Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Make sure to smash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

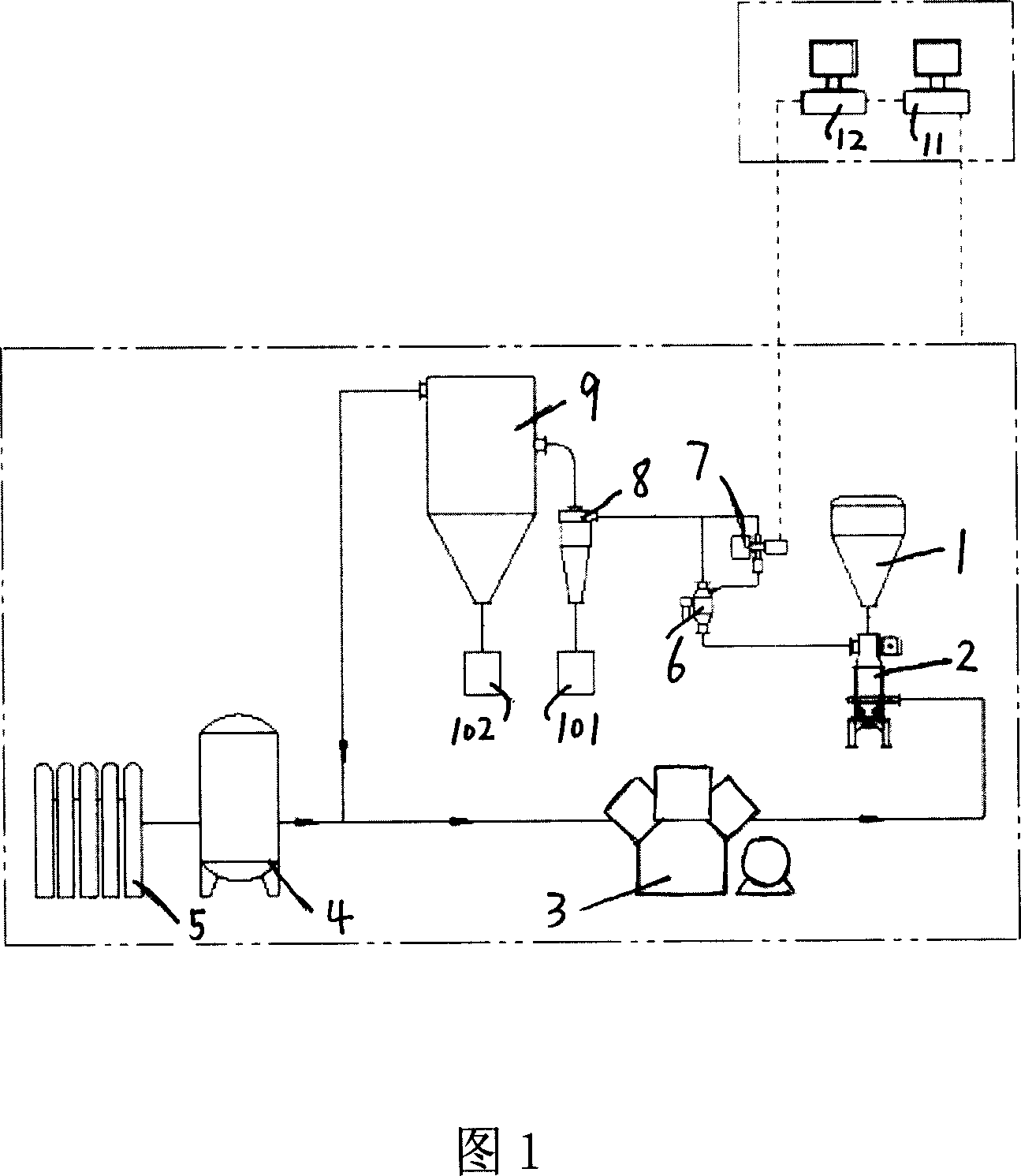

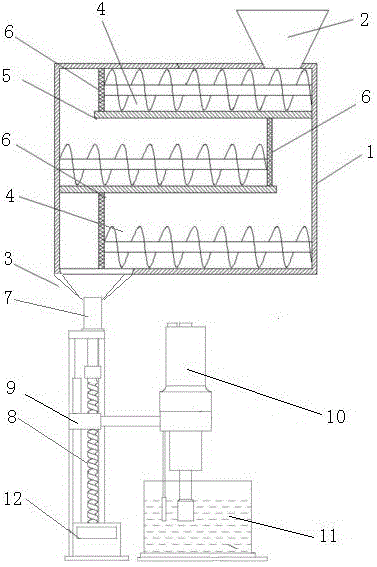

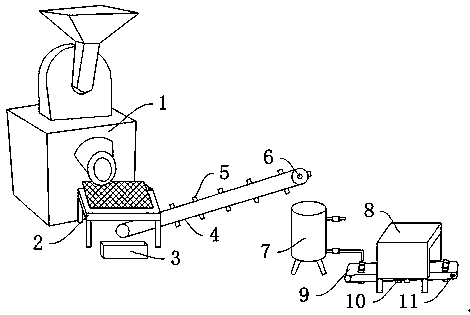

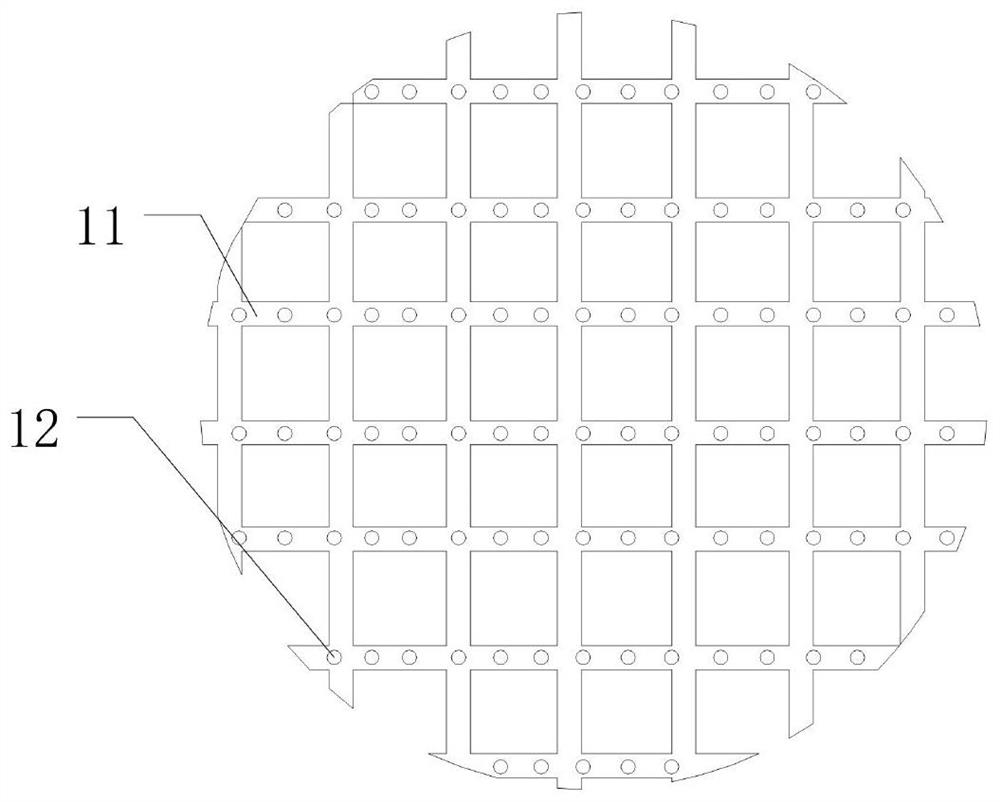

Inert gas protection and on-line detecting ultra-fine comminuting system

InactiveCN101116840AMake sure to smashReduce particle size fluctuation rangeGrain treatmentsStatistical analysisEngineering

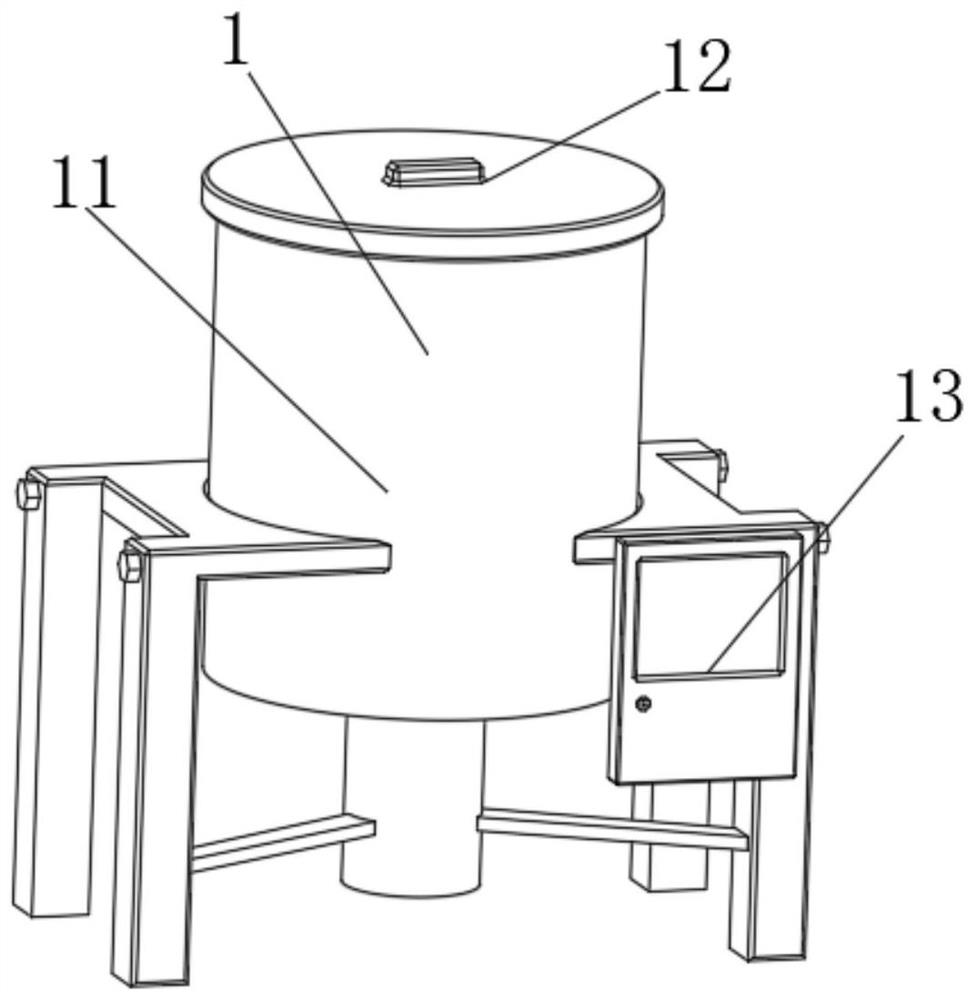

The present invention discloses an inert-gas protection and online detection super fine smashing system, with the technics as follows: the inertia gas is pressurized to 0.8 to 1.0 MPa and transported into the main smashing machine, the raw material fed into the main smashing machine through a hopper flows to a whirlwind separator and a disposal device on the rear after mashed, and then collected into a first and a second final product barrel. The filtrated inertia gas flows back to the air inlet of the compressor. The source of the inert gas and the air storage tank are connected with backflow pipes, to keep the high purity of inert gas in the system through providing the gas. Online sampling devices are arranged on pipes connected with both the main machine and the whirlwind separator, wherein the taken samples pass through a laser detector and return to the whirlwind separator in the smashing system, and the laser detector collects and then transmits the signals to a controlling computer of the online system for statistical analysis, and transmits the signal of granularity to a main controlling computer of the system, the main controlling computer automatically adjusts the parameters of the smashing technics to the best value after comparing the granularity at present with the preset target granularity.

Owner:MIYOU GROUP

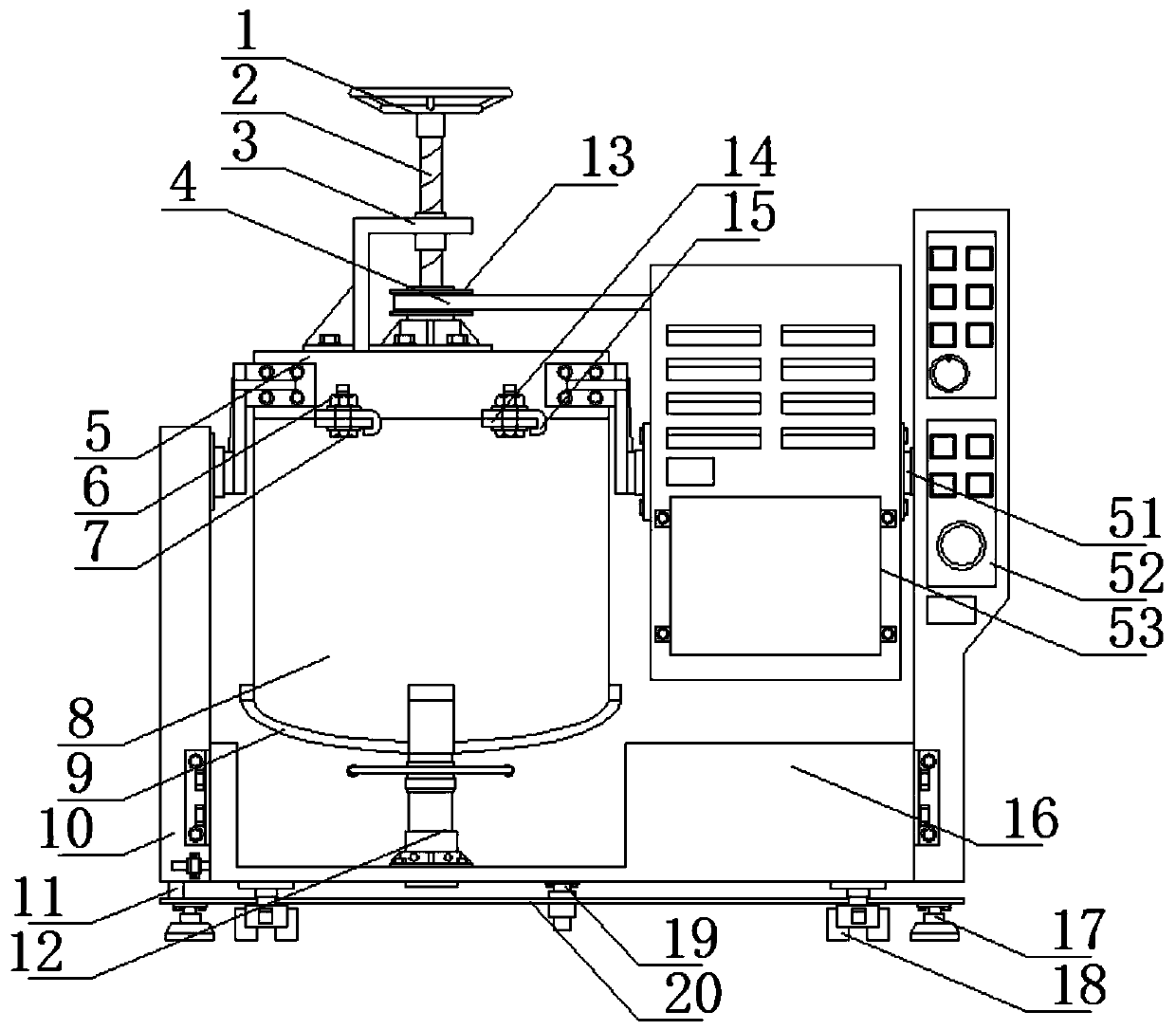

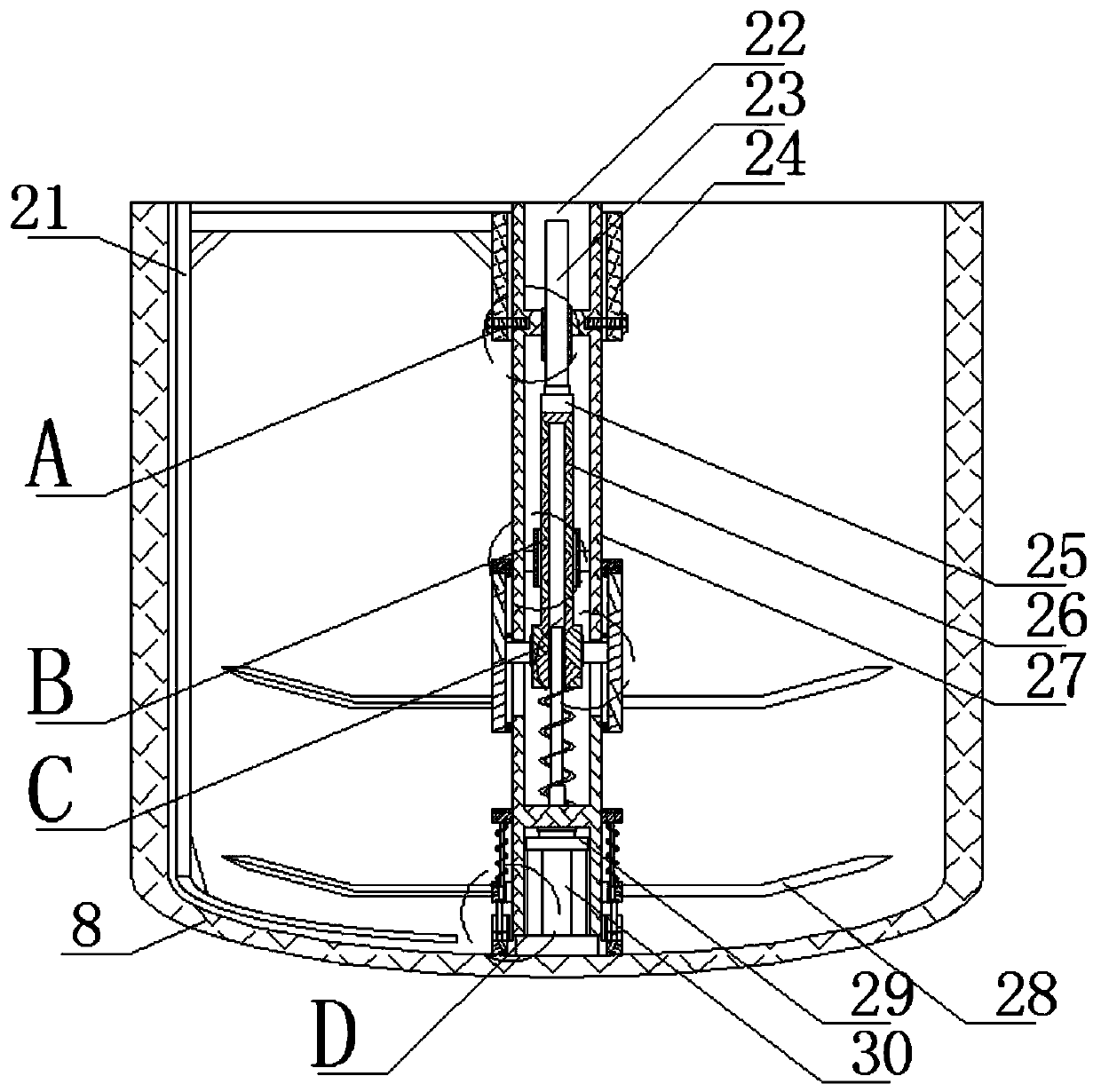

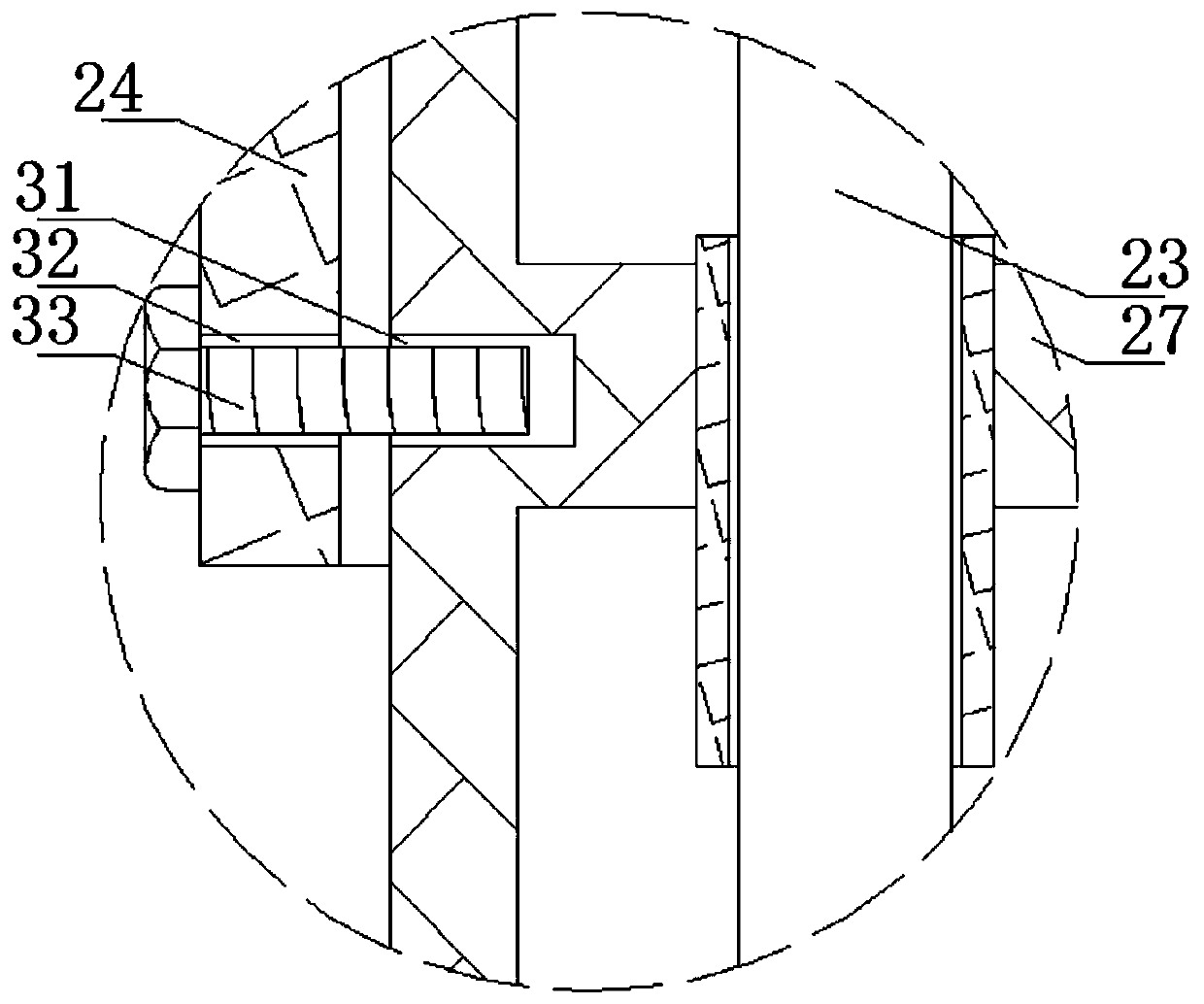

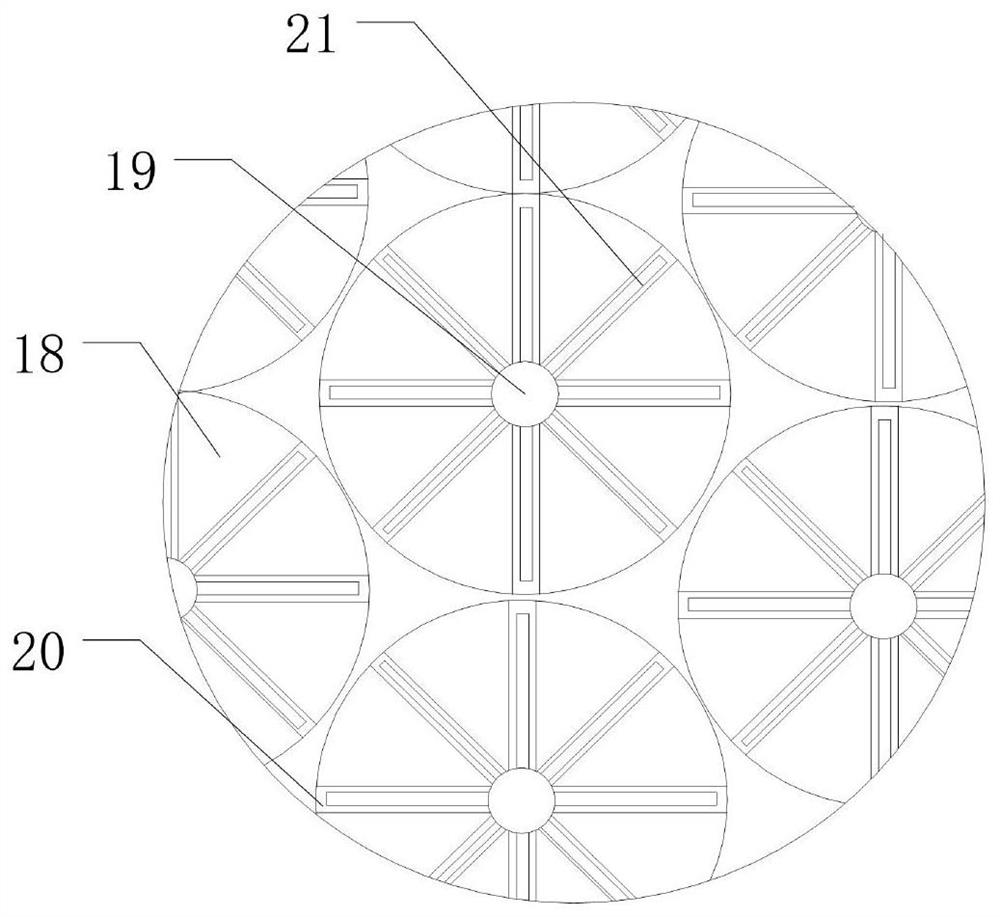

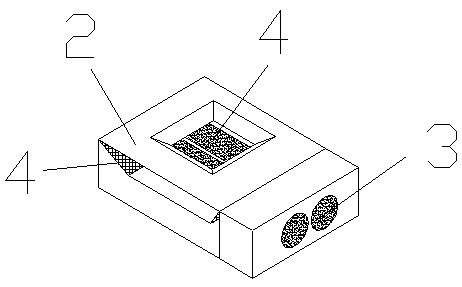

Food processing device capable of improving raw material crushing quality

ActiveCN110801919AGuaranteed stabilityEasy to disassembleGrain treatmentsProcess engineeringManufacturing engineering

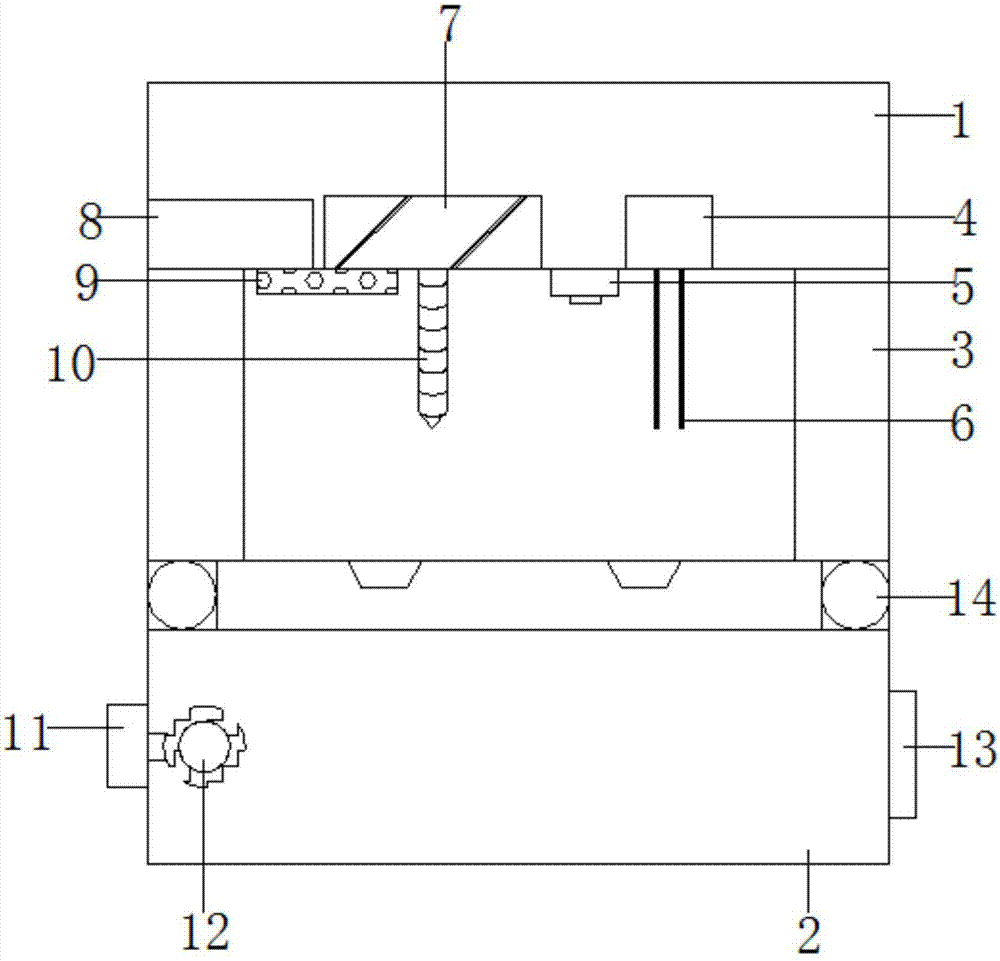

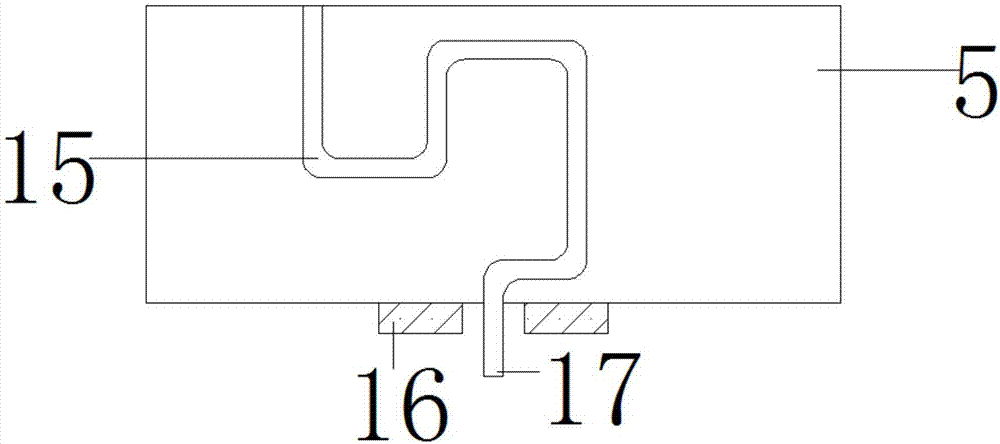

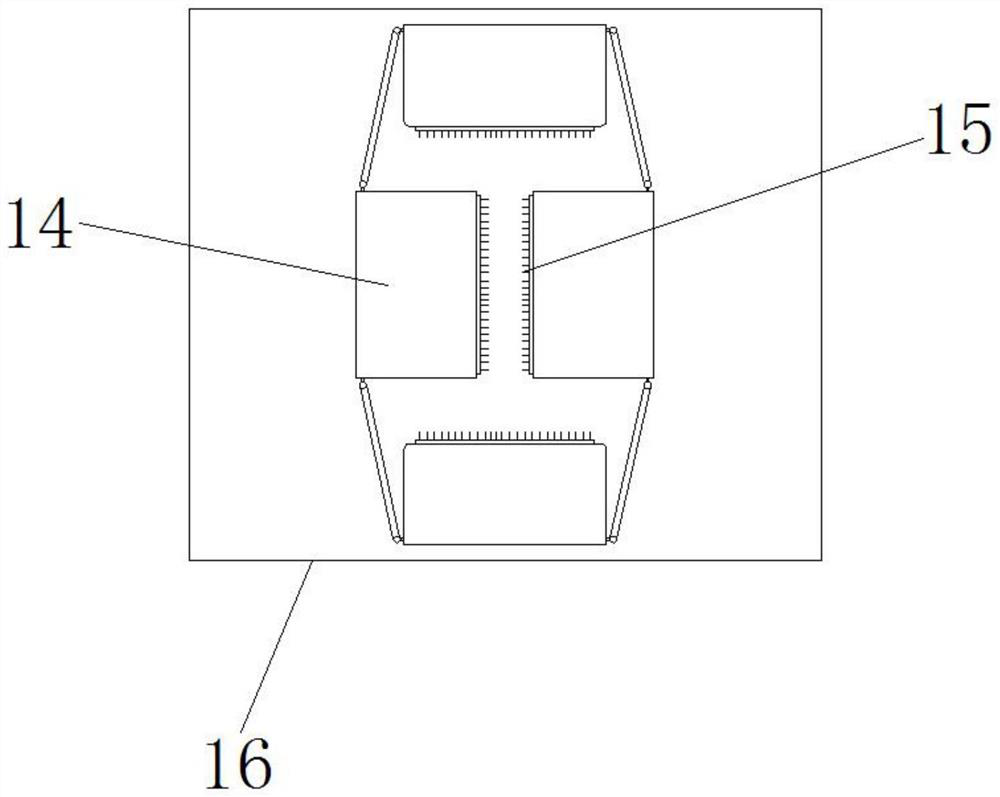

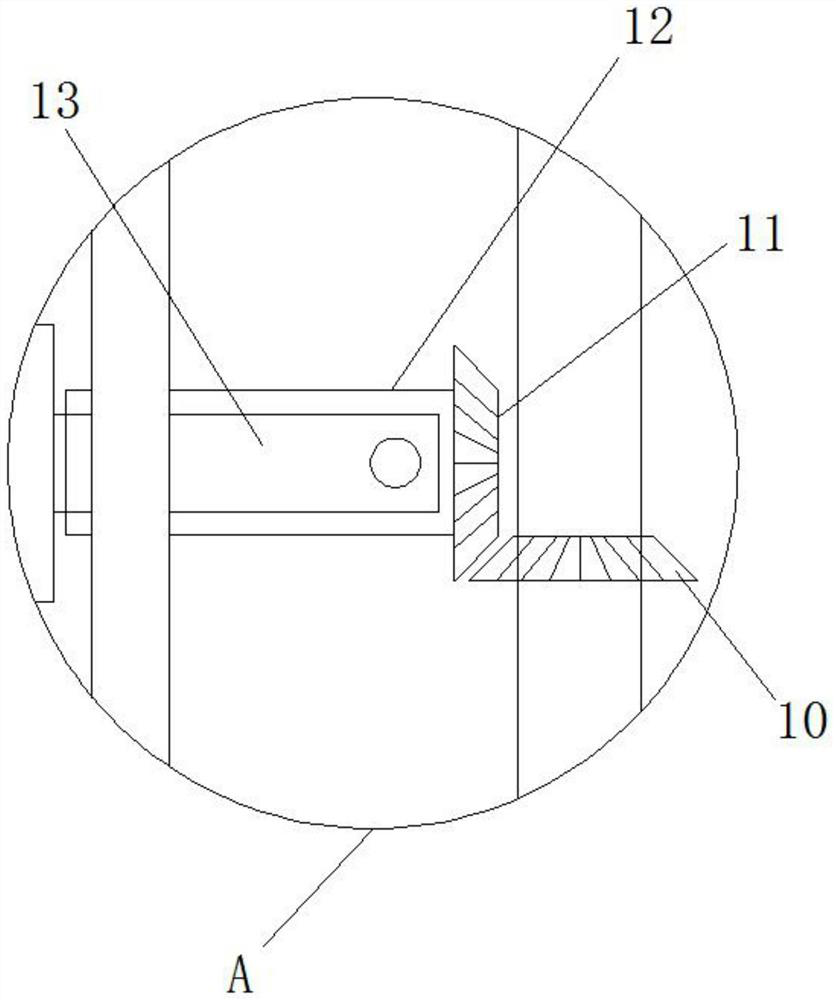

The invention discloses a food processing device capable of improving the raw material crushing quality. The food processing device capable of improving the raw material crushing quality comprises a base. A fixing plate and a control panel are separately fixed to the two sides of the base. A groove is formed in one side of the control panel, and an adjustment mechanism is arranged in the groove. Arotary disc, an installation block and an ejection plate are arranged on the adjustment mechanism. A power mechanism is arranged on the ejection plate and corresponds to the installation block. A crushing barrel is detachably connected to the ejection plate. The food processing device is convenient to move and fix, and the stability of the food processing device is well guaranteed; the positionsof crushing knives can be rapidly adjusted to prevent raw material from adhering to the inner wall of the crushing barrel, and the angle of the crushing barrel can be adjusted to enable the crushing knives to rise or fall during rotation, so that the crushing quality and efficiency are improved; accumulation of the raw materials can be effectively avoided, so that all the raw materials are effectively crushed; and the food processing device can be sealed effectively and is convenient to clean, and the service life of the food processing device is prolonged.

Owner:江西省绿滋肴实业有限公司

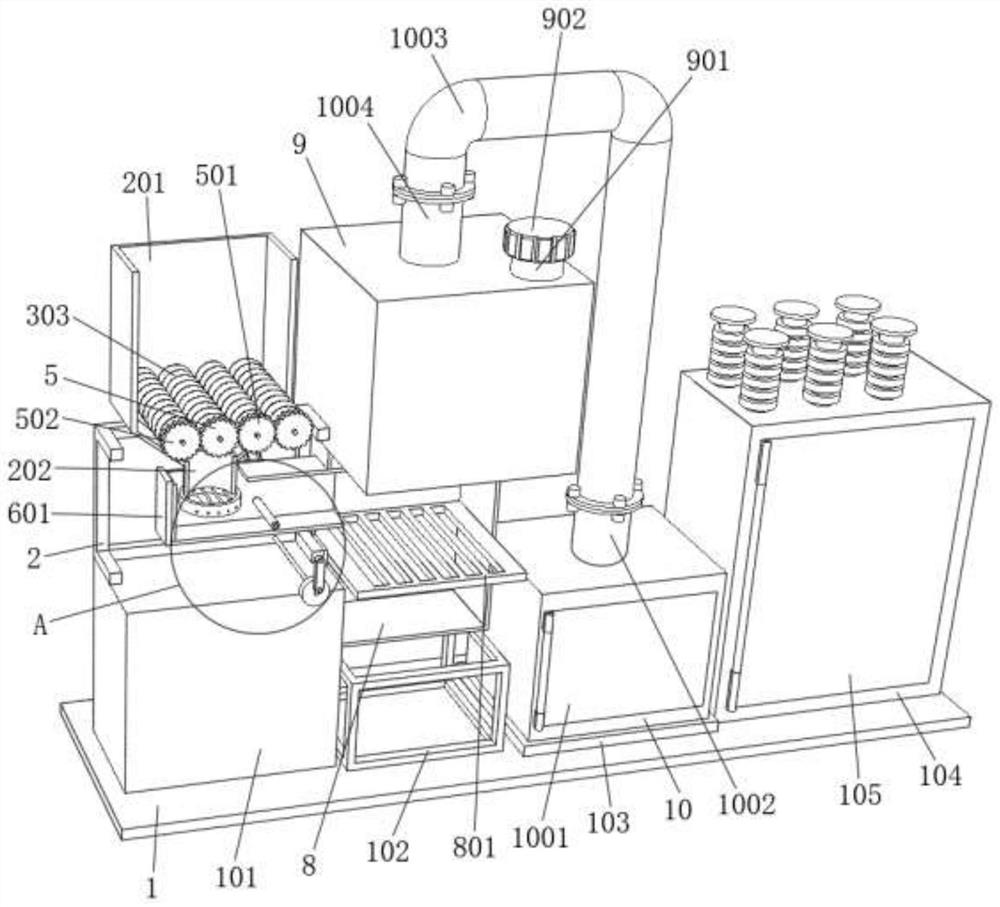

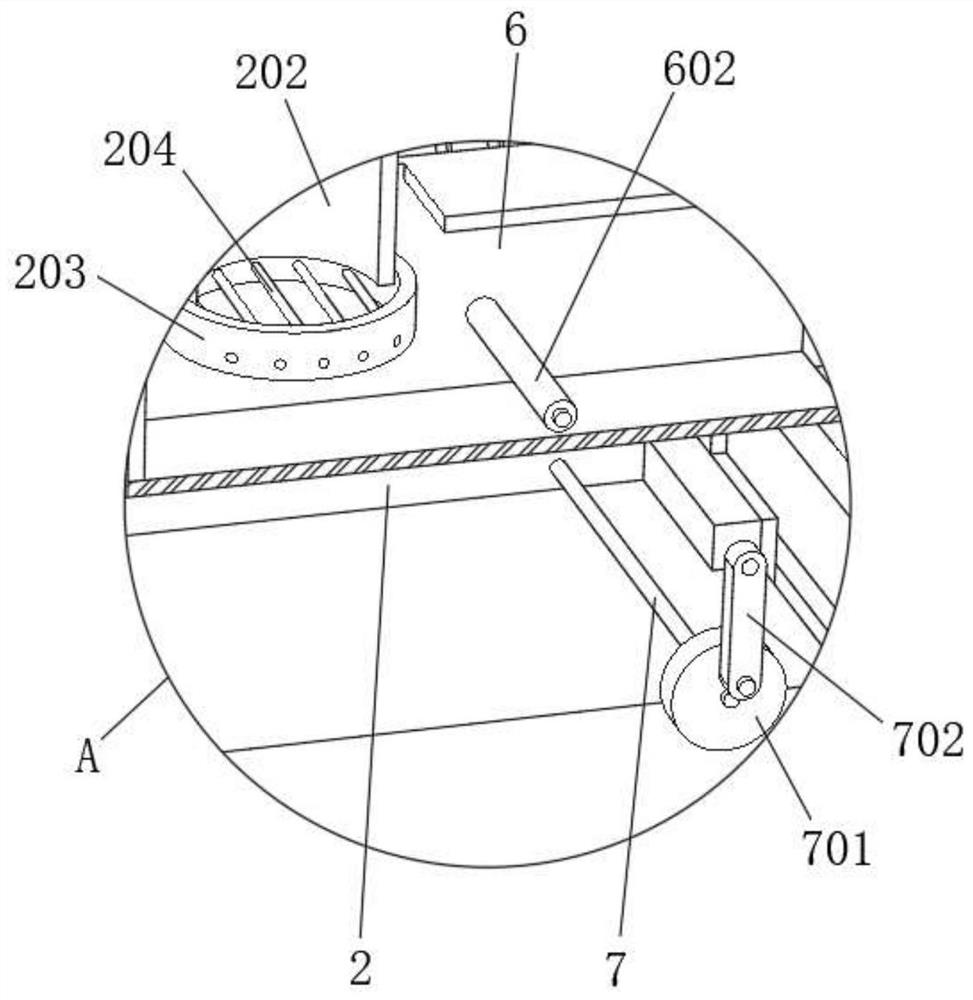

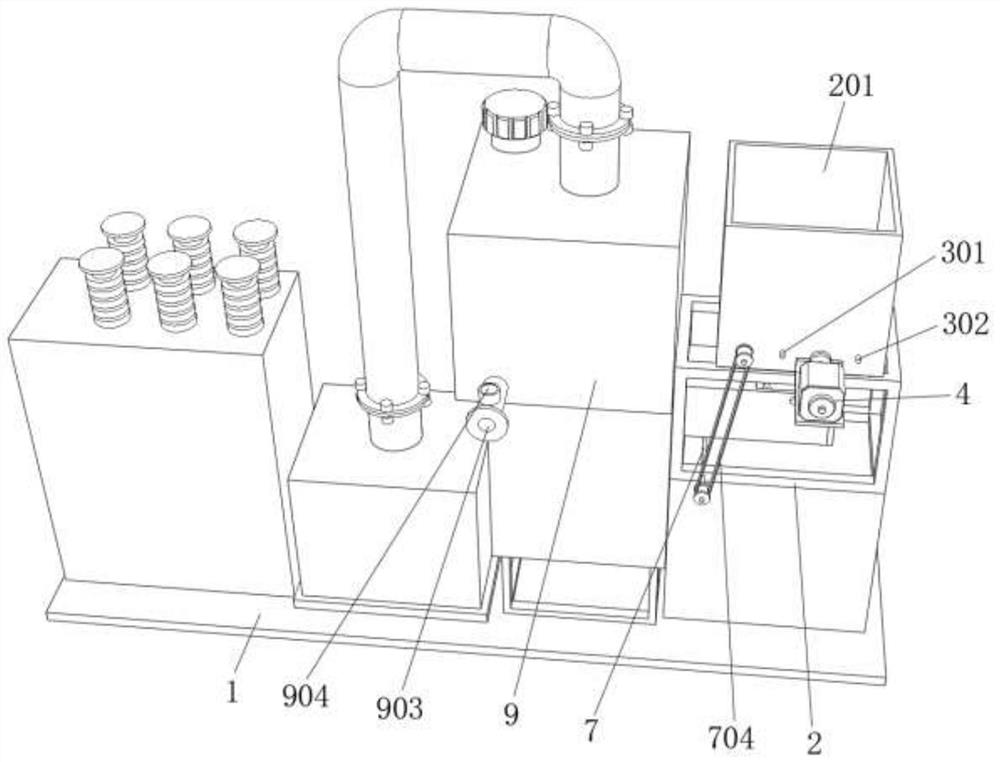

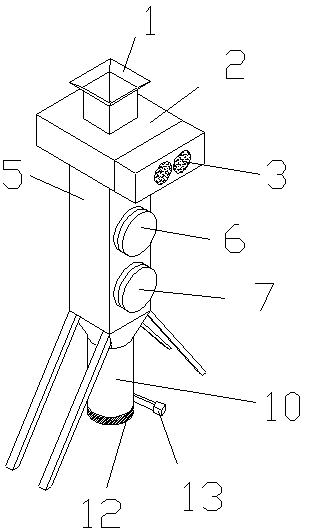

Harmless comprehensive utilization treatment device for field wastes

InactiveCN110326435AMake sure to smashEnsure a virtuous circle and sustainable developmentCuttersHeatDiseaseEngineering

The invention discloses a harmless comprehensive utilization treatment device for field wastes. The device comprises a step platen, a crushing box, a chopping device, a crushing device, a sterilization and conveying device, a stirring mechanism and a temperature control mechanism, wherein a mounting rack is arranged on the left side of the upper end of the step platen, two symmetrically distributed supports are arranged in the middle of the upper end of the step platen, and a conveying barrel is arranged at the upper ends of the supports in a matched manner. According to the harmless comprehensive utilization treatment device for field wastes, thorough crushing of the field wastes is guaranteed through two stages of crushing, minimization of materials is realized, later sterilization and fertilization are facilitated, high-temperature sterilization and turning conveying are performed simultaneously in the conveying process, a cross infection source of diseases is cut off, proper temperature for fermentation is guaranteed, biological implantation and breeding of microorganisms are accelerated, the well fermented and matched materials are returned to the field soil, organic matter and nutrients of the soil are greatly increased, the adverse factors such as soil hardening, poor tilth, excessive heavy metals and the like are solved, and virtuous cycle and sustainable development ofagriculture production are realized.

Owner:江苏艺轩园林景观工程有限公司

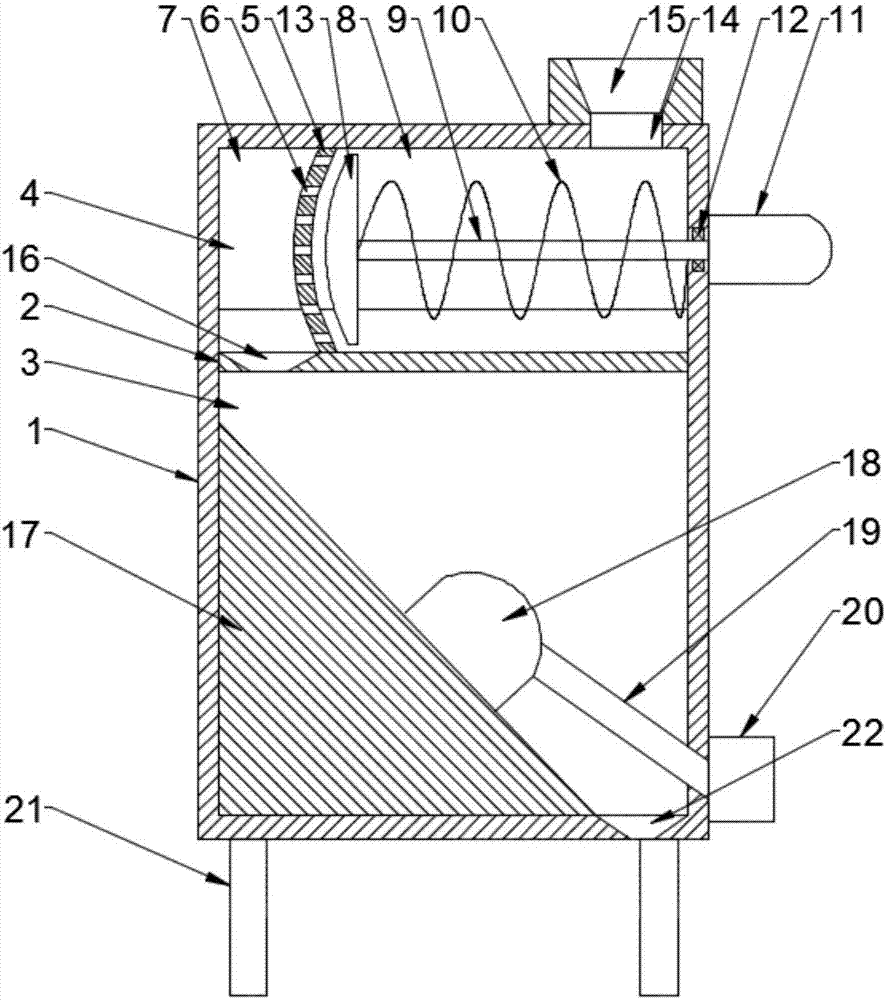

Method and equipment for manufacturing super-high-temperature-resistant ink visible under specific wavelength

ActiveCN113088128AWell mixedEnsure thorough mixingShaking/oscillating/vibrating mixersTransportation and packagingMechanical engineeringEngineering

The invention discloses a method and equipment for manufacturing super-high-temperature-resistant ink visible under a specific wavelength, which relate to the technical field of ink manufacturing. The invention discloses a method and equipment for manufacturing super-high-temperature-resistant ink visible under a specific wavelength. The equipment comprises an external control mechanism used for starting an external control device, a spiral smashing mechanism used for conducting smashing through spiral rotation, a magnetic vibration mechanism used for conducting magnetic vibration, a movable clamping and smashing mechanism used for conducting movable clamping and smashing and a shaking clamping and smashing mechanism used for conducting shaking and smashing, wherein an outer cylinder is arranged in the external control mechanism. According to the method and the equipment for manufacturing super-high-temperature-resistant ink visible under a specific wavelength, the spiral rod rotates in the outer cylinder to mix materials, so that the materials rise along the spiral track of the spiral rod, the materials sinking to the bottom are turned up, and the spiral track rotates along with the rotating shaft, and therefore, the material falling between the air bag and the rotating shaft is jacked up.

Owner:佛山方嘉机电科技有限公司

Bamboo splint perforating machine capable of recycling waste conveniently

InactiveCN107297791AGuaranteed effectGuaranteed to be smoothStationary drilling machinesRevolution surface grinding machinesEngineeringAir blower

The invention discloses a bamboo strip punching machine for recycling waste materials, which comprises a fixed cavity and a storage cavity. A drill rod is arranged at the bottom of the fixed cavity and is connected with an output shaft of a motor. One side of the drill rod is provided with a There is a distance measurer and the distance measurer is connected to the bottom of the fixed cavity, the other side of the drill rod is provided with a grinding rod and the grinder rod is connected to the output shaft of the grinding motor, a storage box is arranged between the drill rod and the grinder rod and The storage box is connected with the bottom of the fixed chamber, and the inside of the storage chamber is provided with a crushing blade connected with the output shaft of the crushing motor. The invention can ensure the smoothness of the inner wall of the grinding hole through the grinding motor, can clean the sawdust in the bamboo and wood strips through the blower, can clean the sawdust motor of the bamboo and wood strips through the crushing motor, and can clean the wood chips in the bamboo and wood strips through the electric telescopic rod. The punching height and depth can be adjusted, the structure is reliable, safe, environmentally friendly, labor-saving, and suitable for wide promotion and use.

Owner:陈建云

Sheep excrement treatment device

The invention discloses a sheep excrement treatment device. The sheep excrement treatment device comprises screens, cutter seats and sleeves. The number of the screens is one less than the number of the cutter seats. The screens and the cutter seats are arranged in an alternate mode. Each cutter seat is arranged above the corresponding screen. A rotating shaft passes through the screens vertically. The rotating shaft is hollowly sleeved with the screens. The outer edges of the screens are connected with the inner surface of a machine shell in a sliding mode, and the screens can only move up and down in the machine shell. The sleeves are coaxially arranged outside the positions, located under the screens and above the cutter seats, of the rotating shaft in a sleeving mode. The screens are fixedly connected with the upper ends of the sleeves, and arc-shaped lower protrusions are arranged at the lower ends of the sleeves for supporting the screens on the cutter seats. Arc-shaped upper protrusions which are located at the same circumference with the arc-shaped lower protrusions are arranged on the upper surfaces of the cutter seats. The sheep excrement treatment device has the effectsthat external power is not needed for vibration, the vibration of the machine shell is reduced, and the service life of the machine body is prolonged.

Owner:务川自治县宏牧羊业有限公司

Cloth dye power manufacturing device

The invention discloses a fabric dyeing dye powder manufacturing device, which comprises a machine body. chamber and the right chamber, the right chamber is provided with a rotating shaft, the rotating shaft is covered with crushing leaves, the right side of the top wall of the right chamber is provided with a feeding hole, the bottom wall of the left chamber is provided with a communication hole; the lower chamber is equipped with There is a guide body, on which there is a second grinding body, on which a push rod is hinged, the other end of the push rod is connected to the reciprocating propulsion device, the bottom wall of the lower chamber is provided with a discharge hole, the discharge hole It is a tapered hole, and the bottom end of the machine body is evenly provided with several legs; the crushing leaves provided in the present invention carry out preliminary crushing treatment on the dye block, and the first grinding body and the second grinding body are set to carry out the first grinding process on the dye particles. Grinding and second grinding, multi-level classification treatment, ensure that the dye particles are completely crushed, and the uniformity of the crushing is relatively good.

Owner:冯飞燕

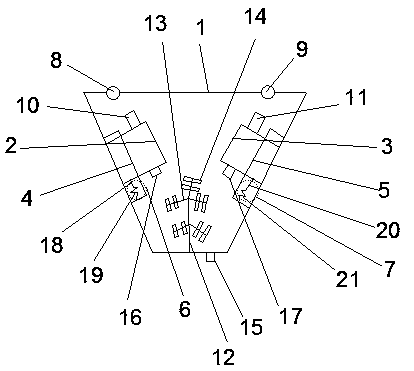

Pulverizer with full pulverizing function

InactiveCN108543600AReasonable structureMake sure to smashGrain treatmentsEngineeringMaterial storage

The invention discloses a pulverizer with a full pulverizing function. The pulverizer structurally comprises a conical shell, a first material storage chamber and a second material storage chamber, wherein a first guide rail is arranged at one side of the conical shell, a second guide rail is arranged at the other side of the conical shell, a first elastic module is arranged at the bottom end of the first guide rail, a second elastic module is arranged at the bottom end of the second guide rail, the first material storage chamber is fixed at one side of the conical shell through the first guide rail, the second material storage chamber is fixed at the other side of the conical shell through the second guide rail, a first feeding opening and a second feeding opening are formed in the top ofthe conical shell, a rotating shaft is arranged inside the conical shell, a plurality of layers of triangle rotating rods are arranged on the rotating shaft from top to bottom, a plurality of bladesare distributed on the rotating rods, and a discharging opening is formed in the bottom of the conical shell. The pulverizer has a reasonable structure, and the insufficient pulverizing of materials caused by excessive feeding is prevented through the control of the feeding of the first material storage chamber and the second material storage chamber.

Owner:如皋市昌旭机械制造有限公司

Chemical fertilizer anti-blocking device

The invention discloses a chemical fertilizer anti-blocking device which comprises a device body. The device body is provided with a feeding opening and a discharging opening, three smashing zones are arranged inside the device body, each smashing zone is internally provided with a spiral agitator, a sliding block is arranged at the discharging position of each spiral agitator, and the discharging position of the smashing zone at the bottom corresponds to the discharging opening. The feeding end is connected to the discharging opening, a transmission mechanism is arranged at the lower end of the feeding end, a suspension force arm is fixedly connected to the transmission mechanism, a base is arranged at the bottom of the transmission mechanism, a motor is connected to the end, far away from the transmission mechanism, of the suspension force arm, and a container for containing dissolved chemical fertilizer is arranged below the motor. The chemical fertilizer anti-blocking device has the beneficial effects that the agitators are arranged to be of spiral structures, so that it is guaranteed that the agitators push fertilizer blocks to advance in the fertilizer block smashing process. According to the device, the three smashing zones are arranged inside the device body, and it is guaranteed that the fertilizer blocks incoming from the feeding opening are sequentially smashed.

Owner:东兴易新环保科技有限公司

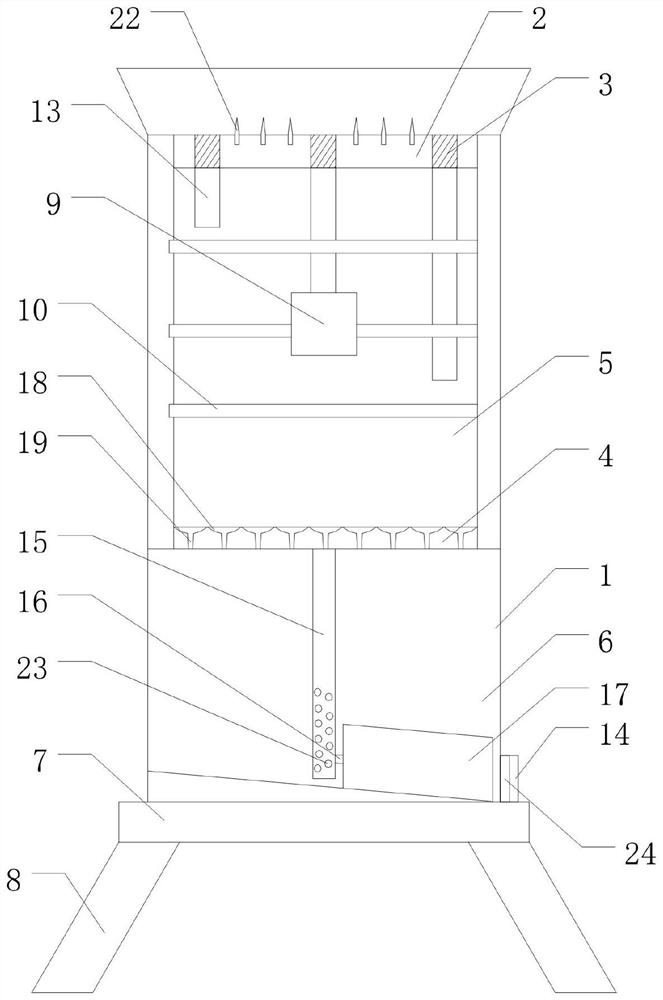

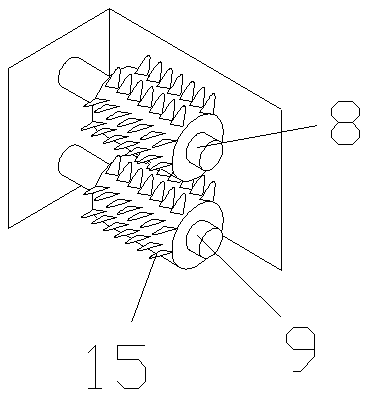

Preparation method of composite humic acid soil remediation agent

InactiveCN113441068ACut off to ensureMake sure to smashMixersSoil remediationEnvironmental engineering

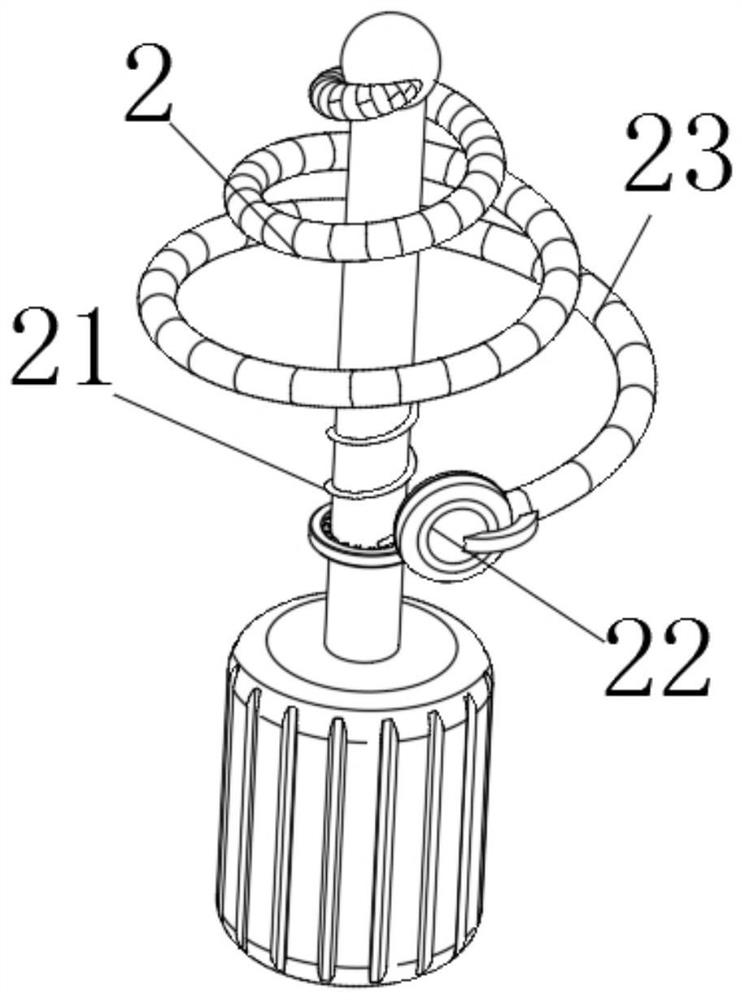

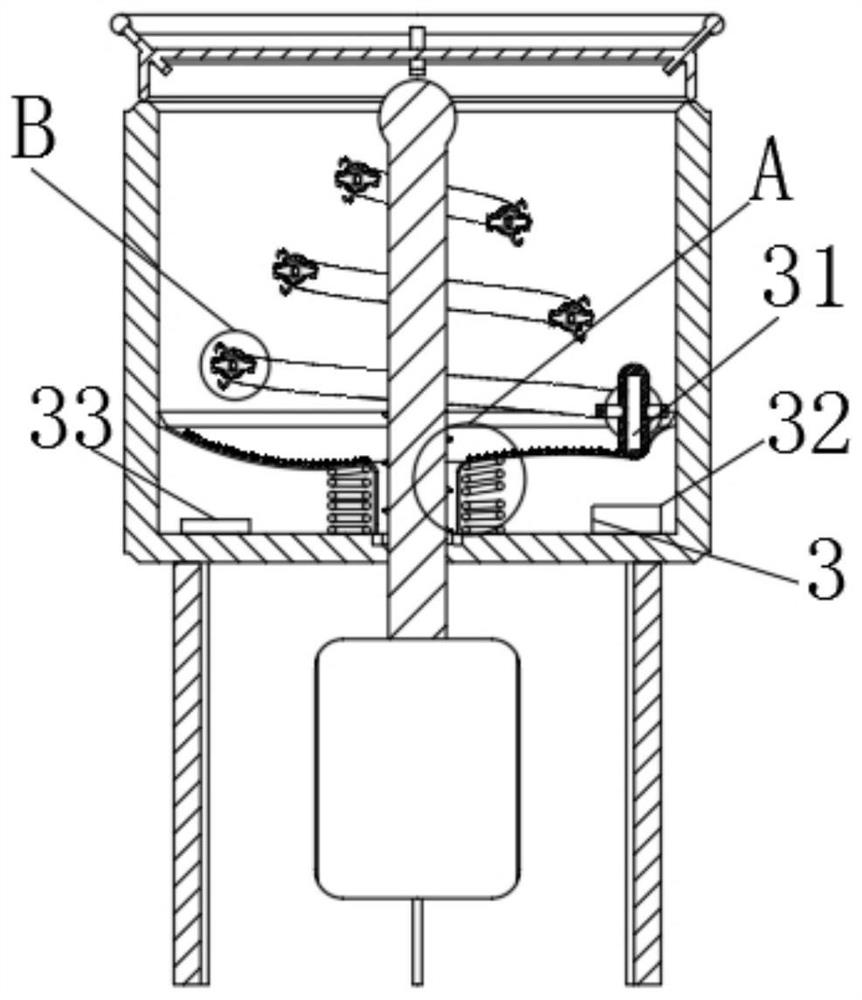

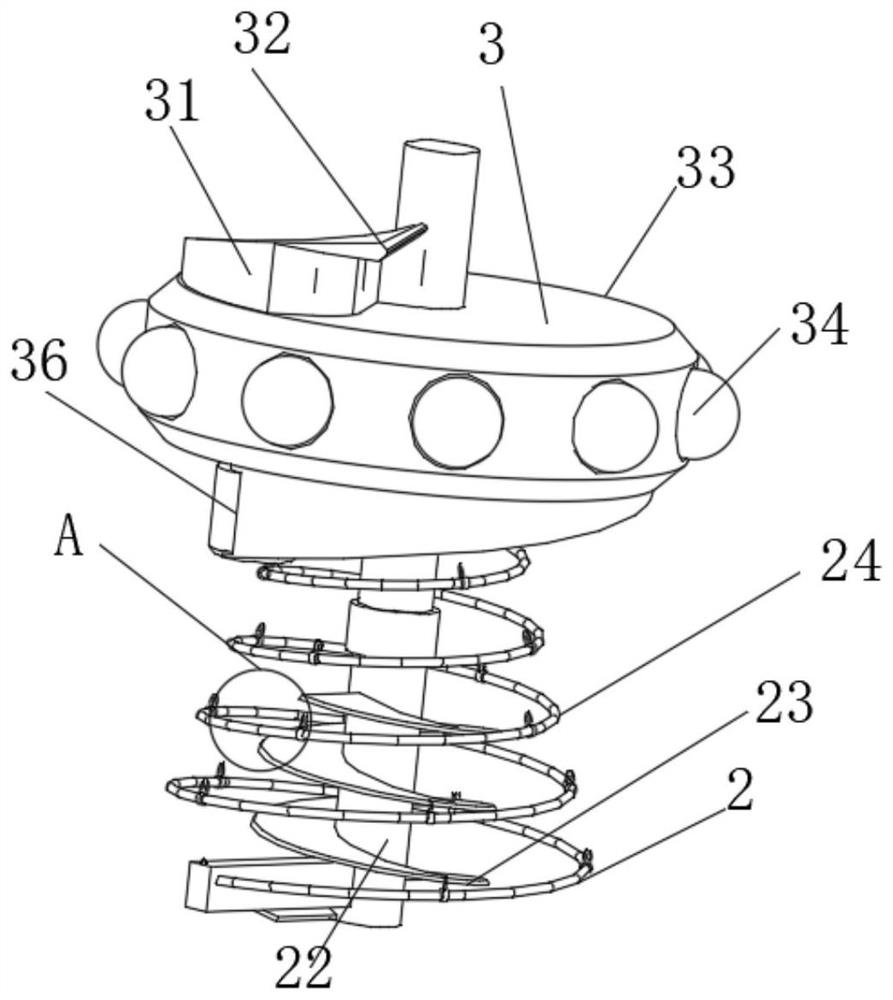

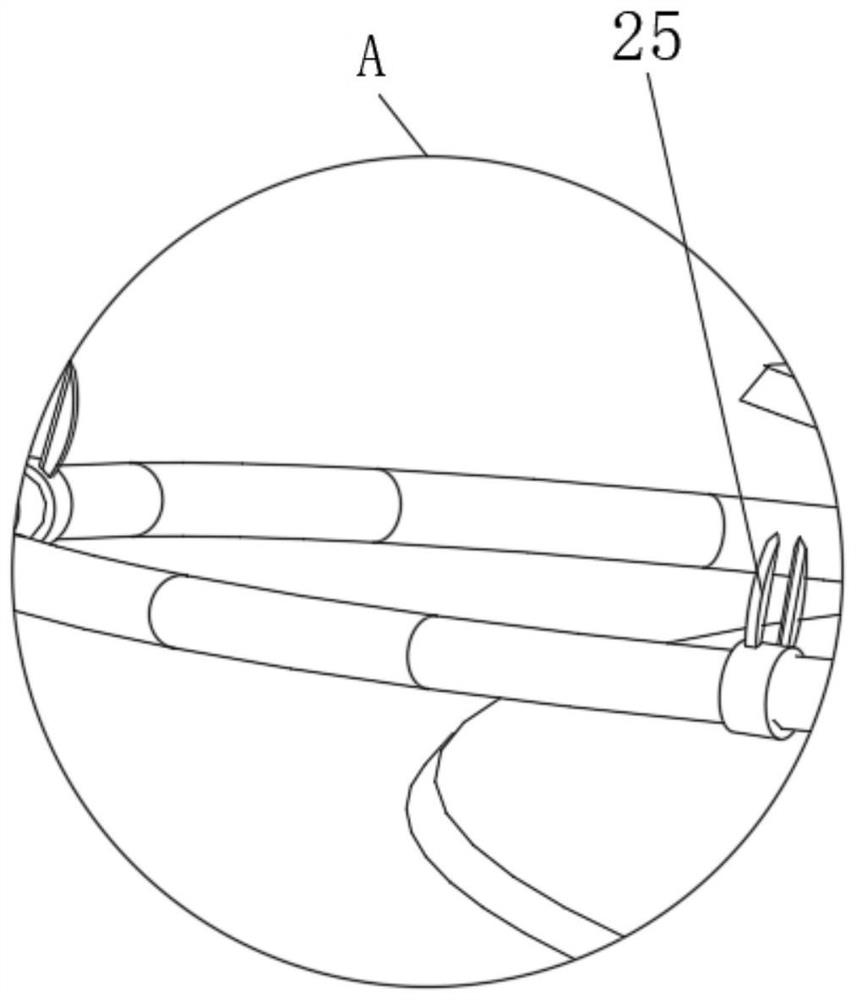

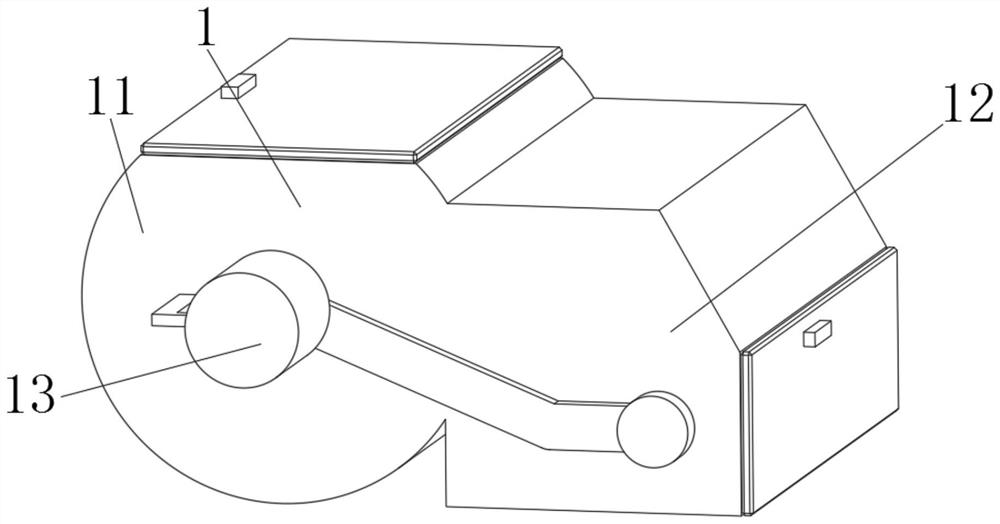

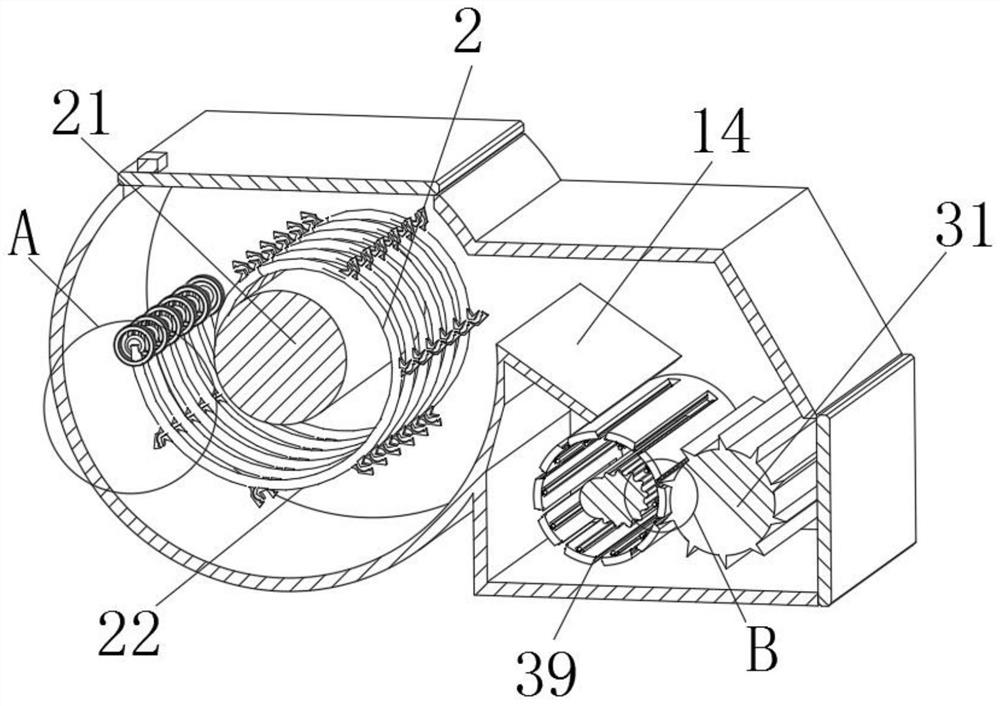

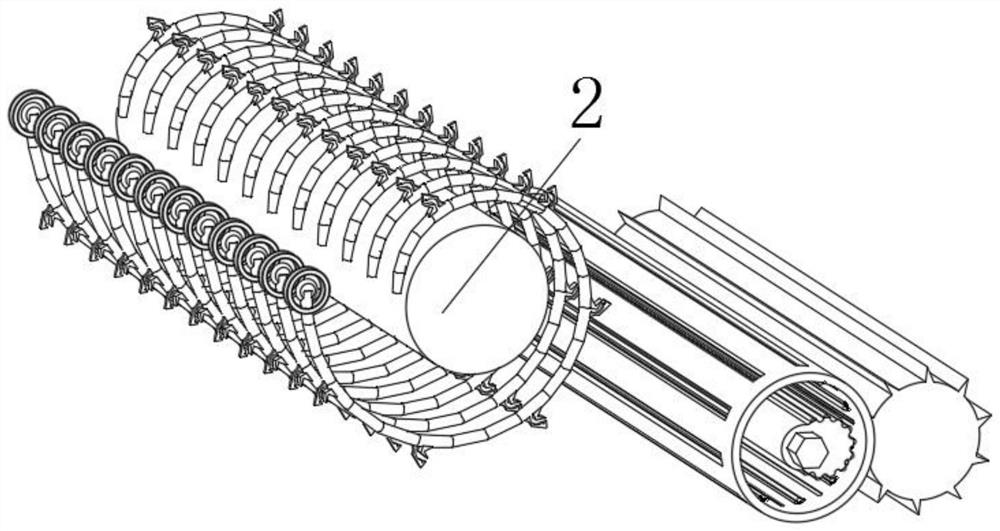

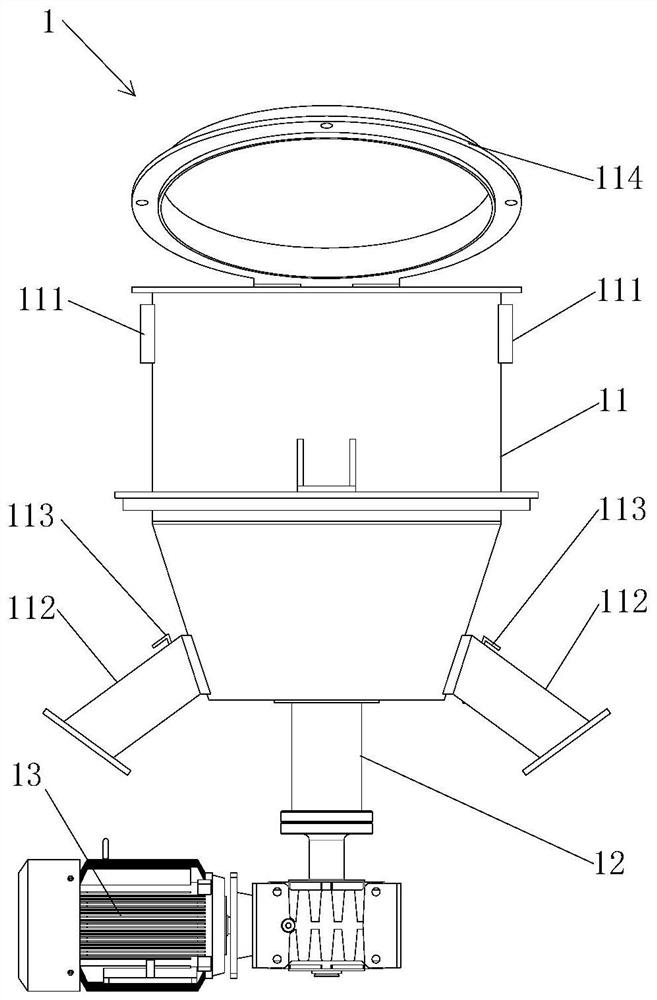

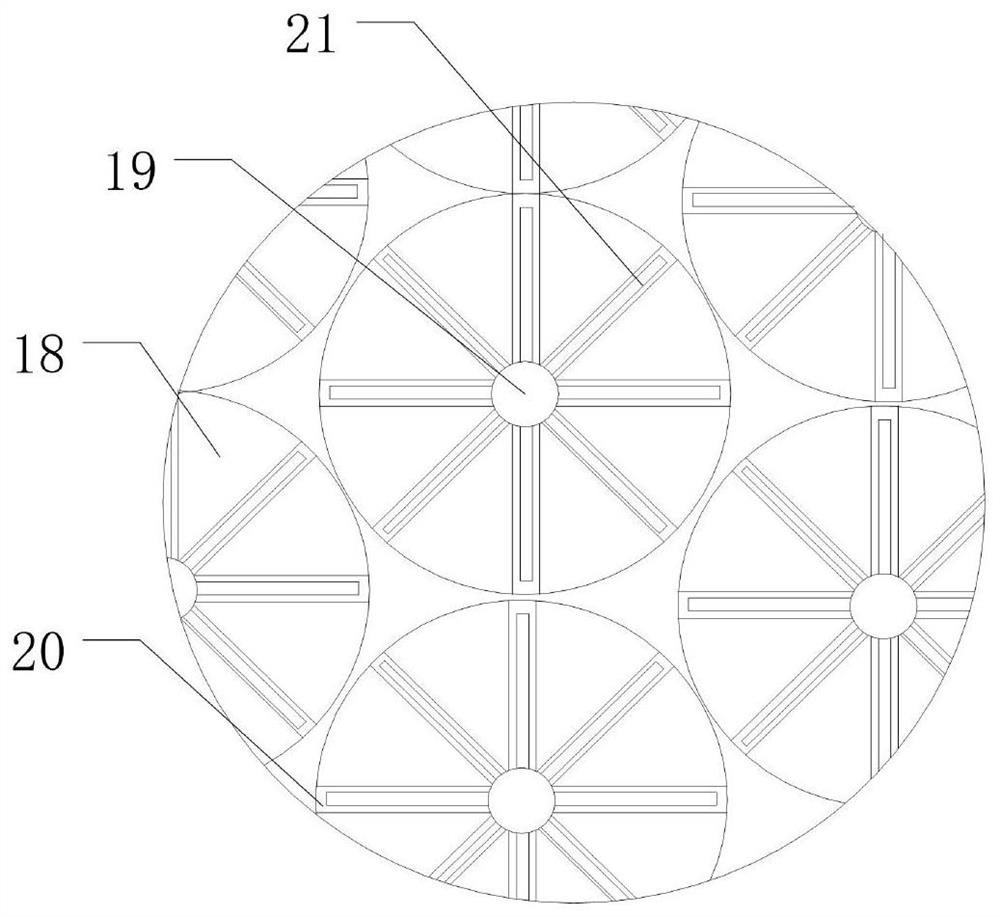

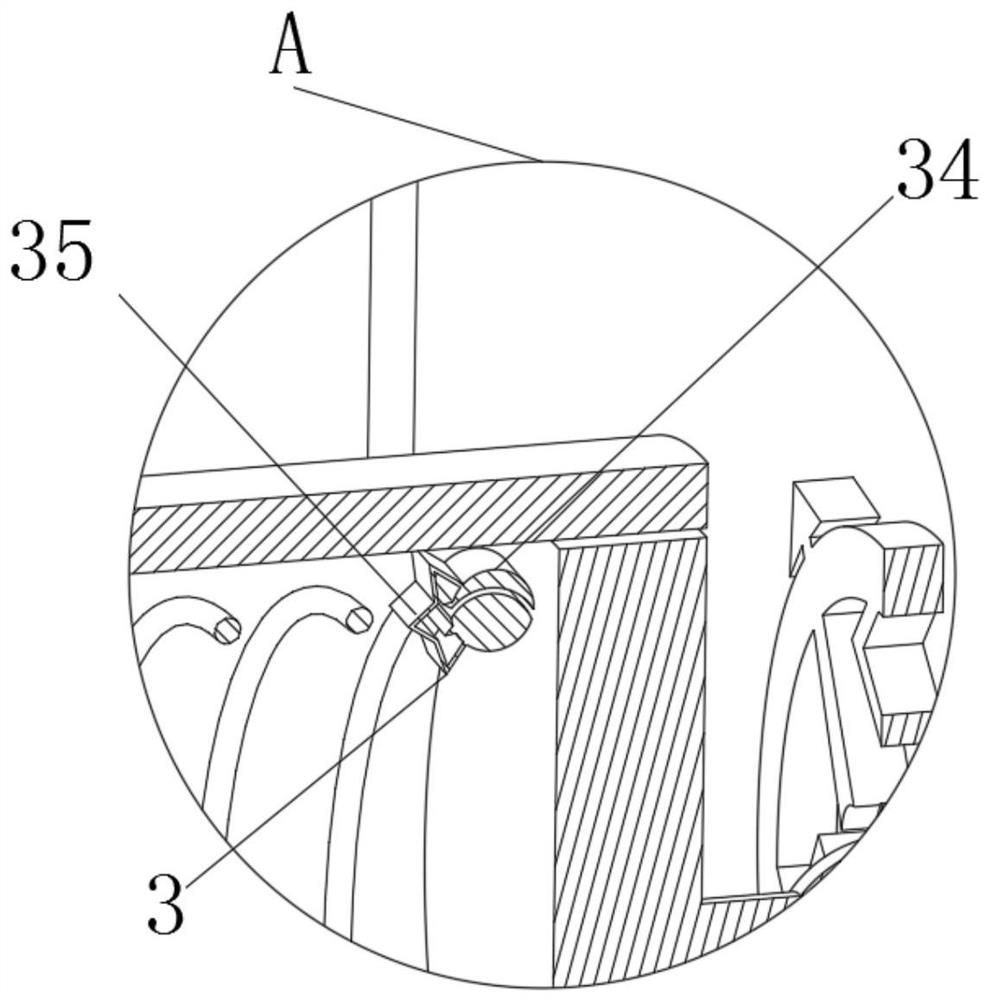

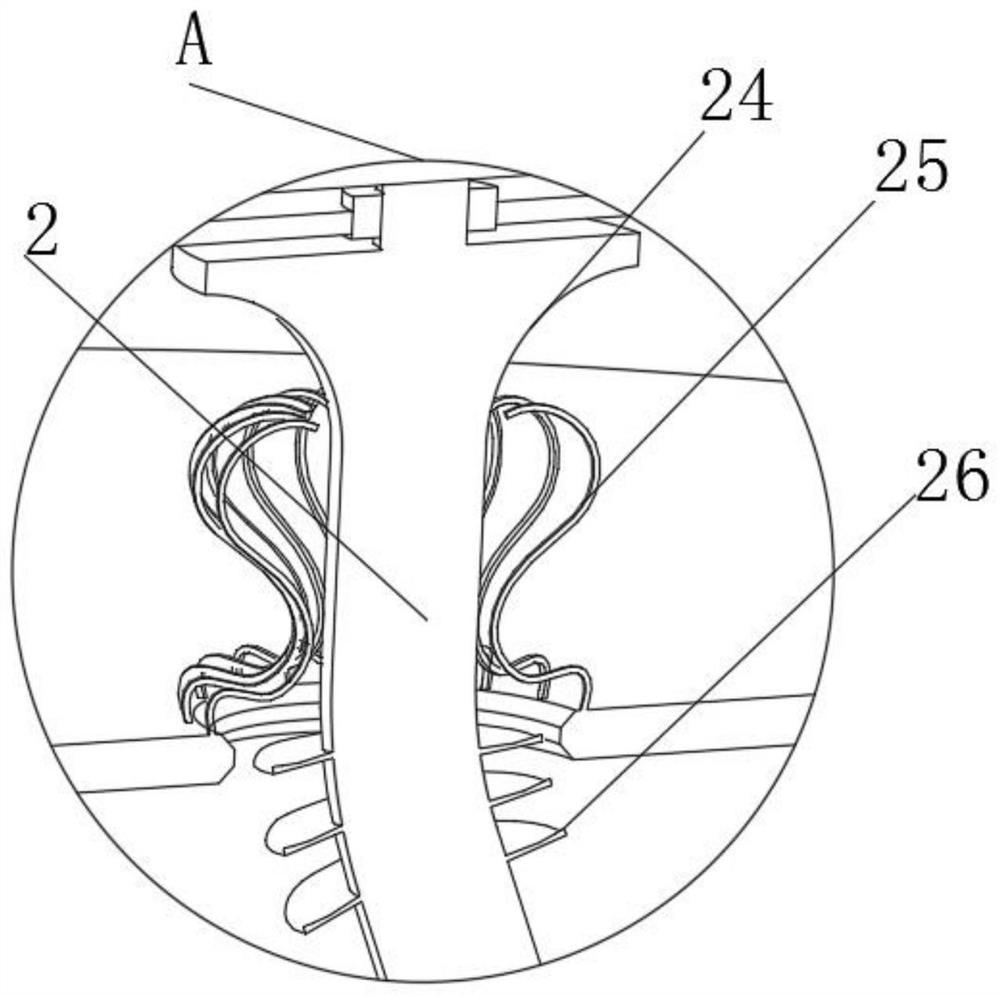

The invention discloses a preparation method of a composite humic acid soil remediation agent, and relates to the technical field of humic acid soil remediation. According to the preparation method of the composite humic acid soil remediation agent, an external control mechanism (1) used for external control, a rotary scattering mechanism (2) used for rotating for scattering and a rotary extrusion mechanism (3) used for rotating for extrusion are included, and a shell (11) is arranged at the bottom of the external control mechanism (1); and the external control mechanism (1) is internally provided with a rotary scattering mechanism (2) through an arranged shell (11). According to the preparation method of the composite humic acid soil remediation agent, various materials such as straw and carbon are cut into required sizes through the cooperation of a first cut-off tool (32) and a second cut-off tool (35), then the materials are guided into a gap between a grinding disc (33) and the shell (11) through a protruding block (31), and an extrusion ball (34) rotates to extrude the materials.

Owner:秦豫川

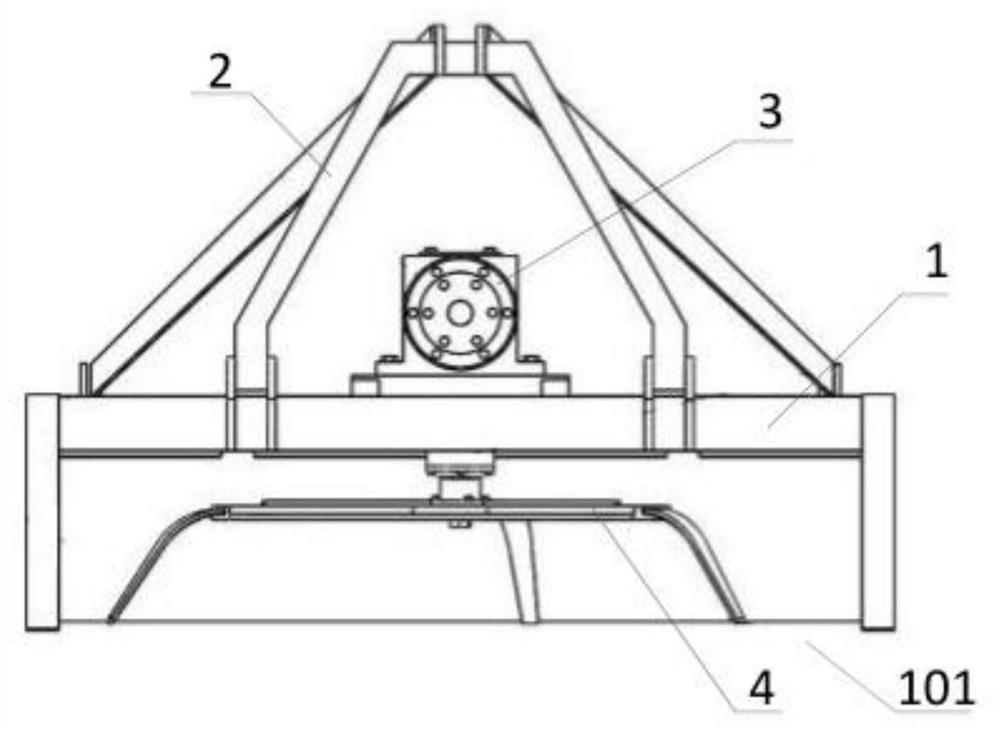

Vertical banana straw crushing and returning machine

The invention discloses a vertical banana straw crushing and returning machine. The machine comprises a rack, a three-point suspension unit, a transmission unit and a crushing unit. The three-point suspension unit is connected with the rack, the three-point suspension unit can be connected with power equipment, the transmission unit is fixed to the rack and can be in transmission connection with the power equipment, the rack is provided with a bottom opening and a side face opening, the bottom opening communicates with the side face opening, the side opening is formed in the side, facing the advancing direction of the power equipment, of the rack, and the rack is arranged on the outside of the crushing unit in a covering mode. The crushing unit comprises a cutter disc and a crushing cutter, the crushing cutter is detachably connected with the cutter disc and can crush banana straw, the cutter disc is in transmission connection with the transmission unit, the transmission unit can drivethe cutter disc to rotate, and a rotating axial line of the cutter disc is perpendicular to a horizontal plane. The cutter disc drives the crushing cutter to rotate during working, the crushing cutter can crush the banana straw, the rack is arranged on the outside of the crushing unit in a covering mode, the banana straw can be prevented from splashing after being crushed, and the straw can be returned to the field.

Owner:HAINAN UNIVERSITY

Device for enabling industry and construction solid waste to be solidified into building material and technology thereof

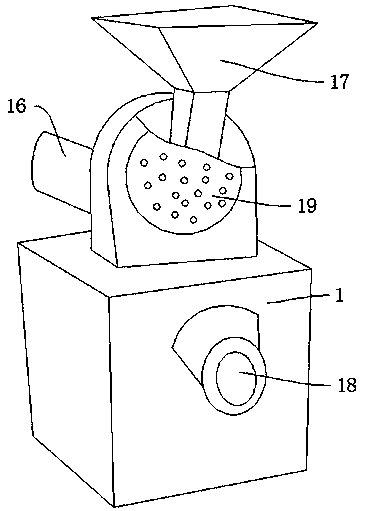

ActiveCN110834026AMake sure to smashAvoid cloggingConstruction waste recoveryTransportation and packagingIndustrial constructionArchitectural engineering

The invention discloses a device for enabling industry and construction solid waste to be solidified into a building material. The device comprises a pulverizer, a screening frame and a shaping box; the pulverizer comprises a feeding hopper, a pulverizing disc is arranged behind the feeding hopper, and a pulverizing motor is arranged behind the pulverizing disc; a discharging outlet is formed in front of the pulverizer; the screening frame is arranged below the discharging outlet, and the upper portion of the screening frame is provided with a screening motor; and the lower portion of the screening motor is provided with a supporting seat, the upper portion of the screening motor is provided with an eccentric wheel, and the upper portion of the eccentric wheel is provided with a connectionshaft. The device has the beneficial effects that the industry and construction solid waste is extruded and pulverized through the pulverizing disc, it is ensured that the solid waste is pulverized,meanwhile, the pulverized solid waste is classified through the screening plate, the indestructible solid waste in the solid waste is separated, blockage in the later period is avoided, and the applicability of the device for enabling the waste to be solidified into the building material is improved; and in addition, the water feeding amount is automatically controlled, thus, the raw material stirring viscosity is ensured, and follow-up shaping is facilitated.

Owner:邱景新

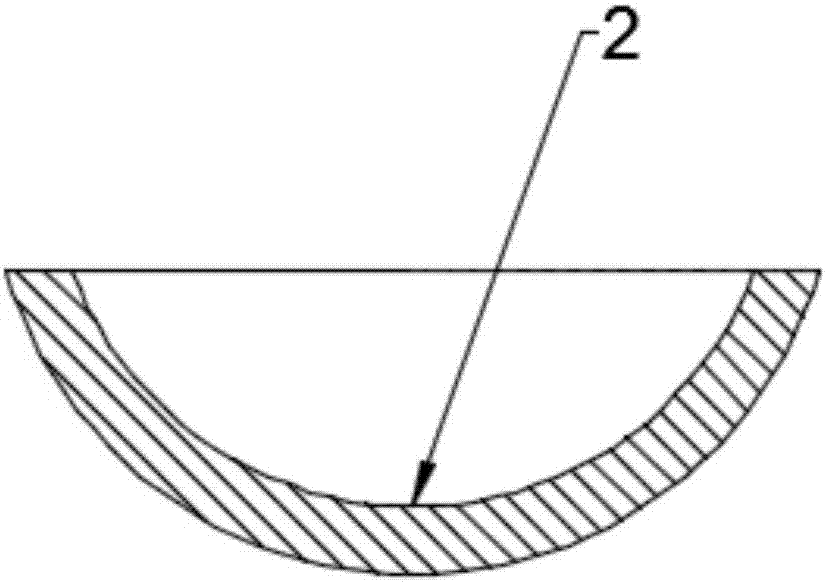

Noise-reducing food processor

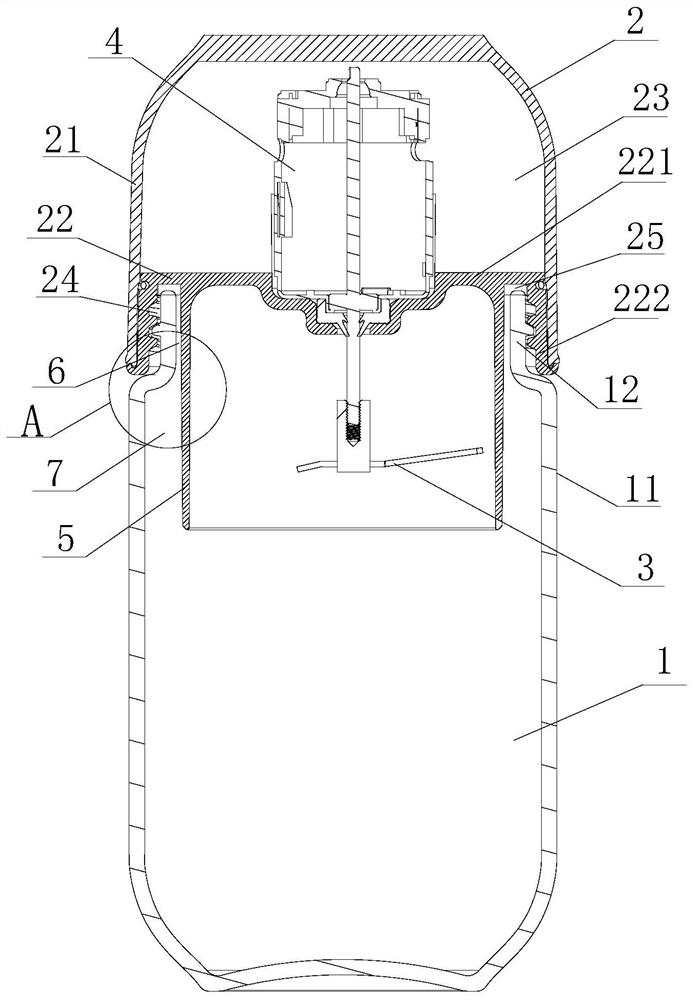

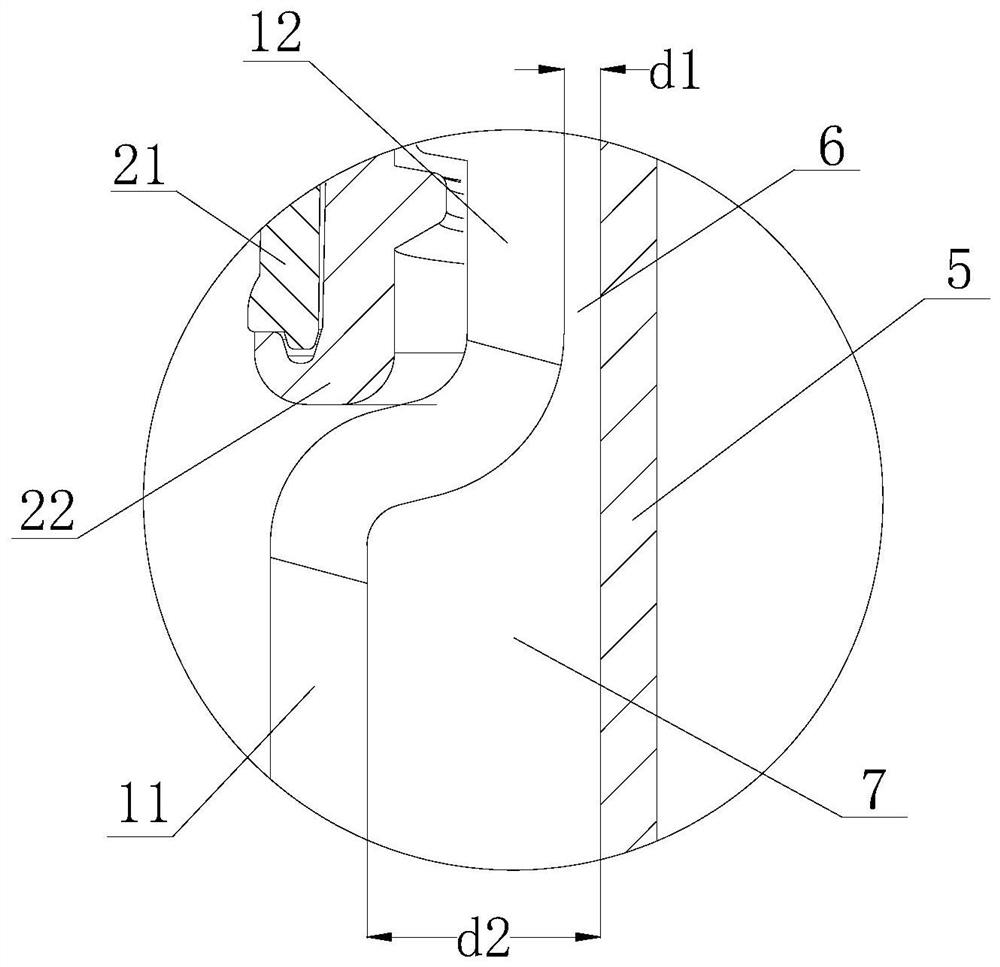

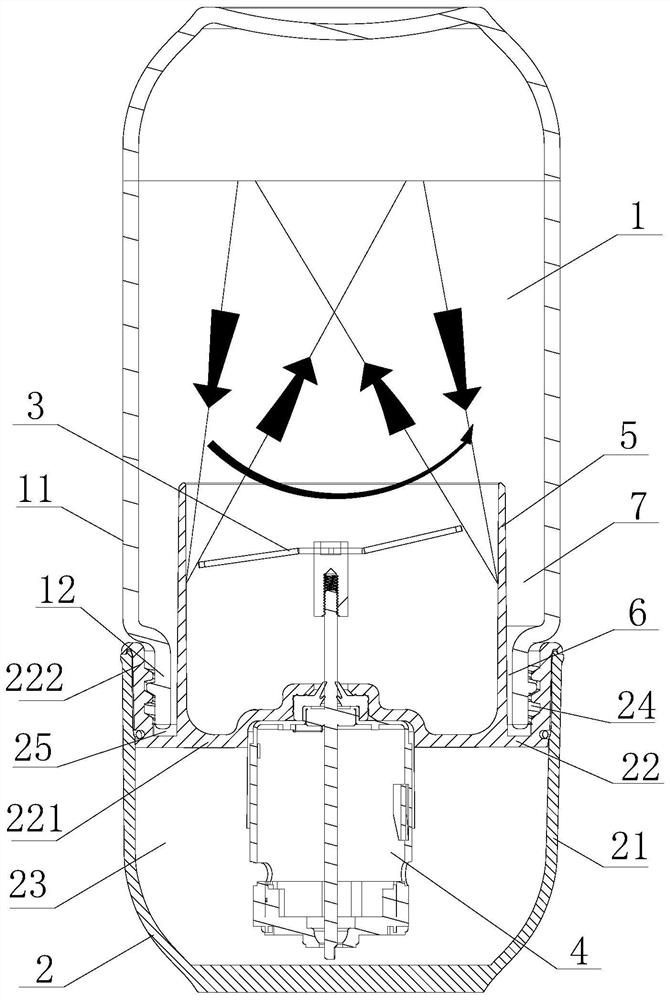

ActiveCN111973011AReduce outward spreadExtended propagation pathKitchen equipmentElectric machineryEngineering

The invention relates to a noise-reducing food processor, which comprises a bowl body and a bowl cover, wherein the bowl body comprises a bowl main body and a bowl mouth. The bowl cover is detachablymounted at the bowl mouth; a crushing knife is arranged at the bottom of the bowl cover; a mounting cavity is arranged inside the bowl cover; a motor for driving the crushing knife to rotate is arranged in the mounting cavity, the inner diameter of the bowl mouth is contracted inwards relative to the inner diameter of the bowl main body, a sound insulation cover surrounding the crushing knife is arranged at the bottom of the bowl cover, the sound insulation cover penetrates through the bowl mouth and extends into the bowl main body, a first annular space is defined by the sound insulation cover and the bowl mouth, and a second annular space is defined by the sound insulation cover and the bowl main body. The bowl mouth is of a necking structure, so that in the noise propagation process, energy of noise is quickly attenuated after the noise is refracted for multiple times in the sound insulation cover, the second annular space and the first annular space, the propagation path of the noise is prolonged, and the noise transmitted outwards when the food processor works is effectively reduced.

Owner:JOYOUNG CO LTD

Crushing device for wood product manufacturing and recycling

InactiveCN114192263ASmash impactEnsure splitTransportation and packagingMixersFiberMechanical engineering

The invention discloses a crushing device for wood product manufacturing and recycling, and relates to the technical field of special wood product manufacturing. The crushing device for wood product manufacturing and recycling comprises an external collecting mechanism used for collecting chippings, a rotary splitting mechanism used for rotating for splitting and a rotary extrusion mechanism used for rotating for extrusion, and a first shell and a second shell are arranged in the external collecting mechanism; a rotary splitting mechanism is arranged in the first shell, and a rotary extrusion mechanism is arranged in the second shell. According to the smashing device for wood product manufacturing and recycling, protruding thorns are clamped into clamping inlets of a shell sleeve, the protruding thorns and cutting thorns are staggered, fibers are cut open, protruding blocks on a third rotating roller are matched with a second round rod and a first round rod for extrusion, rotten wood is extruded, the wood is smashed, and the wood quality is improved. And hard fibers are extruded after being cut, so that the fibers can be further separated.

Owner:余学辉

Intermediate compound of a traditional Chinese medicinal preparation and preparation method and application thereof

InactiveCN101185659AAddressing Adaptive IssuesBreak through the technical problems of decreasing efficiencyPowder deliveryAntipyreticMedicineGum acacia

The invention discloses an intermediate of a liquid Chinese medicine preparation, the preparation and the application thereof, the invention includes pulverization method of single leech ultrafine powder, in particular to a pulverization method of preparing leech ultrafine powder by wet-method ultrafine pulverization method. The method is that leech medical material is pulverized through a traditional method, then added with any one or the compositions of a plurality of gum acacia, betadex, starch and solid carbowax with proper quantity, and then undergone ultrafine pulverization to obtain the preparation intermediate; the intermediate products can be prepared into required dosage forms. This method can improve pulverization efficiency and decrease raw material usage amount in the products.

Owner:北京凯瑞创新医药科技有限公司

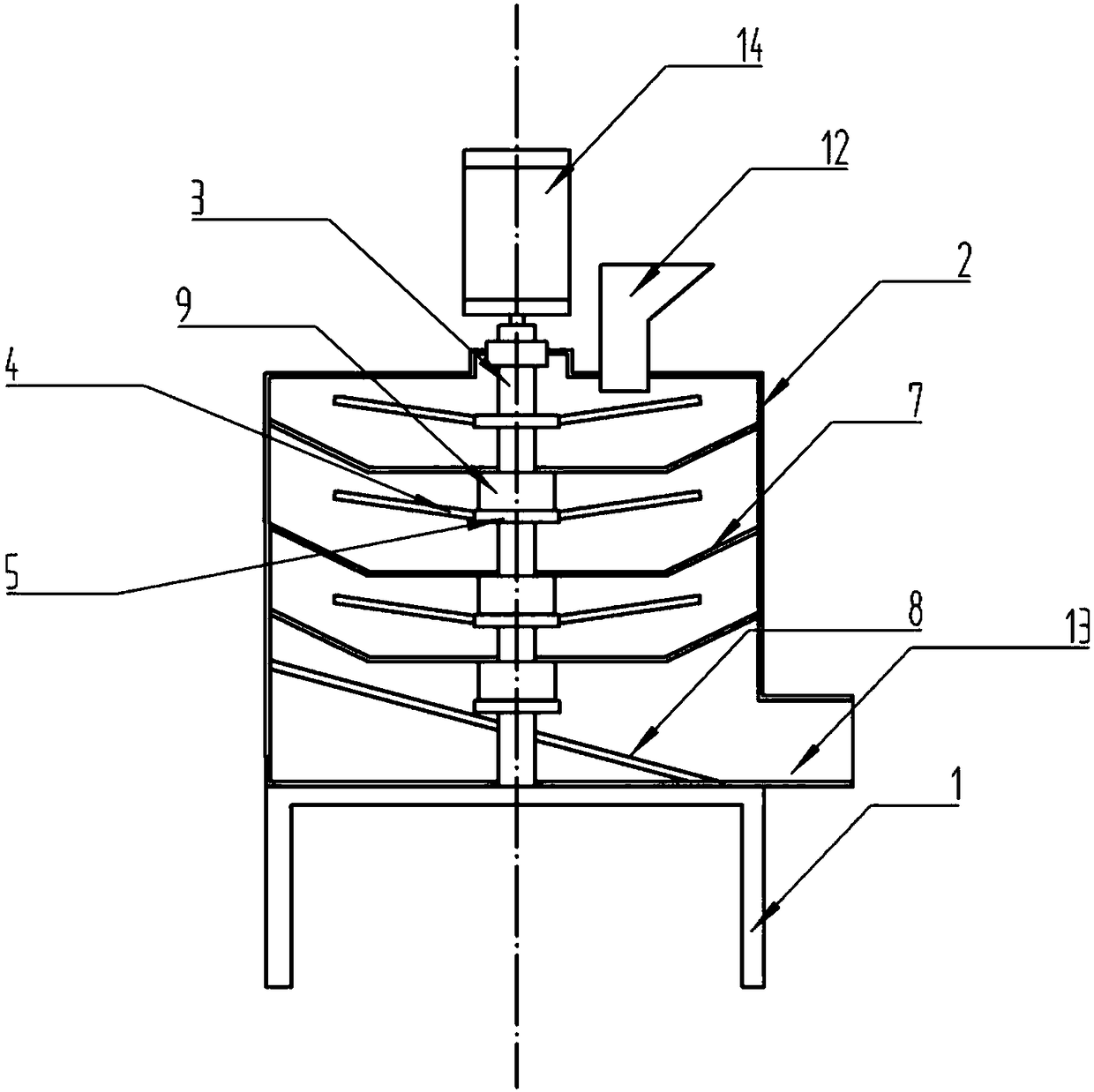

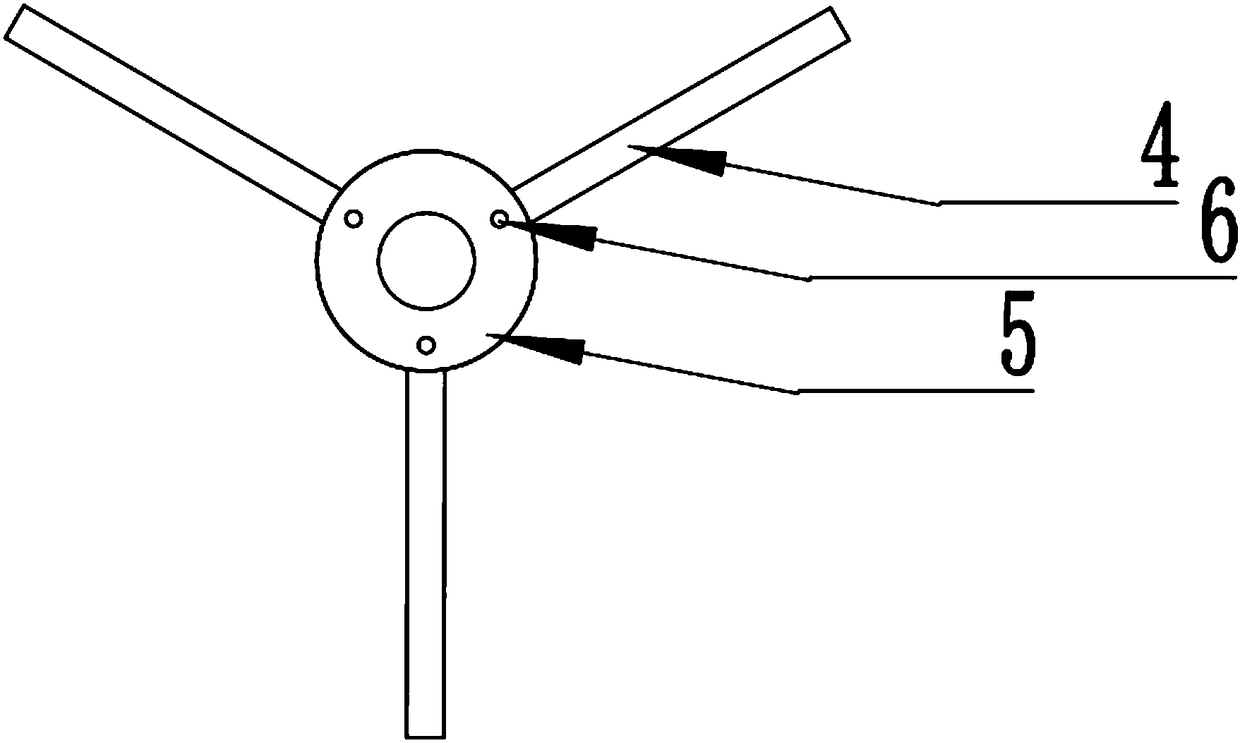

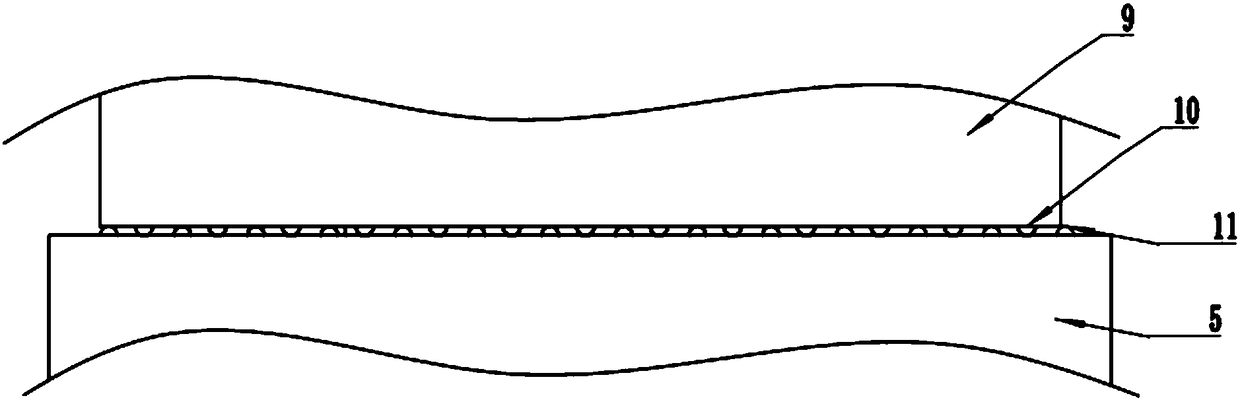

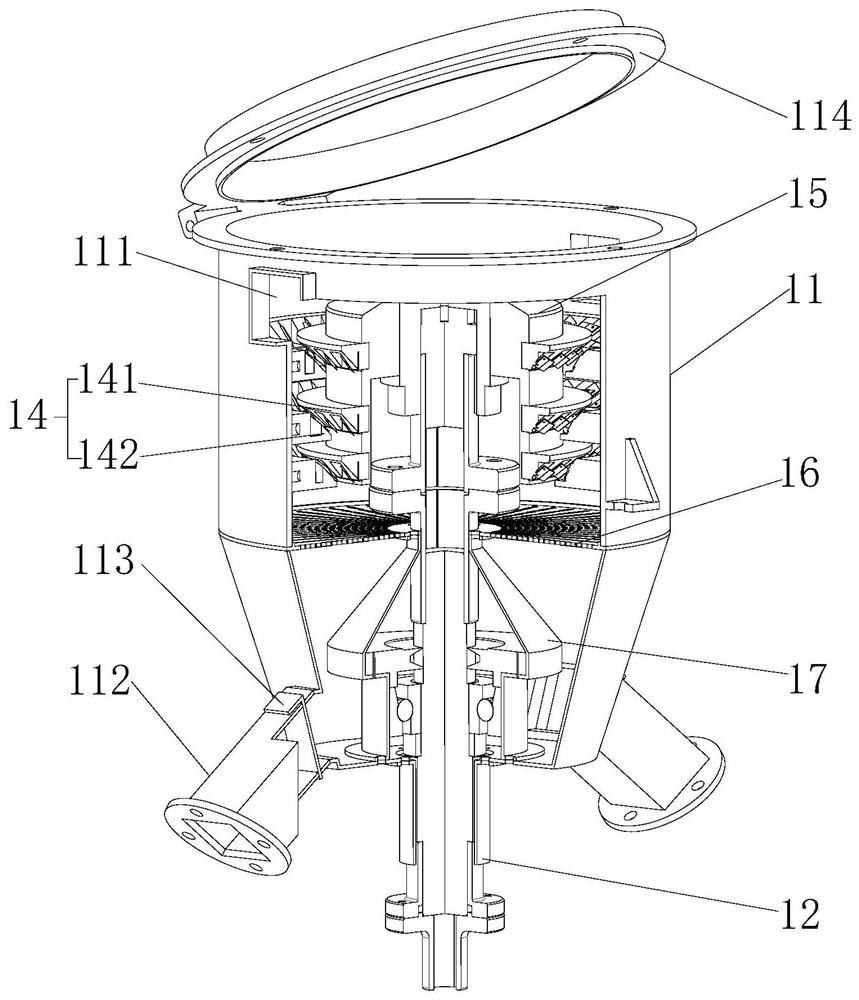

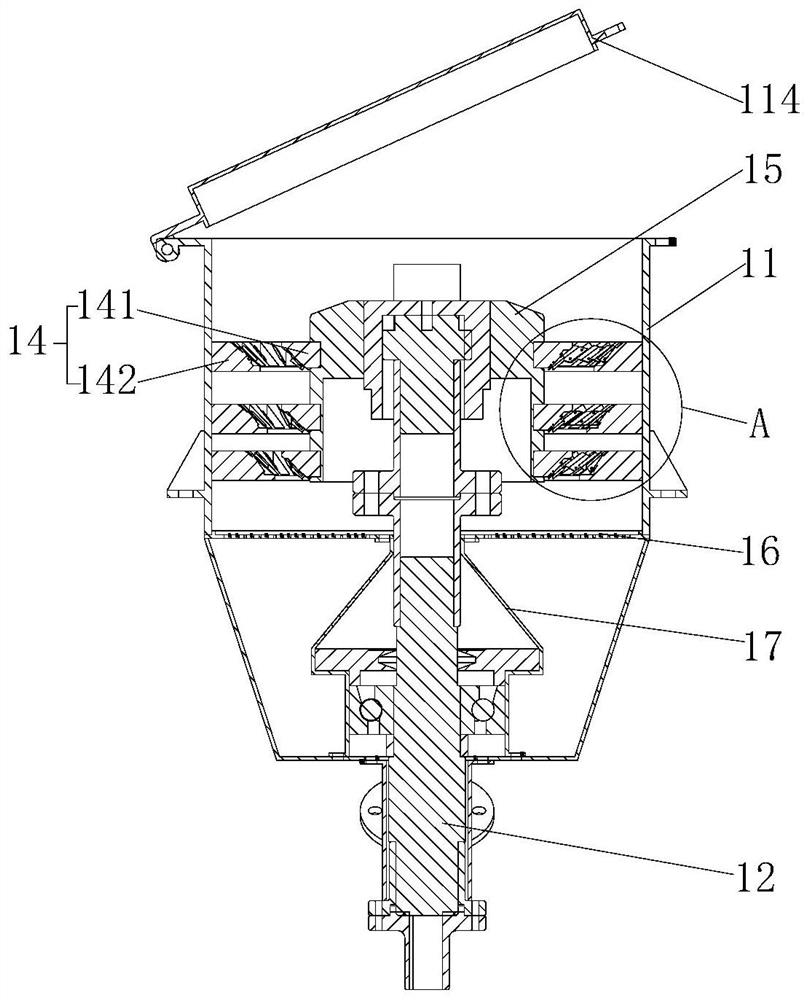

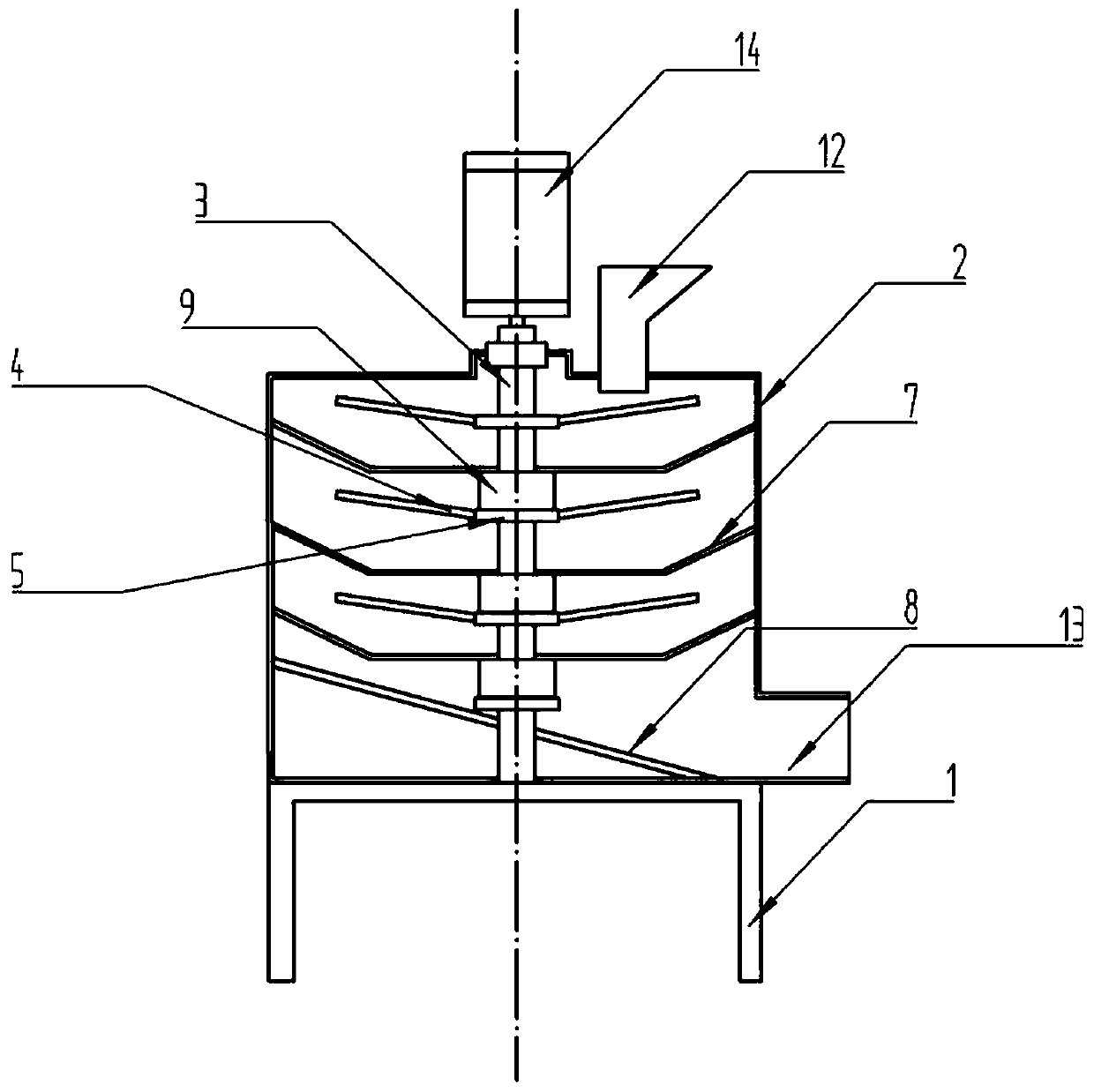

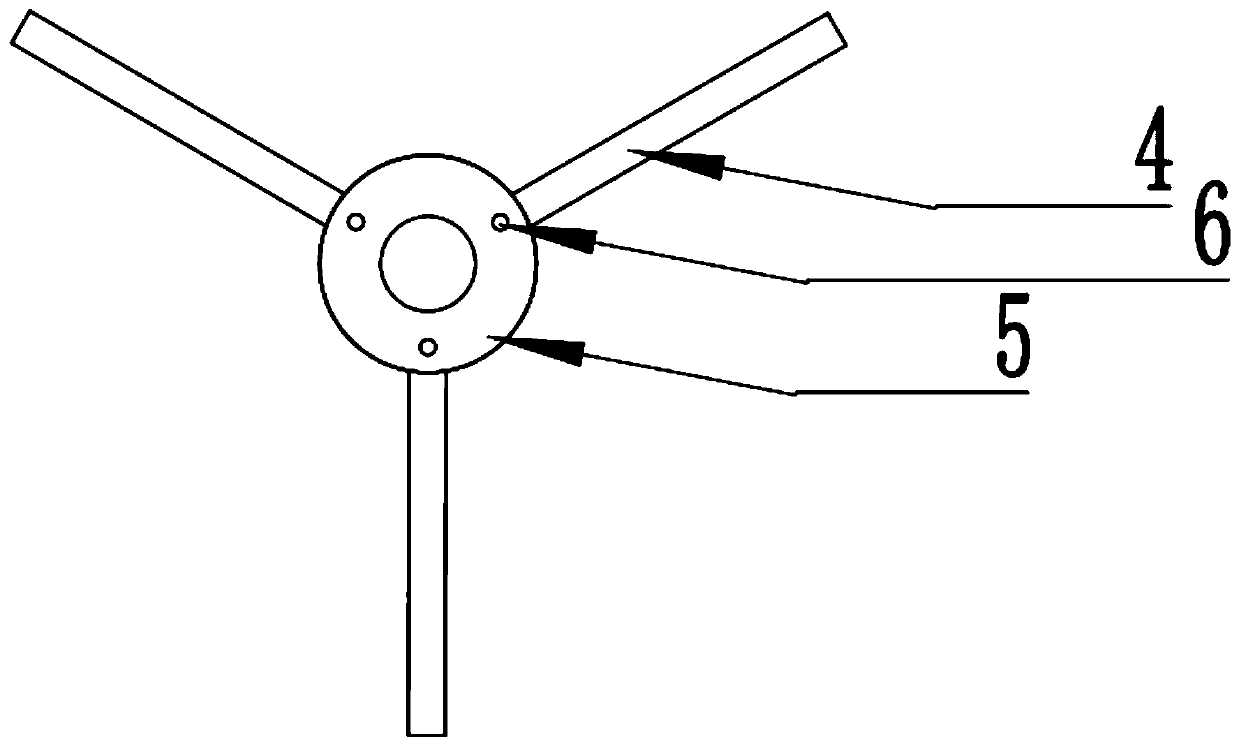

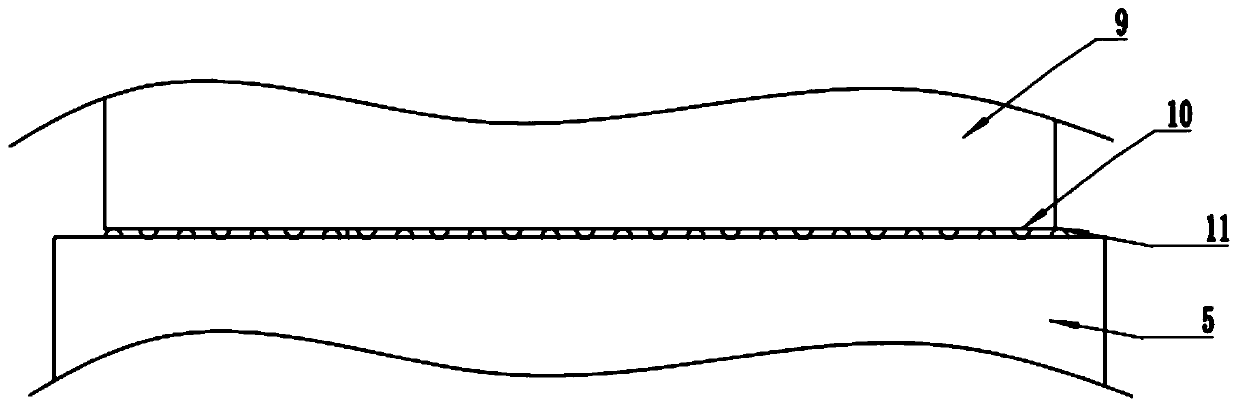

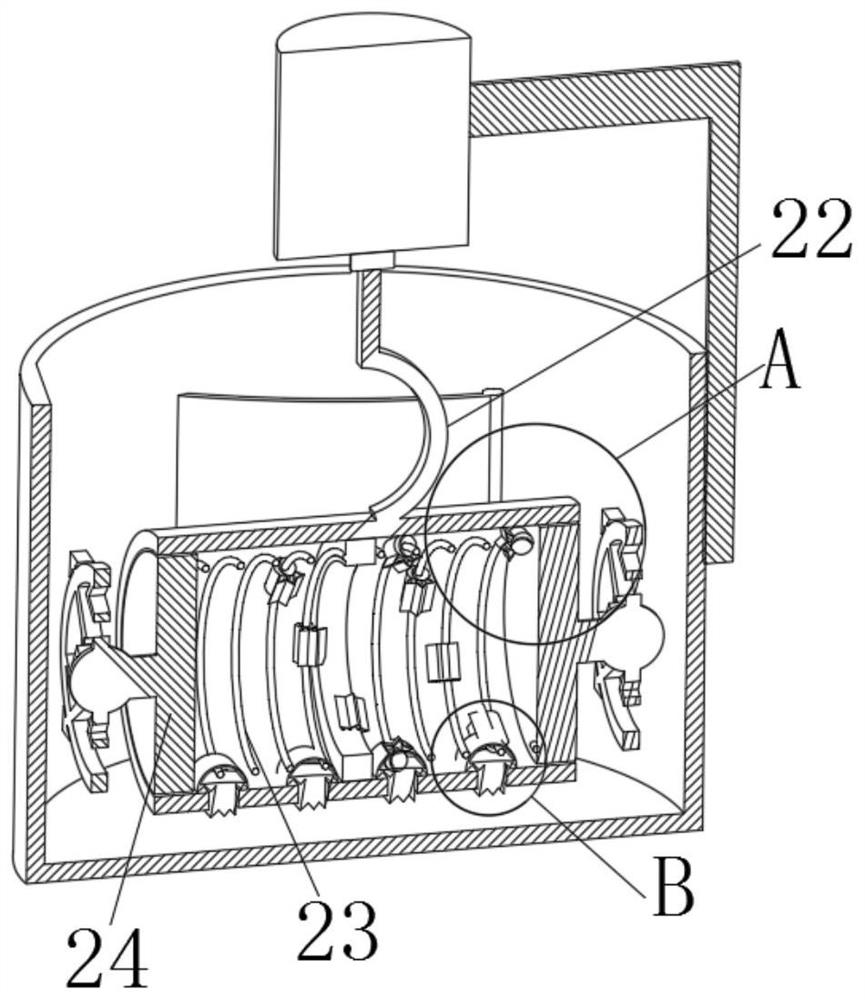

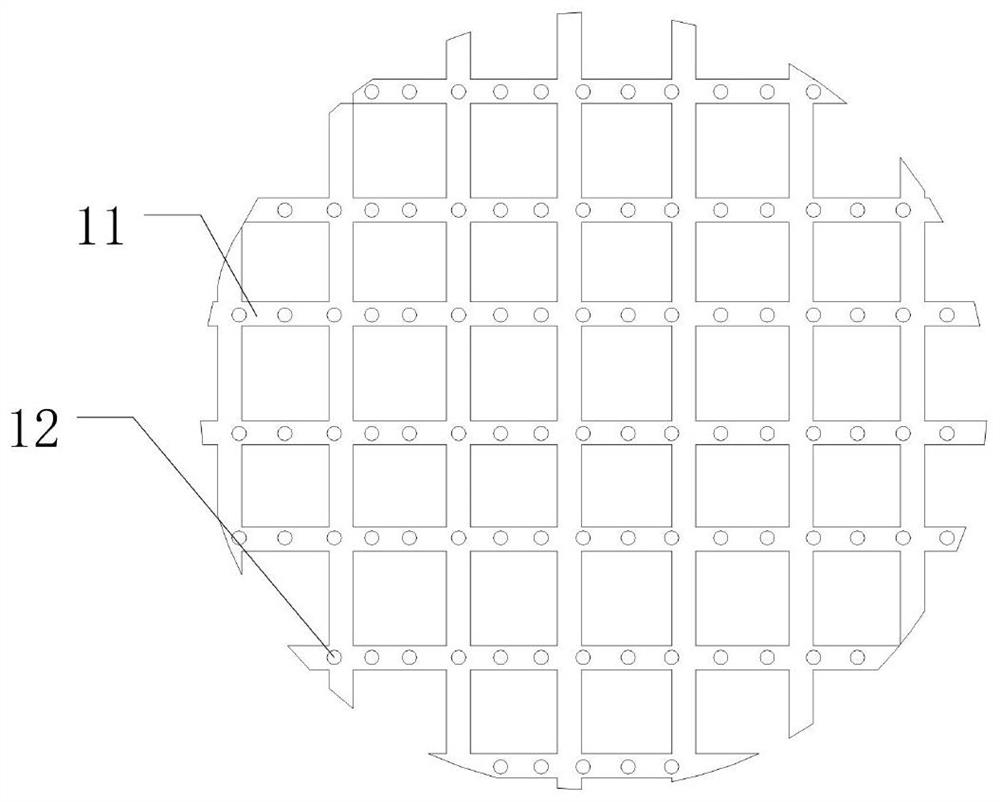

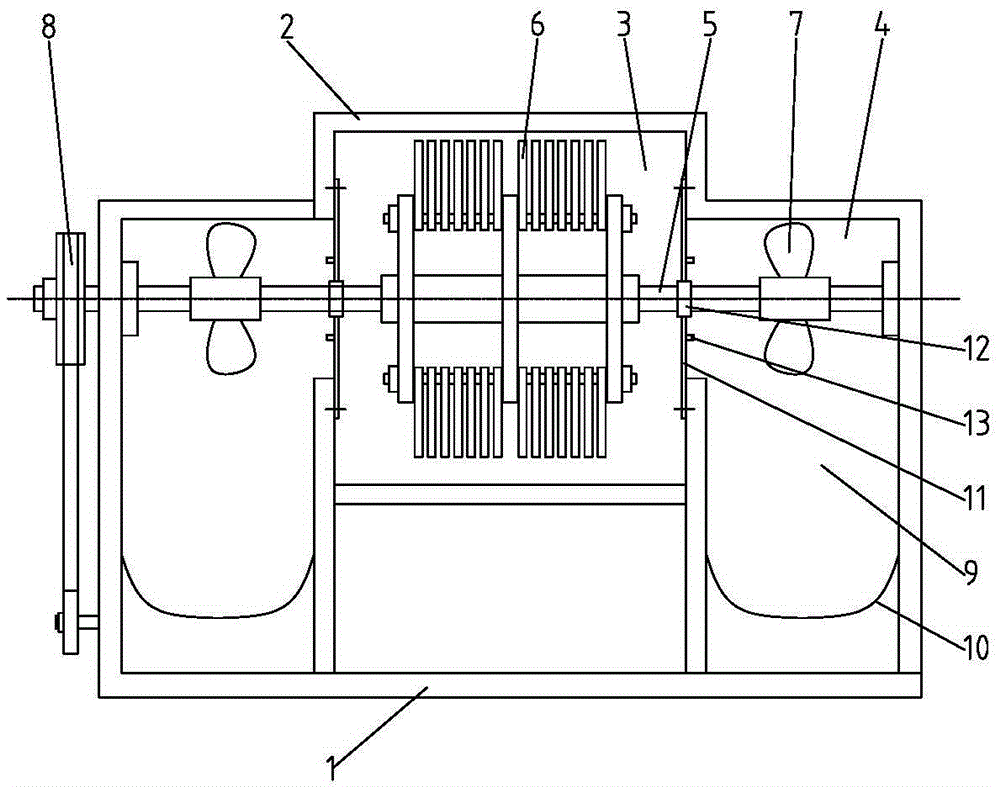

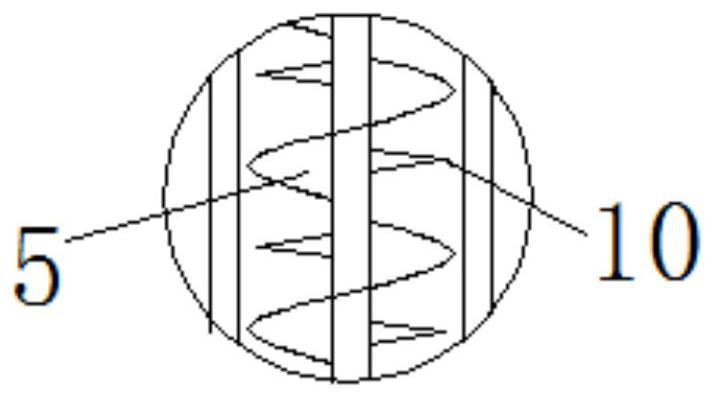

Stirring and crushing unit and 3D printing waste recovery device

InactiveCN112171964AEasy to mix wellMake sure to smashAdditive manufacturing apparatusPlastic recyclingWaste recoveryWaste material

The invention relates to the technical field of 3D printing, in particular to a stirring and crushing unit and a 3D printing waste recovery device. The stirring and crushing unit comprises a shell, arotating shaft and crushing assemblies. A feeding port and a discharging port are arranged on the shell. The rotating shaft is mounted in a vertical rotation manner. At least part of the rotating shaft extends into the shell. The number of the crushing assemblies is at least two. Each crushing assembly comprises a fixed cutter ring and a movable cutter ring which are used in cooperation. The fixedcutter ring is arranged on the inner wall of the shell. The movable cutter ring rotates along with the rotating shaft. The at least two crushing assemblies are arranged in an axially spaced manner. The working surfaces of one fixed cutter ring and the corresponding movable cutter ring are conical surfaces with a radial gap between; and the maximum radial gap and the minimum radial gap between thecutter rings of the at least two crushing assemblies sequentially narrow down downwards in the axial direction. The technical problem that in the prior art, particles obtained after waste is crushedare large in size, and subsequent processing is inconvenient to carry out is solved.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

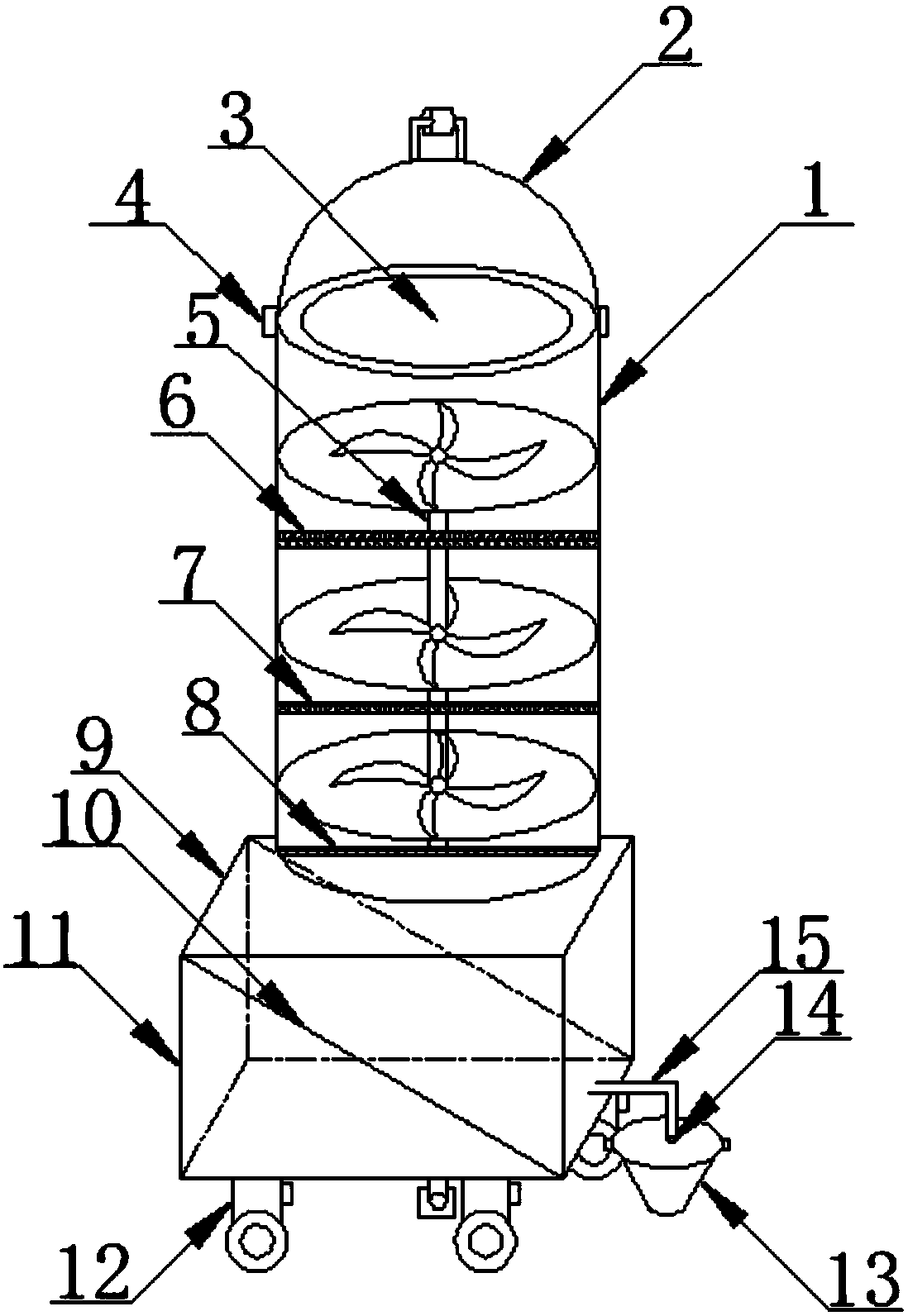

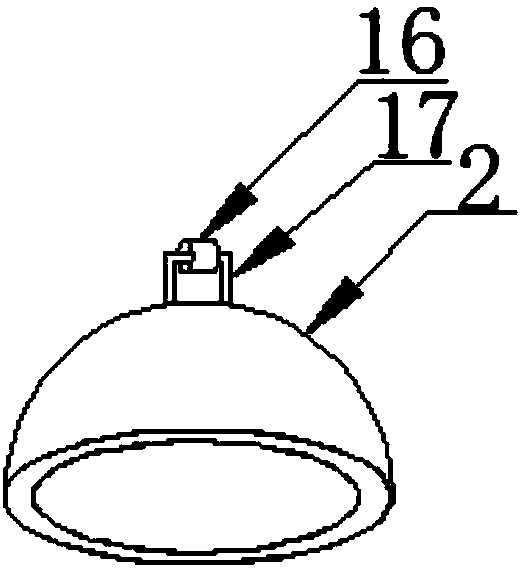

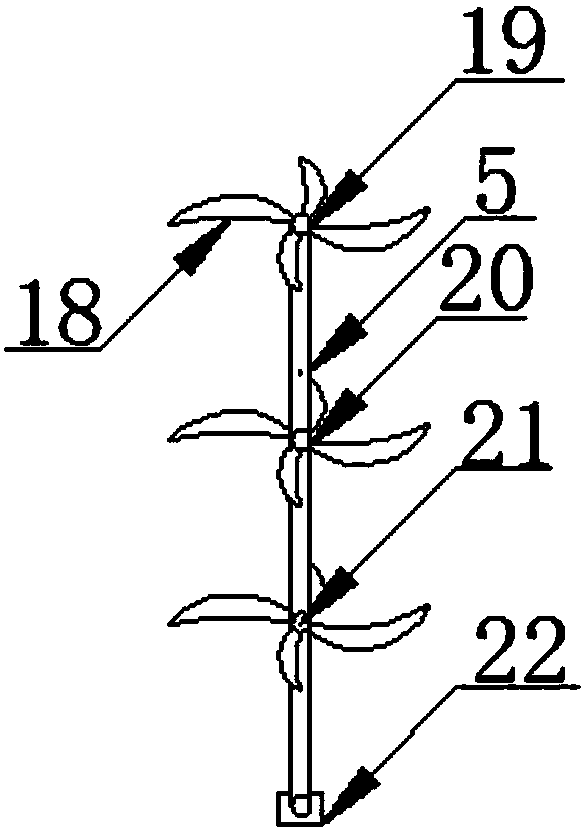

Raw material crusher for firecracker preparation

InactiveCN109772538AMake sure to smashReduce work stressGrain treatmentsFirecrackerPulp and paper industry

A raw material crusher for firecracker preparation comprises a barrel body, a barrel cover, a firecracker raw material inlet, a fixing pressing buckle, a rotating shaft, a first filtering net, a second filtering net, a third filtering net, a discharging chamber, a discharging sliding plate, a wedge-shaped block, a supporting shaft, a material accumulating barrel, a discharging pipe inserting port,a discharging pipe, an antiskid rubber sleeve, a handle, blades, a first cutting set, a second cutting set, a third cutting set, a motor, universal wheels and a fixing screw, wherein the barrel coveris arranged at the upper end of the barrel body; the handle is arranged at the upper end of the barrel cover; the antiskid rubber sleeve is arranged on the outer surface of the handle; the firecracker raw material inlet is formed in the lower end; the fixing pressing buckle is arranged at the left end of the barrel cover; the rotating shaft is arranged in the barrel body; the first cutting set isarranged at the topmost end of the rotating shaft; the blades are arranged at the left end of the first cutting set; and the second cutting assembly is arranged at the lower end of the first cuttingset. With the adoption of the raw material crusher for the firecracker preparation, raw materials can be completely crushed.

Owner:王强

Sheep manure treatment equipment

The invention discloses a sheep excrement treatment device. The sheep excrement treatment device comprises screens, cutter seats and sleeves. The number of the screens is one less than the number of the cutter seats. The screens and the cutter seats are arranged in an alternate mode. Each cutter seat is arranged above the corresponding screen. A rotating shaft passes through the screens vertically. The rotating shaft is hollowly sleeved with the screens. The outer edges of the screens are connected with the inner surface of a machine shell in a sliding mode, and the screens can only move up and down in the machine shell. The sleeves are coaxially arranged outside the positions, located under the screens and above the cutter seats, of the rotating shaft in a sleeving mode. The screens are fixedly connected with the upper ends of the sleeves, and arc-shaped lower protrusions are arranged at the lower ends of the sleeves for supporting the screens on the cutter seats. Arc-shaped upper protrusions which are located at the same circumference with the arc-shaped lower protrusions are arranged on the upper surfaces of the cutter seats. The sheep excrement treatment device has the effectsthat external power is not needed for vibration, the vibration of the machine shell is reduced, and the service life of the machine body is prolonged.

Owner:务川自治县宏牧羊业有限公司

Residue coupling coal power efficient power generation device

PendingCN113203088AAvoid cloggingAvoid falling outSteam generation using pressureBoiler indication operationsPower efficientProcess engineering

The invention relates to the technical field of coupling power generation, and discloses a residue coupling coal power efficient power generation device. The residue coupling coal power efficient power generation device comprises a bottom plate, wherein a supporting seat, a rack, a base and a cabinet body are arranged on the upper surface of the bottom plate; the upper surface of the supporting seat is fixedly connected with a supporting frame; the upper surface of the supporting frame is fixedly connected with a storage hopper; the storage hopper penetrates through the supporting frame; a mounting opening is formed in the bottom of the storage hopper; a mounting barrel is fixedly connected to the interior of the mounting opening; a material conveying barrel is arranged at the bottom of the mounting barrel; one side of the material conveying barrel is fixedly connected with a mounting plate; the two sides of the inner wall of the material conveying barrel are fixedly connected with the same magnet strip; and a movable opening is formed in the upper surface of the material conveying barrel. According to the residue coupling coal power efficient power generation device, residues in the material conveying barrel can be transferred, so that blockage of the material conveying barrel is avoided, and use of the power generation device is facilitated; the mounting plate on the material conveying barrel prevents the residues in the mounting barrel from falling out, so that full utilization of the collected residues is guaranteed; and meanwhile, metal components in the residues are adsorbed and classified, and can be recycled, so that waste of resources is avoided.

Owner:石红杰

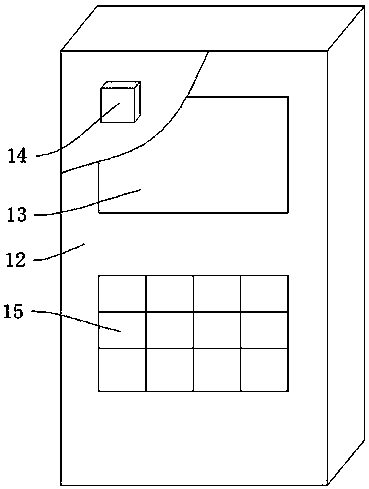

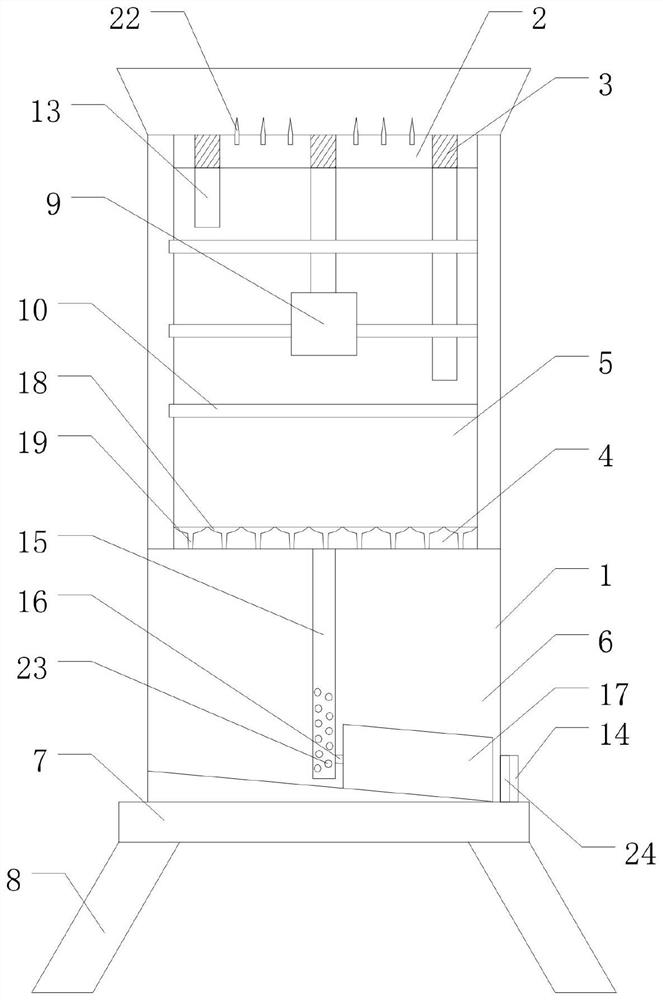

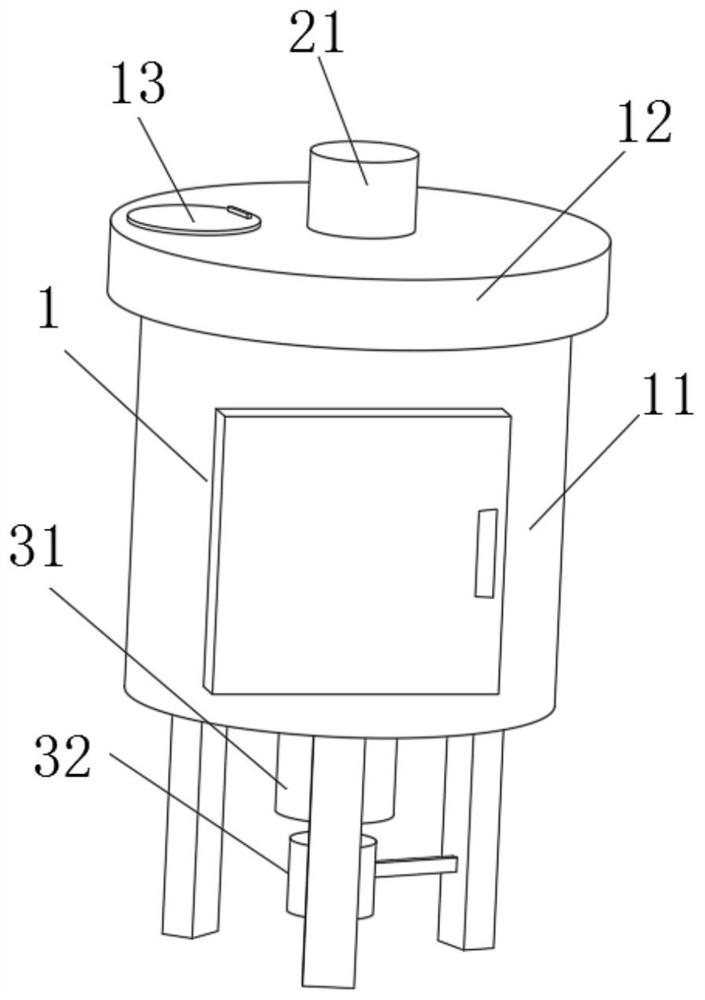

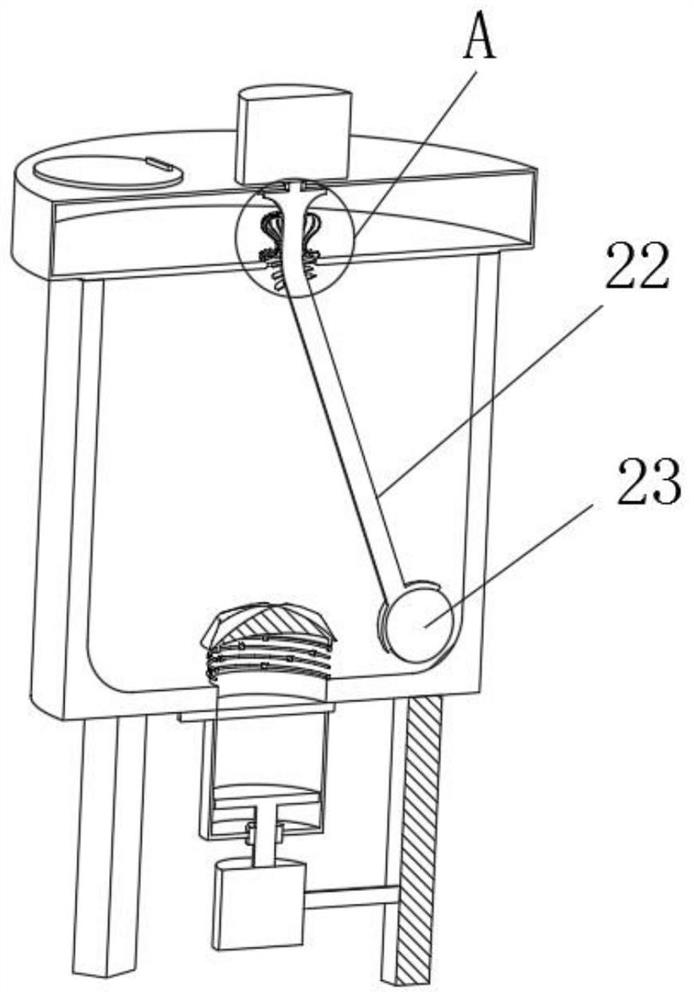

Roselle pharmaceutical drying and crushing device and method of use thereof

ActiveCN113457806BRealize integrated automatic processingSimple processDrying gas arrangementsDrying machines with local agitationBiotechnologyPharmacy

The invention discloses a drying and crushing device for roselle pharmaceuticals and a method for using the device, wherein the device comprises: a casing, a feeding port is opened on the top, a feeding plate is covered on the feeding port, and a feeding plate is opened on the feeding plate. The feed hole; the shell is divided into a drying chamber at the upper part and a crushing chamber at the lower part through a crushing plate arranged in the horizontal direction and the outer edge is connected with the inner wall of the shell; the base includes a frame connected to the bottom of the shell, And the supporting legs that support the frame from the ground; the control mechanism includes a control panel, and a vibration motor, a telescopic motor, a rotating motor and a fan respectively controlled by the control panel; the control panel is arranged on the outer wall of the casing; the vibration motor drives the casing vibration. It realizes the integrated drying and crushing of roselle, simplifies the production process of roselle powder, and improves the production efficiency; at the same time, the processing method of crushing roselle first and then crushing ensures the crushing effect and makes the production process more efficient. The finished roselle powder has uniform particles and high quality.

Owner:GUANGZHOU COLLEGE OF TECH BUSINESS CO LTD

Equipment and method for recycling aggregate from waste concrete

InactiveCN114534856AIncrease the impact frequencyIncrease crushing powerSolid waste managementGrain treatmentsEnvironmental engineeringCrusher

The invention discloses equipment and a method for recycling aggregate from waste concrete, and relates to the technical field of waste concrete recycling. The equipment comprises a concrete crushing mechanism, the concrete crushing mechanism is provided with a shell, the top of the shell is fixedly connected with a rotary stirring mechanism, the concrete crushing mechanism is fixedly connected with the rotary stirring mechanism, the rotary stirring mechanism is provided with an extrusion block, and the extrusion block is fixedly connected with the shell. The outer wall of the extrusion block is fixedly connected with a crushing mechanism, and the rotary stirring mechanism is fixedly connected with the crushing mechanism. According to the equipment and the method for recycling the aggregate from the waste concrete, the extrusion block impacts on the inner wall of the shell, so that the extrusion block extrudes gas in the cylinder, blowing-out of airflow is accelerated, the airflow can blow up dust in the cylinder, and the influence of dust accumulation on concrete smashing is avoided; and the molecular spacing in the gas is reduced.

Owner:金敏

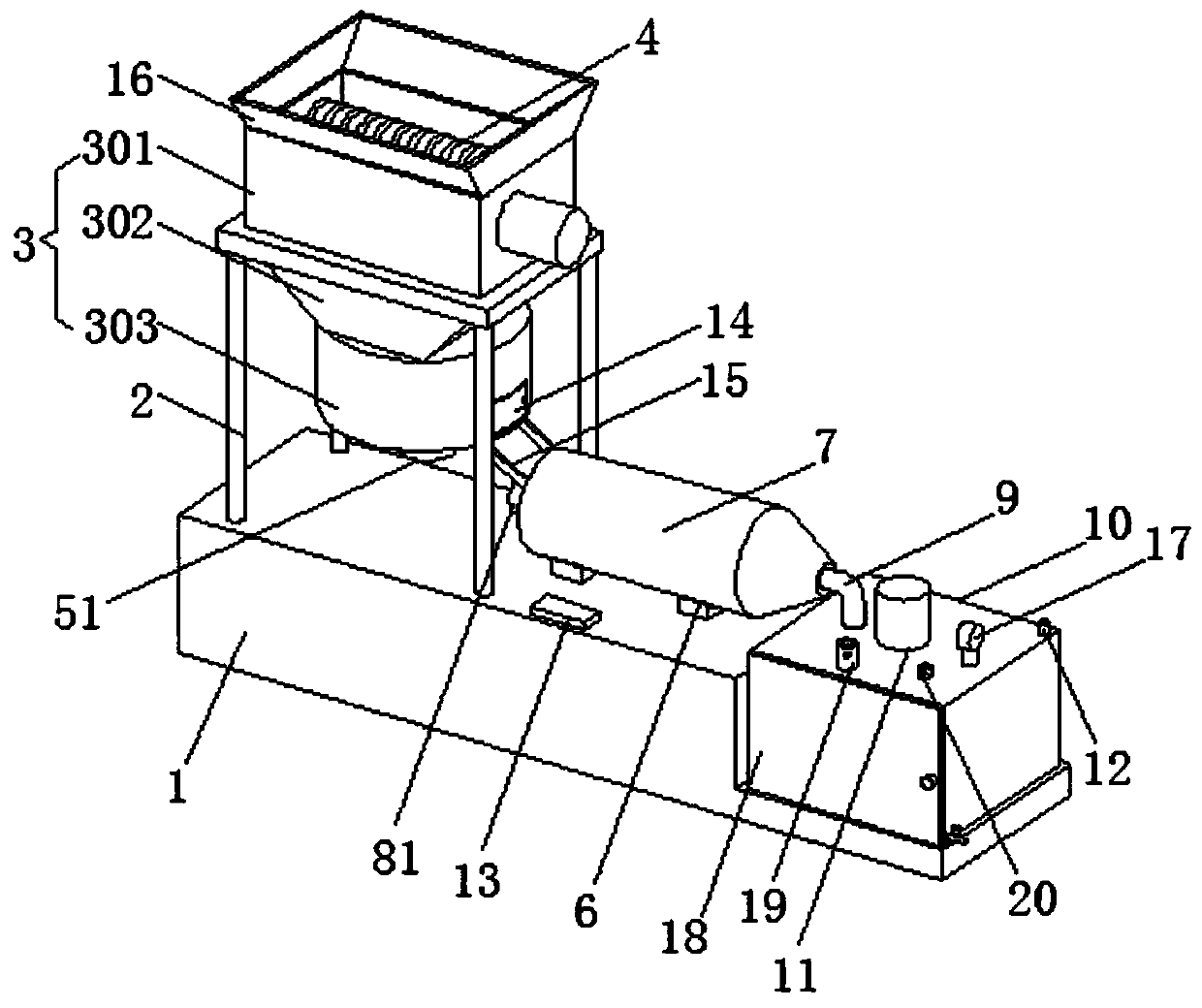

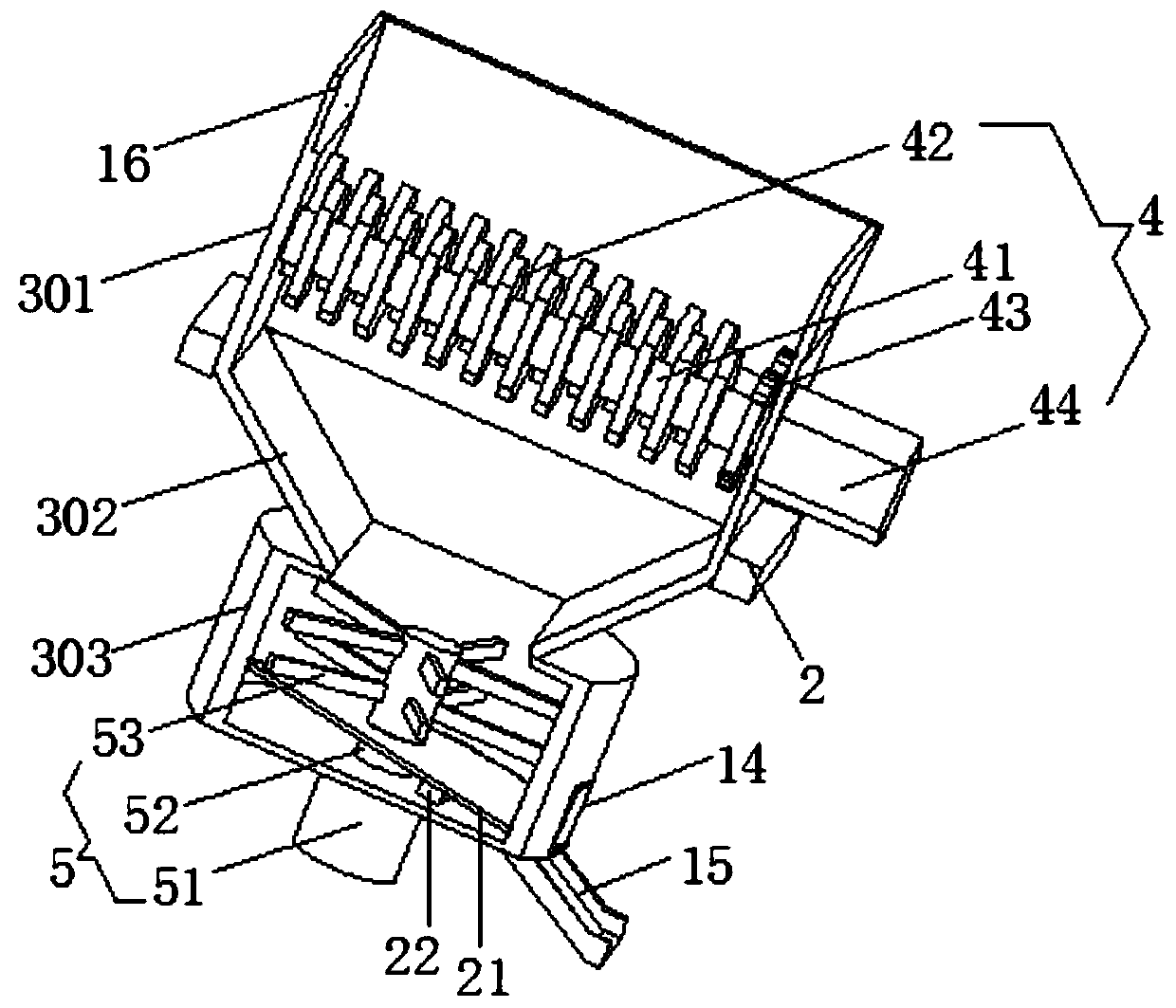

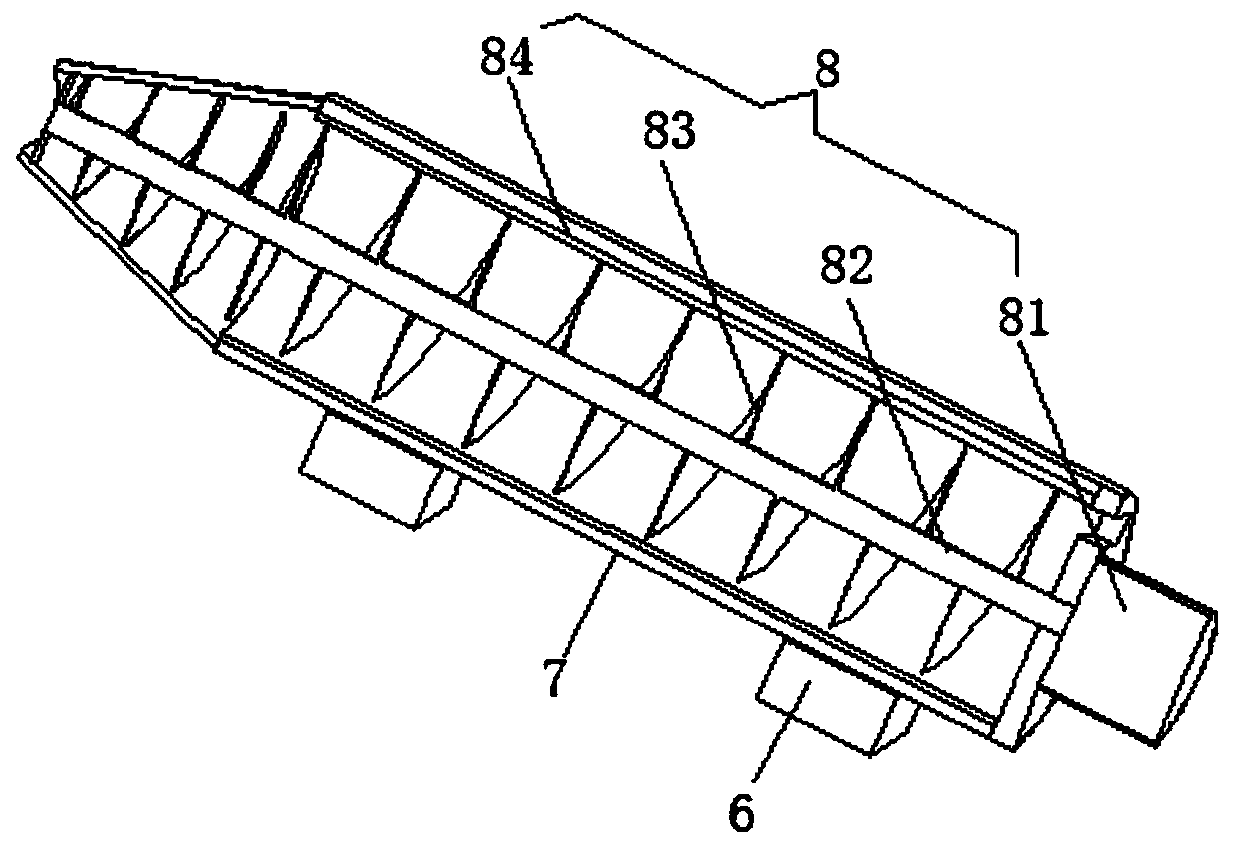

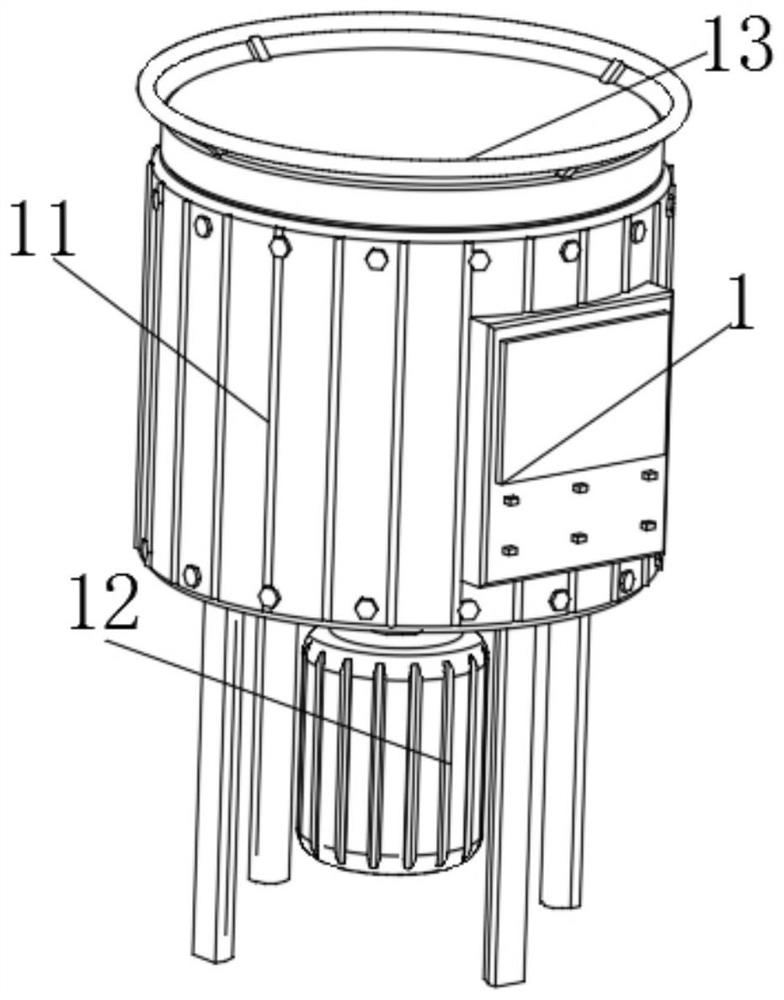

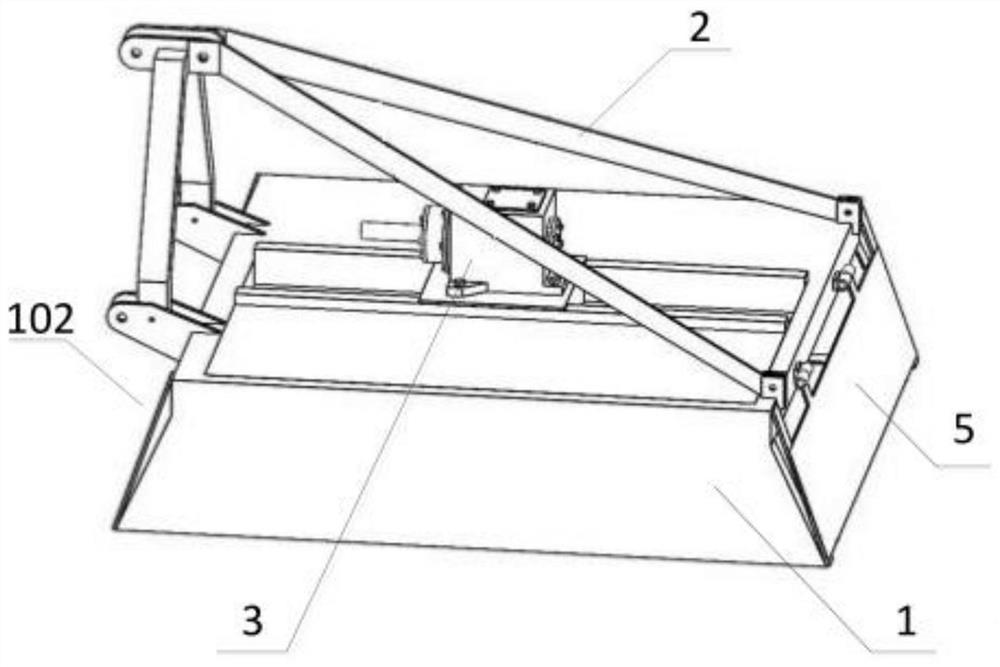

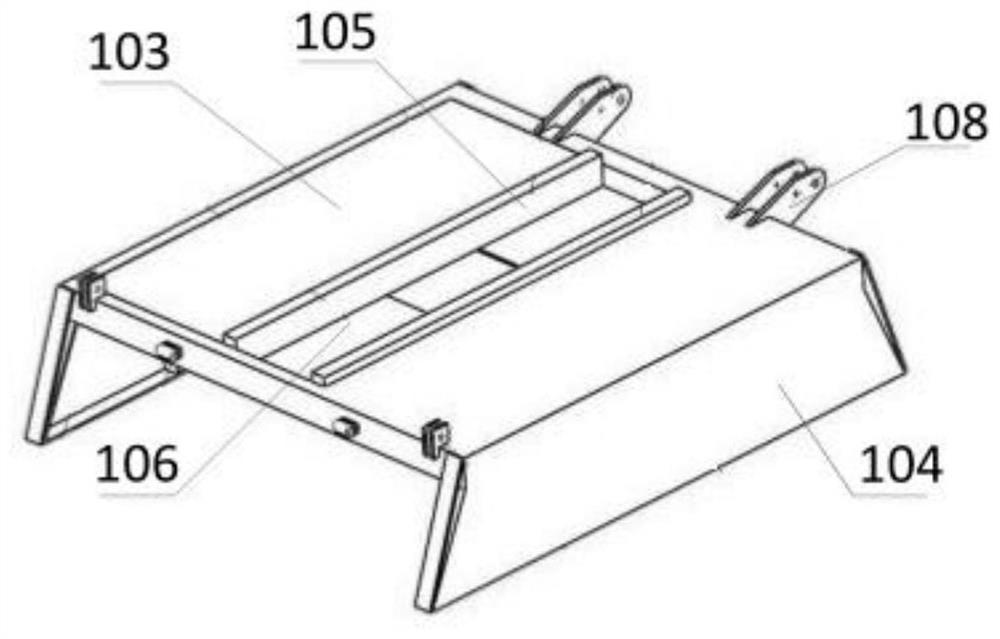

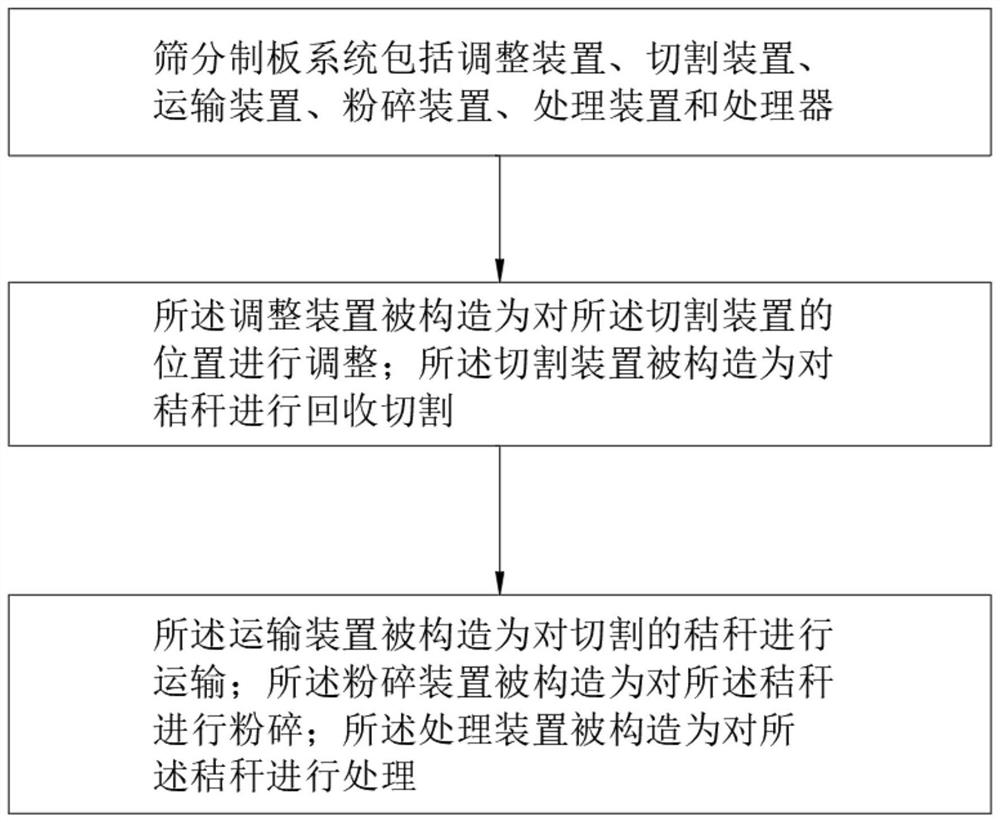

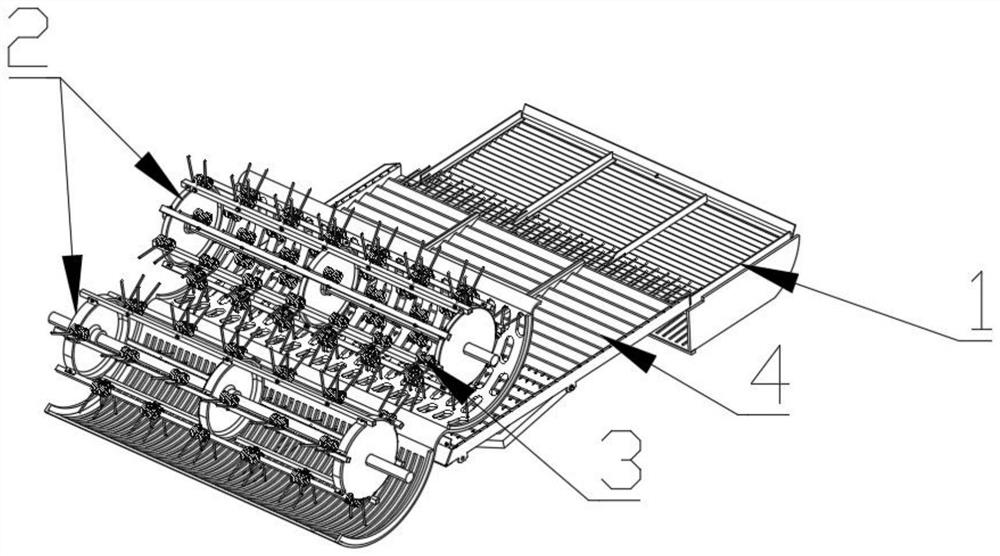

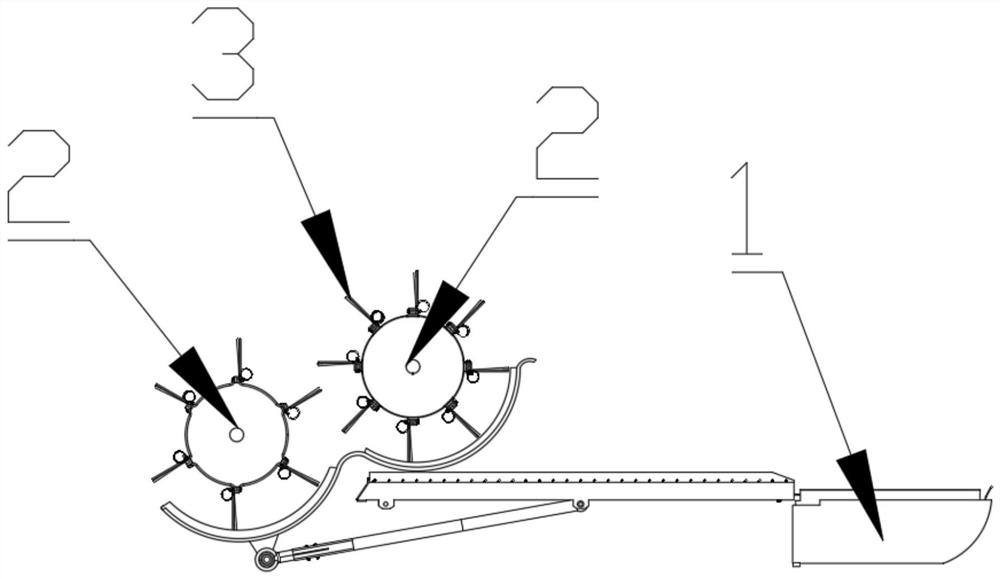

Intelligent control straw harvesting, screening and plate making system

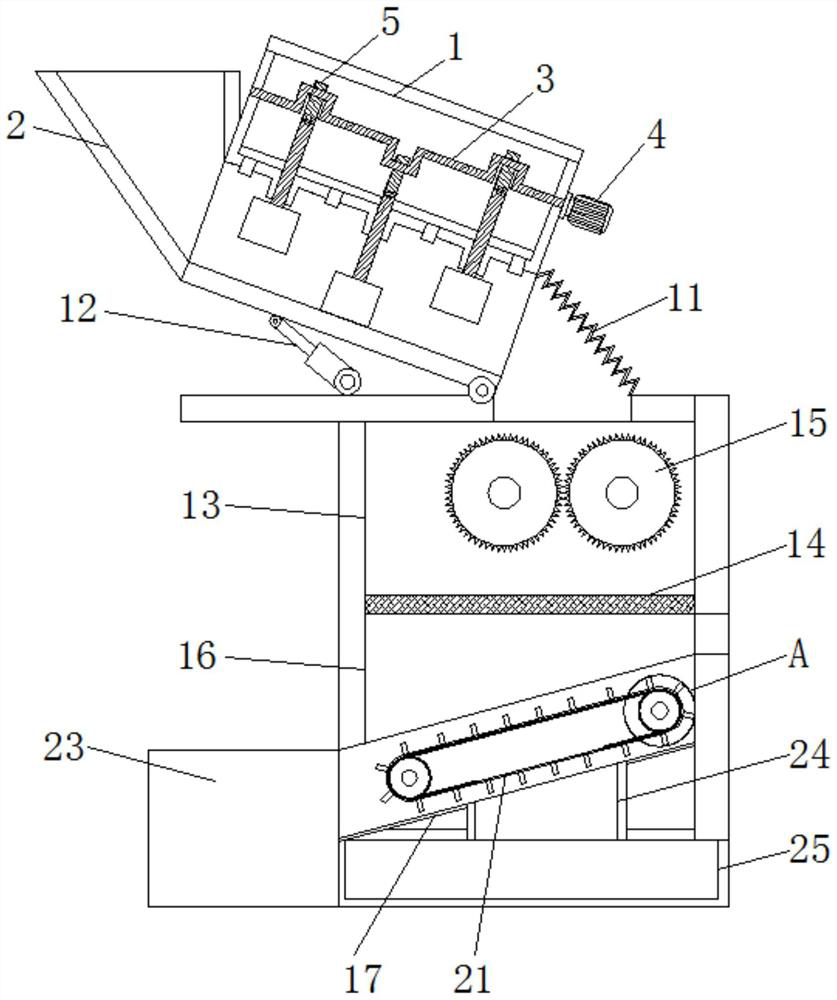

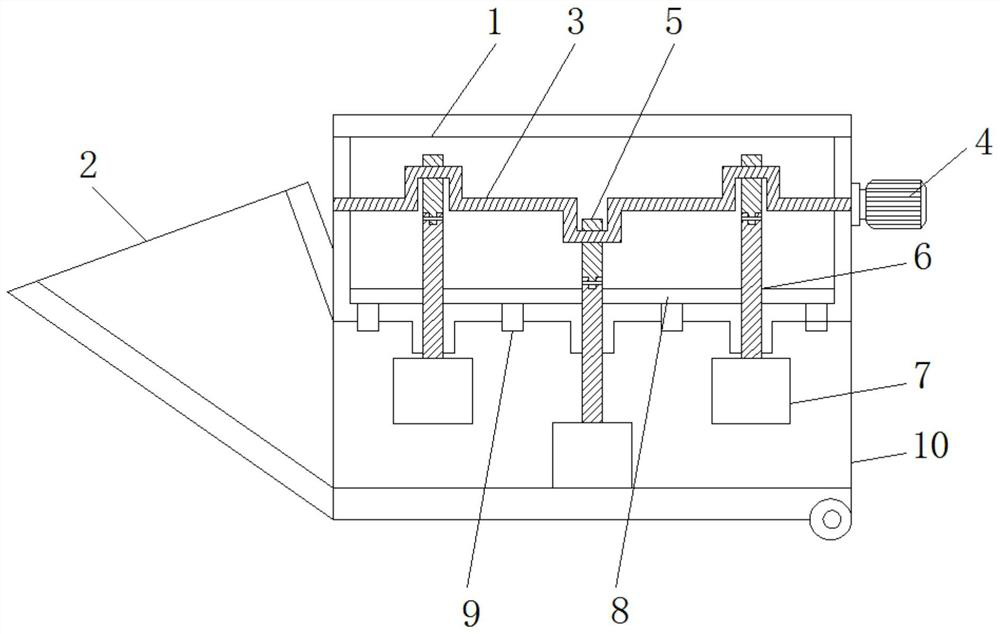

ActiveCN112640646AImprove utilization efficiencyAccurate detectionMowersDomestic articlesAgricultural scienceAgricultural engineering

The invention provides an intelligent control straw harvesting, screening and plate making system which comprises an adjusting device, a cutting device, a conveying device, a smashing device, a processing device and a processor. The adjusting device is constructed to adjust the position of the cutting device; the cutting device is constructed to recycle and cut straw; the conveying device is constructed to convey the cut straw; the smashing device is configured to smash the straw; and the processing device is configured to process the straw. According to the intelligent control straw harvesting, screening and plate making system, the adjusting device is arranged in a recycling cavity, so that dust or soil on the straw can be screened out through the filtering operation of a filtering net, and the dust and the soil are separated from each other.

Owner:湖南登科材料科技有限公司

Drying and grinding device for roselle pharmacy as well as using method of drying and grinding device

ActiveCN113457806ASimple processingUniform powderDrying gas arrangementsDrying machines with local agitationManufacturing efficiencyRoselle Flower

The invention discloses a drying and crushing device for roselle pharmacy as well as a using method of the drying and crushing device.The drying and crushing device comprises a shell, a base and a control mechanism, wherein a feeding port is formed in the top of the shell and covered with a feeding plate; feeding holes are formed in the feeding plate; through a crushing plate which is arranged in the horizontal direction and of which the outer edge is connected with the inner wall of shell, the shell is divided into a drying cavity and a grinding cavity; the drying cavity is positioned at the upper part; the crushing cavity is positioned at the lower part; the base comprises a frame and supporting legs; the frame is connected with the bottom of the shell; the supporting legs are used for supporting the frame away from the ground; the control mechanism comprises a control panel as well as a vibration motor, a telescopic motor, a rotating motor and a fan which are all controlled by the control panel; the control panel is arranged on the outer wall of the shell; and the shell is driven by the vibration motor to vibrate. Consequently, the drying and the grinding of roselle can be integrally achieved, the manufacturing process of roselle powder can be simplified, and the manufacturing efficiency can be improved; and meanwhile, through the processing mode that the roselle is crushed at first and then ground, the grinding effect can be guaranteed, and the manufactured roselle powder can be uniform in particle and high in quality.

Owner:GUANGZHOU COLLEGE OF TECH BUSINESS CO LTD

Grinding device for making cookies

The invention provides a grinding device for making cookies. The grinding device for making cookies comprises a feeding inlet. A primary smashing box is fixedly connected with the lower end of the feeding inlet. Two driving motors are arranged on one side of the primary smashing box and connected with two rolling press rollers in a rotating mode correspondingly, and the two rolling press rollers are located in the primary smashing box. A secondary smashing box is fixedly connected with the lower end of the primary smashing box and located below the two rolling press rollers. A first rotating motor and a second rotating motor are arranged on one side of the secondary smashing box and connected with a first smashing roller and a second smashing roller of the secondary smashing box in a rotating mode. A fine smashing box is arranged at the lower end of the secondary smashing box. A third rotating motor is arranged at the lower end of the fine smashing box, a turbine smashing device is fixed to the upper end of the third rotating motor, and a discharging outlet is formed in one side of the fine smashing box and located in the lower end of the turbine smashing device. By the adoption ofthe grinding device for making cookies, grading smashing operation is conducted by the three smashing boxes, and therefore the smashing operation can be finer. Meanwhile, the turbine smashing operation is conducted, wind force is generated, and therefore the smashed products can be dried and well stored for a long time.

Owner:芜湖喜源味食品有限公司

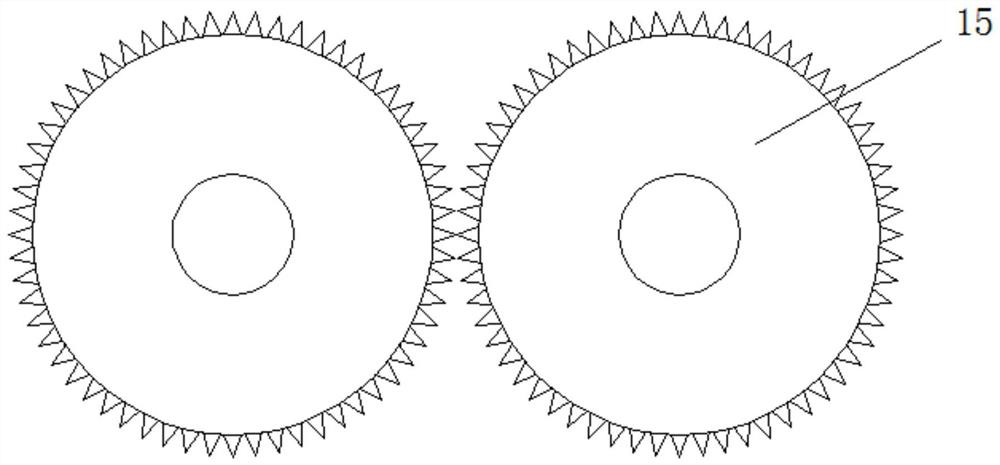

Partition style double-acting ultrafine grinder

InactiveCN106824421AImprove crushing efficiencyGuaranteed to shredGrain treatmentsPulverizerImpeller

The invention discloses a barrier-type double-acting ultrafine pulverizer, which comprises a base, a casing is arranged above the base, a crushing chamber is arranged in the casing, and negative pressure chambers are respectively arranged on both sides of the crushing chamber. Suction chamber, the two negative pressure suction chambers are connected with the crushing chamber, and a rotating shaft passing through the crushing chamber is provided between the two negative pressure suction chambers, and the crushing chamber is equipped with a The tool assembly on the rotating shaft and rotates synchronously with it, and the two negative pressure suction chambers are respectively equipped with negative pressure suction impellers that are set on the rotating shaft and rotate synchronously with it; the two negative pressure suction chambers are connected with the crushing Partitions are respectively arranged between the chambers, and the partitions are fixedly installed on the housing and fitted on the rotating shaft through bearings, and the partitions are arrayed with mesh holes for crushed materials to pass through.

Owner:CHONGQING HUAAO PHARMA IND CO LTD

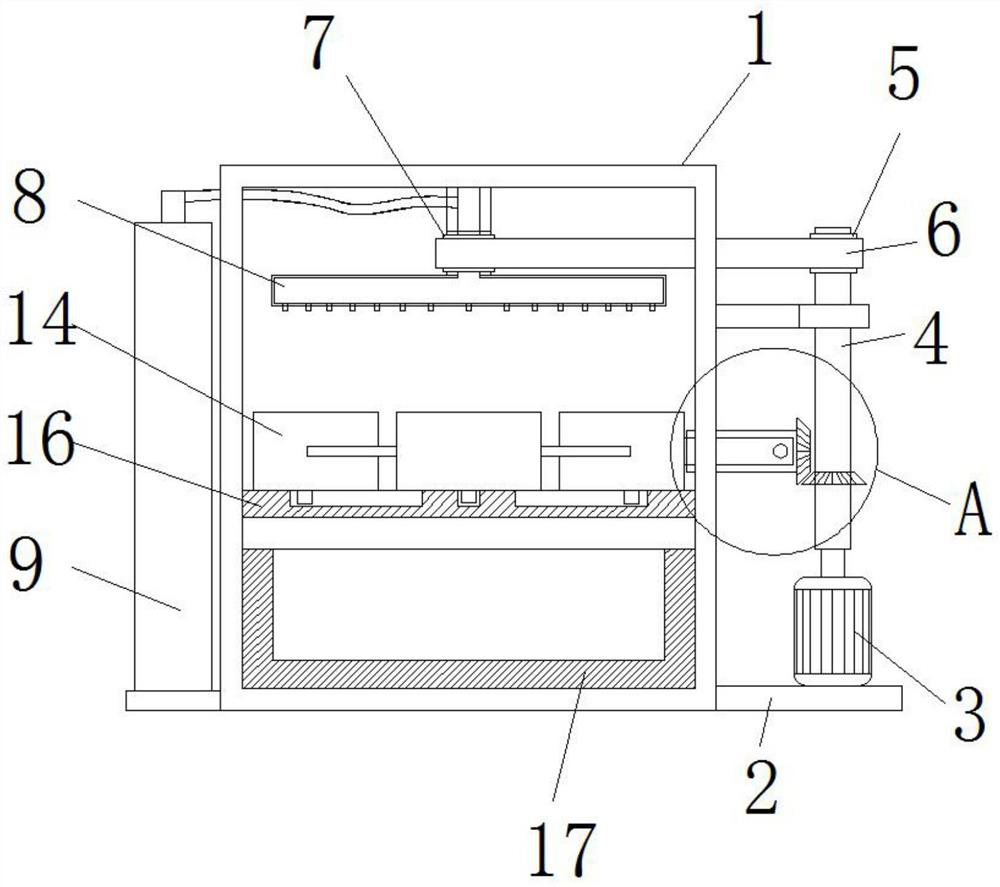

Straw smashing device for manufacturing building materials through straw

PendingCN114731856AImprove crushing effectShorten the timeSolid waste managementCuttersBuilding materialSprocket

The invention belongs to the technical field of smashing devices, particularly relates to a straw smashing device for manufacturing building materials from straw, and aims to solve the problems that most of existing smashing devices are poor in smashing effect, waste a large amount of time and are very low in efficiency, the straw smashing device comprises a box, and one side of the box is fixedly connected with a fixing plate; the top of the fixing plate is fixedly connected with a motor, an output shaft of the motor is provided with a rotating mechanism, the rotating mechanism comprises a vertical rod, a first chain wheel, a chain, a second chain wheel and a sprayer, the vertical rod is fixedly connected with the output shaft of the motor, the first chain wheel is fixedly connected with the vertical rod in a sleeving mode, the chain is connected with the first chain wheel in an engaged mode, and the second chain wheel is connected with the chain in an engaged mode; by means of the straw smashing device, it can be effectively guaranteed that straw is smashed, the smashing effect is greatly improved, and meanwhile a large amount of time is saved.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

An Intelligently Controlled Straw Harvesting, Screening and Board Making System

ActiveCN112640646BImprove utilization efficiencyAccurate detectionMowersFlat articlesEngineeringProcess engineering

The present invention provides an intelligently controlled straw harvesting, screening, and board-making system. The screening and board-making system includes an adjustment device, a cutting device, a transport device, a crushing device, a processing device, and a processor. The adjustment device is configured to The position of the cutting device is adjusted; the cutting device is configured to recycle and cut the straw; the transport device is configured to transport the cut straw; the crushing device is configured to crush the straw; The processing device is configured to process the straw. In the present invention, an adjusting device is arranged in the recovery chamber so that the dust or soil on the straw can pass through the filtering operation of the filter screen so that the soil and dust can be screened out and separated from each other.

Owner:湖南登科材料科技有限公司

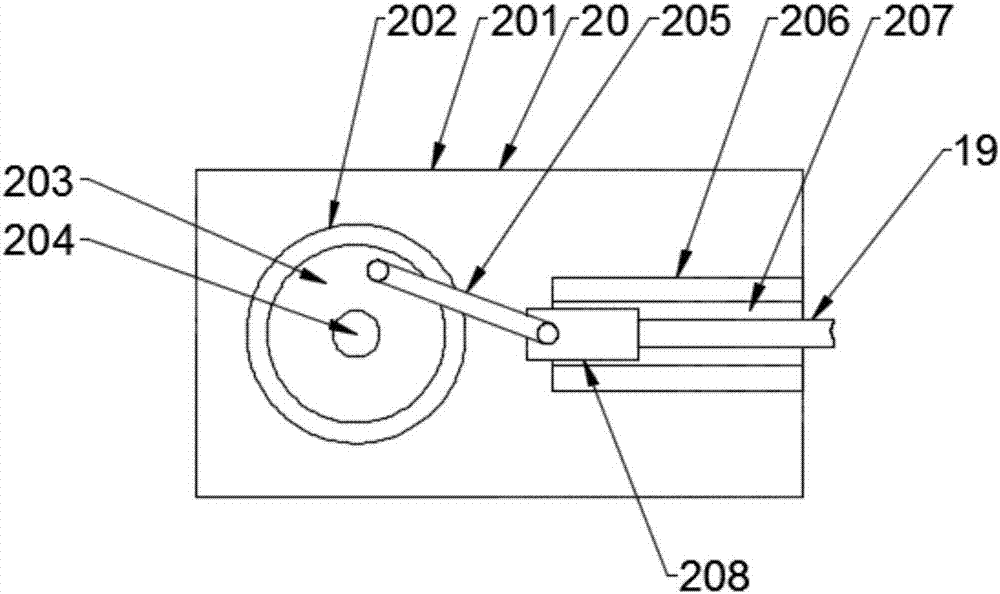

A construction waste crushing device based on the principle of crank rocker

ActiveCN111085291BPlay a pre-crushing effectExtended service lifeUsing liquid separation agentMagnetic separationCrankElectric machine

The invention relates to the technical field of construction waste, and discloses a construction waste crushing device based on the principle of a crank rocker, including a pre-crushing chamber, the outside of the pre-crushing chamber is fixedly connected with a feeding port, and the inside of the pre-crushing chamber A crank rocker is movably connected, and a pre-crushing motor is fixedly connected to the outside of the crank rocker, and a connecting rod is movably connected to the outside of the crank rocker, and an impact rod is hingedly connected to the outside of the connecting rod, and the impact rod The bottom of the hammer is fixedly connected with an impact hammer. Through the combined use of the pre-crushing motor and the impact hammer, the impact hammer is used to impact and crush the construction waste to achieve the effect of pre-crushing the construction waste. The bulk construction waste is processed into small fragments, thereby ensuring the use effect of the subsequent crushing rollers, and preventing large blocks of construction waste from damaging the crushing rollers, thereby increasing the service life of the crushing device.

Owner:江西太平洋宇洪建设有限公司

A soil improvement treatment device with internal circulation function

ActiveCN108207155BConvenience to mergeEasy to separateSpadesSoil lifting machinesEarthquake resistanceCrank

The invention discloses a soil improvement and treatment device with an internal recycle function. The device comprises a base, support rods are arranged at the two sides of the lower end of the basesymmetrically, support sleeves are arranged at the lower ends of the support rods, rolling wheels facilitating device carrying are arranged at the lower ends of the support sleeves, and buffer springsare arranged inside the support sleeves and make the support sleeves and the support rods fixedly connected; a left support plate is arranged at the upper left end of the base, a right support plateis arranged at the upper right end of the base, a machining box is arranged on the base between the left support plate and the right support plate and composed of a first half box and a second half box. The soil improvement and treatment device with the internal recycle function is convenient to carry and good in anti-seismic performance, and a drive screw rotates relative to a drive screw sleevethrough a crank; under the effect of threads, the first half box can slide left and right along with the base, in this way, the first half box and the second half box are convenient to integrate and separate, accordingly, later maintenance of the device is facilitated, internal recycle smash and recovery of soil blocks are achieved, therefore, smashing and mixing effects of the soil blocks are ensured, and the practicability is high.

Owner:山东东沅环境科技有限公司

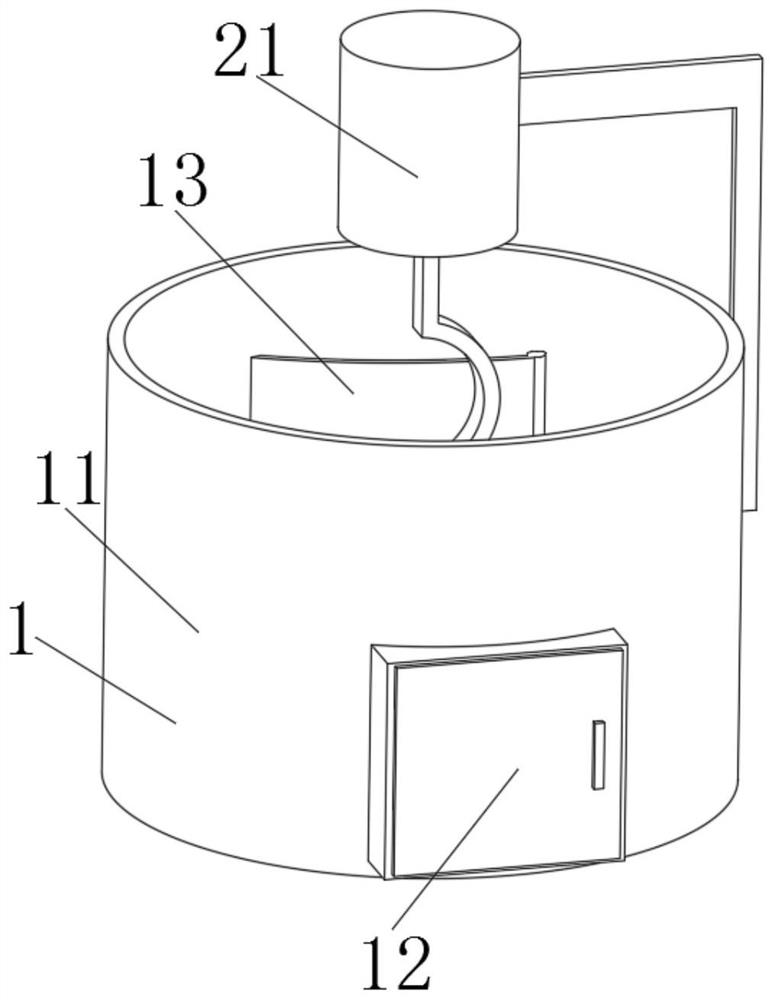

Corn feed manufacturing device for biological agriculture and related industries

PendingCN113953049AGuaranteed collectionMake sure to crushFeeding-stuffGrain treatmentsAgricultural scienceAgricultural engineering

The invention discloses a corn feed manufacturing device for biological agriculture and related industries, and relates to the technical field of biological agriculture and related industries. The corn feed manufacturing device for the biological agriculture and related industries comprises an external collecting mechanism used for external collection, a rotary grinding mechanism used for rotary grinding and an airflow impact mechanism used for airflow impact, a shell is arranged in the external collecting mechanism, and the external collecting mechanism is fixedly connected with the rotary grinding mechanism through the top of the arranged shell. According to the corn feed manufacturing device for the biological agriculture and the related industries, a bent rod is obliquely arranged, in the rotating process, the bent rod continuously winds root hairs, then a spiral plate rotates to drive the root hairs, collection of the root hairs is ensured, an elastic rod is arranged to prevent the root hairs from falling off, airflow is blown out of an extrusion bin, therefore, the corns in the shell fly up, and the corns stacked together are scattered.

Owner:杨东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com