Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Increase separation force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

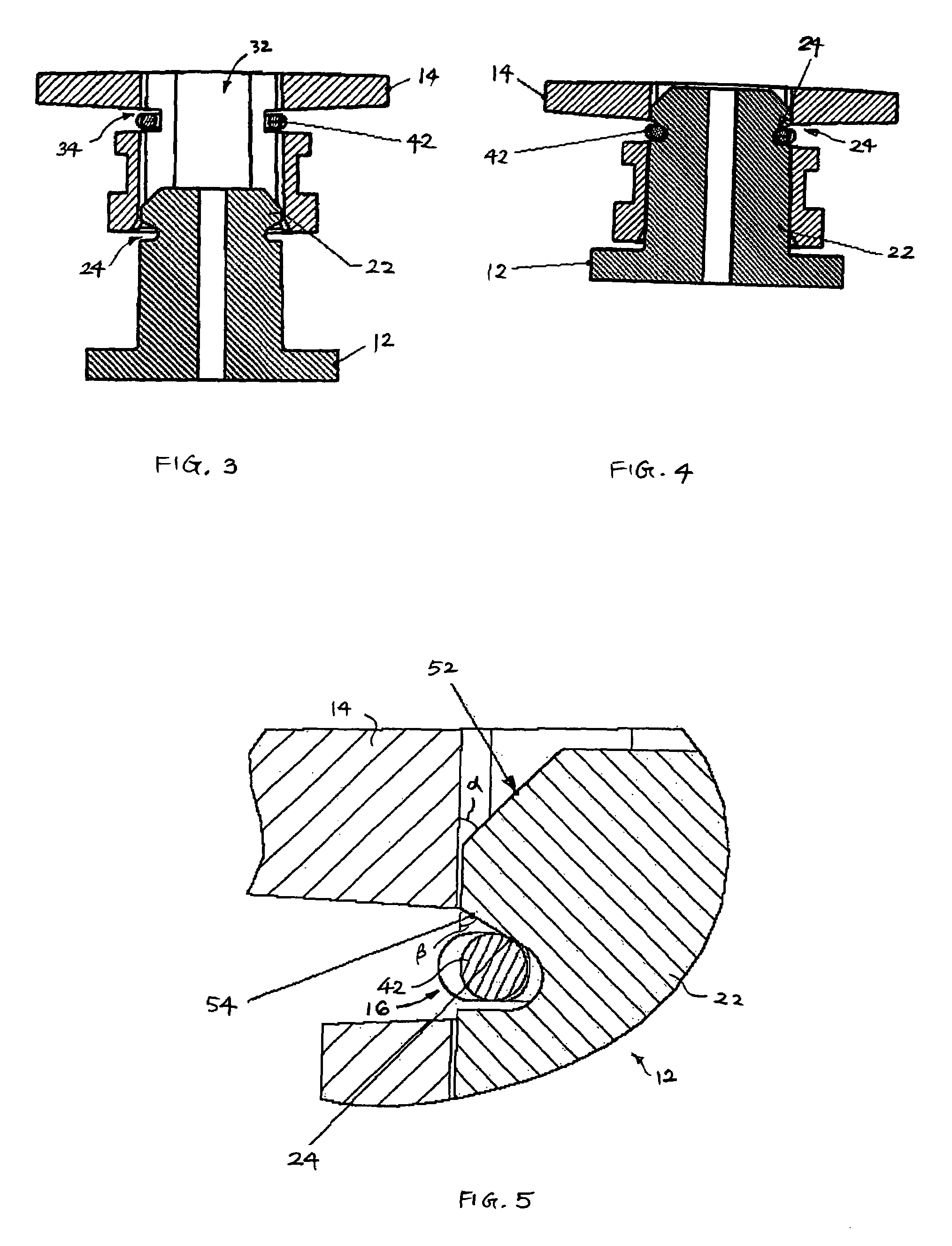

Enclosed Needle Device with Duckbill Release Mechanism

InactiveUS20070191776A1High separation forceEasy to compressInfusion syringesCatheterNeedle catheterCatheterization device

Owner:SMITHS MEDICAL ASD INC

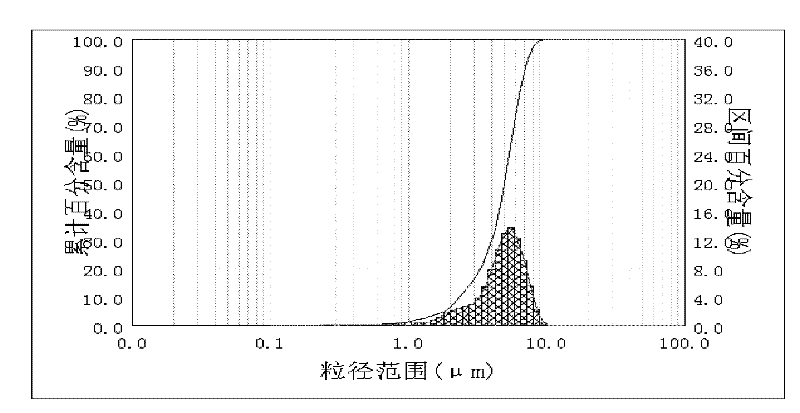

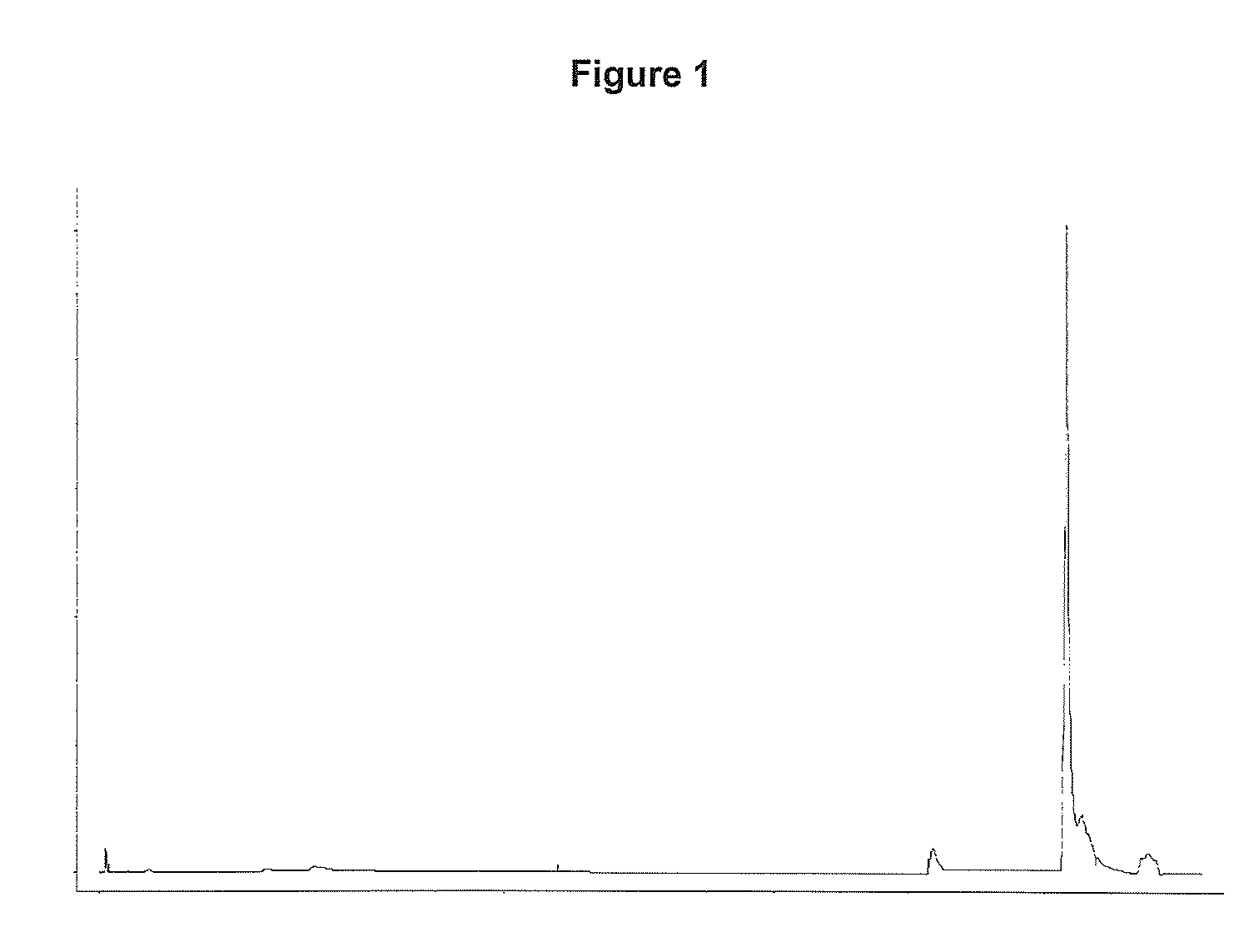

Method for producing rice starch by adopting enzyme method and product obtained by using method

The invention relates to a method for improving the extraction rate of rice starch produced by using an enzyme method. The method comprises the steps of broken rice pretreatment, pulping, enzyme reaction, cyclone washing, dehydration, air flow drying and the like. The invention also relates to the rice starch obtained by the method. The starch granules are small, the starch has uniform granularity (2 to 8 microns) and complete structure, the protein content is less than or equal to 0.35 percent, the quality of the starch reaches American food and drug administration (FDA) standards, the extraction rate of the starch is more than or equal to 90 percent, and the starch can be widely applied in the industries of cosmetics, pharmacy, food, chemical industry and the like.

Owner:JIANGNAN UNIV

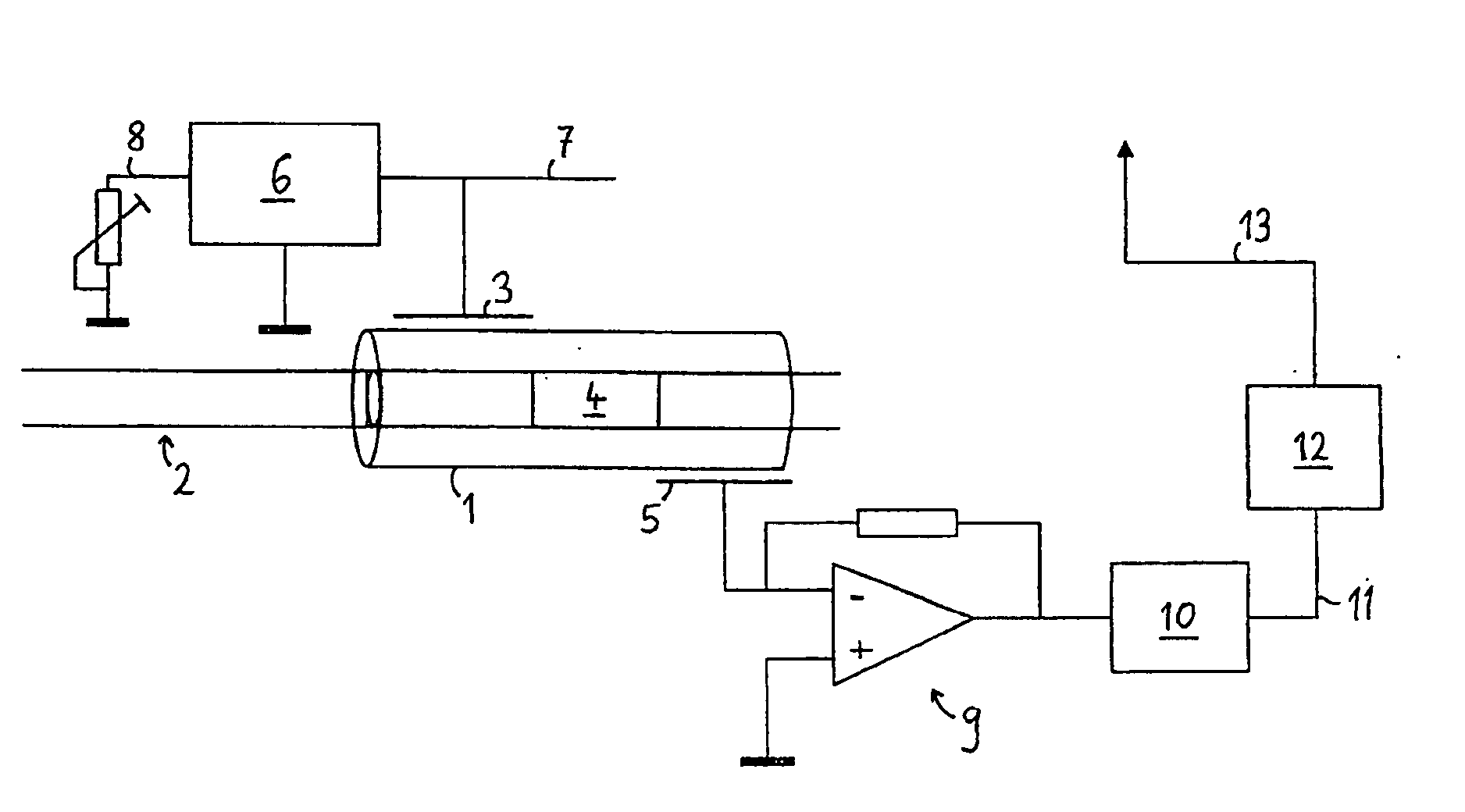

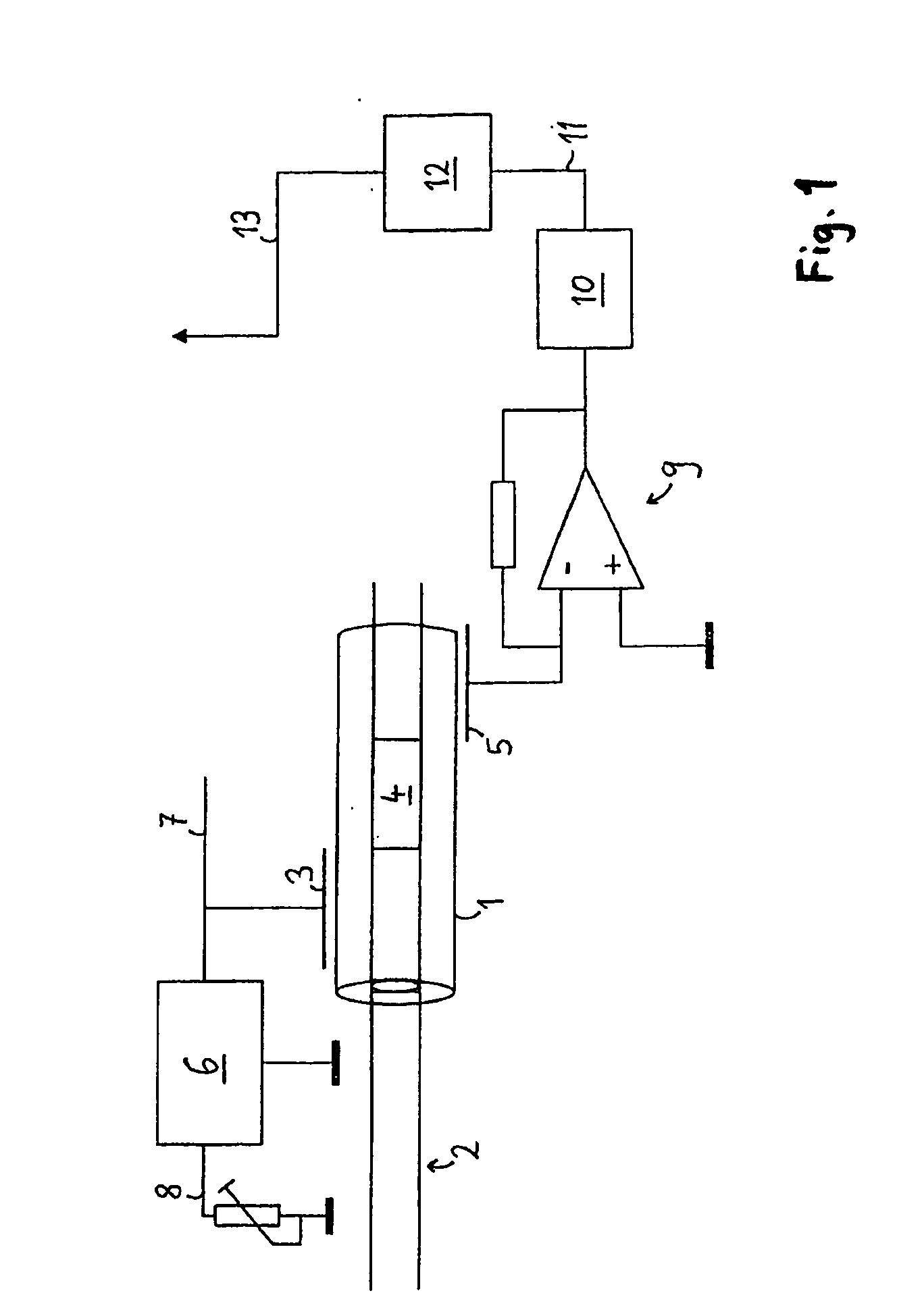

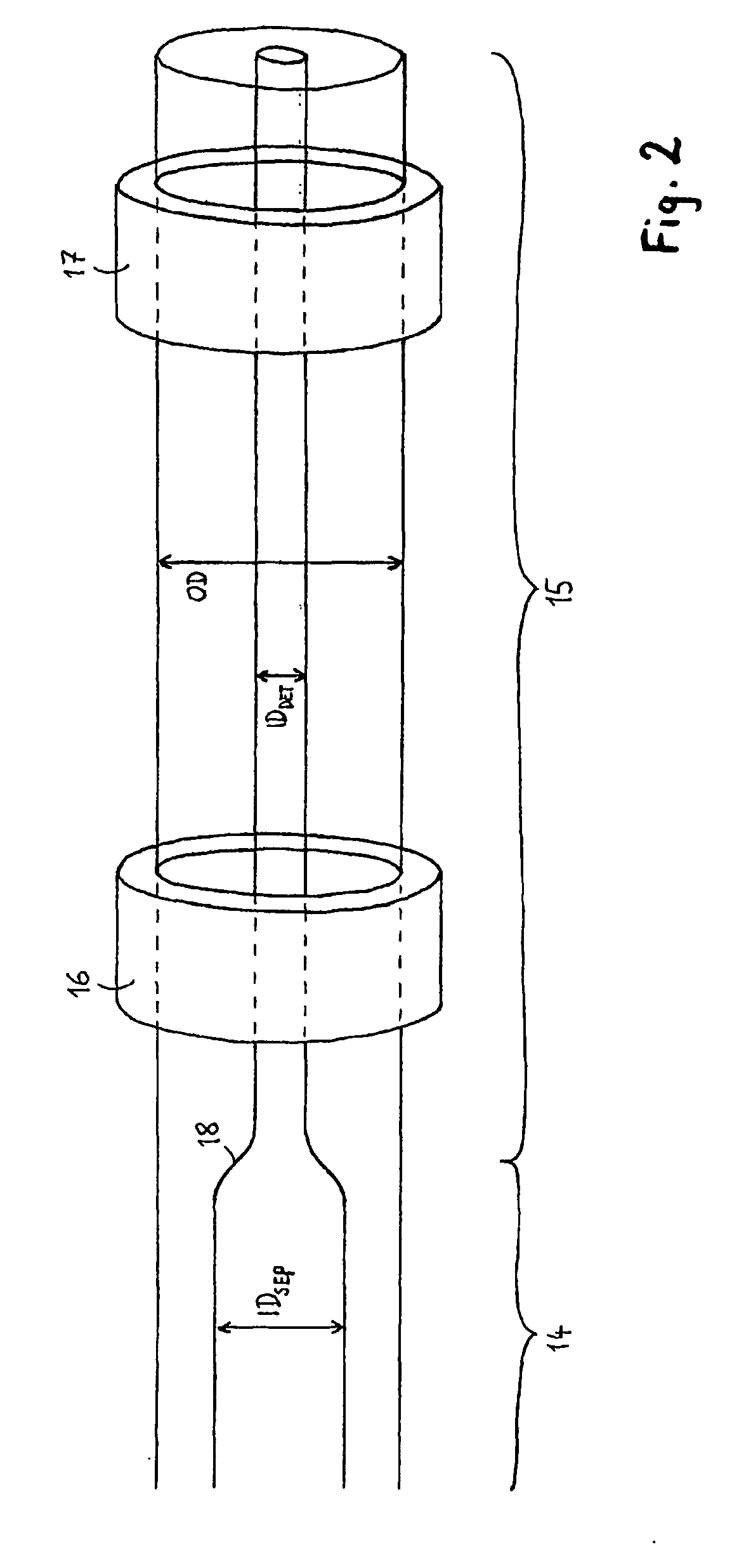

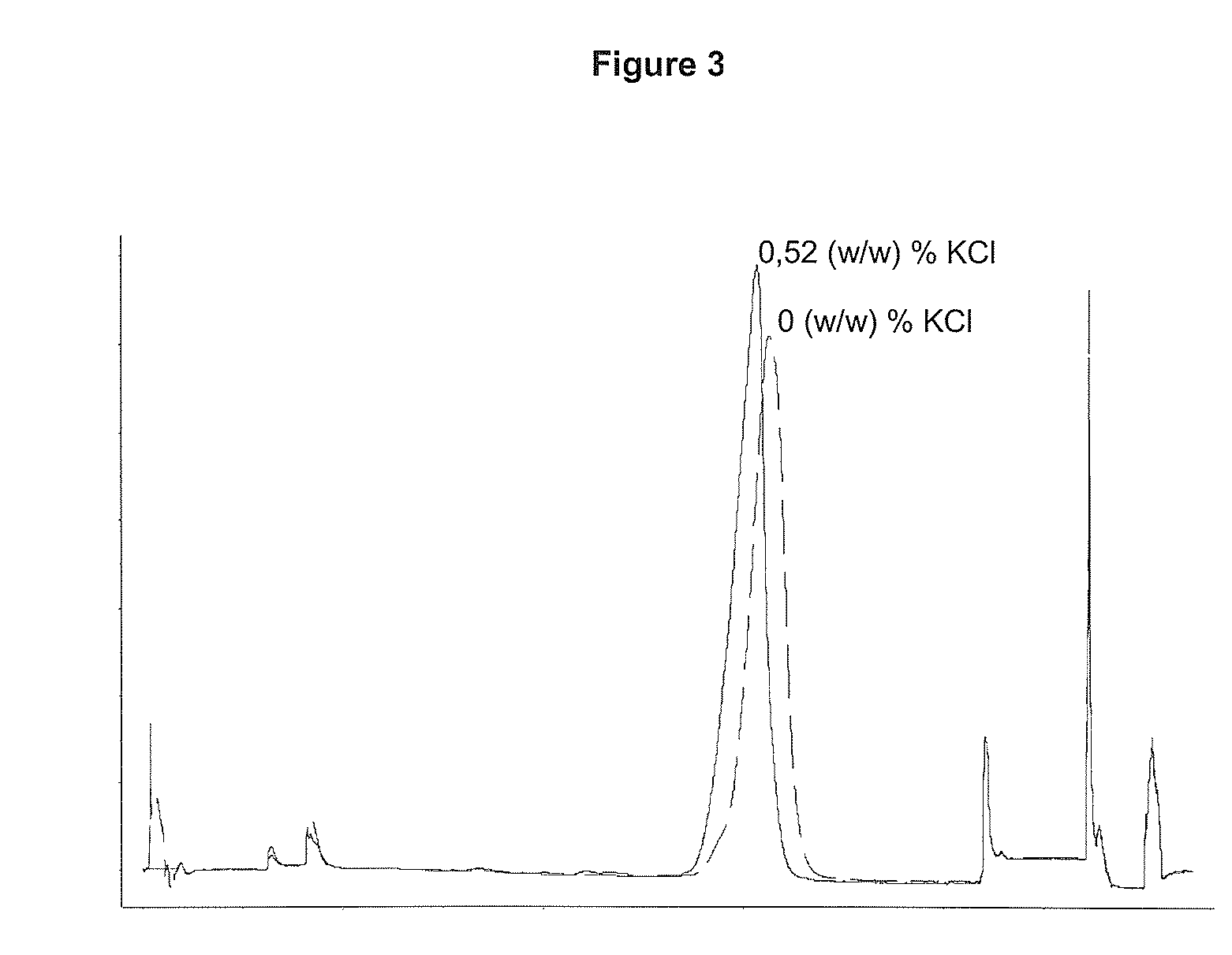

Contactless detection cell with reduced detection channel cross-section

InactiveUS20090201035A1Improve propertiesIncrease separation forceSamplingComponent separationCapacitanceCapacitive coupling

A contactless detection cell (1) for detecting an electrical property of one or more sample compounds in a flow path is described. The contactless detection cell (1) comprises a transmitter electrode (3) adapted for capacitively coupling an AC current into a detection channel (4) of the flow path, and a receiver electrode (5) adapted for receiving the AC current that has been coupled into the detection channel (4). An inner cross-section (IDDET) in at least a section of the detection channel is different than an inner cross-section (IDSEP) of the flow path (2) towards the detection channel (4).

Owner:AGILENT TECH INC

Exhaust gas and gas scrubber fluid cleaning equipment and method

ActiveUS20130037493A1Minimization requirementsReduce decreaseIon-exchanger regenerationExhaust apparatusEngineeringProduct gas

Exhaust gas cleaning equipment including a gas scrubber and a scrubber fluid cleaning equipment for cleaning polluted scrubber fluid. The scrubber fluid cleaning equipment includes a centrifugal separator for separating at least a pollutant phase and a cleaned scrubber fluid from said polluted scrubber fluid. The centrifugal separator has a rotor enclosing a separation space with a stack of separating discs, a separator inlet for polluted scrubber fluid extending into said separation space, a first separator outlet for cleaned scrubber fluid extending from said separation space, and a second separator outlet for the pollutant phase extending from said separation space.

Owner:ALFA LAVAL CORP AB

Purification of proteins using preparative reverse phase chromatography (RPC)

InactiveUS20090036652A1Increase separation forceColony-stimulating factorDepsipeptidesIndustrial scaleReversed-phase chromatography

The present invention provides a method for industrial-scale protein separation by reverse phase chromatography by use of a buffer system and an additional salt.

Owner:NOVO NORDISK AS

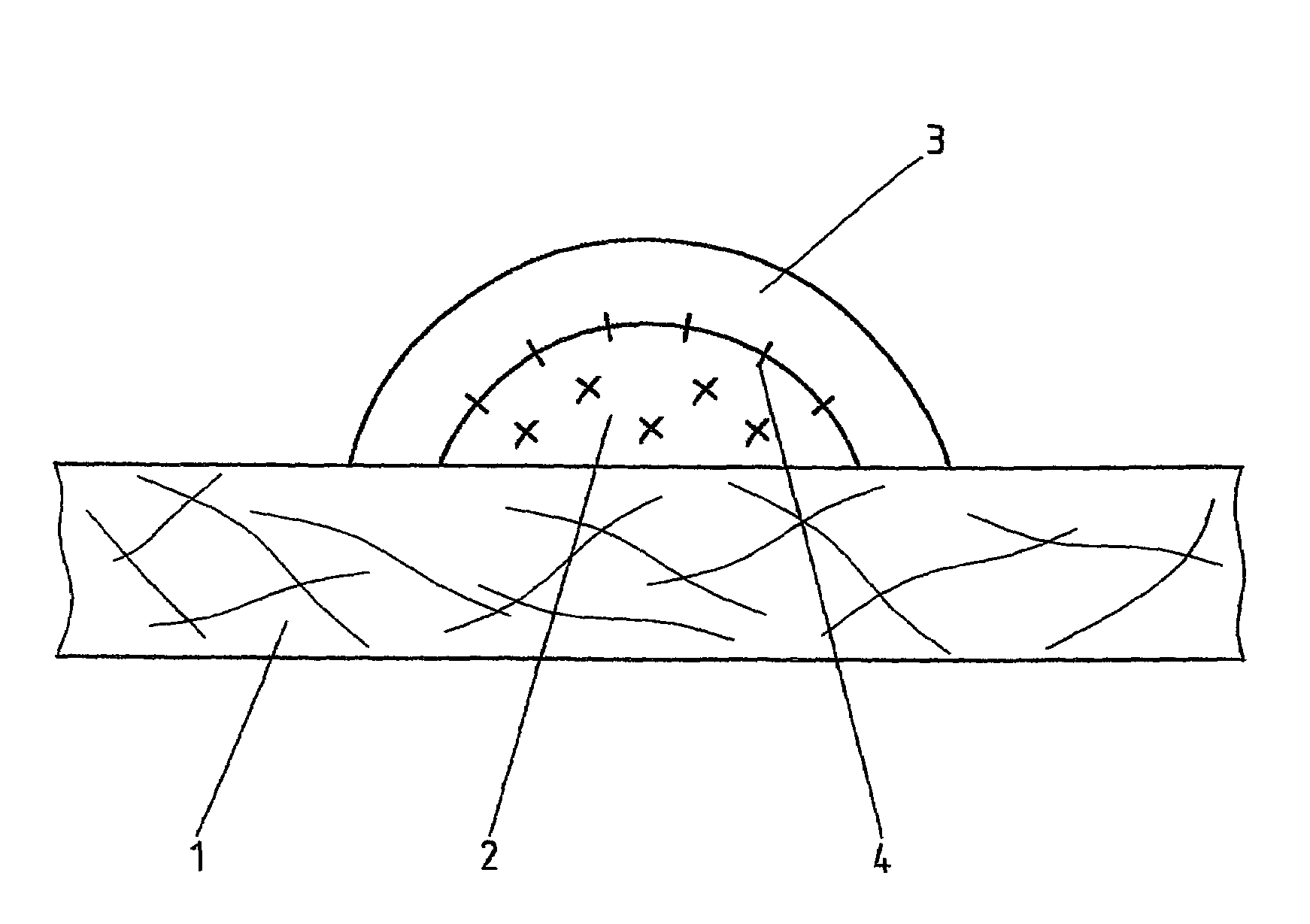

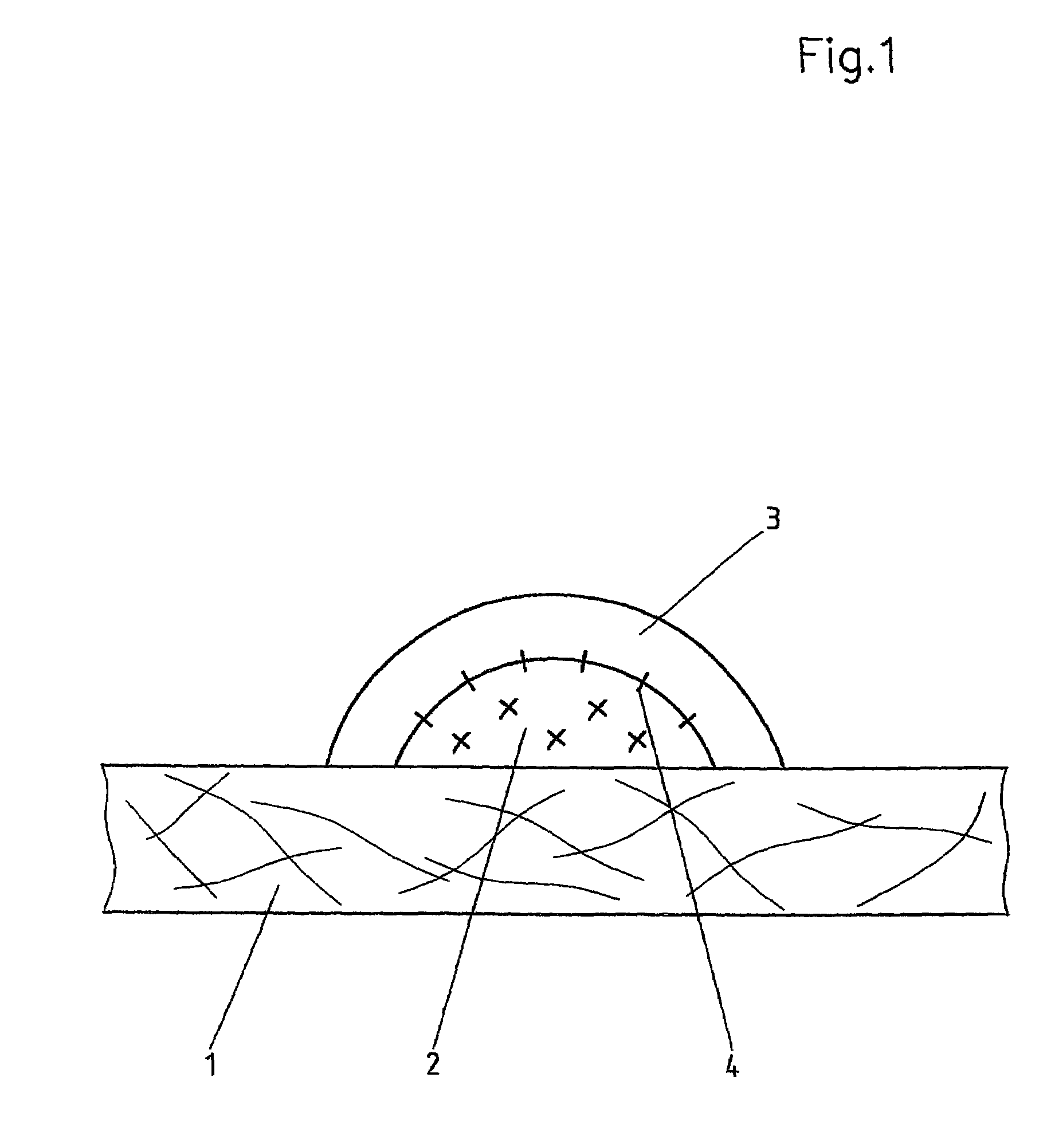

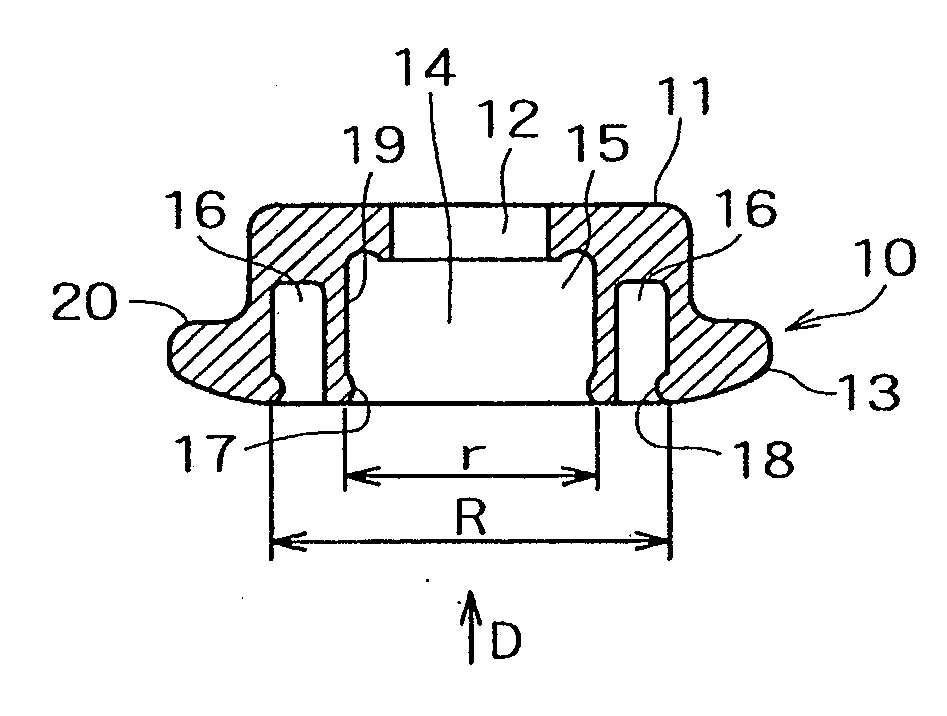

Fusible interlining

InactiveUS6986935B2Improve adhesionIncrease separation forceFilm/foil adhesivesDecorative surface effectsInterliningEpoxy

A fusible interlining includes a textile interlining web coated with a plurality of double-layered adhesive dots on a first side of the textile interlining web. Each of the plurality of double-layered adhesive dots includes a bottom dot facing the interlining web and an upper dot disposed above the bottom dot. Each bottom dot includes a binder paste containing 50 to 95 percent by weight of an acrylate binder dispersion having a glass transition temperature Tg<room temperature and 5 to 50 percent by weight of a substance that is one of an epoxy resin having an epoxy equivalent weight of 500 to 4000 mVal / kg and a copolymer of acrylates and monomers with at least one glycidyl side group. Each bottom dot may further include 0 to 20 percent by weight of a hardener. Each upper dot includes at least one of a copolyamide, a copolyester, a thermoplastic polyurethane and a polyolefin. A ratio of a mass of the bottom dot to a mass of the upper dot is from 1:0.5 to 1:5.

Owner:CARL FREUDENBERG KG

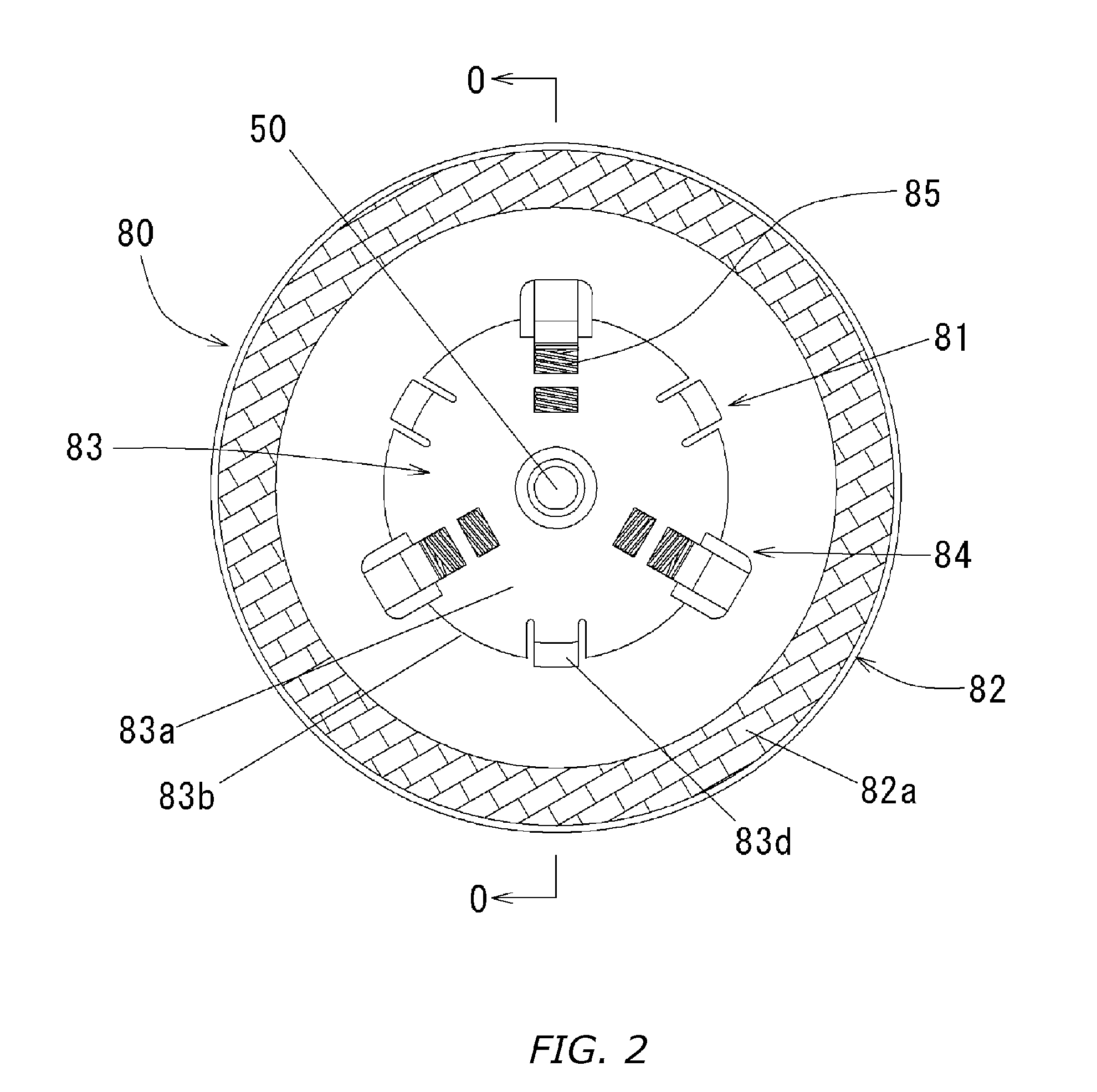

Chucking apparatus and recording disk drive motor having chucking apparatus

ActiveUS7360227B2Increase separation forceIncreased durabilityRecord information storageFlat record carrier containersDrive motorEngineering

Owner:NIDEC CORP

Oilfield poly-surfactant flooding sewage treatment process

InactiveCN103011474AShorten oil-water separation timeShort stayMultistage water/sewage treatmentFilter materialOil field

The invention discloses an oilfield poly-surfactant flooding sewage treatment process, solving the problems that the conventional settling and filtering process is long in running time, large in floor area, high in investment cost and the like. The oilfield poly-surfactant flooding sewage treatment process comprises the following specific steps: 1, performing stabilizing regulation on water quality and water amount of inflowing water by using an inflowing water buffer tank; 2, removing oil slick and most of dispersed oil from water by using a primary swirling static flotation column; 3, mixing outflowing water obtained in the step 2 with a flotation agent through a pipeline, entering a secondary swirling static flotation column, and further removing the dispersed oil, emulsified oil and suspended solids from water; and 4, sending the sewage treated in the step 3 into a two-stage double-filtering material filter, filtering till and the treated sewage reaches a pouring standard for a high-permeability strata, namely the oil content is less than or equal to 20mg / L, the suspended solid content is less than or equal to 20mg / L and the median particle size is less than or equal to 5 microns. By the oilfield poly-surfactant flooding sewage treatment process, the oil removing time is greatly shortened, the floor area is reduced, only a little of flotation agent is added in a running process, the maintenance is simple, and the outflowing water is stable and qualified.

Owner:PETROCHINA CO LTD +2

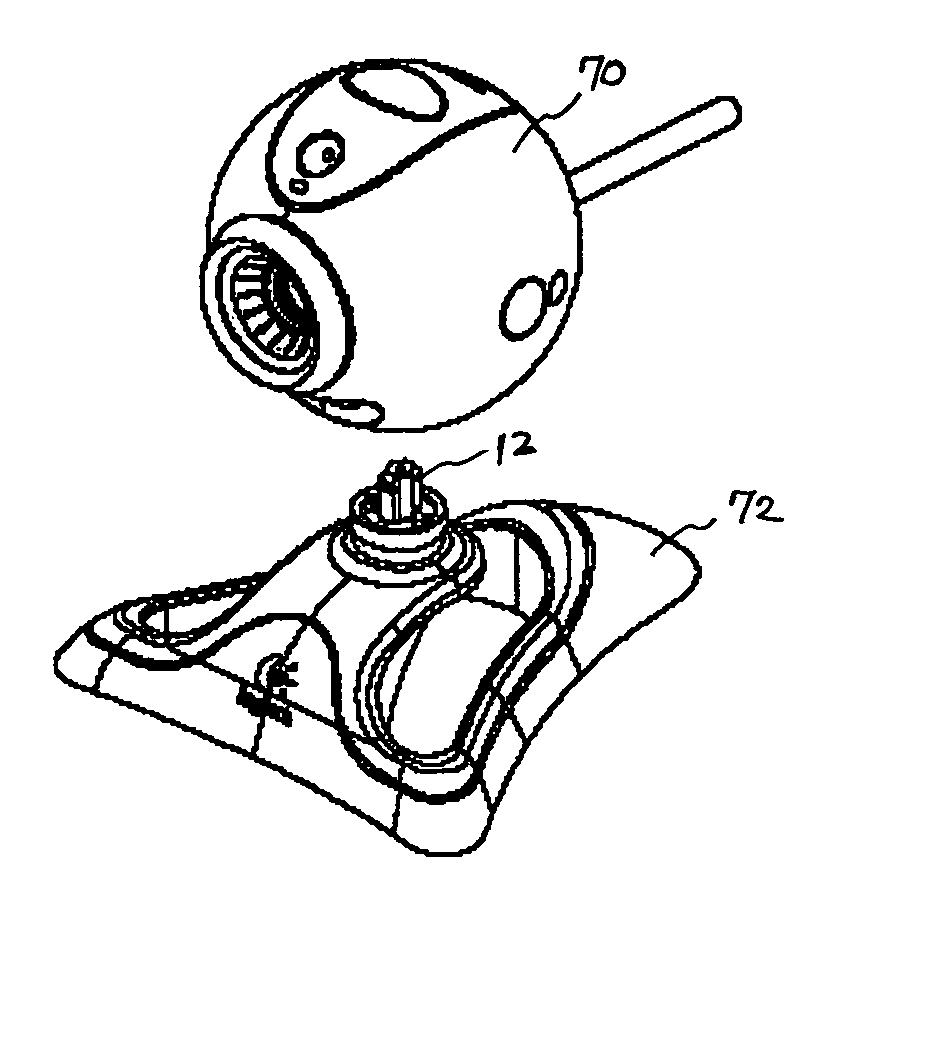

Spring loaded attachment mechanism for camera and base

InactiveUS7374351B2Reduce adhesionIncrease separation forceTelevision system detailsColor television detailsEngineeringMechanical engineering

Owner:LOGITECH EURO SA

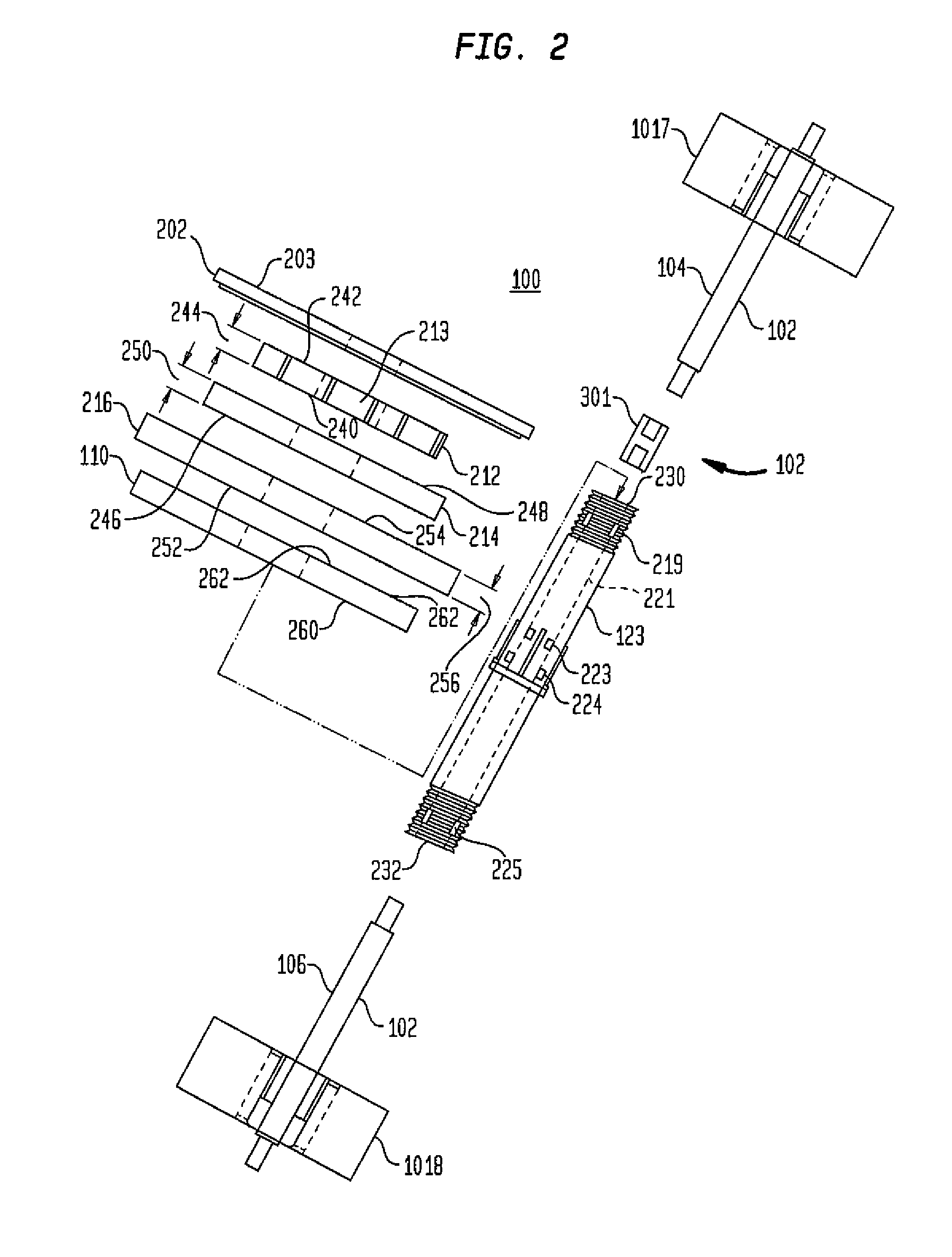

Device and Method For Particle Separation

InactiveUS20110120303A1Increasing centrifugal pressureEasy to separateCombination devicesGas treatmentParticle separationChemistry

A separation device with a gas inlet port that accepts an inlet gas. The inlet gas is composed of a mixture of at least two separable particle components with each component having a different mass. A rotating separation rotor accepts the inlet gas and uses a separator to substantially separate the gas according to mass into two fractions, a heavier and a lighter fraction. One of the fractions is passed to a second separator that further separates that fraction into another two fractions consisting of heavier and lighter fractions. The desired fractions are collected and exhausted from the separation device for use.

Owner:TENOROC

Exhaust gas and gas scrubber fluid cleaning equipment and method

ActiveUS9266055B2Improve the environmentMinimization requirementsIon-exchanger regenerationExhaust apparatusExhaust fumesEngineering

Exhaust gas cleaning equipment including a gas scrubber and a scrubber fluid cleaning equipment for cleaning polluted scrubber fluid. The scrubber fluid cleaning equipment includes a centrifugal separator for separating at least a pollutant phase and a cleaned scrubber fluid from said polluted scrubber fluid. The centrifugal separator has a rotor enclosing a separation space with a stack of separating discs, a separator inlet for polluted scrubber fluid extending into said separation space, a first separator outlet for cleaned scrubber fluid extending from said separation space, and a second separator outlet for the pollutant phase extending from said separation space.

Owner:ALFA LAVAL CORP AB

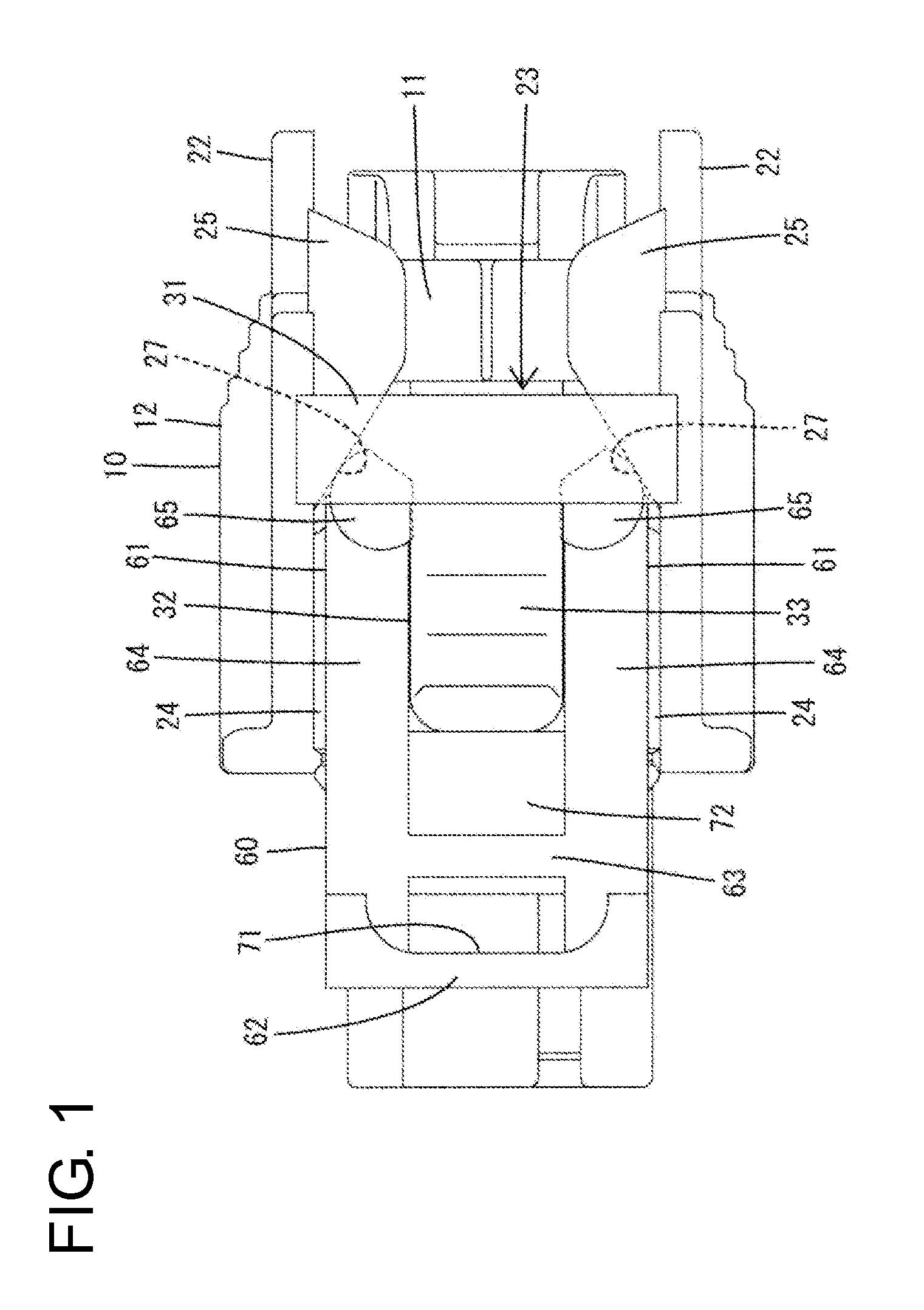

Connector

ActiveUS9431777B2Inhibition releaseImprove reliabilityIncorrect coupling preventionEngineeringElectrical and Electronics engineering

A detector (60) configured to be pressed and moved by a second housing (40) in the process of connecting first and second housings (10, 40) and separate the second housing 40 from the first housing (10) when a connecting operation of the first and second housings is stopped halfway is mounted on the first housing (10). The detector (60) integrally includes a resilient arm (61) configured to apply a separation force to the second housing (40) in a direction to separate the second housing (40) from the first housing (10) by sliding on a guiding surface (27) in one of the first and second housings (10, 40) to be deflected and deformed in a direction intersecting a connecting direction of the first and second housings (10, 40) in the process of connecting the first and second housings (10, 40).

Owner:SUMITOMO WIRING SYST LTD

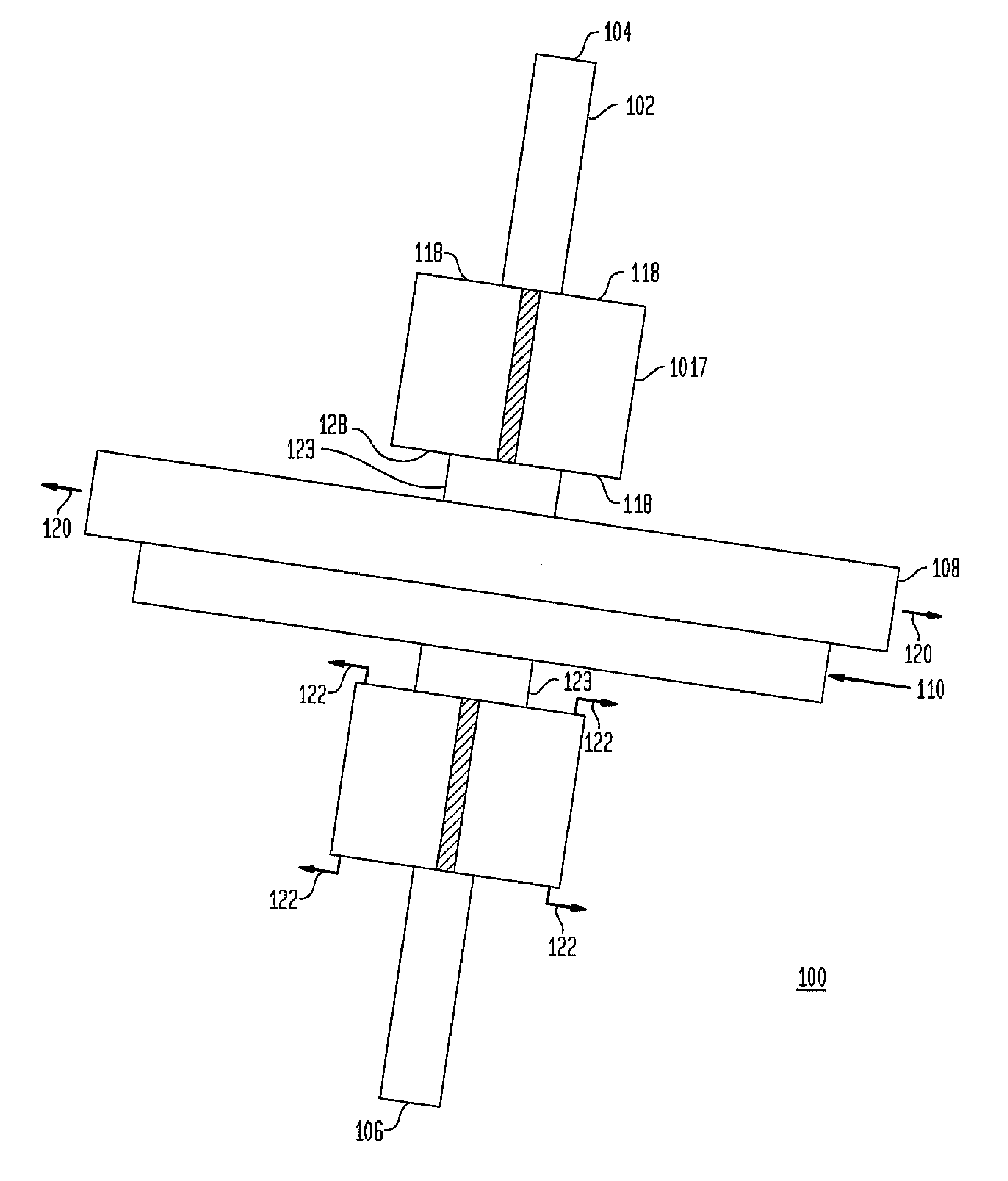

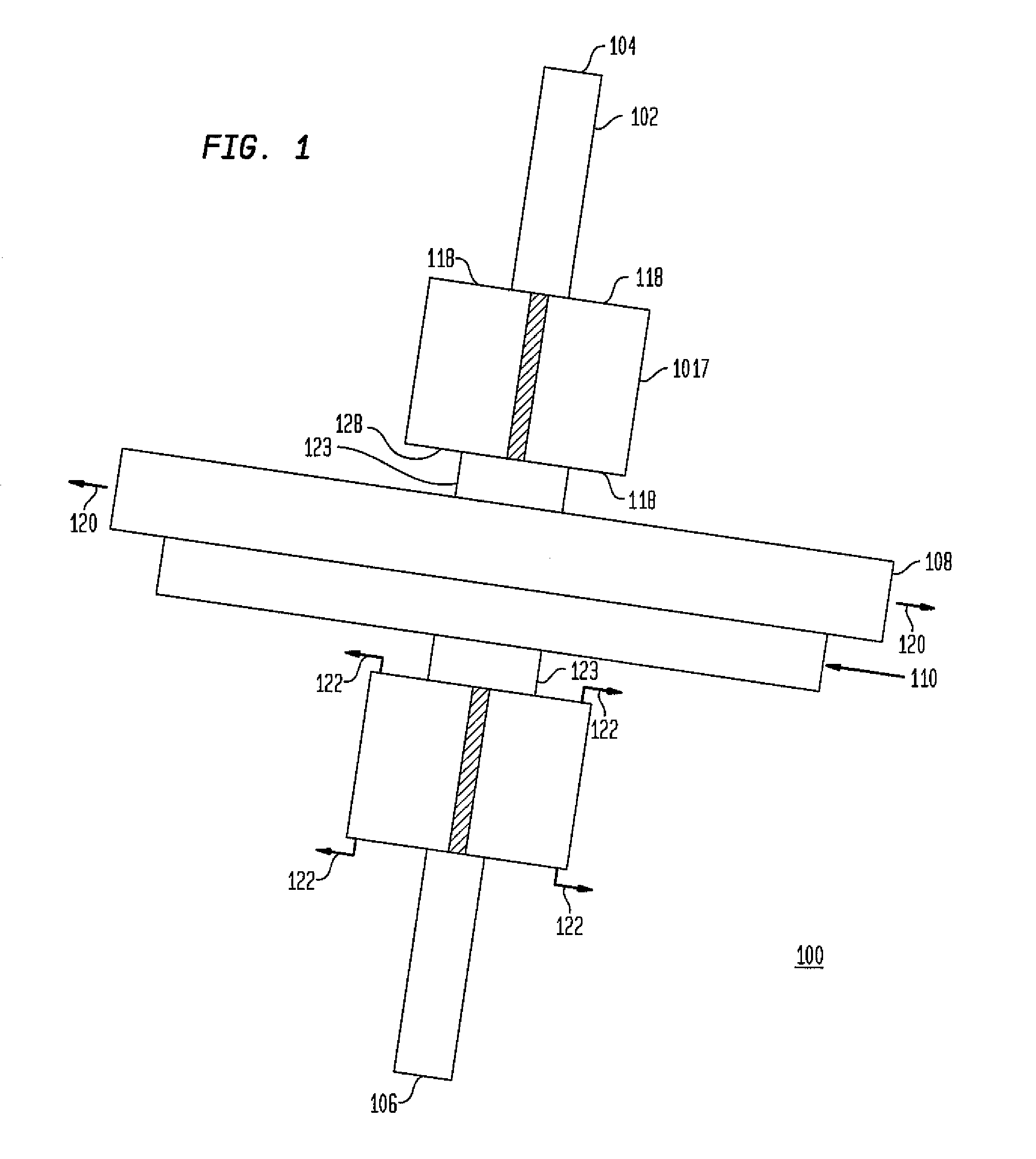

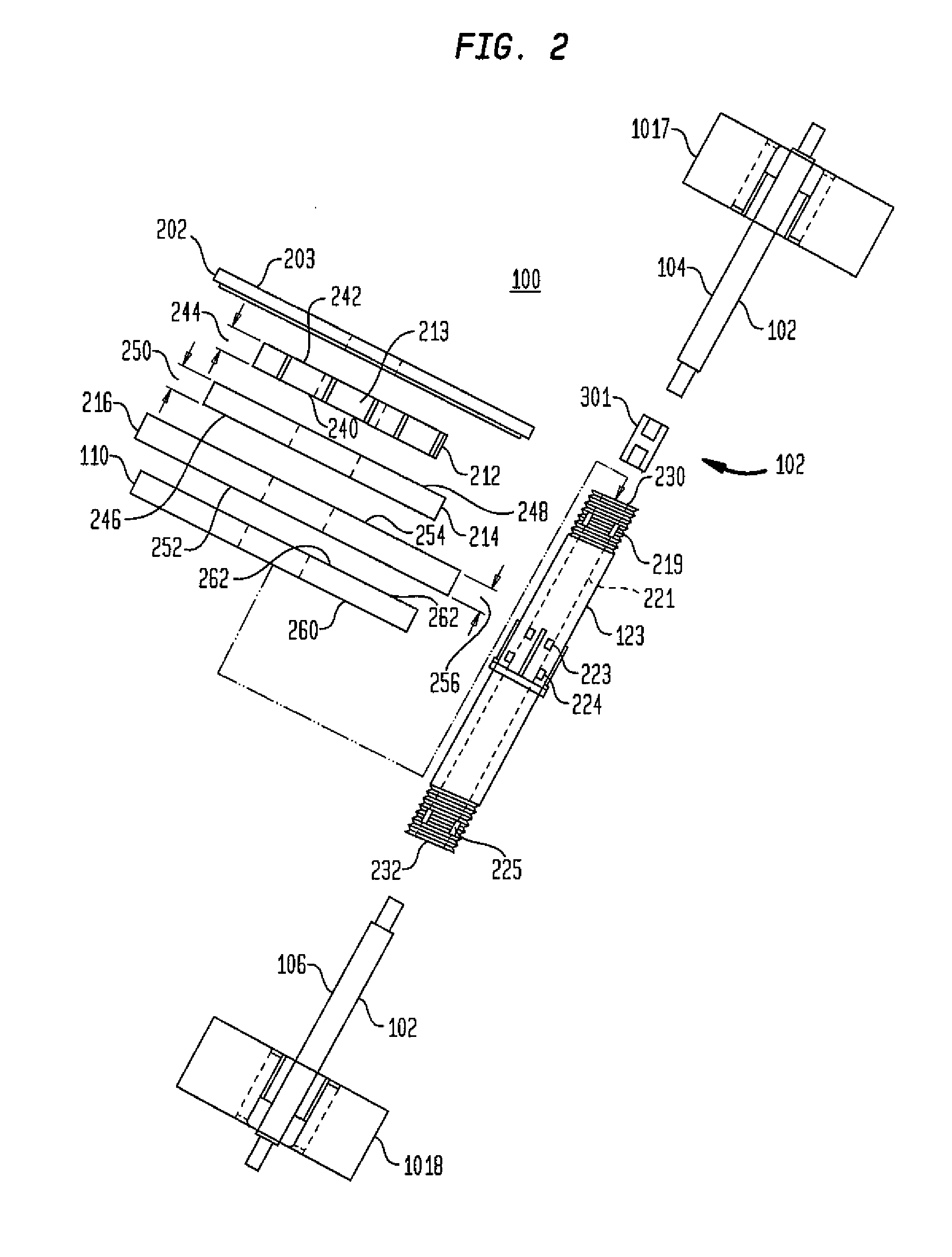

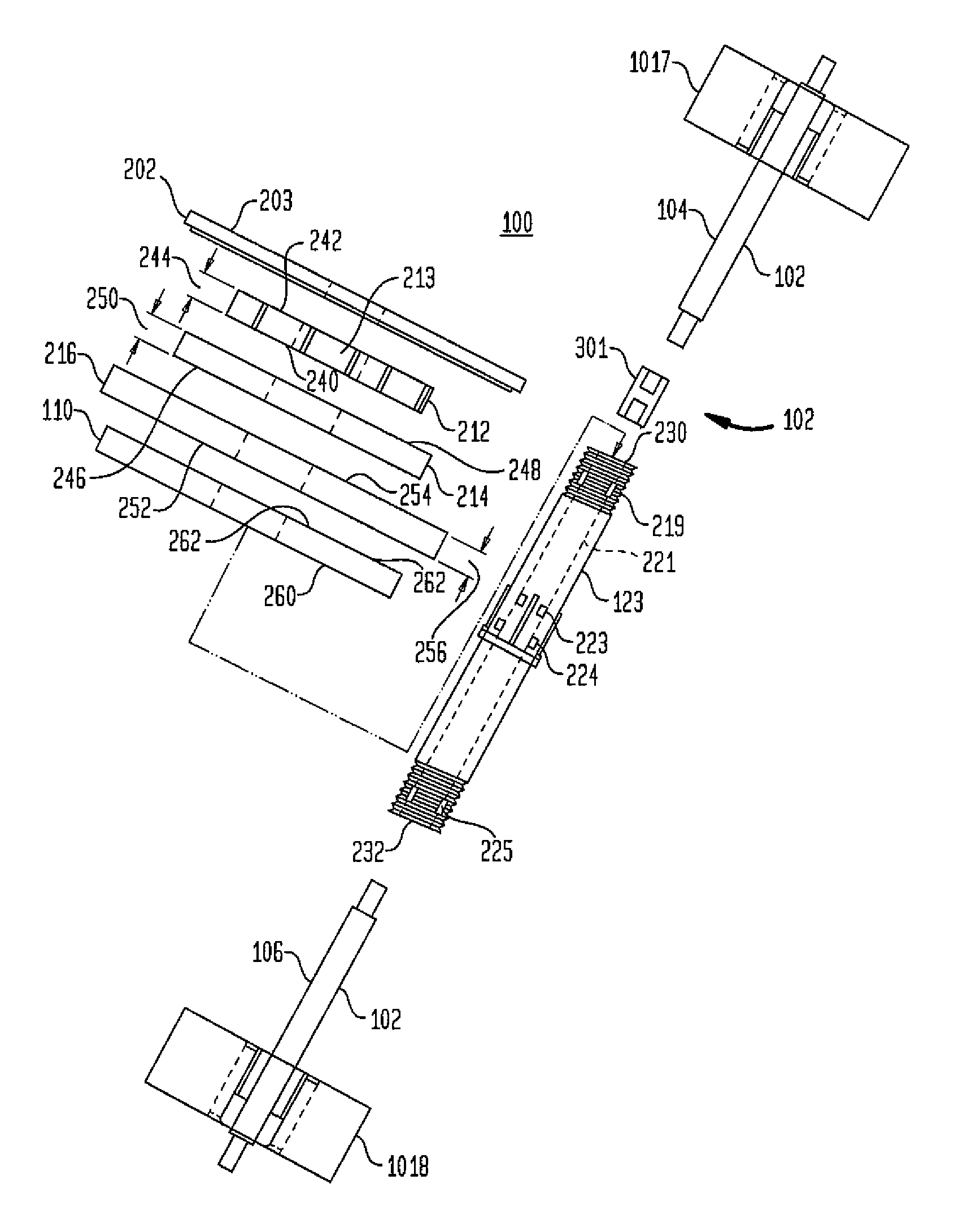

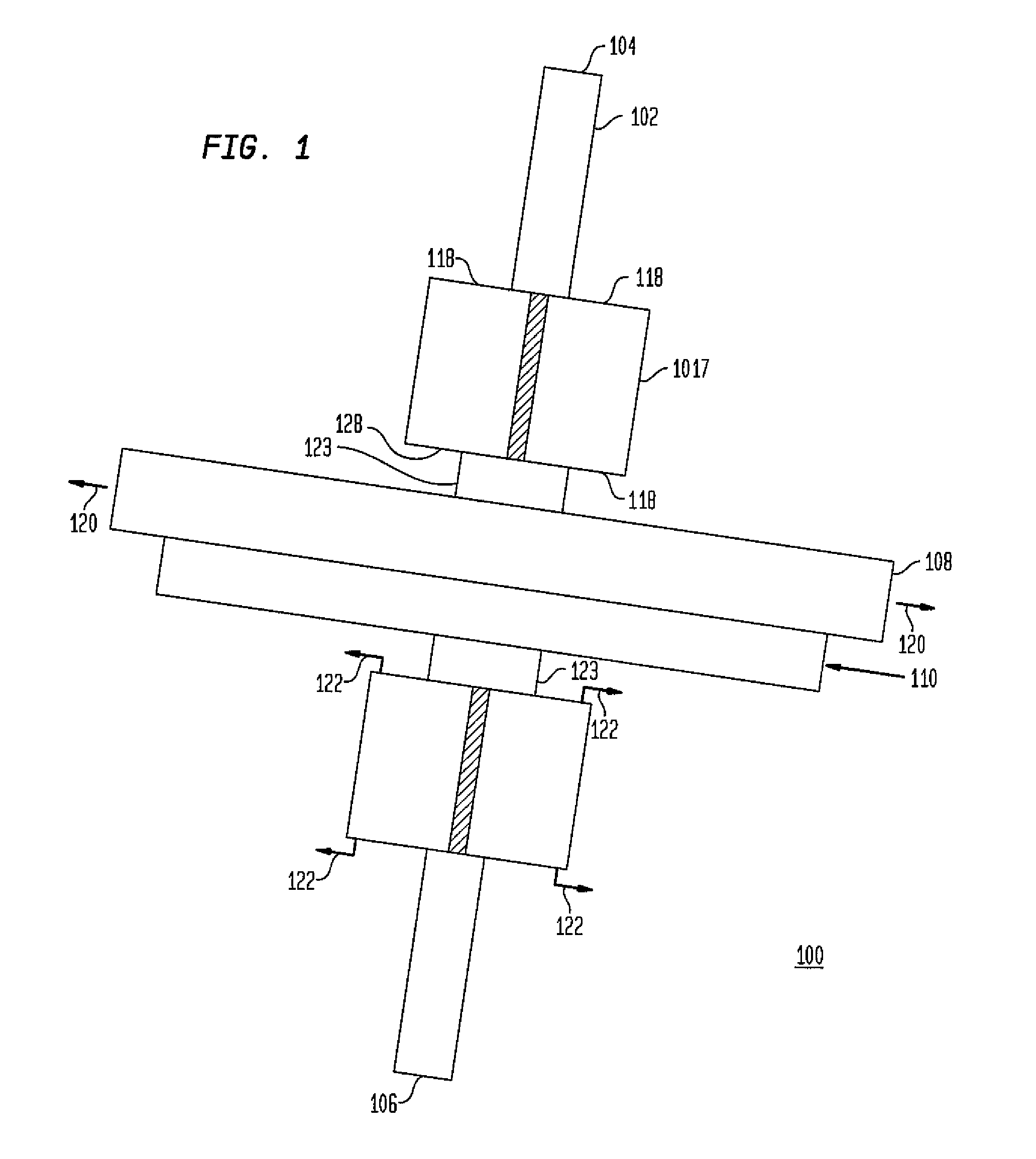

Travelling Wave IMS With Counterflow of Gas

ActiveUS20160320340A1Function increaseIncrease separation forceStability-of-path spectrometersTime-of-flight spectrometersEngineeringMechanical engineering

A method of separating ions according to mass to charge ratio is disclosed. The method comprises: providing a separation device comprising a plurality of electrodes; applying one or more transient DC voltages or potentials to at least some of said electrodes in order to urge ions in a first direction through said separation device; and providing a gas flow in a second direction which is substantially inclined or opposed to said first direction. The opposed gas flow unexpectedly improves the mass to charge ratio separation resolution of the device.

Owner:MICROMASS UK LTD

Female part of a snap fastener

The invention refers to a female part of a snap fastener including a first reception area (15) for locking a first male part (40). According to the invention, the female part further includes a second reception area (16) for locking a second male part (46, 47) is provided.

Owner:YKK CORP

Travelling wave IMS with counterflow of gas

ActiveUS9939408B2Function increaseIncrease separation forceStability-of-path spectrometersTime-of-flight spectrometersMass-to-charge ratioDc voltage

A method of separating ions according to mass to charge ratio is disclosed. The method comprises: providing a separation device comprising a plurality of electrodes; applying one or more transient DC voltages or potentials to at least some of said electrodes in order to urge ions in a first direction through said separation device; and providing a gas flow in a second direction which is substantially inclined or opposed to said first direction. The opposed gas flow unexpectedly improves the mass to charge ratio separation resolution of the device.

Owner:MICROMASS UK LTD

Wash stand

ActiveUS20210123222A1Improve gripIncrease capacityBathroom accessoriesDomestic plumbingEnvironmental geologyMechanical engineering

Owner:GEBRERIT INT

Sliding anchor

InactiveUS20110002745A1Rapidly and reliably detectable mannerIncrease separation forceNutsLoad modified fastenersMechanical engineeringEngineering

Owner:ATLAS COPCO SECOROC AB

Device and method for particle separation

InactiveUS8114179B2Increase forceEasy to separateCombination devicesGas treatmentParticle separationChemistry

A separation device with a gas inlet port that accepts an inlet gas. The inlet gas is composed of a mixture of at least two separable particle components with each component having a different mass. A rotating separation rotor accepts the inlet gas and uses a separator to substantially separate the gas according to mass into two fractions, a heavier and a lighter fraction. One of the fractions is passed to a second separator that further separates that fraction into another two fractions consisting of heavier and lighter fractions. The desired fractions are collected and exhausted from the separation device for use.

Owner:TENOROC

Method for producing rice starch by adopting enzyme method and product obtained by using method

The invention relates to a method for improving the extraction rate of rice starch produced by using an enzyme method. The method comprises the steps of broken rice pretreatment, pulping, enzyme reaction, cyclone washing, dehydration, air flow drying and the like. The invention also relates to the rice starch obtained by the method. The starch granules are small, the starch has uniform granularity (2 to 8 microns) and complete structure, the protein content is less than or equal to 0.35 percent, the quality of the starch reaches American food and drug administration (FDA) standards, the extraction rate of the starch is more than or equal to 90 percent, and the starch can be widely applied in the industries of cosmetics, pharmacy, food, chemical industry and the like.

Owner:JIANGNAN UNIV

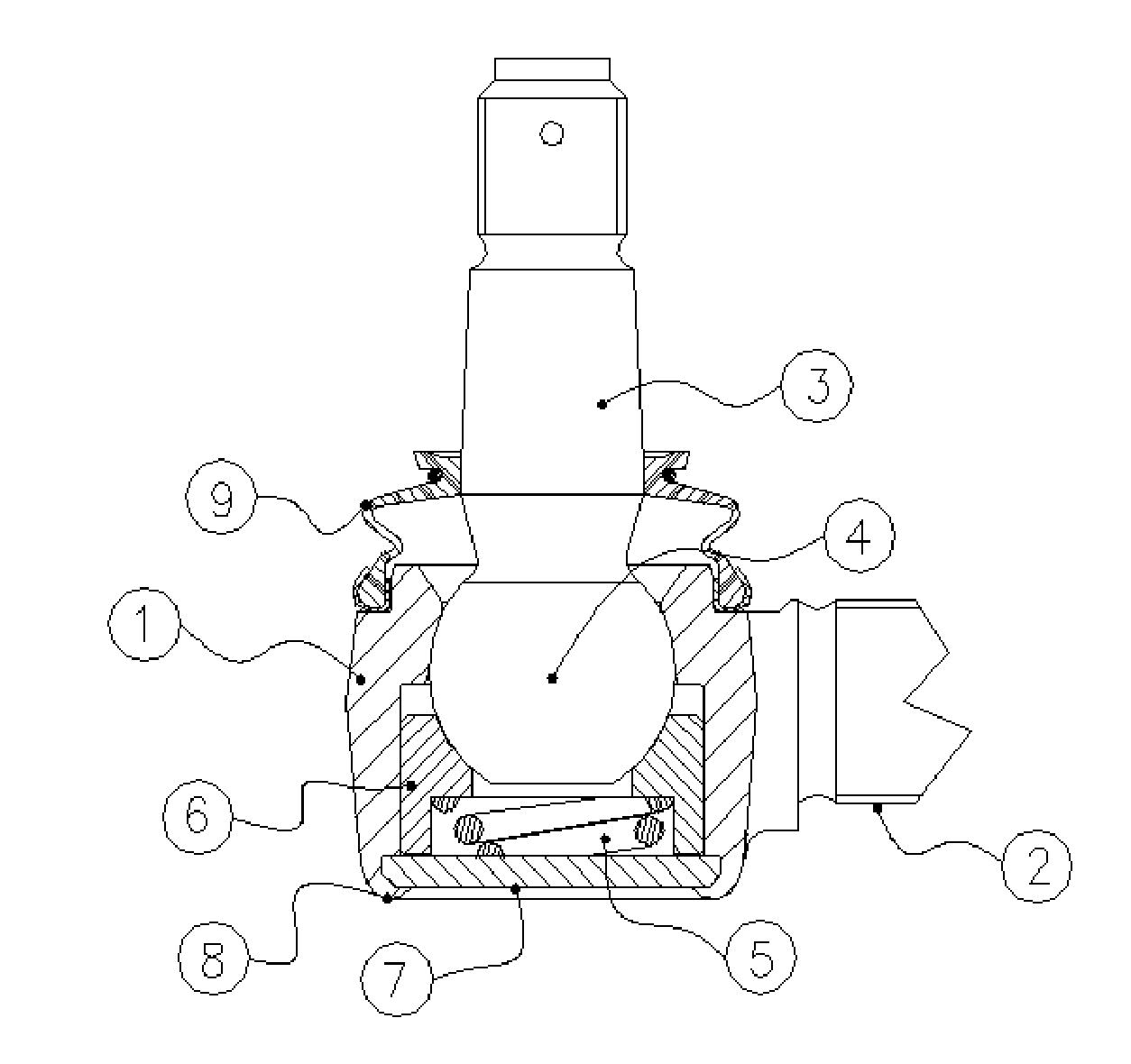

Fail safe ball joint

InactiveUS20160084299A1Improves ball socket separation forceIncrease separation forceCouplings for rigid shaftsPivotal connectionsFail-safeSingle entity

The present invention relates to a steering metallic ball joint mechanism which eliminates undesirable ball socket separation resulting in complete loss of vehicle control. Further, the present invention aims to improve the ball socket separation force in the steering ball joint mechanism subsequently improving vehicle safety. In one aspect, the steering ball joint mechanism is provided with an integral retainer seat on a ball stud to improve ball socket separation force, said ball stud and integral retainer seat forms a single entity. In another aspect, the steering ball joint mechanism is provided with retainer seat positioned in between ball pin and top of bearing cup. The simple construction and application of the retainer seat on a ball joint mechanism aides to retain defined steering linkage configuration even when undesirable excess wear has occurred which can be identified by the user before ball socket separation occurs.

Owner:RANE

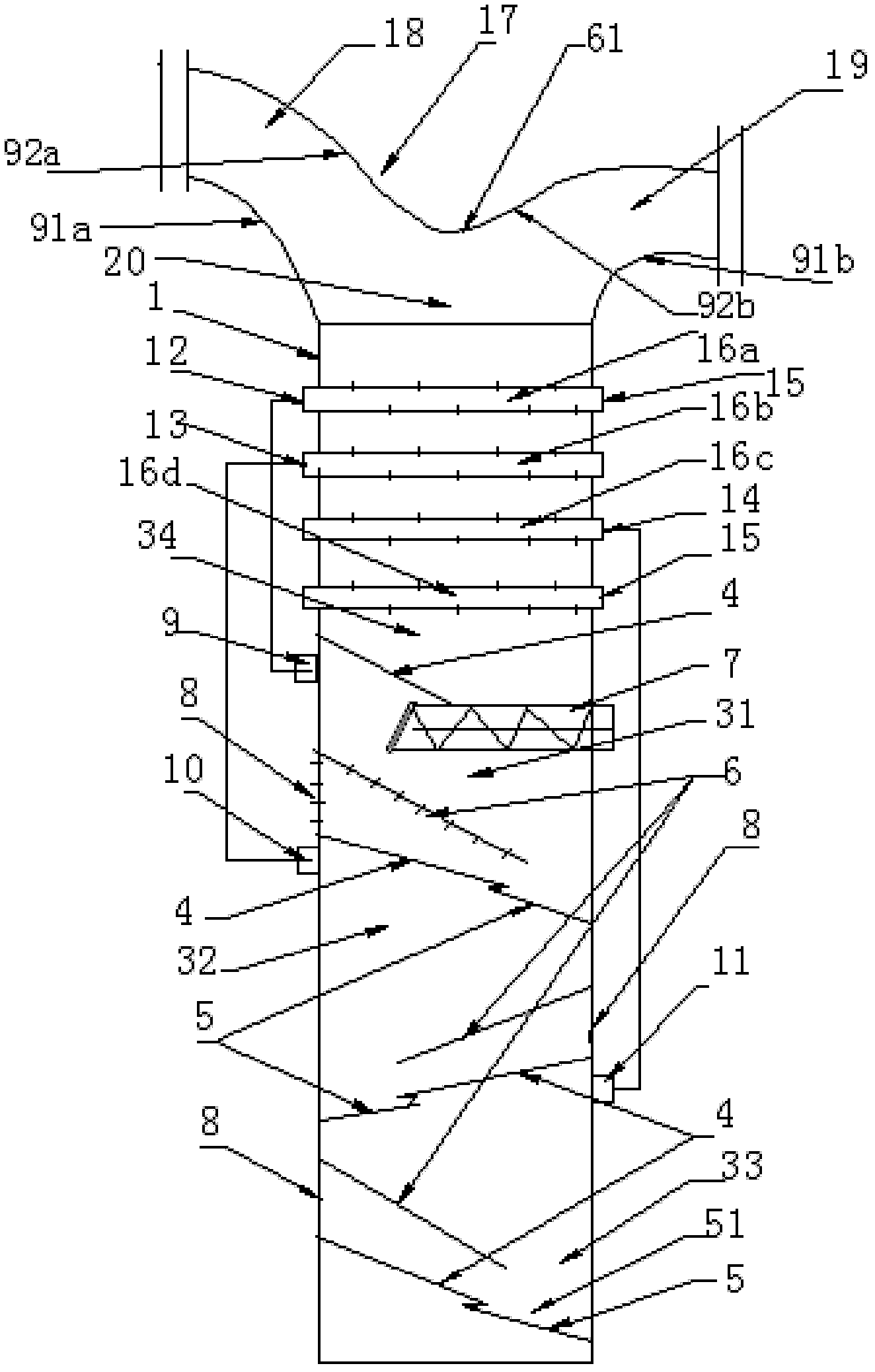

Spiral shaft type separating machine for filament and staple fibers

InactiveCN106906539AIncrease separation forceSolve the problem of fractional separationFibre separationFiberSpiral blade

The invention discloses a spiral shaft type separating machine for filament and staple fibers. The machine comprises a machine frame, a motor, a main shaft, a spiral blade and a mainframe shell, wherein a cylindrical screen is fixed at the periphery of the spiral blade and the main shaft, a material mainstream passage is formed in the cylindrical screen, a negative pressure chamber is formed between the cylindrical screen and the mainframe shell and is arranged continuously in a sectionalized manner, and filter screens are arranged by grade along a material conveying direction; the spiral blade consists of two spiral blades, and hand grips are arranged on surfaces of the spiral blades. Supporting roller guide rails are arranged on the internal wall of the cylindrical screen, supporting roller components are correspondingly arranged on the spiral blades and comprise steel balls embedded in the supporting roller guide rails, and the problem in stability of a long shaft is solved by symmetrical fulcrums. According to the spiral shaft type separating machine for the filament and staple fibers, by adopting a spiral type long shaft conveying scheme, the vacancy in large-scale fiber separation in the field of textiles is filled up.

Owner:林雁 +2

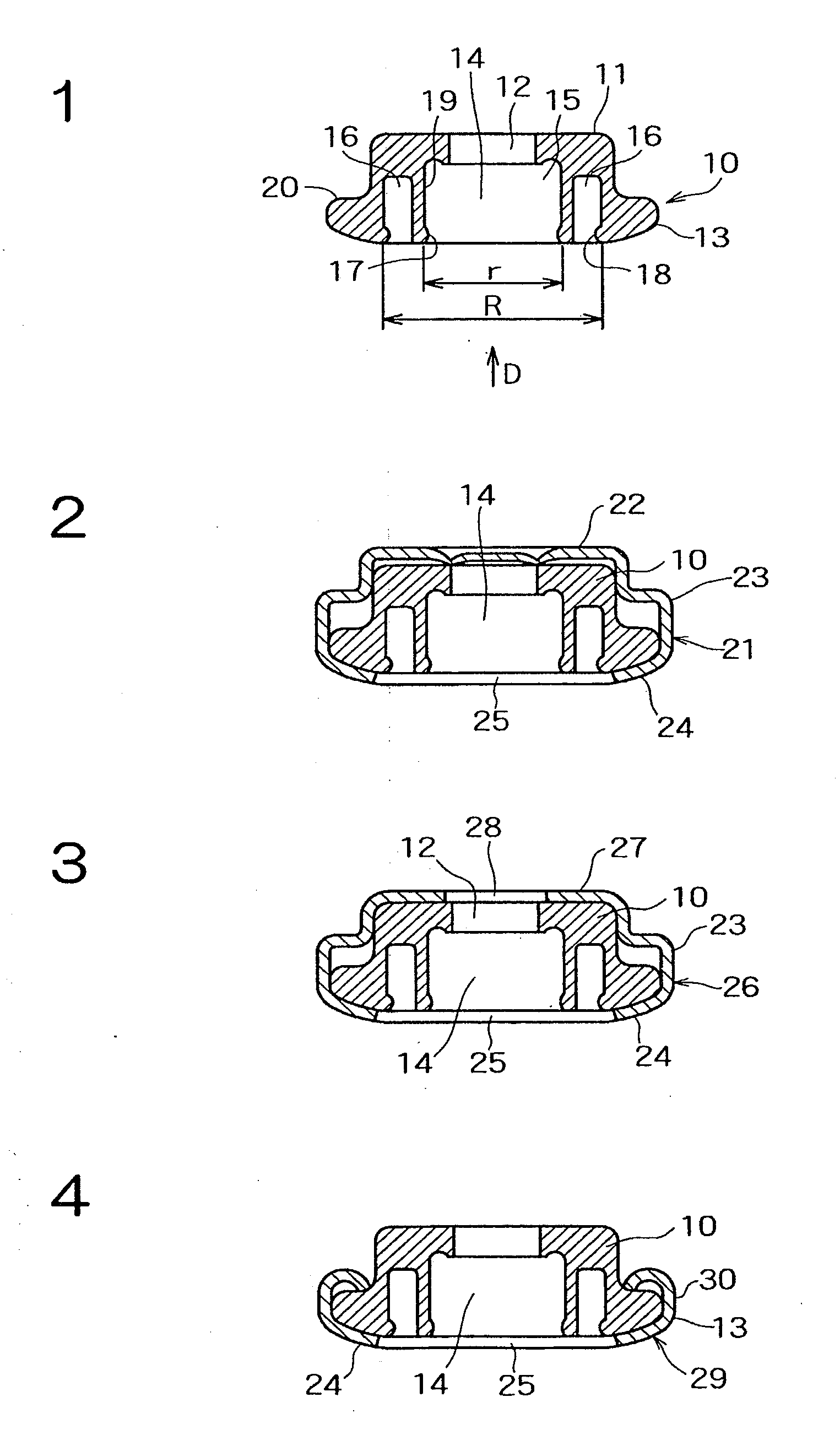

Capsule Closure Device for Closing Two-Piece Capsules

A capsule closure device is for closing two-piece capsules each having a capsule upper portion and a capsule lower portion. The capsule closure device includes a capsule upper portion receiving member and a capsule lower portion receiving member. The capsule upper portion receiving member has a receiving hole and an introduction hole which is arranged coaxially relative to the receiving hole. The capsule upper portion receiving member has at the inner side thereof between the receiving hole and the introduction hole a support shoulder for supporting the capsule upper portion. The capsule upper portion receiving member has at the inner side thereof at the introduction hole at least one ventilation hole.

Owner:HARRO HOFLIGER VERPACKUNGSMASCHEN

Wood processing sawdust processing equipment for forestry engineering

ActiveCN107825532BReduce distanceIncrease separation forceMulti-purpose machinesBark-zones/chip/dust/waste removalForest industryEnvironmental resource management

Owner:华诺家具(深圳)有限公司

Surgical tool

ActiveUS20210169662A1Eliminate the effects ofStable and balanced loadJoint implantsFemoral headsRight femoral headFemoral bone

A surgical tool for separating two components, for example removing a femoral head from a femoral stem, having a four bar chain whose four bars are a first handle (L1), an crossover component (L2), a second handle (L3) and a crossbar (L4) pivotally connected respectively by: a first joint (J1) between the first handle and the crossover component; a second, crossover joint (J2) between the crossover component and the second handle; a third joint (J3) between the second handle and the crossbar, and a fourth joint (J4) between the crossbar and the first handle, and wherein, upon application of a gripping force to the first and second handles, the first and second jaws separate from one another so as to separate the two components engaged therewith.

Owner:OXFORD UNIV INNOVATION LTD

Connector

ActiveCN101740946BIncrease separation forceSemi-assembly preventionCoupling device detailsEngineeringRestoring force

The present invention prevents two connector housings of a connector from being in a half-fitted condition by increasing restoring force which separates the two housing. A connector includes: a first connector housing including a lock projection; a second connector housing to be fitted to the first connector housing and integrally including a lock arm which is elastically deformed by the lock projection and is engaged with the lock projection; a lock ensuring member including a body which is attached to the second connector housing and movable between an allowing position and a preventing position, and an interference arm which is integrally provided on the body and includes a pressing projection. The pressing projection presses the lock arm while the lock projection deforms the lock arm at the allowing position, and the interference arm abuts the lock arm so as to prohibit the lock arm from deforming in the preventing position.

Owner:YAZAKI CORP

Purification of proteins using preparative reverse phase chromatography (RPC)

InactiveUS8921518B2Increase separation forceColony-stimulating factorPeptide preparation methodsIndustrial scaleReversed-phase chromatography

The present invention provides a method for industrial-scale protein separation by reverse phase chromatography by use of a buffer system and an additional salt.

Owner:NOVO NORDISK AS

Chaff and grain separator

InactiveCN102527640BSimple structureIncrease the lengthGas current separationThermodynamicsEngineering

The invention discloses a chaff and grain separator, which is adapted to characteristics of materials in need of chaff and grain separation and fine in separation effect and comprises multiple stages of pre-separators connected with corresponding separating passages, the upper wall of an input passage and the upper wall of a discharge passage of each stage of pre-separator are located at the same height, a guide of each stage of pre-separator is longer than that of the previous stage of pre-separator, and each stage of the corresponding section of the multi-stage separating passages connected with the multi-stage pre-separators is larger than the corresponding section of the previous stage of pre-separator.

Owner:胡黎明

Surgical tool

ActiveUS11497625B2Eliminate the effects ofStable and balanced loadJoint implantsFemoral headsRight femoral headFemoral bone

A surgical tool for separating two components, for example removing a femoral head from a femoral stem, having a four bar chain whose four bars are a first handle (L1), an crossover component (L2), a second handle (L3) and a crossbar (L4) pivotally connected respectively by: a first joint (J1) between the first handle and the crossover component; a second, crossover joint (J2) between the crossover component and the second handle; a third joint (J3) between the second handle and the crossbar, and a fourth joint (J4) between the crossbar and the first handle, and wherein, upon application of a gripping force to the first and second handles, the first and second jaws separate from one another so as to separate the two components engaged therewith.

Owner:OXFORD UNIV INNOVATION LTD

A pilot test method for producing high-purity mung bean protein powder

ActiveCN107156424BHigh purityIncrease separation forceProtein composition from vegetable seedsBiotechnologyFood additive

The invention discloses a pilot test method for producing high-purity mung bean protein powder and belongs to the technical field of deep processing of agricultural products. According to the pilot test method, mung beans are taken as raw materials; a technological process comprises the process steps of mung bean pre-treatment, pulp-grinding, alkali regulation, horizontal screw separation and slag removal, acid regulation, disc separation, swirl washing, disc concentration, spraying and drying, and the like; a mung bean protein powder product with higher purity is obtained, and the content of proteins is more than or equal to 80 percent. As a food additive, the high-purity mung bean protein powder can be widely applied to the food processing industry; the pilot test method disclosed by the invention is simple in process route, high in degree of automation and wide in industrial application prospect.

Owner:JIANGNAN UNIV

Drying method suitable for high-shrinkage polyester chips

The invention discloses a drying method suitable for high-shrinkage polyester chips, and belongs to the field of polyester chip preparation. The drying method suitable for the high-shrinkage polyester chips comprises the steps that the high-shrinkage polyester chips are conveyed to a conveying device from a hopper in advance; the high-shrinkage polyester chips are put into a boiling bed by the conveying device, and pre-crystallization treatment is carried out; through mutual cooperation of pneumatic isolation shaking balls and telescopic protective bubbles, the floating efficiency of the high-shrinkage polyester chips in the boiling bed can be effectively improved, the high-shrinkage polyester chips which are adhered together can be timely and effectively opened, the isolation effect is effectively improved, the softening deformation condition of the high-shrinkage polyester chips is reduced, and the drying quality is improved; and by adjusting the air pressure and controlling the shaking amplitude of the telescopic protective bubbles, the control difficulty is simplified while the effective isolation and separation effects are effectively achieved, continuous drying of the high-shrinkage polyester chips is facilitated, and the economic benefits of high-shrinkage polyester chip processing are improved.

Owner:冯越

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com