Chaff and grain separator

A technology of separator and pre-separator, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problems of low separation capacity, poor oil quality, and low unit separation volume. , to achieve the effect of increased separation capacity, low separation power and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

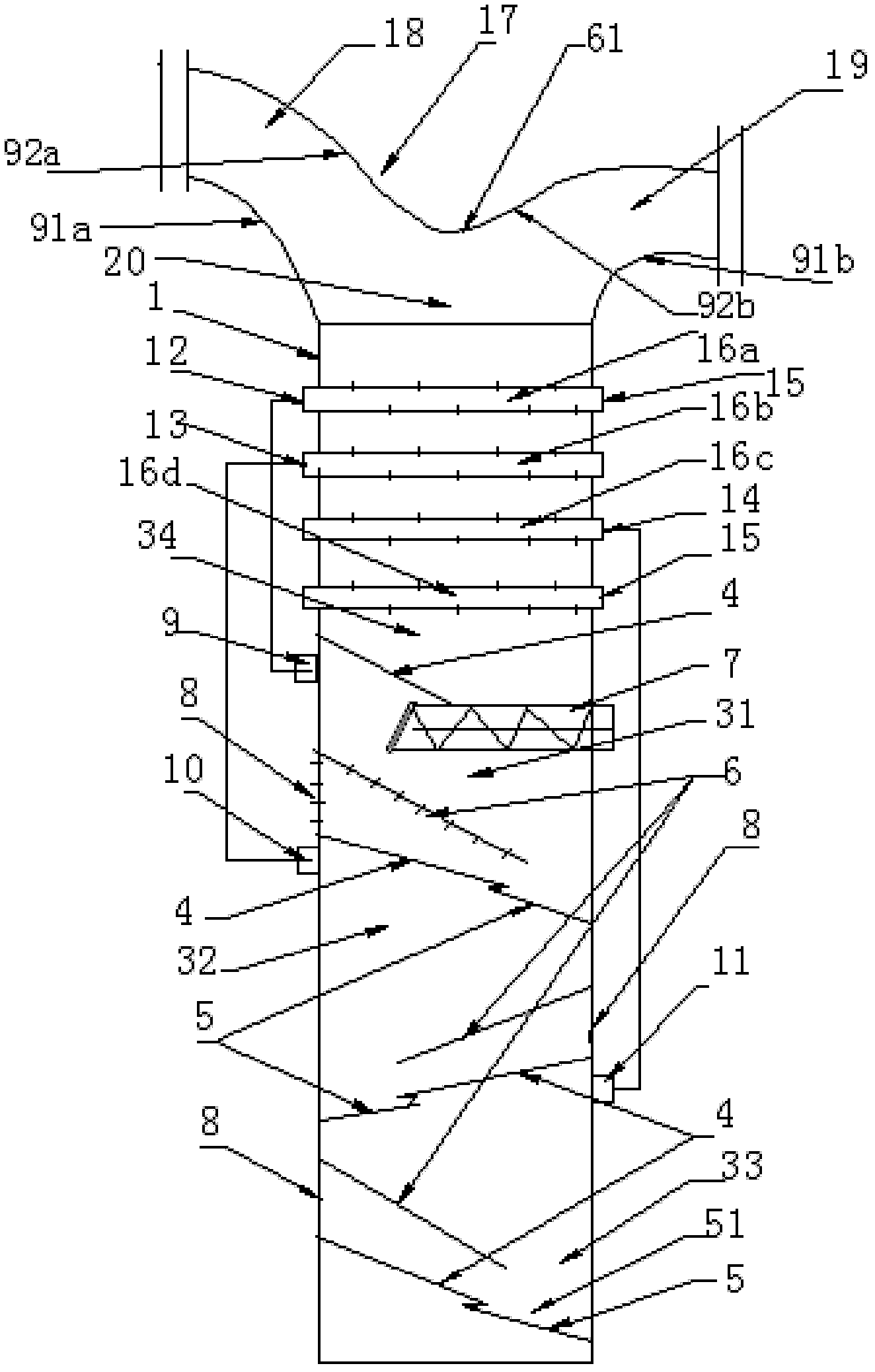

[0017] The present invention will be further described through embodiment now in conjunction with accompanying drawing. Such as figure 1 As shown, the multi-stage pre-separator of this example includes a multi-stage pre-separator 17a composed of four pre-separators 17, and the multi-stage pre-separator 17a is from the first-stage pre-separator 17a1 of the total material import to the last-stage pre-separator The outlet of the discharge channel of the device 17a4 is horizontal or horizontal, and the four separation channels 1 located below the pre-separator 17 are respectively connected in the up and down direction through the upward trumpet tube and the corresponding drainage channel 20 of the multi-stage pre-separator 17a Four stages of separation channels 1a-1d are formed.

[0018] The predivider 17, which is similar to the special-shaped tee, is composed of two arc-shaped elbow pipes connected back to each other, and the input channel 18 and the discharge channel 19 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com