Potato surface earth rapid separation mechanism

A technology of quick separation and potatoes, applied in the fields of application, food processing, food science, etc., can solve the problems of increasing the overall length, high transportation cost, long chute length, etc., to achieve faster separation speed, low transportation cost, Overall weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

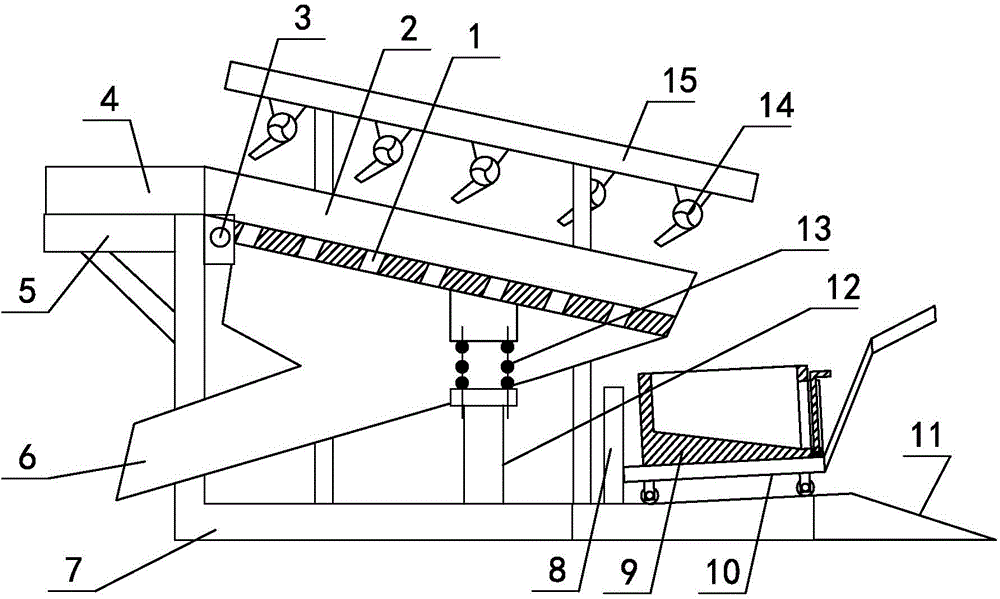

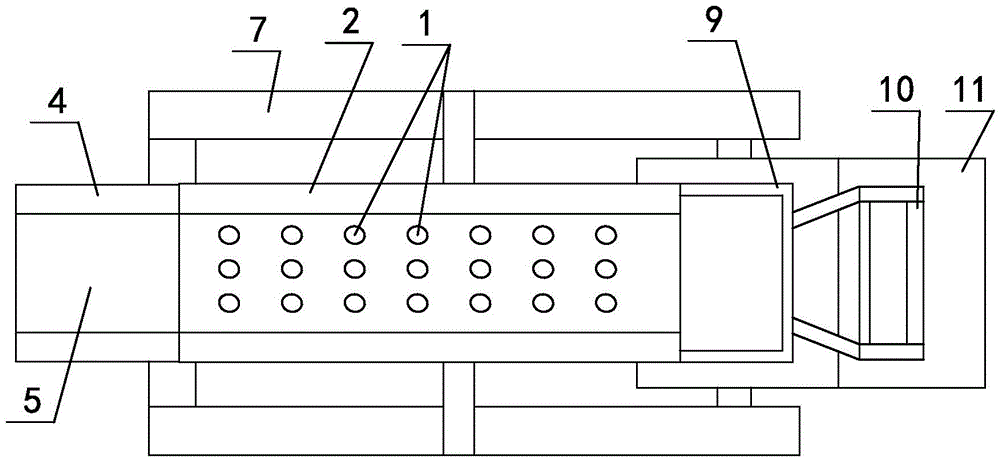

[0019] Such as figure 1 , figure 2 As shown, the quick release mechanism for soil on potatoes includes a support 7 with an L-shaped structure as a whole. On the support 7, a chute 2 with a high left side and a low right side is obliquely arranged. Leakage hole 1 is provided with feeding plate 5 horizontally at the entrance of the upper left end of chute 2, and baffle plates 4 are fixed on the front and rear side walls of feeding plate 5, and the right end of feeding plate 5 is close to the entrance of the upper left end of chute 2. At the bottom of the chute, the right end of the baffle plate 4 is closely attached to the chute wall at the entrance of the upper left end of the chute 2. Corresponding to the excavation direction of the leak hole 1, a soil collection and processing channel 6 is arranged below the chute 2, and a channel 6 is arranged on the support 7 in the horizontal direction. There is a bottom plate 11, the upper surface of the bottom plate 11 is divided into ...

Embodiment 2

[0023] Change on the basis of embodiment one, soil leakage hole 1 diameter is changed into 30mm; The vertical distance of described small blower fan 14 to the bottom of chute 2 becomes 400mm; The inclination angle of described chute 2 becomes 40 degree; So The overall length of the chute 2 becomes 2500mm. Others are the same as embodiment one.

Embodiment 3

[0025] Change on the basis of embodiment one, soil leakage hole 1 diameter is changed into 25mm; The vertical distance of described small blower fan 14 to chute 2 groove bottoms becomes 450mm; The inclination angle of described chute 2 becomes 30 degrees; So The overall length of the chute 2 becomes 2000mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com