Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Increase the processing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

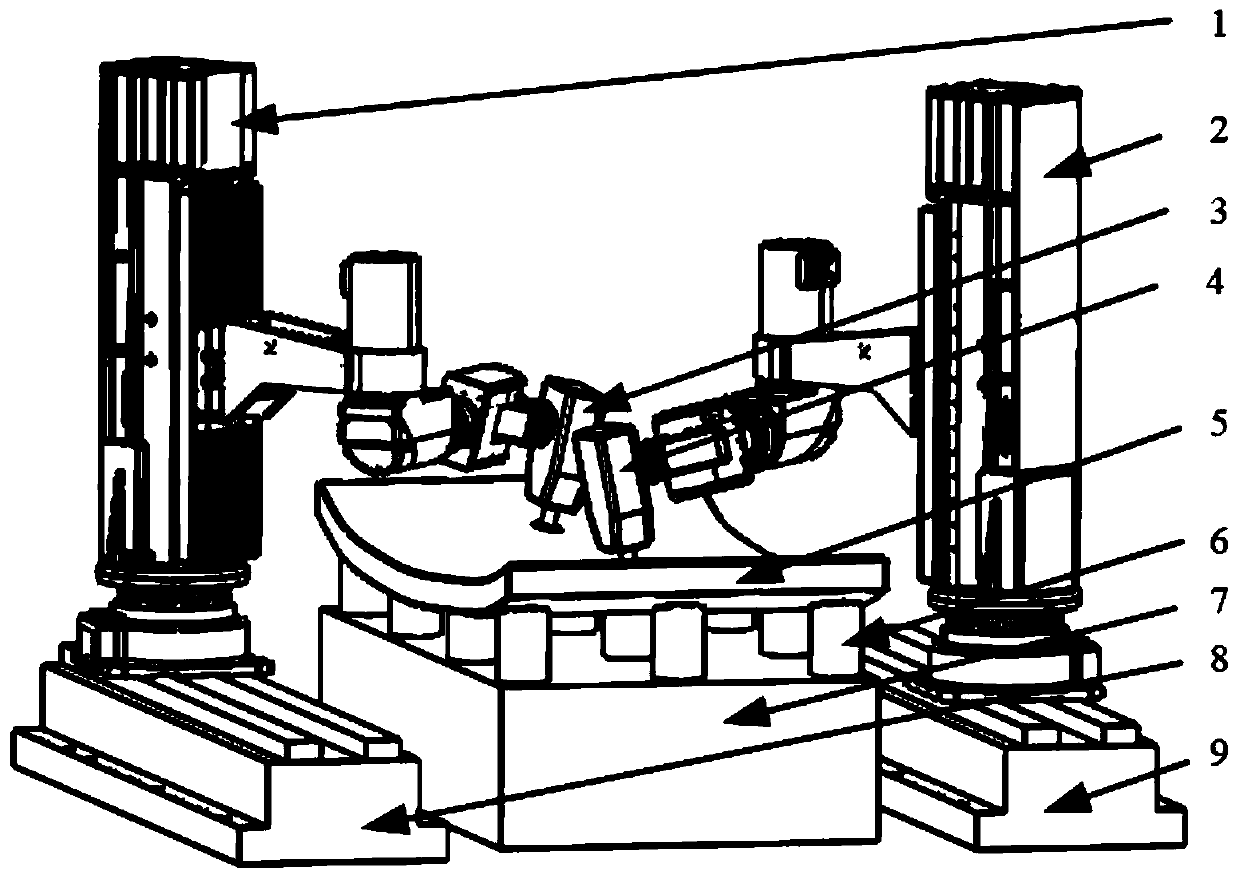

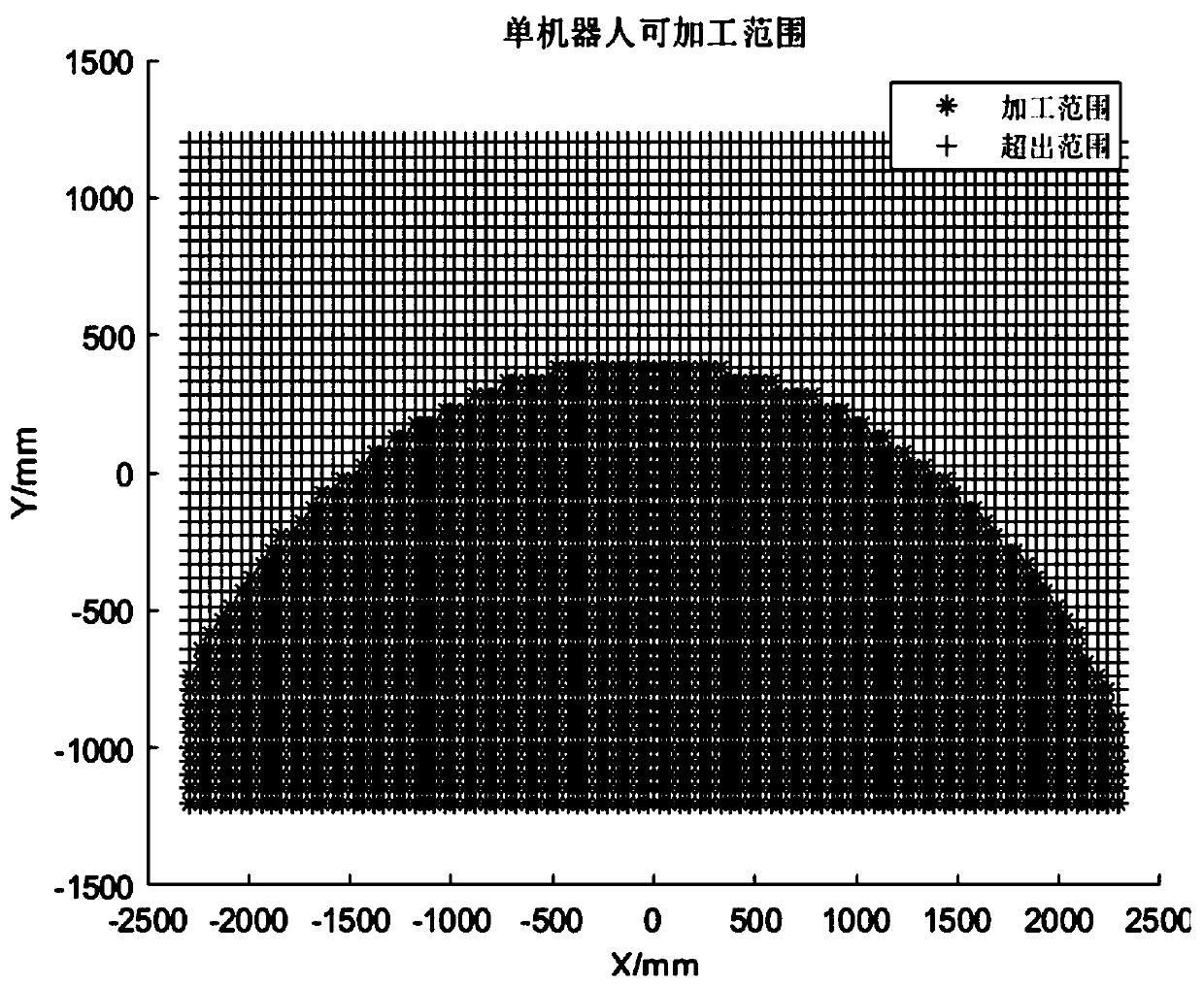

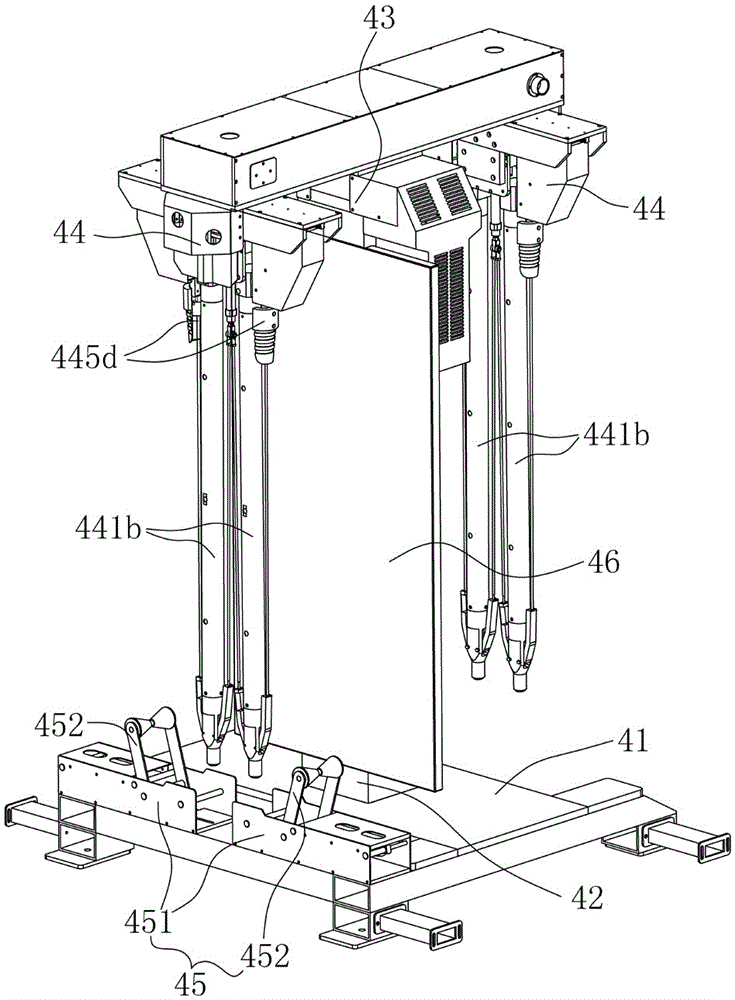

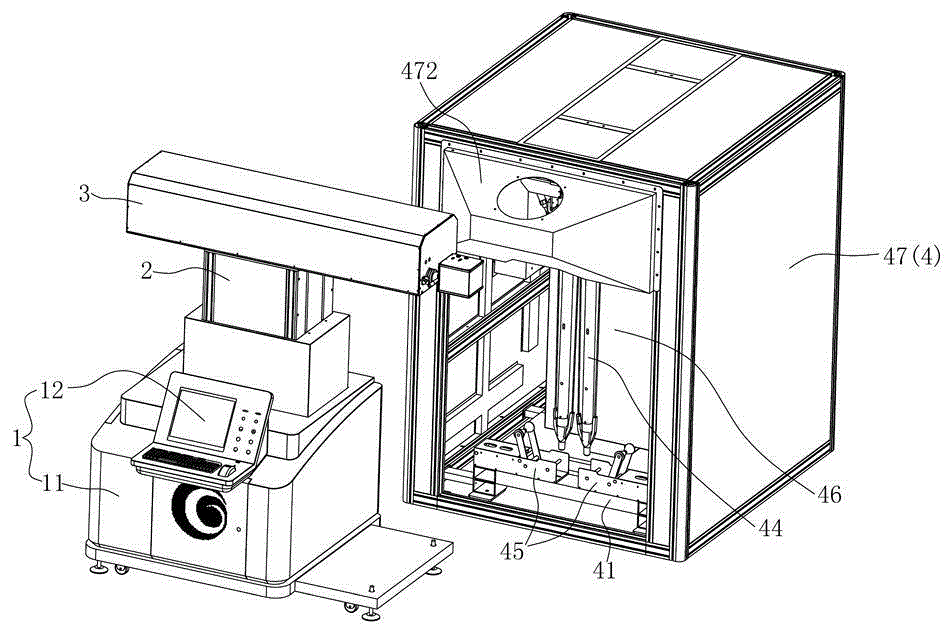

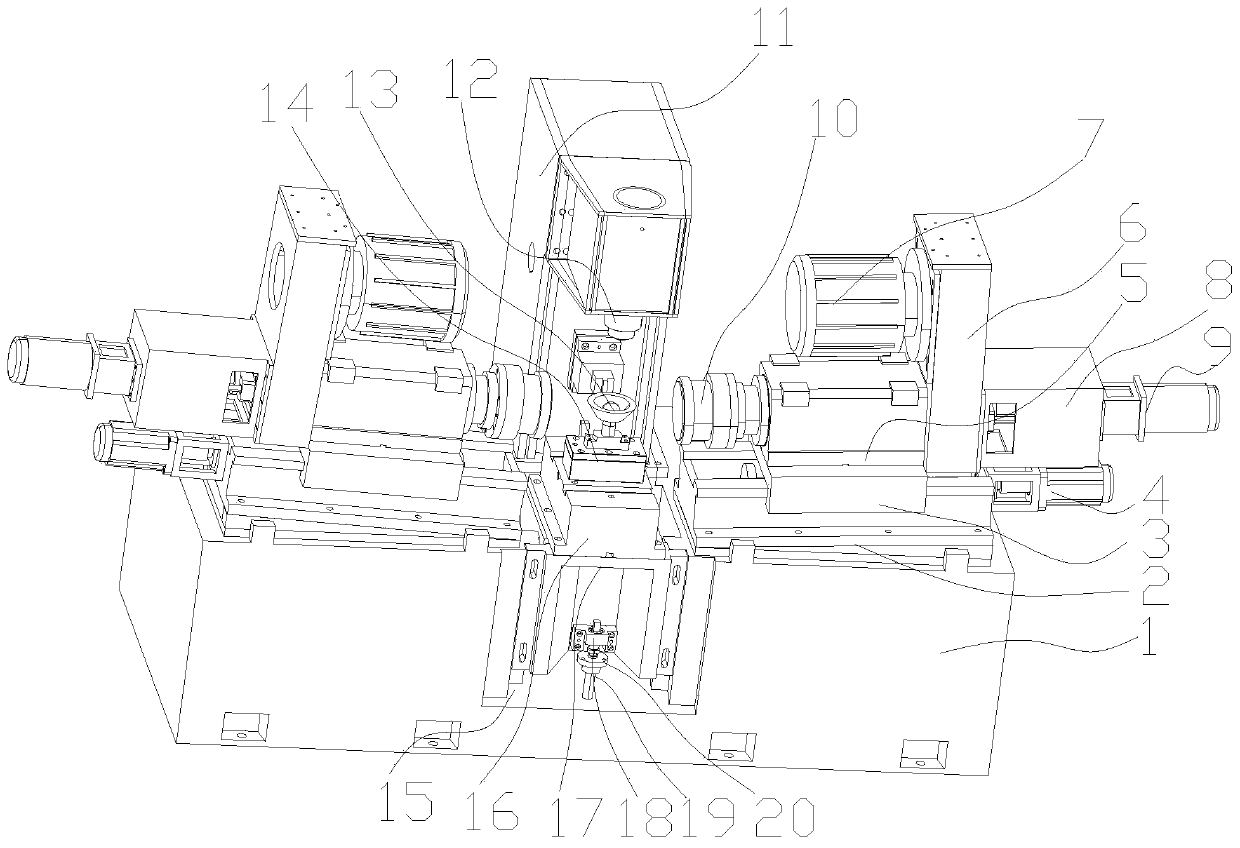

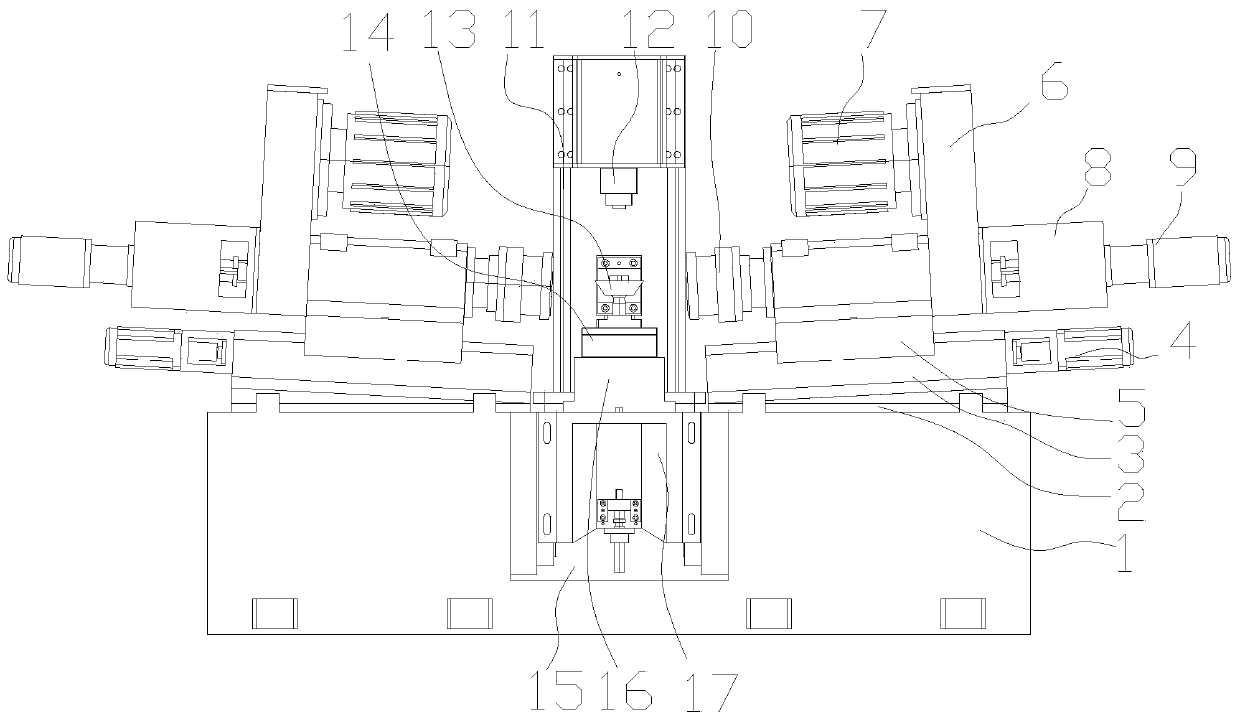

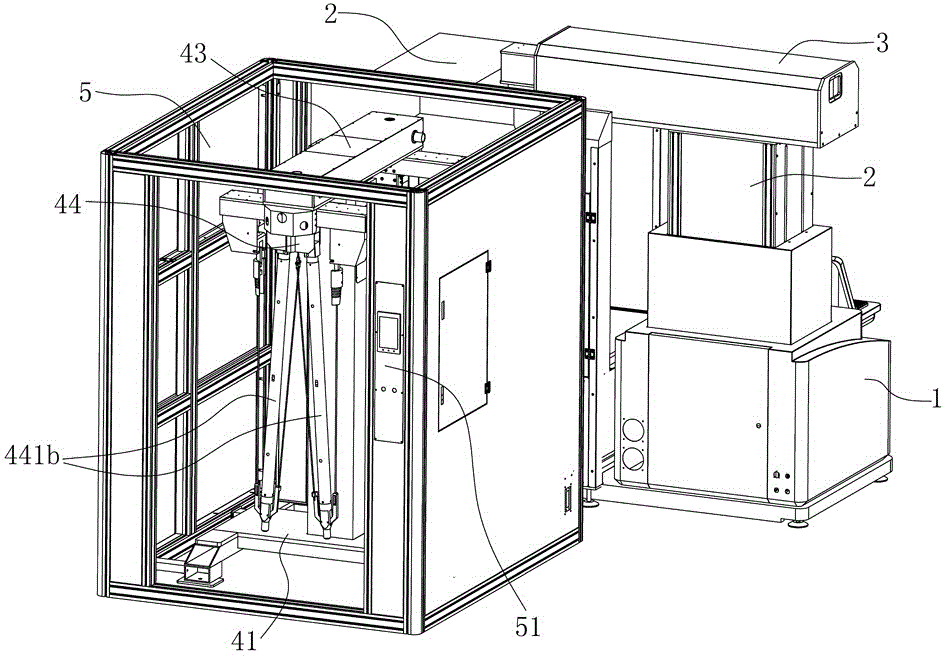

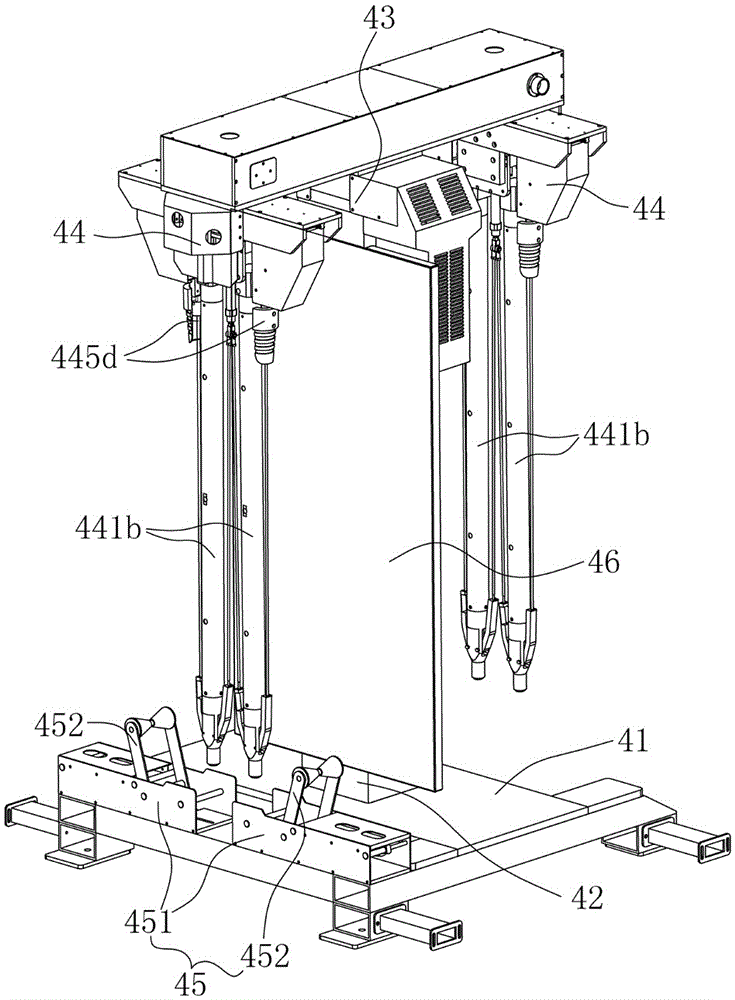

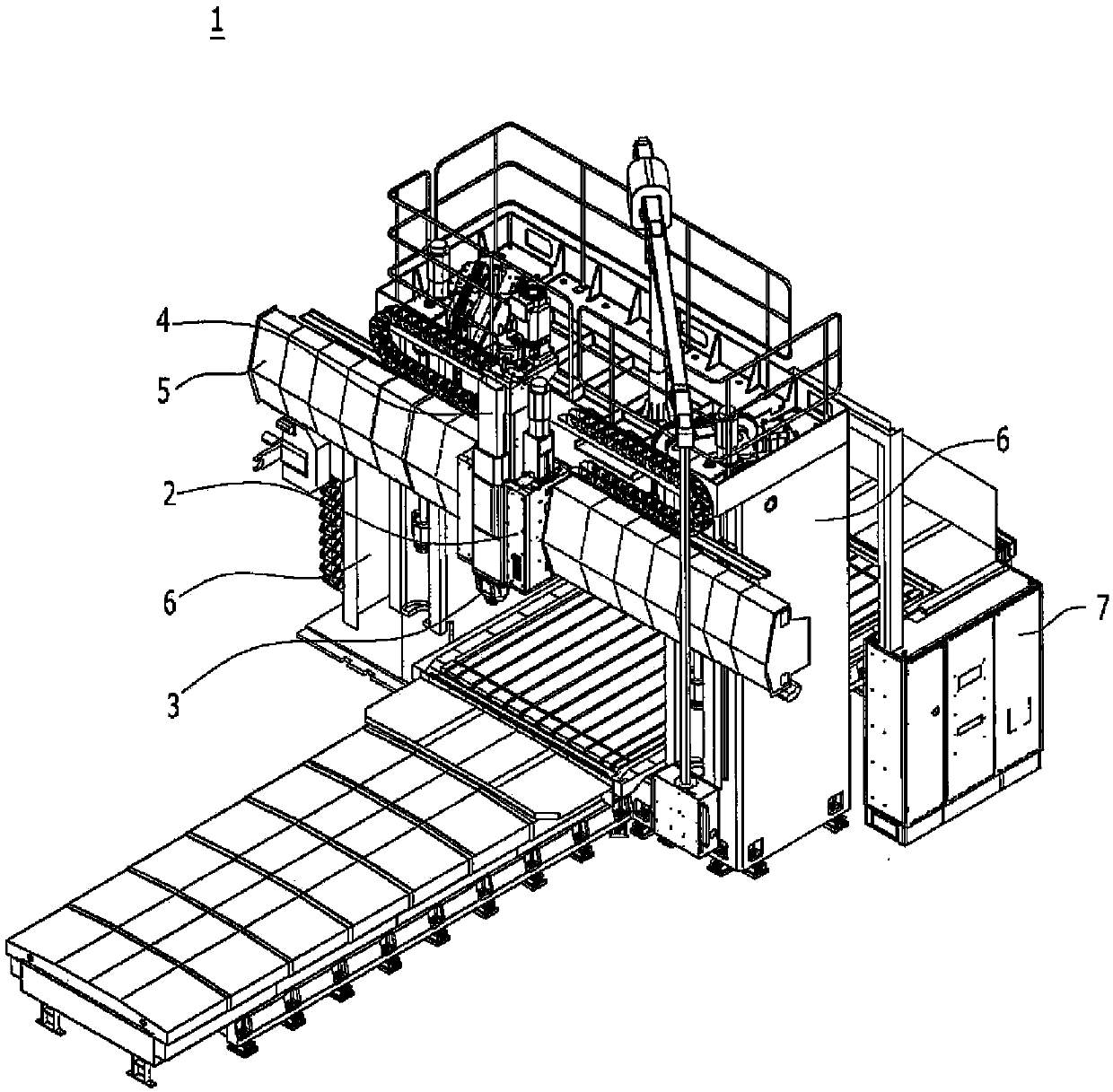

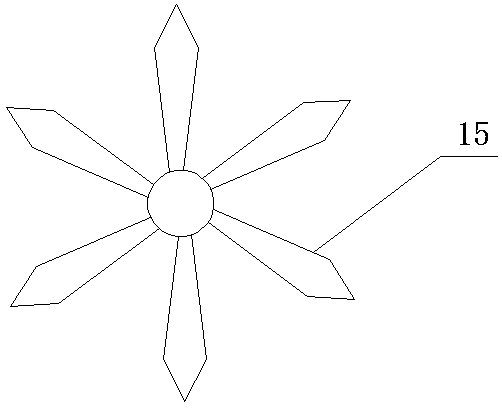

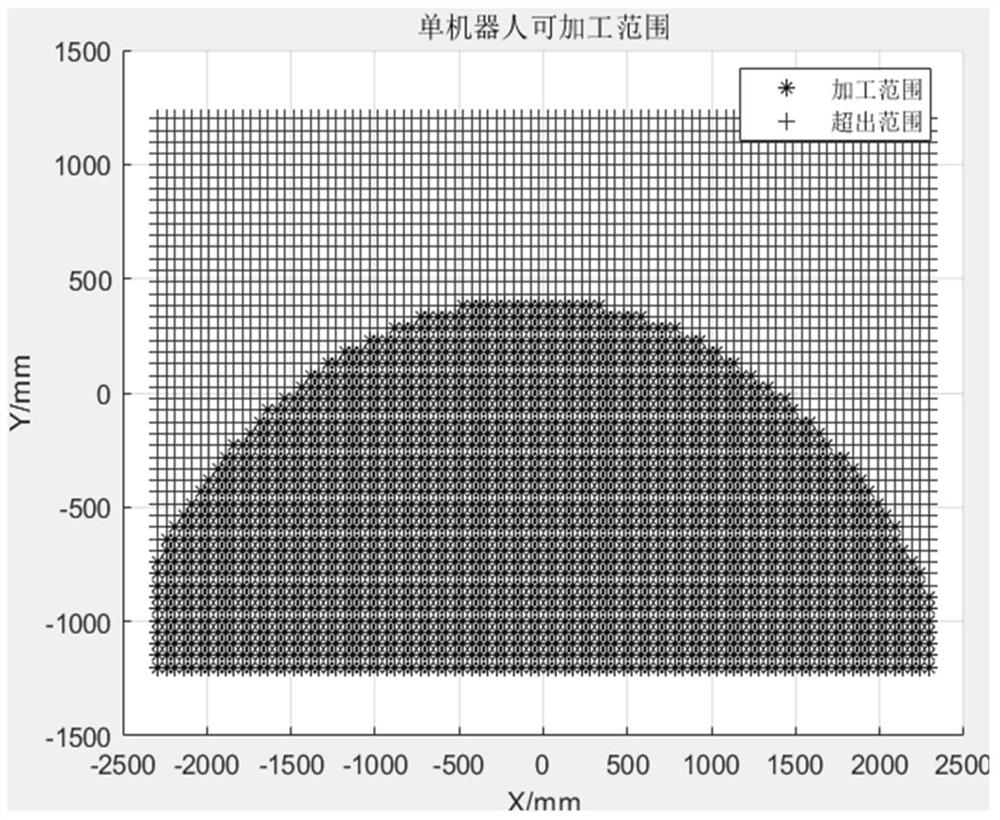

Multi-robot precision machining system and method for large-aperture integral optical element

ActiveCN110732932AShorten the production cycleSave handling timeOptical surface grinding machinesLapping machinesOptical processingRobot machining

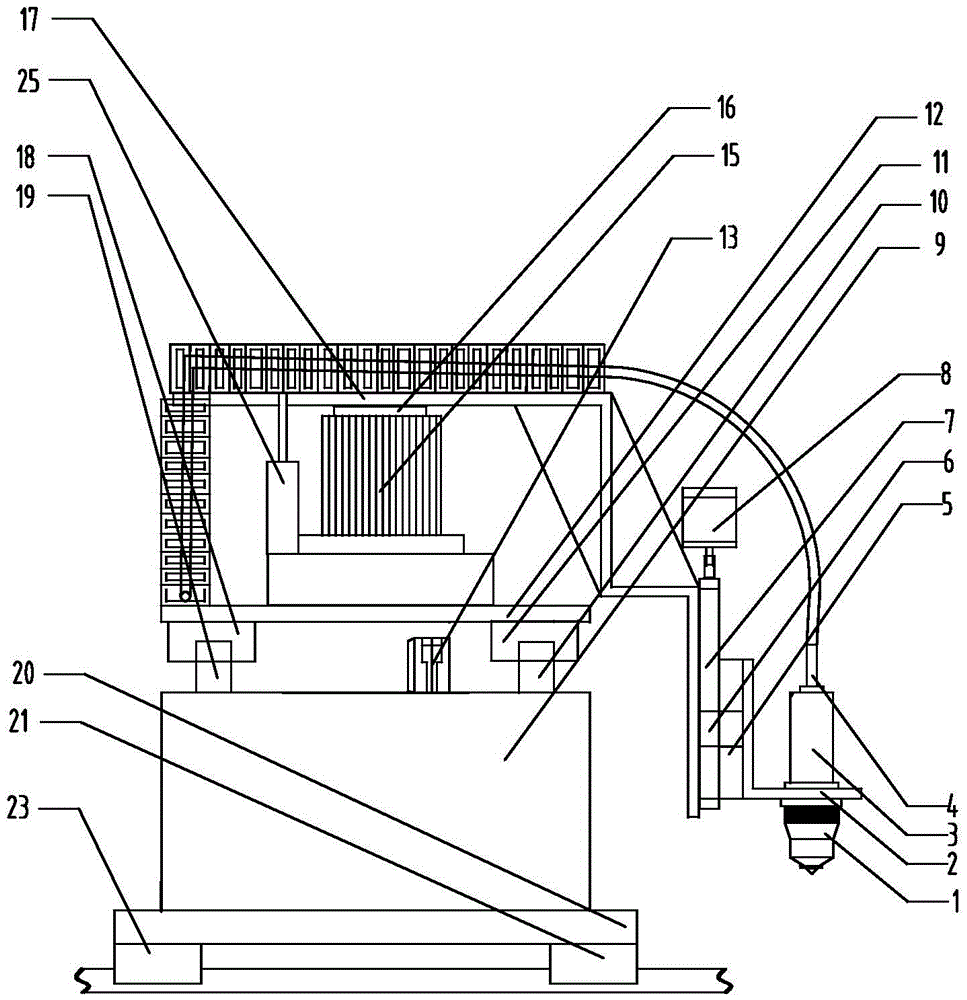

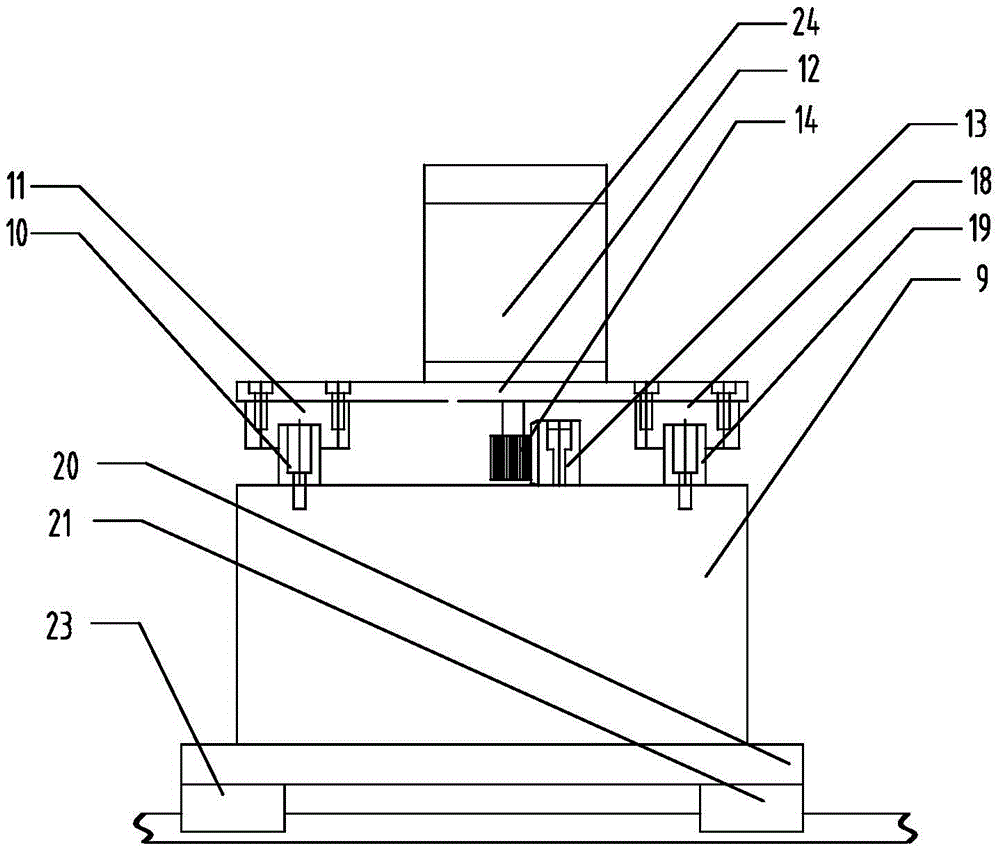

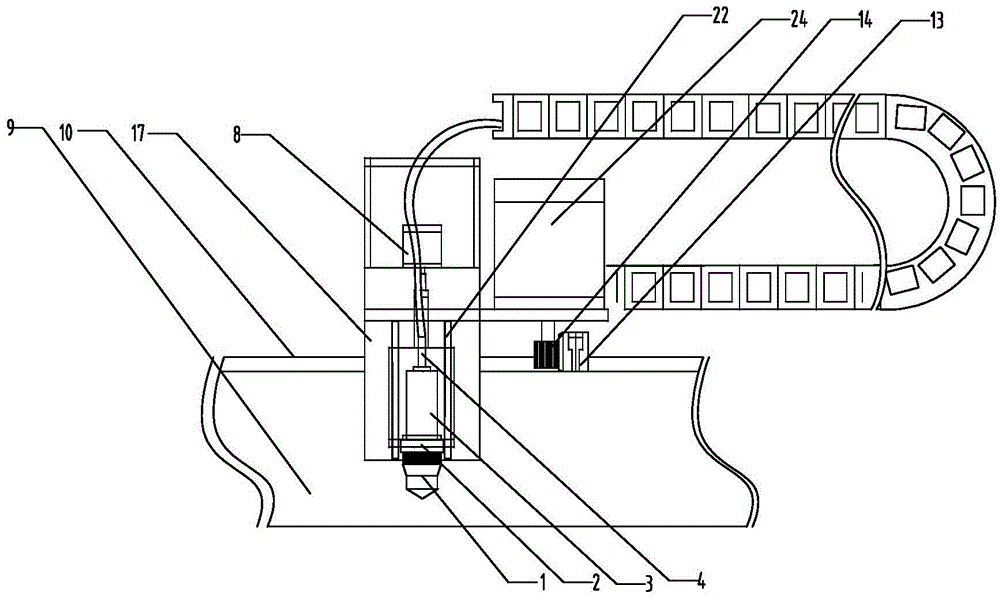

The invention discloses a multi-robot precision machining system and a method for a large-aperture integral optical element. The multi-robot precision machining system comprises a robot machining system part and a modular machining tool, the modular machining tool comprises a grinding disk machining module, a polishing fluid supply recycling tool head module and a magnetorheological polishing toolhead module. The multi-robot precision machining system and method adopts a flexible intelligent robot with the low cost for machining, by means of multi-robot collaborative machining, machining of large-aperture integrated optical elements with various curvature is realized, meanwhile, the manufacturing efficiency of the optical elements is greatly improved, and a highly integrated modular chemical tool head enables the machining system to be able to conduct grinding modification, polishing modification and precision polishing modification on the large-aperture integral optical elements. Thesystem completes the whole optical machining process, the manufacturing cost of the large-aperture optical elements is greatly saved, and the cycle of the large-aperture optical elements is greatly shortened.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

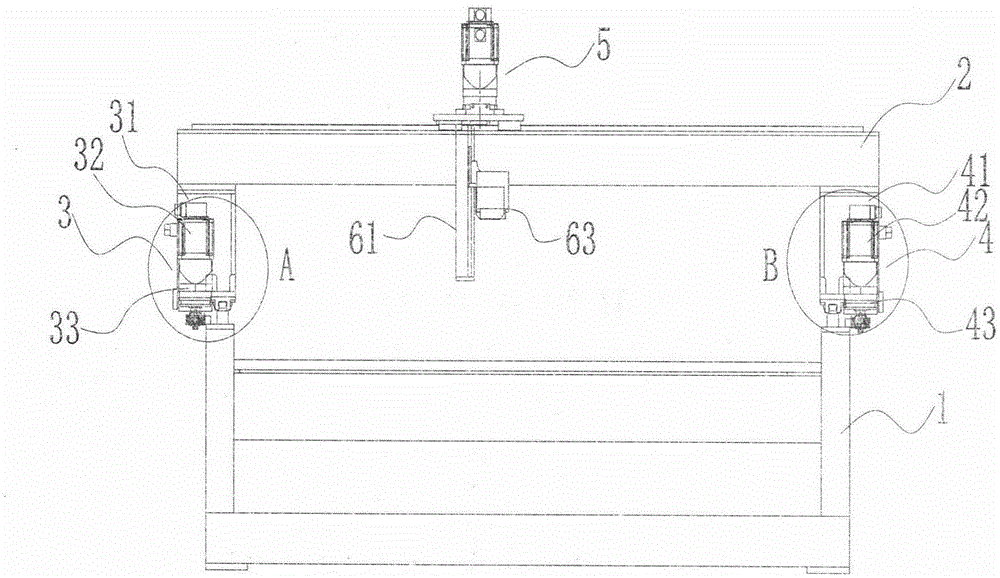

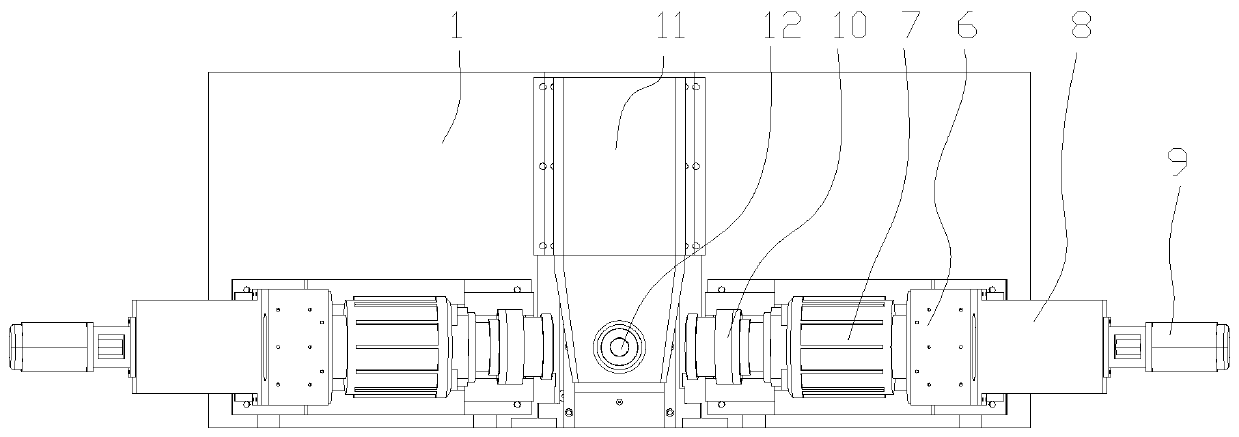

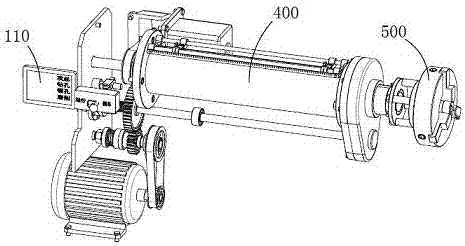

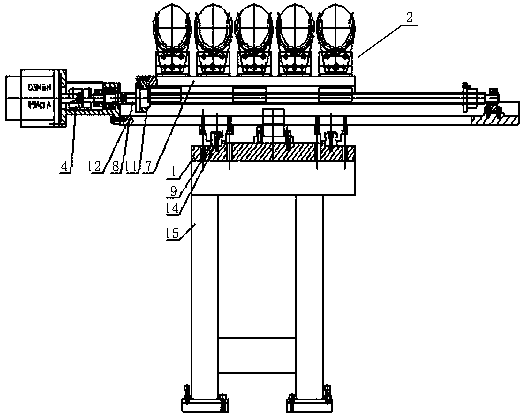

Integrated laser cutting machine for large-format gantry fiber optic conducting tube plate

InactiveCN103692088AImprove cutting efficiencyLarge processing areaLaser beam welding apparatusLaser cuttingMachine tool

The invention relates to an integrated laser cutting machine for a large-format gantry fiber optic conducting tube plate. The integrated laser cutting machine comprises a cutting workbench, wherein the two ends of the cutting workbench are respectively and fixedly provided with a first Y-axis guide rail and a second Y-axis guide rail, and a first beam mounting plate and a second beam mounting plate are respectively and fixedly arranged on the first Y-axis guide rail and the second Y-axis guide rail in a sliding way, and are fixedly connected by a beam; a first X-axis guide rail and a second X-axis guide rail are fixedly arranged on the beam, and an A-axis rotation DDR motor is fixedly arranged on the first X-axis guide rail and the second X-axis guide rail in a sliding way; an L-shaped rotation supporting plate is arranged on an output shaft of the A-axis rotation DDR motor, and a Z-axis movement assembly capable of making vertical up-and-down movement is arranged on the L-shaped rotation supporting plate; a laser cutting component is arranged on the Z-axis movement assembly. The machining can be carried out at both sides of the beam and the side of a machine tool, and the machining, loading and unloading can be simultaneously realized.

Owner:武汉华俄激光工程有限公司

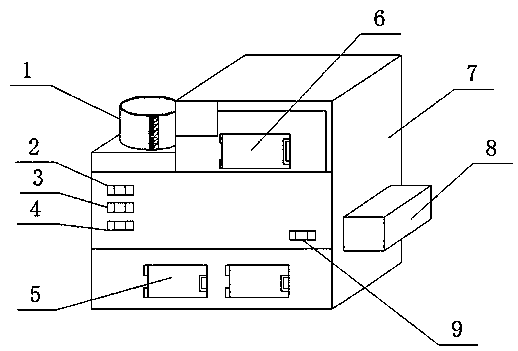

Machining method of laser marking machine

The invention relates to the technical field of laser marking, and discloses a machining method of a laser marking machine. The laser marking machine is composed of a control unit and a light path assembly arranged on the control unit through a lifting table. A 3D vertical supporting rotating device is arranged behind one end of the light path assembly and comprises a bottom frame, a stand column arranged on the bottom frame, a rotating device arranged at the top end of the stand column, pipe expanding devices arranged at the two ends of the rotating device and an expanding mechanism arranged below one pipe expanding device. Each pipe expanding device comprises a pipe expanding part. The machining method of the laser marking machine comprises the first step of equipment preparing, the second step of material matching, the third step of laser machining, the fourth step of material replacing and the fifth step of resetting shutdown. According to the machining method of the laser marking machine, it is guaranteed that the appearance effect of finished products is uniform, the product yield is increased, the machining method is simplified, and the machining efficiency is improved as a whole.

Owner:GBOS LASER INC

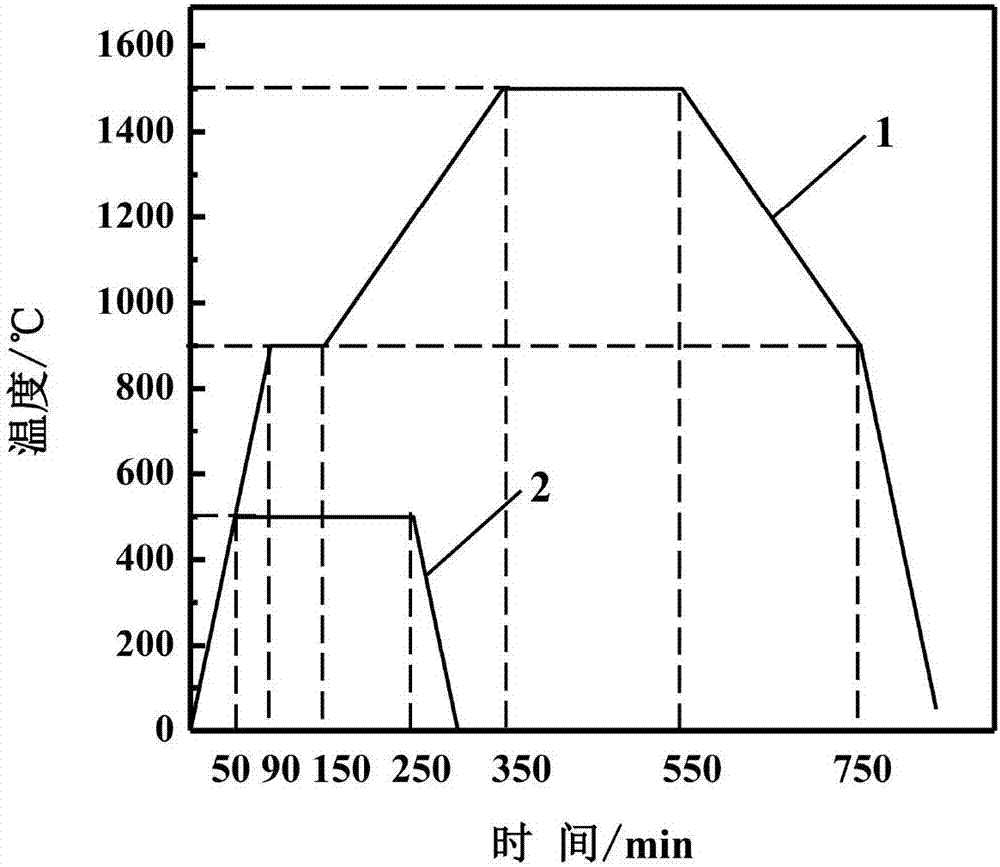

ZrB2-SiC eutectic composite ceramic solidification preparation method

The invention discloses a ZrB2-SiC eutectic composite ceramic directional solidification preparation method. A laser beam of a high-energy CO2 laser device serves as a heating source, ZrB2-SiC composite ceramics of eutectic components are rapidly zone-melted by small light spots, and a melting zone is stabilized by accurately controlling laser power and scanning rate, rapidly cooled and continuously solidified to obtain an anisotropic ZrB2-SiC eutectic composite ceramic with a refined structure and phase distribution uniformity. The microstructure of the obtained ZrB2-SiC eutectic composite ceramic is a labyrinth laminated eutectic structure. Compared with a ZrB2-SiC composite ceramic obtained by conventional sintering preparation technology, the ZrB2-SiC eutectic composite ceramic has the advantages that two phases of the structure are firmly combined, the structure is refined, a phase interface is clean, intergranular amorphous phases are avoided, and mechanical property can be further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

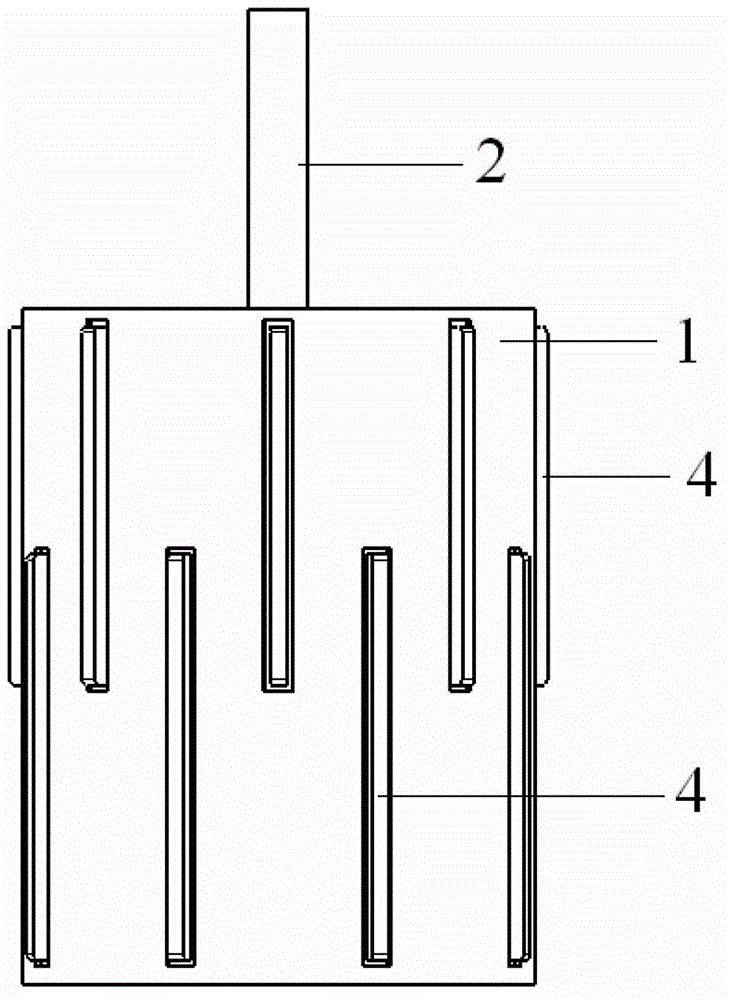

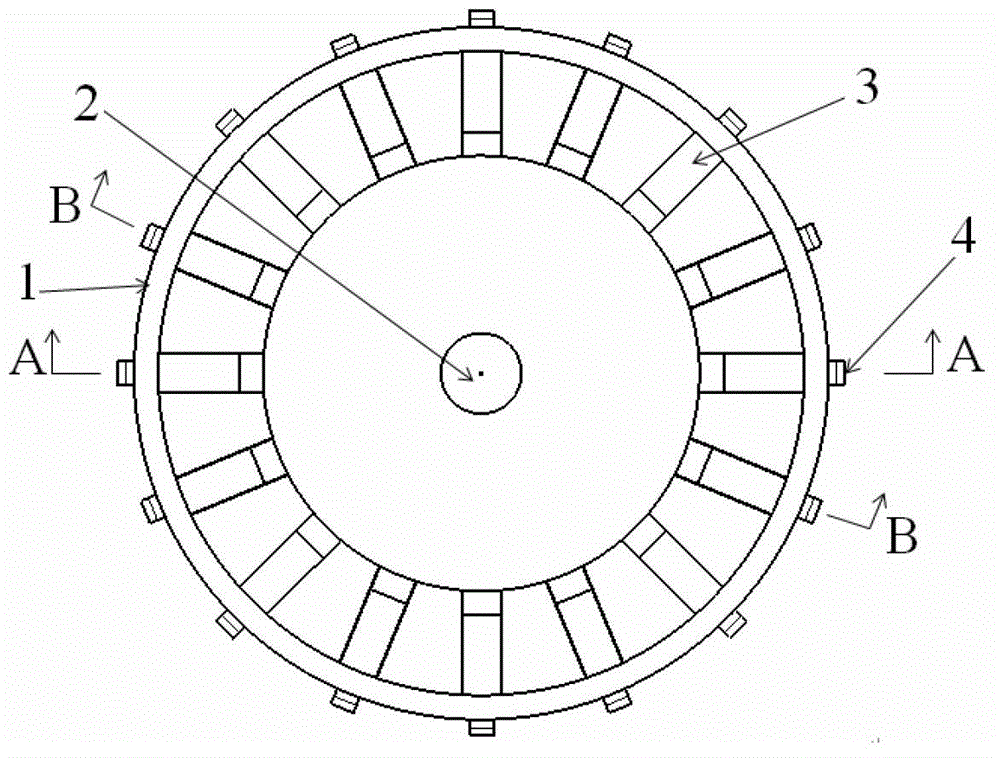

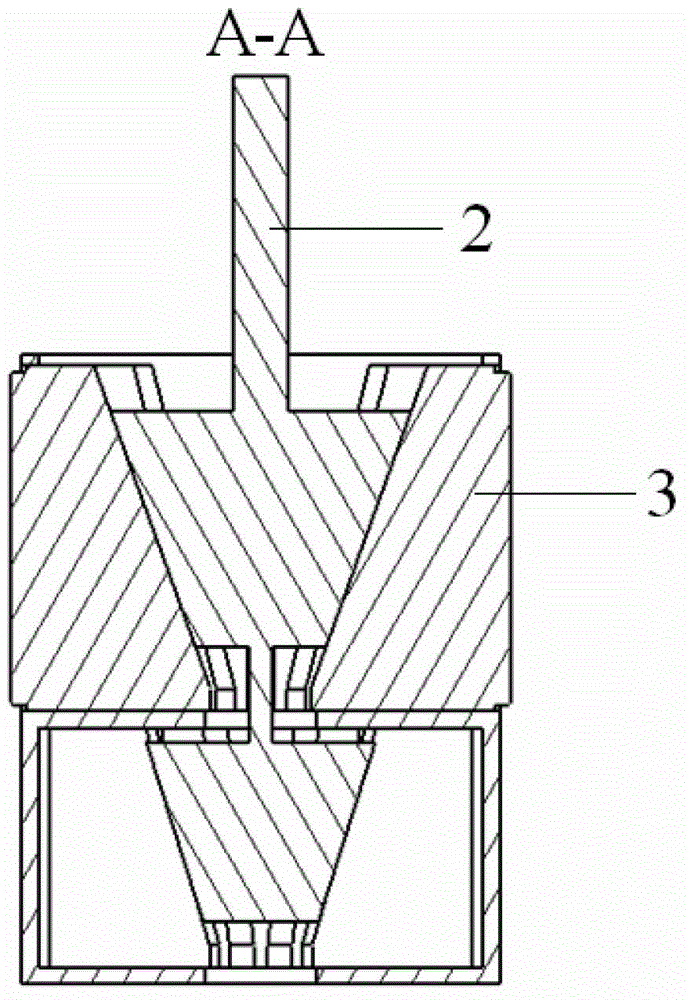

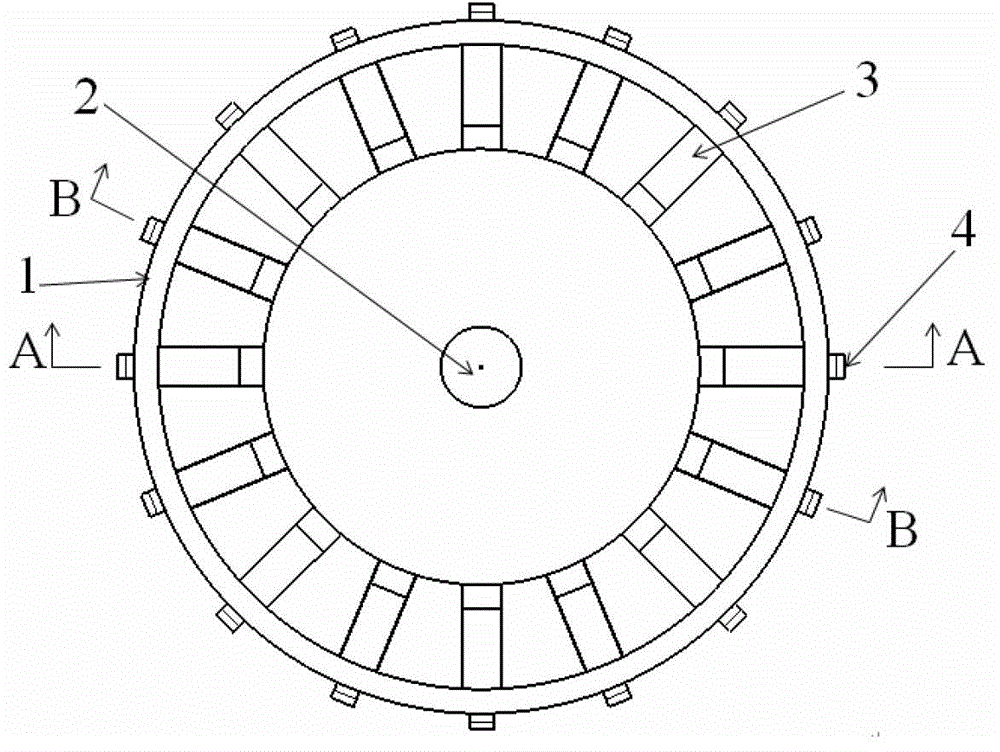

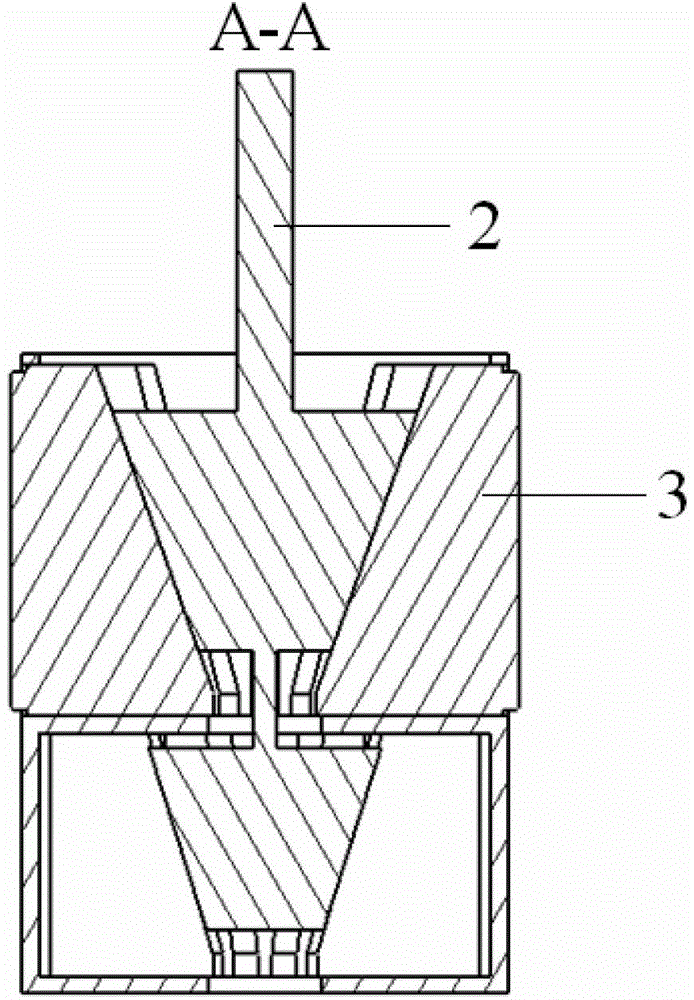

Perfect cylindrical hole honing head device and structure method thereof

ActiveCN102744671AEvenly distributedUniform honing removal amountHoning toolsEngineeringWall material

The invention relates to a perfect cylindrical hole honing head device and a structure method thereof. The device comprises a hollow cylindrical structure, a honing head rack, a feeding rod, oilstone bases and oilstones, base holes are peripherally and alternately arranged on the honing head rack in a staggered manner, the feeding rod is disposed in the center of the honing rack, the oilstone bases are mounted in the base holes, and the oilstones are fixed onto the oilstone bases. The structure method includes computing lengths of honing head stroke ranges and lengths of the oilstones which correspond to various curves; computing mutual position relation among the oilstones; and designing and manufacturing the honing head device with the oilstone distribution meeting a result of the last step. The distribution of the oilstones and acting areas of the oilstones are adjusted, and effects that tracks of grains are generally distributed uniformly and honing quantity of wall materials of the cylinder hole tends to be uniform are achieved.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

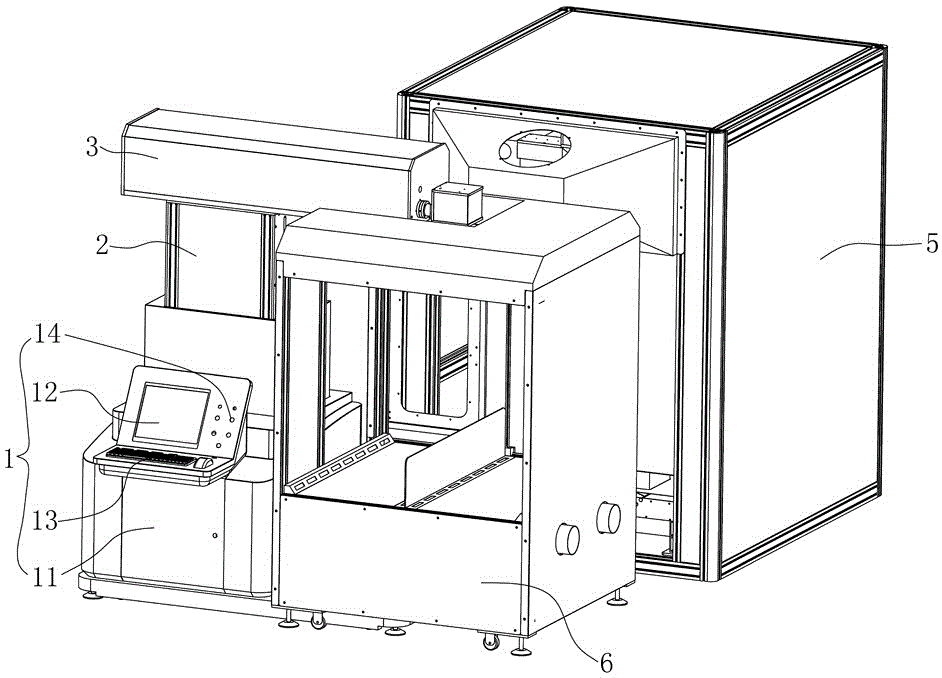

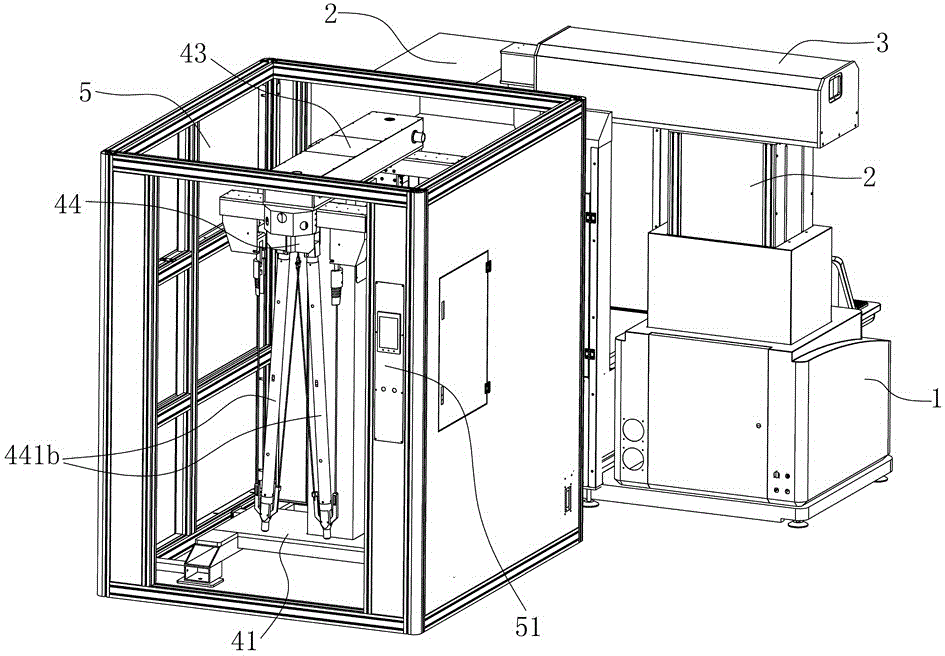

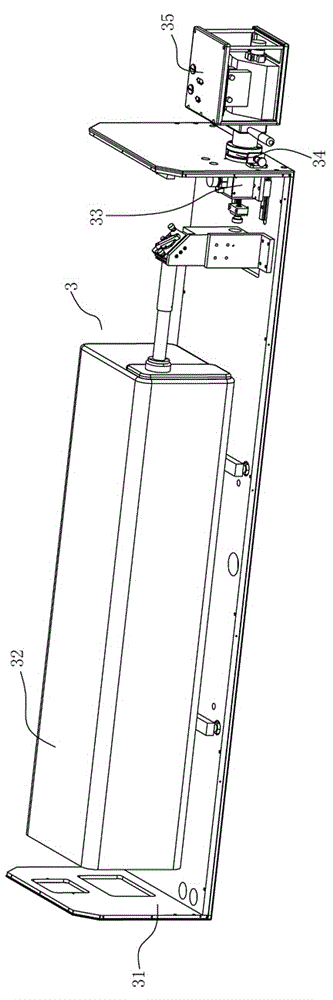

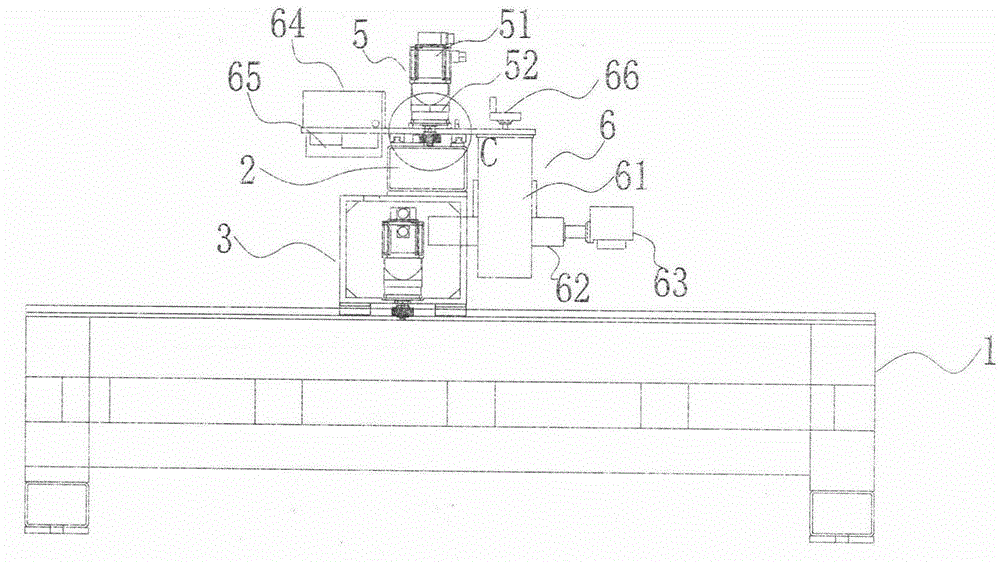

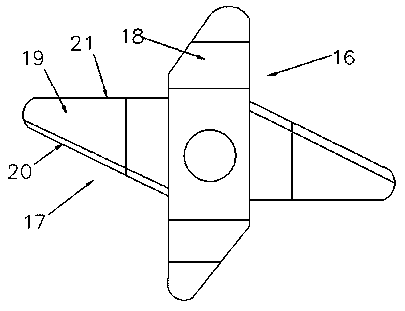

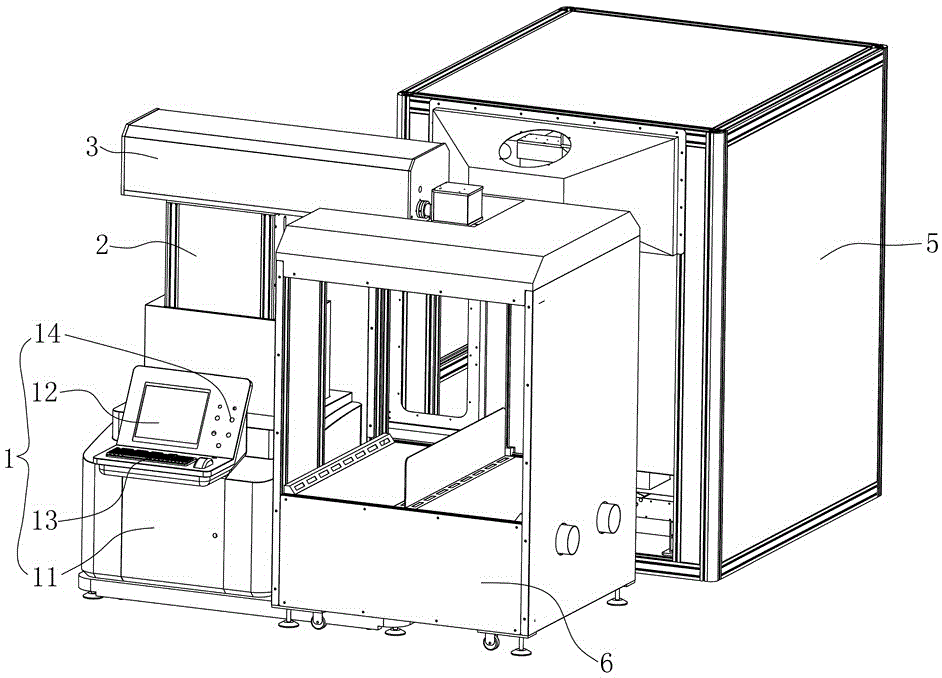

3D (three-dimensional) laser water washing system for denim

InactiveCN105002680AIncrease the processing areaShort transition timeDry-cleaning apparatus for textilesTextile treatment carriersLaser processingDenim

The invention relates to the technical field of laser processing equipment and discloses a 3D (three-dimensional) laser water washing system for denim. The system comprises a control unit, wherein a light path assembly is connected on the control unit through a lifting unit and used for performing laser processing on the surface of a material; a 3D vertical supporting and rotating unit is arranged behind the control unit and comprises a base frame, a stand column arranged on the base frame, a rotating part arranged on the stand column, supporting parts arranged at two ends of the rotating part and unfolding parts arranged on the base frame and below the supporting parts, the rotating part is used for adjusting work stations of the supporting parts, and the supporting parts are used for supporting the to-be-processed material so that a 3D processing surface can be formed. With the adoption of the 3D laser water washing system, the processing method is more flexible, patterns on a labeled product are more vivid, people can have stronger stereoscopic impressions, the unification of the appearance effect of a finished product is guaranteed, the yield of products is improved, and the processing efficiency is improved on the whole.

Owner:GBOS LASER INC

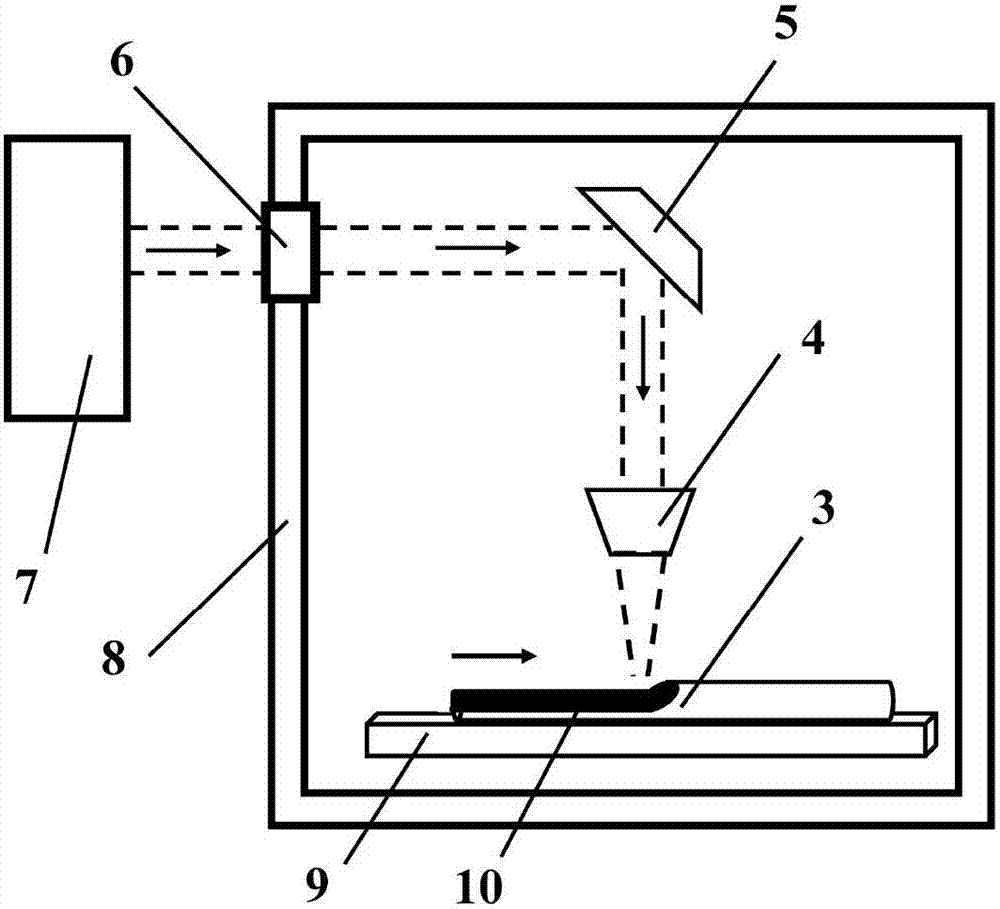

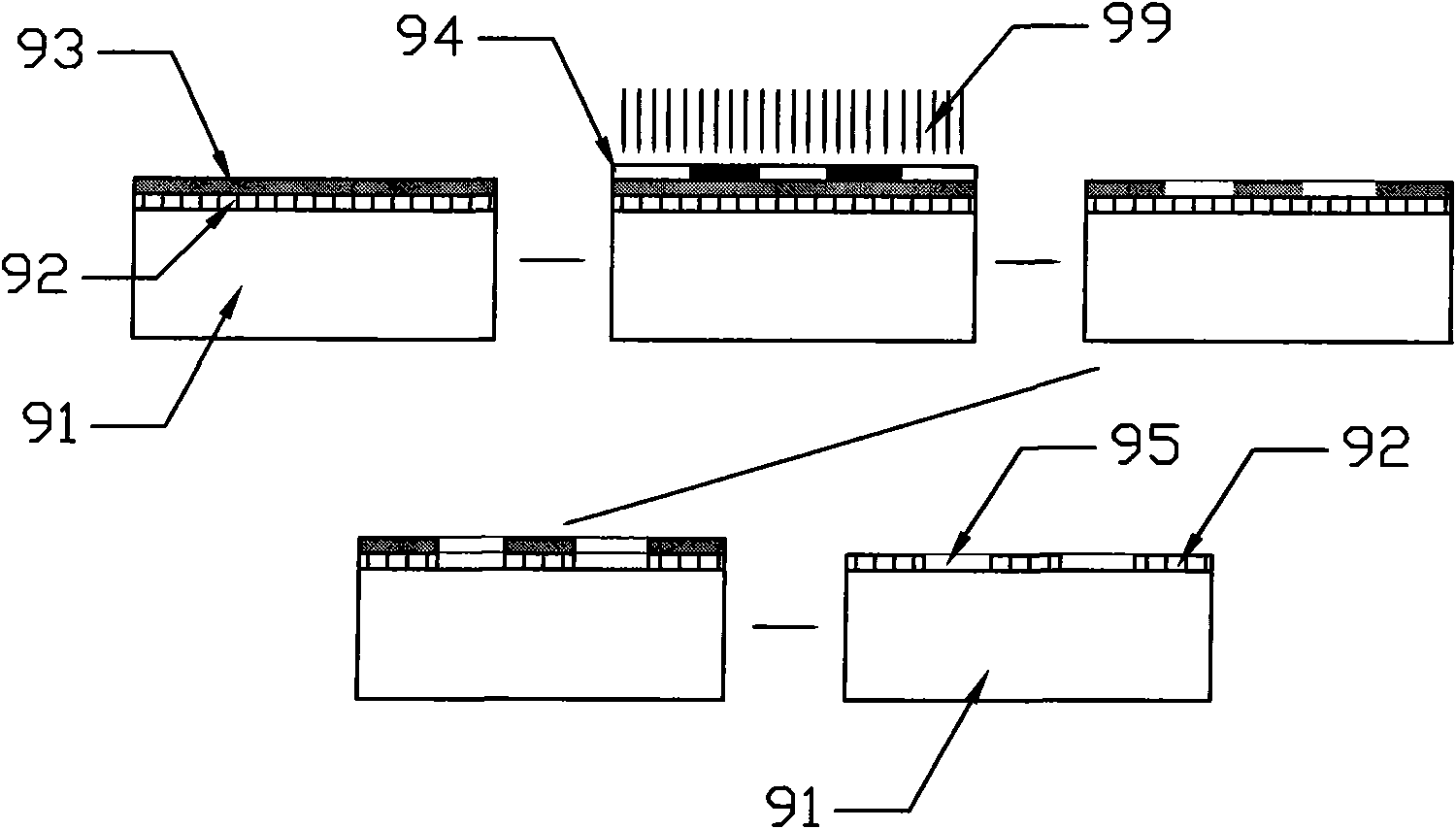

Large size conductive substrate thick circuit write-through device and write-through technology thereof

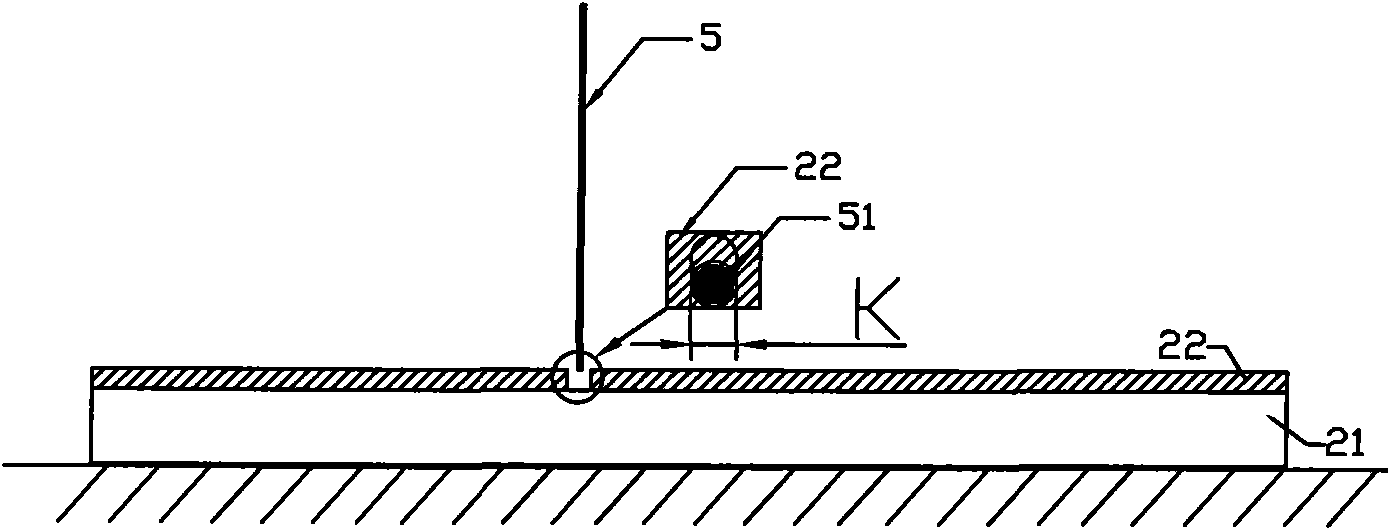

InactiveCN101661227AIncrease the processing areaReduce wiring costsPhotomechanical exposure apparatusMicrolithography exposure apparatusWire widthLaser transmitter

The invention discloses a large size conductive substrate thick circuit write-through device and write-through technology thereof. The device comprises a controller, a platform, a conductive substrateto be written through, a laser transmitter and a polarizer unit arranged on the laser path; wherein the platform is static, and more than one polarizer unit are arranged, so as to form a multi-polarizer array above the platform. The controller drives the multi-polarizer array to control the focus of the laser path to move at certain speed along etching direction, the multi-polarizer array with relatively fixed mechanical structure is utilized to realize circuit detail drawing write-through on the full size of a conductive substrate, thus providing a feasible technology approach for rapidly and accurately write-through preparation of thick circuit with wire width more than 30 microns on a large size conductive substrate. The invention has the special effects of low wiring cost, minimum wire width and minimum wire distance as short as 30 microns, large processing size, fast processing speed and high location and repeated write-through performance.

Owner:杨飞

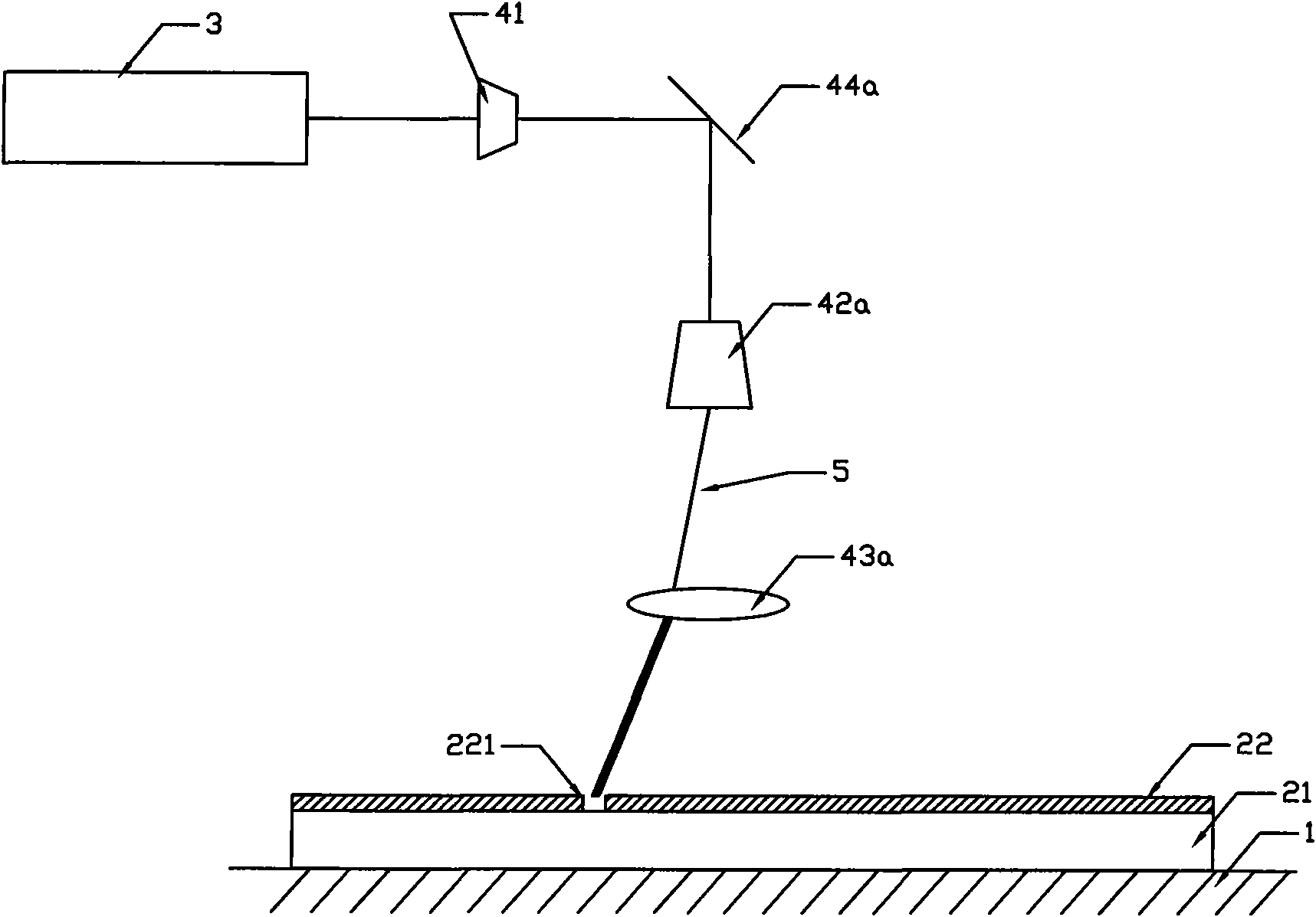

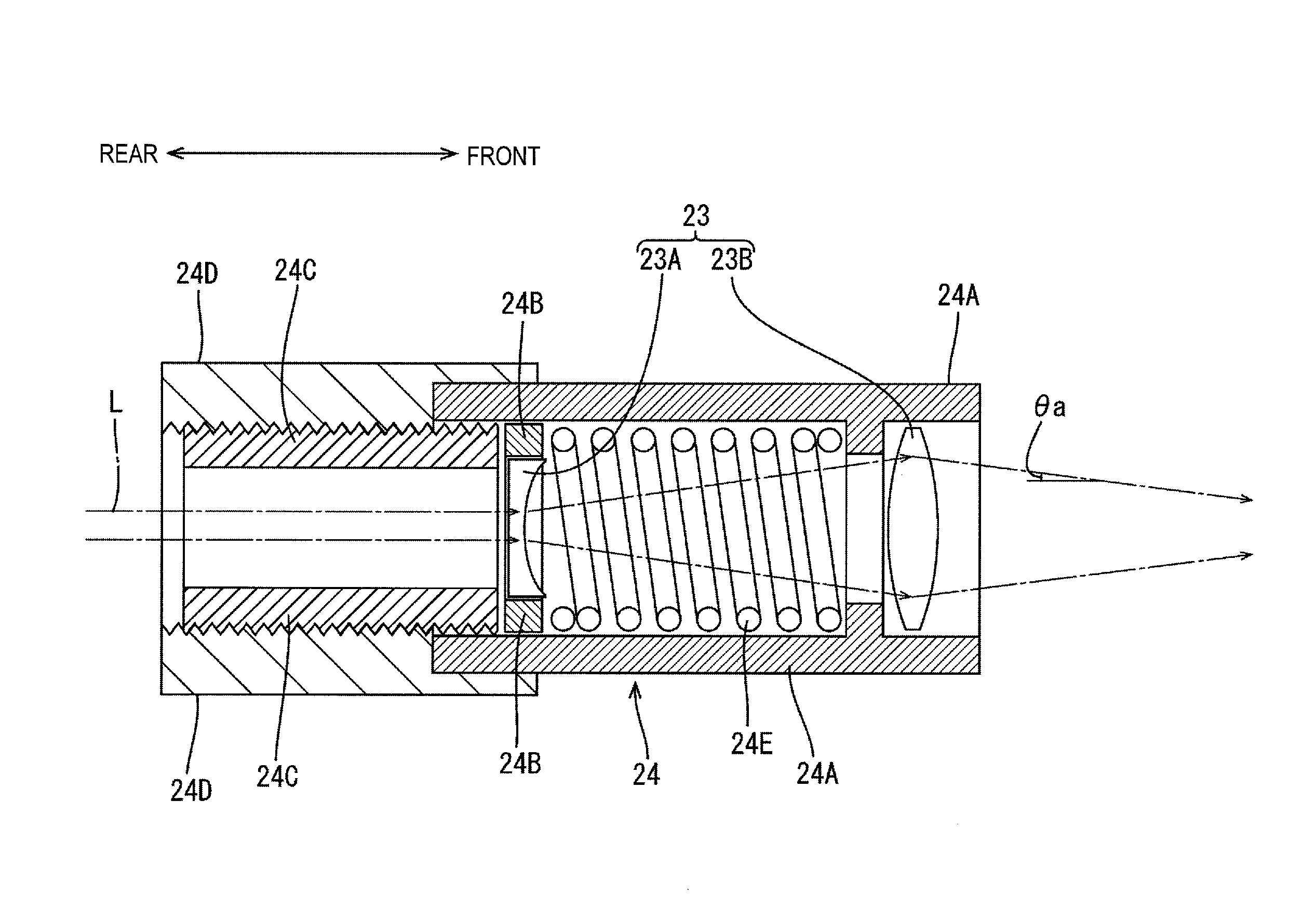

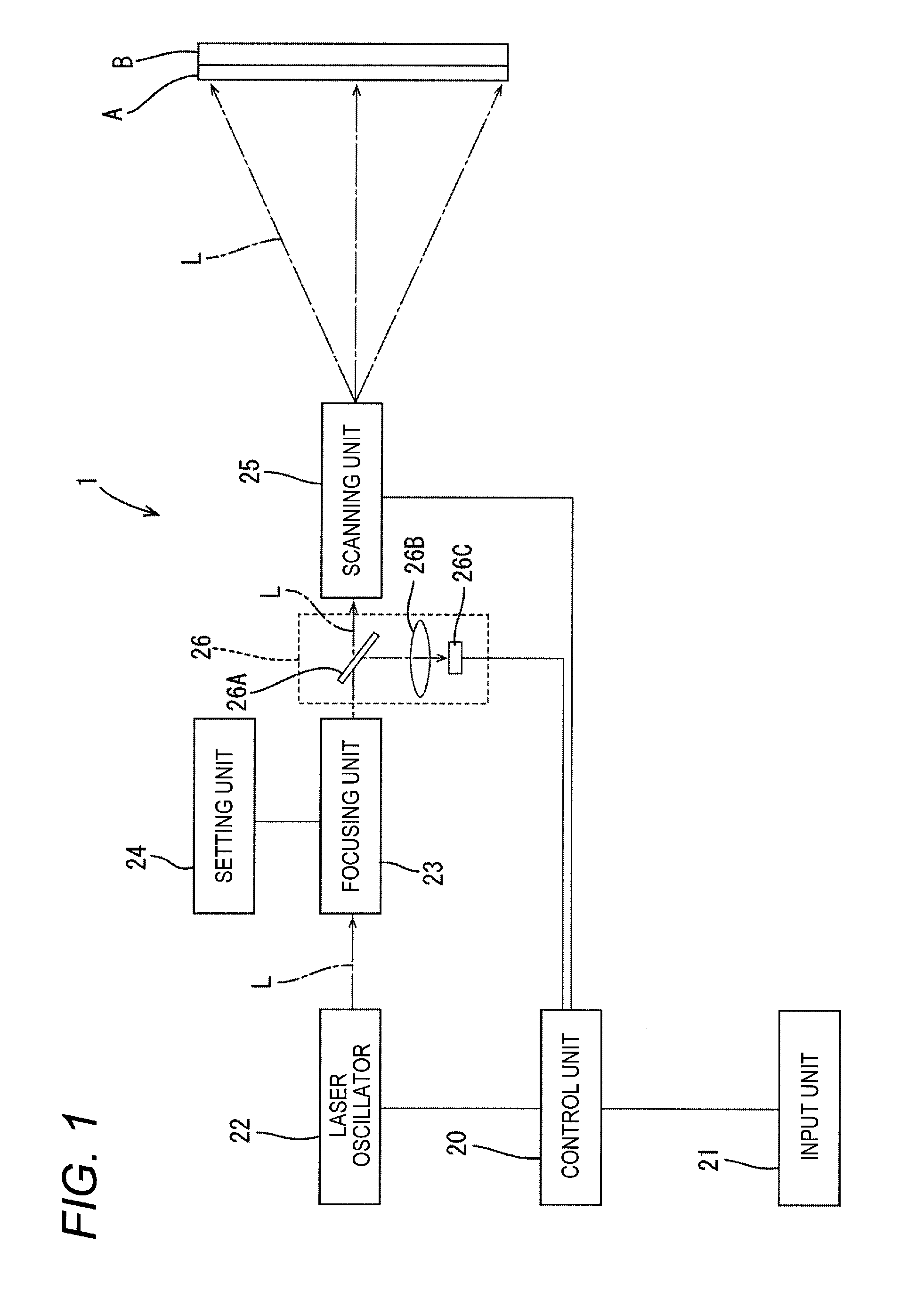

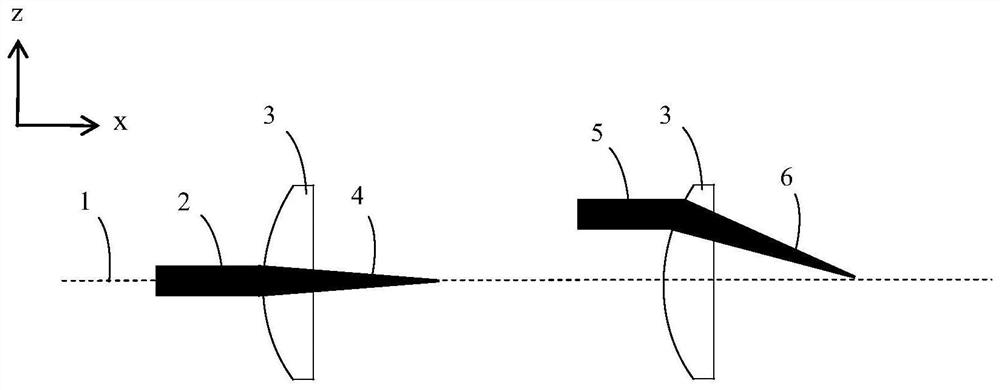

Laser processing machine and focusing angle setting method of laser processing machine

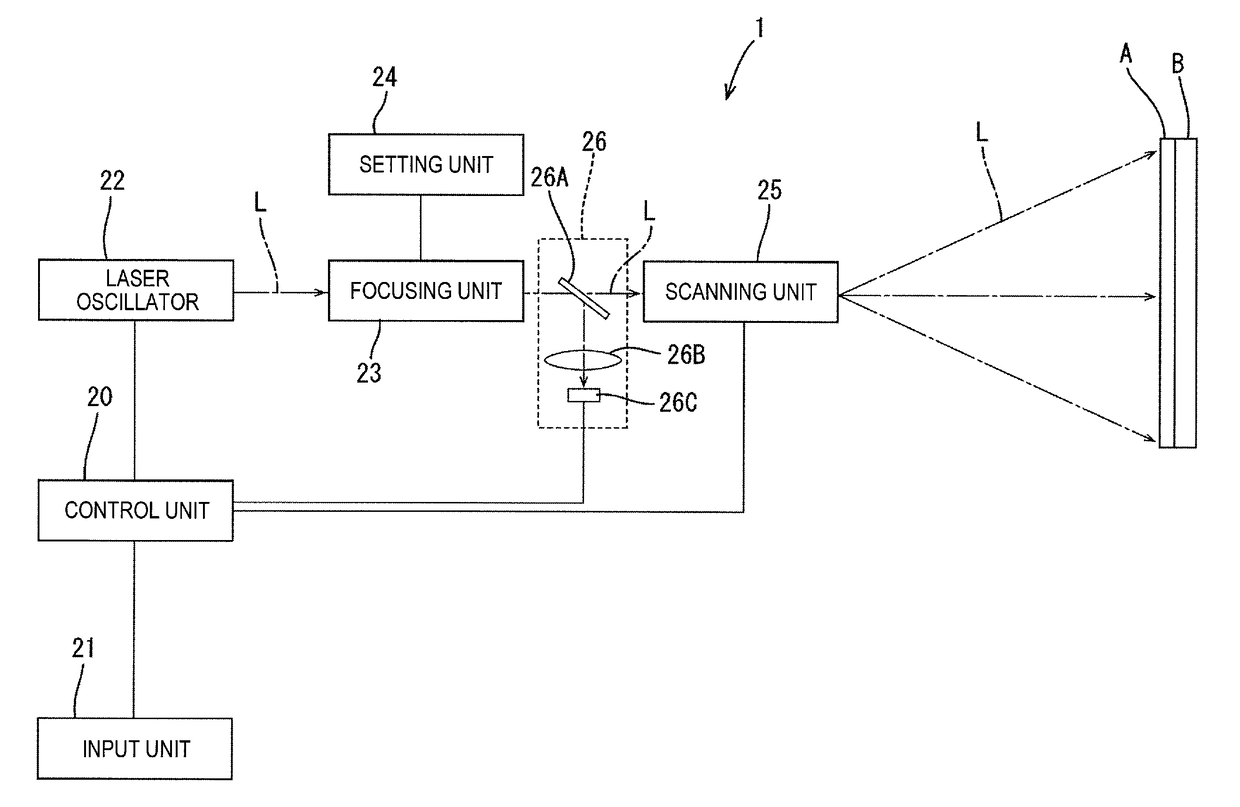

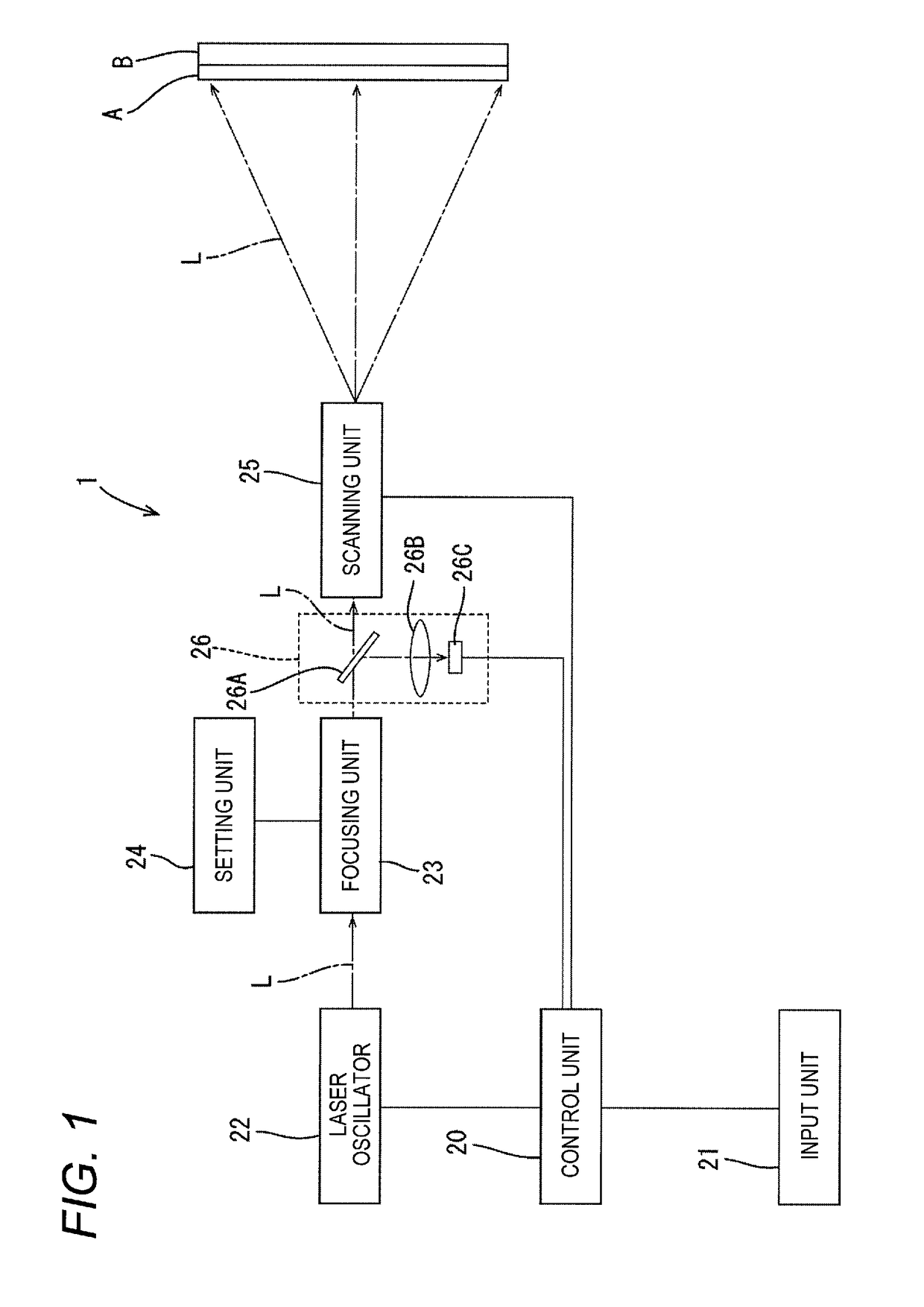

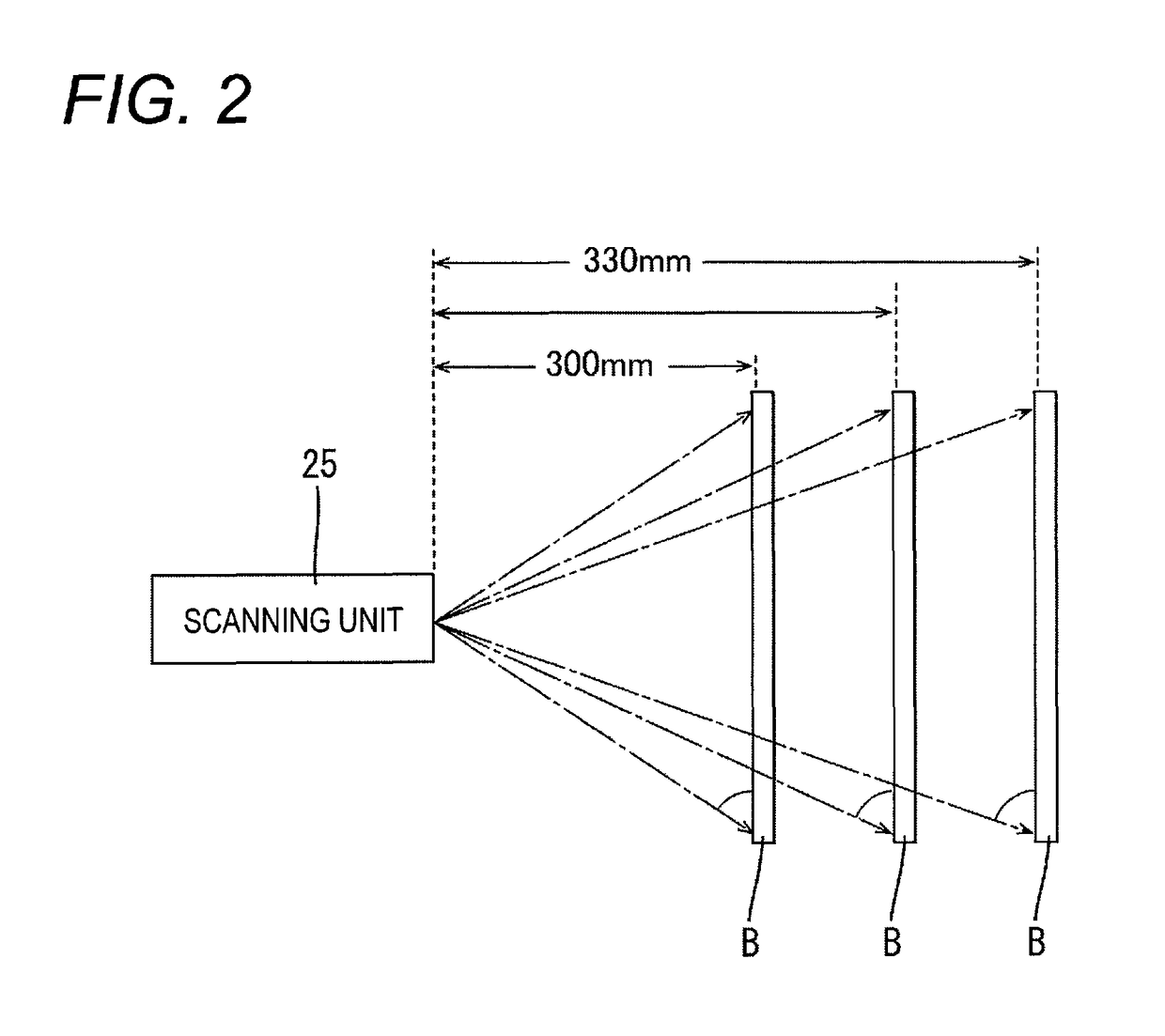

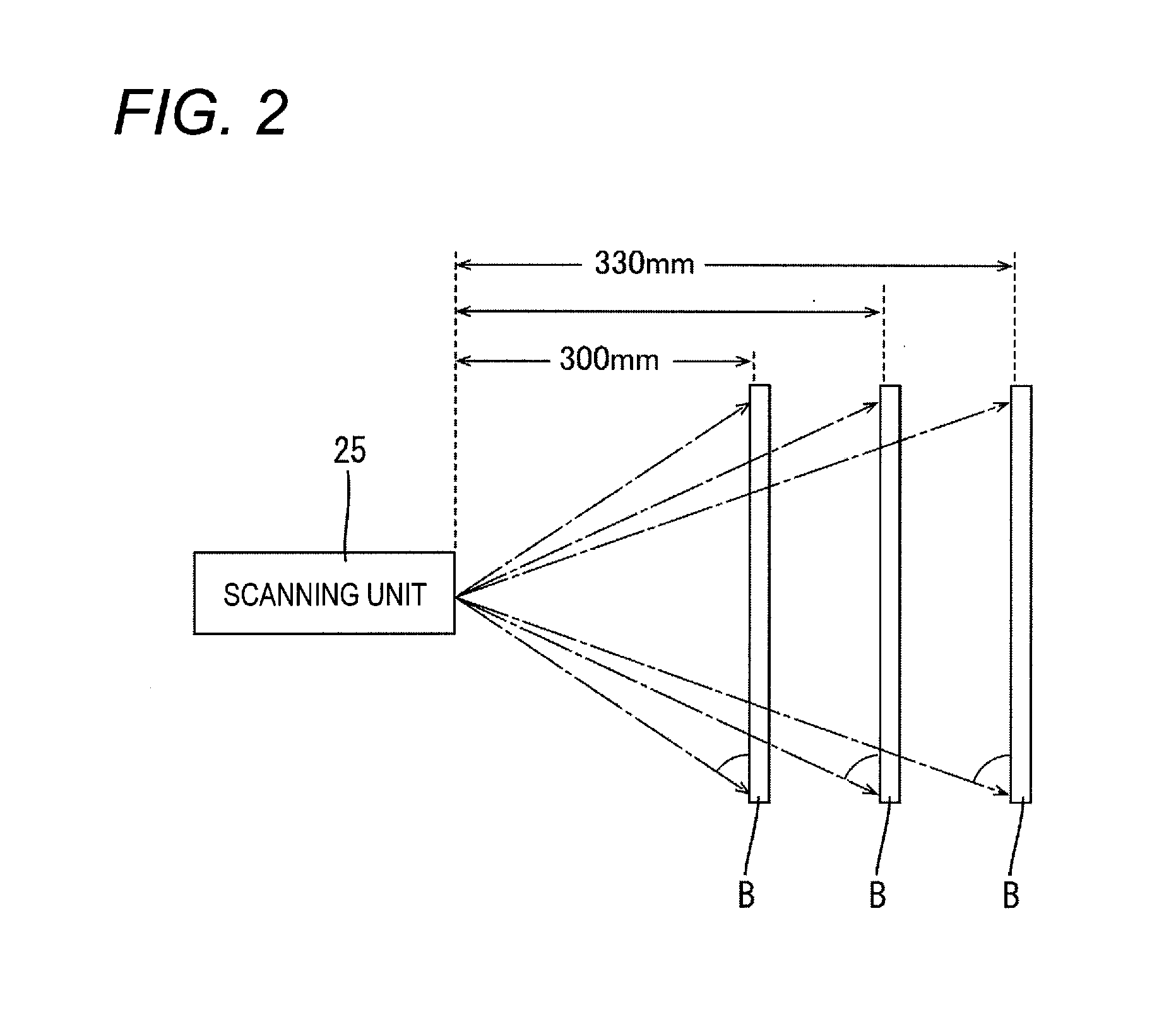

ActiveUS9703111B2Avoid processing qualityIncrease the areaOptical devices for laserLaser beam welding apparatusTarget surfaceLaser processing

A laser processing machine includes: a laser oscillator which emits laser light; a scanning unit which scans a processing target surface of a work by deflecting the laser light emitted from the laser oscillator; and a focusing unit which is disposed between the laser oscillator and the scanning unit and which focuses the laser light emitted from the laser oscillator. The focusing unit is set so as to focus the laser light at a second position that is more distant from a first position where the laser light is incident vertically than a third position that is farthest from the first position in the processing target surface of the work.

Owner:PANASONIC INDAL DEVICES SUNX

Gantry type laser engraving machine

InactiveCN106466762AHigh precisionGood rigidityLaser beam welding apparatusFuselageMechanical transmission

The invention relates to a gantry type laser engraving machine. The gantry type laser engraving machine comprises a gantry body which is provided with two X-axis guide rail mechanisms; a crossbeam vertical to the X-axis guide rail mechanisms is arranged above the gantry body; the two ends of the crossbeam are respectively connected with the X-axis guide rail mechanisms through an X1-axis servo system and an X2-axis servo system and are capable of sliding on the X-axis guide rail mechanisms; a Y-axis guide rail mechanism capable of extending along the length direction of the crossbeam is arranged on the crossbeam; a Y-axis servo system is arranged on the Y-axis guide rail mechanism; one side of the Y-axis servo system is connected with a laser engraving mechanism. The gantry type laser engraving machine adopts a gantry type body, an imported double-drive servo system, a gear, a rack, a speed reducer and the like for mechanical transmission, and has the characteristics of high precision, good rigidity, high speed, stable running, large machining breadth and the like.

Owner:NINGBO SHENGYING AUTOMATIC EQUIP

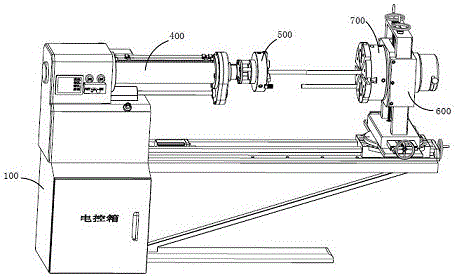

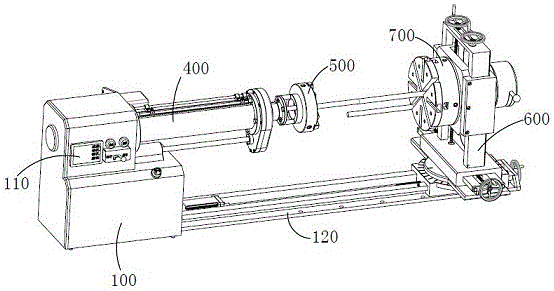

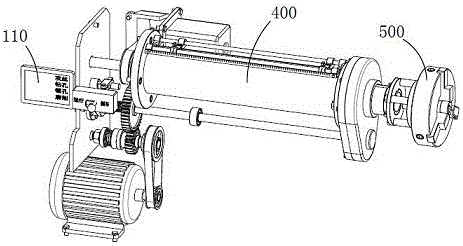

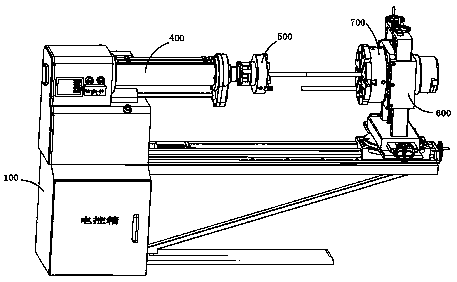

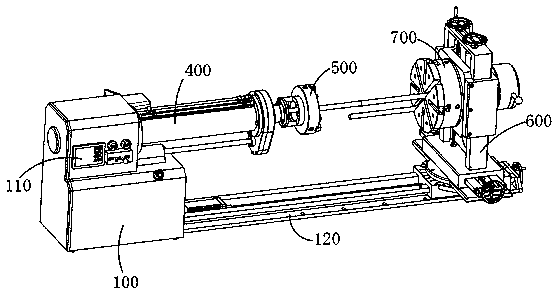

Special machine tool for sealing surface machining of hard sealing valve bodies

ActiveCN110281043AImprove processing efficiencyImprove processing qualityPositioning apparatusMetal-working holdersBody positionsMachining process

The invention relates to the technical field of machining equipment, in particular to a special machine tool for sealing surface machining of hard sealing valve bodies. The machine tool comprises a base, and a valve body positioning and machining device arranged above the base; the valve body positioning and machining device consists of a valve body positioning device and a valve body machining device; the valve body machining device consists of adjustable valve body machining mechanisms distributed on the two sides of the valve body positioning device in a mirror image mode; and each adjustable valve body machining mechanism consists of an adjustable support mechanism, a valve body end surface machining mechanism and a tool bit module rotating radius adjusting mechanism. The machine tool is simple in structure, can stably position the valve bodies to be machined, and can synchronously machine two end surfaces of the valve bodies through the two valve body end surface machining mechanisms arranged in a mirror image mode to improve the machining efficiency; and in the machining process, through adjustment of the rotating radius of tool bit modules, the machining area of the tool bit modules is gradually enlarged, so that the machining of the whole surfaces of the valve bodies is finished, and the machining efficiency and the machining quality of the valve bodies are improved.

Owner:安徽速诚智能科技有限公司

Laser processing machine and focusing angle setting method of laser processing machine

ActiveUS20160349525A1Improve processing qualitySimple configurationOptical devices for laserLaser beam welding apparatusTarget surfaceLaser processing

A laser processing machine includes: a laser oscillator which emits laser light; a scanning unit which scans a processing target surface of a work by deflecting the laser light emitted from the laser oscillator; and a focusing unit which is disposed between the laser oscillator and the scanning unit and which focuses the laser light emitted from the laser oscillator. The focusing unit is set so as to focus the laser light at a second position that is more distant from a first position where the laser light is incident vertically than a third position that is farthest from the first position in the processing target surface of the work.

Owner:PANASONIC INDAL DEVICES SUNX

Large format gantry fiber optic tube plate integrated laser cutting machine

InactiveCN103692088BIncrease the processing areaImprove cutting efficiencyLaser beam welding apparatusLaser cuttingEngineering

The invention relates to an integrated laser cutting machine for a large-format gantry fiber optic conducting tube plate. The integrated laser cutting machine comprises a cutting workbench, wherein the two ends of the cutting workbench are respectively and fixedly provided with a first Y-axis guide rail and a second Y-axis guide rail, and a first beam mounting plate and a second beam mounting plate are respectively and fixedly arranged on the first Y-axis guide rail and the second Y-axis guide rail in a sliding way, and are fixedly connected by a beam; a first X-axis guide rail and a second X-axis guide rail are fixedly arranged on the beam, and an A-axis rotation DDR motor is fixedly arranged on the first X-axis guide rail and the second X-axis guide rail in a sliding way; an L-shaped rotation supporting plate is arranged on an output shaft of the A-axis rotation DDR motor, and a Z-axis movement assembly capable of making vertical up-and-down movement is arranged on the L-shaped rotation supporting plate; a laser cutting component is arranged on the Z-axis movement assembly. The machining can be carried out at both sides of the beam and the side of a machine tool, and the machining, loading and unloading can be simultaneously realized.

Owner:武汉华俄激光工程有限公司

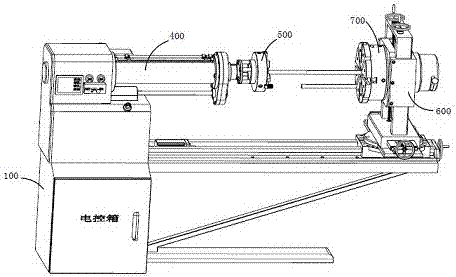

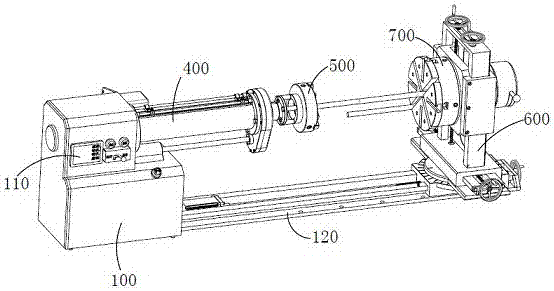

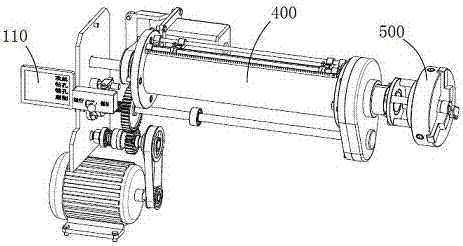

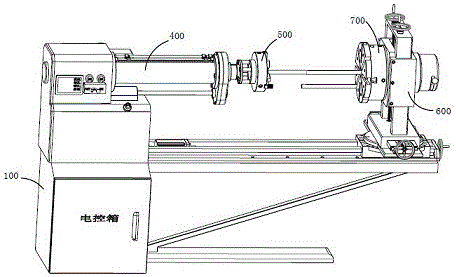

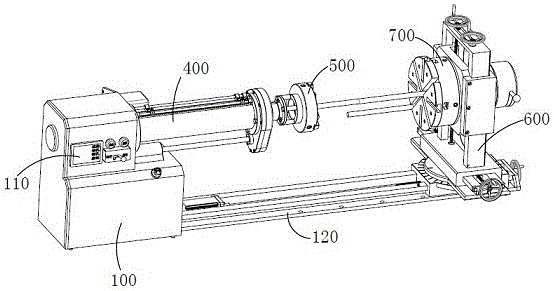

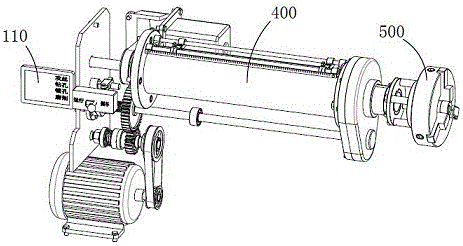

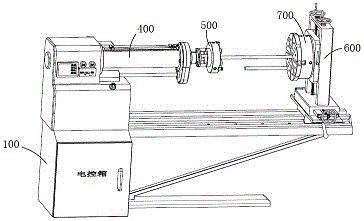

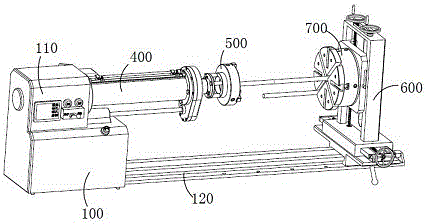

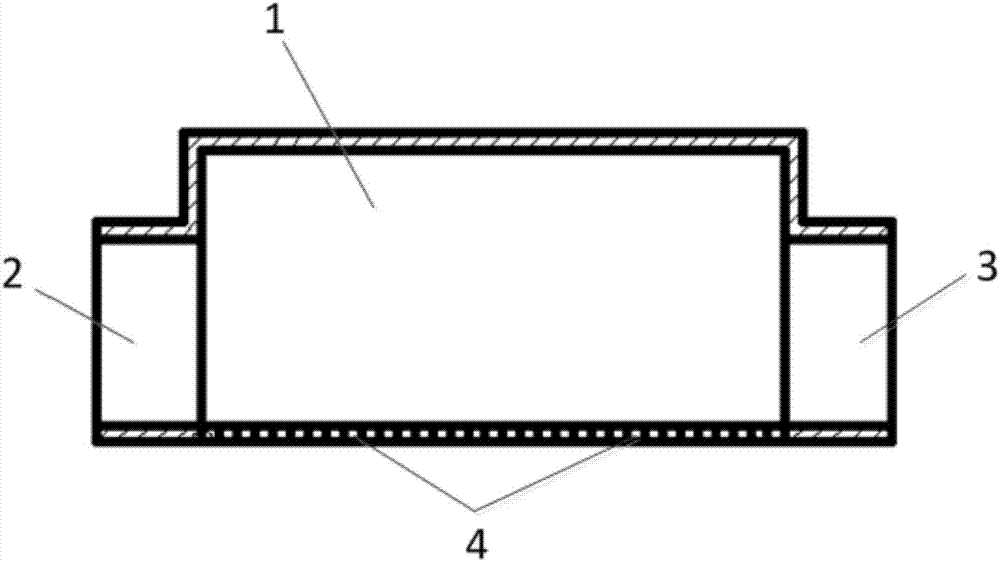

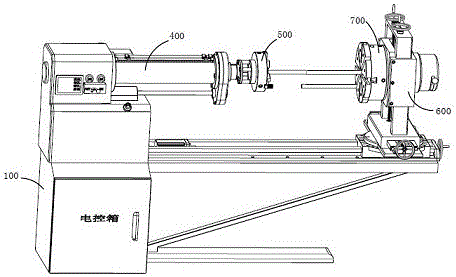

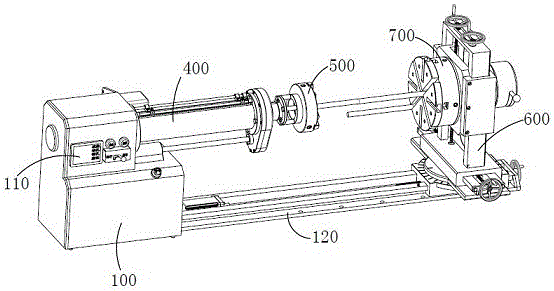

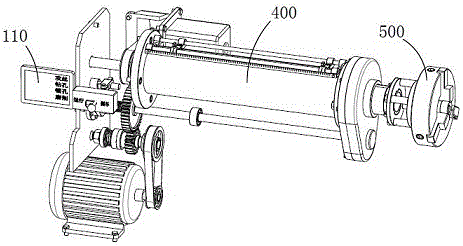

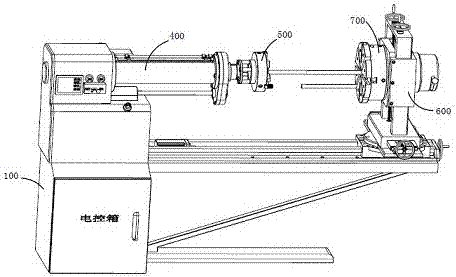

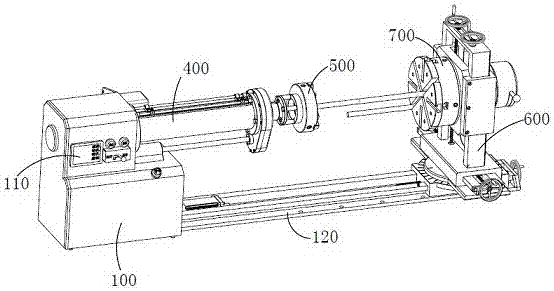

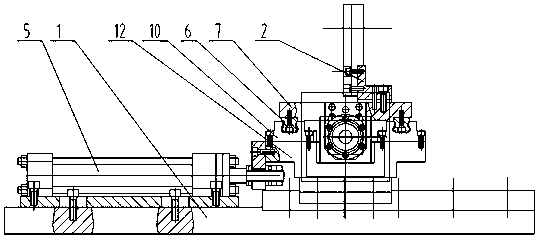

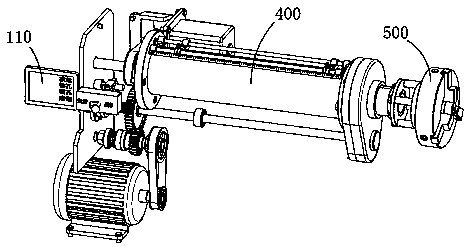

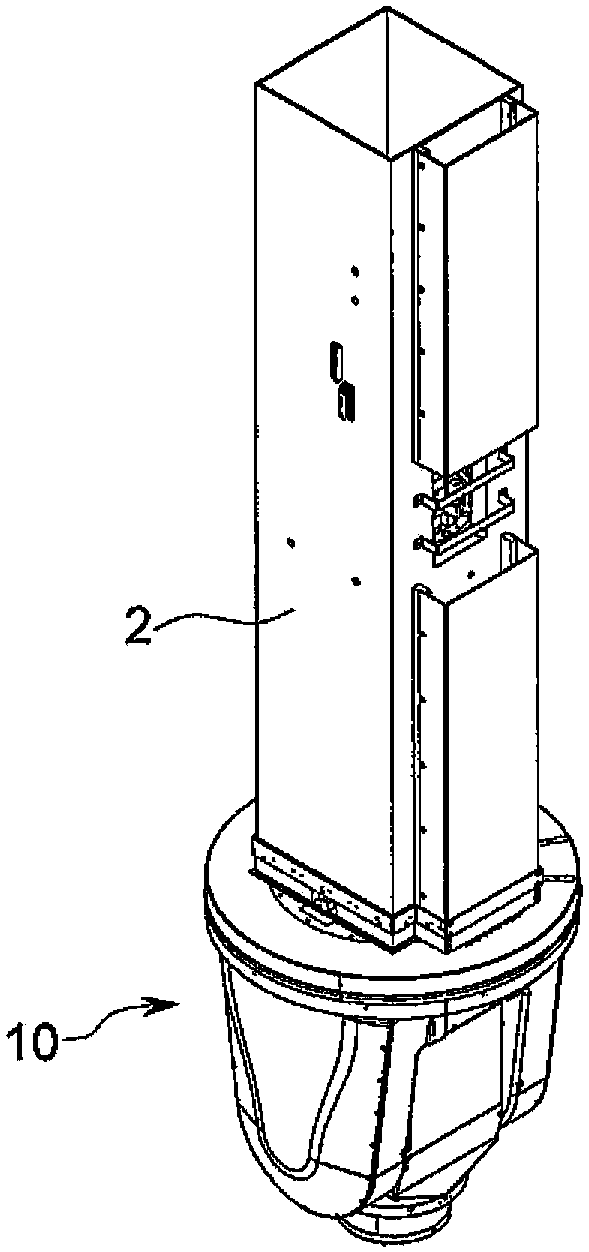

Multi-axis numerical control machine

The invention discloses a multi-axis numerical control machine. The multi-axis numerical control machine can drive a workpiece clamping mechanism to axially move along an X axis, a Y axis and a Z axis and rotate around the Z axis and the Y axis. A movement bracket comprises a first sliding plate body, a second sliding plate body and a third sliding plate body; through nuts, the first sliding plate body is connected with a Z axial lead screw which is installed on a rack, arranged in the axial direction of the Z axis and can rotate around the axis of the Z axial lead screw; the first sliding plate body is further connected with the rack through a third guide mechanism, and the guiding direction of the third guide mechanism extends in the axis direction of the Z axis; and the first sliding plate body is fixedly connected with a movement piece in the third guide mechanism which comprises a Z axial guide rail or a Z axial guide rod which is installed on the rack and arranged in the axis direction of the Z axis, and the movement piece of the third guide mechanism is a Z axial sliding block or a sliding sleeve which is matched with the Z axial guide rail or the Z axial guide rod.

Owner:山东加昆自动化科技有限公司

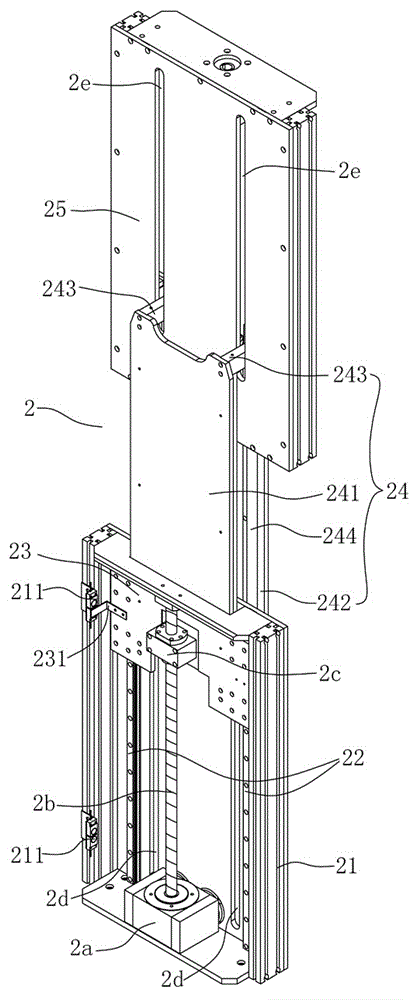

Moving bracket applied to multi-axle numerical control machine tool

InactiveCN105904234AIncrease the processing areaFeeding apparatusLarge fixed membersNumerical controlSlide plate

The invention discloses a moving bracket applied to a multi-axle numerical control machine tool; and the moving bracket can drive a workpiece clamping mechanism to move in X, Y and Z axle directions and to rotate around Z and Y axles. The moving bracket comprises a first slide plate body, a second slide plate body and a third slide plate body; the first slide plate body is connected with a Z-axle lead screw mounted on the frame, arranged in the Z-axle direction and capable of rotating around self axis through a nut; the first slide plate body is also connected with the frame through a third guide mechanism; a guide direction of the third guide mechanism extends in the Z-axle direction; the first slide plate body is fixedly connected with a moving piece in the third guide mechanism; the third guide mechanism includes a Z-axle guide rail or a Z-axle guide rod mounted on the frame and arranged in the Z-axle direction; and the moving piece of the third guide mechanism is a Z-axle slide block or slide sleeve matched with the Z-axle guide rail or the Z-axle guide rod.

Owner:张玲玲

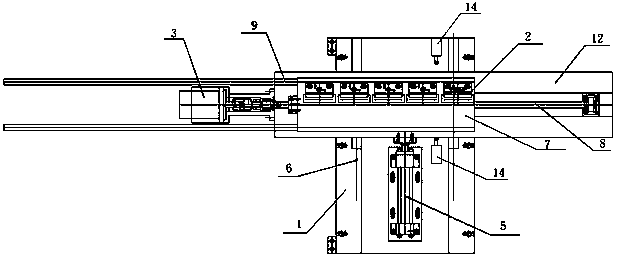

Dual-power mechanism applied to high-precision numerical control machine tool

InactiveCN105904227AIncrease the processing areaOther manufacturing equipments/toolsLarge fixed membersNumerical controlEngineering

The invention discloses a dual-power mechanism applied to a high-precision numerical control machine tool. The dual-power mechanism comprises a sleeve, a connecting shell fixedly connected with the sleeve, a second main shaft sleeved with the sleeve and an output shaft. A third gear and a fourth gear which are engaged with each other are arranged in the connecting shell in a paired manner. The second main shaft is a lead screw and is sleeved with a displacement block body. The displacement block body is connected with the second main shaft through a screw nut. The displacement block body is connected with the sleeve through a first guide mechanism. The guide direction of the first guide mechanism is the same as the length direction of the sleeve. The displacement block body is connected with a moving piece of the first guide mechanism. An annular step concentric with the displacement block body is arranged on the displacement block body. The outer portion of the second main shaft is sleeved with the output shaft. An end groove is formed in the driving end of the output shaft and connected with the annular step through a bearing. A second guide groove extending in the axis direction of the output shaft is formed in the output shaft. The fourth gear is matched with the second guide groove through a key and connected to the outer portion of the output shaft in a sleeving manner.

Owner:张玲玲

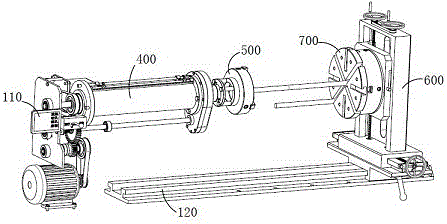

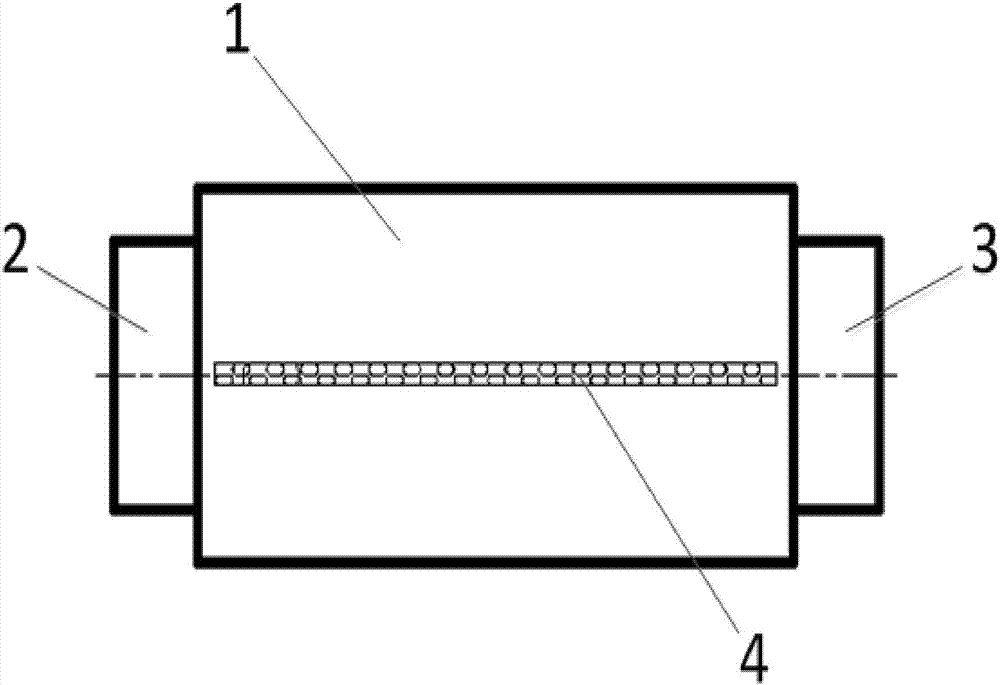

Drencher discharge head based on electro-jet mask processing

PendingCN107052485AGuaranteed uniformityGuaranteed radial continuityMachining working media supply/regenerationEngineeringSprayer

The invention discloses a drencher discharge head based on electro-jet mask processing. The drencher discharge head comprises a cylindrical sprayer cavity, wherein a row of liquid outlets are formed in the outer wall of the bottom of the sprayer cavity in the length direction of the sprayer cavity; a first liquid inlet is formed in one end of the sprayer cavity; a second liquid inlet is formed in the other end of the sprayer cavity; and the bottoms of the inner walls of the first liquid inlet and the second liquid inlet are flush with the upper surfaces of the liquid outlets. During application of the drencher discharge head, each of the first liquid inlet and the second liquid inlet is connected with a liquid supply pipe, and an electrolyte flows into the sprayer cavity through the first liquid inlet and the second liquid inlet and flows out from the row of liquid outlets to form a jet electrolytic processing water curtain, so that jet machining can flexibly adapt to processing workpieces with different mask structures, and accordingly, the flexibility of jet electrolytic processing is improved.

Owner:GUANGDONG UNIV OF TECH

Kinetic energy input control device applied to multi-axis numerical control machine tool

InactiveCN105904226AIncrease the processing areaMachine tool componentsFeeding apparatusNumerical controlLocking mechanism

The invention discloses a kinetic energy input control device applied to a multi-axis numerical control machine tool. The kinetic energy input control device comprises a first main shaft, a locking mechanism connected with the first main shaft and a shifting mechanism connected with the locking mechanism. The driving end of the first main shaft is connected with the locking mechanism. The locking mechanism comprises a second gear connected to the first main shaft in a sleeving manner, a transposition and locking disc fixedly connected to the first main shaft in a sleeving manner and a fixing and locking disc connected to the first main shaft in a sleeving manner and fixed to a rack. An axial keyway is formed in the first main shaft in the axis direction of the first main shaft. The outer portion of the first main shaft is movably sleeved with the second gear which is matched with the axial keyway through a key. A locking protrusion is arranged on the transposition and locking disc. A locking groove matched with the locking protrusion is formed in the fixing and locking disc. An annular shifting groove concentric with the transposition and locking disc is formed in the transposition and locking disc. A second spring connected to the first main shaft in a sleeving manner is mounted between the transposition and locking disc and the second gear.

Owner:张玲玲

Kinetic energy input device of multi-shaft numerical control machine tool

ActiveCN107262756AIncrease the processing areaChucksPositioning apparatusNumerical controlLocking mechanism

The invention discloses a kinetic energy input device of a multi-shaft numerical control machine tool. The kinetic energy input device comprises a first main shaft, a locking mechanism connected with the first machine shaft and a shifting mechanism connected with the locking mechanism; the drive end of the first main shaft is connected with the locking mechanism, the locking mechanism comprises a second gear, a movable locking disc and a fixed locking disc, wherein the second gear is connected to the first main shaft in a sleeved manner, the movable locking disc is fixedly connected to the first main shaft in a sleeved manner, and the fixed locking disc is connected to the first main shaft in a sleeved manner and fixed to a rack; the first main shaft is provided with an axial key groove formed in the axis direction of the first main shaft, and the second gear is matched with the axial key groove through a key and is movably connected outside the first main shaft in a sleeved manner; the movable locking disc is provided with a locking protrusion, the fixed locking disc is provided with a locking groove matched with the locking protrusion, and the movable locking disc is provided with an annular shifting groove, wherein the annular shifting groove and the movable locking disc are concentrically arranged; and a second spring connected to the first main shaft in a sleeved manner is installed between the movable locking disc and the second gear.

Owner:上海丰荷智能科技有限公司

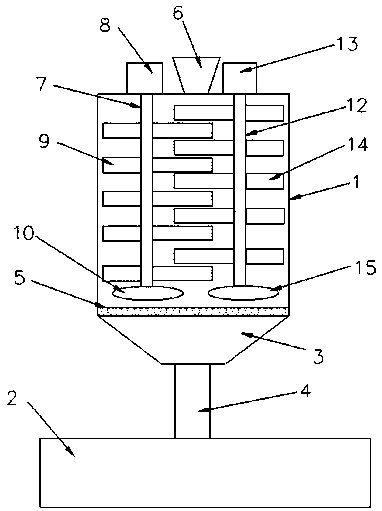

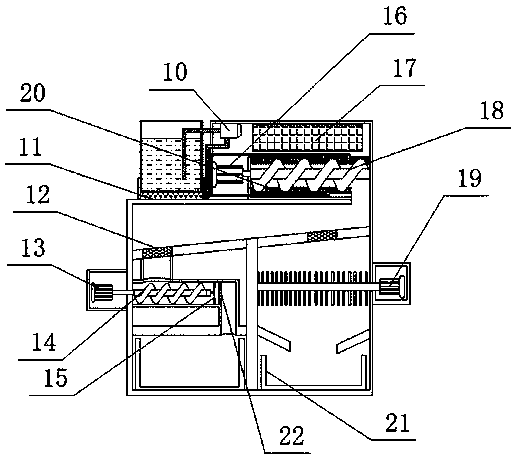

Building stone pulverizing machine

ActiveCN109513499ASmooth millingIncrease contact areaGrain treatmentsMechanical engineeringEngineering

The invention discloses a building stone pulverizing machine. The building stone pulverizing machine comprises a pulverizing box and a powder collecting box. Two pulverizing assemblies are arranged inthe pulverizing box. A discharging bin is arranged at the bottom of the pulverizing box and communicates with the powder collecting box through a discharging pipe. A filter screen is arranged in thedischarging bin. The top of the pulverizing box is provided with a feeding port. The two pulverizing assemblies are divided into the first pulverizing assembly and the second pulverizing assembly. Thebuilding stone pulverizing machine is novel in structure design, convenient to operate, capable of achieving uniform building stone pulverizing, high in pulverizing quality and capable of sieving thepulverized stone powder, and the later machining quality of the stone powder is improved.

Owner:QINGDAO HAIDE ROAD & BRIDGE ENG

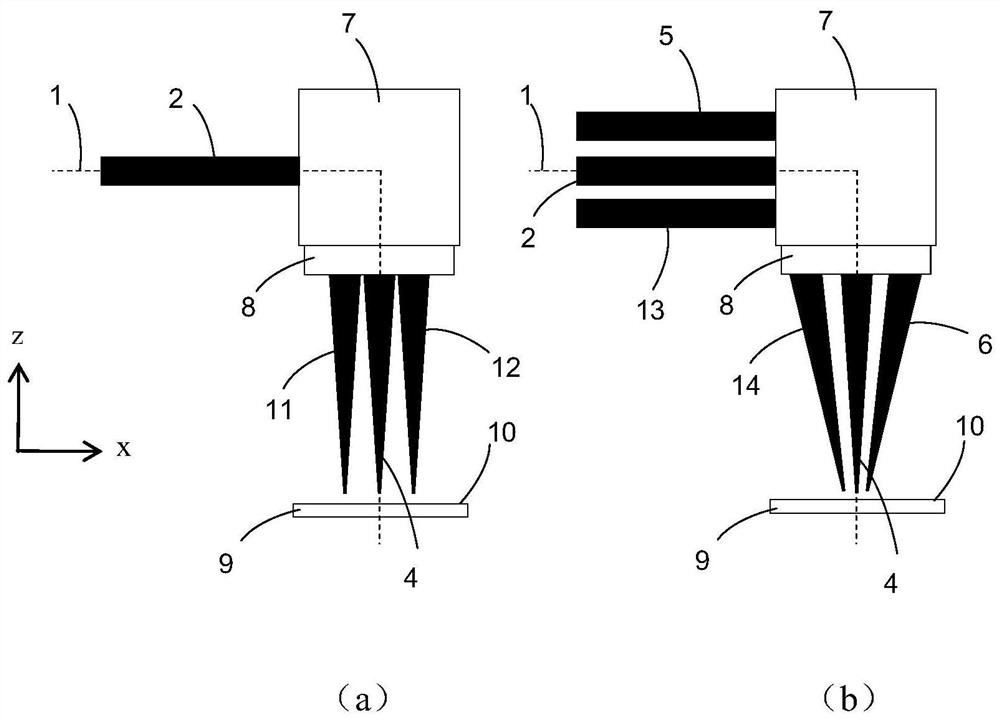

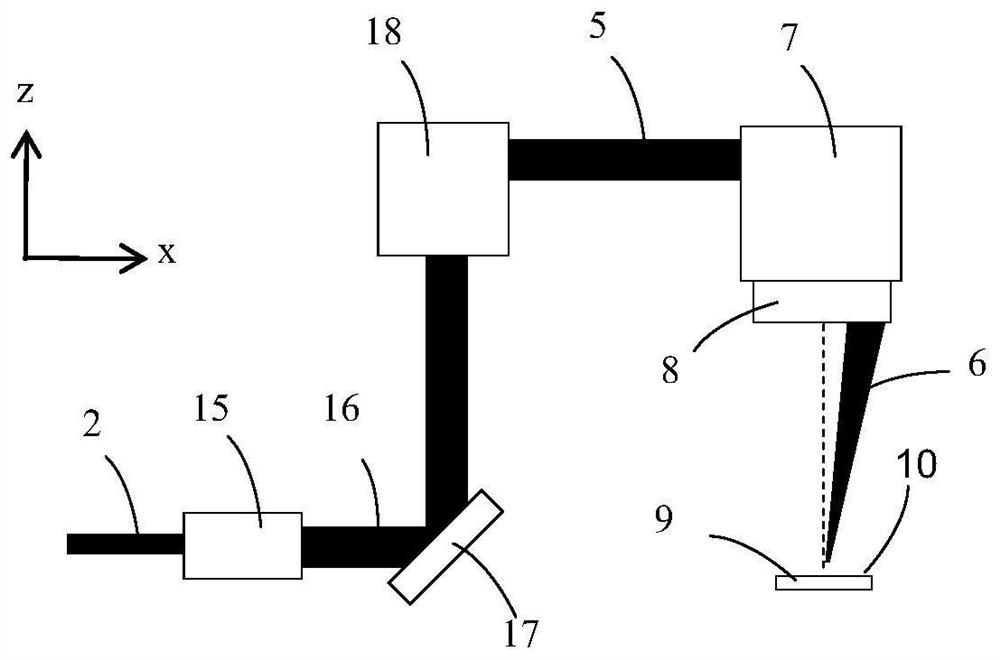

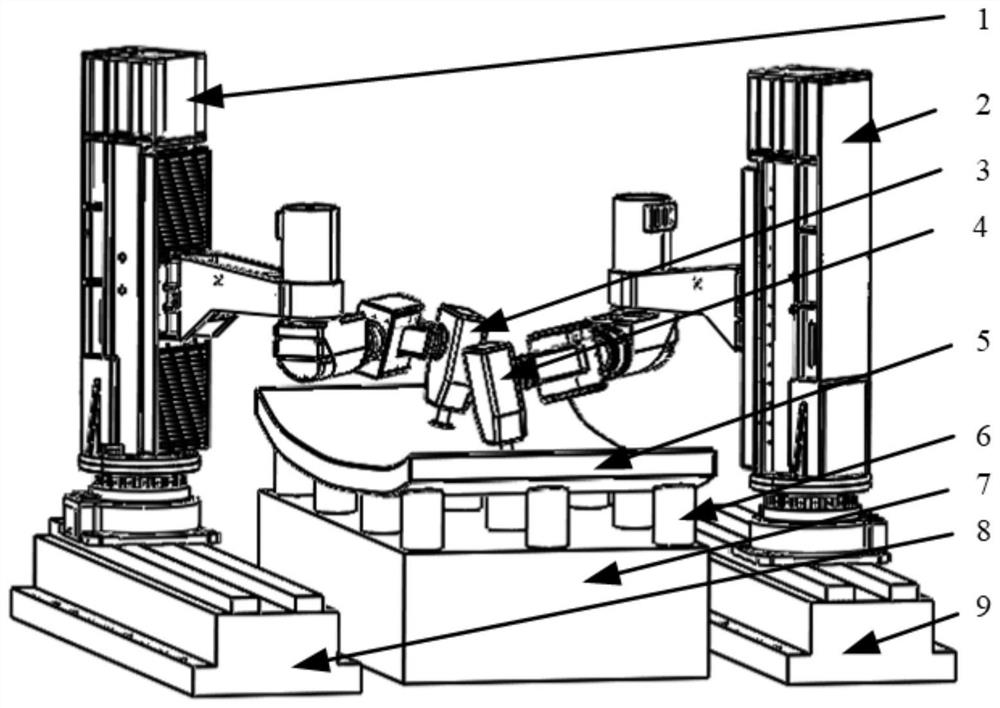

Multi-axis laser scanning optical system

ActiveCN113319425AIncrease the processing areaHigh Efficiency EtchingLaser beam welding apparatusLaser processingLight beam

The invention belongs to the field of laser processing, and discloses a multi-axis laser scanning optical system. The multi-axis laser scanning optical system comprises a dynamic focusing module (15), a light beam parallel translation module (18), a two-dimensional scanning module (7) and a focusing module (8), wherein the dynamic focusing module is used for controlling the diameter of a laser beam and the Z coordinate of the focus of the output laser, and the light beam parallel translation module is used for adjusting the projection position of the laser beam transmission direction on the Y axis and the projection position of the laser beam transmission direction on the Z axis. According to the system, the off-axis direction and the off-axis distance of the laser beam input to a two-dimensional scanning module along the Y axis and the Z axis can be regulated and controlled based on the principle that the included angle between the focused parallel off-axis laser beam and a focal plane can change, and the included angle alpha between the propagation direction of the output laser beam and the Y-axis direction and the included angle beta between the propagation direction and the X-axis direction are regulated and controlled, so that multi-axis regulation and control of the laser are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

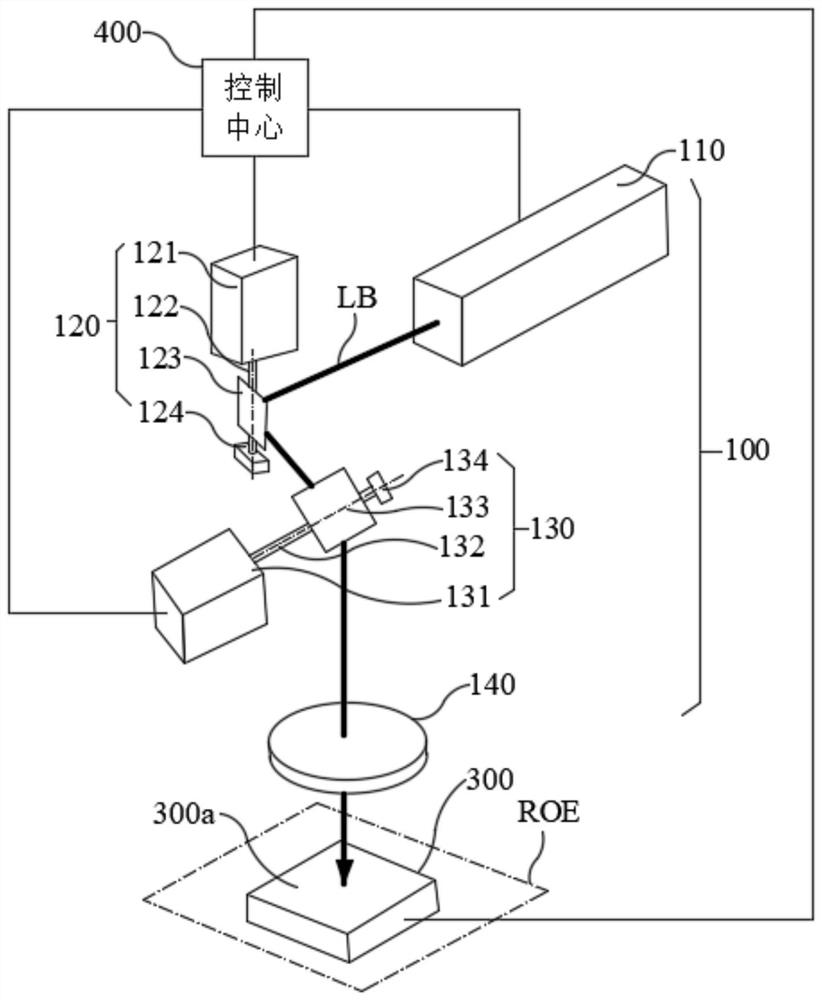

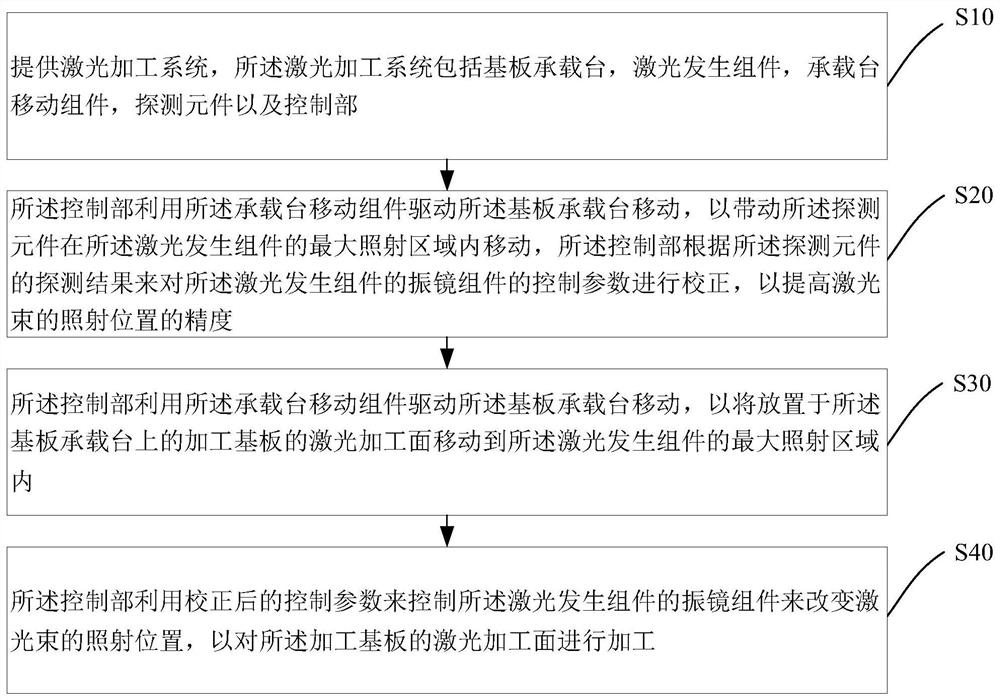

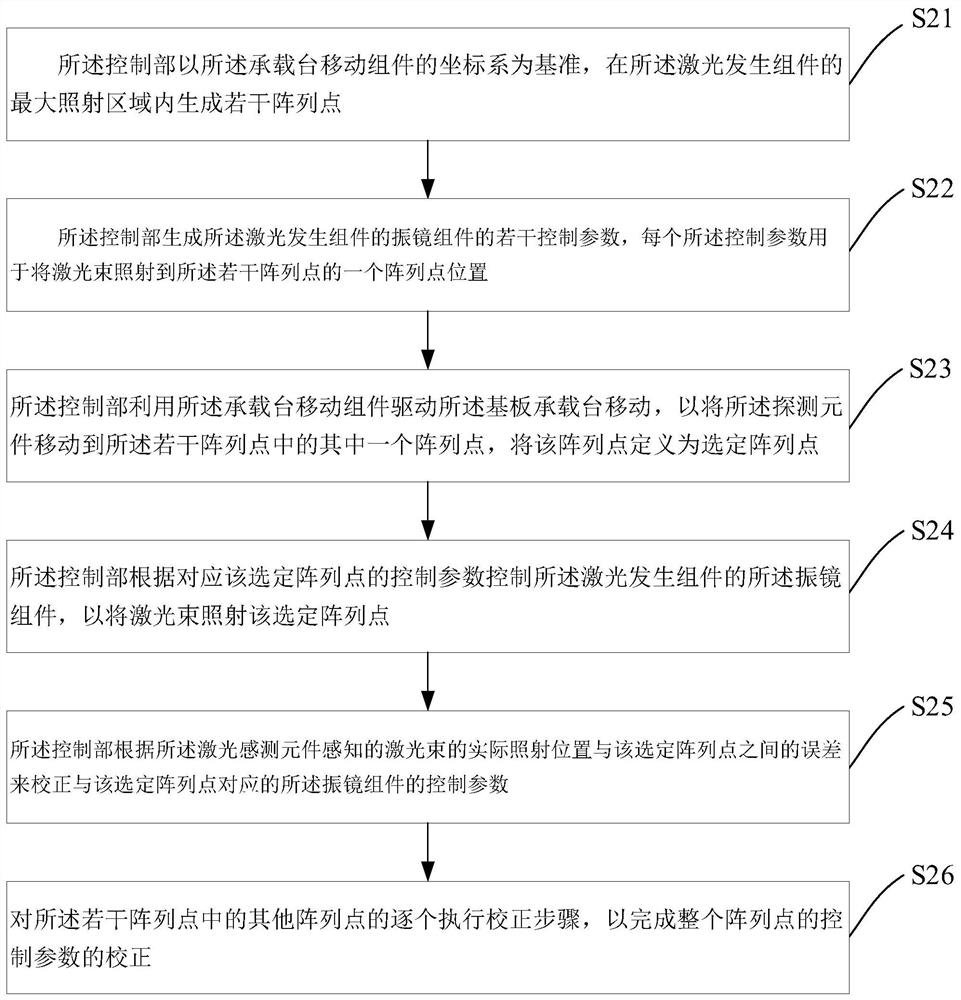

Laser processing system and laser processing method

InactiveCN111872564AHigh precisionImprove operational efficiencyLaser beam welding apparatusLaser processingLight sensing

The invention provides a laser processing system and a laser processing method. The laser processing system involves a base plate bearing table, a laser generation assembly, a bearing table moving assembly, a laser sensing element and a control part; the laser generation assembly is arranged on one side of the table board of the base plate bearing table and comprises a laser oscillator, a pair ofgalvanometer assemblies and a light condensing element, and the bearing table moving assembly is connected with the base plate bearing table; the laser sensing element is arranged and fixed on the outer side of the base plate bearing table, and a light beam sensing surface of the laser sensing element and the table board of the base plate bearing table are located on the same horizontal plane; andthe control part is connected with the laser generation assembly, the bearing table moving assembly and the laser sensing element, the control part utilizes the bearing table moving assembly to drivethe base plate bearing table to move so as to drive the laser sensing element to move in the maximum irradiation area of the laser generation assembly, and corrects control parameters of the galvanometer assemblies of the laser generation assembly according to a detection result of the laser sensing element. Therefore, the precision of irradiation positions of laser beams of the laser processingsystem is improved.

Owner:江苏亚威艾欧斯激光科技有限公司

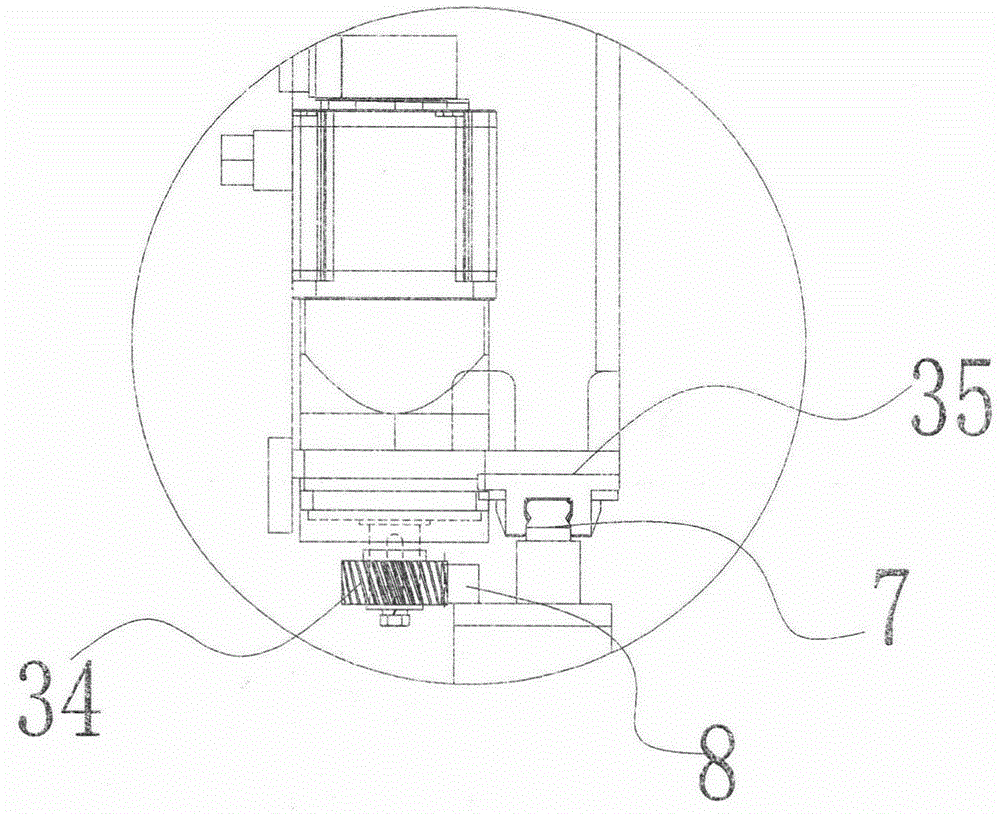

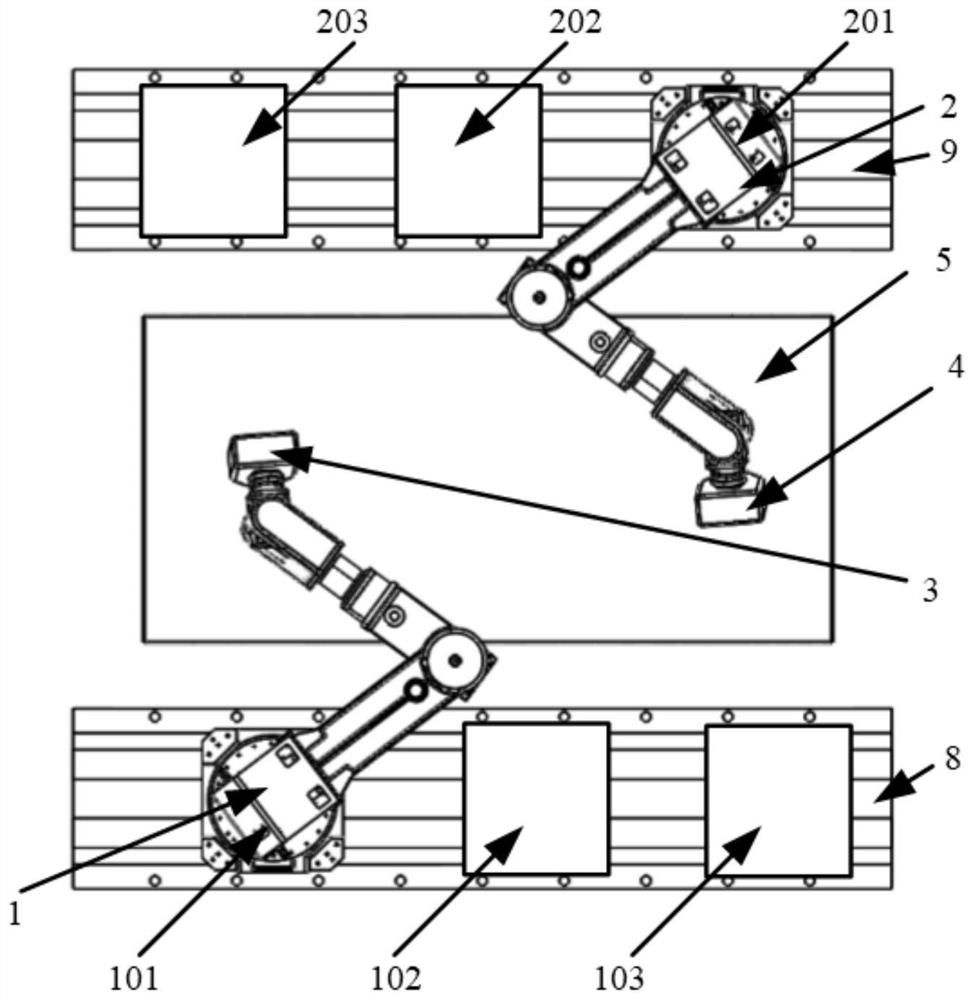

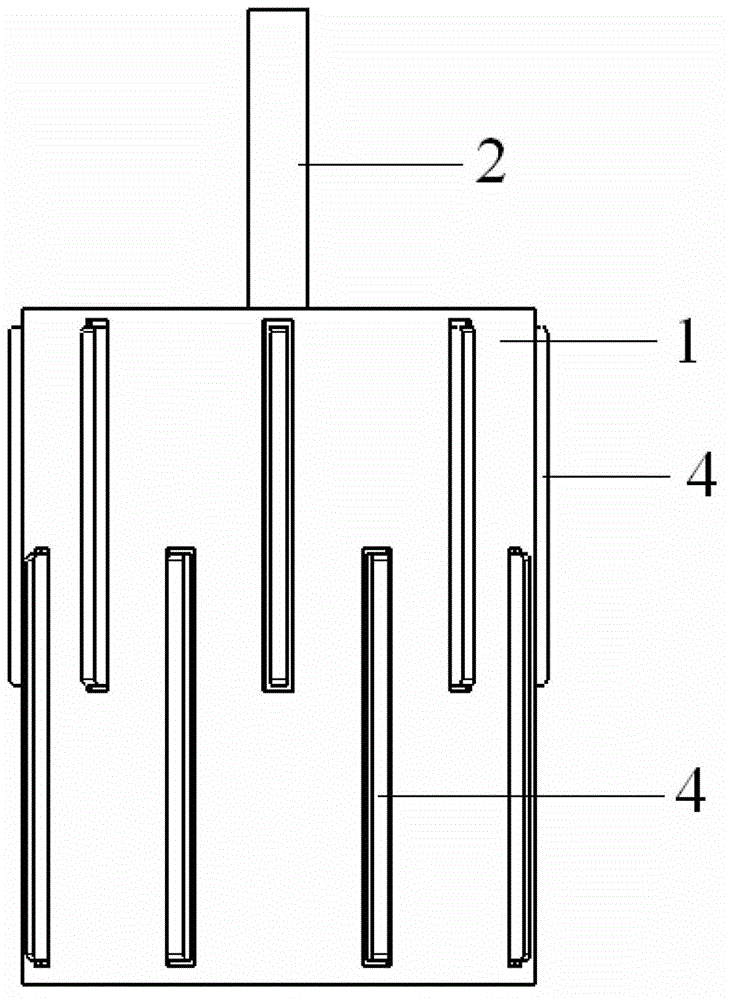

Push-pull type straight row tool magazine

PendingCN108311928AReduce volumeIncrease the processing areaPositioning apparatusMetal-working holdersHydraulic cylinderCoupling

The invention provides a push-pull type straight row tool magazine which comprises tool bases. The multiple tool bases are installed on a first supporting plate side by side. A first linear guide railis fixed to the bottom of the first supporting plate, a first sliding block paired with the first linear guide rail is fixed to a second supporting plate, a ball screw is fixed to the second supporting plate, a feed screw nut paired with the ball screw is fixed to the bottom of the first supporting plate, the ball screw is connected with a driving motor through a coupler, the bottom of the secondsupporting plate is provided with a second sliding block paired with a second linear guide rail, the second linear guide rail is perpendicular to the first linear guide rail and fixed to a tool magazine machine body, a hydraulic cylinder is further fixed to the tool magazine machine body, and the hydraulic cylinder is fixedly connected with the second supporting plate. The telescopic structural design is adopted, the tool magazine is pulled out of a machining area when a machine tool works, and stretches into the machining area during tool changing, the size of the tool magazine of the machine tool is greatly reduced, the tool replacing function is achieved, and the large machining area is ensured.

Owner:安徽普瑟斯智能科技股份有限公司

Overload protection mechanism applied to multi-axis numerical control machine tool

InactiveCN105904273AIncrease the processing areaDriving apparatusMetal working apparatusNumerical controlGear wheel

The invention discloses an overload protection mechanism applied to a multi-axis numerical control machine tool. The overload protection mechanism comprises a first gear, a second gear and a driven friction disc, wherein the first gear and the second gear are engaged with each other and arranged in a paired manner, and the driven friction disc is fixed to the first gear and is concentric with the first gear. A driving shaft is movably sleeved with the first gear through a bearing. The driving shaft is provided with an outer thread and connected with a screw nut through the outer thread in a threaded manner. The screw nut is fixedly connected with a baffle ring. The driving shaft is further sleeved with a driving friction disc matched with the driven friction disc. The driving shaft is provided with friction keyways formed in the axial direction of the driving shaft. The driving friction disc is matched with the friction keyways through keys so that the driving friction disc can move in the axis direction relative to the driving shaft. The driven friction disc is provided with friction protrusions / friction grooves. The driving friction disc is provided with friction grooves / friction protrusions matched with the driven friction disc. A first spring is mounted between the baffle ring and the driving friction disc.

Owner:张玲玲

A multi-axis CNC machine tool

The invention discloses a workpiece clamping mechanism capable of deflecting around the Z axis in the fixed direction at a fixed angel at a fixed rotation speed. The workpiece clamping mechanism comprises a bottom plate, a big bevel gear wheel, small bevel gear wheels, a chuck body and four claw discs, wherein the bottom plate is movably connected with a movable bracket and can rotate around the axis of the movable bracket, the big bevel gear wheel is movably connected with the bottom plate and can rotate around the axis of the bottom plate, the small bevel gear wheels matched with the big bevel gear wheel are mounted on the bottom plate, the chuck body is connected with the outer portion of the bottom plate and the big bevel gear wheel in a sleeving manner and fixed to the bottom plate, and the four claw discs are the same in size and slidably connected with the chuck body. The bottom plate is mounted between the big bevel gear wheel and a third sliding plate body. The central angle of the claw discs is 90 degrees, and the four claw discs can be spliced into a complete circle. An annular step which is concentric with the big bevel gear wheel and is connected with the center of the bottom plate is arranged on the big bevel gear wheel. The other end face of the center of the bottom plate is further connected with a rotary shaft in the Z axis direction, and a planar spiral groove is formed in the back of the big bevel gear wheel.

Owner:SHANDONG JONCA AUTOMATION TECH CO LTD

Processing method of laser marking machine

The invention relates to the technical field of laser marking, and discloses a machining method of a laser marking machine. The laser marking machine is composed of a control unit and a light path assembly arranged on the control unit through a lifting table. A 3D vertical supporting rotating device is arranged behind one end of the light path assembly and comprises a bottom frame, a stand column arranged on the bottom frame, a rotating device arranged at the top end of the stand column, pipe expanding devices arranged at the two ends of the rotating device and an expanding mechanism arranged below one pipe expanding device. Each pipe expanding device comprises a pipe expanding part. The machining method of the laser marking machine comprises the first step of equipment preparing, the second step of material matching, the third step of laser machining, the fourth step of material replacing and the fifth step of resetting shutdown. According to the machining method of the laser marking machine, it is guaranteed that the appearance effect of finished products is uniform, the product yield is increased, the machining method is simplified, and the machining efficiency is improved as a whole.

Owner:GBOS LASER INC

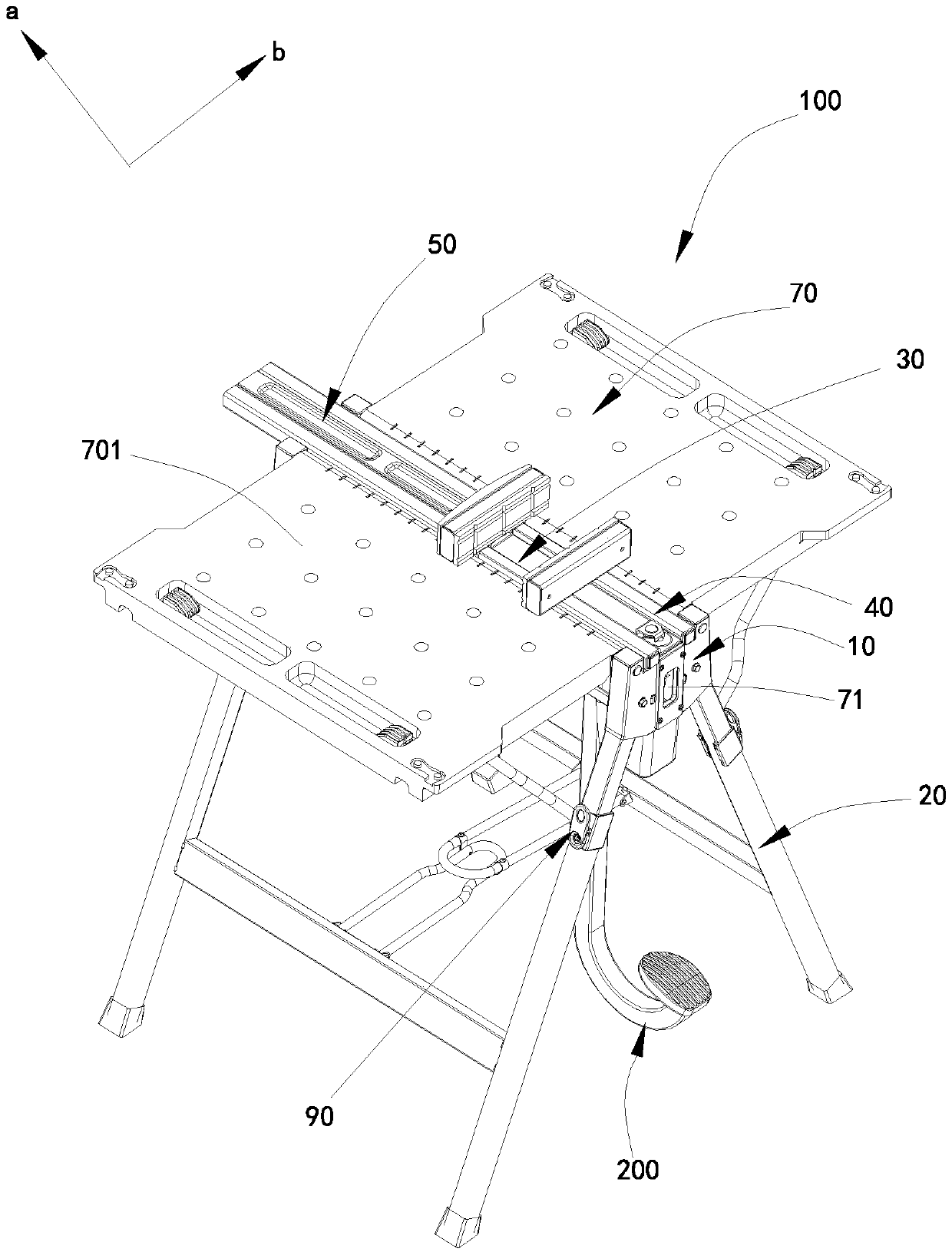

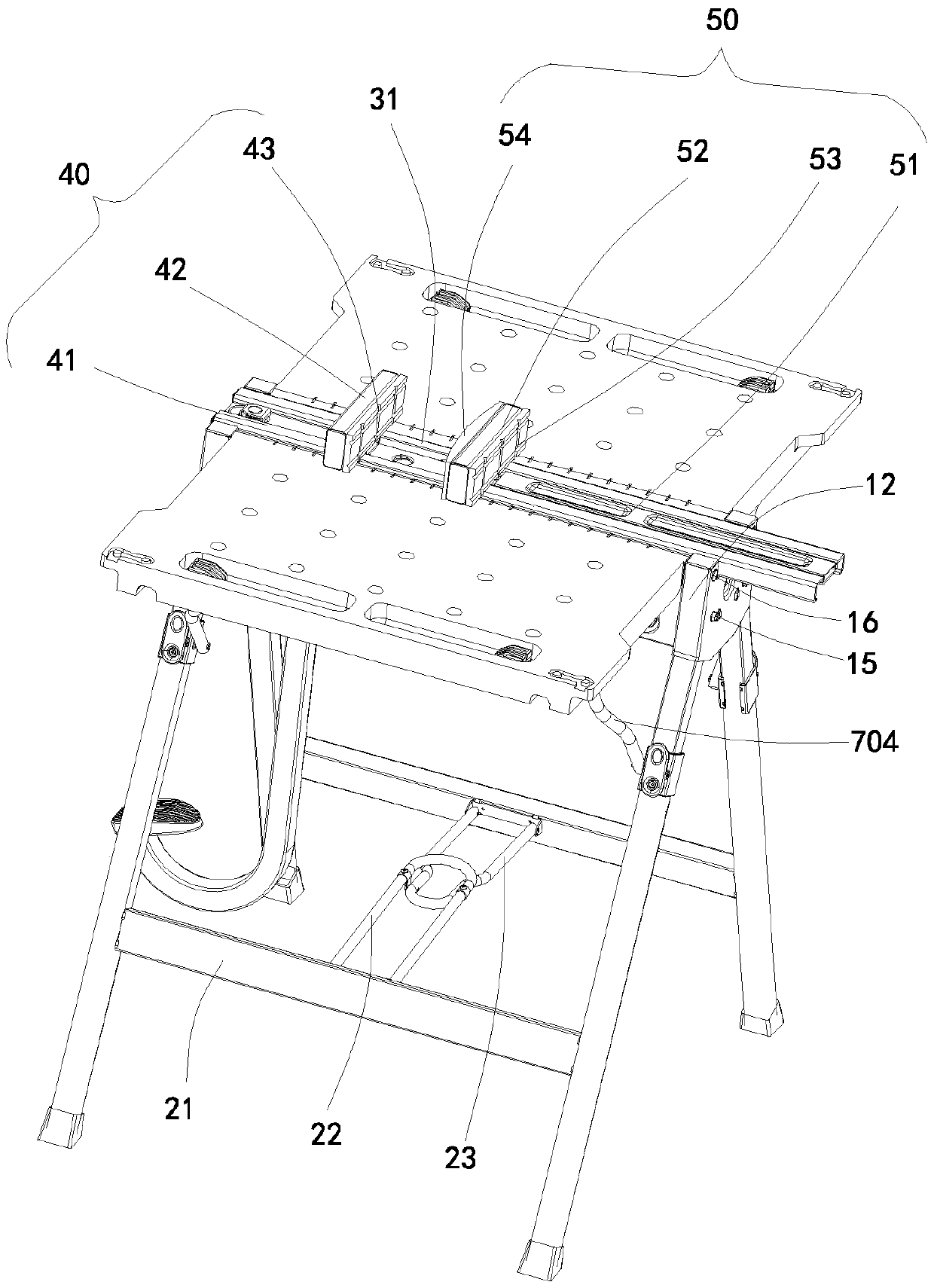

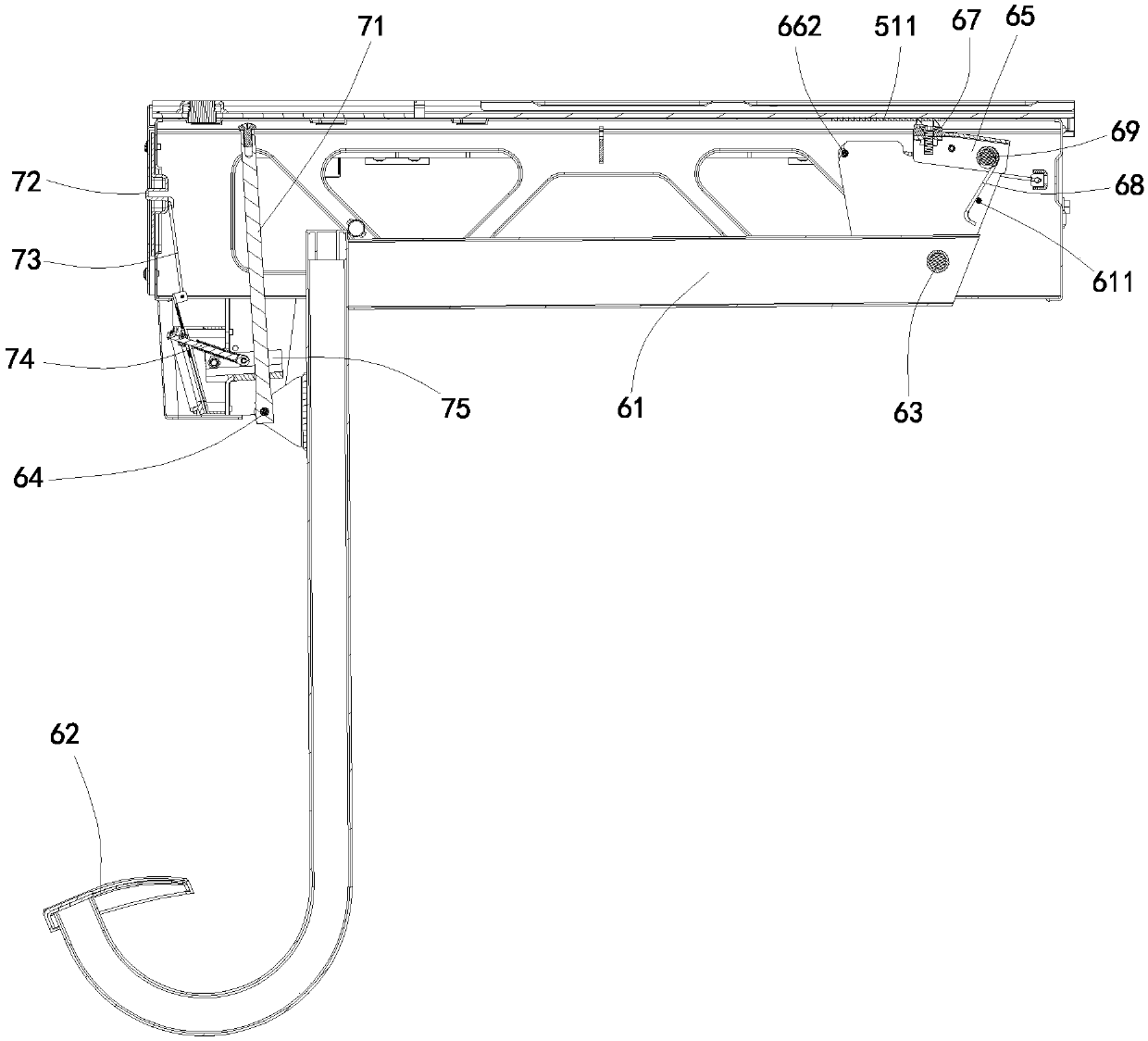

Clamping mechanism

InactiveCN110125887AGreat gripIncrease the processing areaMulti-purpose machinesWork benchesEngineeringWorking space

A clamping mechanism comprises a base, a plurality of supporting legs, a fixed guide rail, a first clamping part, a second clamping part and a driving mechanism, wherein the multiple supporting legs are connected with the base in a matched mode and support the base; the fixed guide rail is arranged on the base and is provided with a first surface opposite to the supporting legs; the first clampingpart is arranged on the fixed guide rail; the second clamping part is movably arranged on the fixed guide rail; and the driving mechanism drives the second clamping part to move towards the first clamping part in the direction close to the first clamping part so that a workpiece can be clamped. The clamping mechanism further comprises a workbench connected to the base. The workbench is provided with a working surface. The workbench can move between a working position and a non-working position. When the workbench is in the working position, the working surface is not lower than the first surface and is used for supporting the workpiece; and when the workbench is in the non-working position, the working surface is not higher than the first surface. The clamping mechanism provided by the invention is provided with an auxiliary supporting face, the workpiece is clamped through the first clamping part and the second clamping part, large-sized workpieces can be better supported through theauxiliary supporting face provided by the workbench, and clamping stability is guaranteed.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

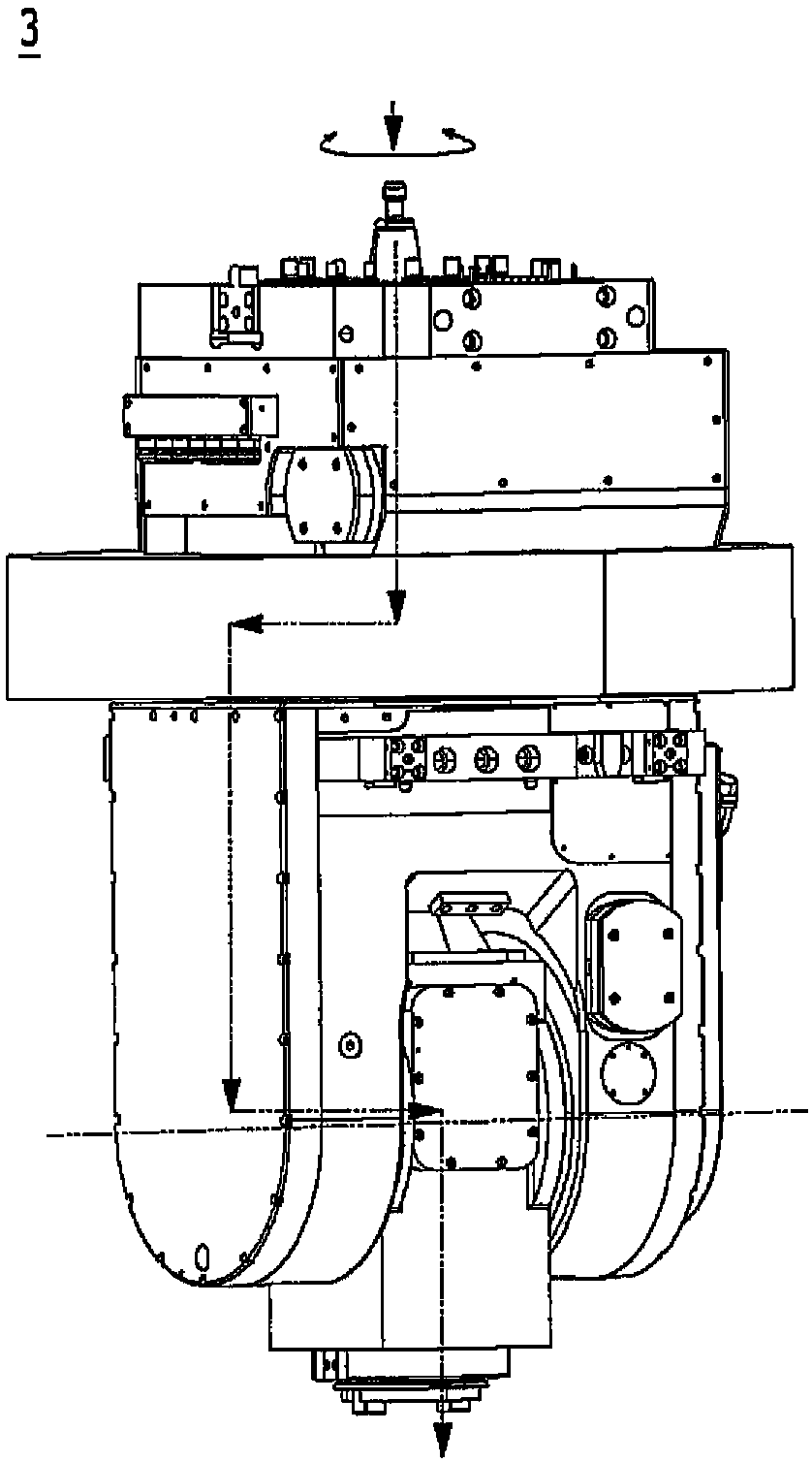

Universal spindle box device for machine tools

ActiveCN104690305BShorten the lengthReduce widthLarge fixed membersResidual vibrationMiniaturization

The invention relates to an all-powerful spindle box device used for a machine tool, and specifically relates to an all-powerful spindle box device used for a machine tool. The device uses a rotation which receives rotary power of a sliding block spindle to make a rotation main body portion rotate, uses an additional working unit which is used as a power source to make a spindle box part rotate, and uses an inclination unit to make vibration minimum when the spindle box part inclines. The all-powerful spindle box device can realize miniaturization and light weight, reduces backlash generated when the rotation rotates, so as to reduce reduction of flexible rigidity and residual vibration, and increases processing regions and processing precision.

Owner:DN SOLUTIONS CO LTD

Meat grinder for multi-stage food processing

InactiveCN108722609AIncrease the processing areaVersatileGrain treatmentsMeat processing devicesHinge angleEngineering

The invention provides a meat grinder machine for multi-stage food processing, comprising a housing, wherein the front side of the housing is provided with a mounting groove, a mounting hole 1 and a mounting hole 2, there are 4 mounting grooves, and the inside walls of the mounting grooves are connected with a sterilization button, a meat grinding button, a meat cutting button and a feed button respectively through screws, the inside walls of the mounting hole 1 and the mounting hole 2 are connected with a feeding door and a reclaiming door are respectively connected with through a hinge, andthere are 2 mounting holes 2, the top of the housing is provided with a mounting groove, and the water tank penetrates inside the mounting groove, the two sides of the housing are respectively weldedwith a motor box 1 and a motor box 2, and the inner side walls of the motor box 1 and the motor box 2 are respectively welded with a motor 3 and a motor 1 through a motor base. The meat grinder for multi-stage food processing has the advantages of novel design, simple operation and convenience in use.

Owner:广西鹿寨县越雅生物科技有限公司

Multi-robot precision machining system and method for large-aperture integral optical element

ActiveCN110732932BShorten the production cycleSave handling timeOptical surface grinding machinesLapping machinesOptical processingRobot machining

The invention discloses a multi-robot precision machining system and method for a large-diameter integrated optical element, including a robot machining system part and a modularized machining tool. The modular processing tool includes a grinding disc processing module, a polishing liquid supply recovery tool head module and a magneto-rheological polishing tool head module. The invention adopts low-cost but flexible and intelligent robots for processing, and realizes the processing of large-diameter integral optical elements with various curvatures through cooperative processing of multiple robots, and greatly improves the manufacturing efficiency of the optical elements. The highly integrated modular tool head enables the processing system to perform grinding, polishing and precision polishing and modification of large-diameter integral optical elements. One system completes the entire set of optical processing procedures, which greatly saves Manufacturing cost and cycle time of large aperture optical components.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

A cylindrical hole honing head device and its construction method

ActiveCN102744671BEvenly distributedUniform honing removal amountHoning toolsMechanical engineeringWall material

The invention relates to a perfect cylindrical hole honing head device and a structure method thereof. The device comprises a hollow cylindrical structure, a honing head rack, a feeding rod, oilstone bases and oilstones, base holes are peripherally and alternately arranged on the honing head rack in a staggered manner, the feeding rod is disposed in the center of the honing rack, the oilstone bases are mounted in the base holes, and the oilstones are fixed onto the oilstone bases. The structure method includes computing lengths of honing head stroke ranges and lengths of the oilstones which correspond to various curves; computing mutual position relation among the oilstones; and designing and manufacturing the honing head device with the oilstone distribution meeting a result of the last step. The distribution of the oilstones and acting areas of the oilstones are adjusted, and effects that tracks of grains are generally distributed uniformly and honing quantity of wall materials of the cylinder hole tends to be uniform are achieved.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com