Method for producing rice starch by adopting enzyme method and product obtained by using method

A technology of rice starch and enzymatic method, applied in the field of rice starch, can solve the problems of ineffective separation of starch and protein, reduction of starch extraction rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1: Method for improving the extraction rate of rice starch produced by enzymatic method of the present invention

[0083] The steps of this method are as follows:

[0084] (1) Broken rice pretreatment

[0085] Weigh 500 kg of early indica rice (starch content 76.5%), transport it to the soaking tank through a vibrating screen, iron remover, and bucket elevator, rinse the broken rice once with water according to the weight ratio of broken rice and water of 1:1, and discard the rice washing water , and then soak the broken rice with the same amount of water for 2.5 hours, and transport the soaked raw materials to a hammer mill through a stainless steel conveyor belt for coarse crushing to 60 mesh to obtain rice milk.

[0086] (2) Refining

[0087] The pulverized slurry is input into a colloid mill for grinding, and the ground rice slurry is passed through an 80-mesh centrifugal sieve, then water is added to adjust the weight percent concentration of the rice s...

Embodiment 2

[0096] Example 2: Method for improving the extraction rate of rice starch produced by enzymatic method of the present invention

[0097] The steps of this method are as follows:

[0098] (1) Broken rice pretreatment

[0099]Weigh 600kg of early indica rice (starch content 77.4%), transport it to the soaking tank through a vibrating screen, iron remover, and bucket elevator, rinse the broken rice once with water according to the weight ratio of broken rice and water of 1: 1.5, and discard the rice washing water , and then soak the broken rice with the same amount of water for 2 hours, and transport the soaked raw materials to a hammer mill through a stainless steel conveyor belt for coarse grinding to 60 mesh to obtain rice milk.

[0100] (2) Refining

[0101] The pulverized slurry is input into the colloid mill produced by Wenzhou Haolong Colloid Mill Factory Company for grinding, and the rice slurry after grinding is passed through an 80-mesh centrifugal sieve, and then w...

Embodiment 3

[0110] Example 3: Method for improving the extraction rate of rice starch produced by enzymatic method of the present invention

[0111] The steps of this method are as follows:

[0112] (1) Broken rice pretreatment

[0113] Weigh 800 kg of early indica rice (starch content 76.1%), transport it to the soaking tank through a vibrating screen, iron remover, and bucket elevator, rinse the broken rice once with water according to the weight ratio of broken rice and water of 1:2, and discard the rice washing water , and then soak the broken rice with the same amount of water for 3 hours, and transport the soaked raw materials to a hammer mill through a stainless steel conveyor belt for coarse crushing to 60 meshes to obtain rice milk.

[0114] (2) Refining

[0115] The pulverized slurry is input into a colloid mill for grinding, and the ground rice slurry is passed through an 80-mesh centrifugal sieve, then water is added to adjust the weight percent concentration of the rice s...

PUM

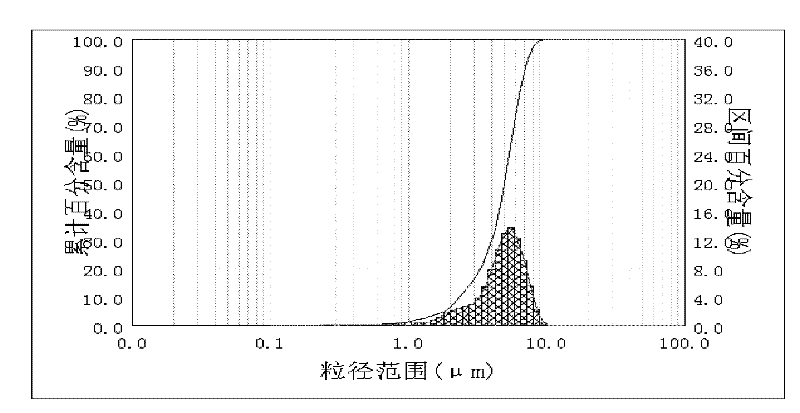

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com