Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

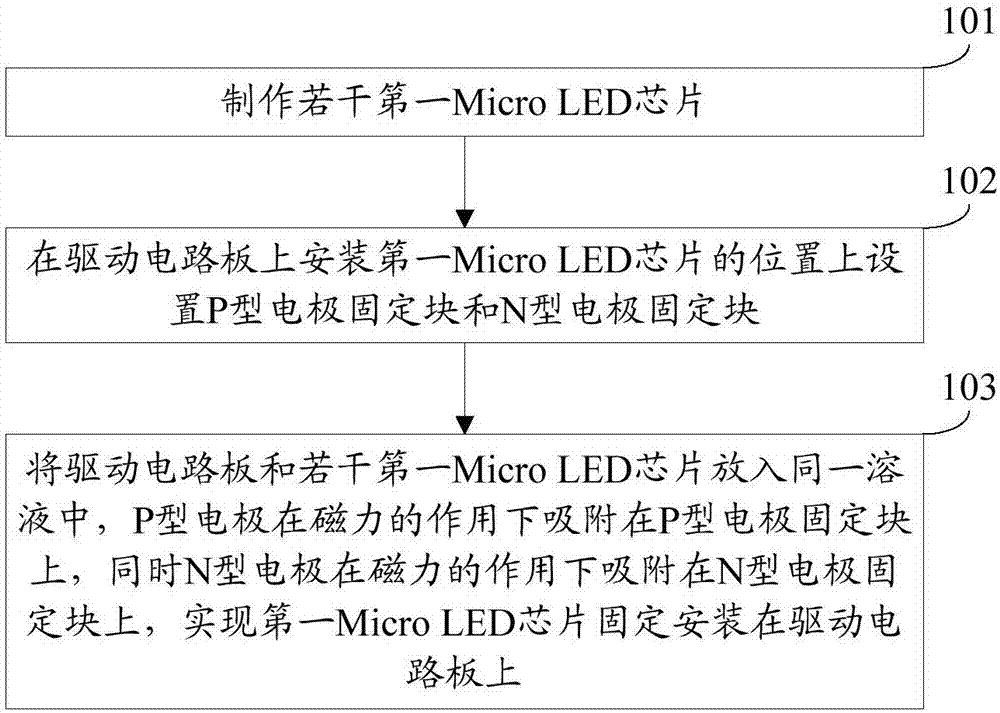

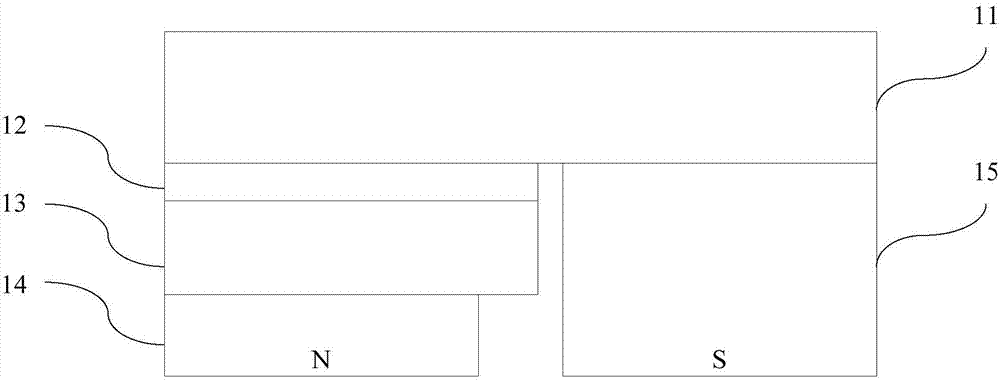

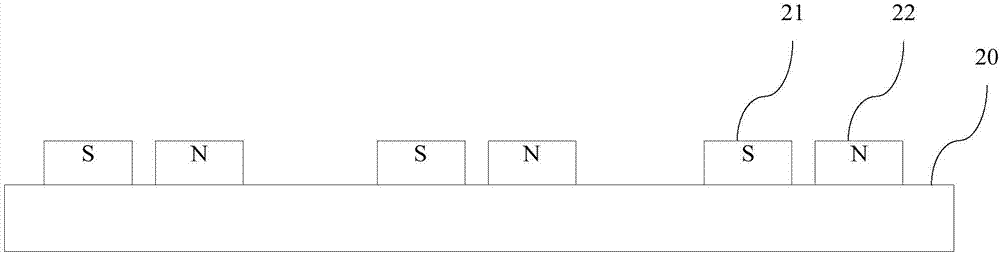

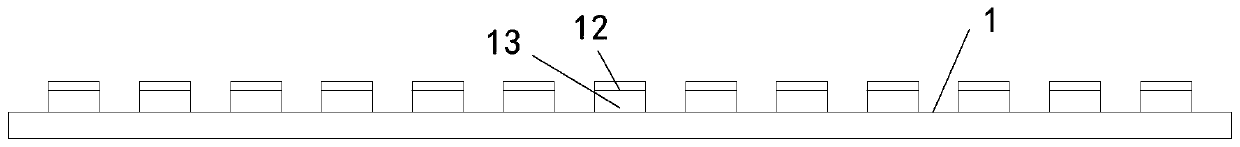

Mass transfer method of Micro LED (Light Emitting Diode) chips

ActiveCN107425101AMass transferIncrease productivityPrinted circuit aspectsSolid-state devicesMagnetic polesEngineering

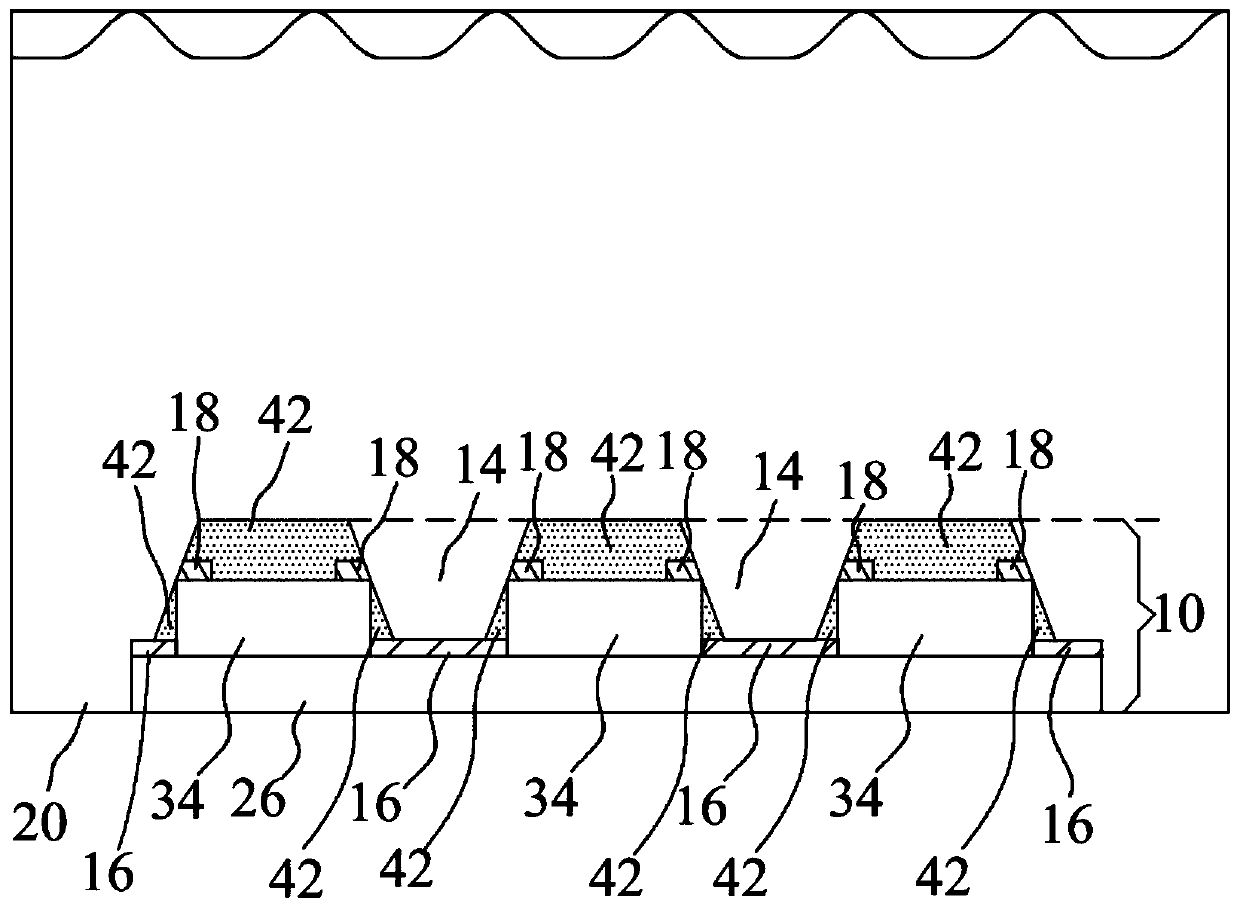

The invention discloses a mass transfer method of Micro LED (Light Emitting Diode) chips, and belongs to the technical field of a semiconductor. The mass transfer method comprises the steps of: producing a plurality of first Micro LED chips, wherein the same sides of P-type electrodes and N-type electrodes of the first Micro LED chips are contrary name magnetic poles; arranging P-type electrode fixing blocks and N-type electrode fixing blocks at positions on a driving circuit board, where the first Micro LED chips are mounted, wherein the opposite sides of the P-type electrode fixing blocks and the P-type electrodes are contrary name magnetic poles, and the opposite sides of the N-type electrode fixing blocks and the N-type electrodes are contrary name magnetic poles; placing the driving circuit board and a plurality of first Micro LED chips into the same solution, and fixedly mounting the first Micro LED chips on the driving circuit board under the action of a magnetic force. The mass transfer method disclosed by the invention can implement mass transfer of the Micro LED chips, and does not have the problem that when one chip has defects, all chips need to be replaced; production efficiency is improved; and production cost is reduced.

Owner:HC SEMITEK ZHEJIANG CO LTD

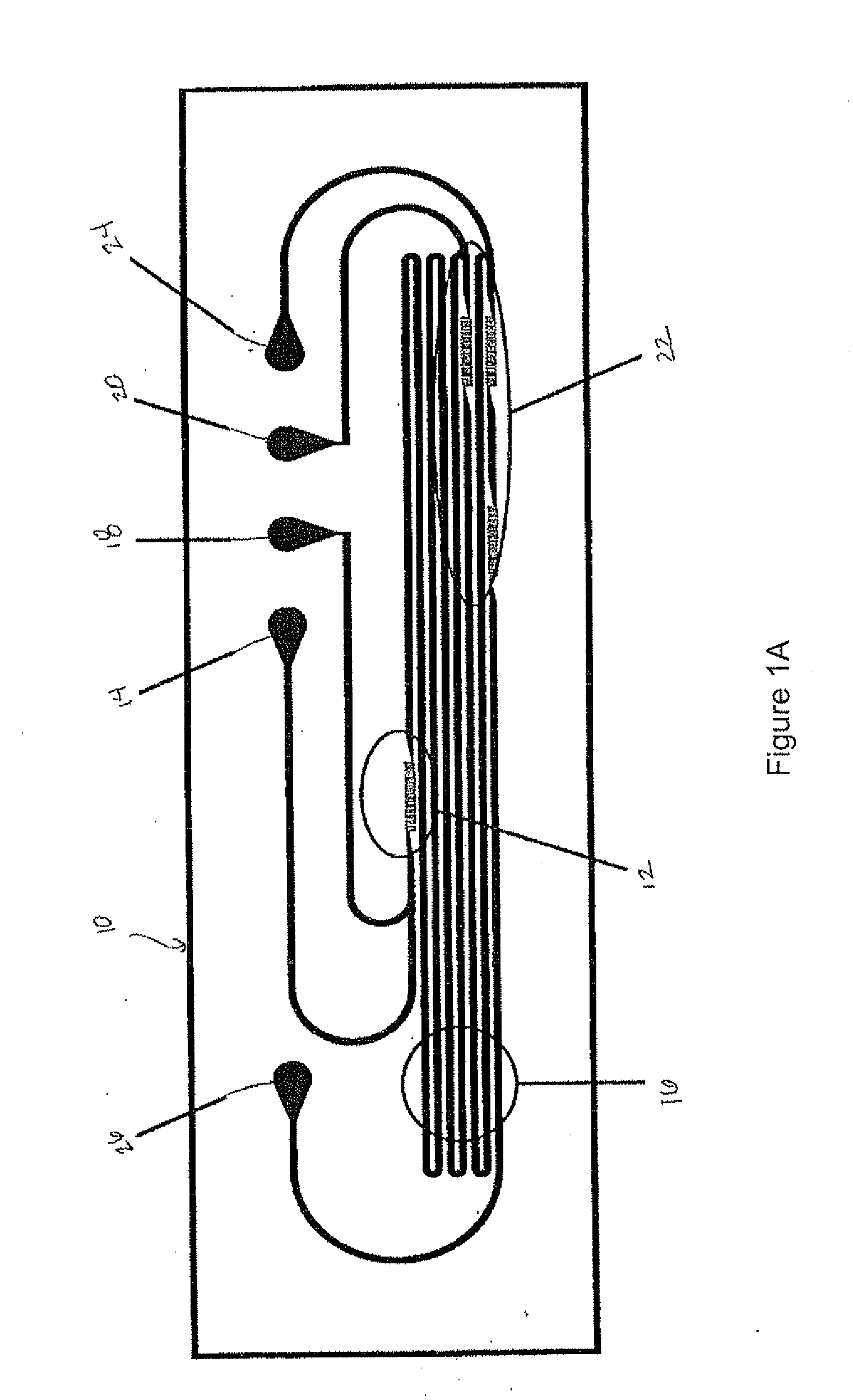

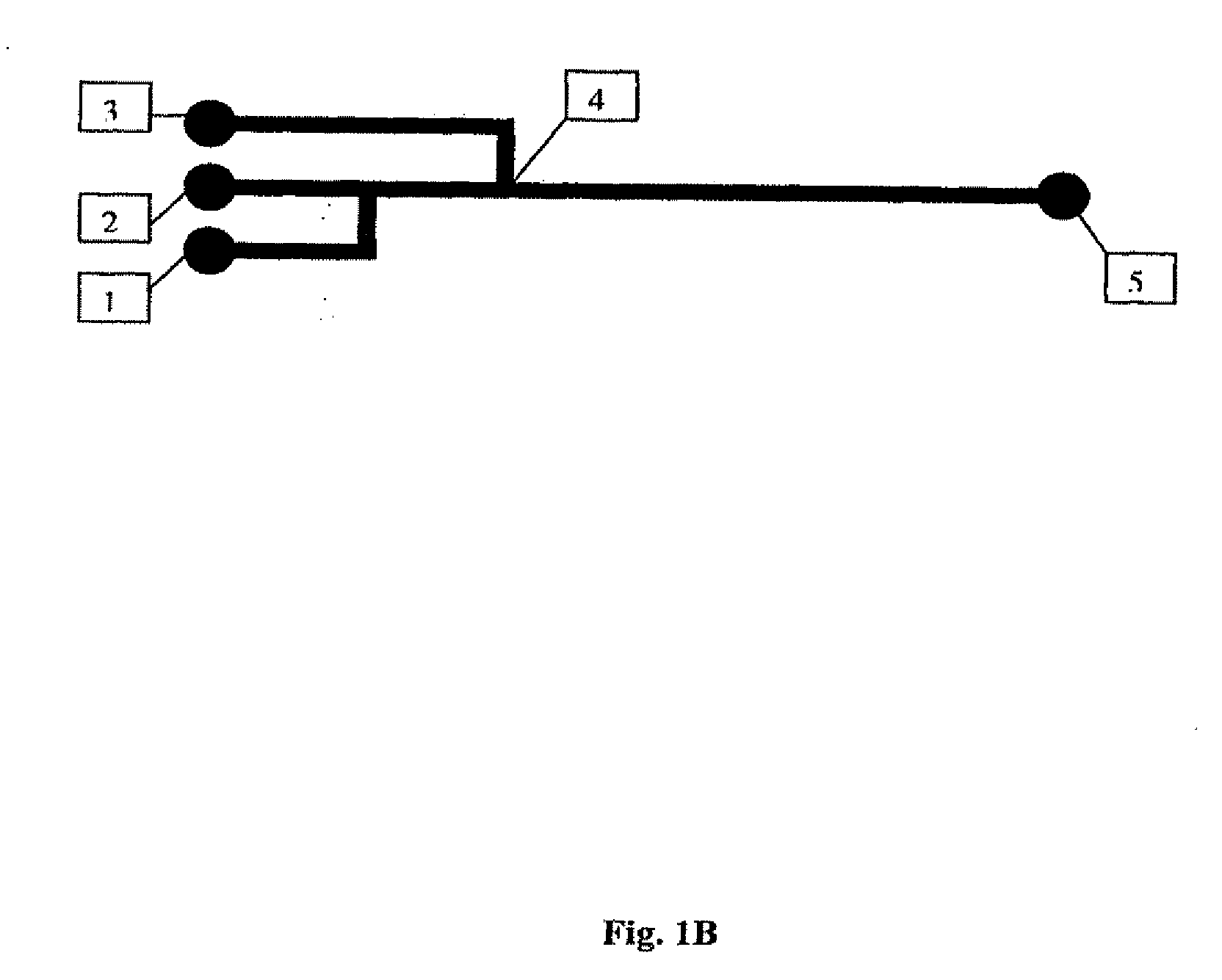

Microchemical method and apparatus for synthesis and coating of colloidal nanoparticles

InactiveUS20080087545A1Aggressive processing conditionsRealize the structureFlow mixersVolume/mass flow measurementCrystallographyBatch processing

The present invention represents a radical departure from most conventional macro-scale batch processing methods employed to synthesize and coat colloidal nanoparticles. Synthesis and coating are in series and in-situ, obviating the need for numerous cumbersome, and often expensive intermediate-processing steps. In one embodiment, the invention is a method and apparatus for synthesizing colloidal nanoparticles. In another embodiment, the invention is a method and apparatus for enabling coating of colloidal nanoparticles using an electrophoretic switch for contacting and separating said colloid nanoparticles.

Owner:MASSACHUSETTS INST OF TECH

Microchemical method and apparatus for synthesis and coating of colloidal nanoparticles

InactiveUS20050016851A1Aggressive processing conditionsHeat massFlow mixersVolume/mass flow measurementNanometreElectrophoresis

The present invention represents a radical departure from most conventional macro-scale batch processing methods employed to synthesize and coat colloidal nanoparticles. Synthesis and coating are in series and in-situ, obviating the need for numerous cumbersome, and often expensive intermediate-processing steps. In one embodiment, the invention is a method and apparatus for synthesizing colloidal nanoparticles. In another embodiment, the invention is a method and apparatus for enabling coating of colloidal nanoparticles using an electrophoretic switch for contacting and separating said colloid nanoparticles.

Owner:JENSEN KLAVS F +1

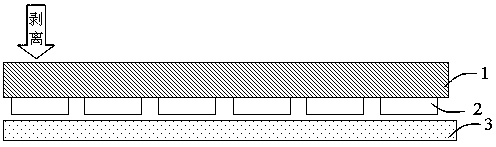

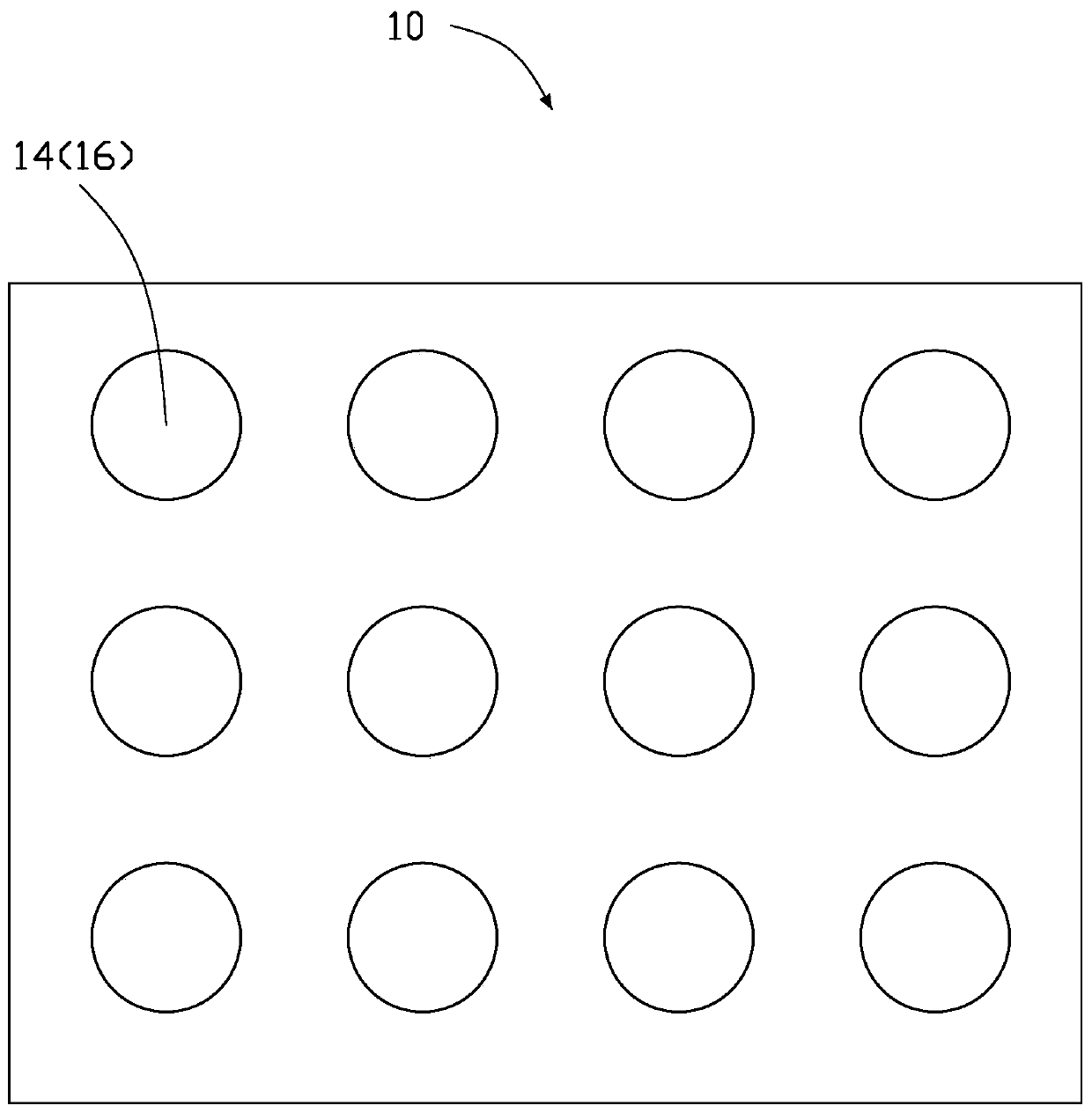

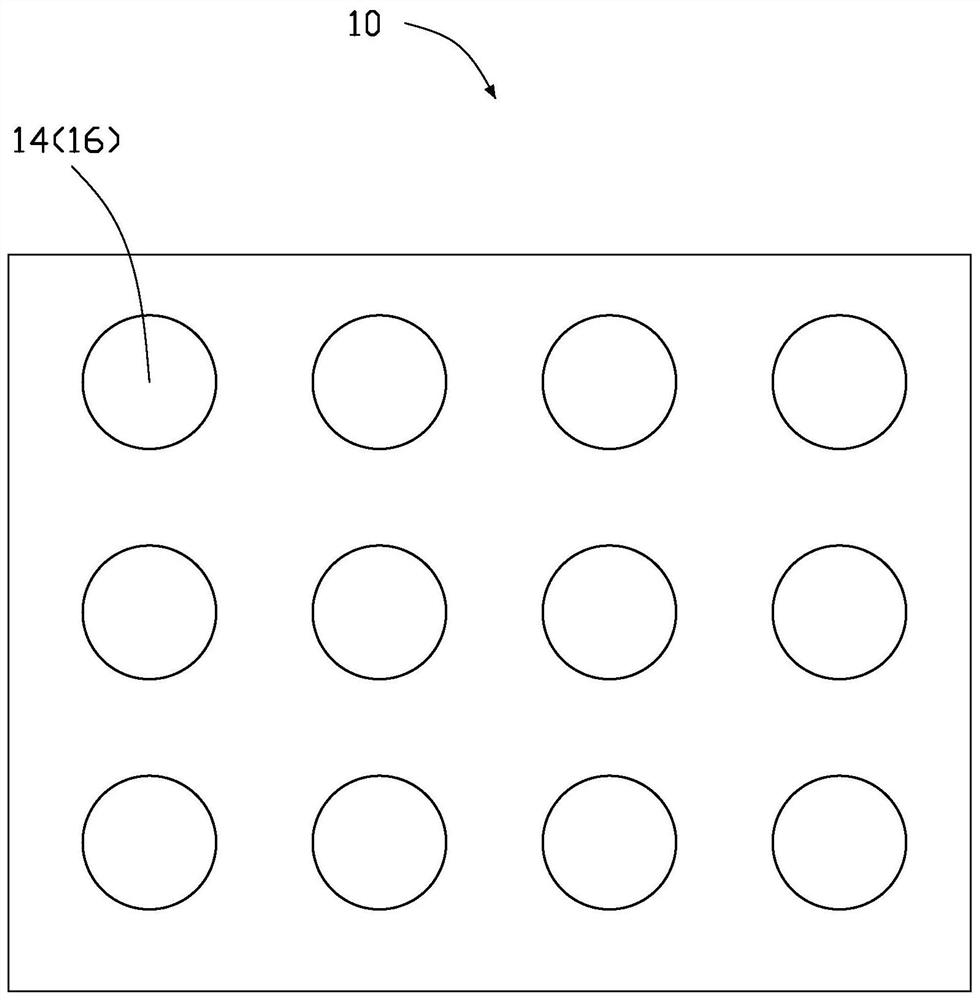

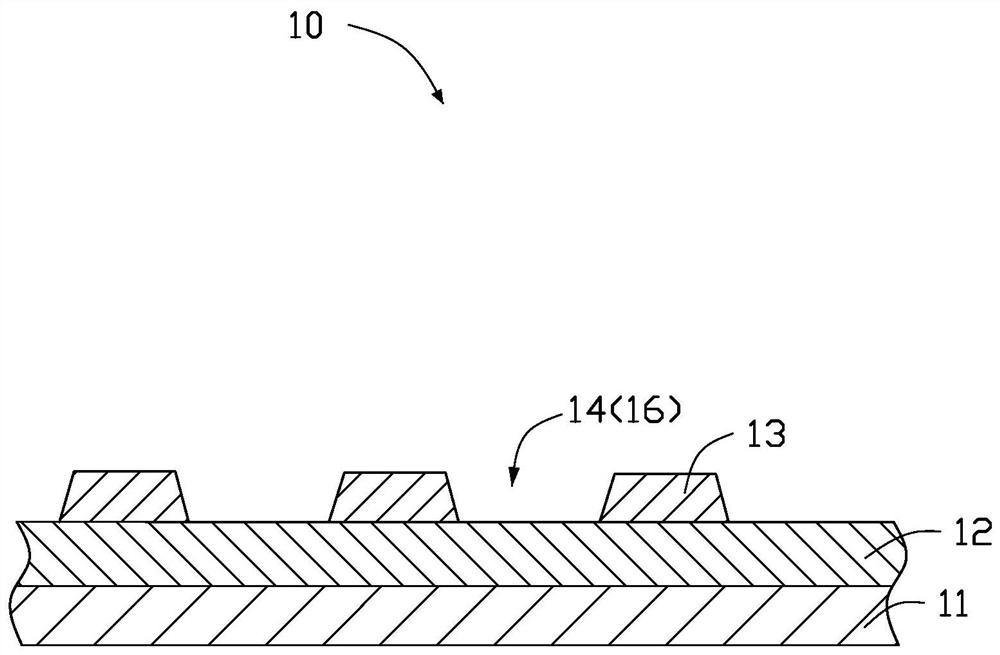

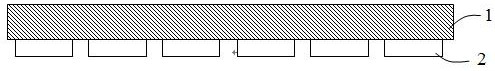

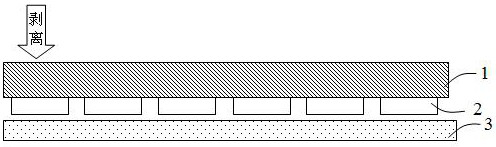

Mass transfer method of micro LED chips

ActiveCN110148655ASimple and fast mass transferHigh precisionSolid-state devicesSemiconductor/solid-state device manufacturingMass transferEngineering

The invention discloses a mass transfer method of micro LED chips, which comprises the steps of preparing micro LED chips on a growth substrate; equipping a temporary carrier with a sticky surface onone side; placing the chips on the surface of the growth substrate towards the temporary carrier, stripping the chips from the growth substrate and dropping the chips to the surface of the temporary carrier; preparing a stamp with a specific material, wherein the surface of the stamp is provided with regularly arranged bumps, and the surfaces of the bumps are sticky; placing the side with bumps ofthe stamp towards the surface of the temporary carrier, carrying out UV irradiating or heating on the temporary carrier, and enabling the bumps in the stamp to take down the corresponding chips fromthe surface of the temporary carrier; placing the stamp with the chips towards a target substrate, transferring the chips to the surface of the target substrate by means of bonding, and carrying out UV irradiating or heating on the bumps on the stamp so as to remove the stamp; and repeating the steps S2-S6 until the mass transfer of the chips is completed. The mass transfer method is simple and convenient, can achieve the purpose without complex equipment and saves a lot of cost.

Owner:北京易美新创科技有限公司

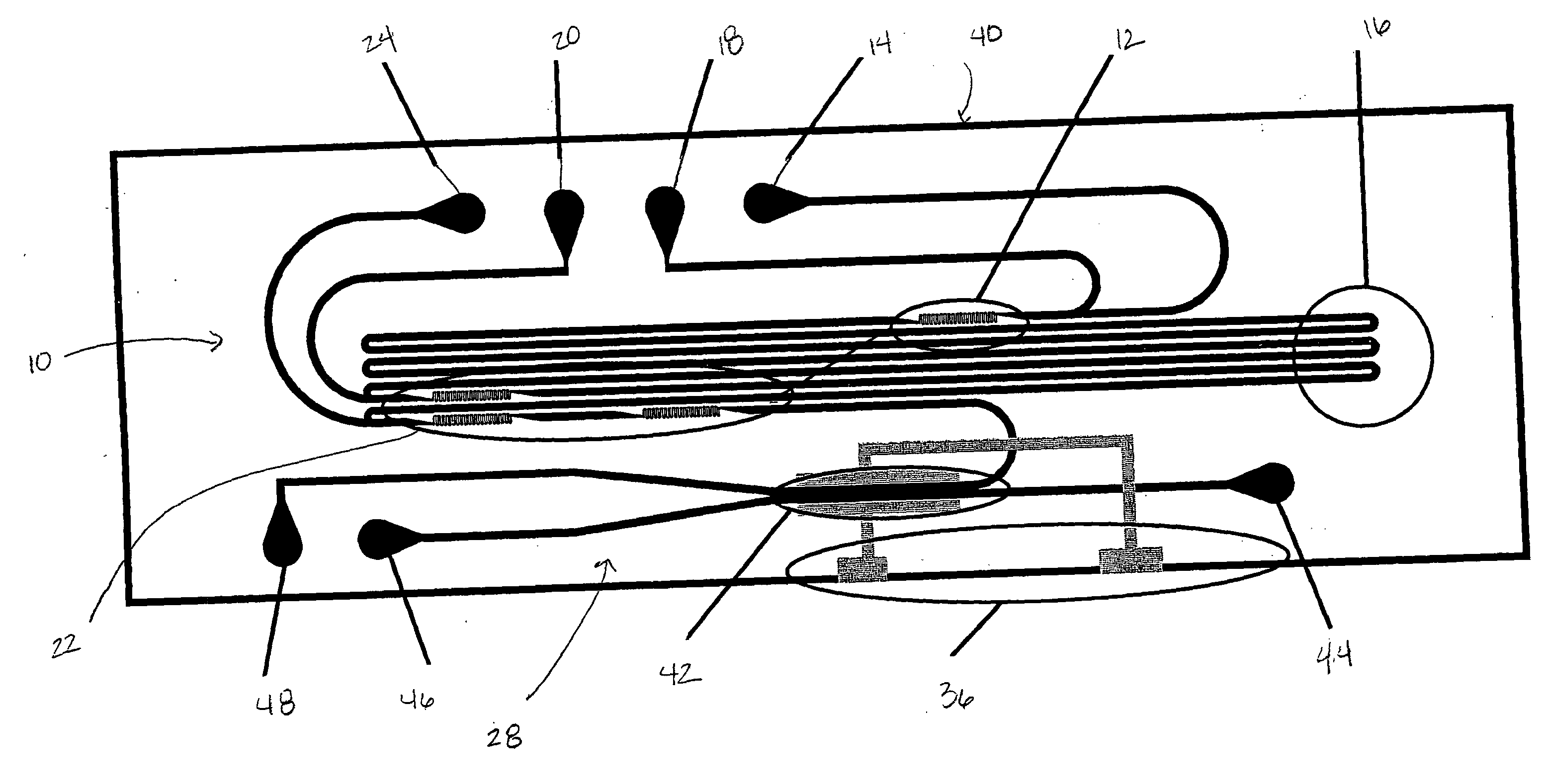

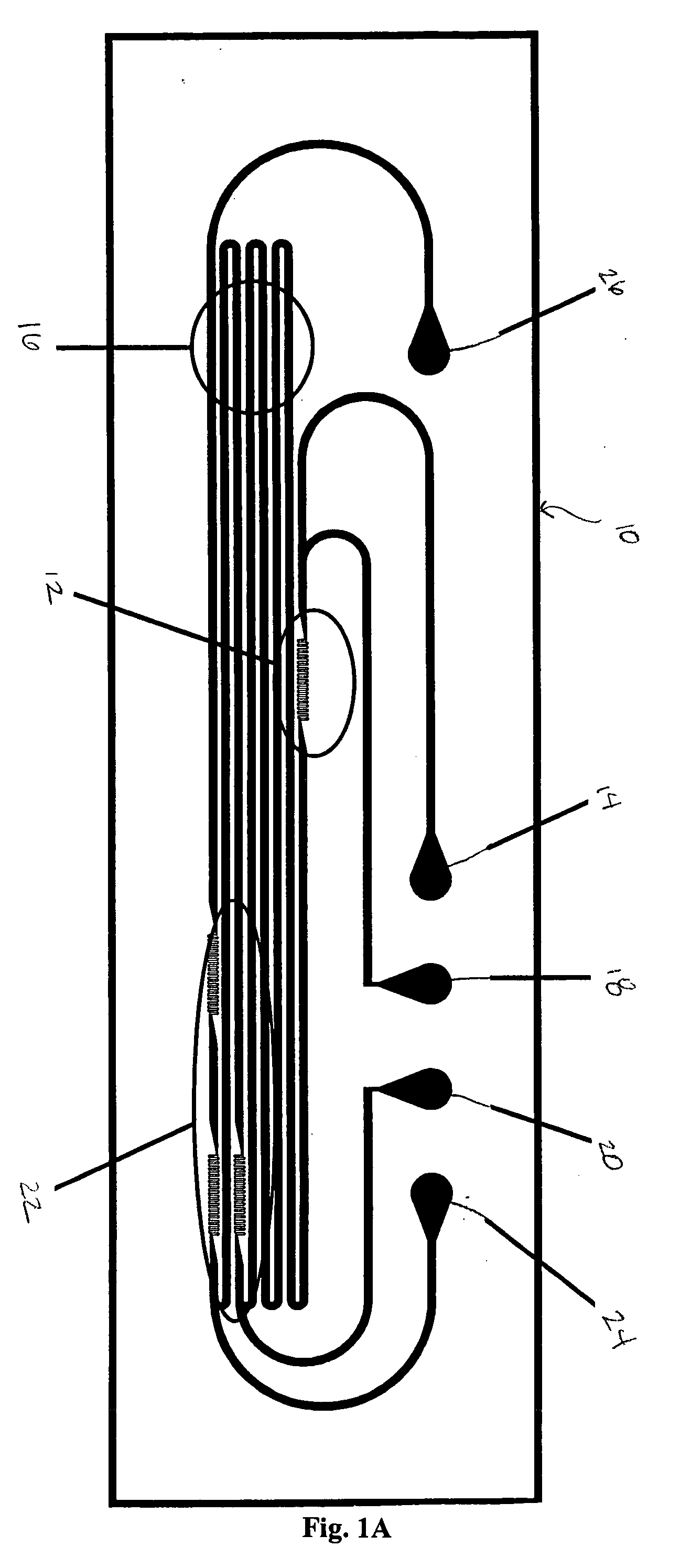

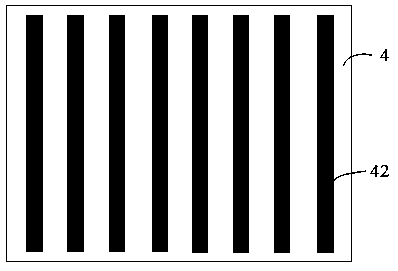

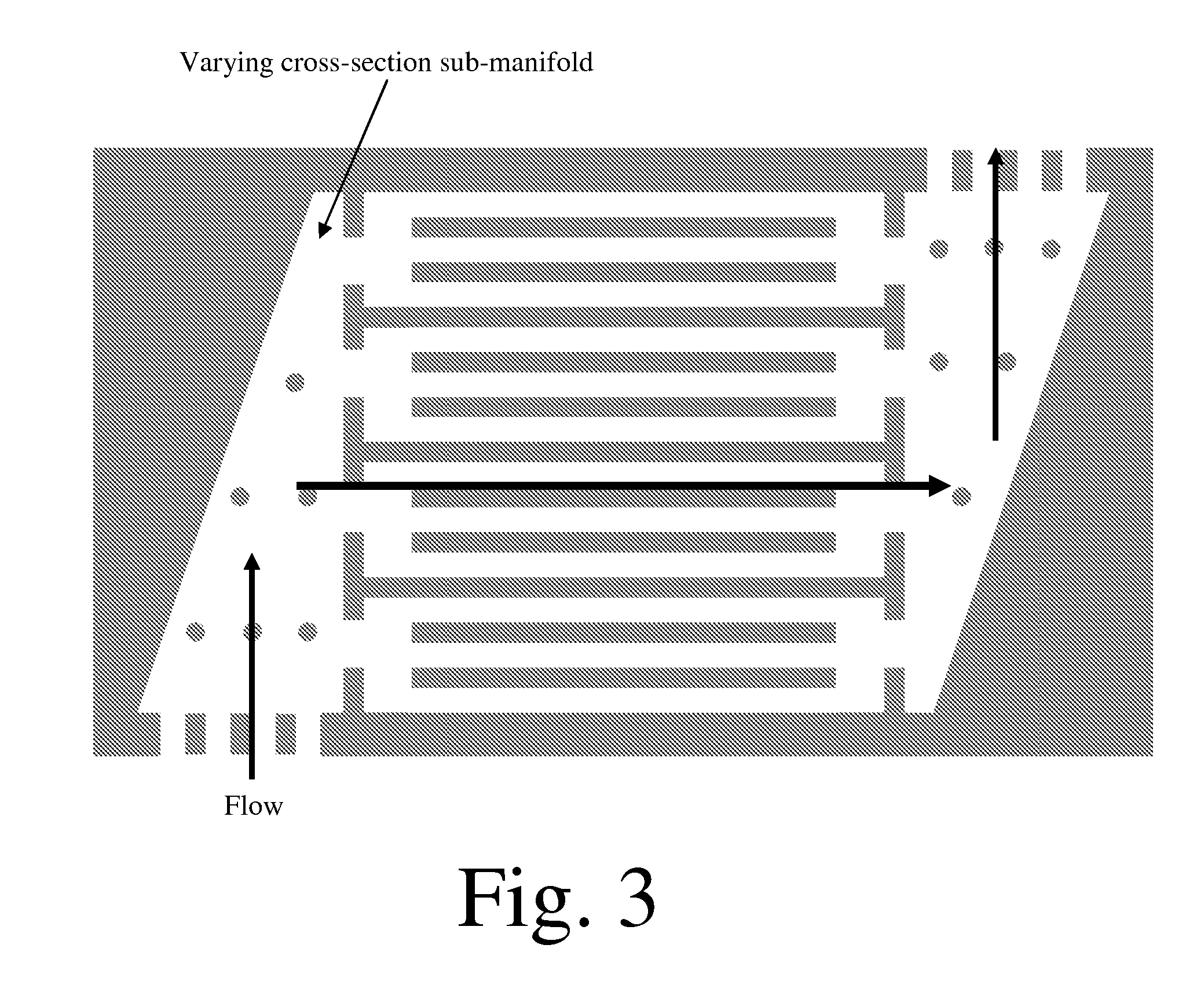

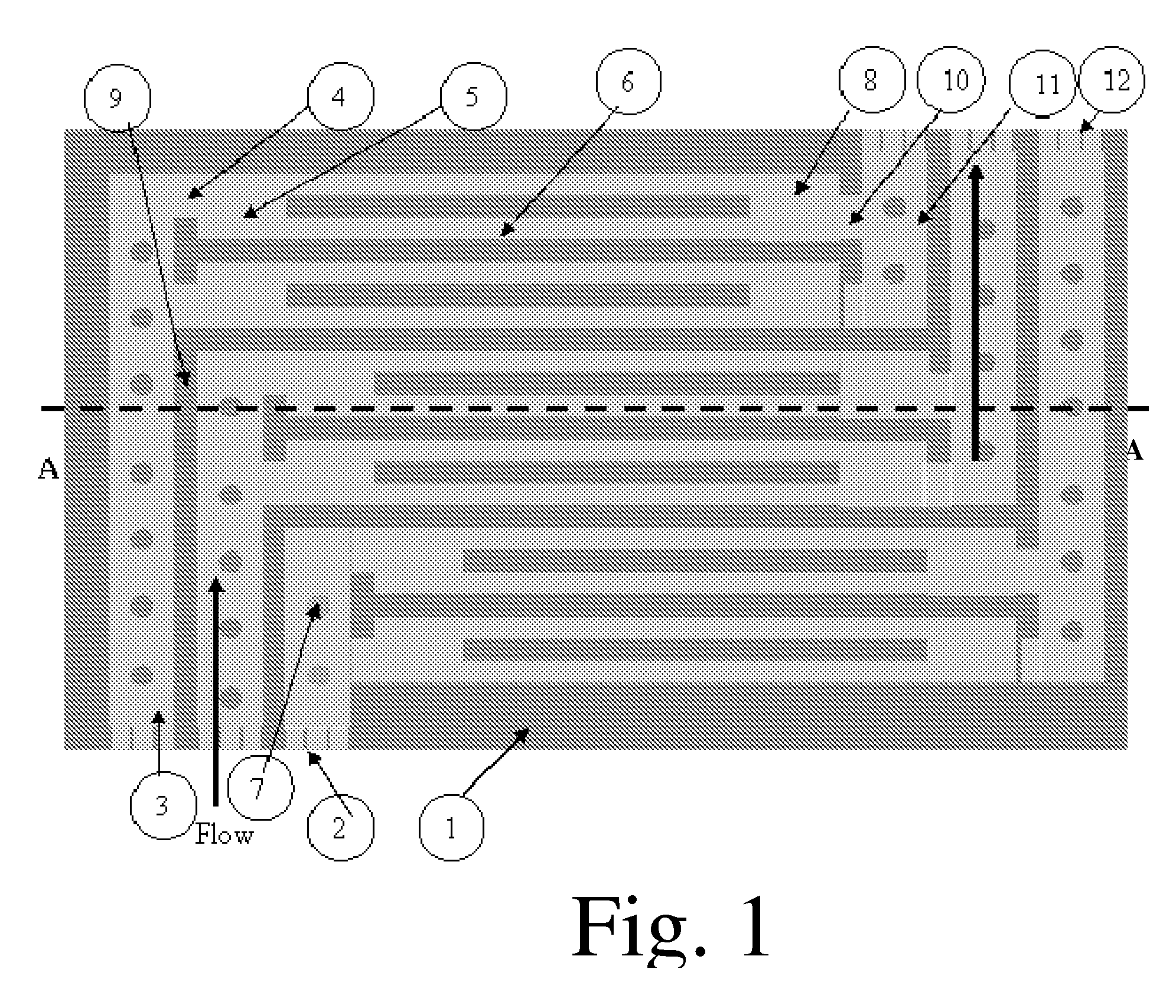

Microchannel Apparatus and Methods Of Conducting Unit Operations With Disrupted Flow

InactiveUS20070298486A1Heat transfer coefficientMaximize heat transferBioreactor/fermenter combinationsBiological substance pretreatmentsHeat fluxUnit operation

The invention described herein concerns microchannel apparatus that contains, within the same device, at least one manifold and multiple connecting microchannels that connect with the manifold. For superior heat or mass flux in the device, the volume of the connecting microchannels should exceed the volume of manifold or manifolds. Methods of conducting unit operations in microchannel devices having simultaneous disrupted and non-disrupted flow through microchannels is also described.

Owner:VELOCYS CORPORATION

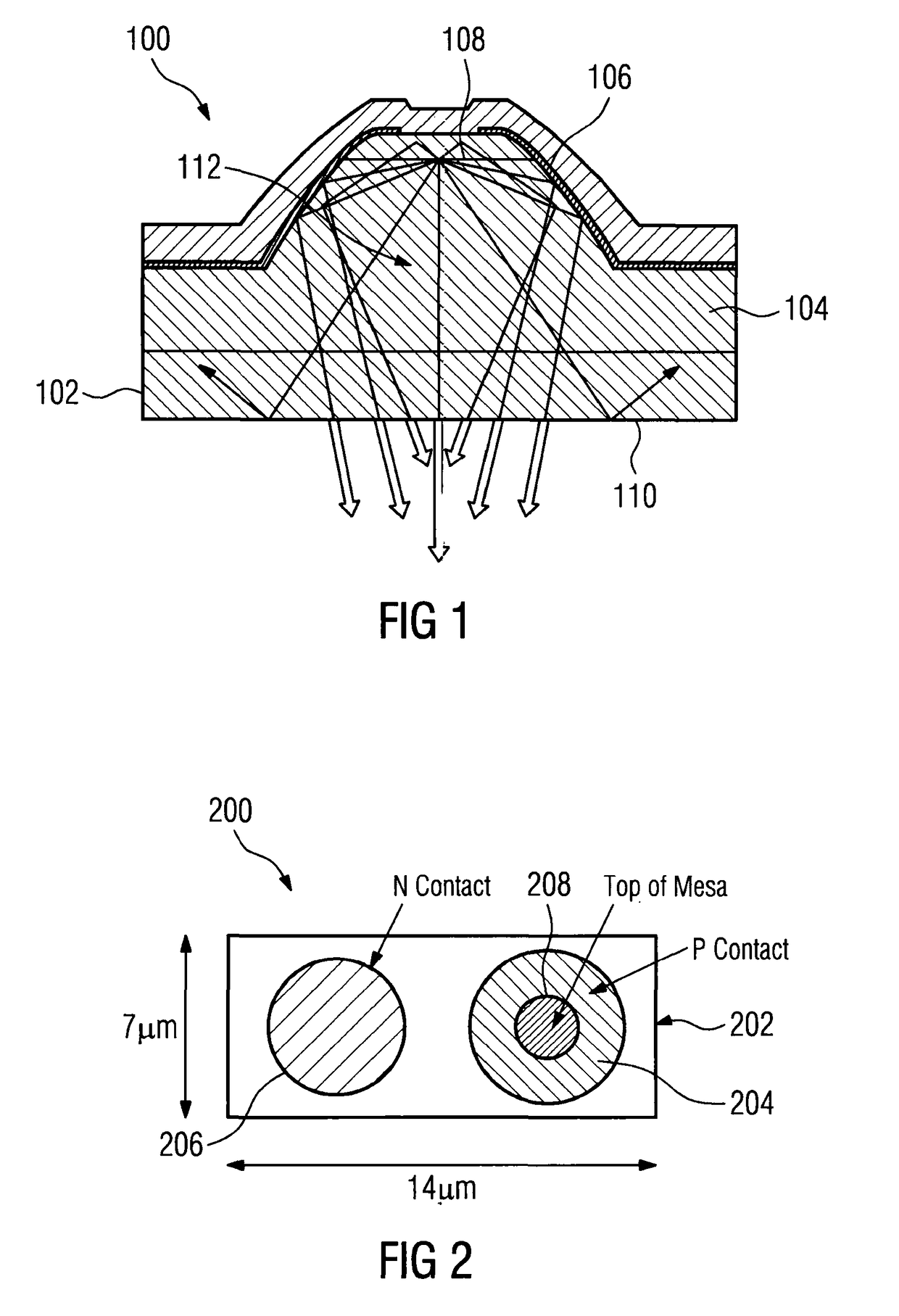

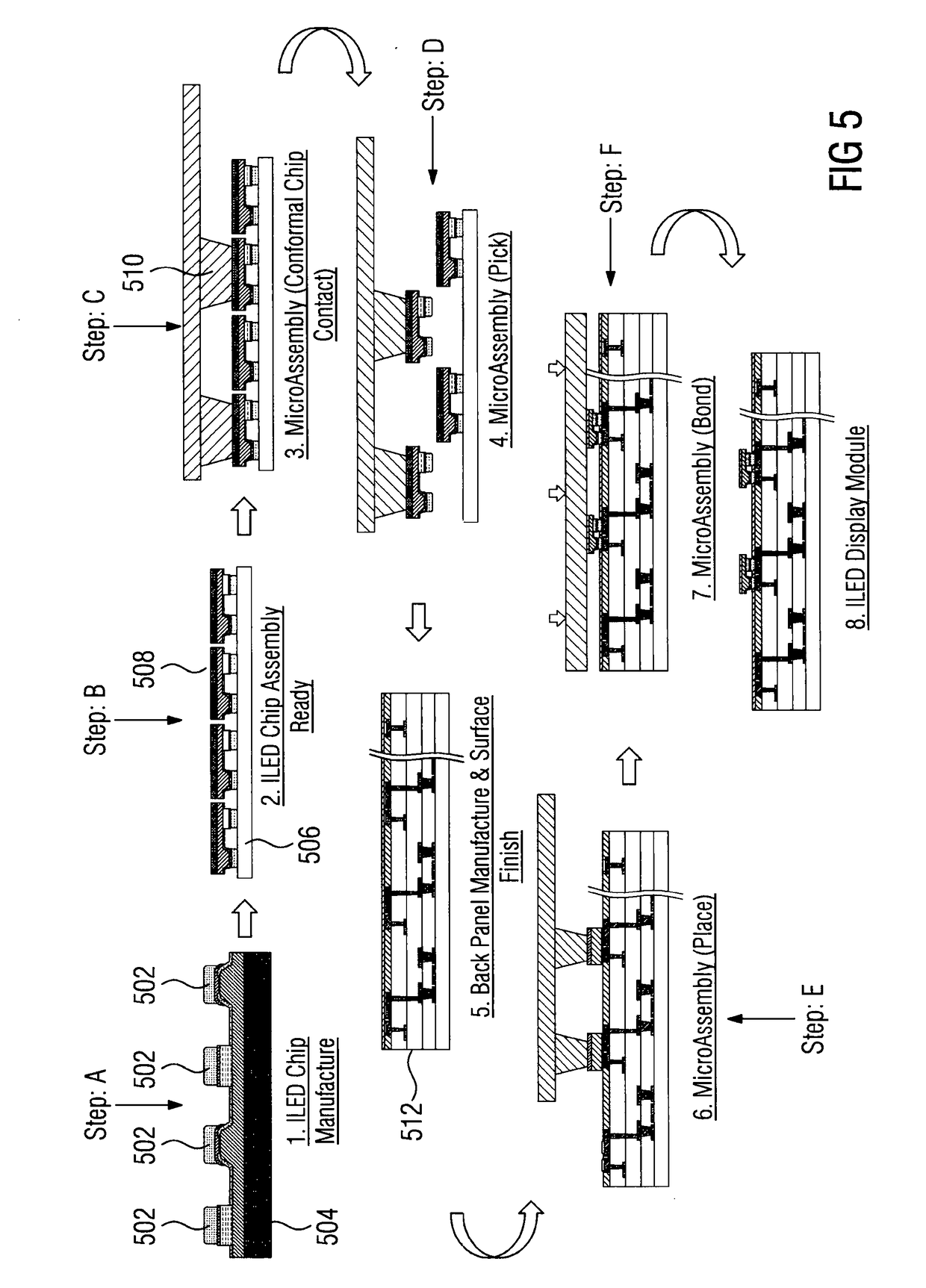

Assembly of semiconductor devices

ActiveUS20190027075A1High resolutionImprove throughputSemiconductor/solid-state device testing/measurementStatic indicating devicesEngineeringSemiconductor

Owner:META PLATFORMS TECH LLC

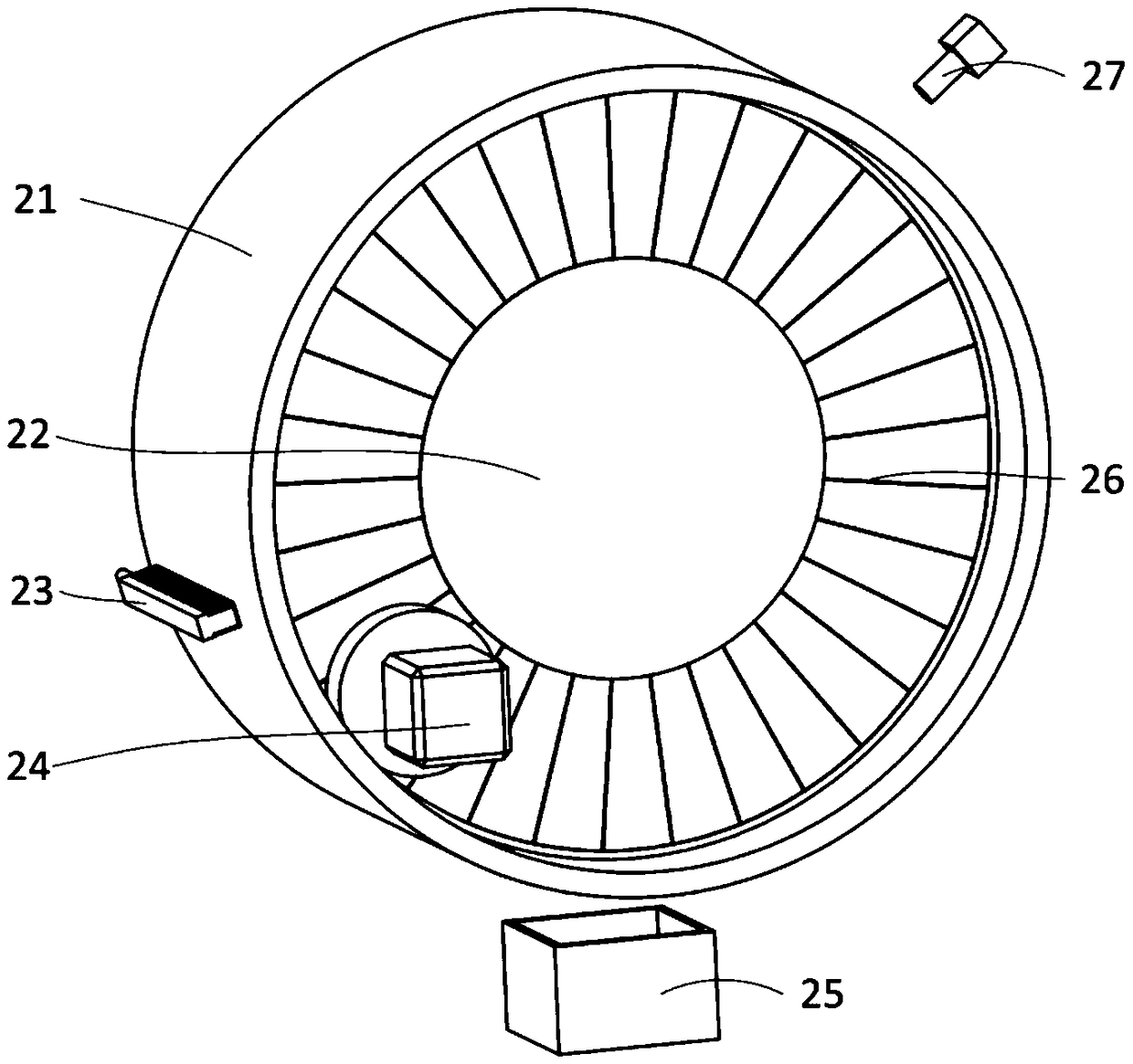

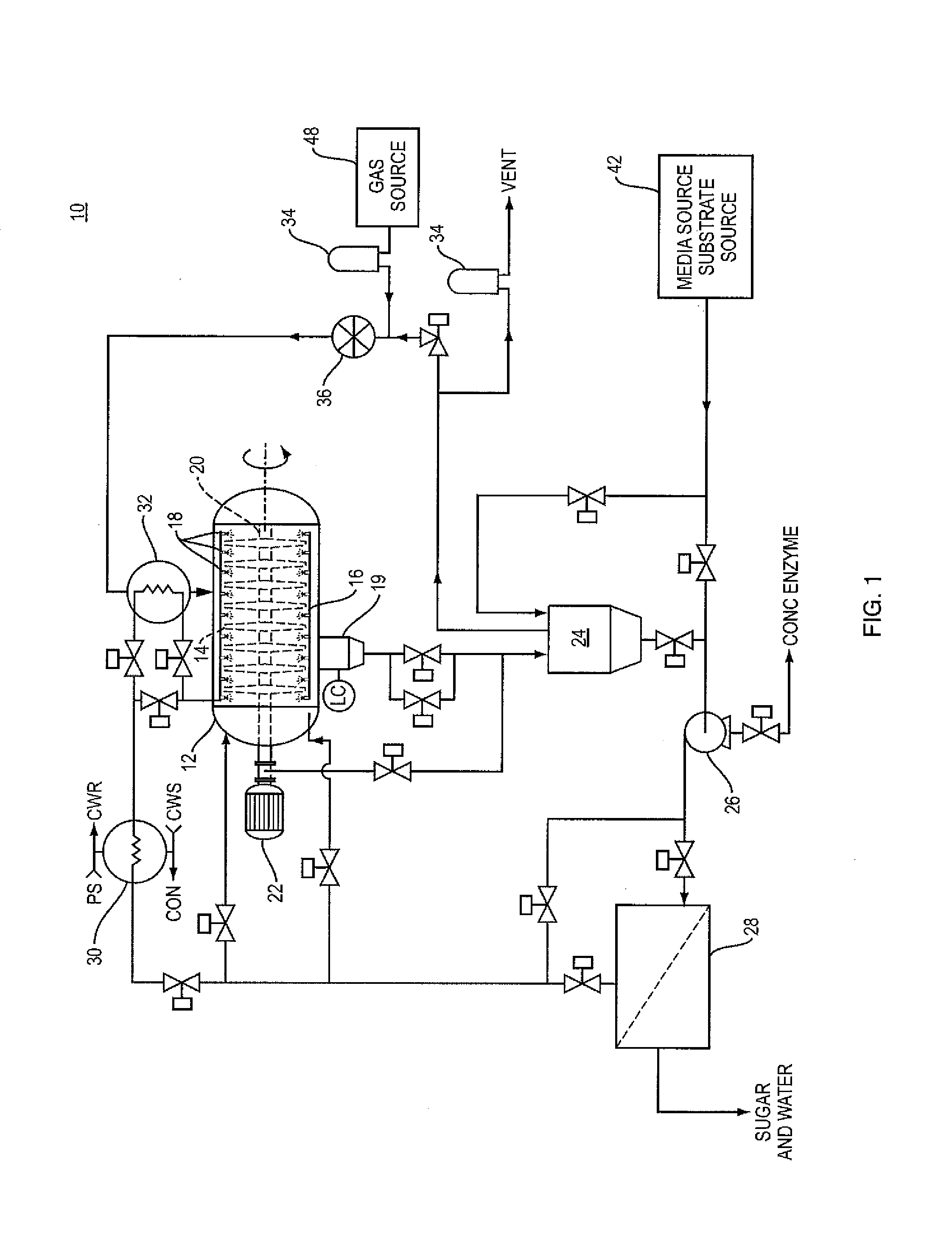

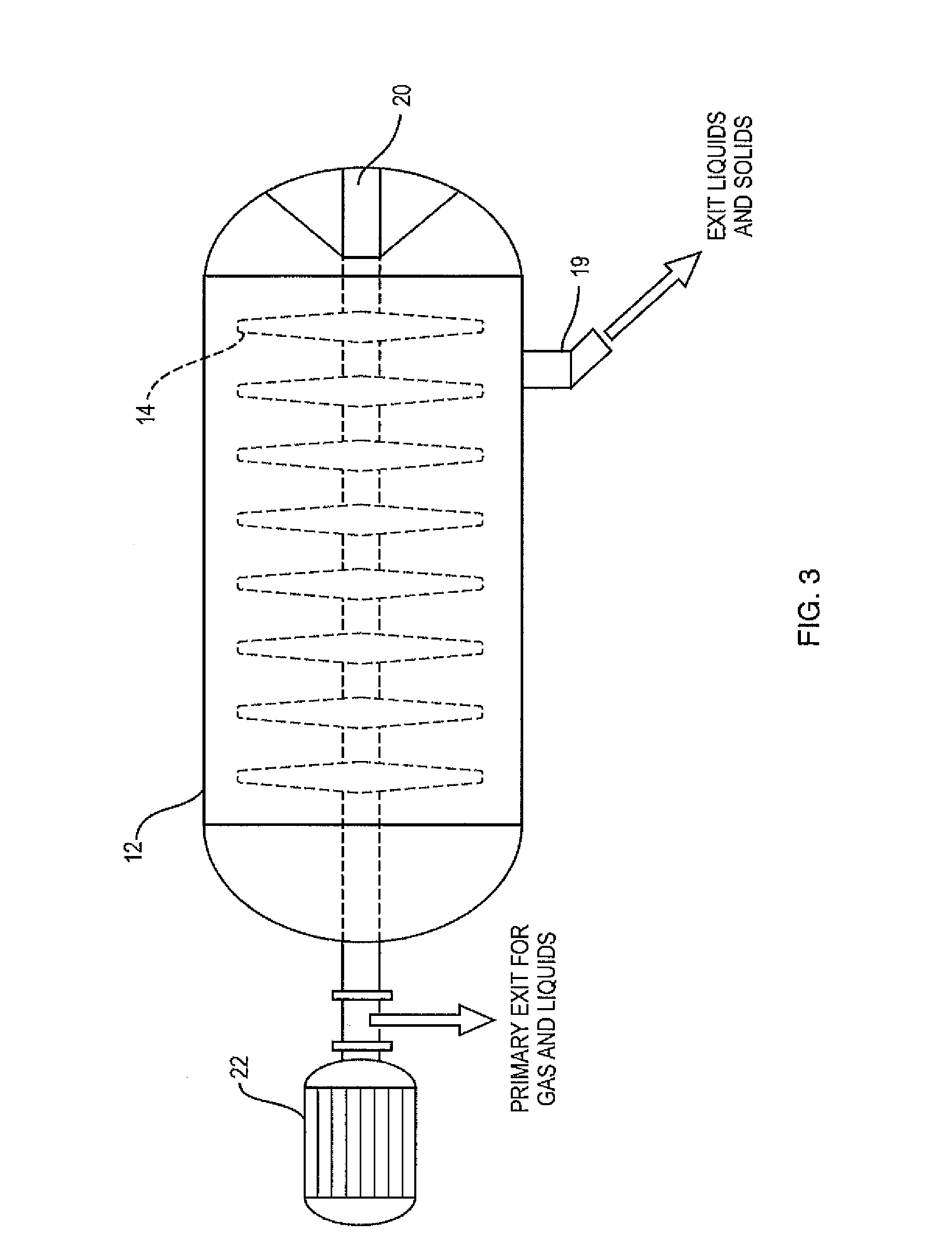

System and method for producing biomaterials

InactiveUS20110195462A1Suitable for useEffective drainageBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismChitin formation

A bioreactor system for manufacturing and extracting a desired biomaterial from a microorganism by fermenting the microorganism in the bioreactor. The system includes a horizontal reactor vessel, one or more vertical discs rotatably mounted around a hollow shaft, a motor to power the shaft, and one or more spray nozzles arranged to spray required liquids on to the discs. The system is arranged so that the microorganism is not kept submerged within the reactor vessel during the fermentation process. The system is suitable for any type of microorganism, including fungi and bacteria, and can be modified to produce many types of desired biomaterials, including antibiotics, enzymes, ethanol, butanol, chitin, and chitosan. The method of the present invention generally provides steps for placing substrate on the vertical discs of the reactor vessel, inoculating the discs, introducing media, fermenting the microorganism, and extracting the desired biomaterial from the reactor vessel.

Owner:RENEWABLE PROCESS TECH

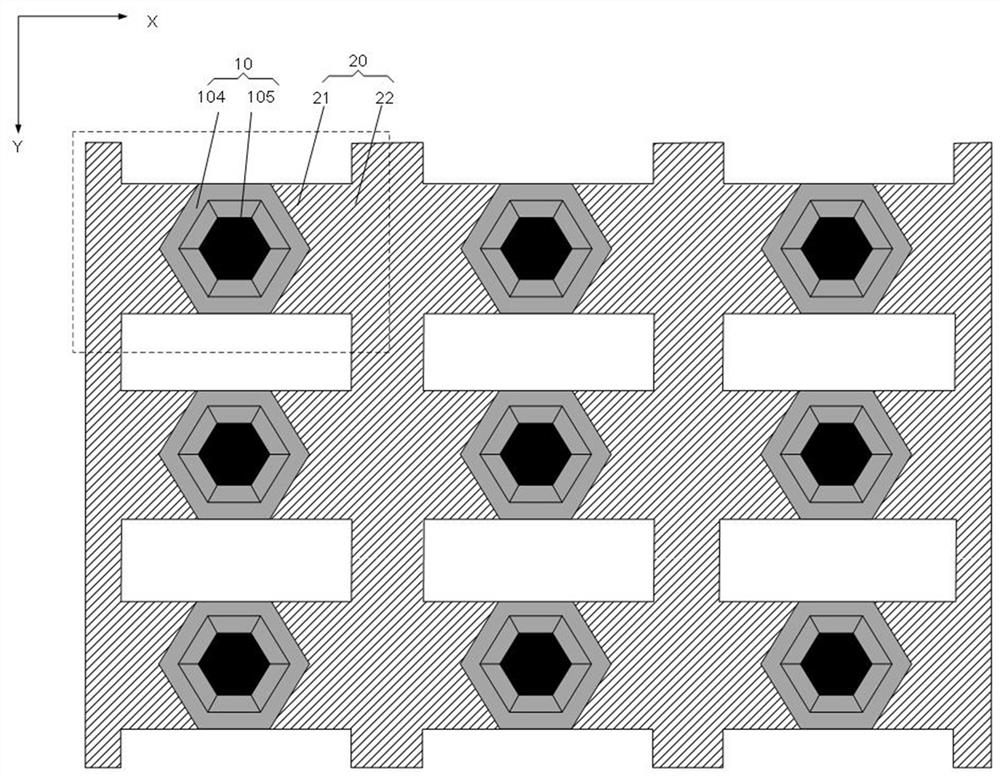

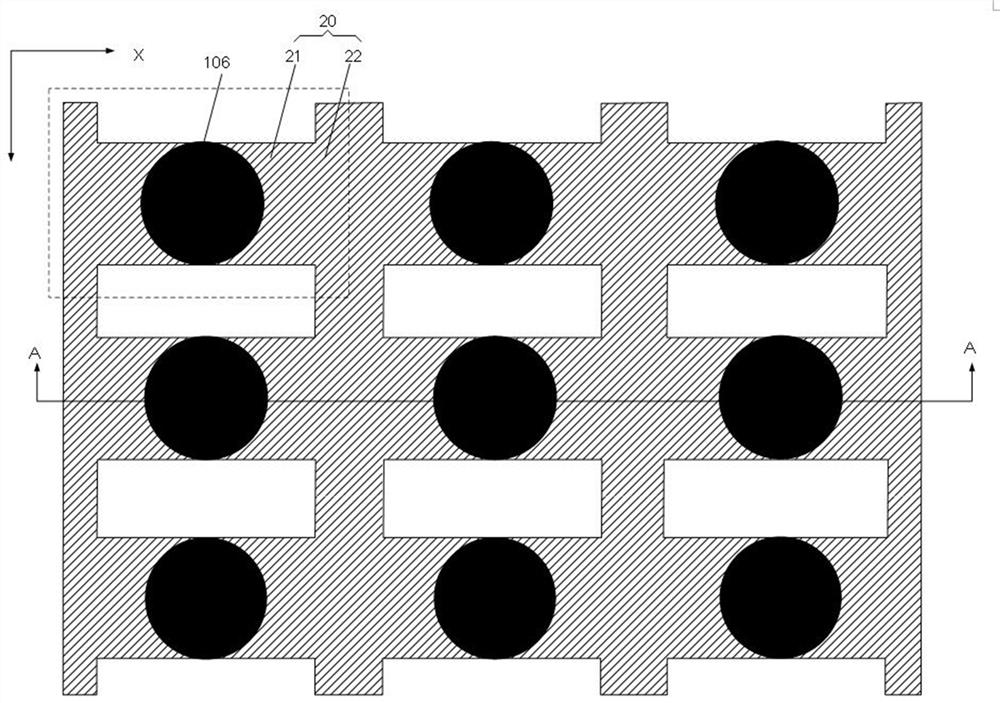

Microelement capable of being tested and micro-transferred, manufacturing, testing and transferring method of microelement and display device

PendingCN111933627AAchieving current extensionImprove light extraction efficiencySemiconductor/solid-state device testing/measurementSolid-state devicesDisplay devicePhysics

The invention provides a microelement capable of being tested and micro-transferred, a manufacturing, testing and transferring method of the microelement and a display device. A first electrode and asecond electrode of a LED chip extend to the surface of a bonding layer corresponding to a groove through the side wall of the LED chip respectively, so that the first electrode and the second electrode are exposed above the groove and play a role in supporting the LED chip in an inverted suspended state. And meanwhile, the first test electrode and the second test electrode can be used for carrying out an electrical test before the LED core particles are transferred, so that the yield screening of the LED core particles is realized, the LED core particles with abnormal electrical properties are prevented from being transferred to the substrate, and the repair cost is further reduced. And then, in a subsequent transfer process, metal of the first electrode and the second electrode exposed above the groove can be used as a chain for mass transfer, an exposed bonding layer is used as an anchor, and the micro-element is positioned to each anchor through transfer equipment, so that mass transfer of the micro-element can be realized.

Owner:XIAMEN QIANZHAO SEMICON TECH CO LTD

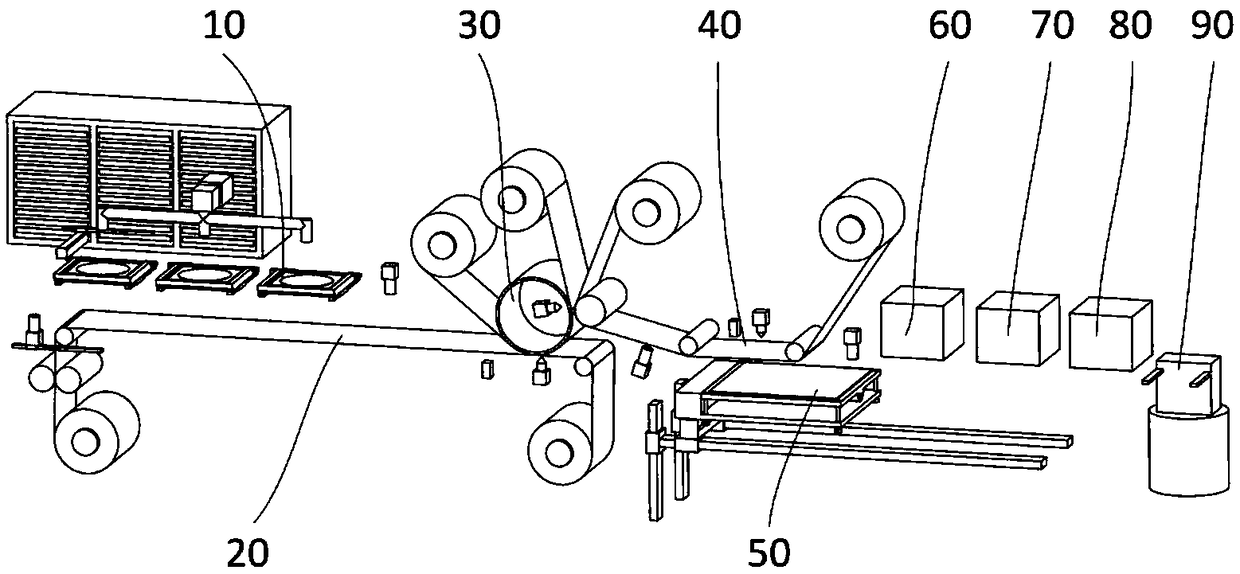

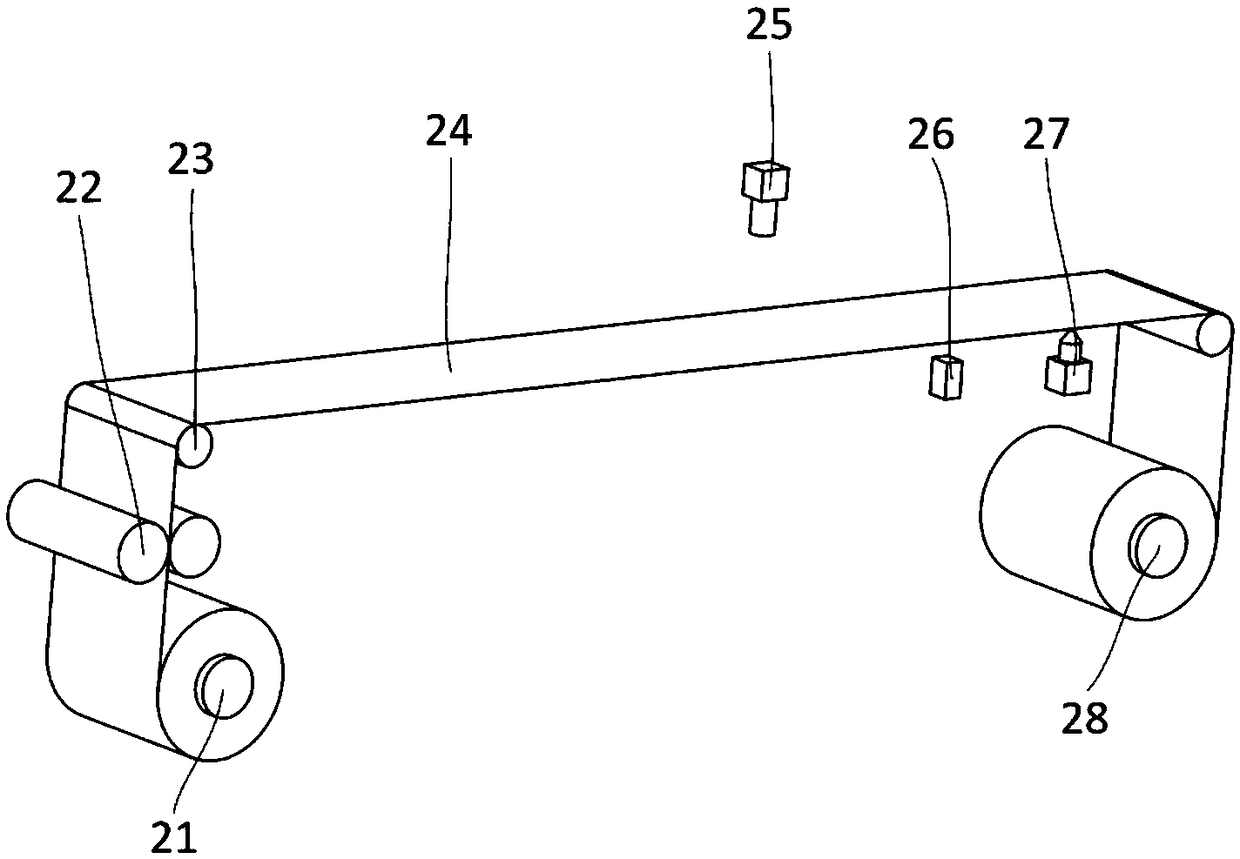

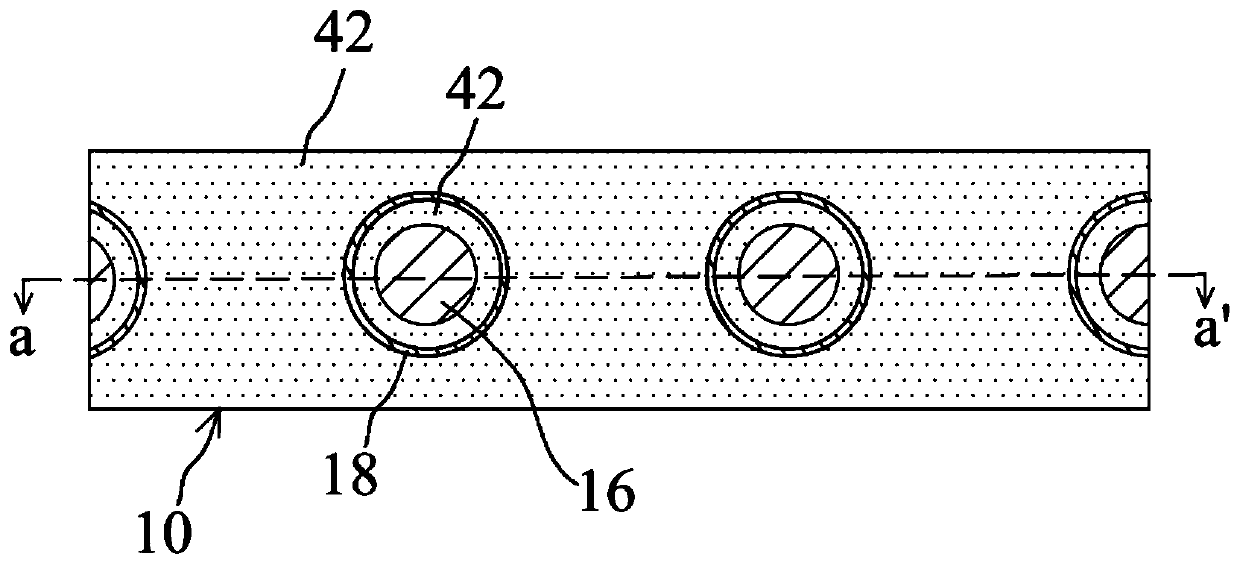

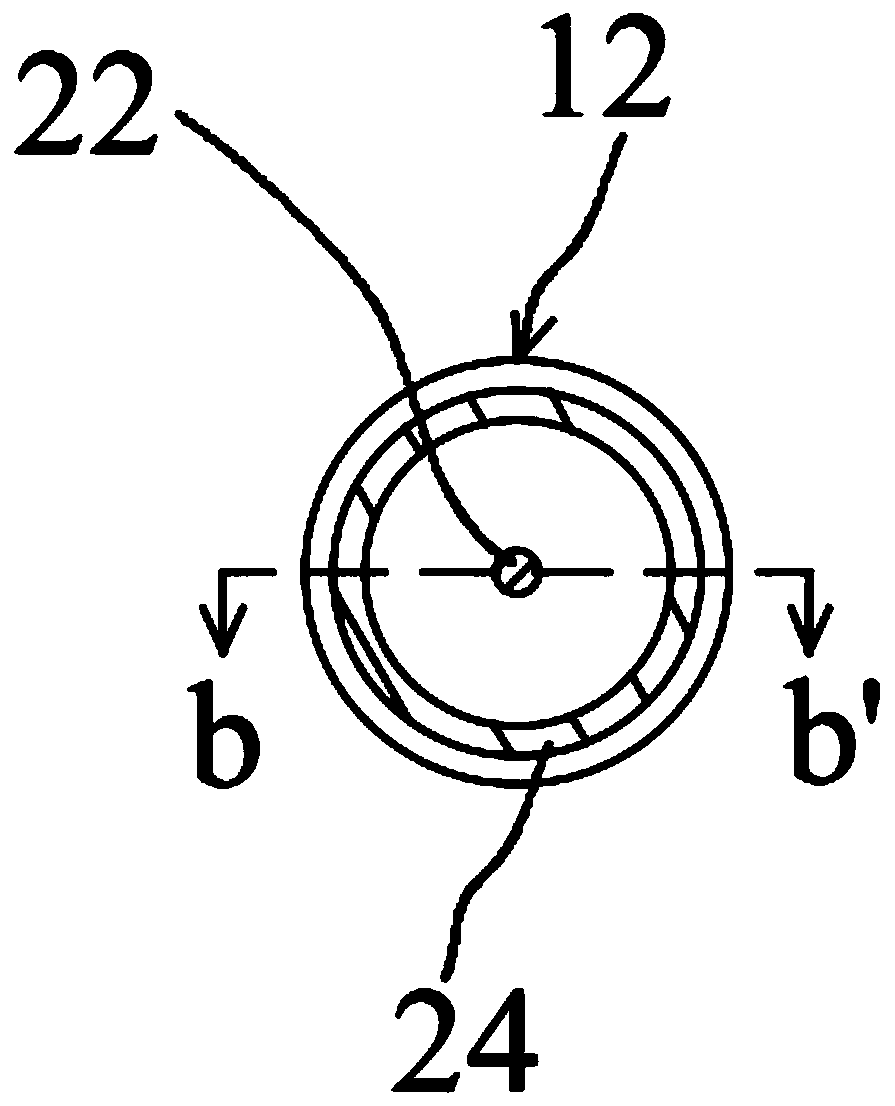

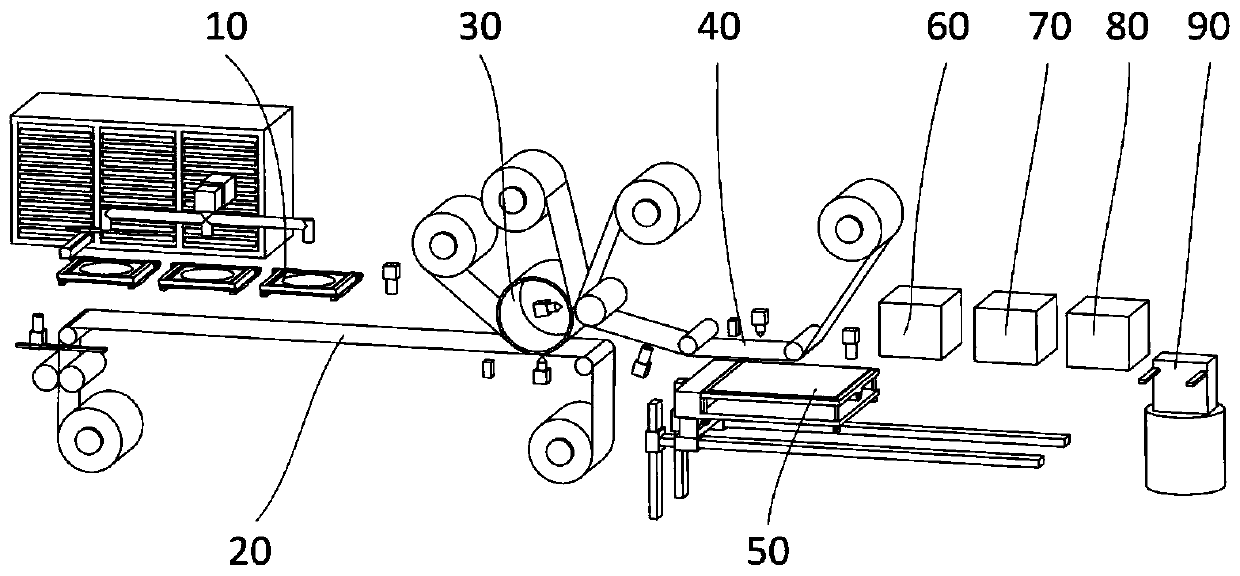

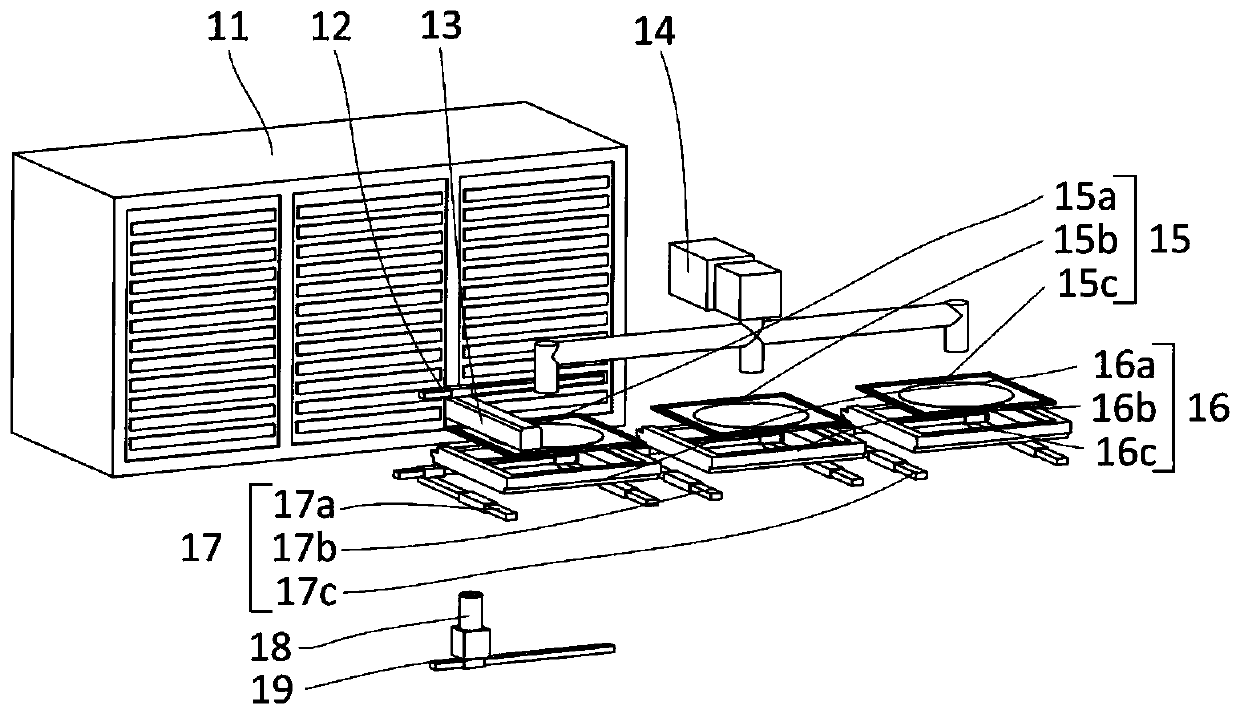

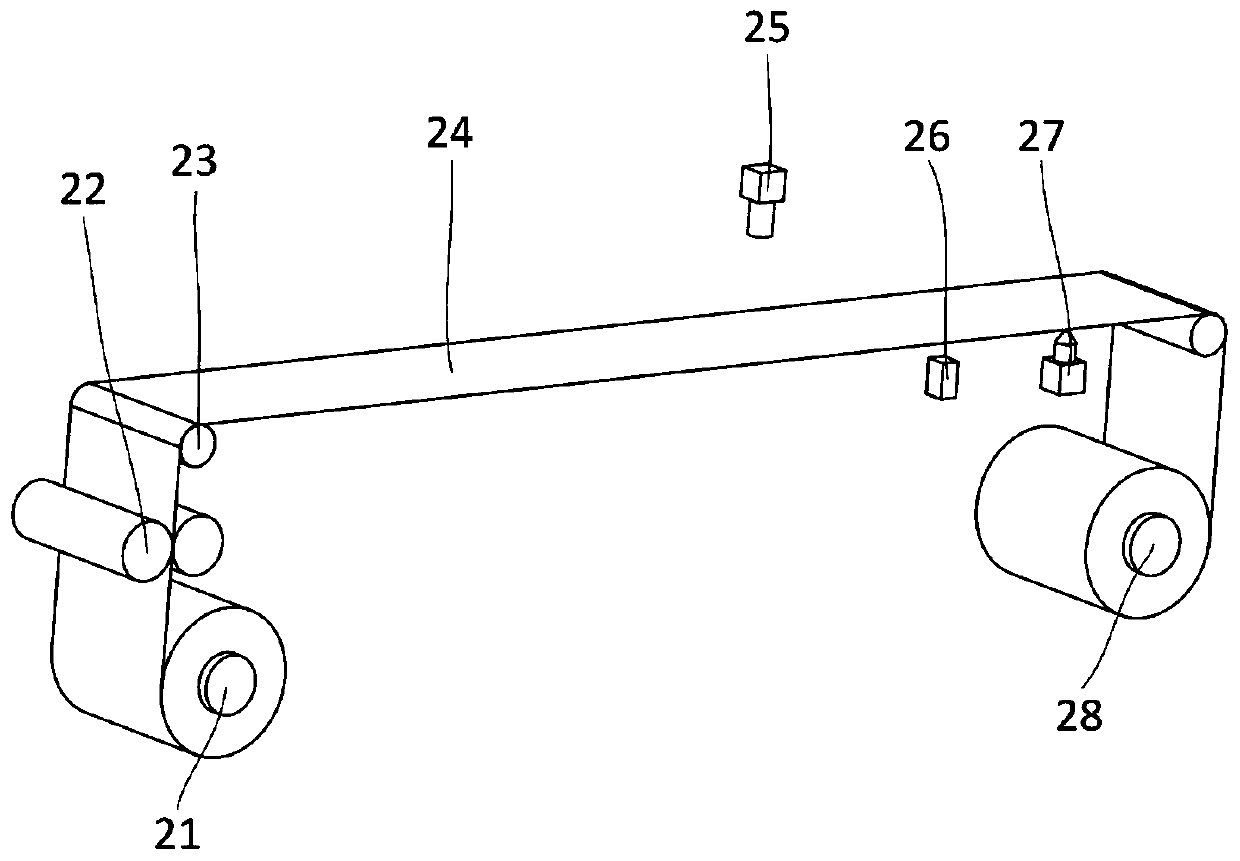

A micro device laser peeling huge quantity transfer device and method based on winding process

ActiveCN109244196AIncrease productivityReduce manufacturing costSemiconductor/solid-state device manufacturingConveyor partsLaser technologyEngineering

The invention belongs to the technical field of semiconductors, and particularly discloses a micro device laser peeling huge quantity transfer device and method based on winding process, The inventioncomprises a micro device stripping and transferring module, an auxiliary tape carrying module, a transition tape carrying module, a transfer tape carrying module, a substrate carrying module, a microdevice filling module, a curing module, a packaging module and a substrate transferring module, wherein the micro device stripping and transferring module is used for realizing the detection and stripping of the micro device; The auxiliary tape module is used to adhere the stripping micro-device; The transition tape module is used for picking up the micro device and transferring it to the transfer tape module. The transfer tape module is used for picking up the micro device and transferring it to the substrate carrying module. A substrate carry module is used for pas that micro device into afilling module, a curing module, a packaging module and a substrate handling module to realize filling, curing, packaging and loading and unloading. The invention realizes the massive transfer of themicro device by using the winding process and the laser technology, and has the advantages of high production efficiency, low production cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of light emitting display

ActiveCN109888067AMass transferReached transferSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention discloses a preparation method of a light emitting display. The preparation method comprises the steps of providing a packaging substrate, sinking the packaging substrate into a suspension, sinking a plurality of light emitting diodes into the suspension, and horizontally injecting the suspension, wherein a plurality of recesses are arranged at the top of the packaging substrate; each recess is provided with a first electrode region and a second electrode region in different height; the light emitting diodes are provided with planes and curved surfaces; the suspension has different flow rates on the planes and the curved surfaces of the light emitting diodes; all the light emitting diodes are respectively embedded into all the recesses according to the different flow rates; and each light emitting diode is electrically connected with the first electrode region and the second electrode region of the corresponding recess to form the light emitting display. According to thepreparation method, the packaging substrate and the light emitting diodes are assembled according to a bernoullis theorem on the premise that no damage is caused to the packaging substrate or the light emitting diodes.

Owner:INTERFACE TECH CHENGDU CO LTD +2

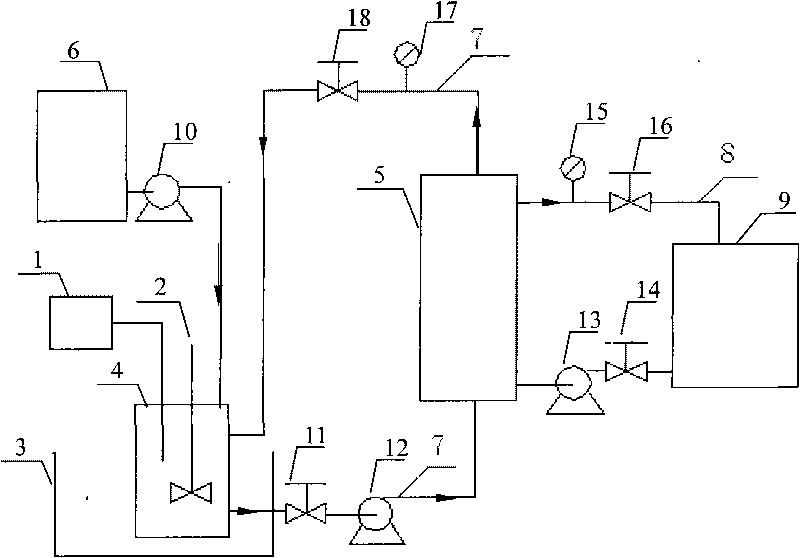

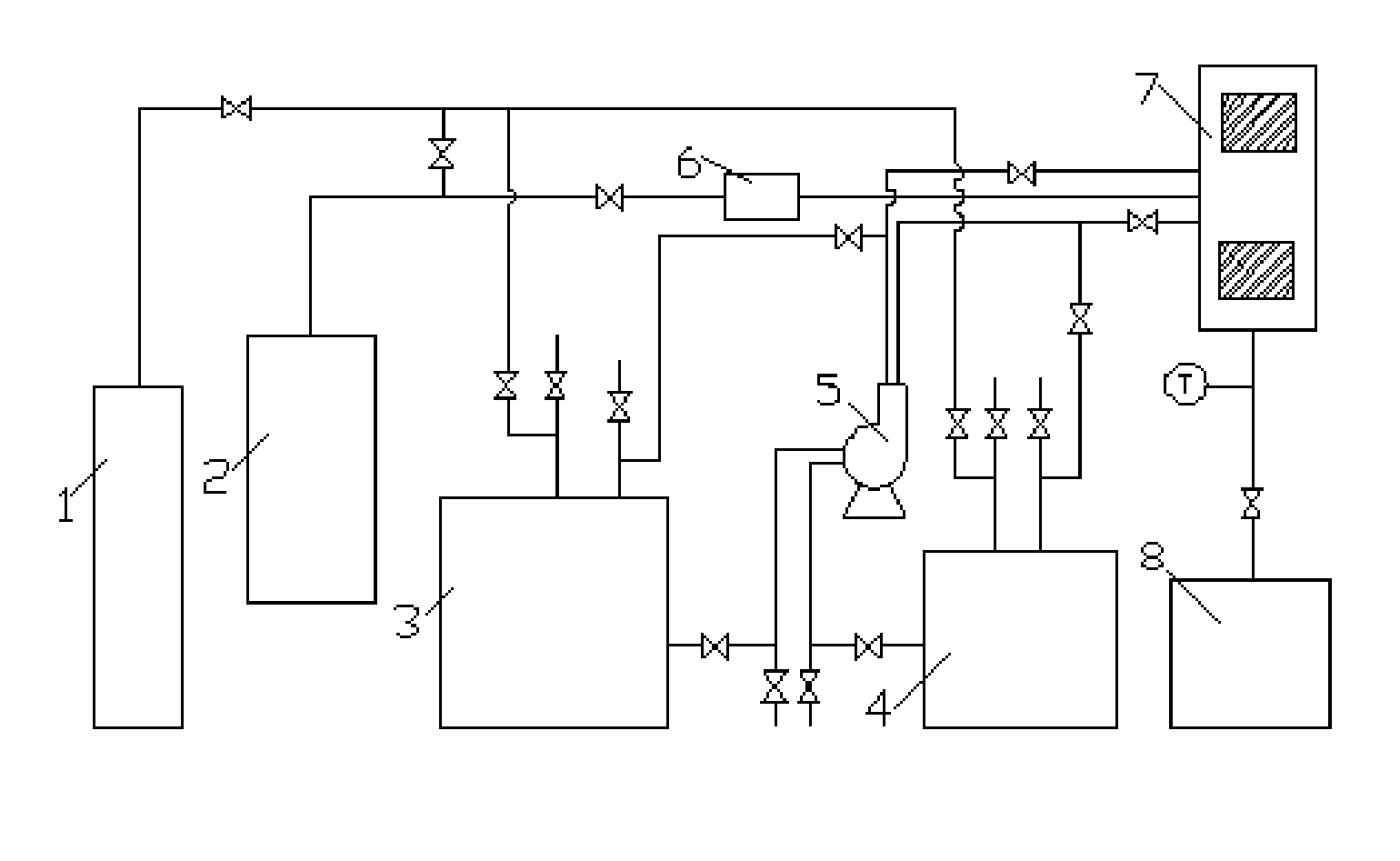

Whey protein antihypertensive peptide prepared by utilizing continuous enzyme membrane reactor and special device thereof

ActiveCN101724555AAchieve recyclingImprove utilization efficiencyApparatus sterilizationAlbumin peptidesPeristaltic pumpEnzyme membrane

The invention discloses a whey protein antihypertensive peptide prepared by utilizing a continuous enzyme membrane reactor and a special device thereof. The continuous enzyme membrane reactor provided by the invention comprises a reactive tank (4), an ultrafiltration membrane assembly (5), a circulating system (7), a collecting tank (9) and a feed tank (6), wherein the reactive tank (4) is connected with the ultrafiltration membrane assembly (5) through the circulating system (7), the feed tank (6) is connected with the reactive tank (4) through a pipeline, and a peristaltic pump (10) is arranged on the pipeline. After whey protein is preprocessed through dissolution, hydration and the like, the antihypertensive peptide is prepared in the continuous enzyme membrane reactor by adopting thetechnologies of proteolysis and membrane separation and coupling. The enzyme membrane reactor shows excellent stability in the operating process, and the ultrafiltration amount thereof always keeps more than 90 percent after the enzyme membrane reactor continuously works for 12 hours. The protein recovery rate reaches more than 78 percent, and the highest suppression ratio of an ACE can reach 90.11 percent.

Owner:CHINA AGRI UNIV

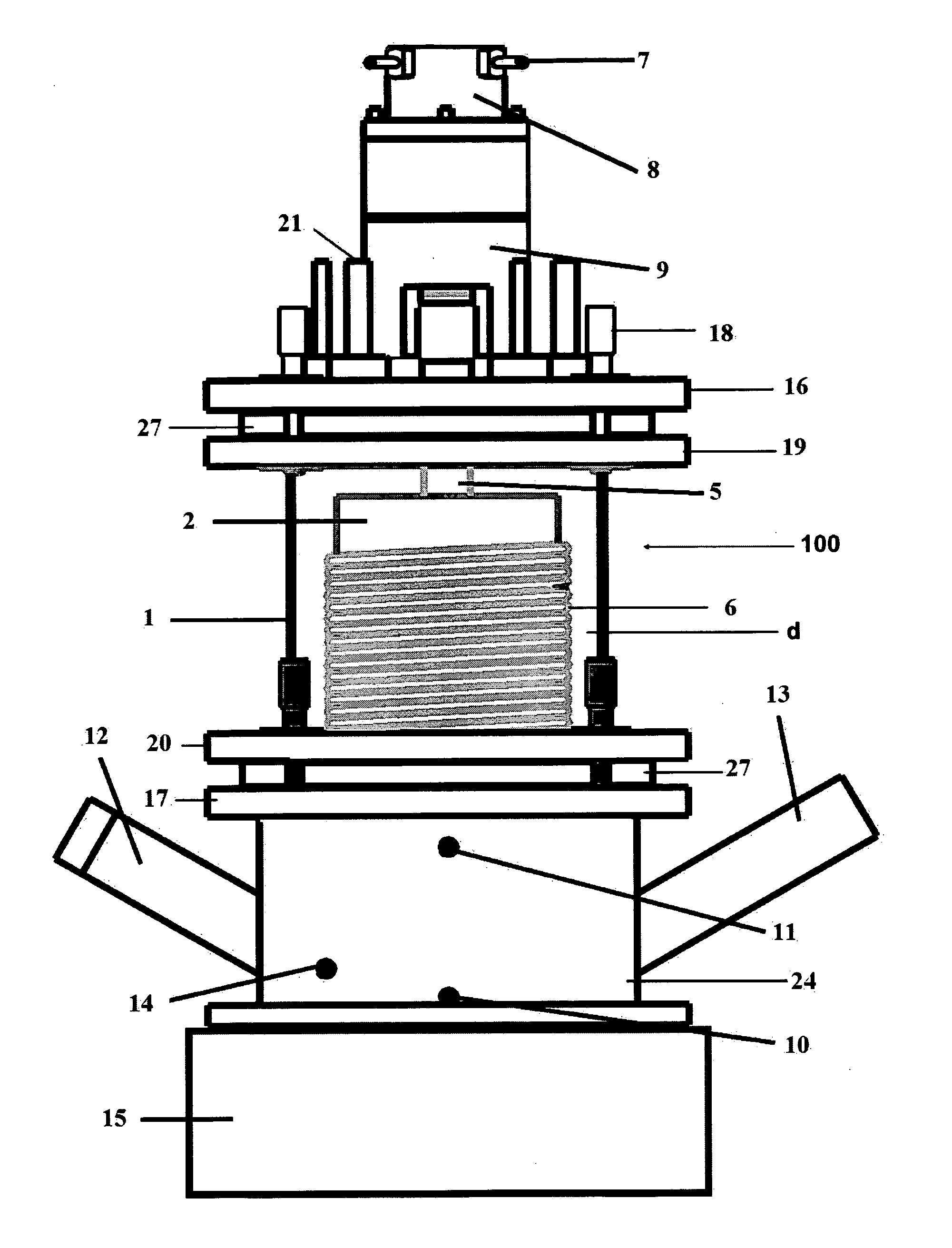

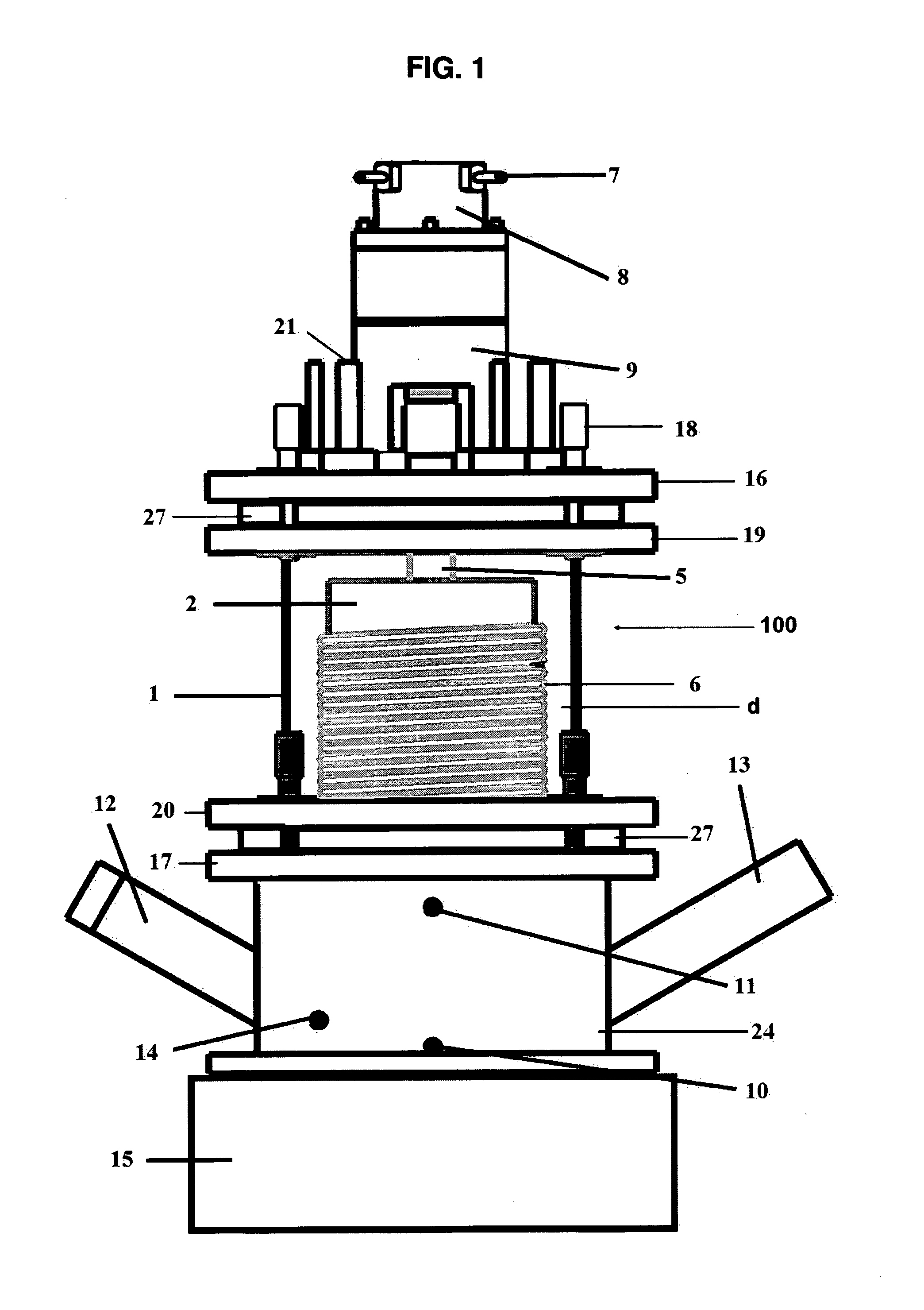

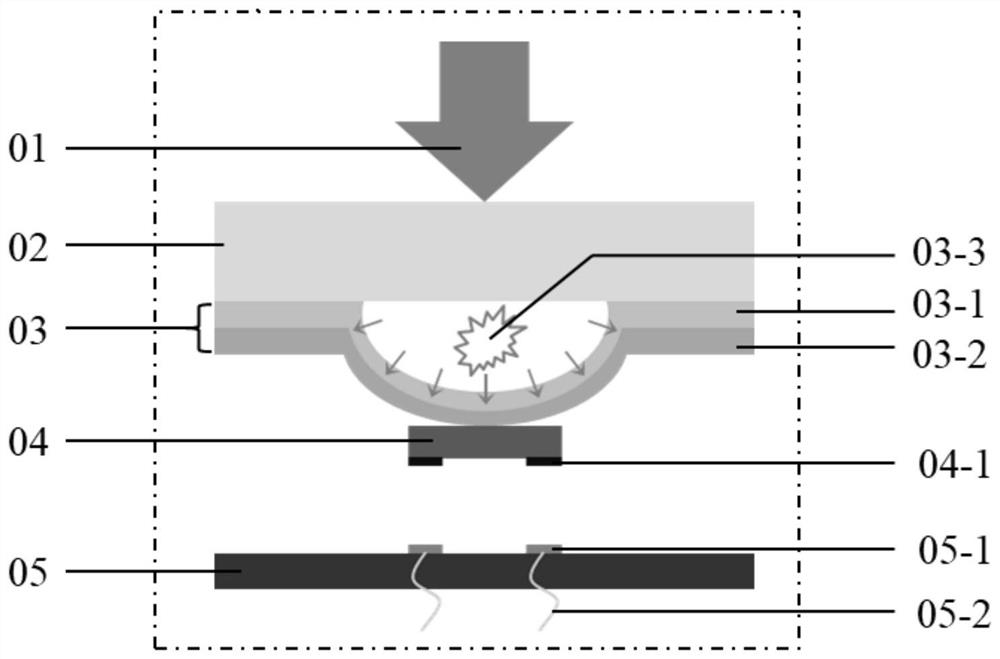

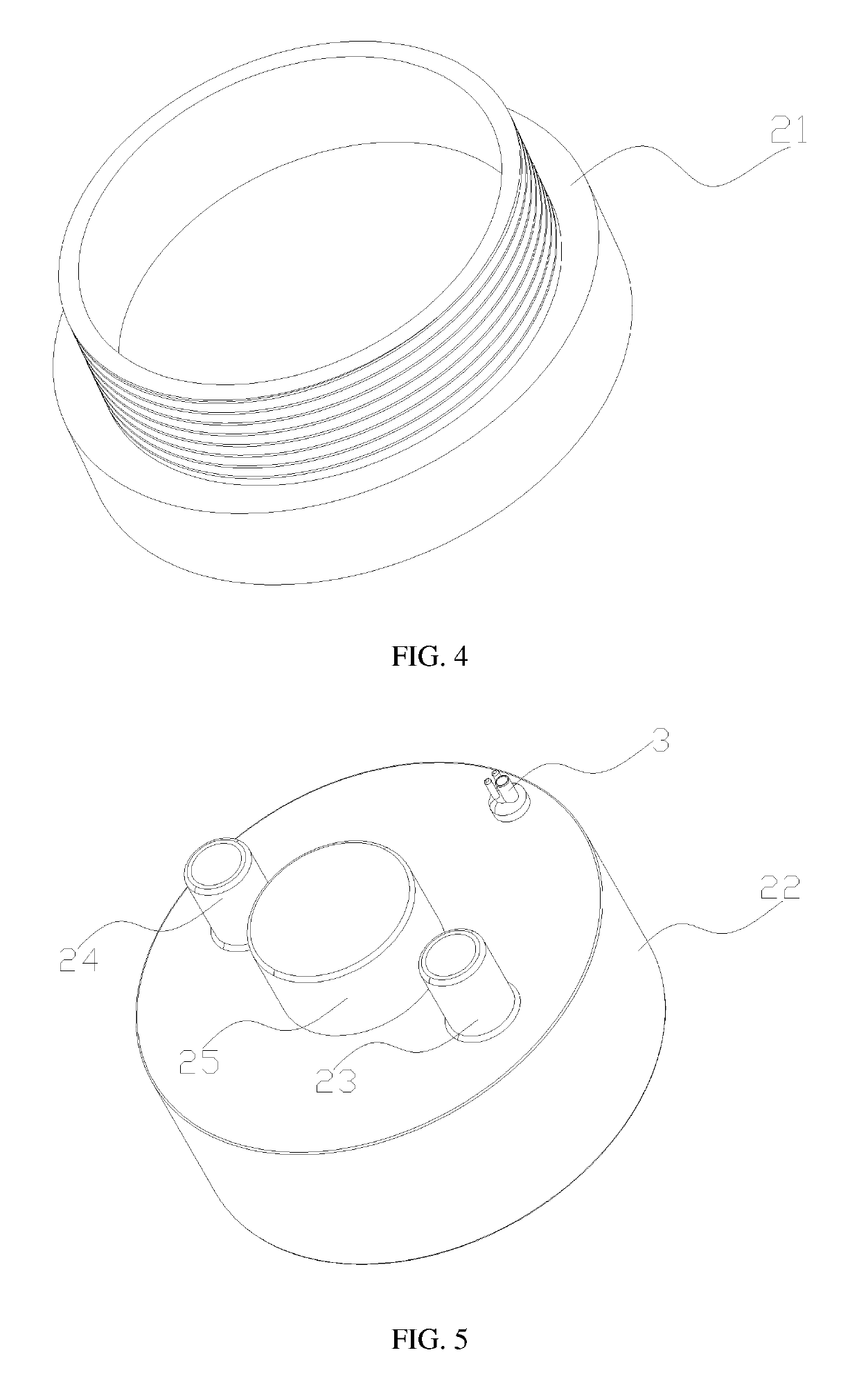

Taylor Vortex Flow Bioreactor for Cell Culture

InactiveUS20110117639A1Efficient transferHeat massBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMicrocarrier

The invention concerns a rotating wall vessel bioreactor (100) using Taylor vortex flow for cell culture in the annular space between the two concentric cylindrical bodies, wherein the internal one (2) is rotating and the external one (1) is stationary. The internal rotating body (2) is composed of an external wall around which a polymeric tubular membrane (6) is wrapped, which is connected to the hollow tubular axis (5) of the internal body (2) for the introduction of gases into the annular space (d). Said annular space (d) is filled with a suspension of cells or cells immobilized on microcarriers.

Owner:UNIVE FEDERAL DE SAO CARLOS

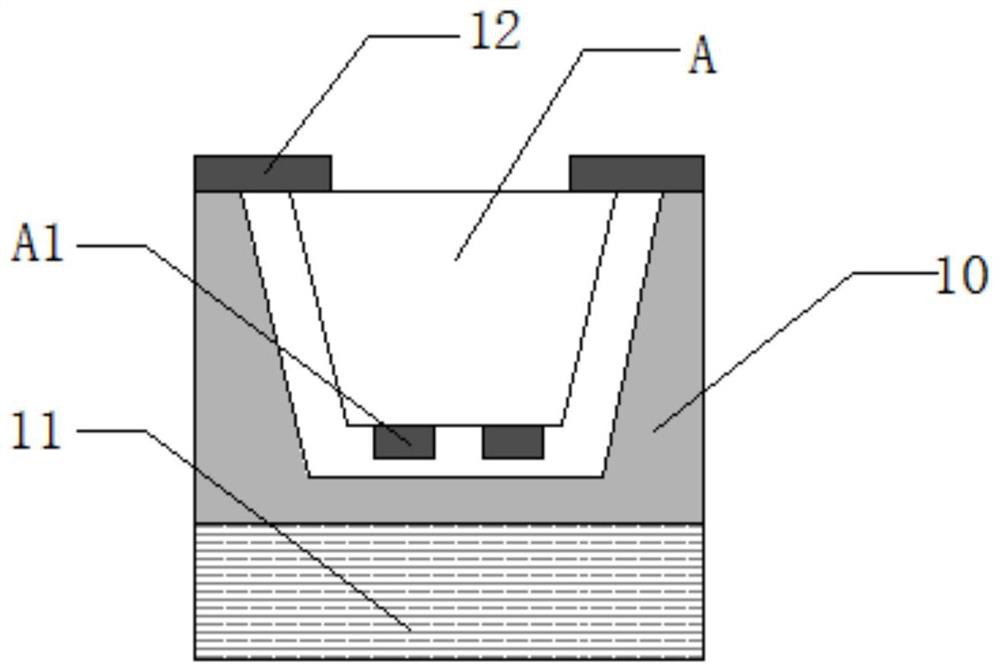

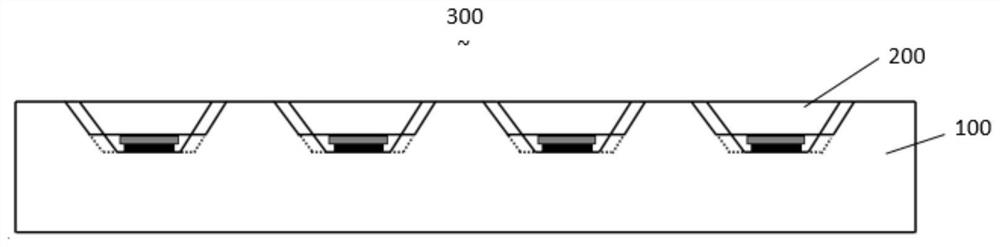

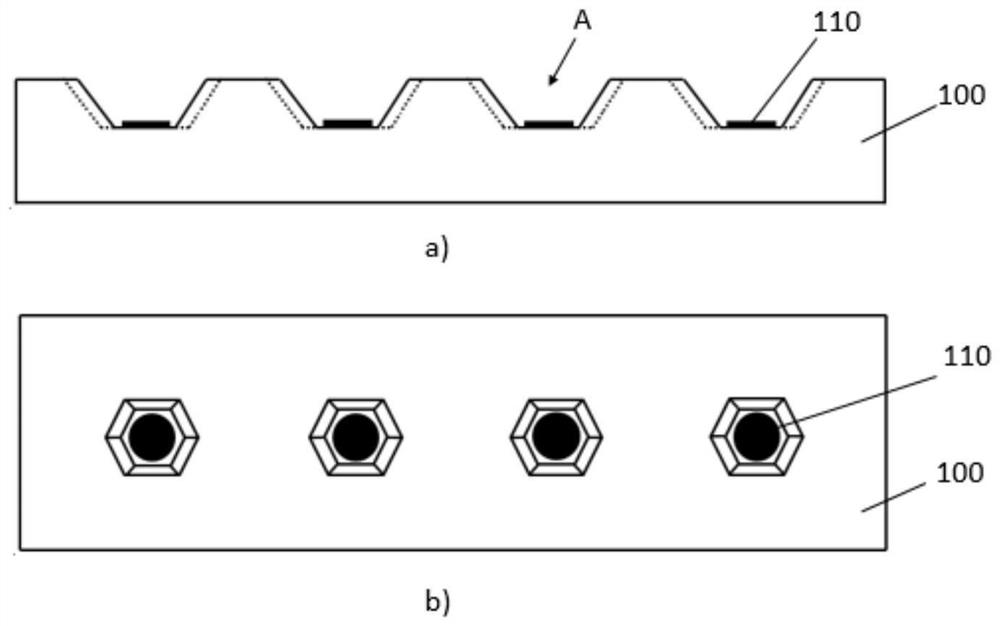

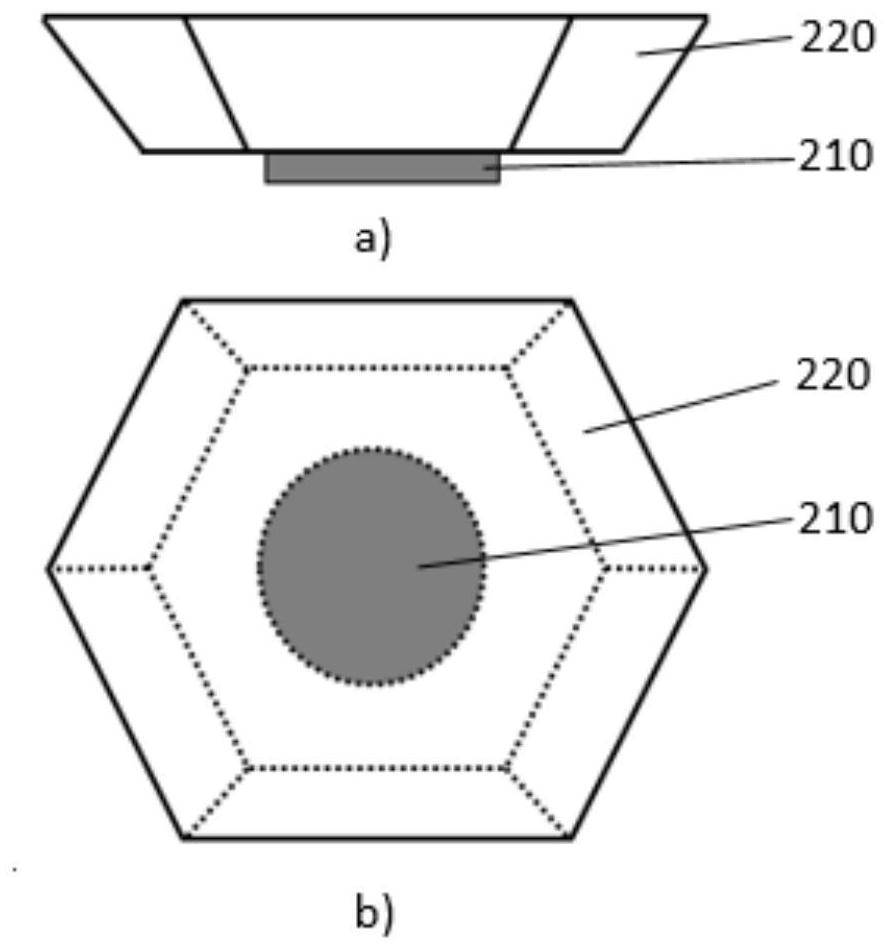

Micro light-emitting diode display panel and preparation method thereof

ActiveCN111816751AHigh precisionPrevent embeddingSolid-state devicesSemiconductor devicesEngineeringLight-emitting diode

The invention discloses a micro light-emitting diode display panel and a preparation method thereof, the micro light-emitting diode display panel comprises: a driving back plate, wherein one surface of the driving back plate is provided with a plurality of grooves, the bottom of each groove is provided with a first magnetic electrode, and the sectional dimensions of the grooves are gradually increased from bottom to top; and a micro light-emitting diode which is embedded into the groove of the driving back plate, wherein a second magnetic electrode is arranged at one end of the micro light-emitting diode, the second magnetic electrode and the first magnetic electrode are in contact with each other, and the maximum section size of the micro light-emitting diode is not smaller than that of the groove. In this way, the transfer efficiency of the micro light-emitting diode can be improved, and large-scale transfer is achieved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

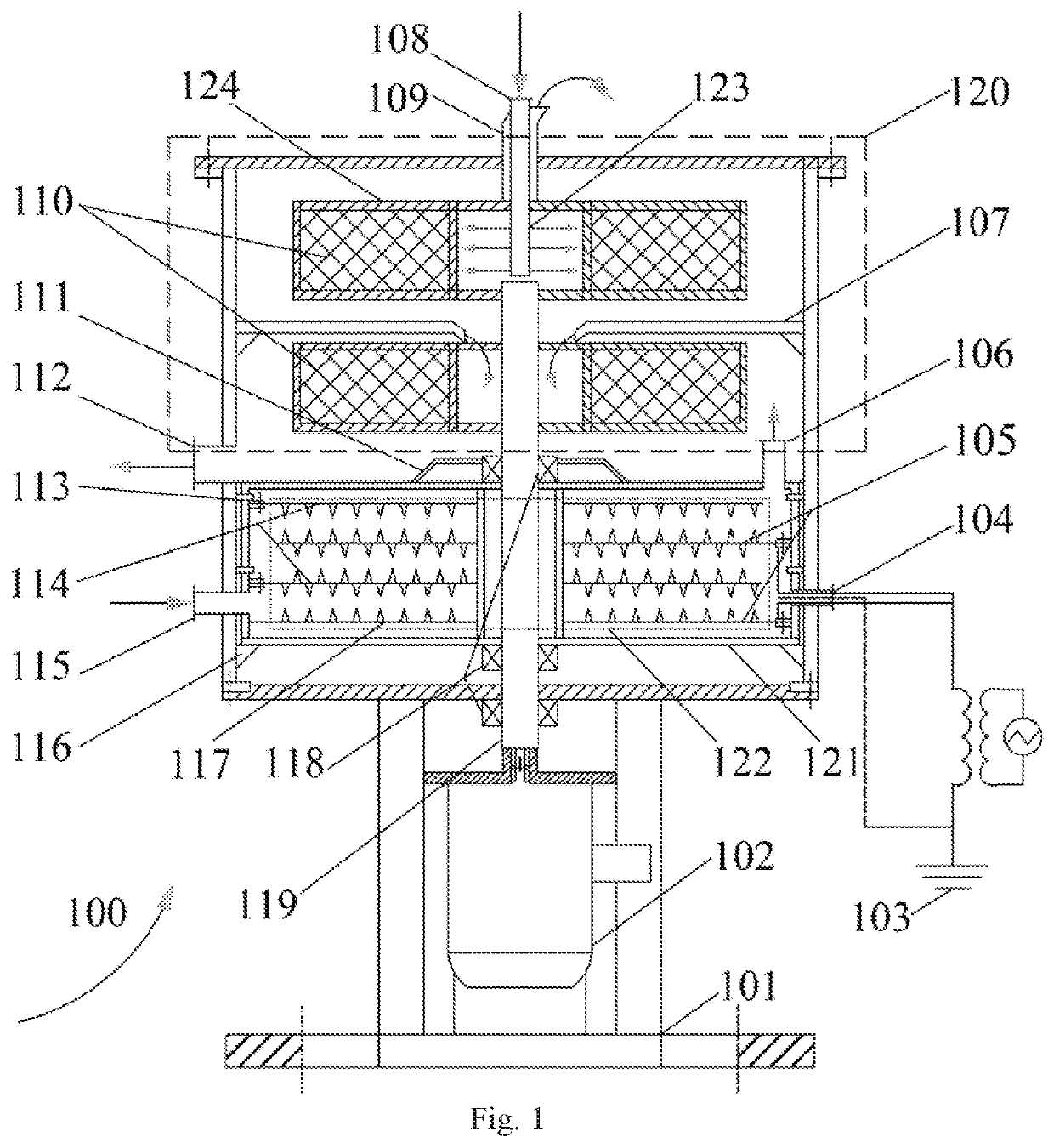

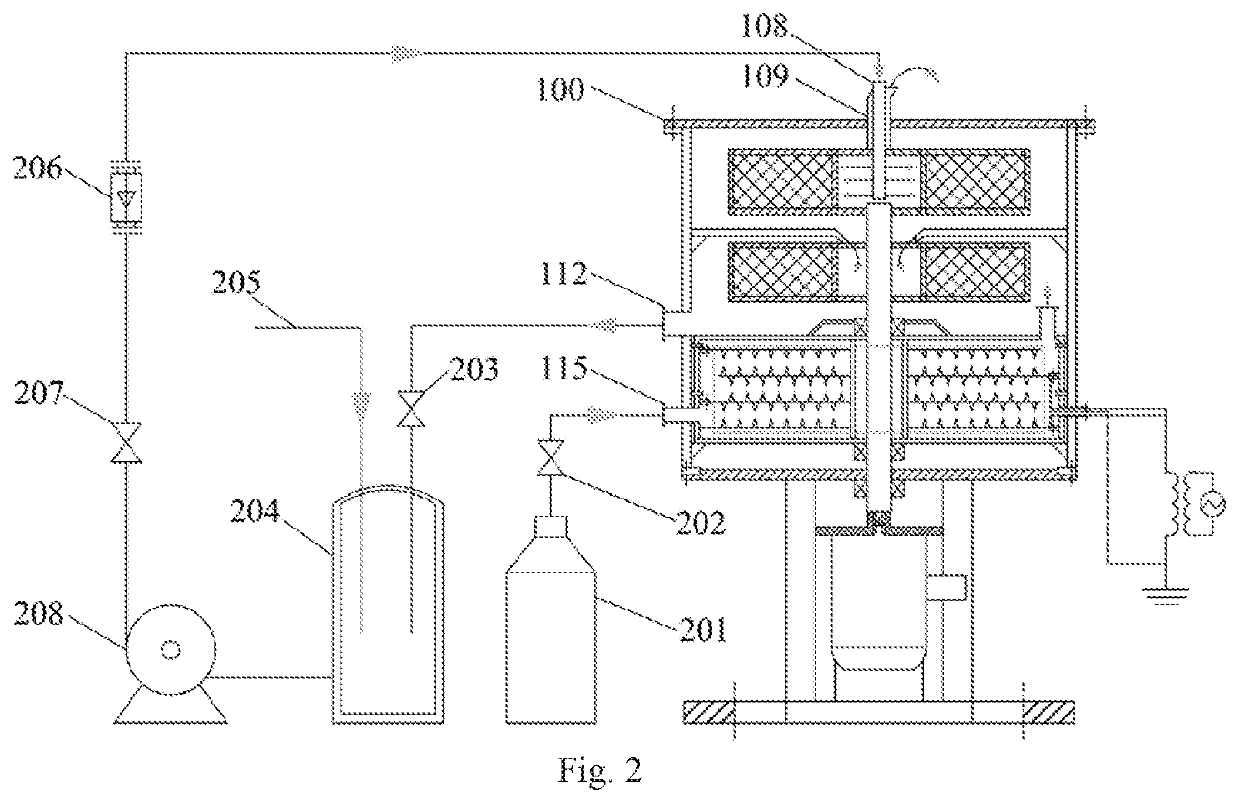

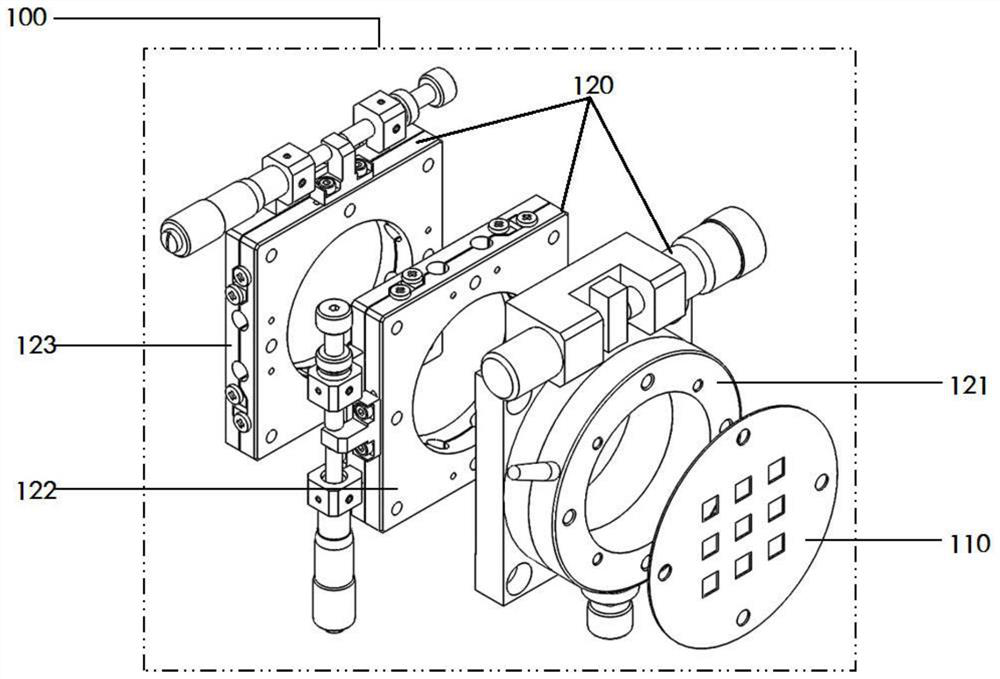

Gas-phase oxidation/decomposition and absorption integrated device and application thereof

ActiveUS20200038804A1Mass transferHigh removal rateGas treatmentDispersed particle separationPlasma generatorDistributor

Provided are a gas phase oxidation / decomposition and absorption integrated device and application thereof in a gas-liquid system. The device comprises a housing (100), a motor (102), and a boost regulator (103); the housing (100) is internally provided with a rotating chamber (120) and a discharge chamber (122); the rotating chamber (120) comprises a rotating shaft (119), a turntable (124), a liquid distributor (123), packing layers (110), a guiding round table (111), a liquid inlet (108), a liquid outlet (112), and a first gas outlet (109); the discharge chamber (122) is located under the rotating chamber (120) and comprises a discharge chamber housing (121) and a plasma generator.

Owner:BEIJING UNIV OF CHEM TECH

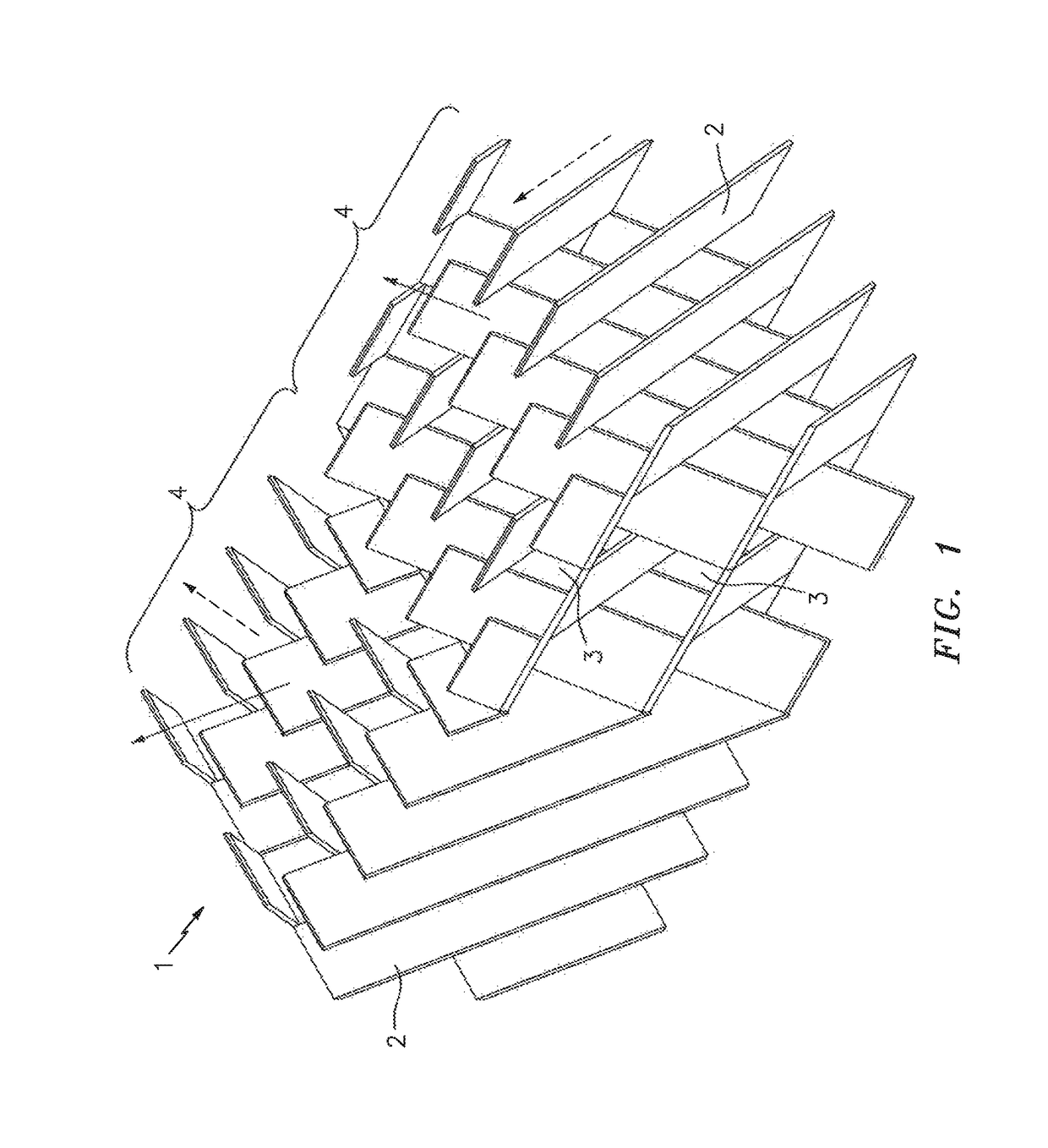

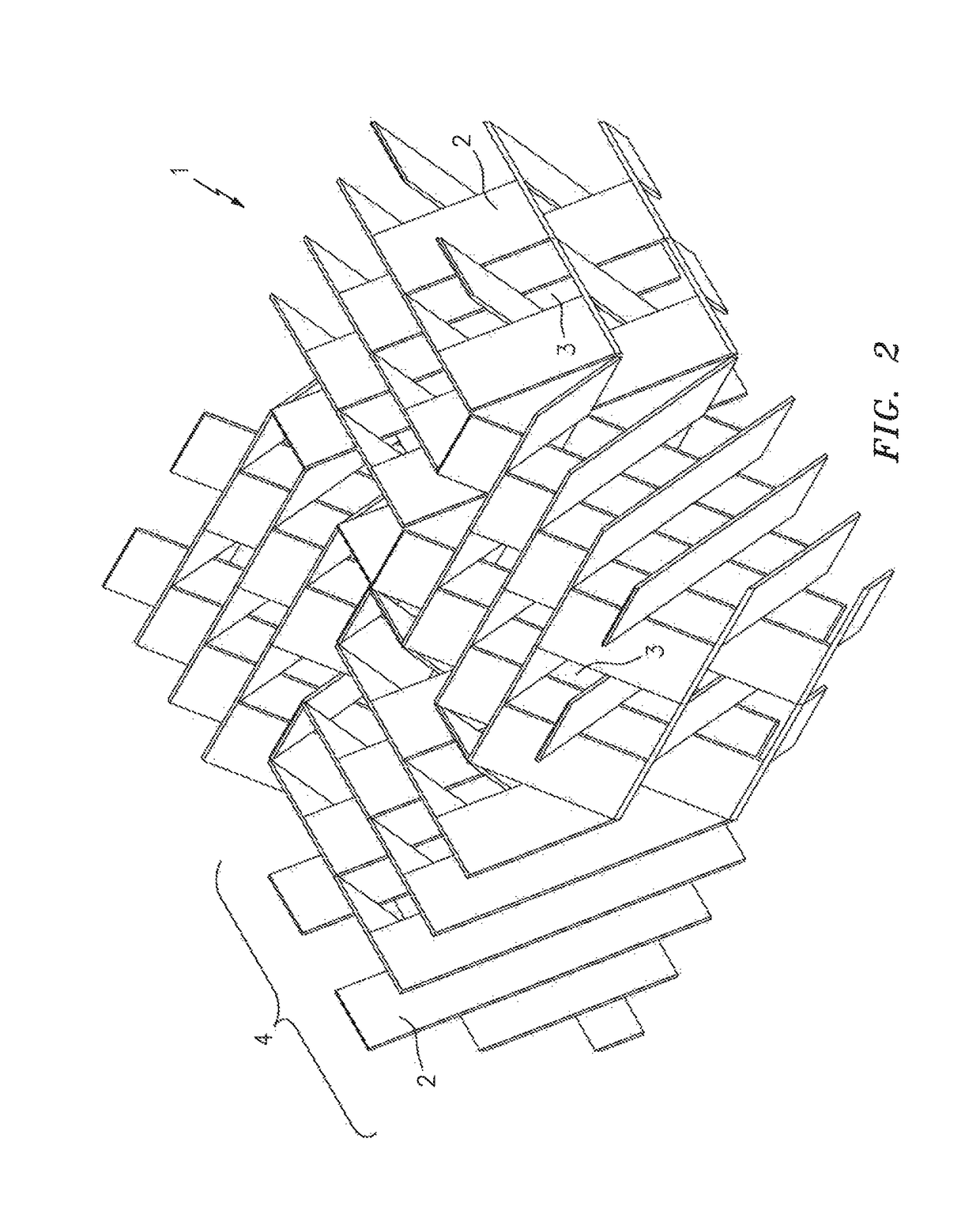

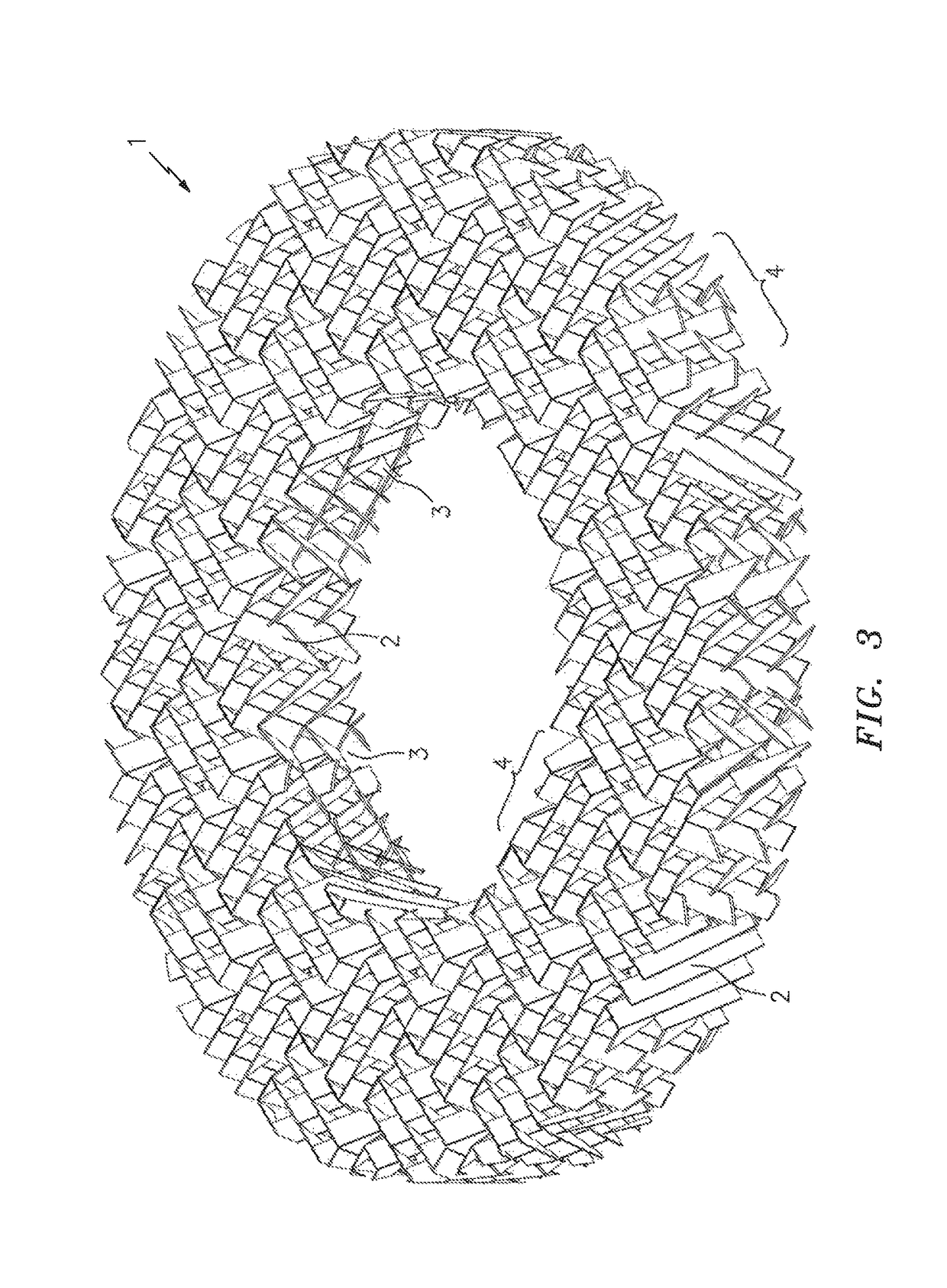

Multi directional device for vapor-solid mixing

ActiveUS10150054B1Reduce channelingReduce phase separationDispersed particle separationSolid sorbent liquid separationFluidized bedGas phase

A packing system is disclosed that has a series of flat blades arranged to promote mixing in a fluidized bed such as one in a FCC stripper, with an upward flowing gas stream and a downward flowing solid particle stream. The blade arrangement provides for different gas solids flow directions within a single layer of packing system to enhance cross mixing of gas and catalyst in all directions and reduces the potential for gas and catalyst bypassing. The blade arrangement has splits which minimizes the tendency for phase separation around the blade. The arrangement and sizing of the blades is intended to promote intimate contact between the two phases to ensure efficient mass transfer of material trapped inside the particles to the gas phase. The arrangement of the blades prevents excessive bubble growth and channeling, both of which reduce surface area for mass transfer.

Owner:TECH PRECESS TECH INC

LED transfer method and preparation method of LED display panel

ActiveCN110416124AMass transferImprove accuracySolid-state devicesSemiconductor/solid-state device manufacturingLED displayEngineering

An LED transferring method comprises the following steps: providing a receiving substrate and a plurality of LEDs, wherein the receiving substrate is provided with a plurality of receiving areas, eachreceiving area is used for correspondingly receiving one LED, and the two opposite ends of each LED are provided with a first electrode and a second electrode which are opposite in magnetism or magnetic attraction materials respectively; magnetically adsorbing a plurality of LEDs by using the first electromagnetic flat plate, so that each LED is transferred to a first platform after keeping a first electrode upward or a second electrode upward; magnetically adsorbing a plurality of LEDs on the first platform by using a second electromagnetic flat plate, and transferring the LEDs to a second platform after coarse positioning; and adsorbing the plurality of LEDs on the second platform by using a third electromagnetic flat plate, so that the LEDs are correspondingly transferred to the receiving area of the receiving substrate after being finely positioned. The invention further provides a preparation method of an LED display panel.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

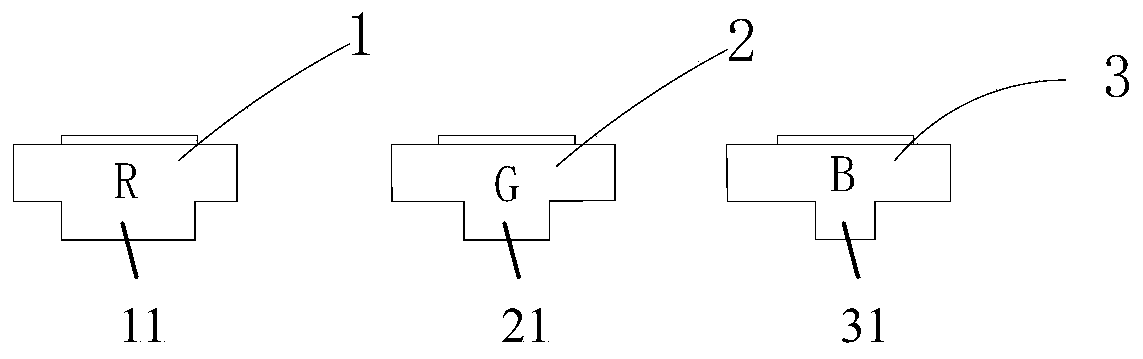

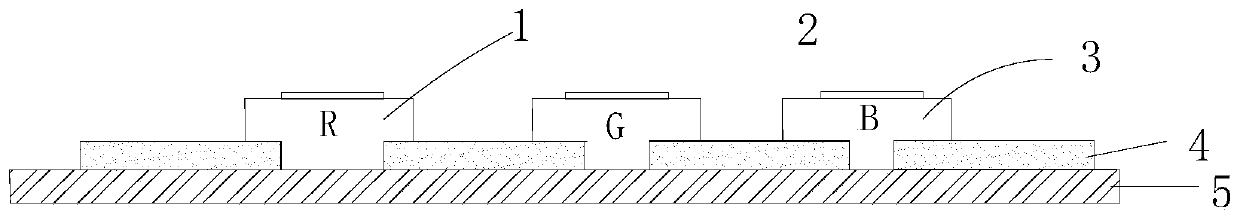

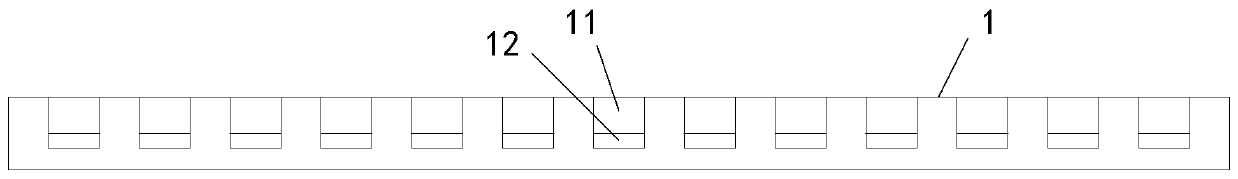

Preparation method of Mini LED display module

PendingCN111063675AHigh mechanical strengthImprove reliabilitySolid-state devicesSemiconductor devicesEpoxyPolyester

The invention provides a Mini LED display module preparation method. The method comprises the steps that a red light wafer, a green light wafer and a blue light wafer which are of a vertical structureare prepared, and one side of a P electrode of each of the red light wafer, the green light wafer and the blue light wafer is of a boss structure; a polyester film is prepared on the surface of a supporting film, and grooves matching the boss structures on one sides of the P electrodes of the red light wafer, the green light wafer and the blue light wafer respectively are prepared in the polyester film; the red light wafer, the green light wafer and the blue light wafer are embedded into the groove of the polyester film in sequence; the red light wafer, the green light wafer and the blue light wafer are transferred to the surface of the transparent conductive substrate through one side of an N electrode, and the support film and the polyester film are removed; epoxy resin glue is filled among the red light wafer, the green light wafer and the blue light wafer; and the red light wafer, the green light wafer and the blue light wafer are welded with the substrate with the circuit throughone side of the P electrode to finish the preparation of the Mini LED display module. A large amount of wafers can be transferred easily and conveniently, and the prepared Mini LED display module ishigh in mechanical strength and good in reliability.

Owner:LATTICE POWER (JIANGXI) CORP

Method and system for transferring large number of MicroLED chips

InactiveCN110993636AEasy to operateImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsIon adsorption

The invention discloses a method for transferring a large number of MicroLED chips. The method comprises the following steps: providing a substrate, arranging a first metal layer on the surface of thesubstrate,wherein passivated metal is selected as the first metal layer, and the resistivity of the passivated metal is less than or equal to 110 n[Omega].m; arranging a second metal layer on the bottom surface of a MicroLED chip, wherein the second metal layer is made of second metal, and the second metal can adsorb anions after being irradiated by the UV light source; cleaning surface ions ofthe first metal layer through a plasma cleaning machine to enable the first metal layer to carry positive ions; irradiating the second metal layer of the MicroLED chip with ultraviolet light to enablethe second metal layer to carry negative ions; and putting the substrate and the MicroLED chip in non-conductive liquid, and the transferring the MicroLED chip to the substrate through electric ion adsorption. By the adoption of the method for transferring the large number of MicroLED chips, large-scale transfer is achieved, operation is easy, efficiency is high, and positioning is accurate.

Owner:FOSHAN NATIONSTAR SEMICON

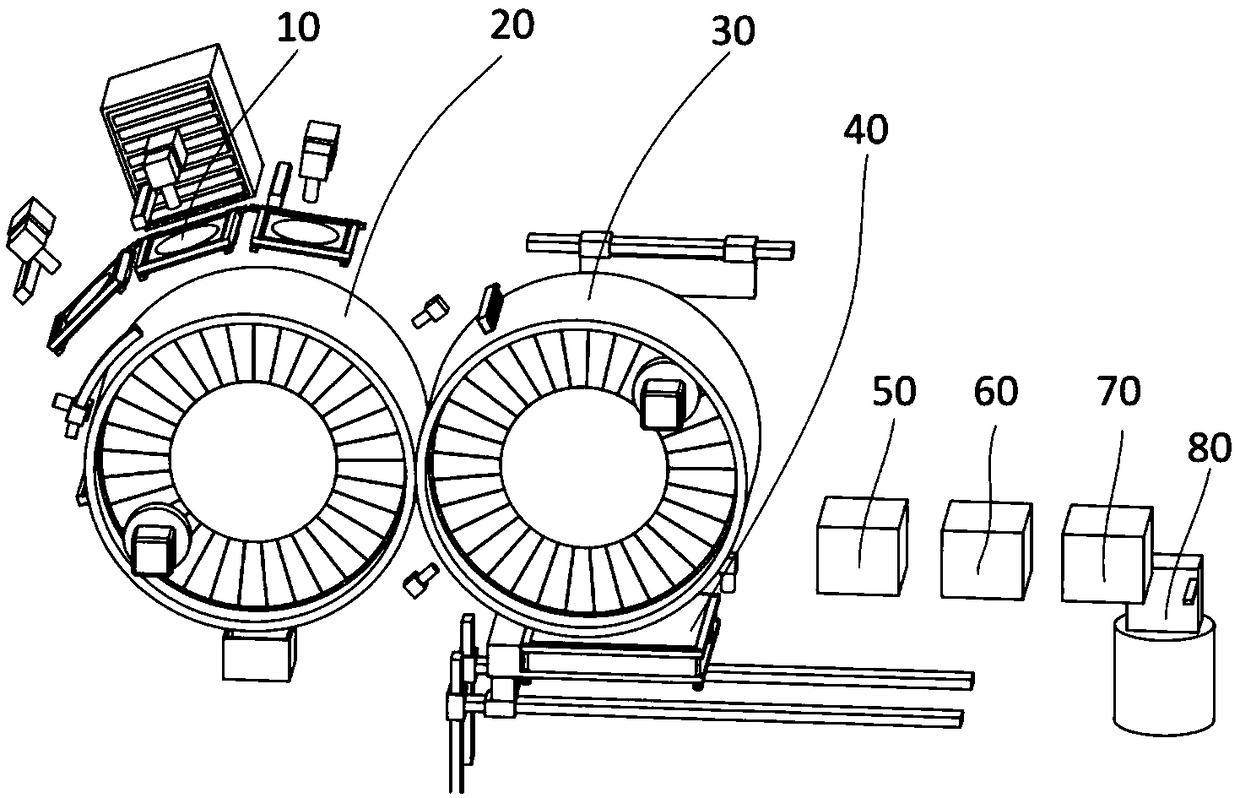

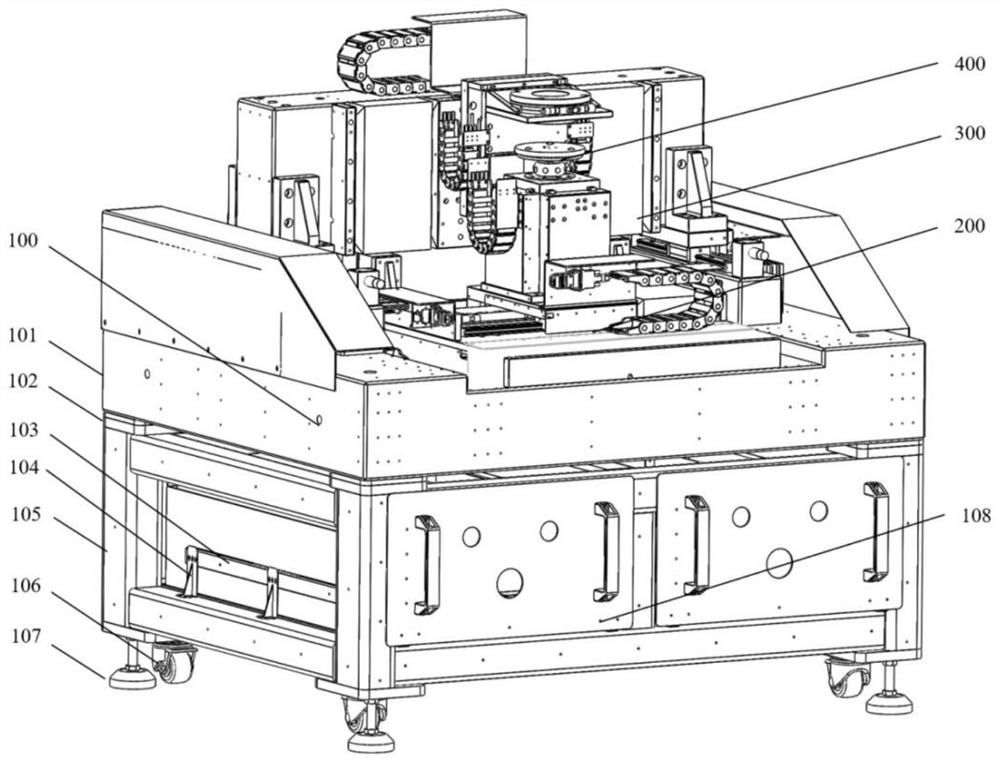

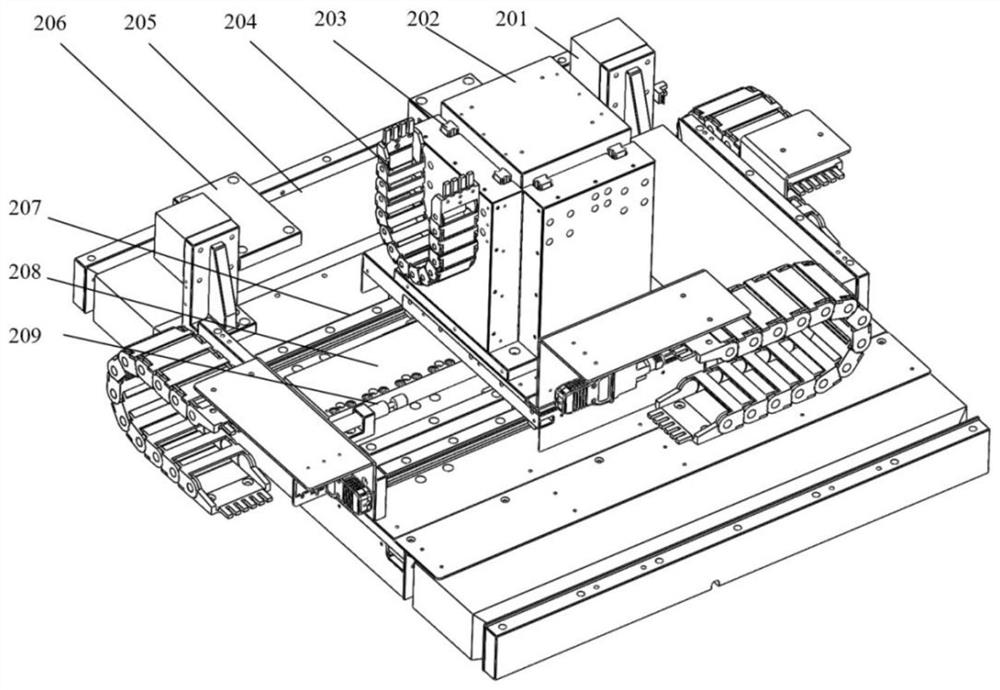

A microdevice mass transfer device and method based on differential speed matching of transfer axes

ActiveCN109244021AMass transferIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingMass transferEngineering

The invention belongs to the technical field of semiconductors, and particularly discloses a micro device mass transfer device and method based on differential speed matching of transfer axes, which comprises a microdevice stripping transfer module, a primary transfer shaft module, a secondary transfer shaft module, a substrate bearing module, a microdevice filling module, a curing module, a packaging module and a substrate handling module, wherein the microdevice stripping transfer module is used for stripping and transferring the microdevice to the primary transfer shaft module; The primarytransfer shaft module is used for picking up the microdevices and adjusting the spacing of the microdevices. The secondary transfer shaft module is used for picking up the microdevices on the primarytransfer shaft module and adjusting the spacing of the microdevices; The substrate carrying module is used for picking up the micro devices on the secondary transfer shaft module and sending them intothe micro device filling module, the curing module, the encapsulation module and the substrate handling module to realize filling, curing, encapsulation and loading and unloading. The invention realizes the massive transfer of the micro device by using the differential speed matching of the transfer shaft, which has the advantages of high production efficiency and low production cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Microchannel Apparatus and Methods of Conducting Unit Operations With Disrupted Flow

InactiveUS20160038904A1Increase heatAdd additional massCatalytic crackingOrganic compound preparationUnit operationBiomedical engineering

The invention described herein concerns microchannel apparatus that contains, within the same device, at least one manifold and multiple connecting microchannels that connect with the manifold. For superior heat or mass flux in the device, the volume of the connecting microchannels should exceed the volume of manifold or manifolds. Methods of conducting unit operations in microchannel devices having simultaneous disrupted and non-disrupted flow through microchannels is also described.

Owner:VELOCYS CORPORATION

Chip weakening structure, manufacturing method thereof, mass transfer method and display panel

ActiveCN113451352AAct as a temporary connectionPrecise positioningSolid-state devicesSemiconductor devicesMechanical engineeringElectrical and Electronics engineering

The invention discloses a chip weakening structure, a manufacturing method of the chip weakening structure, a mass transfer method and a display panel. The LED chip weakening structure comprises a plurality of Micro-LED chips and connecting bridges located between the adjacent Micro-LED chips. On the one hand, the connecting bridge plays a role in temporary connection, and the problems of poor precision and low efficiency of mass transfer caused by random scattering of the Micro-LED chips with the vertical structures after falling off from the substrate are avoided; on the other hand, the connecting bridges fix the positions of the Micro-LED chips of the vertical structures, so the Micro-LED chips of the vertical structures can be conveniently positioned by a clamping or adsorption device in the mass transfer process, the transfer precision can be improved, and mass transfer can be quickly realized.

Owner:SHENZHEN SITAN TECH CO LTD

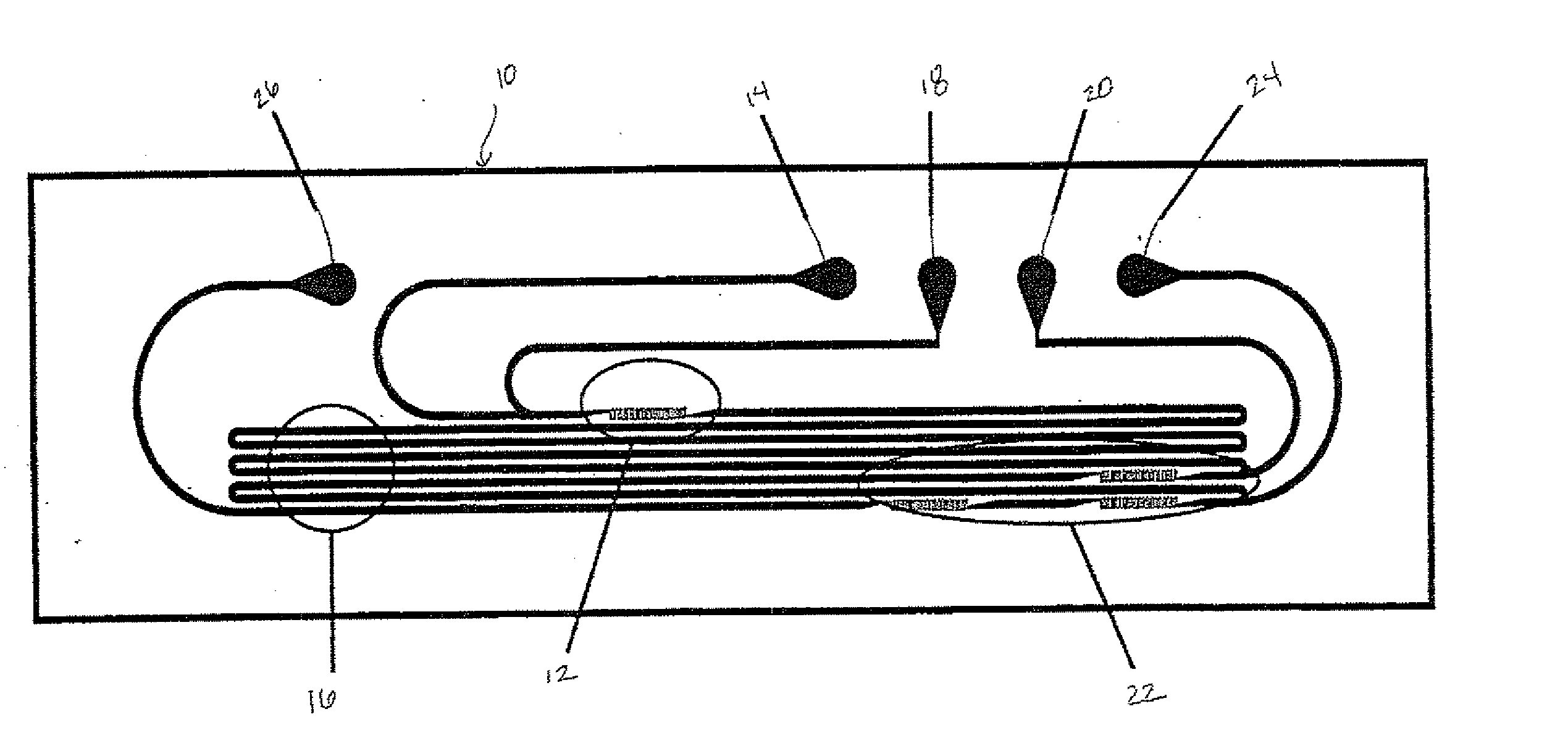

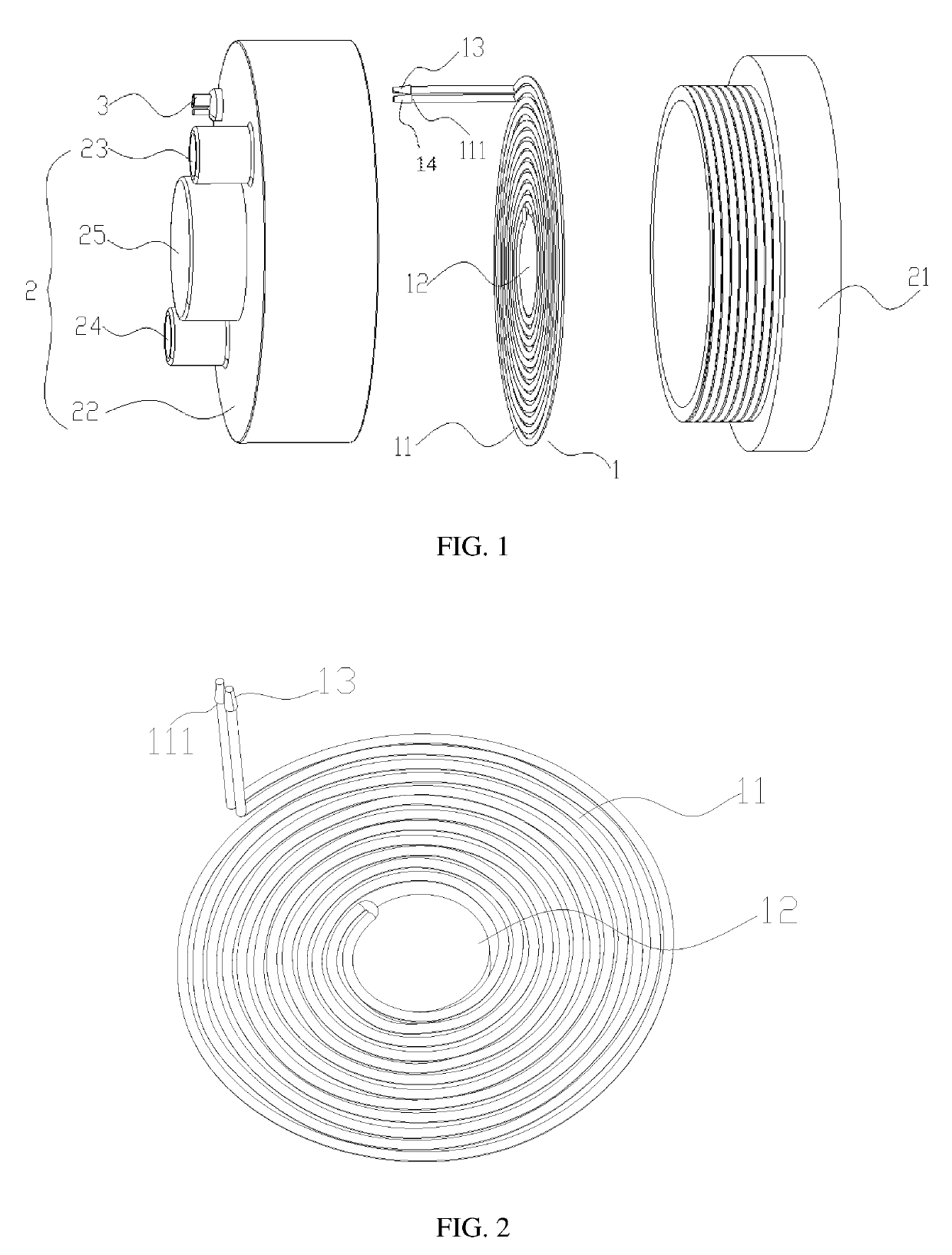

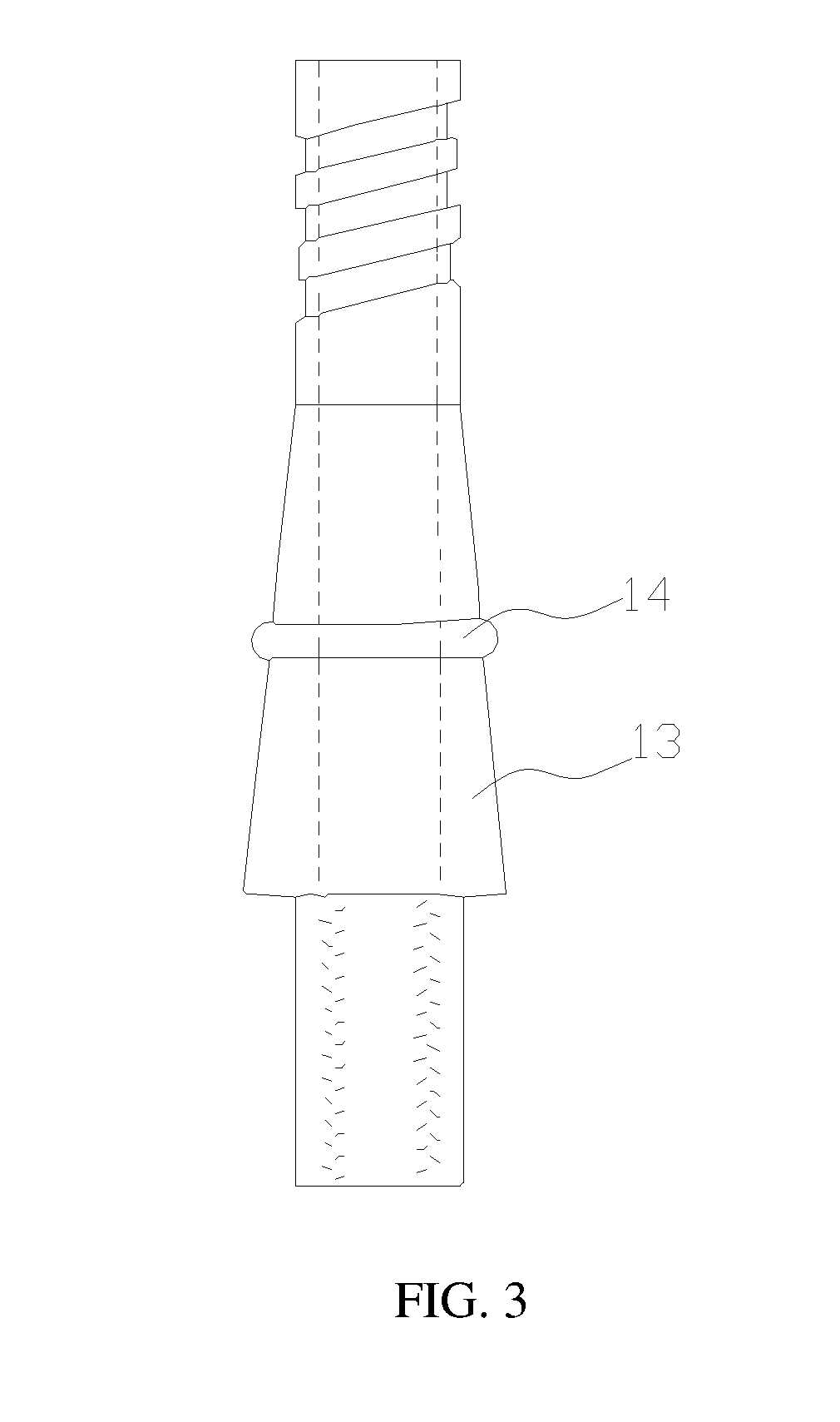

Spring tube type flexible micro chemical reactor

ActiveUS20190099735A1Increase heatEnhanced mass transferChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsChemical reactorProcess engineering

The present invention provides a spring tube type flexible micro chemical reactor. It comprises a reactor body, a thermal control device, and a gas generating device. The spring tube type flexible micro chemical reactor enhances the heat and mass transfer using the scroll spring tube, which is able to achieve accurate mixing and dynamic adjustment of the heat and mass transfer and is able to effectively solve the problems of blocking of channels by solid reactant, the poor portability of the reaction, etc.

Owner:DONGGUAN UNIV OF TECH

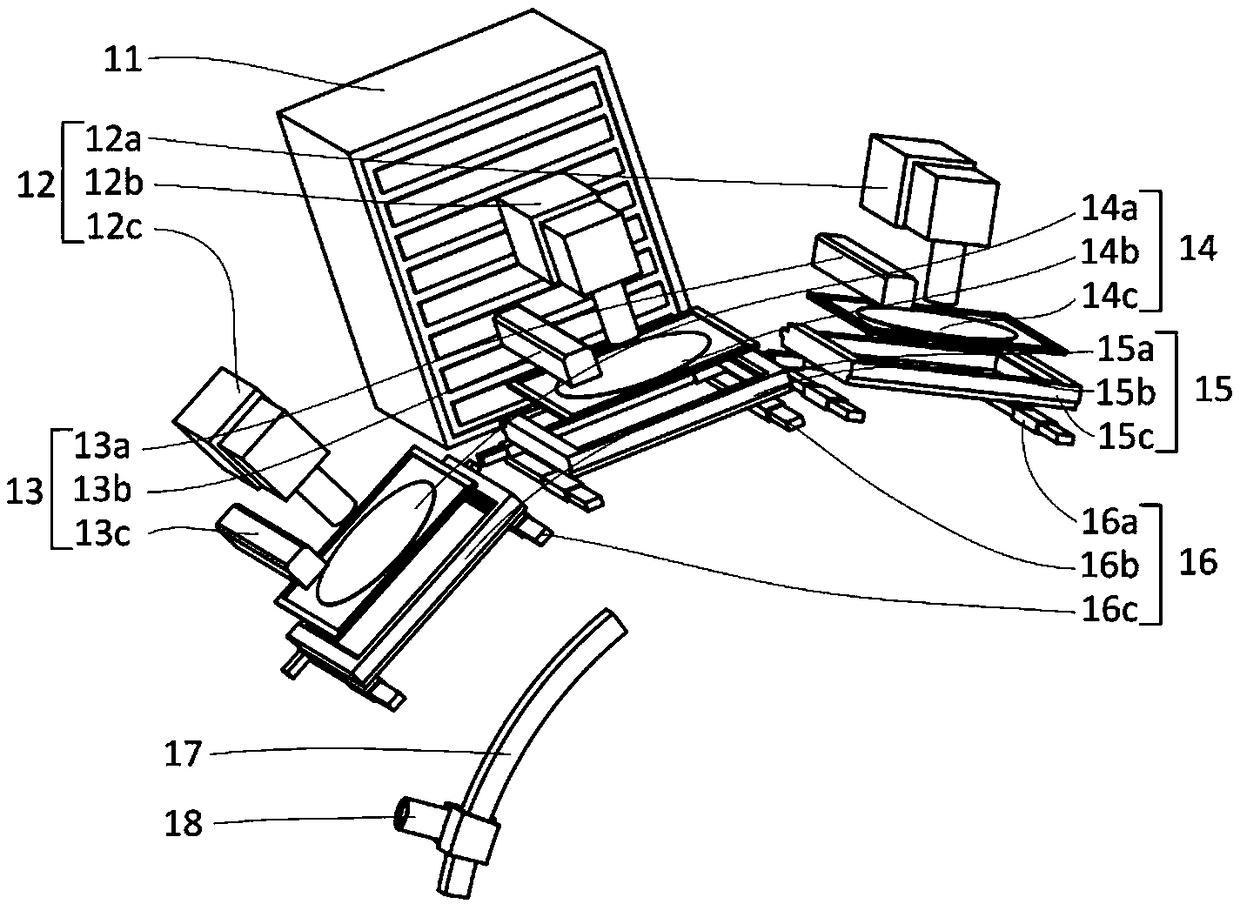

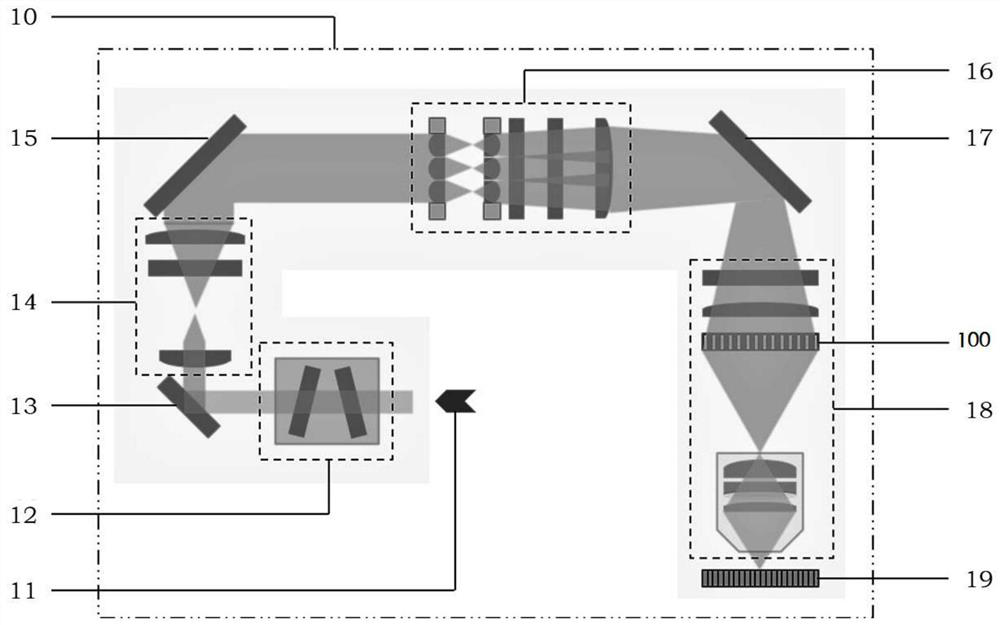

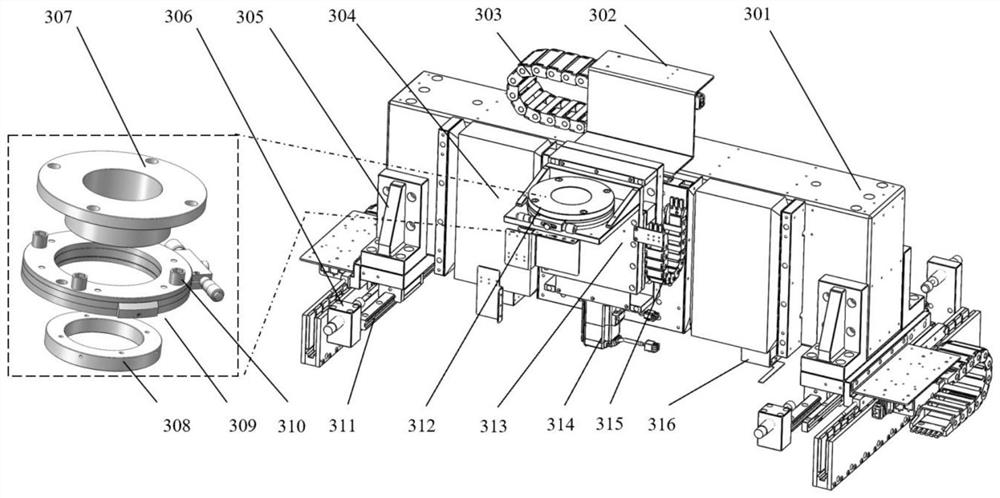

Alignment device and alignment method for mass transfer of micro LED through laser assistance

PendingCN113921439AAchieve precise alignmentSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention belongs to the related technical field of micro LED mass transfer, and discloses an alignment device and an alignment method for mass transfer of a micro LED through laser assistance, and the device comprises a mask projection assembly which comprises a self-defined mask plate and a mask plate fine adjustment device; the self-defined mask plate is provided with a hollow pattern; the mask plate fine adjustment device comprises a manual rotary table, a Z-direction displacement table and an X-direction displacement table which are connected in sequence; the self-defined mask plate is connected to the end part of the manual turntable; a camera alignment system comprises at least two cameras, a cross wire is arranged in the view center of each camera, and each camera is arranged on the corresponding Y-direction displacement table; and a motion platform system comprises a chip motion module and a drive circuit motion module, and alignment and positioning of a light spot, a chip and a drive circuit are achieved through a cross wire of a camera. According to the invention, accurate calibration and alignment of the laser spot, the chip and the driving circuit can be realized, the structure is simple, and the application value is great.

Owner:HUAZHONG UNIV OF SCI & TECH

Spring tube type flexible micro chemical reactor

ActiveUS10252241B1Simple structureEasy to adjustChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsChemical reactorProcess engineering

The present invention provides a spring tube type flexible micro chemical reactor. It comprises a reactor body, a thermal control device, and a gas generating device. The spring tube type flexible micro chemical reactor enhances the heat and mass transfer using the scroll spring tube, which is able to achieve accurate mixing and dynamic adjustment of the heat and mass transfer and is able to effectively solve the problems of blocking of channels by solid reactant, the poor portability of the reaction, etc.

Owner:DONGGUAN UNIV OF TECH

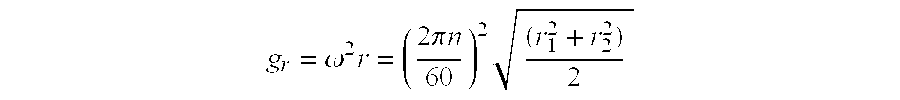

Method for synthesis of butyl rubber

InactiveUS20090286948A1Stable high gravityGood dispersionChemical/physical/physico-chemical processesPolymer scienceCationic polymerization

This invention puts forward a process of preparing butyl rubber. High gravity devices are used as polymerization reactor. The mixture of isomonoolefin and conjugated diolefin monomers and the diluent, and the mixture of the initiator and diluent are pumped at a certain ratio into a high-gravity reactor to conduct cationic polymerization in the high-gravity environment. After polymerization, the monomers and the diluent are removed from the product to obtain butyl rubber polymers with number-average molecular weight of 80000˜300000 and molecular weight distribution index of 1.9˜3.6. The high gravity polymerization method of this invention can tremendously intensify micro-mixing, mass transfer and heat transfer in the reaction. Compared to the conventional stirred polymerization method, this invention features small reactor volume, at least 30-fold shorter residence time of substances in the high gravity reactor, low cost, low energy consumption and high production efficiency.

Owner:BEIJING UNIV OF CHEM TECH

Micro LED mass transfer self-leveling device and application thereof

PendingCN114023669ASelf-adjusting parallelismImprove parallelismSemiconductor/solid-state device manufacturingConveyor partsElectric machineEngineering

The invention belongs to the related technical field of semiconductors, and discloses a Micro LED mass transfer self-leveling device and application thereof. The device comprises: a lower wafer motion table which comprises a first support with the freedom degrees in the X direction, the Y direction and the Z direction and a sliding table; an upper wafer moving platform which comprises a second bracket with degrees of freedom in X, Y and Z directions and an adsorption structure; and a substrate direct-driven self-leveling micro holder which comprises a spherical motor and a self-leveling micro holder, wherein the spherical motor is arranged on the sliding table, and the self-leveling micro holder is driven by the spherical motor to rotate or lock in the X, Y or Z direction. The self-leveling micro holder comprises a synchronous adjusting disc and a lower wafer adsorption disc, a plurality of top columns are arranged on the surface of the synchronous adjusting disc, a force sensor is arranged above each top column, and the lower wafer adsorption disc is provided with holes corresponding to the top columns so that the force sensors can protrude out of the surface of the lower wafer adsorption disc. The device is not limited by the area of the transfer head, the parallelism in the large-plane transfer process can be achieved, and the transfer efficiency is remarkably improved.

Owner:HUAZHONG UNIV OF SCI & TECH

System and method for producing biomaterials

A bioreactor system for manufacturing and extracting a desired biomaterial from a microorganism by fermenting the microorganism in the bioreactor. The system includes a horizontal reactor vessel, one or more vertical discs rotatably mounted around a hollow shaft, a motor to power the shaft, and one or more spray nozzles arranged to spray required liquids on to the discs. The system is arranged so that the microorganism is not kept submerged within the reactor vessel during the fermentation process. The system is suitable for any type of microorganism, including fungi and bacteria, and can be modified to produce many types of desired biomaterials, including antibiotics, enzymes, ethanol, butanol, chitin, and chitosan. The method of the present invention generally provides steps for placing substrate on the vertical discs of the reactor vessel, inoculating the discs, introducing media, fermenting the microorganism, and extracting the desired biomaterial from the reactor vessel.

Owner:LEWA PROCESS TECH

Transfer method of led and preparation method of led display panel

ActiveCN110416124BMass transferImprove accuracySolid-state devicesSemiconductor/solid-state device manufacturingLED displayEngineering

A method for transferring LEDs, which includes the following steps: providing a receiving substrate and a plurality of LEDs, the receiving substrate has a plurality of receiving areas, each receiving area is used to receive one LED correspondingly, and the opposite ends of each LED are respectively provided with The magnetically opposite first electrode and second electrode can be used for magnetically attracting materials; using the first electromagnetic plate to magnetically adsorb multiple LEDs, so that each LED can be transferred to a first electrode with the first electrode facing up or the second electrode facing up. A platform; using a second electromagnetic flat plate to magnetically adsorb a plurality of LEDs on the first platform, and transfer them to a second platform after rough positioning; and utilizing a third electromagnetic flat plate to adsorb a plurality of LEDs on the second platform, Make it finely positioned and transfer to the receiving area of the receiving substrate correspondingly. Also provided is a method for preparing the LED display panel.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

A device and method for laser lift-off mass transfer of micro-device based on winding process

ActiveCN109244196BIncrease productivityReduce manufacturing costSemiconductor/solid-state device manufacturingConveyor partsLaser technologyMicro devices

Owner:HUAZHONG UNIV OF SCI & TECH

Micro-LED chip mass transfer method

ActiveCN110148655BMass transferLow costSolid-state devicesSemiconductor/solid-state device manufacturingMechanical engineeringMaterials science

The invention discloses a mass transfer method of micro LED chips, which comprises the steps of preparing micro LED chips on a growth substrate; equipping a temporary carrier with a sticky surface onone side; placing the chips on the surface of the growth substrate towards the temporary carrier, stripping the chips from the growth substrate and dropping the chips to the surface of the temporary carrier; preparing a stamp with a specific material, wherein the surface of the stamp is provided with regularly arranged bumps, and the surfaces of the bumps are sticky; placing the side with bumps ofthe stamp towards the surface of the temporary carrier, carrying out UV irradiating or heating on the temporary carrier, and enabling the bumps in the stamp to take down the corresponding chips fromthe surface of the temporary carrier; placing the stamp with the chips towards a target substrate, transferring the chips to the surface of the target substrate by means of bonding, and carrying out UV irradiating or heating on the bumps on the stamp so as to remove the stamp; and repeating the steps S2-S6 until the mass transfer of the chips is completed. The mass transfer method is simple and convenient, can achieve the purpose without complex equipment and saves a lot of cost.

Owner:北京易美新创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com