Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improved magnetostriction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

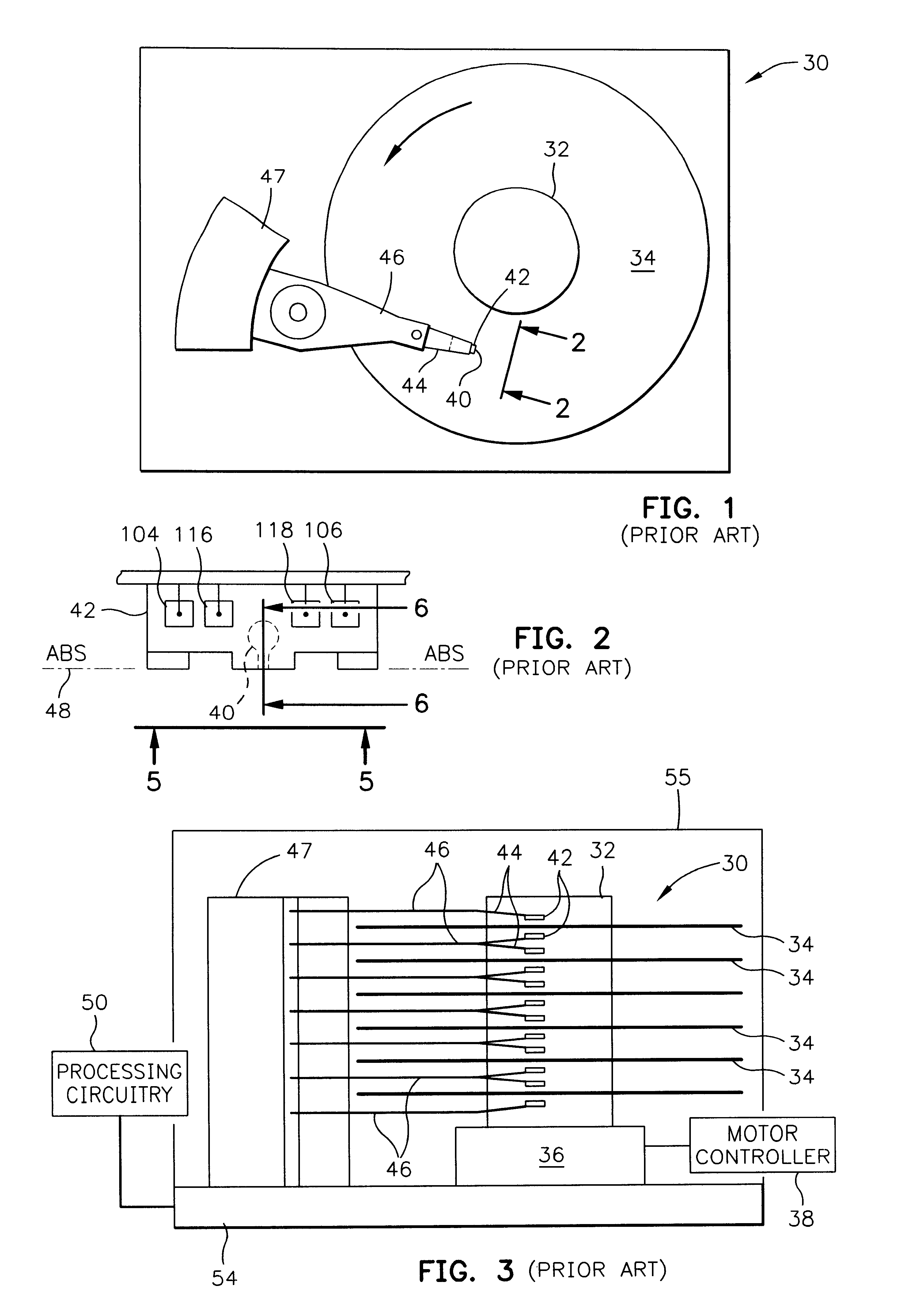

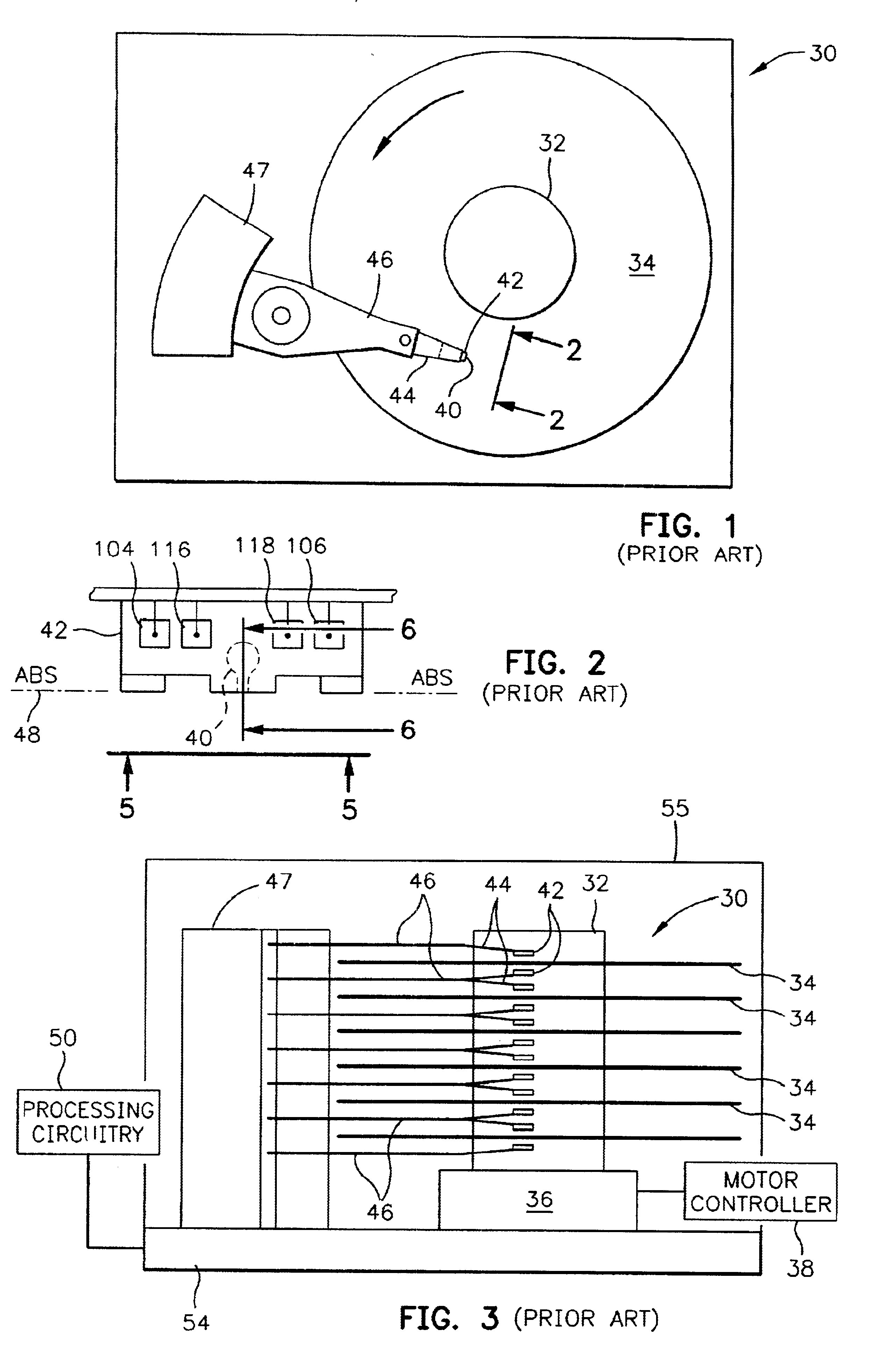

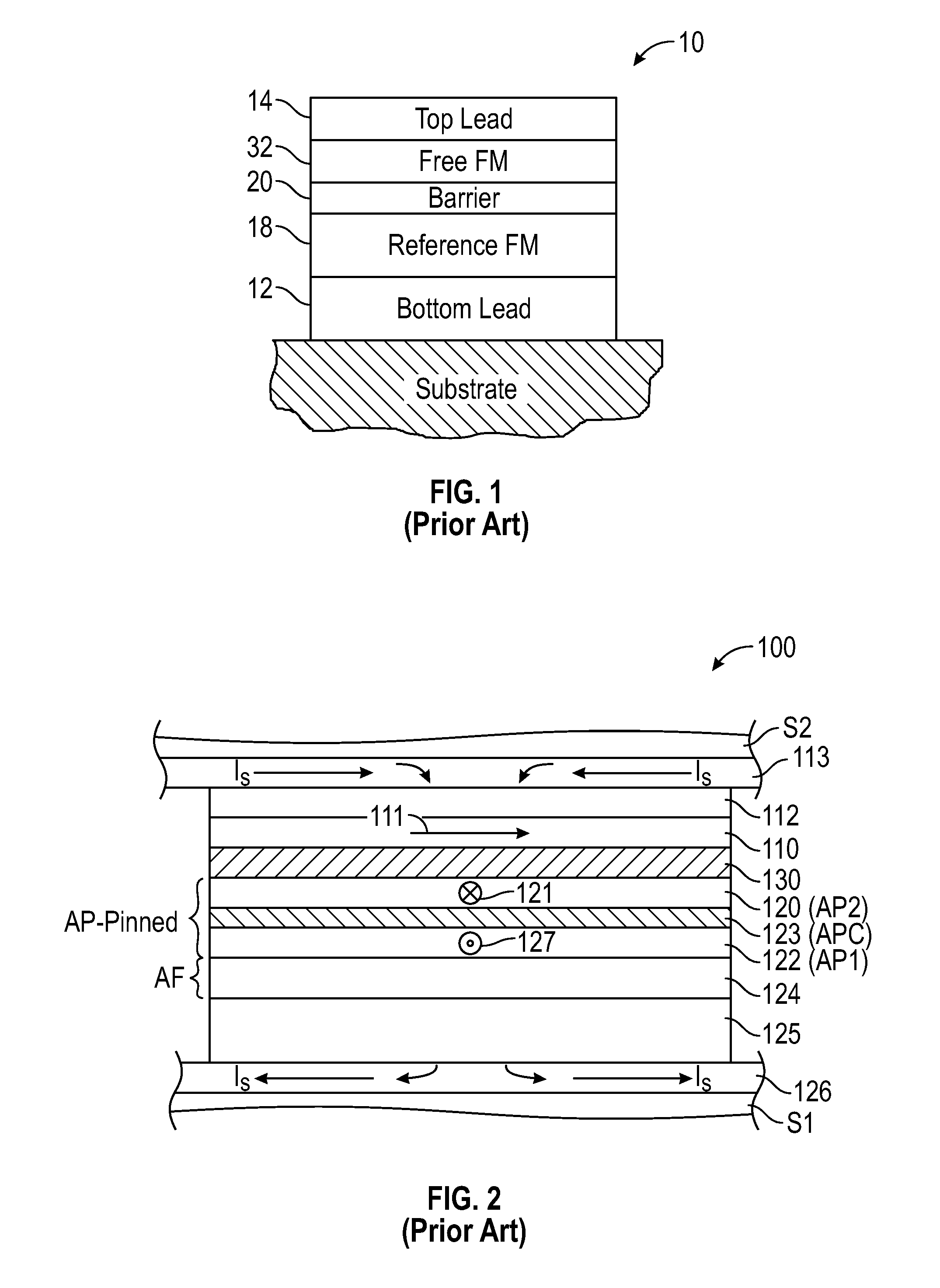

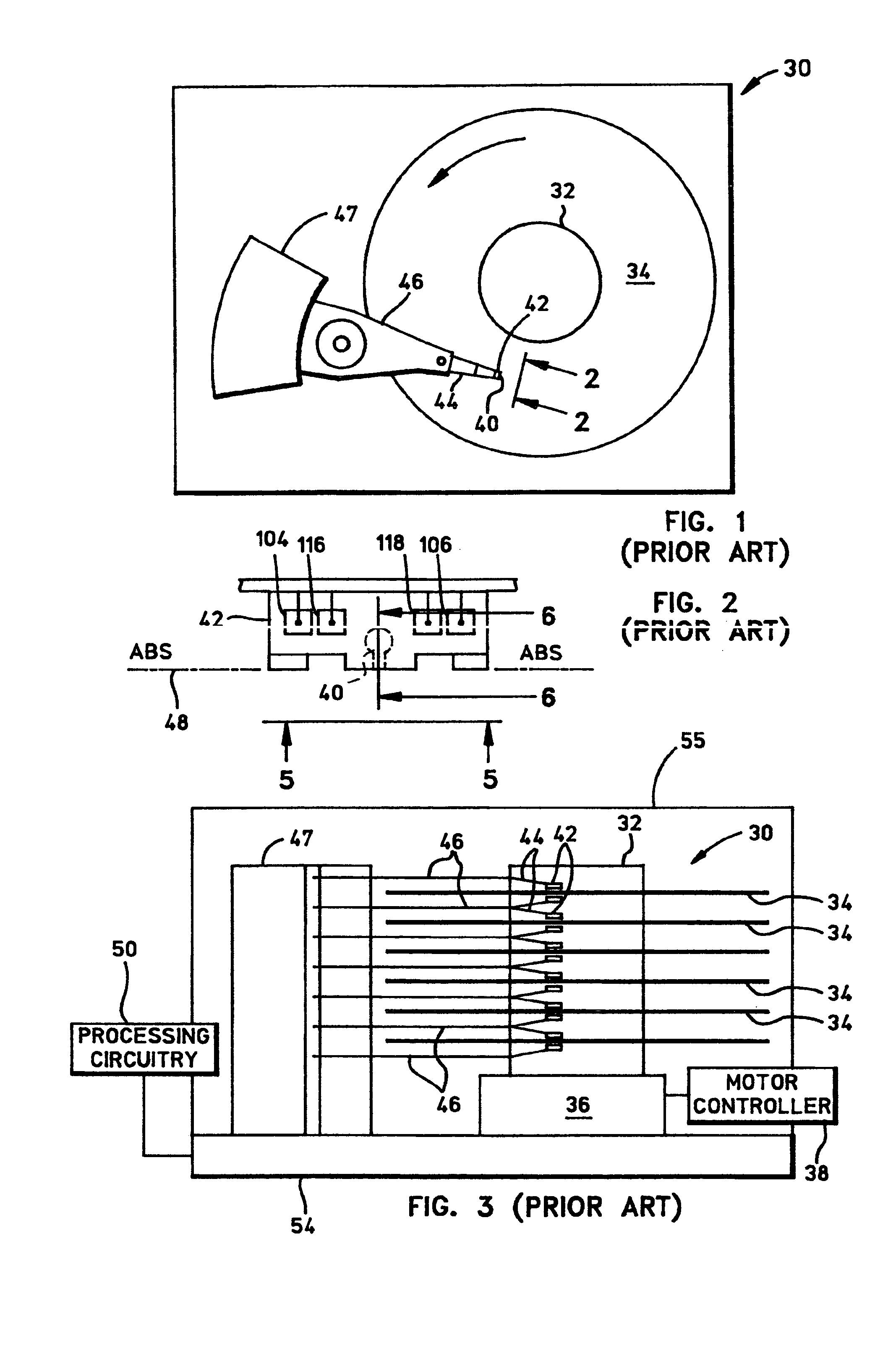

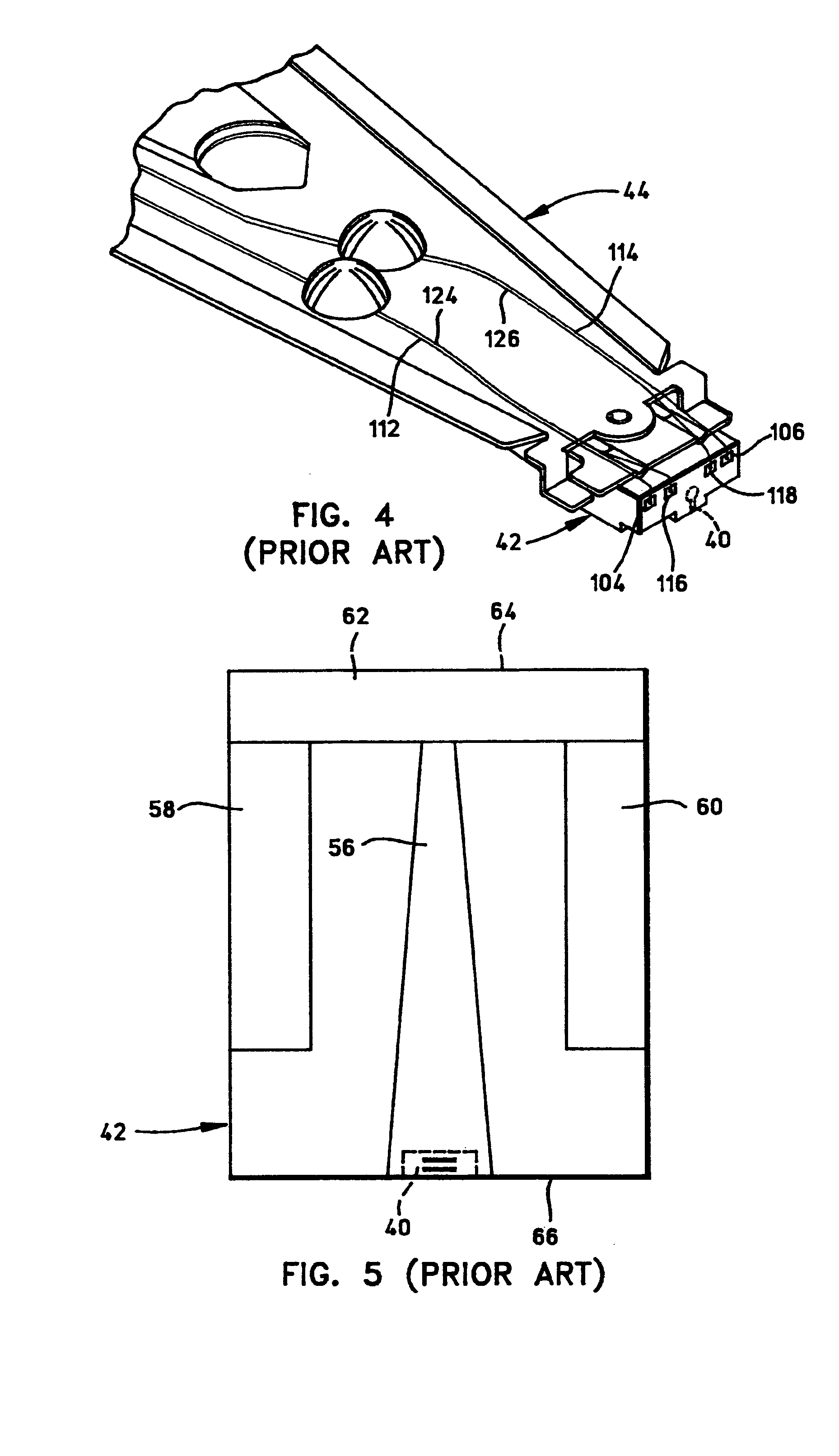

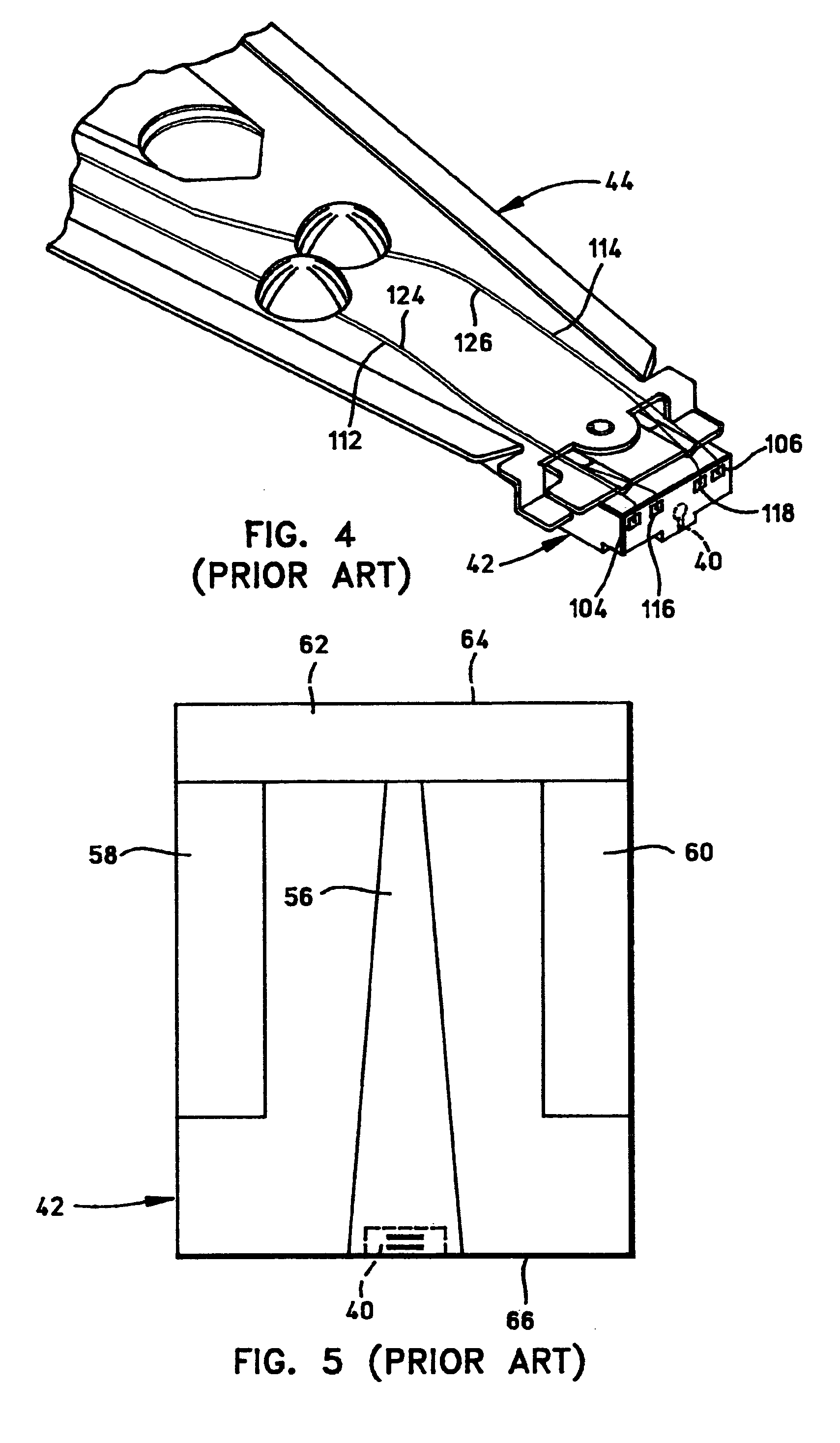

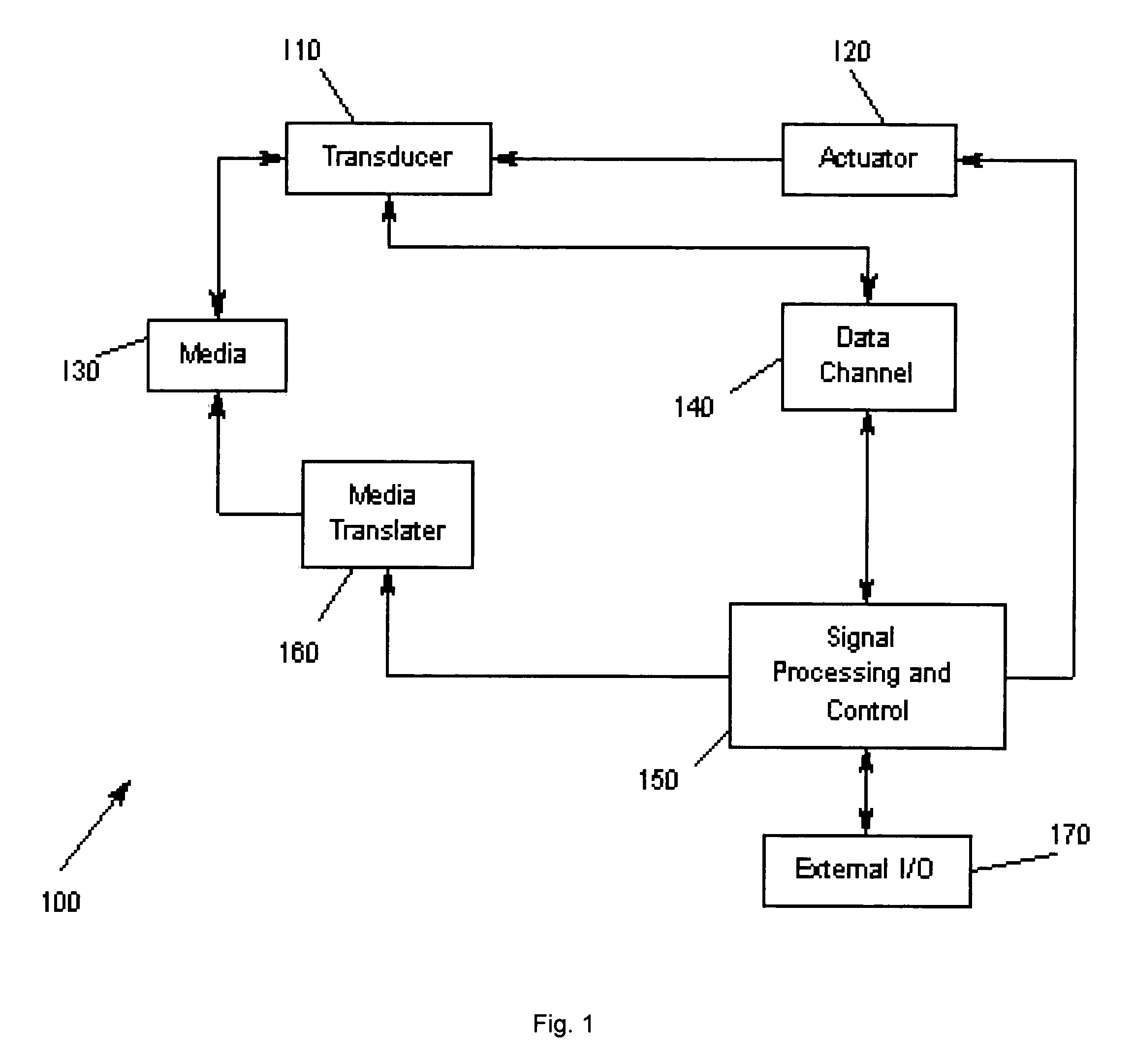

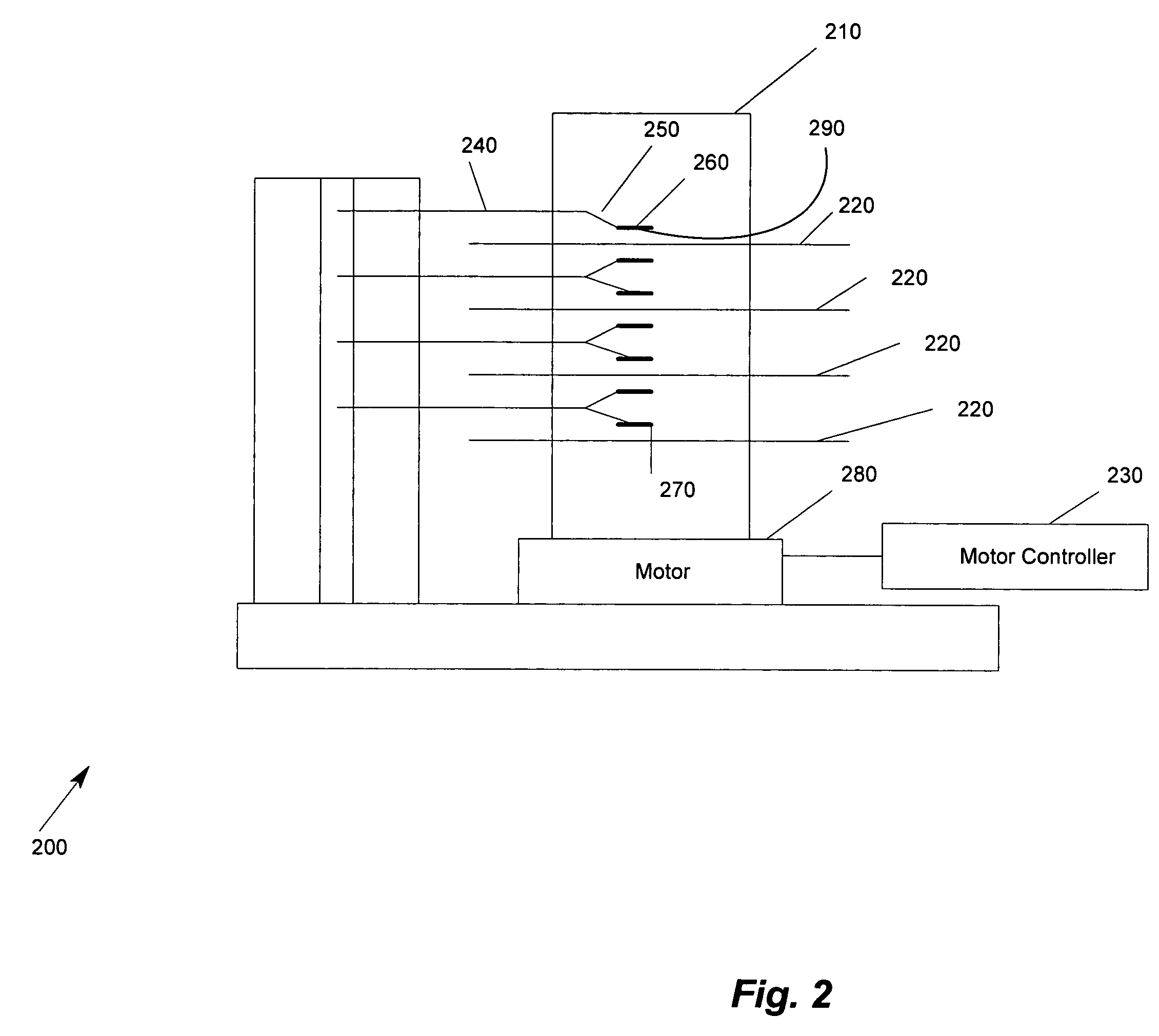

Spin valve sensor with exchange biased free layer and antiparallel (AP) pinned layer pinned without a pinning layer

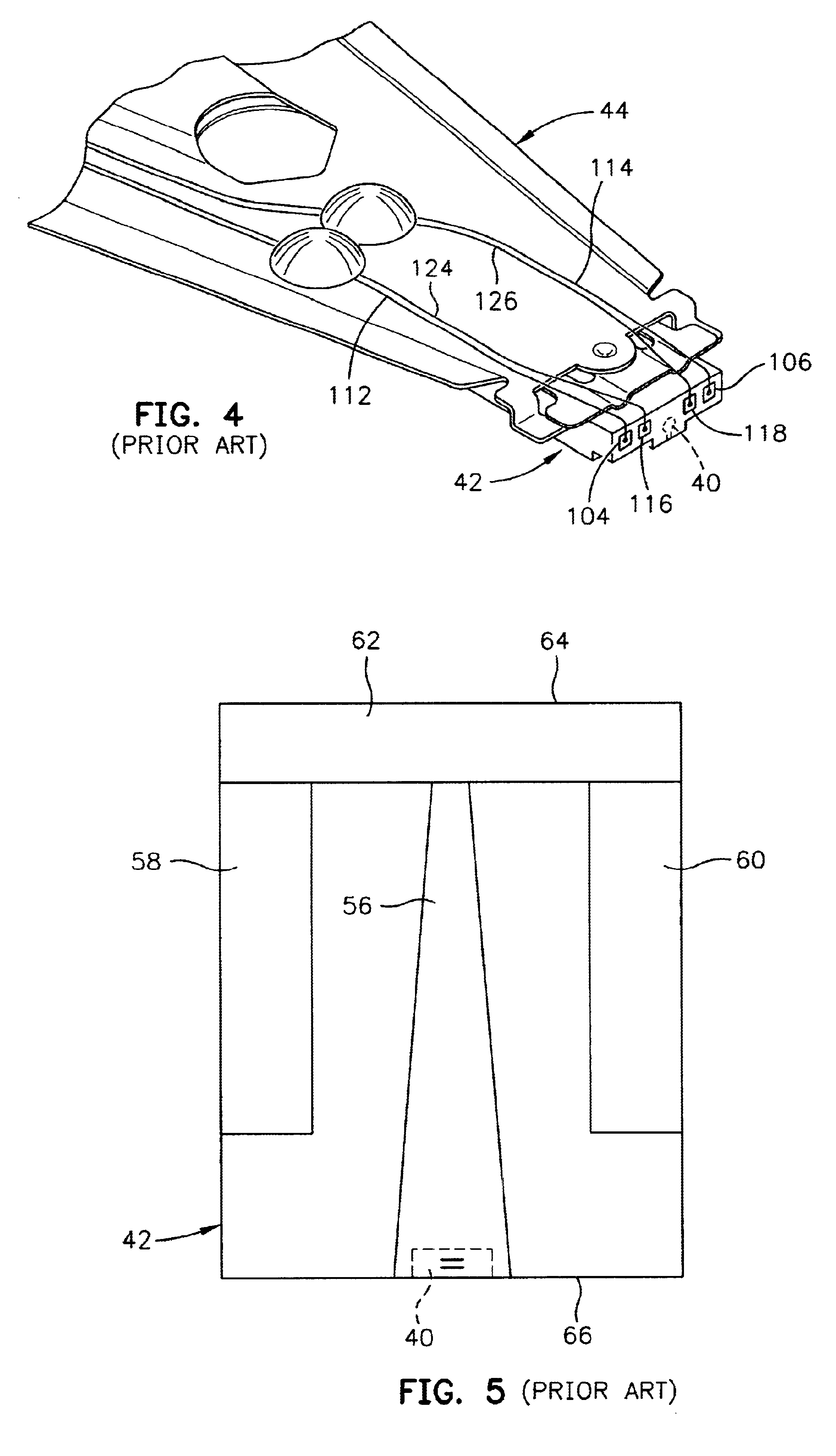

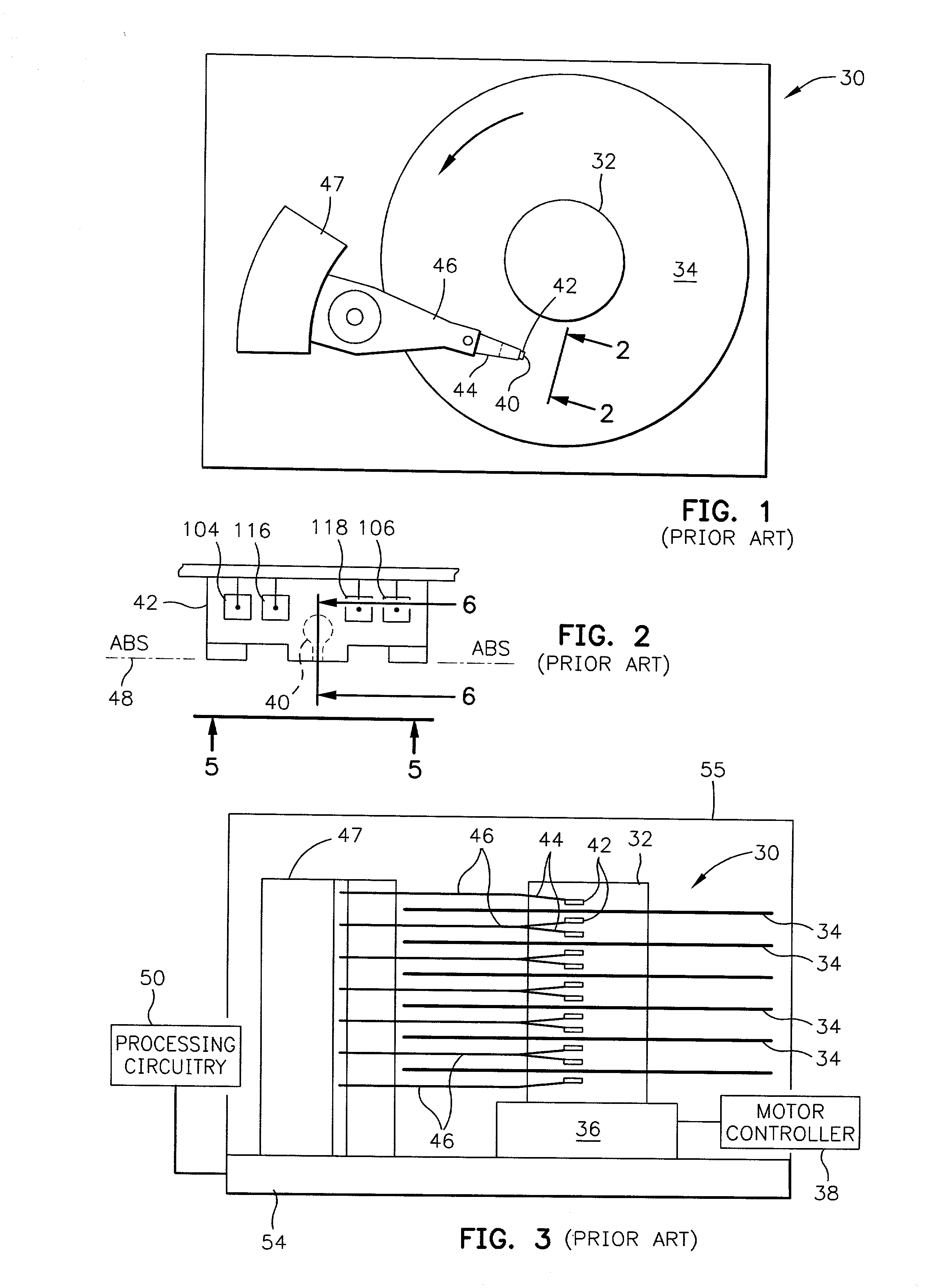

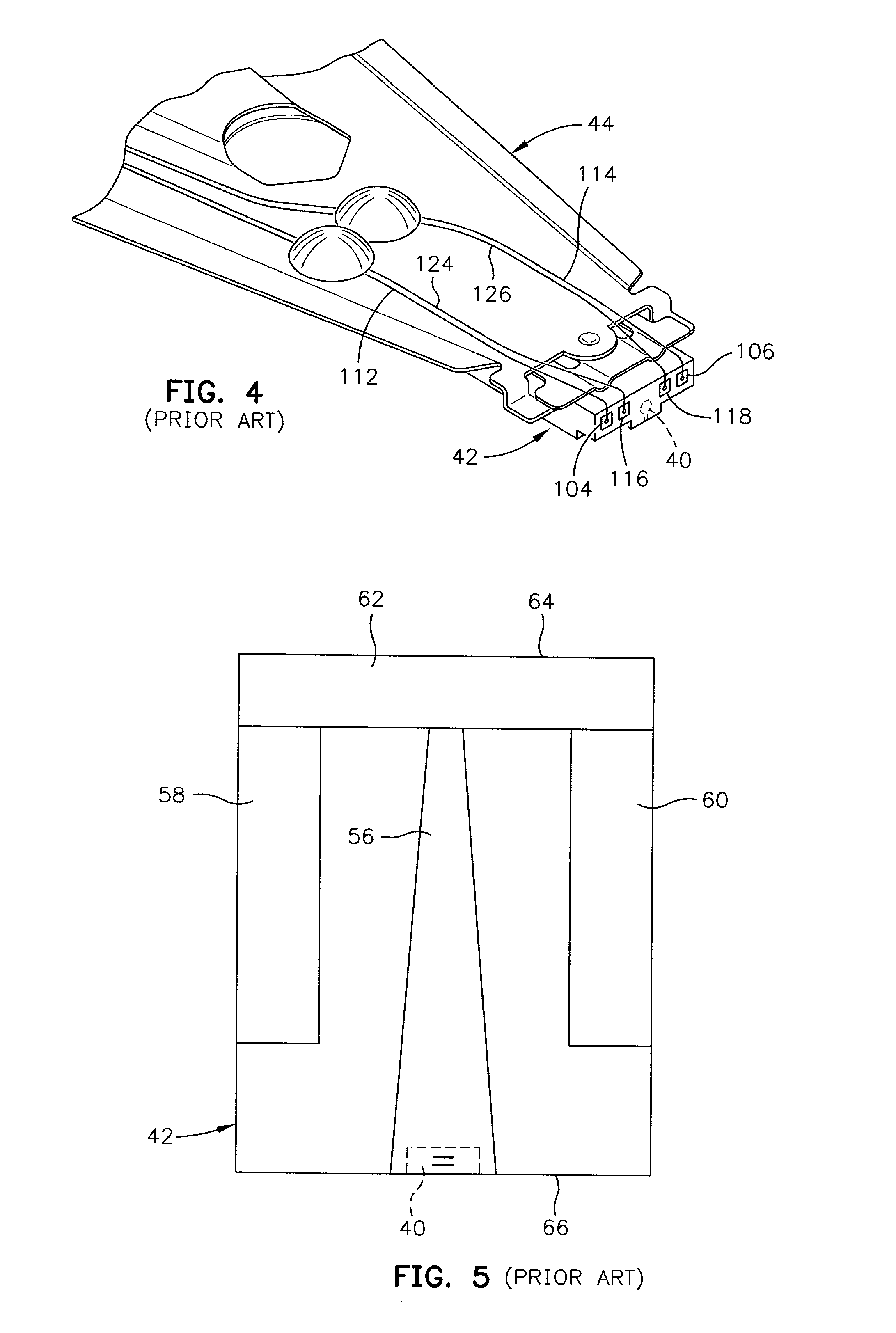

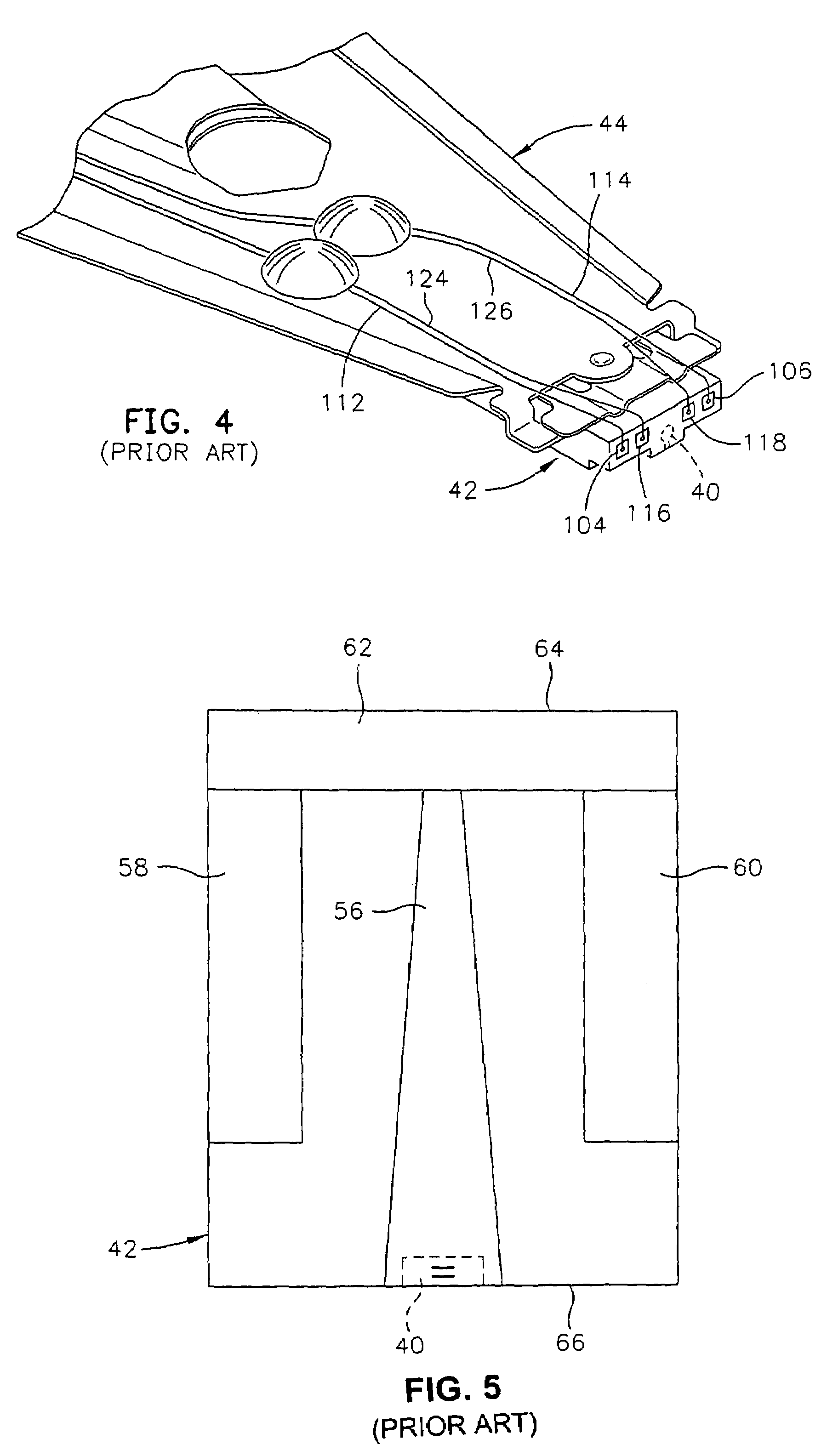

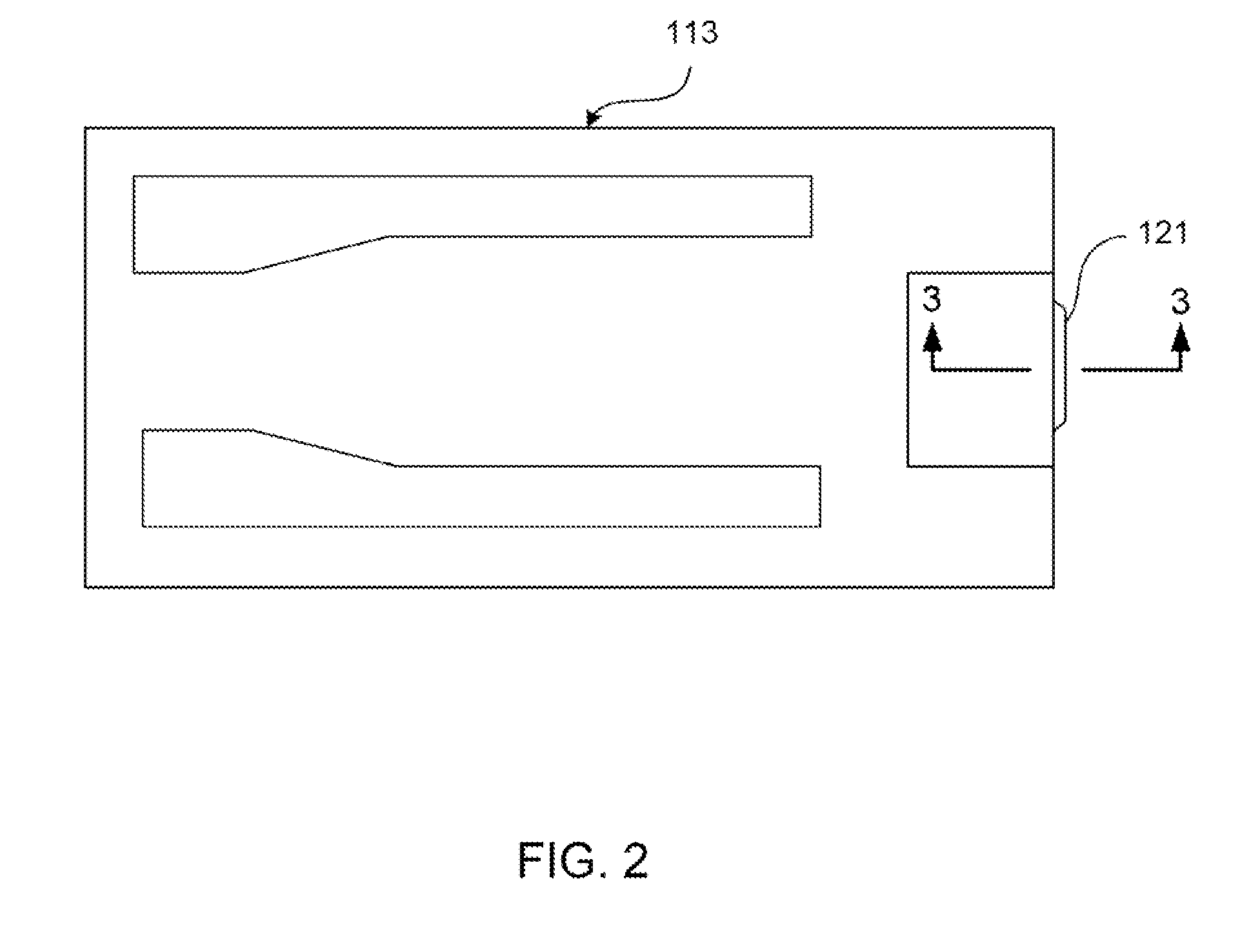

InactiveUS20030179515A1Improved magnetostrictionImprovement factorNanoinformaticsHeads using thin filmsEngineeringLateral extension

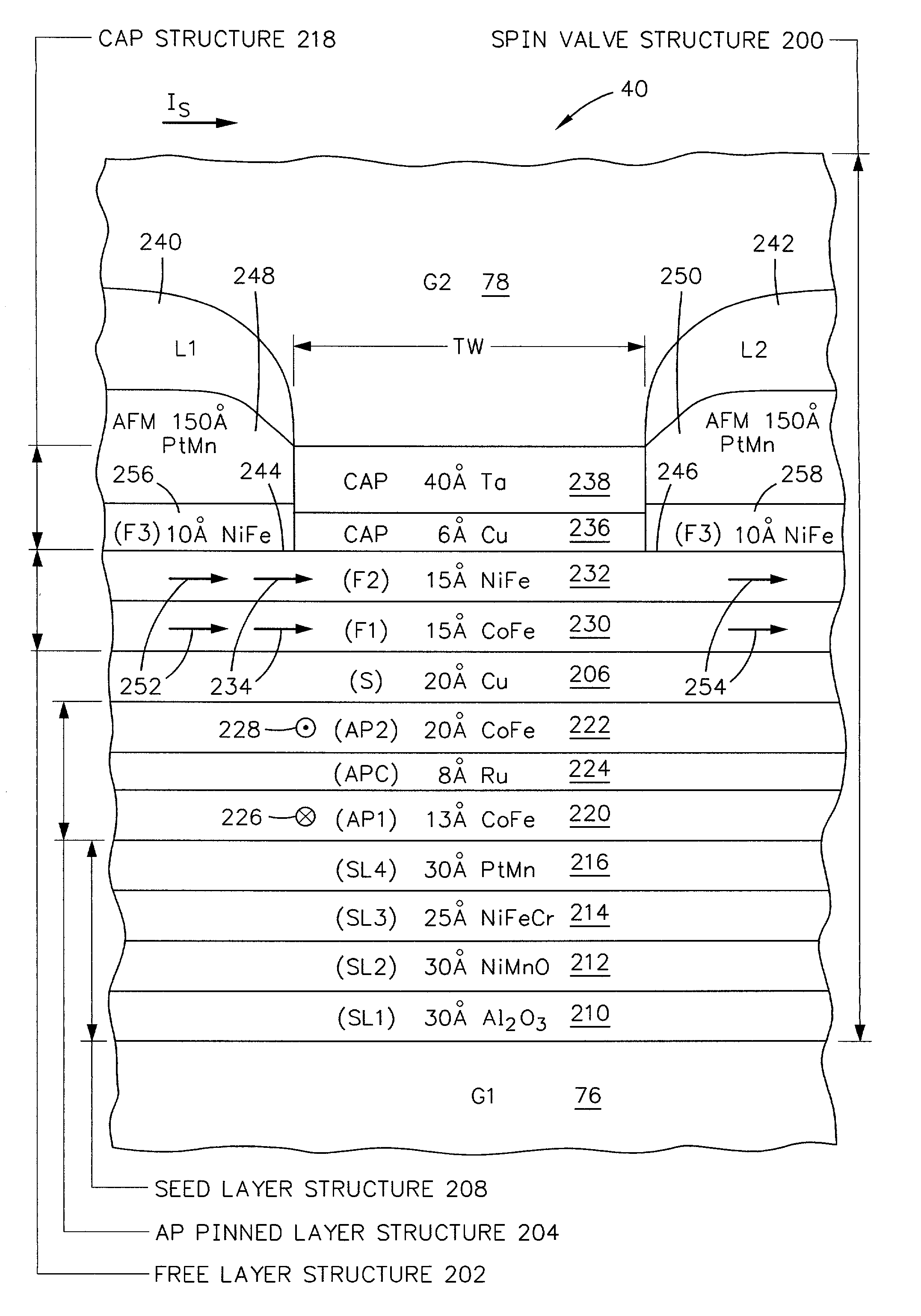

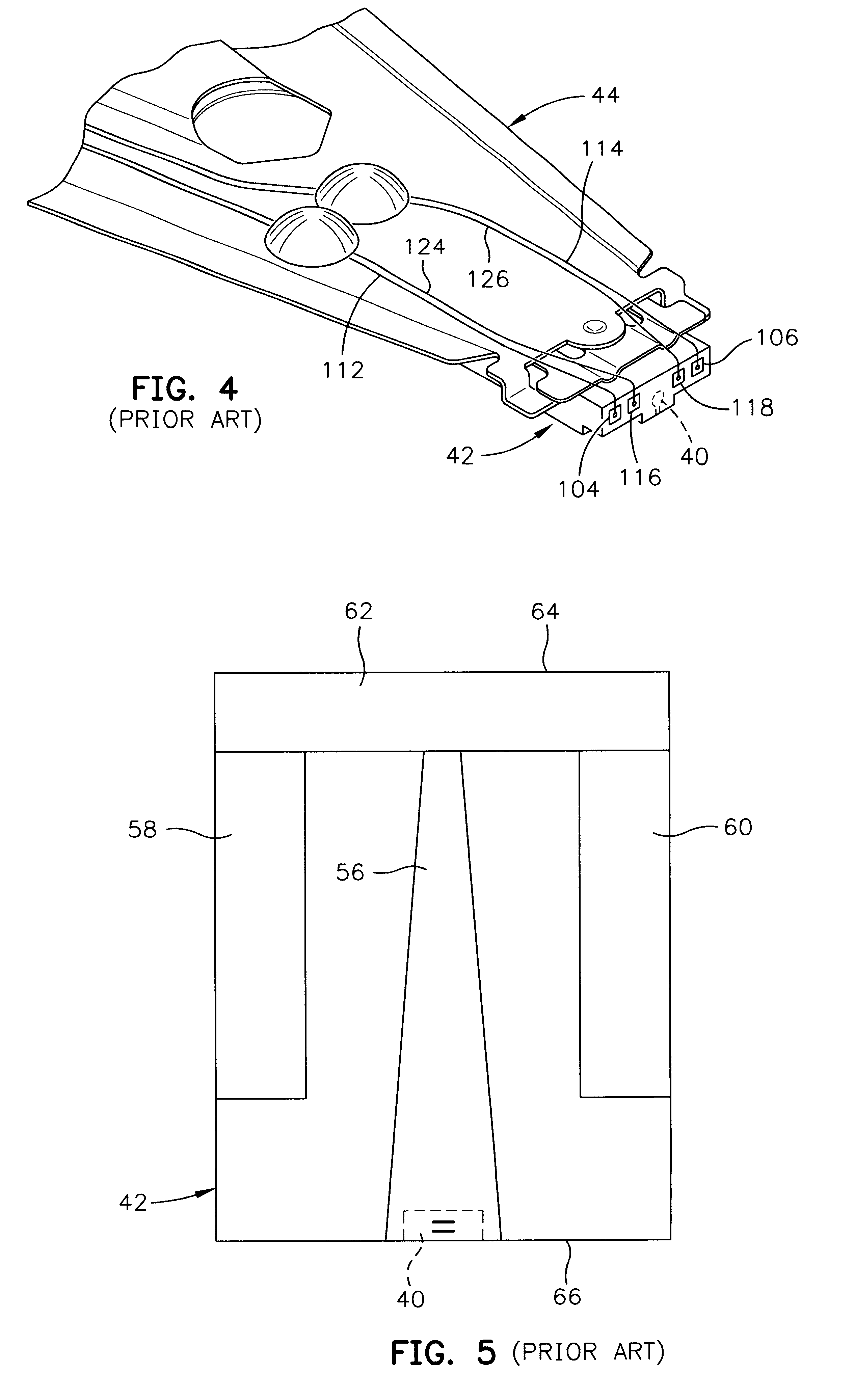

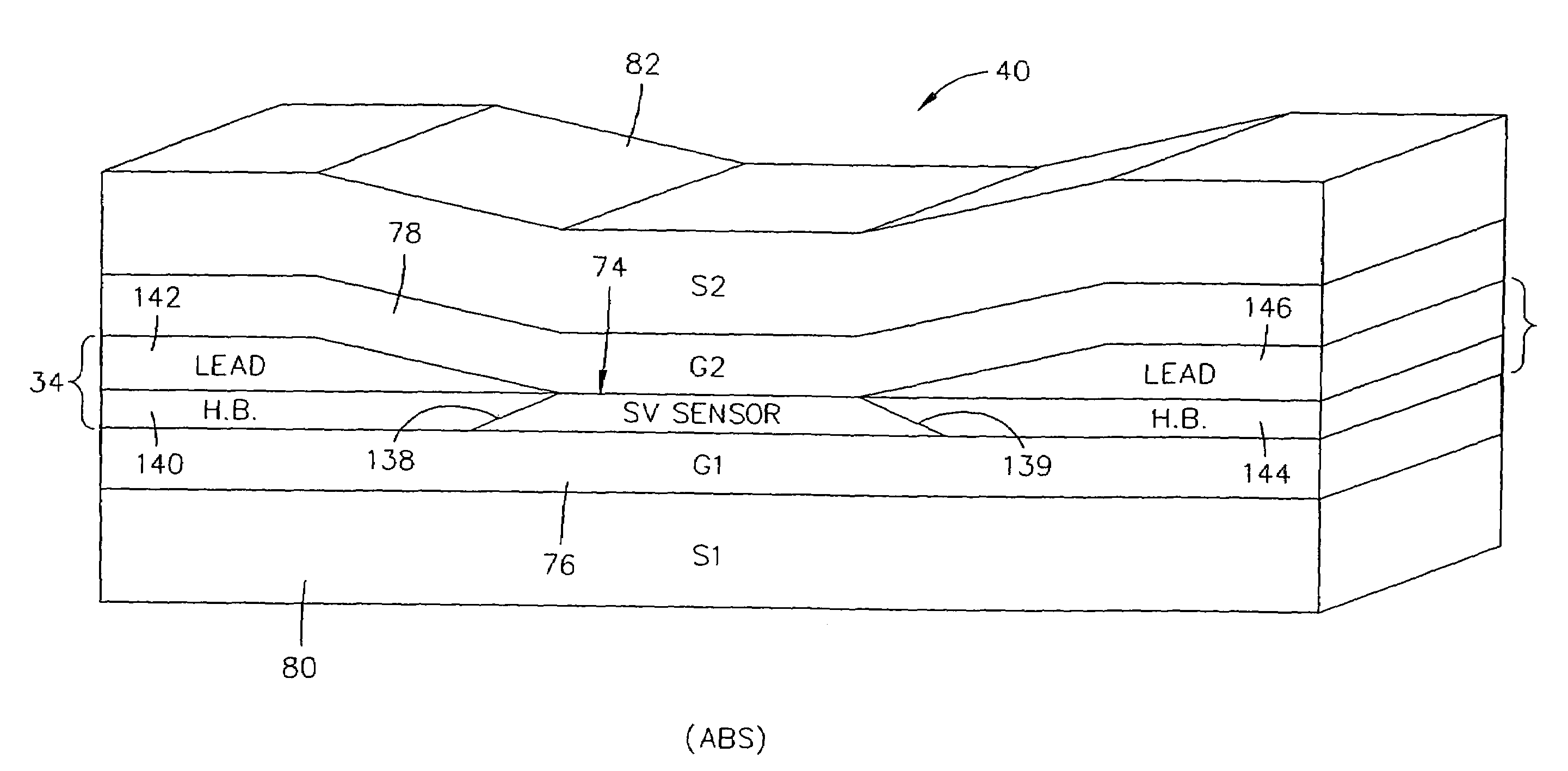

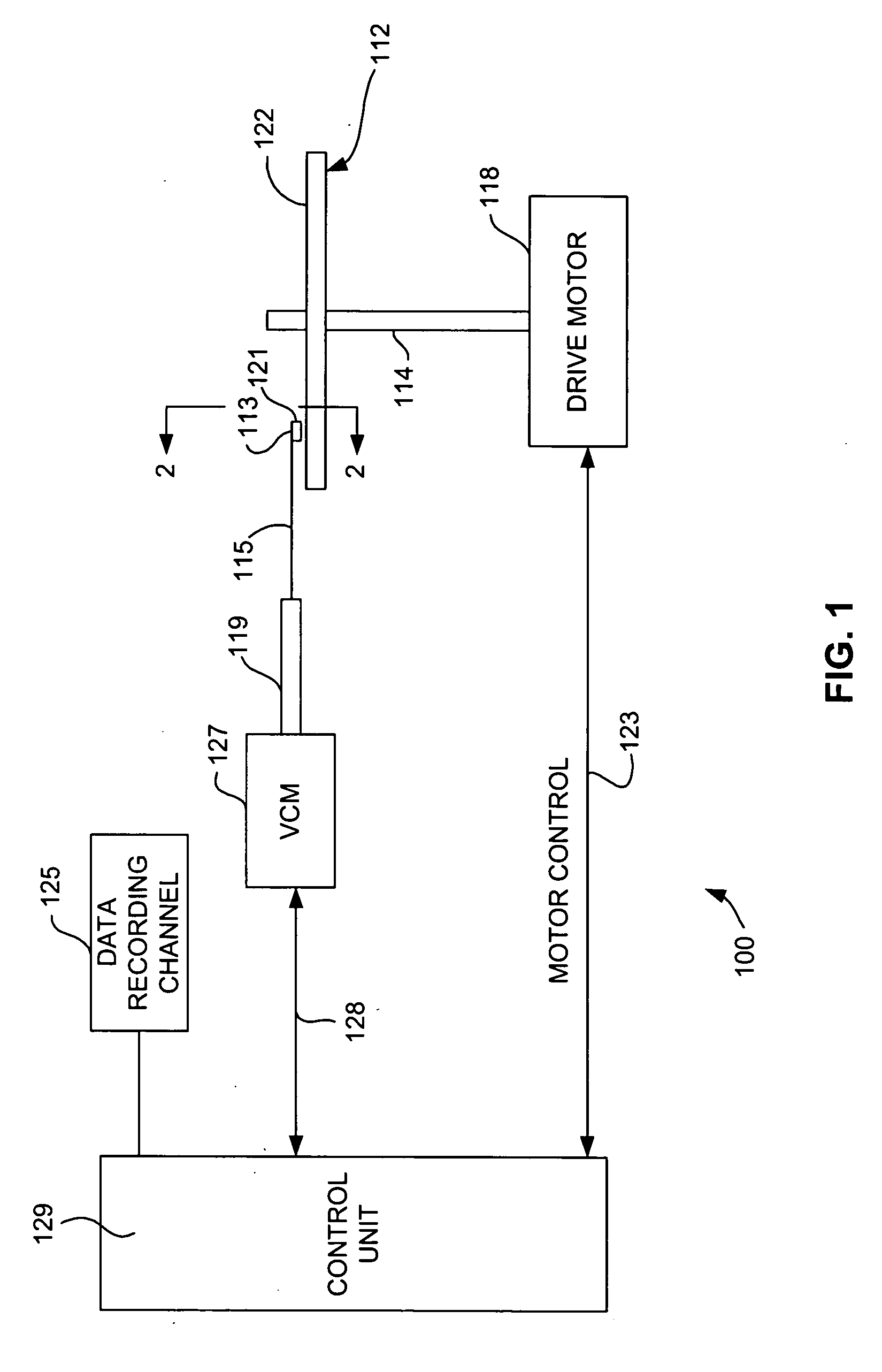

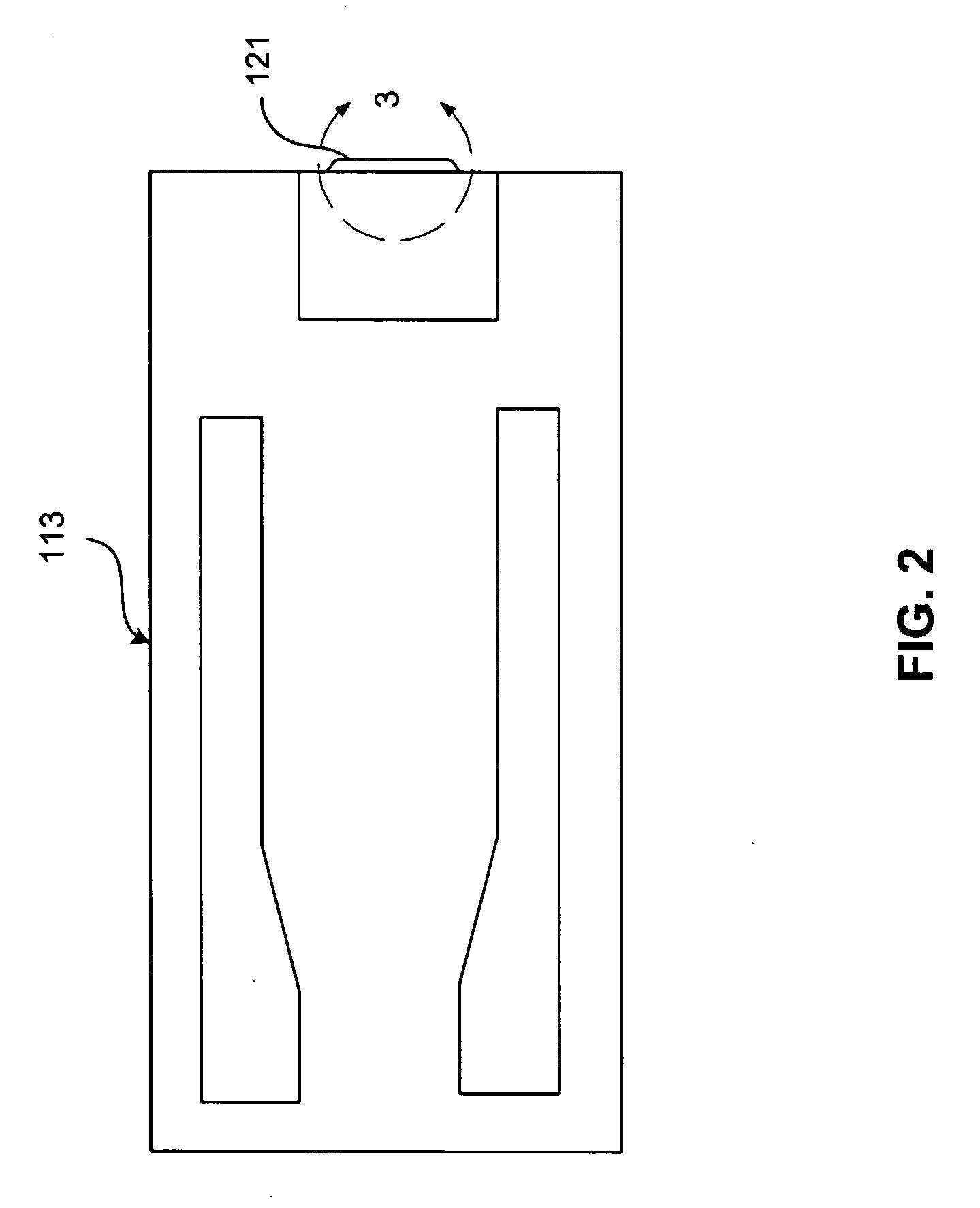

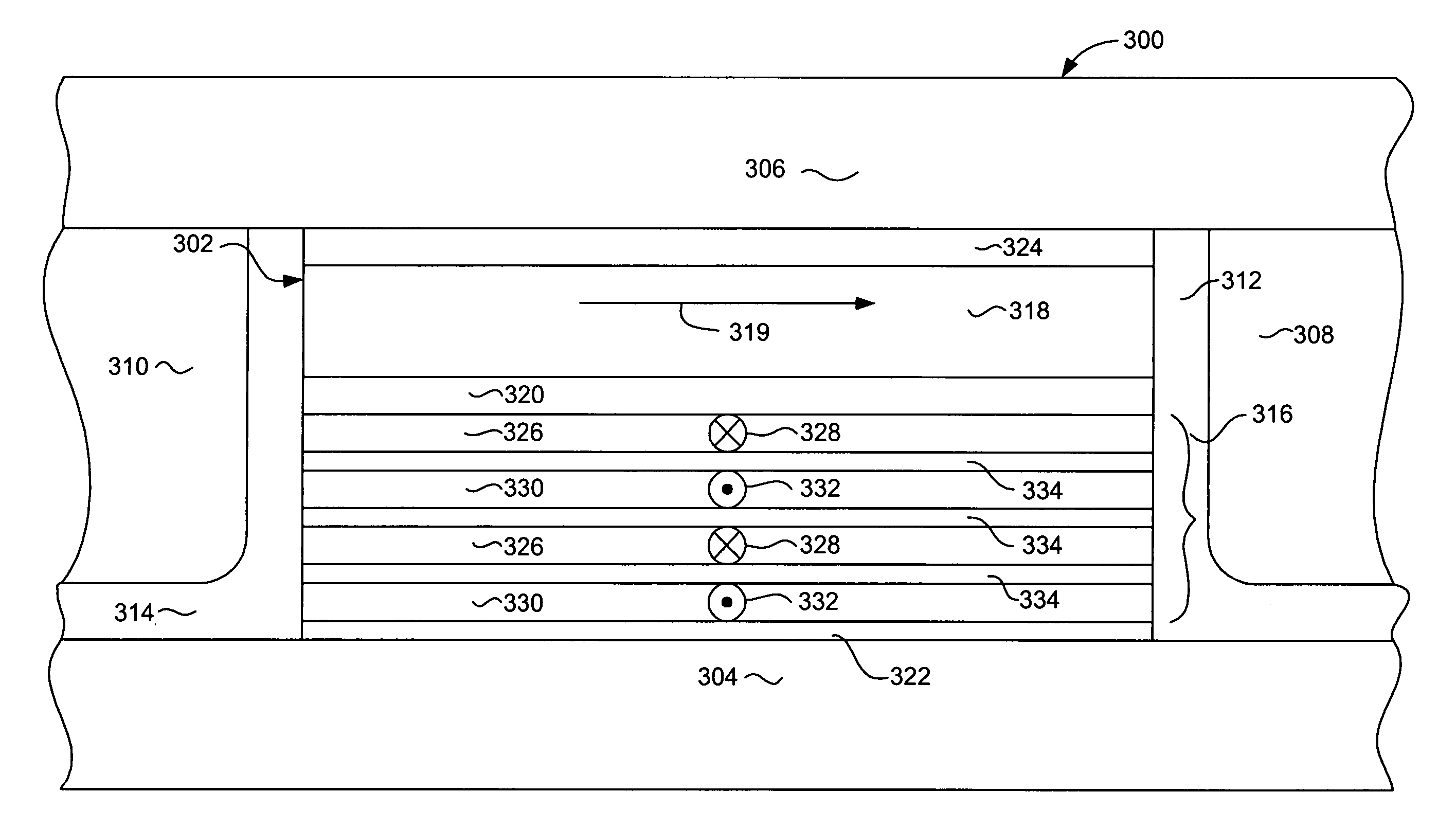

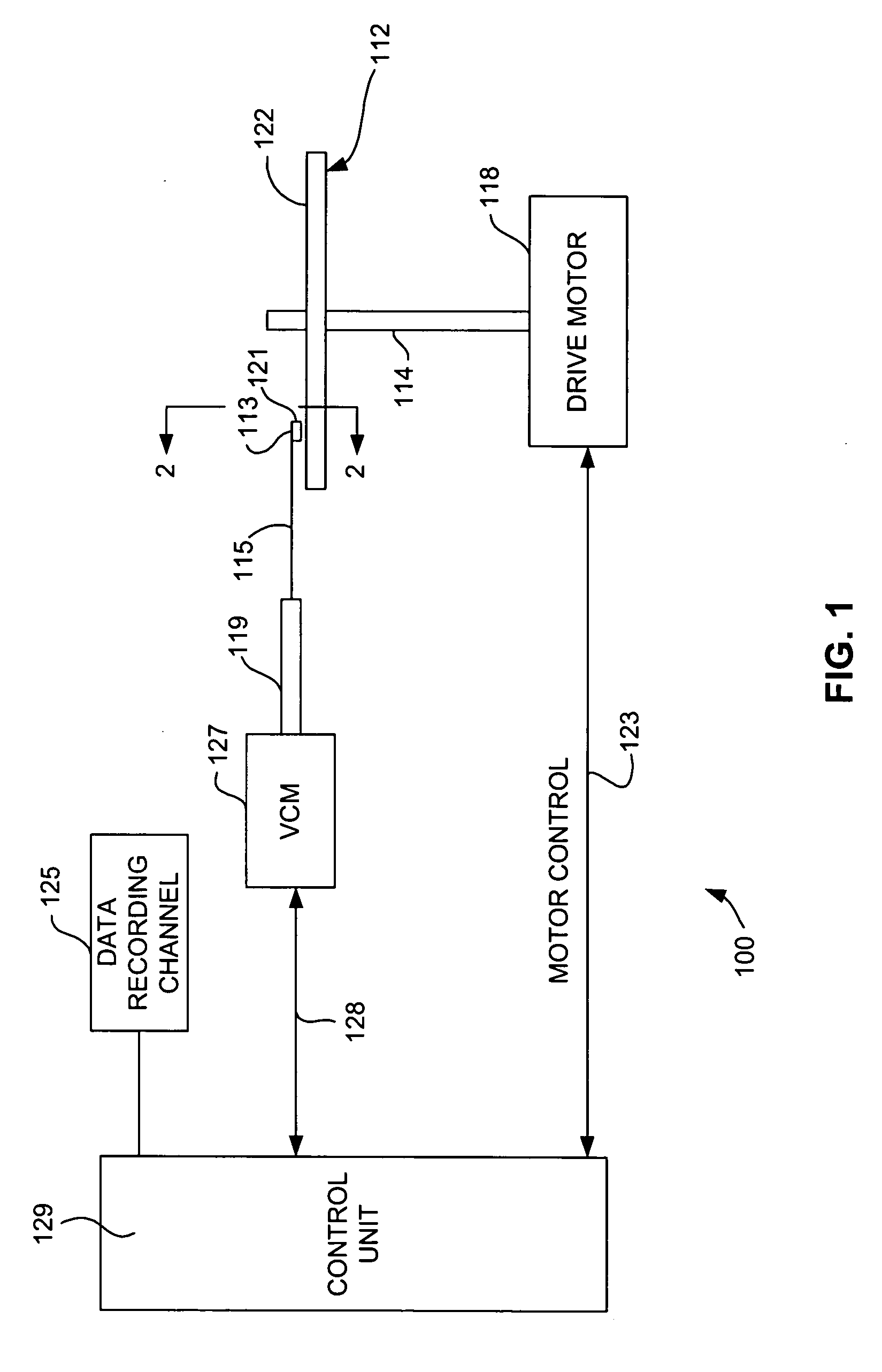

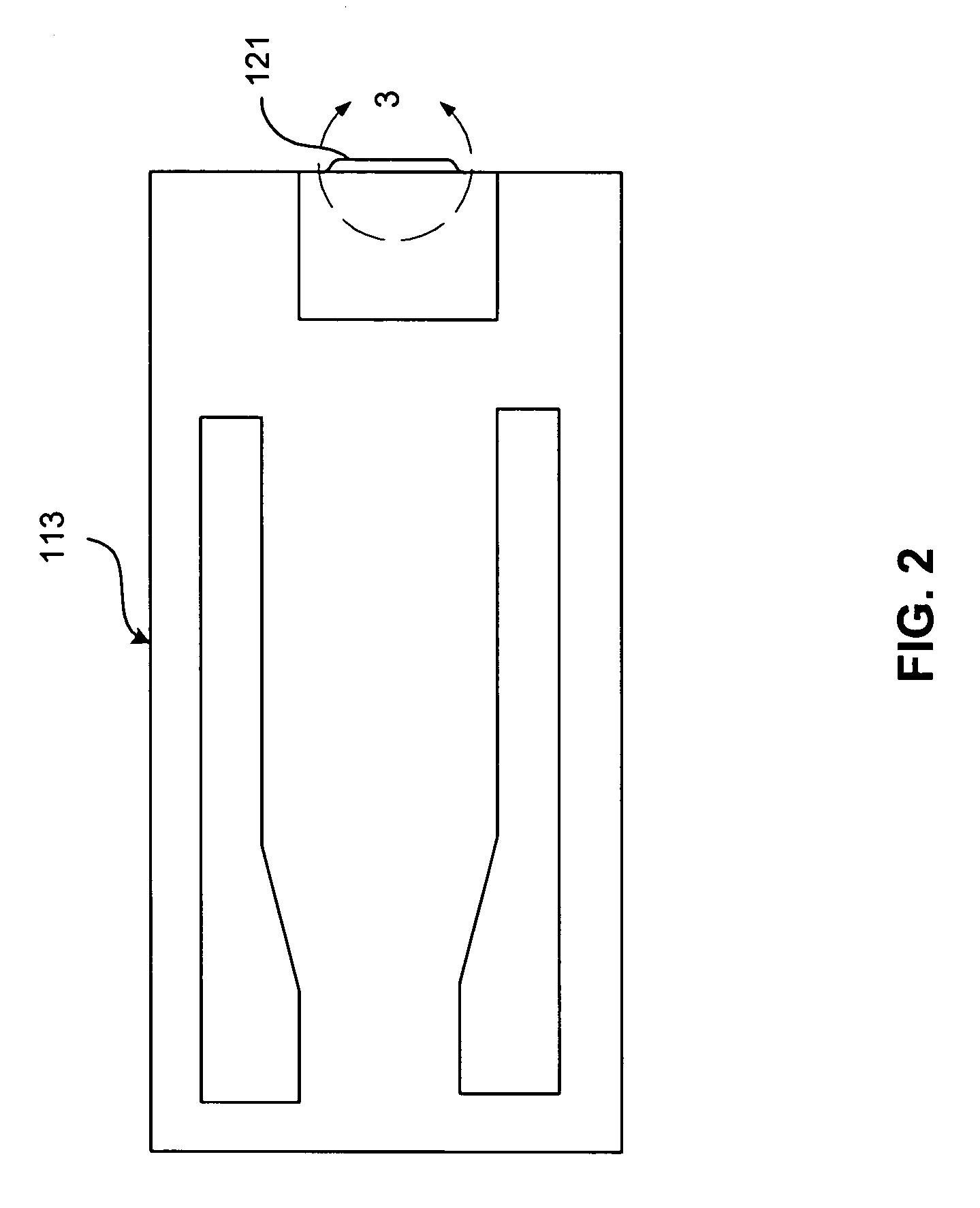

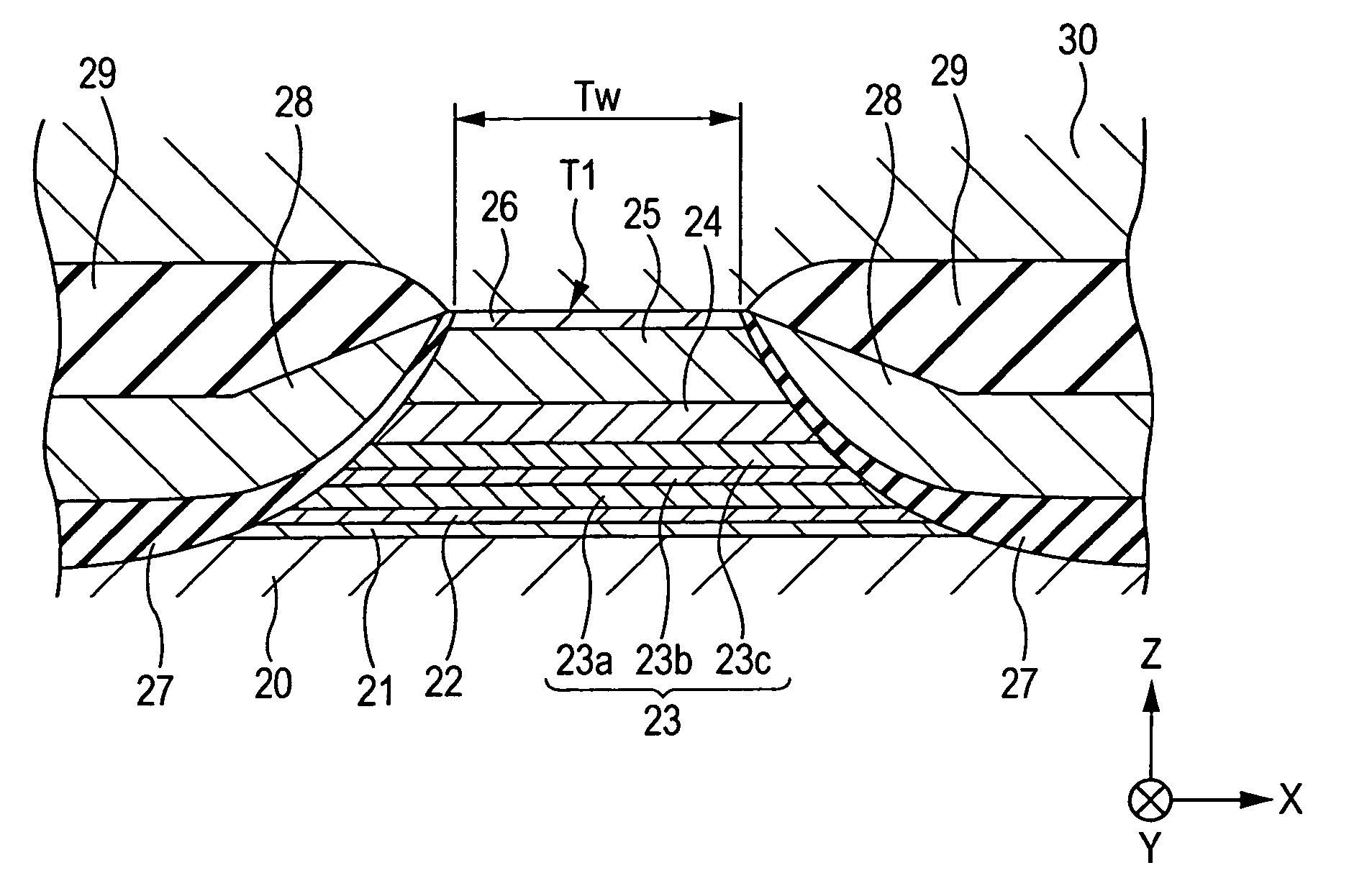

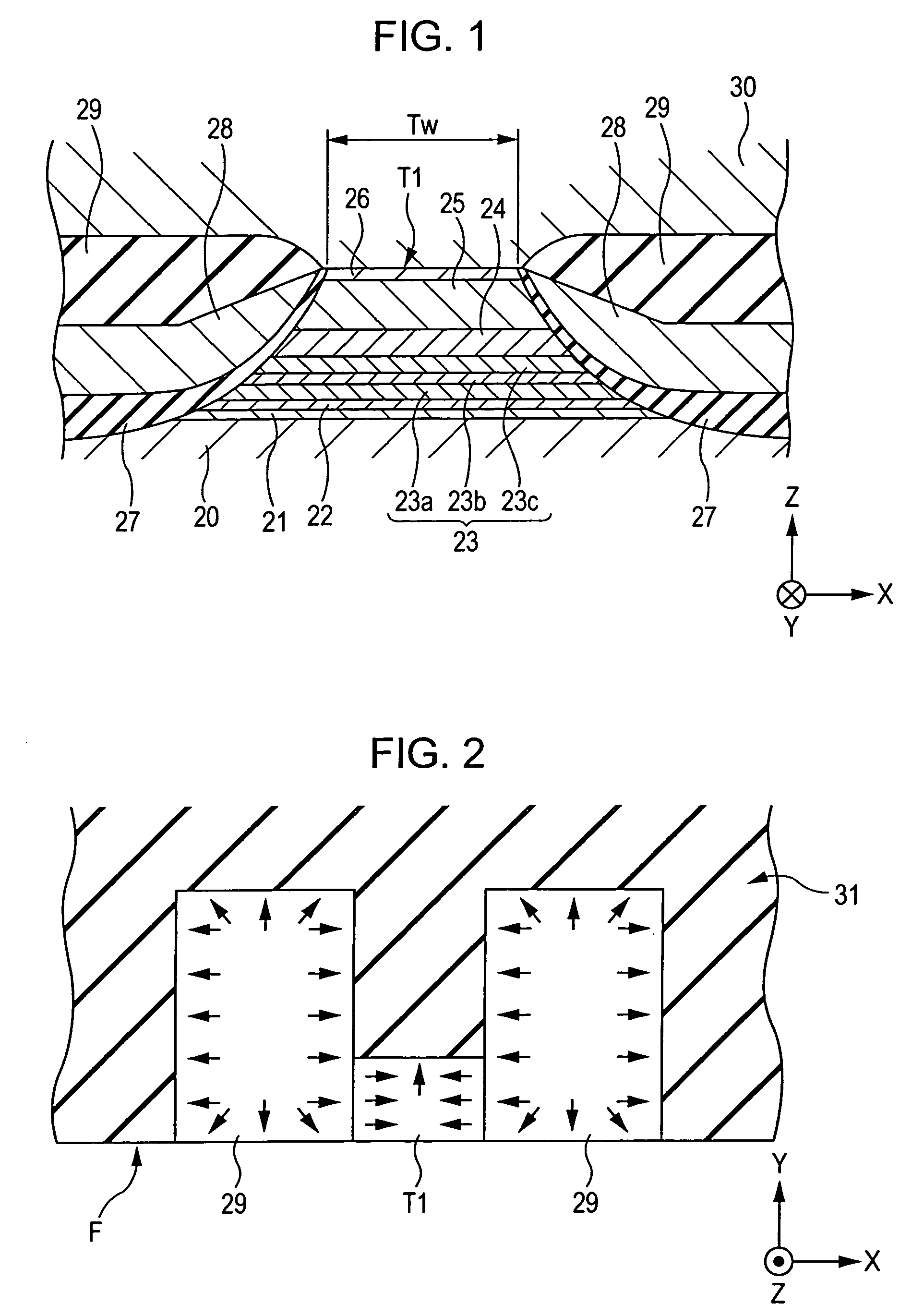

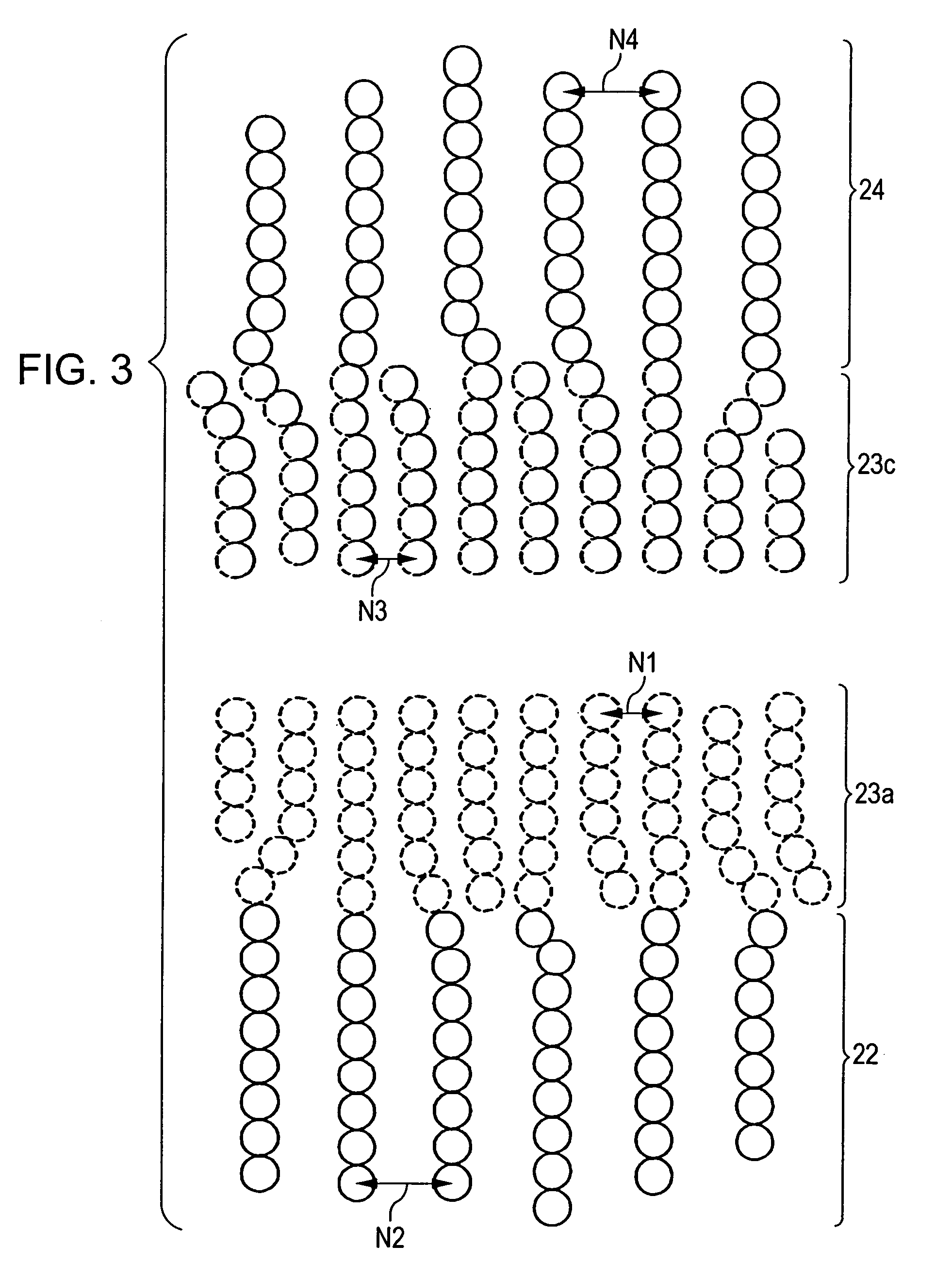

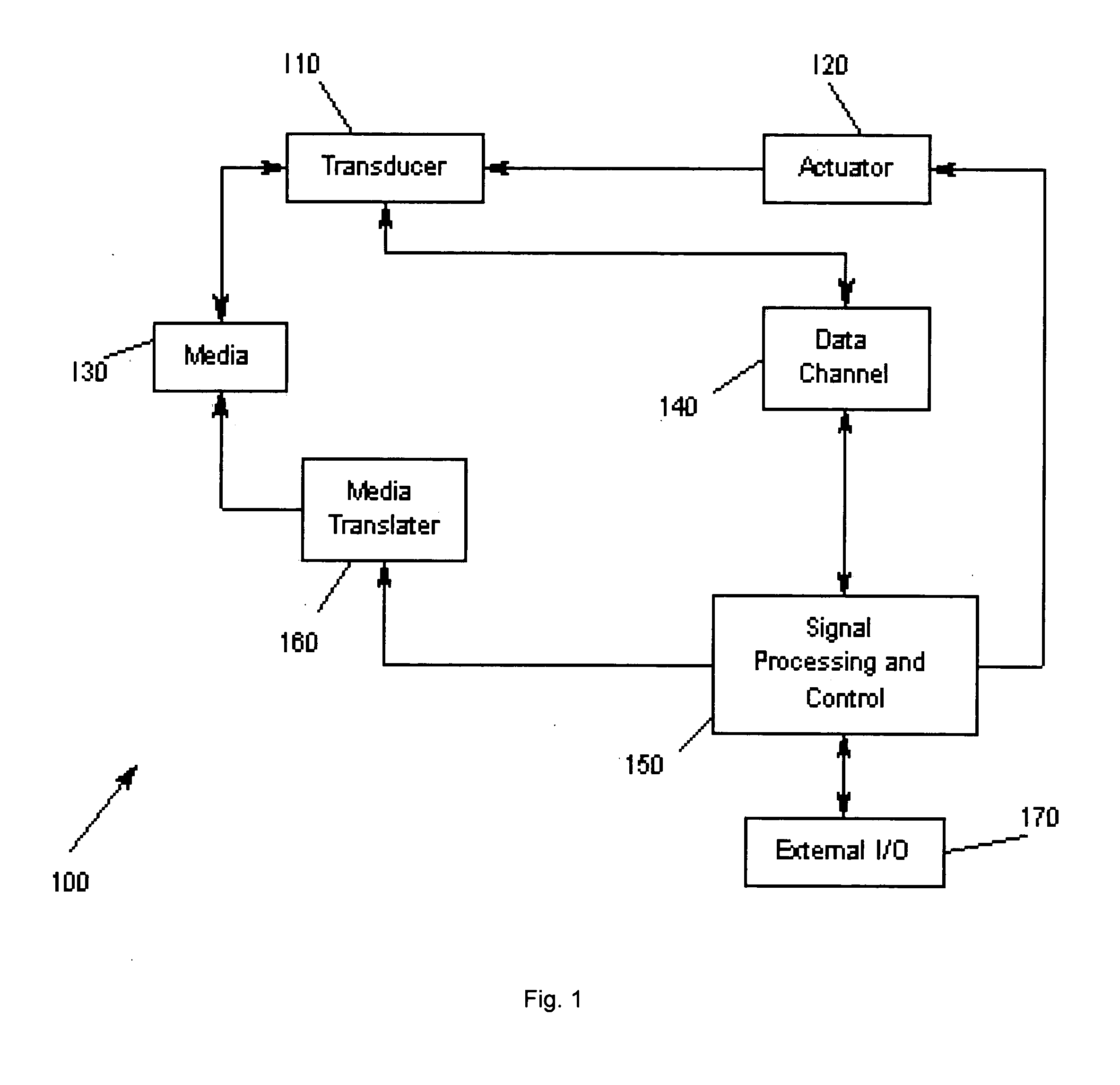

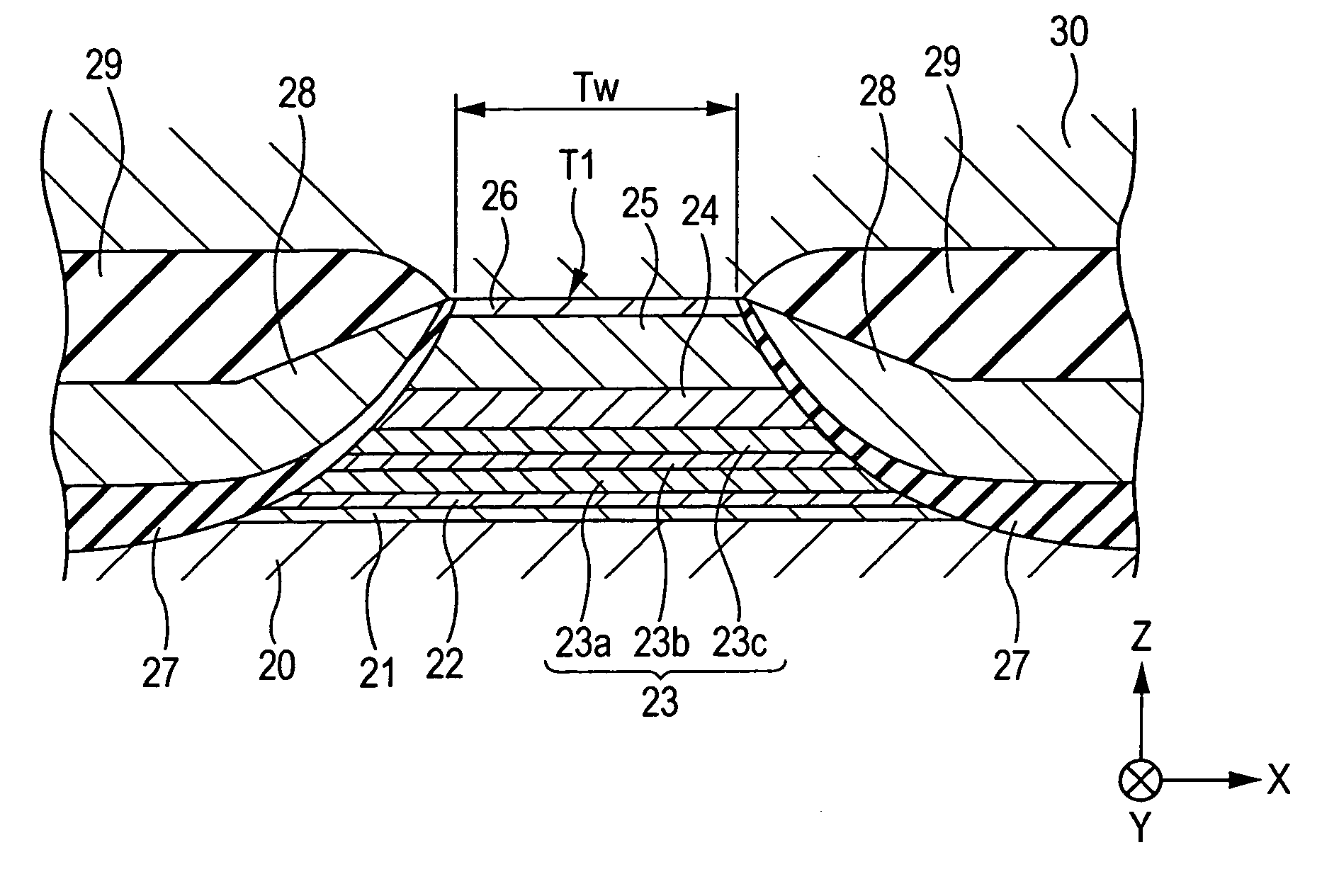

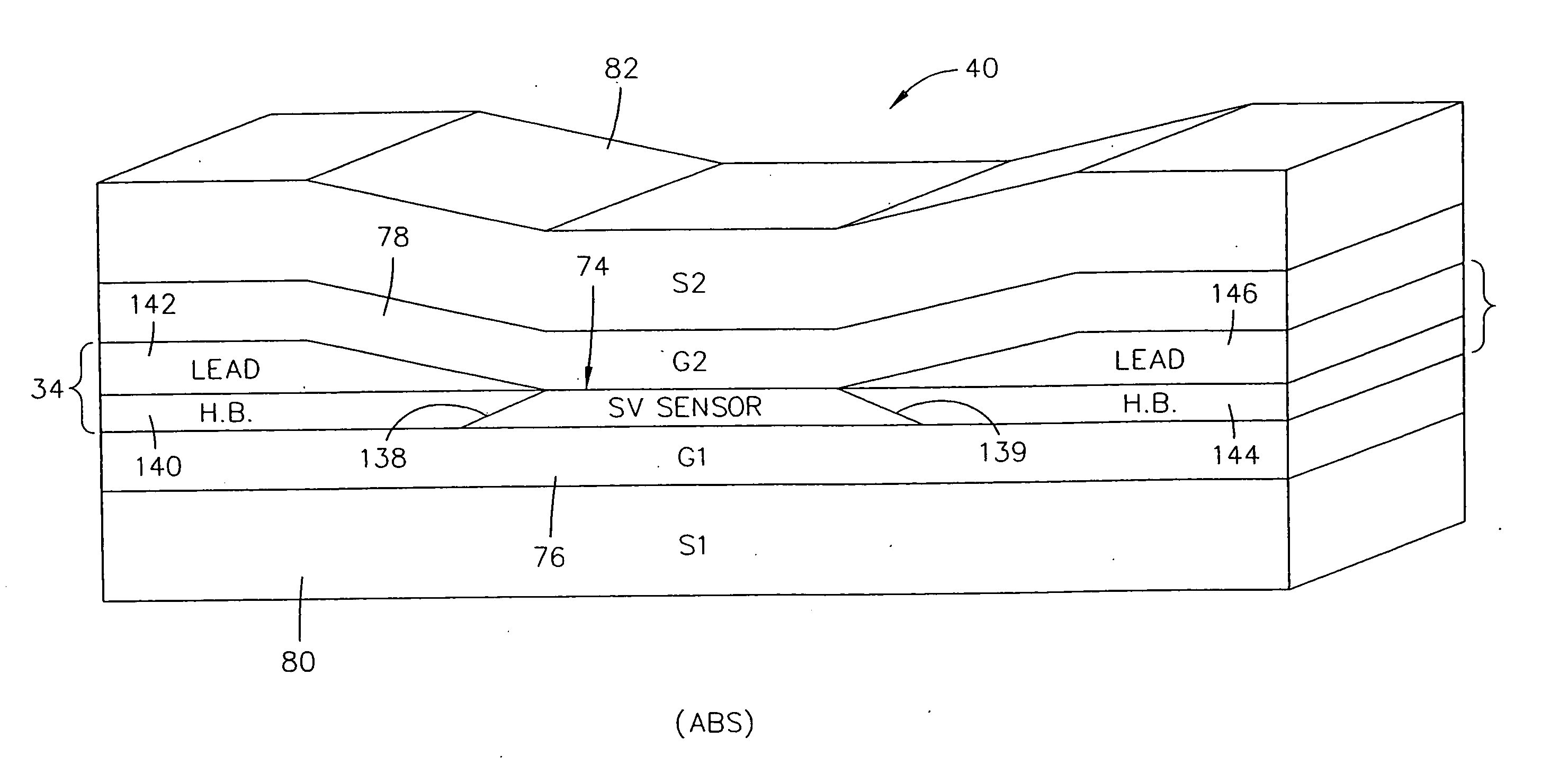

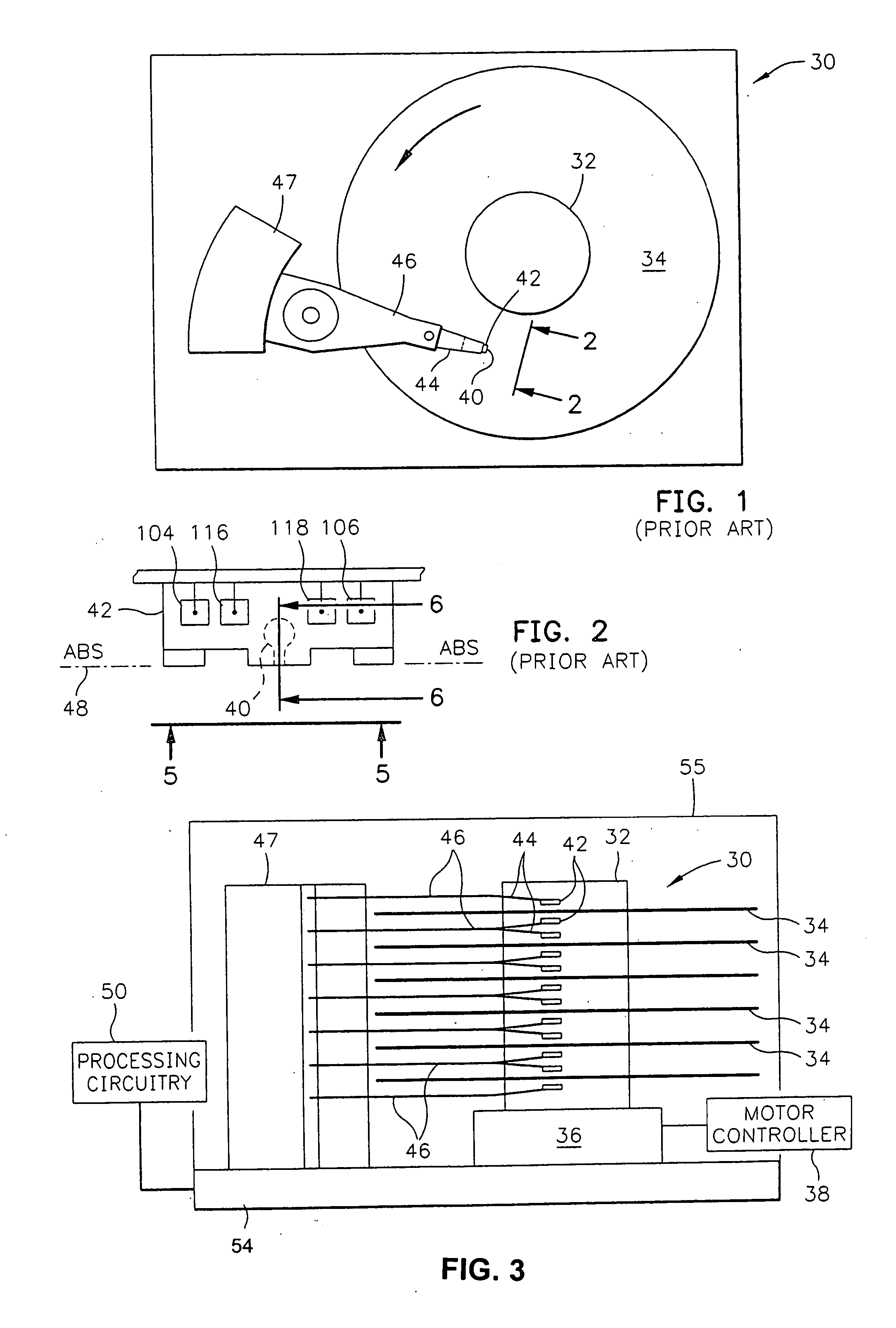

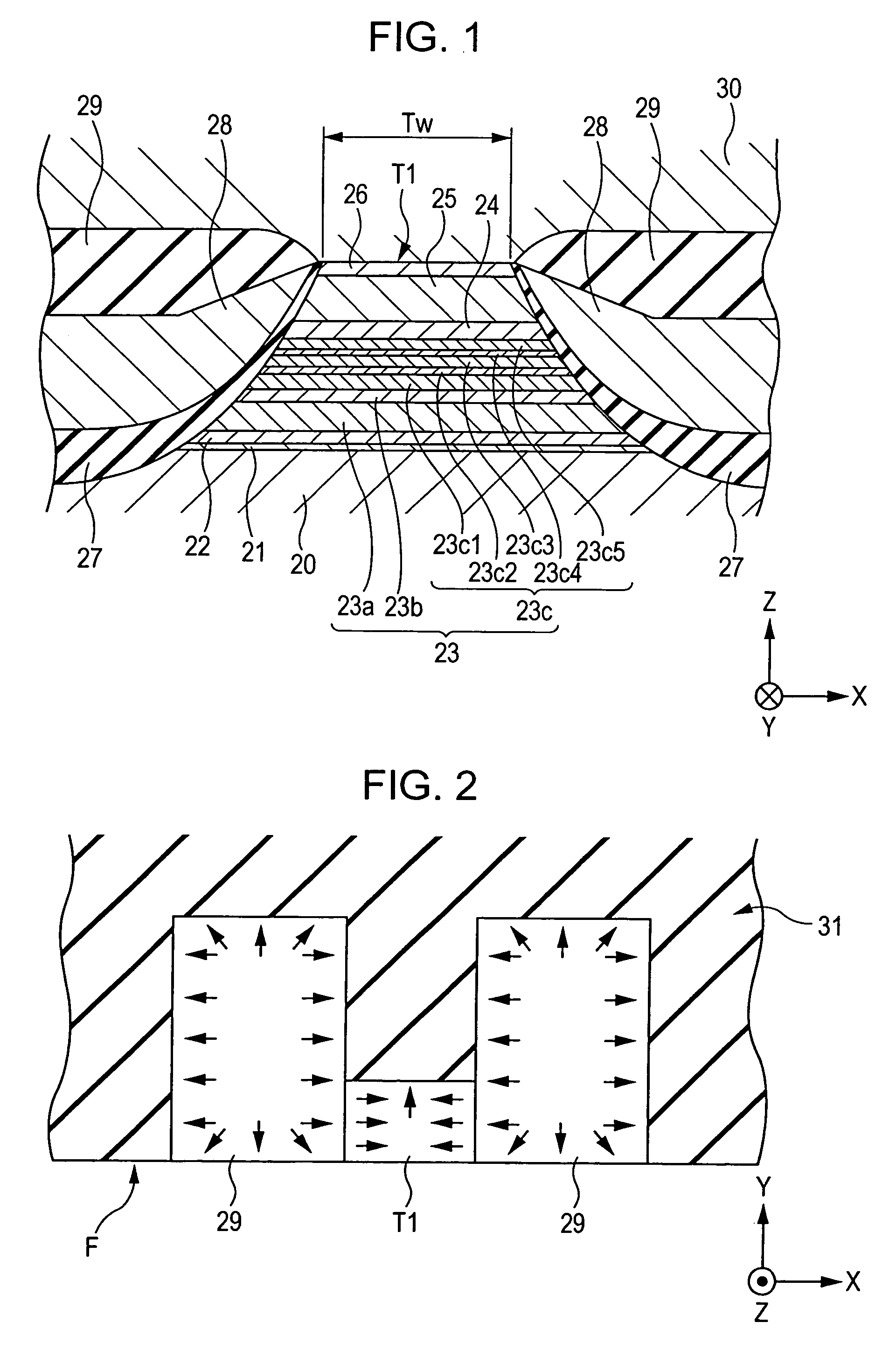

A spin valve sensor includes an antiparallel (AP) pinned layer structure which is self-pinned without the assistance of an antiferromagnetic (AFM) pinning layer. A free layer of the spin valve sensor has first and second wing portions which extend laterally beyond a track width of the spin valve sensor and are exchange coupled to first and second AFM pinning layers. Magnetic moments of the wing portions of the free layer are pinned parallel to the ABS and parallel to major planes of the layers of the sensor for magnetically stabilizing the central portion of the free layer which is located within the track width.

Owner:IBM CORP

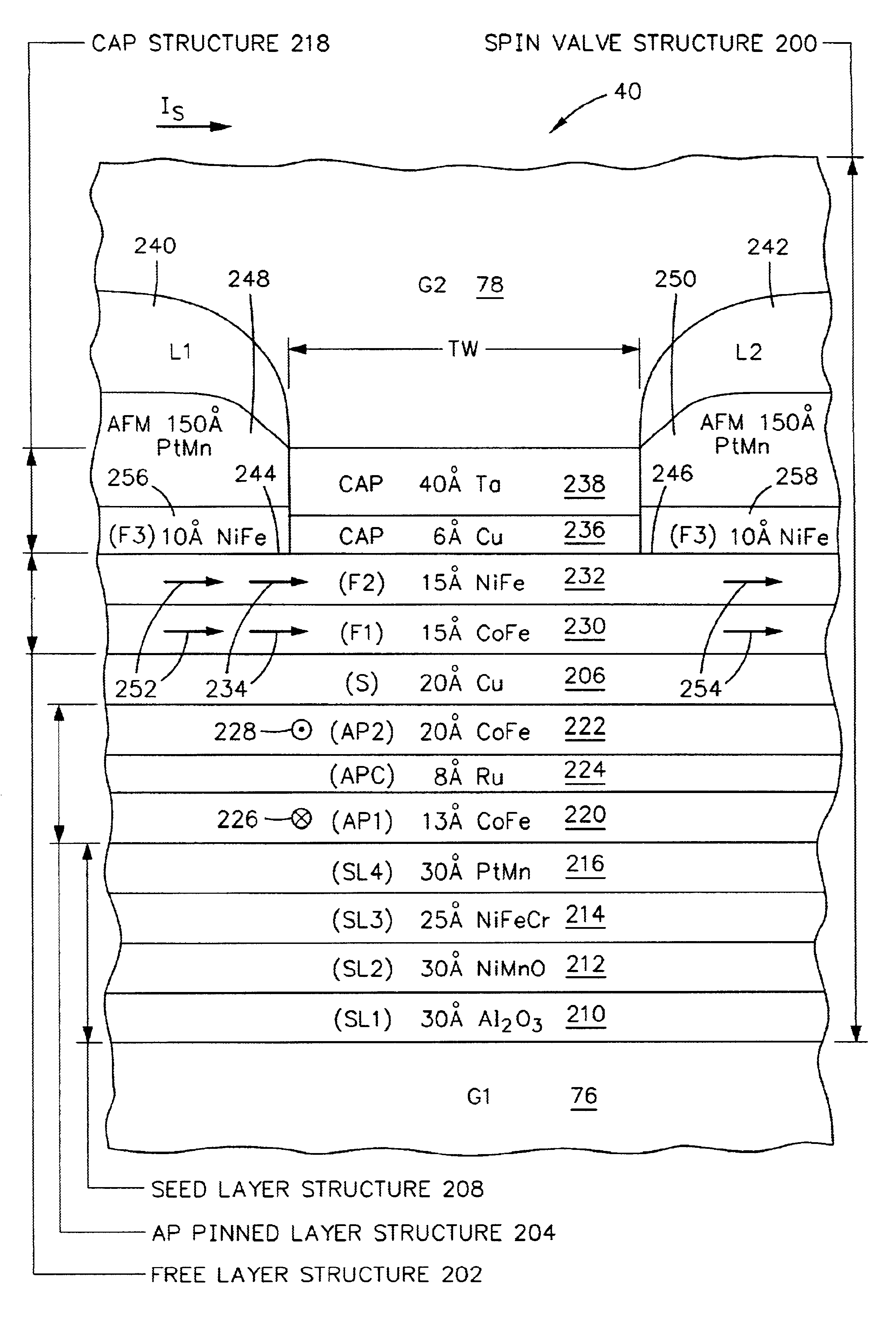

Spin valve sensor with in-stack biased free layer and antiparallel (AP) pinned layer pinned without a pinning layer

InactiveUS6856493B2Improved magnetostrictionImprovement factorNanoinformaticsHeads using thin filmsCouplingOptoelectronics

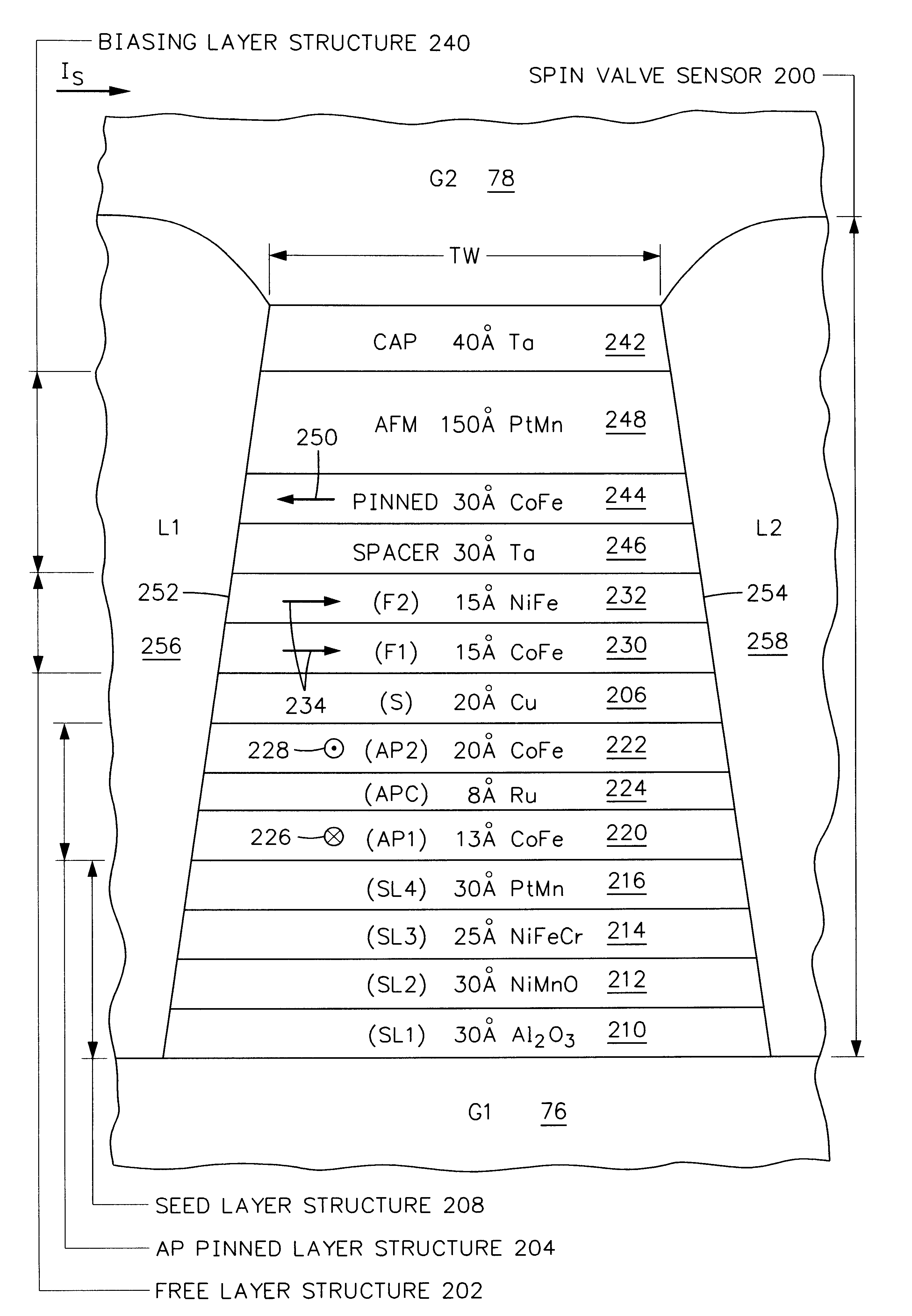

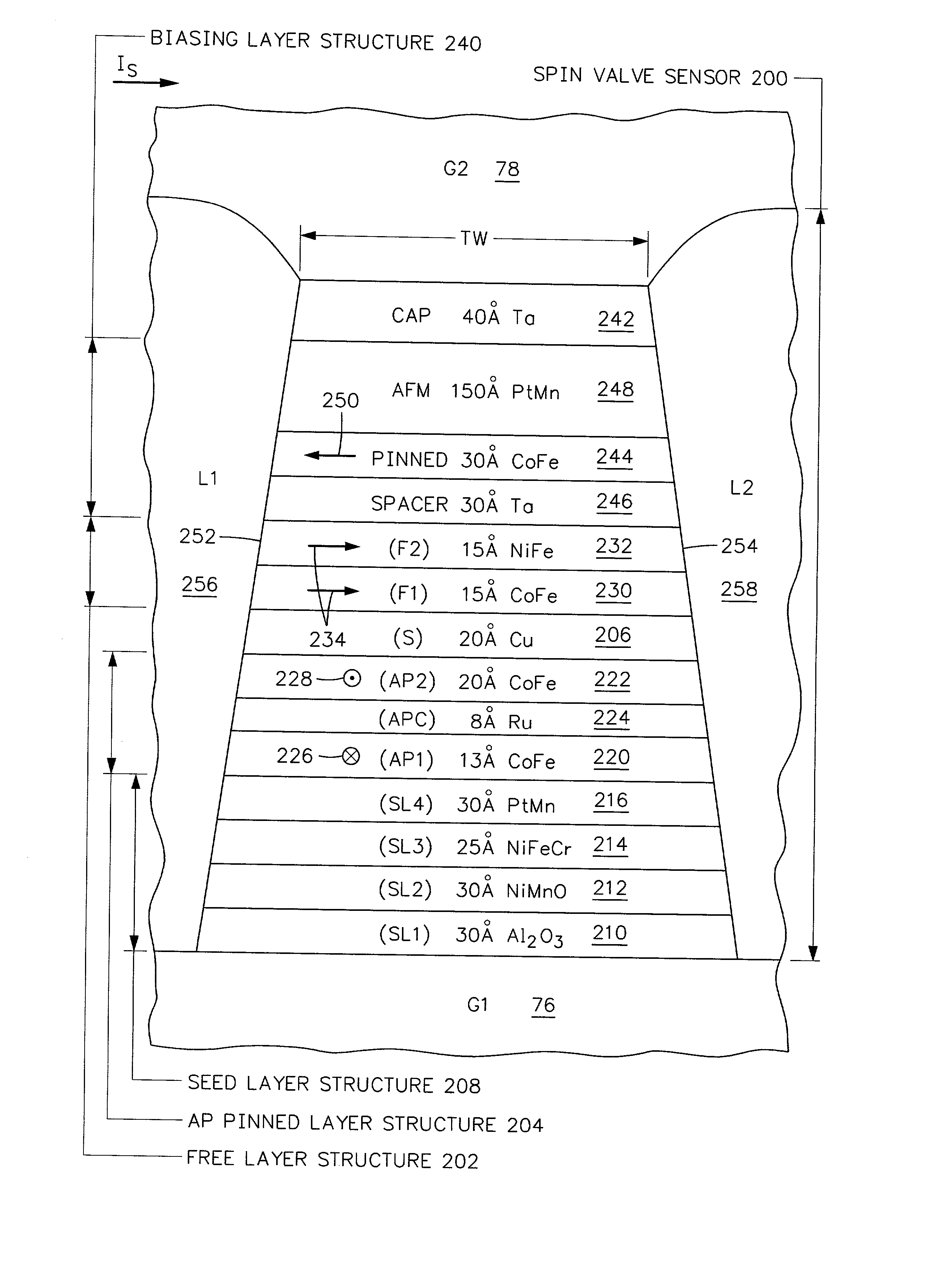

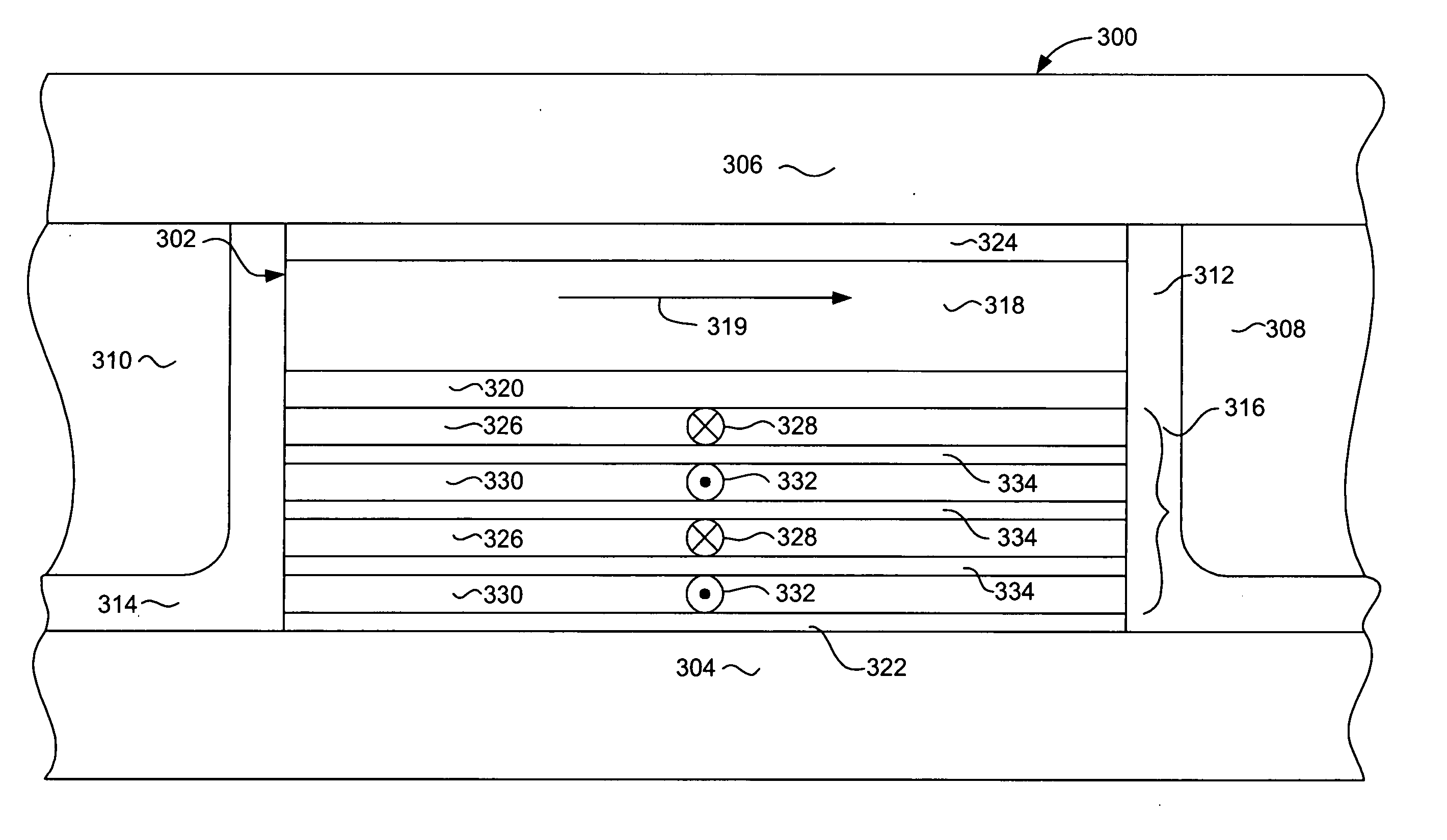

A spin valve sensor has an antiparallel (AP) pinned layer structure which has ferromagnetic first and second AP pinned layers that are separated by an antiparallel coupling layer. The first and second AP pinned layers are self-pinned antiparallel with respect to one another without the assistance of an antiferromagnetic (AFM) pinning layer. The spin valve sensor further includes an in-stack longitudinal biasing layer structure which is magnetostatically coupled to the free layer for longitudinally biasing a magnetic moment of the free layer parallel to an air bearing surface and parallel to major planes of the layers of the sensor. The only AFM pinning layer employed is in the biasing layer structure so that when the magnetic spins of the AFM pinning layer are set the orientations of the magnetic moments of the AP pinned layer structure are not disturbed.

Owner:INT BUSINESS MASCH CORP

Spin valve sensor with exchange biased free layer and antiparallel (AP) pinned layer pinned without a pinning layer

InactiveUS6865062B2Improve stabilityHigh amplitude read outputNanoinformaticsHeads using thin filmsLateral extensionEngineering

A spin valve sensor includes an antiparallel (AP) pinned layer structure which is self-pinned without the assistance of an antiferromagnetic (AFM) pinning layer. A free layer of the spin valve sensor has first and second wing portions which extend laterally beyond a track width of the spin valve sensor and are exchange coupled to first and second AFM pinning layers. Magnetic moments of the wing portions of the free layer are pinned parallel to the ABS and parallel to major planes of the layers of the sensor for magnetically stabilizing the central portion of the free layer which is located within the track width.

Owner:INT BUSINESS MASCH CORP

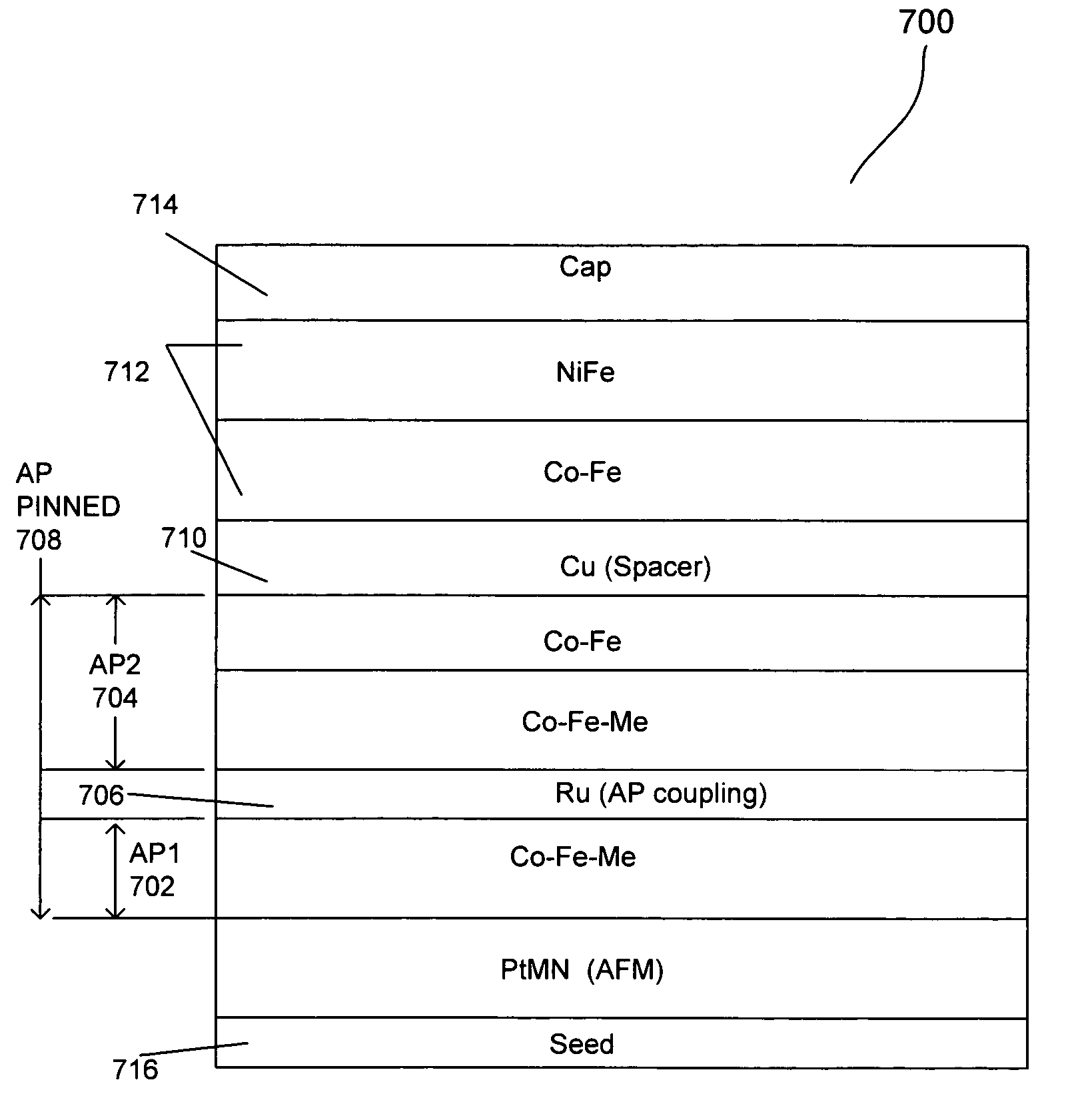

Spin valve sensor with in-stack biased free layer and antiparallel (AP) pinned layer pinned without a pinning layer

InactiveUS20030179513A1Improved magnetostrictionImprovement factorNanoinformaticsHeads using thin filmsCouplingOptoelectronics

A spin valve sensor has an antiparallel (AP) pinned layer structure which has ferromagnetic first and second AP pinned layers that are separated by an antiparallel coupling layer. The first and second AP pinned layers are self-pinned antiparallel with respect to one another without the assistance of an antiferromagnetic (AFM) pinning layer. The spin valve sensor further includes an in-stack longitudinal biasing layer structure which is magnetostatically coupled to the free layer for longitudinally biasing a magnetic moment of the free layer parallel to an air bearing surface and parallel to major planes of the layers of the sensor. The only AFM pinning layer employed is in the biasing layer structure so that when the magnetic spins of the AFM pinning layer are set the orientations of the magnetic moments of the AP pinned layer structure are not disturbed.

Owner:IBM CORP

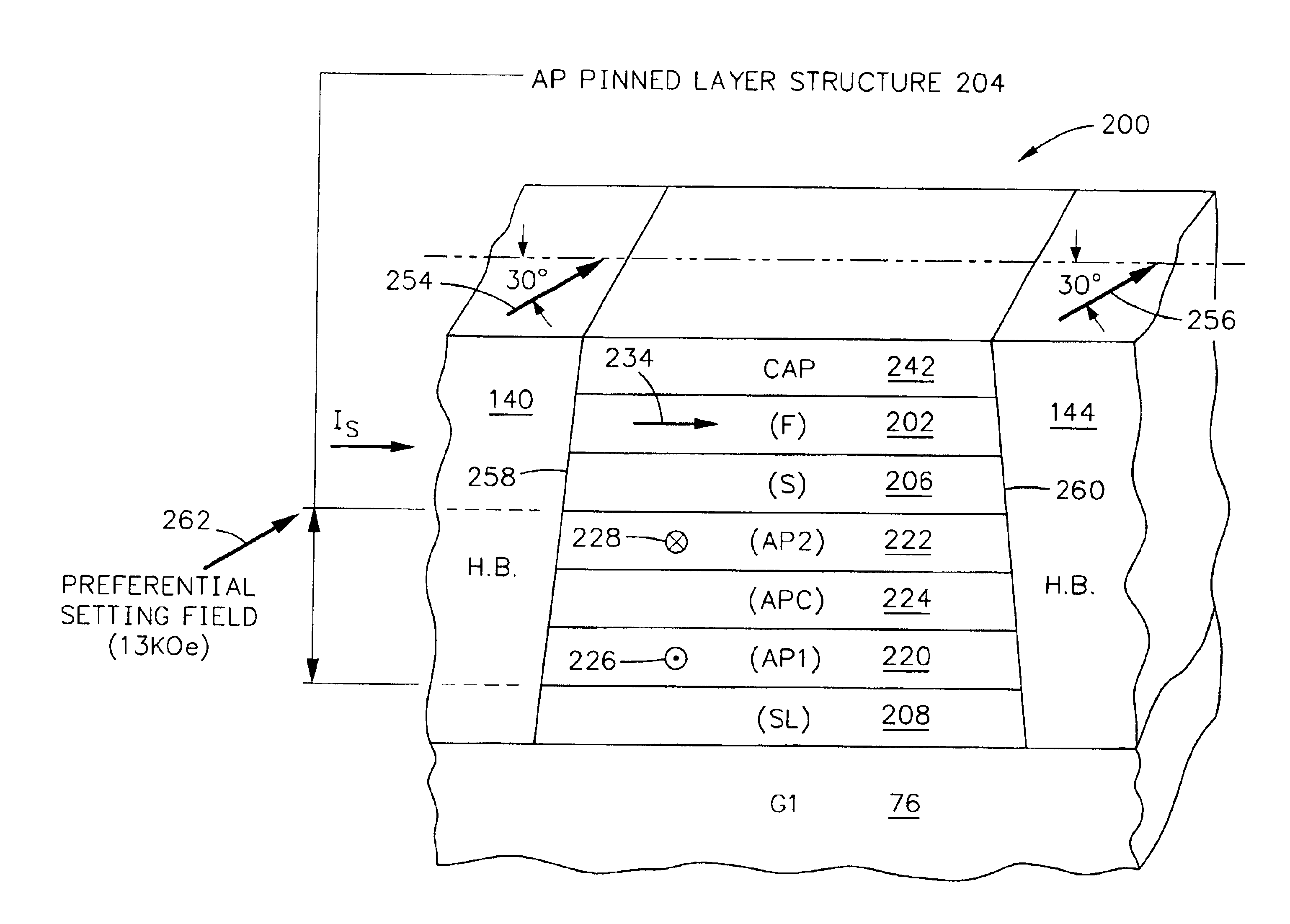

Method of setting self-pinned AP pinned layers with a canted field

InactiveUS6866751B2Reduce thicknessImproved magnetostrictionNanomagnetismDisposition/mounting of recording headsCouplingAcute angle

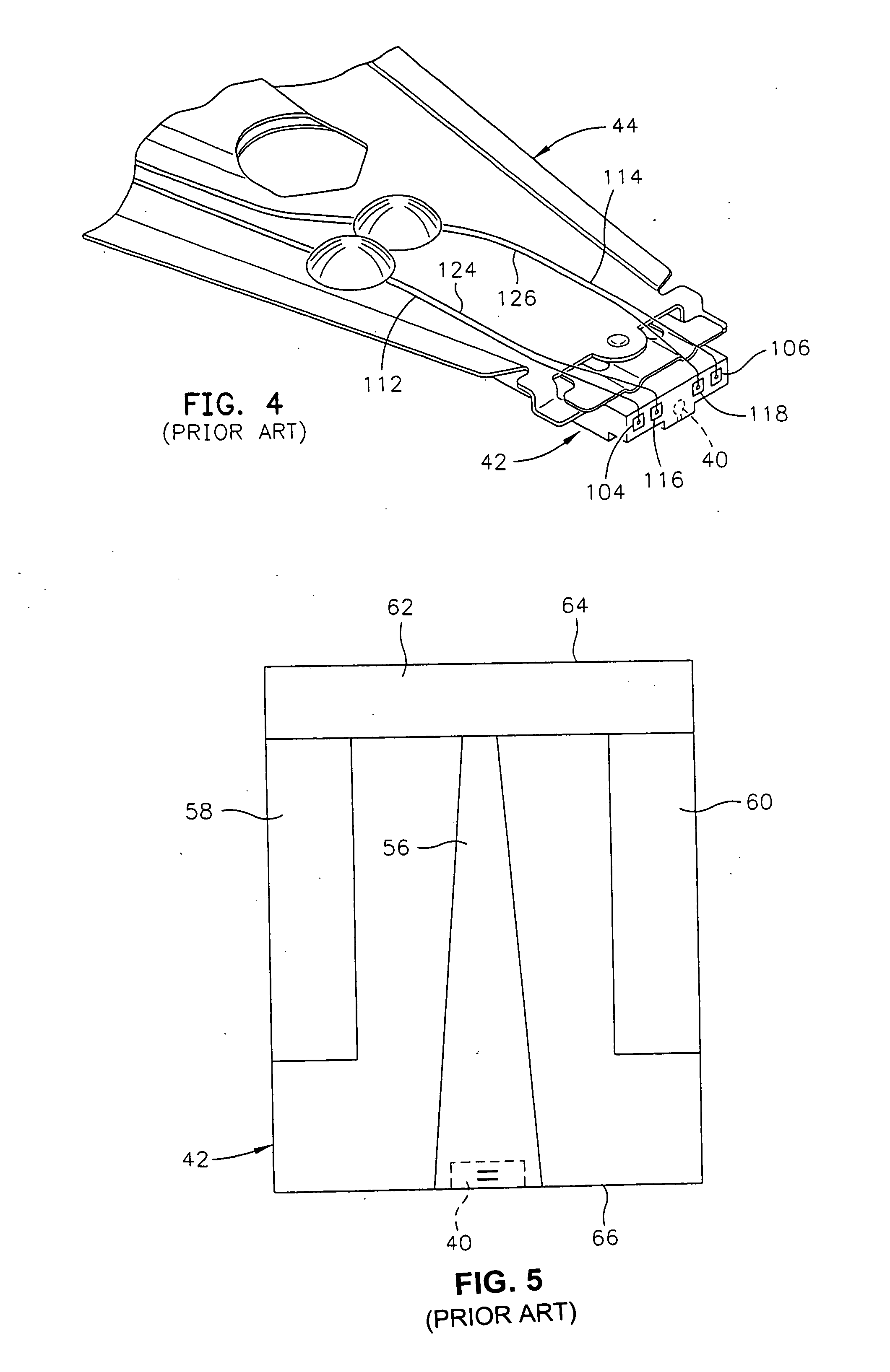

A spin valve sensor in a read head has a spacer layer which is located between a self-pinned AP pinned layer structure and a free layer structure. The free layer structure is longitudinally stabilized by first and second hard bias layers which abut first and second side surfaces of the spin valve sensor. The AP pinned layer structure has an antiparallel coupling layer (APC) which is located between first and second AP pinned layers (AP1) and (AP2). The invention employs a preferential setting of the magnetic moments of the AP pinned layers by applying a field at an acute angle to the head surface in a plane parallel to the major planes of the layers of the sensor. The preferential setting sets a proper polarity of each AP pinned layer, which polarity conforms to processing circuitry employed with the spin valve sensor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

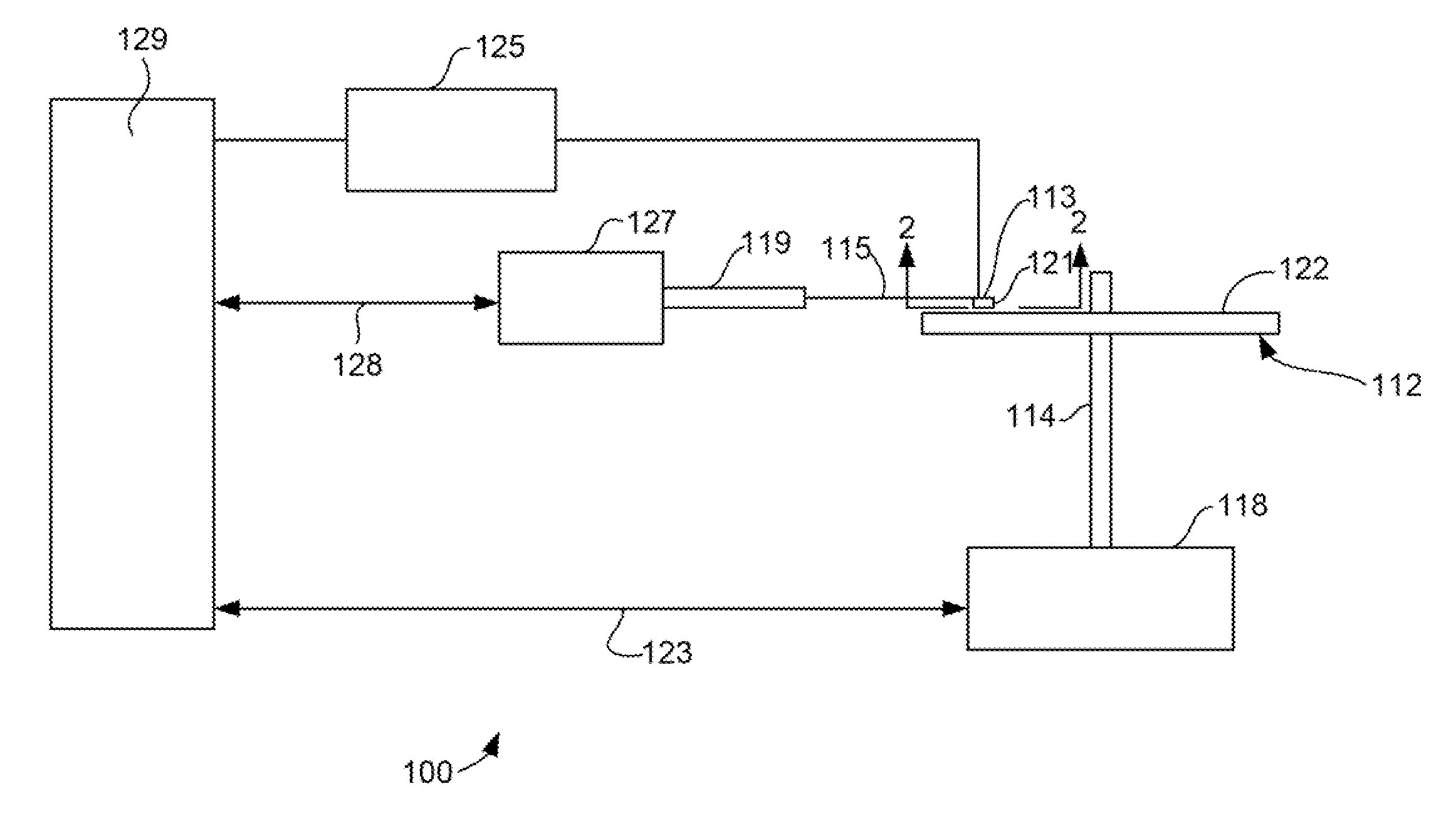

Method for resetting pinned layer magnetization in a magnetoresistive sensor

InactiveUS7370404B2Acceptable performance and reliabilityReduce thicknessElectrical transducersNanomagnetismCouplingAcute angle

A spin valve sensor in a read head has a spacer layer which is located between a self-pinned AP pinned layer structure and a free layer structure. The free layer structure is longitudinally stabilized by first and second hard bias layers which abut first and second side surfaces of the spin valve sensor. The AP pinned layer structure has an antiparallel coupling layer (APC) which is located between first and second AP pinned layers (AP1) and (AP2). The invention employs a resetting process for setting of the magnetic moments of the AP pinned layers by applying a field at an acute angle to the head surface in a plane parallel to the major planes of the layers of the sensor. The resetting process sets a proper polarity of each AP pinned layer, which polarity conforms to processing circuitry employed with the spin valve sensor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

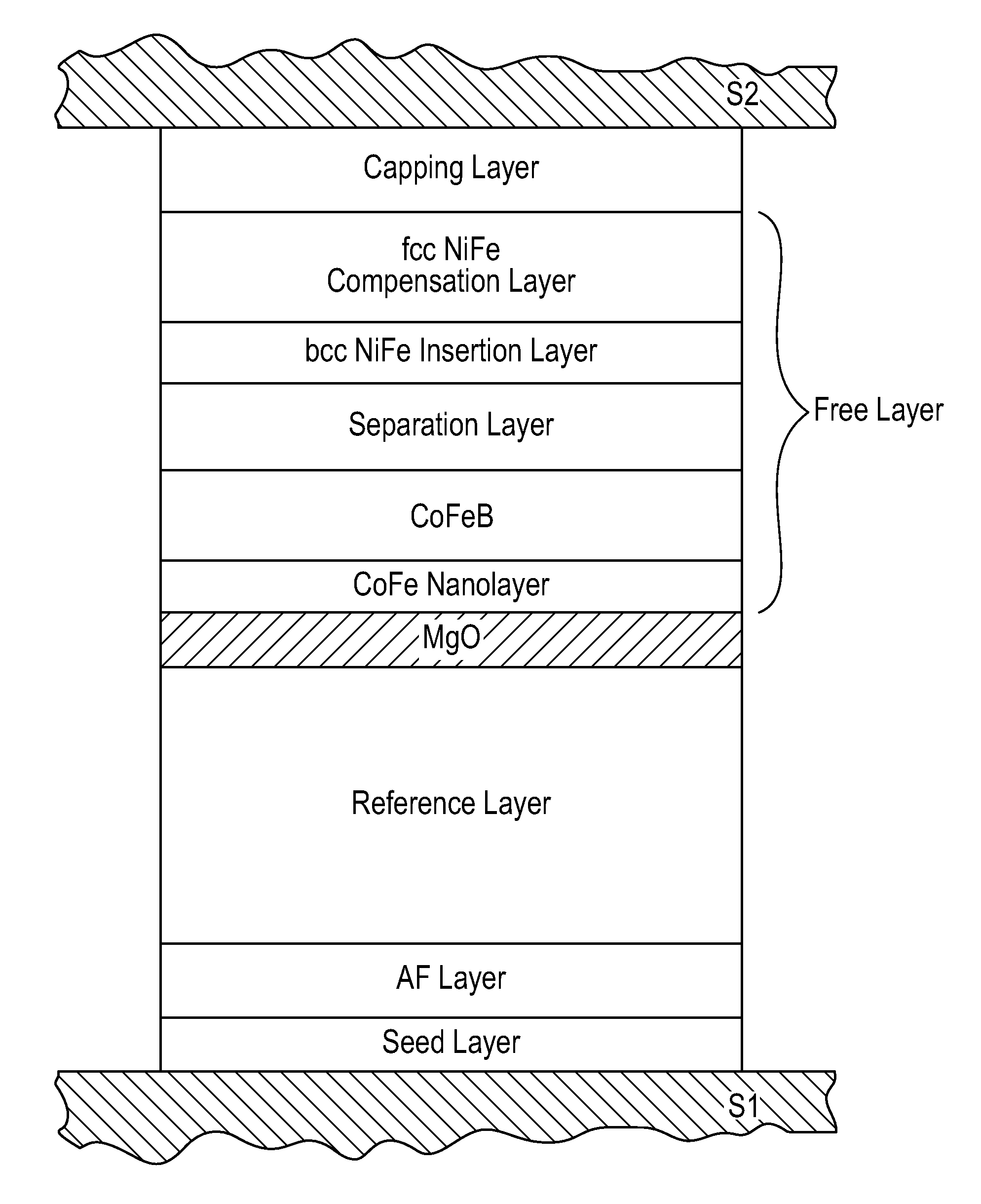

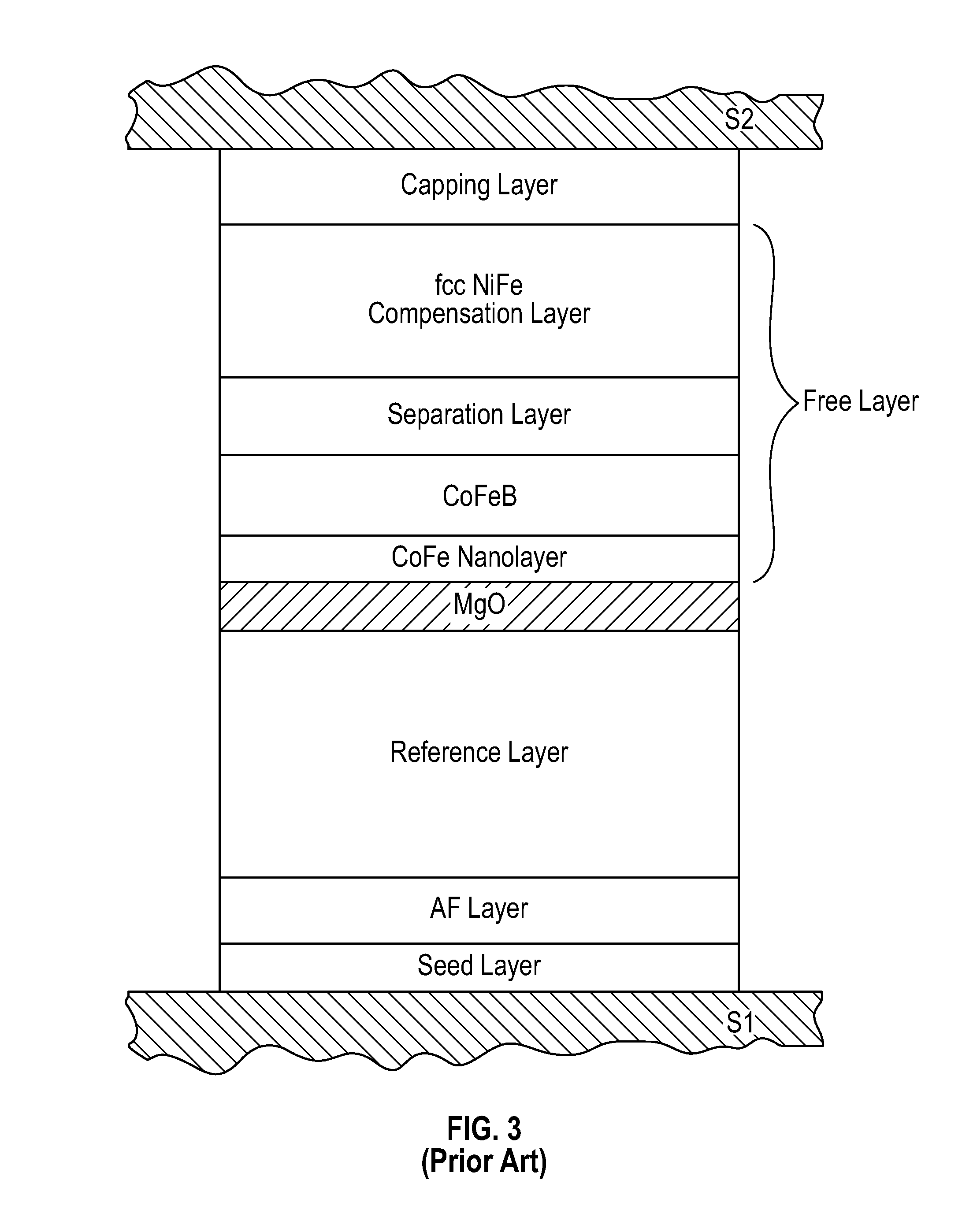

Tunneling magnetoresistive (TMR) device with magnesium oxide tunneling barrier layer and free layer having insertion layer

ActiveUS9177573B1Gain is not constantIncreased TMRNanomagnetismMagnetic measurementsDamping constantOptoelectronics

A tunneling magnetoresistance (TMR) device has a thin MgO tunneling barrier layer and a free ferromagnetic multilayer. The free ferromagnetic multilayer includes a CoFeB first ferromagnetic layer, a face-centered-cubic (fcc) NiFe compensation layer with negative magnetostriction, and a body-centered-cubic (bcc) NiFe insertion layer between the CoFeB layer and the fcc NiFe compensation layer. An optional ferromagnetic nanolayer may be located between the MgO barrier layer and the CoFeB layer. An optional amorphous separation layer may be located between the CoFeB layer and the bcc NiFe insertion layer. The bcc NiFe insertion layer (and the optional amorphous separation layer if it is used) prevents the fcc NiFe layer from adversely affecting the crystalline formation of the MgO and CoFeB layers during annealing. The bcc NiFe insertion layer also increases the TMR and lowers the Gilbert damping constant of the free ferromagnetic multilayer.

Owner:WESTERN DIGITAL TECH INC

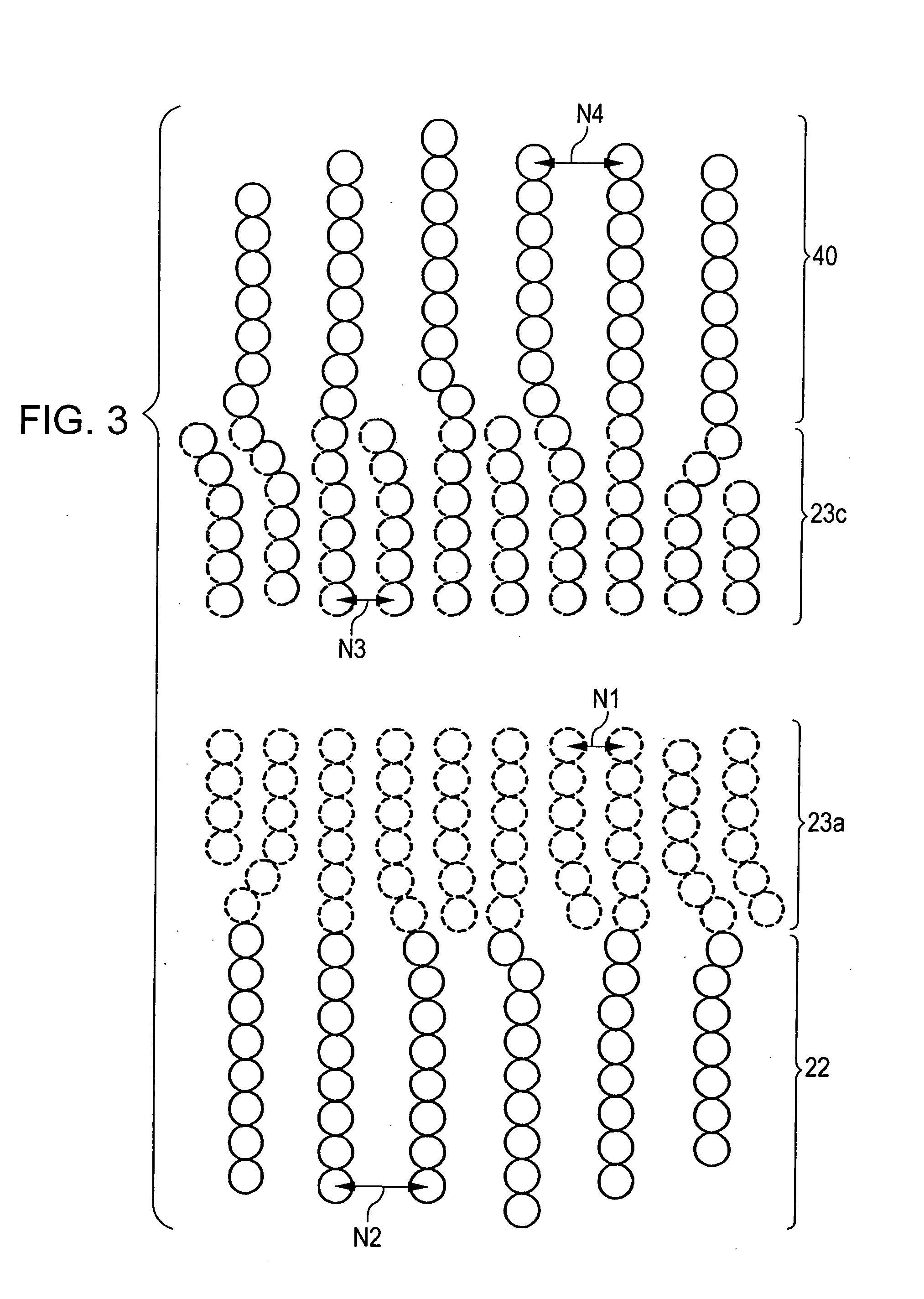

Current perpendicular to plane (CPP) GMR structure having vanadium doped, AP coupled, multi-layered pinned structure

InactiveUS20060087771A1Reduces spin dependent scatteringMinimizing negative dRRecord information storageManufacture of flux-sensitive headsVanadium dopingSpins

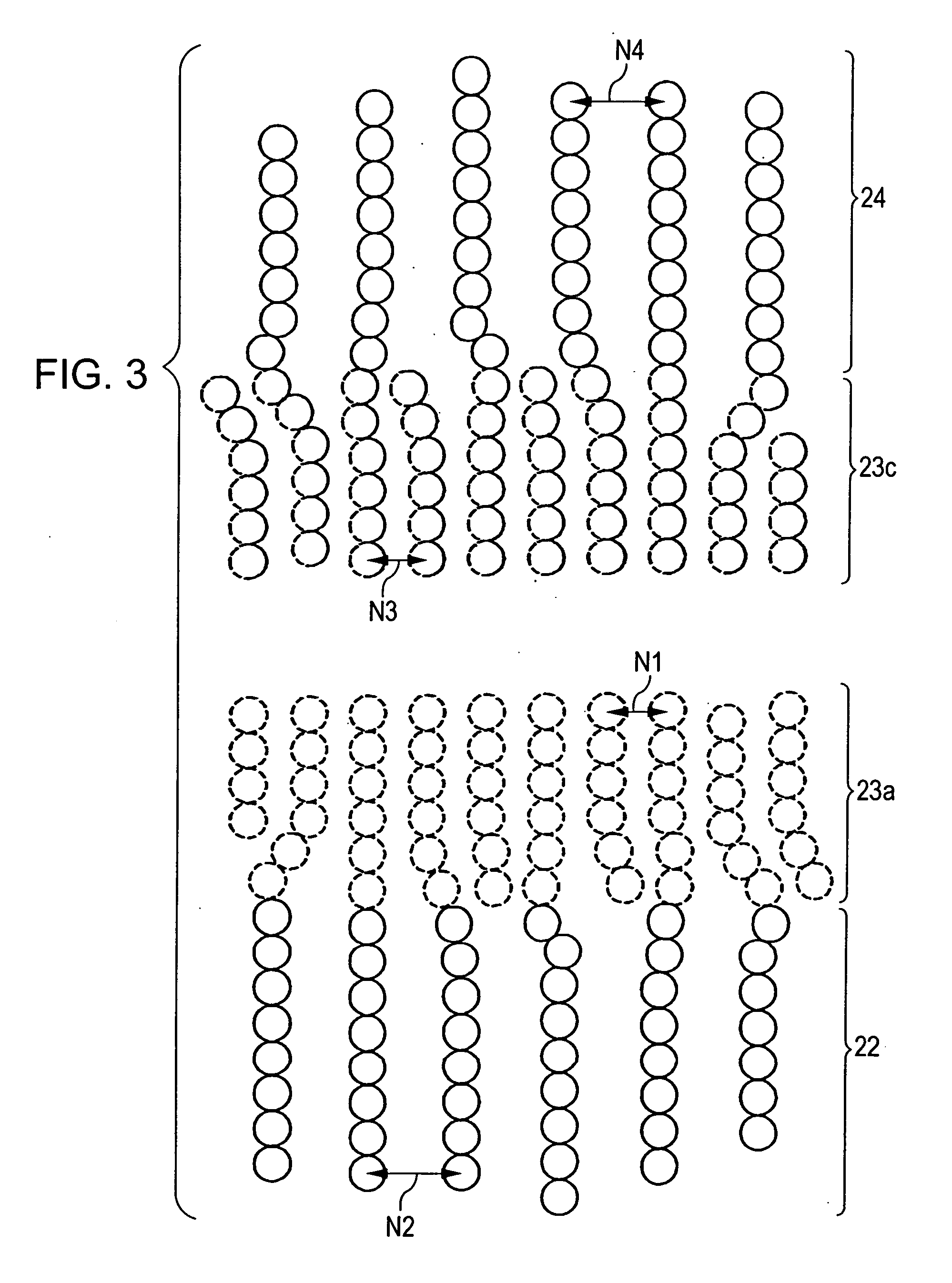

A current perpendicular to plane (CPP) giant magnetoresistive (GMR) sensor having an antiparallel coupled (AP coupled) pinned layer structure wherein the pinning layer have a greatly reduced negative contribution to dR. The pinned layer structure includes a first a first set of magnetic layers such as CoFe and a second set of magnetic layer comprising CoFeV that are antiparallel coupled with the first set of magnetic layers. The magnetic layers of the pinned layer structure alternate between a one of the first set of magnetic layers (eg. CoFe) and one of the second set of magnetic layers (CoFeV). The magnetic layers of the first set contribute to the GMR of the sensor and provide a positive magnetostriction that assists with the pinning of the pinned layer structure. The magnetic layers of the second set contribute pinning, but do not contribute to GMR. The presence of V in the second set of greatly reduces the negative contribution to dR that would otherwise be provided by these pinning layers of the second set by reducing the spin dependent electron scattering through these layers.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

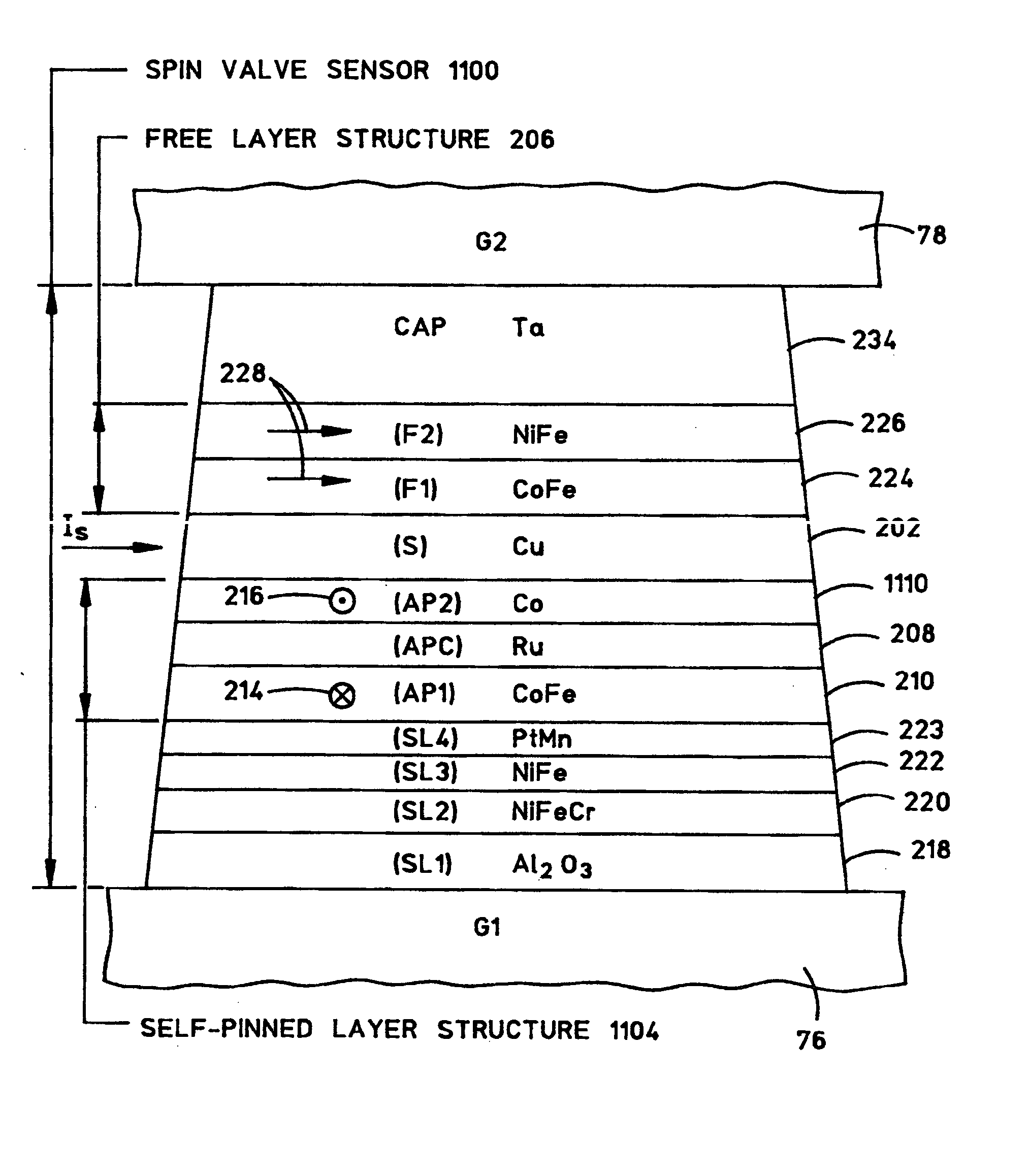

Spin valve sensor having an antiparallel (AP) self-pinned layer structure comprising cobalt for high magnetostriction

InactiveUS20050068693A1Improved magnetostrictionImprove effectRecord information storageManufacture of flux-sensitive headsElectrically conductiveIron content

In one illustrative embodiment of the invention, a spin valve sensor of a magnetic head has a free layer structure; an antiparallel (AP) self-pinned layer structure; and a non-magnetic electrically conductive spacer layer in between the free layer structure and the AP self-pinned layer structure. The AP self-pinned layer structure includes a first AP pinned layer; a second AP pinned layer; an antiparallel coupling (APC) layer formed between the first and the second AP pinned layers. At least one of the first and the second AP pinned layers is made of cobalt having no iron content. The other AP pinned layer may be formed of cobalt, cobalt-iron, or other suitable material. The use of cobalt in the AP self-pinned layer structure increases its magnetostriction to increase the self-pinning effect. Preferably, the first AP pinned layer is cobalt-iron and the second AP pinned layer is cobalt which provides for both an increase in magnetostriction and magnetoresistive coefficient Δr / R of the sensor.

Owner:WESTERN DIGITAL TECH INC

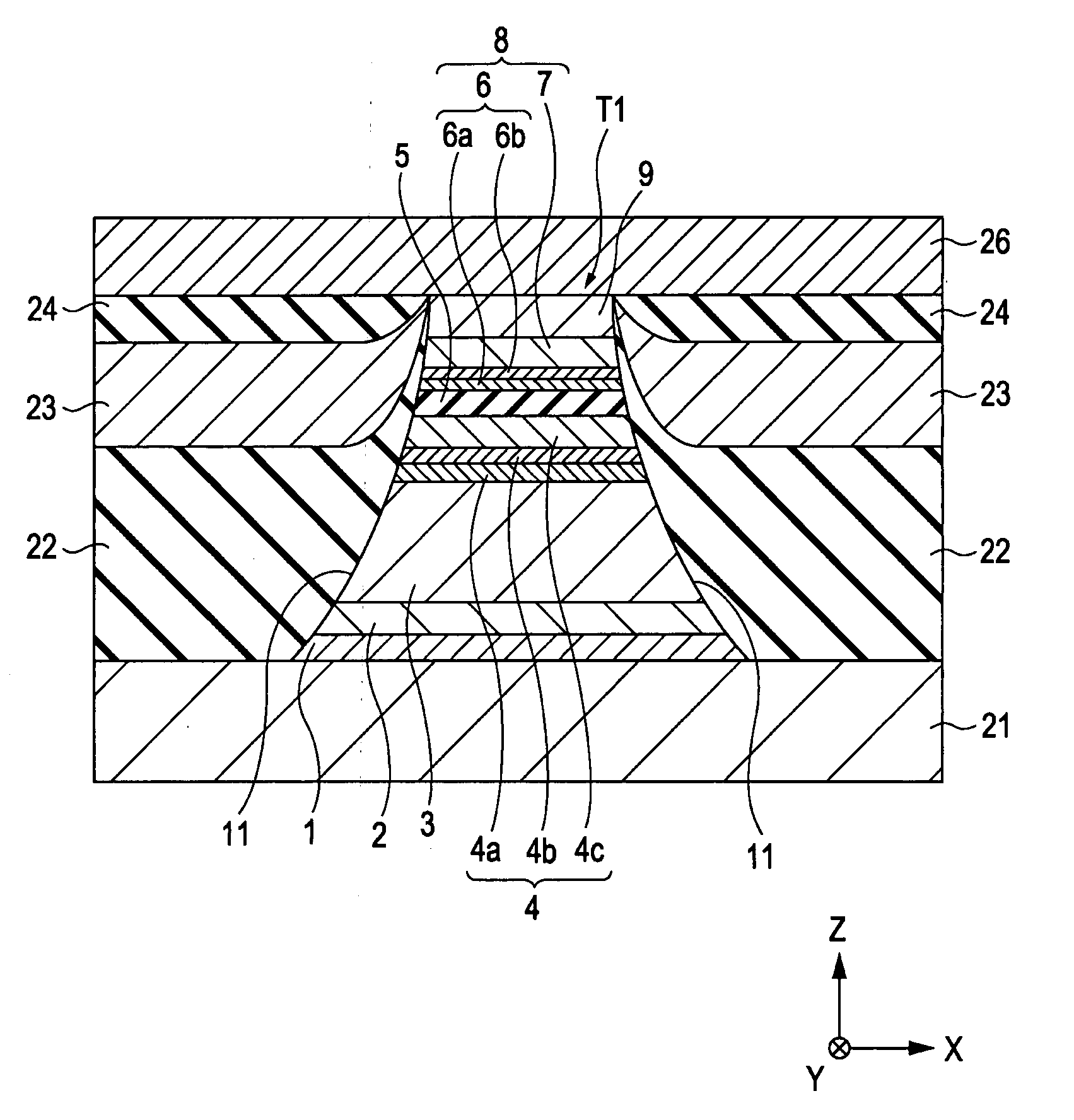

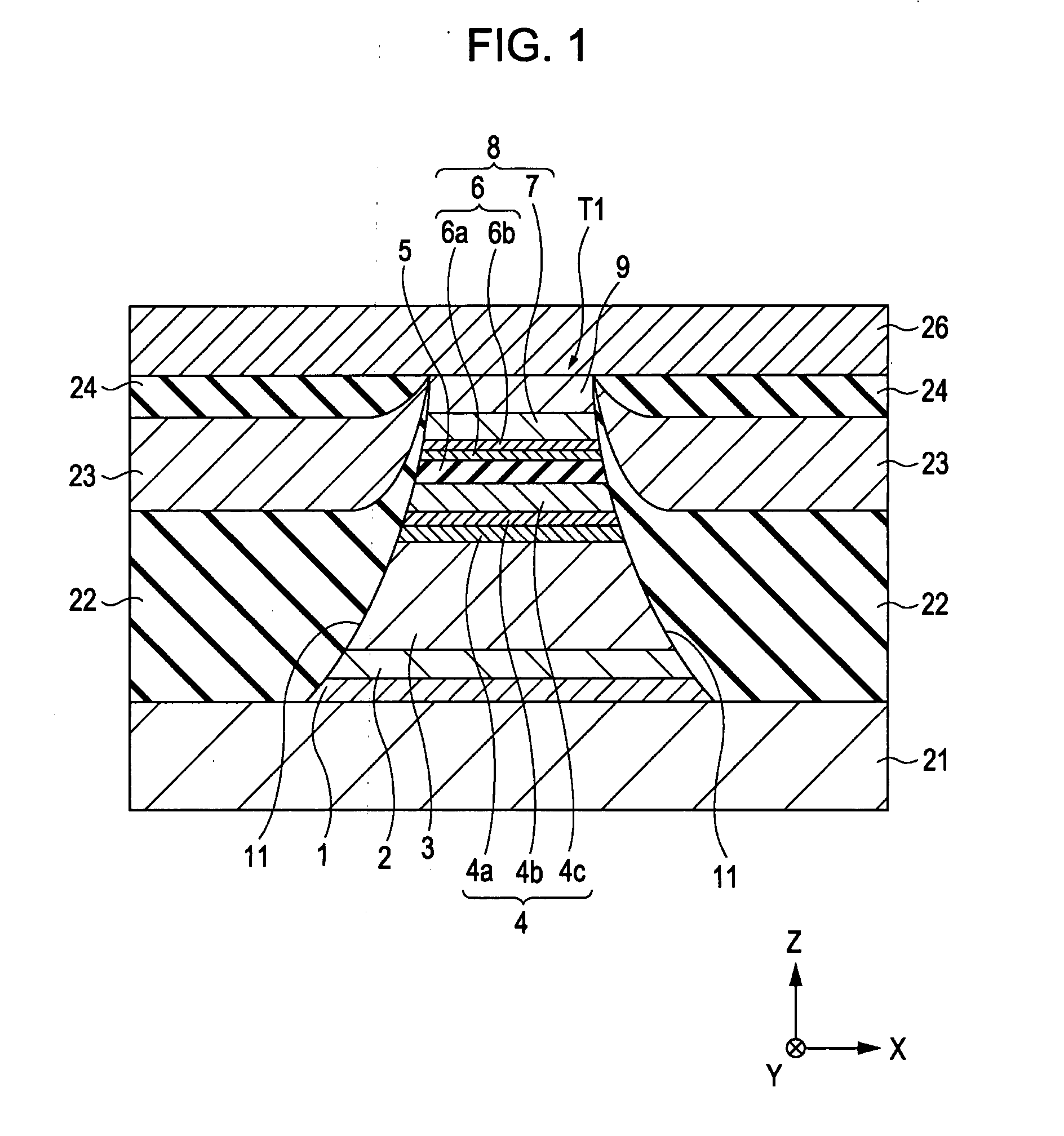

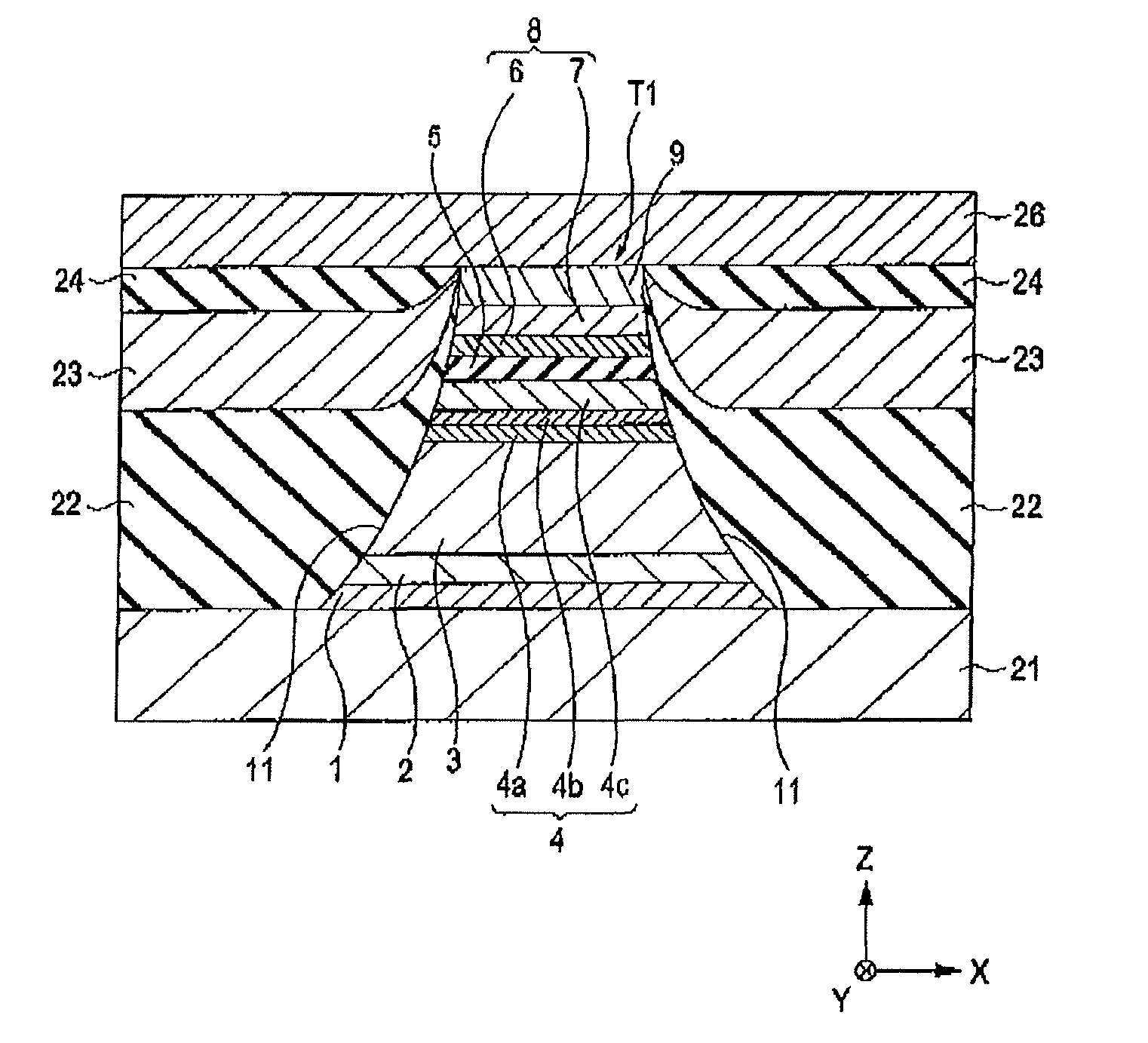

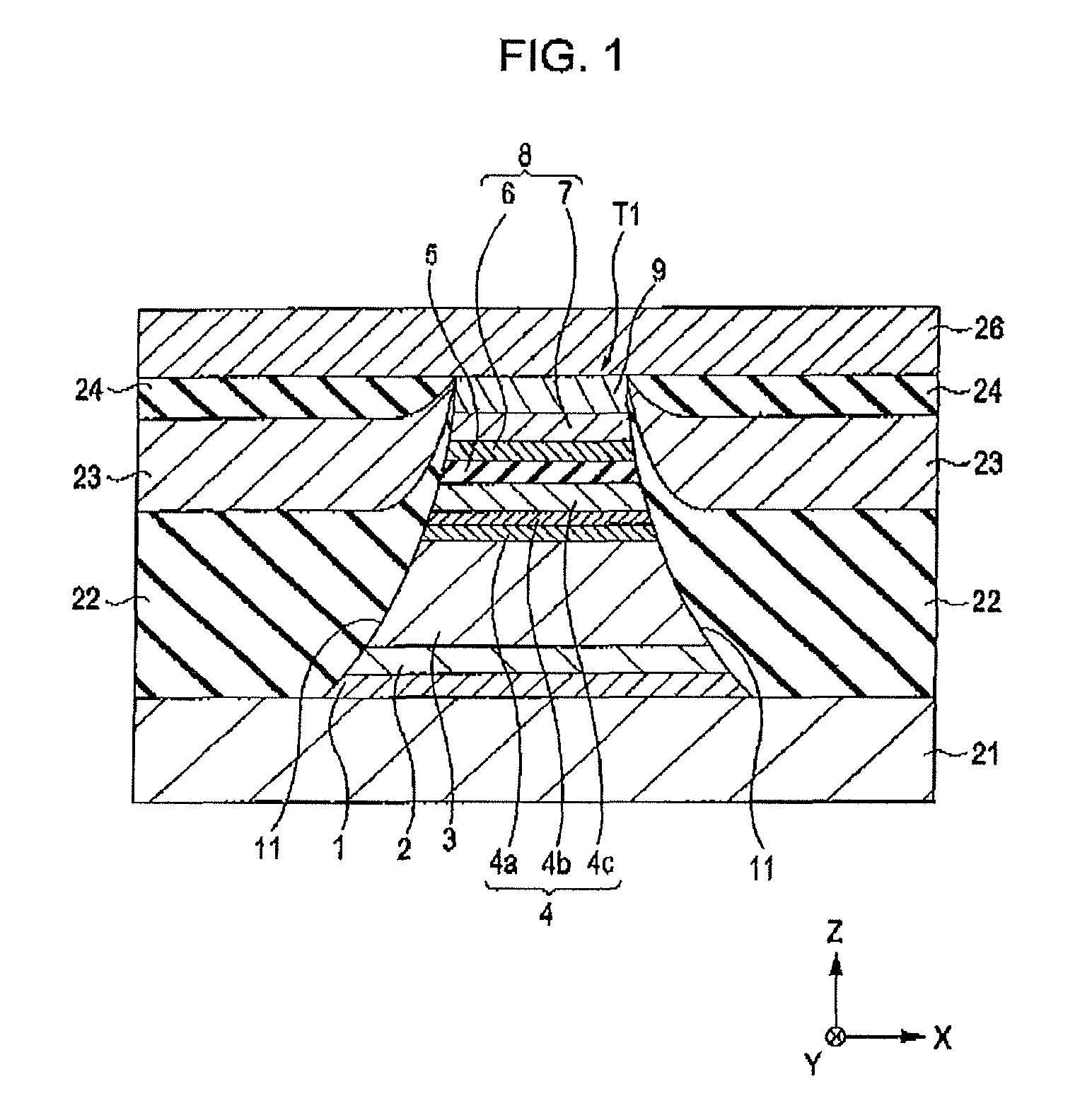

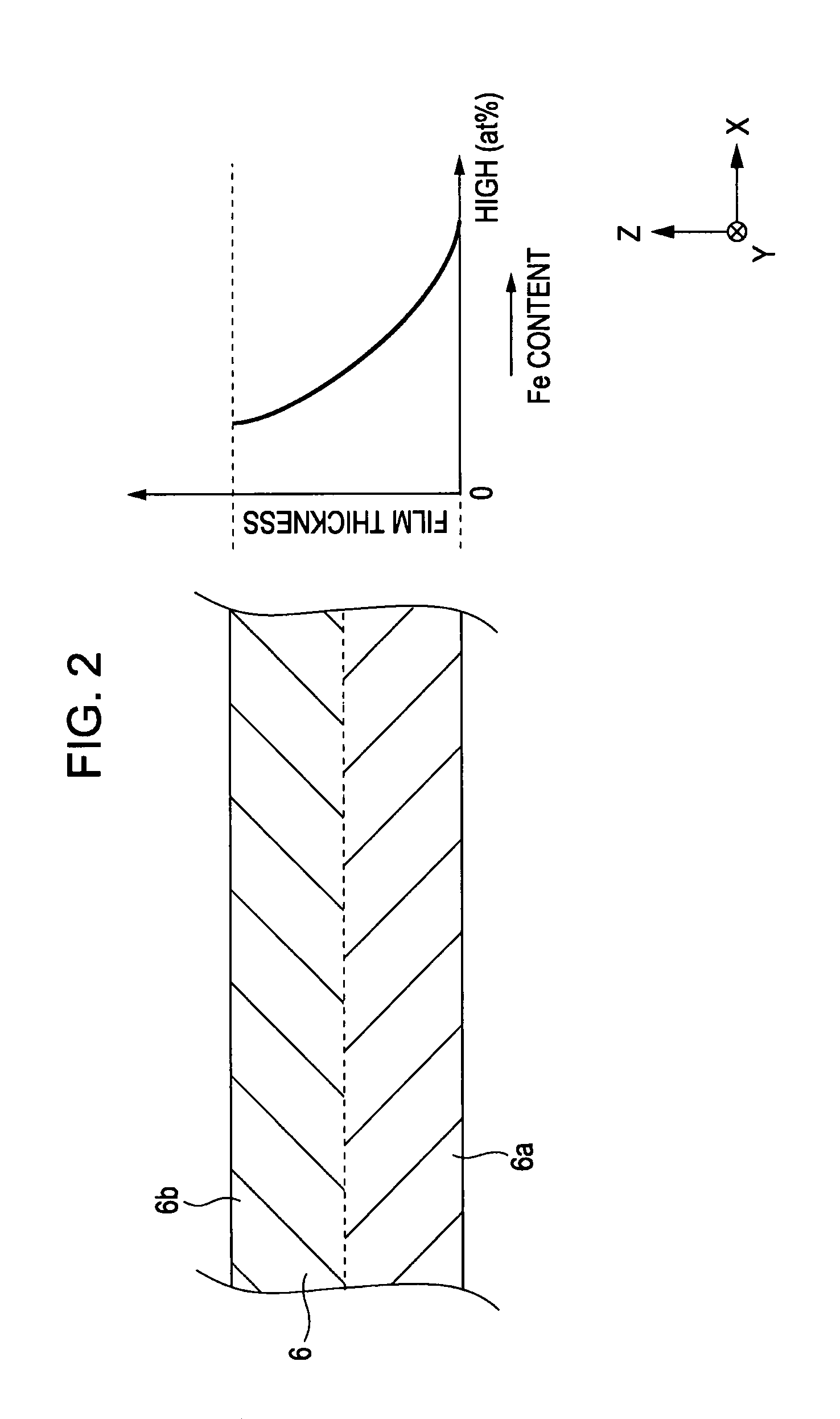

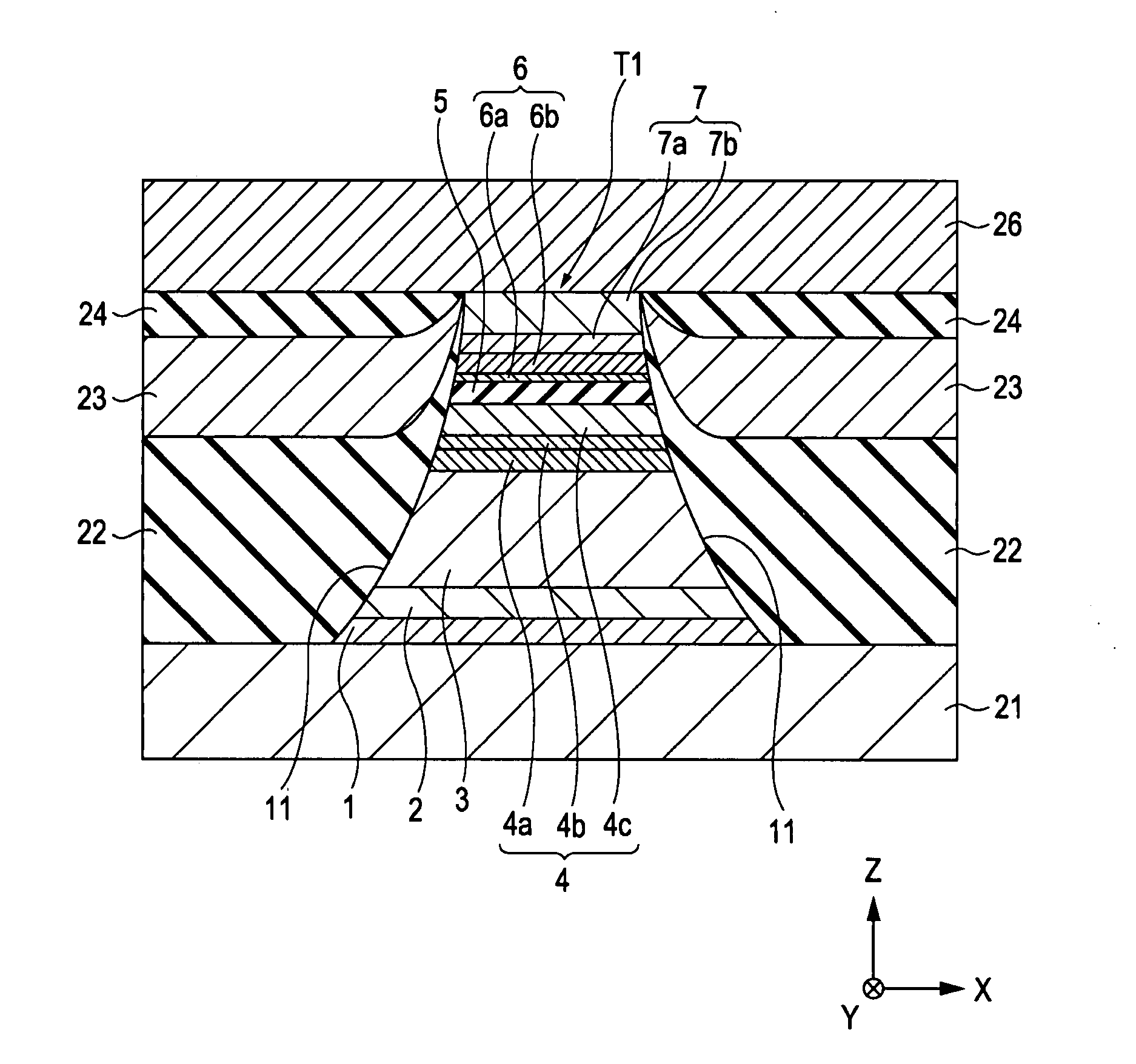

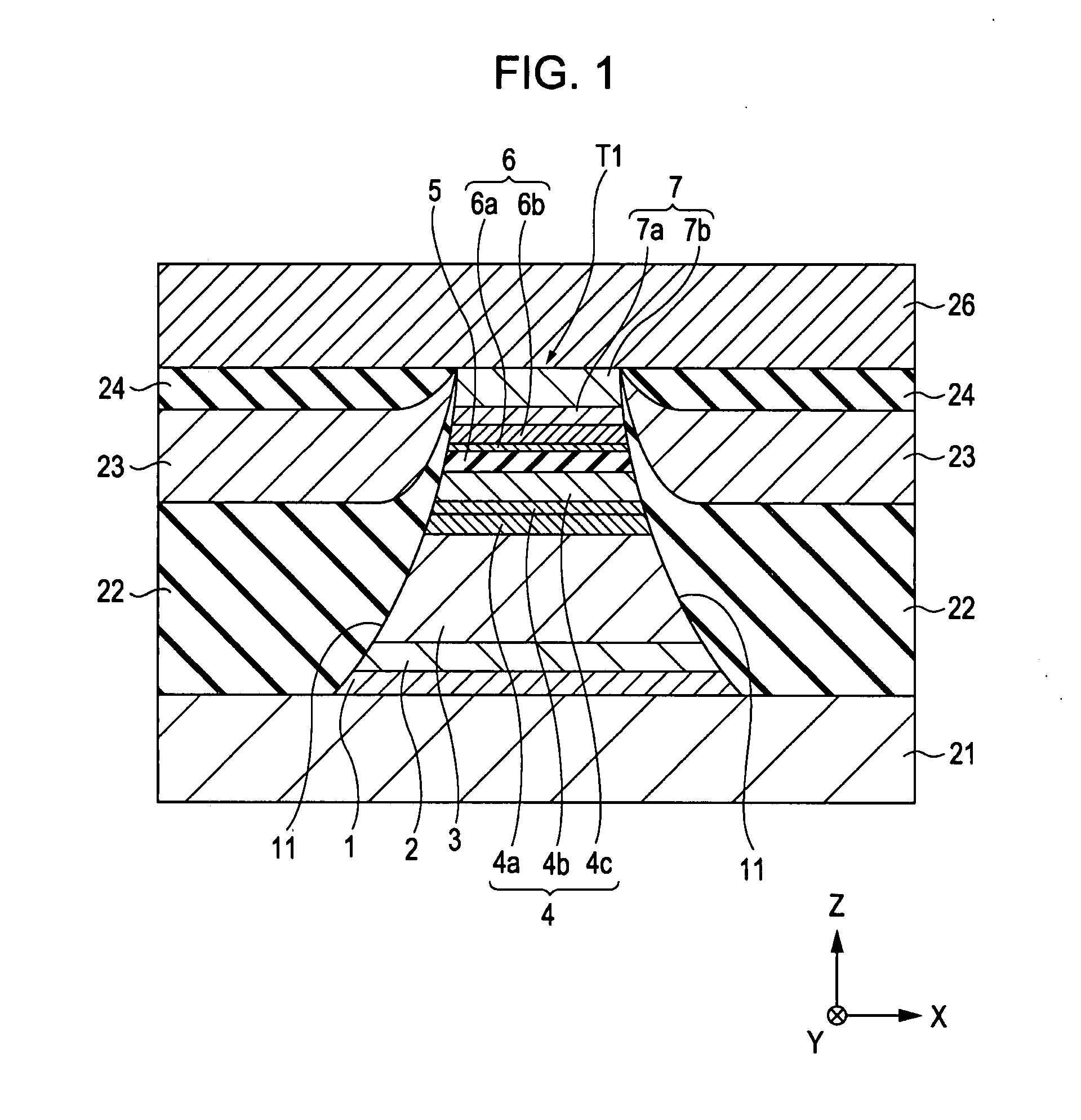

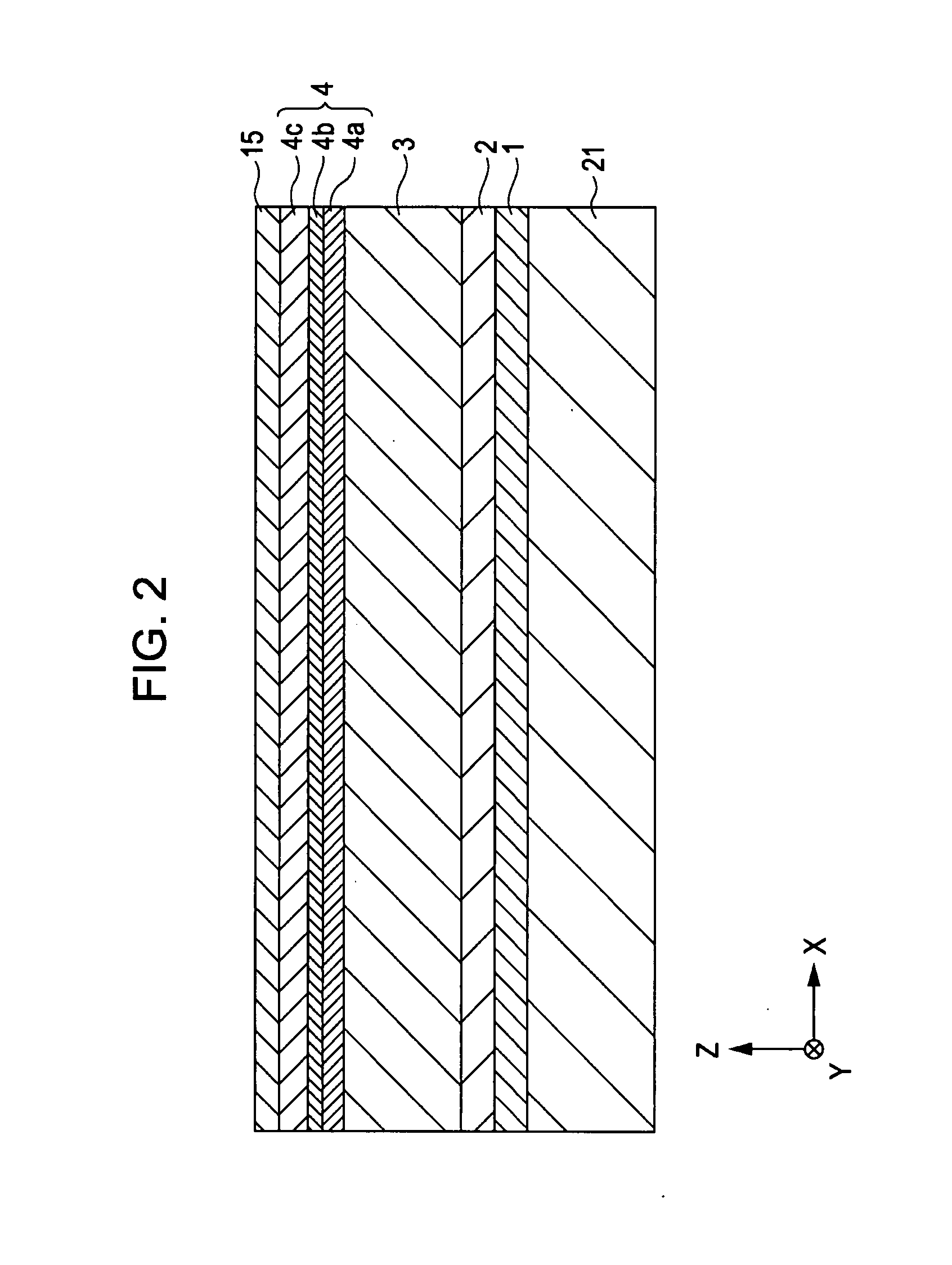

Tunneling magnetic sensing element including enhancing layer having high Fe concentration in the vicinity of barrier layer and method for manufacturing tunneling magnetic sensing element

ActiveUS20080030907A1Increase rate of changeImproved magnetostrictionNanomagnetismMagnetic measurementsAlloyMagnetic layer

A tunneling magnetic sensing element is provided, in which an increase in the magnetostriction of a free magnetic layer is reduced and the rate of change in resistance is high. A laminate T1 constituting the tunneling magnetic sensing element includes a portion in which a pinned magnetic layer, a barrier layer, and a free magnetic layer are disposed in that order from the bottom. An enhancing layer disposed on the barrier layer side of the free magnetic layer includes a first enhancing layer on the barrier layer side and a second enhancing layer on the soft magnetic layer side, and the Fe content of a CoFe alloy constituting the first enhancing layer is specified to be larger than the Fe content of the CoFe alloy of the second enhancing layer.

Owner:TDK CORPARATION

Current perpendicular to plane (CPP) GMR structure having vanadium doped, AP coupled, multi-layered pinned structure

InactiveUS7268982B2Reduces spin dependent scatteringMinimizing negative dRRecord information storageManufacture of flux-sensitive headsVanadium dopingSpins

A current perpendicular to plane (CPP) giant magnetoresistive (GMR) sensor having an antiparallel coupled (AP coupled) pinned layer structure wherein the pinning layer have a greatly reduced negative contribution to dR. The pinned layer structure includes a first a first set of magnetic layers such as CoFe and a second set of magnetic layer comprising CoFeV that are antiparallel coupled with the first set of magnetic layers. The magnetic layers of the pinned layer structure alternate between a one of the first set of magnetic layers (eg. CoFe) and one of the second set of magnetic layers (CoFeV). The magnetic layers of the first set contribute to the GMR of the sensor and provide a positive magnetostriction that assists with the pinning of the pinned layer structure. The magnetic layers of the second set contribute pinning, but do not contribute to GMR. The presence of V in the second set of greatly reduces the negative contribution to dR that would otherwise be provided by these pinning layers of the second set by reducing the spin dependent electron scattering through these layers.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

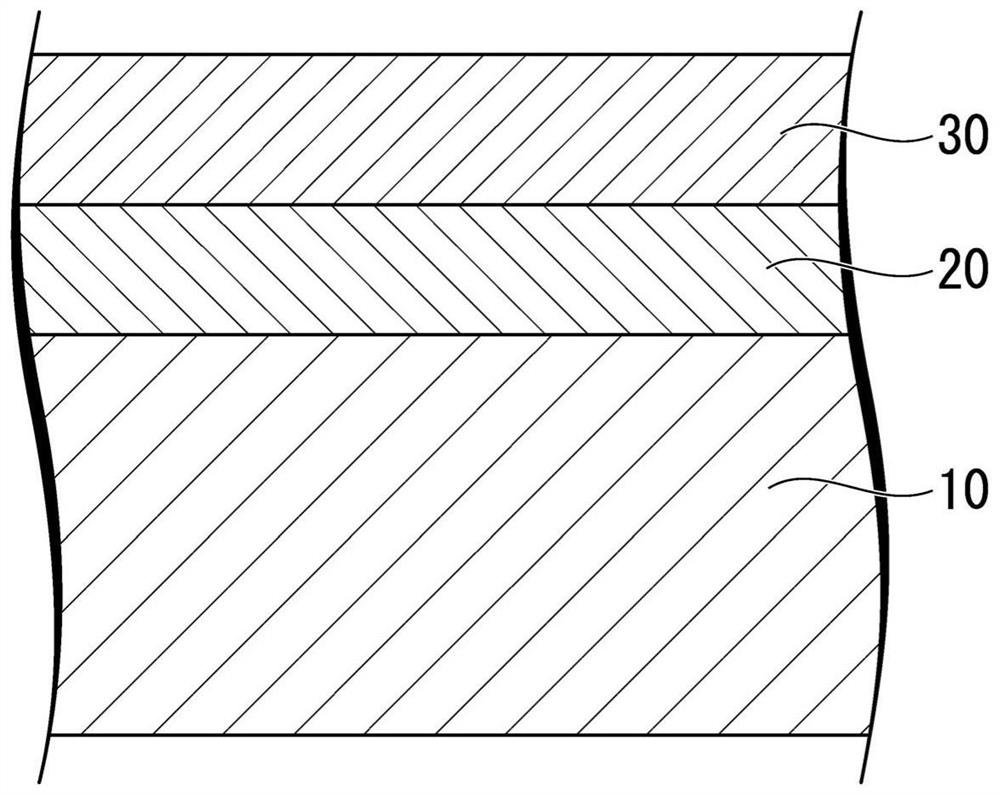

Grain oriented electrical steel flat product comprising an insulation coating

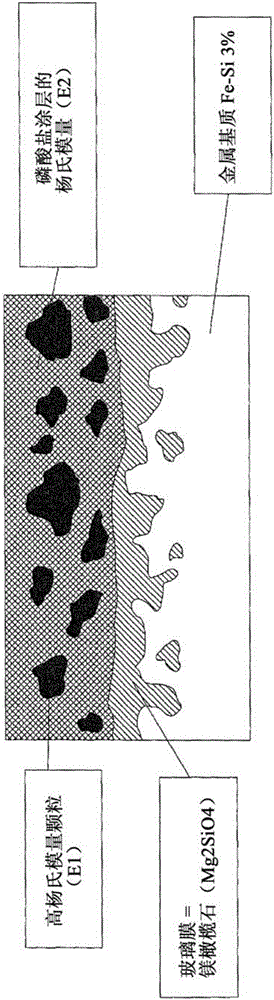

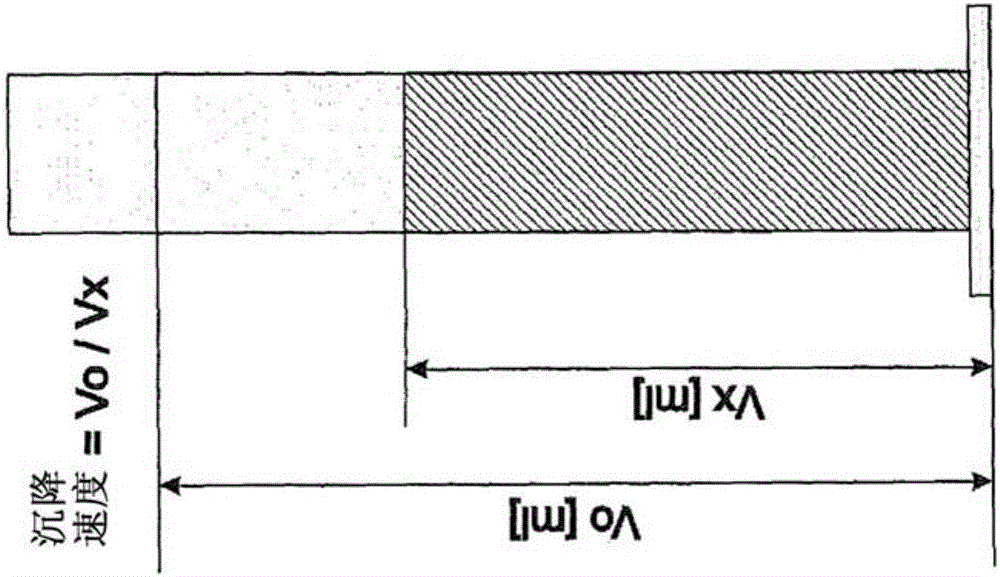

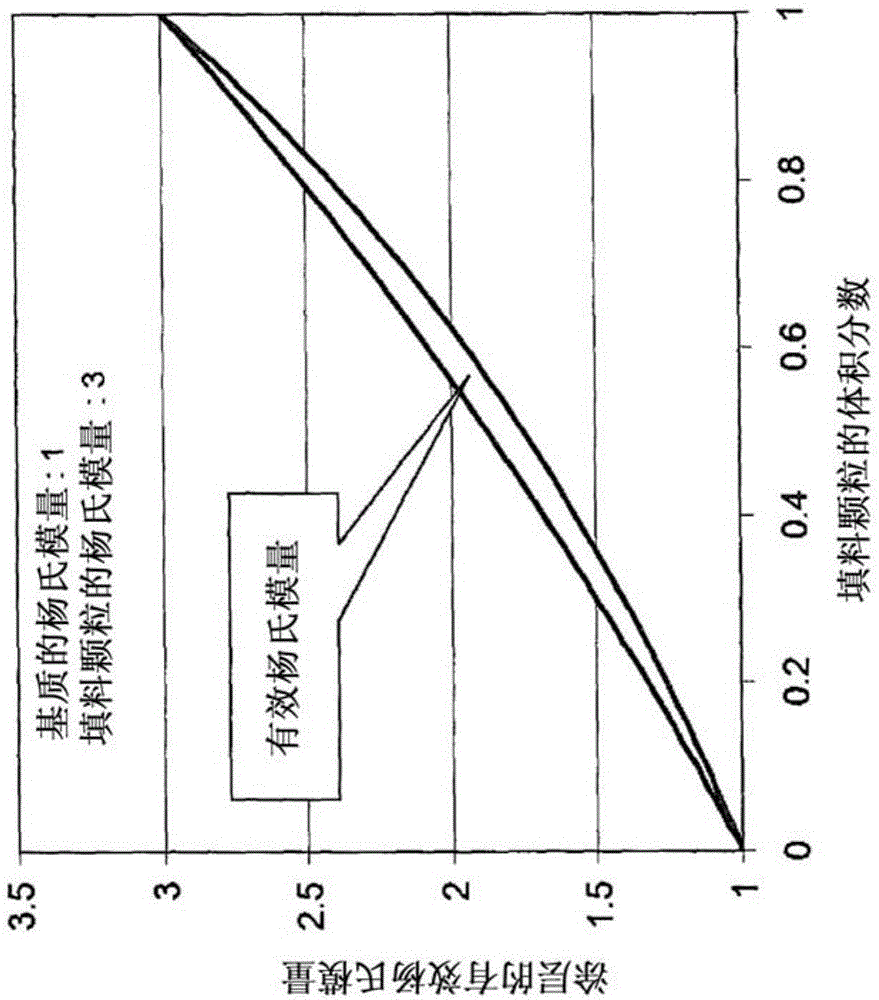

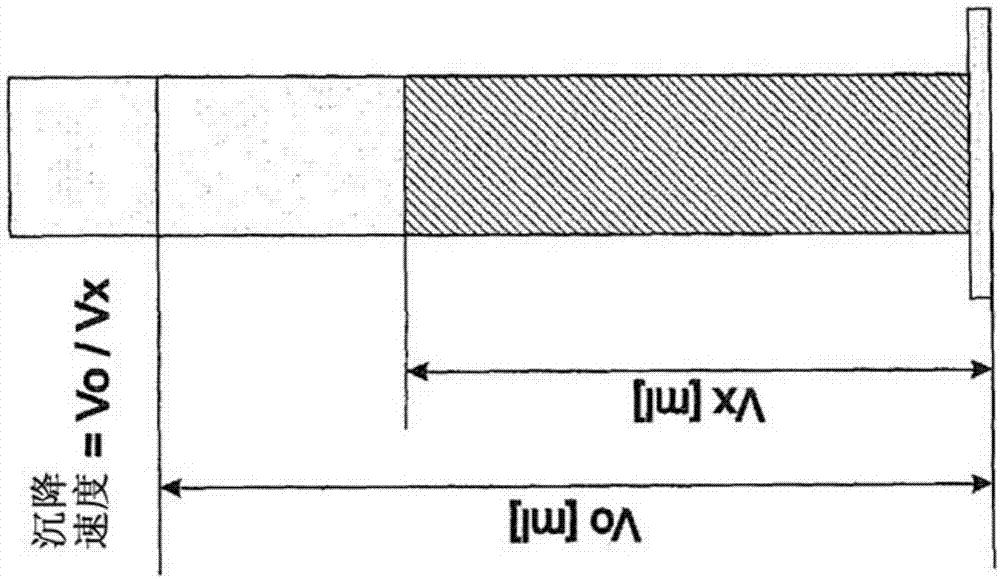

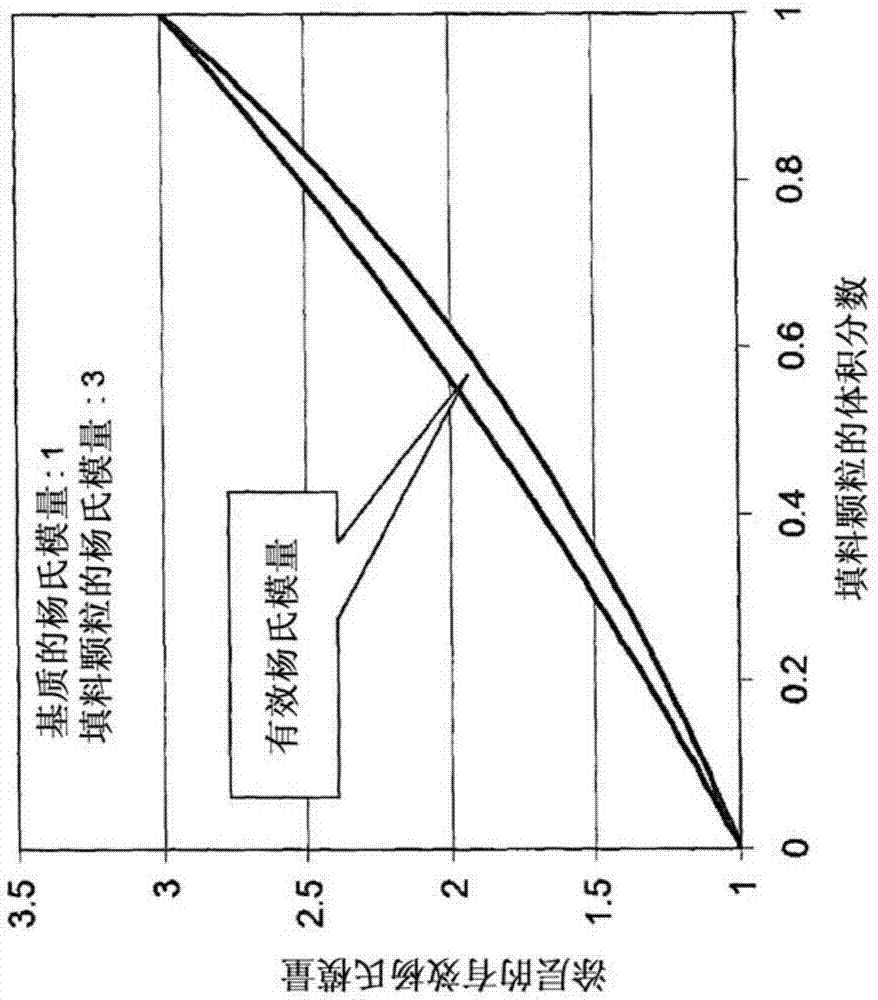

InactiveCN105980584AFiller Particle OptimizationHigh densityLayered productsInorganic material magnetismChromium CompoundsElectrical steel

The grain oriented electrical steel flat product according to the invention comprises an insulation coating layer being applied on at least one surface of the flat product the insulating coating comprising a matrix containing phosphate and silica. The insulation additionally contains filler particles, said filler particles comprising a core consisting of a high Young's modulus material and a shell, the shell surrounding said core and consisting of a material by which the filler particles are bonded to the matrix. In this way it is possible to obviate the need to add chromium compounds to the insulation coating of the grain oriented electrical steel flat product.

Owner:THYSSEN KRUPP STAHL AG

Tunneling magnetic sensing element including enhancing layer having high Fe concentration in the vicinity of barrier layer

ActiveUS7898776B2Increase rate of changeImproved magnetostrictionNanomagnetismMagnetic measurementsAlloyMagnetic layer

A tunneling magnetic sensing element is provided, in which an increase in the magnetostriction of a free magnetic layer is reduced and the rate of change in resistance is high. A laminate T1 constituting the tunneling magnetic sensing element includes a portion in which a pinned magnetic layer, a barrier layer, and a free magnetic layer are disposed in that order from the bottom. An enhancing layer disposed on the barrier layer side of the free magnetic layer includes a first enhancing layer on the barrier layer side and a second enhancing layer on the soft magnetic layer side, and the Fe content of a CoFe alloy constituting the first enhancing layer is specified to be larger than the Fe content of the CoFe alloy of the second enhancing layer.

Owner:TDK CORPARATION

Self-pinned magnetic detecting element

ActiveUS20050280953A1Higher specific resistancePrevent spin-independent scatteringNanomagnetismMagnetic measurementsMagneto elasticMagnetization

A CPP magnetic detecting element having a pinned magnetic layer whose magnetization is fixed by its uniaxial anisotropy in a structure that CIP magnetic detecting elements do not allow. In the CPP magnetic detecting element, the upper and lower surfaces of a pinned magnetic layer is disposed between nonmagnetic metal magnetostriction-enhancing layers. CPP magnetic detecting elements allow this structure without degrading the GMR effect. Thus, the magnetostriction coefficient of the pinned magnetic layer can be increased from above and below to produce an appropriate magnetoelasticity. Consequently, the magnetization of the pinned magnetic layer can be more firmly fixed.

Owner:TDK CORPARATION

Magnetic detecting element having a self-pinned layer

ActiveUS7268984B2Higher specific resistancePrevent spin-independent scatteringNanomagnetismMagnetic measurementsMagnetizationNon magnetic

A CPP magnetic detecting element having a pinned magnetic layer whose magnetization is fixed by its uniaxial anisotropy in a structure that CIP magnetic detecting elements do not allow. In the CPP magnetic detecting element, the upper and lower surfaces of a pinned magnetic layer having an artificial ferrimagnetic structure are disposed between a magnetostriction-enhancing layer made of a nonmagnetic metal and a nonmagnetic material layer having a higher lattice constant than Cu. CPP magnetic detecting elements allow this structure without reducing the variation in resistance per unit area ΔR·A. Thus, the magnetostriction coefficient of the pinned magnetic layer can be increased from above and below, thereby more firmly fixing the magnetization of the pinned magnetic layer.

Owner:TDK CORPARATION

Method and apparatus having improved magnetic read head sensors

InactiveUS20060067012A1Improved magnetostrictionIncrease resistanceNanomagnetismNanoinformaticsHigh resistanceElastic anisotropy

A method and apparatus for an improved magnetic read sensor having synthetic or AP pinned layers with high resistance and high magnetoelastic anisotropy is disclosed. A pinned layer includes a cobalt-iron ternary alloy, where a third constituent of the cobalt-iron ternary alloy layer is selected for increasing the resistance and magnetoelastic anisotropy of the cobalt-iron ternary alloy layer.

Owner:WESTERN DIGITAL TECH INC

Magnetic detecting element having a self-pinned layer

ActiveUS20050280955A1Reduce valueImproved magnetostrictionNanomagnetismMagnetic measurementsNuclear magnetic resonanceMagnetic layer

A CPP magnetic detecting element having a pinned magnetic layer whose magnetization is fixed by its uniaxial anisotropy in a structure that CIP magnetic detecting elements do not allow. In the CPP magnetic detecting element, the upper and lower surfaces of a pinned magnetic layer having an artificial ferrimagnetic structure are disposed between a magnetostriction-enhancing layer made of a nonmagnetic metal and a nonmagnetic material layer having a higher lattice constant than Cu. CPP magnetic detecting elements allow this structure without reducing the variation in resistance per unit area ΔR·A. Thus, the magnetostriction coefficient of the pinned magnetic layer can be increased from above and below, thereby more firmly fixing the magnetization of the pinned magnetic layer.

Owner:TDK CORPARATION

Method of resetting AP pinned layers with a canted field

InactiveUS20050011066A1Improve magnetostriction uniaxial anisotropy fieldHigh coefficientElectrical transducersNanomagnetismPhysicsAcute angle

A spin valve sensor in a read head has a spacer layer which is located between a self-pinned AP pinned layer structure and a free layer structure. The free layer structure is longitudinally stabilized by first and second hard bias layers which abut first and second side surfaces of the spin valve sensor. The AP pinned layer structure has an antiparallel coupling layer (APC) which is located between first and second AP pinned layers (AP1) and (AP2). The invention employs a resetting process for setting of the magnetic moments of the AP pinned layers by applying a field at an acute angle to the head surface in a plane parallel to the major planes of the layers of the sensor. The resetting process sets a proper polarity of each AP pinned layer, which polarity conforms to processing circuitry employed with the spin valve sensor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Spin valve sensor having an antiparallel (AP) self-pinned layer structure comprising cobalt for high magnetostriction

InactiveUS7119997B2Improved magnetostrictionGood effectRecord information storageManufacture of flux-sensitive headsCouplingNon magnetic

In one illustrative embodiment of the invention, a spin valve sensor of a magnetic head has a free layer structure; an antiparallel (AP) self-pinned layer structure; and a non-magnetic electrically conductive spacer layer in between the free layer structure and the AP self-pinned layer structure. The AP self-pinned layer structure includes a first AP pinned layer; a second AP pinned layer; an antiparallel coupling (APC) layer formed between the first and the second AP pinned layers. At least one of the first and the second AP pinned layers is made of cobalt having no iron content. The other AP pinned layer may be formed of cobalt, cobalt-iron, or other suitable material. The use of cobalt in the AP self-pinned layer structure increases its magnetostriction to increase the self-pinning effect. Preferably, the first AP pinned layer is cobalt-iron and the second AP pinned layer is cobalt which provides for both an increase in magnetostriction and magnetoresistive coefficient Δr / R of the sensor.

Owner:WESTERN DIGITAL TECH INC

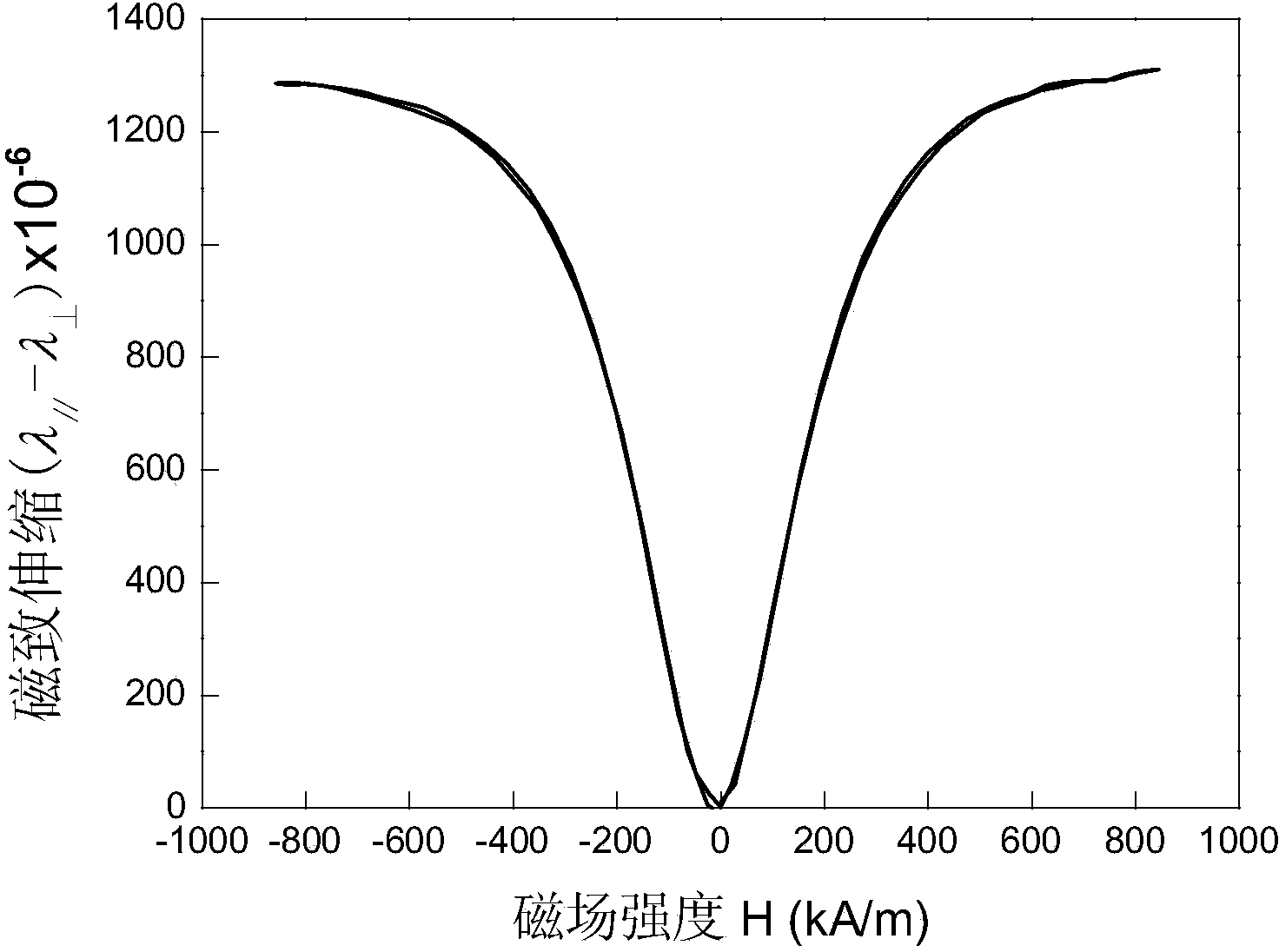

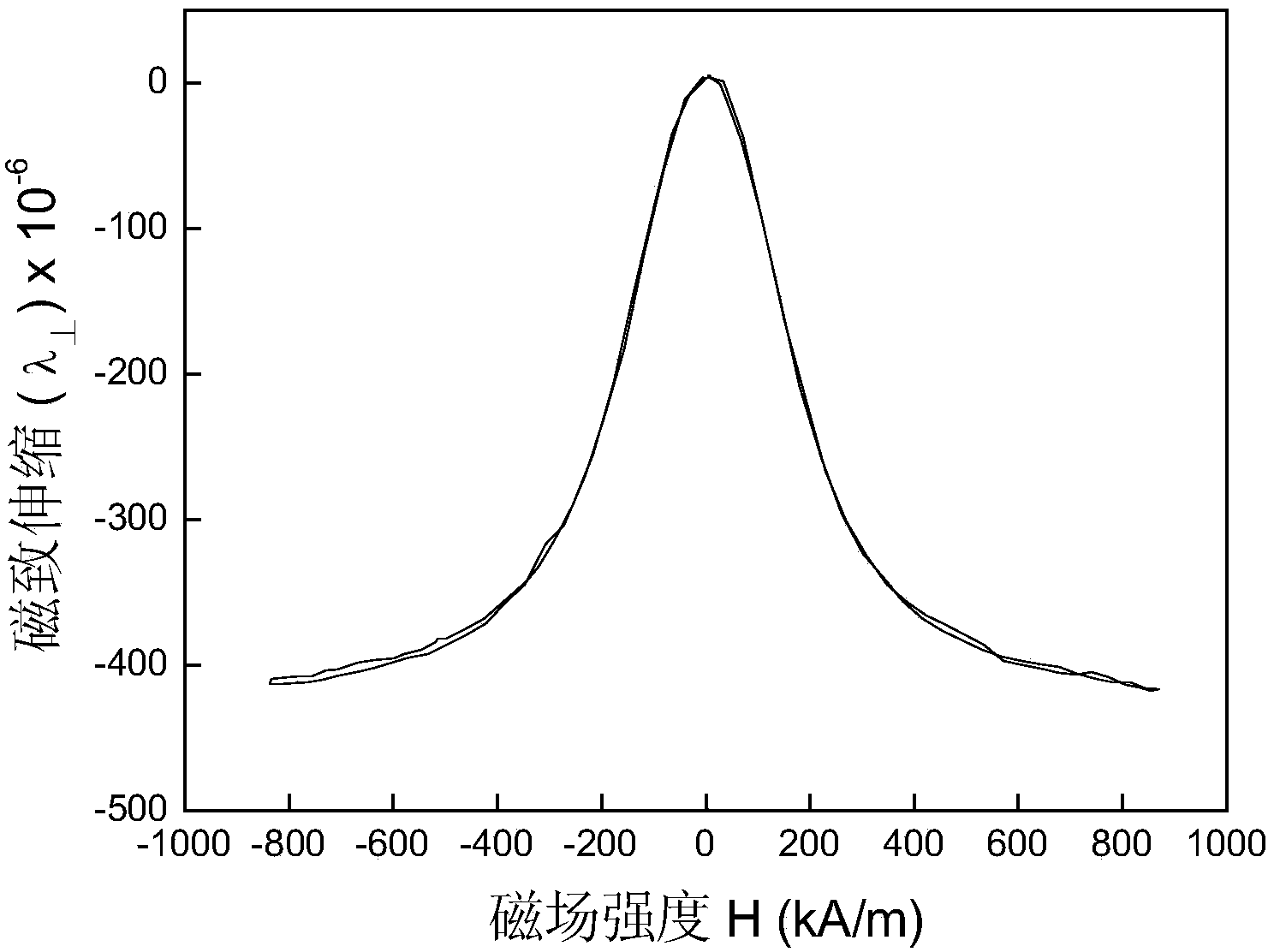

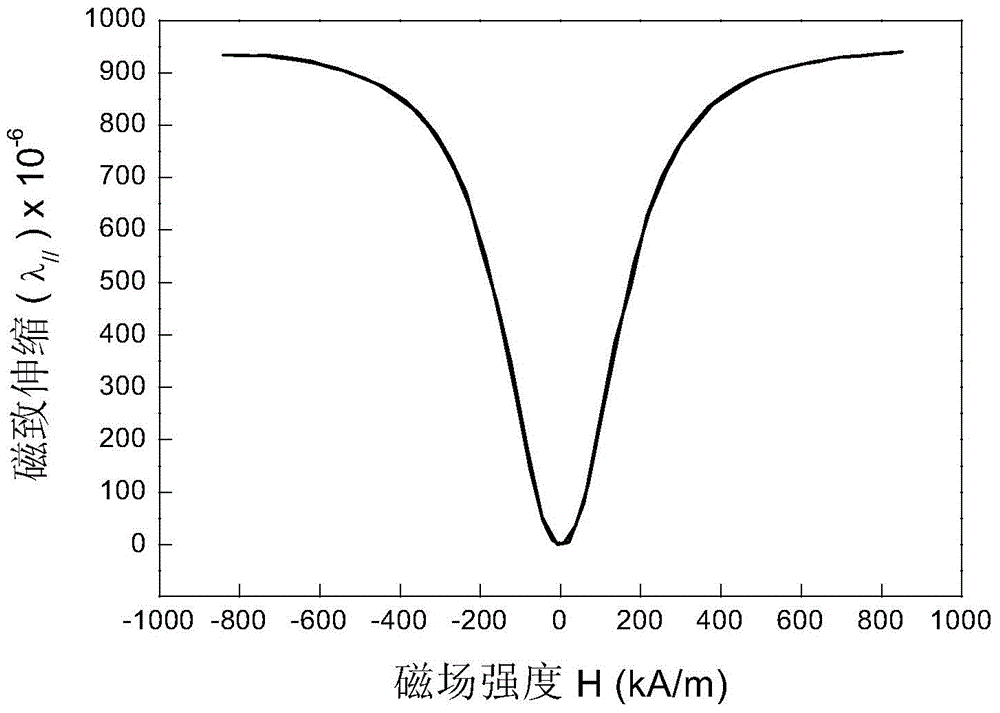

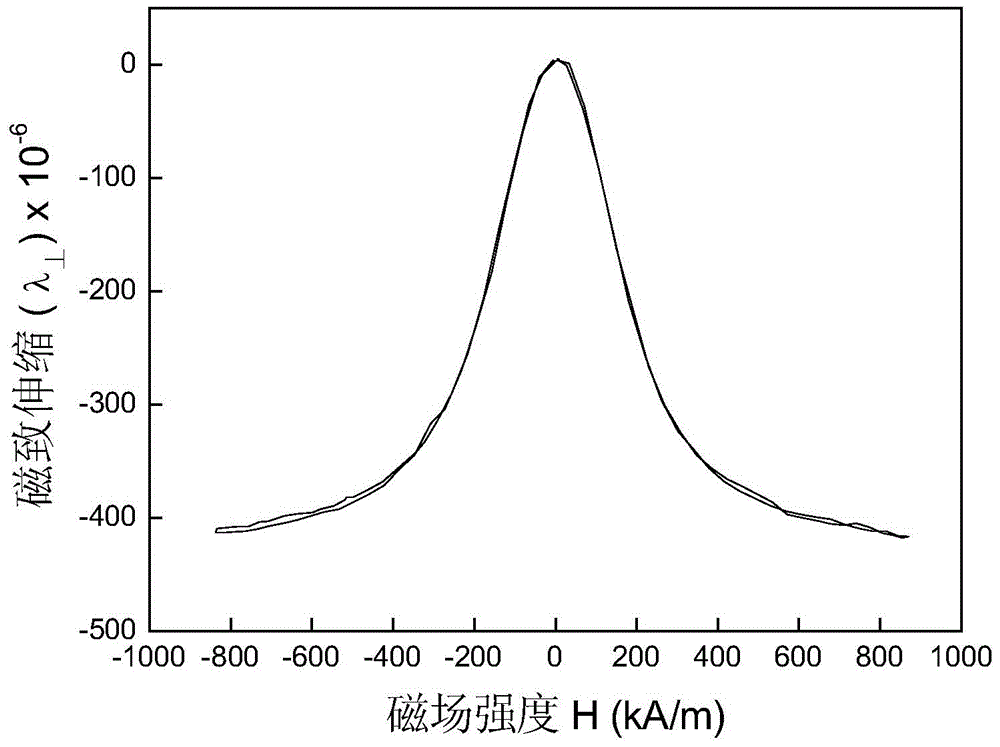

Fe-Ni metal-based magnetostrictive material and preparation method thereof

The invention discloses a Fe-Ni metal-based magnetostrictive material. The Fe-Ni metal-based magnetostrictive material comprises the following components in percentage by weight: 25-42% of Fe, 20-46% of Ni, 4-6% of Cr, 2-3% of Ti, 1-2% of Si, 0-1% of Al, and 0-26% of Co; and the sum of the weight percentages of all the components is 100%. The invention further discloses a preparation method of the Fe-Ni metal-based magnetostrictive material: all the weighed components are mixed, pressed for molding and smelted to an alloy; and then, the alloy is absorbed and cast to an alloy rod for forging, is heated under the vacuum condition, is hotly rolled and polished to eliminate the surface scale, is coldly drawn on a wire drawing machine, and is thermally treated to obtain the Fe-Ni metal-based magnetostrictive material. The preparation method is simple, is high in efficiency, and is convenient for large-scale batch production.

Owner:XIAN UNIV OF TECH

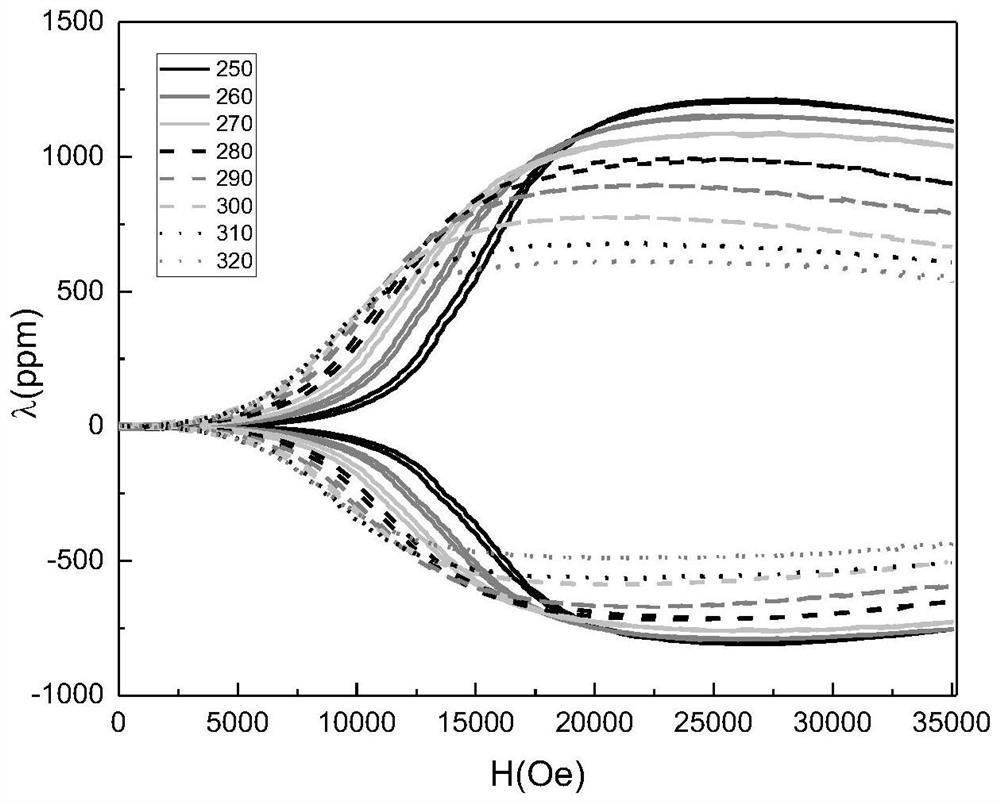

Preparing method of Tb-Dy-Ho-Fe giant magnetostrictive material

ActiveCN103451514AOptimizing the Magnetic Domain StructureImproved magnetostrictionHysteresisRare earth

The invention provides a preparing method of a Tb-Dy-Ho-Fe giant magnetostrictive material. The material comprises the components of Tb1-x-yDyxHoyFez, wherein x is 0.45-0.65, y is 0.08-0.25, and z is 1.9-2.0. The preparing method comprises the steps that first, metal raw materials are mixed, electric arc melting is conducted on the metal raw materials to obtain an alloy ingot, then the alloy ingot is poured and cast, high-temperature homogenizing annealing is conducted, and a furnace is cooled to be at an indoor temperature; then, magnetic heat treatment of stress is applied under the protection of high-purity argon, and at last the tombarthite iron giant magnetostrictive material is obtained. According to the preparing method of the Tb-Dy-Ho-Fe giant magnetostrictive material, the combined action of the stress, a magnetic filed and the temperature is used for adjusting magnetic domain distribution of rod-shaped materials, magnetic domains in the material are oriented according to a certain direction, the magnetic domain structure of the material is optimized, magnetostrictive hysteresis of the material is obviously reduced, the magnetostriction and magnetic field curves are in linear relation, and saturated magnetostriction is increased.

Owner:HEBEI UNIV OF TECH

Magnetic sensor having improved resistance to thermal stress induced instability

ActiveUS20120106006A1Increasing block temperatureImproved antiparallel couplingManufacture head surfaceNanomagnetismStress inducedThermal variation

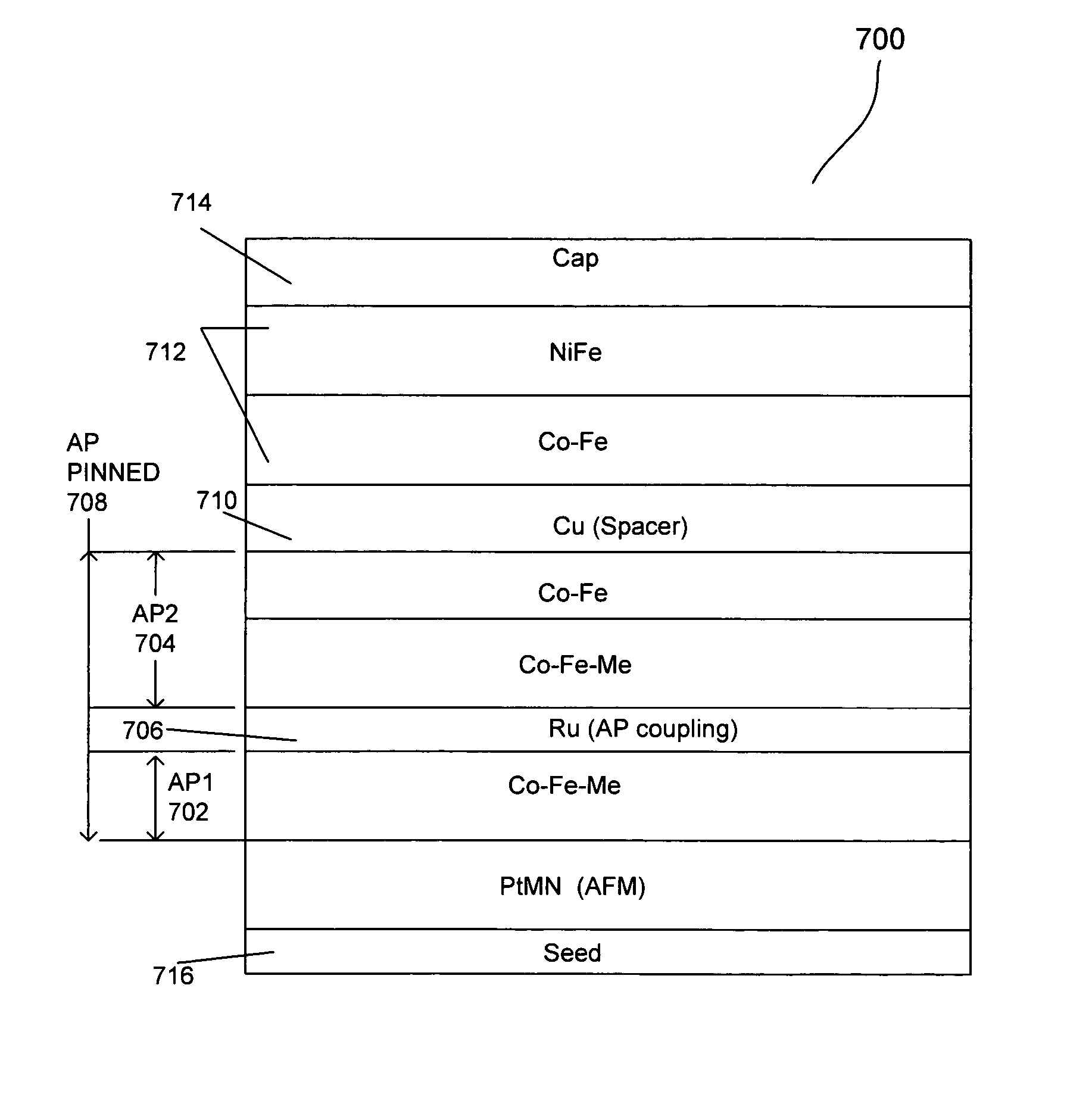

A magnetic read sensor having improved robustness to withstand thermal variations resulting from thermal fly height heating. Improved thermal robustness comes as a result of improved pinned layer pinning. The read head includes an AFM layer having an increased thickness to provide a higher blocking temperature. The read head further includes a pinned layer structure that includes a first magnetic layer adjacent to and exchange coupled with the AFM layer. The first layer comprises a Co—Fe layer with an increased Fe content of 20-30 atomic percent. The pinned layer structure also includes a second magnetic layer that is antiparallel coupled with the AP1 layer. The AP2 layer can be a multi-layer structure that includes a layer of CoFe, a layer of Co—Fe—Hf formed on the layer of Co—Fe, a layer of Co—Fe—B formed on the layer of Co—Fe—Hf, and a second layer of Co—Fe formed on the layer of Co—Fe—B.

Owner:WESTERN DIGITAL TECH INC

Method and apparatus having improved magnetic read head sensors

InactiveUS7538988B2Improved magnetostrictionIncrease resistanceNanomagnetismNanoinformaticsHigh resistanceCobalt

A method and apparatus for an improved magnetic read sensor having synthetic or AP pinned layers with high resistance and high magnetoelastic anisotropy is disclosed. A pinned layer includes a cobalt-iron ternary alloy, where a third constituent of the cobalt-iron ternary alloy layer is selected for increasing the resistance and magnetoelastic anisotropy of the cobalt-iron ternary alloy layer.

Owner:WESTERN DIGITAL TECH INC

Magnetic sensing device with multilayered pinned magnetic layer having magnetostriction-enhancing layer

ActiveUS20050280954A1Improve reliabilityEfficient magnetizationNanomagnetismMagnetic measurementsInter layerNon magnetic

A magnetic sensing device is presented that has a multilayer material with a pinned magnetic layer, a nonmagnetic material layer, and a free magnetic layer. The pinned magnetic layer is a composite with a nonmagnetic intermediate layer and magnetic thin-film layers separated from each other by the nonmagnetic intermediate layer. A first nonmagnetic magnetostriction-enhancing layer is on the pinned magnetic layer and contacts a first thin-film layer placed farthest from the nonmagnetic material layer. At least one of the magnetic thin-film layers has a composite structure with a second nonmagnetic magnetostriction-enhancing layer and magnetic layers separated from each other by the second magnetostriction-enhancing layer. All of the magnetic layers are magnetized in the same direction antiparallel to the adjacent magnetic thin-film layer. At least some crystals of the first and second magnetostriction-enhancing layers and the first thin-film layer / magnetic layers are epitaxial or heteroepitaxial.

Owner:TDK CORPARATION

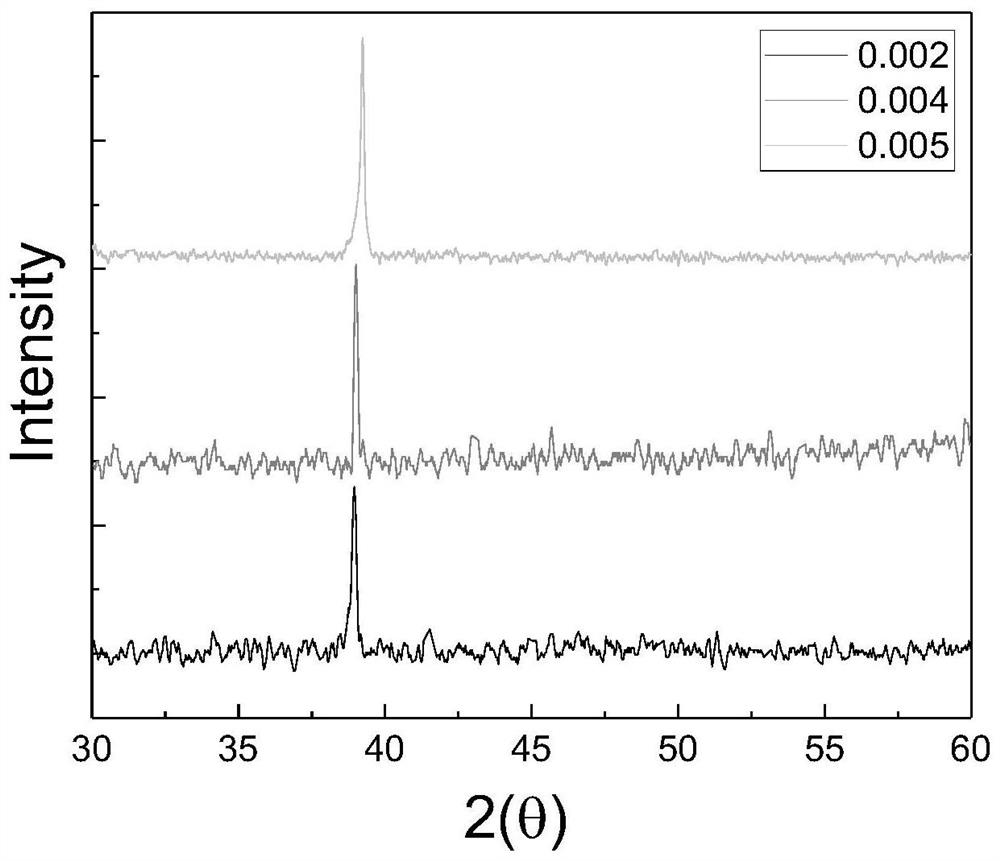

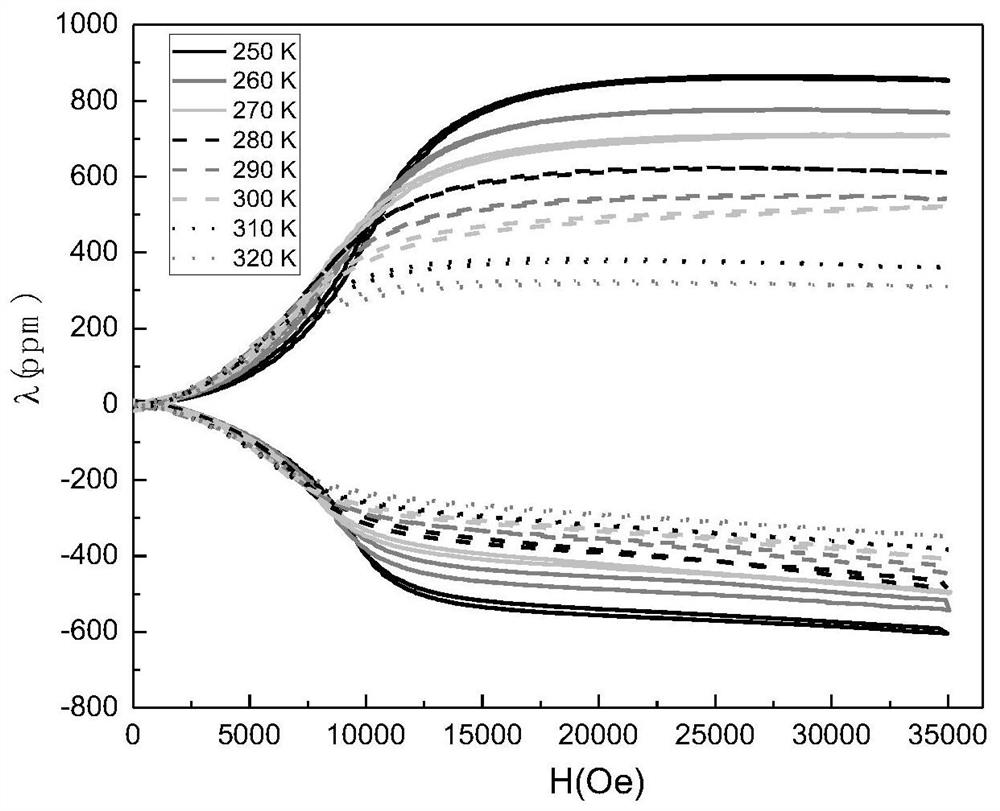

Co-Ni-Mn-Si-Tb giant magnetostrictive material and preparation method thereof

ActiveCN112575237ALower critical fieldImproved magnetostrictionMagnetostrictive material selectionAlloyMagnetic characteristic

The invention provides a Co-Ni-Mn-Si-Tb giant magnetostrictive material and a preparation method thereof. The Co-Ni-Mn-Si-Tb giant magnetostrictive material comprises the following components: Co0. 97Ni0. 03MnSi (1-x) Tb<x> (x is equal to 0, 0.002, 0.004, 0.005). The preparation method comprises the following steps of mixing and smelting raw materials into an alloy, then slicing and sealing a tube, and finally performing annealing at high temperature and naturally cooling with furnace fire. The material prepared by the preparation method disclosed by the invention has the characteristics of metamagnetic property, texture <112> orientation, good magnetostriction property (Co0. 97Ni0. 03MnSi0. 995Tb0.005 reaches 1000ppm at 290K), no hysteresis and low critical field. The preparation method is simple in process, time and cost can be saved, and meanwhile, a simple and feasible method is provided for quickly preparing the oriented texture.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Grain oriented electrical steel flat products with insulating coating

InactiveCN105980584BAvoid the needImprove tensile stressLayered productsInorganic material magnetismChromium CompoundsElectrical steel

A grain oriented electrical steel flat according to the invention comprising an insulating coating applied to at least one surface of said flat, the insulating coating comprising a matrix comprising phosphate and silicon dioxide. The insulating layer also includes filler particles comprising a core of high Young's modulus material and a shell surrounding the core and of a material that binds the filler particles to the substrate. In this way, the need to add chromium compounds to the insulating coating of grain oriented electrical steel flats can be avoided.

Owner:THYSSEN KRUPP STAHL AG

Preparing method of Tb-Dy-Ho-Fe giant magnetostrictive material

ActiveCN103451514BOptimizing the Magnetic Domain StructureImproved magnetostrictionHysteresisRare earth

Owner:HEBEI UNIV OF TECH

Tunnel type magnetic sensor having protective layer formed from Pt or Ru on free magnetic layer, and method for manufacturing the same

InactiveUS20080055786A1Increase rate of changeDecrease magnetostriction λNanomagnetismMagnetic measurementsPlatinumHigh rate

A tunnel type magnetic sensor includes a fixed magnetic layer that has magnetization fixed in one direction, an insulating barrier layer, and a free magnetic layer that has magnetization varied by an external magnetic field, which are laminated in that order from the bottom. The insulating barrier layer is formed from titanium oxide, and on the free magnetic layer, a first protective layer of platinum or ruthenium is formed. Accordingly, compared to the structure in which the first protective layer is not formed or the first protective layer is formed from Al, Ti, Cu, or IrMn, while a high rate of change in resistance is maintained, the magnetostriction of the free magnetic layer can be effectively decreased. When the insulating barrier layer is formed from aluminum oxide, the rate of change in resistance is decreased, or the magnetostriction of the free magnetic layer cannot be effectively decreased.

Owner:TDK CORPARATION

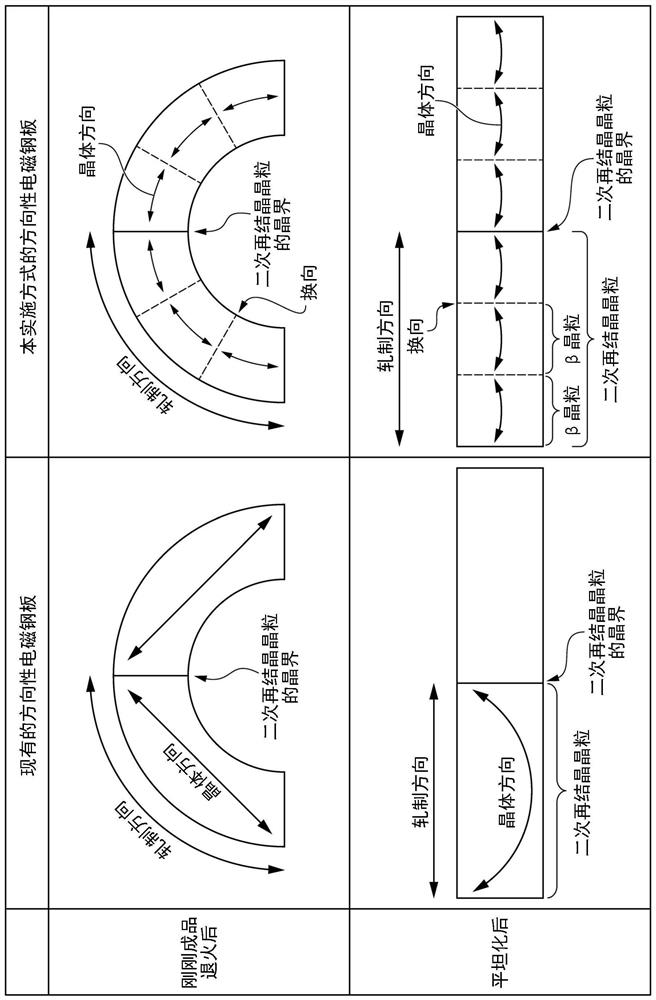

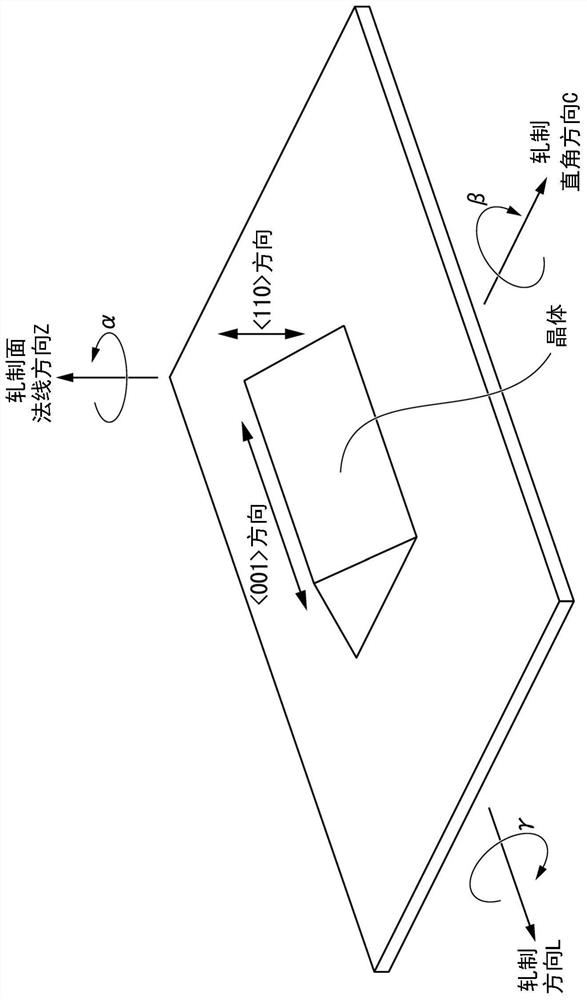

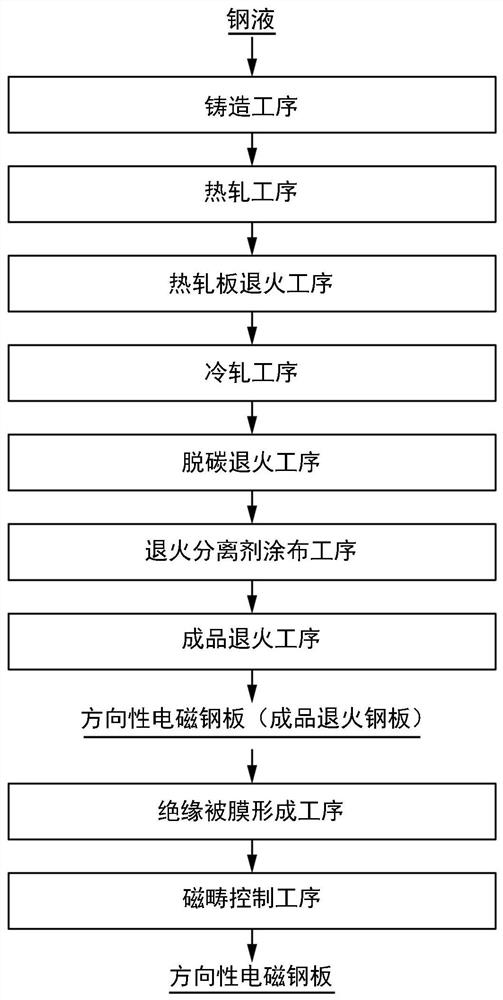

Grain-oriented electrical steel sheet

ActiveCN112513306BImproved magnetostrictionInorganic material magnetismFurnace typesElectrical steelCrystal orientation

A grain-oriented electrical steel sheet having a texture oriented towards a Goss orientation, where the deviation angle of the crystal orientation measured at two measurement points adjacent to each other at an interval of 1 mm on the sheet surface is expressed as (α 1 beta 1 gamma 1 ) and (α 2 beta 2 gamma 2 ), define the boundary condition BA as |β 2 ‑β 1 |≥0.5°, the boundary condition BB is defined as [(α 2 ‑α 1 ) 2 +(β 2 ‑β 1 ) 2 +(γ 2 ‑γ 1 ) 2 ] 1 / 2 When ≥2.0°, there are grain boundaries that satisfy the boundary condition BA and do not satisfy the boundary condition BB.

Owner:NIPPON STEEL CORP

grain-oriented electrical steel sheet

ActiveCN112513305BImproved magnetostrictionInorganic material magnetismFurnace typesElectrical steelCrystal orientation

A grain-oriented electrical steel sheet having a texture oriented in a Gaussian orientation, and the deviation angle of the crystal orientation measured at two measurement points adjacent to the sheet surface and at an interval of 1 mm is expressed as (α 1 beta 1 γ 1 ) and (α 2 beta 2 γ 2 ), the boundary condition BA is defined as |γ 2 ‑γ 1 |≥0.5°, the boundary condition BB is defined as [(α 2 ‑α 1 ) 2 +(β 2 ‑β 1 ) 2 +(γ 2 ‑γ 1 ) 2 ] 1 / 2 When ≥2.0°, there are grain boundaries that satisfy the boundary condition BA and do not satisfy the boundary condition BB.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com