Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Make sure to drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

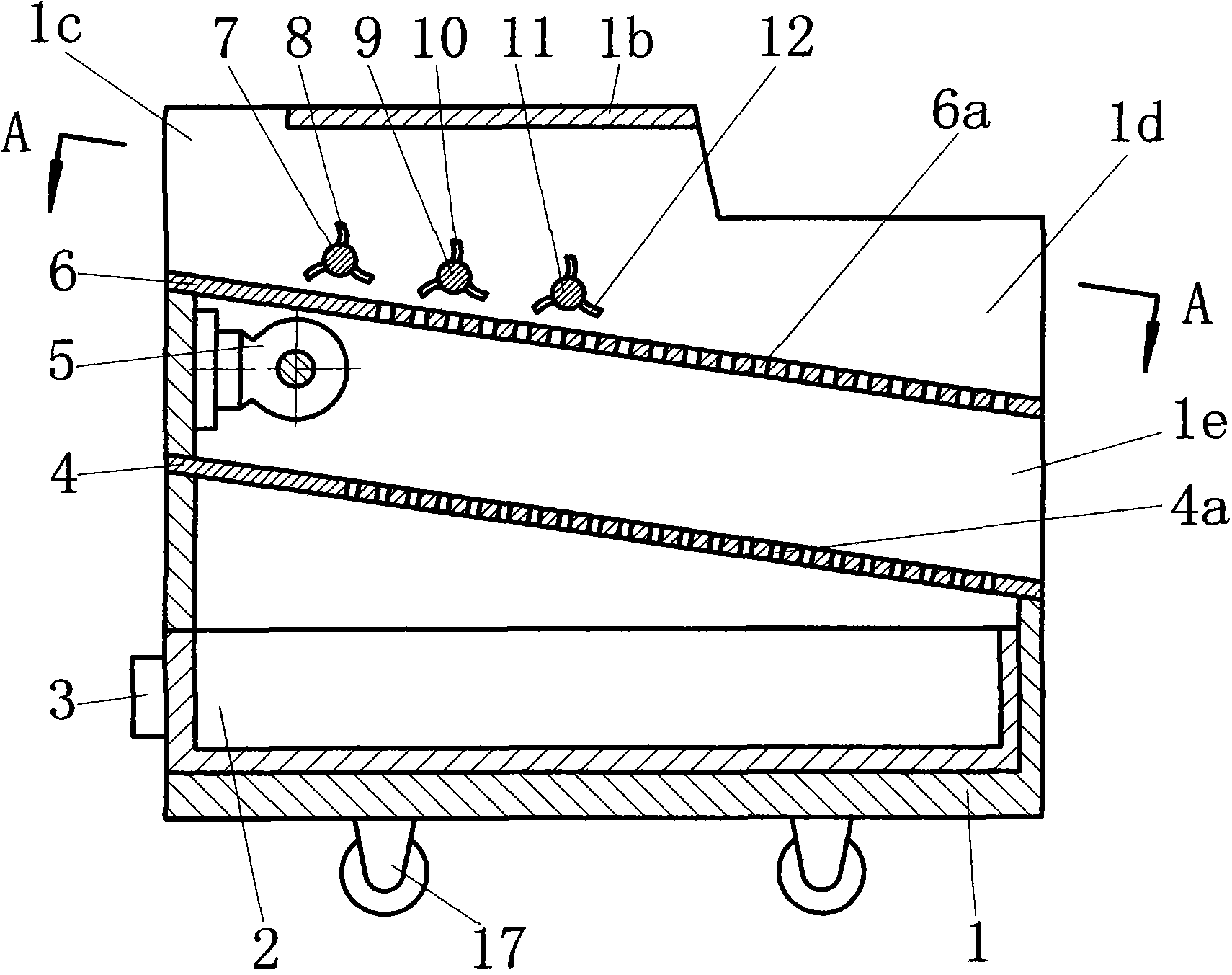

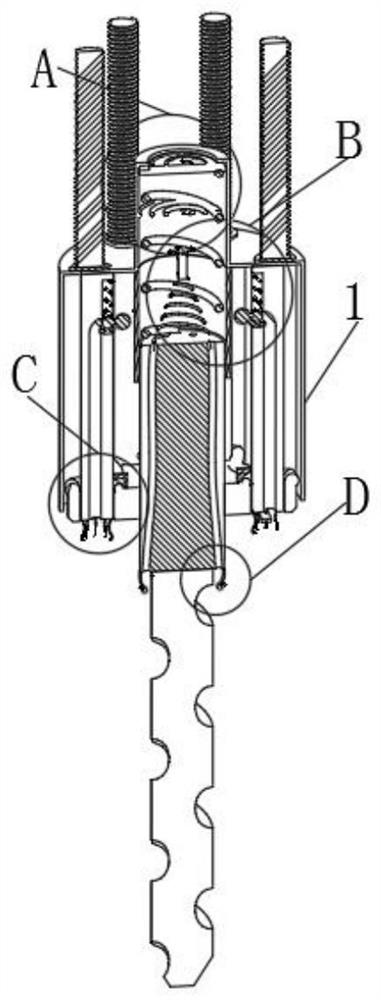

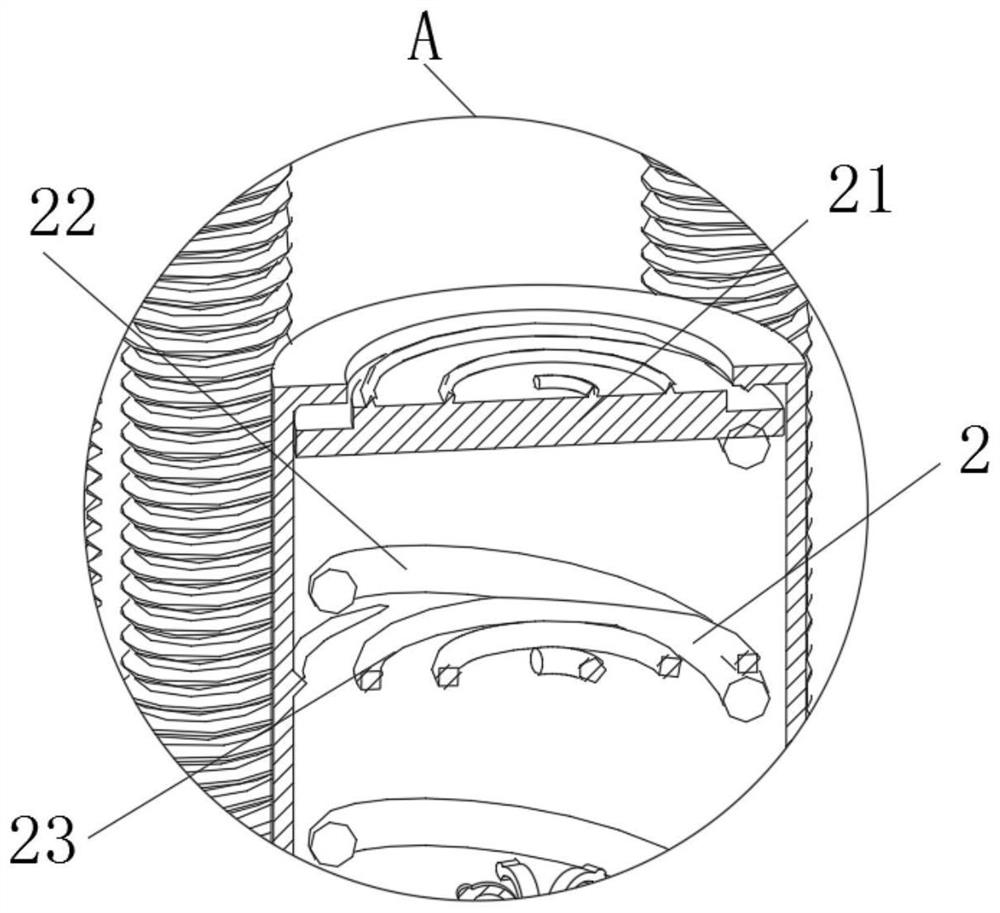

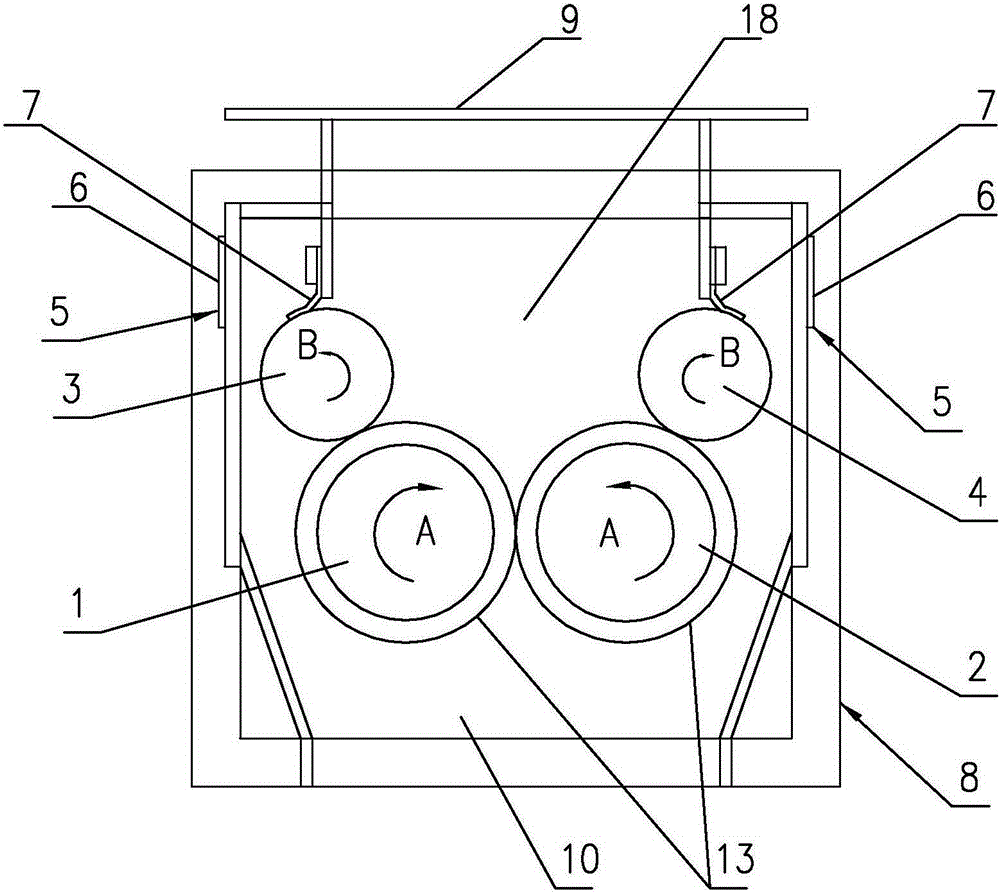

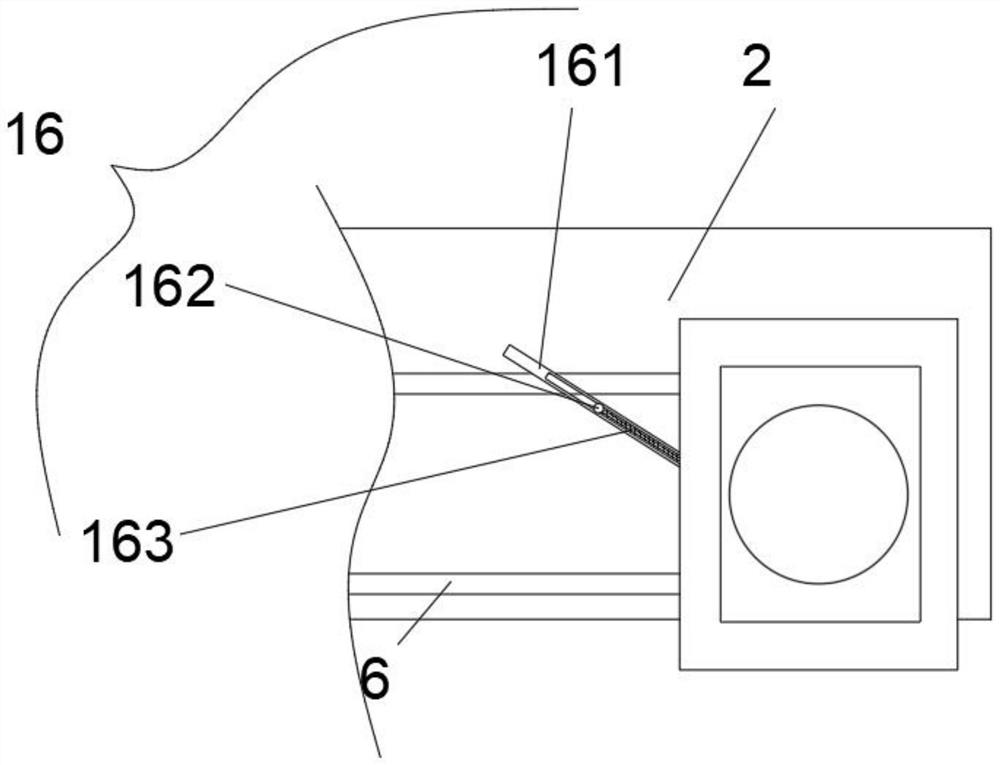

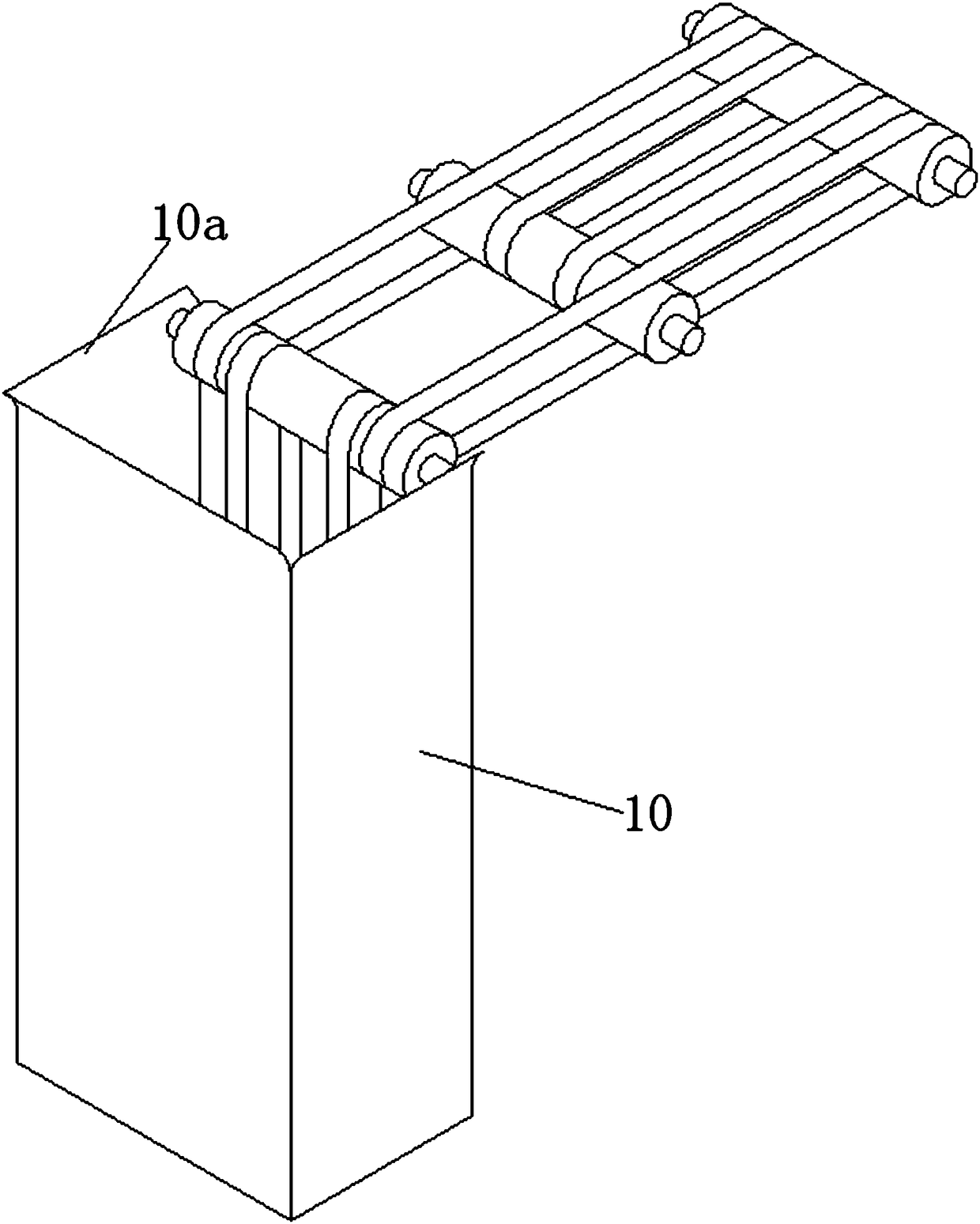

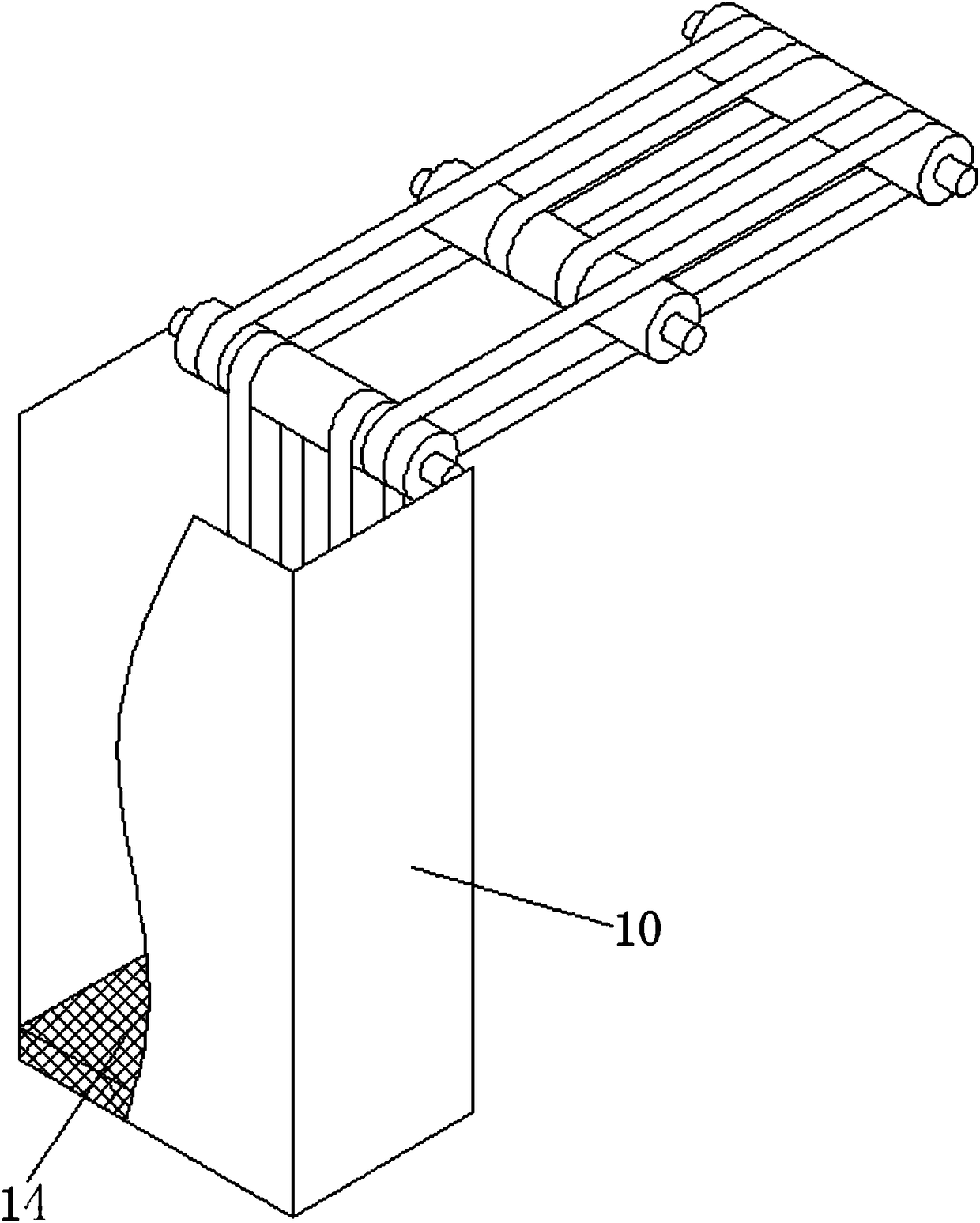

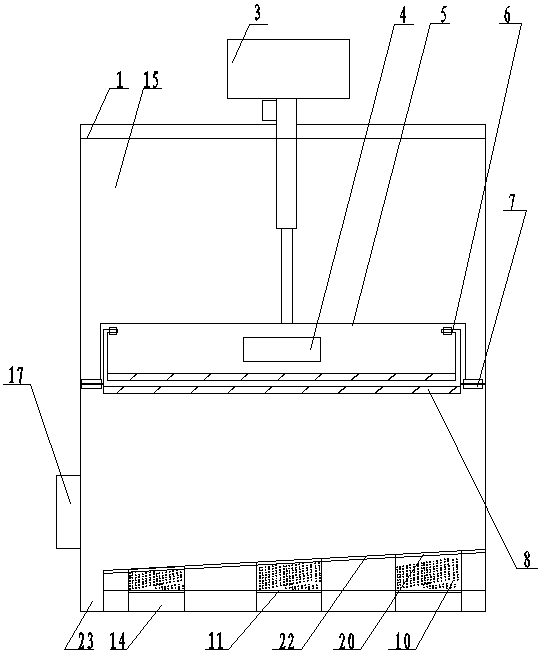

Sealing valve discharge method and discharge device using same

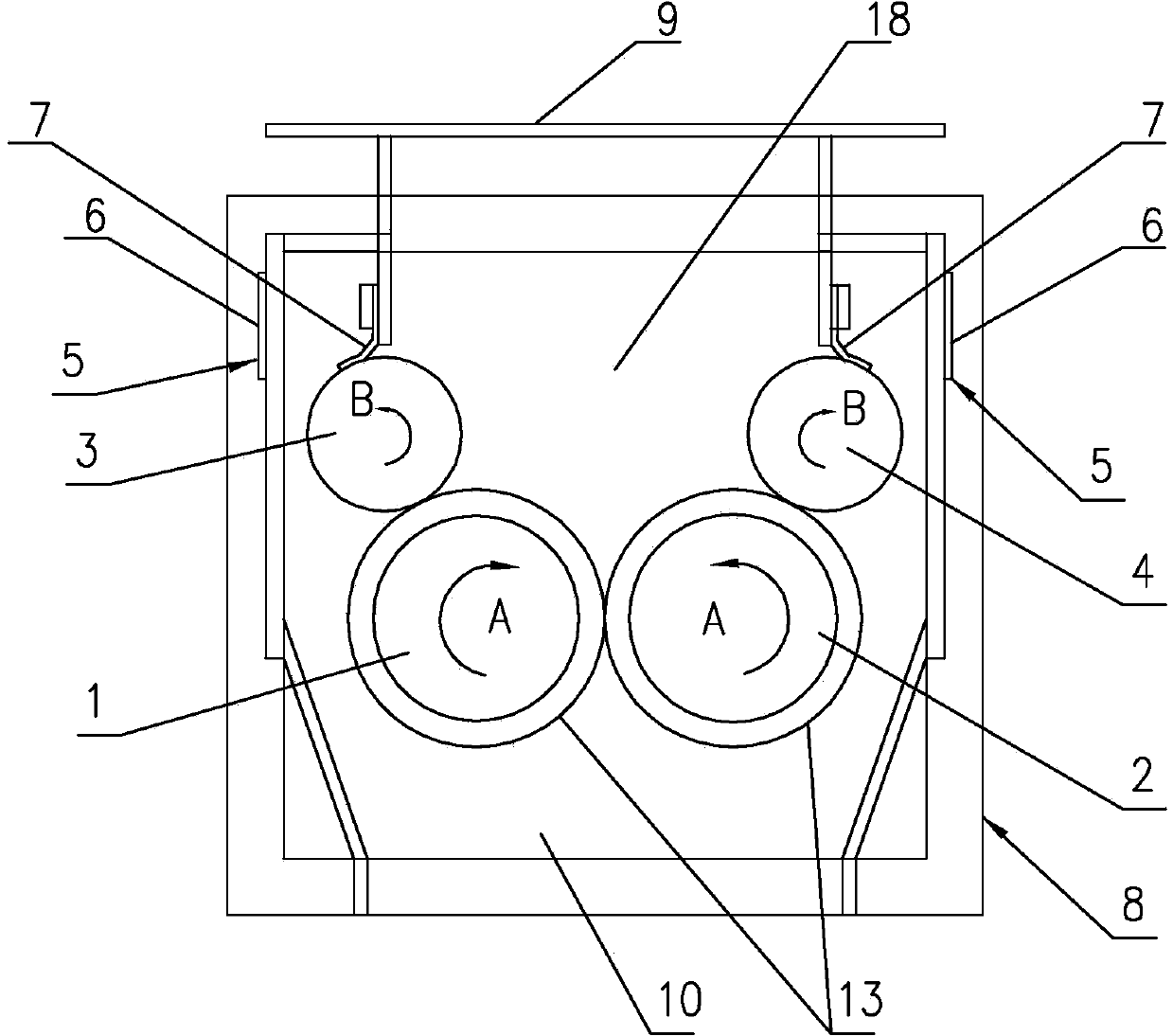

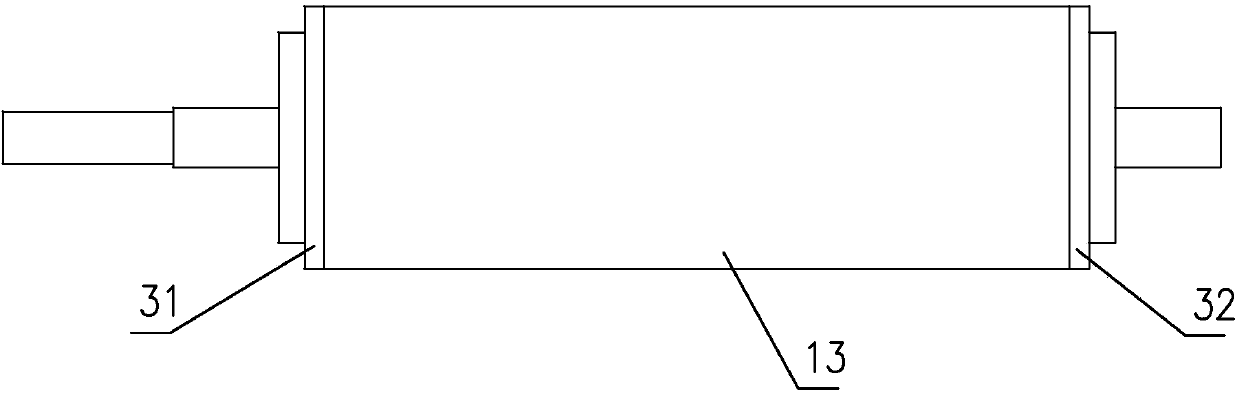

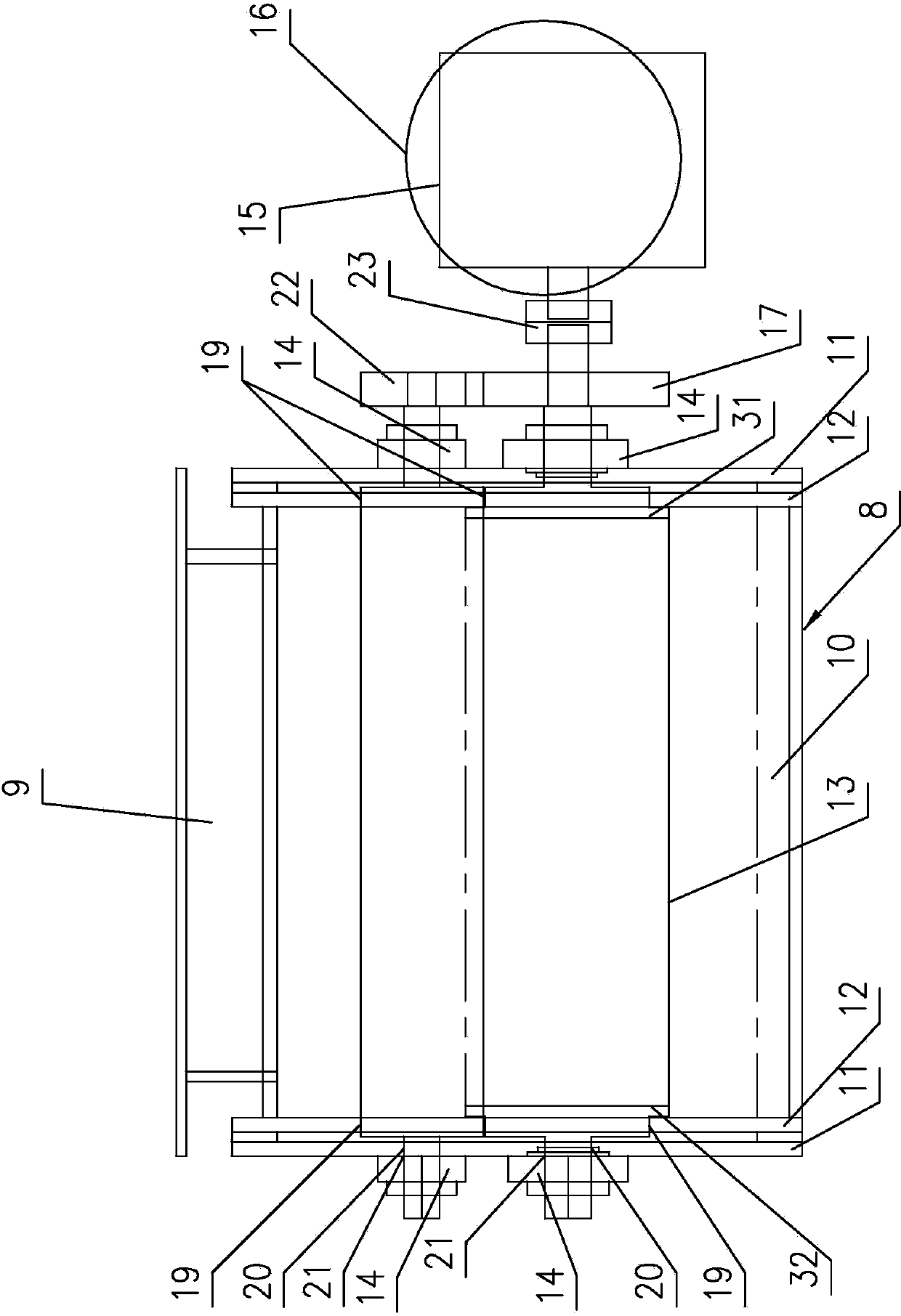

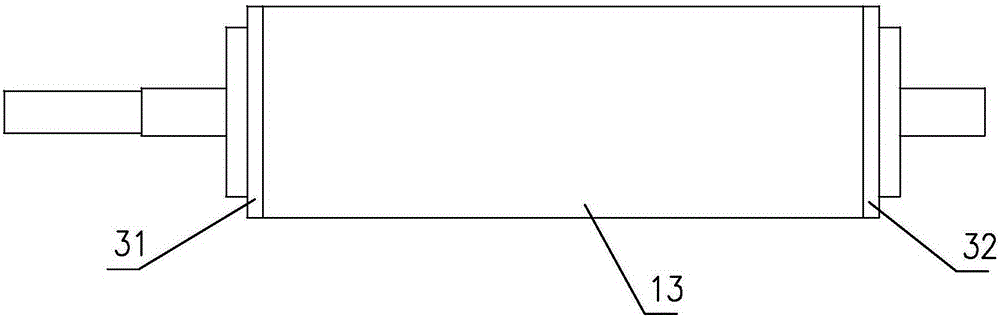

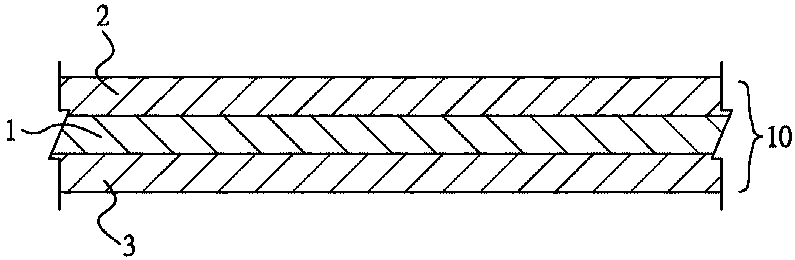

The invention discloses a sealing valve discharge method. A pair of parallel, mutually compressed and reversely inward rotatable rollers are arranged in a mounting space, the rollers and the mounting space enclose a sealed space, and materials are squeezed out from discharge spaces of the rollers. The outer walls of the rollers are coated by elastic wear-resistant rubber coatings, the rubber coatings on the two rollers are clingy, the materials are squeezed out from the discharge spaces between the rubber coatings on the two rollers, a pair of compression devices are mounted on one of the rollers, and the materials squeeze the rollers to move outwards through the compression devices to form the discharge spaces, so that the materials can be squeezed out from the discharge spaces. The sealing valve discharge method is reliable in running, smooth in discharge, particularly applicable to textile industry and regenerated cotton industry and also applicable to the industry of discharged ash without massive hard objects, and sealing is ensured.

Owner:喻成进

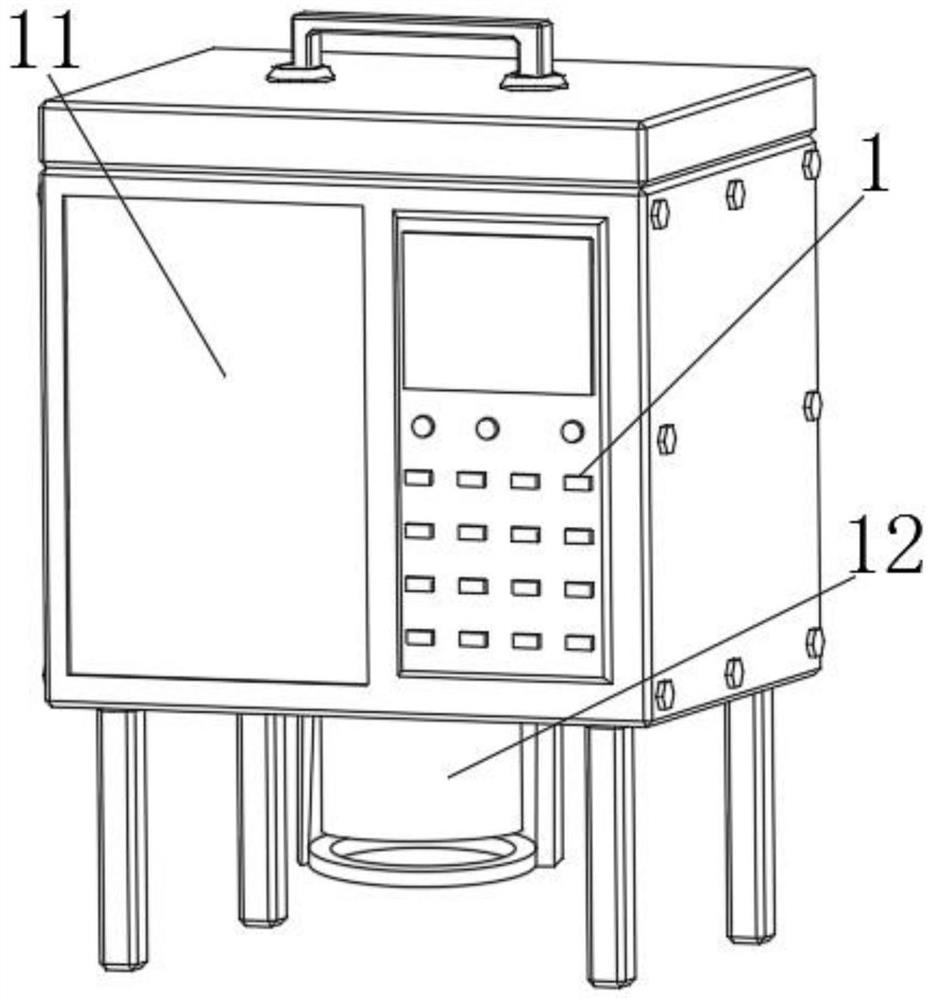

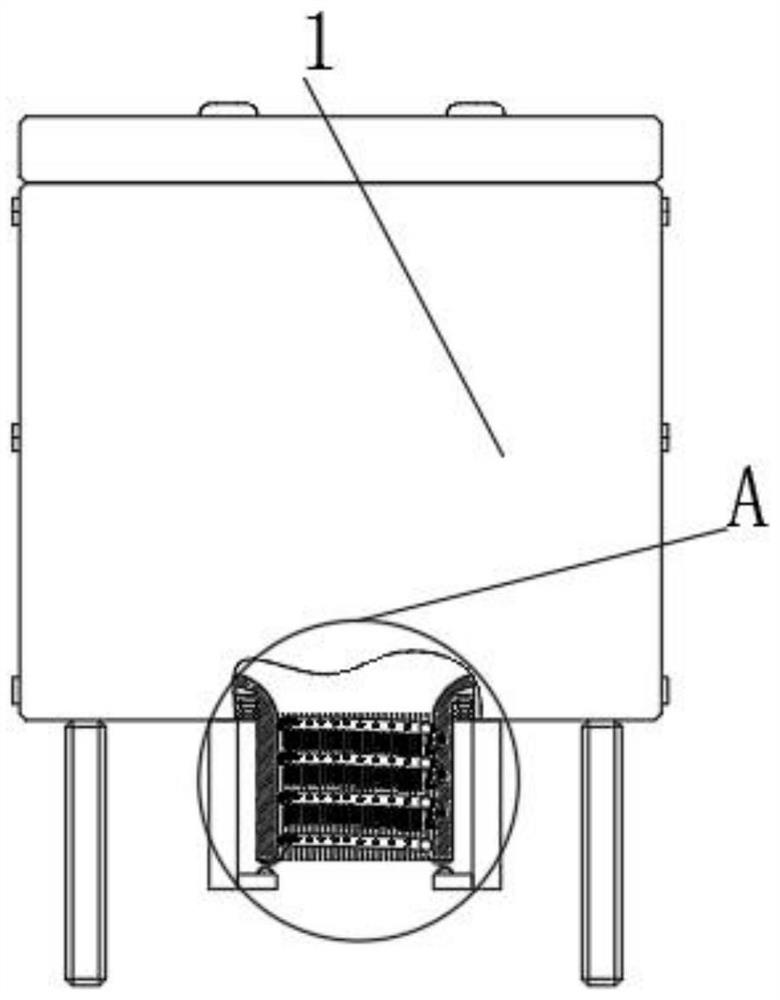

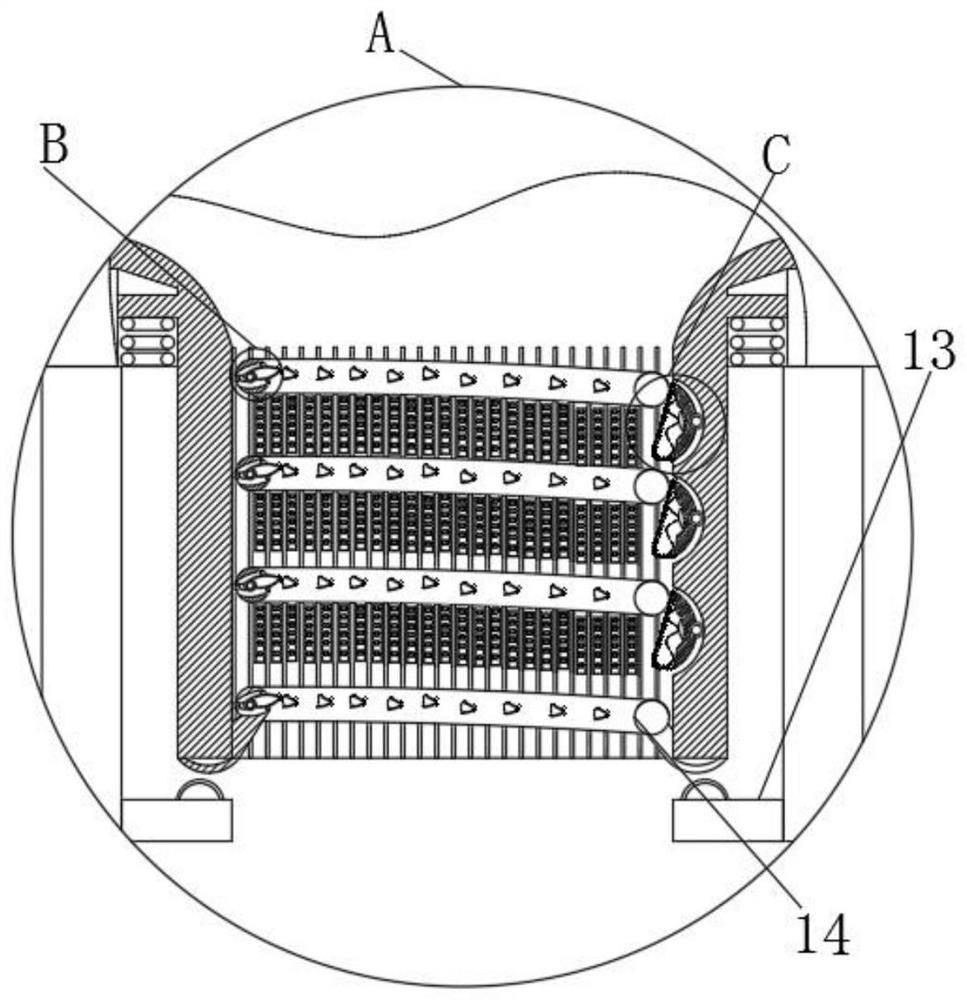

Electromagnetic chuck controller applied to production field

ActiveCN113522811AAccelerate decayGuaranteed cleaning effectCleaning using toolsCleaning using gasesElastic vibrationEngineering

The invention discloses an electromagnetic chuck controller applied to a production field, and relates to the technical field of electromagnetic chuck controllers. The electromagnetic chuck controller applied to the production field comprises an electromagnetic control mechanism used for electromagnetic control, an elastic vibration mechanism used for elastic vibration and an electrified cleaning mechanism used for cleaning a device, wherein a chuck is arranged in the electromagnetic control mechanism, the electromagnetic control mechanism is fixedly connected with an elastic vibration mechanism through the outer wall of the arranged chuck, and the electromagnetic control mechanism is fixedly connected with an electrified cleaning mechanism through the bottom of the arranged suction cup. According to the electromagnetic chuck controller applied to the production field, after a first elastic spring and a second elastic spring are electrified, magnetism is generated between screw pitches, so that the first elastic spring and the second elastic spring are shrunk, the shrunk first elastic spring can clamp scraps on the outer wall of the chuck, after the second elastic spring is shrunk, air in an air bag is extruded and sprayed out, and therefore, dust at the bottom of the chuck is cleaned.

Owner:南通茂业电子科技有限公司

Construction plate paint spraying device for constructional engineering

InactiveCN111992400AEasy to fixPrevent fallingPretreated surfacesCoatingsElectric machineStructural engineering

The invention discloses a construction plate paint spraying device for constructional engineering, and relates to the field of constructional engineering paint spraying equipment. The problem that efficiency is low due to the fact that paint cannot be sprayed on the two faces of a plate simultaneously is solved. The equipment specifically comprises an outer shell and two paint spraying frames, a motor is fixed to the outer wall of one side of the outer shell through screws, connecting rods are rotationally connected to the inner walls of the two sides of the outer shell correspondingly, one connecting rod is connected with the output end of the motor through a coupler, a rotating frame is welded to the outer walls of one sides of the two connecting rods, and second sliding grooves are formed in the outer walls of the two sides of the rotating frame correspondingly. According to the construction plate paint spraying device for the constructional engineering, by arranging the rotating frame, the motor is started, the connecting rods are rotated, the rotating frame is driven to rotate, the rotating frame rotates to a vertical state, the two paint spraying frames are located on the twosides of the rotating frame, paint spraying is conducted on the two faces of the plate through a lifting mechanism, and due to the fact that the device is fixed through the side edges of the plate, therefore, paint spraying of the front face and the back face of the plate cannot be affected, and the purpose of improving the paint spraying efficiency can be achieved.

Owner:中际建设(深圳)有限公司

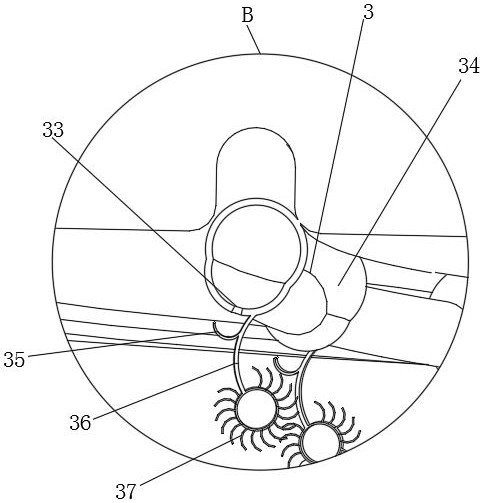

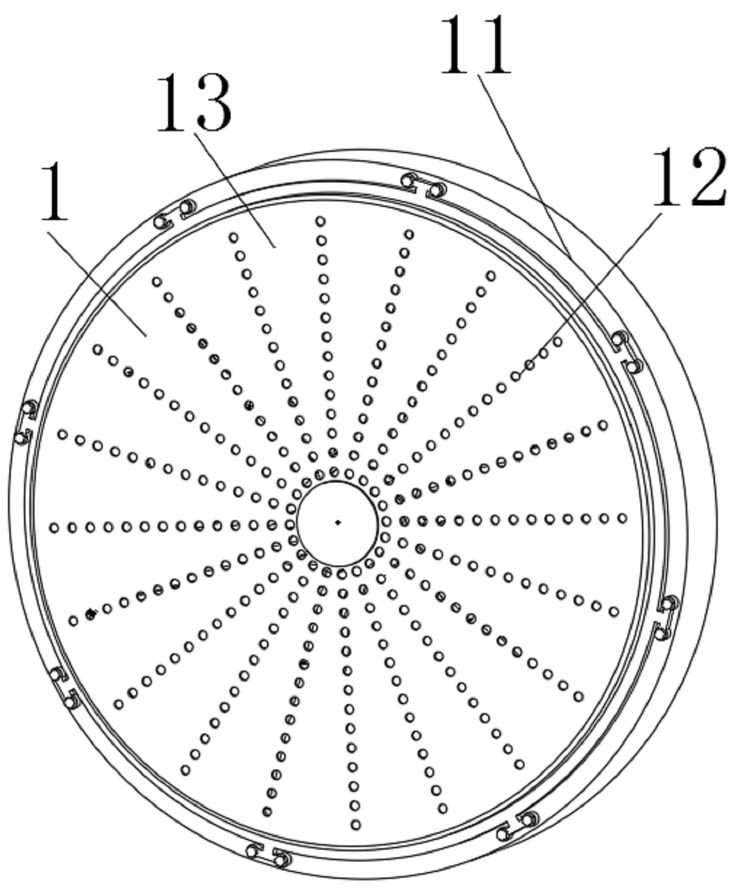

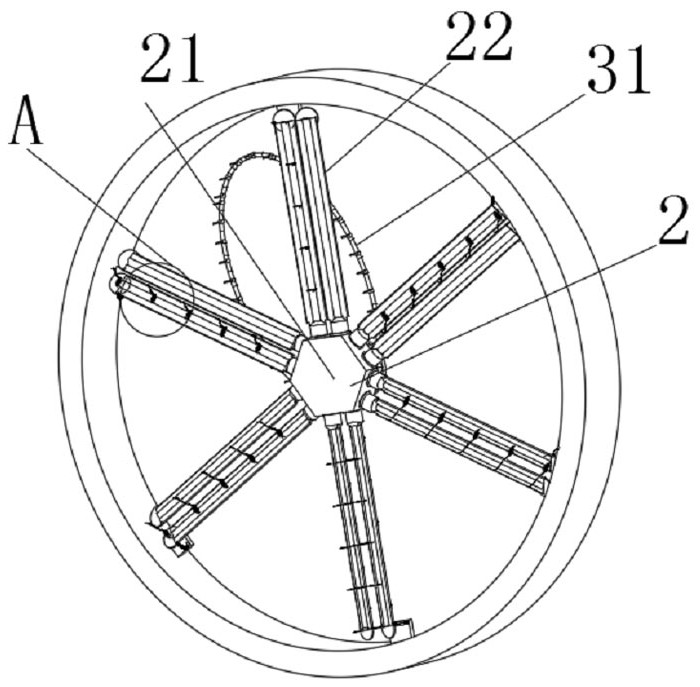

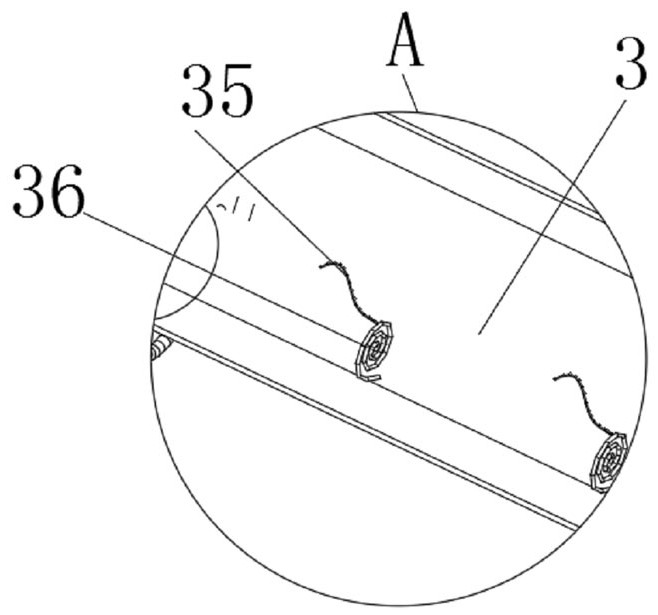

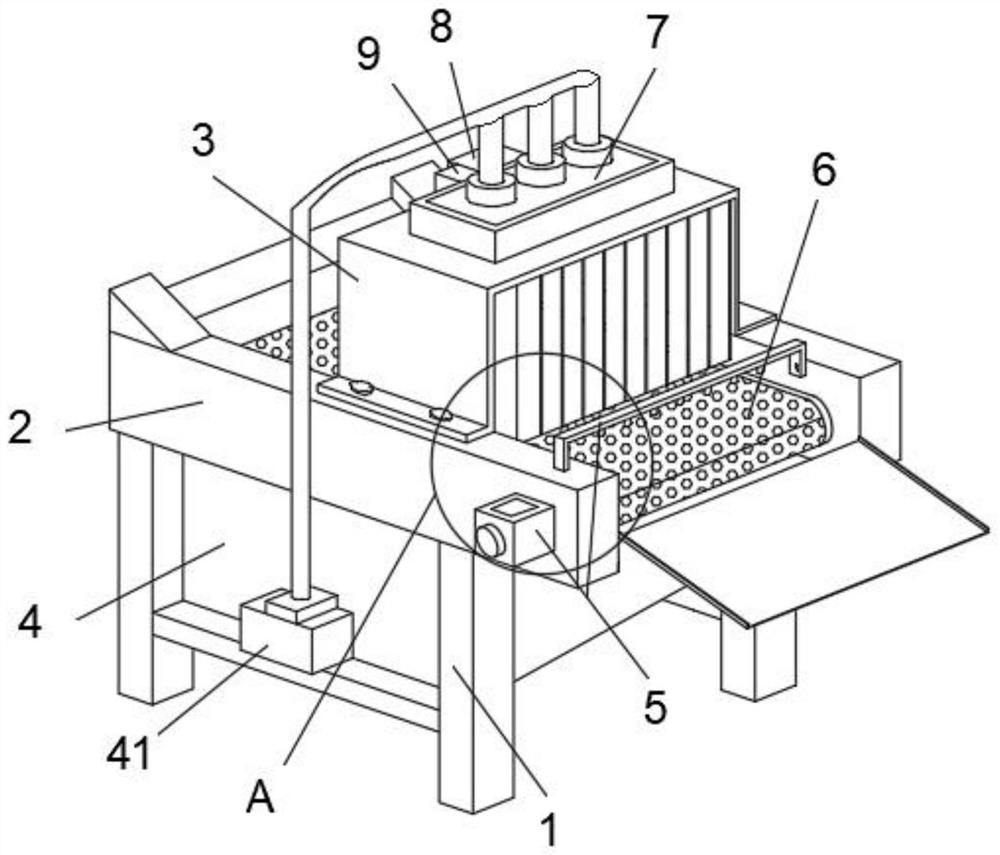

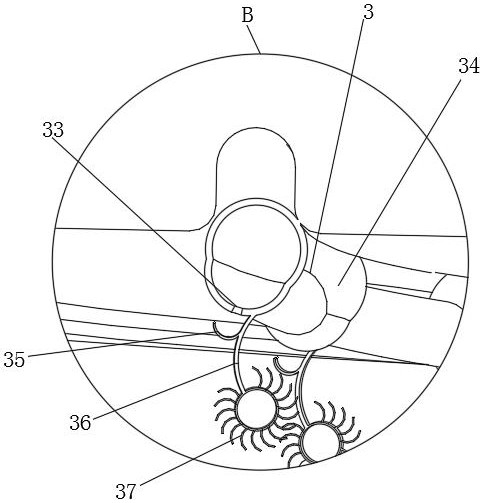

Anti-blocking exhaust fan special for food processing factory

InactiveCN113638918AGuaranteed cleaning effectMake sure to dropPump componentsPump installationsProcess engineeringFan blade

The invention discloses an anti-blocking exhaust fan special for a food processing factory, and relates to the technical field of food processing factories. The anti-blocking exhaust fan special for the food processing factory comprises a factory exhaust mechanism used for factory exhaust, a rotary cleaning mechanism used for rotary cleaning and a movable cleaning mechanism used for movable cleaning, and a filter screen is arranged in the factory exhaust mechanism; and the factory exhaust mechanism is provided with the rotary cleaning mechanism through the inner wall of the filter screen, and the outer wall of the rotary cleaning mechanism is fixedly connected with the movable cleaning mechanism. According to the anti-blocking exhaust fan special for the food processing factory, an air bag rotates along with fan blades, the air bag is inflated to intercept and collect chippings, when air flow generation is stopped, a spring in the air bag tensions the air bag to contract under the large elasticity of the spring, it is ensured that the chippings in the air bag are discharged, and when a movable rope is close to the fan blades, a first cleaning brush can clean away the chippings on the movable rope.

Owner:南通西南机械制造有限公司

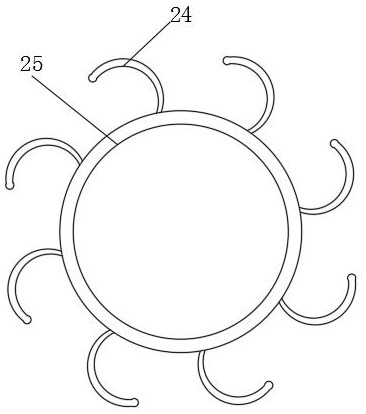

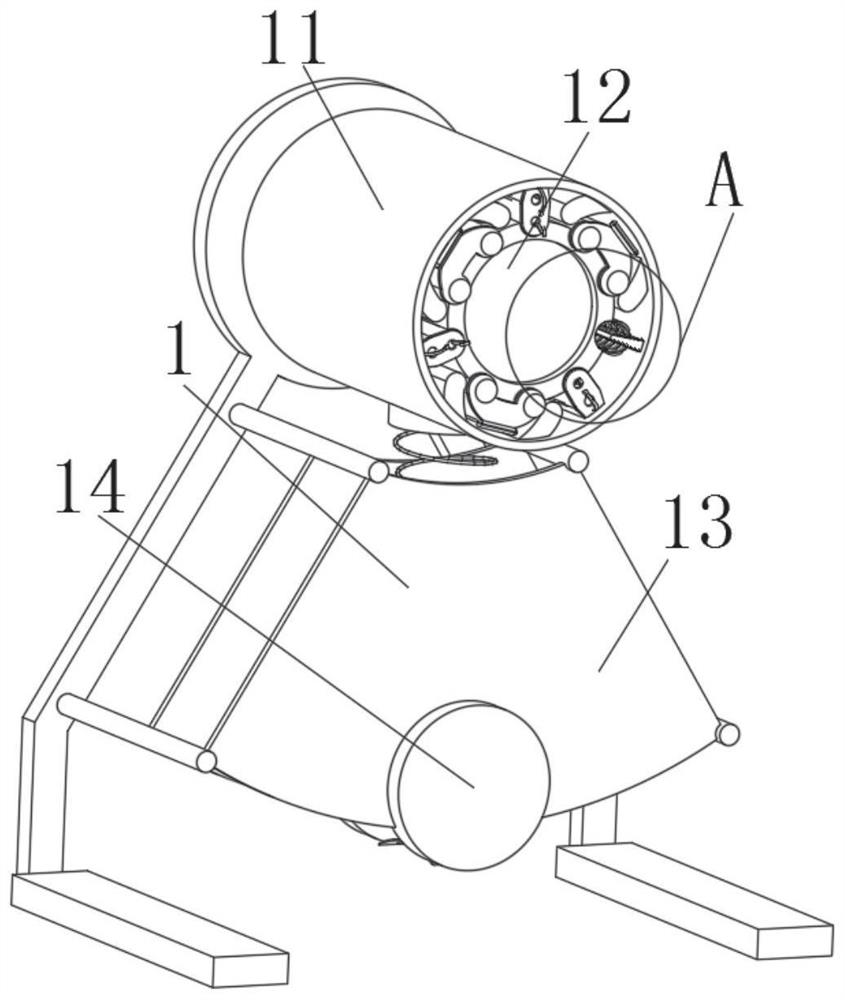

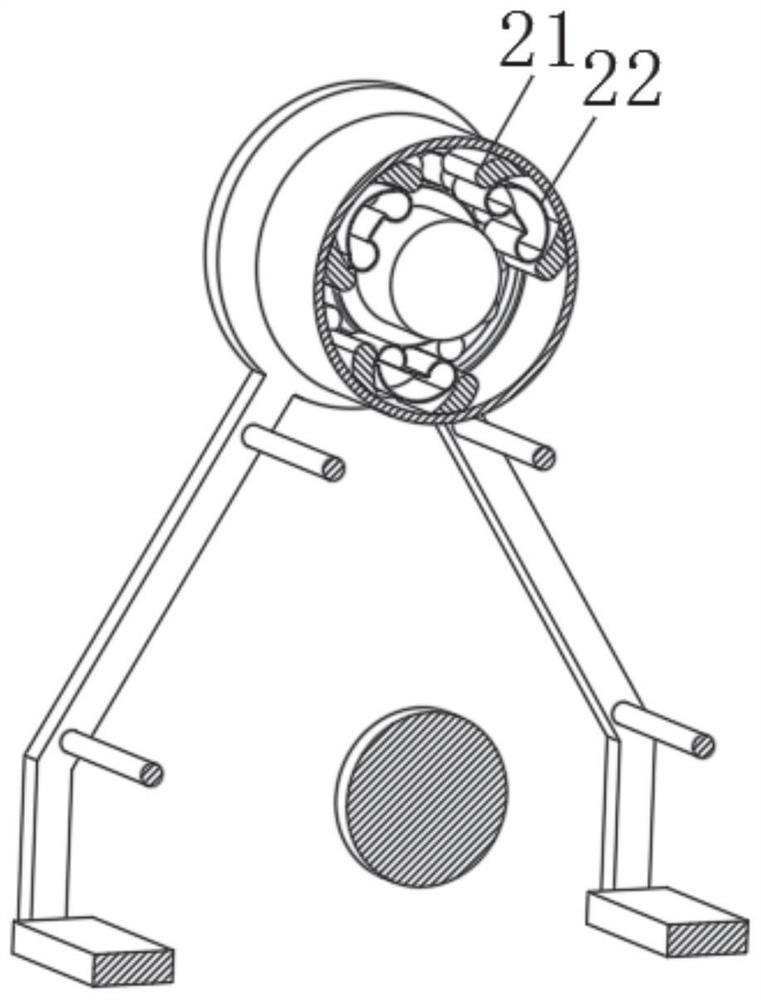

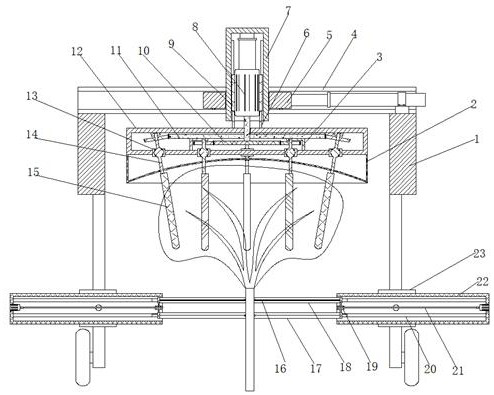

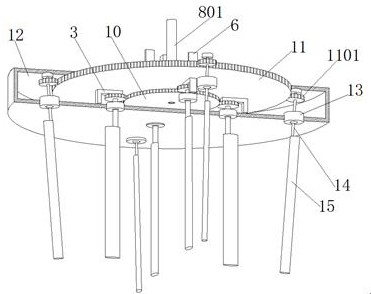

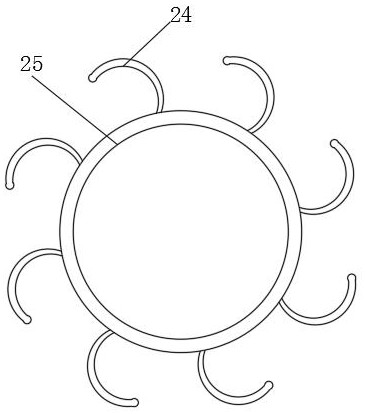

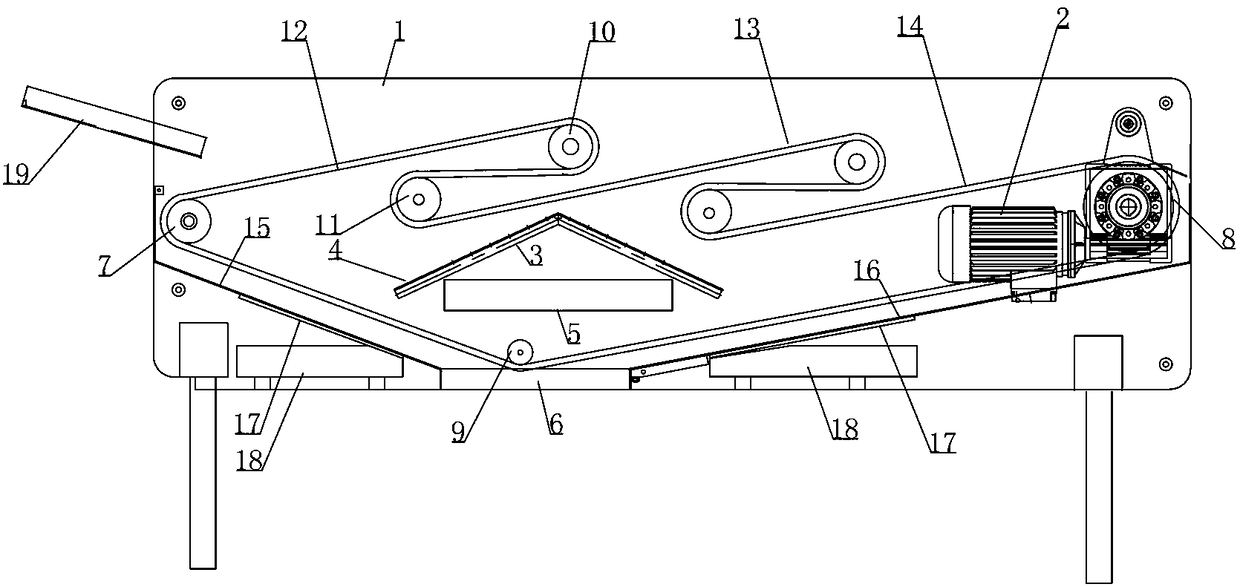

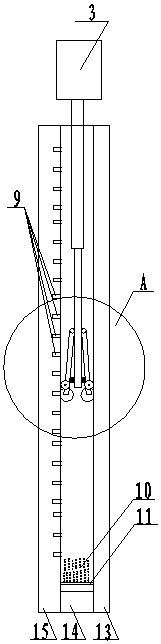

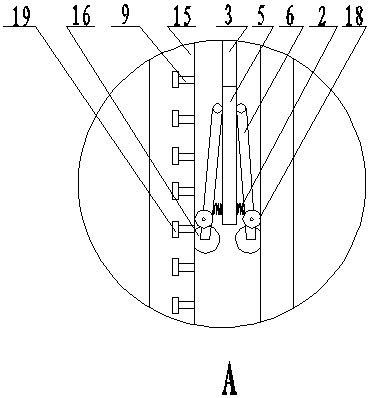

Automatic sesame shelling and sieving machine

ActiveCN103966013AWork lessPrevent fallingFatty-oils/fats productionMechanical engineeringSesame seed

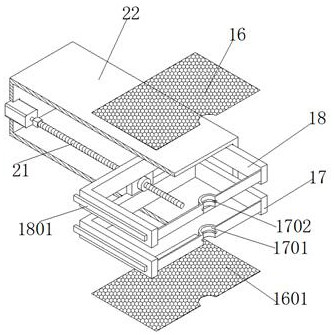

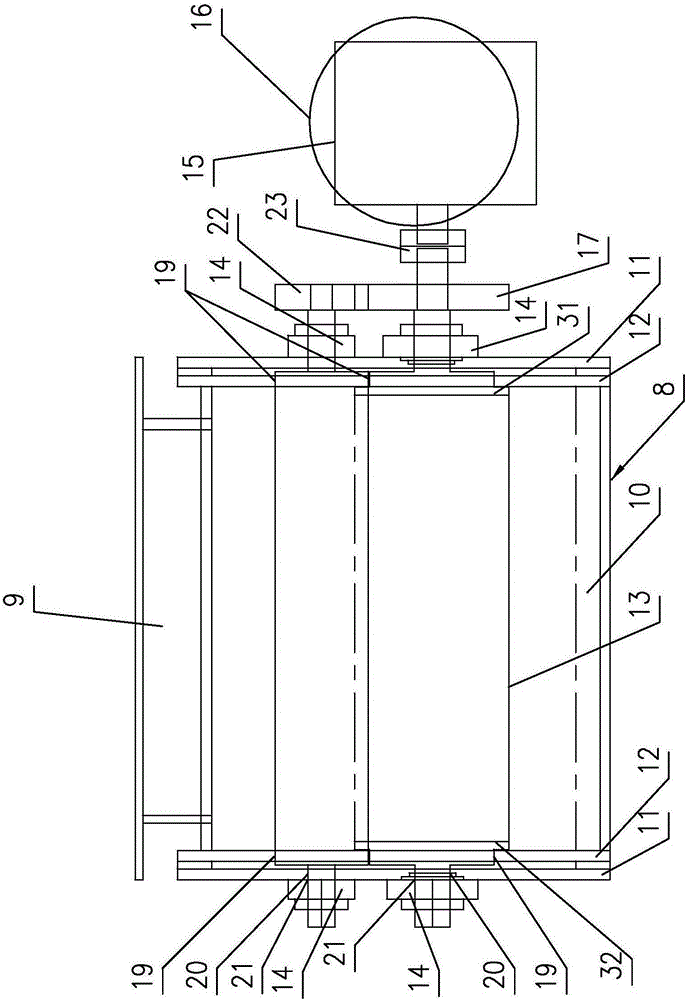

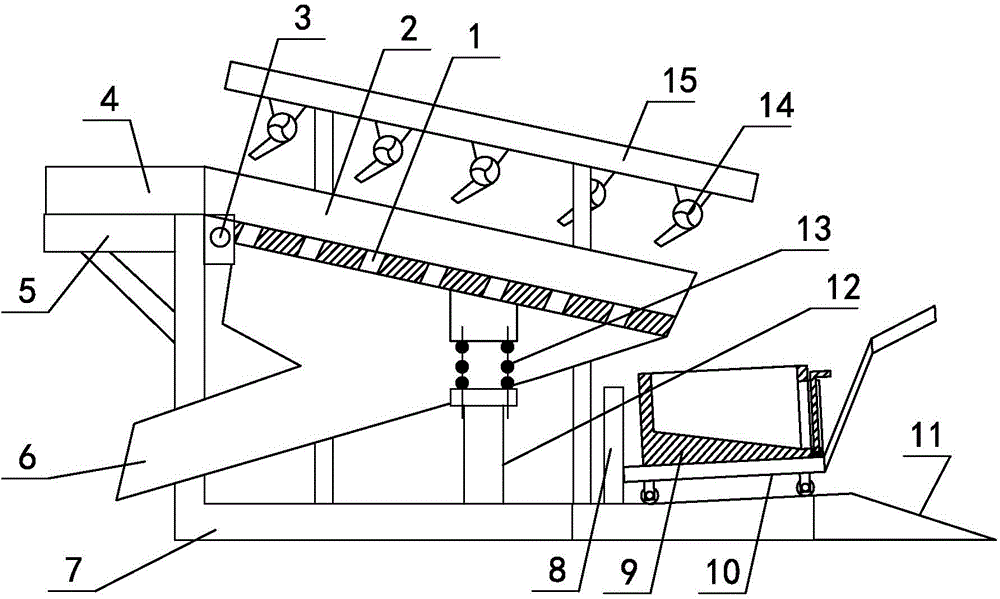

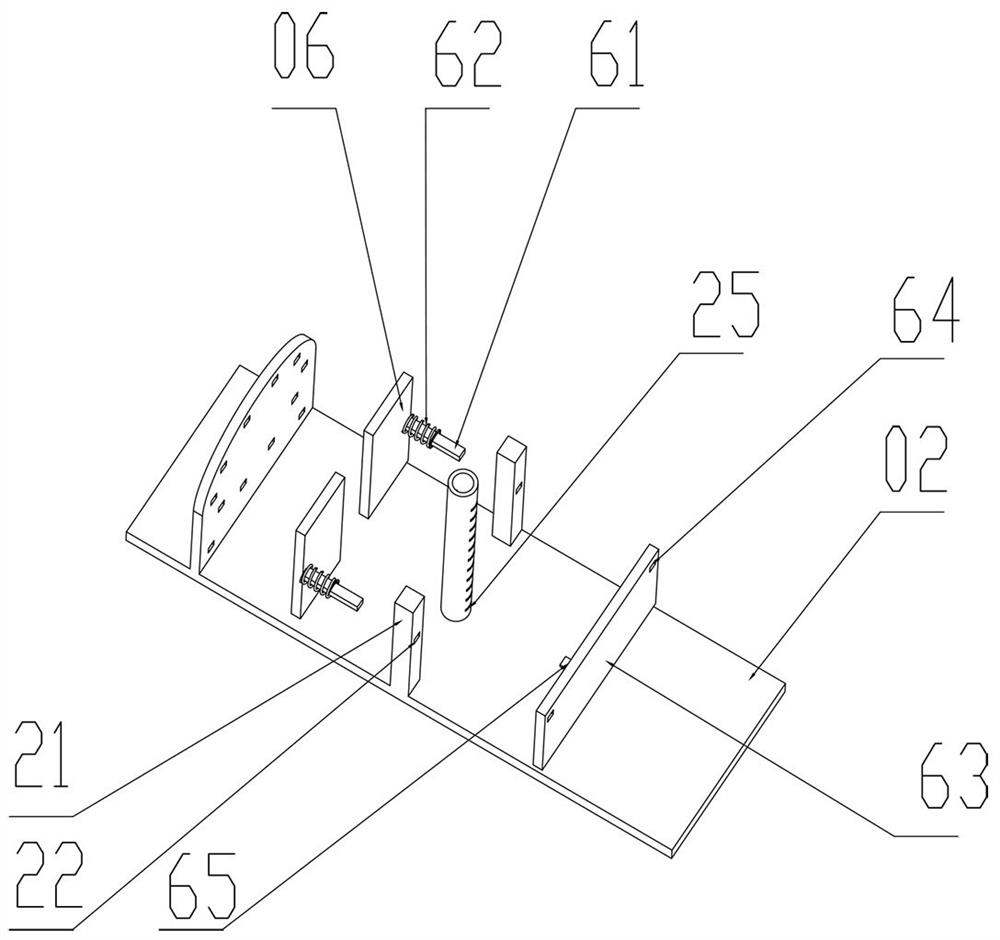

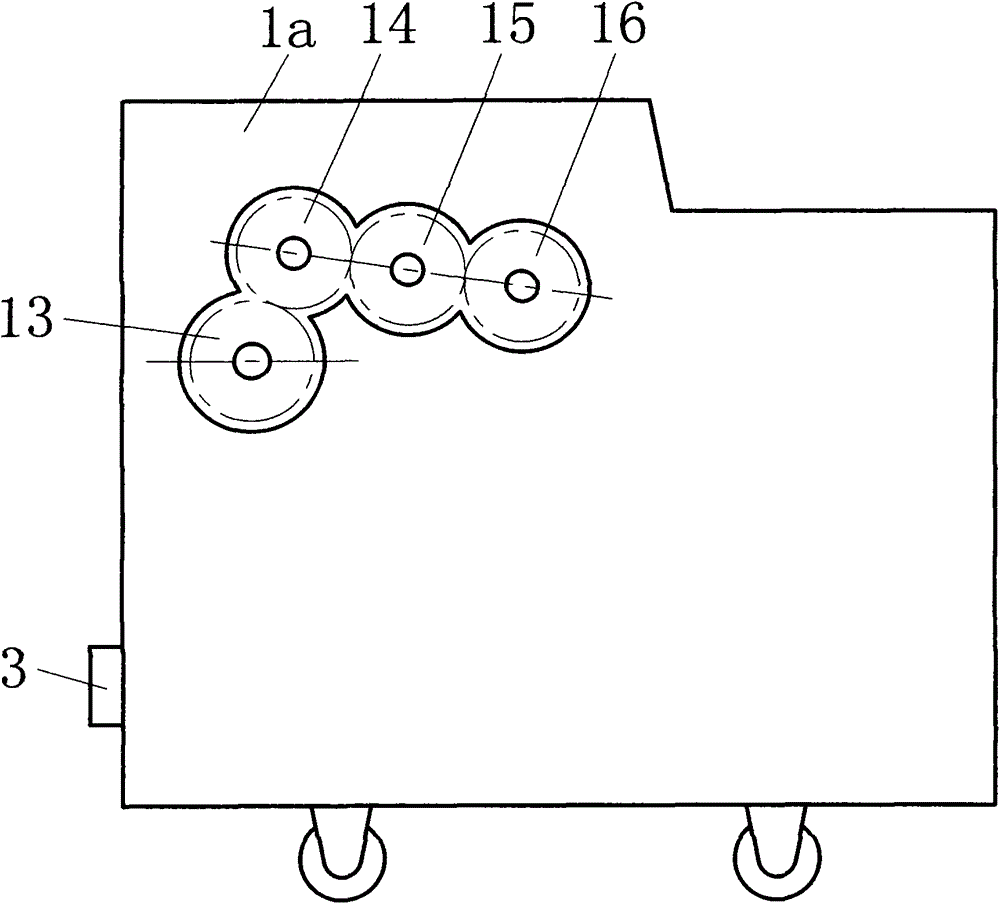

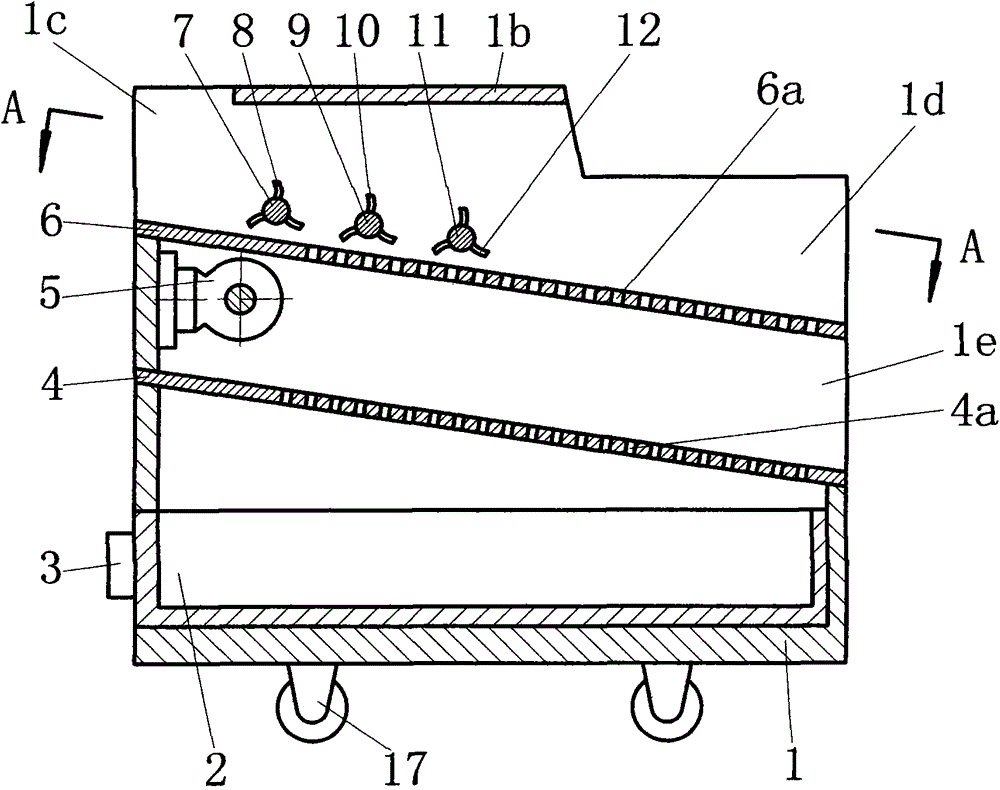

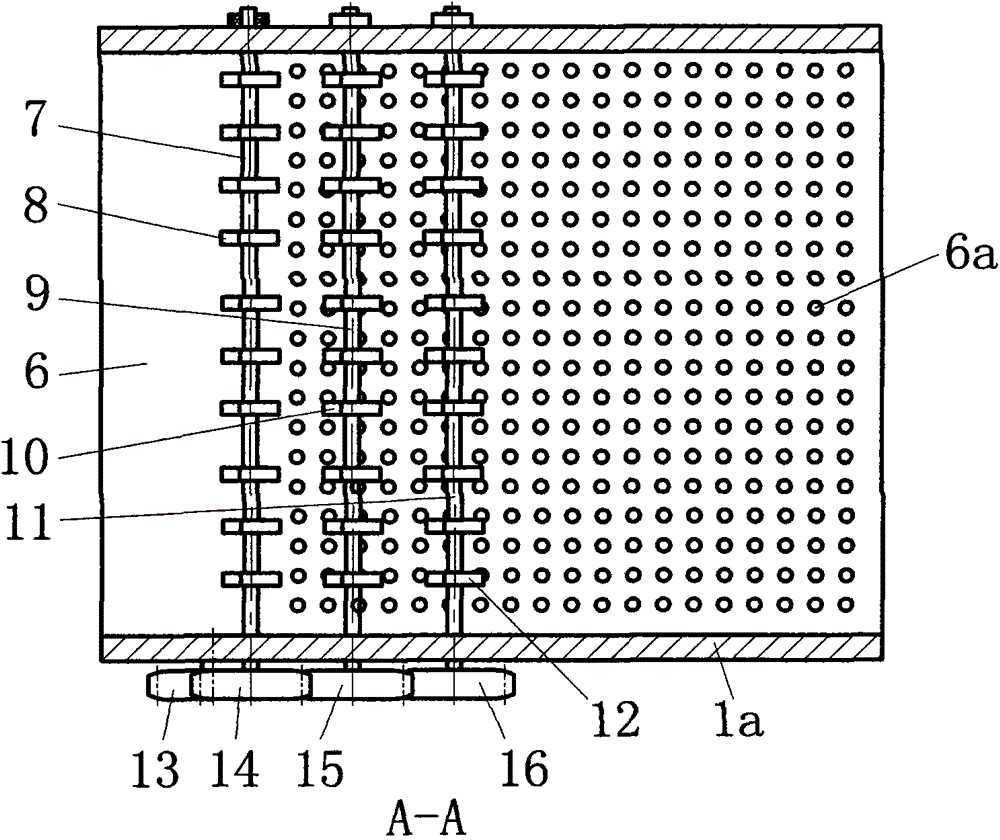

The invention relates to an automatic sesame shelling and sieving machine comprising a rack, wherein the front and rear sides of the rack are symmetrically provided with mounting plates; the lower part of the rack is in sliding connection with a storage cabinet located in the rack; a first sieve plate is obliquely fixed at the middle part of the rack; a second sieve plate is obliquely arranged at the medium-upper part of the rack; a motor is arranged between the first sieve plate and the second sieve plate and is fixed on the rack; a shelling device is arranged above the second sieve plate; a transmission device is arranged at the front sides of the mounting plates; the shelling device is connected with the motor through the transmission device; the transmission device is driven by the motor, and then the power is transferred to the shelling device, therefore, shelling treatment on sesame is realized. The automatic sesame shelling and sieving machine has the advantages of reasonable structural design, low manufacturing cost, convenience in use and the like; the aim of efficiently sieving the sesame is achieved; a two-stage sieving way is adopted, so that sesame shelling, fine sesame sieving and sesame collecting processes are achieved, the manpower and material investments are reduced, and the sesame sieving quality is ensured.

Owner:黄翰天

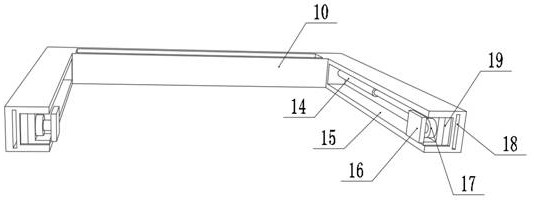

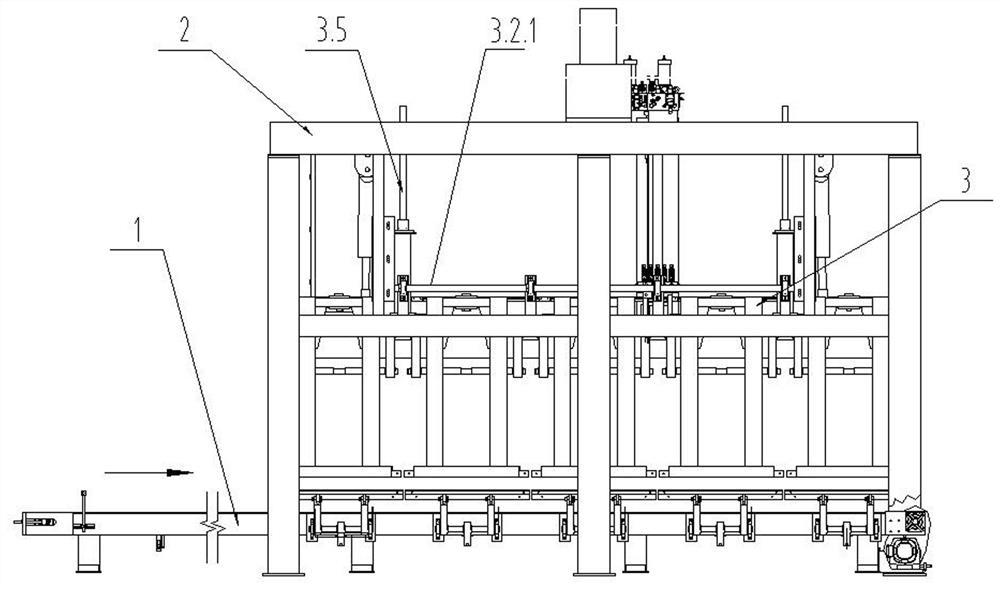

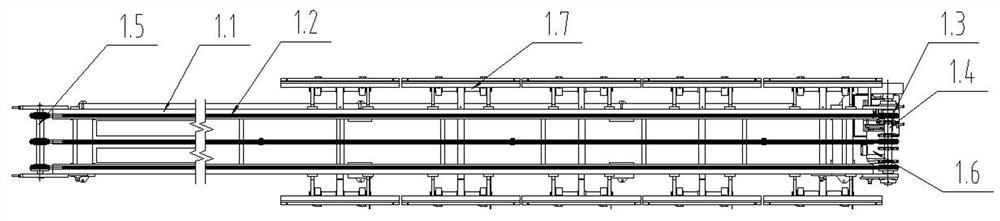

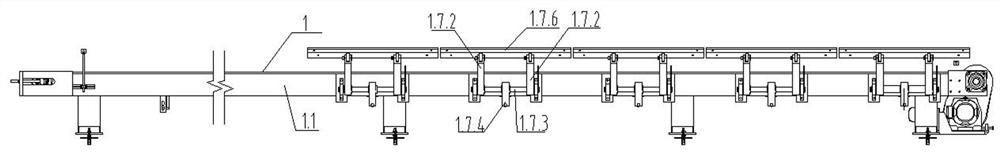

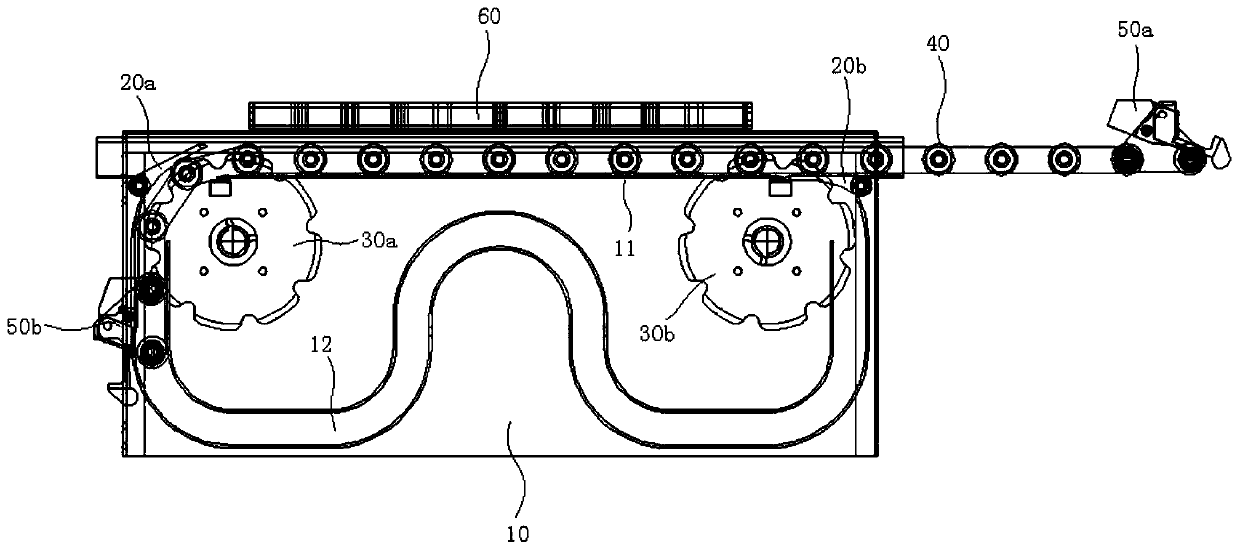

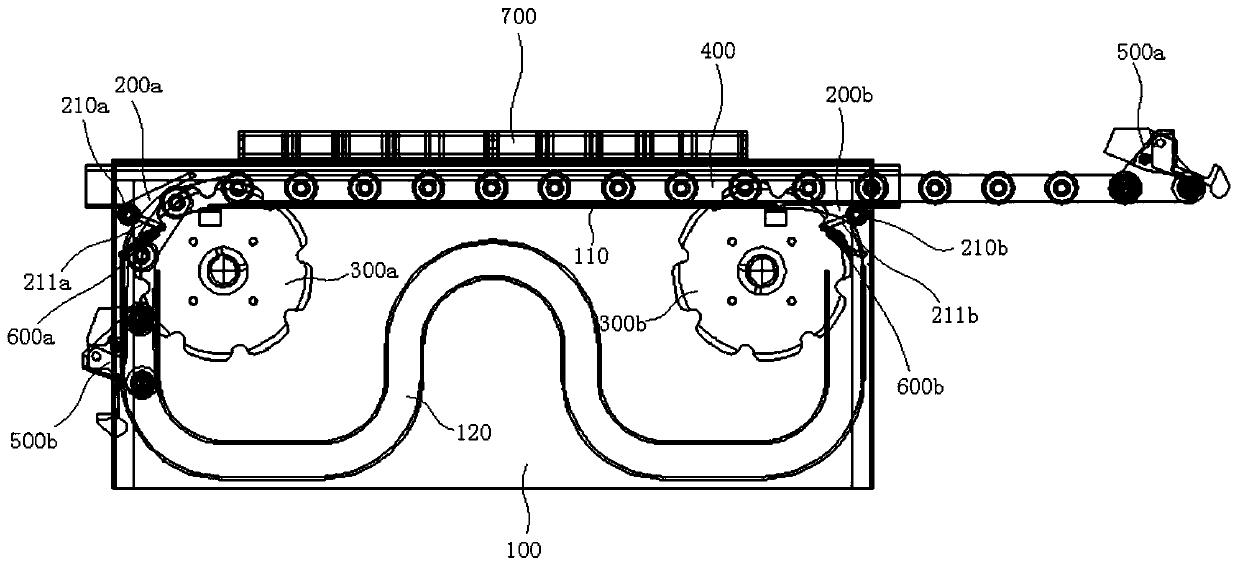

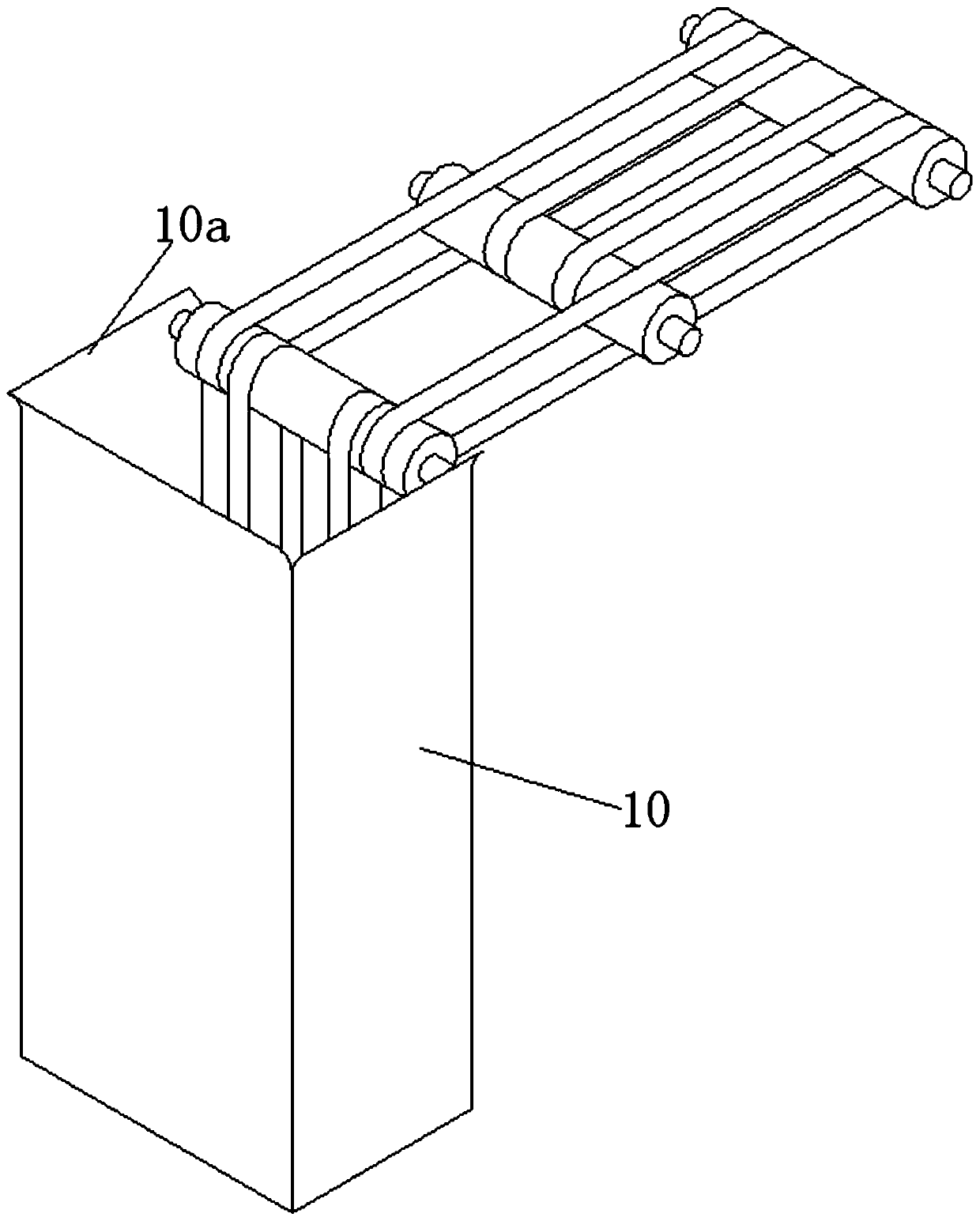

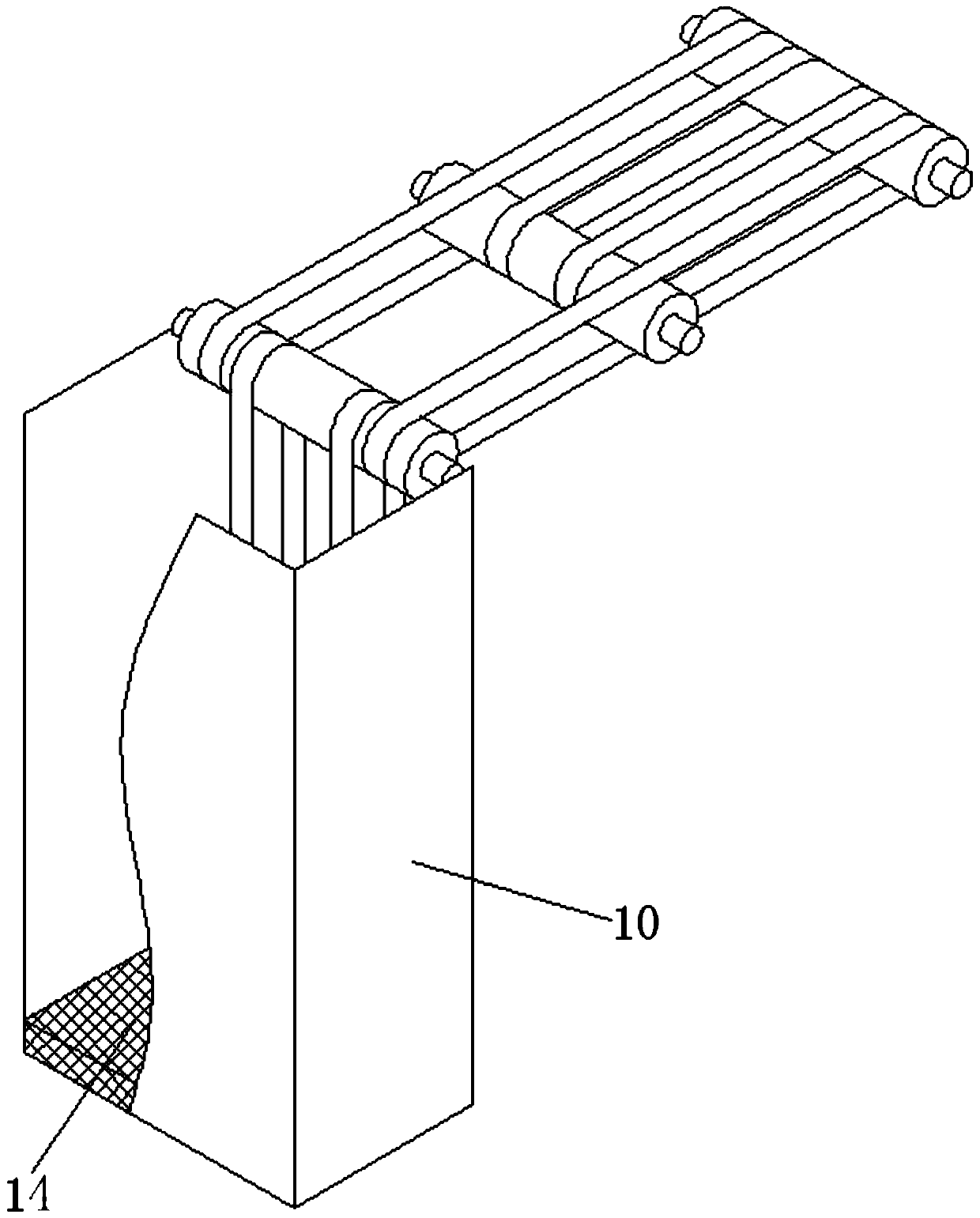

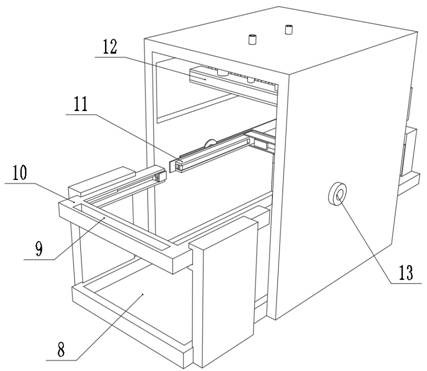

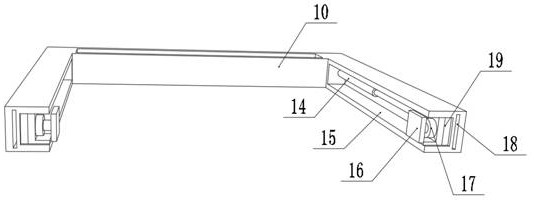

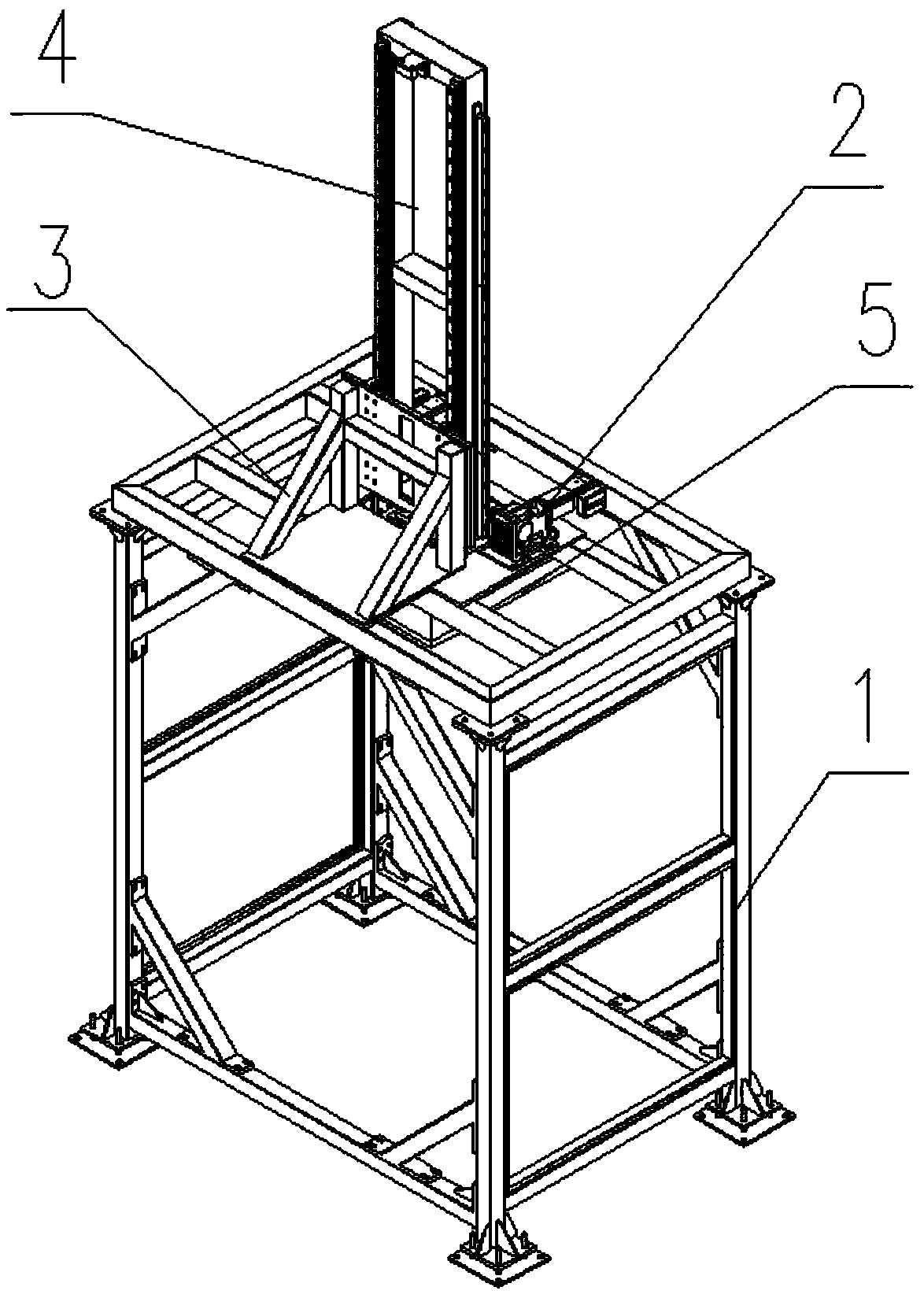

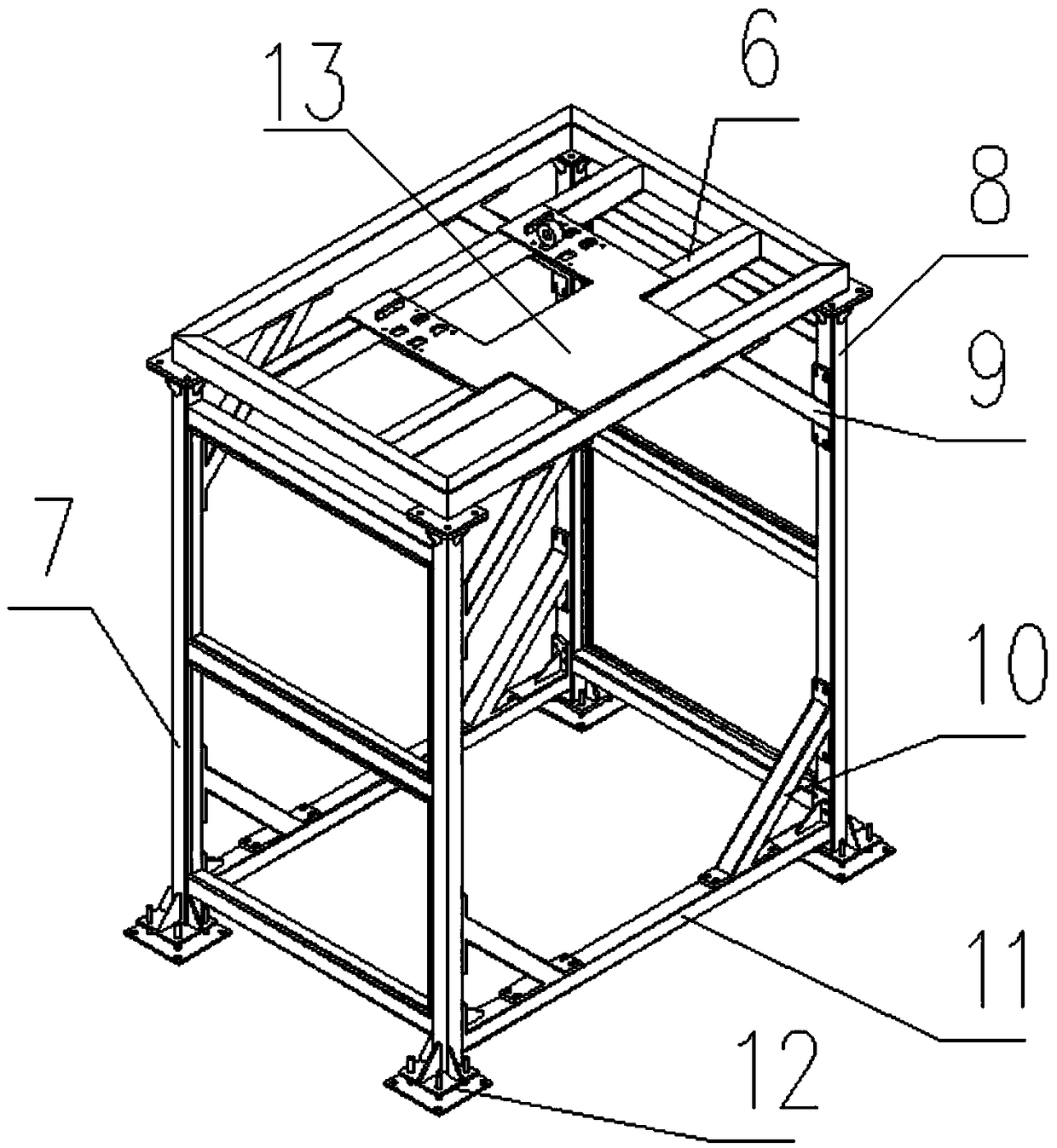

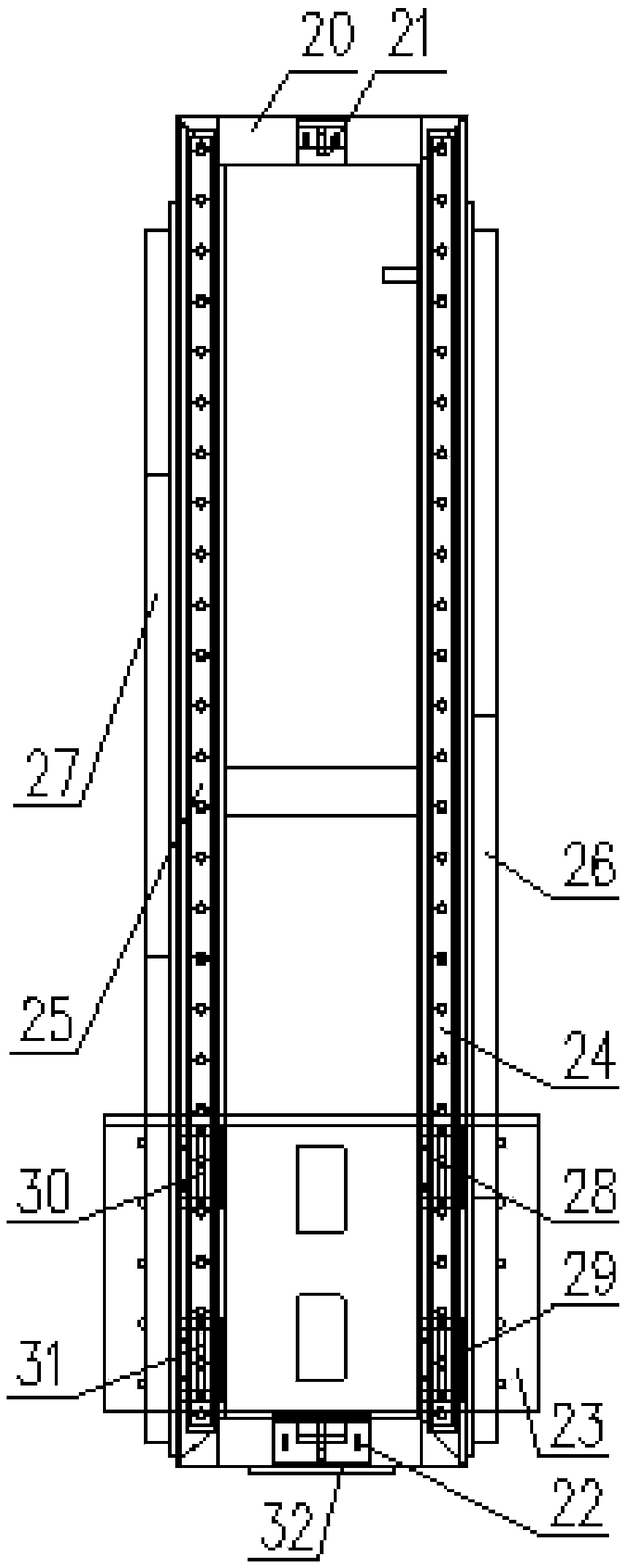

Parting conveying method and parting conveying device for aerated concrete products

PendingCN112079126AReduce complexityMeet the requirements of automated productionConveyorsStacking articlesStructural engineeringTransfer line

The invention relates to a parting conveying method and a parting conveying device for aerated concrete products. According to the method, by means of coordination of clamping devices, clamping jaw mechanisms and a conveying line, an adhered aerated concrete product stack is parted and conveyed layer by layer from bottom to top. The parting conveying device comprises the conveying line, a fixing frame and the clamping jaw mechanisms, wherein the clamping devices are arranged on the conveying line to clamp the bottommost layer of the aerated concrete product stack, the clamping jaw mechanisms are arranged on the fixing frame through lifting mechanisms and can clamp the aerated concrete products at the sub-bottom layer, and the conveying line can convey the parted aerated concrete products to the next station. The parting conveying device provided by the invention is stable and reliable in operation and can meet the process requirements of the market for continuous work of automatic sorting, grouping, stacking and packaging of the aerated concrete products.

Owner:洛阳腾和达智能装备有限公司

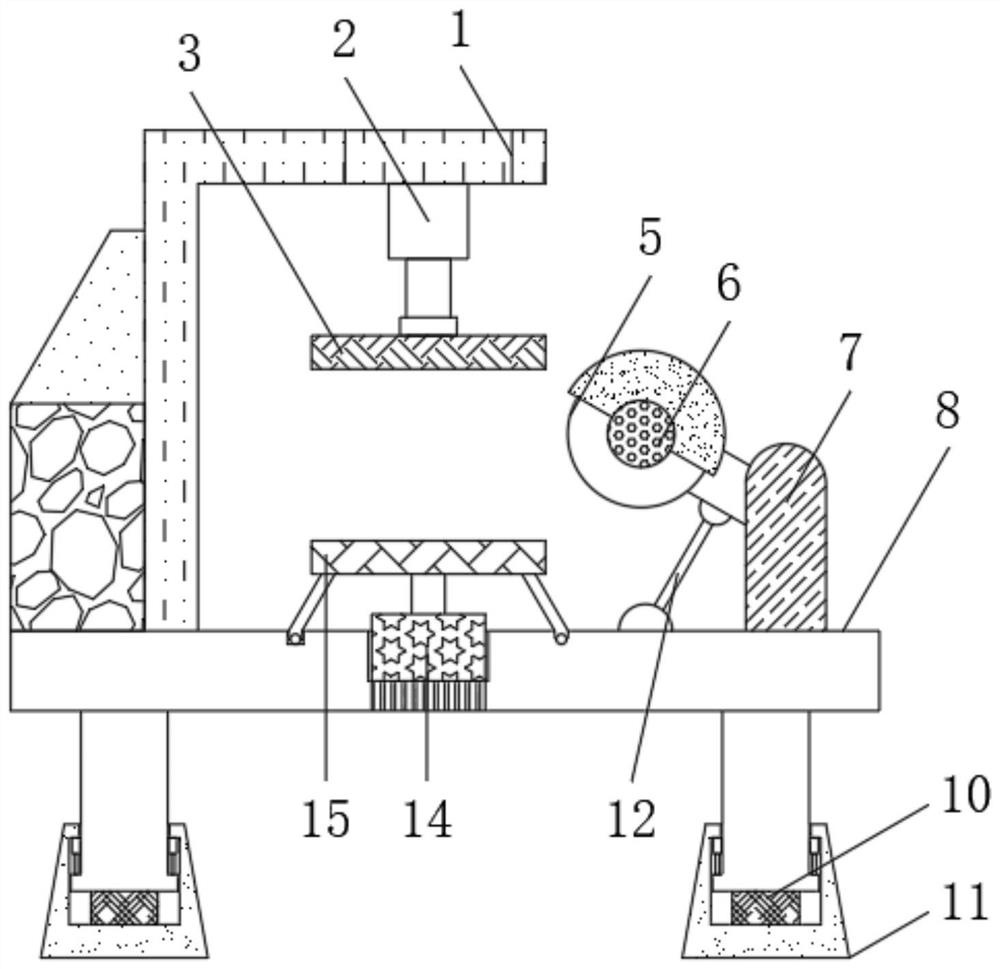

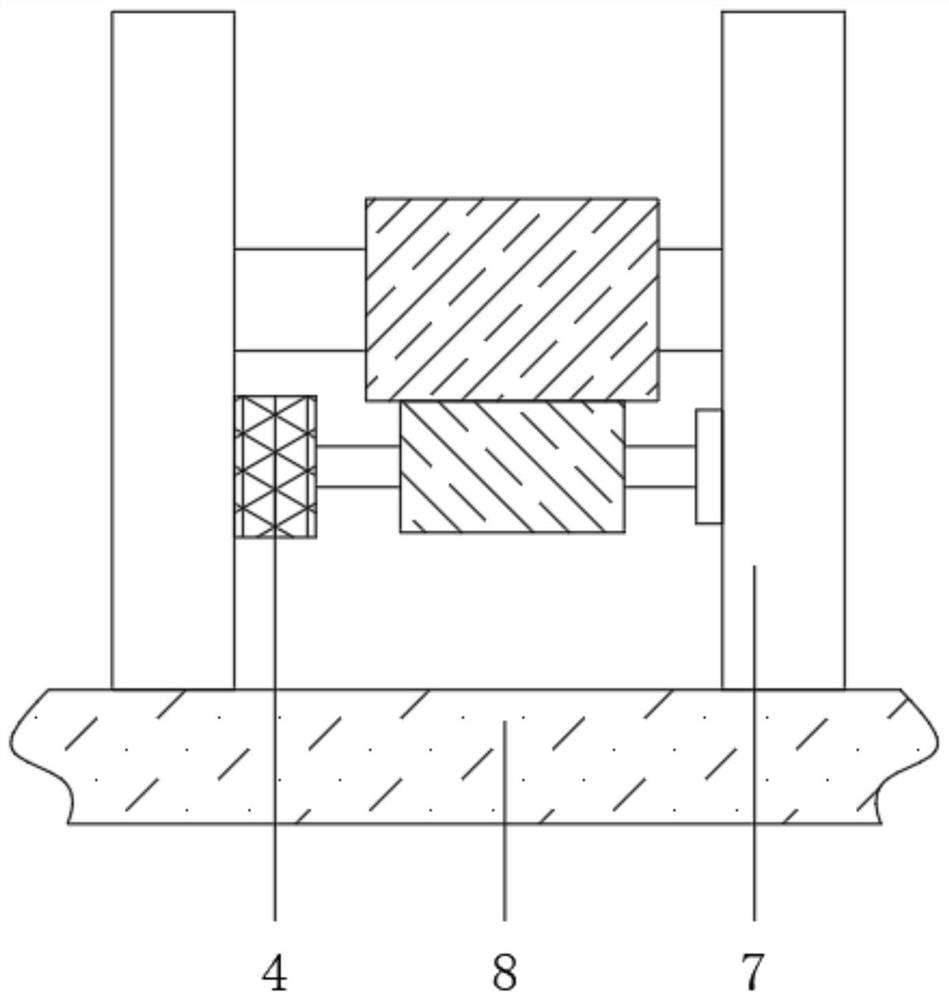

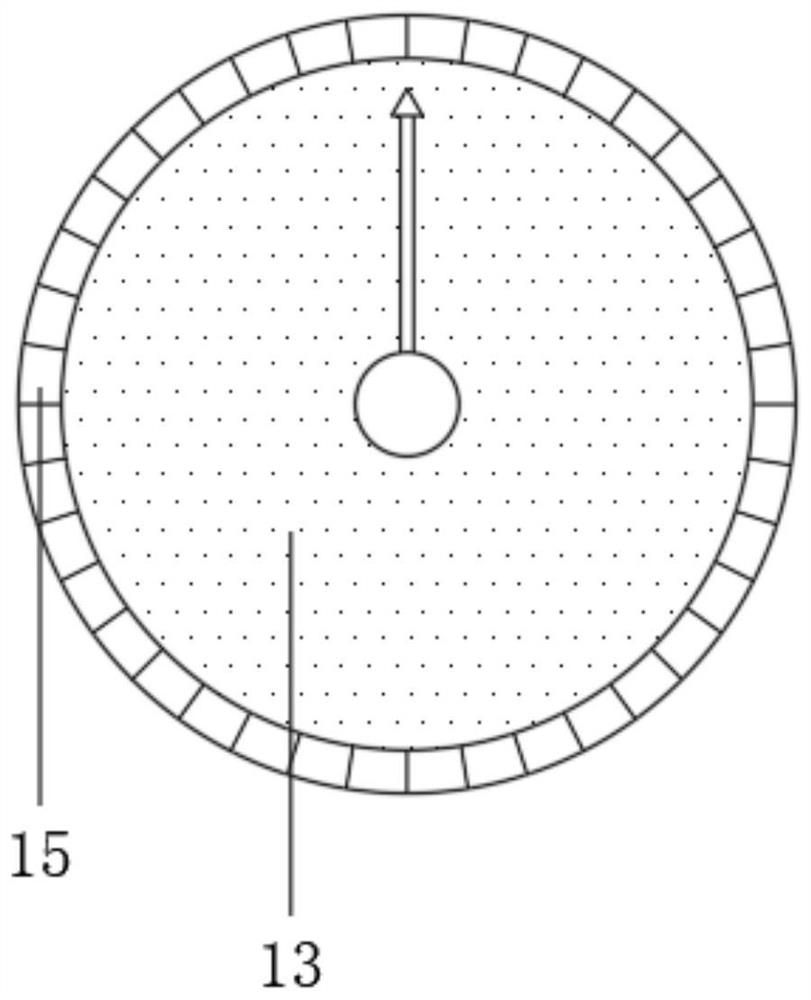

Angle adjustable fiber product cutting machine

InactiveCN112297092AIntegrity guaranteedMake sure to dropFouling preventionNon-rotating vibration suppressionFiberElectric machinery

The invention belongs to the technical field of fiber product processing, in particular to an angle adjustable fiber product cutting machine. In order to solve the problems that in the prior art, it is inconvenient to adjust a fiber product, fragments and dust pollute the environment severely and the physical health of a worker is harmed, the invention provides a scheme as follows: the angle adjustable fiber product cutting machine comprises a base. An L-shaped side plate is mounted on one side of the outer wall of the top end of the base through bolts, a hydraulic column is fixedly mounted onthe outer wall of the bottom end of the L-shaped side plate, the bottom end of the hydraulic column is rotatably connected to a pressure plate in a sleeving manner through a bearing, a third motor isinlaid in the middle of the base, a cutting table is rotatably mounted at the upper end of the third motor through a rotating shaft, and an angle plate is rotatably connected to the outer peripheralwall of the cutting table in a sleeving manner. As a fiber plate block is located between the pressure plate and the cutting table, along with work of the third motor, the cutting table and the angleplate are rotatably connected in a clamped manner, so that the fiber plate block, the pressure plate and the cutting table rotate integrally at needed angles. A second motor works, and a cutting wheelrotates to cut an angle of the fiber plate block.

Owner:连云港新东方家纺有限公司

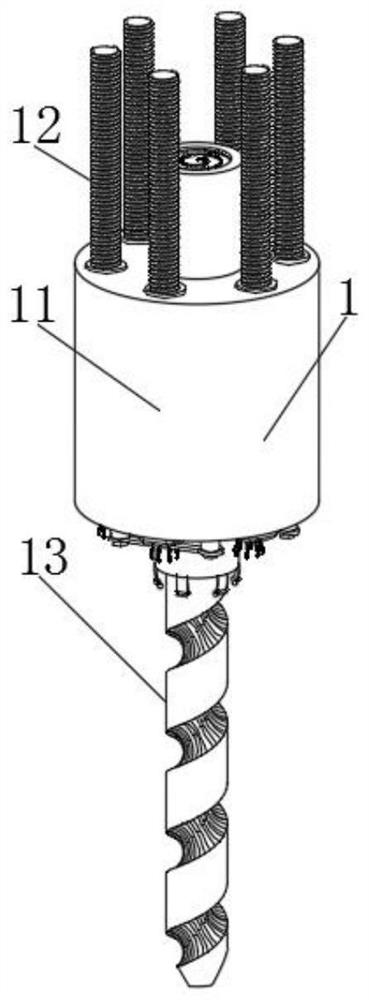

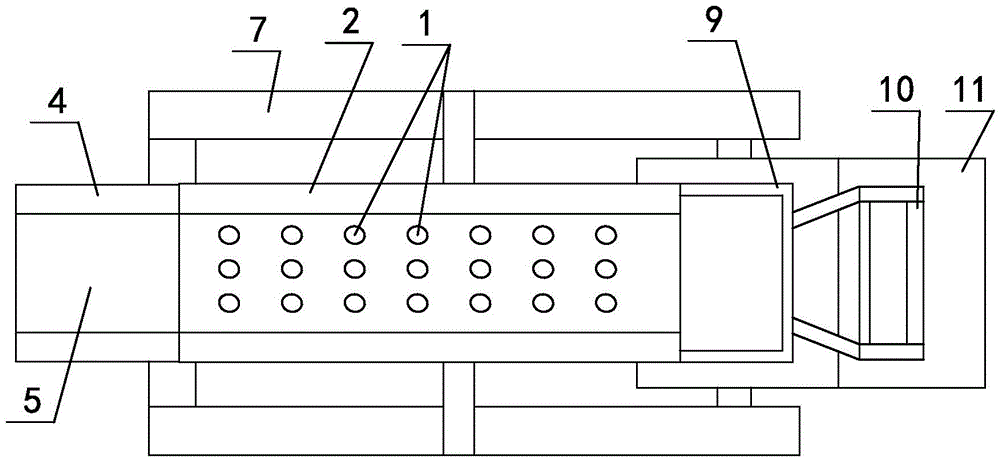

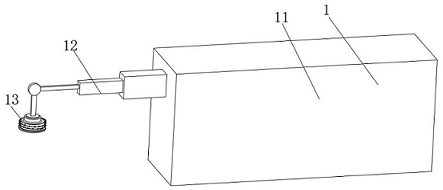

Processing device for electronic product production

InactiveCN114653984AMake sure to dropSpeed up the fallBoring/drilling componentsMaintainance and safety accessoriesIndustrial engineeringDrill bit

The invention discloses a processing device for electronic product production, and relates to the technical field of electronic product production. The machining device for electronic product production comprises a product punching mechanism, a shell is arranged in the product punching mechanism, an airflow cleaning mechanism is fixedly connected to the inner top of the shell, the product punching mechanism is fixedly connected with the airflow cleaning mechanism, and an airflow compression mechanism is fixedly connected to the inner wall of the shell; and the product punching mechanism is fixedly connected with the airflow compression mechanism. According to the machining device for electronic product production, a drill bit ascends in the punching process, gas between the drill bit and the inner top of the shell is squeezed out, a hole in the drill bit is small, airflow is slowly blown out, the drill bit ascends all the time, and therefore the airflow is blown out all the time, and the machining efficiency is improved. And therefore, the chippings on the outer wall of the drill bit are cleaned under the guide of the guide plate, and falling of the chippings on the outer wall of the drill bit is ensured.

Owner:郑礼刚

4D construction simulation animation rapid production equipment and method for project bidding

PendingCN113934099AHigh vibration frequencyReduce consumptionProjectorsAnimationHouse buildingIndustrial engineering

The invention discloses 4D construction simulation animation rapid production equipment and method for project bidding, which relate to the technical field of house construction. According to the 4D construction simulation animation rapid production method for engineering bidding, a magnetic repulsion mechanism generating shaking based on magnetic repulsion, an airflow cleaning mechanism used for airflow flowing for cleaning and a vibration deicing mechanism used for vibration for deicing are included, and an outer cylinder is arranged in the magnetic repulsion mechanism; the inner wall of the outer cylinder is fixedly connected with an airflow cleaning mechanism, the magnetic repulsion mechanism is fixedly connected with the airflow cleaning mechanism, and the inner wall of the outer cylinder is fixedly connected with a vibration deicing mechanism. According to the 4D construction simulation animation rapid production method for engineering bidding, the first air bag is extruded by the extrusion block, and the air flow blown out of the air outlet is increased after the air in the first air bag is extruded, so that ice on the surface of the projector can be cleaned, and removal of the ice is ensured.

Owner:CHINA RAILWAY URBAN CONSTR GRP

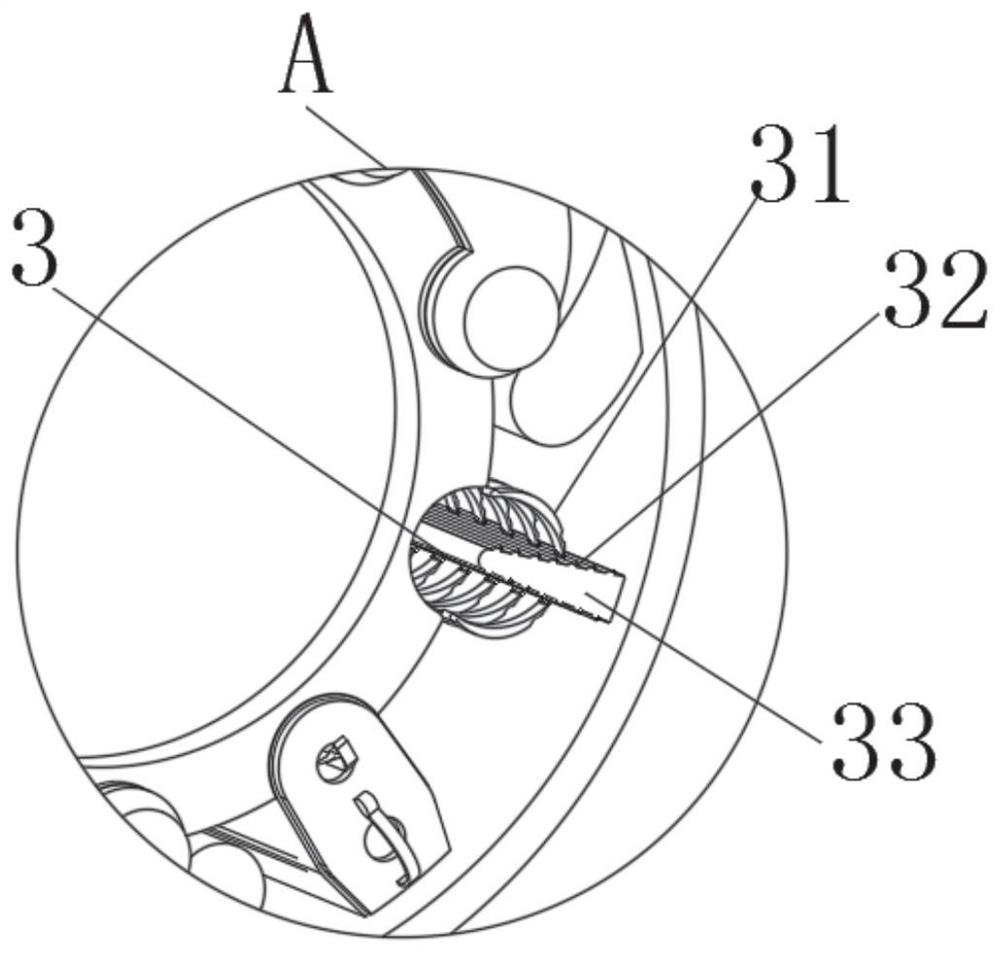

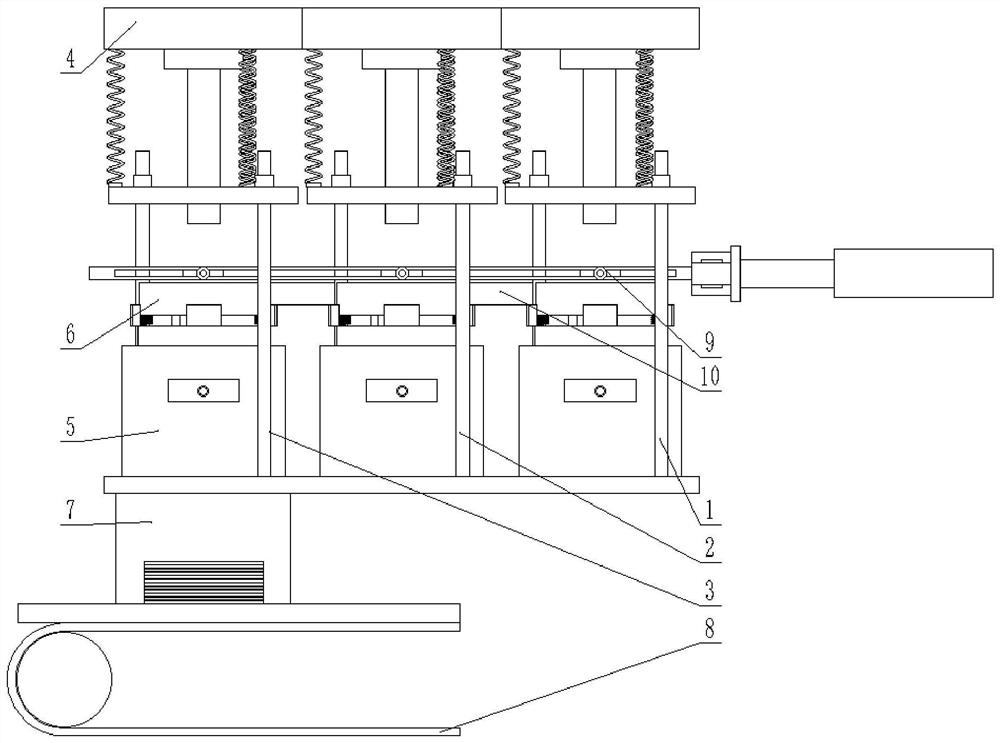

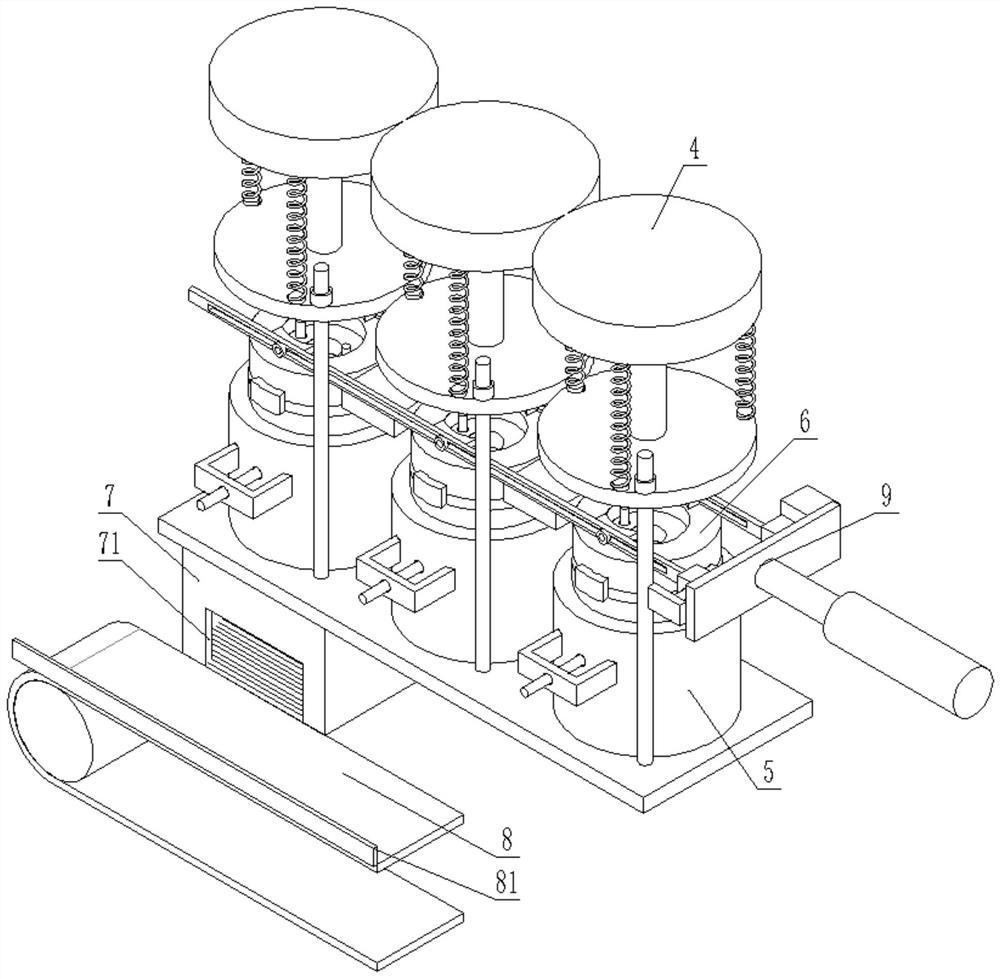

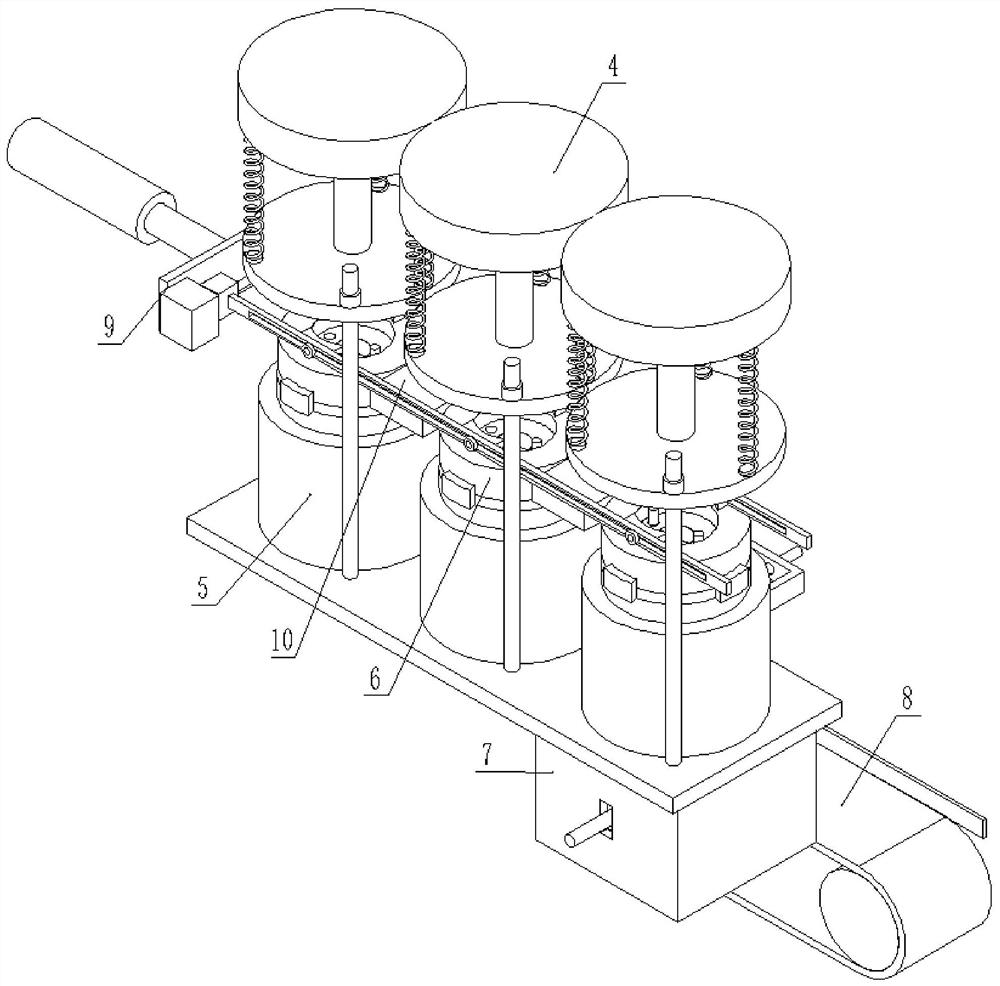

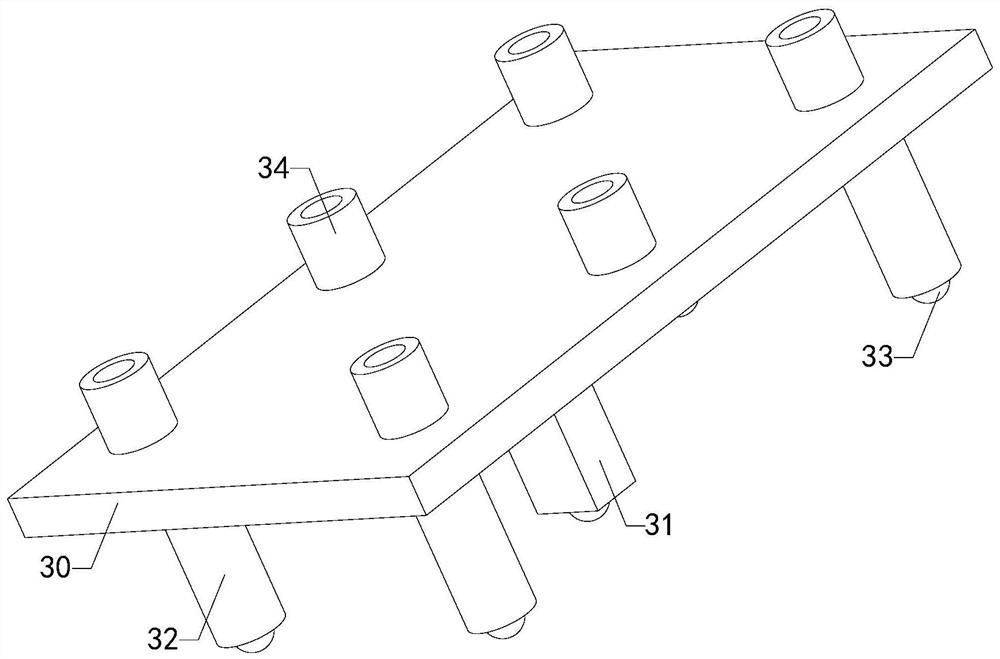

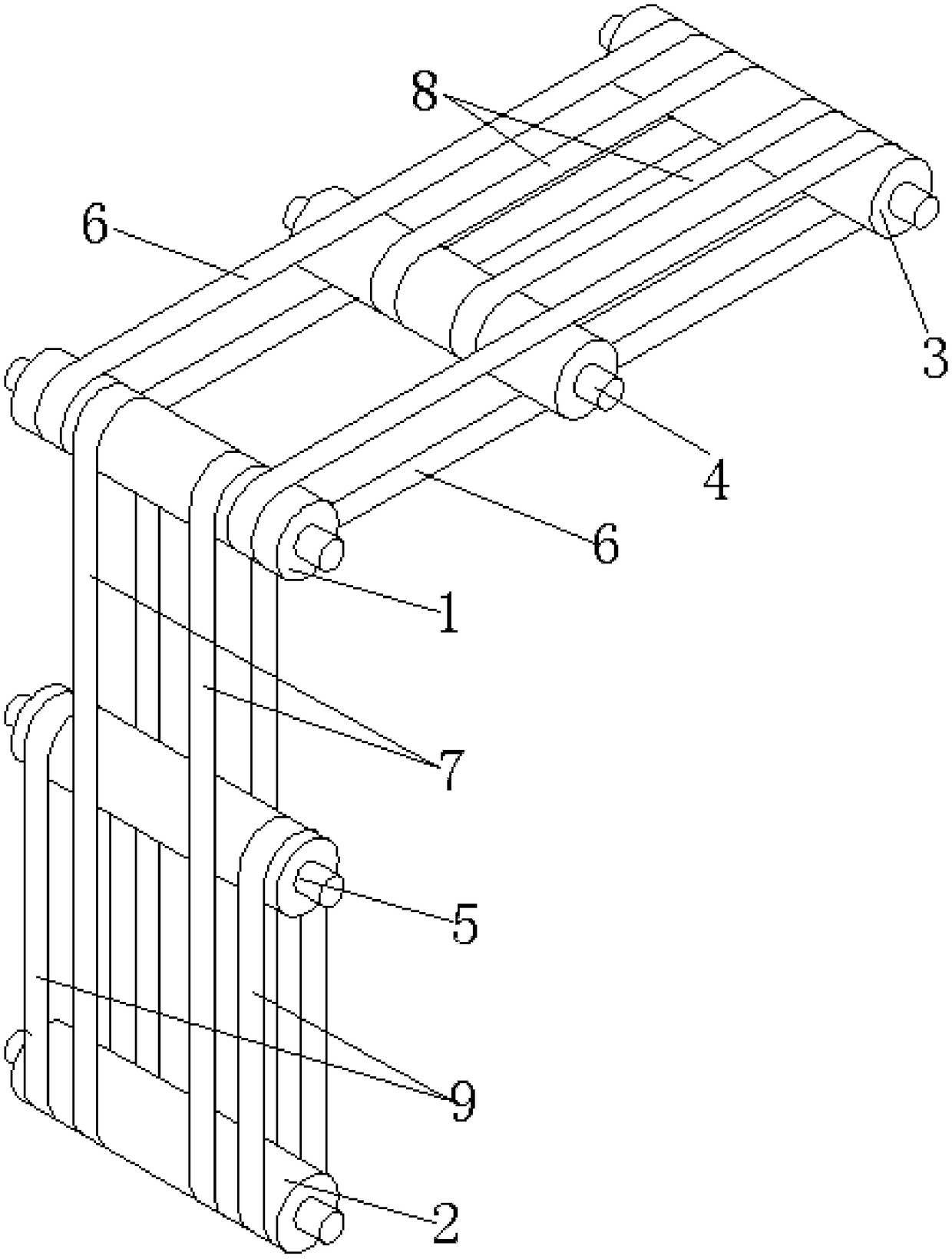

A stamping device for machining inner and outer rings of bearings

ActiveCN113333581BMake sure to dropReasonable structural designMetal-working feeding devicesStripping-off devicesPunchingWaste collection

The invention discloses a stamping device for processing the inner and outer rings of a bearing, which comprises a pier roughing station, a punching station and a punching station arranged in sequence, and the stations are respectively provided with a stamping mechanism and a height-adjustable stamping seat and a lower mold, a resettable lower mold is installed on one side of the stamping seat, a resettable ejector pin is installed on the inner side of the stamping seat, and one end of the ejector pin matches the material in the lower mold; A waste material collection box is provided at the lower part of the stamping seat on the hole station, and a conveying line with a baffle is provided on one side of the waste material collection box. The invention has a reasonable structural design, and the materials are processed in the sequence of pier thickness, groove punching and punching, which can reduce processing difficulty. Installing the lower mold and ejector rod through elastic parts can play a shock-absorbing role without affecting the stamping effect, prevent the stamping mechanism from directly contacting the lower mold to generate noise, and can make the material on the lower mold relative to the material after cutting The waste forms a displacement difference.

Owner:临清市同兴轴承锻造有限公司

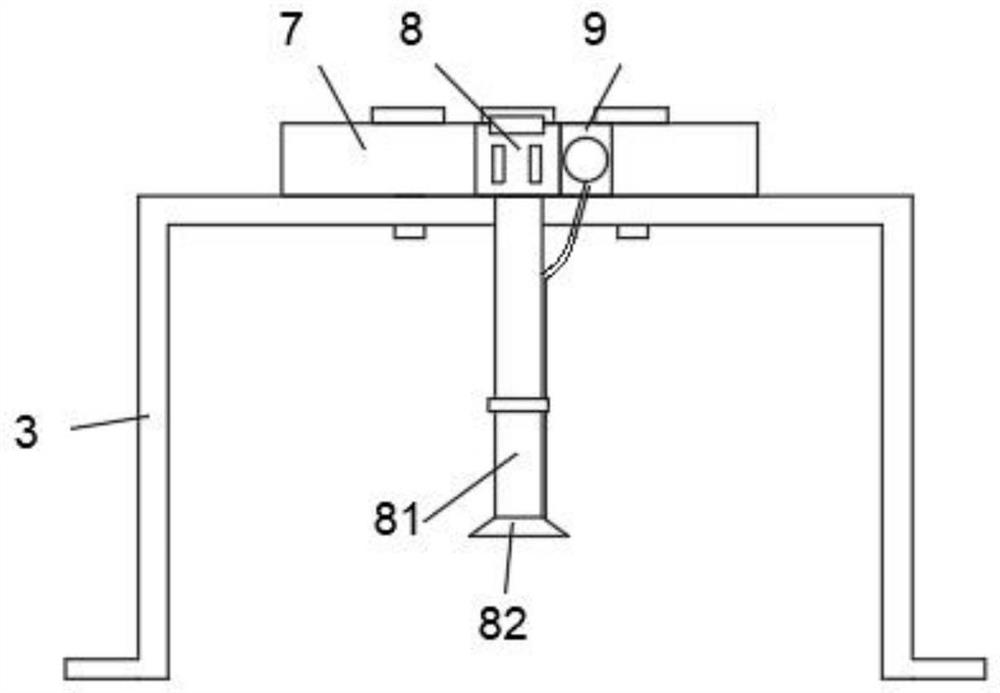

Sweet-scented osmanthus collecting device for sweet-scented osmanthus tea making

The invention belongs to the technical field of scented tea making, particularly relates to a sweet-scented osmanthus collecting device for sweet-scented osmanthus tea making, aims to solve the problem of more difficult separation caused by easy tearing of leaves when petals are separated and collected, and provides the following scheme. The sweet-scented osmanthus collecting device for sweet-scented osmanthus tea making comprises a supporting frame provided with four supporting legs, wherein the supporting frame comprises two parallel side plates, two parallel channel steel cross beams with opposite openings are fixed between the top ends of the two side plates, the same rectangular sliding frame is slidably connected between the two channel steel cross beams, a driving motor is slidablyconnected into the rectangular sliding frame, and four guide strips are fixed to the outer wall of the driving motor. When the device is used, when petals of a sweet-scented osmanthus tree need to becollected, only all eccentric rods need to be inserted into the tree from the top end of the pruned sweet-scented osmanthus tree of a spherical structure, then a driving motor is started, at the moment, the eccentric rods can intermittently impact a trunk to vibrate a supporting rod, and then the petals which do not fall off yet are shaken off.

Owner:刘效龙

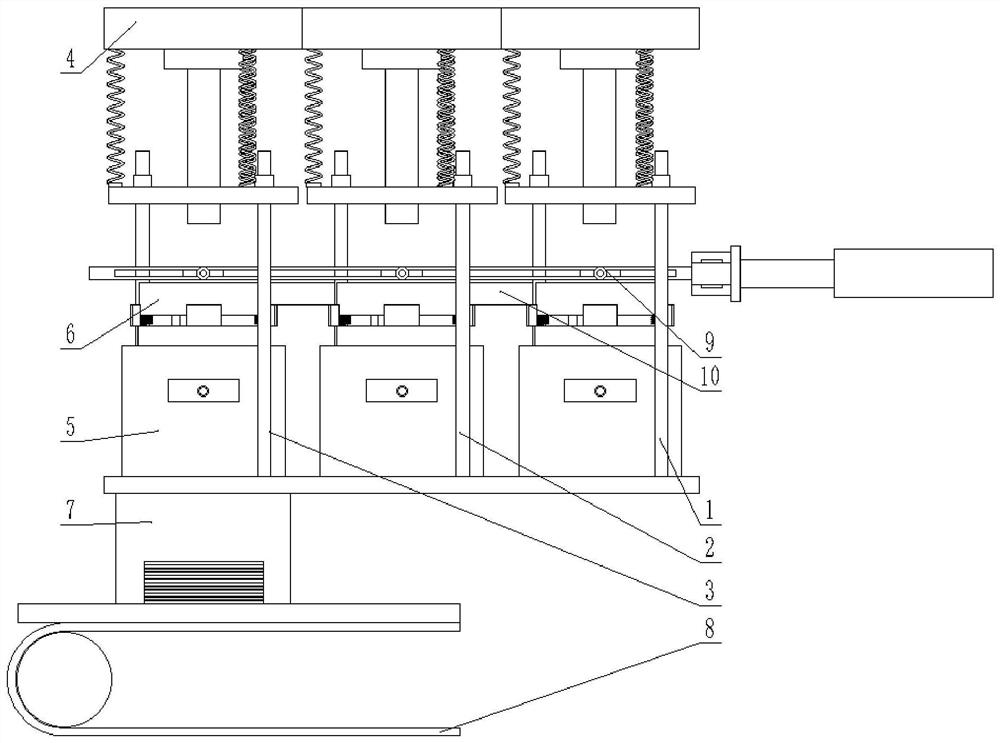

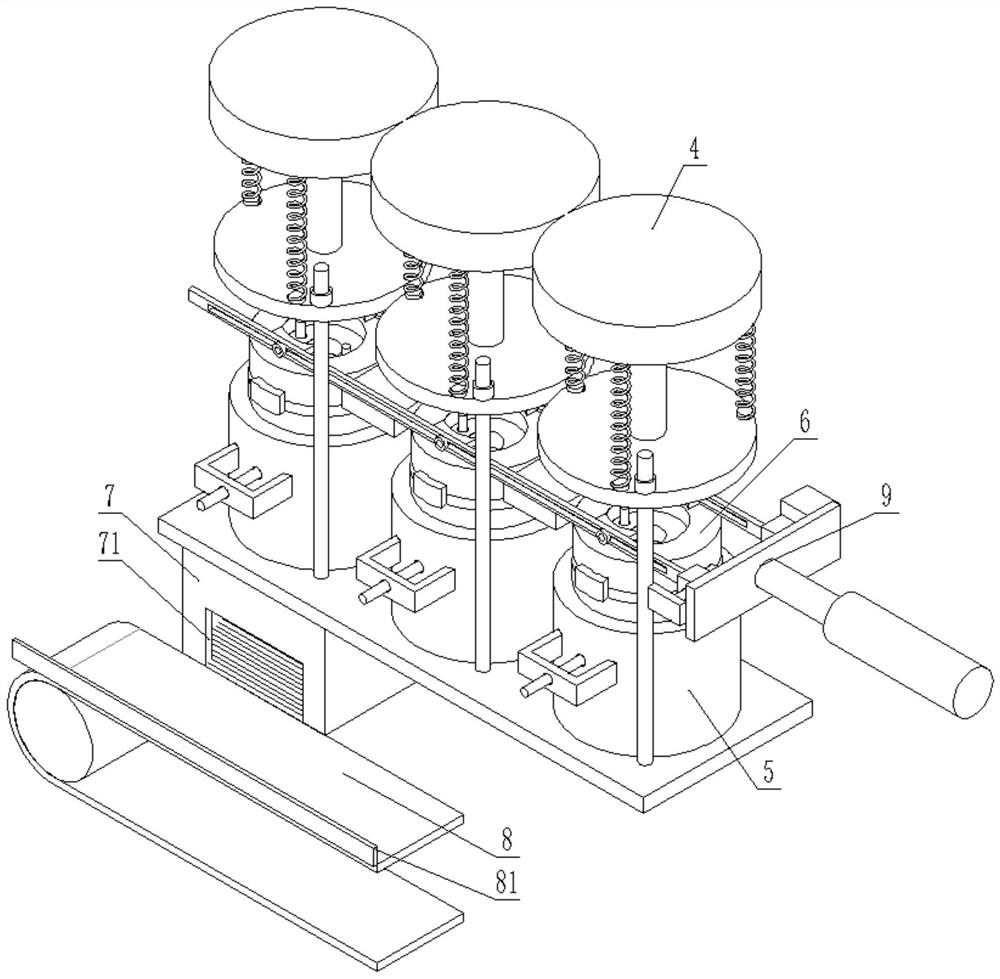

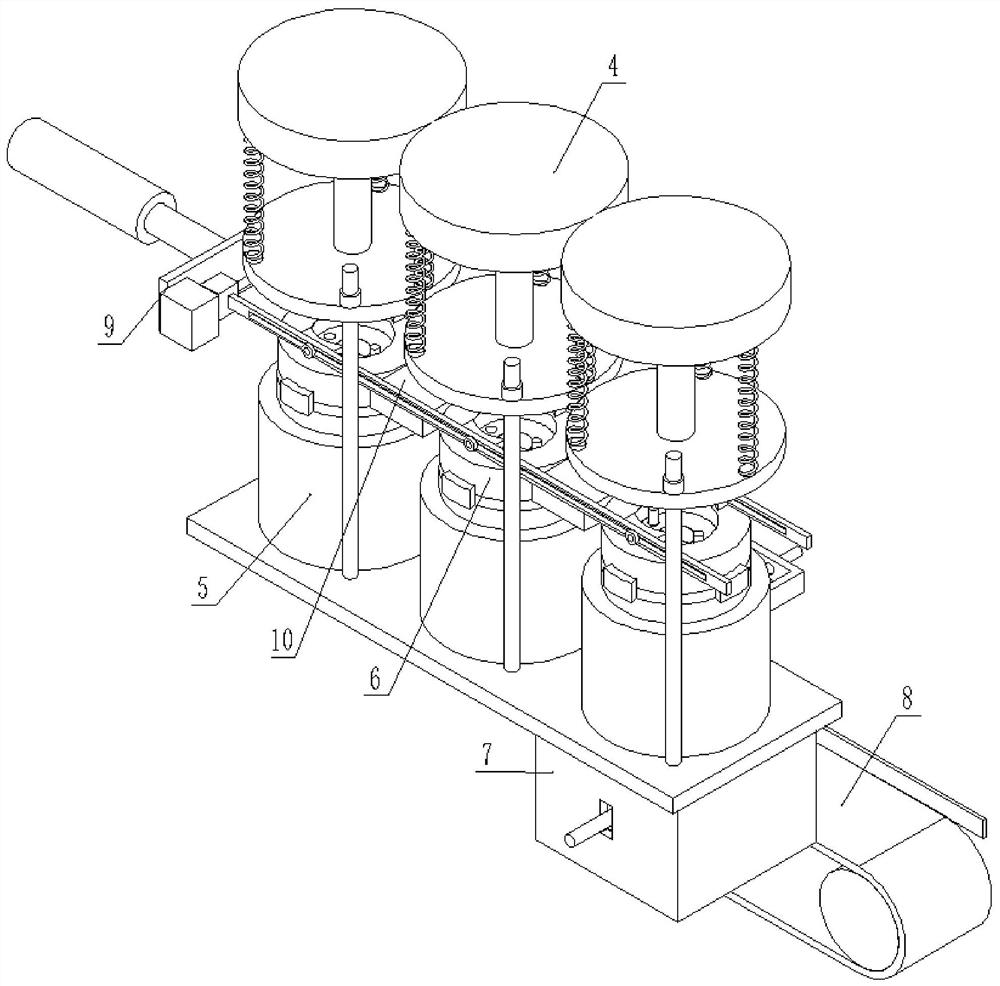

A sealing valve discharge device

InactiveCN103738683BGuaranteed uptimeSmooth unloadingRotary conveyorsWear resistantCompression device

The invention discloses a sealing valve discharge method. A pair of parallel, mutually compressed and reversely inward rotatable rollers are arranged in a mounting space, the rollers and the mounting space enclose a sealed space, and materials are squeezed out from discharge spaces of the rollers. The outer walls of the rollers are coated by elastic wear-resistant rubber coatings, the rubber coatings on the two rollers are clingy, the materials are squeezed out from the discharge spaces between the rubber coatings on the two rollers, a pair of compression devices are mounted on one of the rollers, and the materials squeeze the rollers to move outwards through the compression devices to form the discharge spaces, so that the materials can be squeezed out from the discharge spaces. The sealing valve discharge method is reliable in running, smooth in discharge, particularly applicable to textile industry and regenerated cotton industry and also applicable to the industry of discharged ash without massive hard objects, and sealing is ensured.

Owner:喻成进

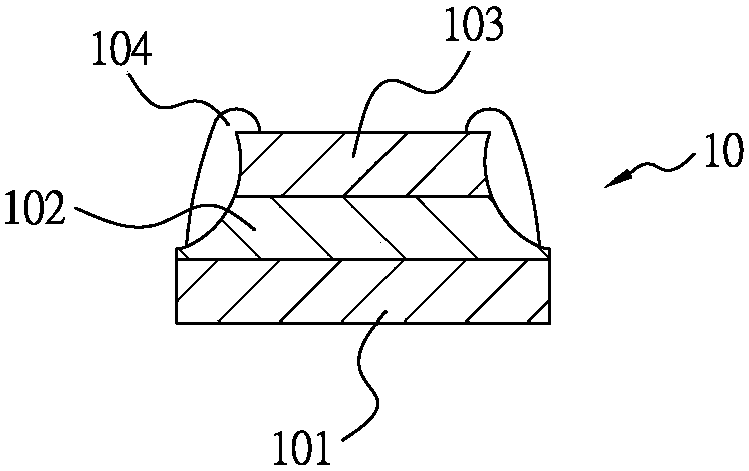

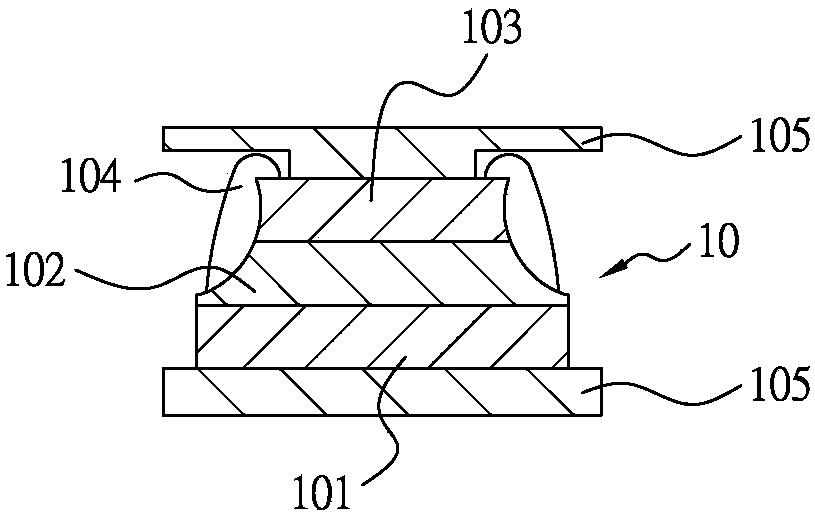

Manufacturing method of diode having ladder type structure

InactiveCN108962747AImprove performanceMake sure to dropSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringGrain structure

The invention provides a manufacturing method of a diode having a ladder type structure. The diode crystal grain structure mainly comprises an N-type semiconductor layer, wherein a P-type semiconductor layer is stacked on one side of the N-type semiconductor layer, and an N+ type semiconductor layer is attached to the other side of the N-type semiconductor layer; a trench is formed in a peripheryof the P-type semiconductor layer; an insulating protective layer is arranged at the periphery of the N-type semiconductor layer and in the trench of the P-type semiconductor layer, and the top surface of the insulating protective layer is not higher than the top surface of the P-type semiconductor layer; and through the design of the trench of the P-type semiconductor layer, the height of the insulating protective layer is reduced so as to ensure improvement of the excellent rate of the subsequent packaging process and improvement of the overall efficiency of the diode.

Owner:YEA SHIN TECH

Potato surface earth rapid separation mechanism

The present invention relates to a potato surface earth rapid separation mechanism and belongs to the technical field of earth cleaning. The mechanism includes a bracket in an ''L'' type structure. A chute which is high in the left and low in the right is arranged on the bracket in a tilt manner, a number of earth leaking holes are arranged on the chute bottom of the chute, a material feeding plate is arranged at the inlet of the upper left end of the chute, baffle plates are fixed on both side walls of the front and the back of the material feeding plate, an earth collecting and treating channel is arranged at the lower part of the chute, a bottom plate is arranged in a horizontal direction of the bracket, the upper surface of the bottom plate is divided into a slope surface and a placing surface, a potato collecting tank is arranged at a material falling place of an outlet at the lower right corner of the chute, a fan mounting bracket is arranged vertically on the bracket in a horizontal direction, a number of small-sized fans are arranged on the fan mounting bracket, the left upper end of the chute is hingedly connected to the top of the bracket in a vertical direction via a pivot, a supporting leg is arranged at the bottom, and a spring is arranged between the supporting leg and the chute. The mechanism effectively shortens the length of the chute, reduces the weight of the whole body, and lowers the transportation cost.

Owner:CHONGQING PINGMENG AGRI DEV

Bidirectional push-pull trolley for pusher furnace

PendingCN110775552AMake sure to dropGuaranteed to passMechanical conveyorsSprocketStructural engineering

The invention discloses a bidirectional push-pull trolley for a pusher furnace. The bidirectional push-pull trolley comprises a rack, a left-side one-way handle, a right-side one-way handle, a left push chain wheel, a right push chain wheel, a push-pull chain, a left push-pull hook head and a right push-pull hook head; and the bidirectional push-pull trolley further comprises left and right forcedreset mechanisms arranged on the rack for forcibly resetting the left and right one-way handles to horizontal positions. The bidirectional push-pull trolley for the pusher furnace has the beneficialeffects that the left and right forced reset mechanisms can forcibly reset the left and right one-way handles to the horizontal positions, so that it is ensured that the left and right one-way handlesfall, it is ensured that the left and right push-pull hook heads can pass, and it is ensured that the condition that the left and right push-pull hook heads are subjected to impact failure in the process of pushing a material plate travelling to the left and right due to the fact that the left and right one-way handles do not fall is avoided, so that the failure rate is reduced, and the reliability of the equipment is improved.

Owner:胡双大

Adaptive shaping device for fixing false tooth

PendingCN114871905AFast and accurate grindingImprove stabilityGrinding drivesArtificial teethFixed prosthodonticEngineering

The invention relates to the technical field of shaping equipment, in particular to an adaptive shaping device for fixing a denture, which is characterized in that the denture is clamped and fixed by a clamping mechanism, the height of a grinding head is adjusted by a lifting mechanism, and a second cylinder stretches out and draws back to drive a first cylinder to rotate by taking the joint of the first cylinder and a fixing plate as a circle center; a first air cylinder can adjust the left-right position of a grinding head, so that a false tooth can be quickly and accurately ground and shaped, the stability is high, and in the shaping process, shaping waste is collected through a waste box; comprising a base, a bottom column and a fixing seat, the bottom column is fixedly arranged at the bottom of the base, and the fixing seat is fixedly arranged at the top of the base; the grinding device further comprises a guide plate, a waste box, a protective net, a clamping mechanism, a lifting mechanism, an adjusting mechanism, a grinding mechanism and an oscillating mechanism, an inner groove is formed in the inner end of the fixing base, the guide plate is fixedly arranged at the top of the inner groove, and the waste box is installed in the inner groove through the oscillating mechanism and located below the guide plate.

Owner:徐婷

Dirt removing device for display screen processing

ActiveCN113305085AMake sure to dropAvoid secondary pollutionCleaning using gasesCleaning using liquidsElectric machineryStructural engineering

A dirt removing device for display screen processing comprises a base and a top frame. Side plates are welded to the two sides of the top end of the base, and a conveying belt used for conveying a display screen is assembled between the two sets of side plates. The top frame is assembled between the top ends of the two sets of side plates, a water inlet piece is installed on the top of the top frame, and an electric air cylinder is installed on the upper surface of the top frame. The dirt removing device is characterized in that a blocking frame assembly is adopted on the surface of the output shaft of a driving motor, the whole blocking frame assembly can be driven to rotate while conveying operation is conducted on the conveying belt, a movable rod circularly conducts vertical swing type processing on the conveying belt, it can be guaranteed that water stains or impurities on the conveying belt fall off to a certain degree, and the conveying belt is protected, and therefore, secondary pollution to the subsequent to-be-cleaned display screen is avoided; and a suction cup and the electric air cylinder are combined for use, one side of the display screen can be sucked in the top frame, the front side and the back side of the display screen can be cleaned in the top frame under the action of the conveying belt, and the comprehensiveness of dirt removing operation is embodied.

Owner:深圳市豪博讯电子科技有限公司

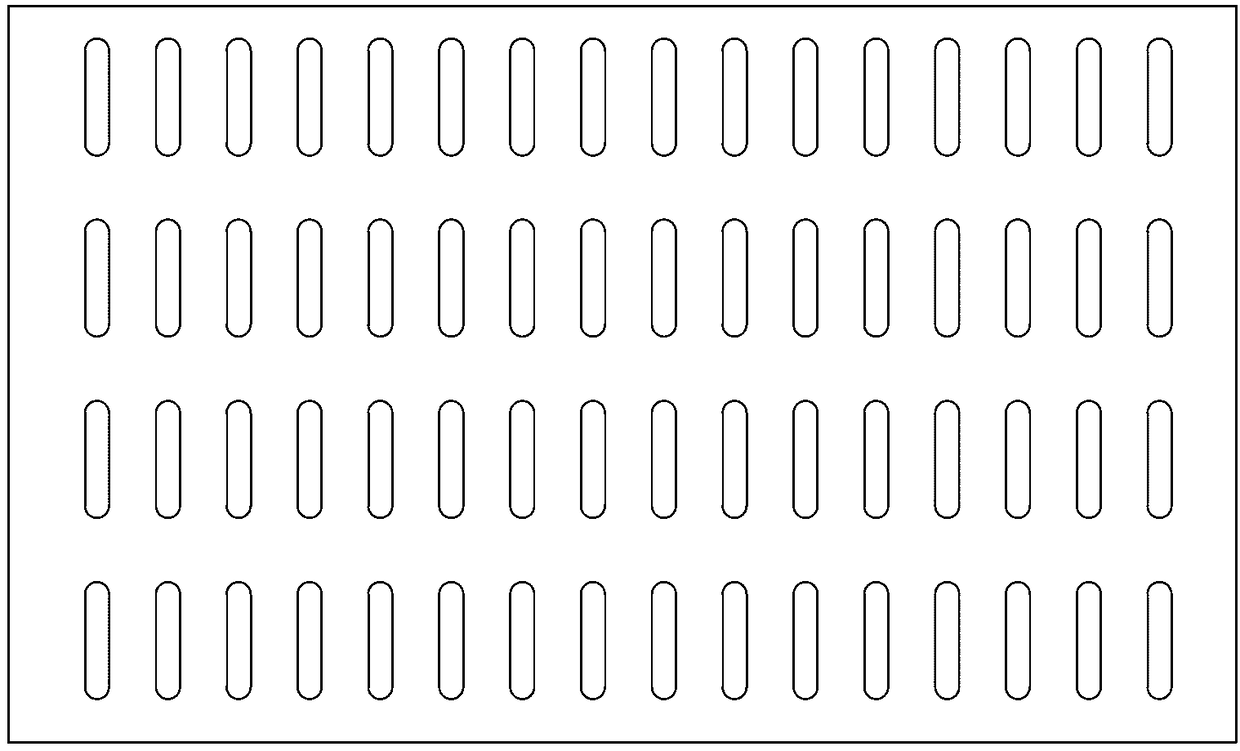

An English teaching blackboard for drawing four-line grids

InactiveCN105856917BPhenomena that affect wind speedSmall particle sizeBoard cleaning devicesWriting boardsWire gridBoard structure

Owner:NANYANG INST OF TECH

An Electromagnetic Chuck Controller Applied to the Production Site

ActiveCN113522811BAccelerate decayGuaranteed cleaning effectCleaning using toolsCleaning using gasesElastic vibrationEngineering

The invention discloses an electromagnetic chuck controller applied to a production site, and relates to the technical field of electromagnetic chuck controllers. The electromagnetic chuck controller applied to the production site includes an electromagnetic control mechanism for electromagnetic control, an elastic vibration mechanism for elastic vibration, and an energized cleaning mechanism for cleaning the device. The inside of the electromagnetic control mechanism is provided with The suction cup, the electromagnetic control mechanism is fixedly connected with an elastic vibration mechanism through the outer wall of the suction cup, and the electromagnetic control mechanism is fixedly connected with an energized cleaning mechanism through the bottom of the suction cup. The electromagnetic chuck controller applied to the production site, after the first elastic spring and the second elastic spring are energized, magnetism is generated between the thread pitches after energization, so that the first elastic spring and the second elastic spring contract, and the first elastic spring shrinks. The debris on the outer wall of the suction cup can be clamped. After the second elastic spring contracts, the gas in the air bag is squeezed and ejected, thereby cleaning the dust at the bottom of the suction cup.

Owner:南通茂业电子科技有限公司

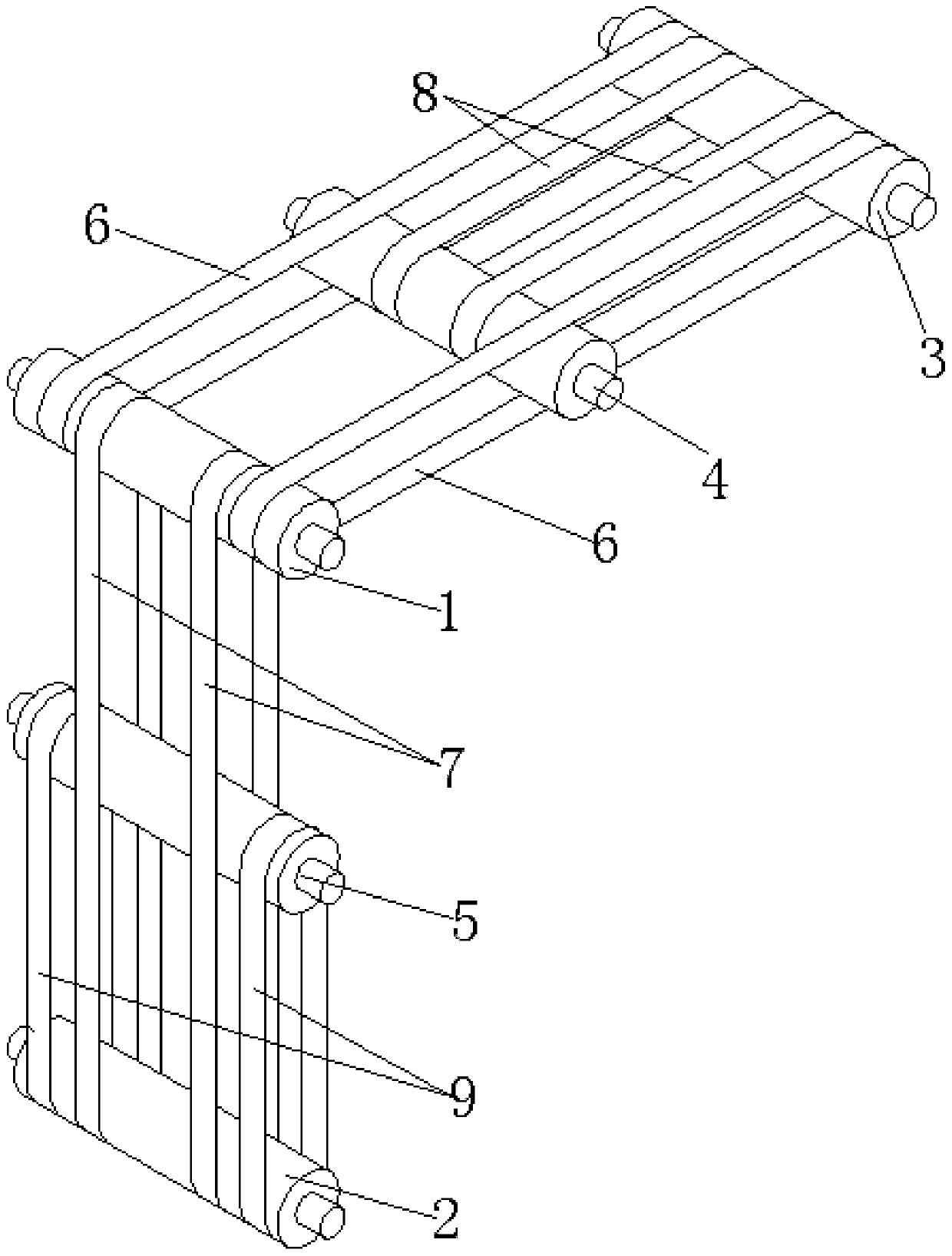

Pendulant conveying belt applied to heat dissipation fins

Owner:KUNSHA KEMO PRECISION MACHINE

Stone cake material separating machine

The invention provides a stone cake material separating machine. The stone cake material separating machine effectively solves the problem that stone cake residues still adhere to stone after stone cakes are separated from the stone. According to the technical scheme, the stone cake material separating machine comprises a rack and a driving wheel set, the two ends of the driving wheel set are rotatably connected to the rack, the driving wheel set is driven by a driving motor, the driving wheel set is wound with a separating mesh belt, a V-shaped stone guiding groove fixed to the rack is arranged below the separating mesh belt, the two slopes of the V-shaped stone guiding groove are provided with first filter plates for filtering dregs, a first receiving hopper matched with the first filterplates are arranged below the two first filter plates, and a stone recovery bin is arranged below the first receiving hopper. The separating mesh belt is a single mesh belt, only one power is neededfor realizing stone cake transfer, the residues on the separated stone fall into the receiving hopper through the filter plates, and separation of the stone and the residues is achieved.

Owner:新乡市豫吉食品机械有限公司

A scenic energy-saving display panel

ActiveCN105949548BMake sure to dropDischarge in timeChemical industryIdentification meansSolenoid valveBackplane

The invention discloses an energy-saving display panel at a scenic spot. The display panel comprises a back plate and a front plate. The back surface of the back plate is provided with a plurality of micro-magnetic bases. A cleaning mechanism is arranged between the back plate and the front plate. Between the back plate and the front plate, 2-5 fans are parallel to each other at the bottom thereof and the openings of the fans are upward. The upper portion of each fan is provided with a filter screen and the upper portion of each filter screen is provided with an inclined plate. The inclined plate is provided with a solenoid valve positioned opposite to the above fan. The lower portion of each inclined plate is provided with a recoverer. The upper portion of each filter screen is provided with a plurality of iron particles and the outer peripheries of the iron particles are coated with color. According to the technical scheme of the invention, the display panel is provided aiming at the phenomenon that the circuit laying and the maintenance at a scenic spot are difficult in the prior art. A double-layer plate structural design is adopted, and a plurality of fans are arranged between the lower parts of the front plate and the back plate. Meanwhile, a structural form composed of a plurality of micro-magnetic bases is arranged on the back surface of the back plate. Through hierarchically controlling the magnetic force and the fans, patterns and / or texts, which are obviously distinguished in color, are formed. Moreover, the patterns and / or the texts can be stored for a long time at the cost of only a small amount of electrical energy each time. Therefore, the display panel is worthy of application and popularization.

Owner:HENAN DANJIANG GRAND VIEW GARDEN TOURISM CO LTD

An oscillating conveyor belt for cooling fins

Owner:KUNSHA KEMO PRECISION MACHINE

Preschool education display teaching aid and operation method

The invention discloses a preschool education display teaching aid and an operation method. The preschool education display teaching aid comprises a collecting box, an inclined plane, a base, a guide column, a guide hole, a plus hole, an equal hole, a blocking hole, a blanking column, a blanking hole, a first hole, a second hole, a third hole, a fourth hole, a fifth hole, a sixth hole, a seventh hole, an eighth hole, a ninth hole, a key plate, a zero key hole, a first key hole, a second key hole, a third key hole, a fourth key hole, a fifth key hole, a sixth key hole, a seventh key hole, an eighth key hole, a ninth key hole, keys, buttons, numbers, a push plate, a front baffle, a rear baffle insertion piece, keys, a plus button, an equal button, a rack, a hopper, a spiral bulge, a lower opening, a gear and glass balls, the interior of the collecting box is provided with the inclined plane, the upper part of the collecting box is fixedly connected with the base, the left side of the base is provided with the key plate, the right side of the key plate is provided with the blanking column, and the middle of the blanking column is provided with the blanking hole.

Owner:JIAMUSI UNIVERSITY

An automatic sesame shelling and screening machine

ActiveCN103966013BRealize the collectionReduce investmentFatty-oils/fats productionEngineeringMechanical engineering

The invention relates to an automatic sesame shelling and sieving machine comprising a rack, wherein the front and rear sides of the rack are symmetrically provided with mounting plates; the lower part of the rack is in sliding connection with a storage cabinet located in the rack; a first sieve plate is obliquely fixed at the middle part of the rack; a second sieve plate is obliquely arranged at the medium-upper part of the rack; a motor is arranged between the first sieve plate and the second sieve plate and is fixed on the rack; a shelling device is arranged above the second sieve plate; a transmission device is arranged at the front sides of the mounting plates; the shelling device is connected with the motor through the transmission device; the transmission device is driven by the motor, and then the power is transferred to the shelling device, therefore, shelling treatment on sesame is realized. The automatic sesame shelling and sieving machine has the advantages of reasonable structural design, low manufacturing cost, convenience in use and the like; the aim of efficiently sieving the sesame is achieved; a two-stage sieving way is adopted, so that sesame shelling, fine sesame sieving and sesame collecting processes are achieved, the manpower and material investments are reduced, and the sesame sieving quality is ensured.

Owner:黄翰天

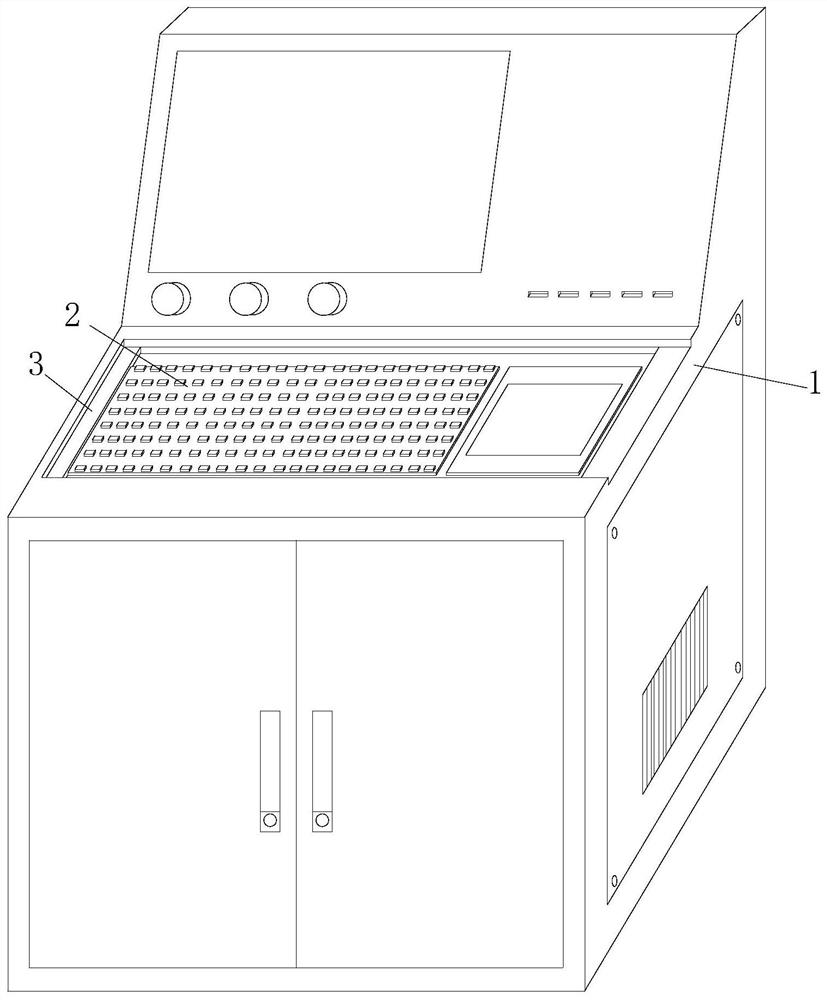

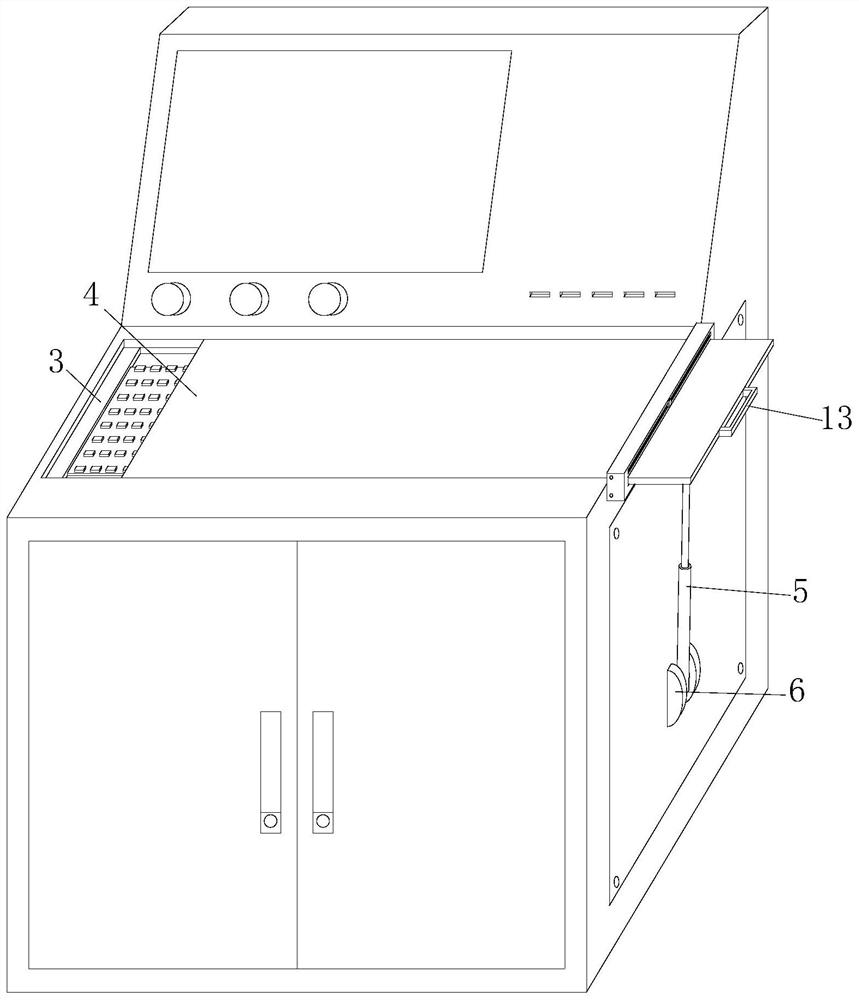

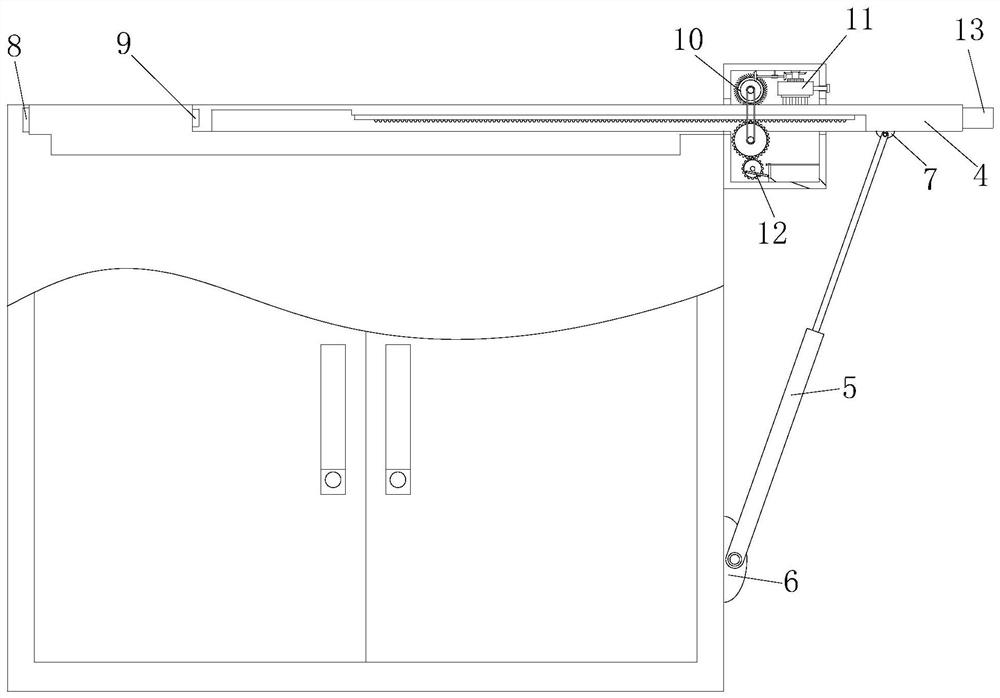

an english teaching device

ActiveCN112974460BAchieve protectionExtended cleaning cyclePulpitsLecternsSoftware engineeringIndustrial engineering

Owner:EASTERN LIAONING UNIV

A construction board paint spraying device for construction engineering

The invention discloses a painting device for construction boards used in construction engineering, and relates to the field of construction engineering painting equipment; in order to solve the problem that the two sides of the board cannot be painted at the same time, resulting in the problem of low efficiency; the device specifically includes a shell and two paint spraying racks , the outer wall on one side of the housing is fixed with a motor by screws, the inner walls on both sides of the housing are respectively connected with connecting rods, one of the connecting rods is connected with the output end of the motor through a coupling, and the outer walls on one side of the two connecting rods are welded with rotating frame, and the outer walls on both sides of the turret are respectively provided with second sliding grooves. The present invention is provided with a turret, starts the motor, rotates the connecting rod, drives the turret to rotate, and makes the turret rotate to a vertical state. It is fixed by the side of the board, so it will not affect the painting on the front and back of the board, and can improve the painting efficiency.

Owner:中际建设(深圳)有限公司

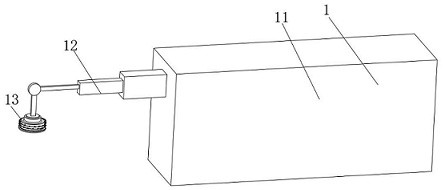

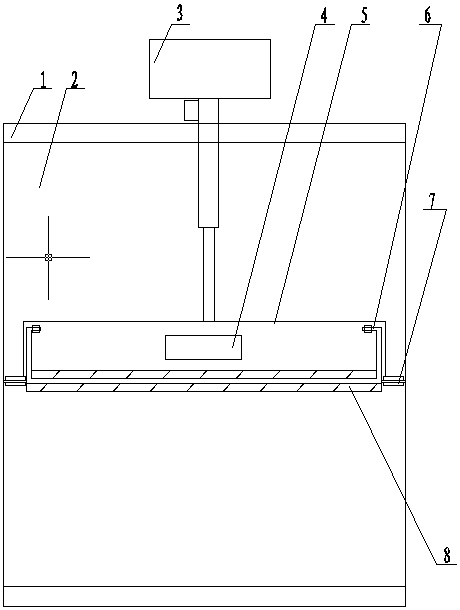

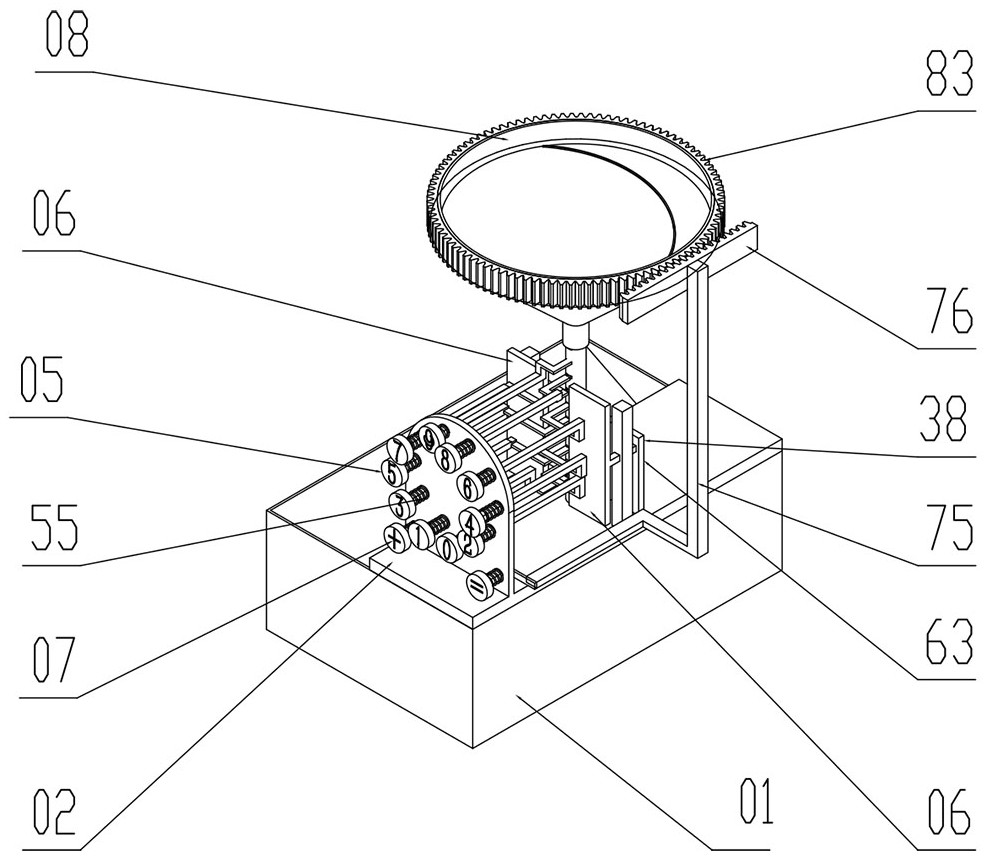

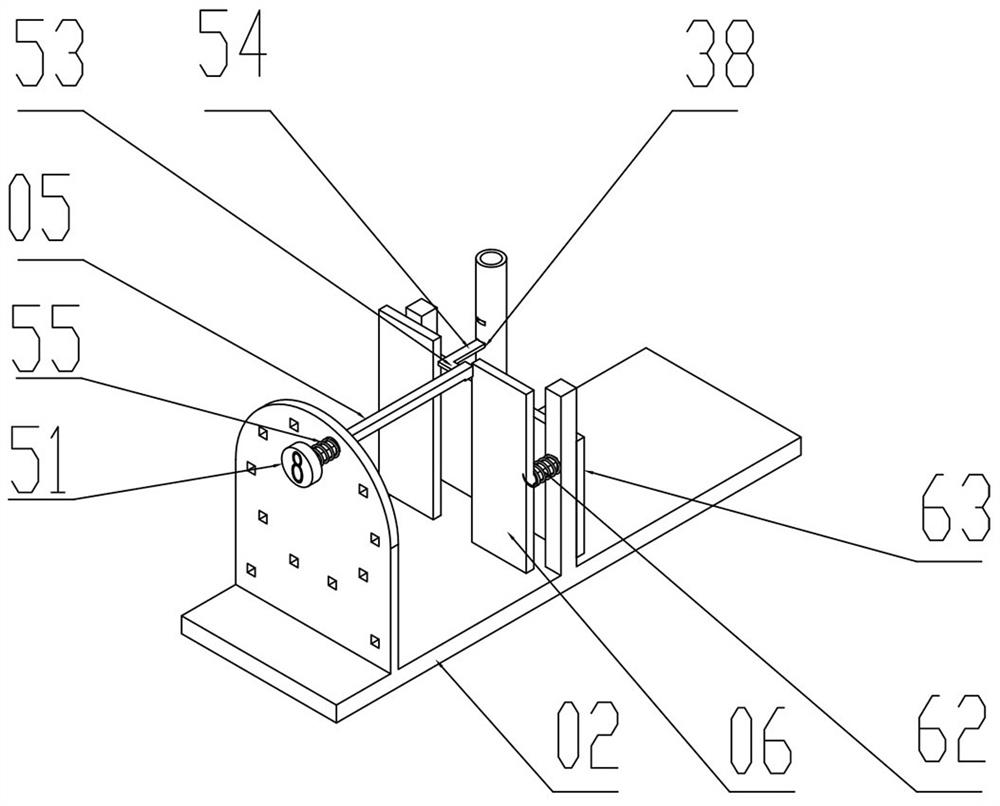

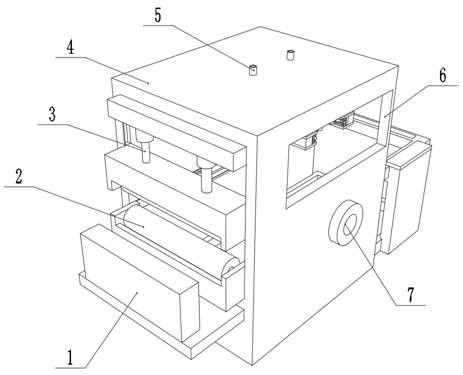

Pipe tobacco compacting equipment for pipe tobacco encasement process

The invention belongs to the technical field of tobacco machinery and relates to pipe tobacco compacting equipment for a pipe tobacco encasement process. The equipment comprises a rack, a driving device and a pressing device which are installed on the rack and a pressing head installed on the pressing device. The pressing device is fixed to the rack. The driving device is in gear connection with the pressing device. The pressing device is driven to rise and fall through gear rack transmission. The pressing head is arranged at the bottom of the pressing device. The pressing head rises and fallsalong with rising and falling of the pressing device, and thus pipe tobacco is compacted. The pipe tobacco compacting equipment for the pipe tobacco encasement process is used to achieve accurate, damage-free and agglomeration-free compacting operation of the pipe tobacco; utilization ratio of the pipe tobacco boxes can be improved significantly; and transporting cost of the pipe tobacco is lowered.

Owner:云南昆船电子设备有限公司

Gas-driven biological cell engineering incubator and use method thereof

PendingCN113647276AGuaranteed unblockingGuaranteed dredging effectClimate change adaptationGreenhouse cultivationEngineeringMechanical engineering

The invention discloses a gas-driven biological cell engineering incubator and a use method thereof, and relates to the technical field of biological cell engineering. According to the gas-driven biological cell engineering incubator and the use method thereof, the gas-driven biological cell engineering incubator comprises an external control mechanism for externally culturing organisms, a magnetic vibration mechanism for magnetically vibrating, an elastic splitting mechanism for elastically splitting, elastic crushing mechanisms for elastically crushing and a movable crushing mechanism for movably crushing, a slag outlet is formed in the external control mechanism, and a plurality of elastic crushing mechanisms are arranged on the inner wall of the slag outlet formed in the external control mechanism. According to the gas-driven biological cell engineering incubator and the use method thereof, the slag outlet is blocked to enable the slag outlet to descend, and a screw rod rotates and shrinks after being in contact with a first magnetic block, so that fallen leaves and soil are extruded, and dredging of the slag outlet is ensured.

Owner:顾怀飞

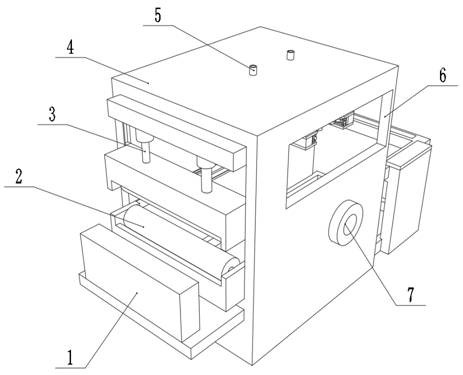

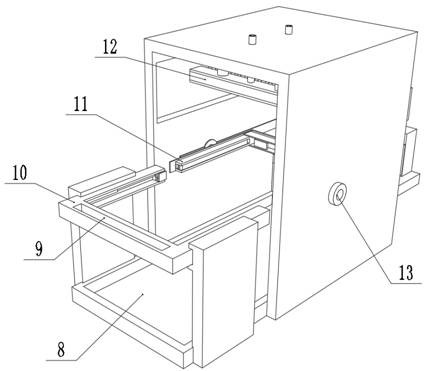

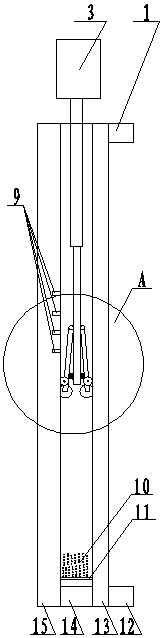

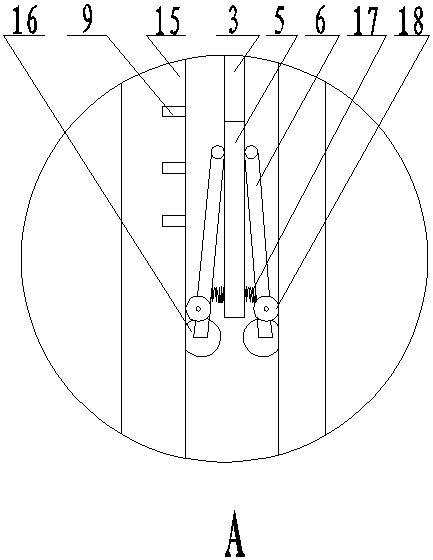

Stamping device for machining inner ring and outer ring of bearing

ActiveCN113333581AMake sure to dropReasonable structural designMetal-working feeding devicesStripping-off devicesPunchingStructural engineering

The invention discloses a stamping device for machining an inner ring and an outer ring of a bearing. The stamping device comprises an upsetting station, a notching station and a stamping station which are sequentially arranged, wherein a stamping mechanism, a height-adjustable stamping seat and a lower die are respectively arranged on the stations, the lower die capable of being reset is arranged on one side of the stamping seat, a resettable ejector rod is mounted on the inner side of the stamping seat, and one end of the ejector rod is matched with a material in the lower die; a waste collecting box is arranged on the lower portion of the stamping seat on the stamping station, and a conveying line with a baffle is arranged on one side of the waste collecting box. The structure design is reasonable, materials are machined according to the sequence of upsetting, notching and punching, and the machining difficulty can be reduced through the sequence. The lower die and the ejector rod are installed through an elastic piece, on the basis that the stamping effect is not affected, the damping effect can be achieved, the stamping mechanism is prevented from making direct and rapid contact with the lower die to generate noise, and materials on the lower die can form displacement difference relative to cut-off waste materials.

Owner:临清市同兴轴承锻造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com