Device for enabling industry and construction solid waste to be solidified into building material and technology thereof

A solid waste and construction technology, applied in the field of building materials, can solve problems such as lack of screening, reduced applicability, and inability to separate waste, and achieve the effects of facilitating later shaping, preventing deformation and cracking, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

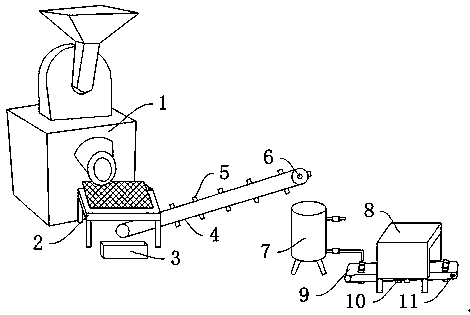

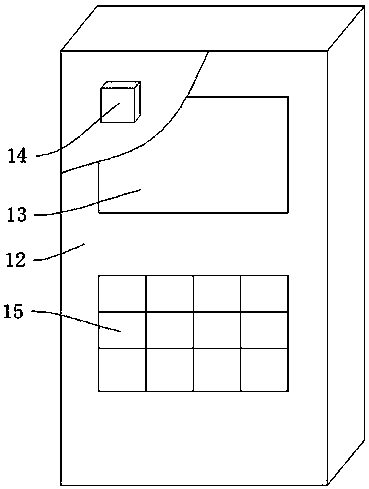

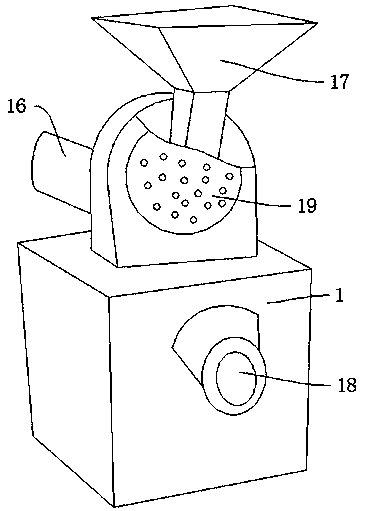

[0052] Such as Figure 1-Figure 9 As shown, a device for solidifying industrial and construction solid waste into building materials includes a pulverizer 1, a screening frame 2, and a shaping box 8. The pulverizer 1 includes a feeding hopper 17, and a pulverizing disc 19 is arranged behind the feeding hopper 17. A crushing motor 16 is arranged behind the crushing disc 19, a discharge port 18 is provided in front of the pulverizer 1, a screening frame 2 is arranged below the discharge port 18, a screening motor 22 is arranged above the screening frame 2, and a screening motor 22 is arranged below the screening motor 22. A support seat 35 is provided, an eccentric wheel 21 is arranged on the screening motor 22, a connecting shaft 23 is arranged on the eccentric wheel 21, a screening plate 20 is arranged on the connecting shaft 23, a collection box 3 is arranged in front of the screening frame 2, and the screening A first conveyor belt 4 is arranged below the sub-frame 2, a firs...

Embodiment 2

[0054] The difference between this embodiment and embodiment 1 is:

[0055] The crushing disc 19 is circular, and the crushing motor 16 and the crushing disc 19 are connected by splines, and the crushing motor 16 and the pulverizer 1 are connected by bolts. Smooth transmission, bolt connection is convenient for disassembly and maintenance of the crushing motor 16.

[0056] In this embodiment, the specific process method includes the following steps:

[0057] a. Put industrial and construction solid waste into the pulverizer 1 from the feed hopper 17, press the setting key 15 to set the parameters of each part, the controller 14 starts the pulverizing motor 16, and the pulverizing motor 16 drives the pulverizing disc 19 to pulverize the solid waste from Outlet 18 discharges.

[0058] b. Solid waste debris falls on the screening plate 20 from the discharge port 18, and the screening motor 22 rotates and drives the eccentric wheel 21 to drive the screening plate 20 to shake thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com