Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Strong hold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

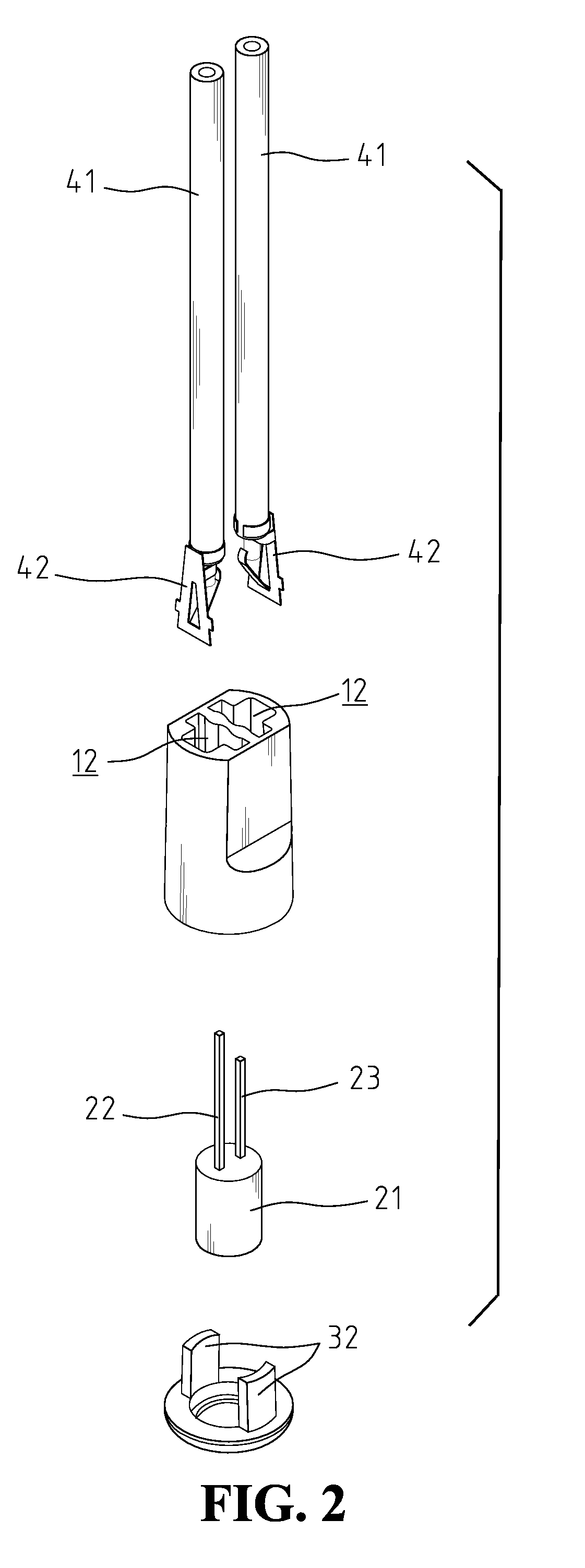

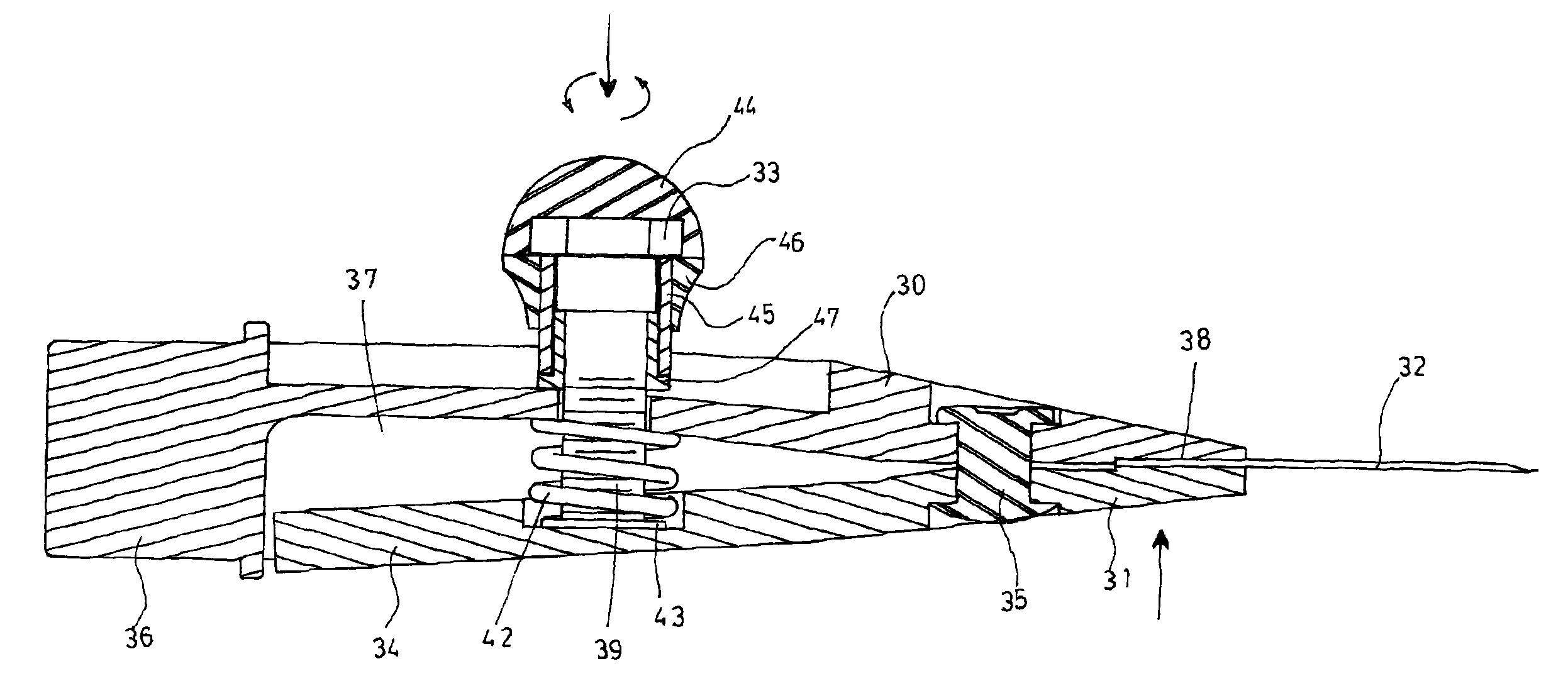

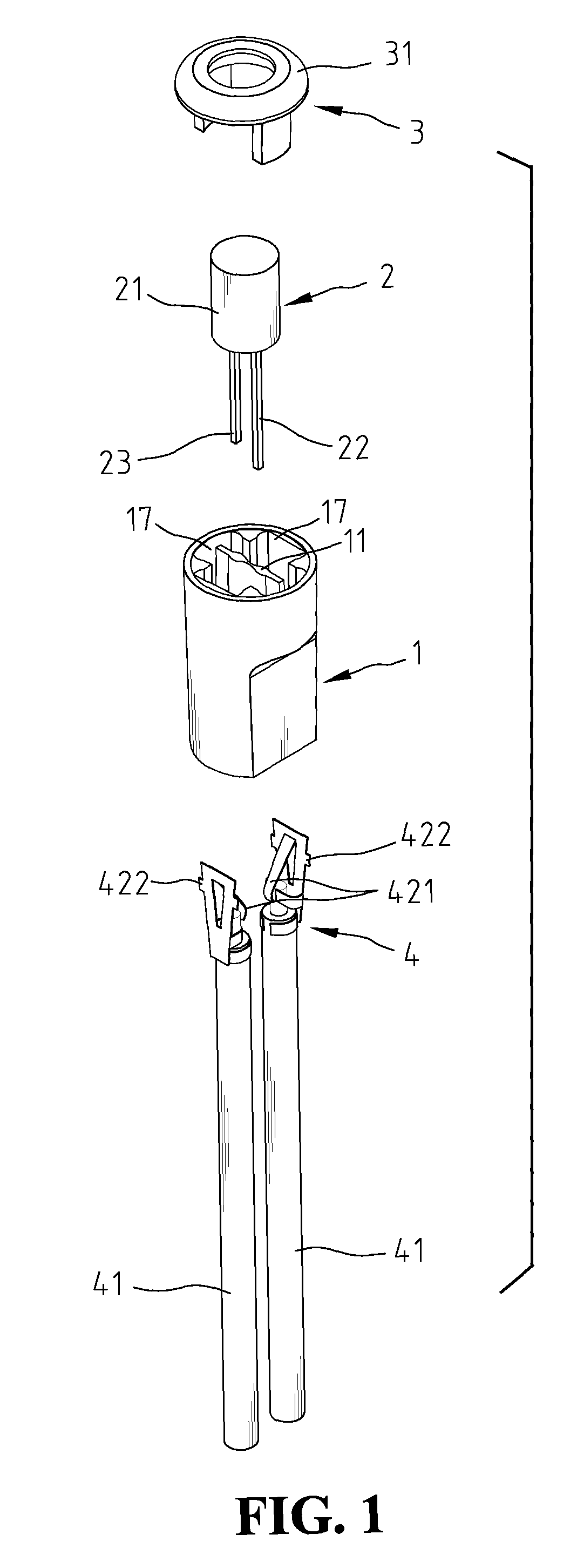

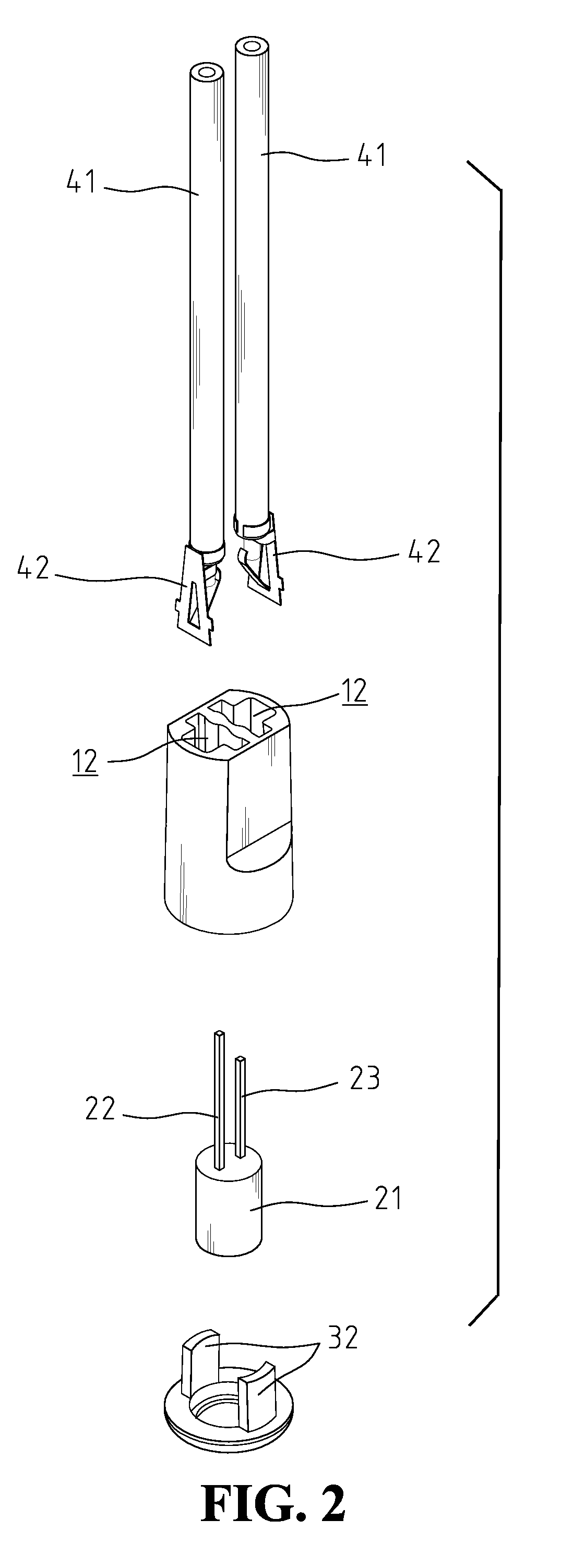

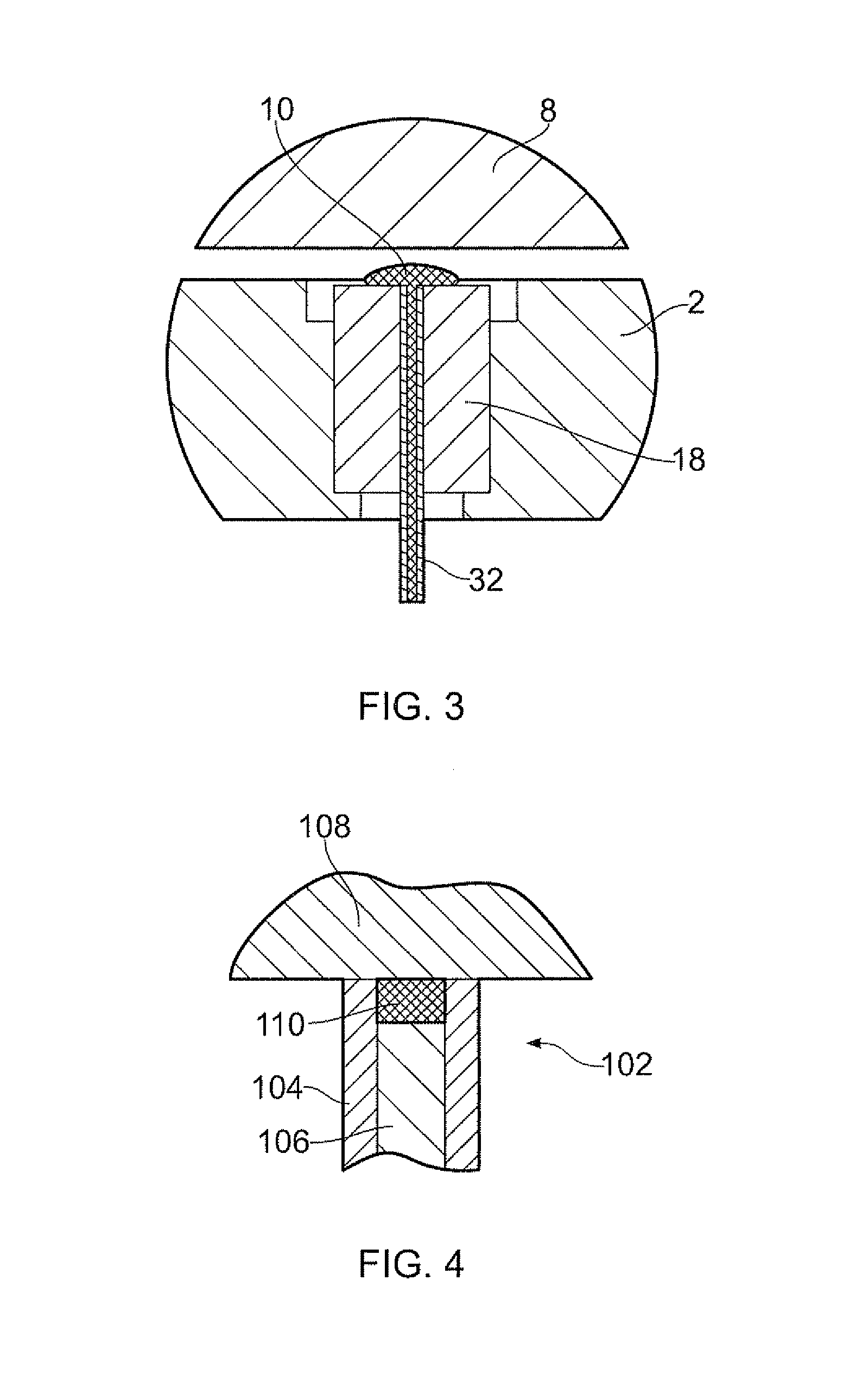

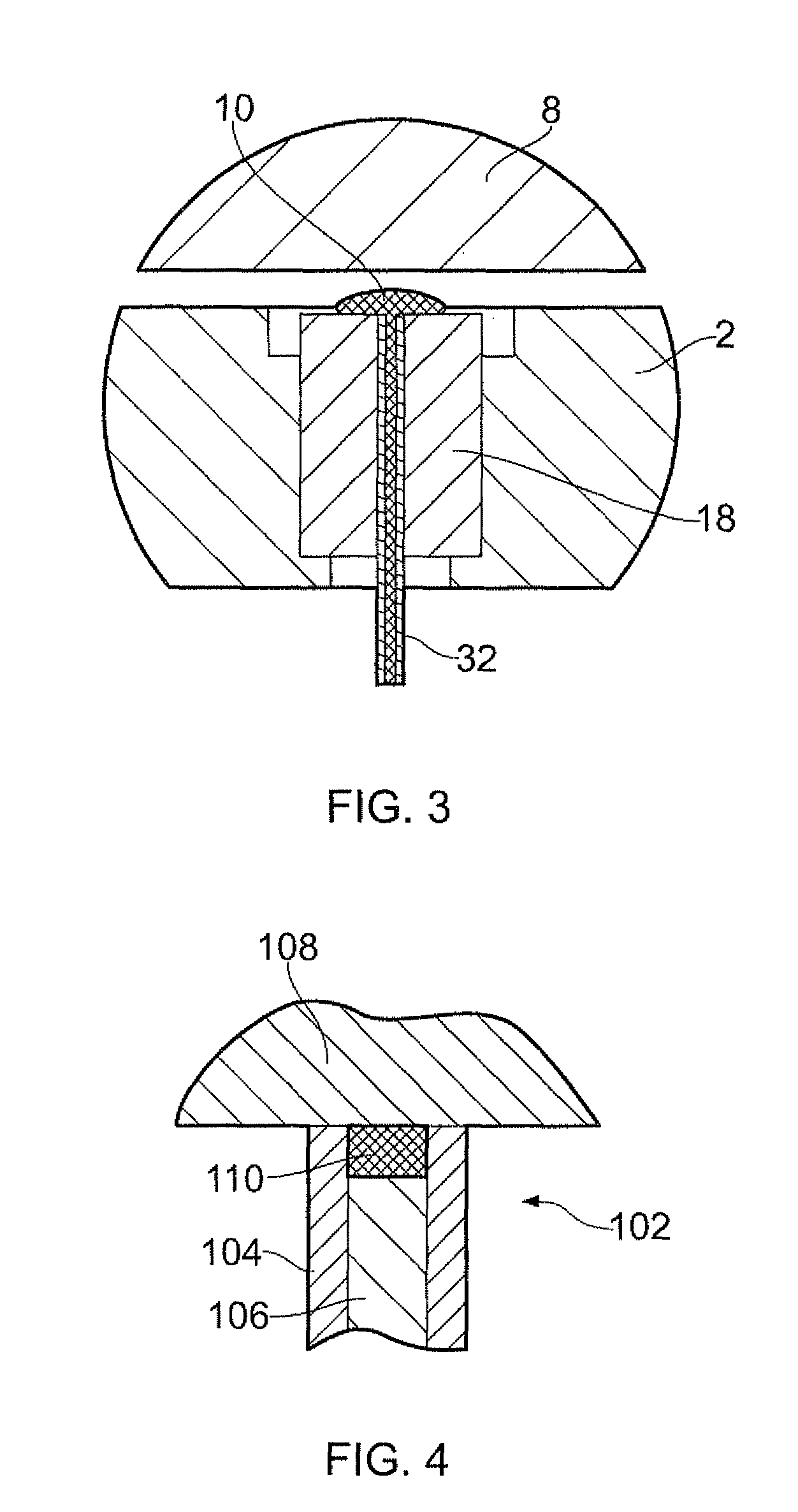

Enclosed Needle Device with Duckbill Release Mechanism

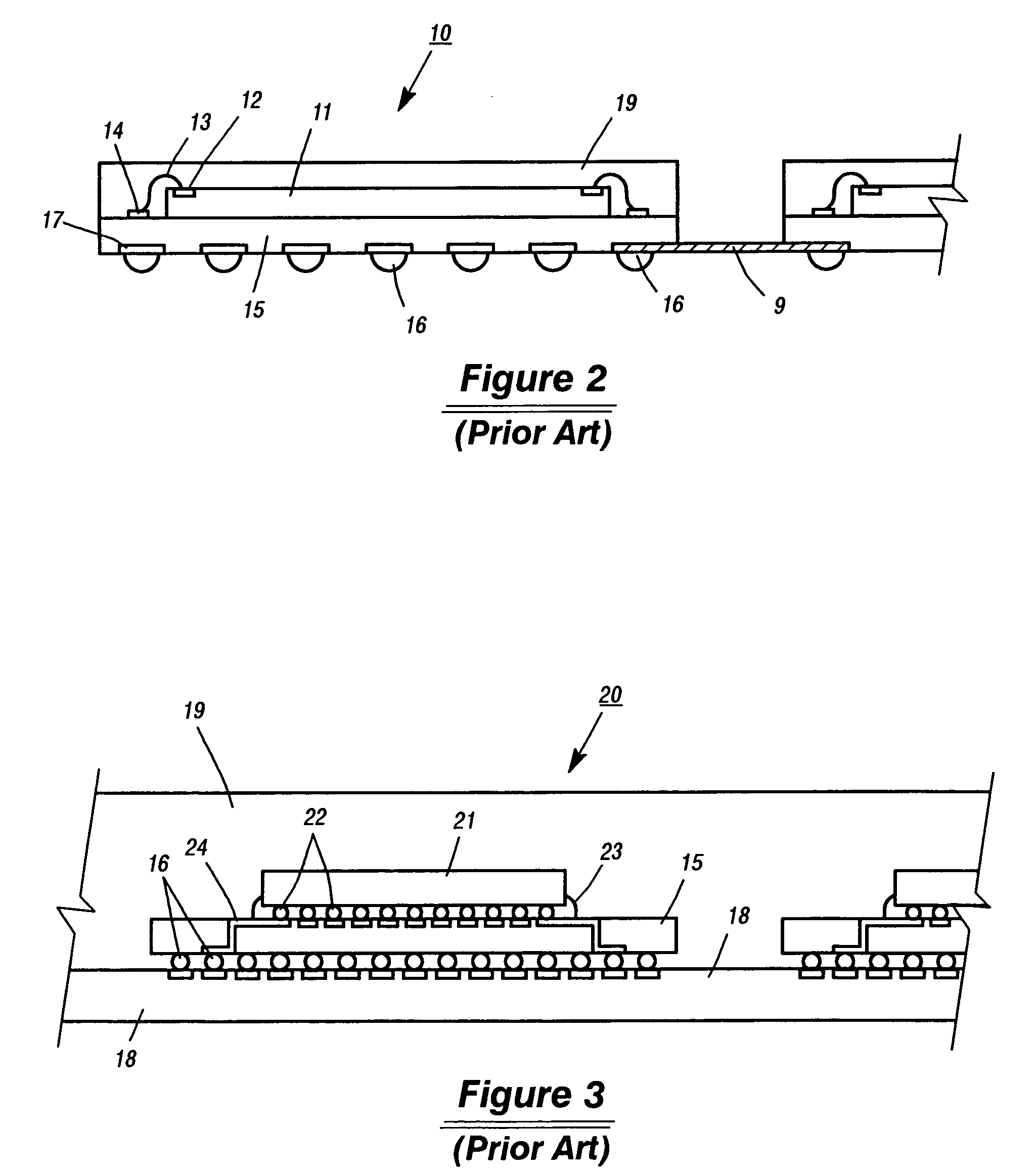

InactiveUS20070191776A1High separation forceEasy to compressInfusion syringesCatheterNeedle catheterCatheterization device

Owner:SMITHS MEDICAL ASD INC

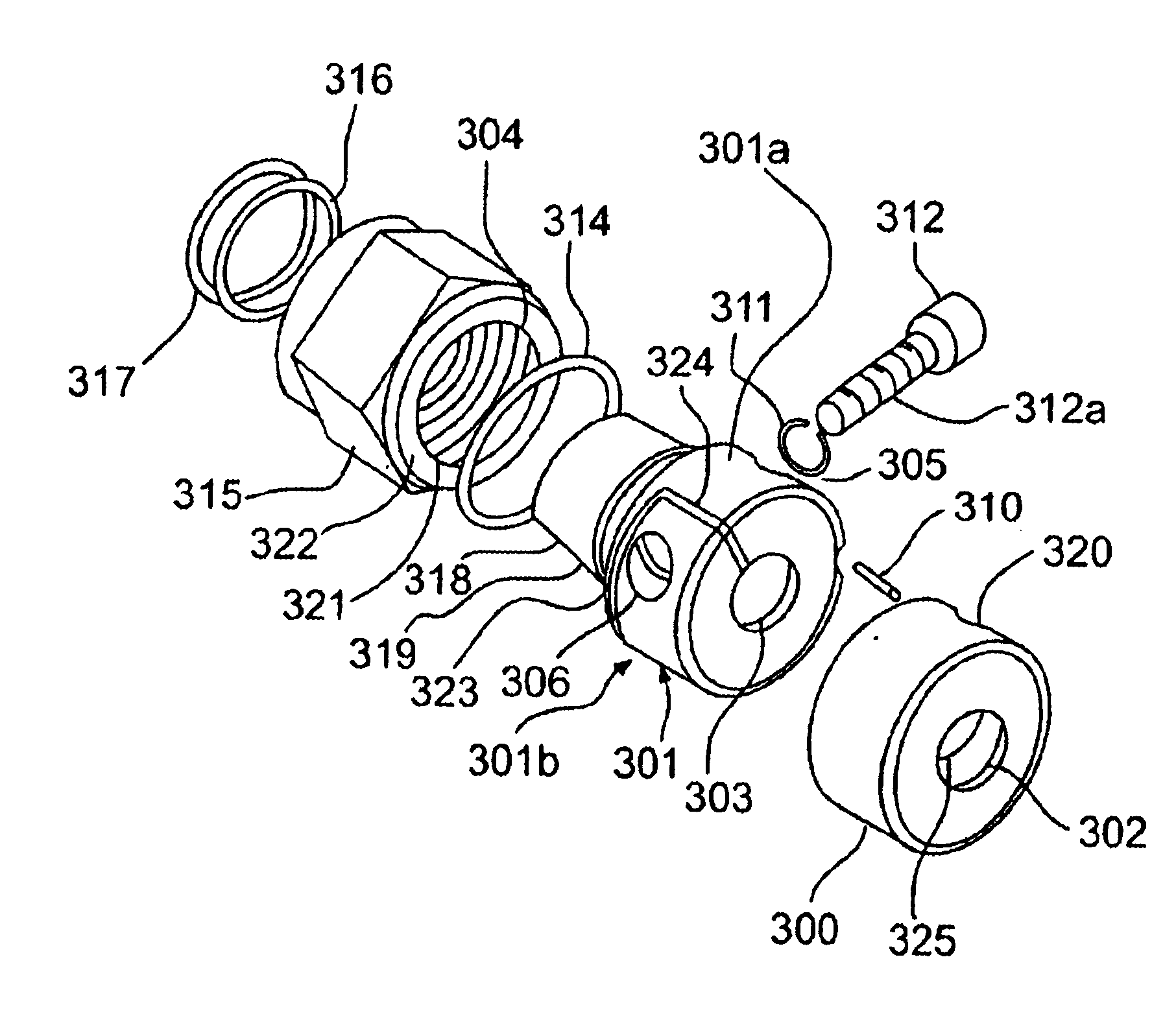

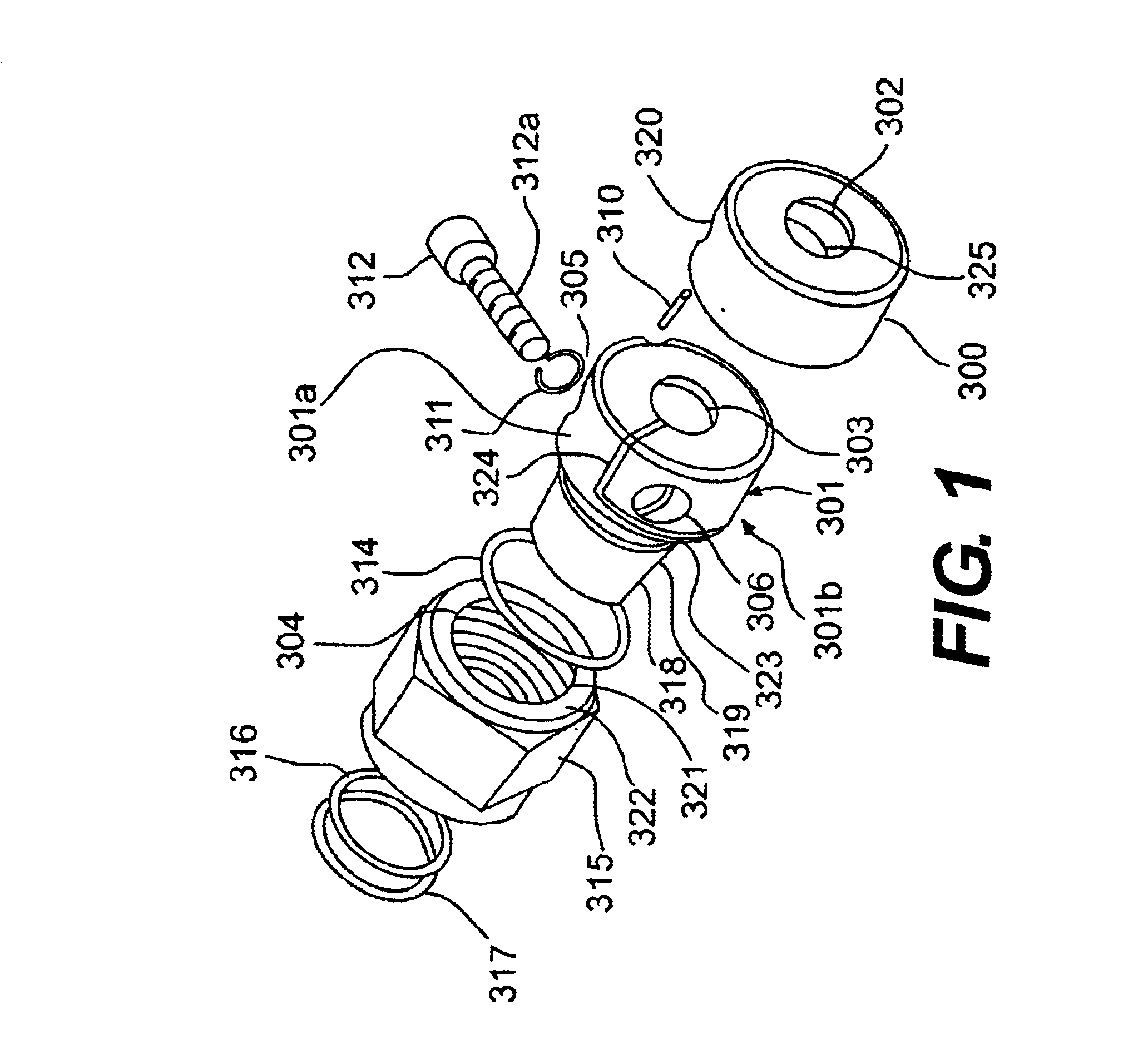

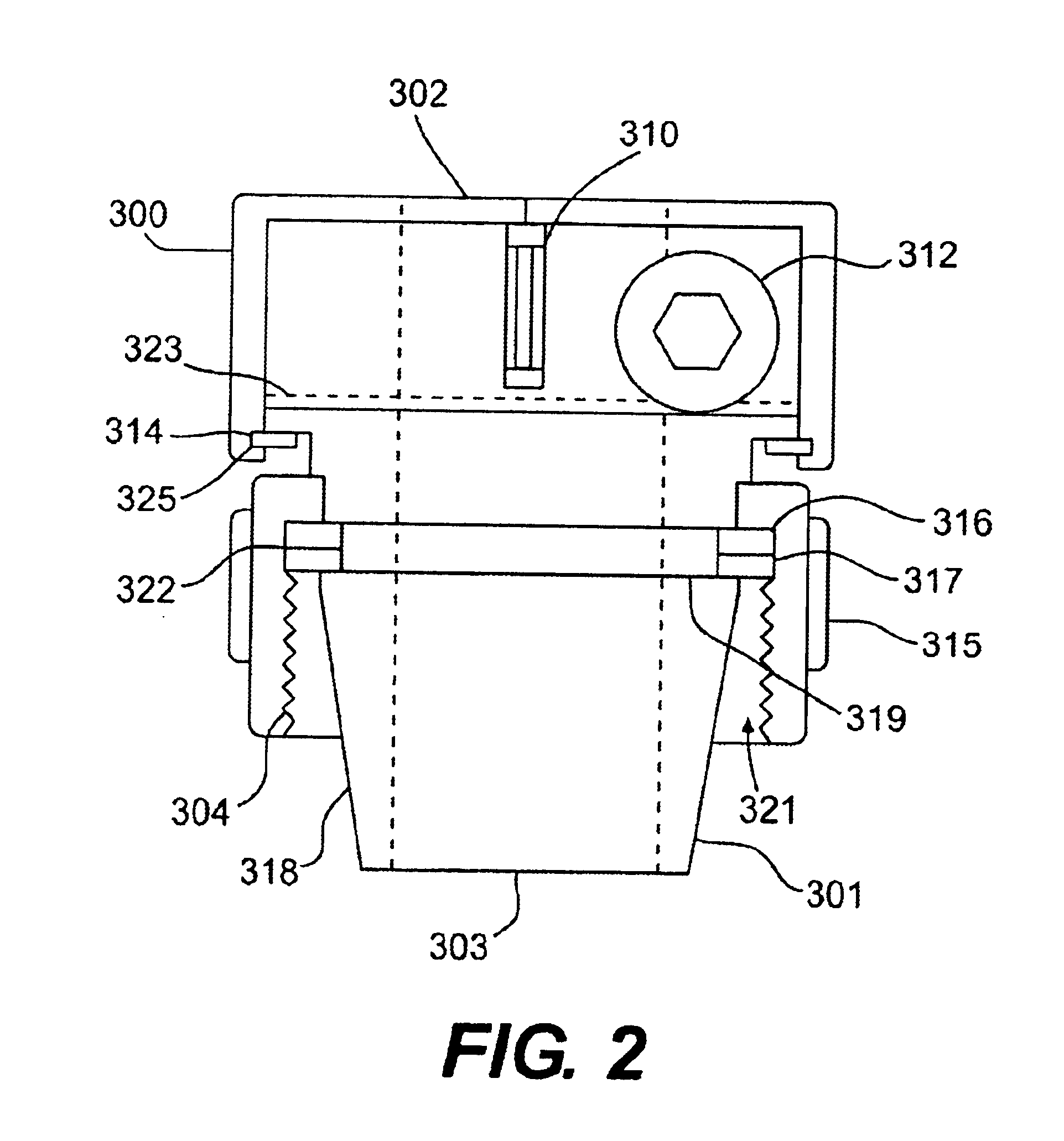

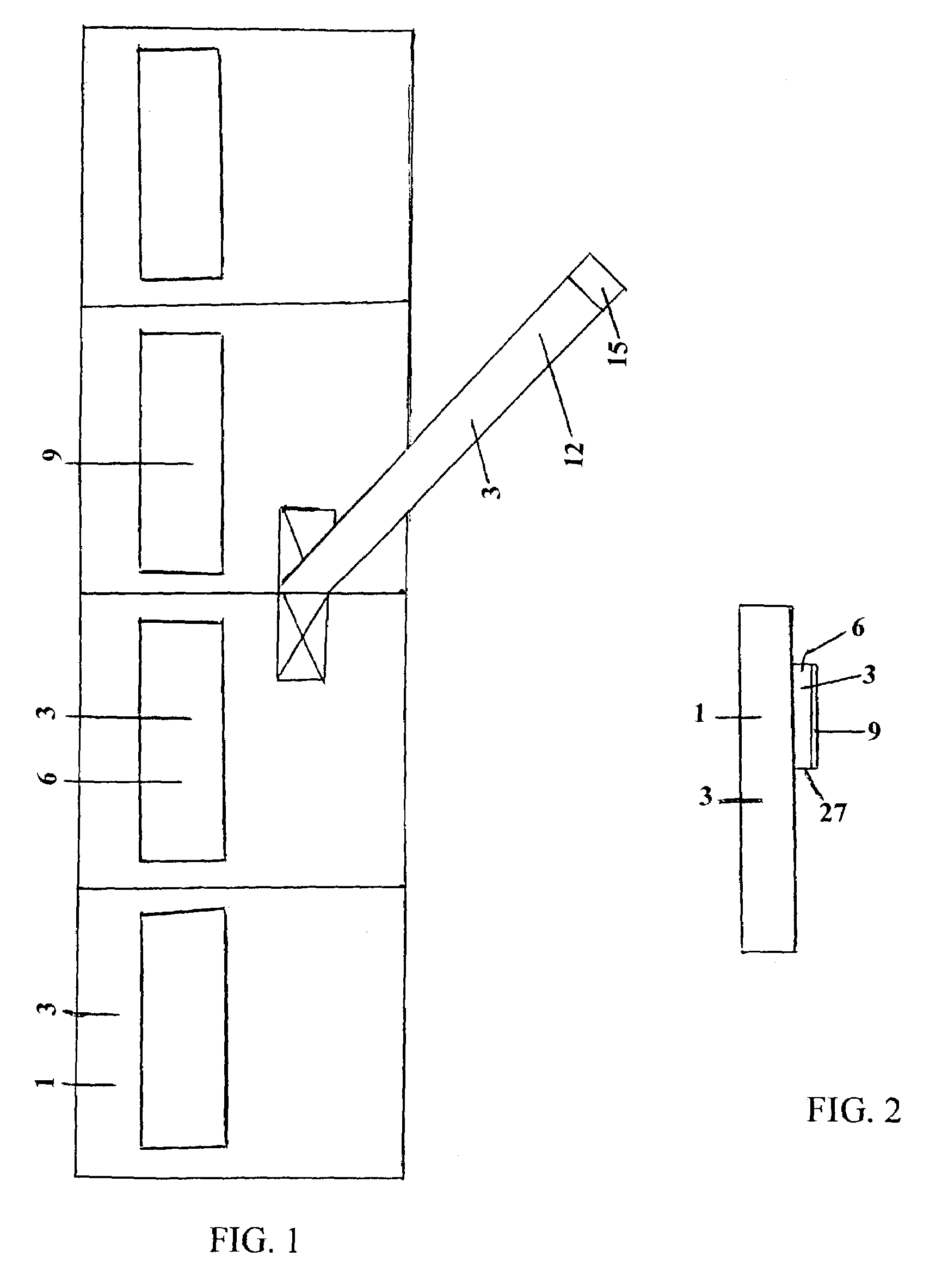

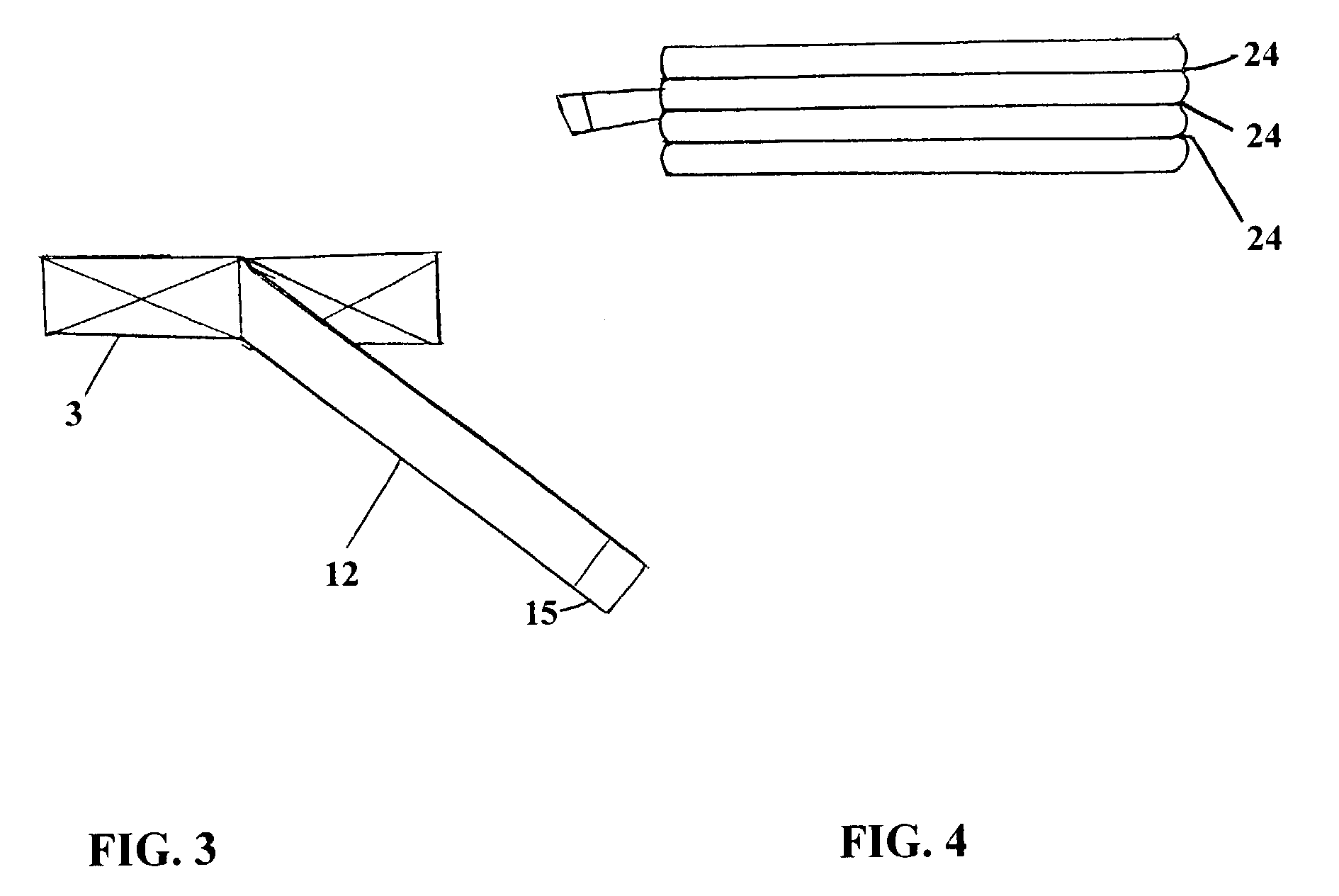

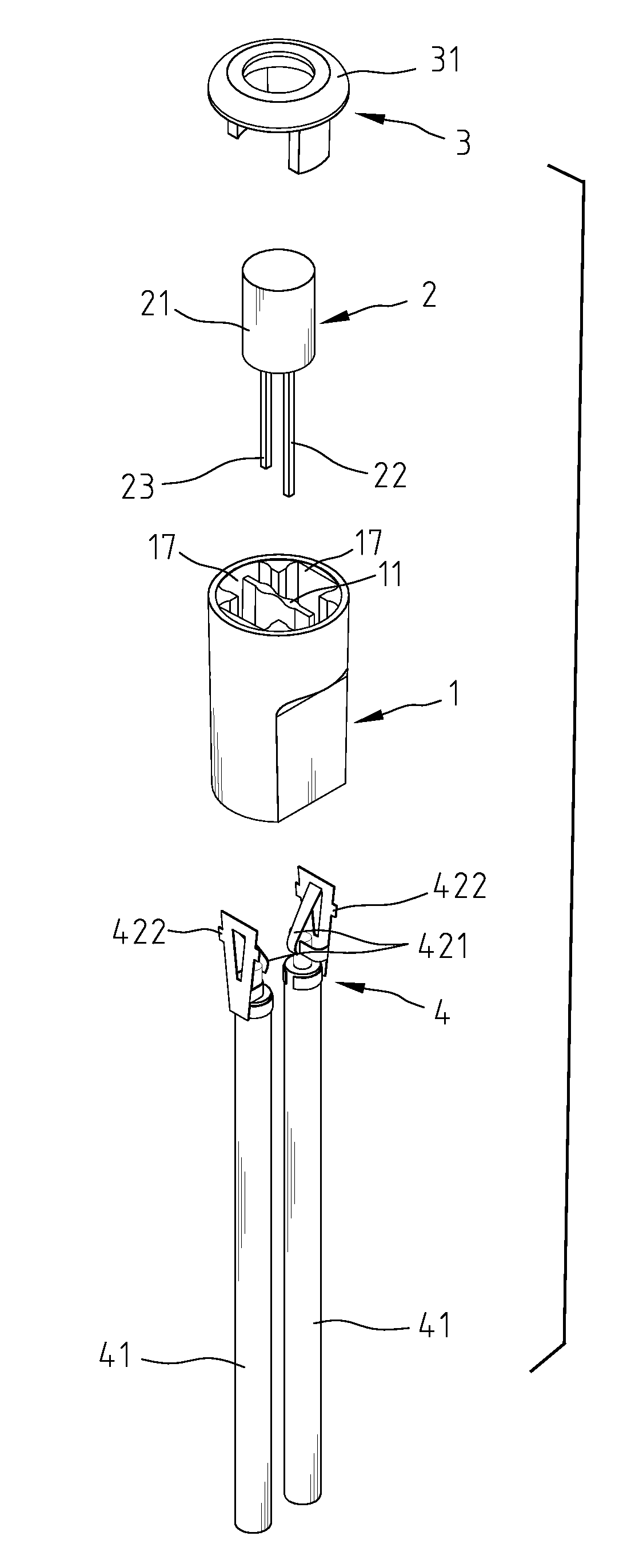

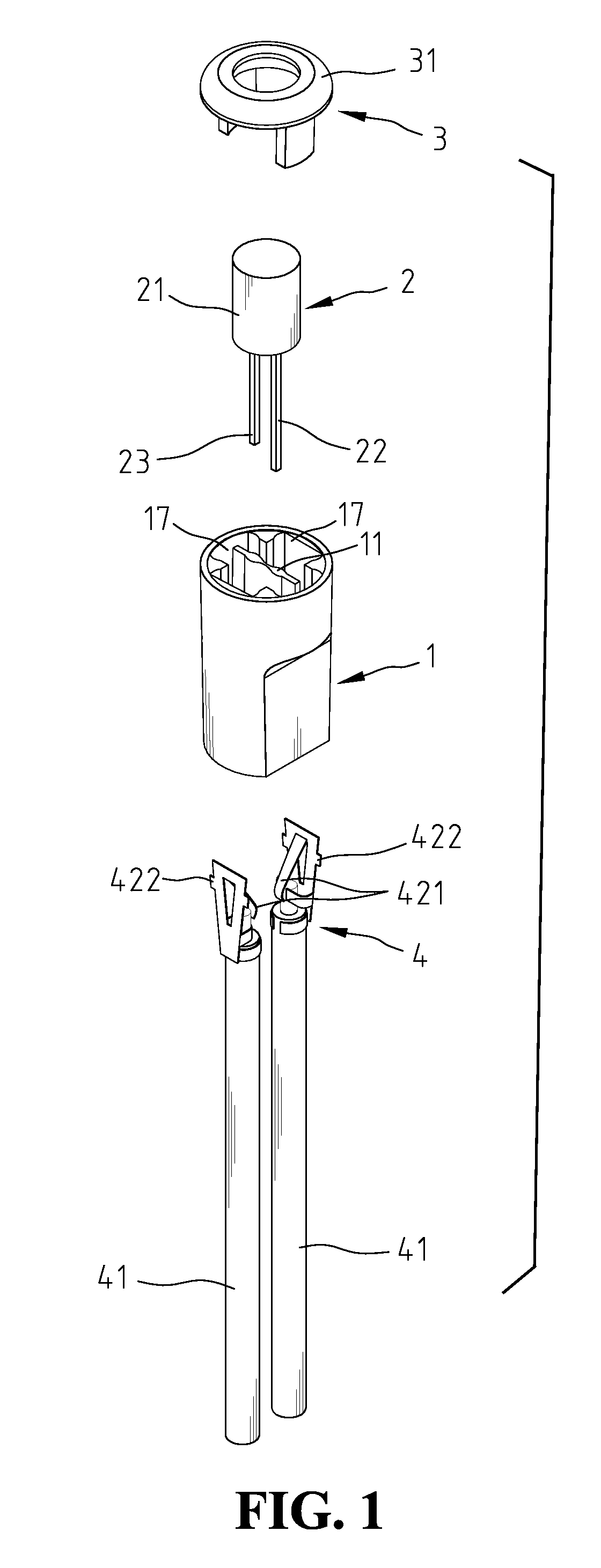

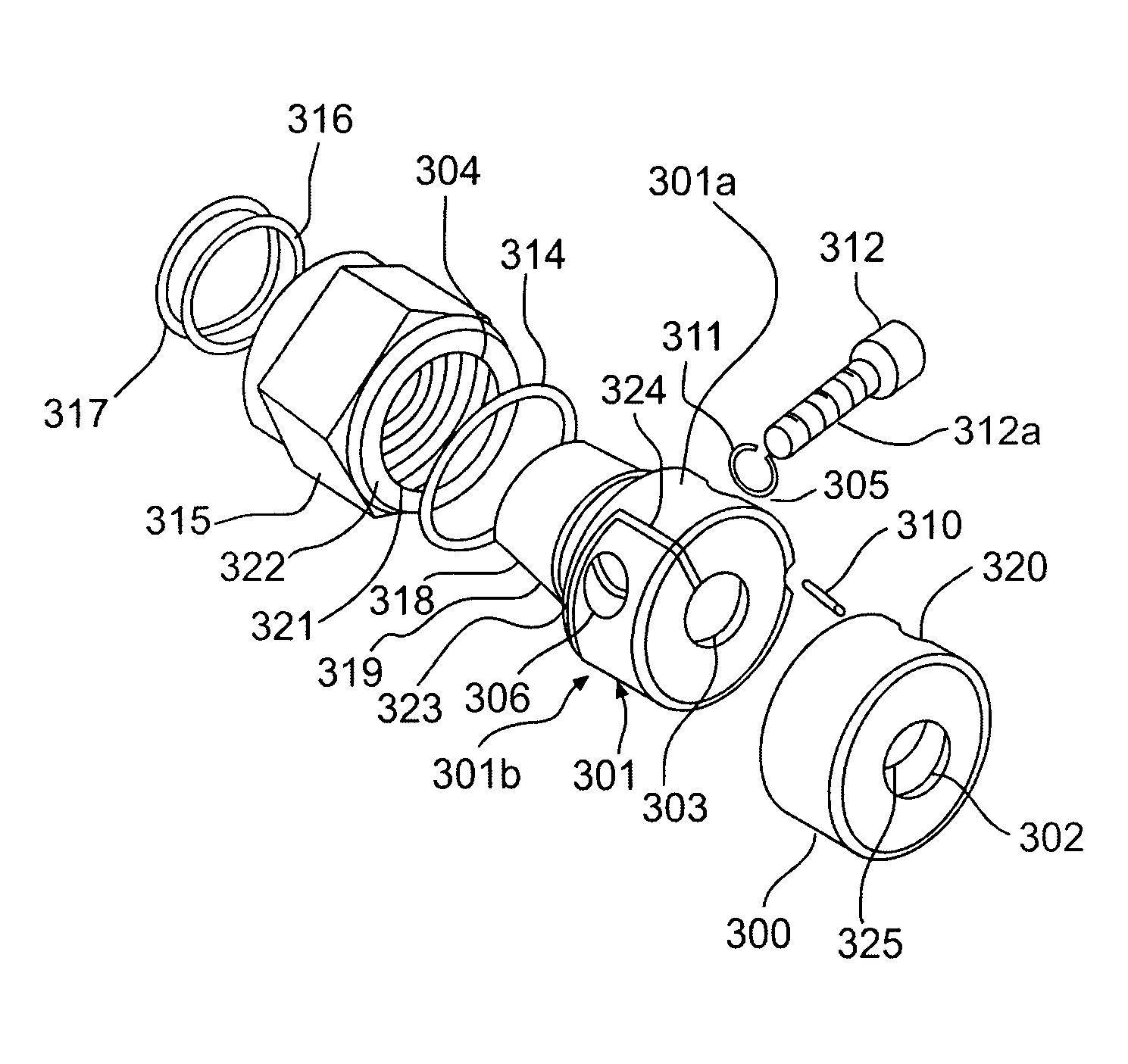

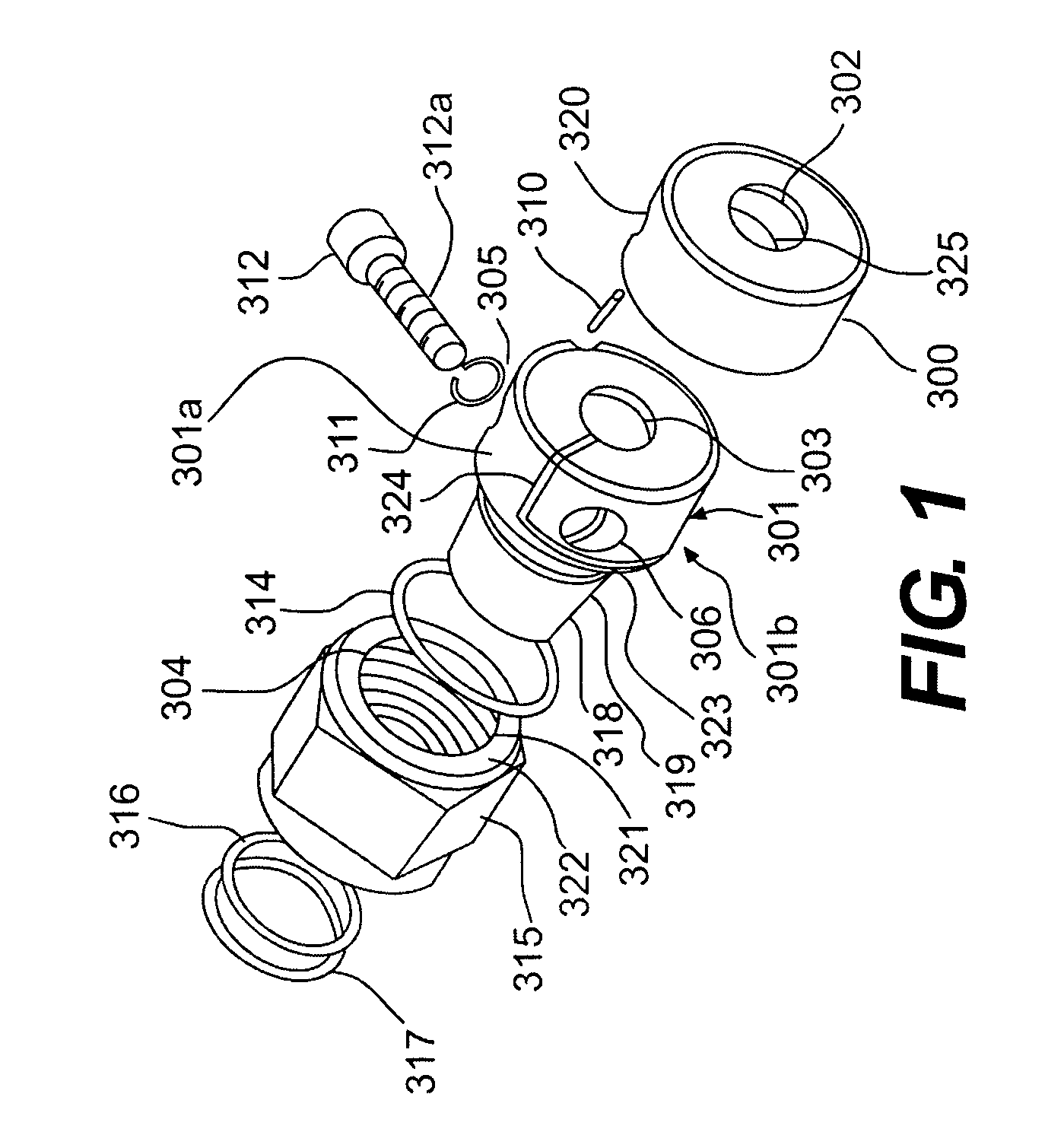

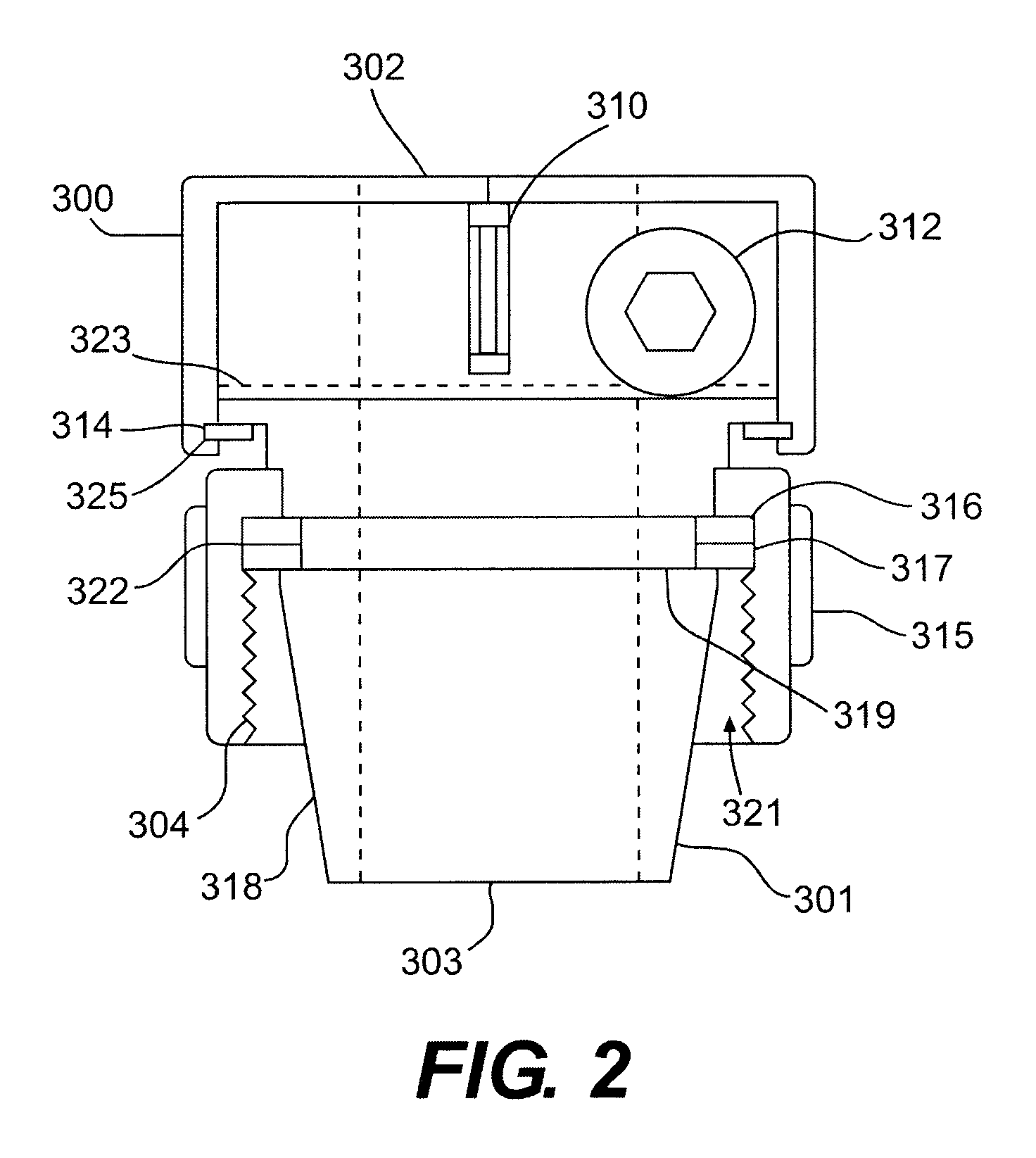

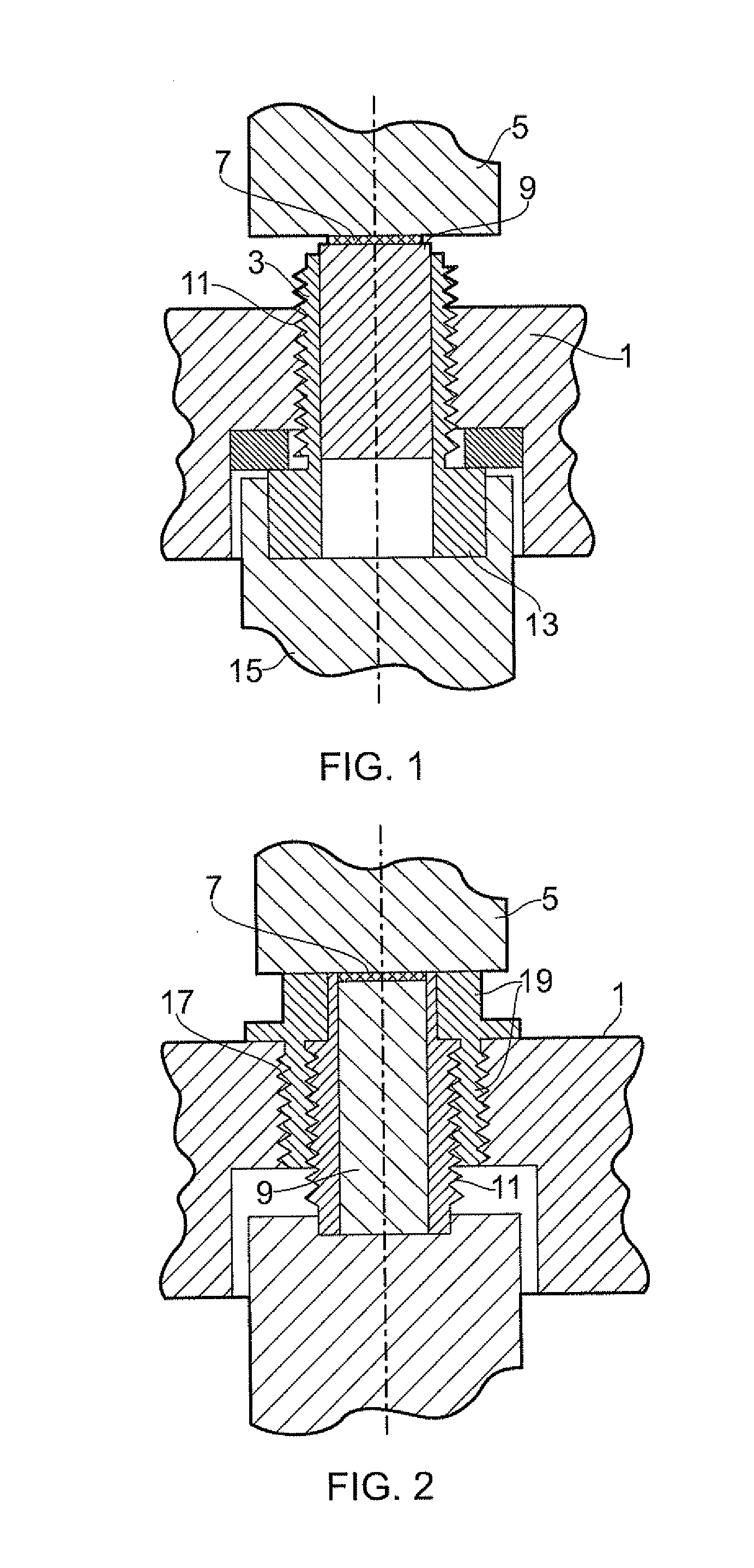

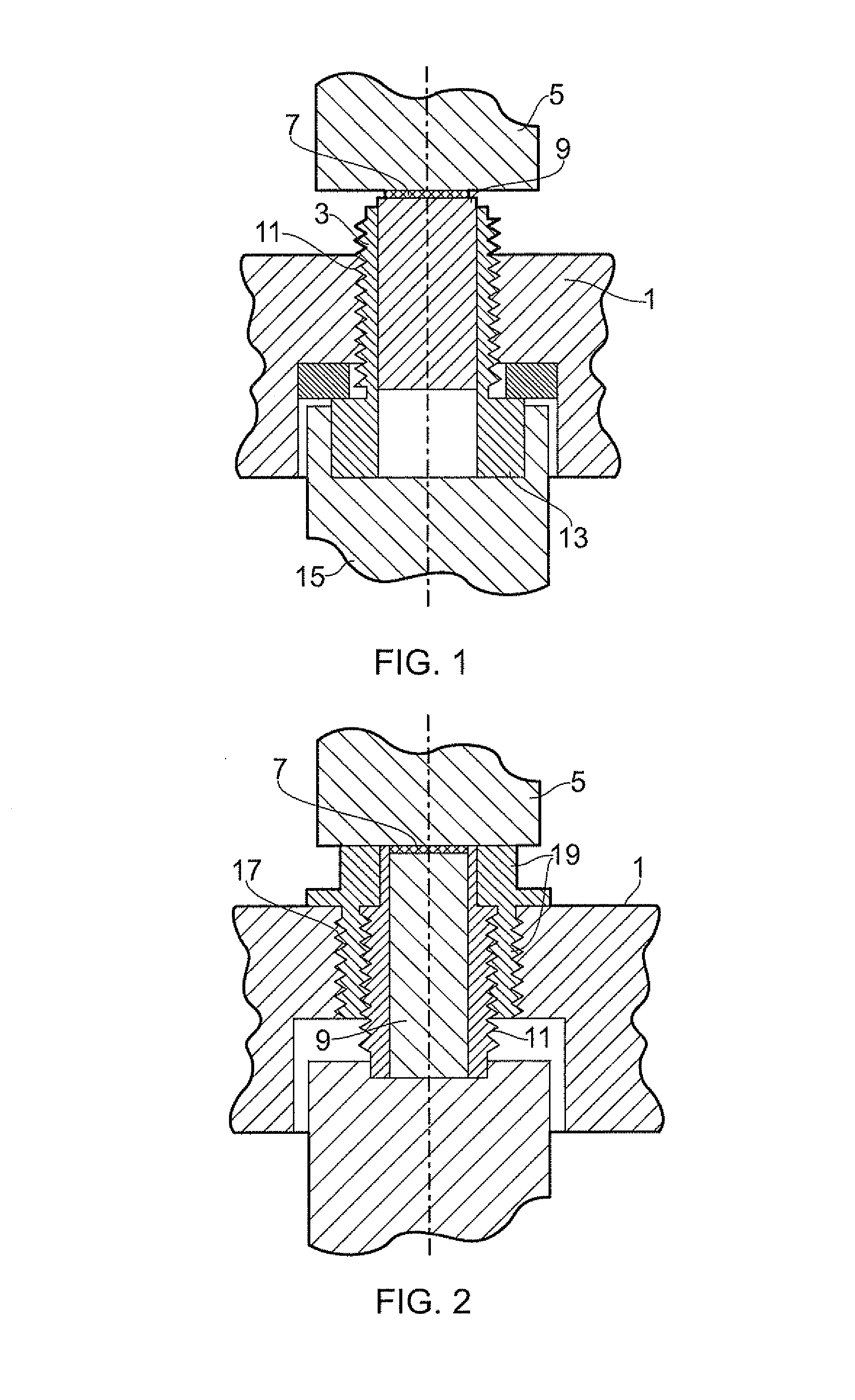

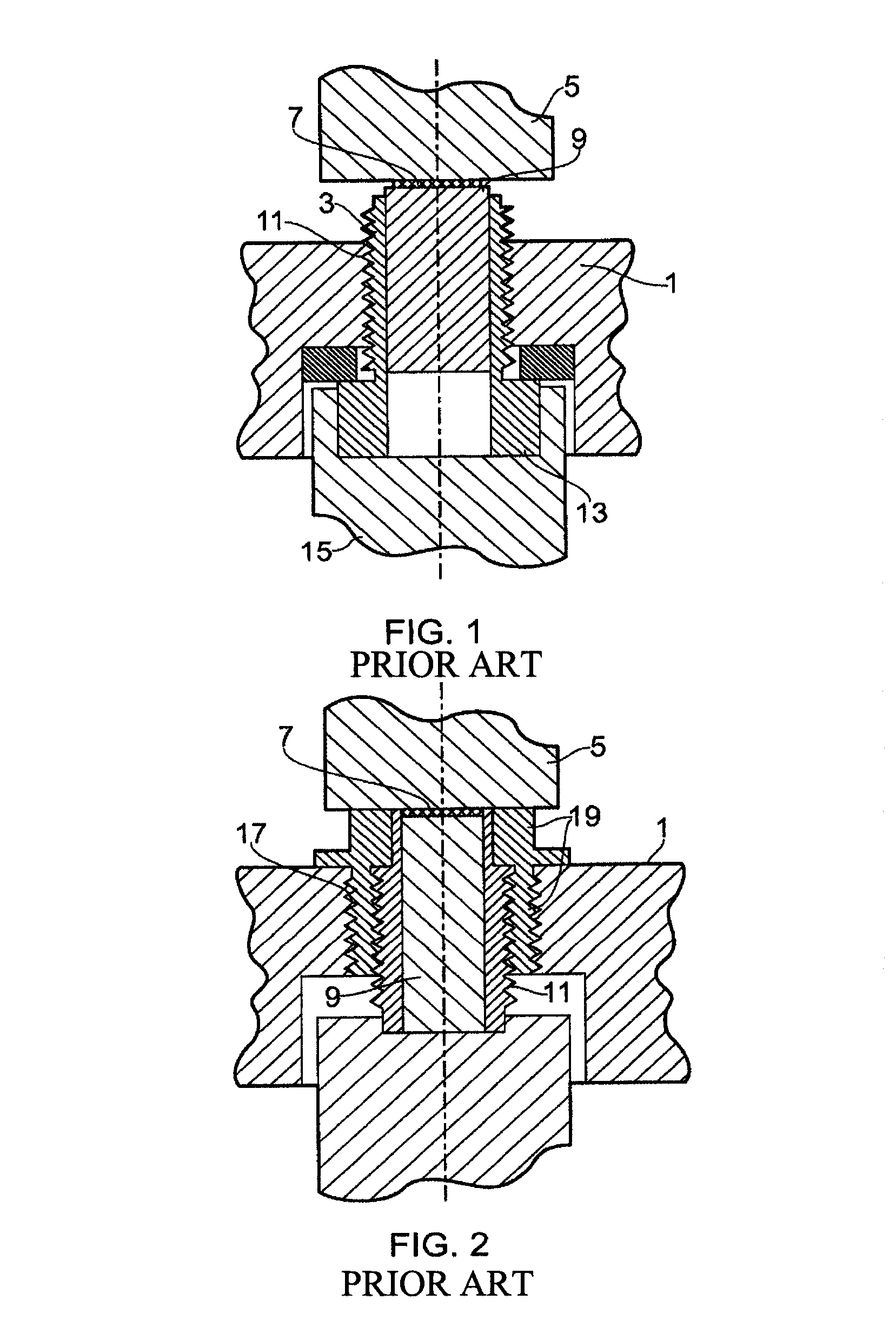

Quick change power tool chuck

InactiveUS6880832B2Prevent angular slippageIncreased holding torqueSleeve/socket jointsChucksPower toolDrill bit

An improved quick change power tool chuck is provided which is principally used on a wood working router but could also be used in many other power tool applications. The key features of the quick change chuck are the unique way that it secures the cutting bit from unwanted slippage, the large mechanical advantage thereof and the speed in which a cutting bit can be removed and replaced. The chuck can be aligned and attached to the power tool in the same manner that a standard collet is aligned and attached to the router spindle.

Owner:DEROSA JOHN L +1

Ding-stopper

InactiveUS7090266B1Efficient use ofAvoid easy removalSuperstructure subunitsRemovable external protective coveringsHigh densityEngineering

A vehicle side protector against dents and scratches due to the impact of a door of an adjacent vehicle. Comprised of high-density blocks, covered with a non-scratch fabric. Attached are strips of covered pads for the purpose of protrusion that will cause the apparatus to fit vehicles with curves, and to prevent smacking sound on contact. Magnetic strips are applied to the strips of covered pads to secure the apparatus to the vehicle. The strap consists of a long strip, and a thick tip joined together to prevent easy theft.

Owner:PRICE PAMELA SHARRON

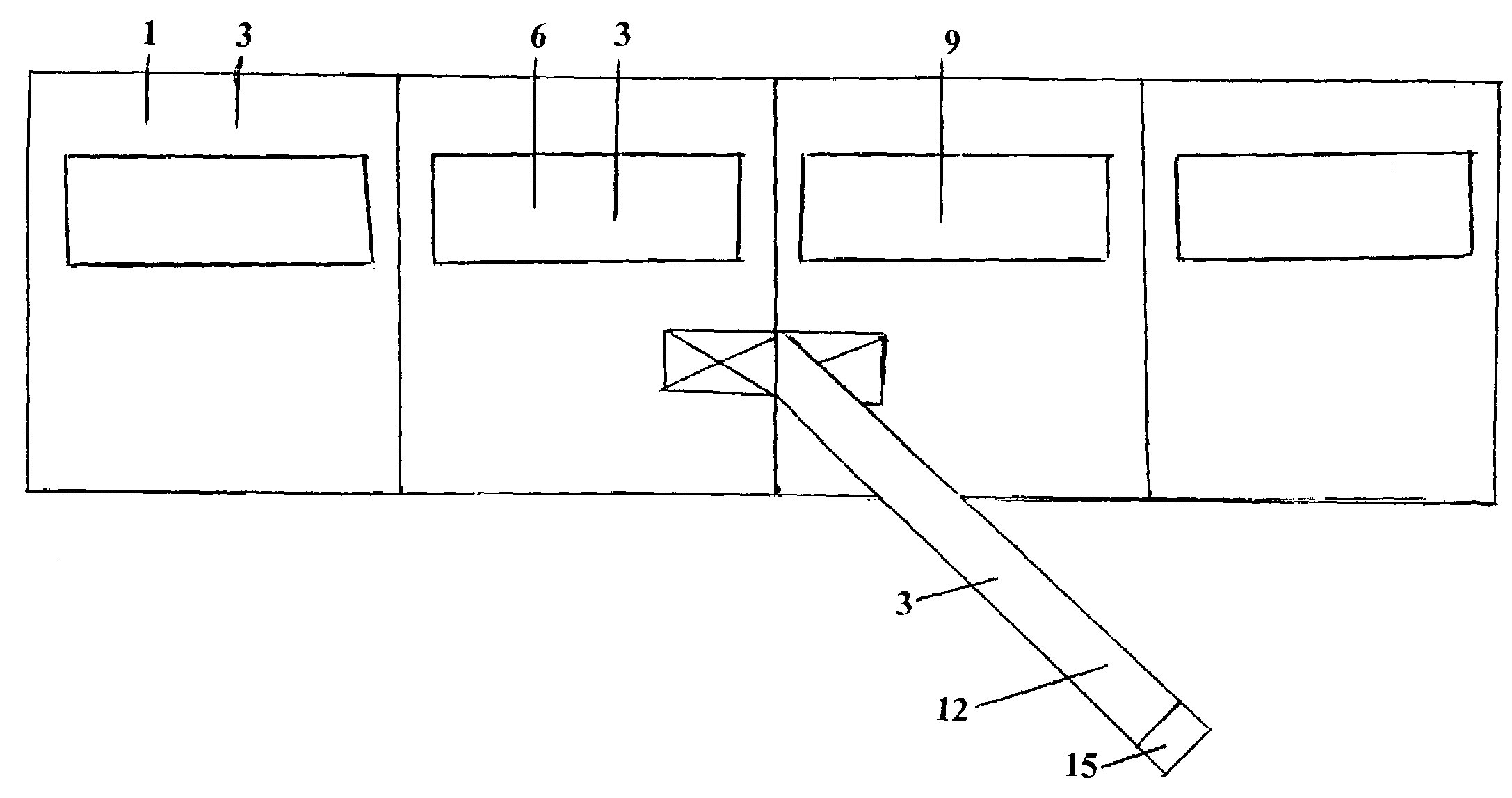

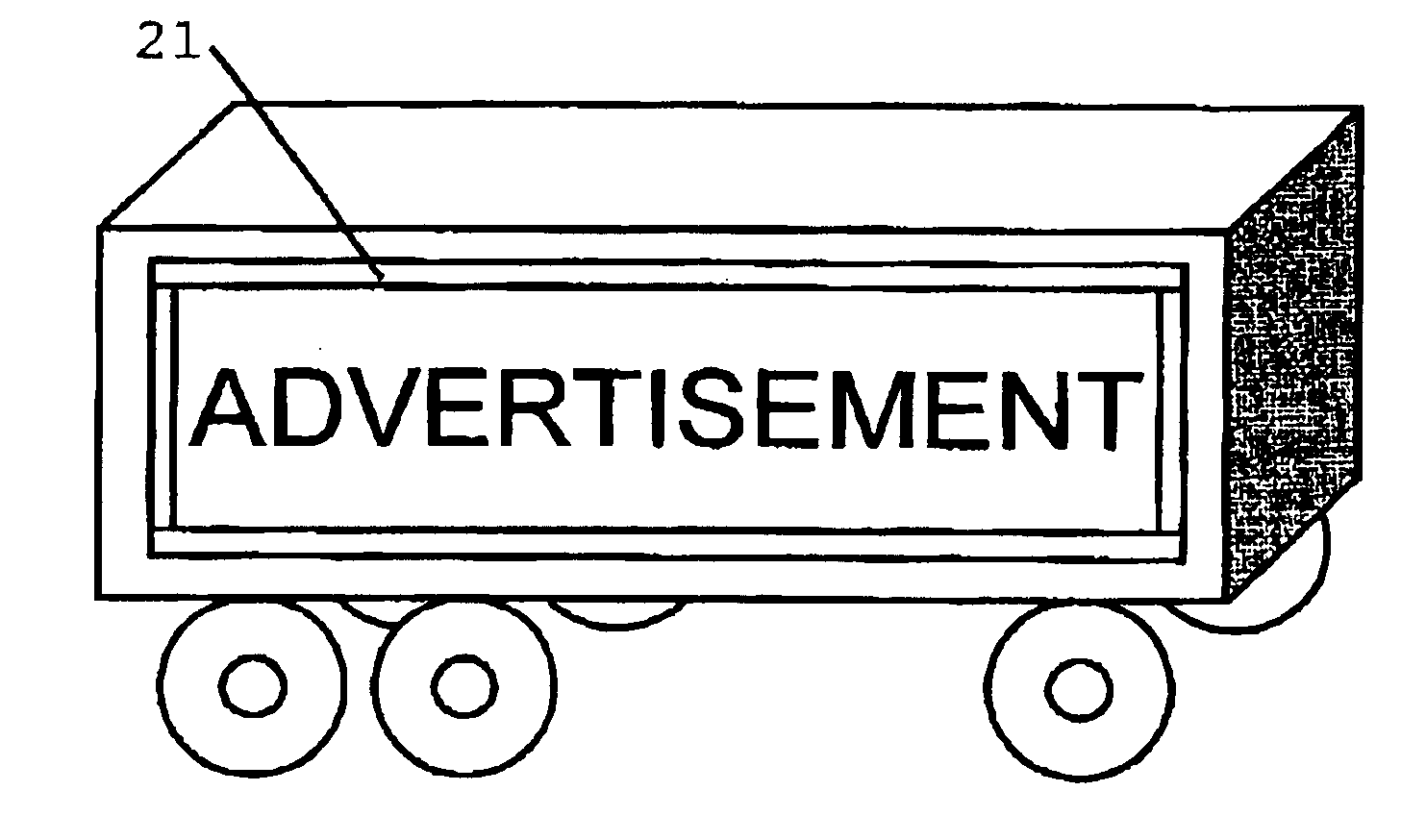

Display panel for a vehicle

InactiveUS6904709B2Easy to removeEasy to reapplyLayered productsMobile visual advertisingEngineeringAutomotive engineering

A display panel, for example an advertising panel, for use on an external surface of a vehicle is described. The display panel comprises a substantially non-permeable flexible sheet and is removably fastened to the vehicle around the around the majority of the perimeter of the flexible sheet. An adapted vehicle, a vehicle and panel assembly, and a method of application are also described. In one embodiment, the fastening material is provided with strategically placed gaps to act as fluid outlets.

Owner:SPEDIAN

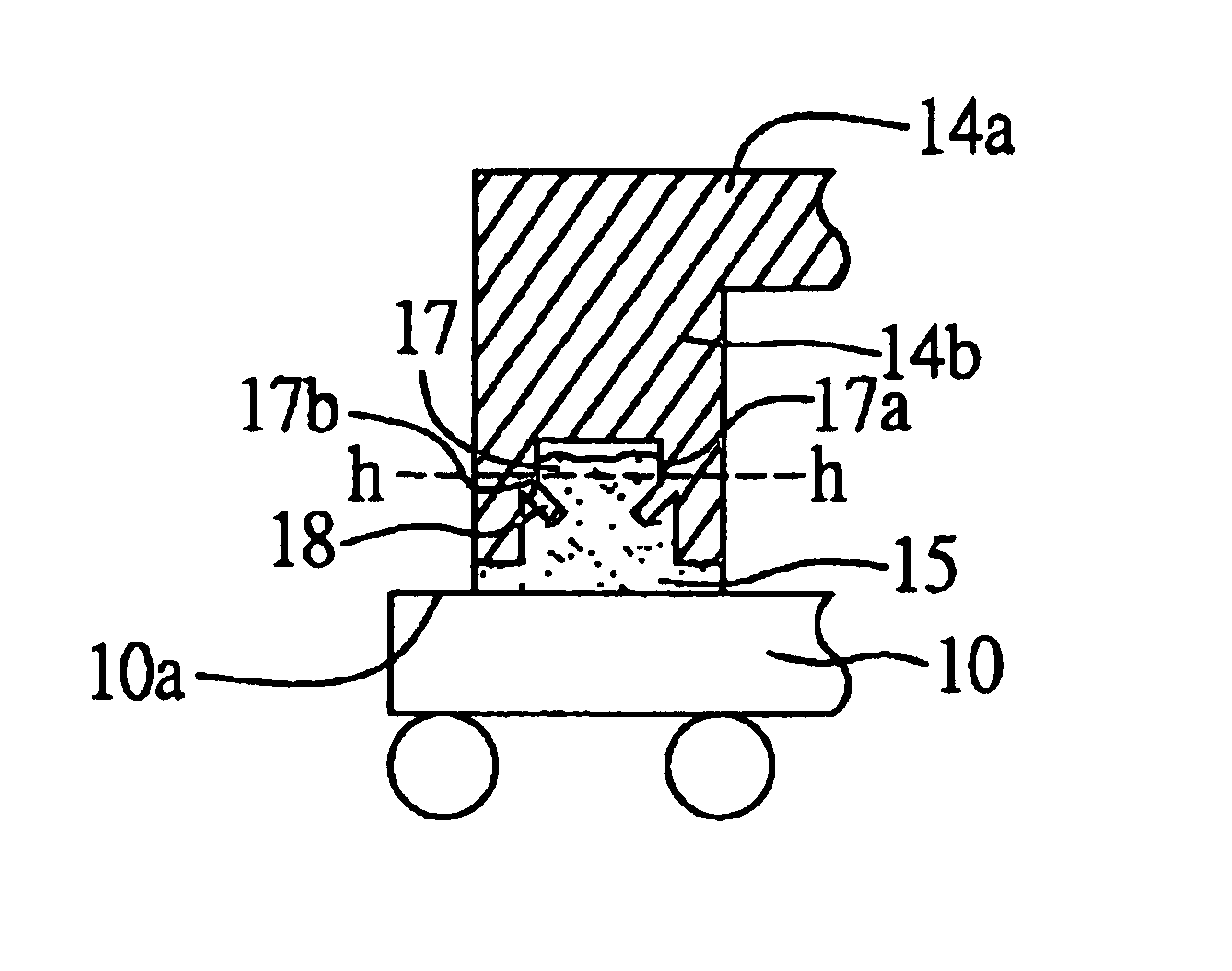

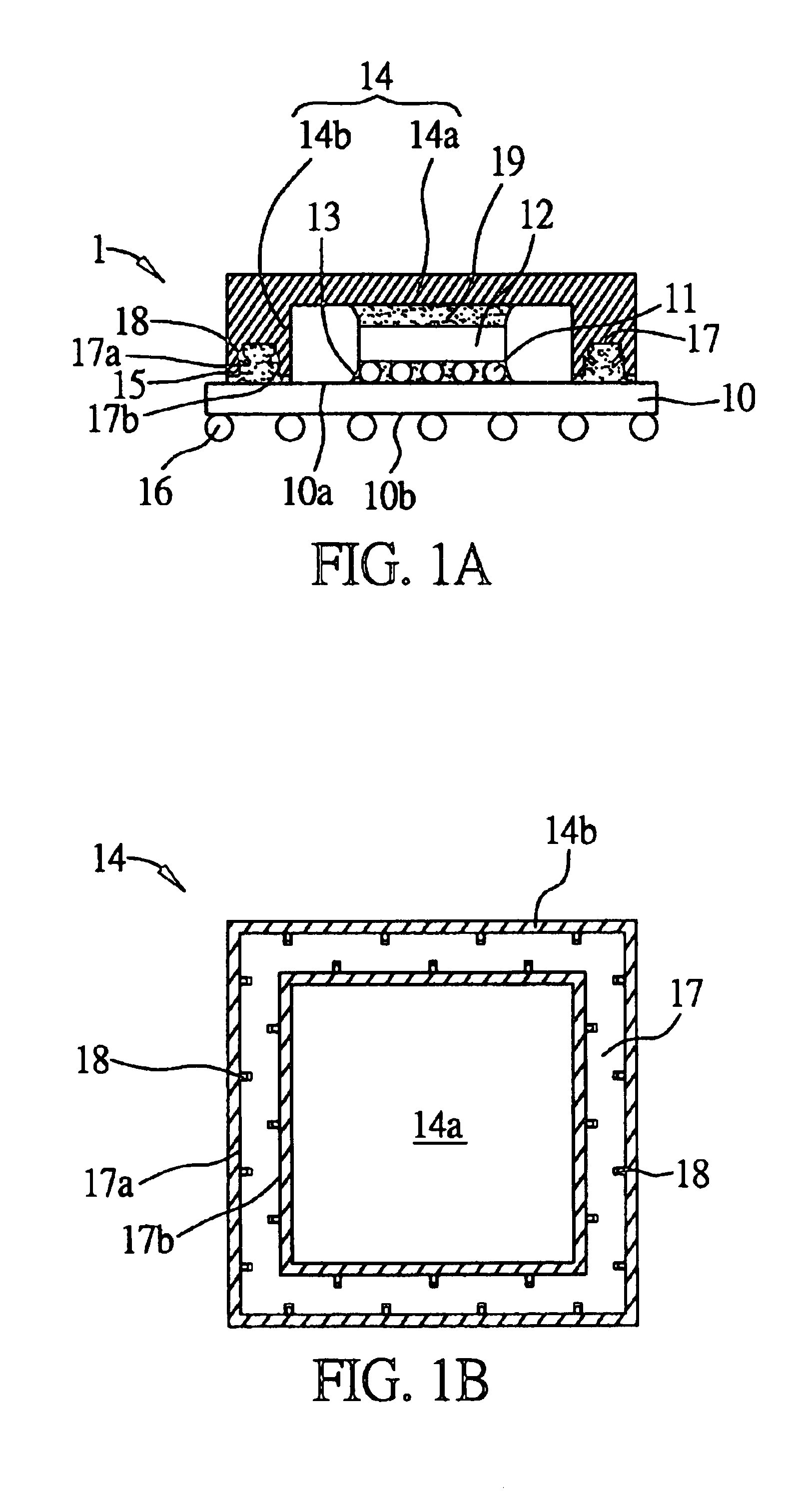

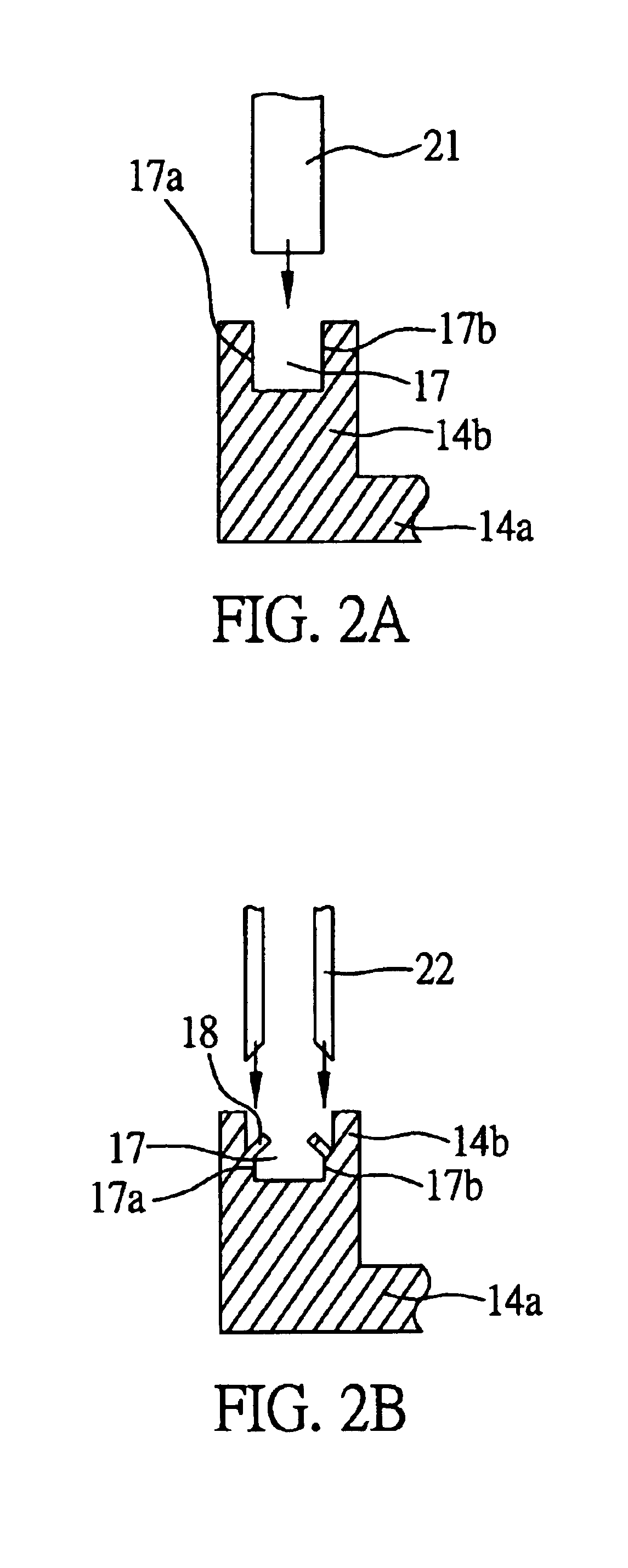

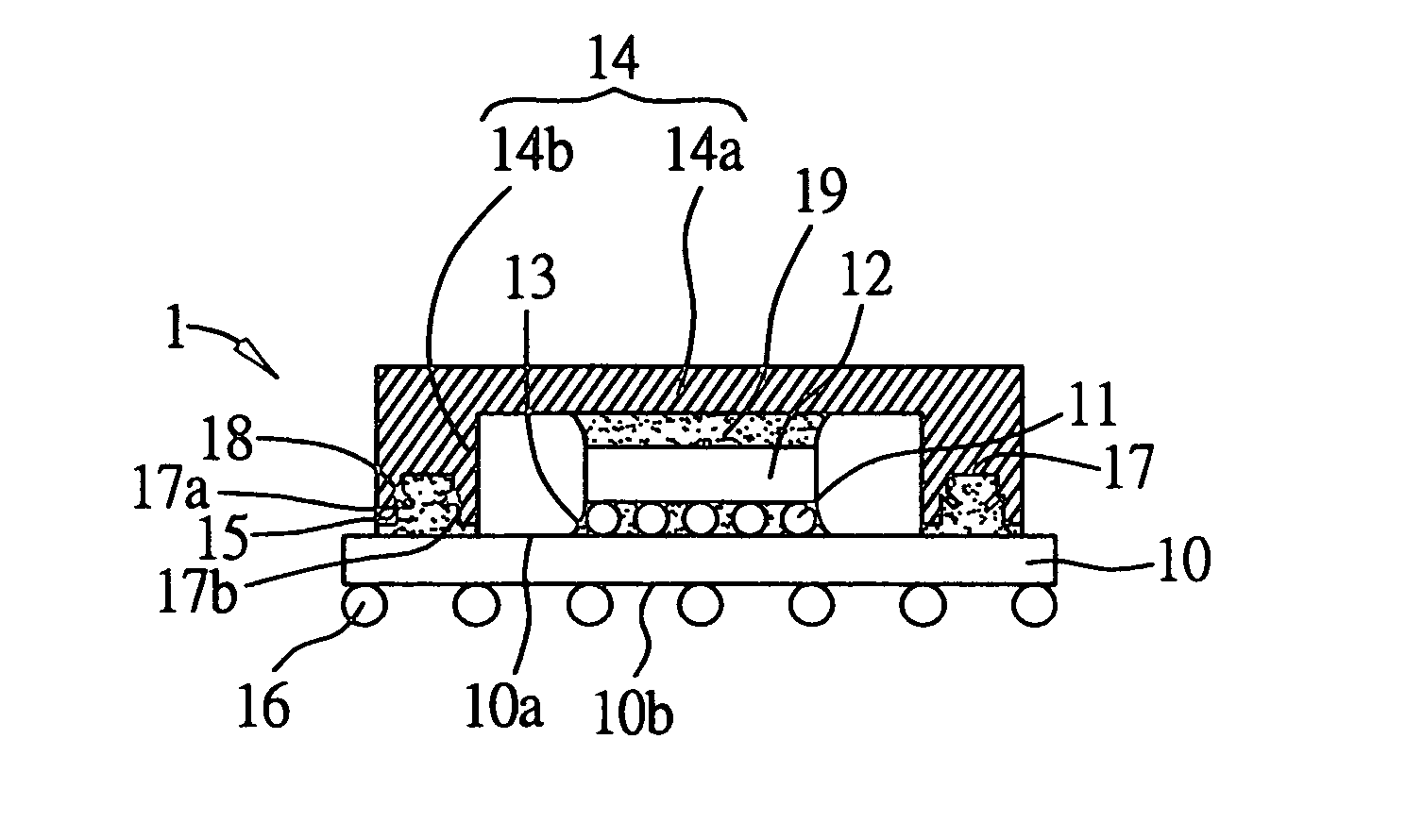

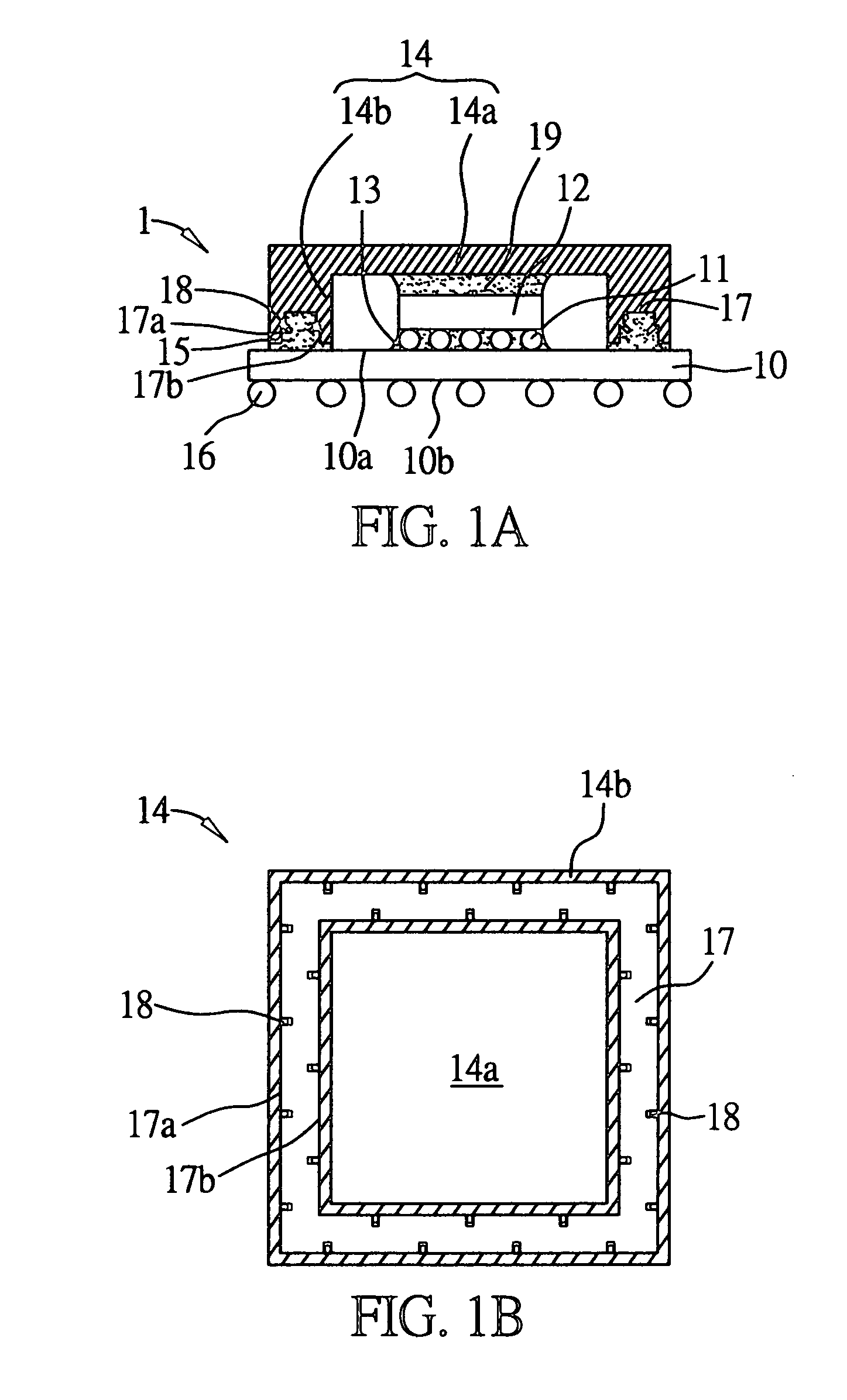

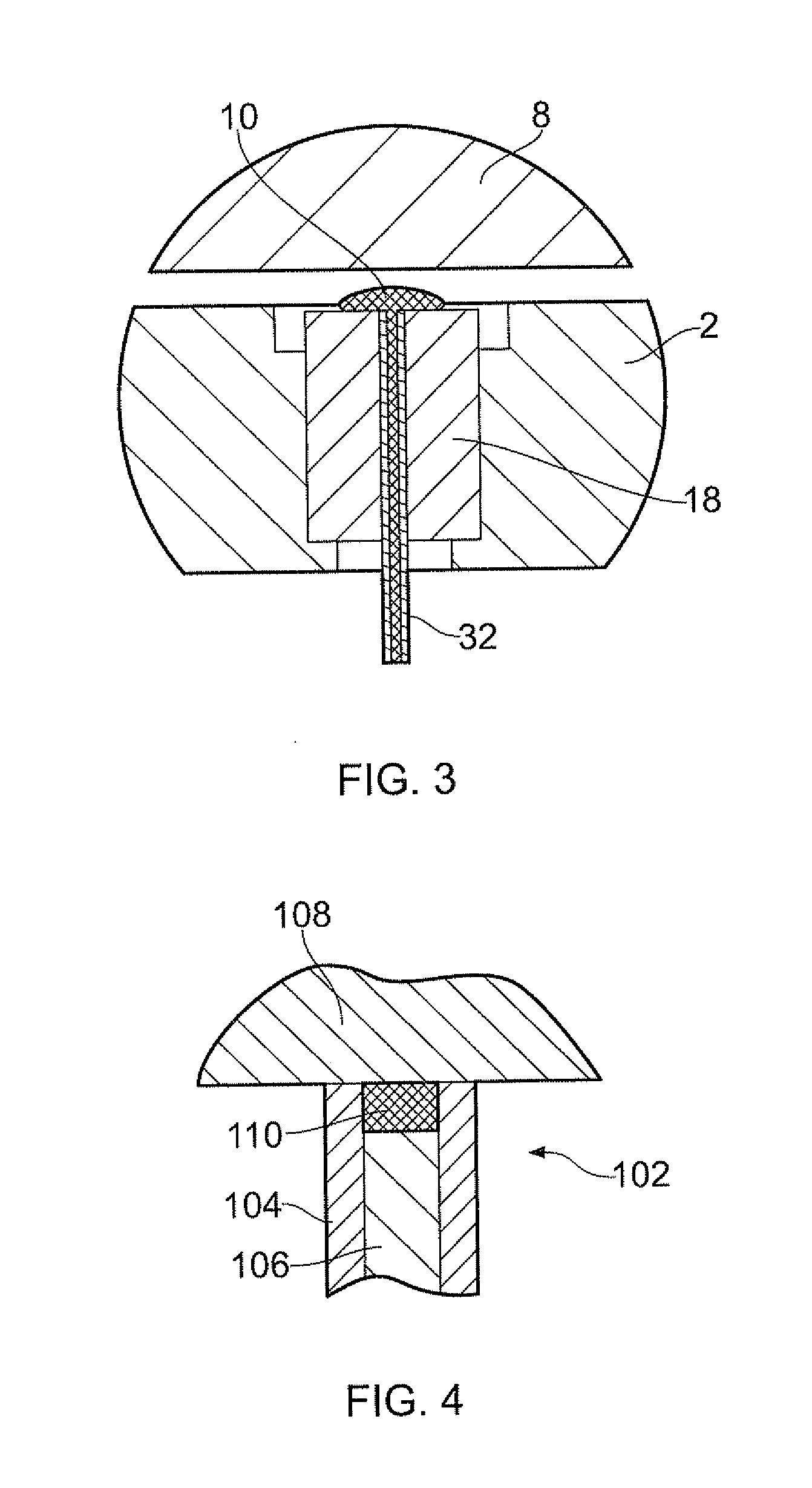

Semiconductor package with heat sink

ActiveUS6856015B1Increase contact areaImprove anchoring abilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor package

A semiconductor package includes a substrate having a top surface and a bottom surface; at least one chip mounted on the top surface of the substrate and electrically connected to the substrate; a heat sink attached to the top surface of the substrate by an adhesive material applied therebetween; and a plurality of solder balls implanted on the bottom surface of the substrate. The heat sink has a flat portion and a support portion connected to the flat portion. The support portion has at least one recess portion facing toward the top surface of the substrate and at least one burr formed on an interior surface of the recess portion such that the adhesive material can fill the recess portion and submerge the burr to provide an anchoring effect to firmly secure the heat sink in position on the substrate.

Owner:SILICONWARE PRECISION IND CO LTD

Semiconductor package with heat sink

InactiveUS20050040519A1Increase contact areaImprove anchoring abilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor package

Owner:SILICONWARE PRECISION IND CO LTD

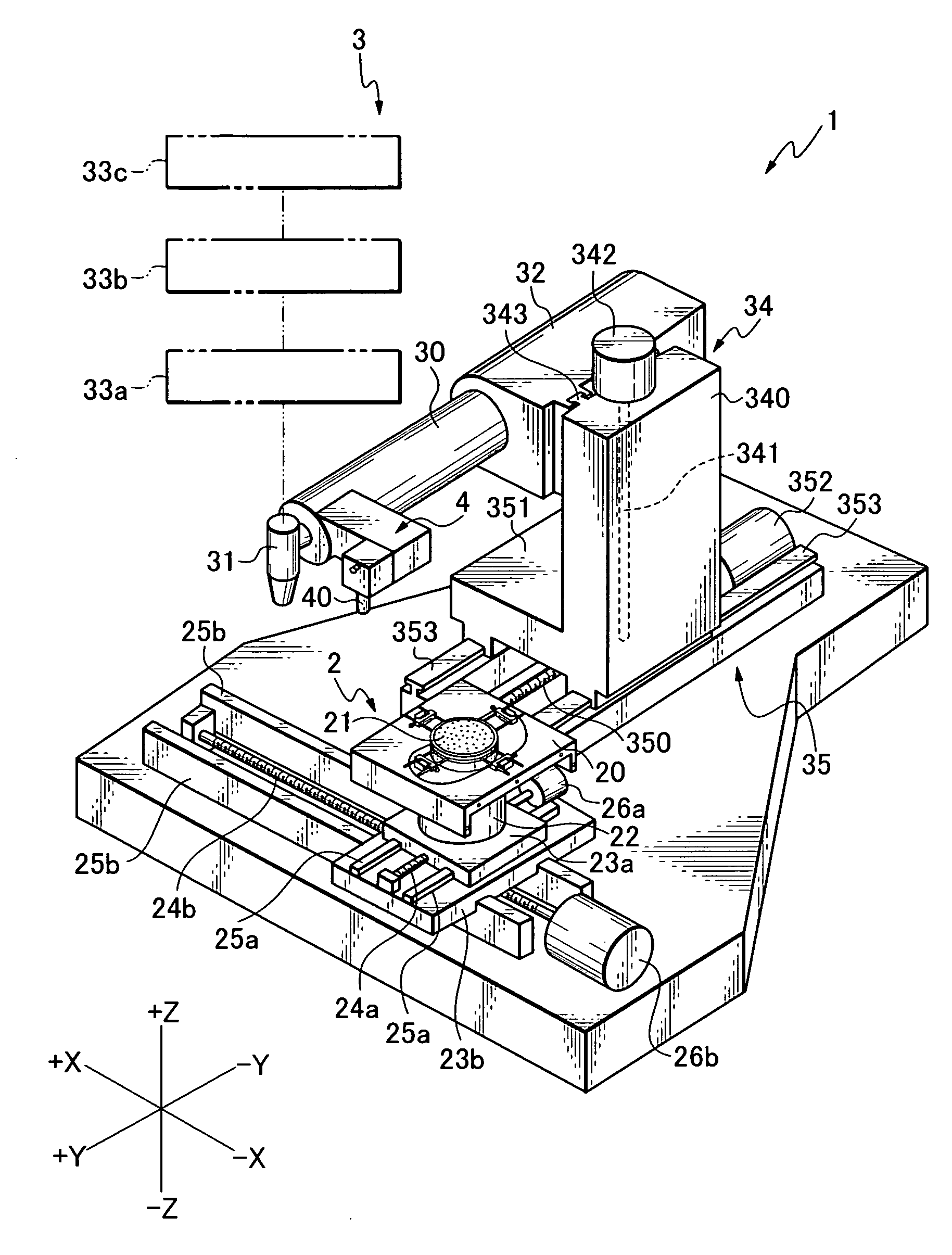

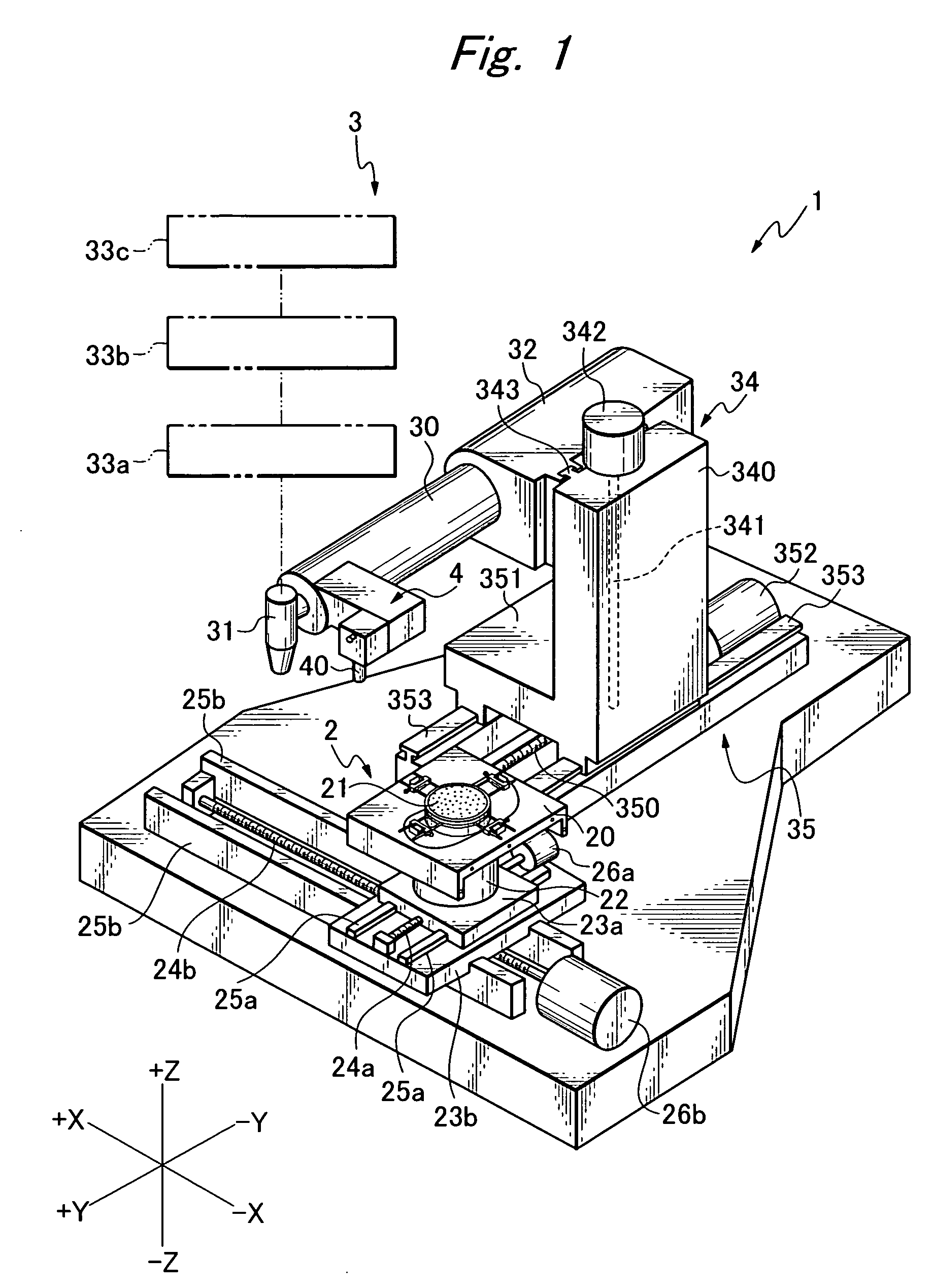

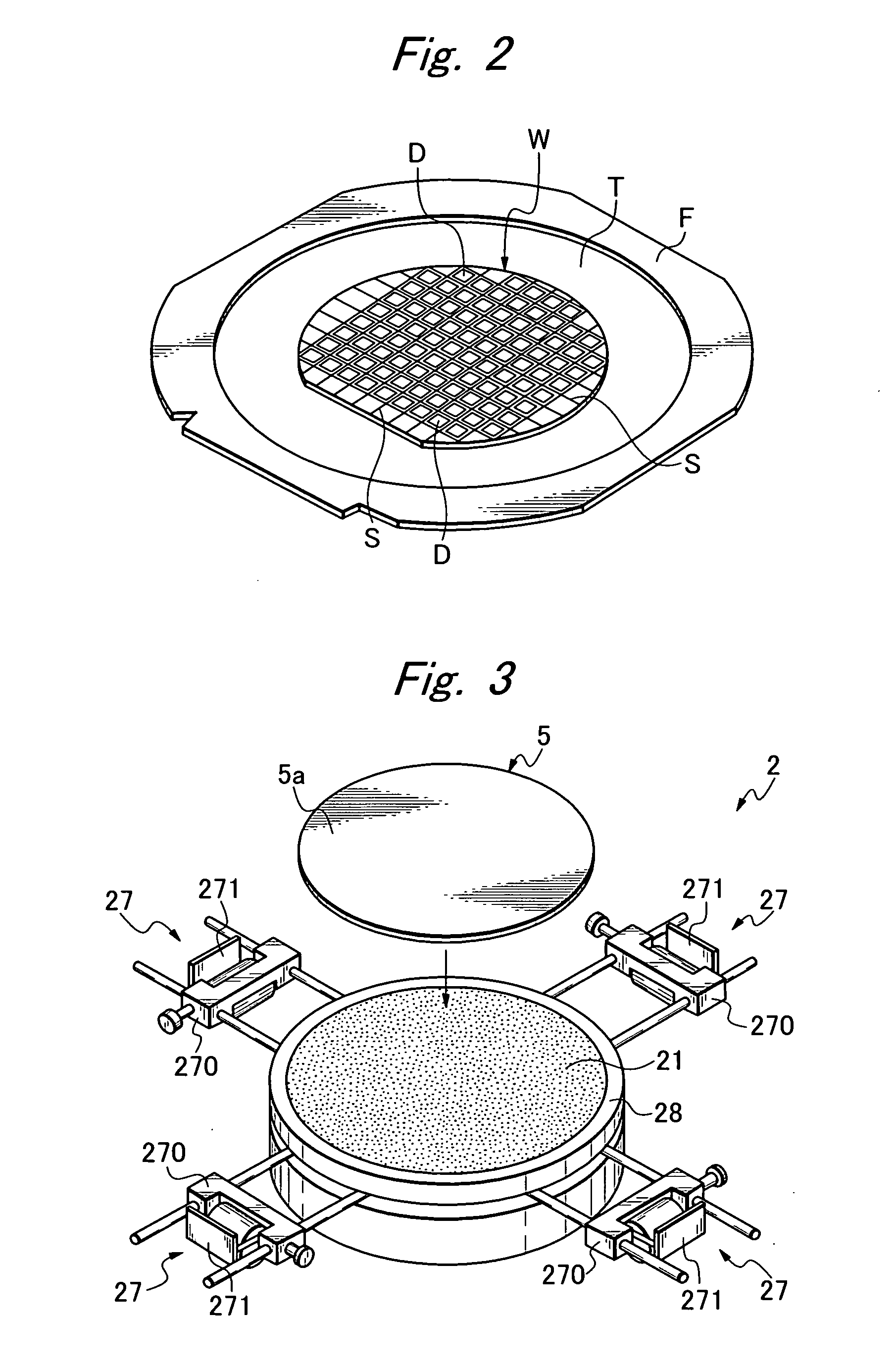

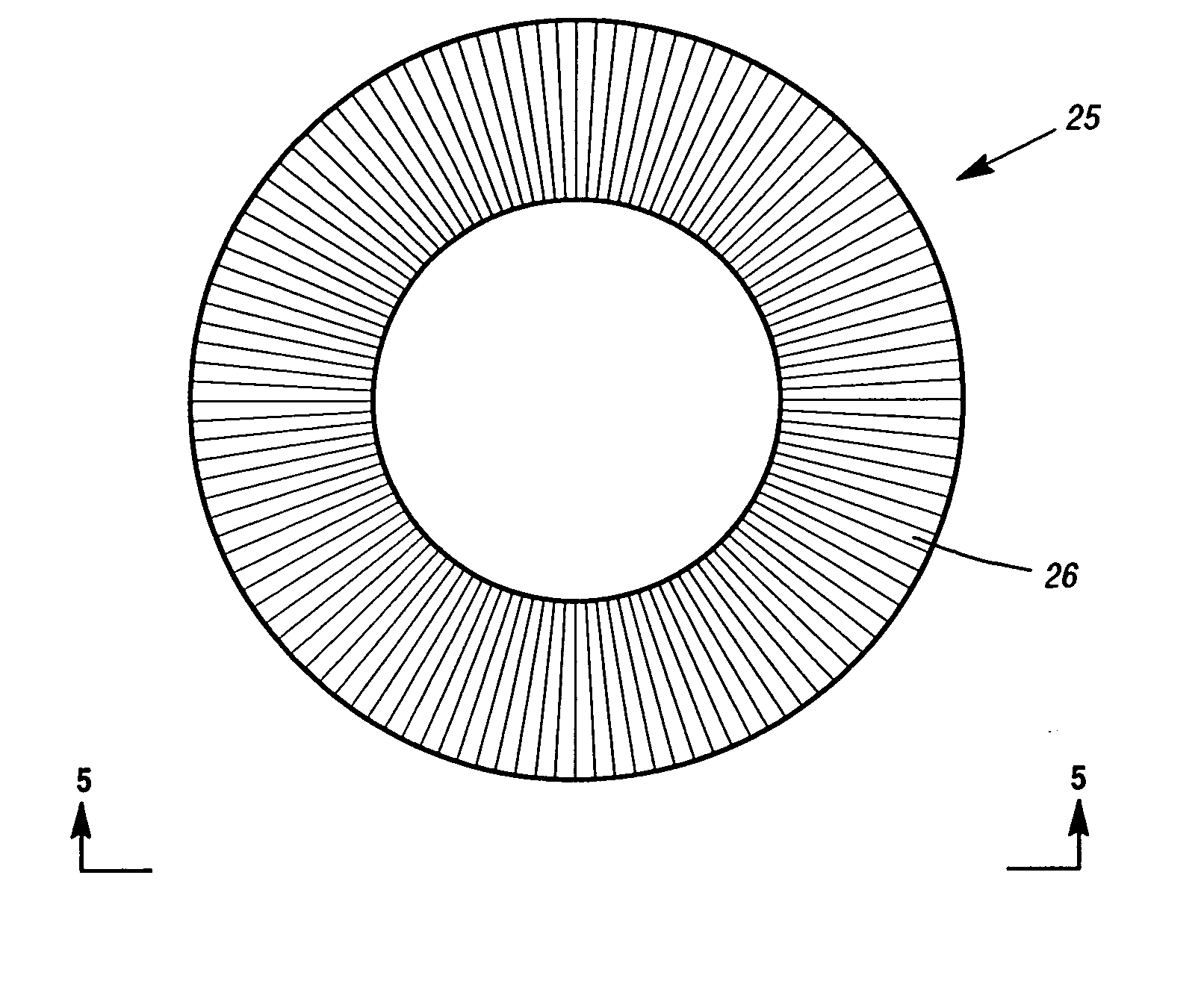

Wafer holding mechanism

ActiveUS20060203222A1Avoid heatingImprove permeabilityWelding/cutting auxillary devicesPhotomechanical apparatusSuction forceEngineering

To prevent heating of a holding table that holds a wafer when using a laser beam to process a wafer, a wafer holding mechanism has a wafer holder having a holding surface that holds a wafer and a suction part formed on an outer peripheral side of the wafer holder, with the wafer held to the holding surface by a suction force transmitted to the holding surface from the suction part through an outer peripheral edge part of the wafer holder. The wafer can be held in place with suction without forming fine holes that penetrate the wafer holder from a front surface thereof to a back surface thereof, and therefore a material of good permeability and dispersibility with respect to the wavelength of the laser light can be selected for the wafer holder.

Owner:DISCO CORP

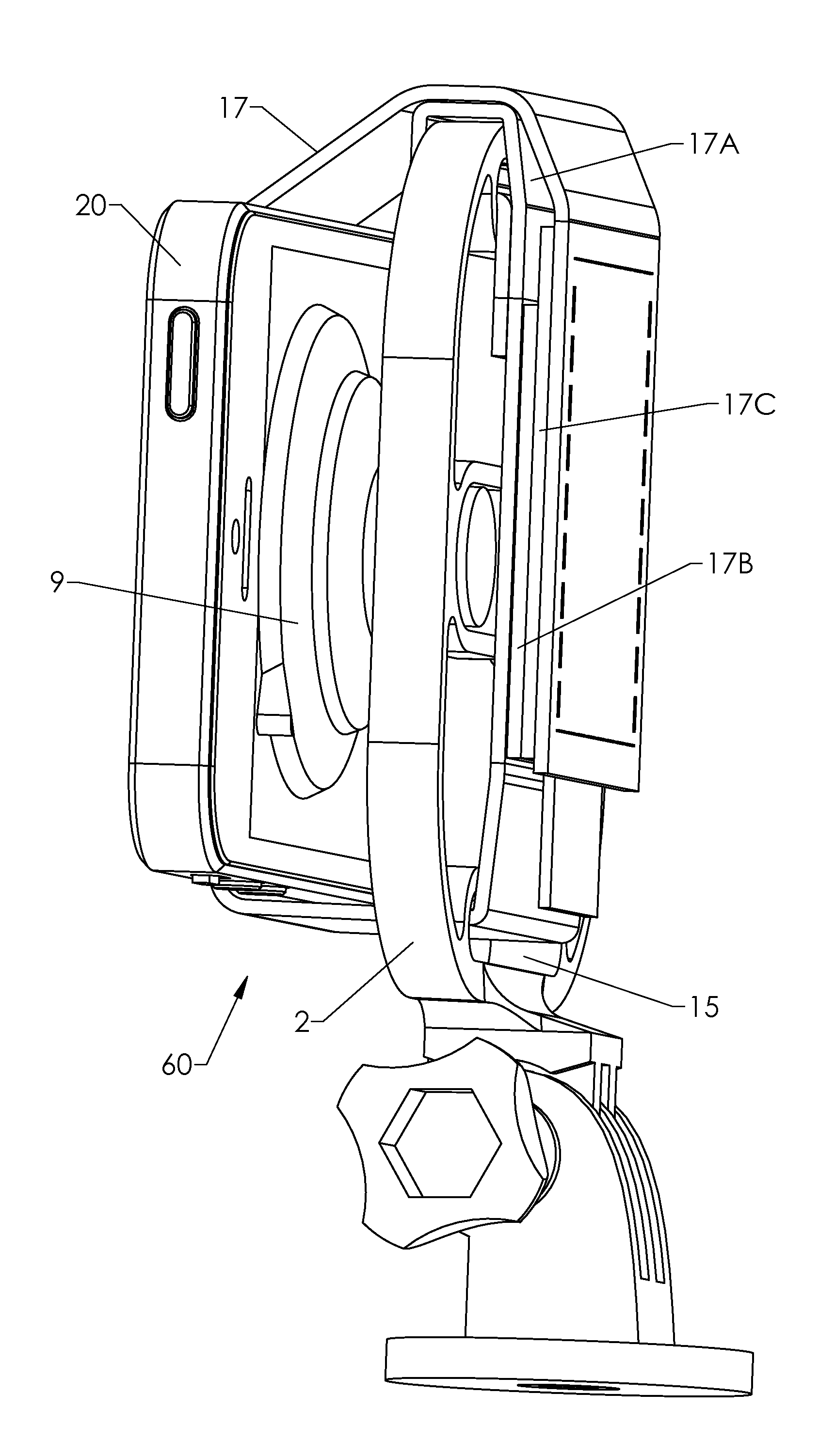

Suction Cup and Strap Mount for Action Video Recording with an Electronic Device

ActiveUS20160381259A1Securely holdAvoid compressionTelevision system detailsSecuring devicesVideo recordEngineering

Owner:JOHNSON AUGUST ANDREW

Structure for christmas light

InactiveUS20100254161A1Easy to assembleStrong holdPoint-like light sourceElectric discharge tubesEngineeringLED lamp

A structure for LED Christmas light is provided, including a light holder, being a hollow body having a separating part connected to the inner wall of the light holder to divide the hollow interior of the light holder into two cavities. Each of the two opposite sides of the inner wall of the light holder connected to the separating part forms a slot and face the surface of the separating part of the two cavities, with each having a guiding channel. Two wire sets are fixed inside the two cavities. An LED light bulb has a positive pin and a negative pin inserted inside the guiding channel, respectively, and being electrically connected to the wire sets. A light cap has a holding part passing the LED light bulb to tightly engage to the top of the light holder so as to fix the LED light bulb to the light holder.

Owner:LIU CHUN MING

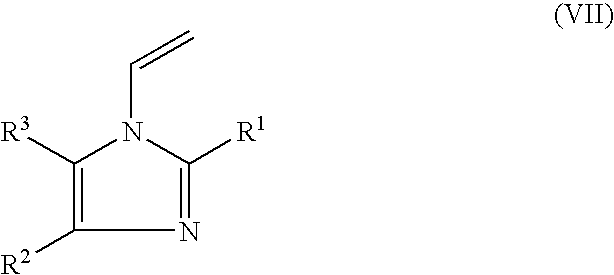

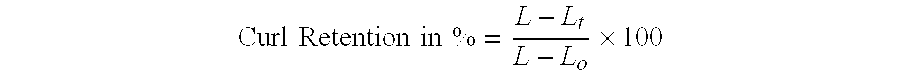

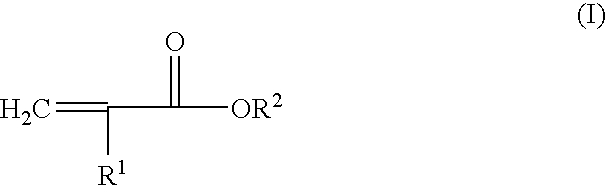

Cosmetically used cross-linked methyl methacrylate-copolymer

InactiveUS20100135917A1Good storage stabilityPromote aggregationCosmetic preparationsHair removalCross-linkDouble bond

The present invention relates to cosmetic preparations which comprise at least one polymer A which comprises, in copolymerized form, methyl methacrylate, methacrylic acid, acrylic acid, if appropriate at least one compound with at least two free-radically polymerizable, olefinically unsaturated double bonds, and if appropriate further olefinically unsaturated compounds, with the proviso that the amount by weight of the methacrylic acid is at least equal to the amount by weight of the acrylic acid.

Owner:BASF AG

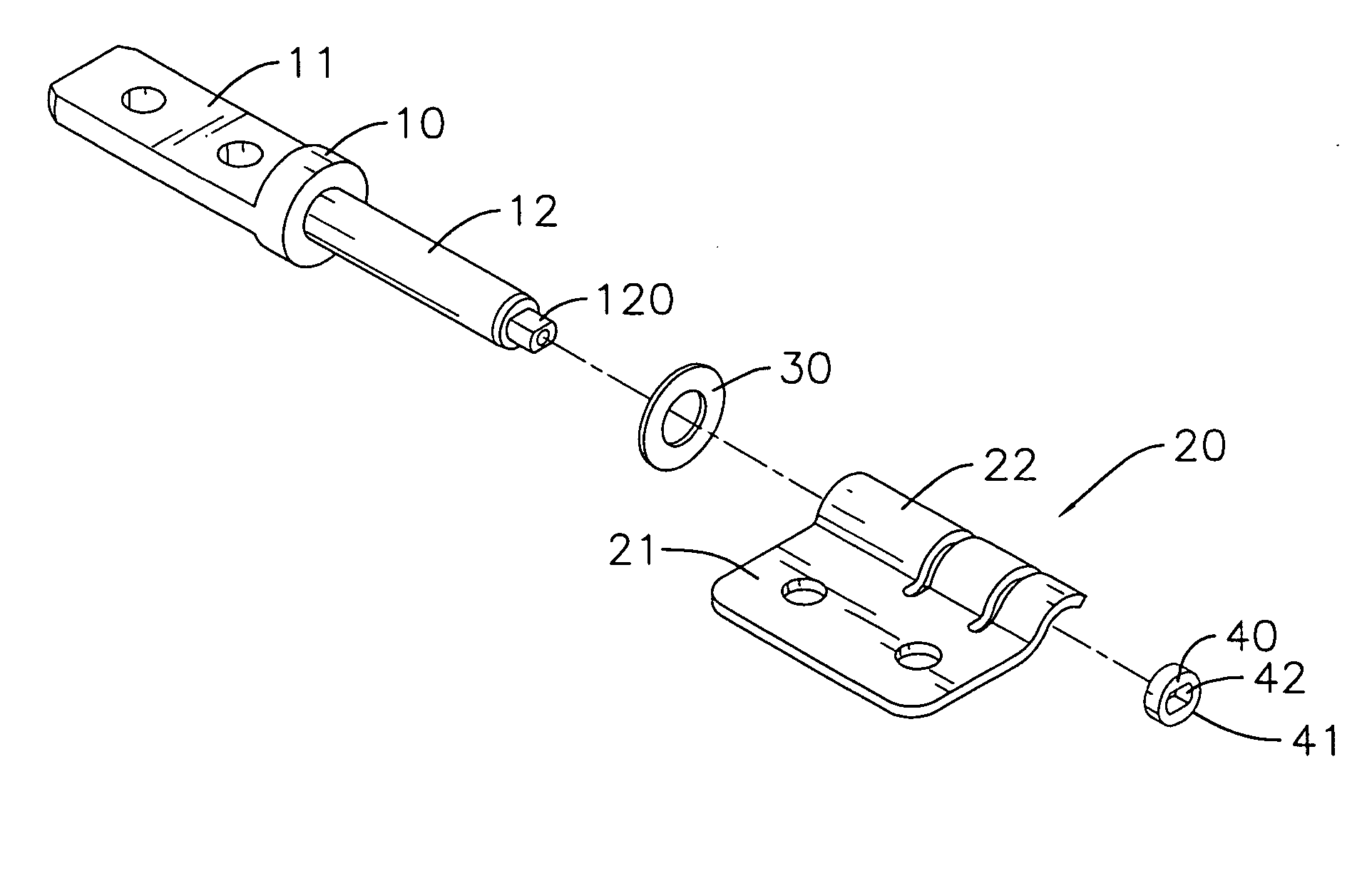

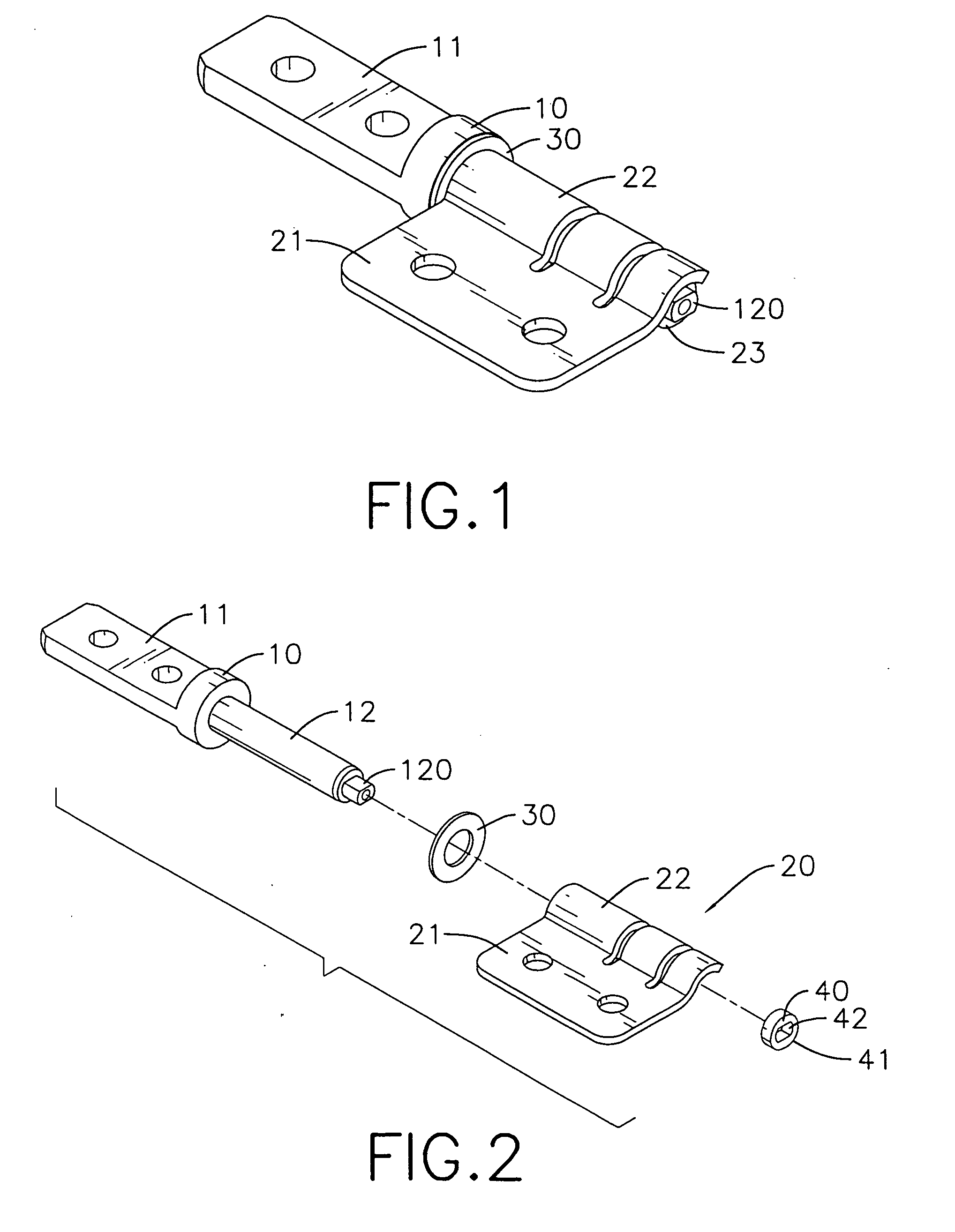

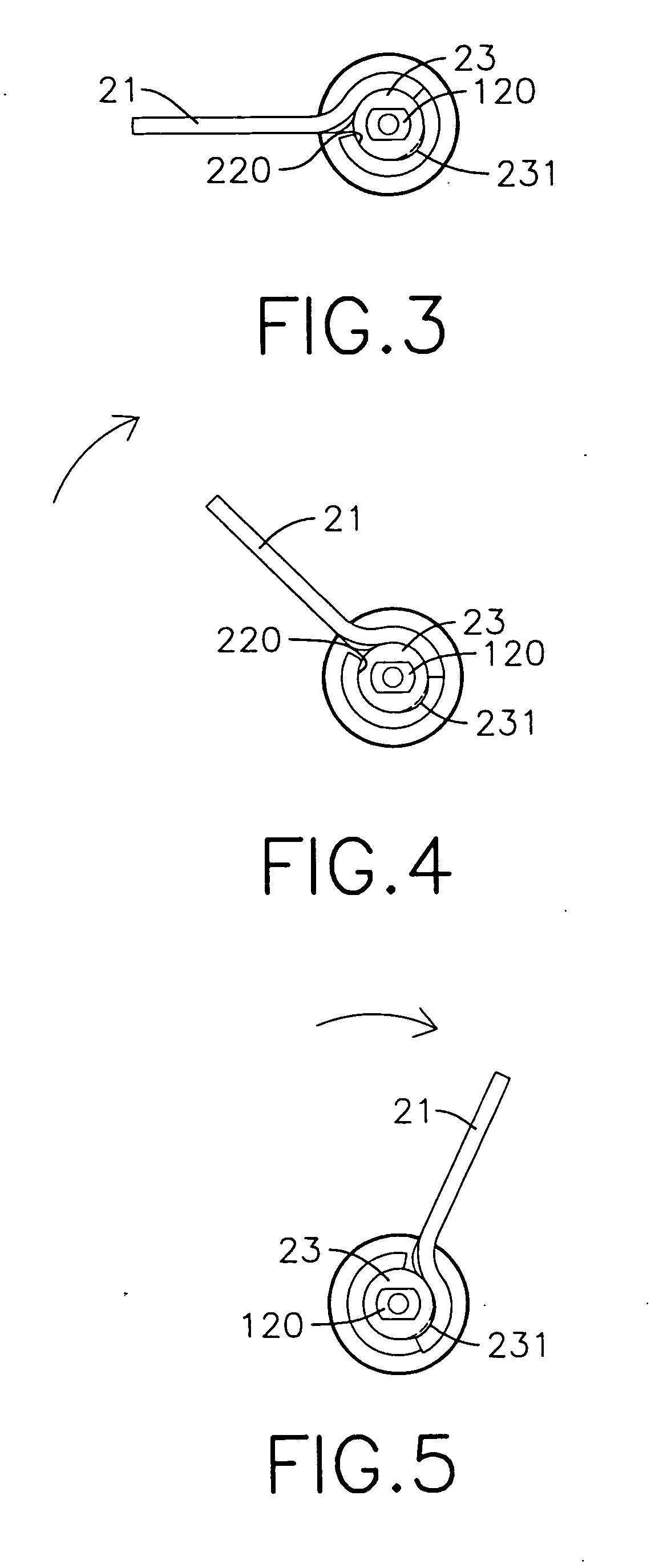

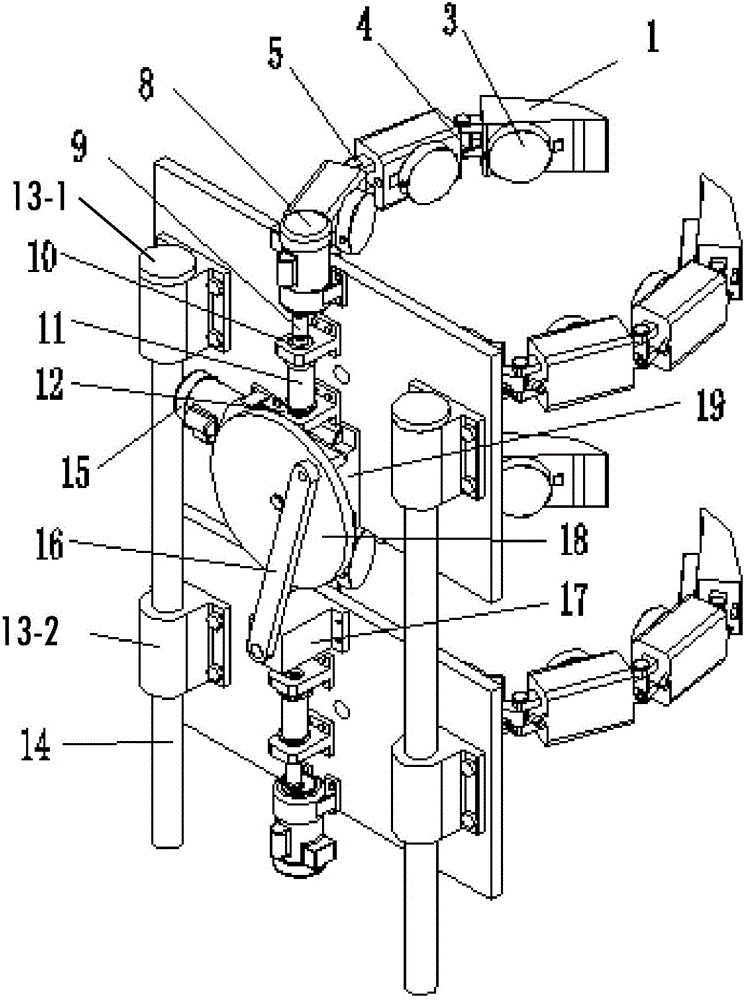

Positioning hinge

InactiveUS20070157433A1Strong holdFriction is generatedWing fastenersHingesFriction forceBiomedical engineering

The positioning hinge has a pintle, a leaf assembly and a positioning element. The pintle is mounted in the leaf assembly and is connected with the positioning element. The leaf assembly has a surface, and the positioning element rubs against the positioning element to generate a growing friction. When the pintle and the leaf assembly are mounted to a cover and a body respectively, the growing friction generated by the positioning element and the leaf assembly makes the cover to be positioned at a desired position relative to the body.

Owner:SHIN ZU SHING

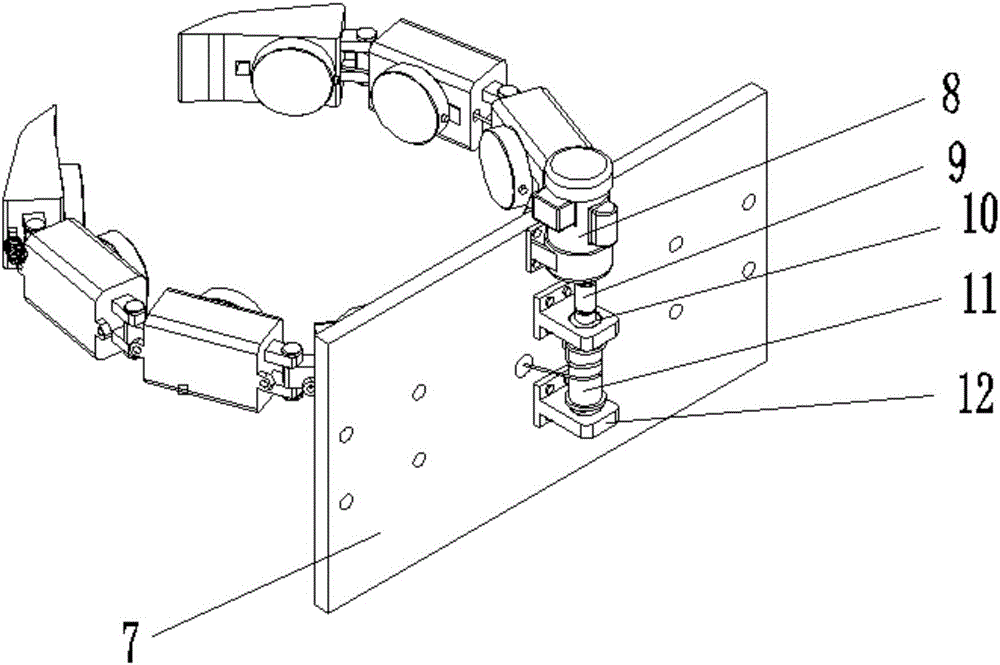

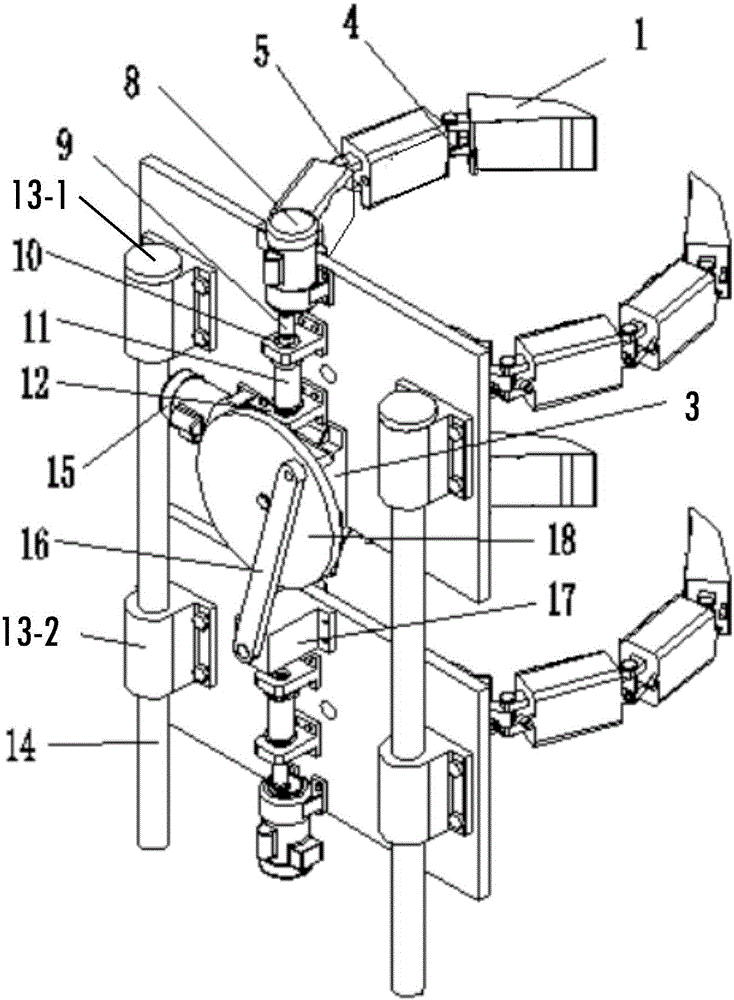

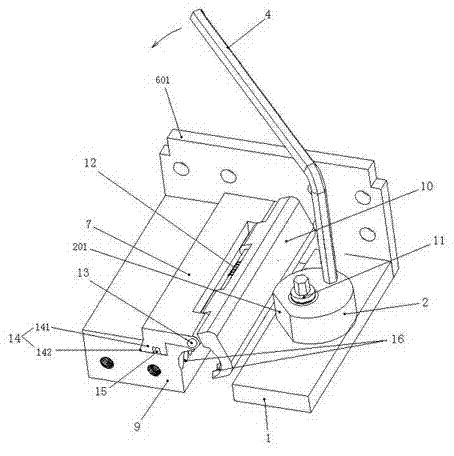

Hooped mine elevator patrol robot mechanism based on electromagnetic chucks

InactiveCN105710887ARealize whether to hold tight or notReduced Power RequirementsGripping headsHoopingElectricity

The invention discloses a hooped mine elevator patrol robot mechanism based on electromagnetic chucks. The hooped mine elevator patrol robot mechanism is integrally divided into an upper mechanical hand part and a lower mechanical hand part which are the same in structure. The two mechanical hand parts are connected through a slider-crank mechanism and a sliding rod-slider mechanism. The two mechanical hand parts are used for alternately hooping an elevator stand column, meanwhile, the slider-crank mechanism and the sliding rod-slider mechanism are combined for achieving alternate ascending of the two mechanical hand parts, and therefore the overall movement of a robot is achieved. All joints are connected in series by the mechanical hand parts through a steel wire rope, and all the joints are connected by the mechanical hand parts through springs. The electromagnetic chucks are arranged on the joints. The steel wire rope is driven through a winch motor to be tensioned and loosened. Under the effect of the restoring force of the springs and with the combination of electricity obtaining and losing of the electromagnetic chucks, mechanical claws are controlled to be opened and closed. The hooped mine elevator patrol robot mechanism is simple and light in structure, flexible in action and high in hooping force, the requirement for power of a motor can be effectively lowered, and the phenomenon that that spray paint or a protection layer on the surface of a cable or a steel material of the elevator is damaged is effectively avoided.

Owner:CHINA UNIV OF MINING & TECH

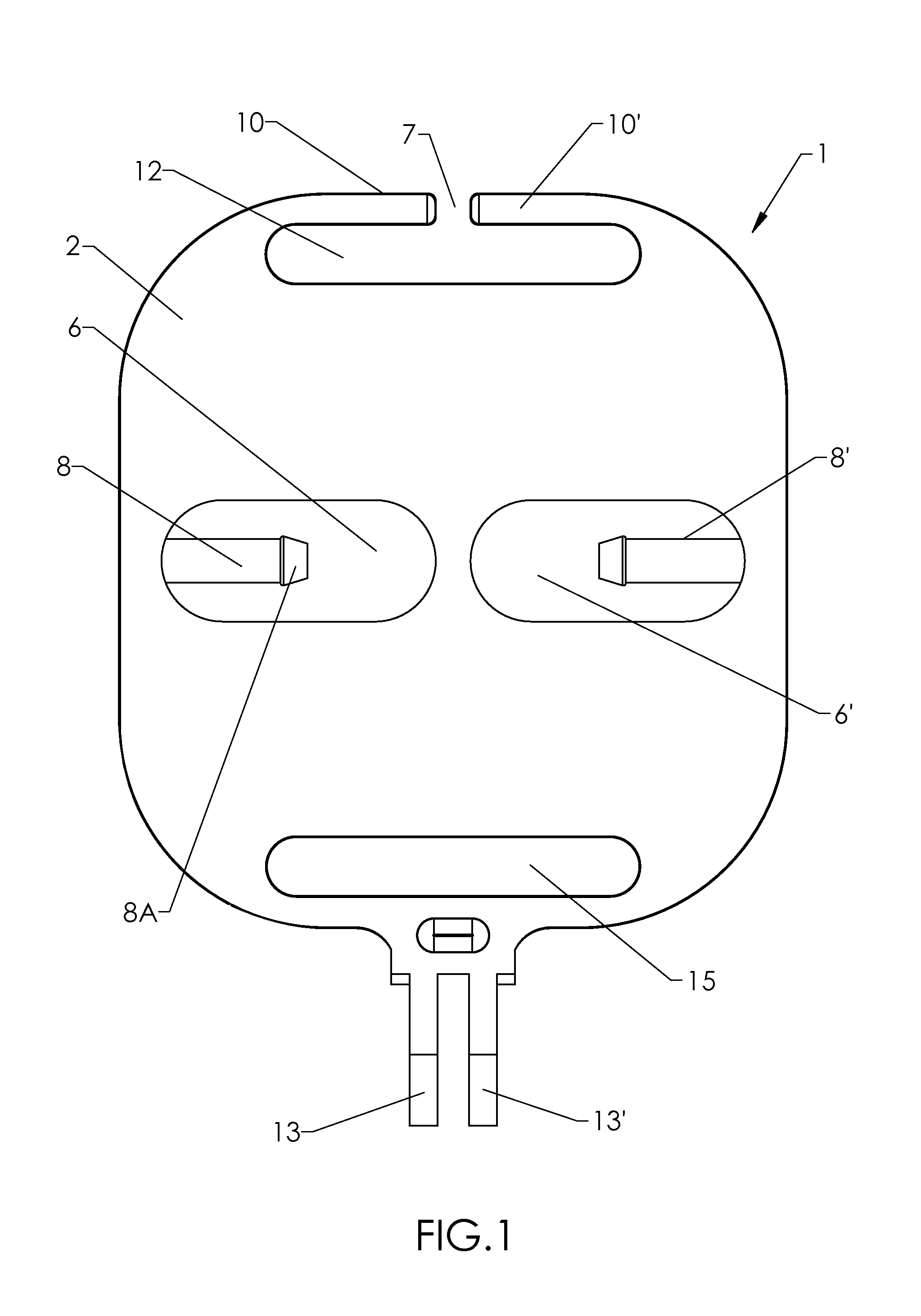

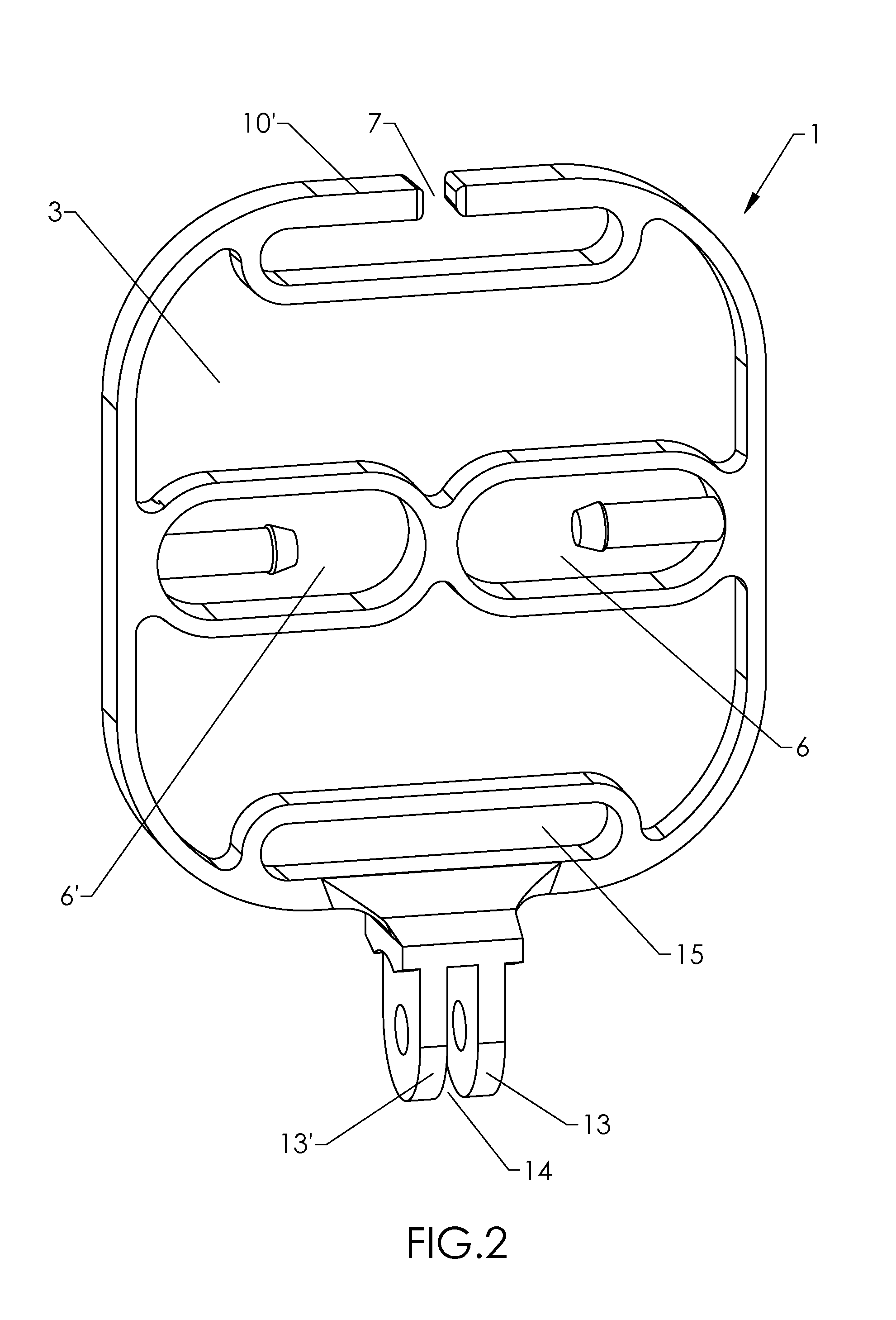

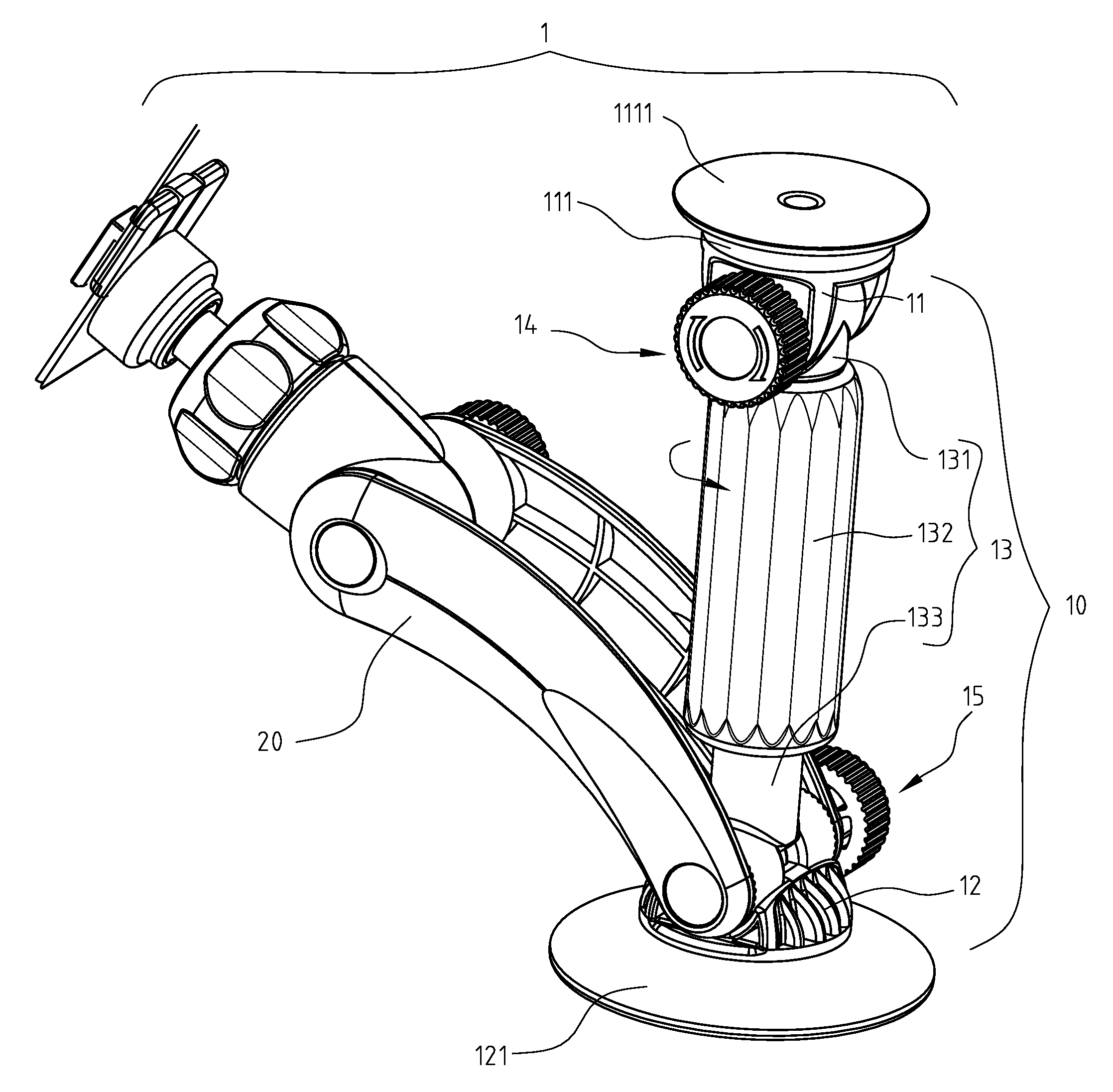

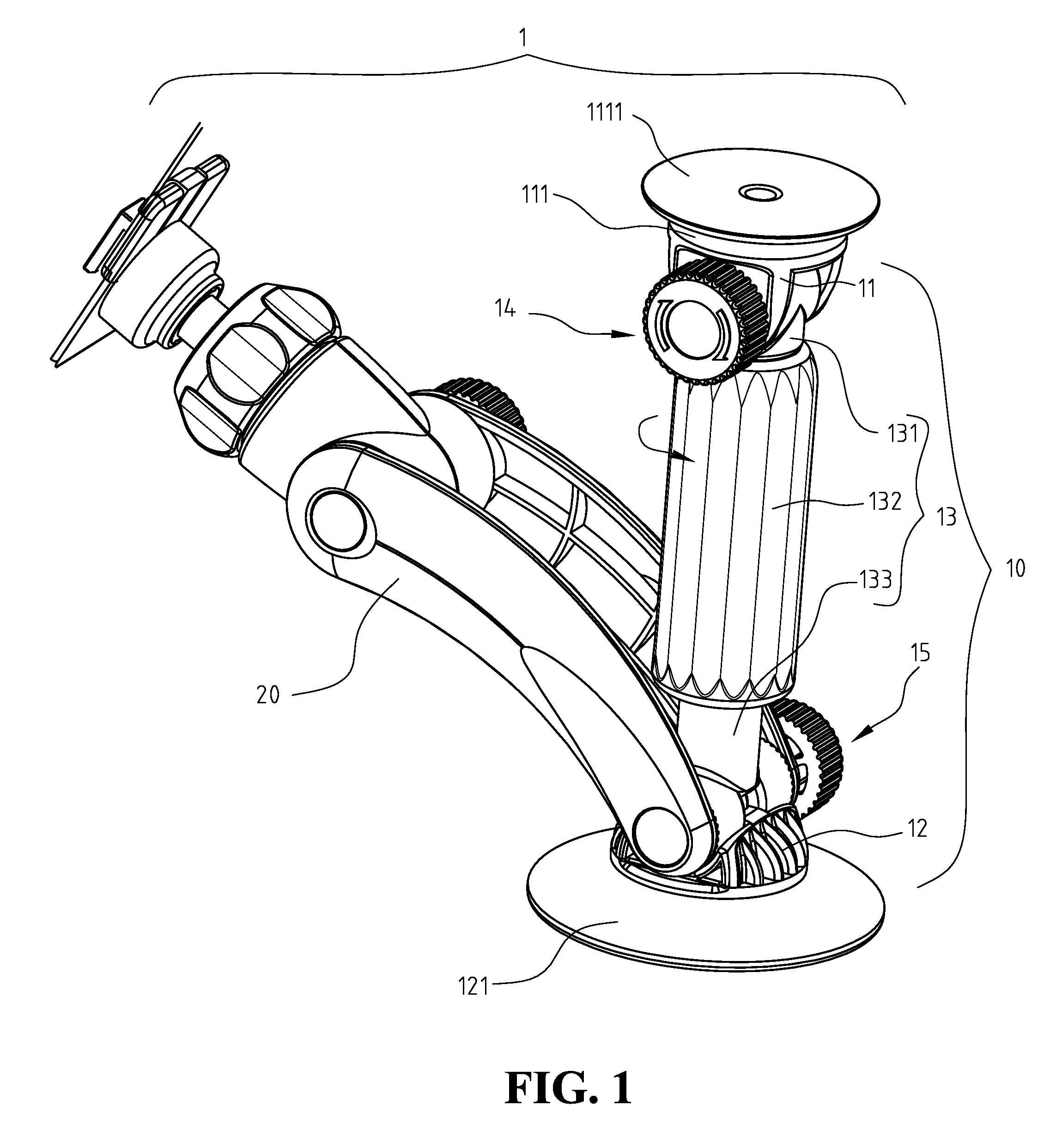

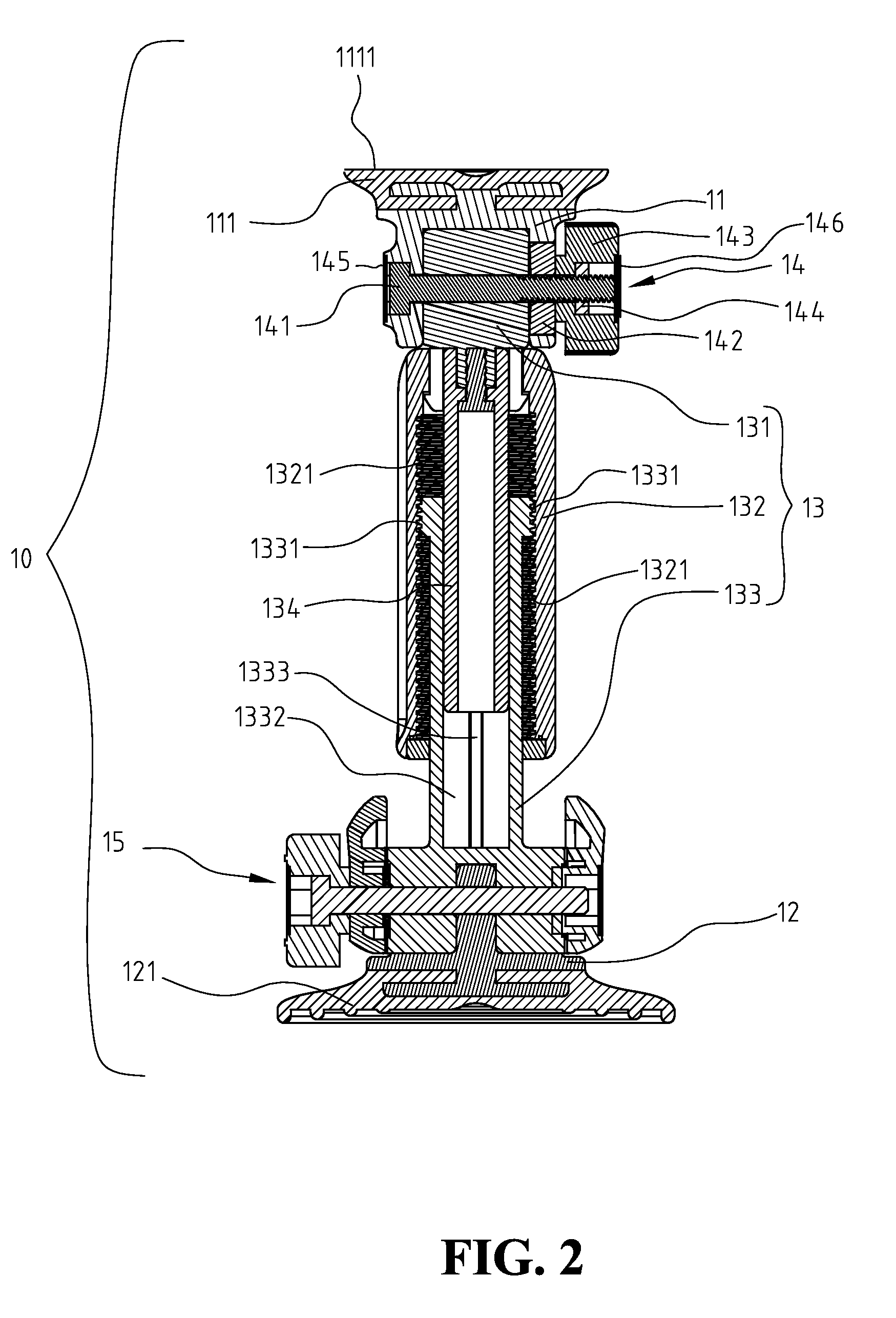

Support Connecting Apparatus For Using Inside Vehicles

A support connecting apparatus for using inside vehicles and being installed in the space between a windshield and an installation surface is provided, including a fixing module and at least a connecting module. The fixing module includes a first fixing unit, a second fixing unit and an adjustable support unit. The first fixing unit and the second fixing unit are connected to the two ends of the adjustable support unit. The adjustable support unit can be adjusted for extending the length or retracting so that the fixing module can be installed in the space between the windshield and the installation surface. The connecting module is connected to the fixing module to provide connection to other objects.

Owner:FAN EAGLE

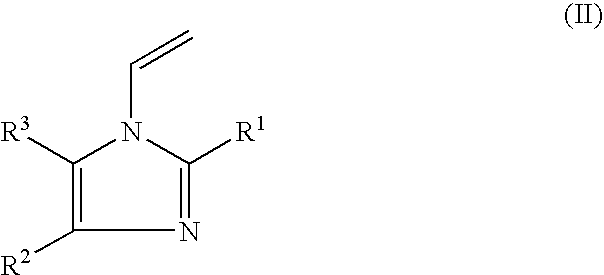

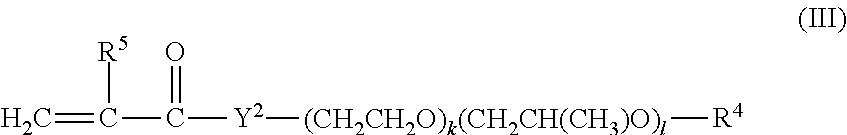

Amphoteric ethyl methacrylate copolymers and use thereof

InactiveUS8034888B2Strong holdImprove abilitiesCosmetic preparationsHair removalDouble bondMethacrylate copolymer

The present invention relates to amphoteric copolymers which comprise ethyl methacrylate, if appropriate a N-vinyllactam compound, at least one monoethylenically unsaturated carboxylic acid and at least one compound with α,β-ethylenically unsaturated double bond and at least one cationogenic and / or cationic group in copolymerized form, to cosmetic and pharmaceutical compositions which comprise such copolymers, to preparation methods, and to the use of these copolymers.

Owner:BASF AG

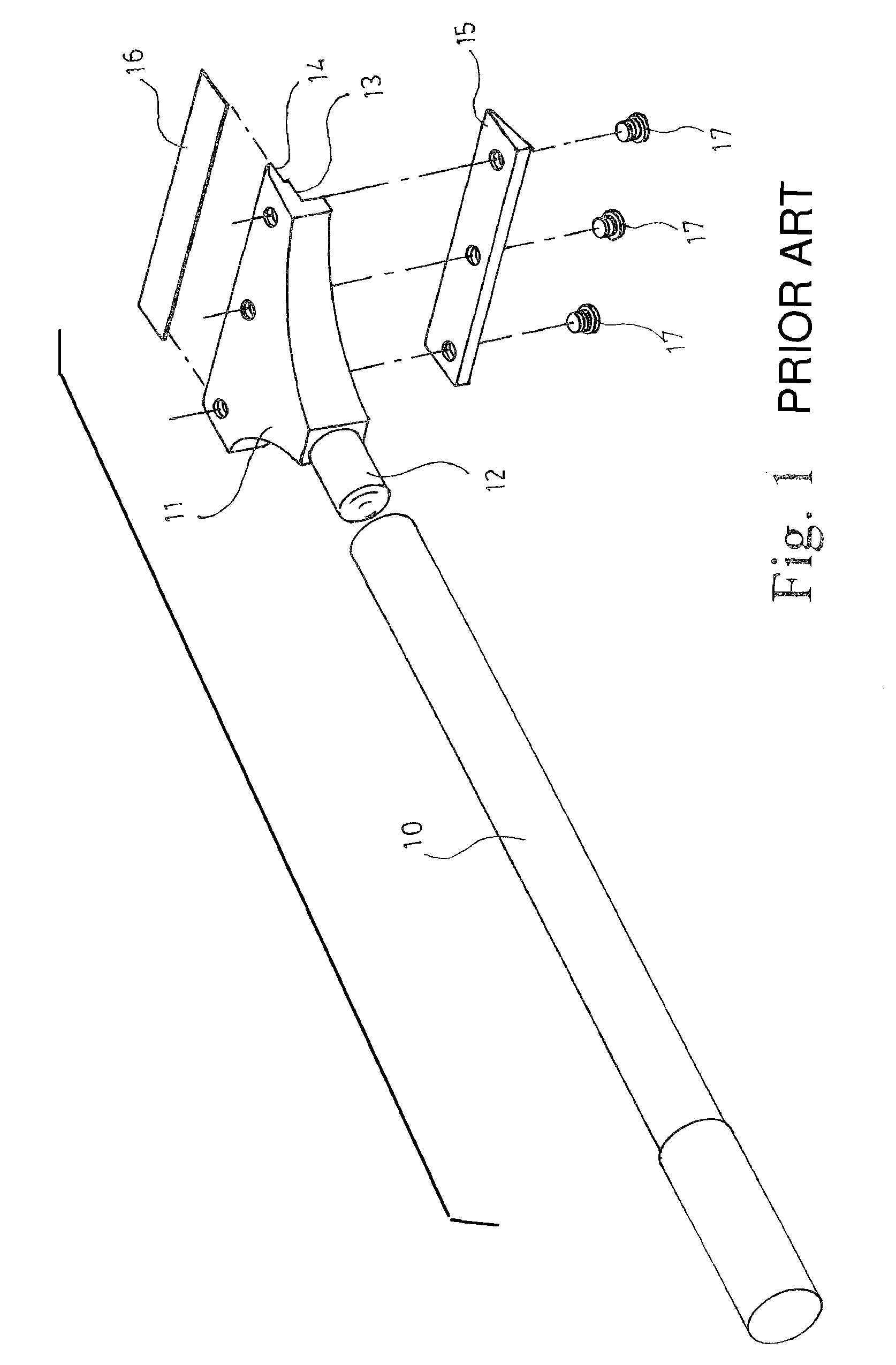

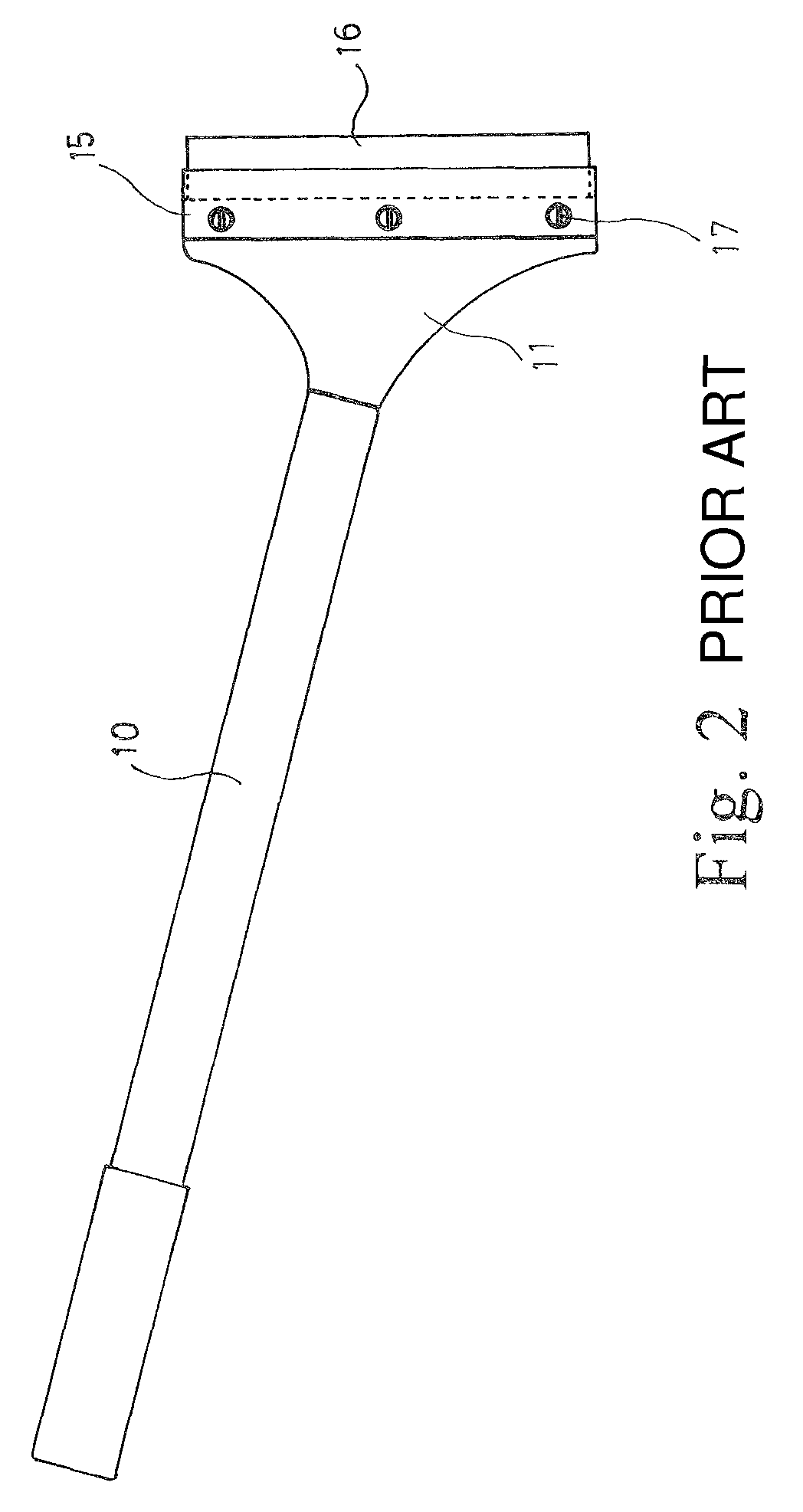

Scraper blade assembly structure

ActiveUS7930831B2PowerfulQuick changeBuilding repairsOther artistic work equipmentsEngineeringAssembly structure

The invention relates to a scraper blade assembly structure. The scraper includes a stem for hand grip and a scraping section in the front. The scraping section includes a jaw plate, a blade and a fastening button. The jaw plate extends backward to form an arm. The jaw plate is attached to the inside of the jaw plate groove of the scraping section by a fastener that also serves as a lever pivot for swinging back and forth. When a fastening button goes into the inside of the jaw plate of the scraping section, it pushes the inner side of the arm of the jaw plate, and so as to generate a great holding power for the front of the jaw plate. Further, the fastening button can be a handle protruding from one side of the scraping section.

Owner:LIN WEN CHEN

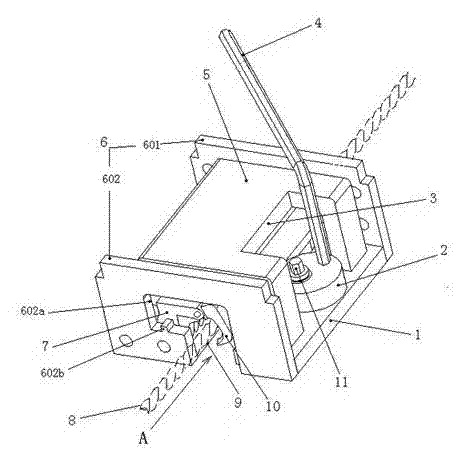

Holding type mine hoist inspection robot

InactiveCN105729487ARealize whether to hold tight or notReduced Power RequirementsGripping headsElectric machineryEngineering

The invention discloses a holding type mine hoist inspection robot. The whole holding type mine hoist inspection robot is divided into an upper mechanical arm part and a lower mechanism arm part which are same in structure, wherein the two mechanical arm parts are connected with each other via a crank block mechanism and a sliding rod-sliding block mechanism; the two mechanical arm parts alternately hold a hoist stand column; meanwhile, due to combination of the crank block mechanism and the sliding rod-sliding block mechanism, the two mechanical arm parts alternately rise, so that the whole movement of the robot is implemented. The mechanical arm parts are used for connecting various joints in series via a steel wire rope; the various joints are connected with one another via a spring; the steel wire rope is driven to tighten and loosen via a hoisting motor; the opening and closing actions of mechanical claws are controlled under control of a restoring force of the spring; the holding type mine hoist inspection robot is simple and light in structure, flexible in actions and strong in holding force; the power requirement of the motor can be effectively reduced; the damage to the sprayed paint or protection layers of the hoist cable rope or the steel surface can be avoided.

Owner:CHINA UNIV OF MINING & TECH

Structure for Christmas light

InactiveUS7950840B2Easy to assembleStrong holdPoint-like light sourceElectric discharge tubesEngineeringLED lamp

A structure for LED Christmas light is provided, including a light holder, being a hollow body having a separating part connected to the inner wall of the light holder to divide the hollow interior of the light holder into two cavities. Each of the two opposite sides of the inner wall of the light holder connected to the separating part forms a slot and face the surface of the separating part of the two cavities, with each having a guiding channel. Two wire sets are fixed inside the two cavities. An LED light bulb has a positive pin and a negative pin inserted inside the guiding channel, respectively, and being electrically connected to the wire sets. A light cap has a holding part passing the LED light bulb to tightly engage to the top of the light holder so as to fix the LED light bulb to the light holder.

Owner:LIU CHUN MING

Quick change power tool chuck

InactiveUS7766586B2Prevent angular slippageIncreased holding torqueSleeve/socket jointsAttachable milling devicesDrive shaftEngineering

Owner:DEROSA JOSEPH C +1

Side hill extreme bar ends

InactiveUS20090314127A1Increased leverageStrong holdMechanical apparatusSteering deviceEngineeringThrottle

Side-hill extreme ergo grip bar ends comprising of an upright or ‘L’ shaped handle bar, ergo curves, and a screw attached to the handle bar, to provide safety, stability and additional leverage to the vehicle rider such as a snowmobiler while making hard turns and side hilling in the mountain slopes. Each bar end grip can be outfitted with an auxiliary throttle trigger. The auxiliary throttle mount is capable on either bar end grip or both bar end grips The ergo grip bar ends provide the snowmobiler the necessary space to accommodate his fingers covered by snow gloves and also provides space for attaching both from auxiliary throttle which can be triggered on inside grip of bar end or outside at bend of ‘L’ for safety and increased mobility. The ergo grip bar ends are made of stiff and strong material to accommodate heavy weight bearing. The top of the bend of ‘L’ contains a soft tip option to avoid discomfort if rider's leg were to come into contact.

Owner:LONGNECKER ADAM

Hair wax products with a liquid or creamy consistency

ActiveUS7906107B2Improve stabilityEasily distributeCosmetic preparationsHair removalButter icingHair wax

Owner:WELLA GMBH

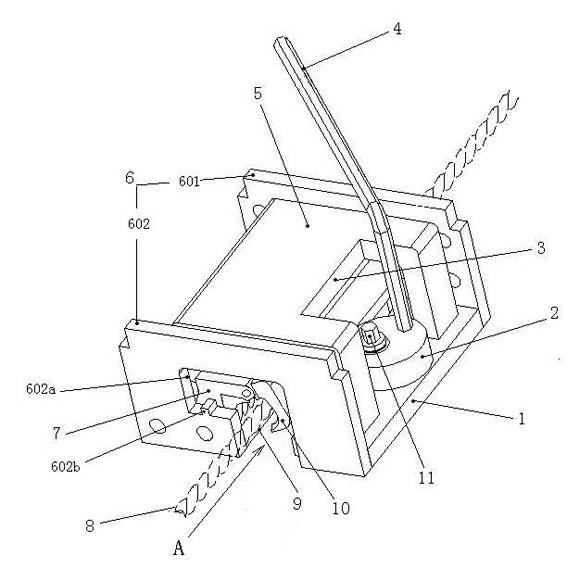

Adhesive fastening elements for holding a workpiece and methods of de-bonding a workpiece from an adhesive fastening element

InactiveUS20130008587A1Accurate directionStrong holdSnap fastenersSecuring devicesEngineeringAdhesive

An adhesive fastening element (602) for holding a workpiece (608), the adhesive fastening element (602) comprising: a body (604, 606) defining a recess (642) for receiving a protrusion (644) of the workpiece (608); wherein, in use, adhesive is applied between an end surface of the recess (642) and an end surface of the protrusion (644) and between a side surface of the recess (642) and a side surface of the protrusion (644) to bond the workpiece (608) to the adhesive fastening element (602). The workpiece (608) may be aligned with a reference point on the adhesive fastening element (602) and the adhesive cured to fix the position of the workpiece (608) relative to the adhesive fastening element (602).

Owner:ROLLS ROYCE PLC

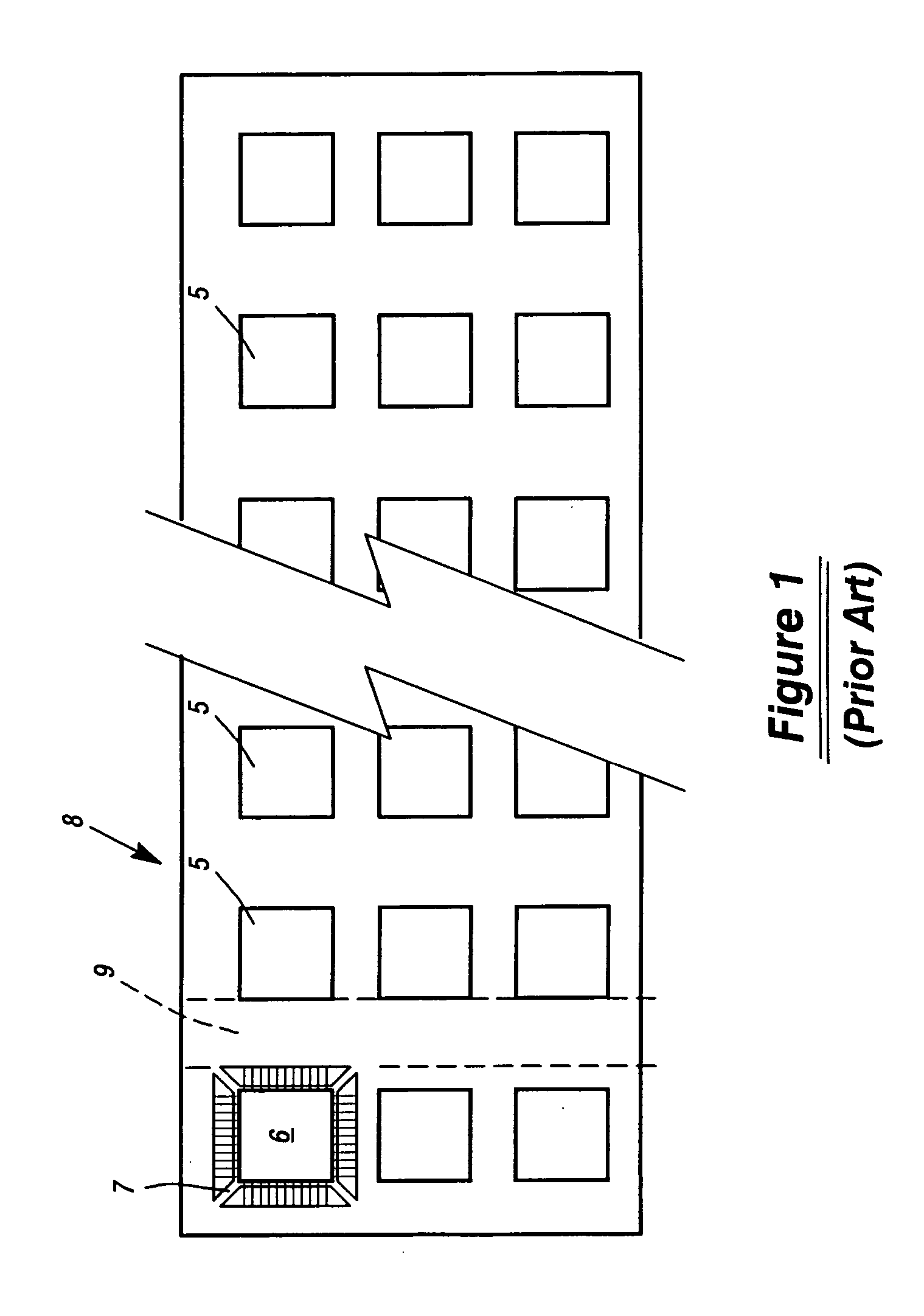

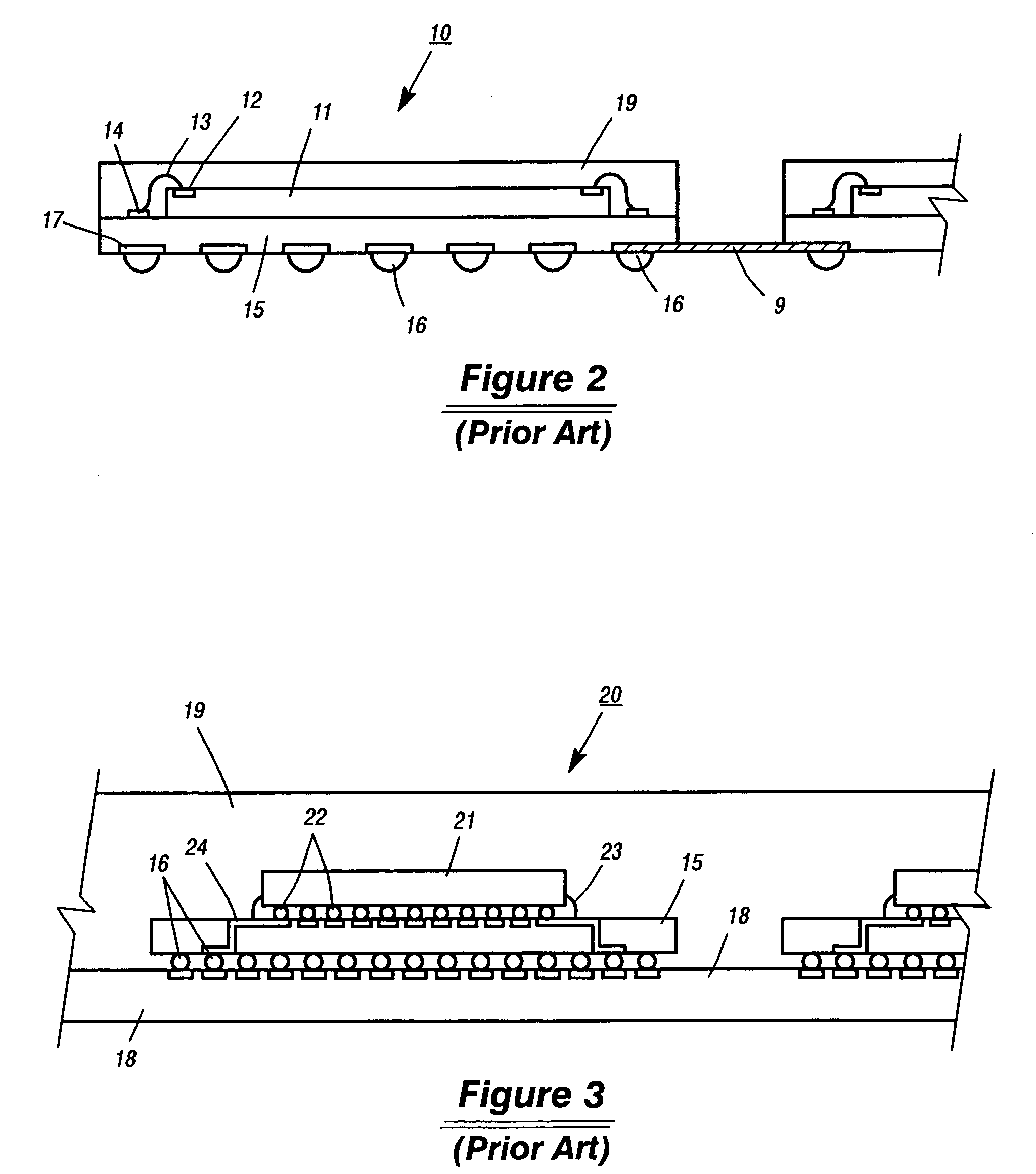

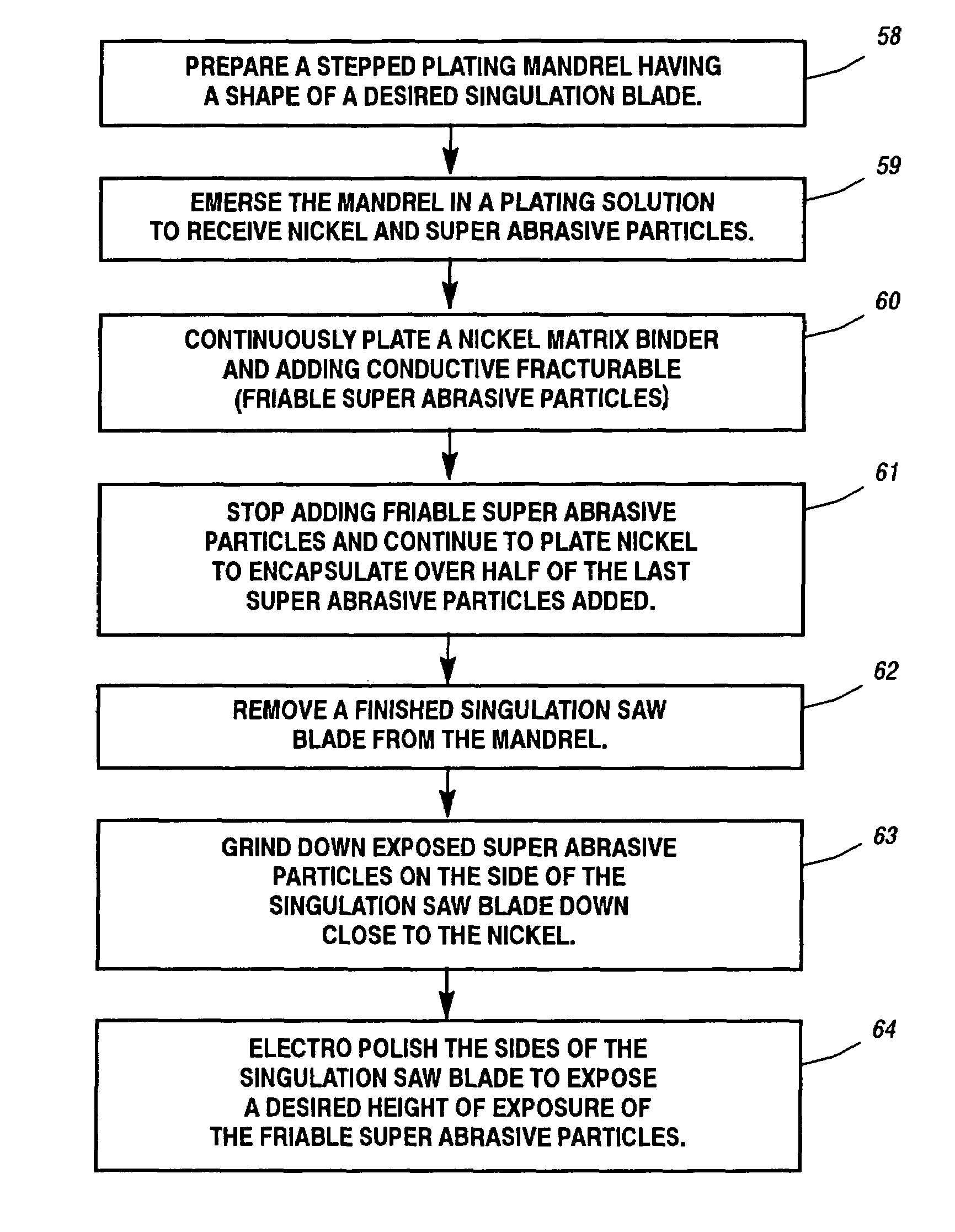

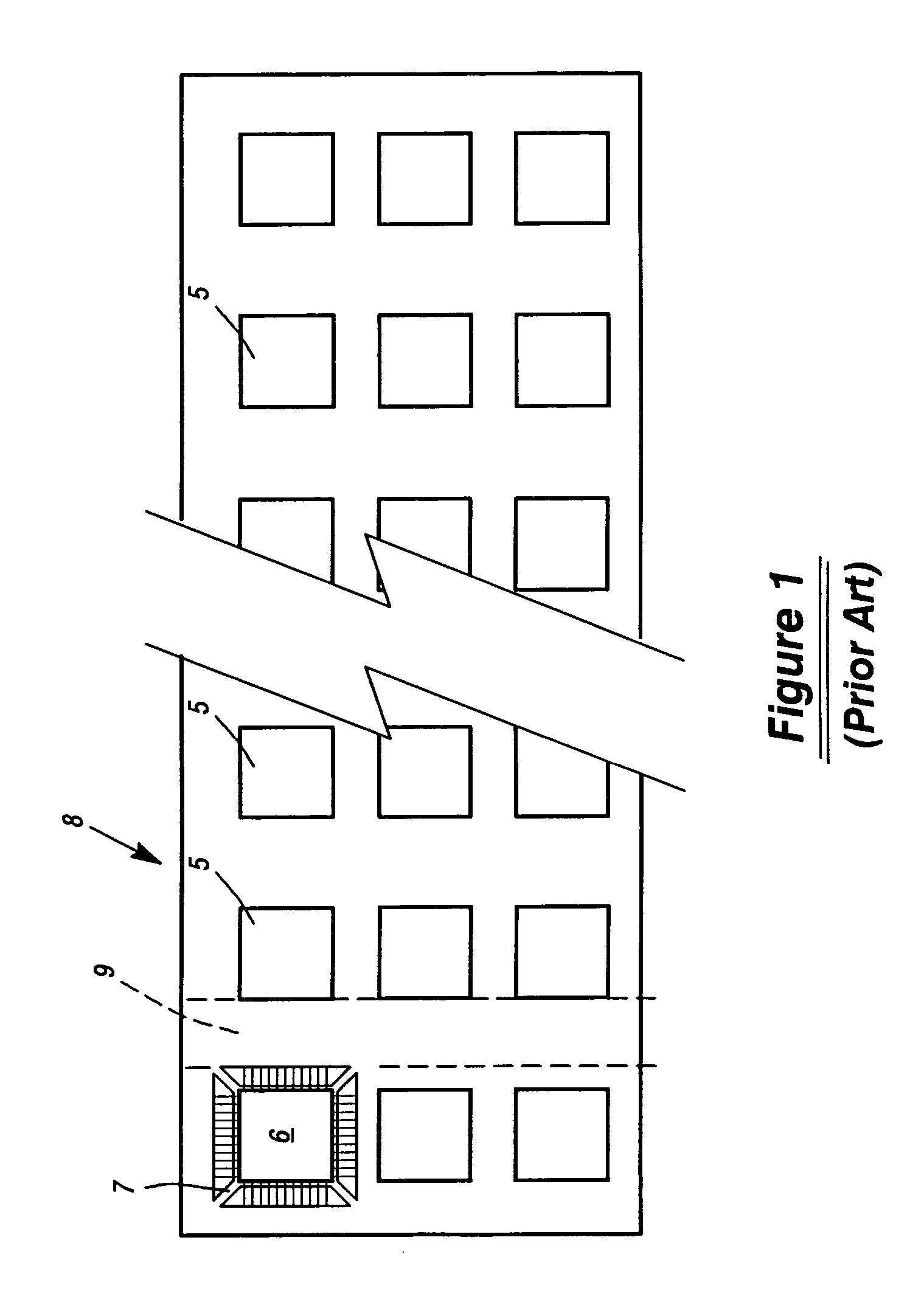

Grindable self-cleaning singulation saw blade and method

InactiveUS20050178241A1Quick cutStrong holdPigmenting treatmentOther chemical processesElectro polishingKnife blades

A super abrasive impregnated singulation saw blade is made by depositing grindable friable super abrasive particles while electro depositing or electroless depositing a strong binder metal such as nickel on a form or mandrel. The deposited super abrasive on the upper side protrudes from the side of the blade and are ground down to or near the binder metal to plannerize the sides of the saw blade and true and balance the saw blade. Post operations include electro polishing to expose equal amounts of super abrasive on the cutting edge or on all sides. Antifriction particles may be added in the side walls or deposited on the outside.

Owner:SMITH DAVID WALTER +1

Grindable self-cleaning singulation saw blade and method

InactiveUS7086394B2Quick cutStrong holdPigmenting treatmentOther chemical processesElectro polishingMetallic Nickel

A super abrasive impregnated singulation saw blade is made by depositing grindable friable super abrasive particles while electro depositing or electroless depositing a strong binder metal such as nickel on a form or mandrel. The deposited super abrasive on the upper side protrudes from the side of the blade and are ground down to or near the binder metal to plannerize the sides of the saw blade and true and balance the saw blade. Post operations include electro polishing to expose equal amounts of super abrasive on the cutting edge or on all sides. Antifriction particles may be added in the side walls or deposited on the outside.

Owner:SMITH DAVID WALTER +1

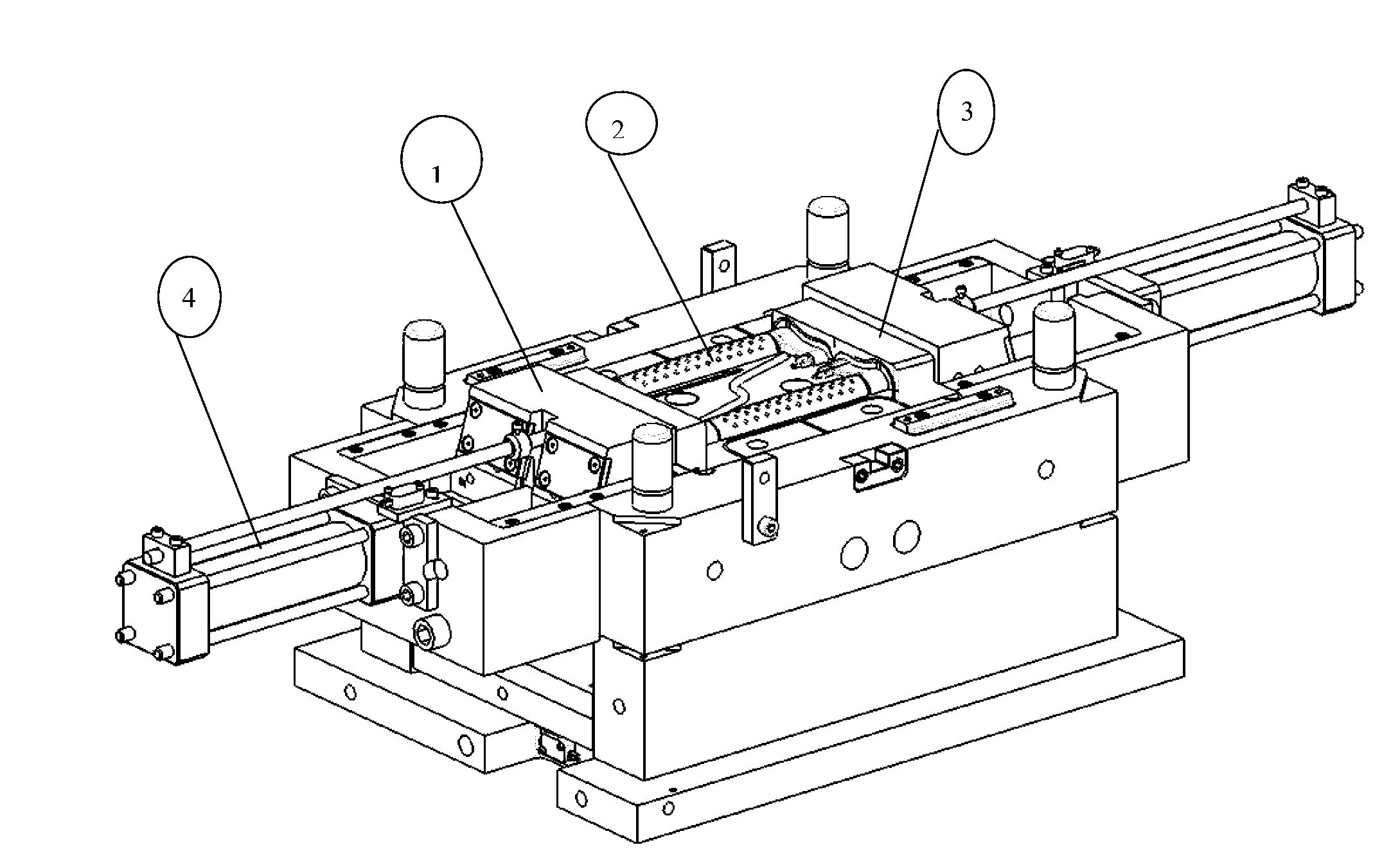

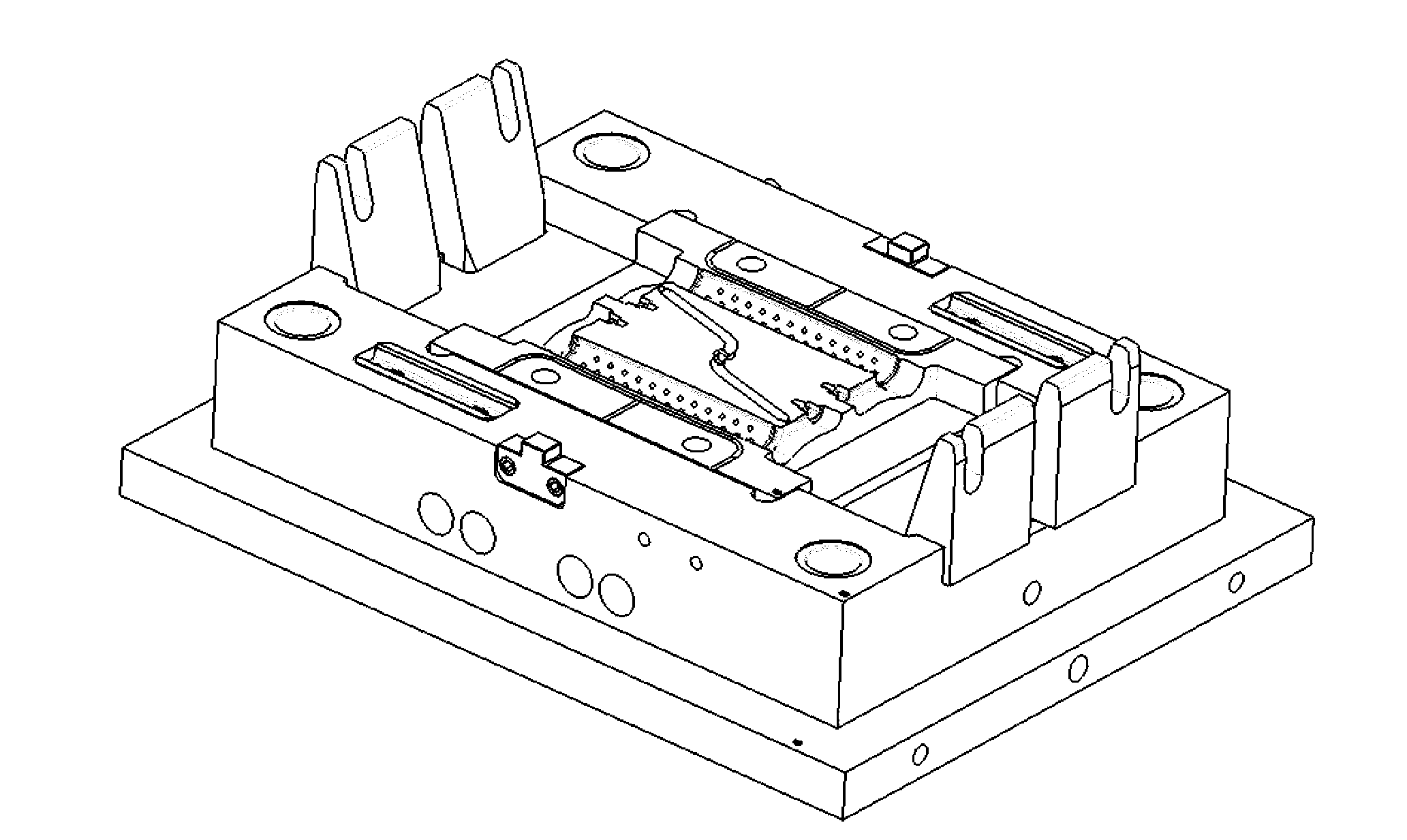

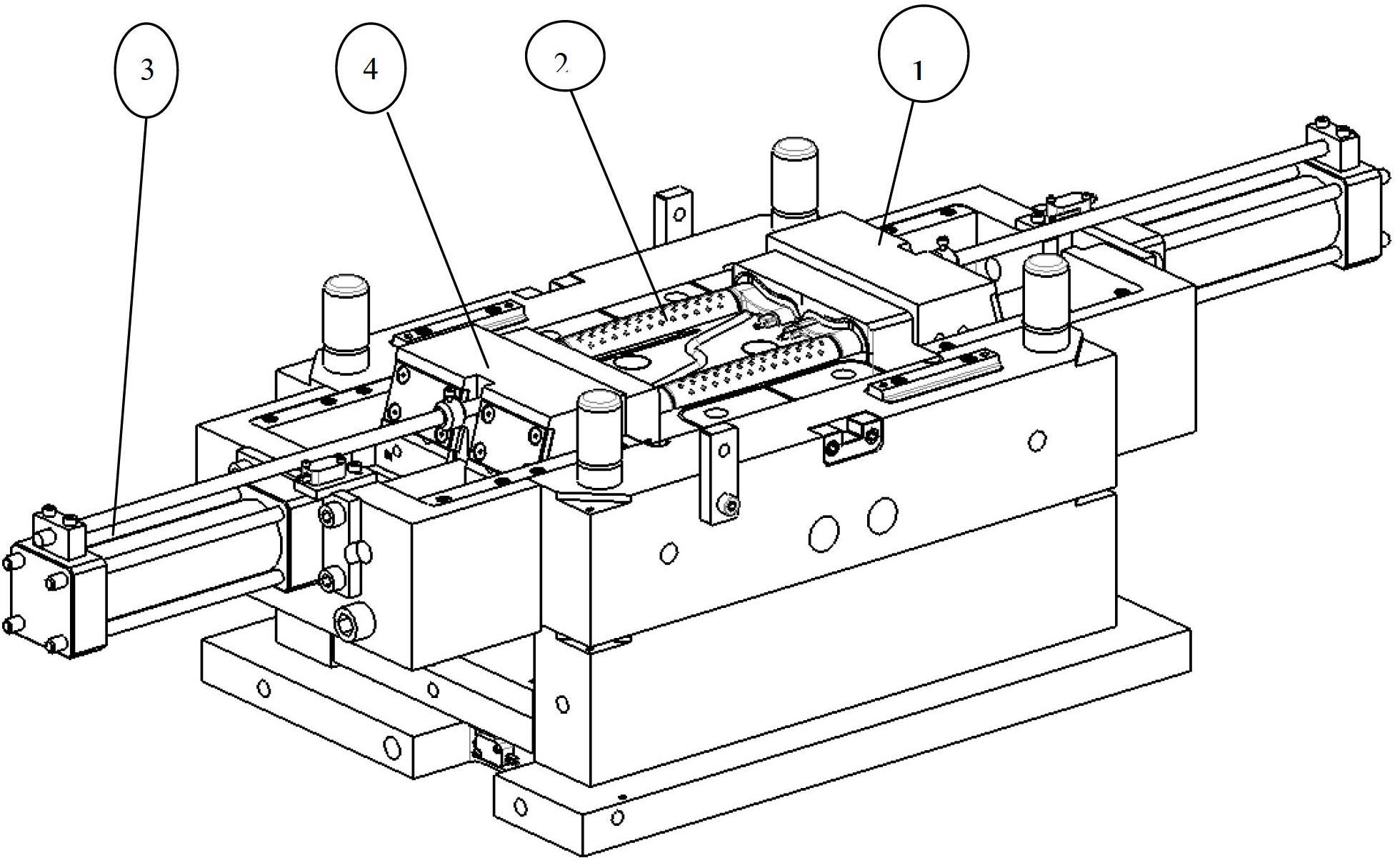

Deformation reducing and uniformly cooling injection mold for long and thin handles and production process

InactiveCN102700070APre-existing process conditionsCurrent situationEngineeringMechanical engineering

The invention relates to a deformation reducing and uniformly cooling injection mold for long and thin handles and a production process. The mold comprises a movable mold, a first side slide block forming mechanism (1), oil cylinder core pulling mechanisms (3) and a second side slide block forming mechanism (4), and is characterized in that the first side slide block forming mechanism (1) and the second side slide block forming mechanism (4) are symmetrically arranged at two sides of the movable mold, the oil cylinder core pulling mechanisms (3) are arranged on respective outer sides of the first side slide block forming mechanism (1) and the second side slide block forming mechanism (4), and a product (2) is arranged between the first side slide block forming mechanism (1) and the second side slide block forming mechanism (4). The deformation reducing and uniformly cooling injection mold for the long and thin handles disclosed by the invention has a stable performance, a uniformly cooling system for movable and fixed molds reduces the forming cycle, the quality of the product can be better guaranteed, and the production efficiency is improved.

Owner:KUSN TUOAN PLASTIC PRODS

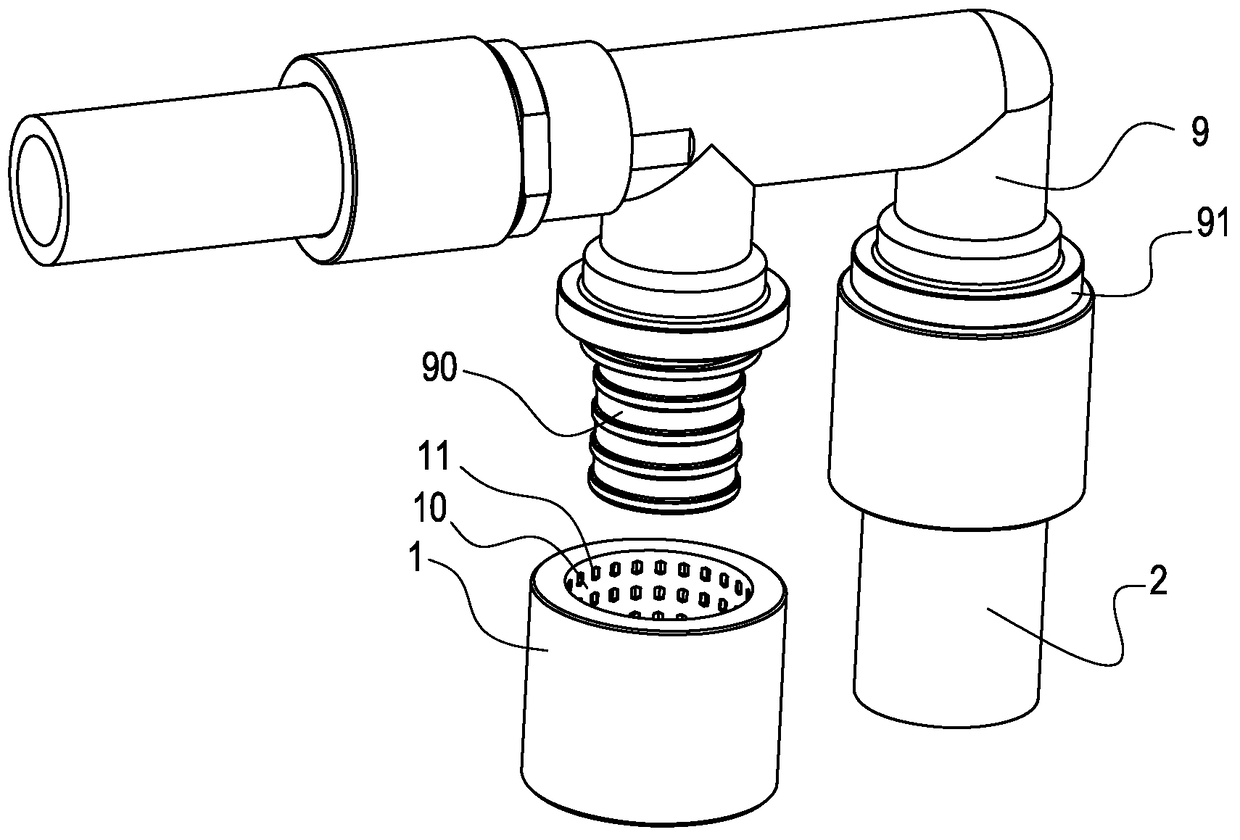

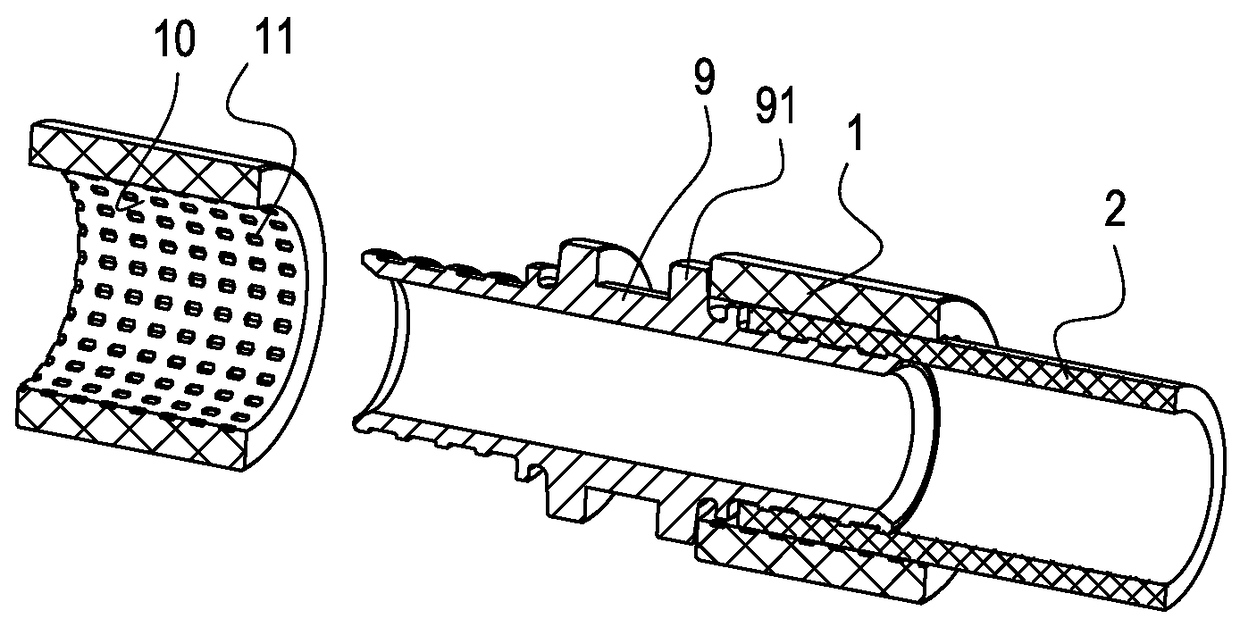

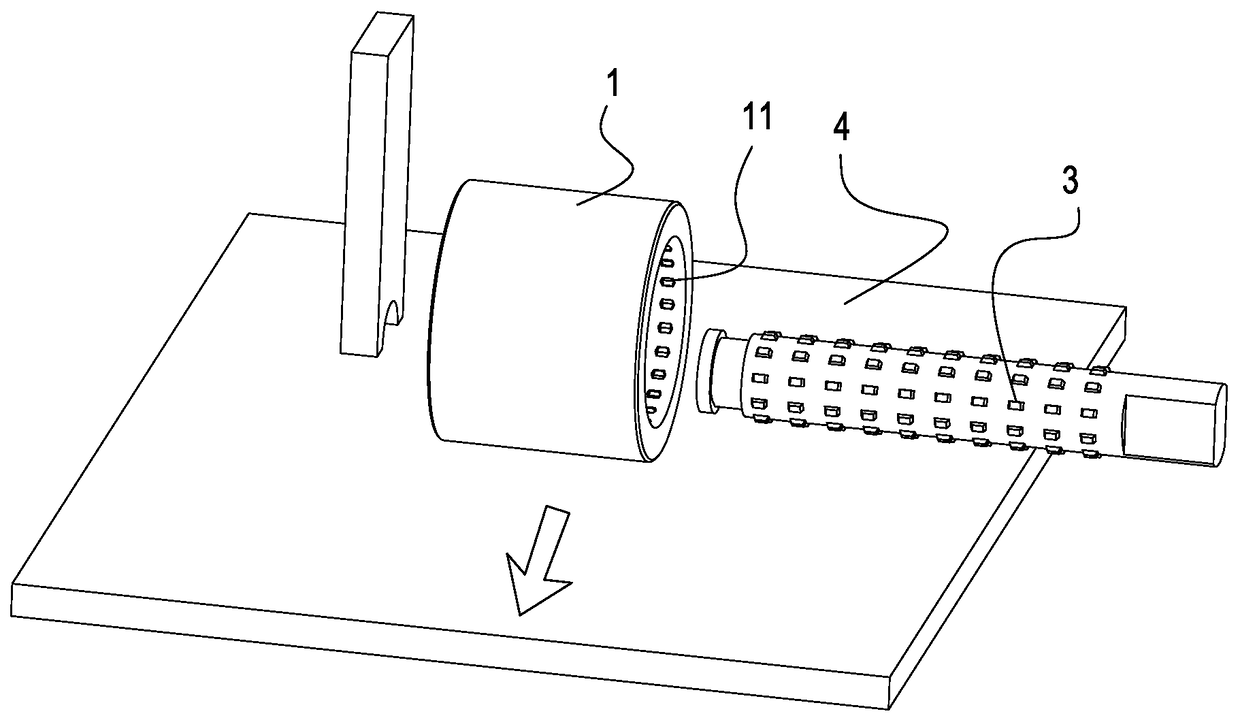

Pipeline fastening clamping ring and machining technology

ActiveCN109340494AAvoid problemsSolve the rotation problemPipe connection arrangementsPlastic materialsPipe fitting

The invention relates to the building pipeline connection technology, in particular to a pipeline fastening clamping ring. The clamping ring is of a cylindrical ring structure. The diameter of the inner wall of the clamping ring is in clearance fit with the outer diameter of a matched pipe, the clamping ring is made from crosslinked polyethylene materials with strong shrinkage performance, no chamfering structure is arranged at the front end of the inner wall of the clamping ring, and the inner wall of the clamping ring is provided with knurling teeth. The invention further discloses a knurling tooth machining technology. The structure of a traditional metal clamping ring is changed, the crosslinked polyethylene materials which are elastic, resistant to high temperature and capable of changing along with the environment temperature are adopted, holding force is kept, and the problem that a gap exists between the pipe and a pipe fitting main body and the problem that the clamping ring is rotated or loosened are solved. Meanwhile, plastic materials low in mass and low in price are adopted, the cost is low, market competitiveness is formed, and feasibility is high.

Owner:TAIZHOU BANCHENG HVAC TECH CO LTD

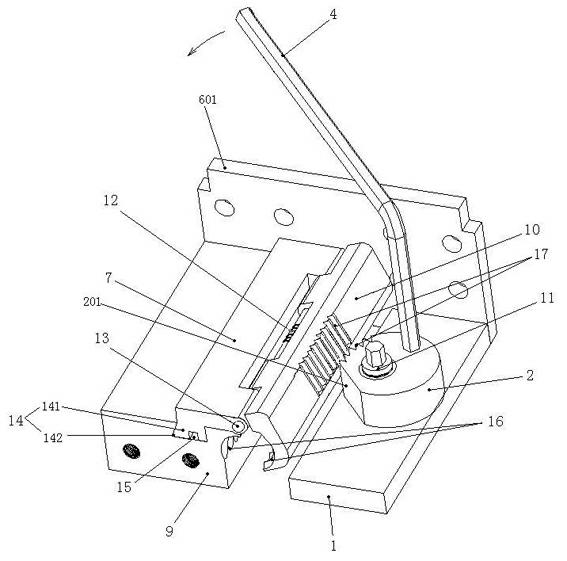

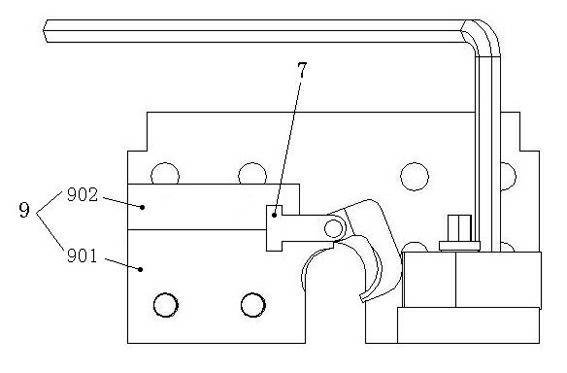

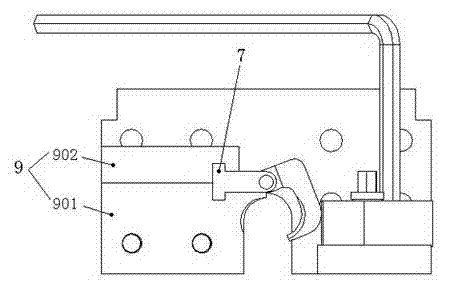

Gear rack type self-locking rope clip

The invention discloses a gear rack type self-locking rope clip. The gear rack type self-locking rope clip comprises a base, wherein a through opening is formed at the bottom of the base; one side of the base along the direction of the through opening is provided with a hinge slide block sliding along the direction; a movable claw tile corresponding to the through opening is hinged on the hinge slide block; one part forming the through opening on the base provided with the hinge slide block is used as a fixed claw tile and forms a rope clipping part together with the movable claw tile; an eccentric cam matched with the movable claw tile through teeth is arranged on the base positioned on the other side of the through opening; and a handle is arranged on the eccentric wheel. The gear rack type self-locking rope clip disclosed by the invention has the advantages of manual pre-clamping and automatic locking functions, simple structure, large rope clipping force, safety, reliability and the like.

Owner:HUNAN UNIV

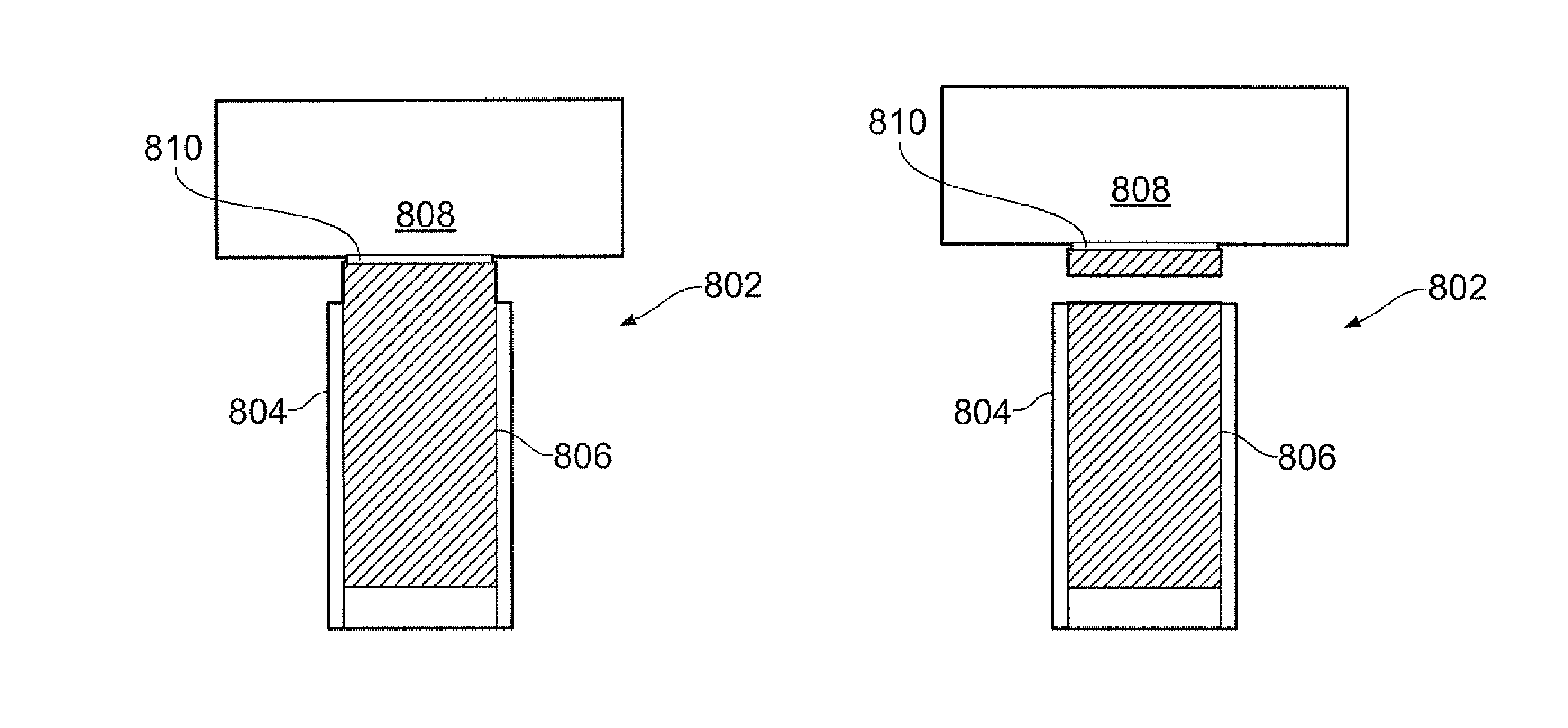

Adhesive fastening elements for holding a workpiece and methods of de-bonding a workpiece from an adhesive fastening element

InactiveUS8900394B2Accurate directionStrong holdLamination ancillary operationsLaminationEngineeringMechanical engineering

An adhesive fastening element (802) for holding a workpiece (808), the adhesive fastening element (802) comprising: an outer member (804); and a consumable inner member (806) disposed inside the outer member (804) and releasably movable relative to the outer member (804) along a longitudinal axis of the adhesive fastening element (802); wherein the consumable inner member (806) comprises a bonding surface which, in use, is bonded by an adhesive (810) to the workpiece (808) and is removed and replaced to detach the workpiece (808) from the adhesive fastening element (802).

Owner:ROLLS ROYCE PLC

Friction self-locking rope clip

InactiveCN102305698AFunctionalRealize self-locking functionVehicle testingShock testingSelf lockingEngineering

The invention discloses a friction self-locking rope clip. The friction self-locking rope clip comprises a base, wherein a through opening is formed at the bottom of the base; one side along the direction of the through opening on the base is provided with a hinge sliding block which slides along the direction; the hinge sliding block is hinged with a movable claw corresponding to the through opening; a part where the through opening is formed on the base with the hinge sliding block is used as a fixed claw; the fixed claw and the movable claw form a rope clipping component; the other side ofthe through opening on the base is provided with an eccentric cam which is in friction fit with the surface of the movable claw; and the eccentric cam is provided with a handle. The friction self-locking rope clip has the advantages of functions of manual pre-clamping and automatic locking, simple structure, large rope clipping force, high safety and reliability, and the like.

Owner:HUNAN UNIV

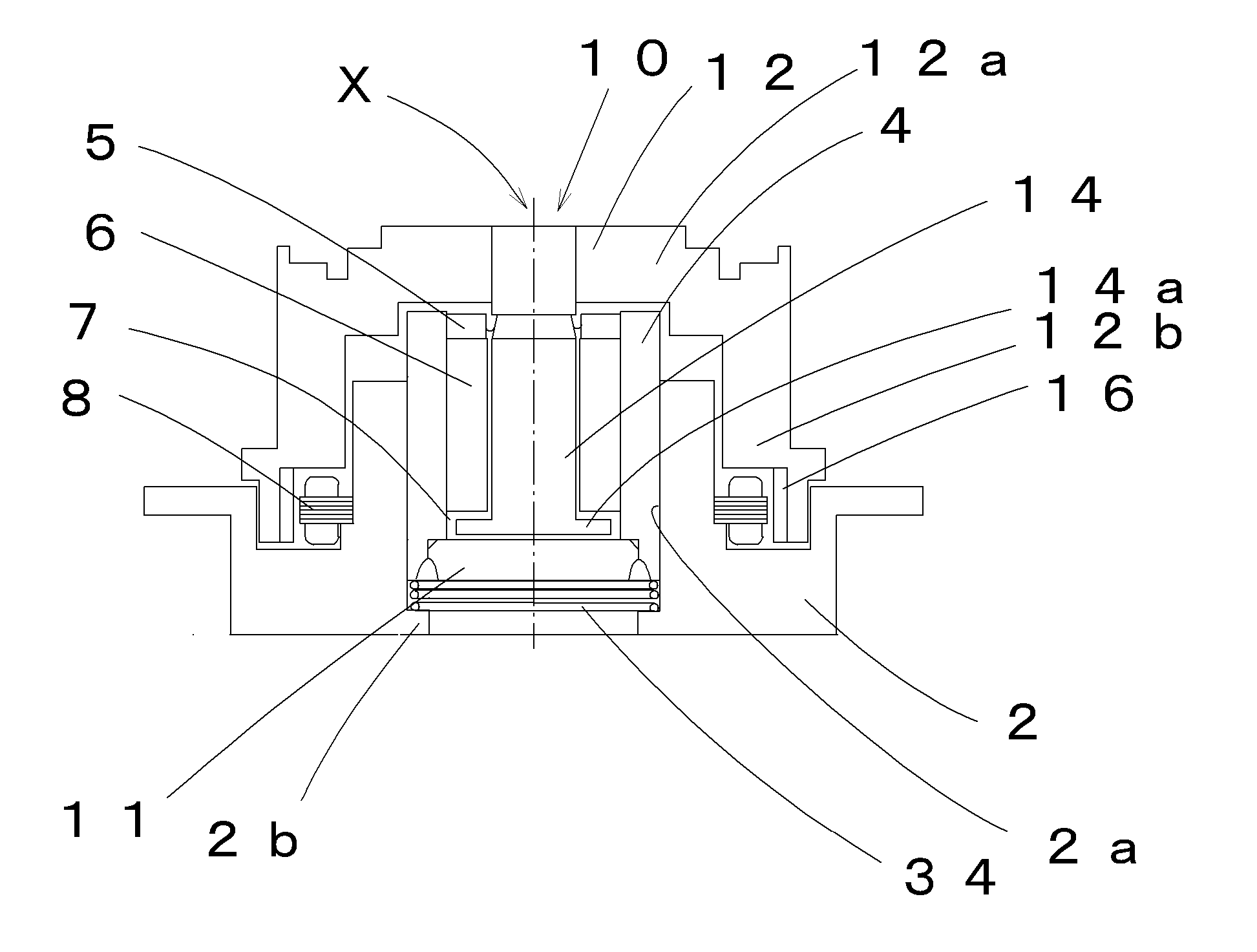

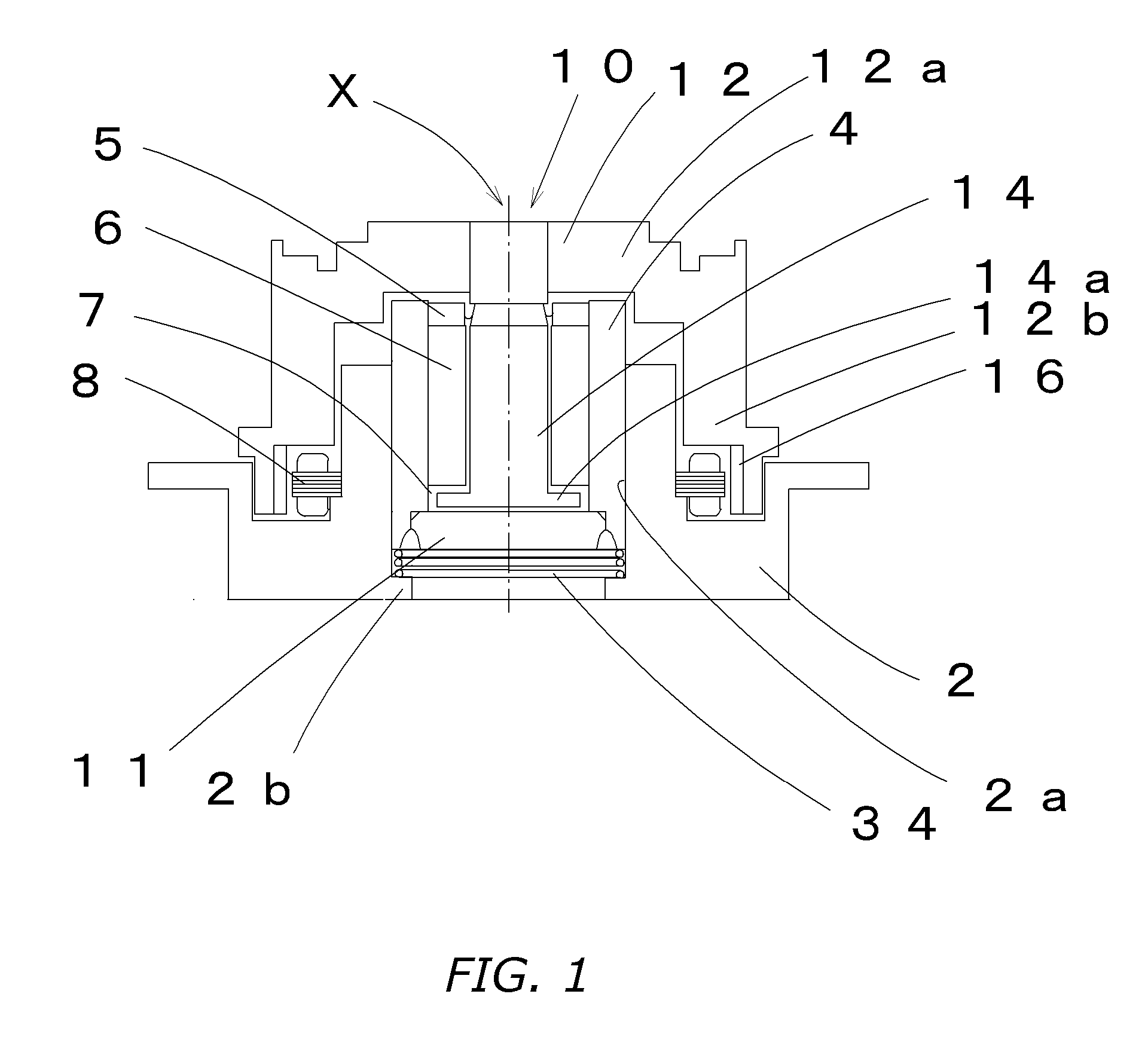

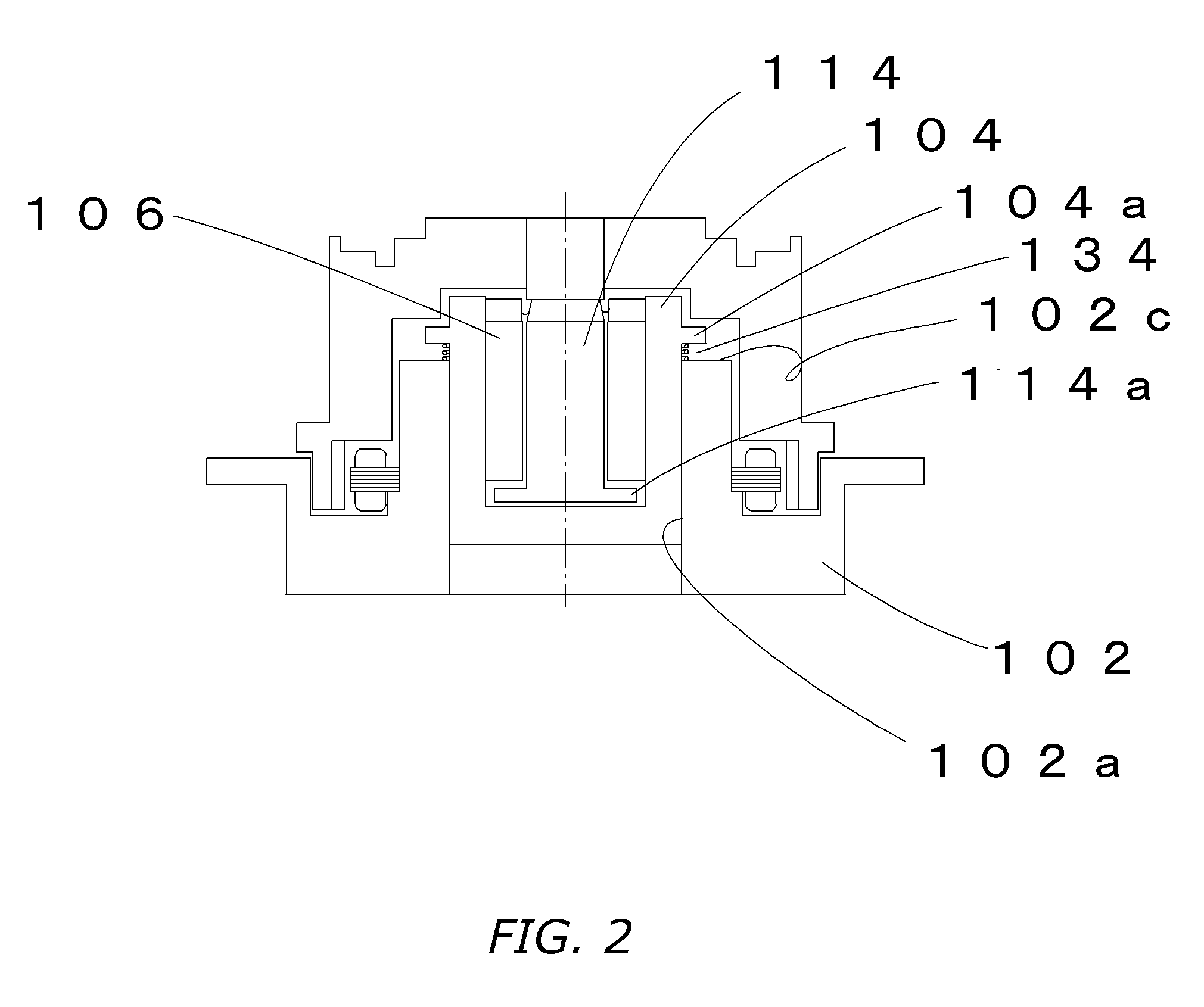

Spindle Motor and Recording Disk Driving Apparatus Having the Spindle Motor

InactiveUS20060215312A1Securing electrical conductionStrong holdAssociation with grounding devicesRecord information storageElectric machineFlange

Spindle motor capable of positively fixing and securing conduction between a housing and a bracket, and a recording disk driving apparatus using the spindle motor. The bracket has a circular through hole, and the housing is fixedly inserted in the circular through hole. A protrusion is formed on at least one of the bracket and the housing. A conductive member is between and in contact with a flange and the bracket or the housing in the direction of the rotary axis to electrically connect the flange and the bracket or the housing. The conductive member is in contact with the flange and the bracket or the housing under an elastic stress.

Owner:NIDEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com