FeNi nanoparticle/epoxy resin composite coated iron-silicon magnetic powder core and preparation method thereof

A technology of epoxy resin and nanoparticles, which is applied in the manufacture of inductors/transformers/magnets, magnetic cores/yokes, and the magnetism of inorganic materials. The preparation process is cumbersome and other problems, and the density is improved, the magnetic domain structure is optimized, and the effect is suitable for popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

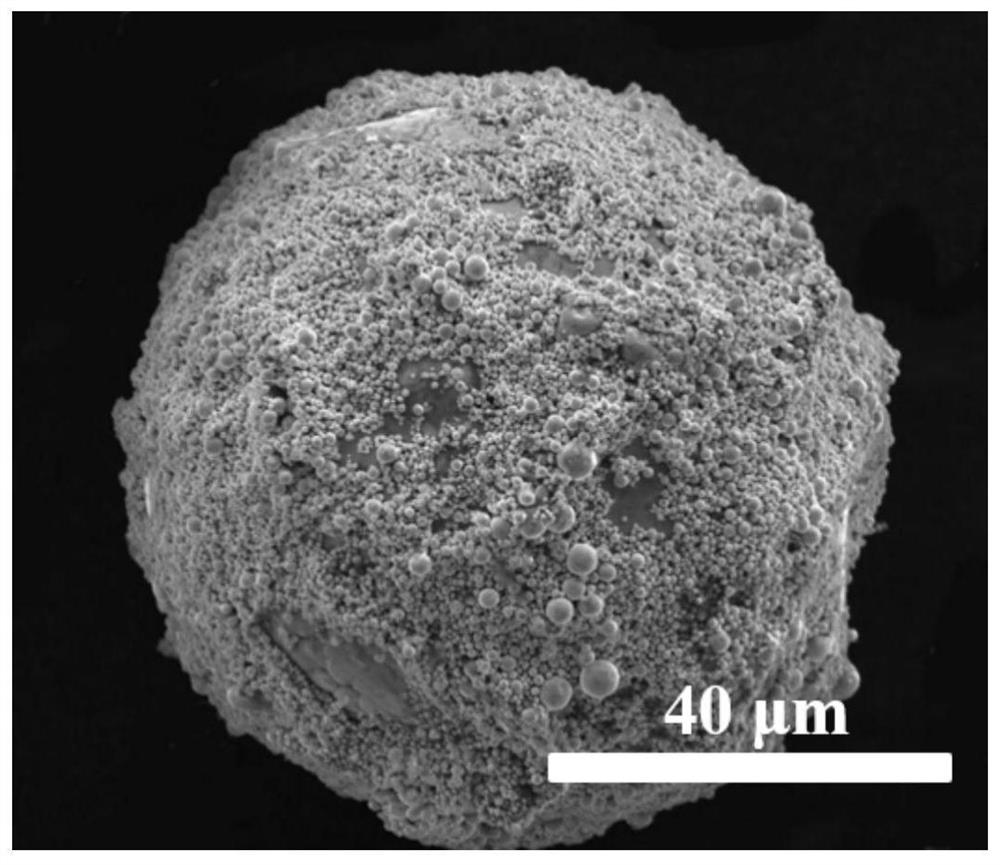

[0036] A FeNi nanoparticle / epoxy resin composite coated iron-silicon magnetic powder core, the preparation method of which comprises the steps of:

[0037] 1) Dry mix the iron-silicon powder and FeNi nanoparticles uniformly according to the weight ratio of 95:5, wherein the amount of iron-silicon powder is 19g, and the amount of FeNi nanoparticles is 1g; the mixing time is 20min, and the mixing speed is 30r / min;

[0038] 2) Weigh 2g of silane coupling agent, add it to 10ml of absolute ethanol, and stir ultrasonically for 5 minutes to obtain silane coupling agent-ethanol solution; add the obtained mixed powder into the prepared silane coupling agent-absolute ethanol solution , ultrasonically stirred and reacted for 10 minutes; then dried in a vacuum dryer, the drying temperature was set at 60°C, and the drying time was 1 hour;

[0039] 3) Add epoxy resin accounting for 1.5% of the obtained dried powder mass into 10 ml of acetone solution, and ultrasonically disperse for 1 min t...

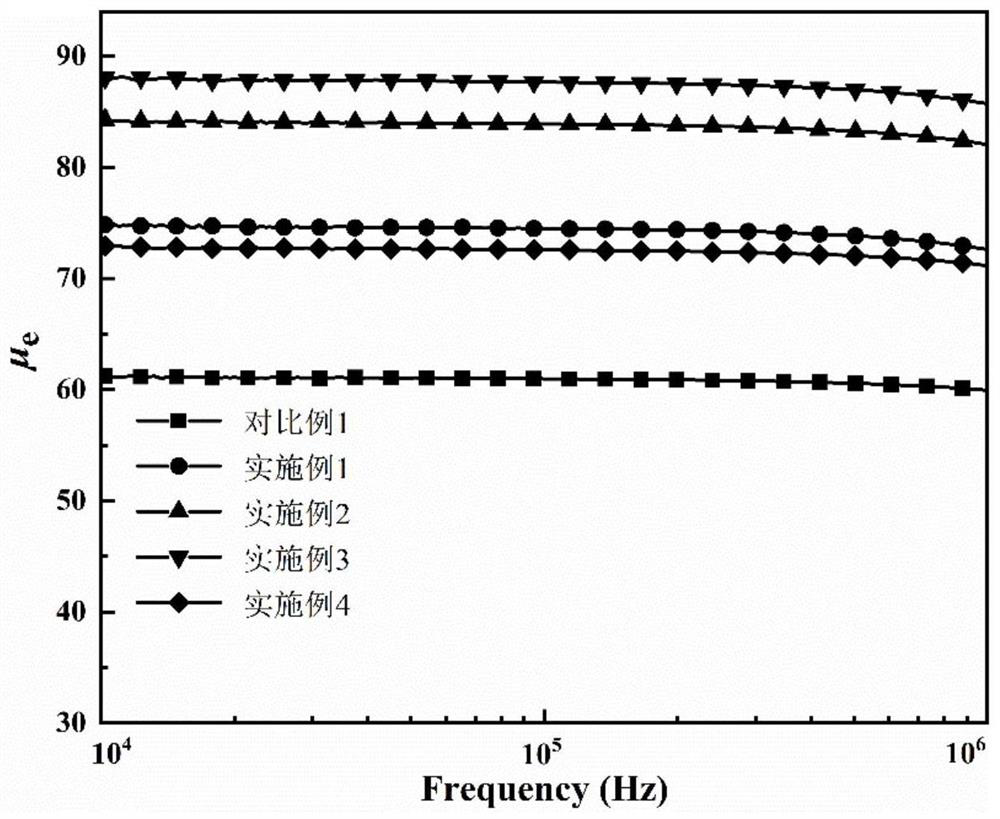

Embodiment 2

[0043] A FeNi nanoparticle / epoxy resin composite-coated iron-silicon magnetic powder core, the difference between its preparation method and Example 1 is that the mass ratio of iron-silicon powder to FeNi nanoparticles in step 1) is 90:10, wherein FeNi The amount of silicon powder is 18g, and the amount of FeNi nanoparticles is 2g.

Embodiment 3

[0045] A FeNi nanoparticle / epoxy resin composite coated iron-silicon magnetic powder core, the difference between its preparation method and Example 1 is that the mass ratio of iron-silicon powder to FeNi nanoparticles in step 1) is 85:5, wherein FeNi The dosage of silicon powder is 17g, and the dosage of FeNi nanoparticles is 3g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com