Preparing method of Tb-Dy-Ho-Fe giant magnetostrictive material

A tb-dy-ho-fe, giant magnetostriction technology, applied in the field of material science and engineering, can solve the problems of complex preparation process, high cost, large magnetostrictive hysteresis, etc., and achieve simple preparation process, magnetostrictive The effect of large expansion and contraction and small magnetostrictive hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Clean the surface of Tb, Dy, Ho and Fe metal block raw materials with a purity of 99.9%, apply pressure to make Tb, Dy and Ho block raw materials into particles with a particle size of less than 5mm, and Fe metal block raw materials It is made into particles with a particle size of less than 3mm to ensure that the composition of the molten alloy is uniform.

[0021] (2) According to the molar ratio Tb: Dy: Ho: Fe = 0.26: 0.53: 0.21: 1.9, mix and put it into the sweet pot of the electric arc furnace, and the electric arc furnace is first vacuumed to 5×10 -3 Above Pa, wash twice with high-purity argon, and then smelt under the protection of high-purity argon, the smelting current is 140-160 amperes, and the time is 20-30 seconds. After that, the alloy ingot is turned over and smelted twice.

[0022] (3) Cast the smelted alloy into a mold with a diameter of 8 mm and a length of 30 mm to produce an alloy rod of 8 mm and a length of 30 mm.

[0023] (4) Clean the surface...

Embodiment 2

[0028] The other steps of this example are the same as Example 1, the difference is that the molar ratio of the metal used in step (1) is changed to Tb:Dy:Ho:Fe=0.26:0.65:0.09:2; the mold in step (3) The size is 10mm in diameter and 40mm in length; the magnetic field heat treatment in step (6) is 350kA / m, 300°C, and 0.5 hours.

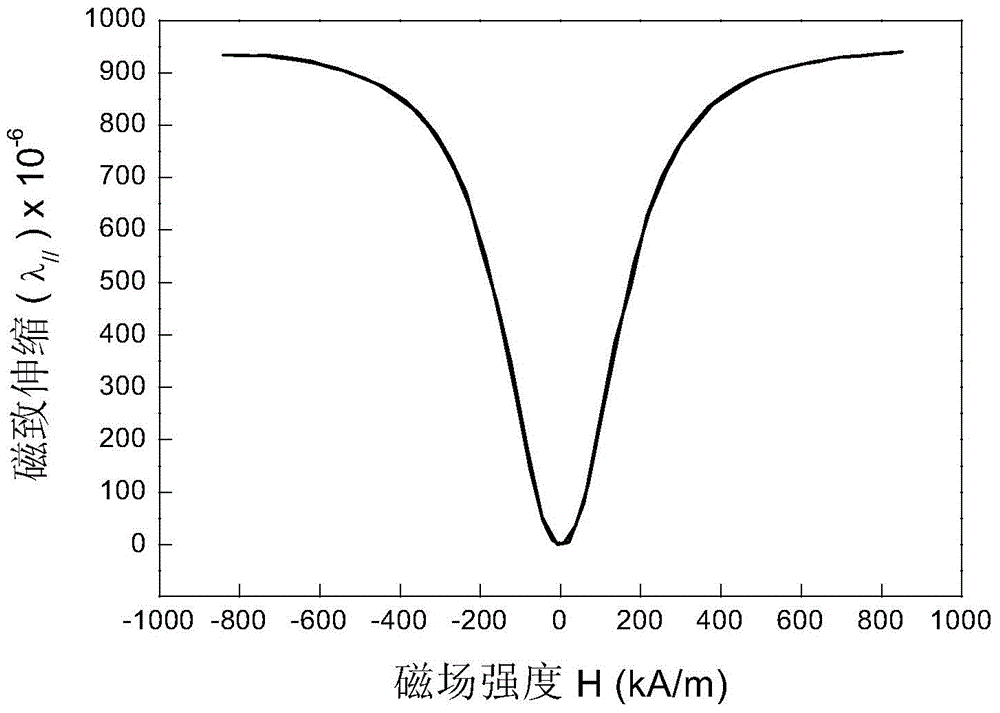

[0029] From attached figure 2 It can be seen that Tb 0.26 Dy 0.65 Ho 0.09 Fe 2 The magnetostriction of the material (λ ∥ -λ ⊥ ) is close to saturation under 400kA / m magnetic field, which is 1160×10 -6 , 770×10 under 200kA / m magnetic field -6 , the magnetostrictive hysteresis of the material in the range of 0-300kA / m is very small, and the hysteresis width is 6.3kA / m.

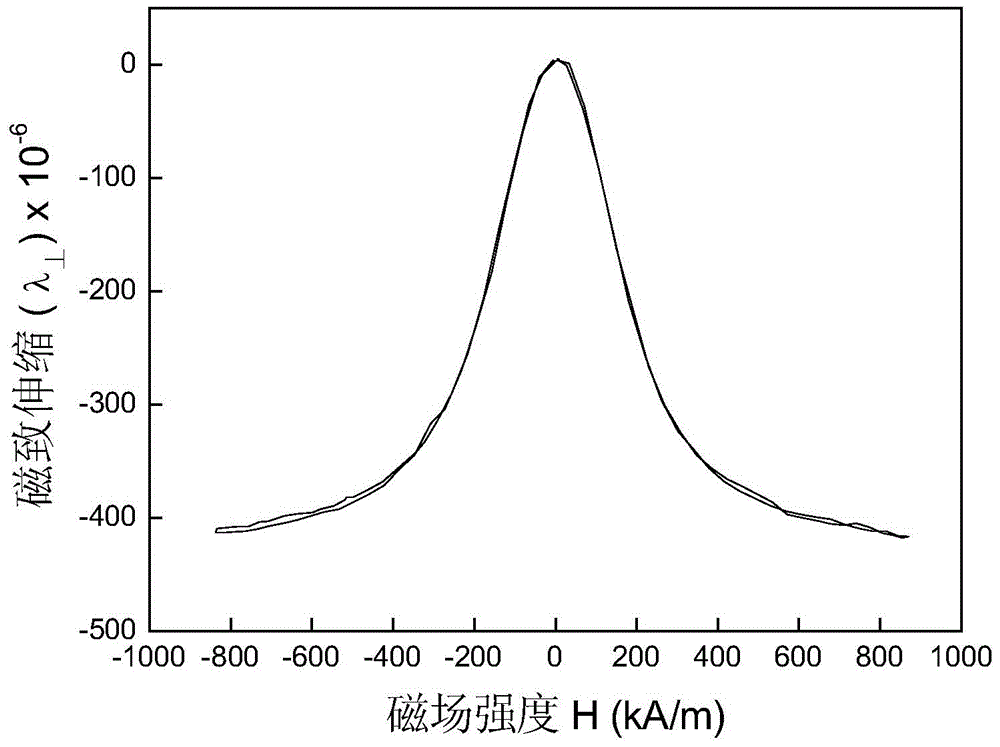

[0030] From attached image 3 It can be seen that Tb 0.26 Dy 0.65 Ho 0.09 Fe 2 The magnetostriction of the material in the direction perpendicular to the magnetic field is -240×10 under a magnetic field of 200kA / m-6 , the magnetostrictive hysteresis of the material in the r...

Embodiment 3

[0033] The other steps of this example are the same as those of Example 1, except that the molar ratio of the metals used in step (1) is changed to Tb:Dy:Ho:Fe=0.26:0.48:0.26:2. A compressive stress of 10 MPa is applied axially to the alloy rod in step (5); the magnetic field heat treatment temperature in step (6) is 270° C., and the time is 0.5 hour.

[0034] From attached Figure 4 It can be seen that Tb 0.26 Dy 0.48 Ho 0.26 Fe 2 The magnetization of the material and the hysteresis of the magnetic field are small, resulting in an improved magnetostrictive hysteresis characteristic of the material.

[0035] The invention can change the distribution of magnetic domains in the material under the combined action of the magnetic field and temperature by performing magnetic field heat treatment on the material. After magnetic field heat treatment, some magnetic domains in the material will be aligned along the direction of the applied magnetic field. For example, for a rod-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com