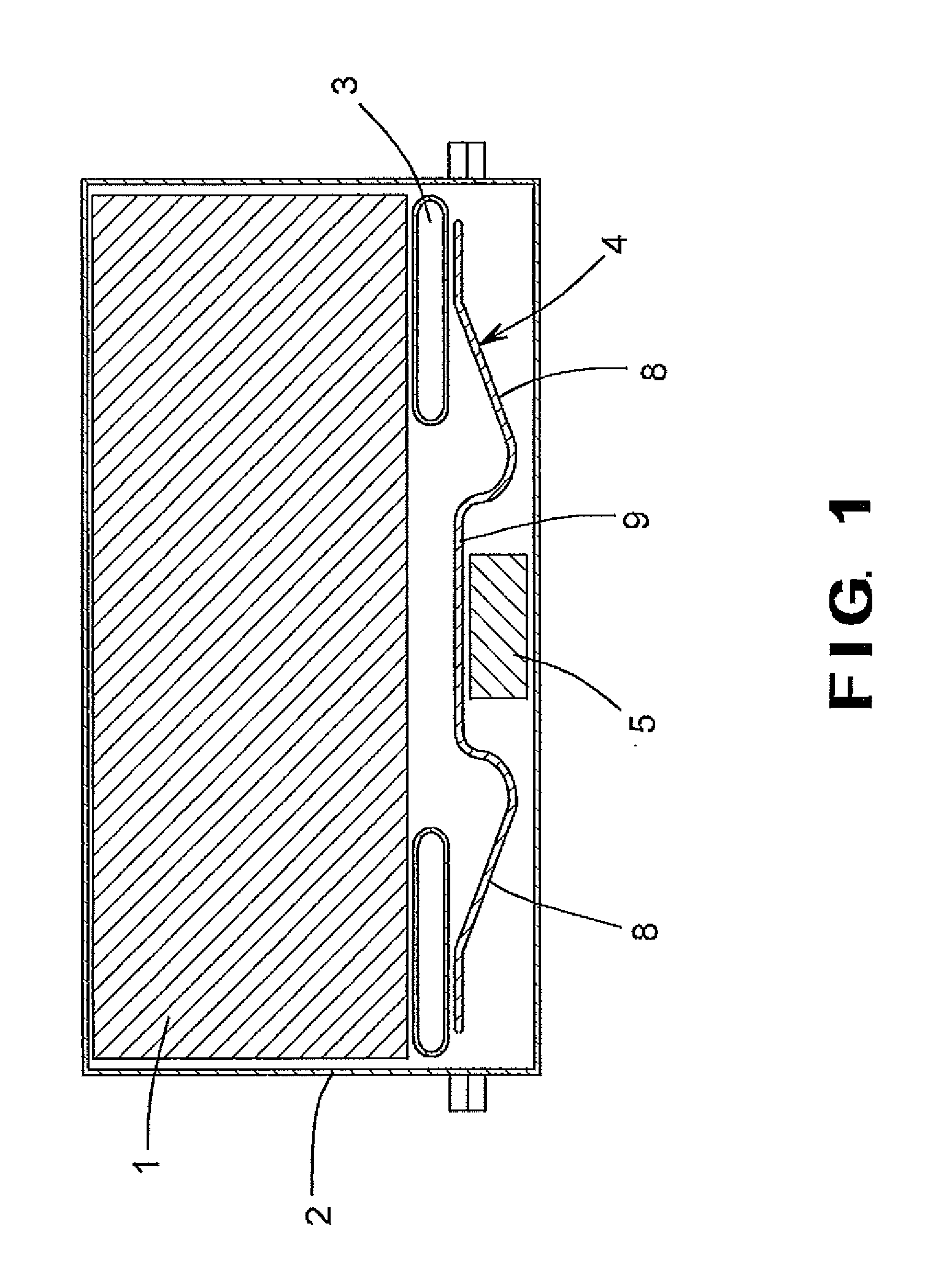

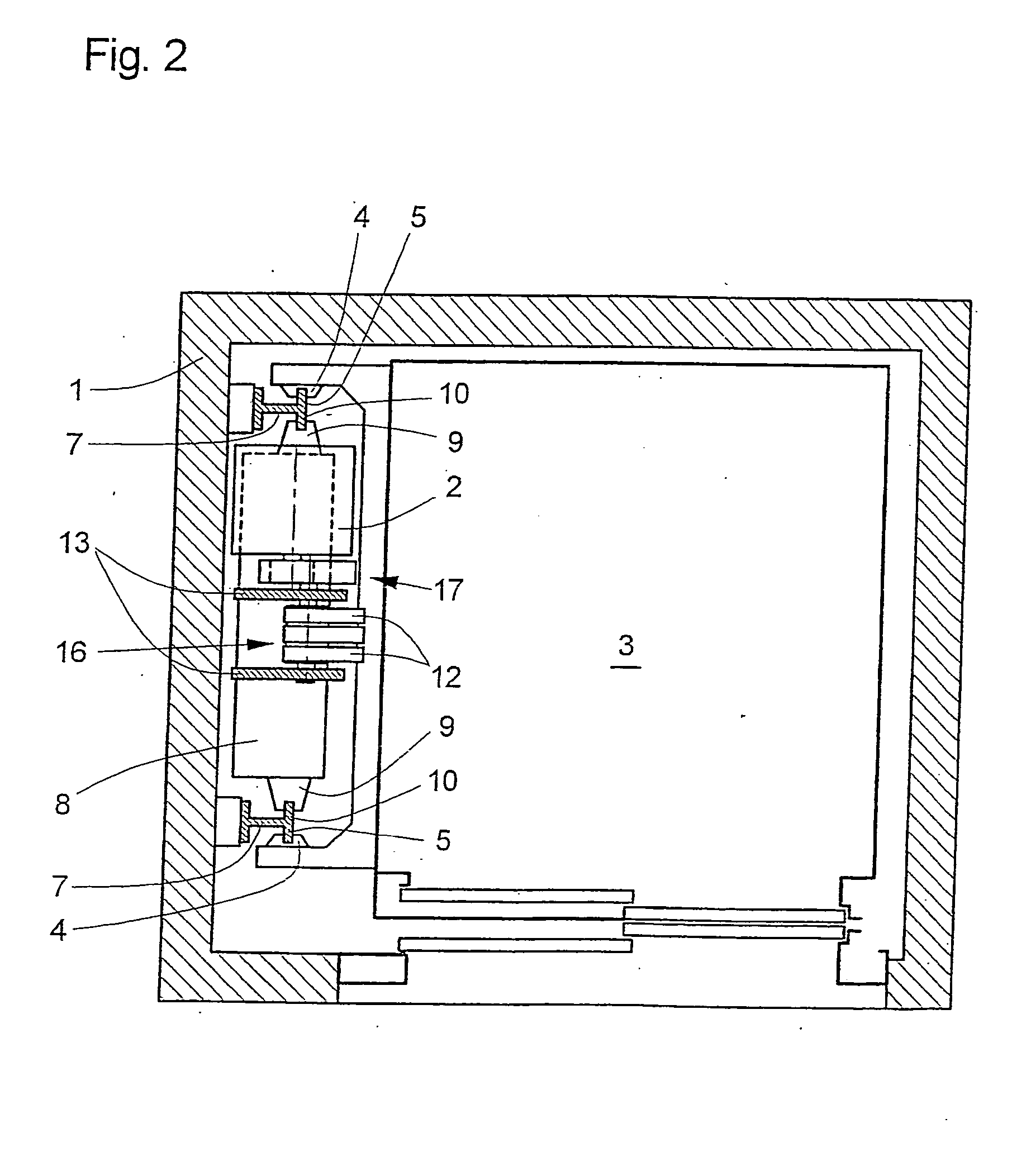

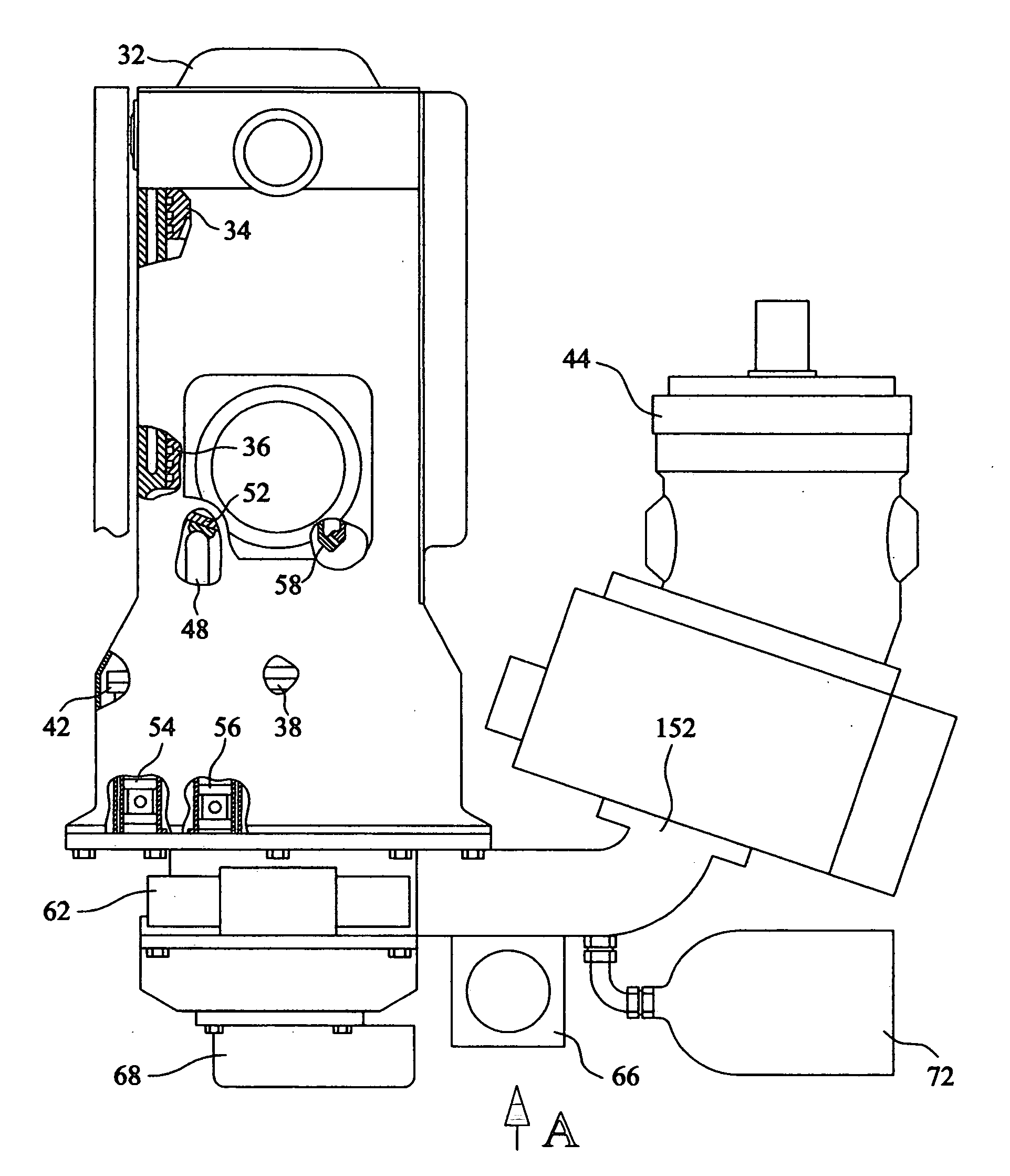

System and method for testing light-emitting devices

ActiveUS20090309606A1Accurate and fast positioningLow costDiode testingPhotometry using multiple detectorsSolar cellOptical energy

A method for testing light-emitting devices in a batch-wise, associated with a system for the same purpose, comprises the steps of: preparing the light-emitting devices on a moving carrier unit in a manner of aligning a predetermined longitudinal direction of the light-emitting devices with a predetermined transportation direction of the moving carrier unit, each of the light-emitting devices further having plural light-emitting elements; transporting orderly the light-emitting devices to pass a test area on a base of the system, in which the base energizes only the light-emitting elements within the test area; and, a solar cell module detecting continuously the energized light-emitting elements within the test area and further forming signals with respect to photo energy received in the test area.

Owner:CHROMA ATE

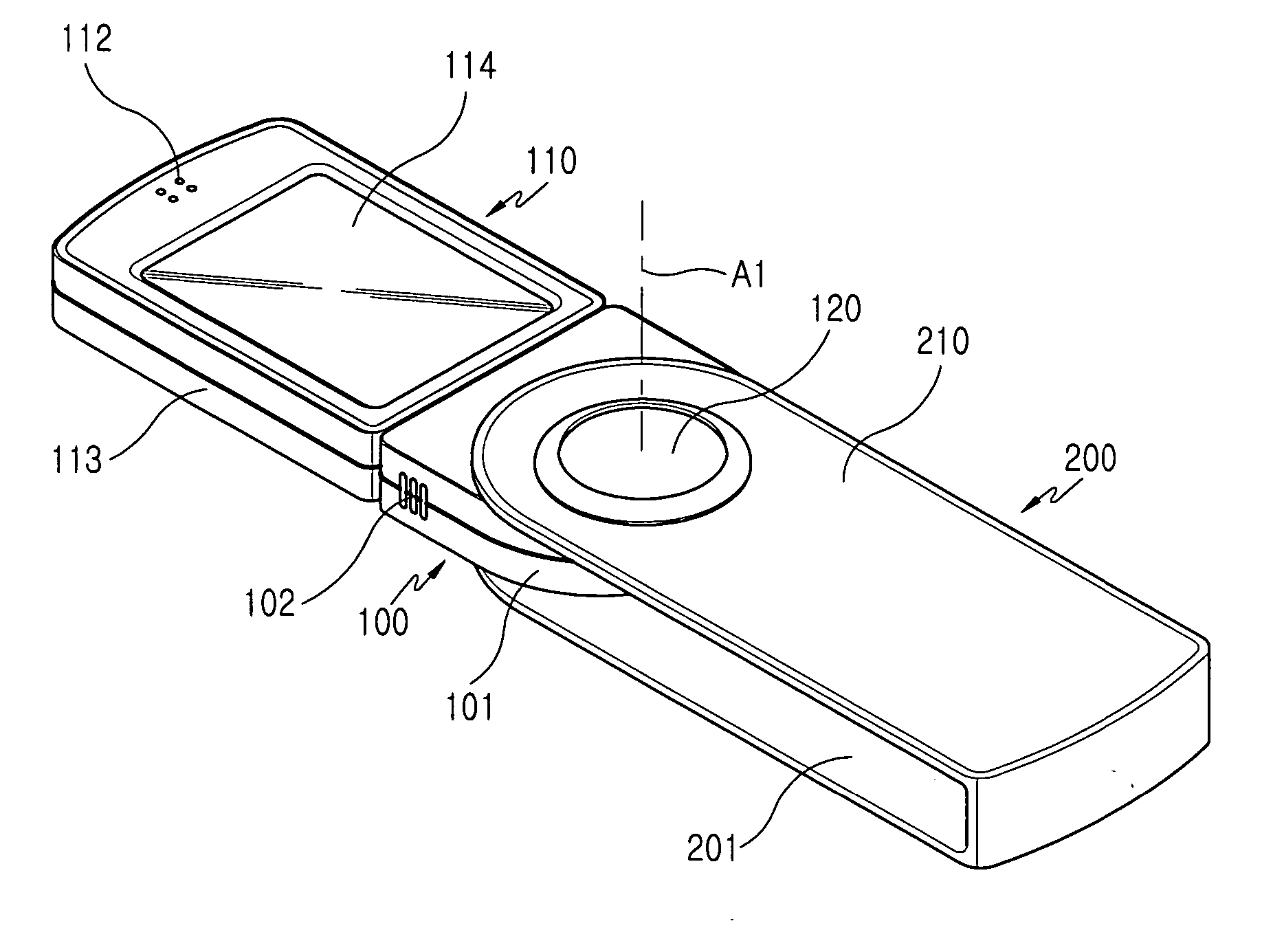

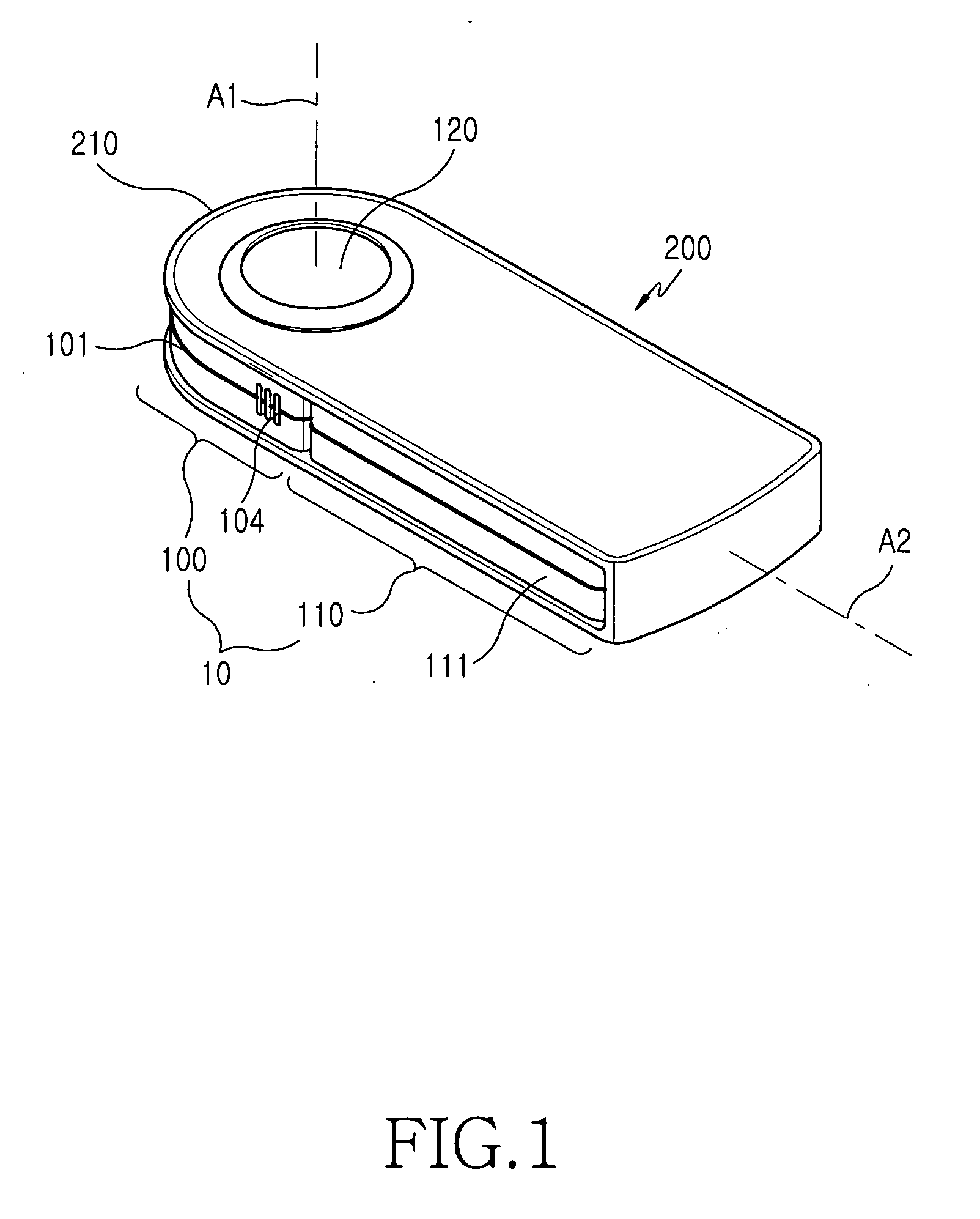

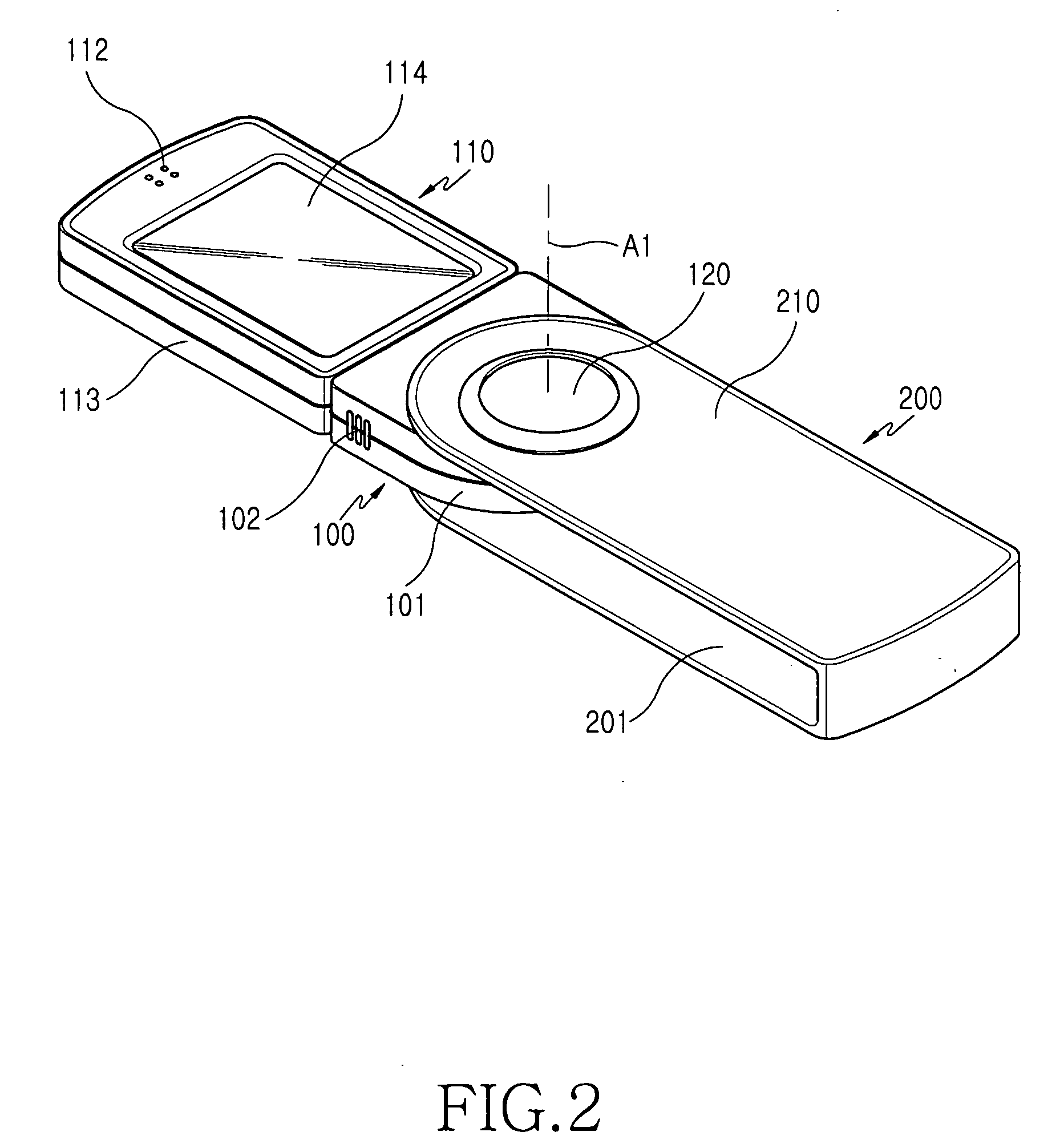

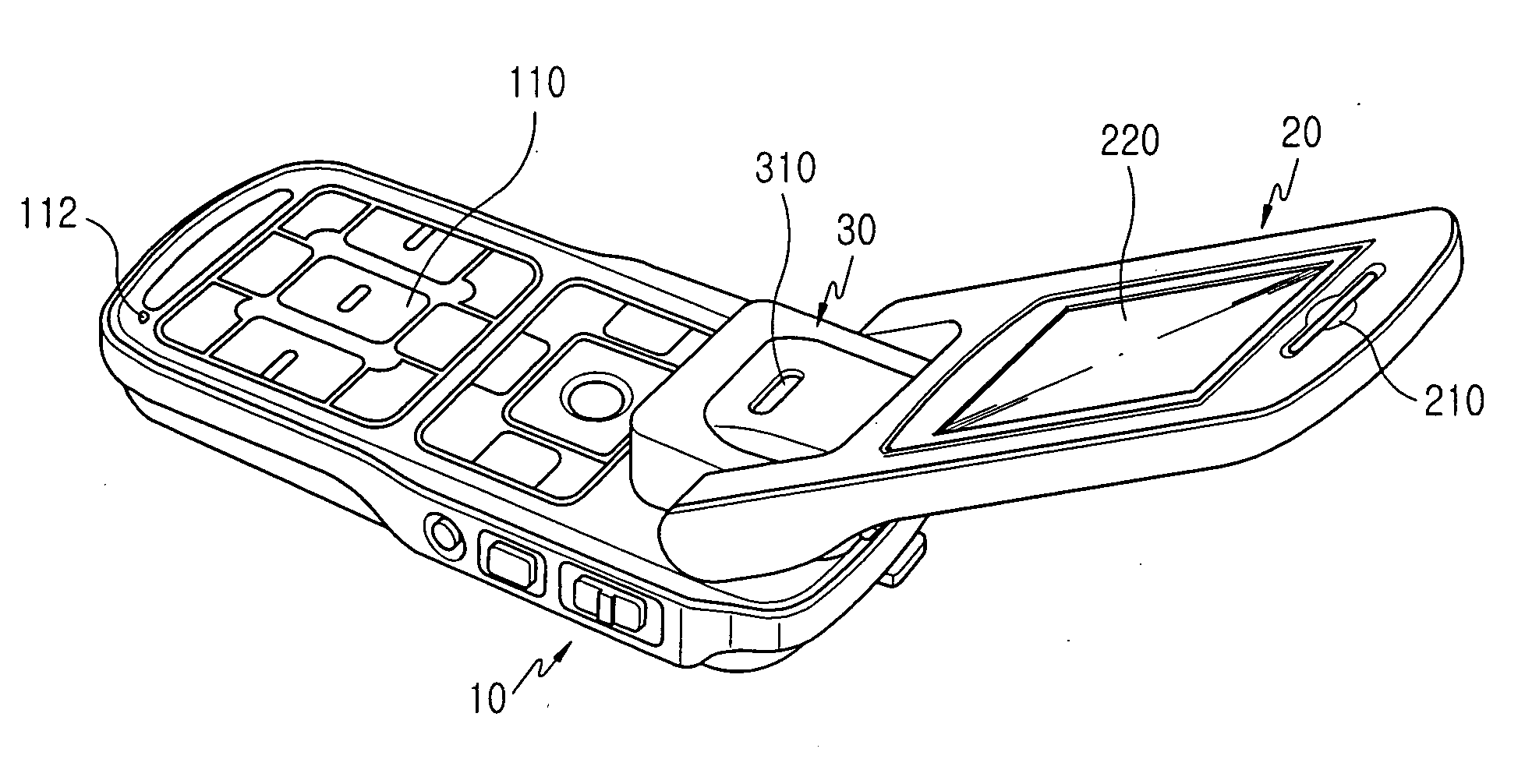

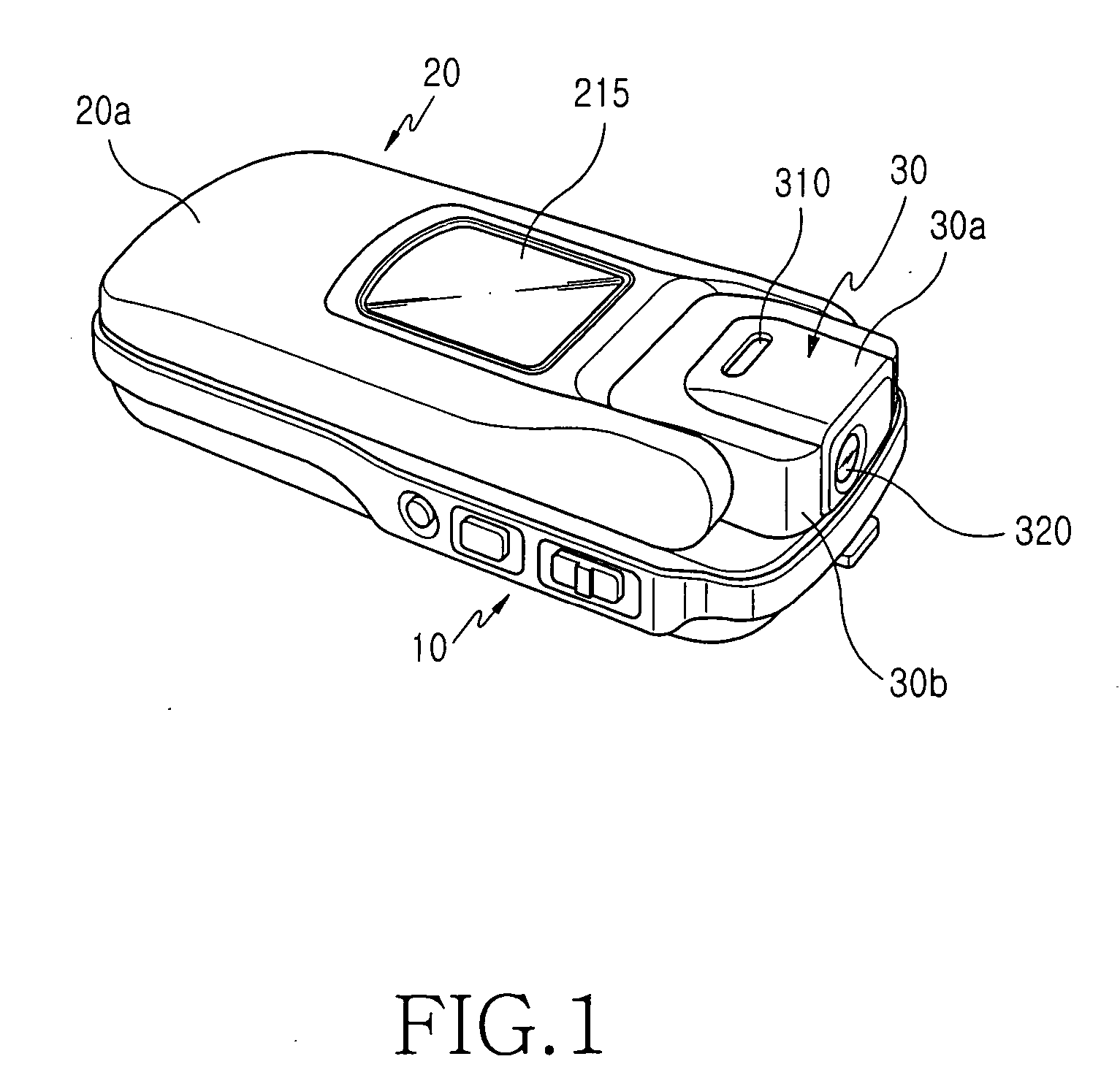

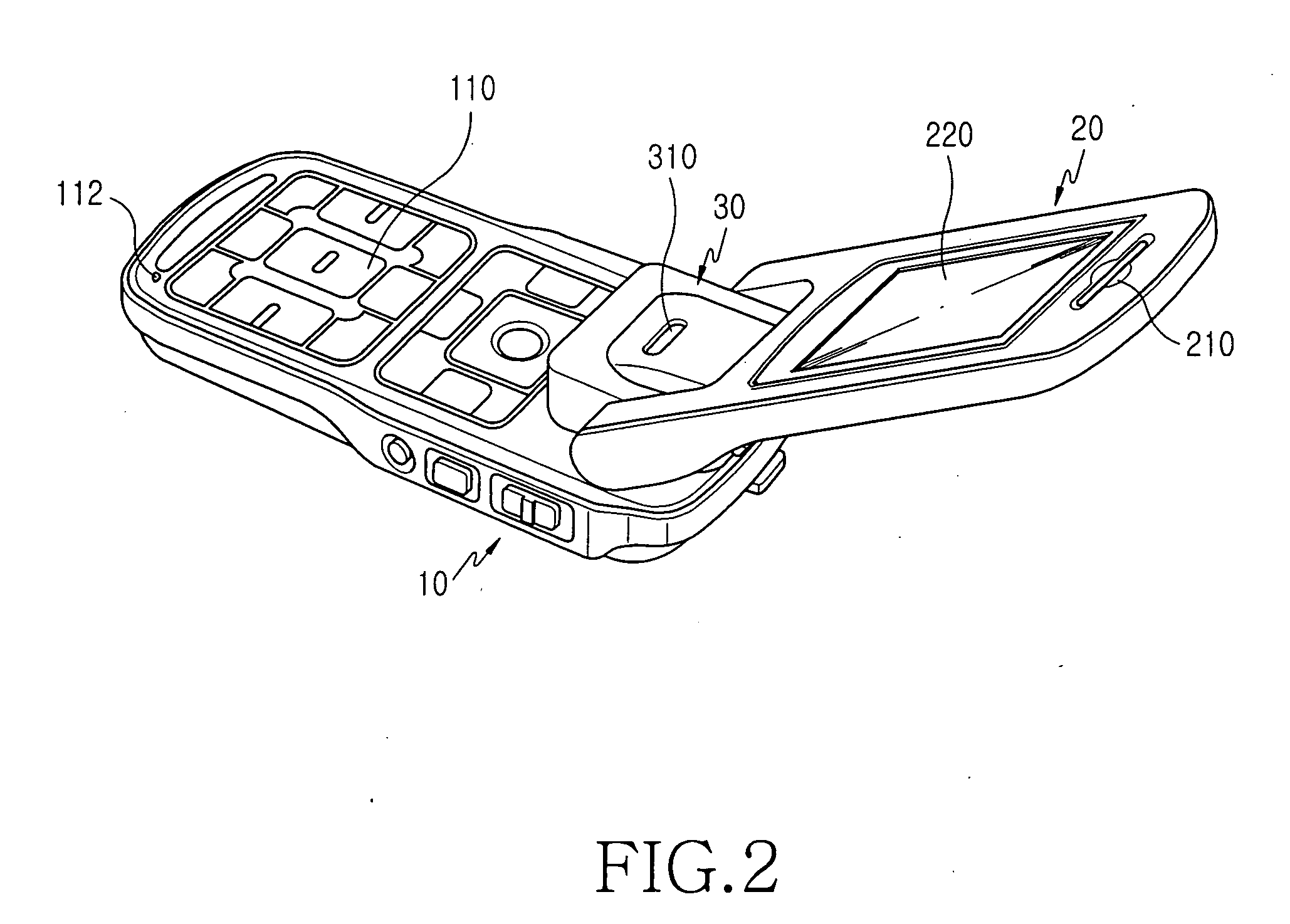

Portable terminal

InactiveUS20070054522A1Easy to holdGood touchTelevision system detailsLive contact access preventionEngineeringMechanical engineering

The portable terminal includes a body assembly, and a case having at least one opening. The case is connected to the body assembly to rotate around a first hinge axis perpendicular to an upper surface of the body assembly, enclosing a predetermined portion of the body assembly to protect or open the body assembly, and operating as a grip regardless of rotation of the body assembly.

Owner:SAMSUNG ELECTRONICS CO LTD

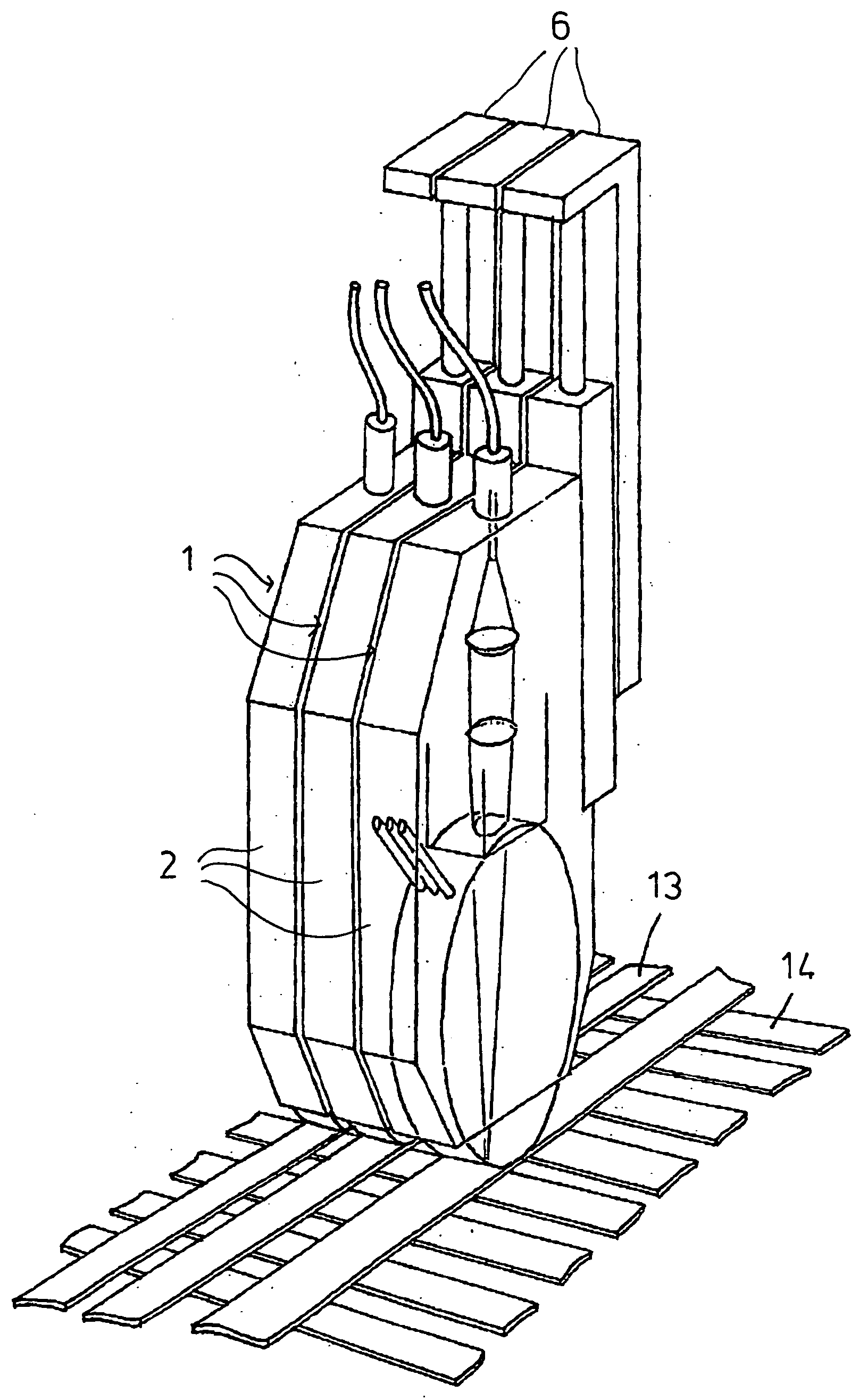

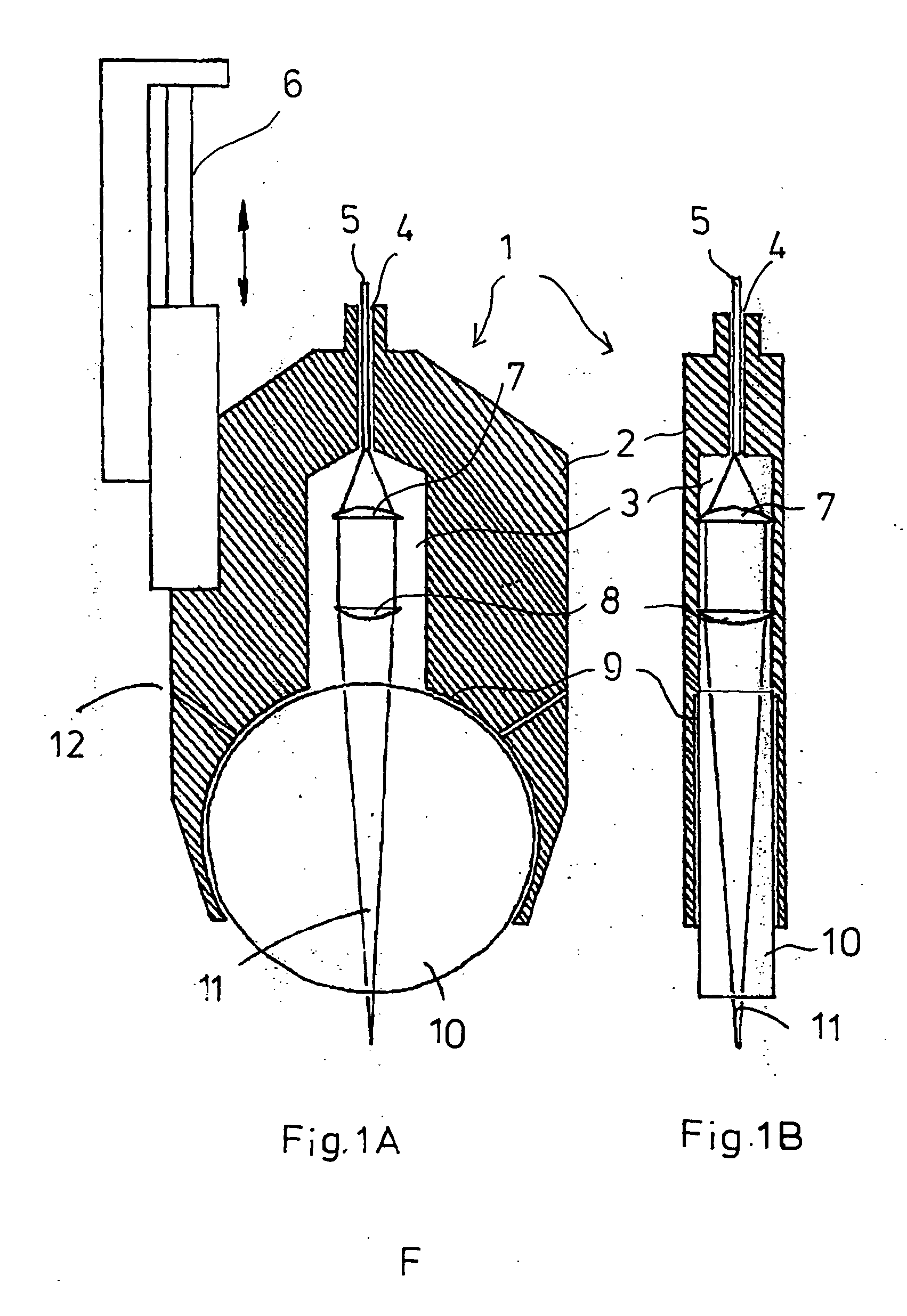

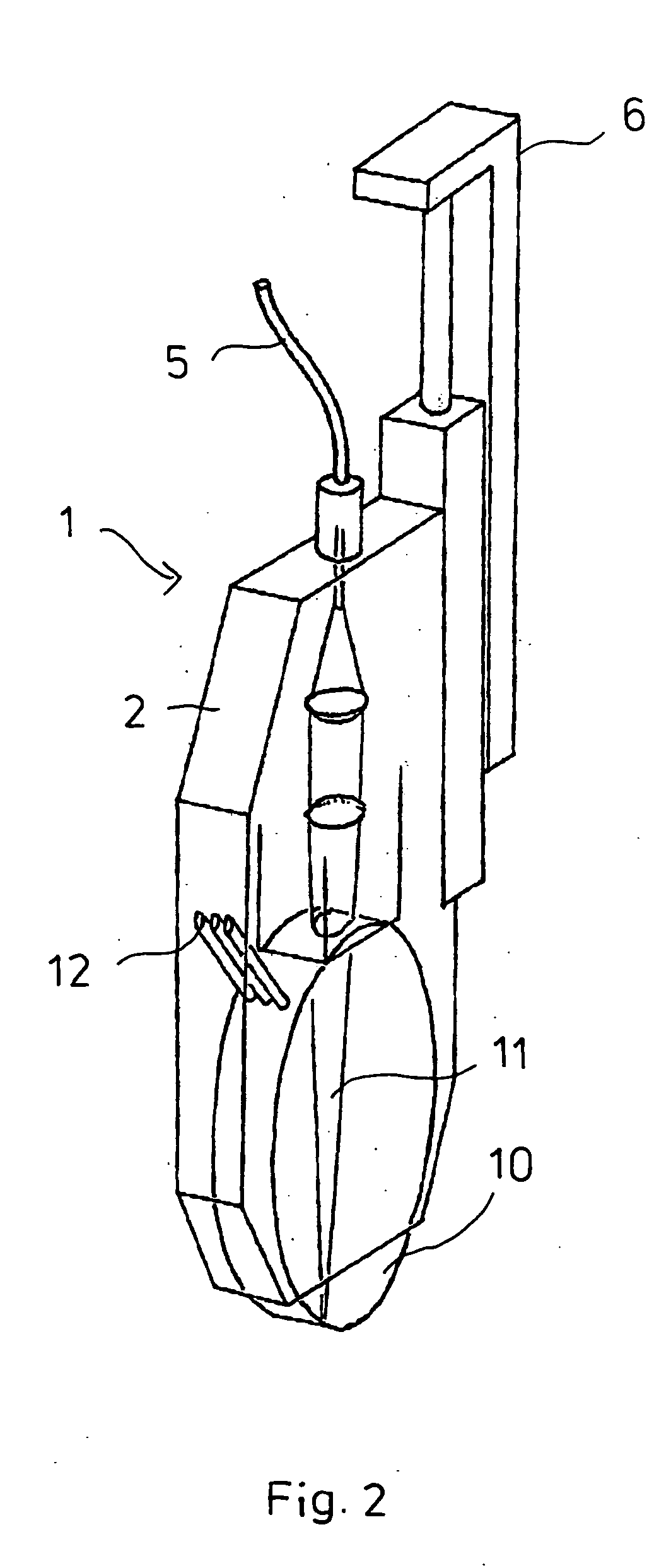

Apparatus for connecting planar plastic materials

InactiveUS20050039855A1Quality improvementEasy swivel movementMechanical working/deformationLamination ancillary operationsMesh gridPlastic materials

An apparatus for welding over a large area according to the laser transmission method, in particular for welding plastic strips to form a grid structure. To this end, a multiplicity of processing heads are assembled to form a unit, so that a high production throughput can be achieved. Spacer devices for setting the distance of the top transparent material strips to be welded are also located between the individual processing heads.

Owner:LEISTER PROCESS TECH

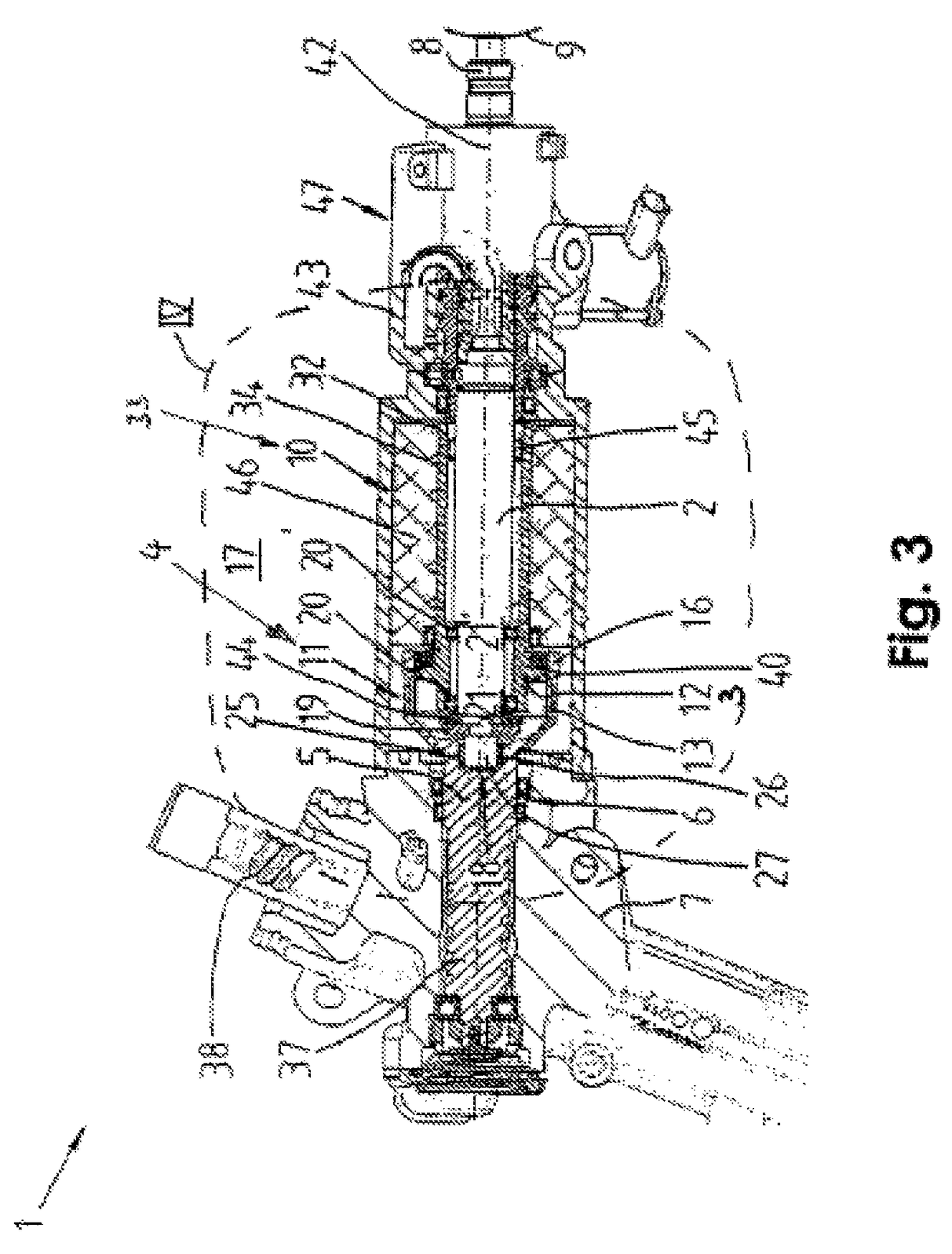

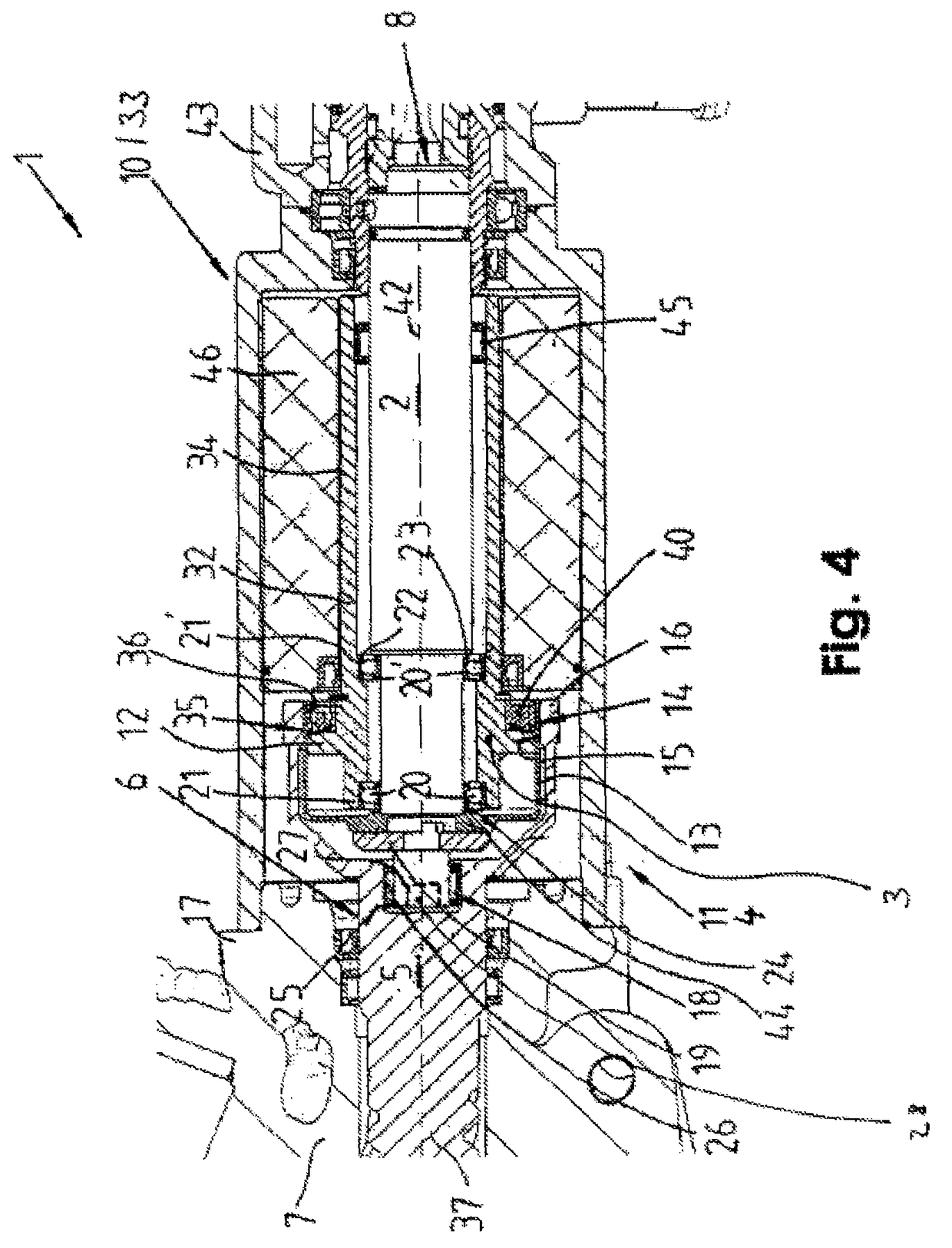

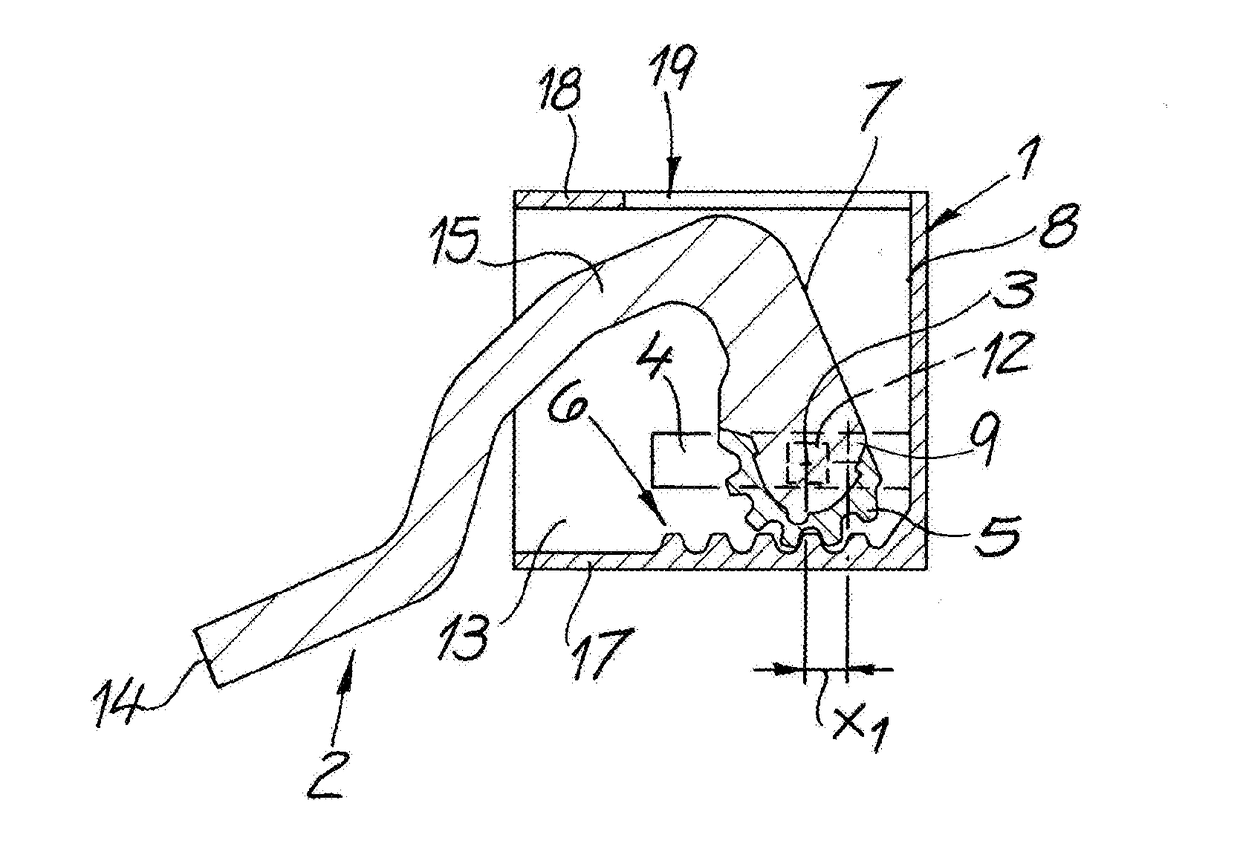

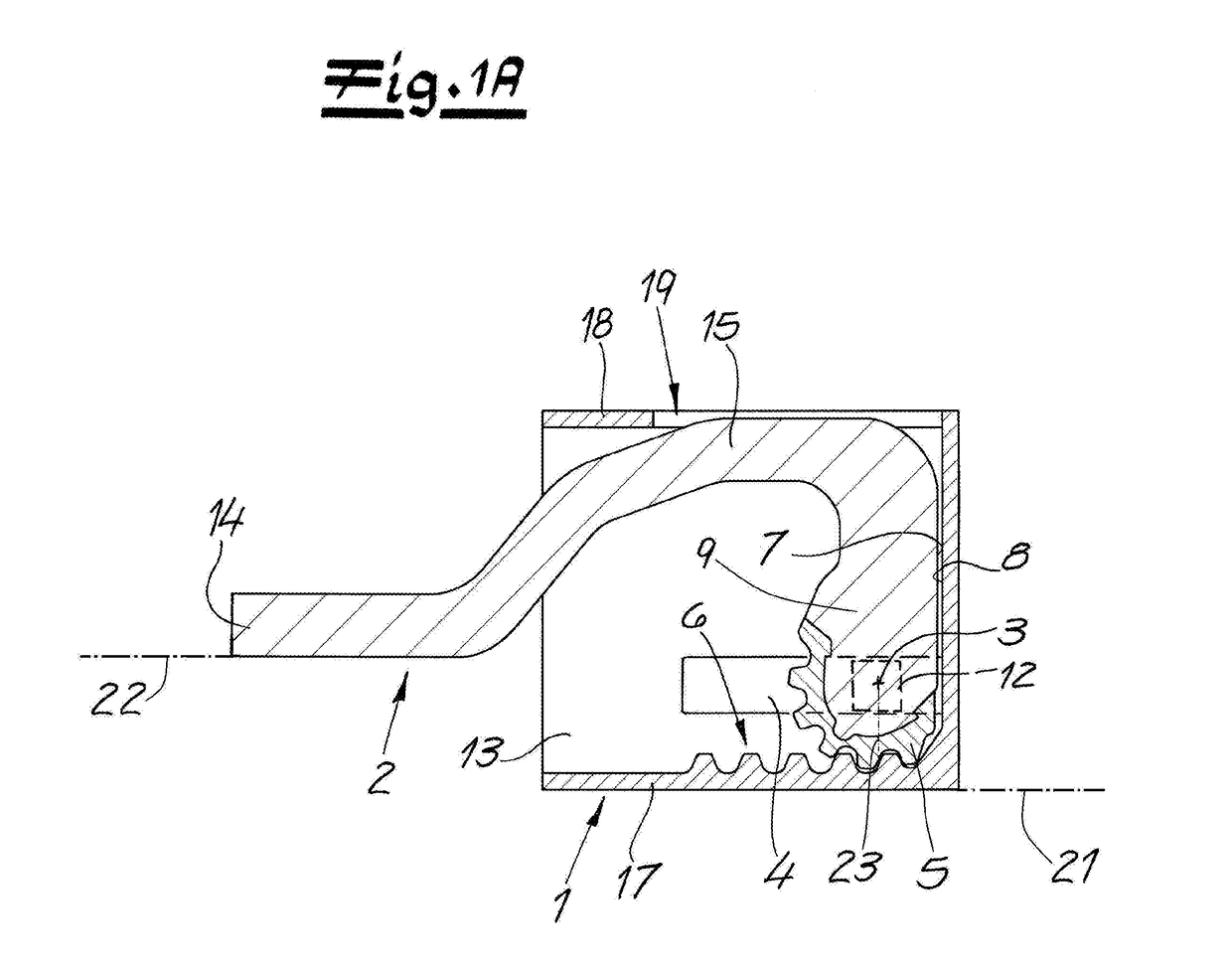

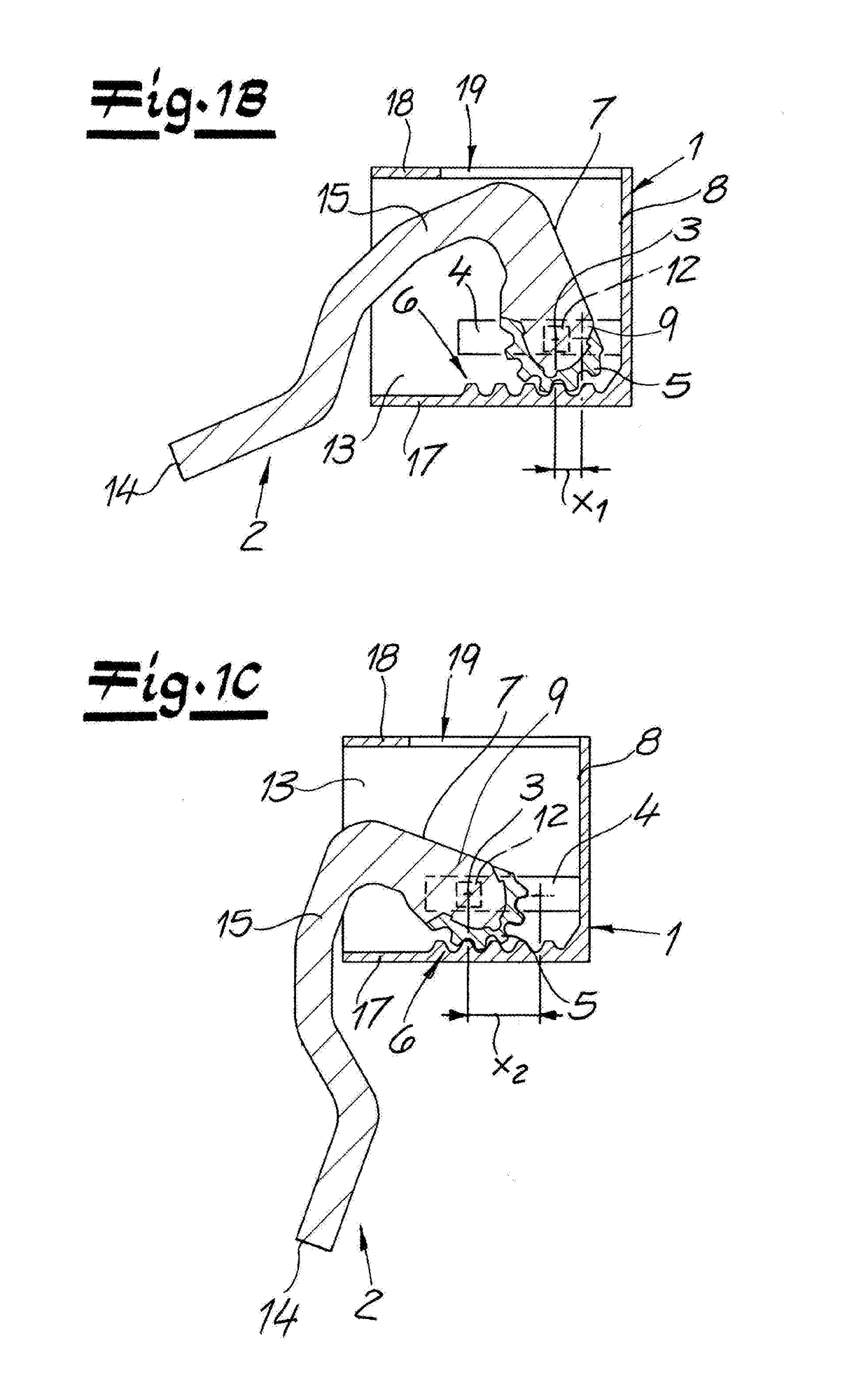

Superimposed steering system for a vehicle

InactiveUS7905317B2Comfortable handlingEasy constructionBall bearingsElectrical steeringMobile vehicleSteering angle

A superimposed steering system for a vehicle, e.g., a servo-assisted or power steering system for a motor vehicle, includes a differential drive, which is configured as a shaft drive and has a first input shaft and a second input shaft, for superimposing the rotational angles that occur in the first and second input shafts on an output shaft of the differential drive. The output shaft acts on an input shaft of a steering gear. The first input shaft interacts with a steering handle by a steering shaft and the second input shaft interacts with a servo motor. A superimposed steering system may apply an additional steering angle, without play, to the output shaft and may have a simple, cost-effective, space-saving construction, while being easy to install. The first input shaft is directly connected in a detachable manner to a radially flexible flex-spline of the shaft drive, the first input shaft passing through an eccentric drive core of the shaft drive, which extends into the radially flexible flex spline.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING

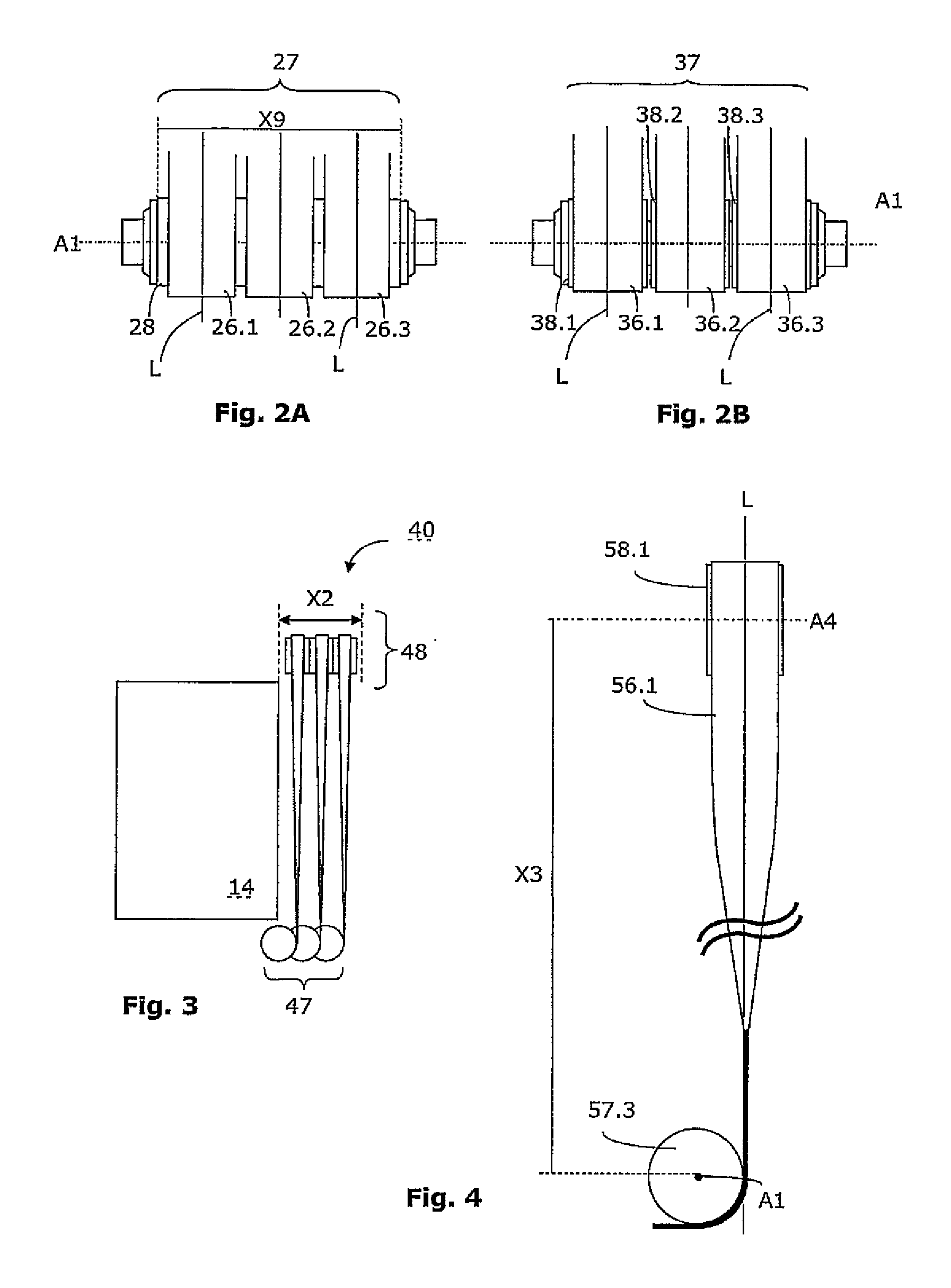

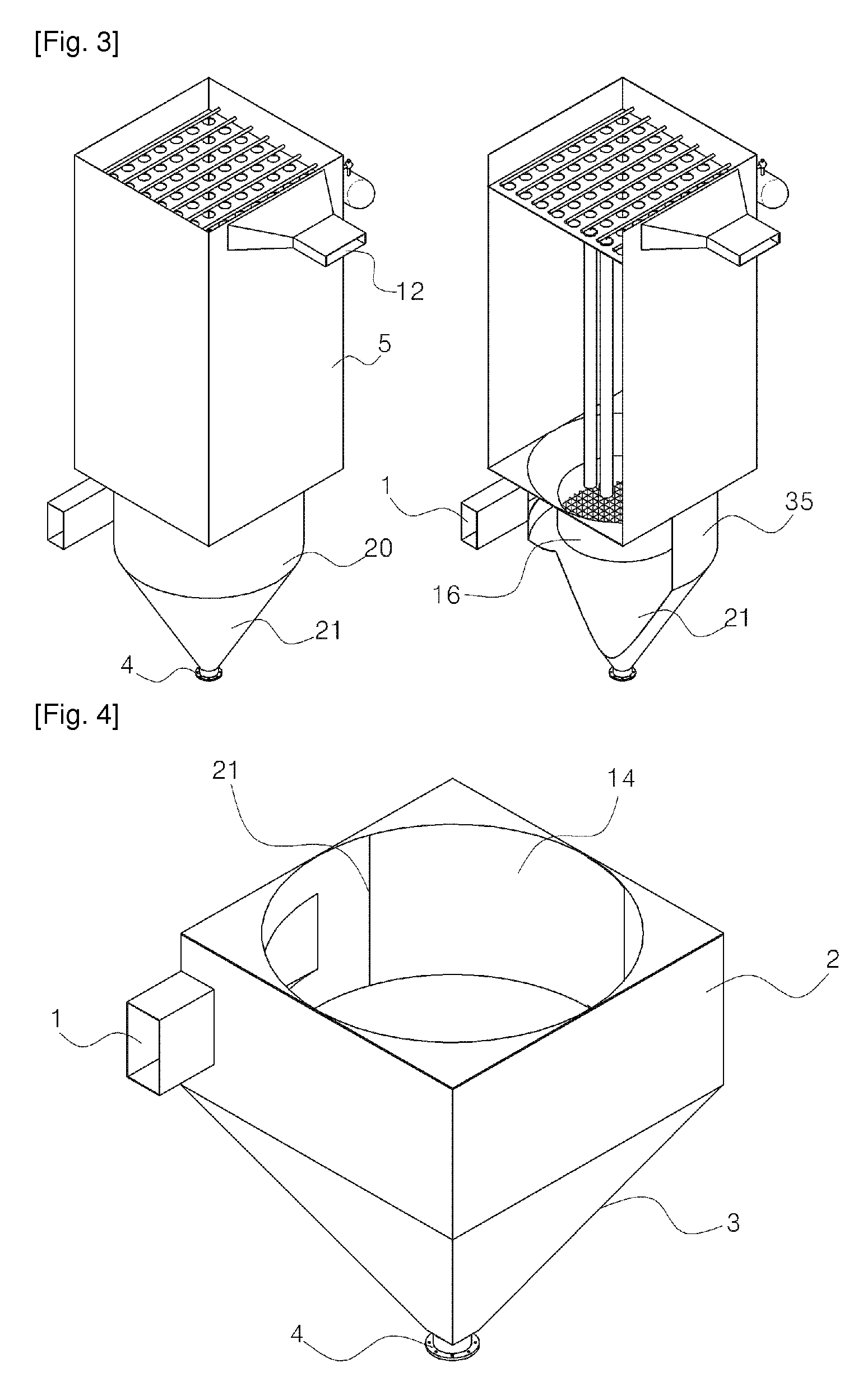

Battery cooler

ActiveUS9531045B2Minimized installation spaceEasy to manufactureSecondary cellsStationary conduit assembliesMechanical engineeringEngineering

Owner:HANON SYST

System and method for testing light-emitting devices

ActiveUS7804589B2Accurate and fast positioningLow costBeam/ray focussing/reflecting arrangementsDiode testingLight energyComputer module

A method for testing light-emitting devices in a batch-wise, associated with a system for the same purpose, comprises the steps of: preparing the light-emitting devices on a moving carrier unit in a manner of aligning a predetermined longitudinal direction of the light-emitting devices with a predetermined transportation direction of the moving carrier unit, each of the light-emitting devices further having plural light-emitting elements; transporting orderly the light-emitting devices to pass a test area on a base of the system, in which the base energizes only the light-emitting elements within the test area; and, a solar cell module detecting continuously the energized light-emitting elements within the test area and further forming signals with respect to photo energy received in the test area.

Owner:CHROMA ATE

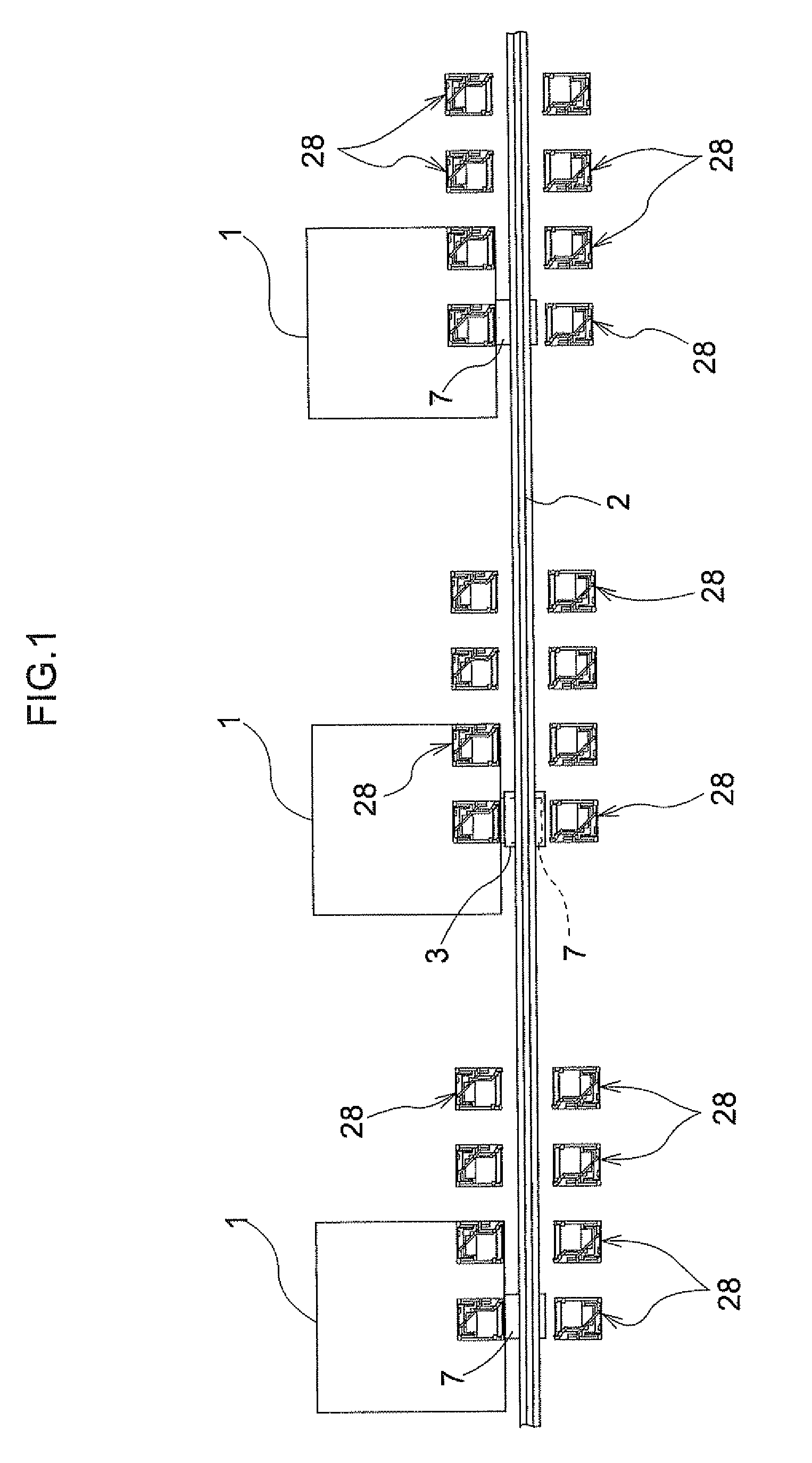

Article Transport Facility

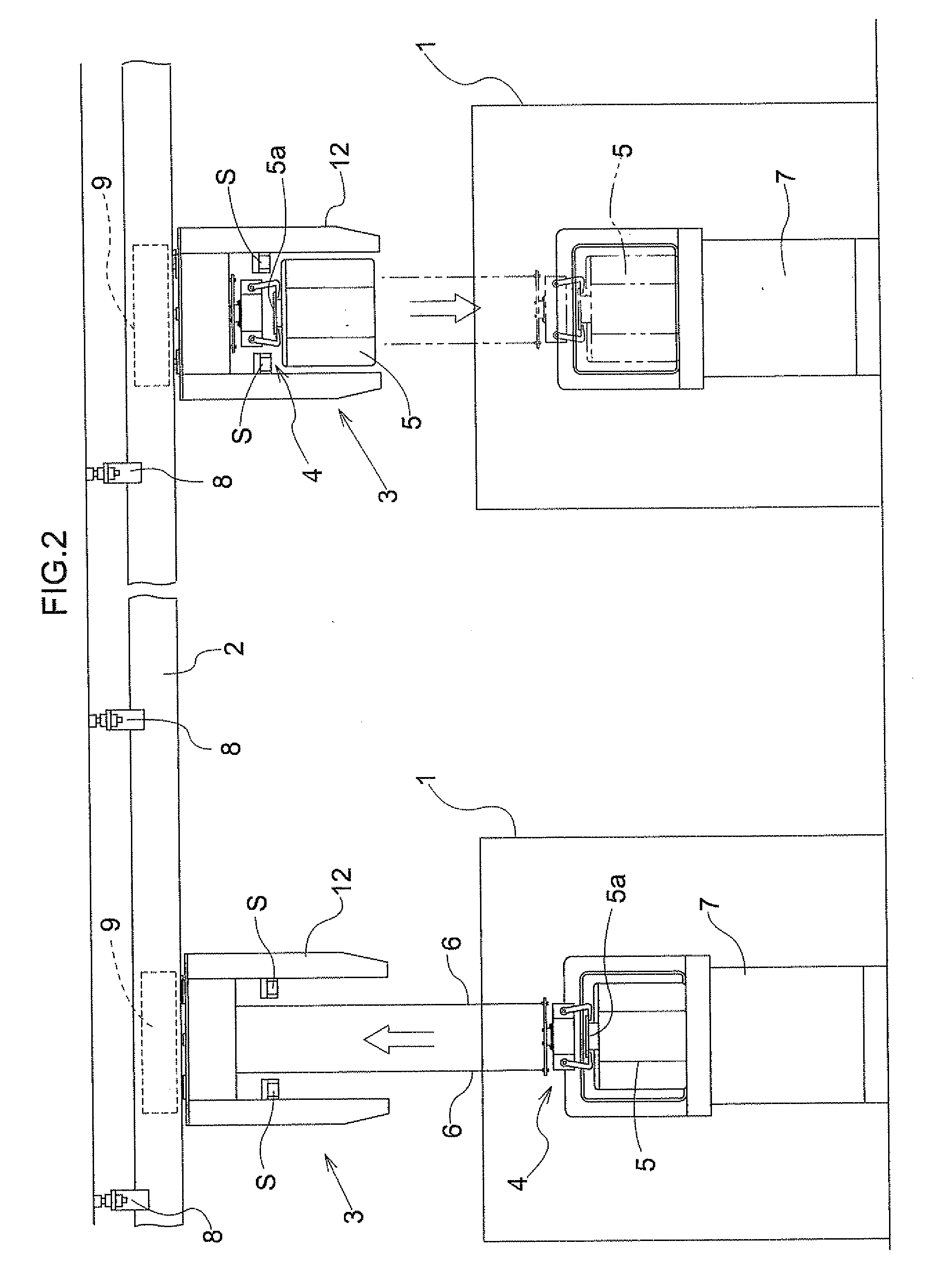

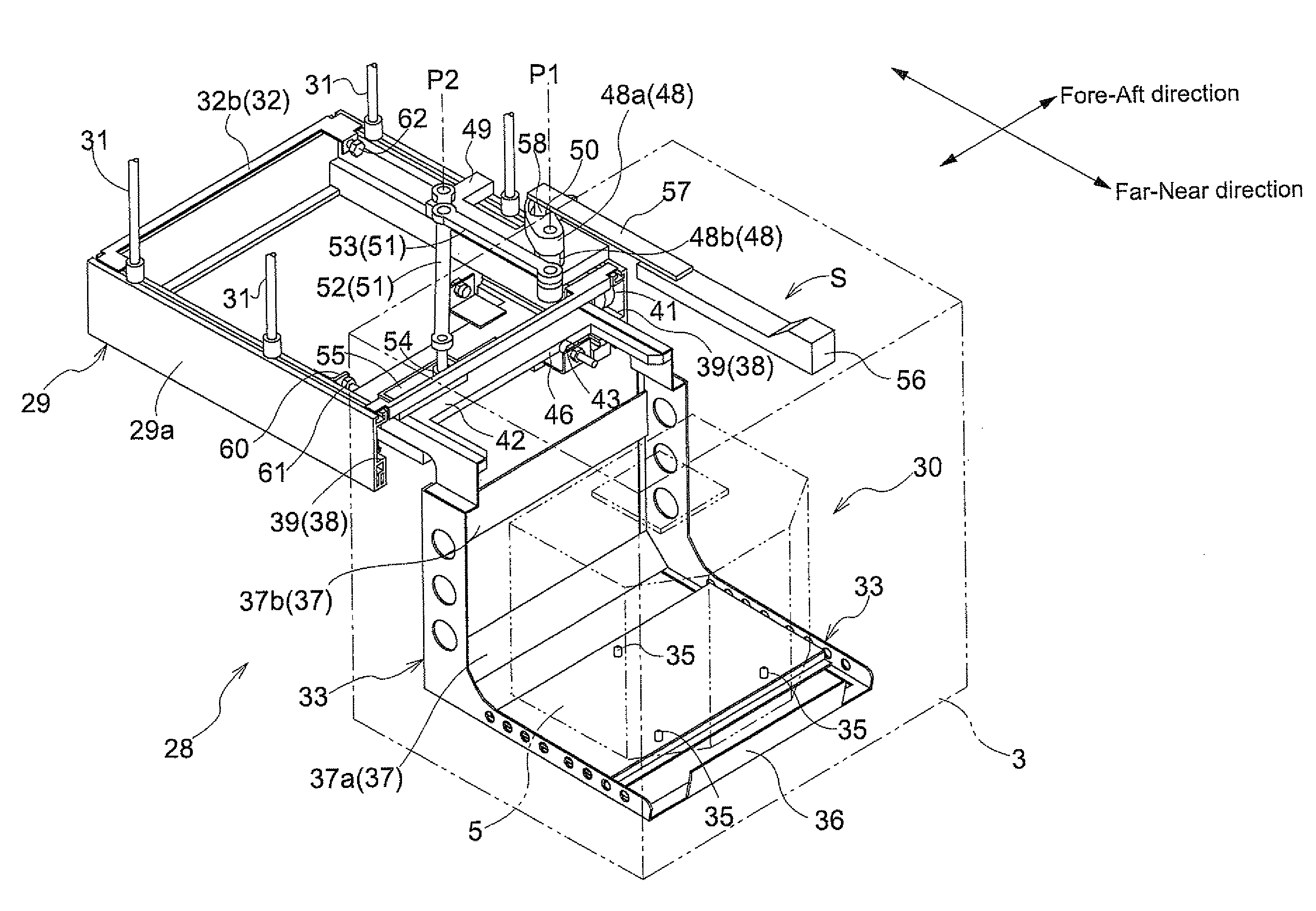

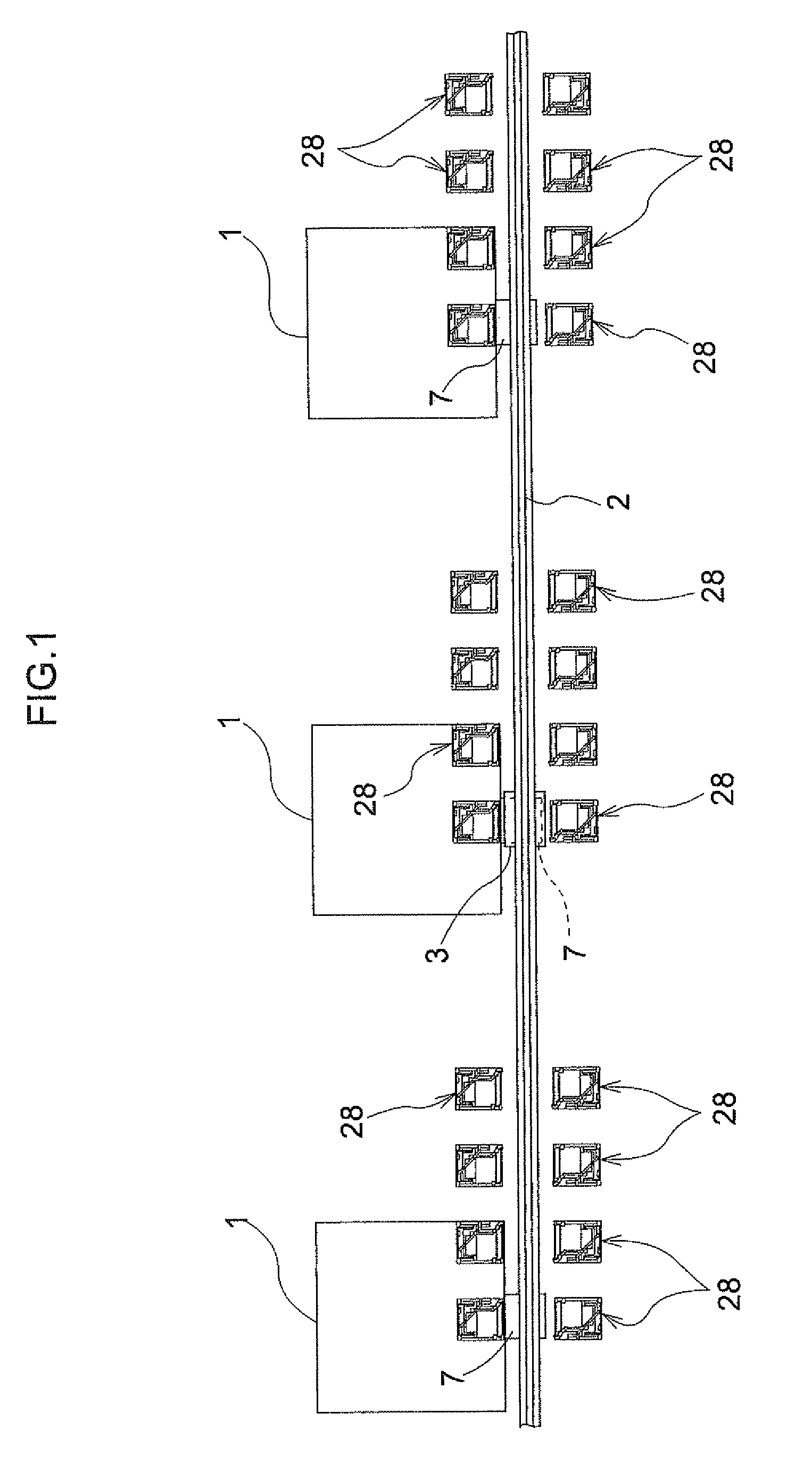

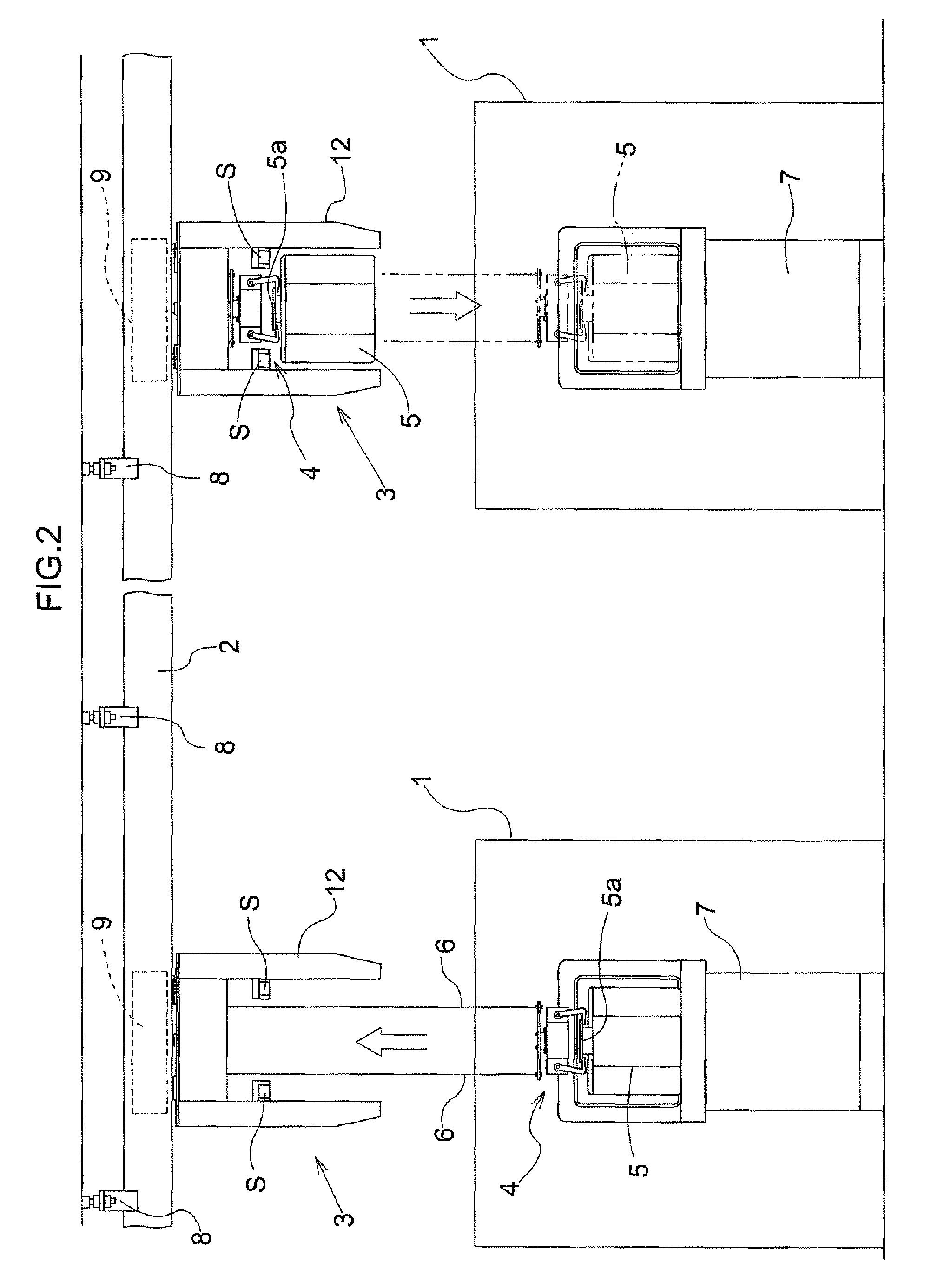

InactiveUS20080219825A1Minimized installation spaceSemiconductor/solid-state device manufacturingTrolley cranesFixed frameEngineering

An article transport facility includes an article carrier movable along a track, and an article rack arranged along the track. Each article rack has a fixed frame, and a movable frame supported to be movable relative to said fixed frame between an extended position projecting toward the track and a retracted position retracted away from the track. A movable guide shiftably supports and guides the movable frame to be movable relative thereto in a shifting direction. A fixed guide is mounted on the fixed frame for supporting and guiding the movable guide to be movable in the shifting direction.

Owner:DAIFUKU CO LTD

Article transport facility

InactiveUS8105005B2Minimized installation spaceSemiconductor/solid-state device manufacturingTrolley cranesFixed frameEngineering

An article transport facility includes an article carrier movable along a track, and an article rack arranged along the track. Each article rack has a fixed frame, and a movable frame supported to be movable relative to said fixed frame between an extended position projecting toward the track and a retracted position retracted away from the track. A movable guide shiftably supports and guides the movable frame to be movable relative thereto in a shifting direction. A fixed guide is mounted on the fixed frame for supporting and guiding the movable guide to be movable in the shifting direction.

Owner:DAIFUKU CO LTD

Elevator and pulley assembly for use in an elevator

An elevator comprises an elevator car and support belts that form a 4:1 suspension for the elevator cabin and that are looped several times beneath the elevator car. Several parallel, flat belts are used and the rollers of at least one fixed roller group that diverts the belts are positioned in such a way that the belt sections of the parallel belts lie vertically above one another in the vicinity of the belt diversion.

Owner:INVENTIO AG

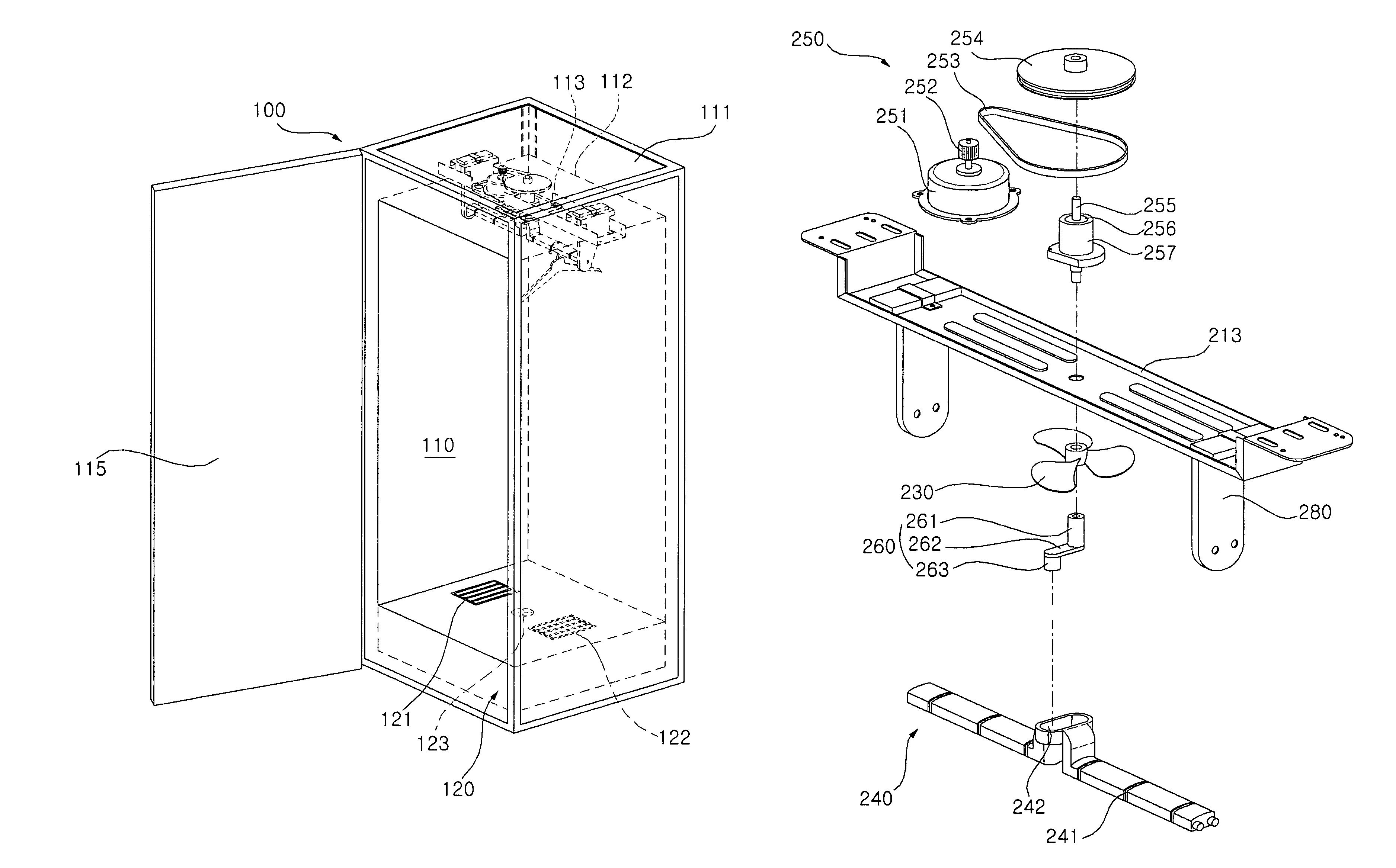

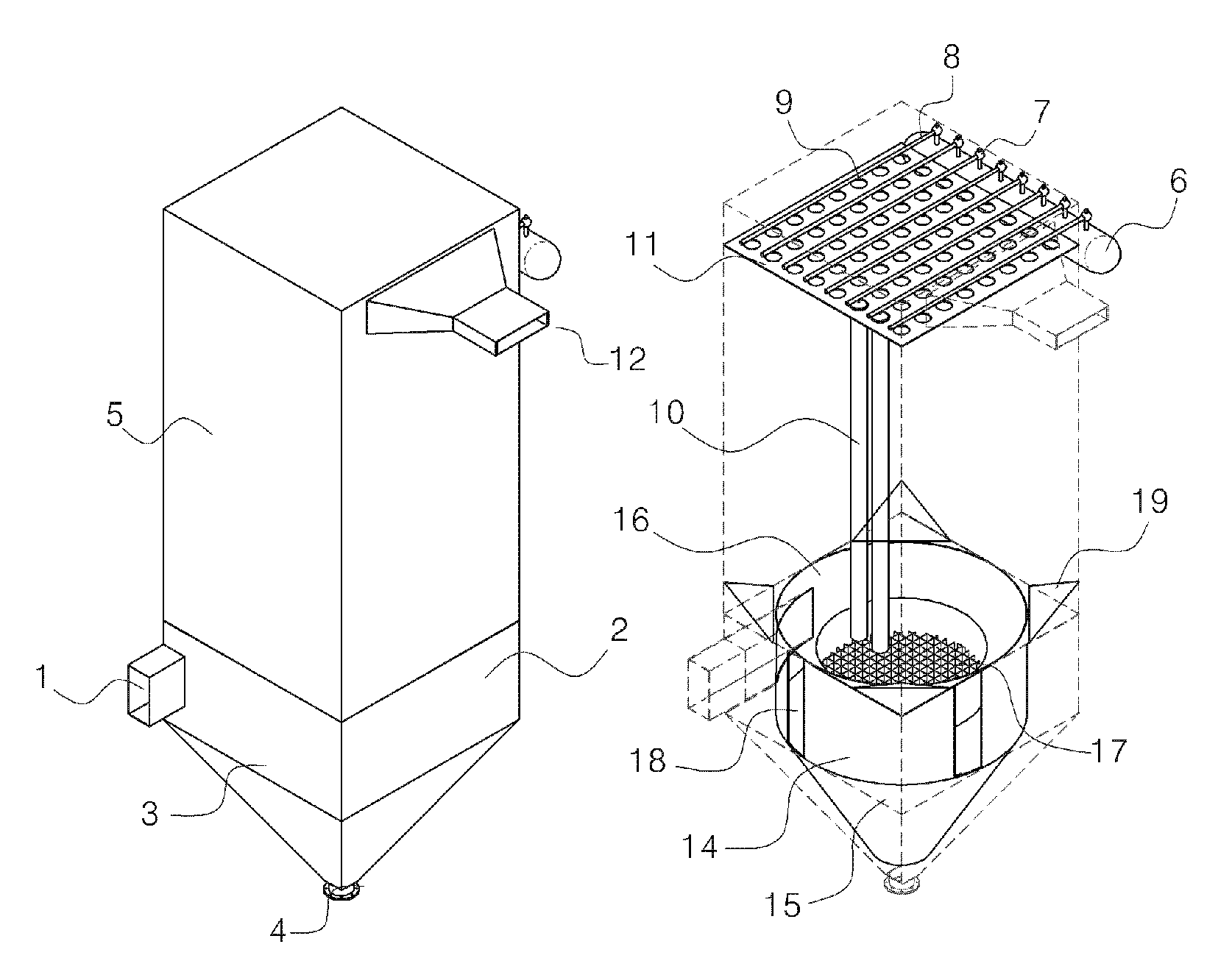

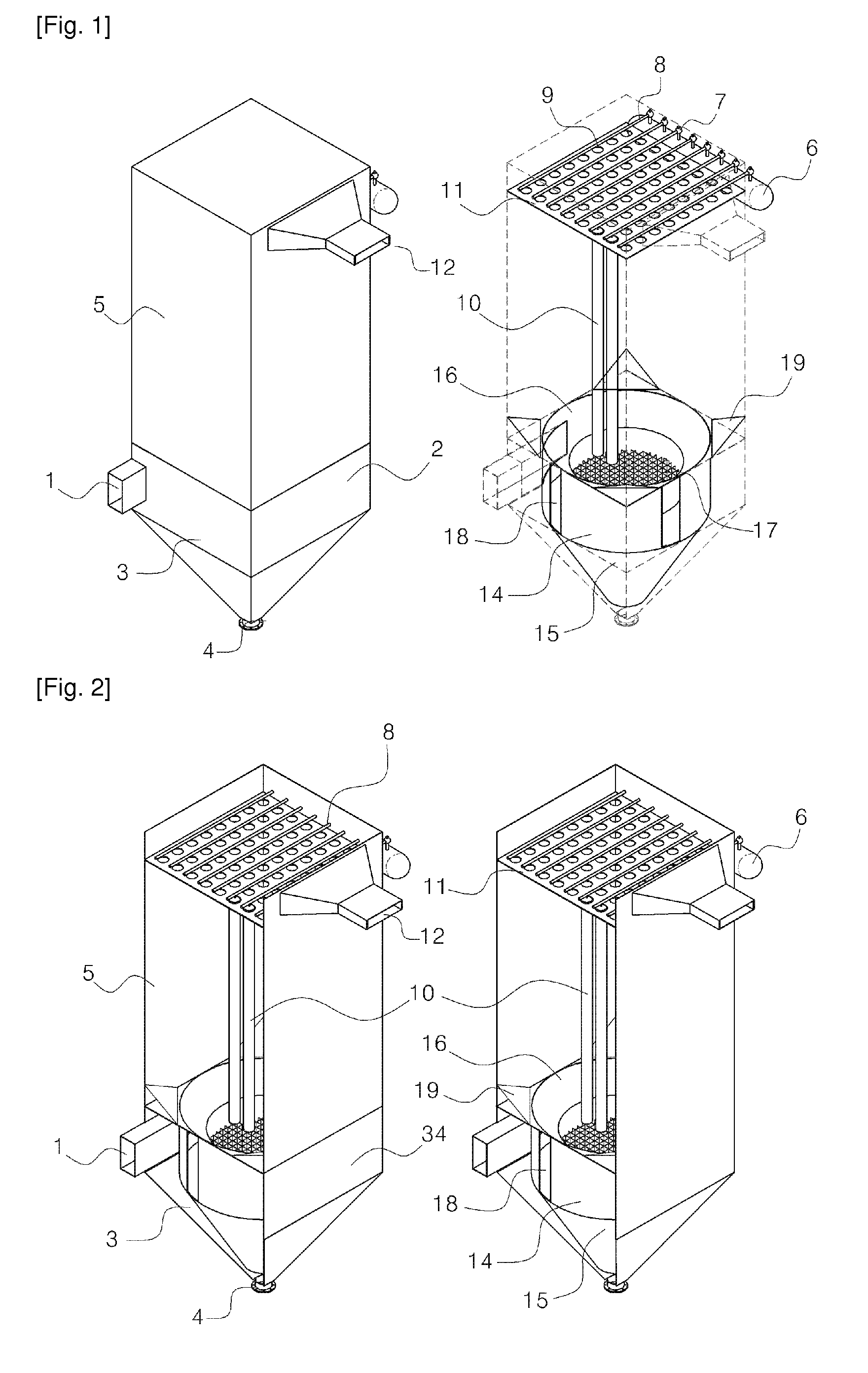

Modularized Hybrid Dust Collector

ActiveUS20100018173A1Extend your lifeRequires minimizationCombination devicesDispersed particle filtrationEngineeringCentrifugal force

There is provided a modularized hybrid dust collector for treating dust generated in various industrial processes. The box-shaped hybrid dust collector includes a first box-shaped dust collecting unit or a first cylindrical dust collecting unit, to which the inertial impaction and the principle of collecting dust using the centrifugal force are applied, and a second box-shaped dust collecting unit implemented by a dust collecting filter such that a problem of employing a cleaner and a limit of capacity, of a conventional cylindrical dust collector, can be overcome, and a high capacity modularized hybrid dust collector in which the box-shaped hybrid dust collector as a basic module and a plurality of dust collector modules are combined.

Owner:KOREA INST OF ENERGY RES

Battery cooling system

ActiveUS20130071707A1Minimized installation spaceSimple, lightweight, and cost-effectiveSecondary cellsCell component detailsEngineeringElectrical and Electronics engineering

A battery cooling system includes a battery and a plurality of battery cooler pipes disposed adjacent the battery. Each of the battery cooler pipes is spaced apart and substantially parallel to an adjacent one of the battery cooler pipes. A clamping element is disposed adjacent at least one of the battery cooler pipes. The clamping element configured to urge the battery cooler pipes against at least a portion of the battery. The clamping element includes a plurality of clamping wings extending outwardly from a center portion of the clamping element. Each of the clamping wings of the clamping element is disposed adjacent at least one of the battery cooler pipes. The battery cooling system may further include a carrier disposed adjacent the center portion of the clamping element to absorb spring forces of the clamping wings.

Owner:HANON SYST

Portable communication apparatus

InactiveUS20060089183A1Easy to useEasy assembly workSubstation equipmentTransmissionCamera lensEngineering

Disclosed is a portable communication apparatus. The portable communication apparatus includes a first housing including a plurality of keys, a second housing including a main display unit and being movable from the first housing about a first hinge axis and being rotated about a second hinge axis, which is perpendicular to the first hinge axis, and a swing hinge housing for allowing the second housing to rotate with respect to the first housing about the first and second hinge axes, which pass through the swing hinge housing. The swing hinge housing is provided at a lateral portion thereof with a camera lens. A bottom surface of the swing hinge housing is rotatably attached to an upper surface of the first housing so that the swing hinge housing is rotated together with the main display unit about the second hinge axis.

Owner:SAMSUNG ELECTRONICS CO LTD

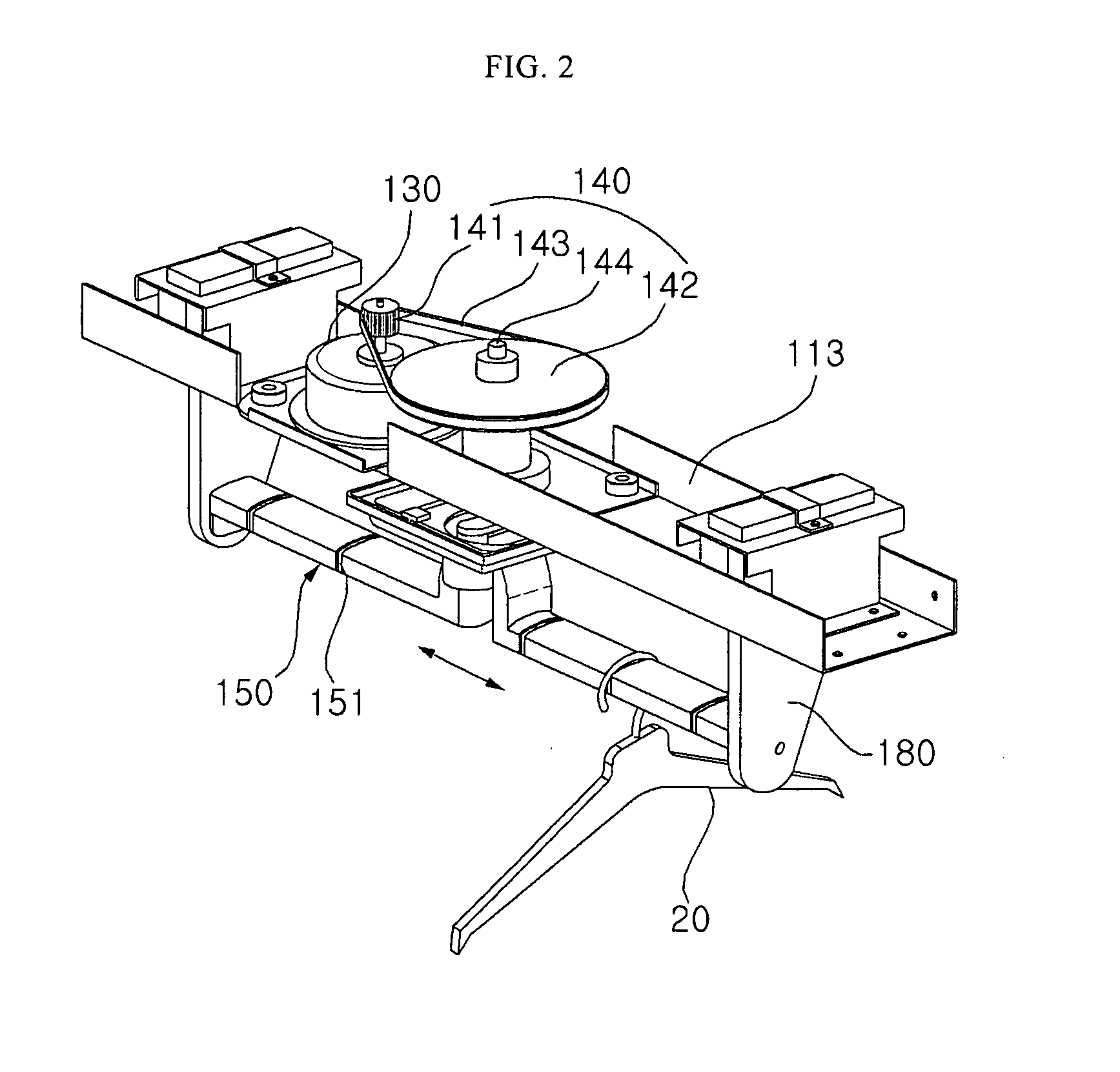

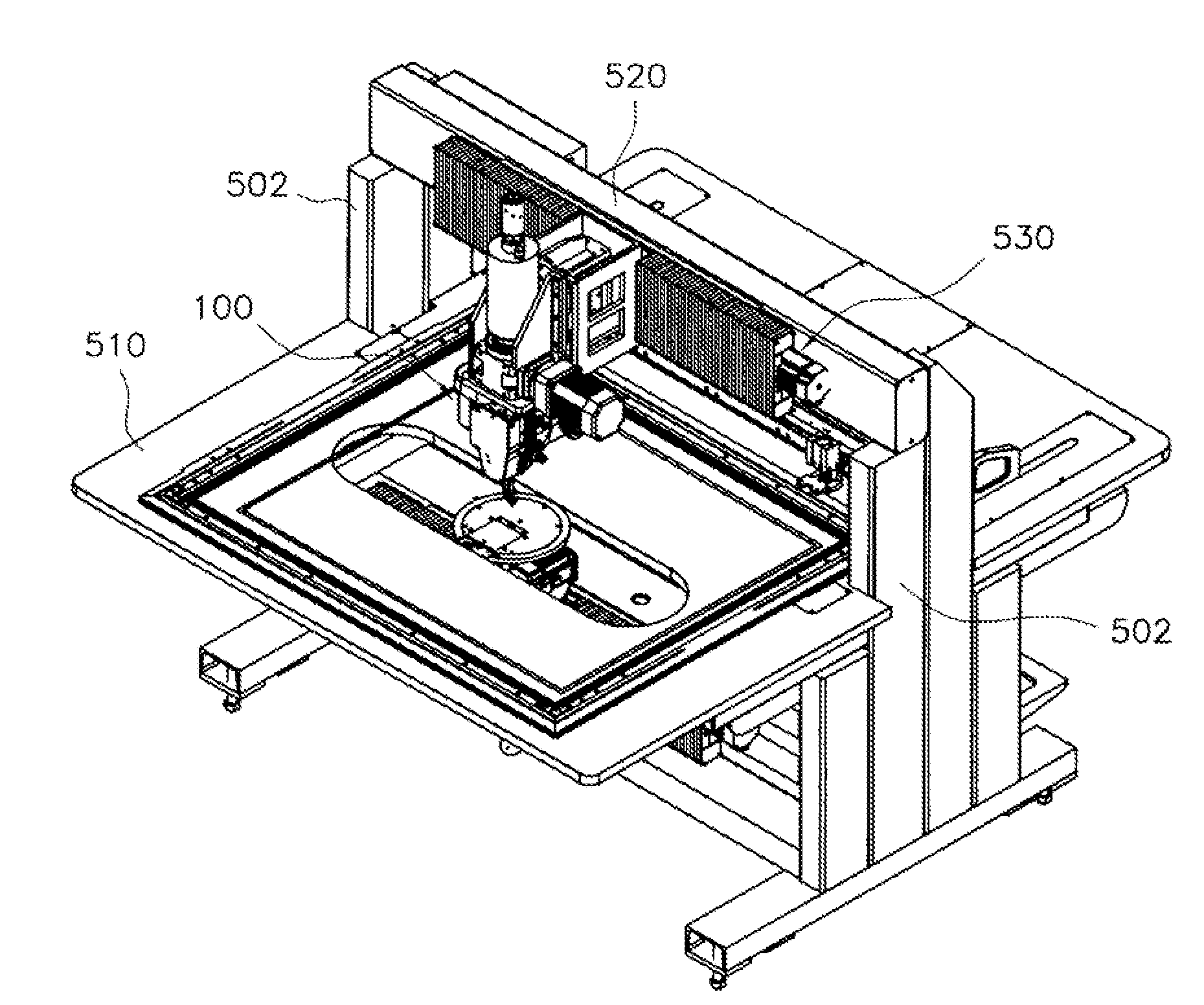

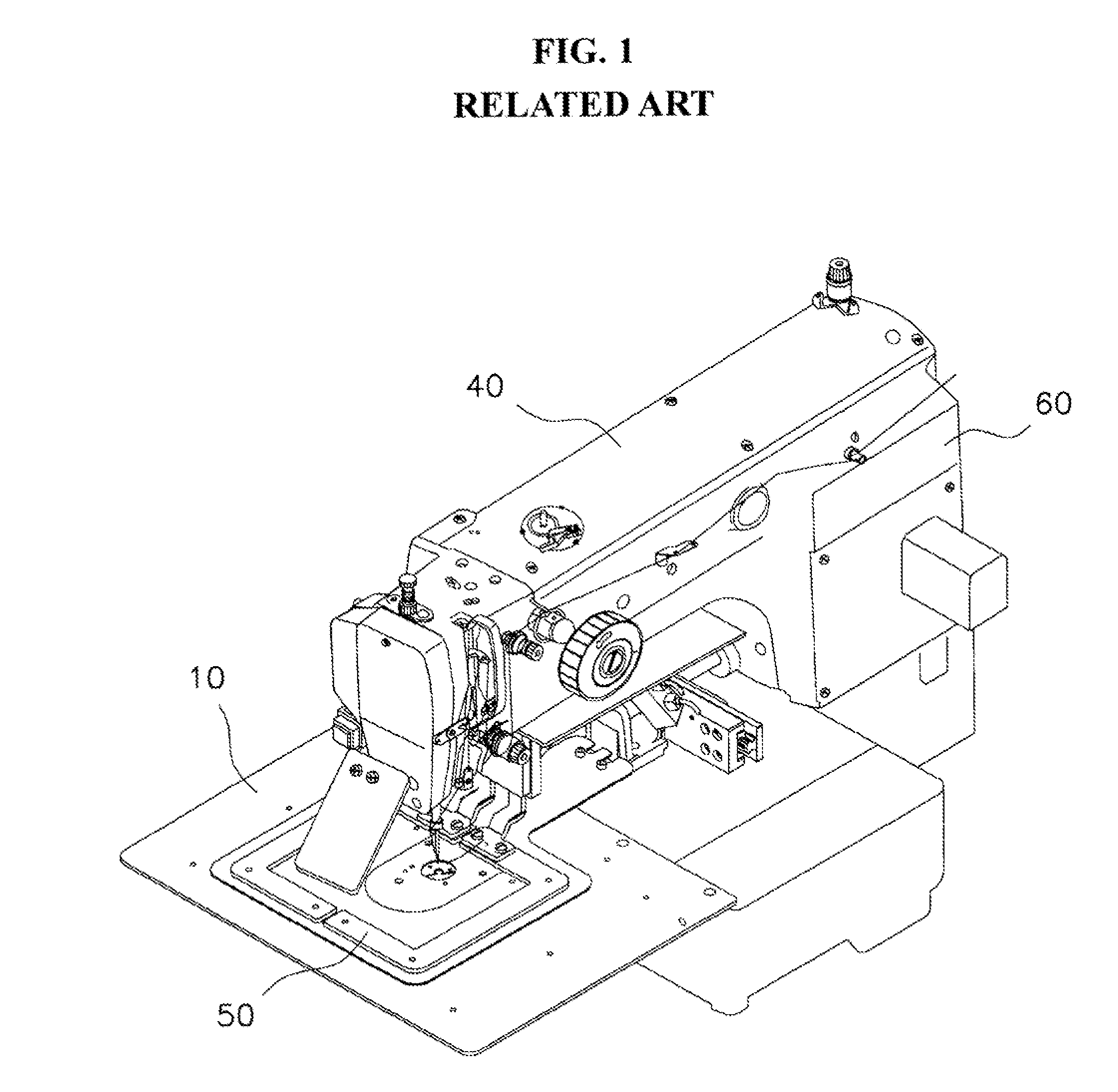

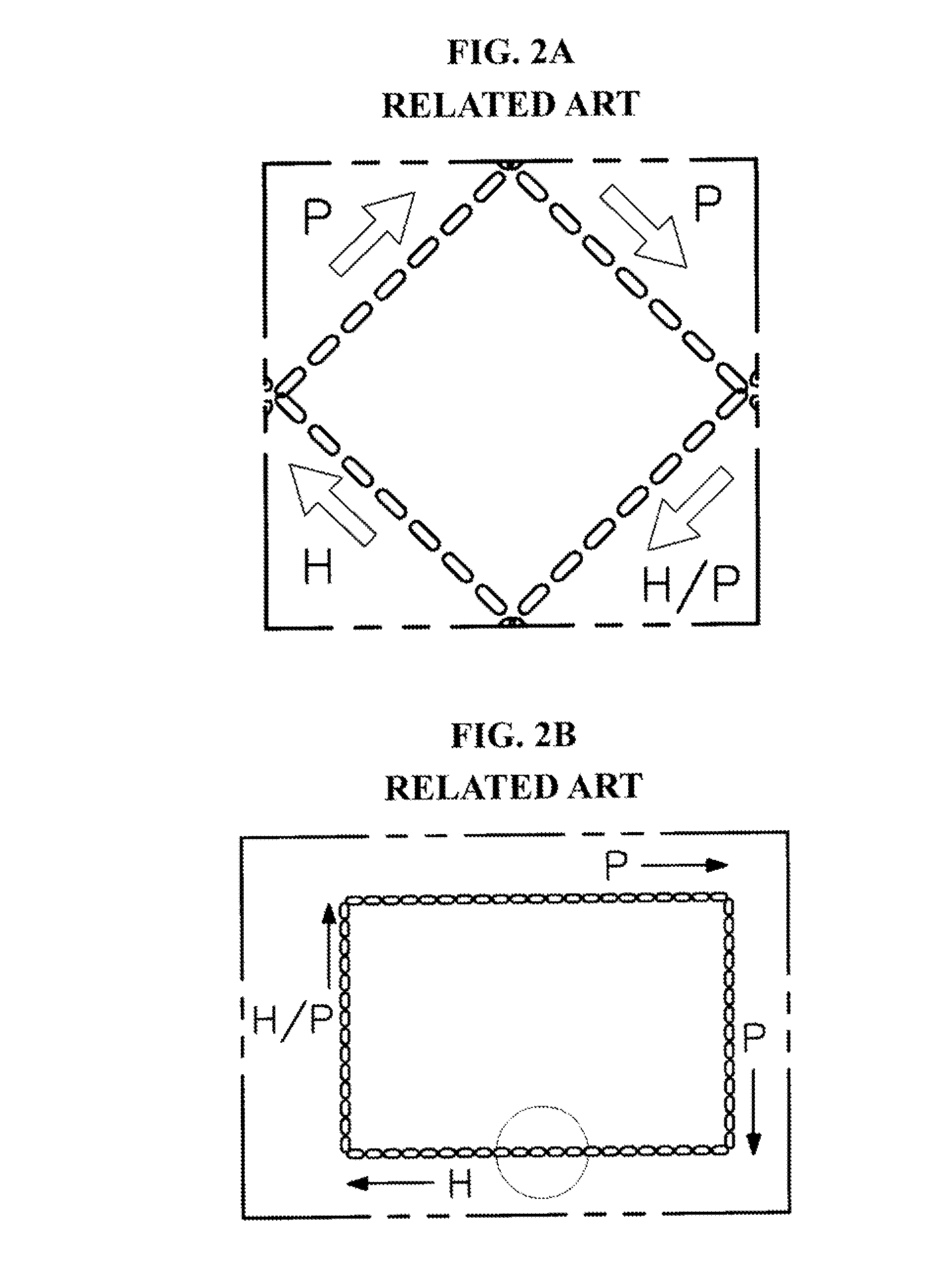

Sewing machine and method of controlling operation of the same

InactiveUS20120145060A1Improve product qualityEasy splicingLeather sewingWork-feeding meansEngineeringSewing machine

A sewing machine is provided, which includes a table, support posts, upper and lower frames, a head unit, a bed unit, an X-axial head-unit-transport means and an X-axial bed-unit-transport means. An object is placed on the table. The support posts are provided on opposite sides of the table. The upper and lower frames connect the support posts to each other. The head unit is provided on the upper frame so as to be movable in an X-axis direction. The head unit has a head-unit-rotating means for rotating a sewing head. The bed unit is provided on the lower frame so as to be movable in the X-axis direction. The bed unit has a bed-unit-rotating means for rotating a sewing bed. The X-axial head-unit-transport means moves the head unit on the upper frame horizontally. The X-axial bed-unit-transport means moves the bed unit on the upper frame horizontally.

Owner:SUNSTAR KK

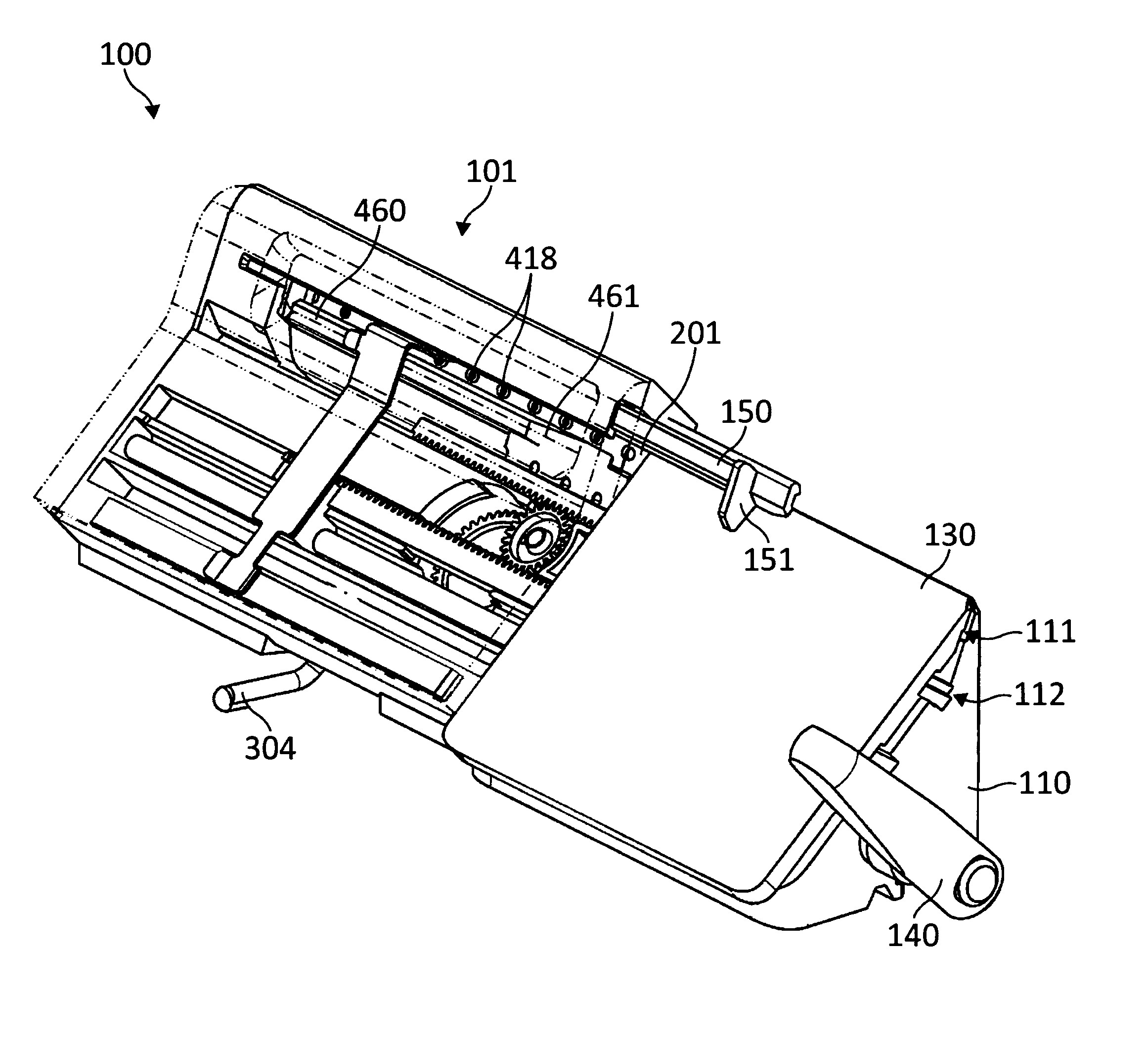

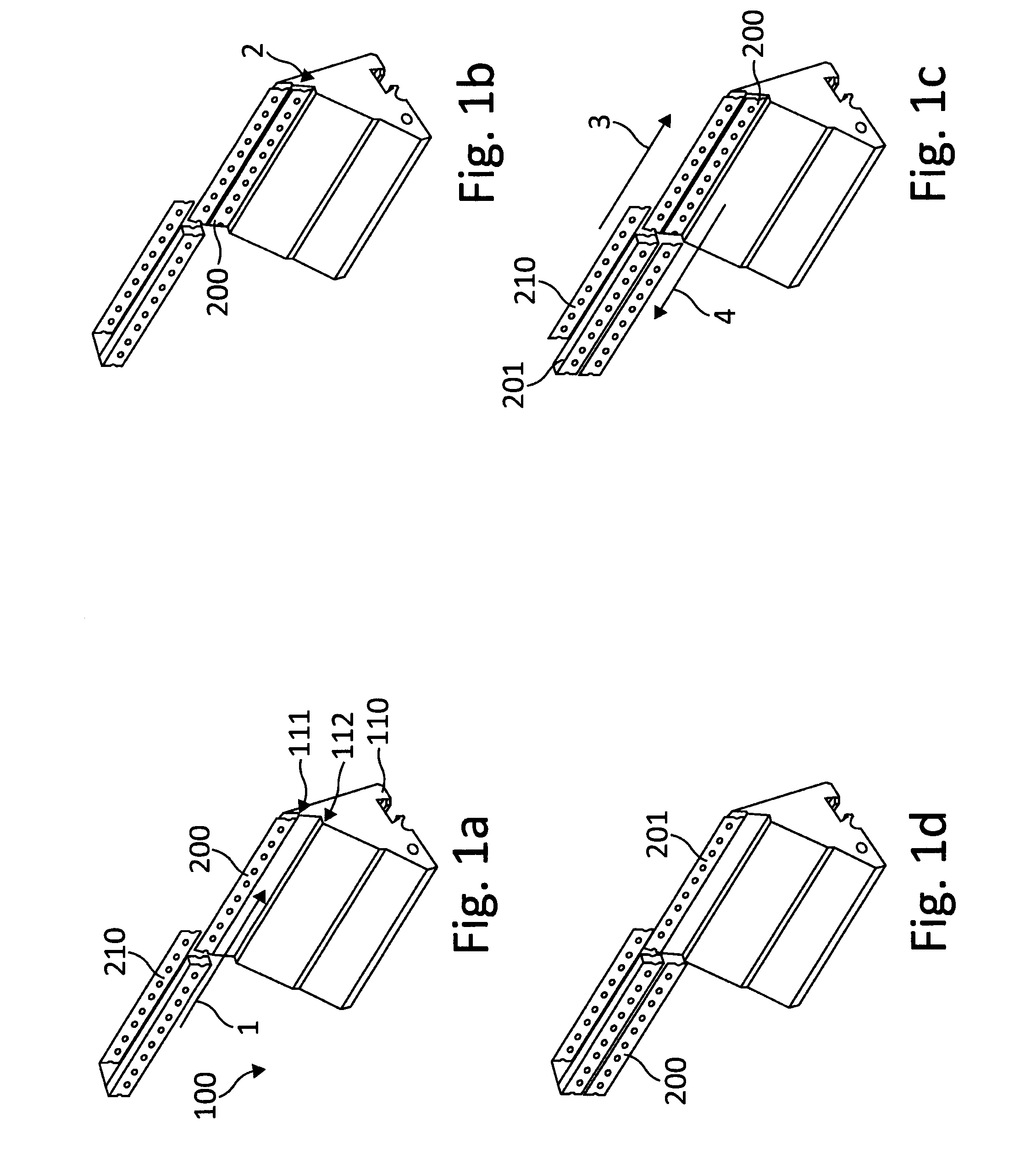

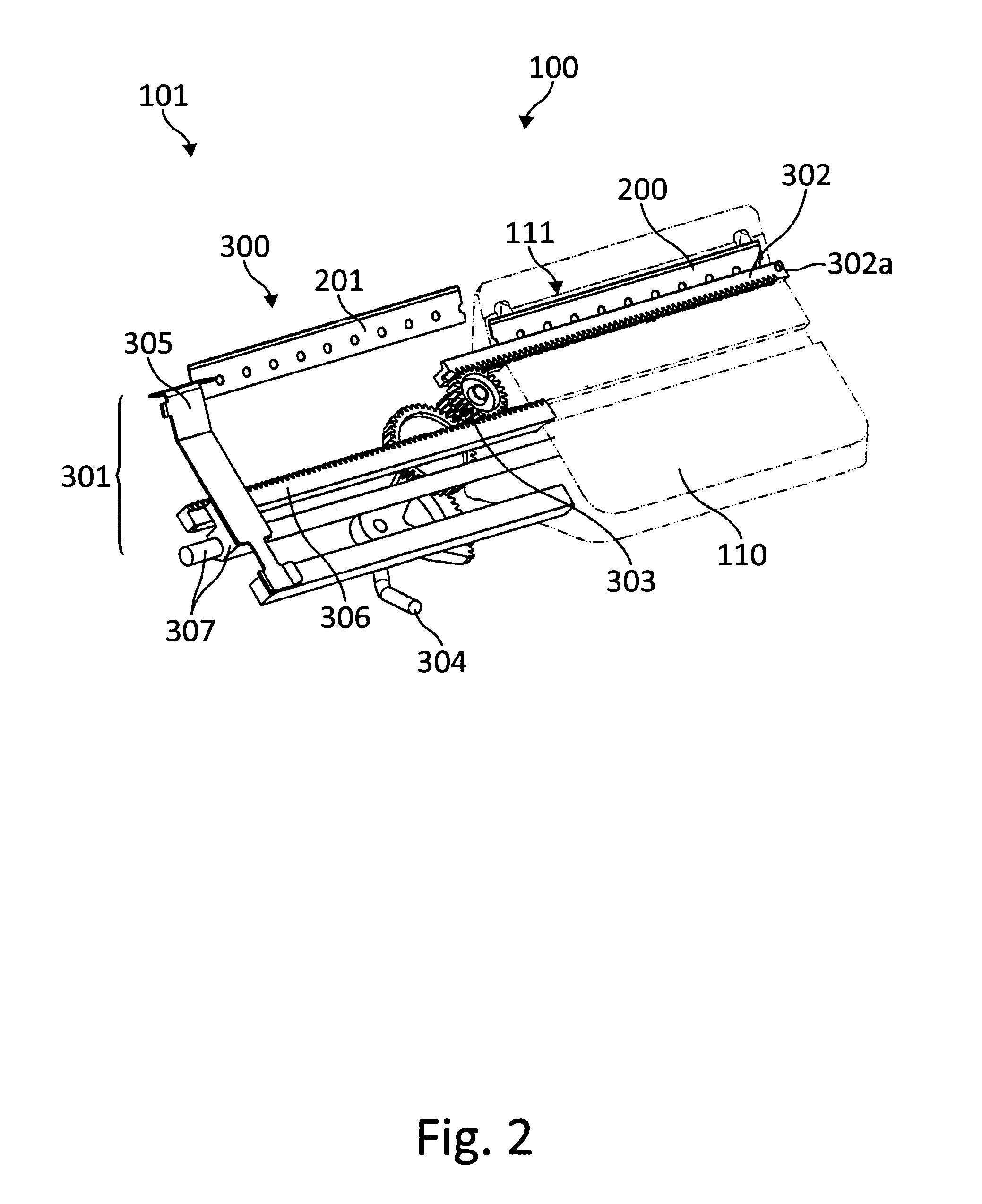

Knife holder having a blade changing apparatus

ActiveUS20140033888A1Reduce widthSimple constructionWithdrawing sample devicesTool changing apparatusEngineeringKnife holder

The invention relates to a knife holder (100) having a blade changing apparatus (102). The knife holder has a first blade receptacle (111) defining a cutting position, a securing means (130, 141, 142) for securing a blade (201) received in the first blade receptacle (111), a second blade receptacle (112) defining an output position, and an ejection means (141, 143, 144a) for ejecting a blade (201) received in the first blade receptacle (111) out of the first blade receptacle (111). The first and the second blade receptacles are arranged in the knife holder in such a way that a blade ejected from the first blade receptacle (111) can travel by gravity into the second blade receptacle (112).

Owner:LEICA BIOSYST NUSSLOCH

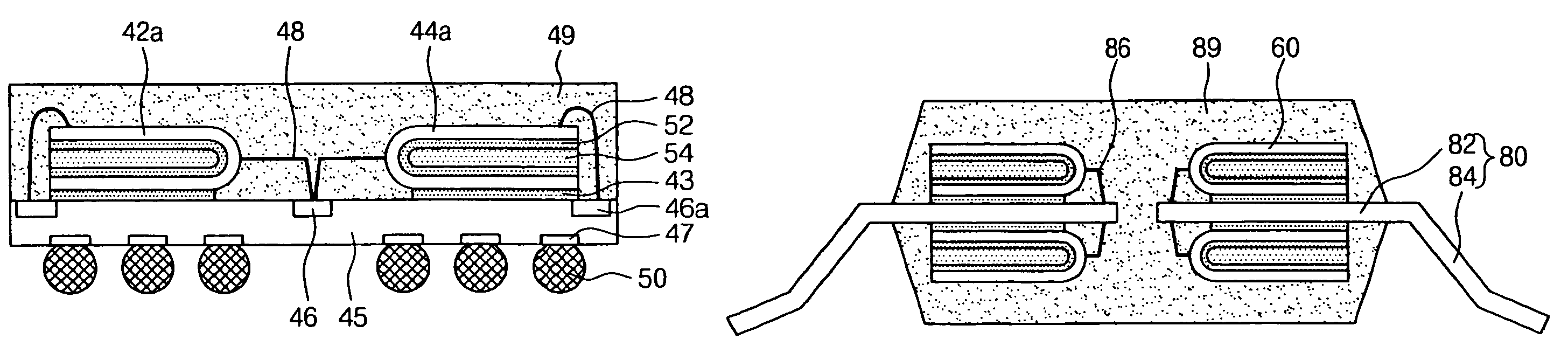

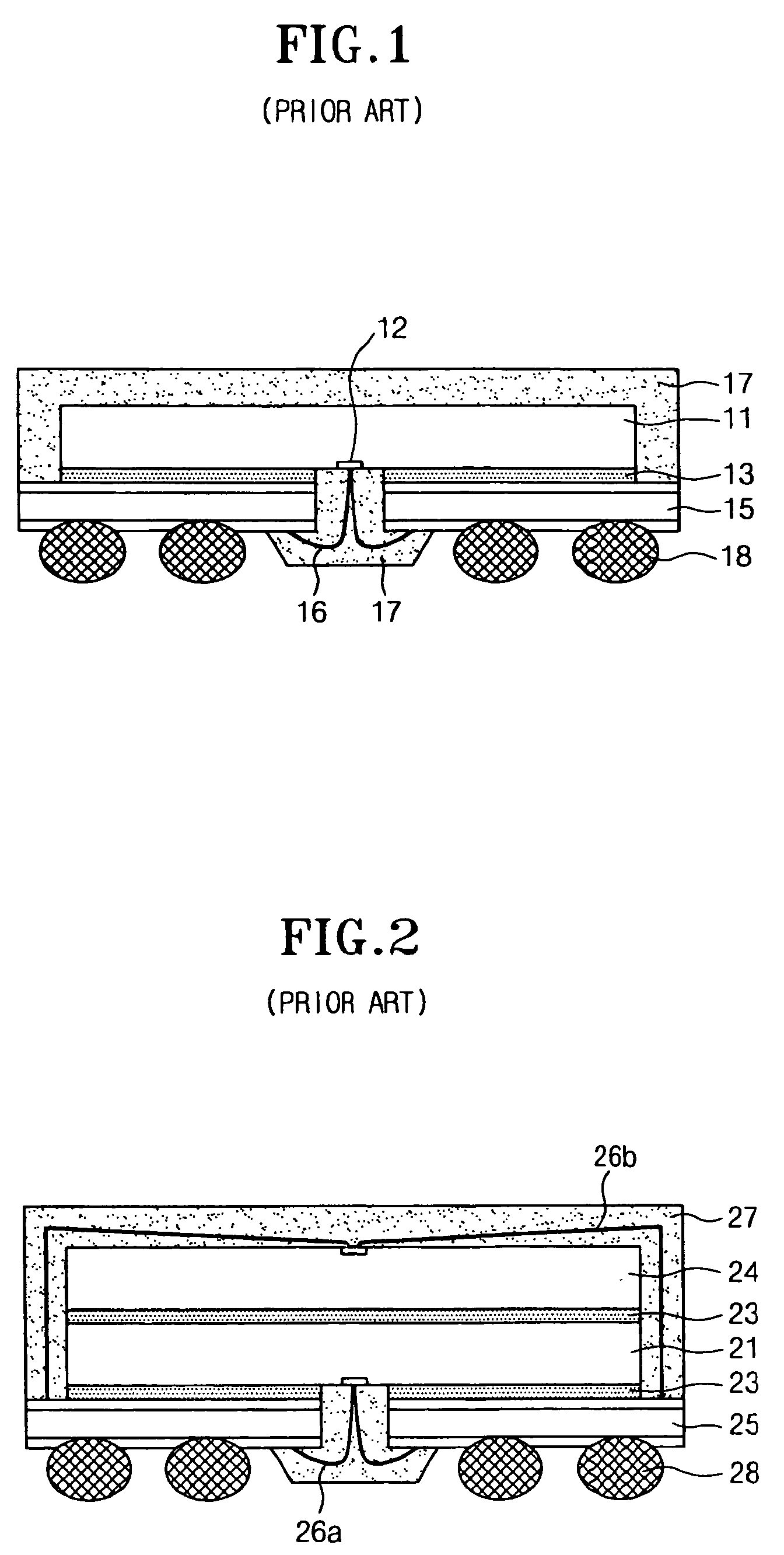

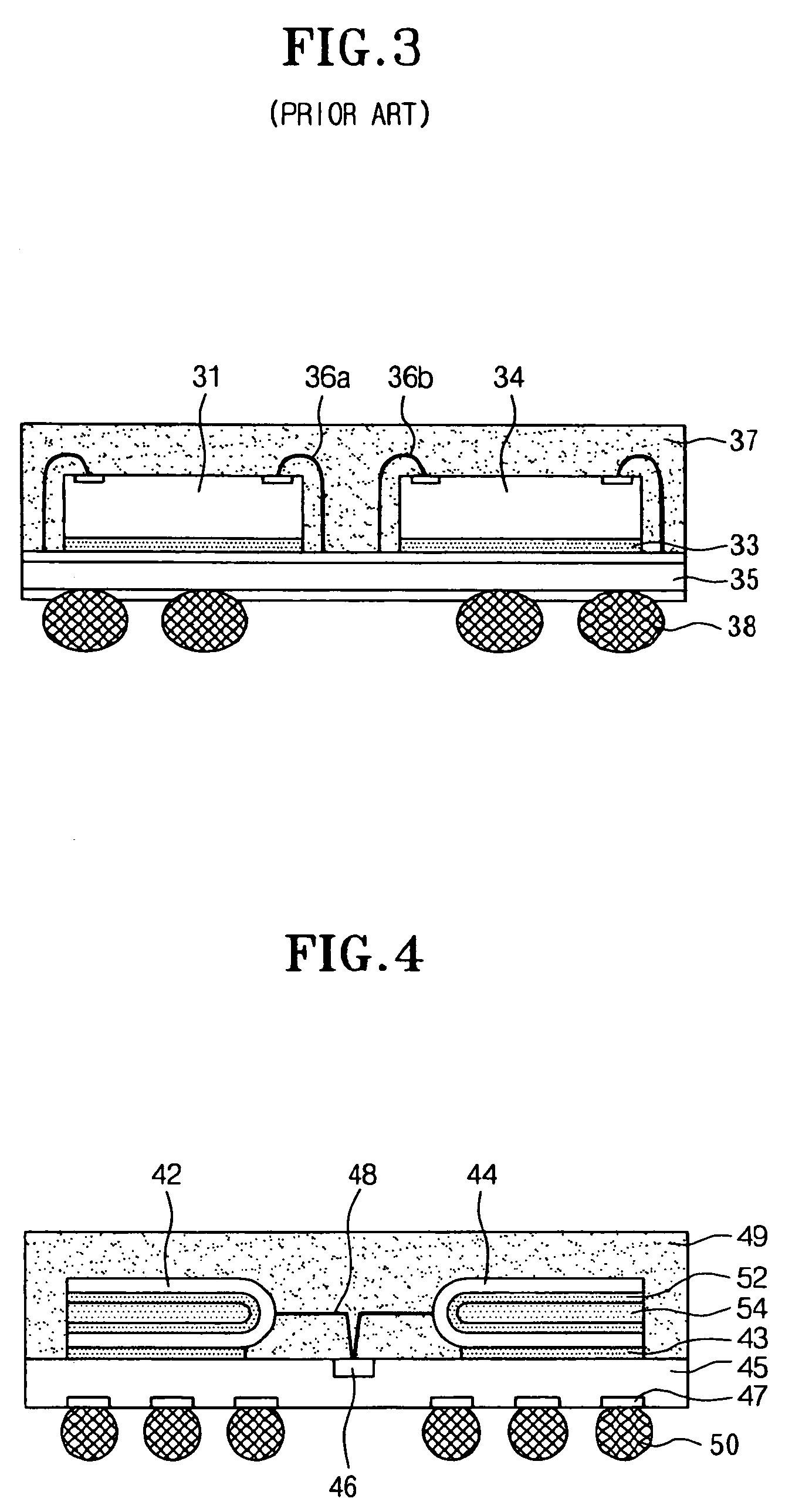

Folding chip planar stack package

InactiveUS7397115B2Reduce manufacturing costSignal transmission is convenientProtective switch detailsSemiconductor/solid-state device detailsSemiconductor chipSolder ball

Owner:SK HYNIX INC

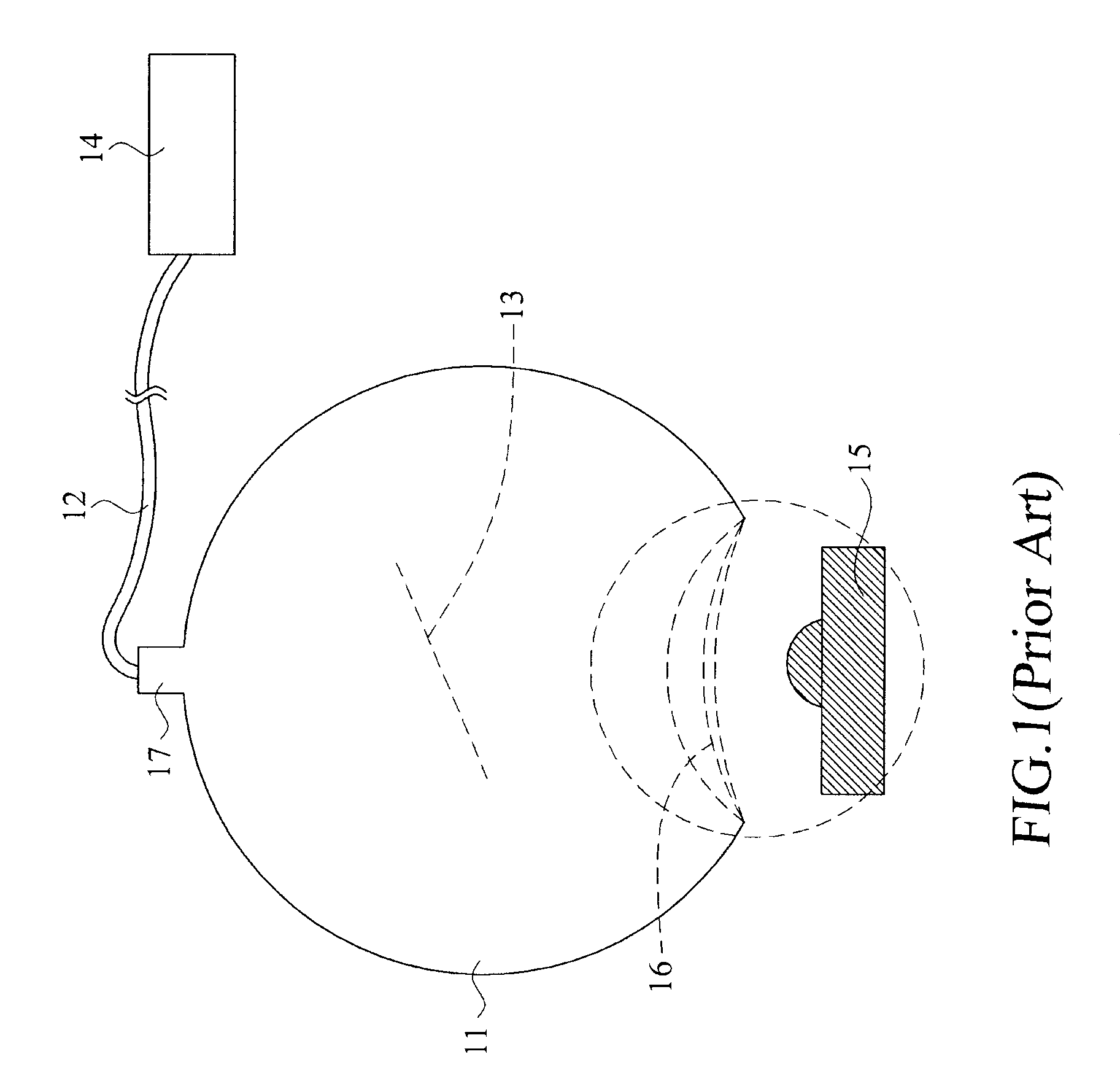

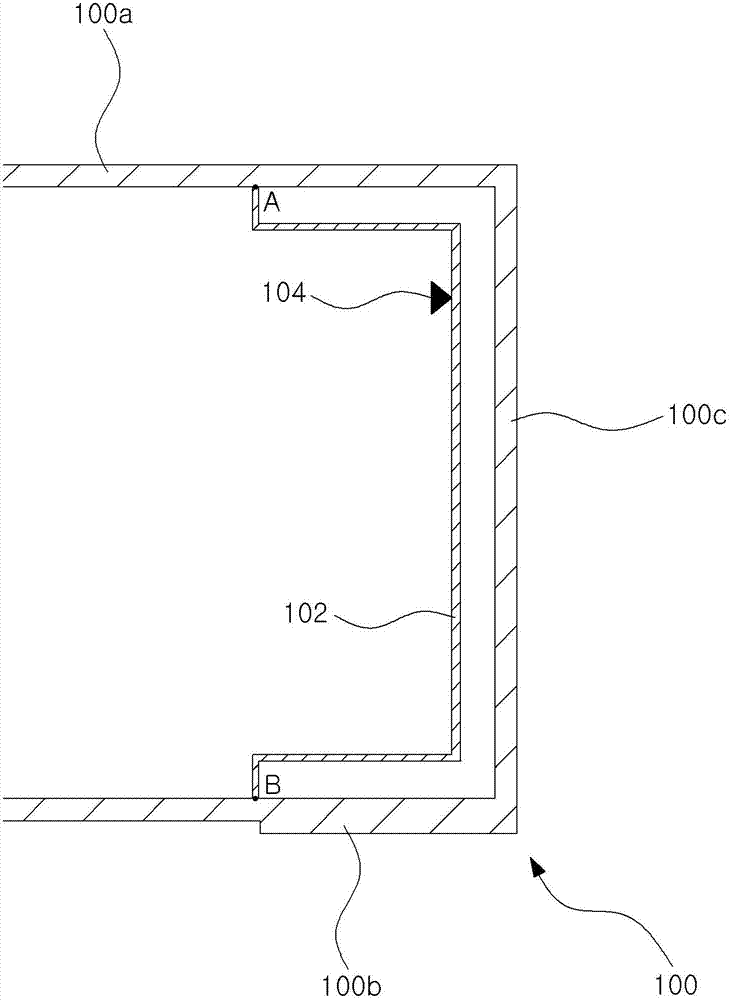

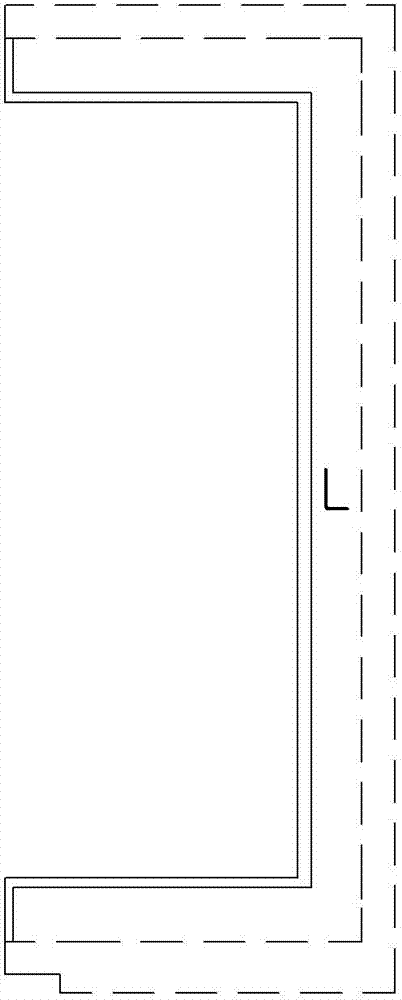

Door or window hinge

InactiveUS20170152690A1Minimized installation spaceCompact designWing accessoriesPin hingesEllipseEngineering

A door or window hinge has a housing having a back wall facing in a predetermined direction and a side wall extending in the direction from the back wall. A rack fixed to the side wall and extending in the direction meshes with a sector gear fixed to an inner end of a hinge body and formed as a partial ellipse having a semimajor axis. The inner body end can rotate in the housing about an axis perpendicular to the direction and slides in the guide in the direction between a closed position with a stop face of the inner end bearing on the back wall and an open position with the inner end spaced in the direction from the back wall. The sector gear is oriented on the inner end such that in the closed position the semimajor axis extends substantially perpendicular to the direction.

Owner:SIMONSWERK

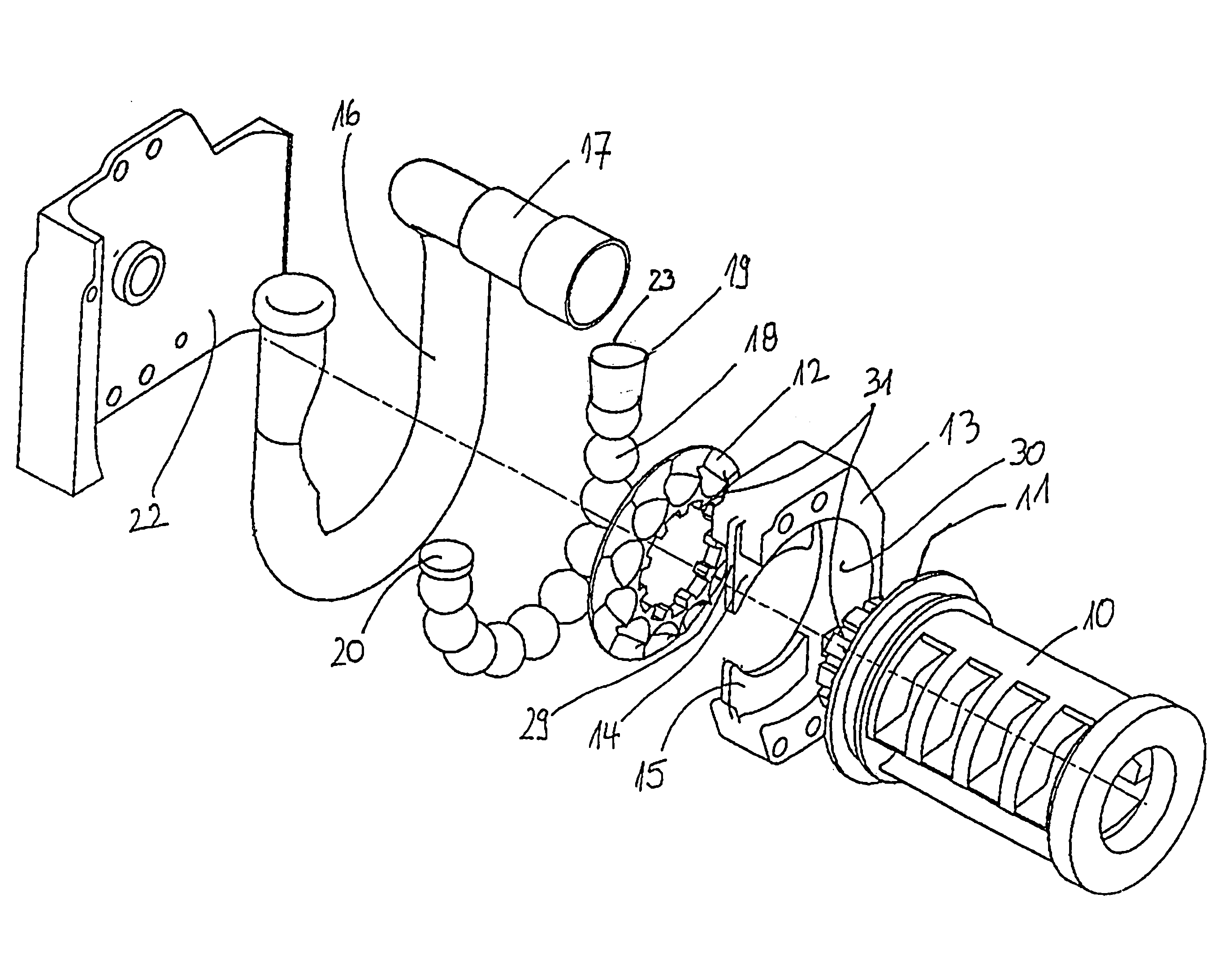

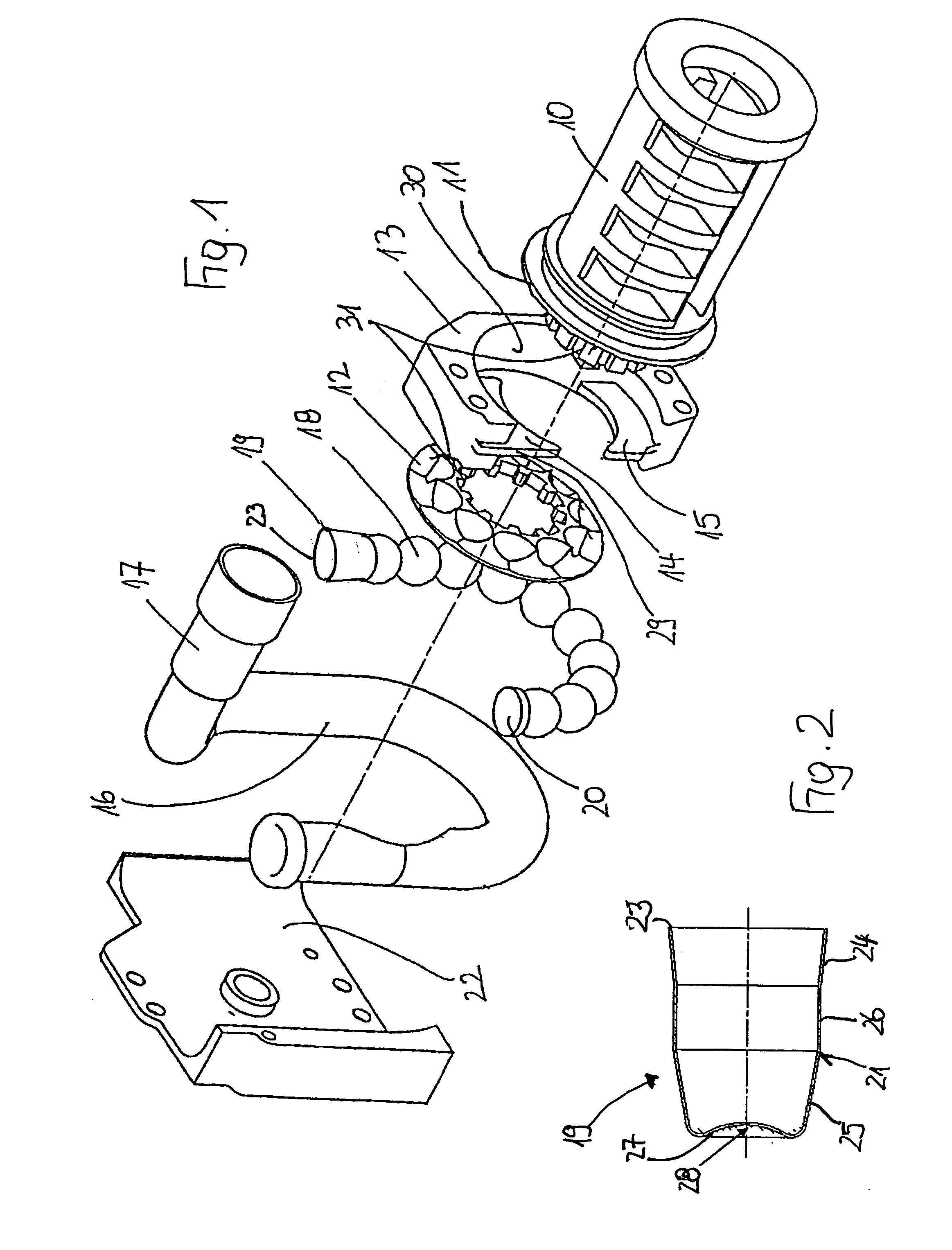

Belt Tensioner With a Cup-Shaped Drive Piston

A belt pretensioner for safety belts, in particular in motor vehicles, with a pretensioner drive which, in the event it is triggered, can be coupled to the belt shaft, and includes a drive wheel which is enclosed over at least part of its volume by a tubular housing which forms a channel in its interior, whereby, in order to drive the drive wheel, a plurality of solid balls, which are accelerated by means of a pyrotechnic drive, can be guided through the channel, and a drive piston for the solid balls is arranged at that end of the channel which is to be acted upon by the gas introduced, characterized in that the drive piston (19) is designed in the manner of a hollow cup and, on its closed end side (27), is provided with an inwardly directed curvature (28) adapted to the contour of a solid ball (18).

Owner:AUTOLIV DEV AB

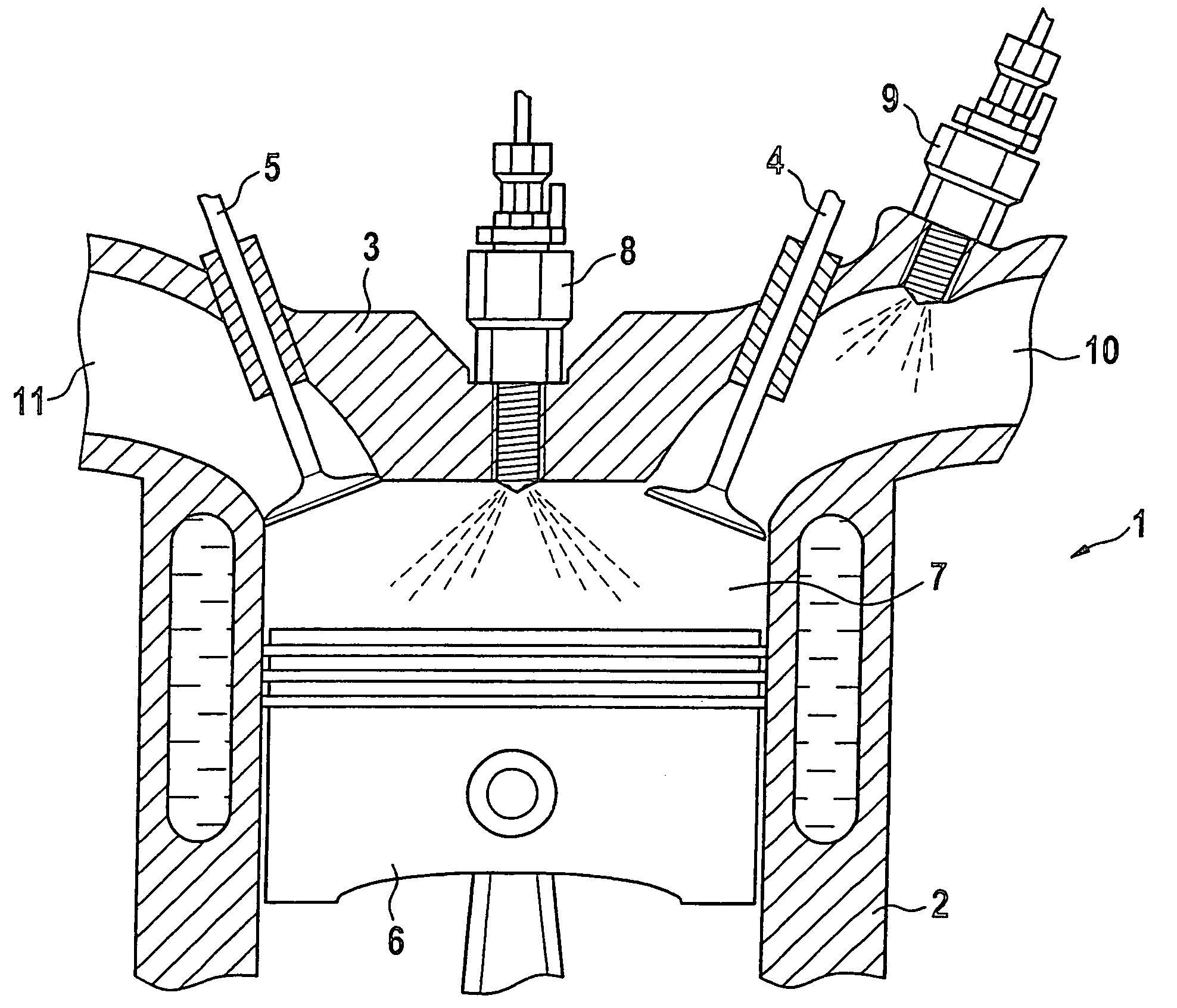

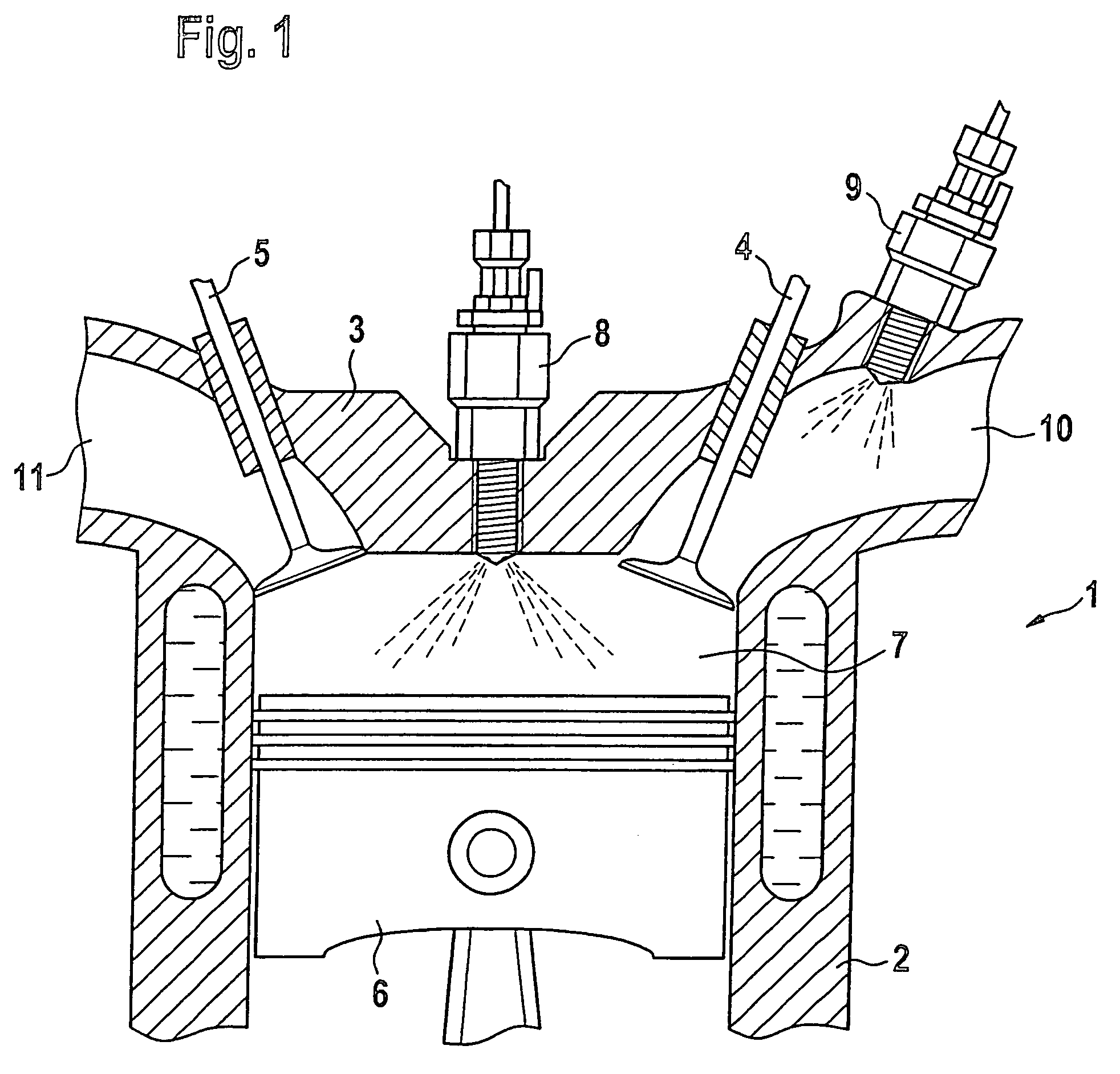

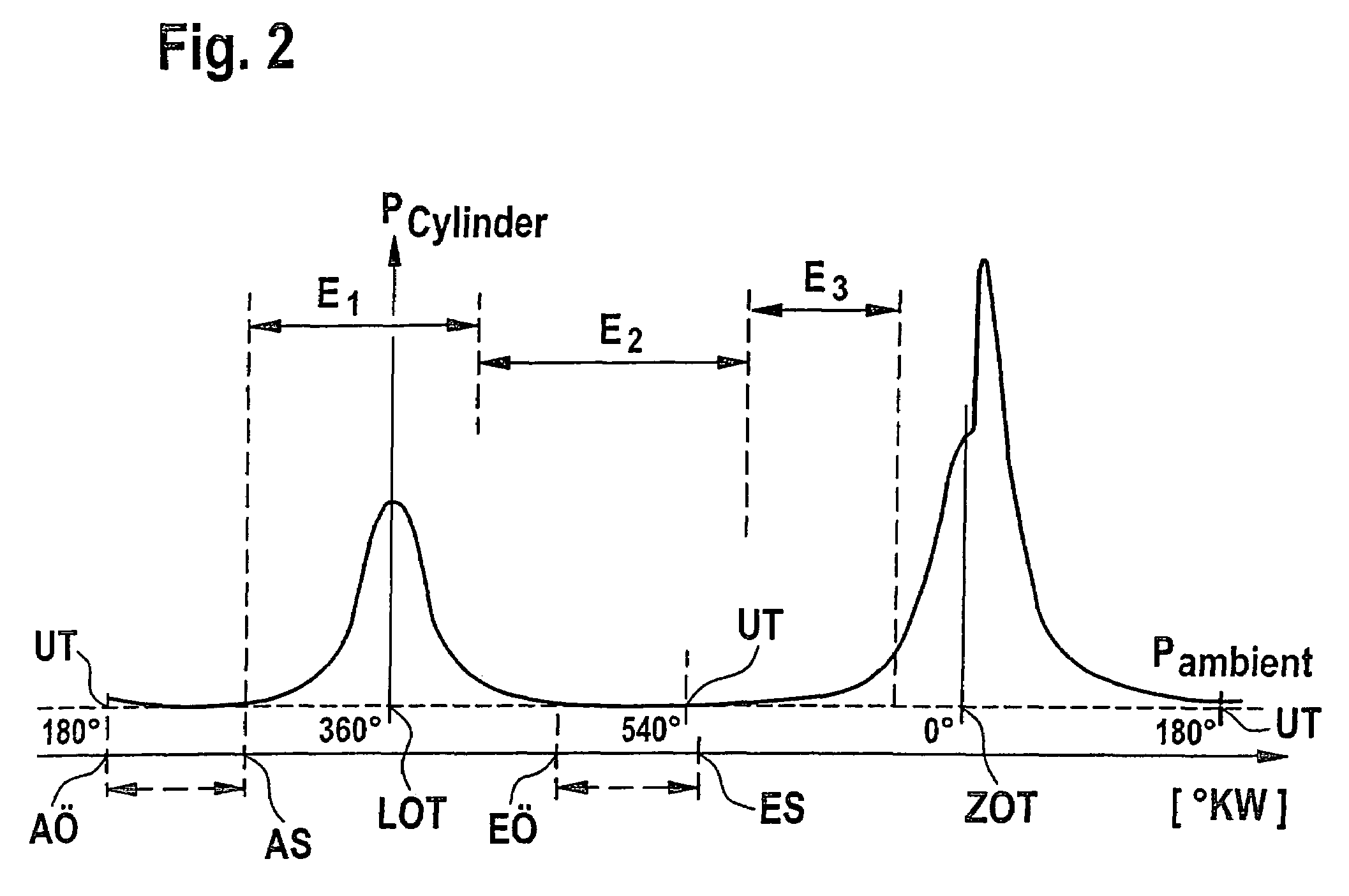

Method of operating an internal combustion engine

ActiveUS7143739B2Promote homogenizationLower raw emissionsElectrical controlInternal combustion piston enginesExternal combustion engineProduct gas

In a method of operating an internal combustion engine in which exhaust gas is retained in the combustion chamber of the internal combustion engine and compressed during a charge change together with fresh combustion air, a first fuel quantity is injected into the retained exhaust gas by means of direct fuel injection, a second fuel quantity is subsequently supplied to the combustion chamber together with the fresh combustion air so that a homogeneous fuel / gas / air mixture is formed in the combustion chamber, and an auto-ignition time of the fuel / gas / air mixture is established as a function of a quantity ratio of the first fuel quantity and the second fuel quantity.

Owner:DAIMLER AG

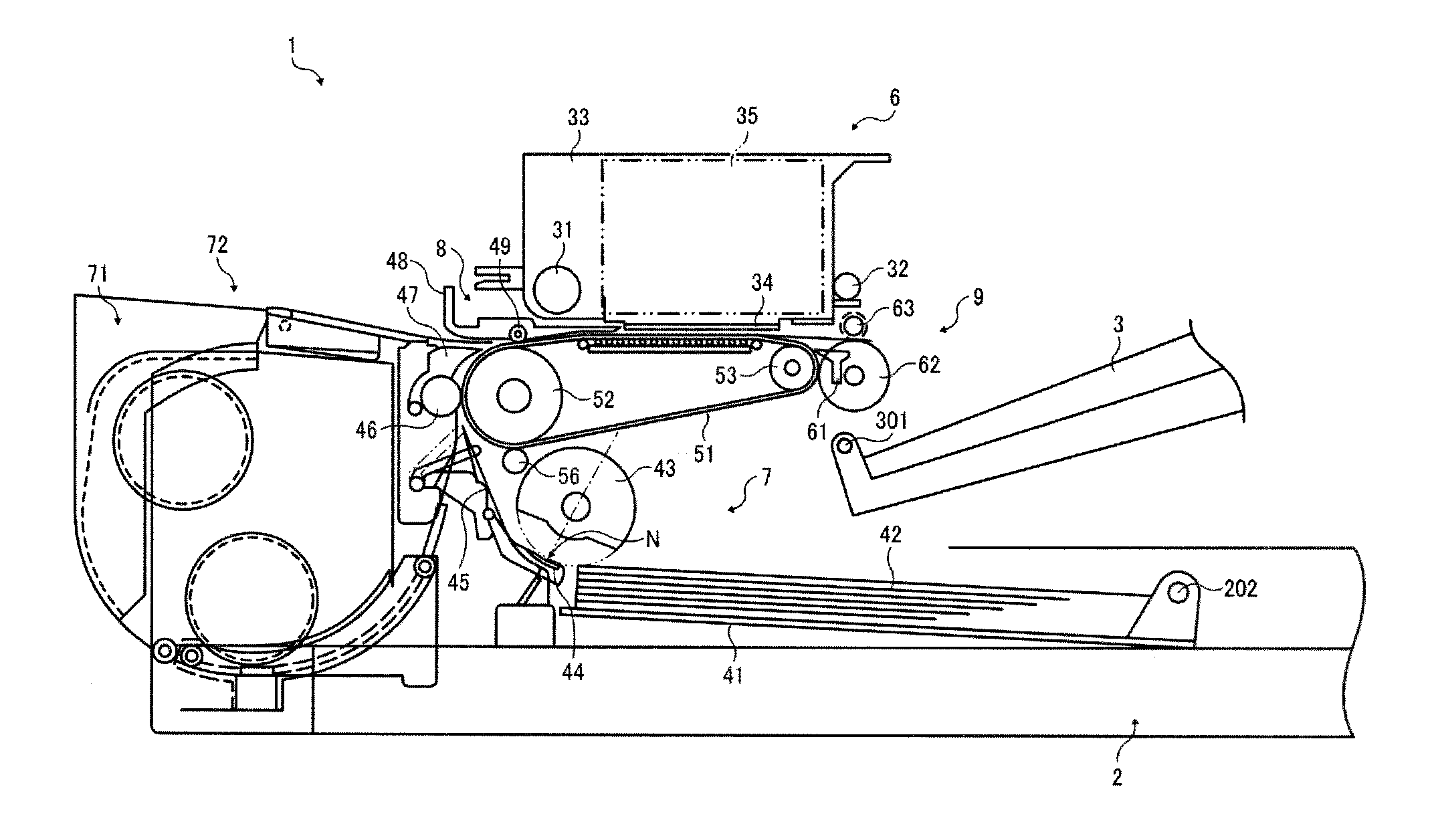

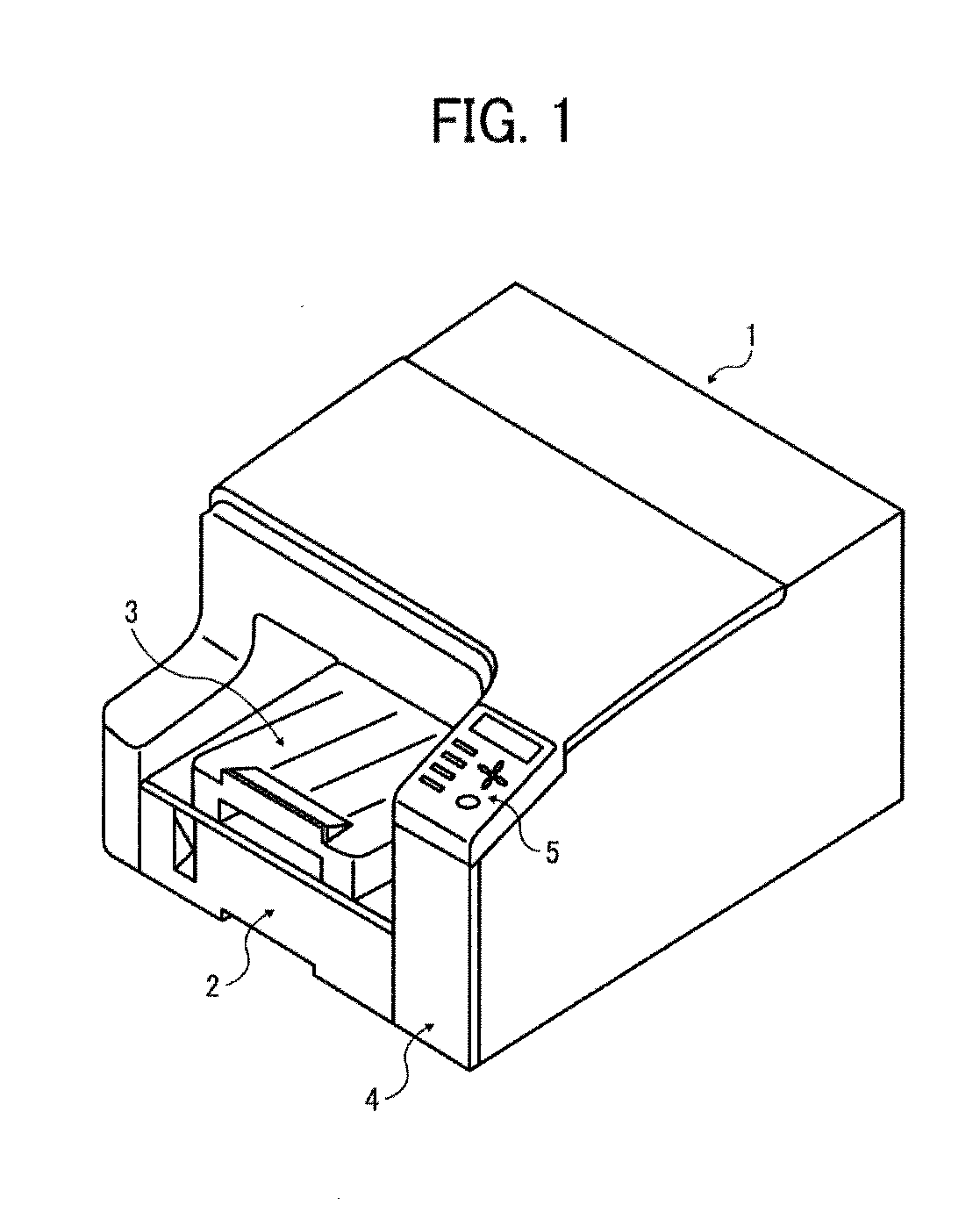

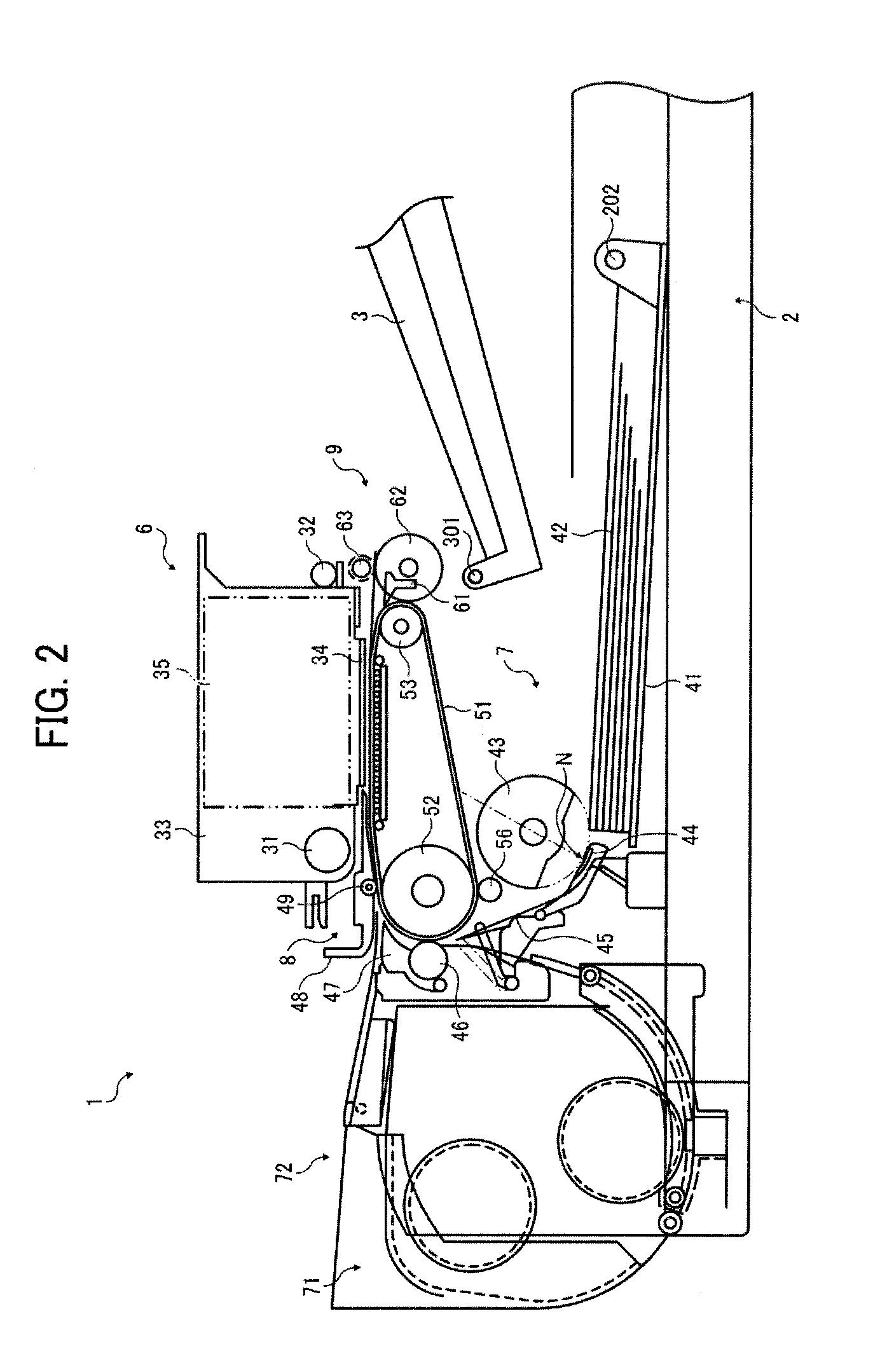

Image forming apparatus

ActiveUS20130134660A1Accurate supplyMinimized installation spaceElectrographic process apparatusPile receiversImage formationEngineering

An image forming apparatus including a sheet container, a sheet stacking member to closably open the sheet container; a restriction unit to restrict a swinging movement of the sheet stacking member, and a stopper mechanism to restrict insertion of the sheet container into the image forming apparatus in a state in which the sheet stacking member swings open from the sheet container. The stopper mechanism includes a stopped member provided to the sheet container and being movable vertically along the swinging movement of the sheet stacking member, and a stopper member provided to the image forming apparatus and being contactable with the stopped member. The stopped member includes a stopped surface contacted by the stopper member in a state in which the stopped member is lifted; and a switching surface adjacent to the stopped surface and vertically moving the stopped member by contact against the stopper member.

Owner:RICOH KK

Elevator system

ActiveUS20050006179A1Great tractionReduced dimensionElevatorsBuilding liftsElevator systemDrive wheel

A wedge-ribbed belt supports an elevator car in a cantilevered mode and engages a drive pulley of a drive mounted at the head of an elevator shaft. The belt has a running surface facing the drive pulley with a plurality of ribs and grooves extending in parallel in a longitudinal direction of the belt. The ribs and grooves can be triangular-shaped or trapezium-shaped in cross section. A plane of the drive pulley is arranged vertically and at right angles to a car wall at a counterweight side of the elevator car.

Owner:INVENTIO AG

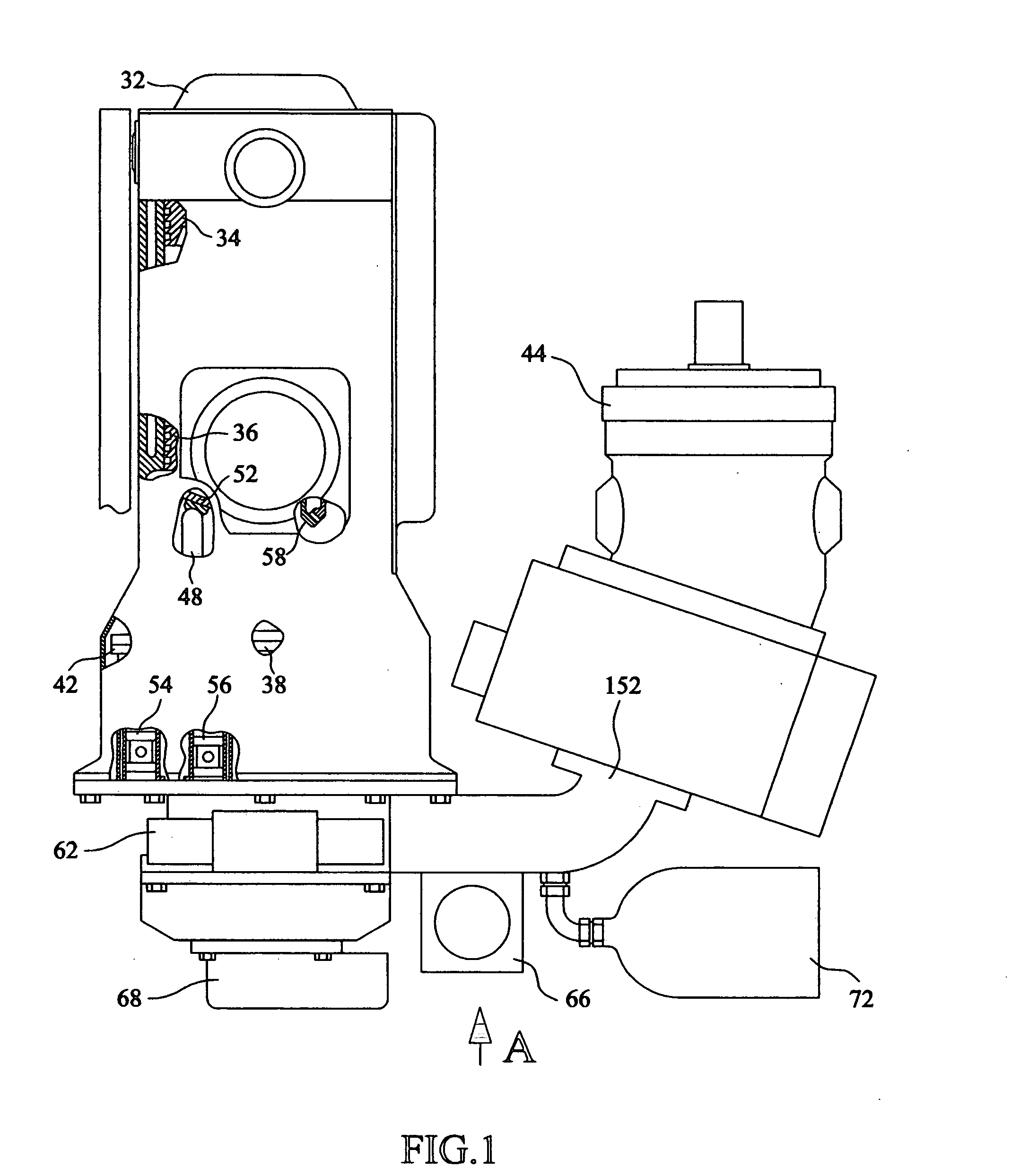

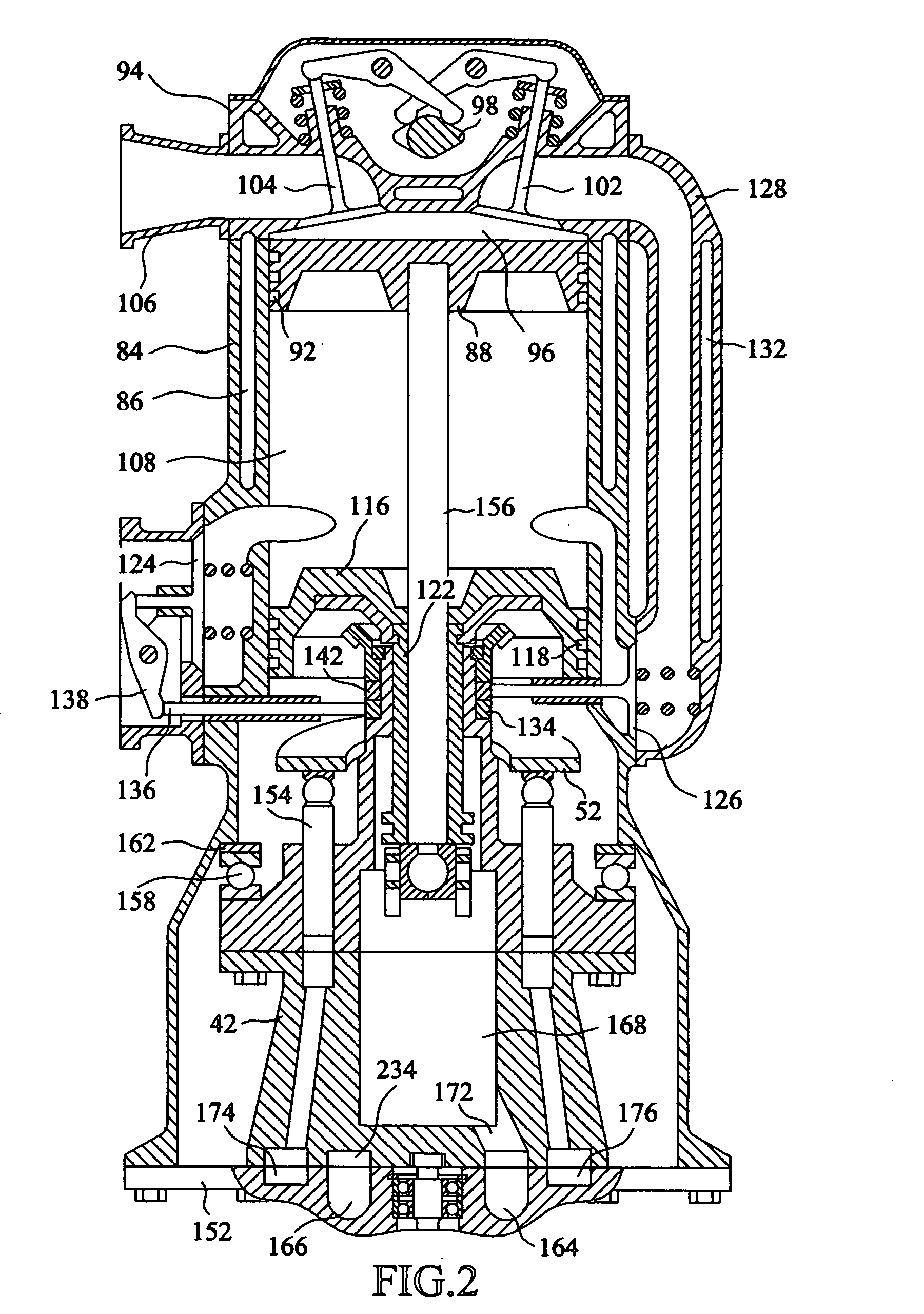

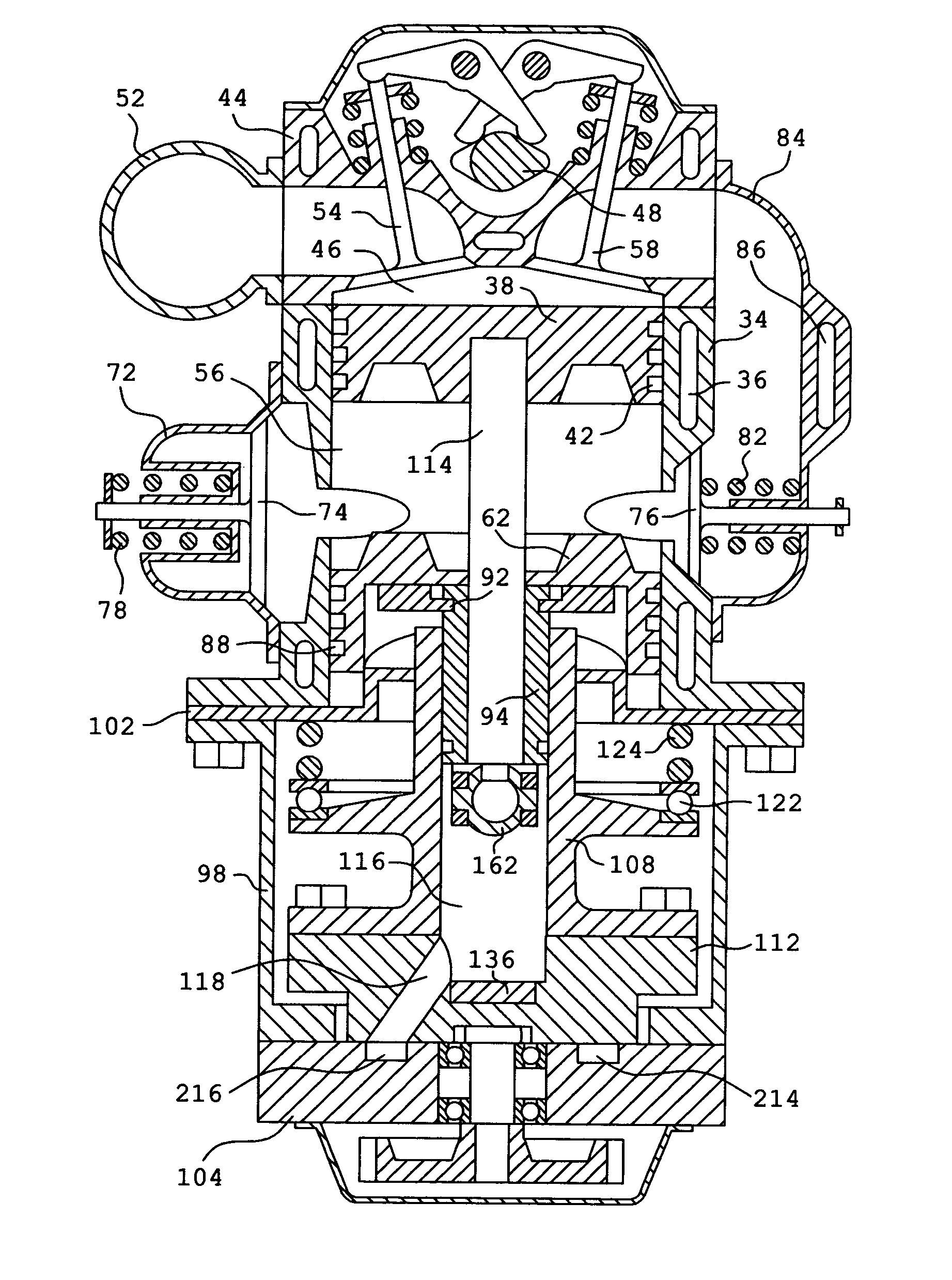

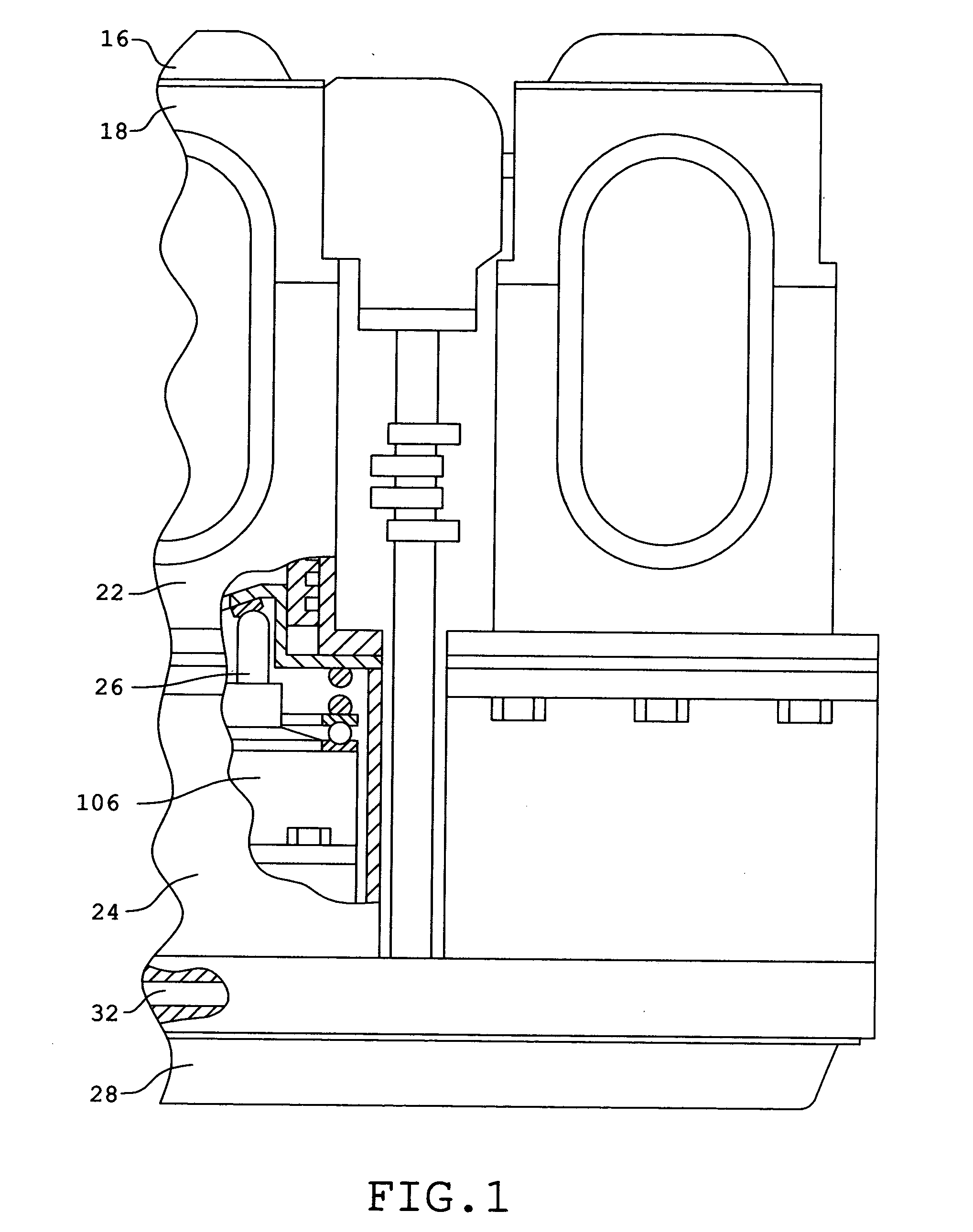

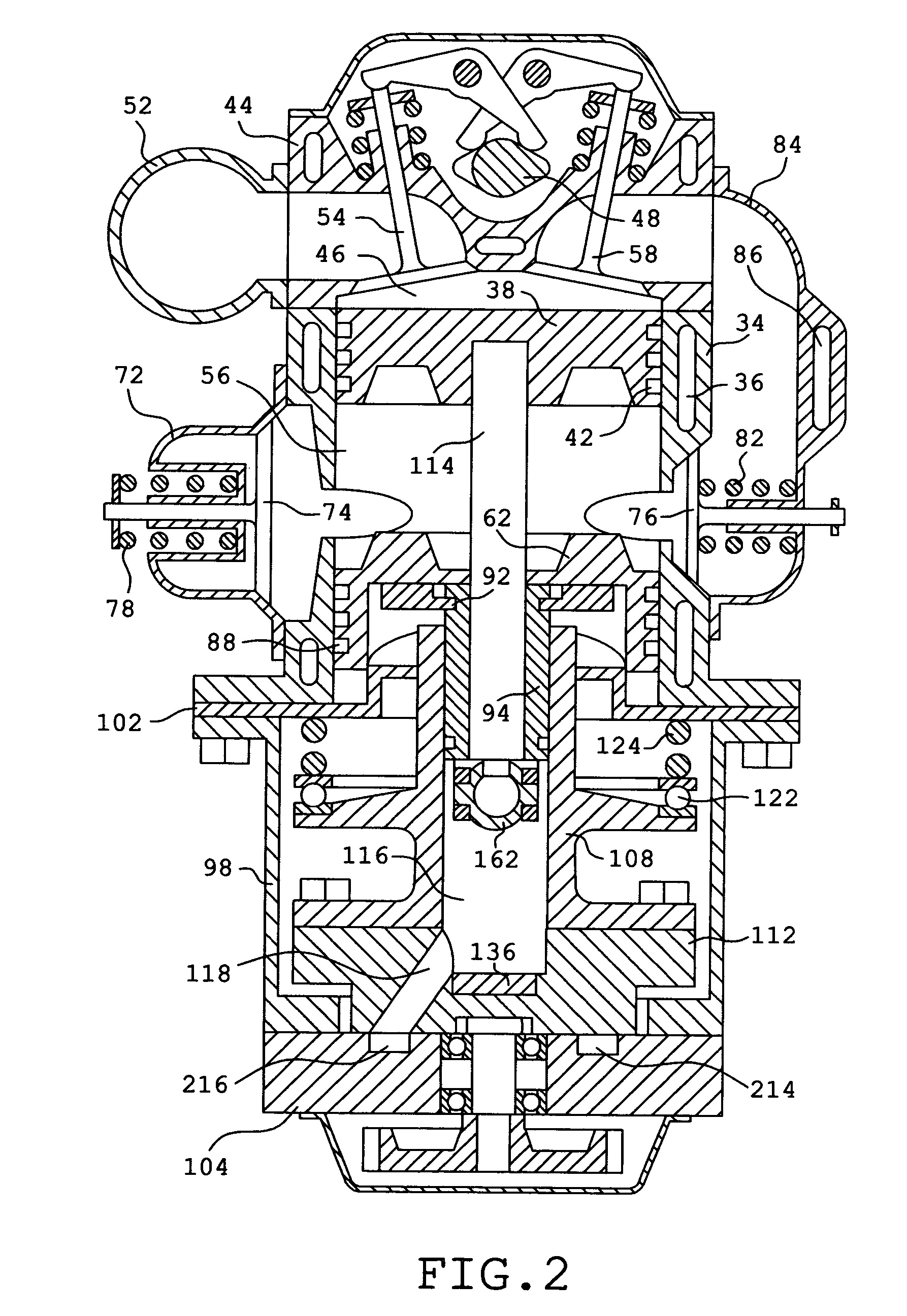

Monocylindrical hybrid powertrain and method of operation

InactiveUS20080134675A1Easy and efficient to manufactureLow priceHybrid vehiclesAuxillary drivesEngineeringHybrid powertrain

The monocylindrical hybrid powertrain comprises a continuously variable volume hybrid engine, pump and hydrostatic motor. The pump plunger fastened to engine piston and the engine cylinder fastened to the hydrostatic motor by valve plate and formed solid monoblock.The hybrid synchronize mechanism swash plate turn changes the engine piston stroke and remains the engine compression ratio. The swash plate shift changes the engine compression ratio for the either kind of fuel use.The hybrid and pneumohydraulic accumulator association transforms the single pump plunger supply pulsation into uniform fluid flow feeding the hydrostatic motor.The hydrostatic motor and the electric motor association allow electric energy accumulation by means of plug-in.Direct energy transmission, variable displacement volume engine, pump and hydrostatic motor and energy recuperation increases the specific power, decreases the weight and installation space and enables to achieve 80 mile per gallon for the car in city conditions.

Owner:EPSHTEYN GRIGORIY

Antenna combined with terminal housing

InactiveCN103078175AInhibition of characteristic changesStable characteristicsAntenna supports/mountingsRadiating elements structural formsComputer terminalEngineering

An antenna combined with a terminal housing is disclosed. The disclosed antenna includes an outer frame radiator, which is joined to a side wall of the terminal housing, and an inner frame radiator, which has one end joined to a first point on the outer frame radiator and the other end joined to a second point on the outer frame radiator, and which forms a loop by joining the outer frame radiator, where a feed signal is provided to the inner frame radiator. The disclosed antenna provides the advantages of preventing property changes caused by contact between a person's body and the terminal, and of minimizing mounting space while maintaining stable characteristics.

Owner:ACE TECH

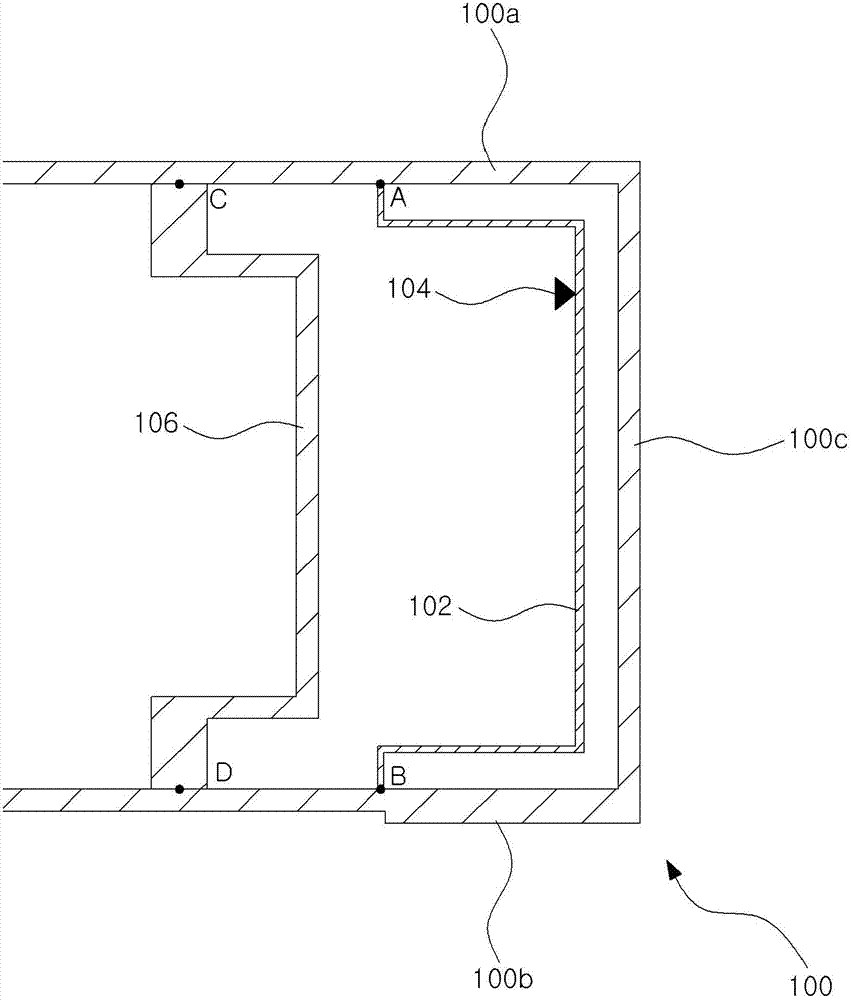

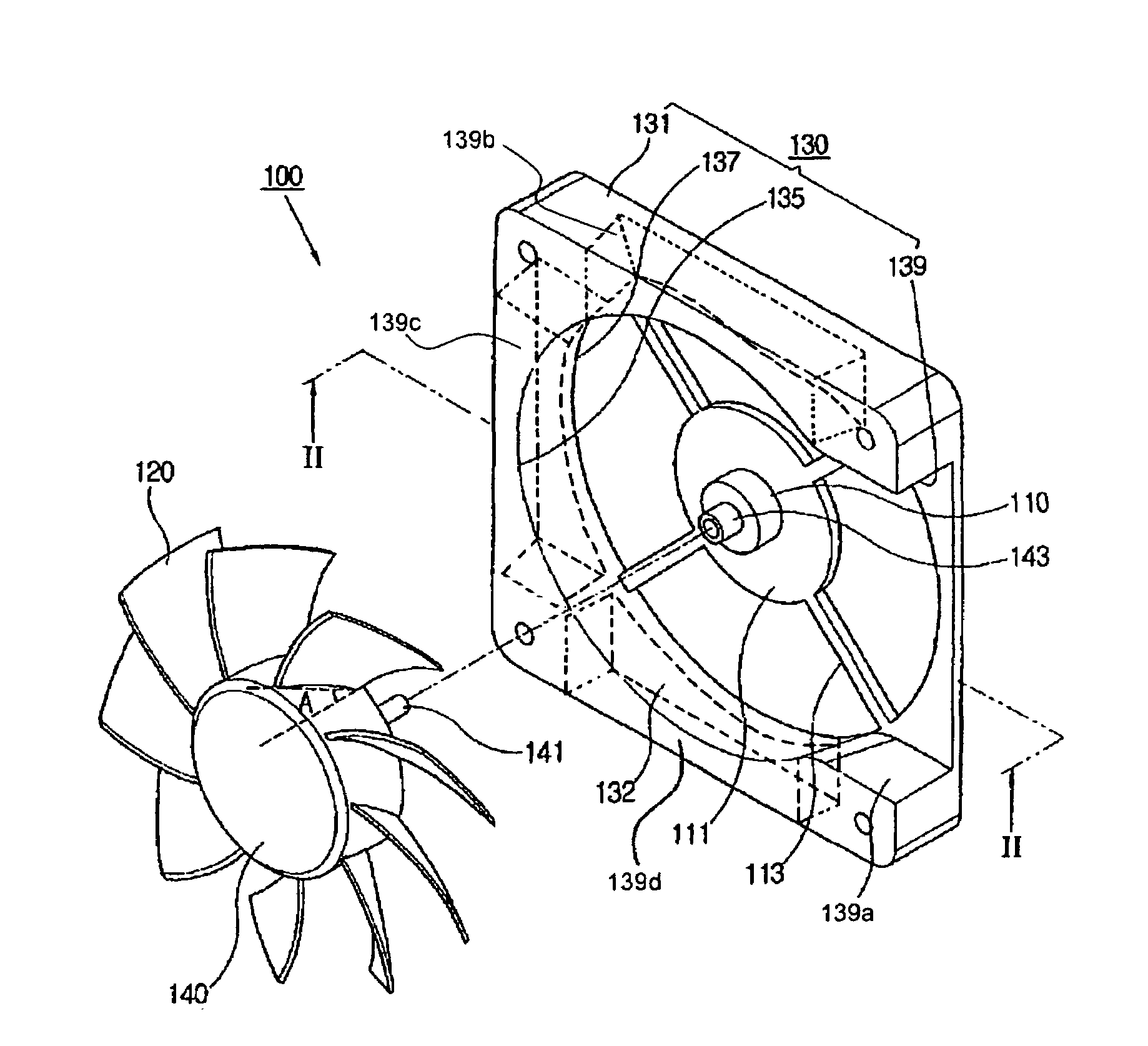

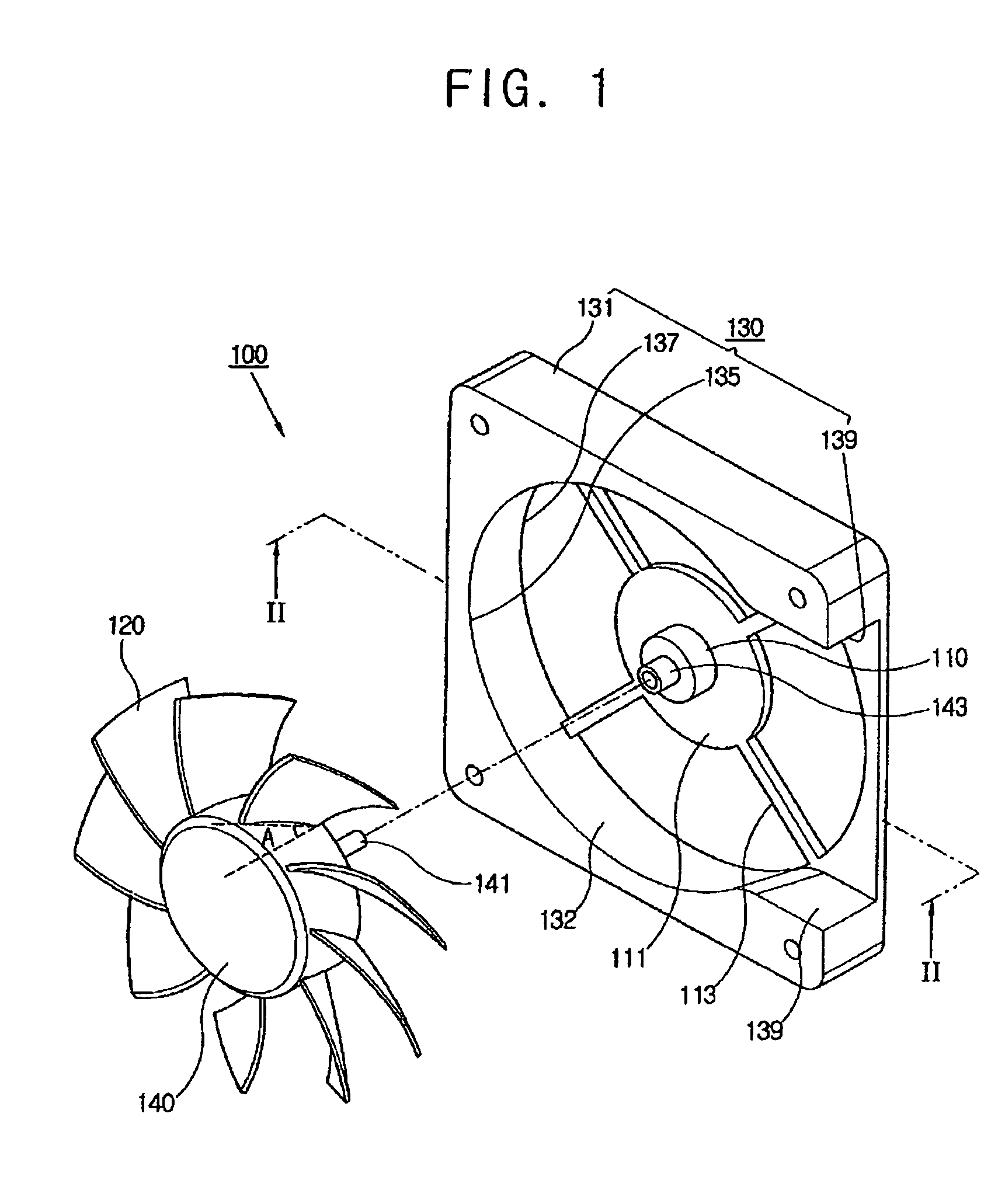

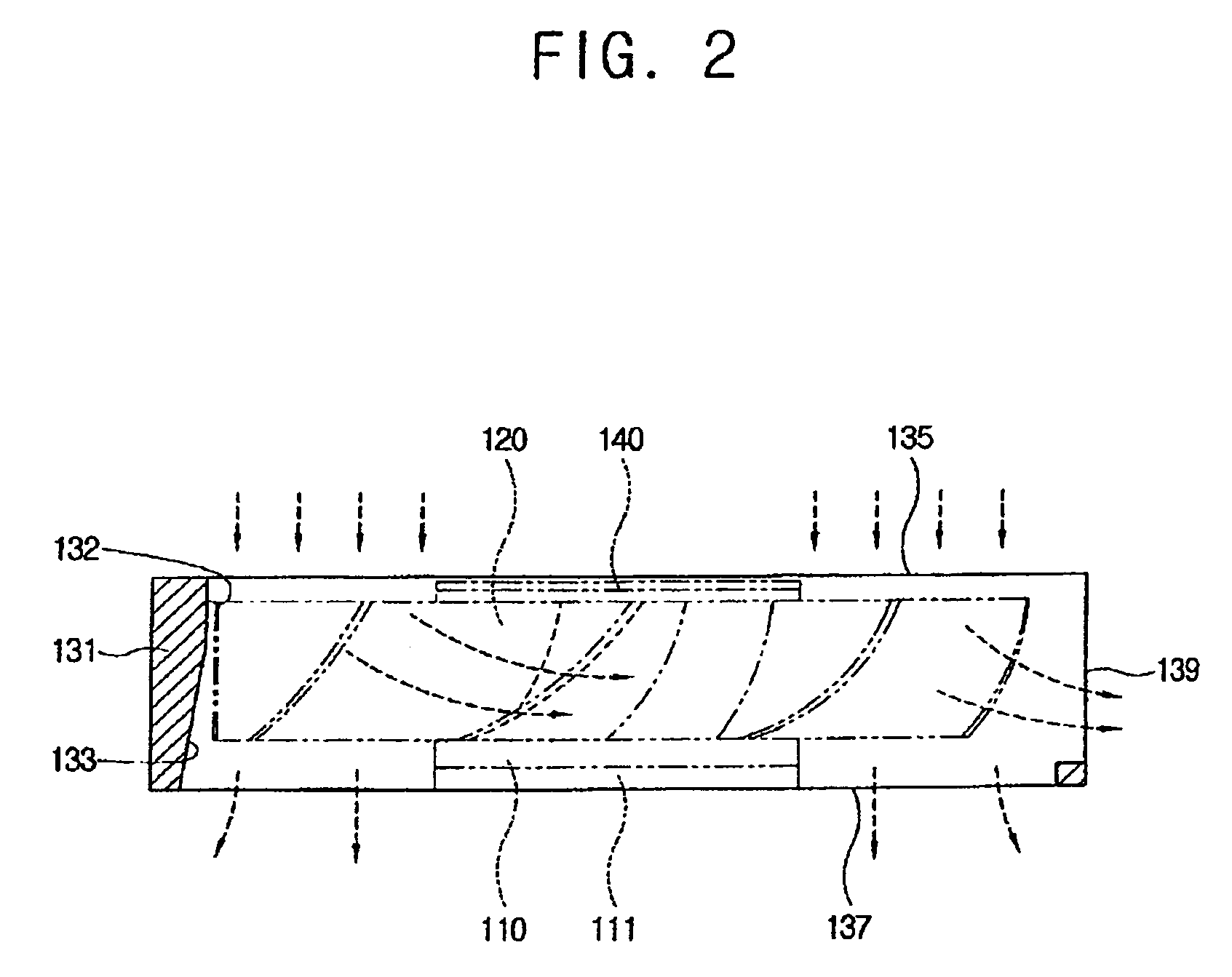

Fan to generate air flow in axial and radial directions

ActiveUS7360992B2Reduce in quantityMinimized installation spacePump componentsWorking fluid for enginesRotational axisDrive motor

A fan including a driving motor, a plurality of blades which are connected to the driving motor to rotate, and a housing having a housing main body to accommodate the driving motor and the blades, an air inhaler that is provided in the housing main body to inhale air toward the plurality of blades, an axial air discharger that is provided in a rotational axis direction of the plurality of blades and a radial air discharger that is provided in a radial direction substantially perpendicular to the rotational axis. The fan generates air flow both in the axial and radial directions, thereby increasing the number of directions in which air flows, reducing the number of fans to be used, minimizing an installation space required, and reducing noise generated by the fans.

Owner:SAMSUNG ELECTRONICS CO LTD

Hybrid two cycle engine, compressor and pump, and method of operation

InactiveUS20050028759A1Easy and efficient to manufactureLow priceFluid couplingsPlural diverse prime-mover propulsion mountingHydraulic pumpEngineering

The hybrid (16) comprises a two cycle engine (18), boosted by the engine power compressor (22) and a hydraulic pump (24). The pump plunger (114) fastened to engine piston (38) and located coaxially with the compressor piston (62) and pump (24) rotor (106), provide direct energy transmission to the compressor and pump. The plunger (114) and compressor piston (62), each connected to one of two diametrically opposite axial push rods (138), (142) of the rotor (106). The push rods synchronize and balance the pistons (38), (62) which move opposite directions into underside of the engine piston space. The rotor canals (118), (226) interact with the valve plate (104) and communicate fluid flow from a pumps of separate rotors. The reducer (28) synchronizes the motion of the separate rotors, activate engine and compressor camshafts (48), (64) and conventional accessory units. The engine can be high power started and restarted irrespective of parking time, since the start, idling and work modes provide a hydraulic distributor (272), pneumohydraulic accumulator (296) and starter pump (298) with pedal (302). Because of direct energy transmission the hybrid increases efficiency and specific power, while minimizing the weight, installation space and fuel consumption necessary in particular for automobile hydrostatic transmission.

Owner:EPSHTEYN GRIGORIY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com