Stone cake material separating machine

A separator and stone technology, which is applied in solid separation, sieves, grids, etc., can solve the problems of polluting stone cakes, affecting stone cake production, and unsatisfactory separation effect and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

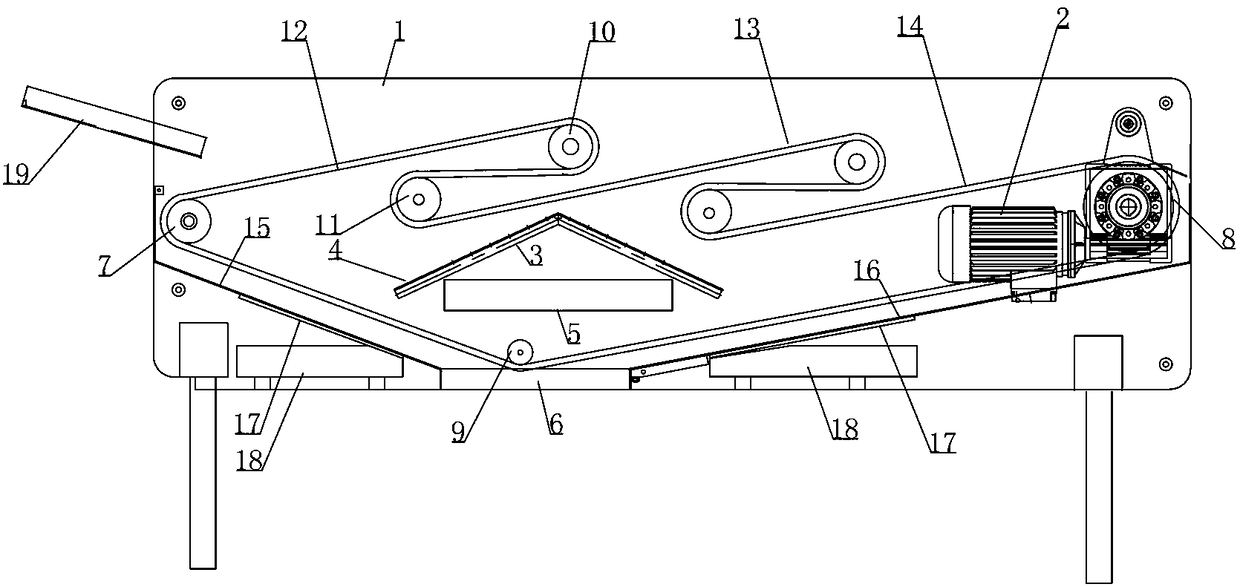

[0020] Embodiment 2, on the basis of Embodiment 1, the drive wheel set includes a first positioning wheel 7 and a second positioning wheel 8 placed on the lateral sides of the frame 1 and located at the upper end of the frame 1, and placed on the first connecting wheel. The frame 1 between the hopper 5 and the gravel recovery bin 6 is provided with a third positioning wheel 9, and the frame 1 between the first positioning wheel 7 and the second positioning wheel 8 is provided with two steering wheel groups. Below the separation net belt between the first positioning wheel 7 and the third positioning wheel 9 is provided with the first stone guide groove 15 parallelly arranged with the separation net belt, between the second positioning wheel 8 and the third positioning wheel 9 The second stone guide groove 16 arranged parallel to the separation mesh belt is provided below the separation mesh belt, and the end of the first stone guide groove 15 and the second stone guide groove 1...

Embodiment 3

[0022] Embodiment 3, on the basis of embodiment 2, two described steering wheel groups are arranged laterally on the frame 1 at intervals, and the described steering wheel groups include a first steering wheel 10 and a second steering wheel 10 arranged along the transmission direction of the separated mesh belt. Wheels 11, the height of the first steering wheel 10 is higher than that of the second steering wheel 11.

[0023] When this embodiment is in use, the steering wheel set includes the first steering wheel 10 and the second steering wheel 11 arranged along the length direction of the separation mesh belt and the height of the first steering wheel 10 is higher than the height of the second steering wheel 11, and the steering wheel set The setting of the separation mesh belt can be divided into multiple separation mesh belts, and there is a height difference between the multi-section separation mesh belts. The setting of the drop difference makes the separation process of t...

Embodiment 4

[0024]Embodiment 4, on the basis of embodiment 3, the separation mesh belt between the first steering wheel 10 close to the first positioning wheel 7 and the first positioning wheel 7 constitutes the first separation mesh belt 12, which is close to the first positioning wheel 7 The separation mesh belt between the second steering wheel 11 and the first steering wheel 10 close to the second positioning wheel 8 constitutes the second separation mesh belt 13, and the second steering wheel 11 close to the second positioning wheel 8 and the second The separation mesh belt between the positioning wheels 8 constitutes the third separation mesh belt 14, and the projection of the first separation mesh belt 12 and the second separation mesh belt 13 and the second separation mesh belt 13 and the third separation mesh belt 14 on the horizontal plane Partially overlapping, the feeding end of the first separation mesh belt 12 is higher than the feeding end of the second separation mesh belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com