Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve the effect of flaw detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

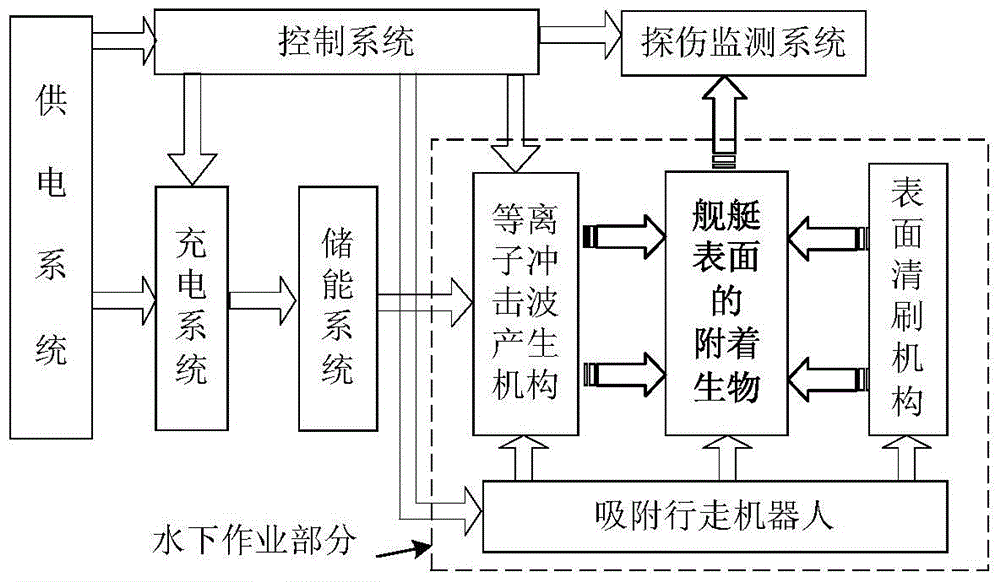

Warship hull descaling and flaw detecting system

InactiveCN103895835ARealize integrated operationVersatileVessel cleaningAnalysing solids using sonic/ultrasonic/infrasonic wavesShock waveNon destructive

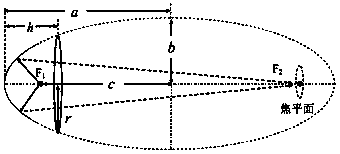

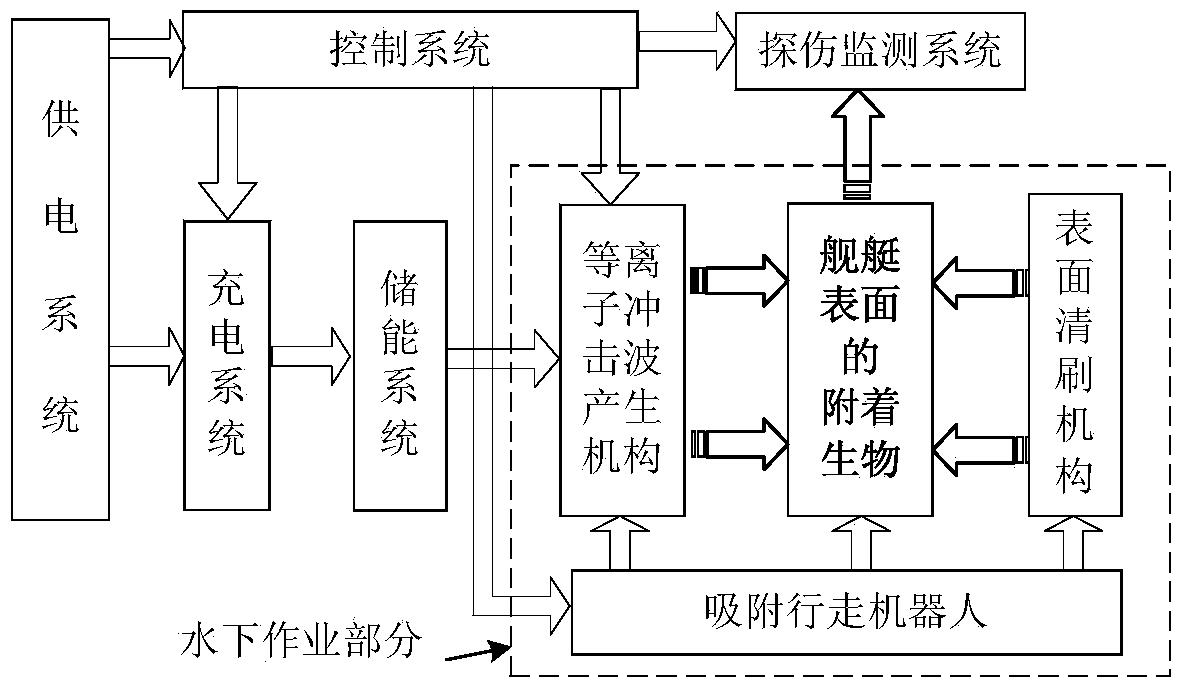

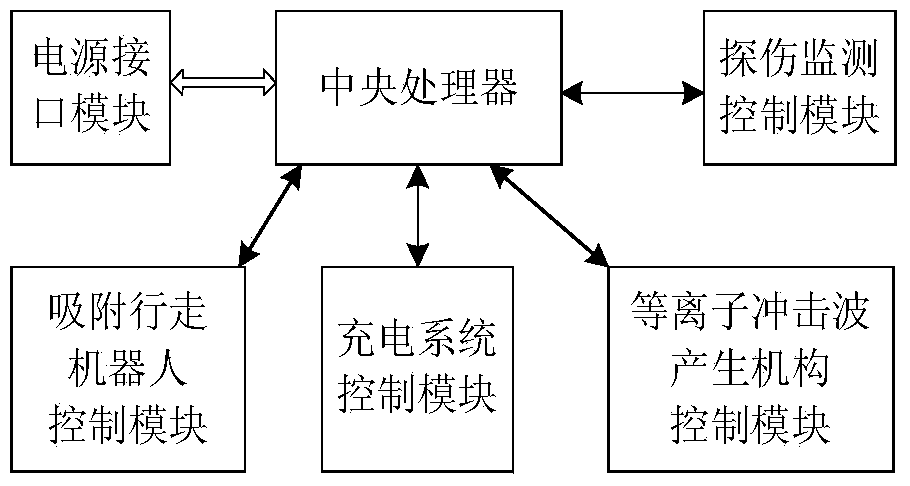

The invention provides a warship hull descaling and flow detecting system which comprises a power supply system, a control system, a charging system, an energy storing system, a plasma shock wave generating mechanism, a flaw detection monitoring system, a surface flushing mechanism and an adsorbing and walking robot. When the system runs, probes of the plasma shock wave generating mechanism, the surface flushing mechanism, the adsorbing and walking robot and the flaw detection monitoring system are in underwater operation. Organisms attached to the surface of a warship hull are subjected to primary cleaning by the aid of strong sound shock waves generated from discharging of underwater plasmas, the organisms attached to the surface of the warship hull fall off or are loosened, and then the loosened attachments are cleaned by the aid of the surface flushing mechanism. The descaling effect can be detected through the flaw detecting system after descaling operation, and non-destructive detection can be performed on the surface of the warship hull.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

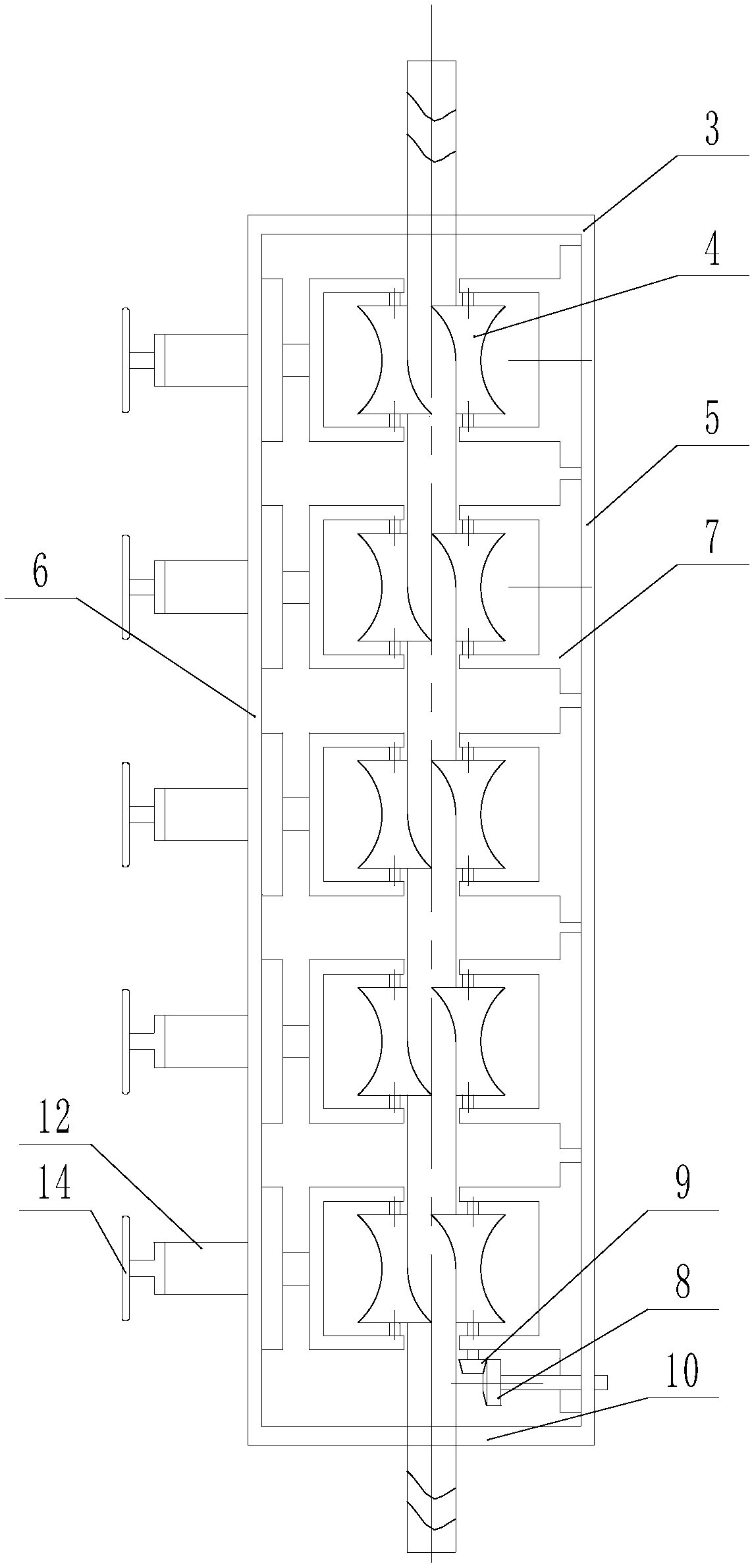

Pipeline ray flaw detection device and flaw detection method

ActiveCN109975328AImprove the effect of flaw detectionMaterial analysis using wave/particle radiationEngineeringWeld line

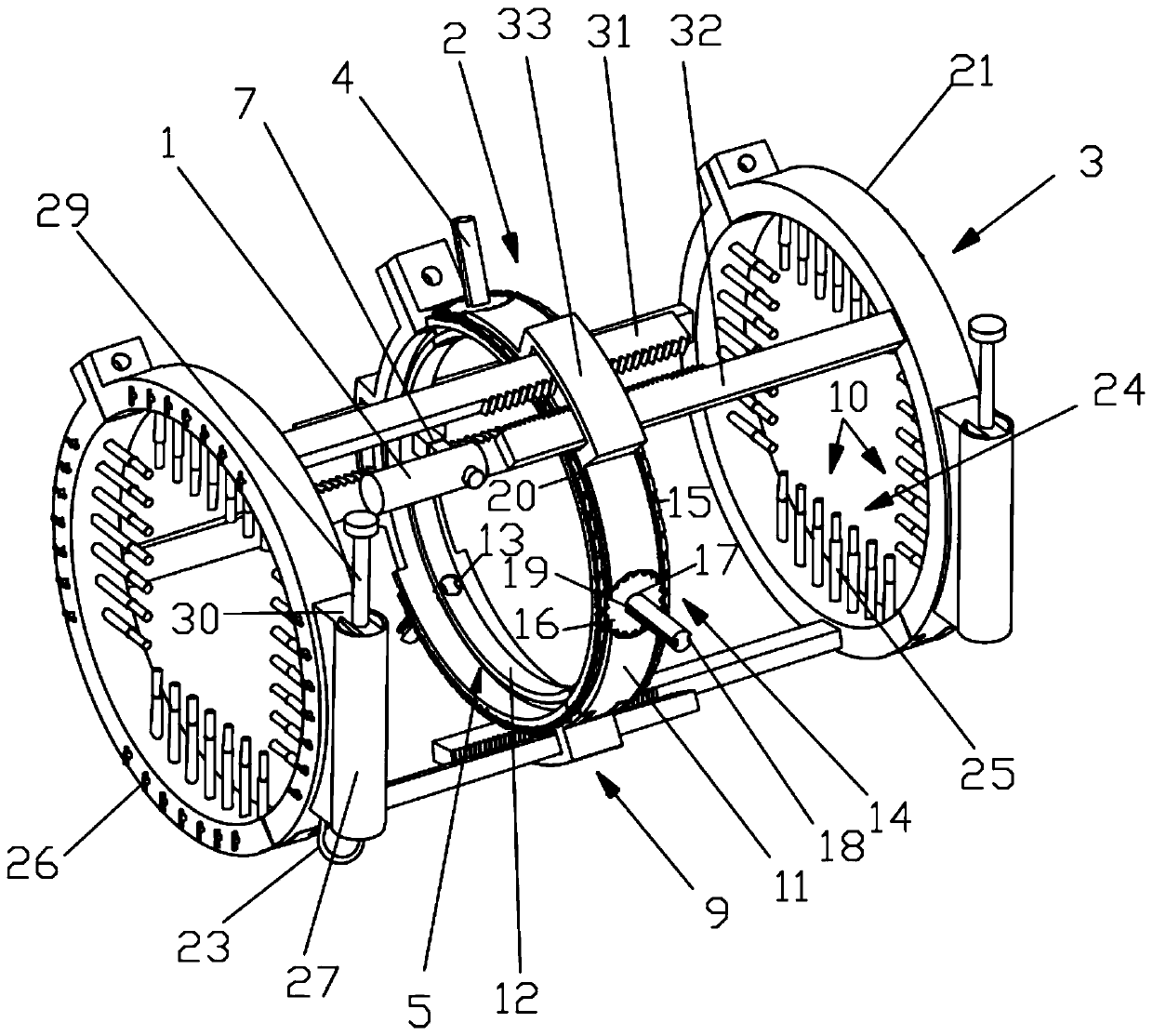

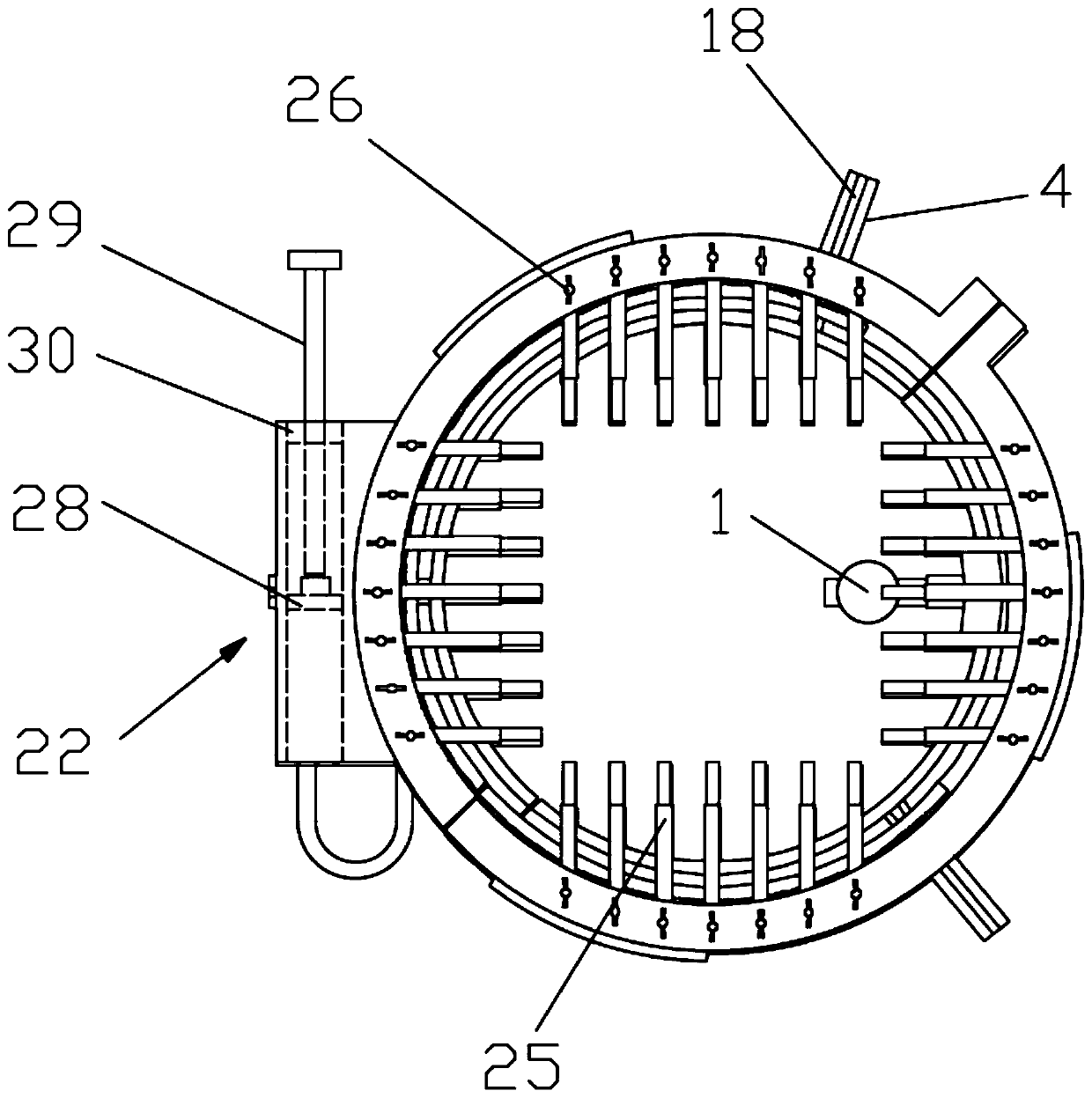

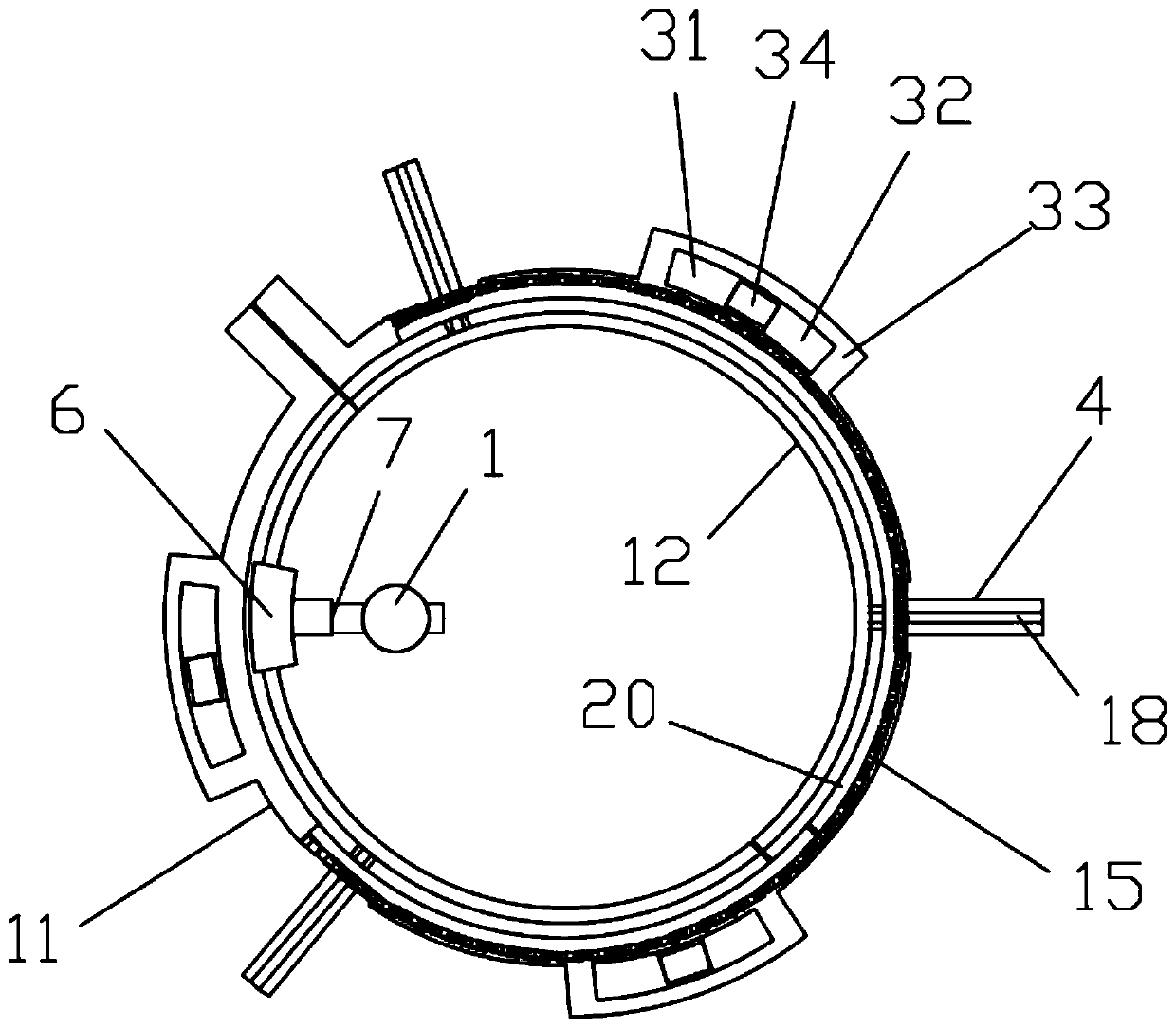

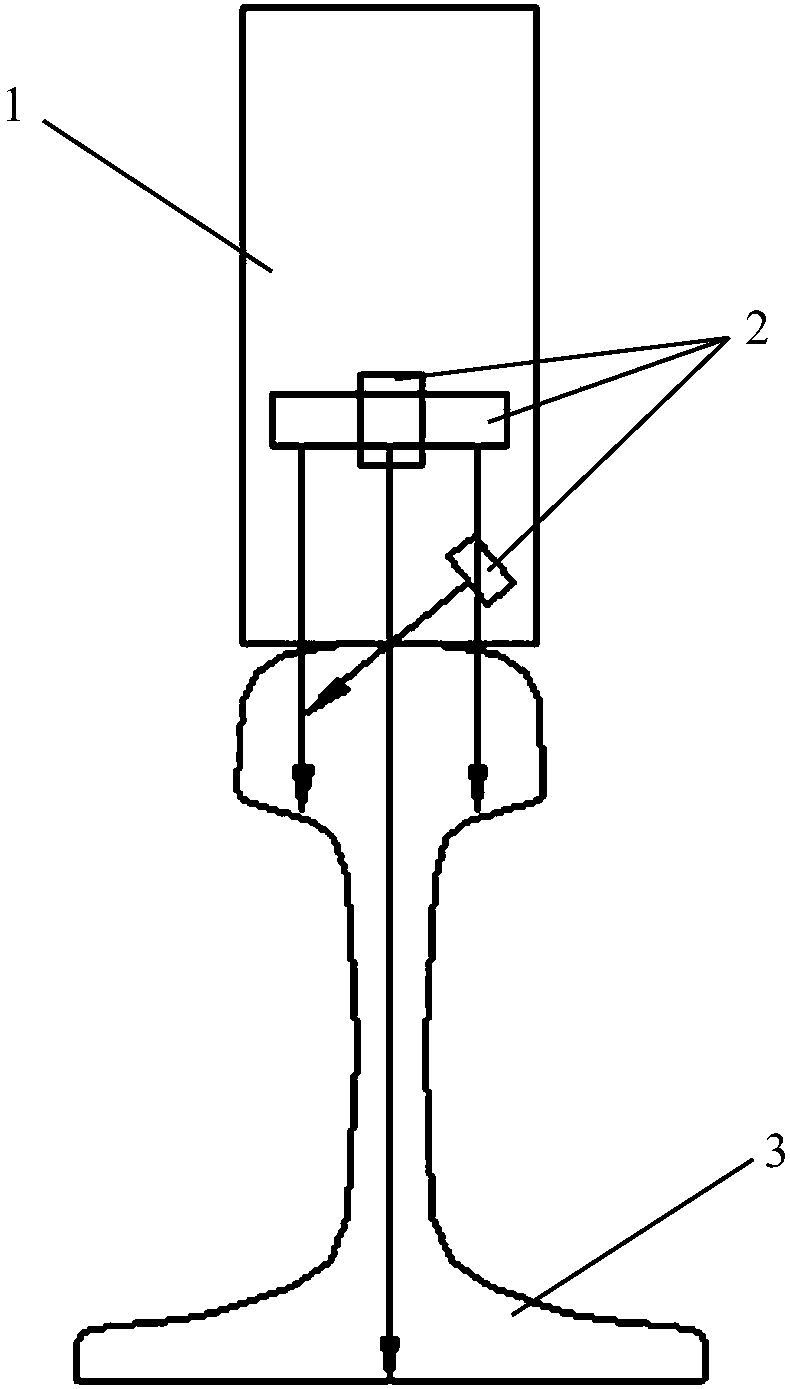

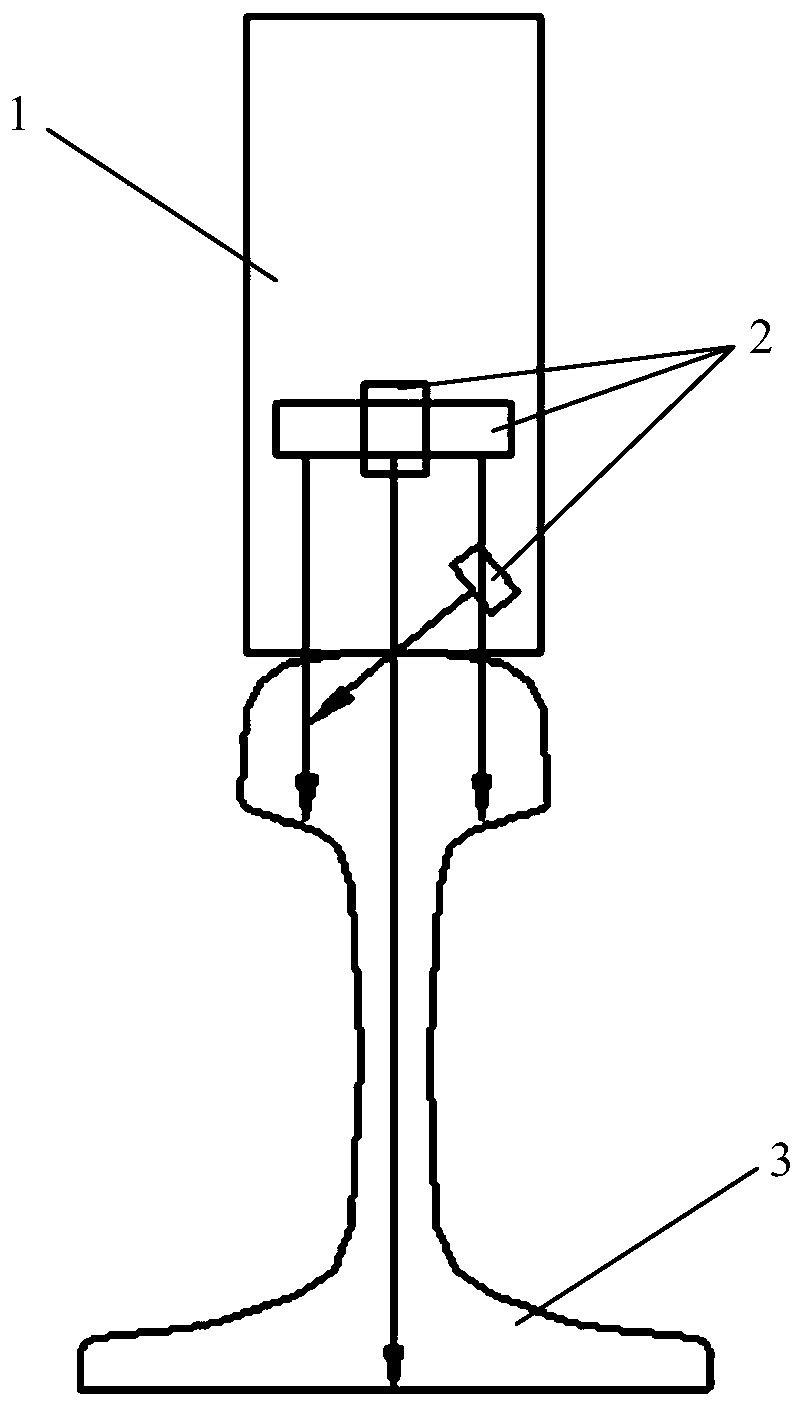

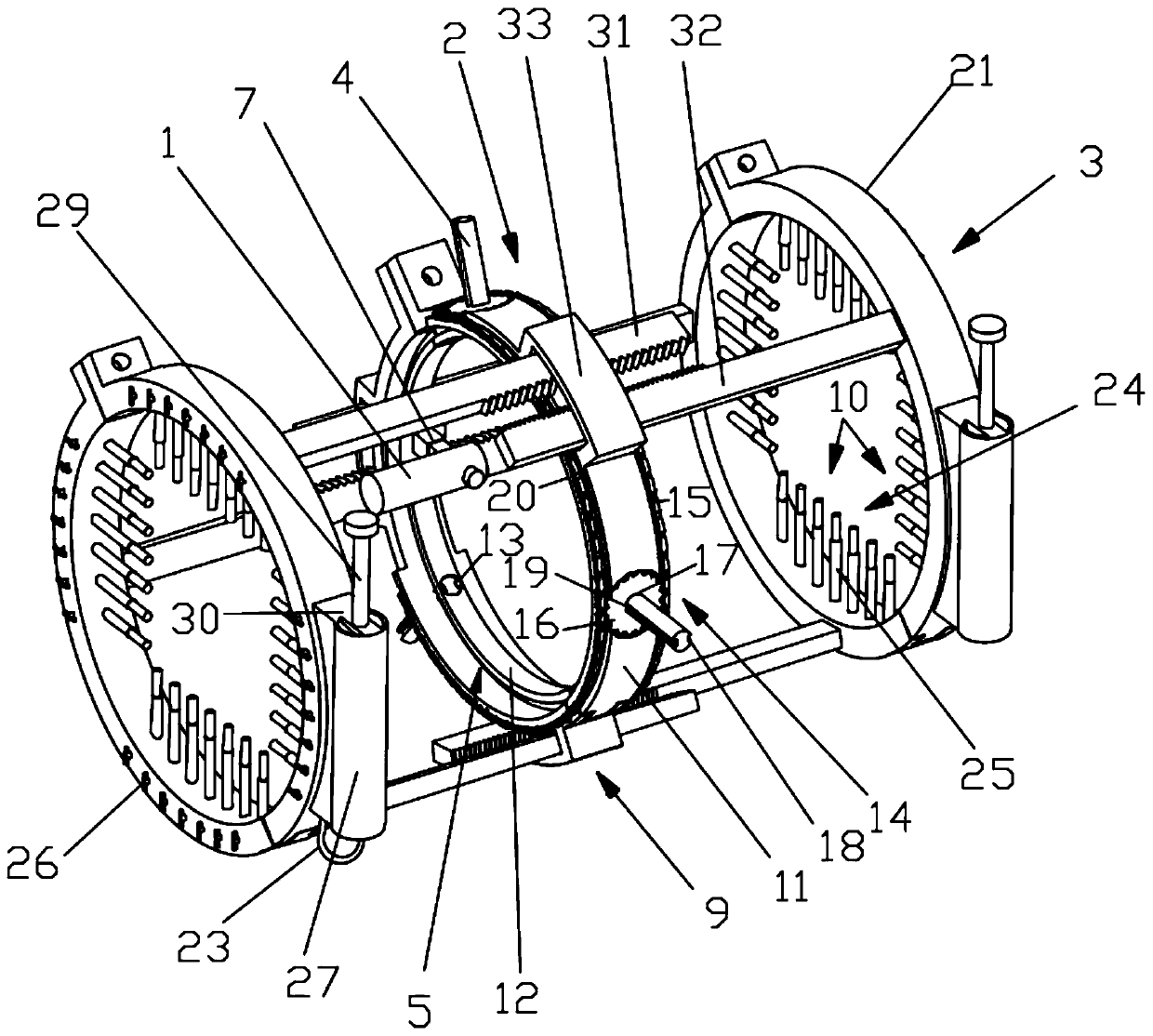

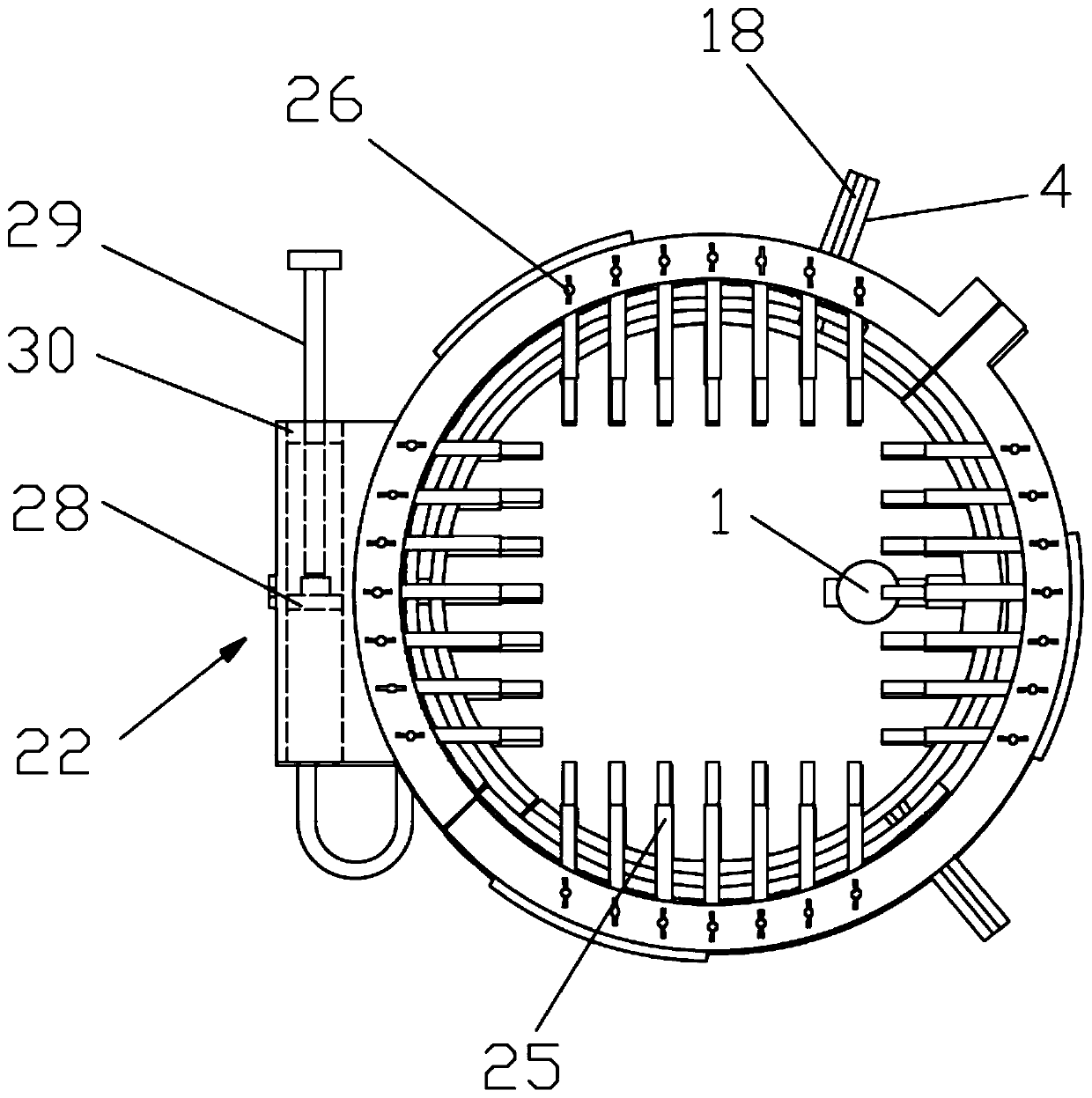

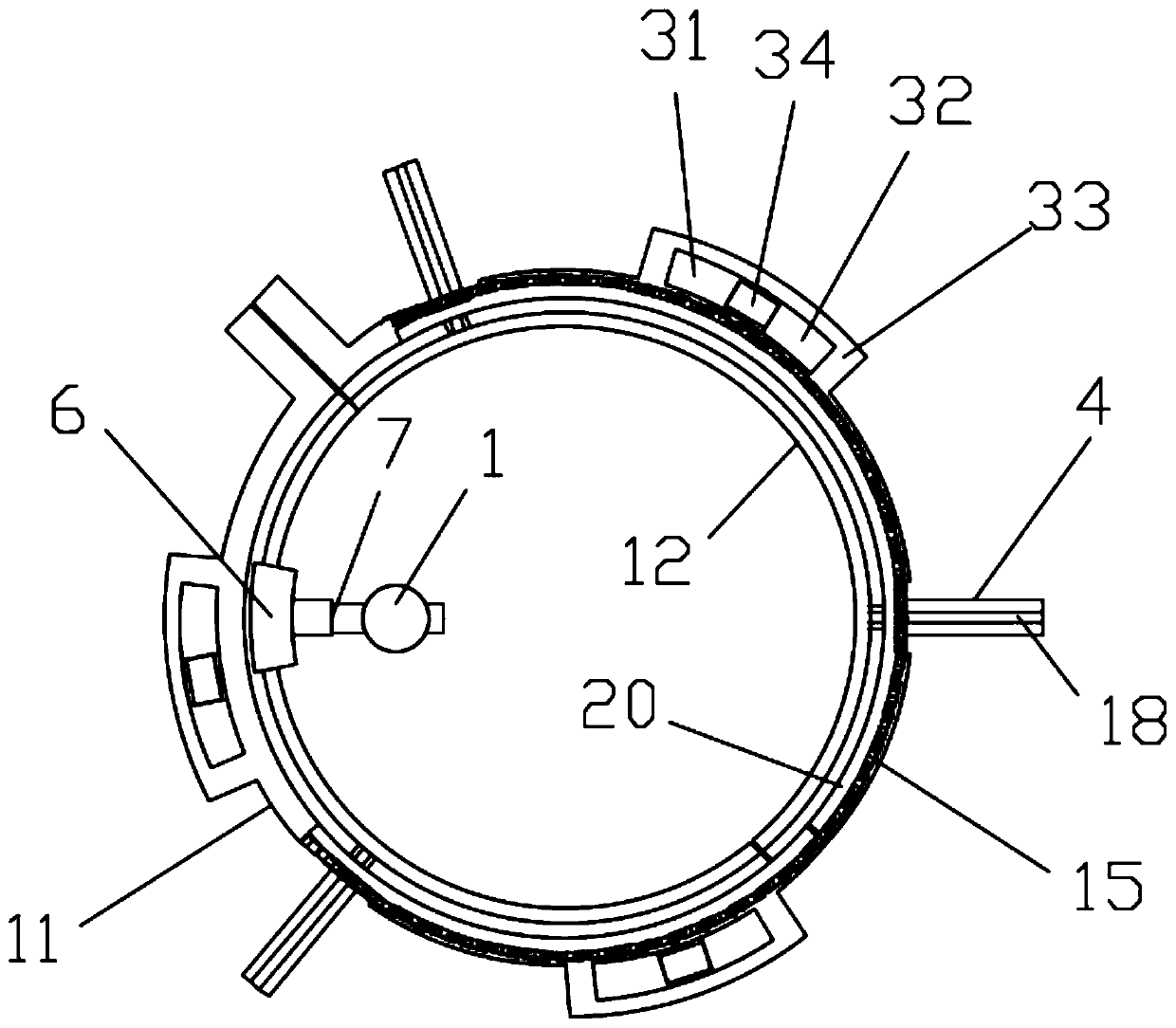

The invention discloses a pipeline ray flaw detection device and a flaw detection method. The pipeline ray flaw detection device comprises a ray flaw detector, a positioning ring and at least two fixing rings; multiple positioning rods are arranged on the positioning ring, the positioning rod and the positioning ring are movably connected to fix a welding line in the middle of the positioning ring; an annular sliding rail is arranged in the positioning ring, a sliding block is arranged on the annular sliding rail, the sliding block is fixedly connected with the ray flaw detector through a telescopic lever; the fixing rings are located at two sides of the positioning ring and connected with the positioning ring through a connecting rod mechanism; and fixing modules for fixing the fixing rings on the pipeline are arranged on the fixing rings. In the process of ensuring the flow detection process of the bend, the detector and the welding line are maintained at the fixed angle and distance, and the flaw detection effect is improved.

Owner:海南民生公用管道检验有限公司

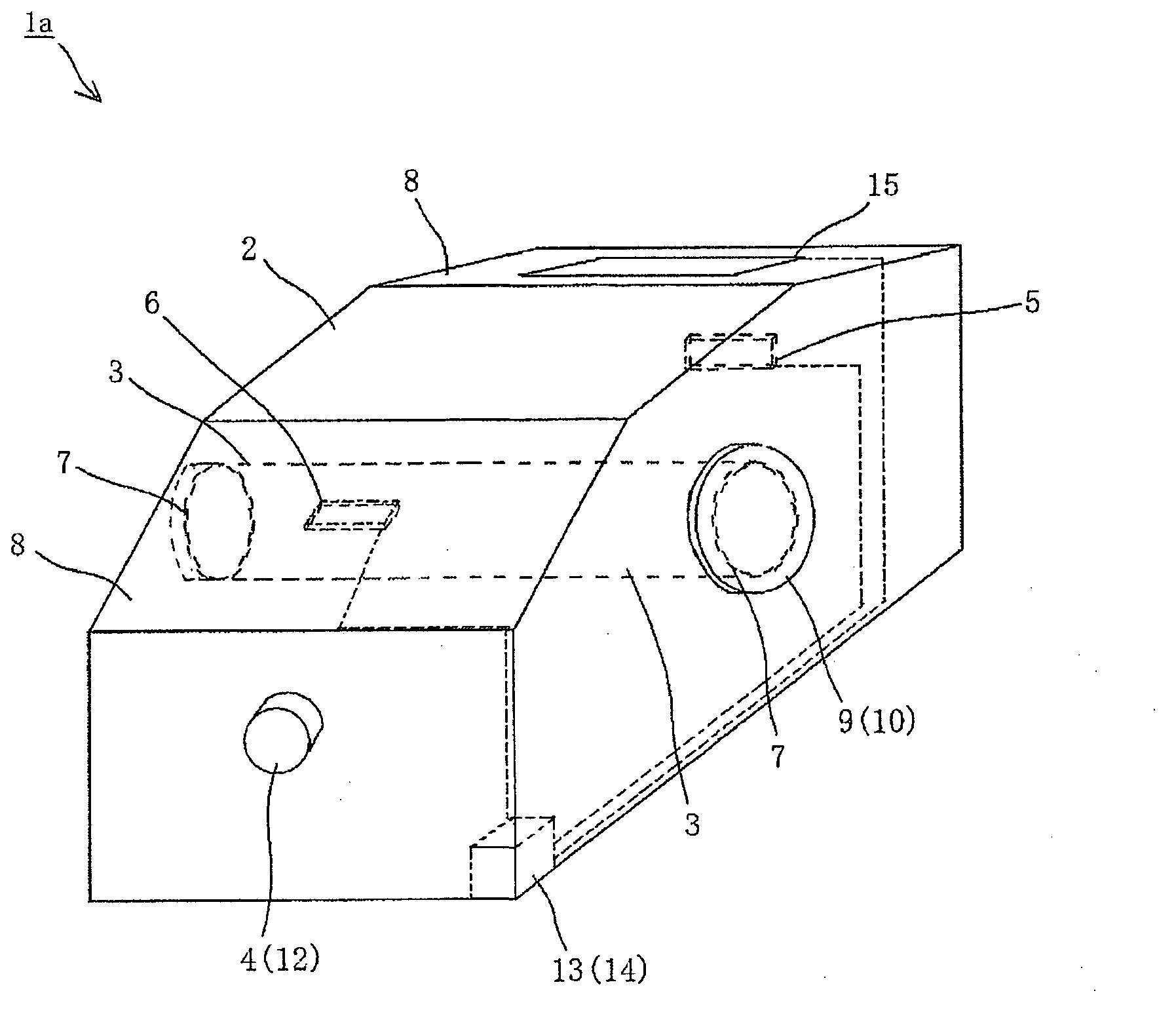

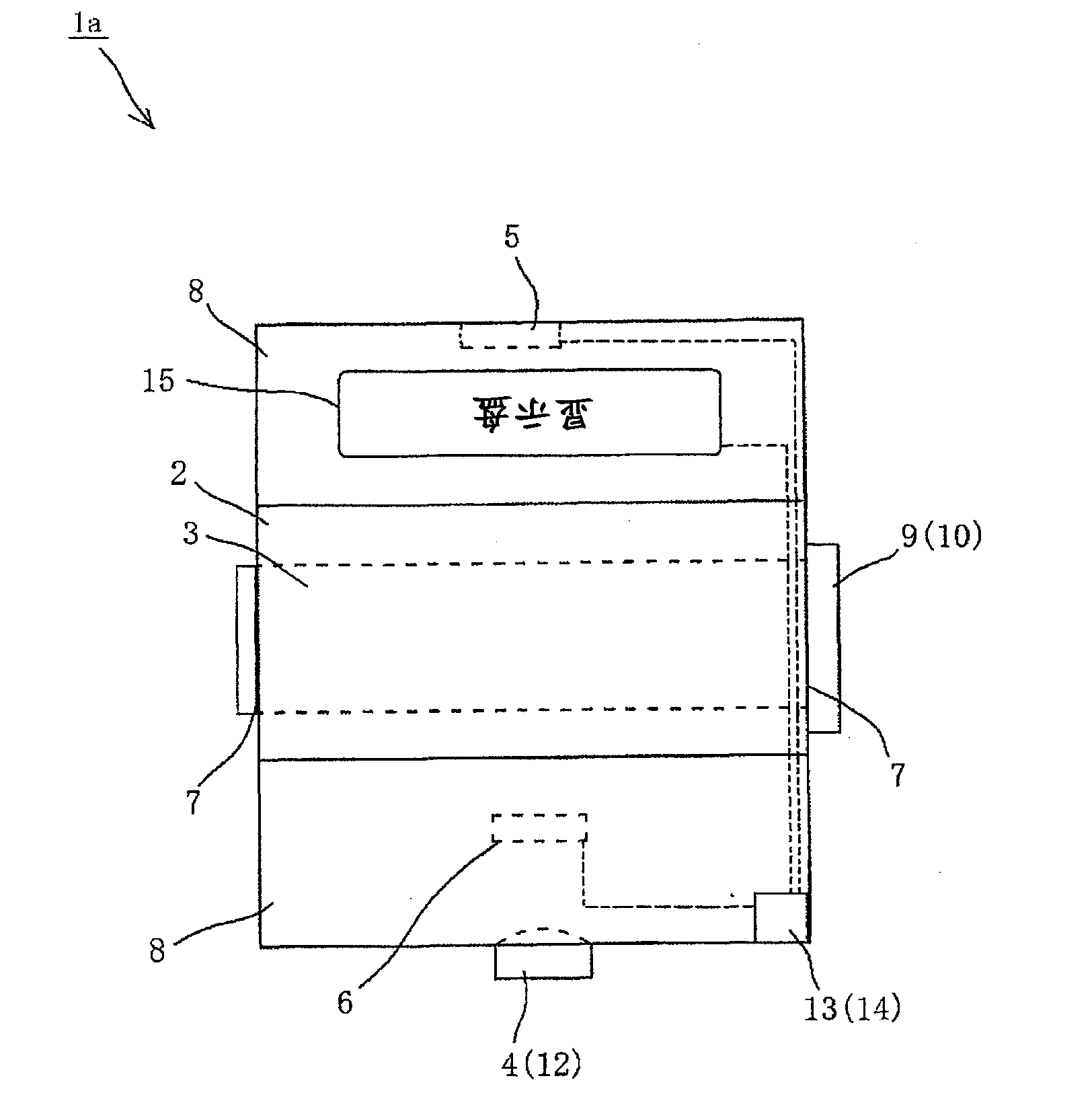

Method and apparatus for measuring the concentration of component in inspection liquid used for wet-type fluorescent magnetic particle testing

ActiveCN102884417AHigh measurement accuracyEasy to operateOptically investigating flaws/contaminationColor/spectral properties measurementsLight sourceSedimentation

In the method, the inspection liquid is stirred and drawn into a transparent measurement container 3. Then, the inspection liquid in the measurement container 3 is irradiated on one side thereof with beams of light from light sources 4a, 4b to capture transmitted beams and visible radiations emitted by excitation. The transmitted beam and the visible radiation are used to measure the concentration of each component in the inspection liquid on the basis of each of the detected values that are provided by detectors 5, 7 for detecting the transmitted beam and a detector 6 for detecting the visible radiation emitted by excitation. The method also measures the concentration of each component in the inspection liquid on the basis of variations in the detected values provided by each detector, the variations resulting from the different sedimentation properties of each component with time.

Owner:MARKTEC CORP

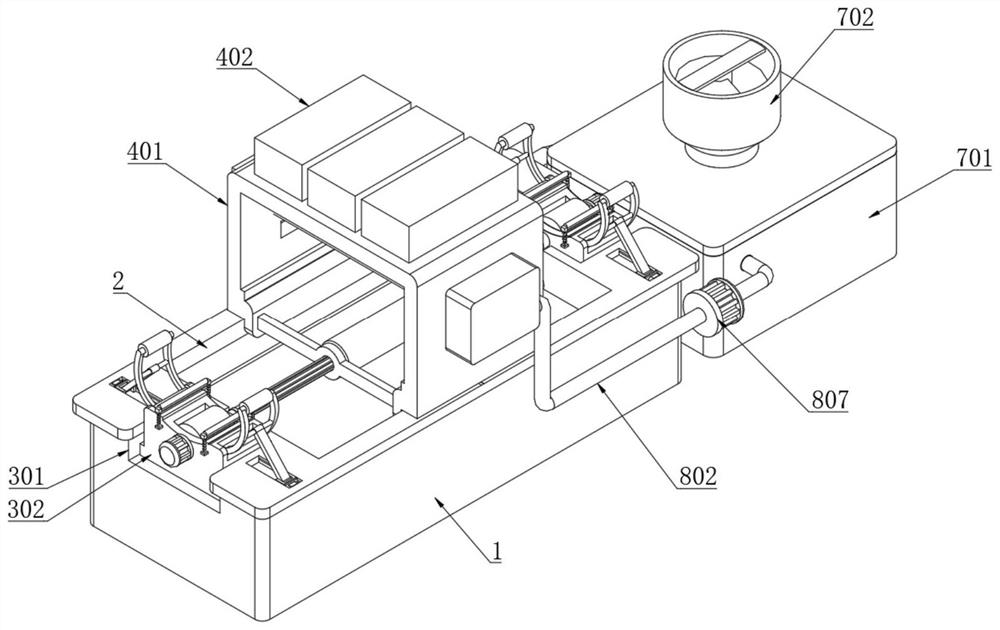

Weld joint nondestructive testing device for pipeline flaw detection

InactiveCN112505059AScientific and reasonable structureEasy to useTransportation and packagingSpraying apparatusLiquid storage tankStructural engineering

The invention discloses a weld joint nondestructive testing device for pipeline flaw detection. The device comprises a machine base, a liquid storage tank is formed in the middle of the top end of themachine base, a wastewater discharging mechanism is arranged in the liquid storage tank, and limiting and screening mechanisms are symmetrically arranged at the positions, corresponding to the two sides of the liquid storage tank, of the top end of the machine base, an efficient spraying mechanism is arranged at the top end, corresponding to the top of the liquid storage tank, of the machine base; each limiting and screening mechanism comprises an embedded groove, a supporting seat and a bearing wheel. The device is scientific and reasonable in structure and safe and convenient to use, the limiting and screening mechanisms are arranged, side guide rollers are pressed to descend through the self-weight of a pipeline, electrode plates at the bottom ends of the side guide rollers are attached to electrode plates at the top ends of bottom blocks, power is supplied to an electromagnet, and electromagnets are matched with magnetic strips, and sliding blocks are pushed to slide, meanwhile, the magnetic force of the electromagnets is increased according to the current conveying strength, and the pushing force of the electromagnets for pushing the magnetic strips is increased, therefore the moving effect of the sliding blocks is guaranteed.

Owner:徐子明

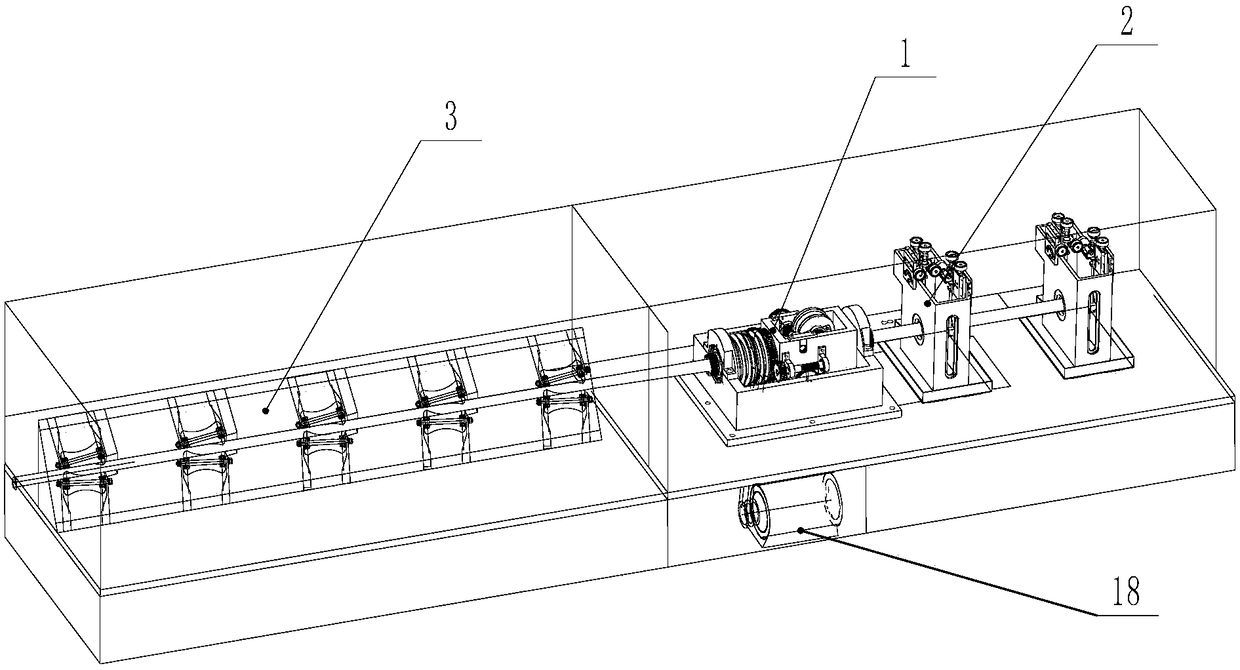

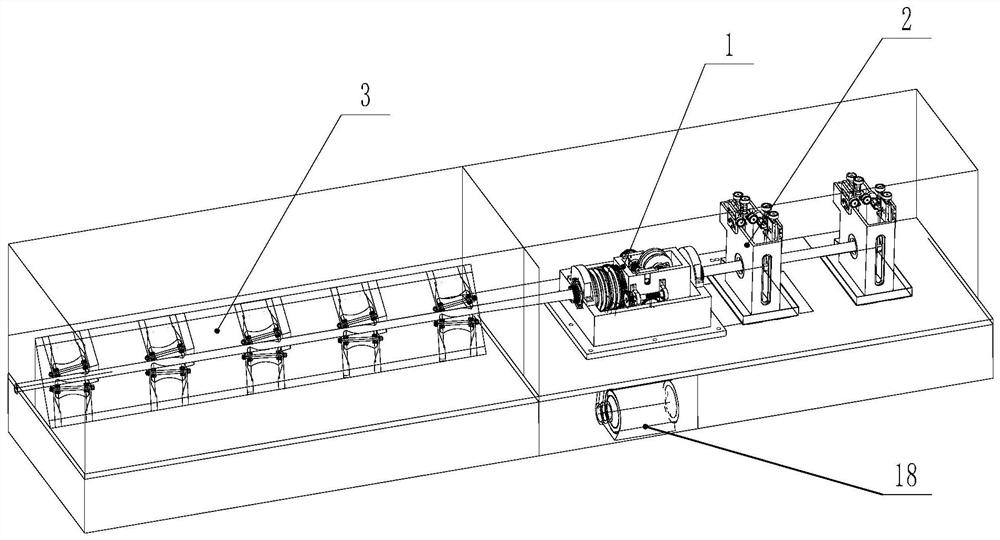

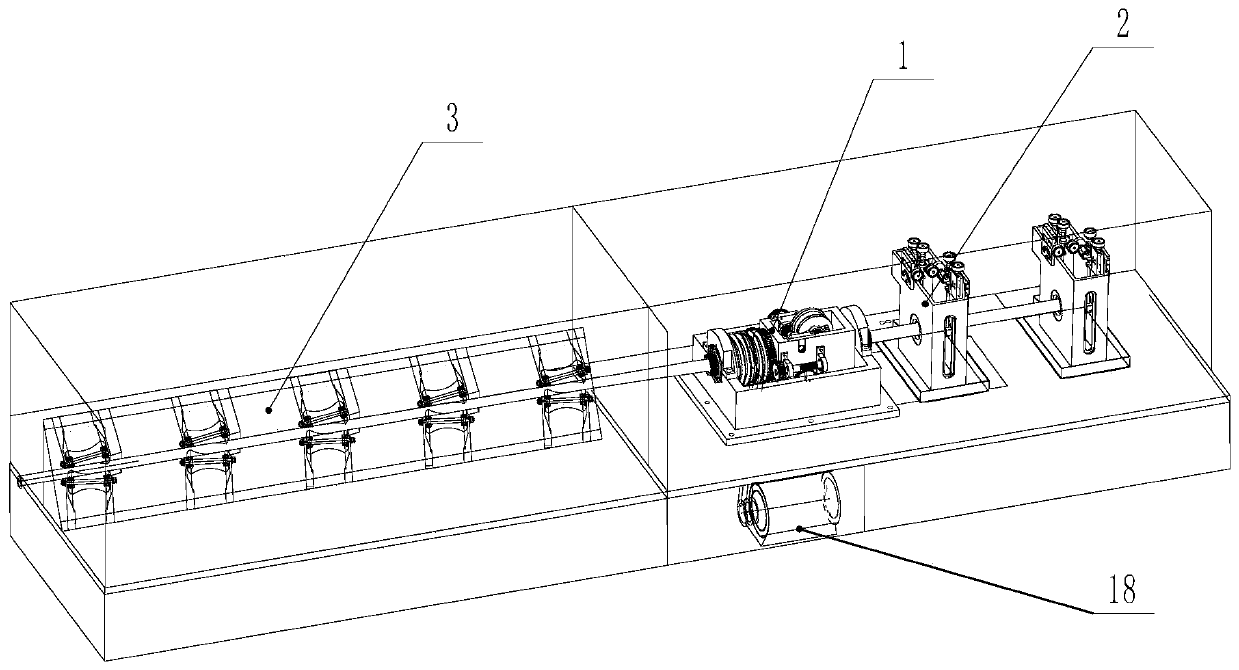

Method for performing rotary feed straightening on metal pipes

ActiveCN109420691AAchieve straighteningImprove the effect of flaw detectionMetal-working feeding devicesPositioning devicesMetal

The invention discloses a method for performing rotary feed straightening on metal pipes. The method comprises the step of realizing feed straightening on the metal pipes by means of straightening rollers arranged in pairs in the process that the metal pipes move forwards in the axial direction, and is characterized in that the metal pipes rotate while moving forwards, and thus, the metal pipes spirally move forwards, and the metal pipes are straightened in the process that the metal pipes spirally move forwards. According to the method disclosed by the invention, the metal pipes can be straightened when being fed before flaw detection so as to improve the flaw detection effect, and the method has the advantages of being simple to implement and having a good straightening effect.

Owner:宝武特冶航研科技有限公司

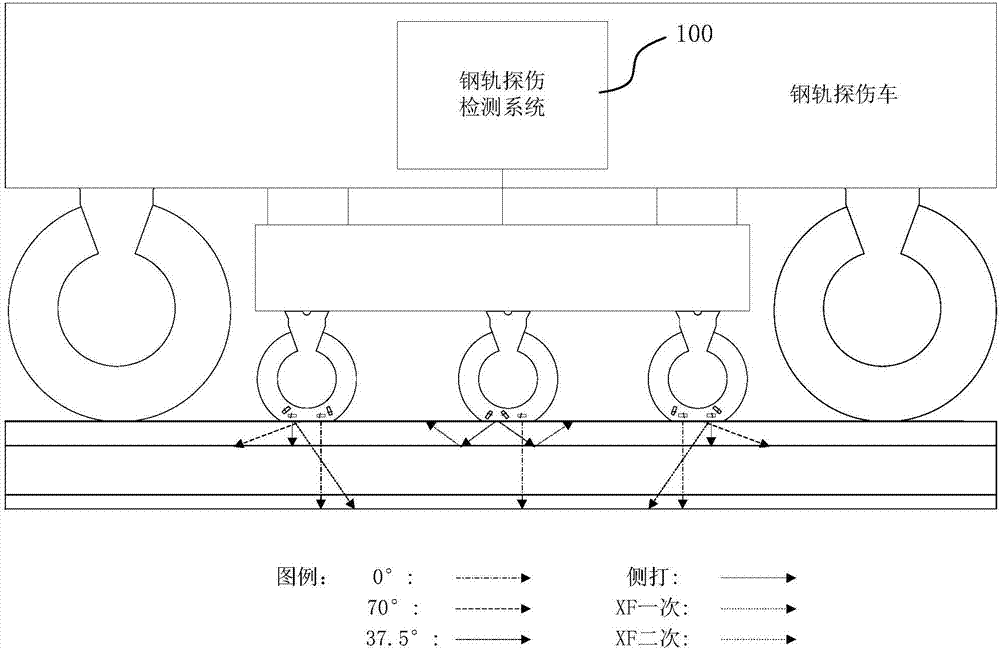

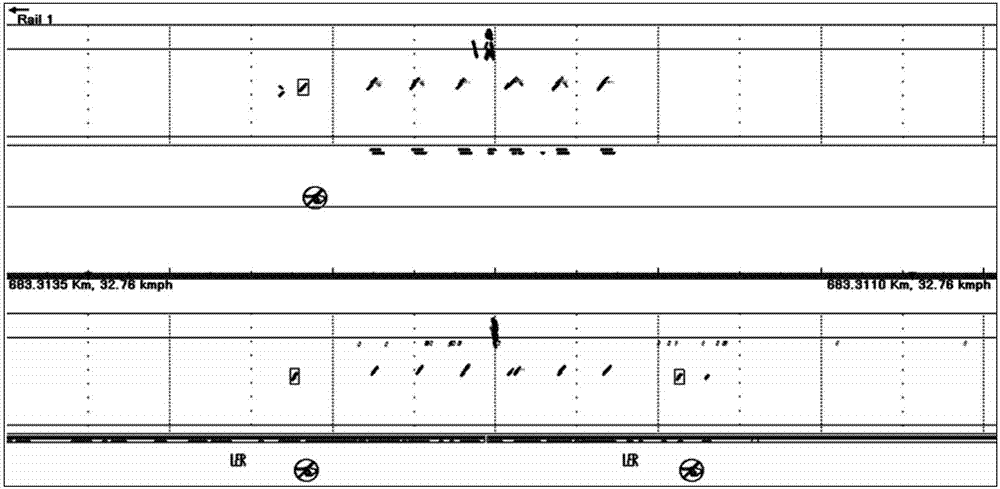

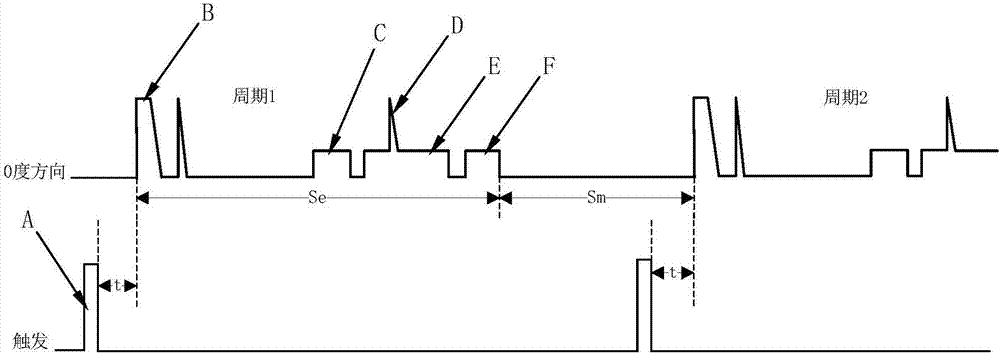

Data display and storage method for steel rail flaw detection operation

InactiveCN107091884AImplement storageAchieve playbackProcessing detected response signalData displaySonification

The invention discloses a data display and storage method for steel rail flaw detection operation. A control unit conducts detection, takes a rising edge or a falling edge of a trigger pulse as an initial point, controls a data acquisition unit to acquire ultrasonic drive signals and ultrasonic echo signals located in an effective gate, outputs the signals to a first input first output (FIFO) memory, simultaneously controls a mileage counting unit to read encoder counted mileage corresponding to the initial point, and then outputs fixed-format data formed by combining the encoder counted mileage and the signals acquired by the data acquisition unit to the FIFO memory. A control unit extracts and compresses data cached in the FIFO memory in a segmented mode, and uploads the data into a real-time controller memory. A real-time controller transmits the data in the memory to an upper computer in real time, the data are processed through the upper computer, A-type display data are sent to an A-type display unit to be displayed, and meanwhile, the A-type display data are sent to a storage unit to be stored. By adoption of the data display and storage method for steel rail flaw detection operation, the technical problems that multiple channels for an existing steel rail flaw detection operation data display and storage mode exist, the data size is large, and the A display data fail to be stored can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

Method for improving core quality and flaw detection eligibility rate of super-thick steel plate

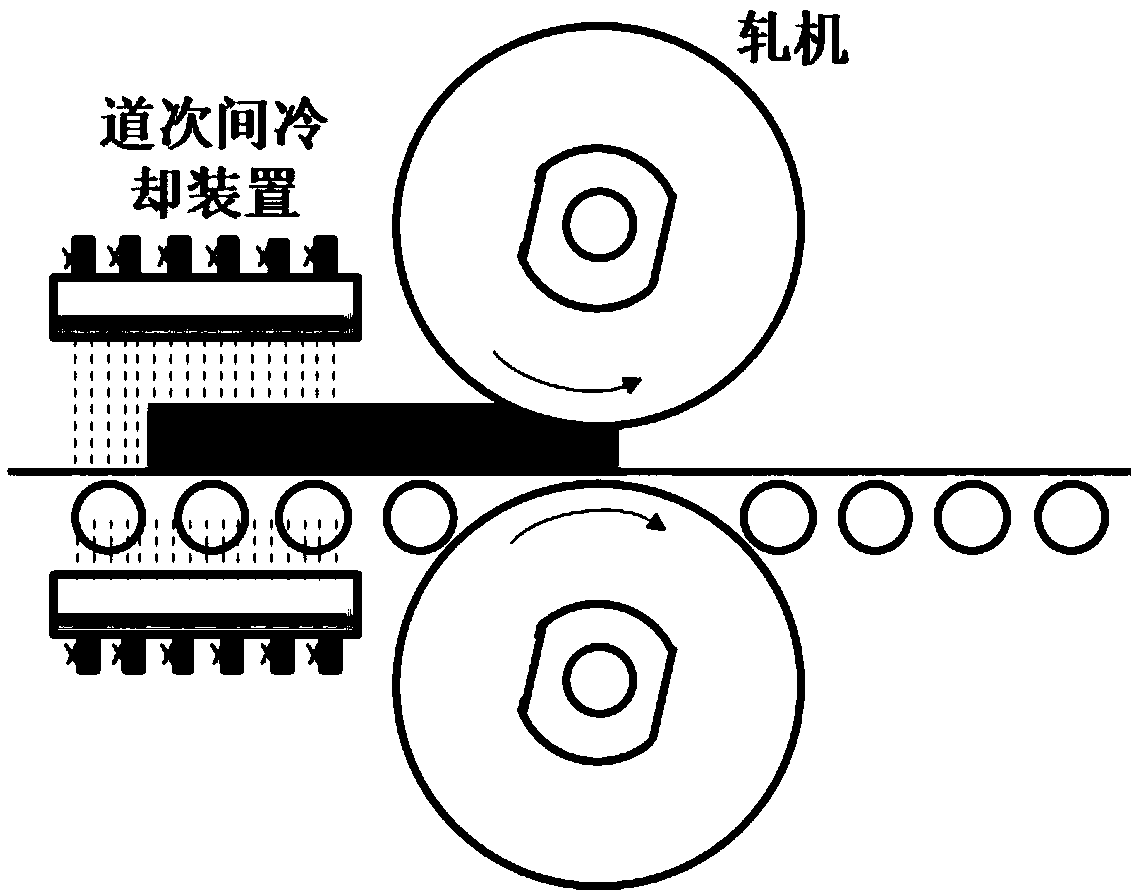

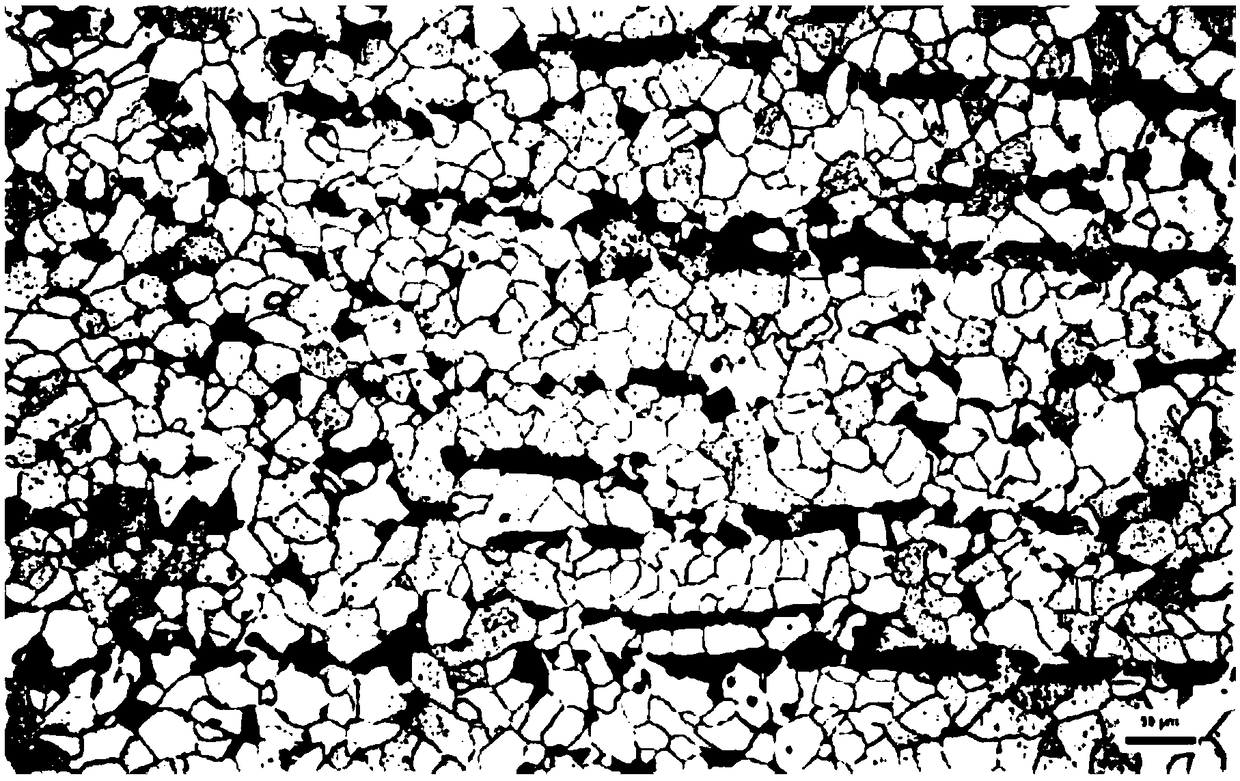

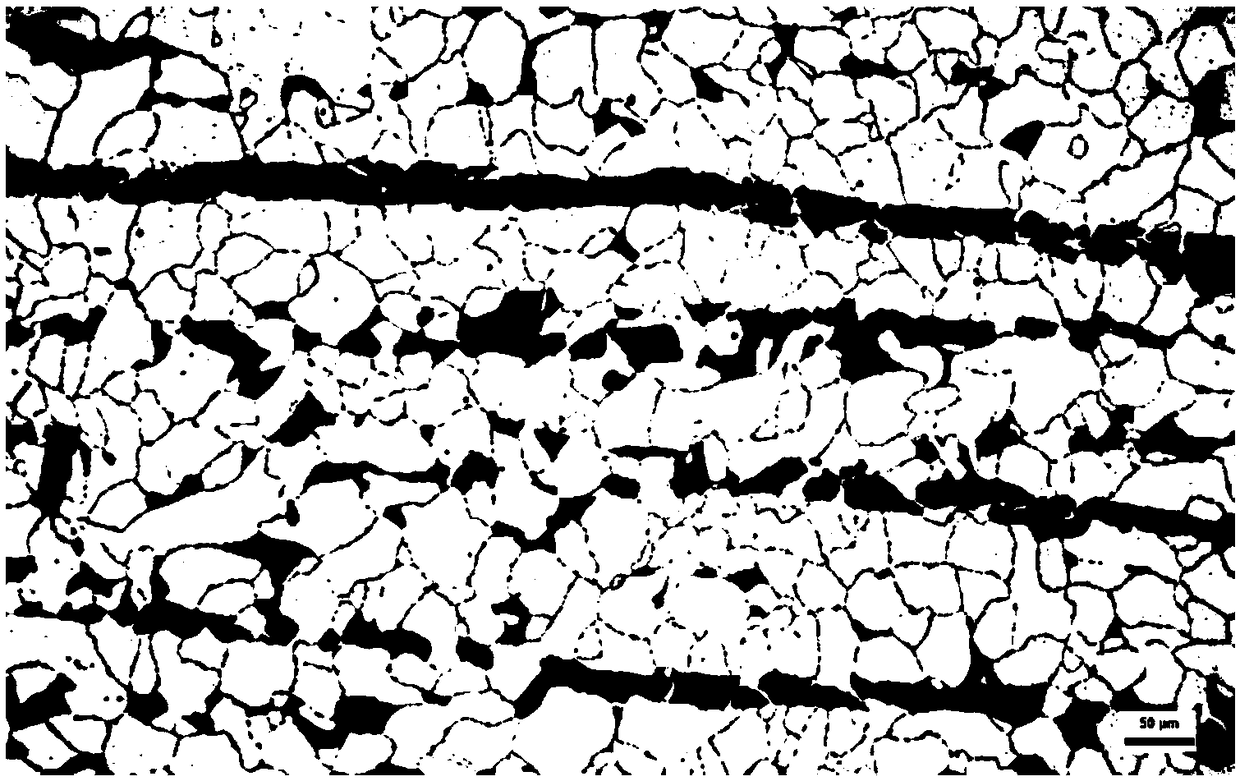

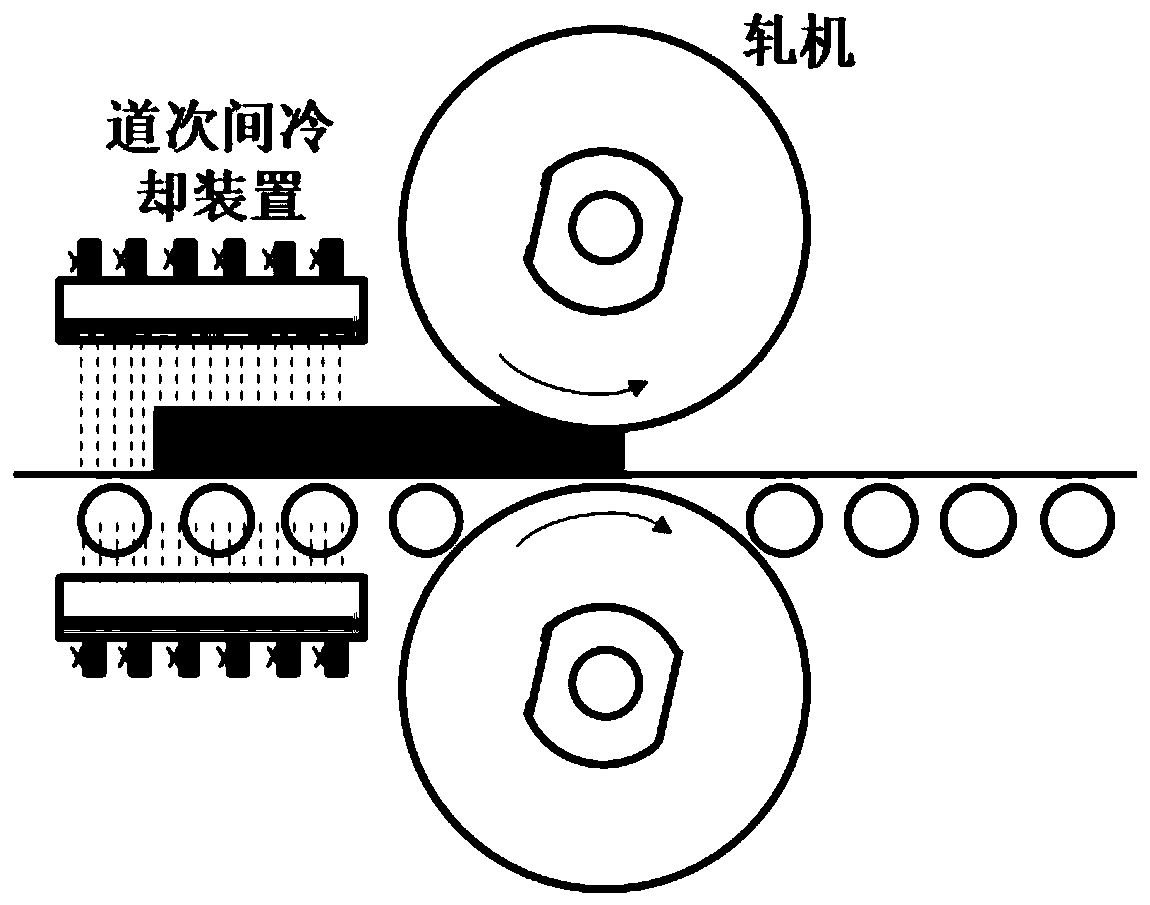

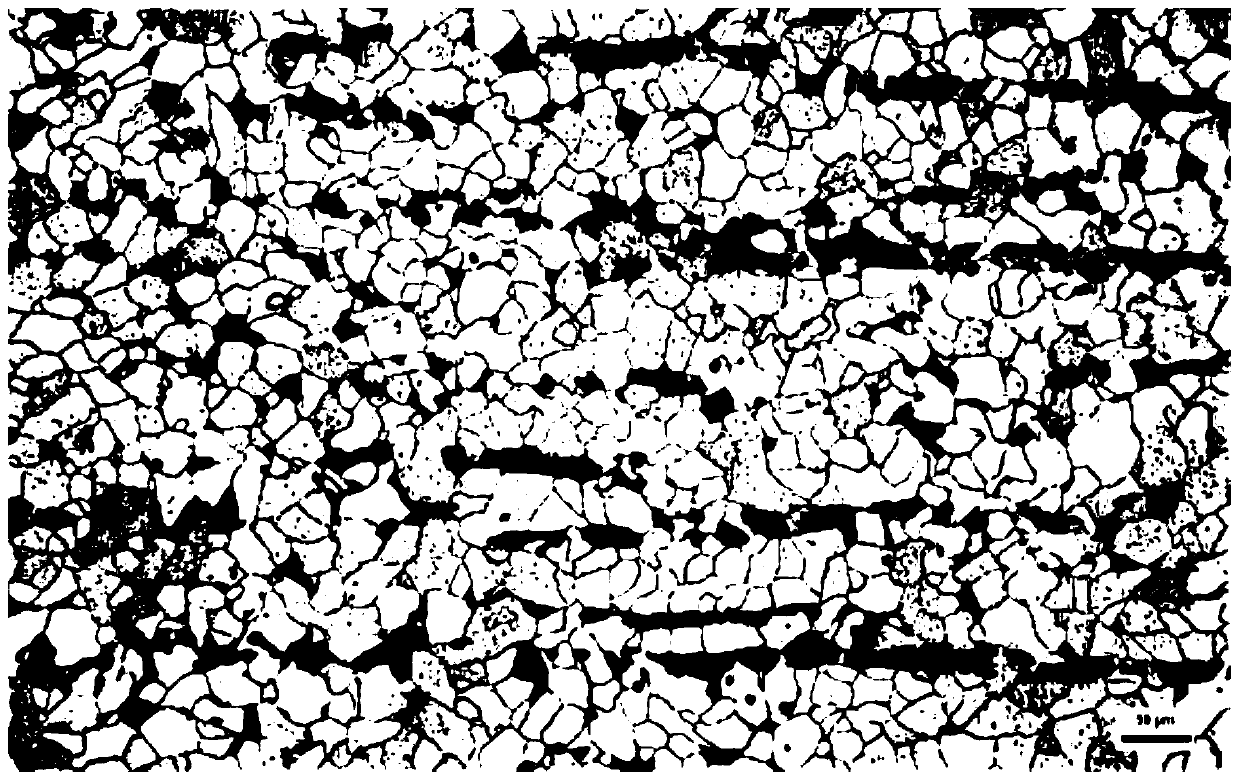

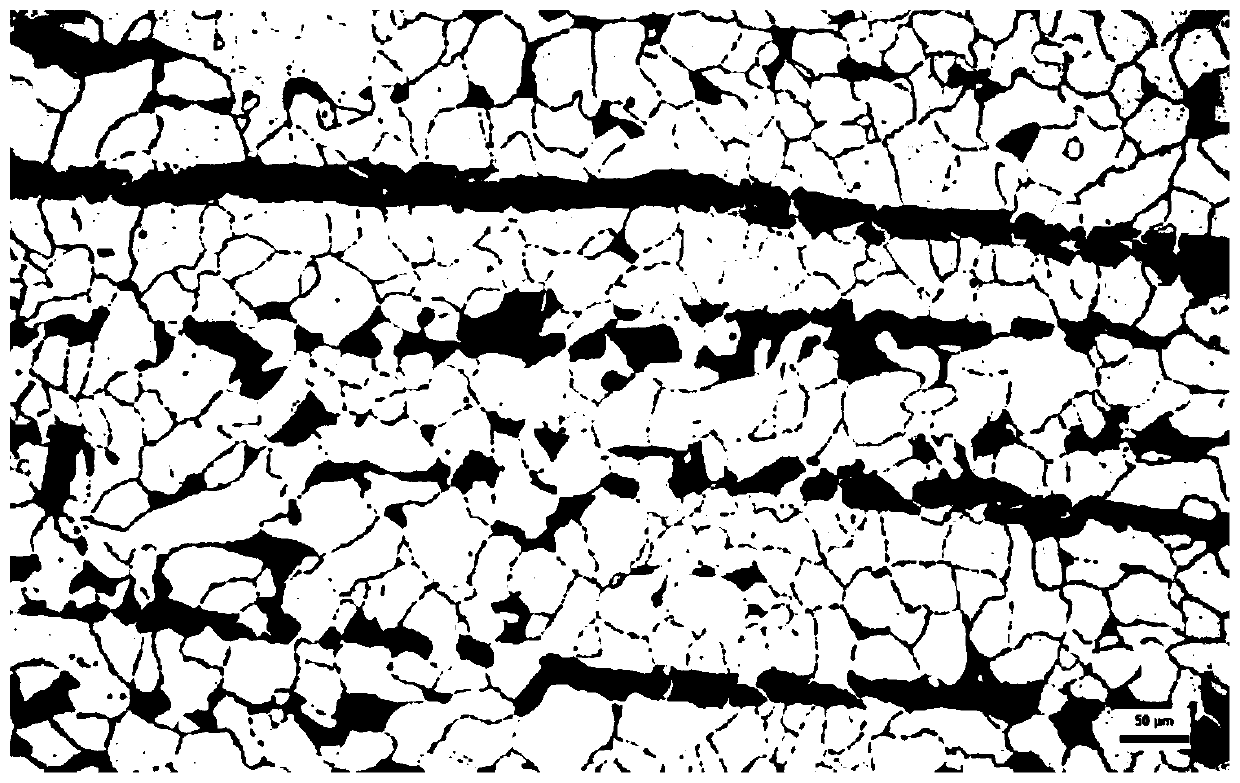

ActiveCN109013711ASave rolling waiting timeReduce waiting timeProfile control deviceReduction rateSteelmaking

The invention provides a method for improving the core quality and the flaw detection eligibility rate of a super-thick steel plate, and belongs to the technical field of ferrous metallurgy. The method improves the core quality and the flaw detection eligibility rate of the super-thick steel plate (greater than or equal to 80mm) based on an inter-pass on-line instant cooling system, and the methodcomprises the following specific process steps that when a continuous casting billet (greater than or equal to 200mm) is not subjected to converter steelmaking or enters into a longitudinal rolling stage after the converter steelmaking is completed, one or more passes of on-line cooling is carried out in a rolling gap by using an instant cooling system near a rolling mill, an initial surface temperature is 850-1000 DEG C, the continuous casting billet enters a cooling zone at a speed of 2-6m / s, the roll speed in the cooling zone is 1-3m / s, the water supply and drainage ratio is (1:2)-(1:6), the total flow of a single group of headers is 200-400m<3> / h, after cooling is performed, the return temperature is controlled at 750-900 DEG C for rolling, and the reduction rate after cooling is greater than 12%. The method for improving the core quality and the flaw detection eligibility rate of the super-thick steel plate enables a core part of the thick plate to be increased through temperature difference rolling, the core quality and the flaw detection eligibility rate are significantly improved, and the yield is further increased.

Owner:NORTHEASTERN UNIV

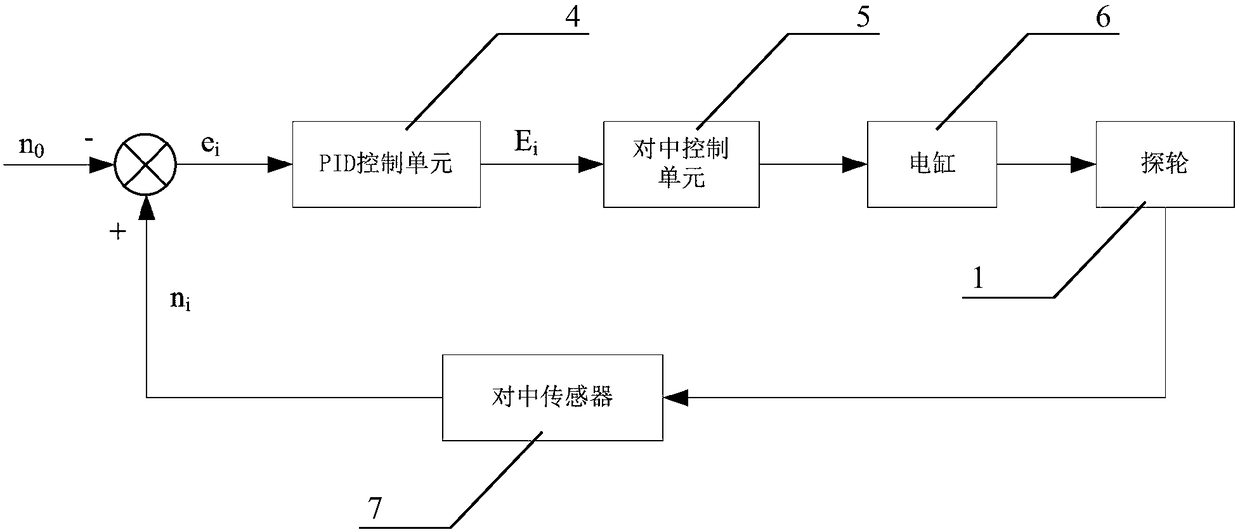

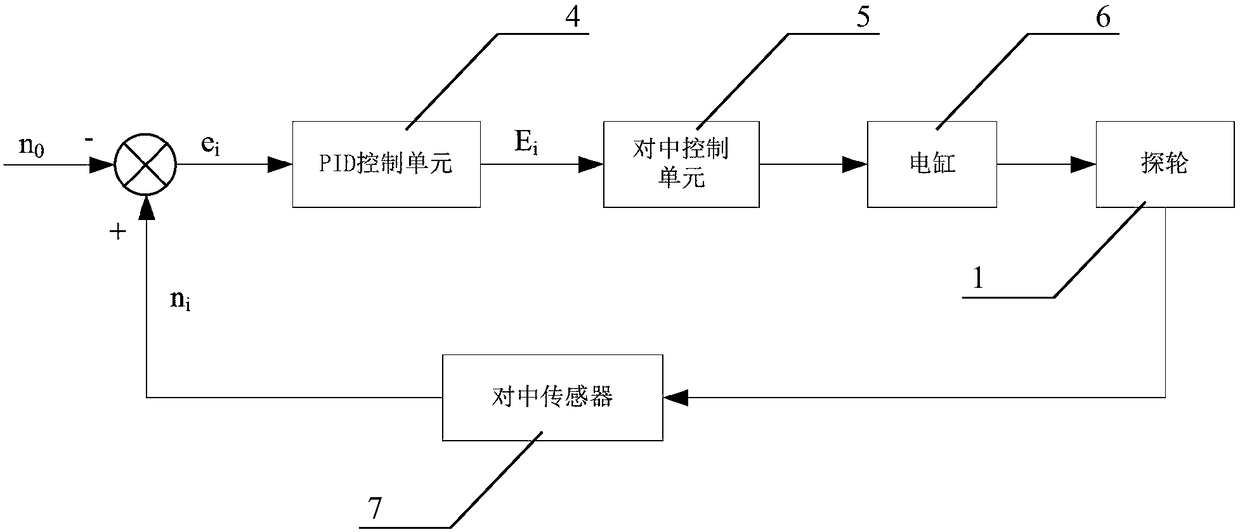

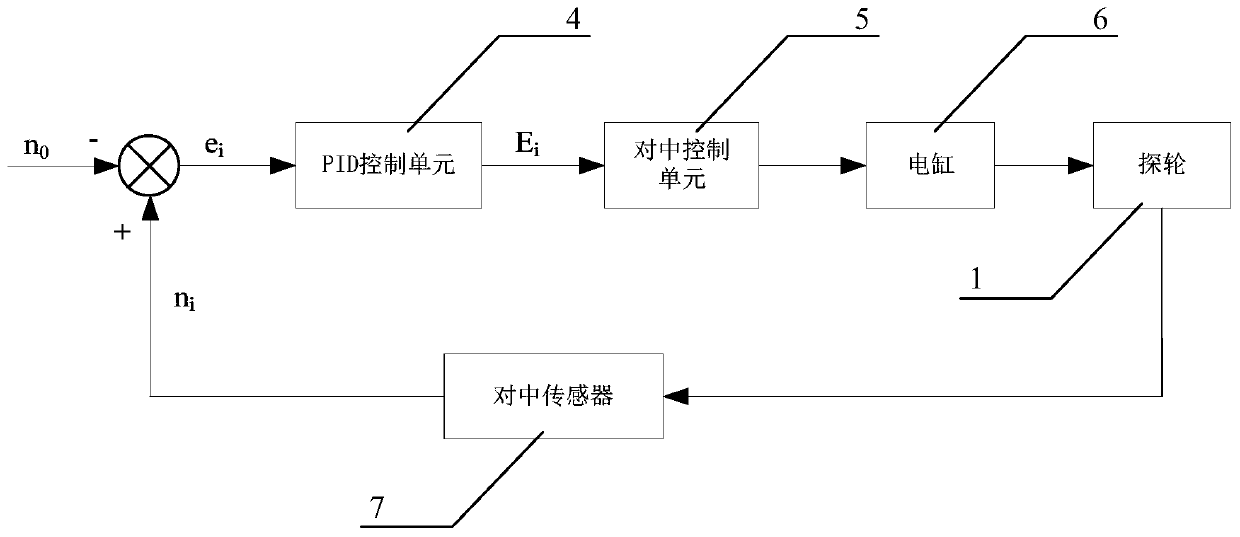

Automatic aligning control method with wearing compensation

ActiveCN108415243AGood effectSolve technical problems with missing bottom wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesControllers with particular characteristicsControl theory

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

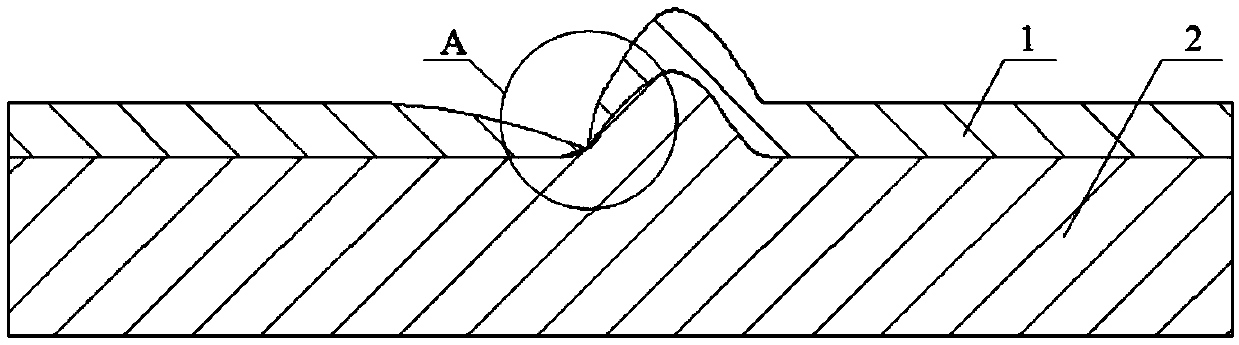

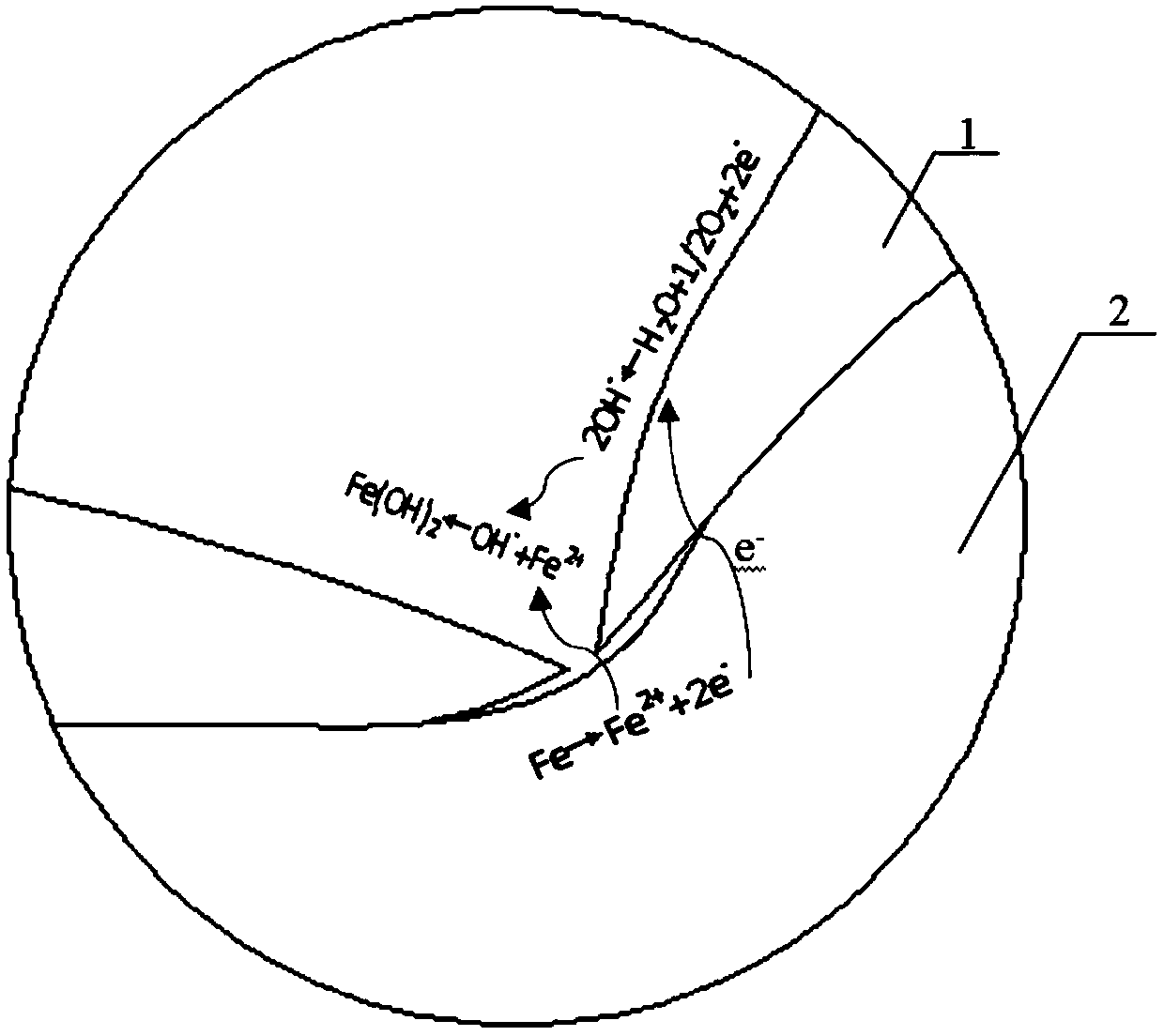

Flaw detecting method for stainless steel/carbon steel composite material

InactiveCN109557107AAccurate flaw detectionEasy to detectPreparing sample for investigationOptically investigating flaws/contaminationCarbon steelGreen rust

The invention discloses a flaw detecting method for a stainless steel / carbon steel composite material. Dark green rust spots appear after the stainless steel / carbon steel composite material is immersed in a sodium chloride solution for a period of time. The portion where the dark green rust spot are located is a damaged portion. Compared with the conventional flaw detecting method, the invention has the advantages of accuracy and low cost.

Owner:南工大溧阳新材料研发中心有限公司

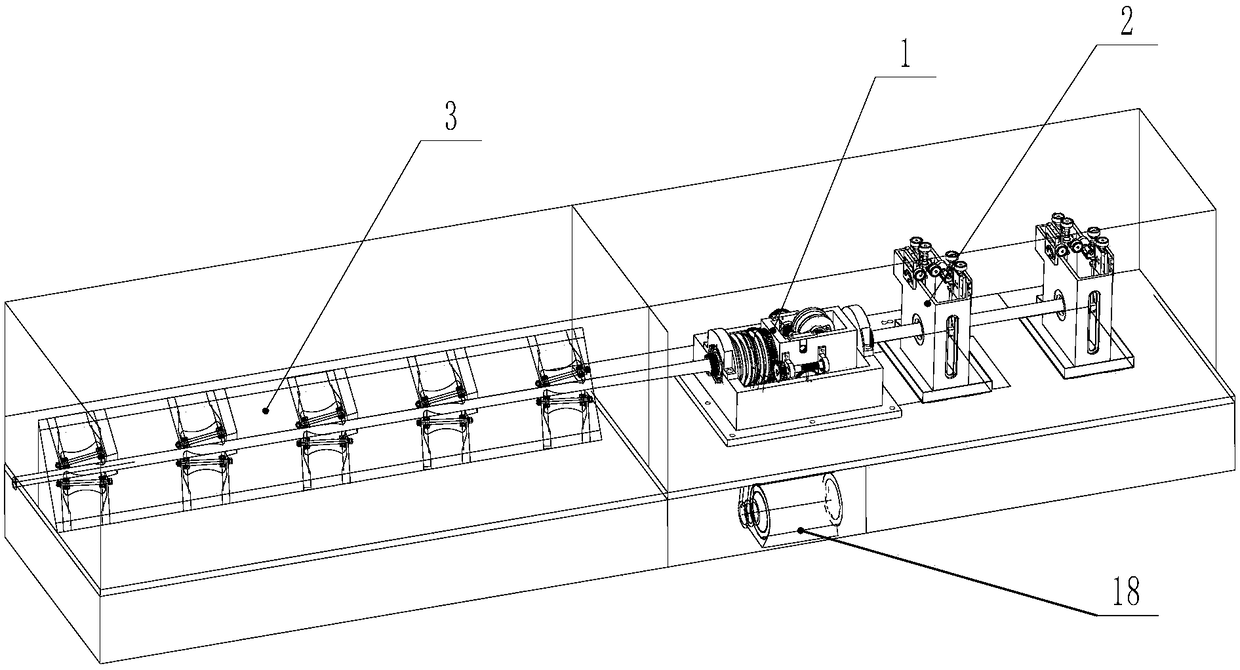

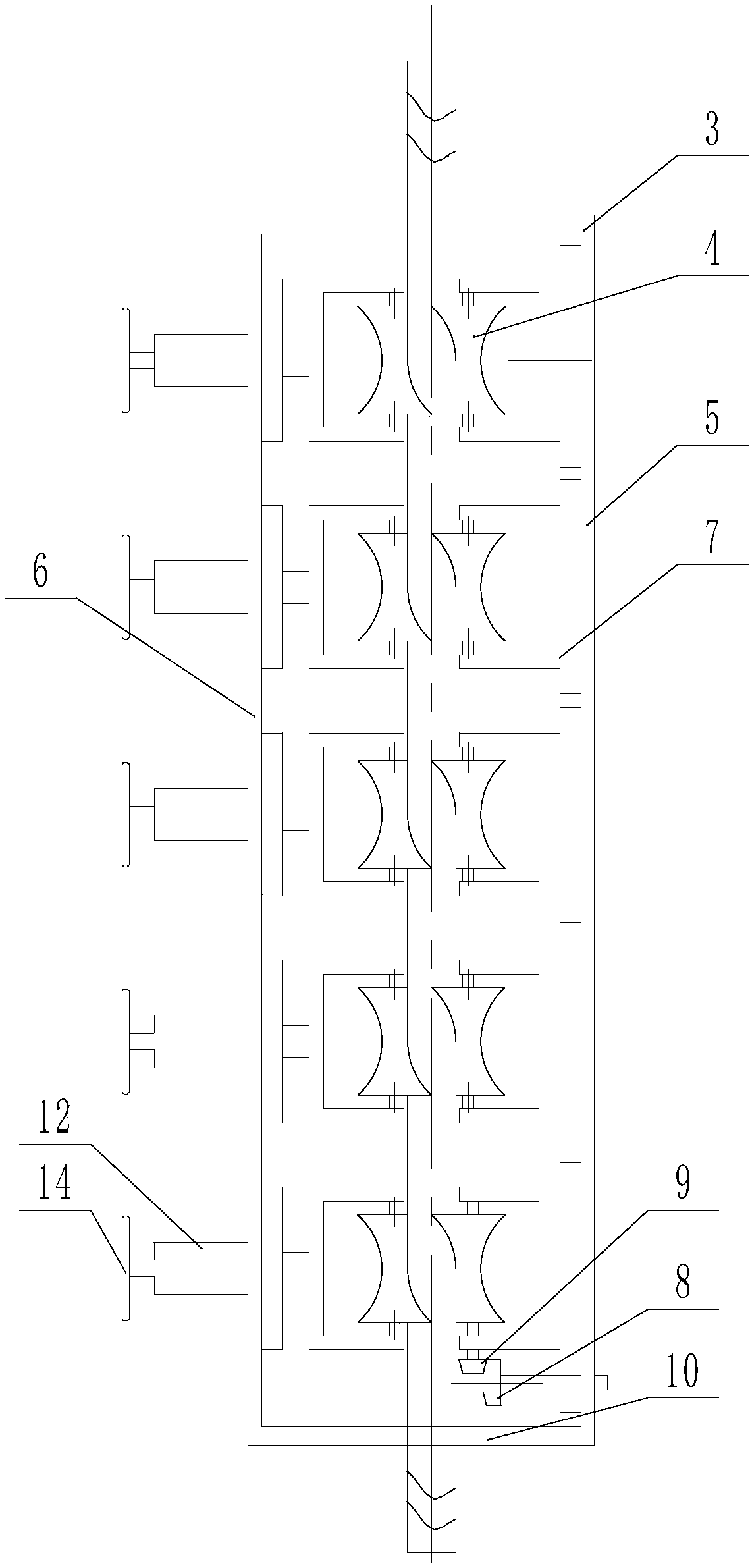

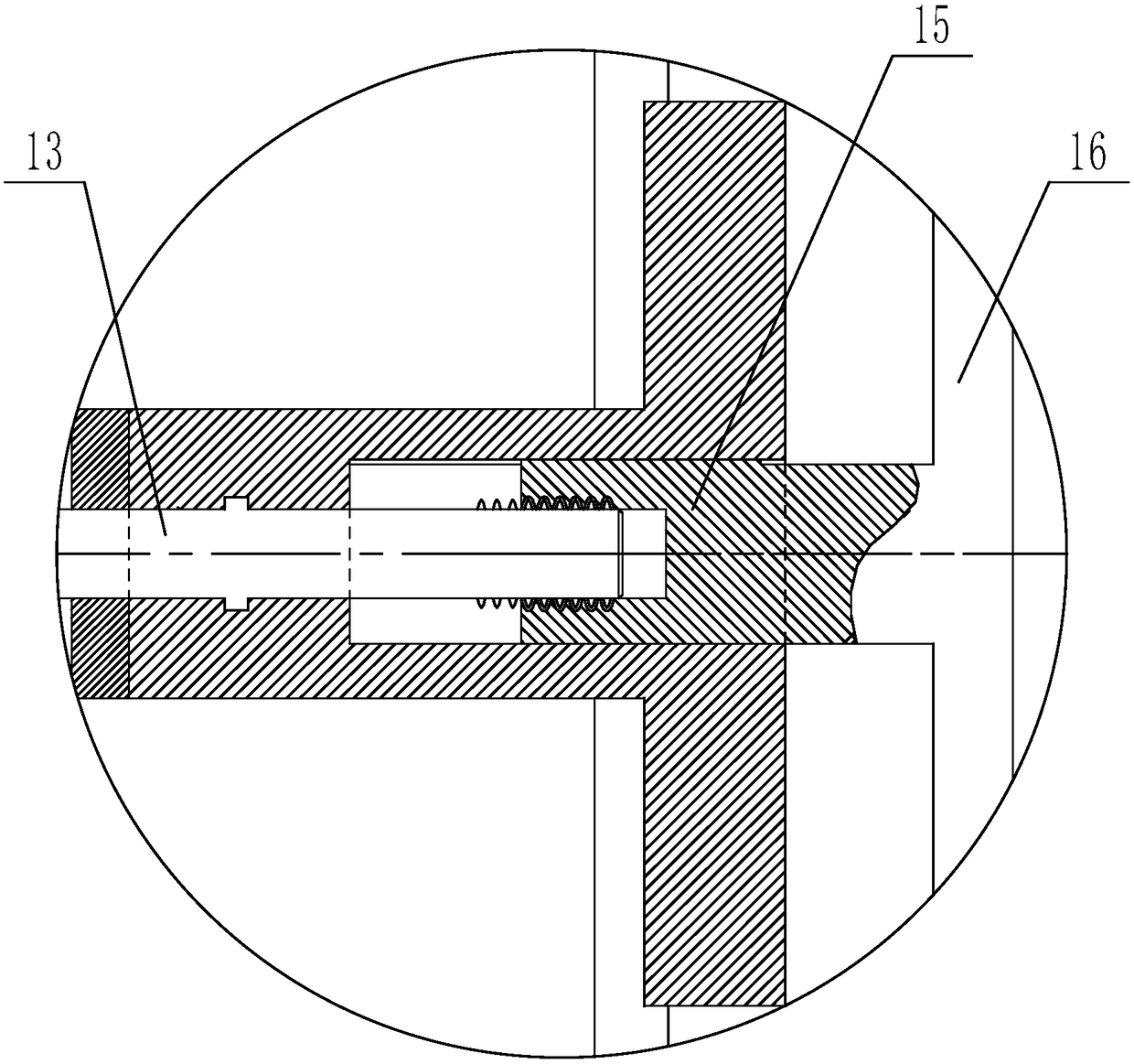

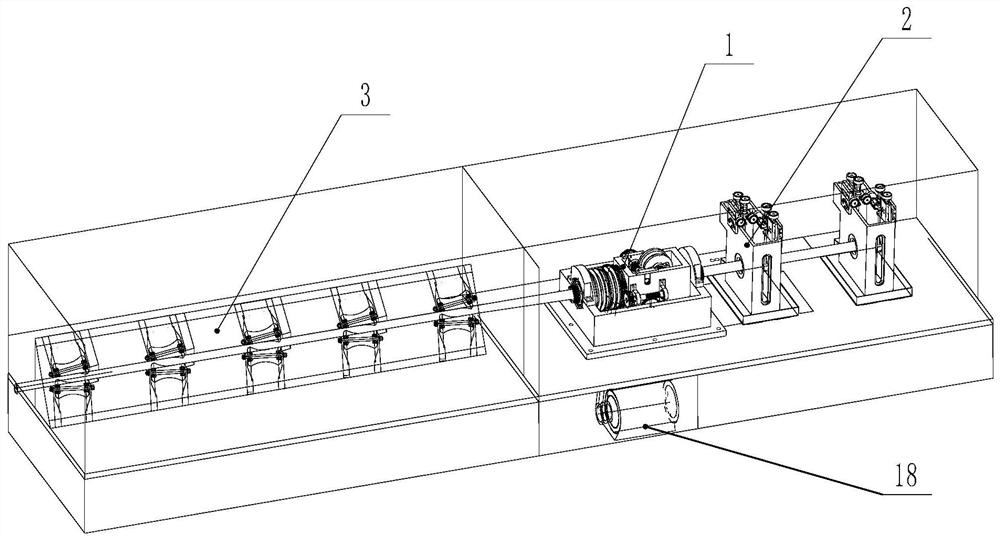

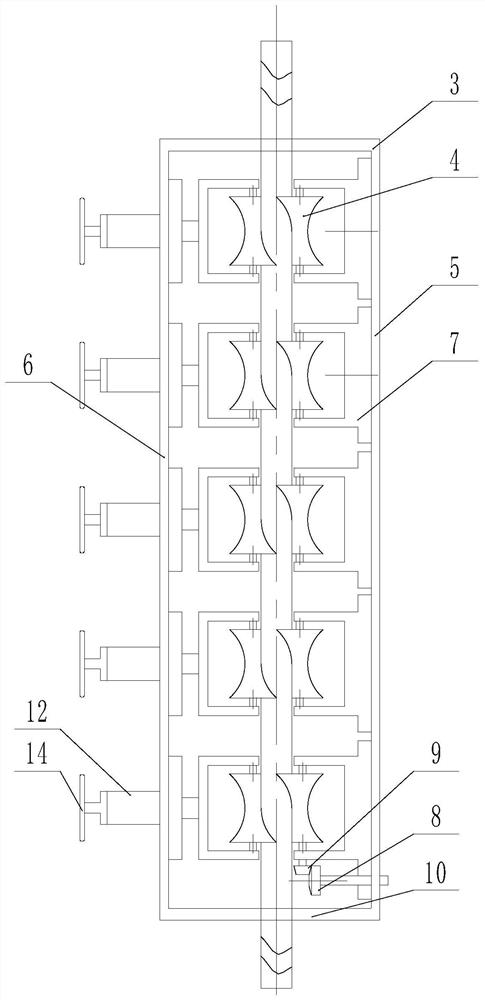

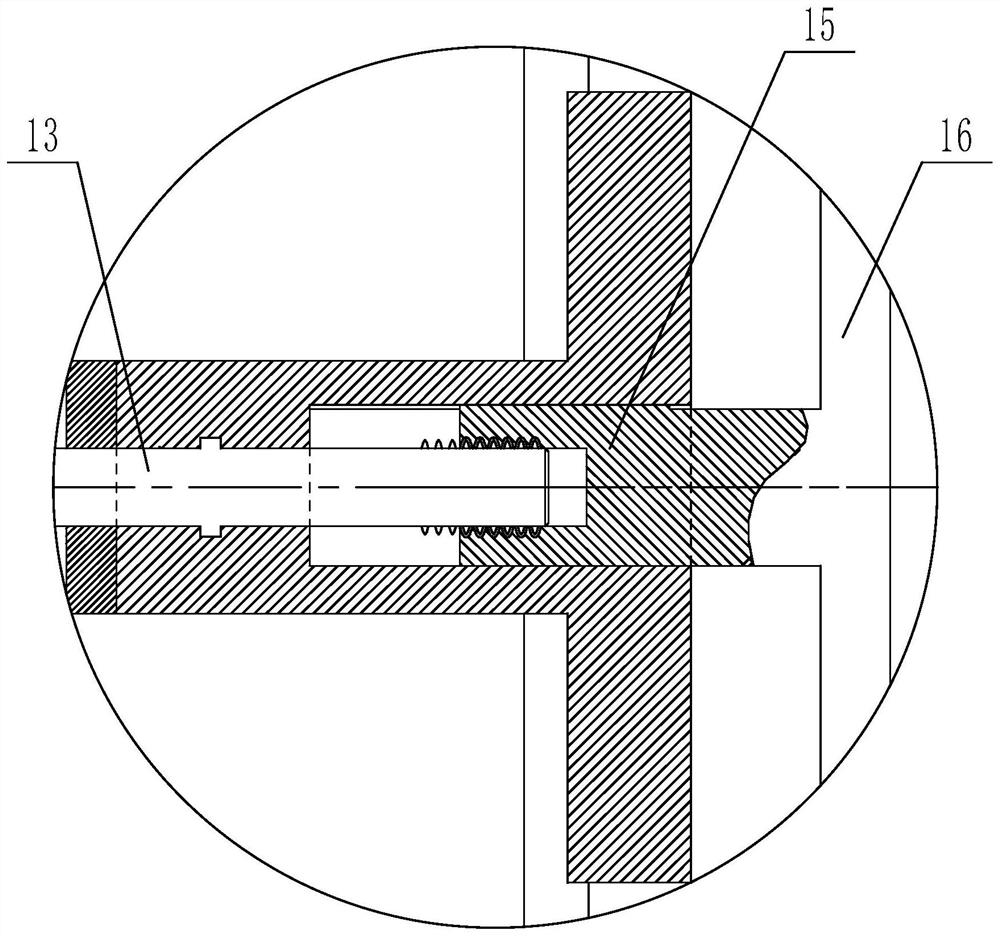

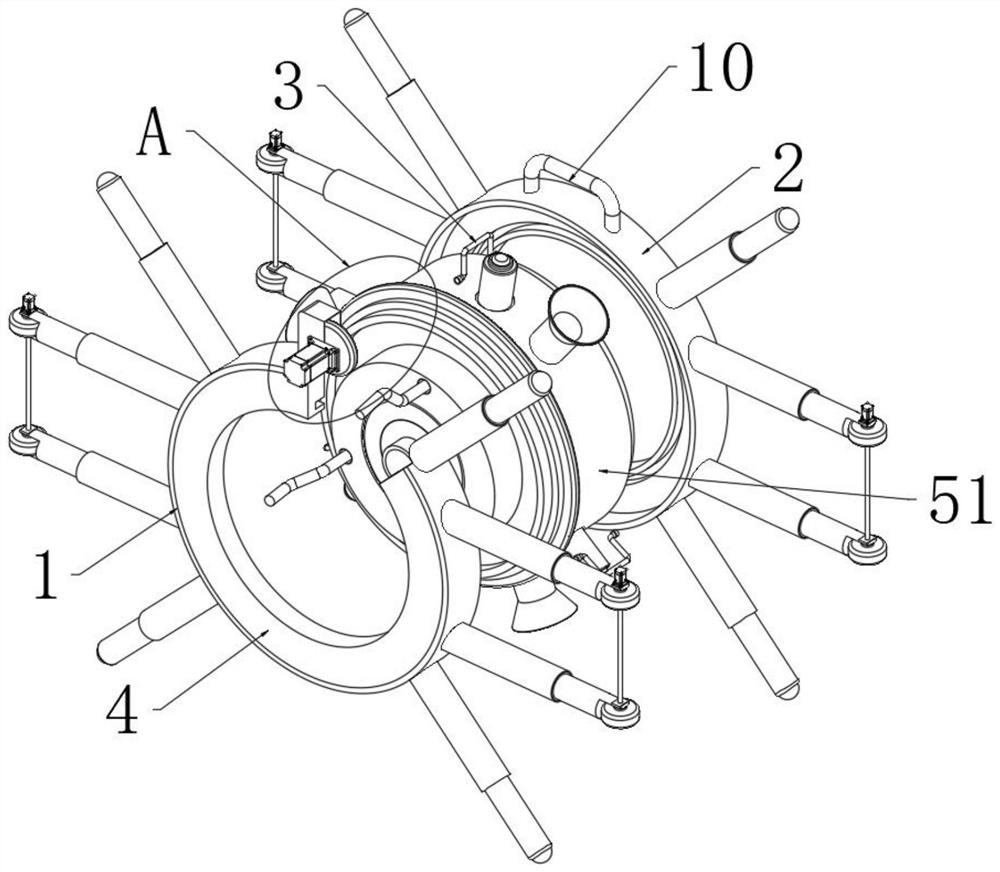

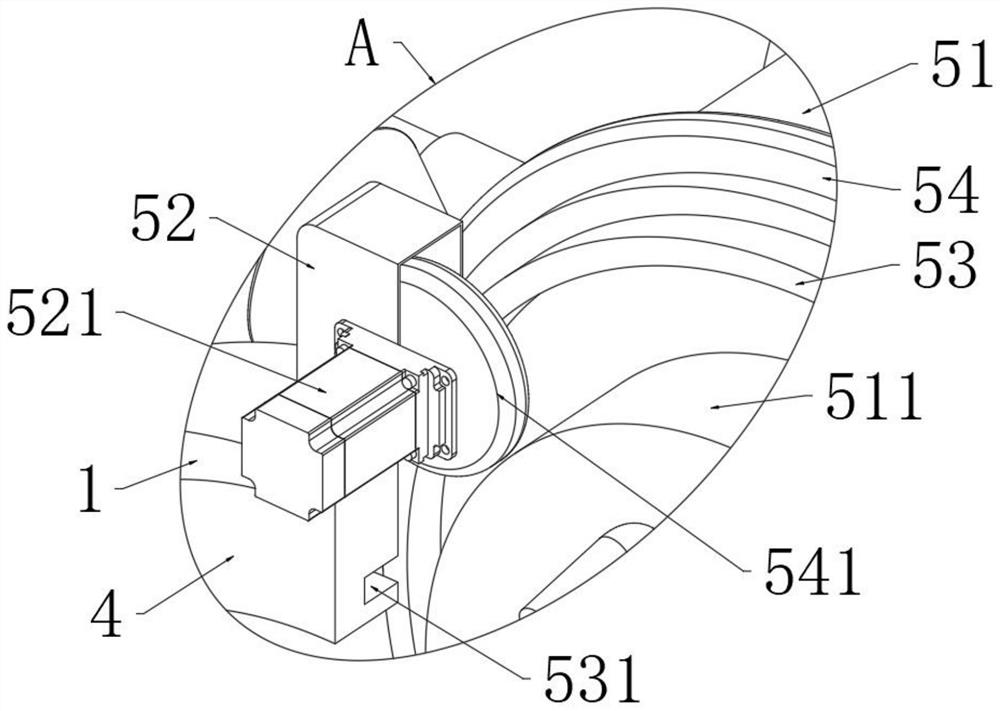

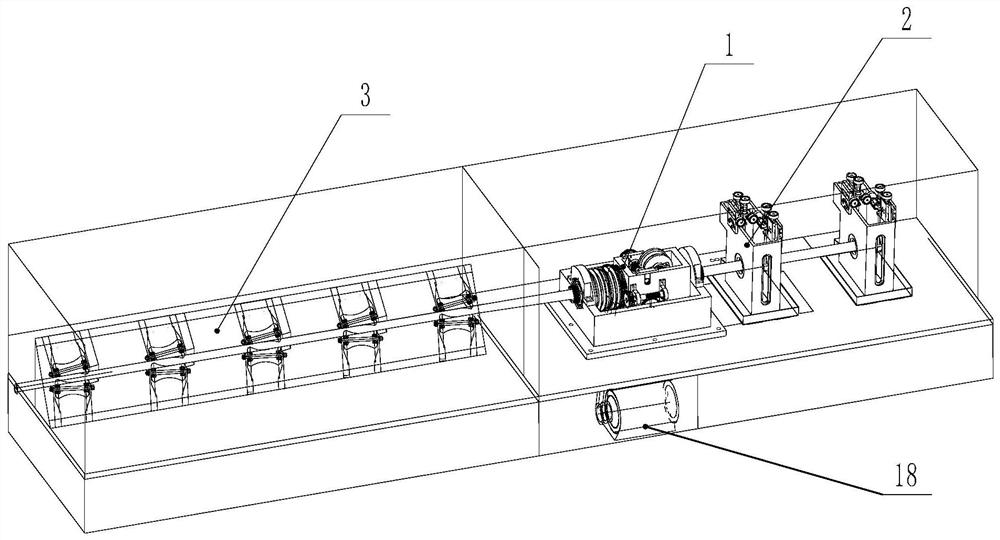

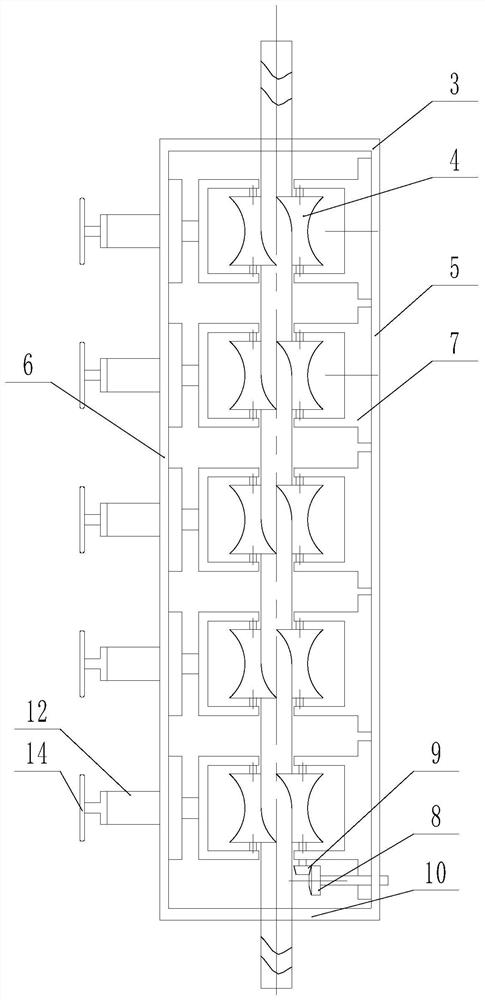

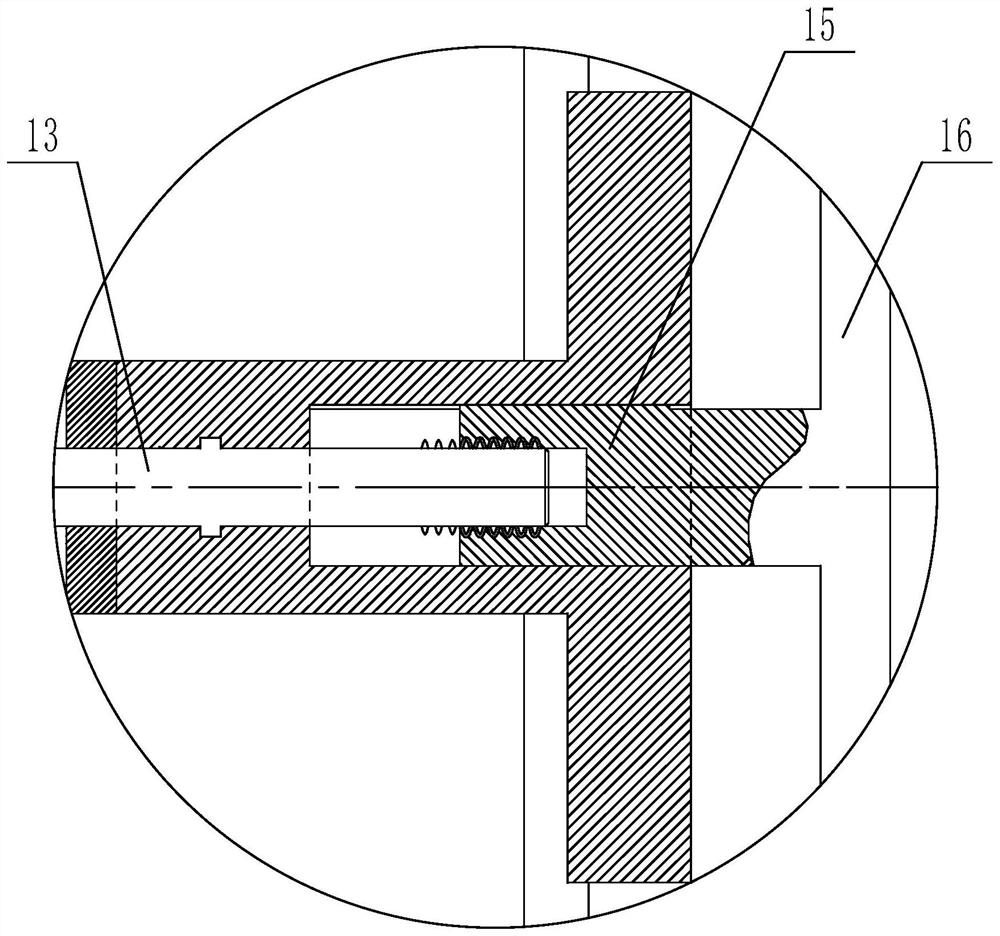

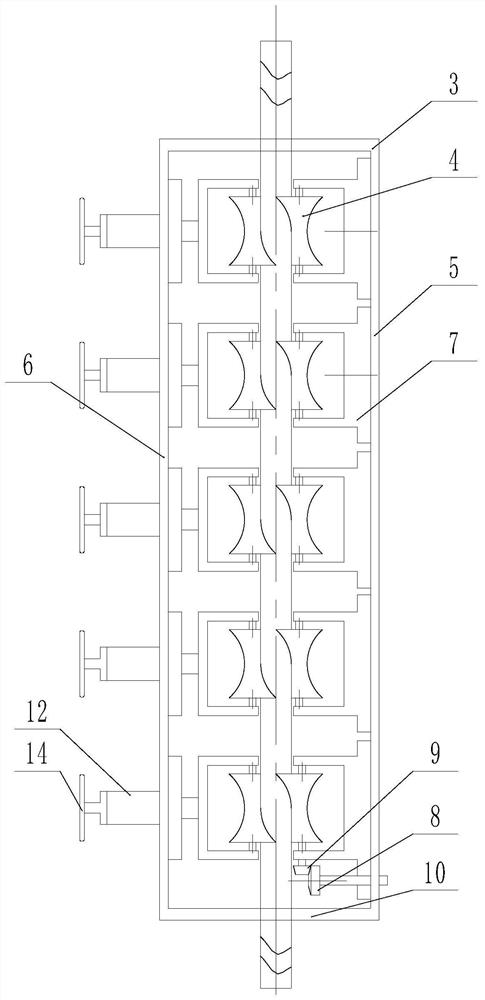

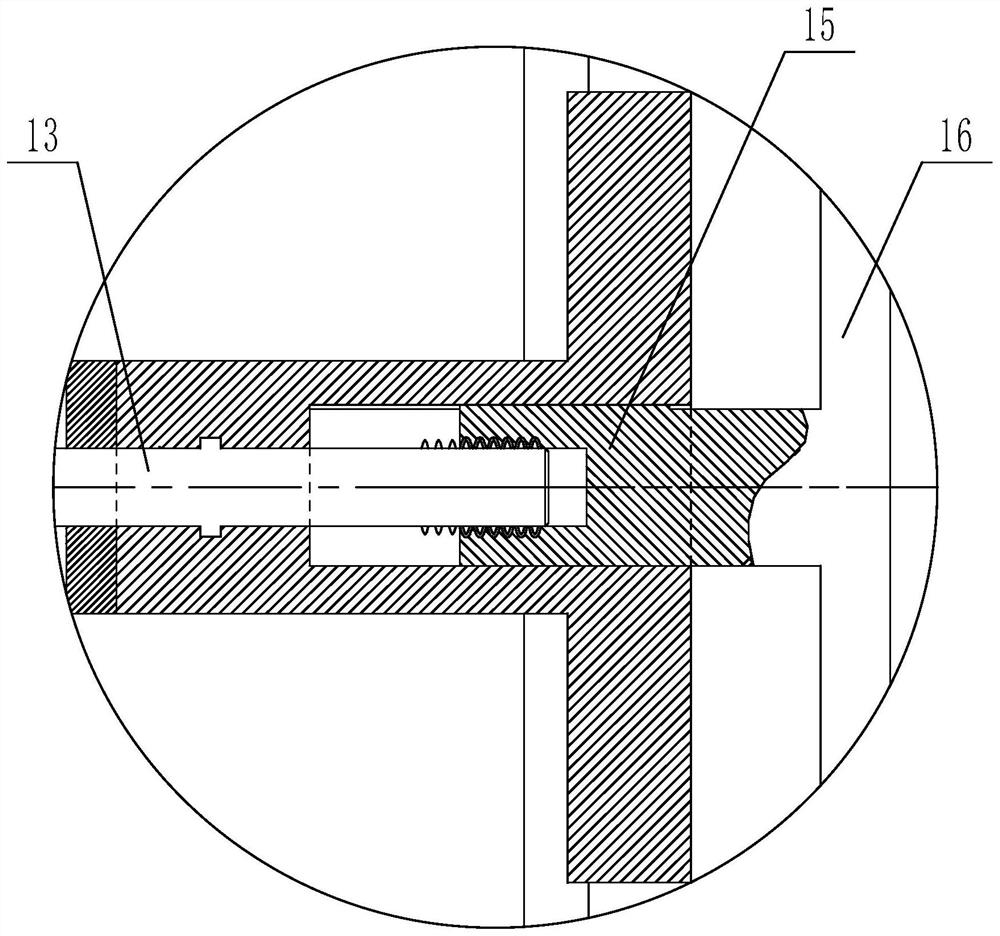

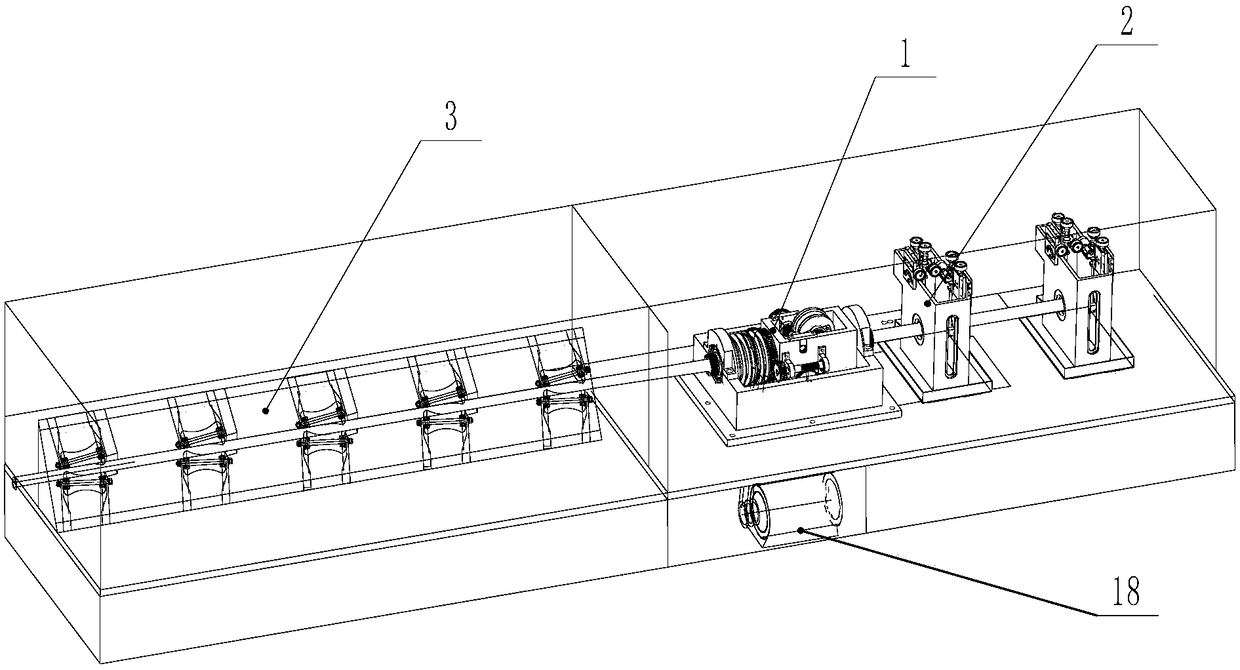

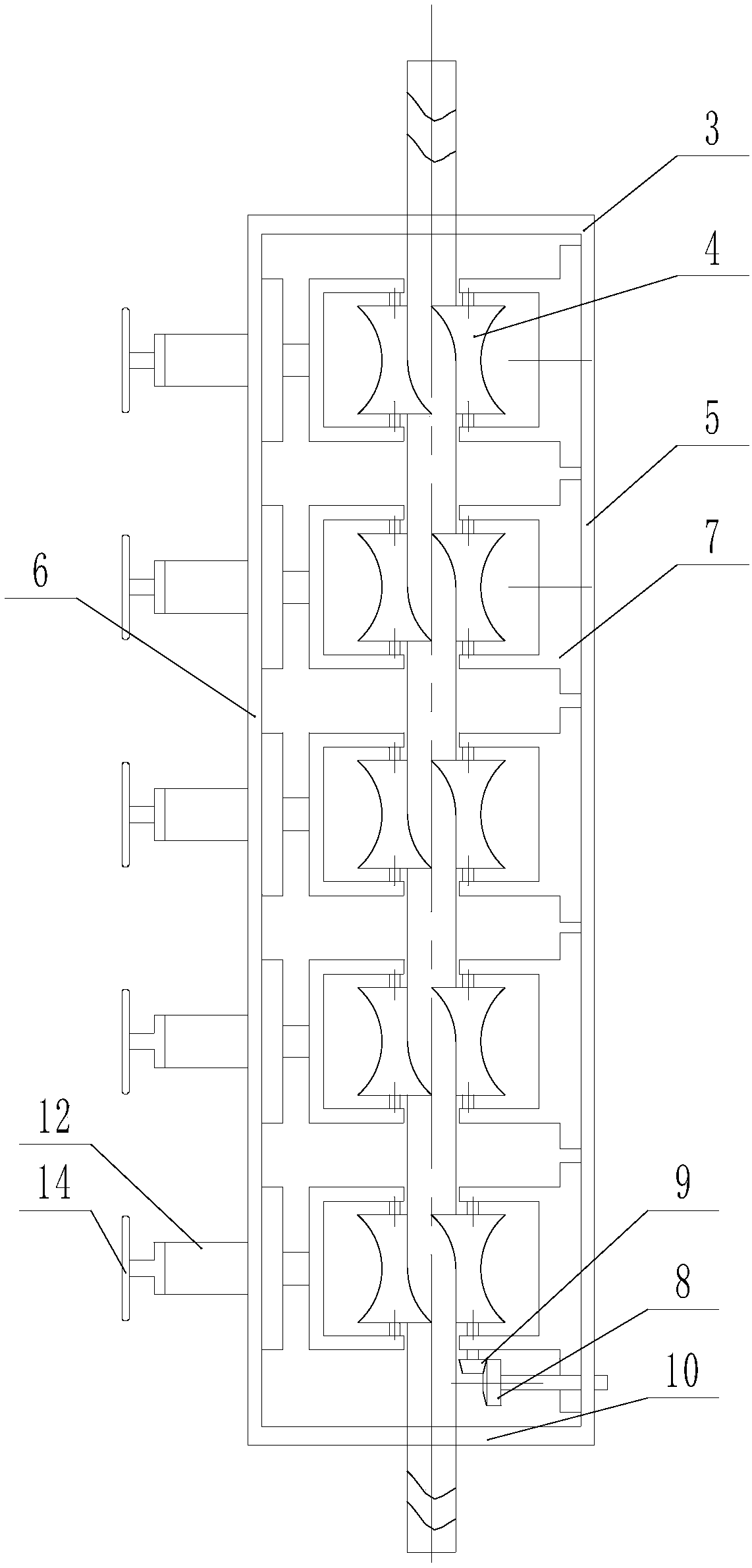

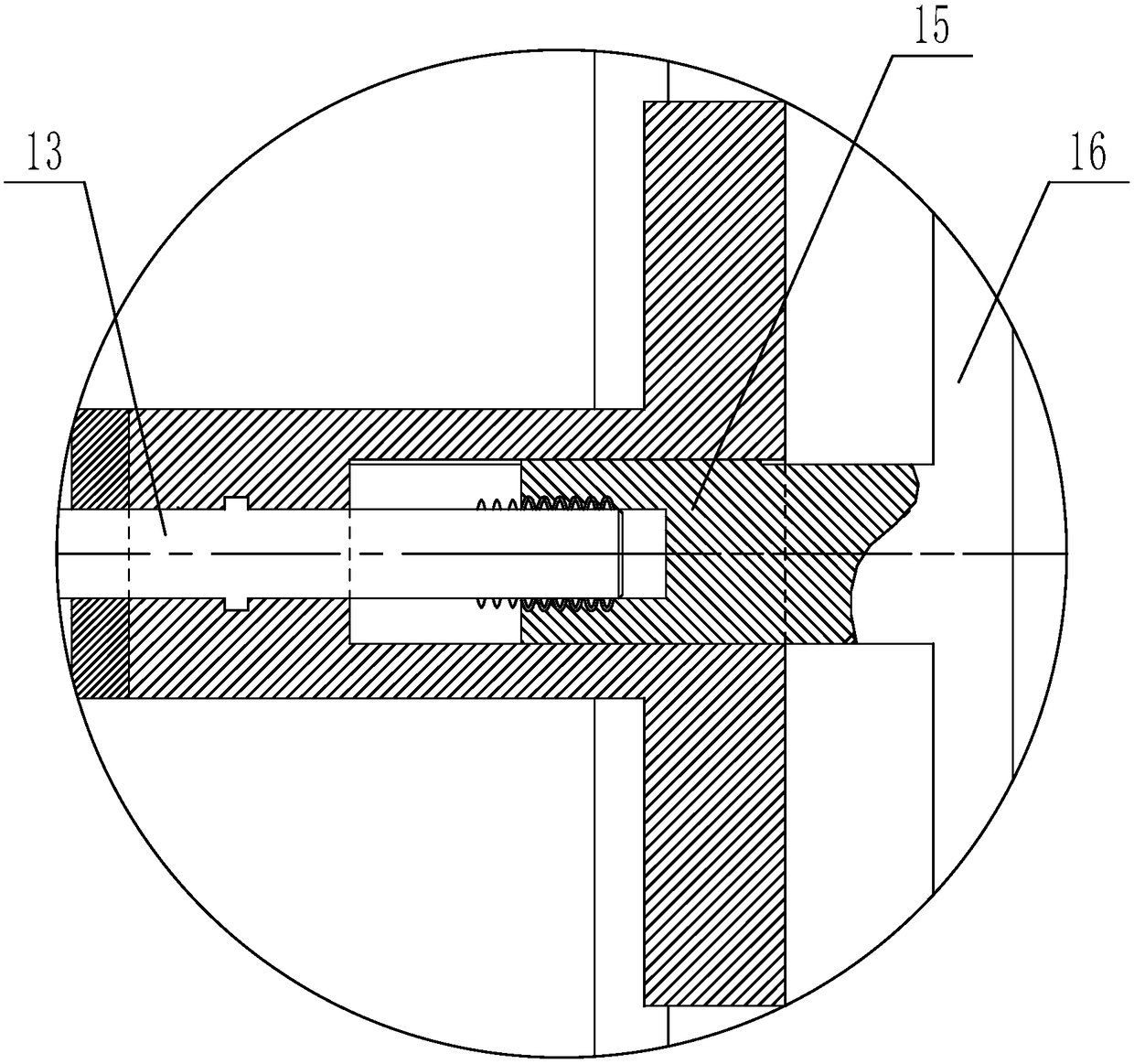

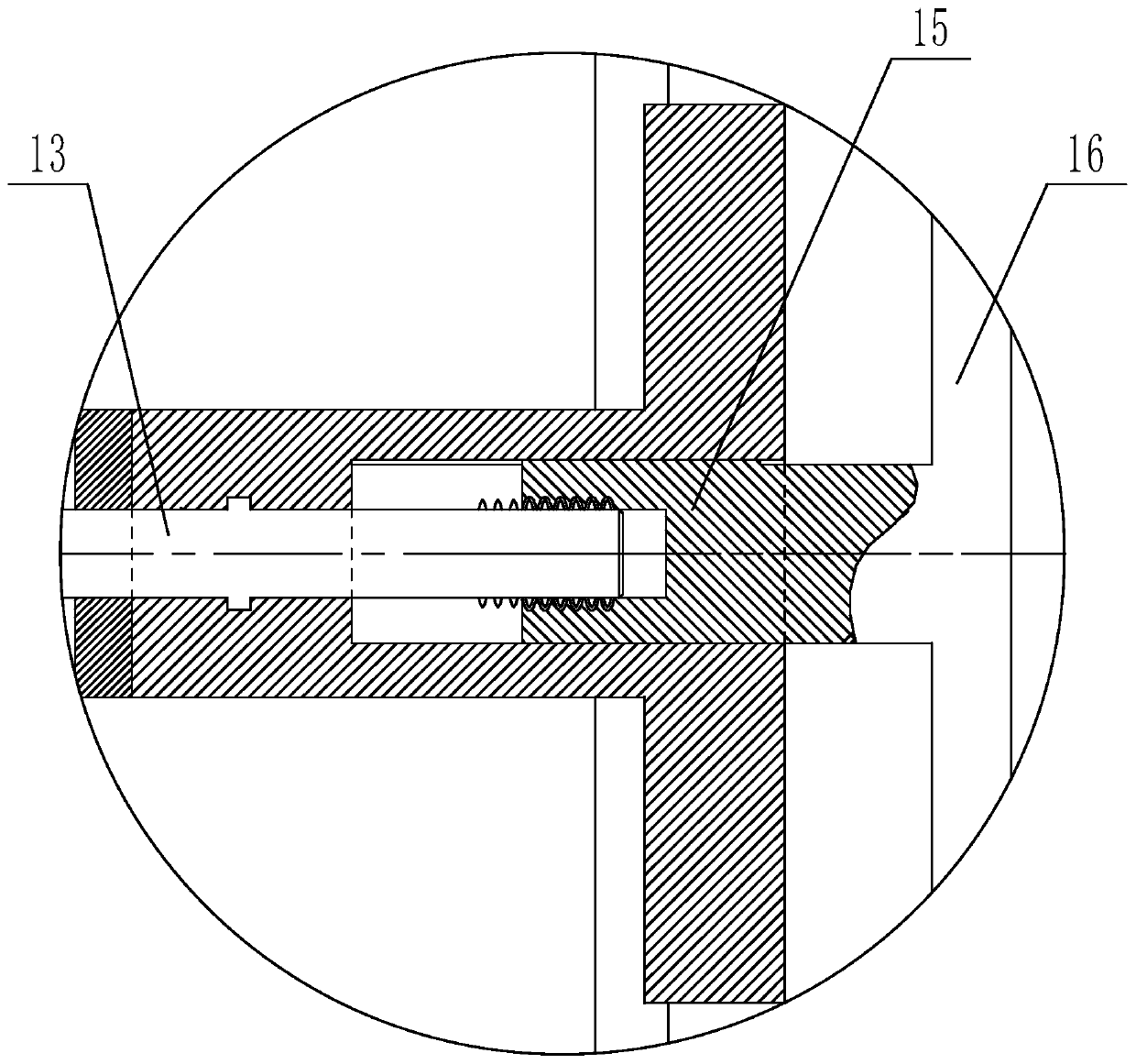

A feeding structure for steel pipe flaw detection

ActiveCN109425518AAchieve straighteningImprove the effect of flaw detectionMaterial analysis using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationEngineeringSpiral line

A feeding structure for steel pipe flaw detection is disclosed. The structure includes a steel pipe transmission device for driving a steel pipe to move along the axial direction and a steel pipe feeding straightening device arranged at the feeding end of the steel pipe transmission device. The structure is characterized in that the steel pipe feeding straightening device comprises straightening rollers arranged in pairs; the circumferential surfaces of the straightening rollers have an arc shape with a concave middle; and two straightening rollers in each pair of the straightening rollers arearranged at two sides at the left-right direction of a steel pipe movement path, with axes of the two straightening rollers being staggered and inclined along the steel pipe movement direction, so that the two straightening rollers are respectively in contact with the steel pipe surface in a symmetrical spiral line manner. The feeding structure can achieve straightening during feeding before steel pipe flaw detection to improve flaw detection effects and has a simple structure and good straightening effects.

Owner:宝武特冶航研科技有限公司

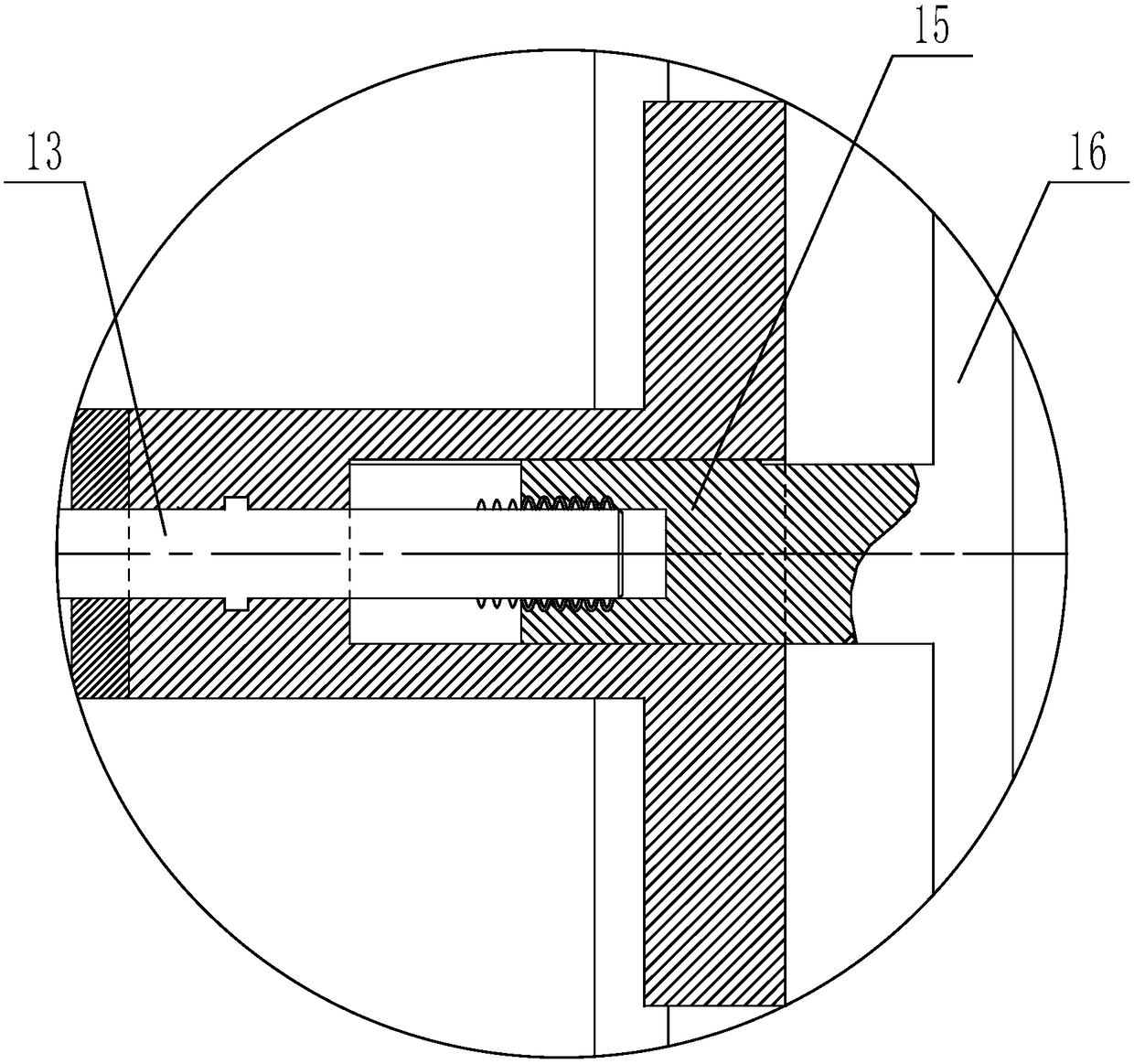

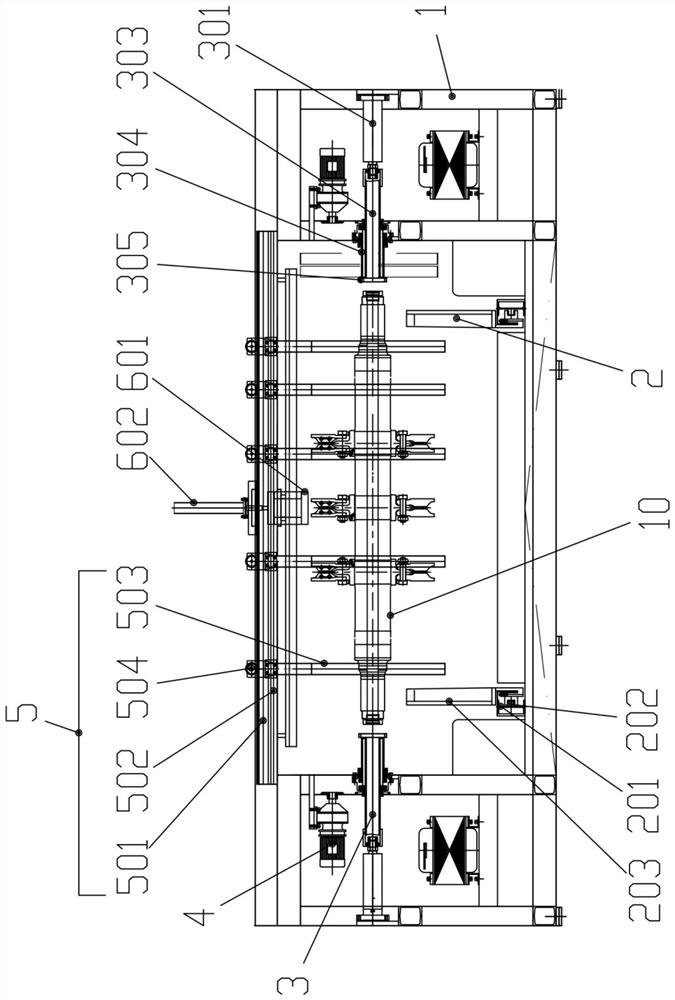

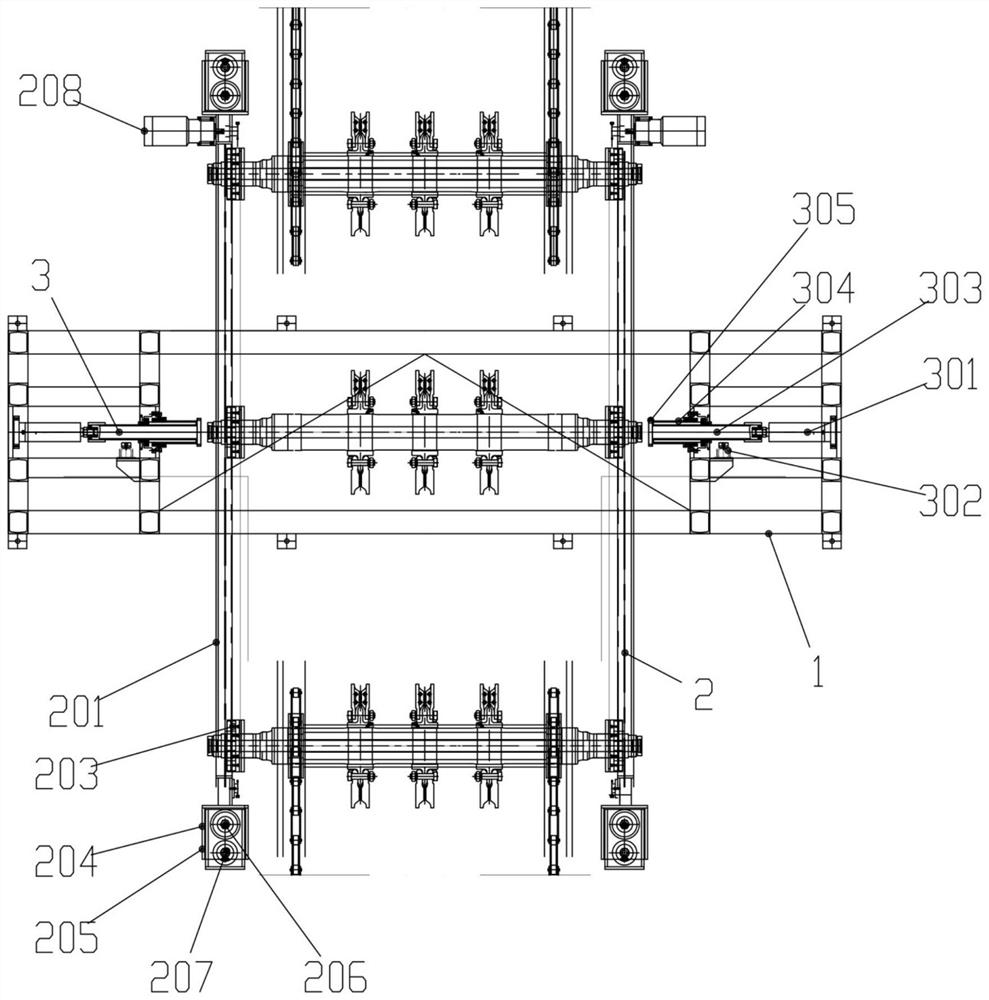

Special pass-type magnetic particle flaw detector for axle with gear

ActiveCN113418981ANo need for manual handlingLabor savingFluorescence/phosphorescenceMaterial magnetic variablesGear wheelControl system

The invention relates to the technical field of magnetic particle inspection, in particular to a special pass-type magnetic particle flaw detector for an axle with a gear. The special pass-type magnetic particle flaw detector comprises a rack, a workpiece transfer mechanism, a circumferential magnetization mechanism, a workpiece rolling mechanism, a longitudinal magnetization mechanism, an independent gear magnetization mechanism, a magnetic suspension spraying mechanism, a fluorescent lamp and an electrical control system, wherein the independent gear magnetization mechanism comprises a cross coil, a mounting plate, a lifting cylinder and a first guide rod; and when the cross coil descends, the gear can be partially surrounded. The special pass-type magnetic particle flaw detector for the axle with the gear can simultaneously complete magnetic flaw detection of the axle and the gear in one flaw detection process, and is convenient and efficient.

Owner:捷航设备制造股份有限公司

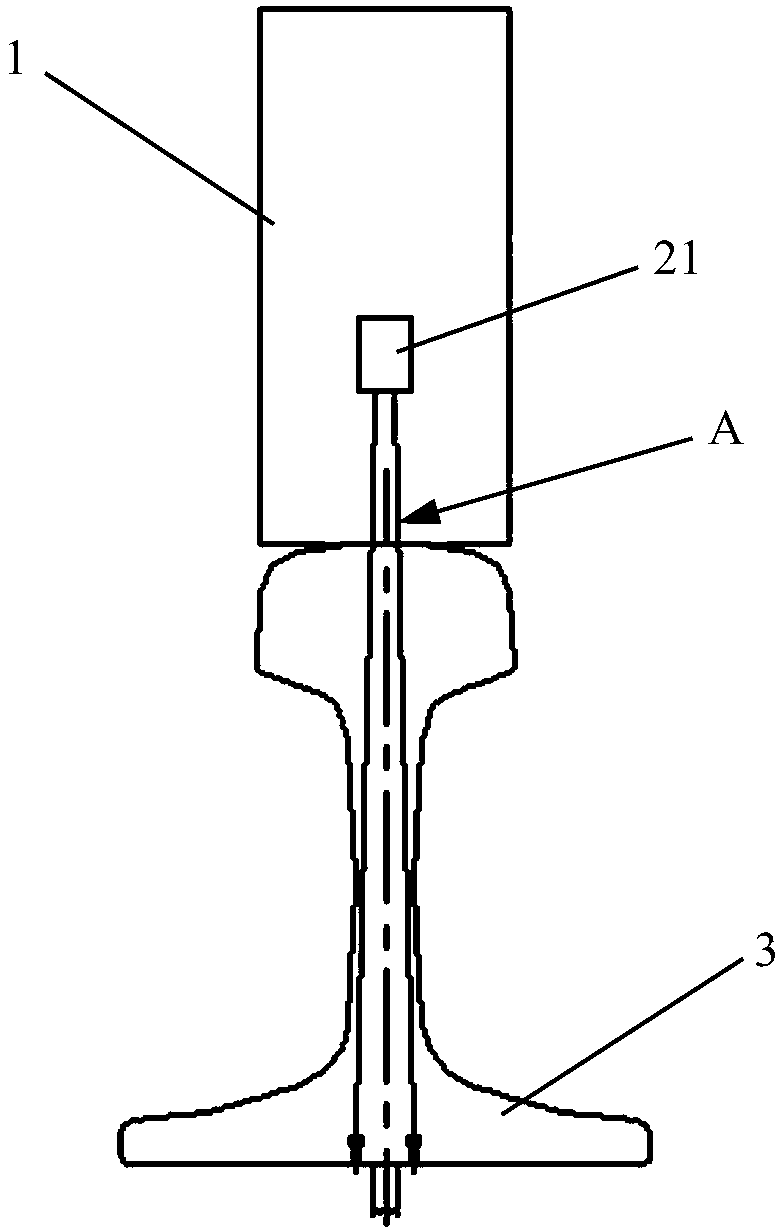

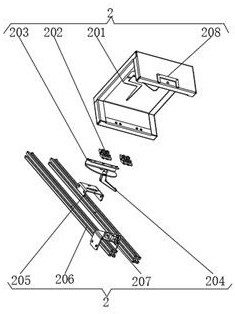

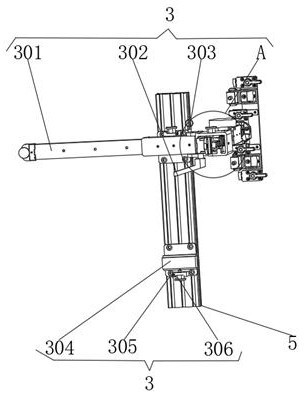

Auto-centering control system having abrasion compensation

ActiveCN108519439AGood effectSolve technical problems with missing bottom wavesMaterial analysis using sonic/ultrasonic/infrasonic wavesControllers with particular characteristicsThree levelControl system

The invention discloses an auto-centering control system having abrasion compensation, which includes: a centering sensor, which acquires profile data of a steel rail and actual position of a detectorwheel; an abrasion compensation computing unit, which calculates the abrasion quantity of a rail head of the steel rail according to the profile data of the steel rail, calculates abrasion compensation quantity according to the abrasion quantity, and compensates a centering basic value according to the abrasion compensation quantity at least by three levels; a PID control unit, which performs PIDcontrol and outputs a control value according to the compensated centering basic value outputted by the abrasion compensation computing unit and the actual position of the detector wheel; a centeringcontrol unit, which generates a driving control signal, which controls action of the detector wheel, according to the control value outputted by the PID control unit. The control system can solve thetechnical problem that on a steel rail, of which the rail head has serious abrasion, serious wave loss still exists even the centering system has normal deviation control.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

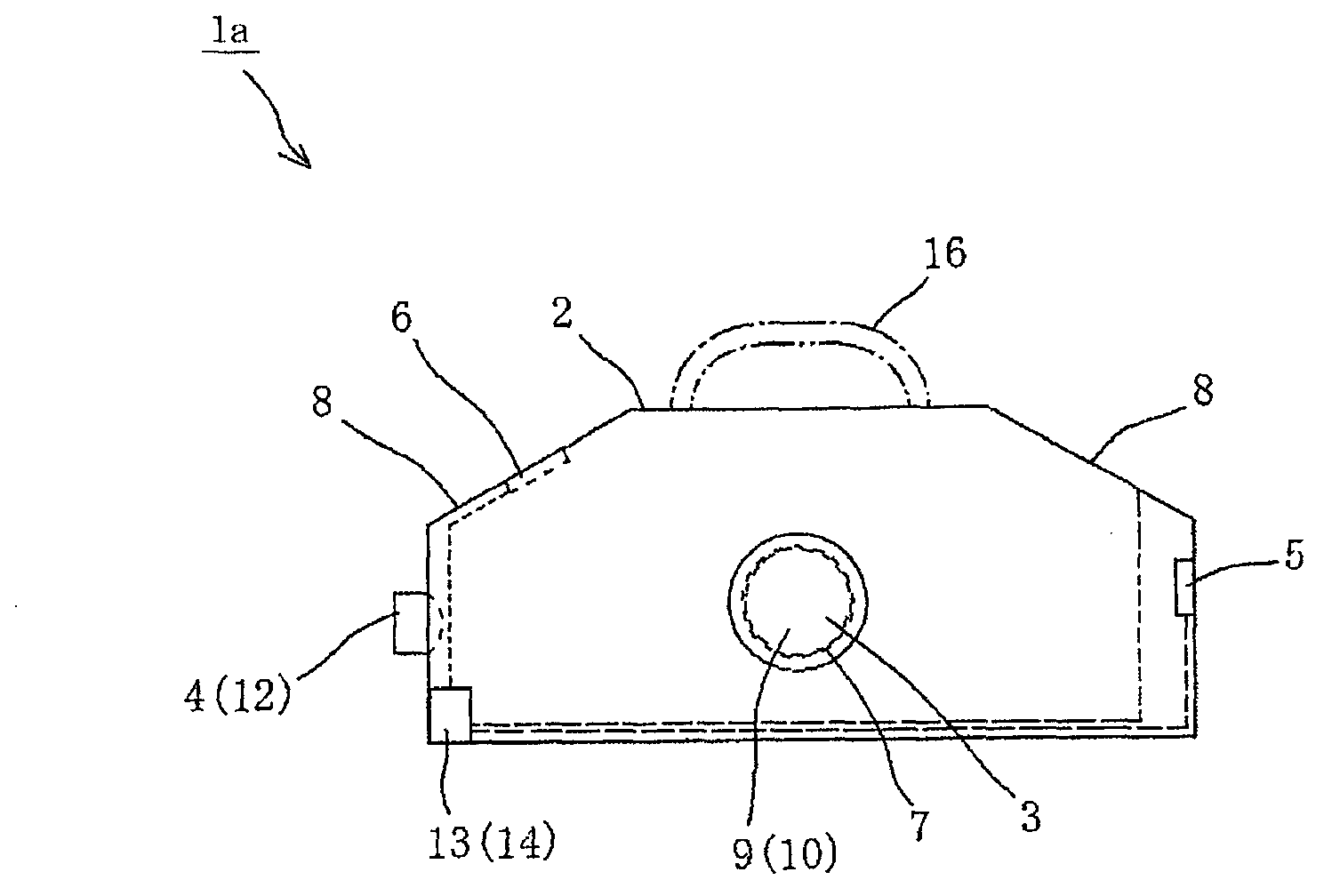

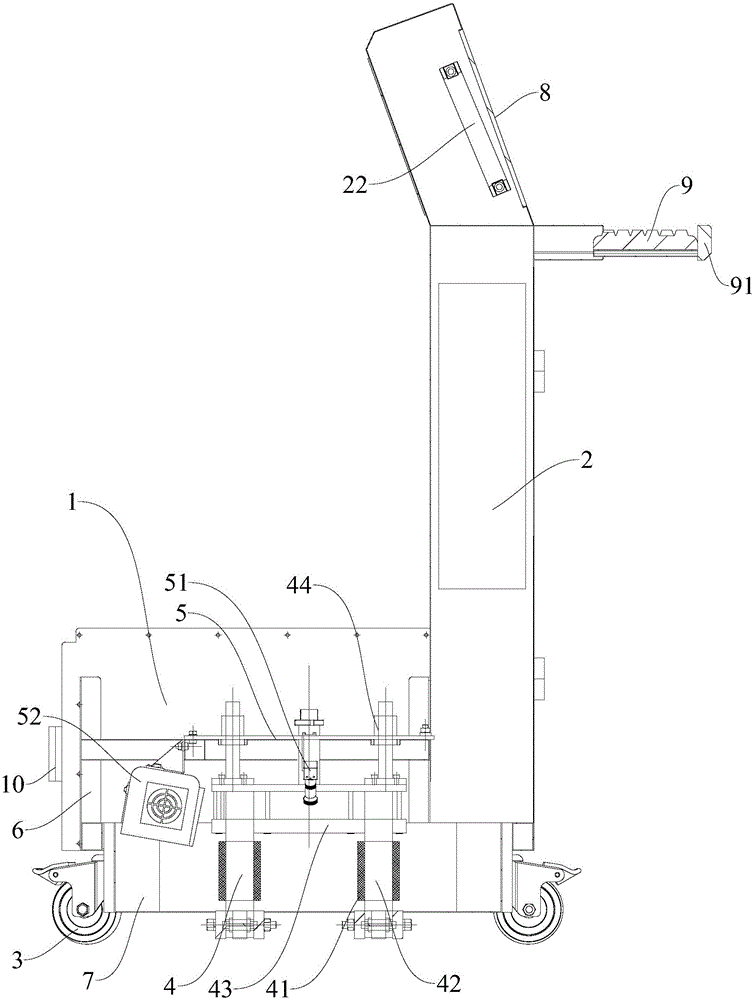

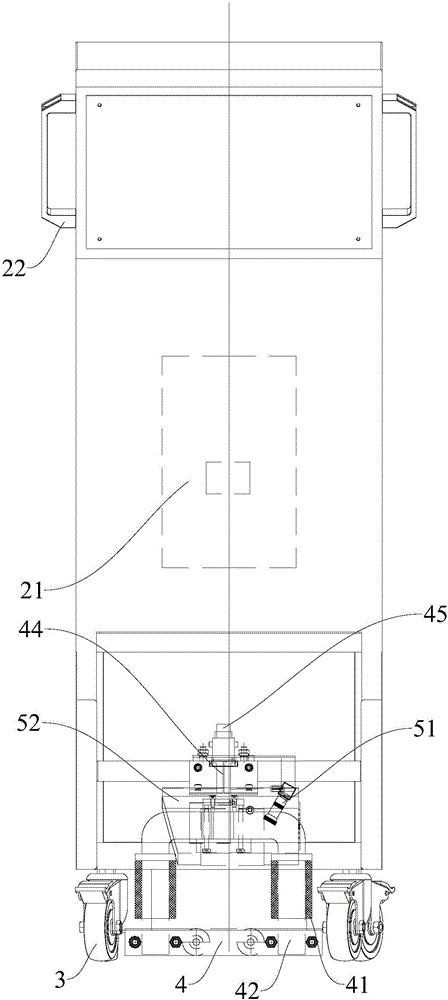

Portable flaw detection trolley for turnout flaw detection

PendingCN113008991AReduce movementImprove stabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesRigid containersGear wheelElectrical and Electronics engineering

The present invention discloses a portable flaw detection trolley for turnout flaw detection. The trolley comprises a flaw detection trolley body, a frame is arranged on the outer wall of the flaw detection trolley body, an instrument tray mechanism is arranged on the outer surface of the upper end of the flaw detection trolley body, and an unhooking mechanism is arranged on the outer surface of the front end of the middle of the flaw detection trolley body. A probe box matrix mechanism is arranged on the outer surface of one side of the unhooking mechanism. According to the portable flaw detection trolley for turnout flaw detection, the instrument tray assembly can rotate by adjusting the rotating ring, the safety of instruments in the instrument tray assembly can be protected, the height of the probe box matrix mechanism can be conveniently adjusted through the moving gear, the adjusting assembly and the moving vertical rod, and the detection accuracy is improved. Therefore, flaw detection can be carried out on the track at different heights, the track detection accuracy of the flaw detection trolley is improved, the stability of the flaw detection trolley can be improved, and a better use prospect is brought to the flaw detection trolley.

Owner:成都申声科技有限公司

Ship hull descaling and flaw detection system

InactiveCN103895835BRealize integrated operationVersatileVessel cleaningAnalysing solids using sonic/ultrasonic/infrasonic wavesShock waveNon destructive

The invention provides a warship hull descaling and flow detecting system which comprises a power supply system, a control system, a charging system, an energy storing system, a plasma shock wave generating mechanism, a flaw detection monitoring system, a surface flushing mechanism and an adsorbing and walking robot. When the system runs, probes of the plasma shock wave generating mechanism, the surface flushing mechanism, the adsorbing and walking robot and the flaw detection monitoring system are in underwater operation. Organisms attached to the surface of a warship hull are subjected to primary cleaning by the aid of strong sound shock waves generated from discharging of underwater plasmas, the organisms attached to the surface of the warship hull fall off or are loosened, and then the loosened attachments are cleaned by the aid of the surface flushing mechanism. The descaling effect can be detected through the flaw detecting system after descaling operation, and non-destructive detection can be performed on the surface of the warship hull.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A Method of Improving the Quality of the Center of Extra-thick Plates and the Qualification Rate of Flaw Detection

ActiveCN109013711BSave rolling waiting timeReduce waiting timeProfile control deviceSteelmakingReduction rate

The invention provides a method for improving the core quality and flaw detection pass rate of extra-thick plates, and belongs to the technical field of iron and steel metallurgy. This method is based on the online instant refrigeration system between passes to improve the core quality and flaw detection qualification rate of extra thick plates (≥80mm). The specific process steps are as follows: the continuous casting billet (≥200mm) does not transfer to steel or the steel transfer ends and enters the longitudinal rolling stage. During the rolling gap, the instant cooling system near the rolling mill is used for one or more passes of online cooling. The initial surface temperature is 850~1000℃, and it enters the cooling zone at a speed of 2~6m / s. The roll speed in the cooling zone is 1~ 3m / s, the upper and lower water ratio is 1:2~1:6, the total flow rate of a single set of headers is 200~400m 3 / h, the return temperature after cooling is controlled at 750~900℃ for rolling, and the reduction rate after cooling is higher than 12%. This method increases the deformation of the core of the thick plate through temperature difference rolling, significantly improves the core quality and flaw detection pass rate, and increases the yield rate.

Owner:NORTHEASTERN UNIV LIAONING

An automatic centering control device with wear compensation

ActiveCN108819963BGood effectSolve technical problems with missing bottom wavesRailway inspection trolleysRailway auxillary equipmentNormal controlControl unit

The invention discloses an automatic centering control device with wear compensation. The automatic centering control device with wear compensation comprises a centering sensor, a wear compensation calculating unit and a PID control unit, wherein the centering sensor is used for obtaining rail outline data of the internal side of a steel rail and an actual position of a wheel detector; the wear compensation calculating unit is used for calculating a railhead wear amount of the steel rail according to the rail outline data of the internal side of the steel rail, calculating the wear compensation amount by using the wear amount and compensating a centering reference value in at least three gears according to the wear compensation amount; and the PID control unit is used for performing PID control according to the compensated centering reference value output by the wear compensation calculating unit and the actual position of the wheel detector and outputting a centering control value. According to the automatic centering control device with wear compensation, the technical problem that the frequency is still seriously lost on the steel rail with serious railhead wear in the case of normal control error of a centering device can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

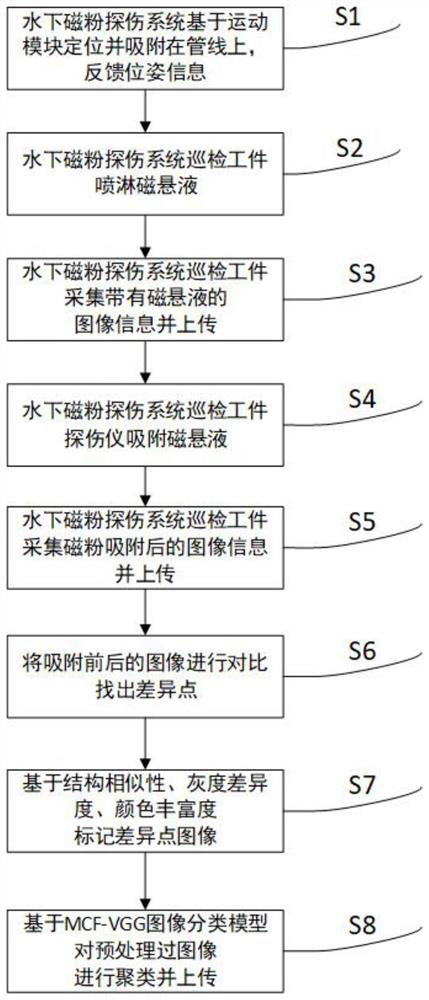

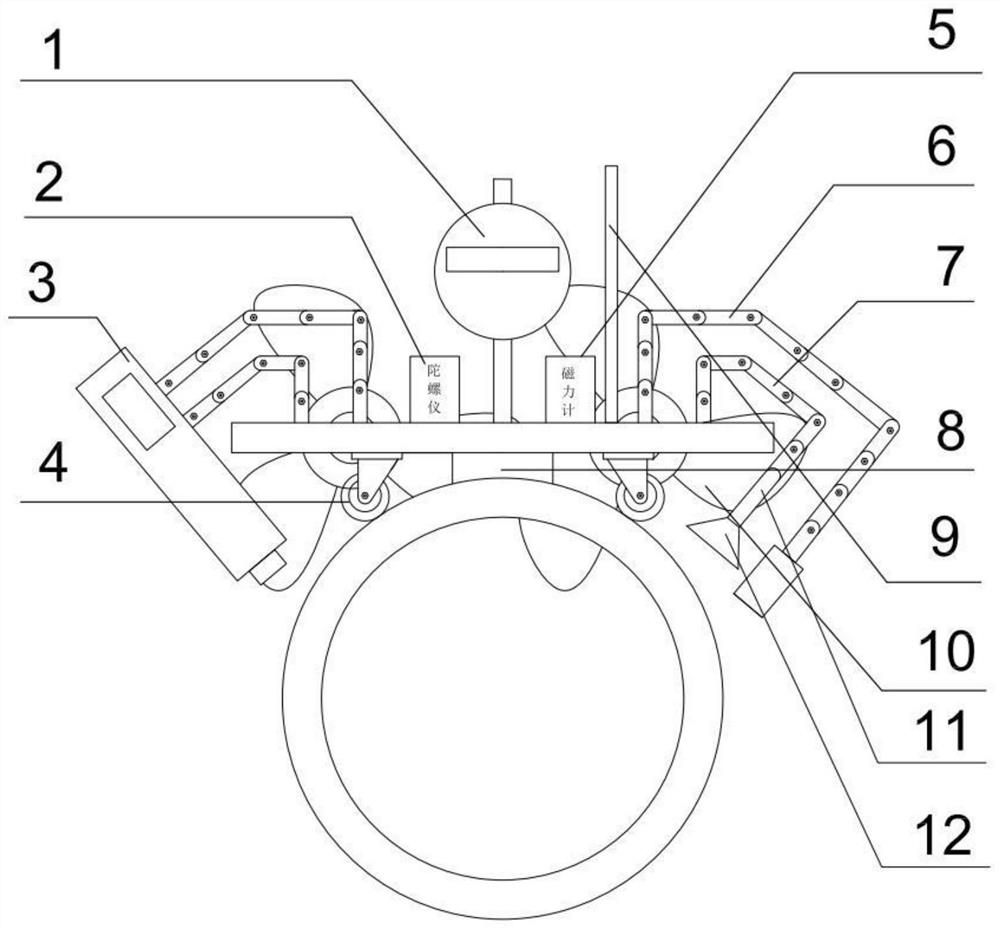

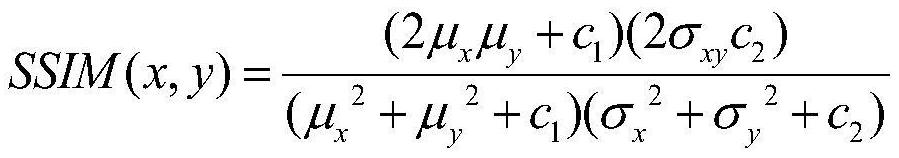

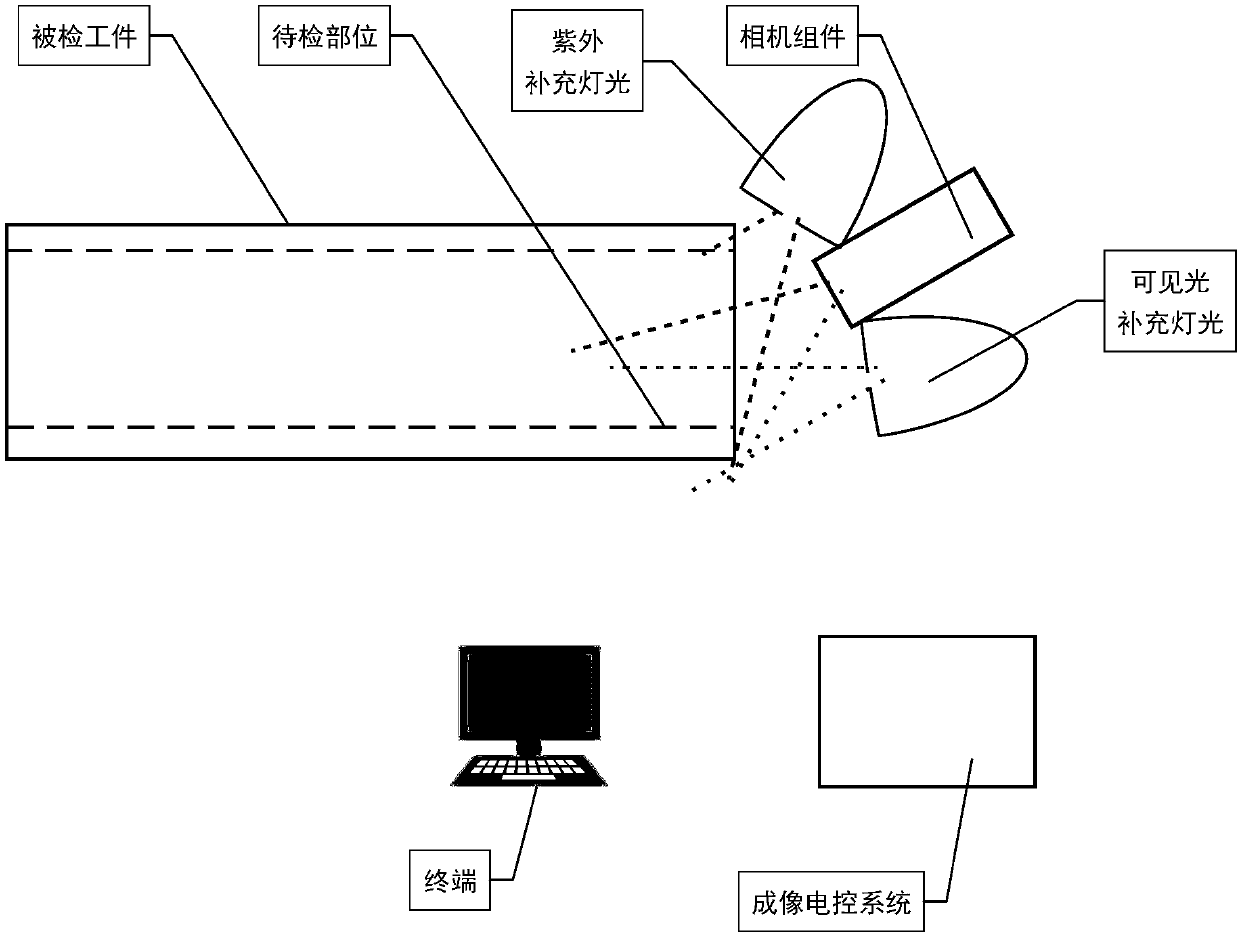

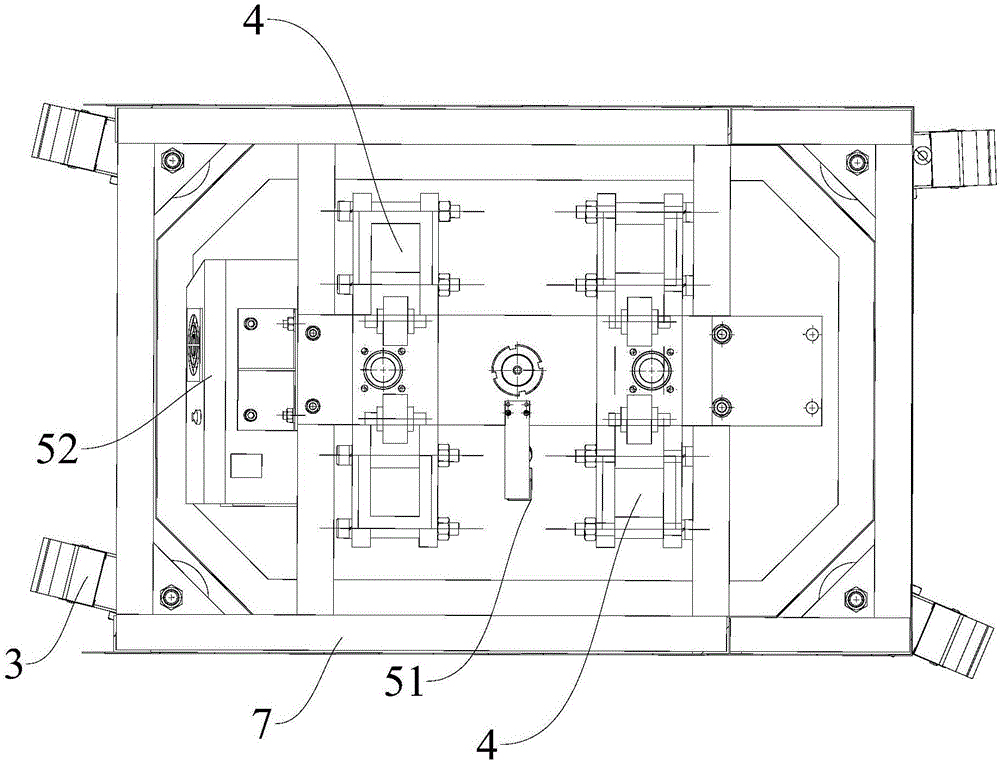

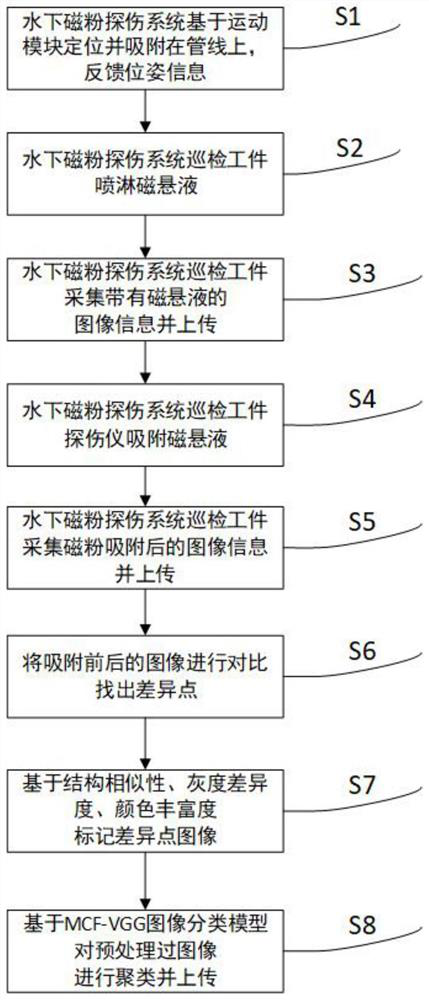

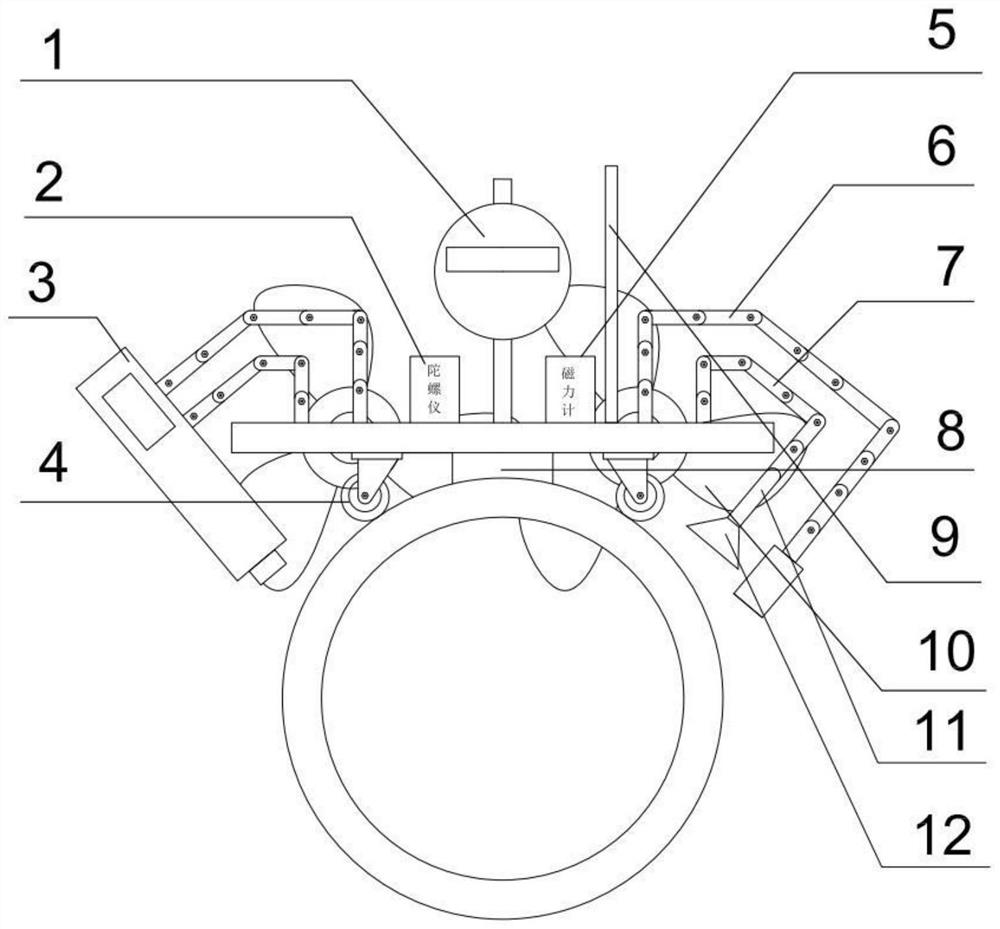

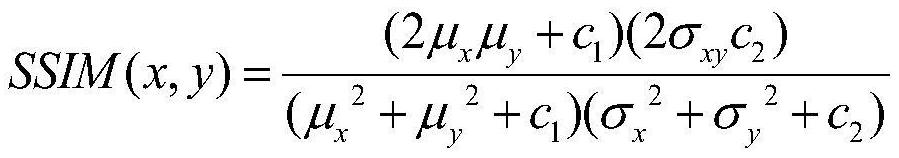

Underwater nondestructive inspection equipment based on combination of vision and magnetic powder and treatment method

ActiveCN112924466ARealize integrated operation processImprove the effect of flaw detectionImage enhancementImage analysisImaging processingCamera module

The invention discloses underwater nondestructive flaw detection equipment based on combination of vision and magnetic powder and a treatment method, flaw detection operation is carried out on an underwater pipeline by adopting a magnetic powder and vision combination mode, the underwater nondestructive flaw detection equipment comprises an underwater nondestructive flaw detection device and an underwater movable platform, and the underwater nondestructive flaw detection device is fixed on the underwater movable platform; the underwater nondestructive inspection device mainly comprises a flaw detector control module, a camera module, a communication module and an image processing module, and the underwater movable platform mainly comprises a motion control module. According to the invention, the motion control module is adopted to realize positioning and movement of the underwater movable platform; spraying of the magnetic suspension is realized by adopting a flaw detector control module; a camera module is adopted to collect image information before and after the underwater magnetic defect detector adsorbs the pipeline; a communication module is adopted to upload position information and image information; by extracting magnetic powder inspection data and visual image data and fusing high-level semantic information, autonomous inspection and nondestructive inspection of the underwater pipeline are realized.

Owner:NANTONG UNIVERSITY

The structure of the feeding part of the steel pipe flaw detection

ActiveCN109425518BAchieve straighteningImprove the effect of flaw detectionMaterial analysis using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationClassical mechanicsPipe

The invention discloses a steel pipe flaw detection feeding part structure, comprising a steel pipe transmission device for driving the steel pipe to move along the axis direction and a steel pipe feeding straightening device arranged at the feeding end of the steel pipe transmission device; The straightening device includes straightening rollers arranged in pairs. The circumferential surface of the straightening rollers is a concave arc in the middle. Two straightening rollers in each pair of straightening rollers are arranged on the left and right sides of the steel pipe movement path, and two The axis lines of the straightening rollers are dislocated and tilted up and down along the moving direction of the steel pipe, so that the two straightening rollers form two symmetrical helical contact with the surface of the steel pipe respectively. The invention can realize the straightening of the steel pipe during flaw detection and improve the flaw detection effect, and has the advantages of simple structure and good straightening effect.

Owner:宝武特冶航研科技有限公司

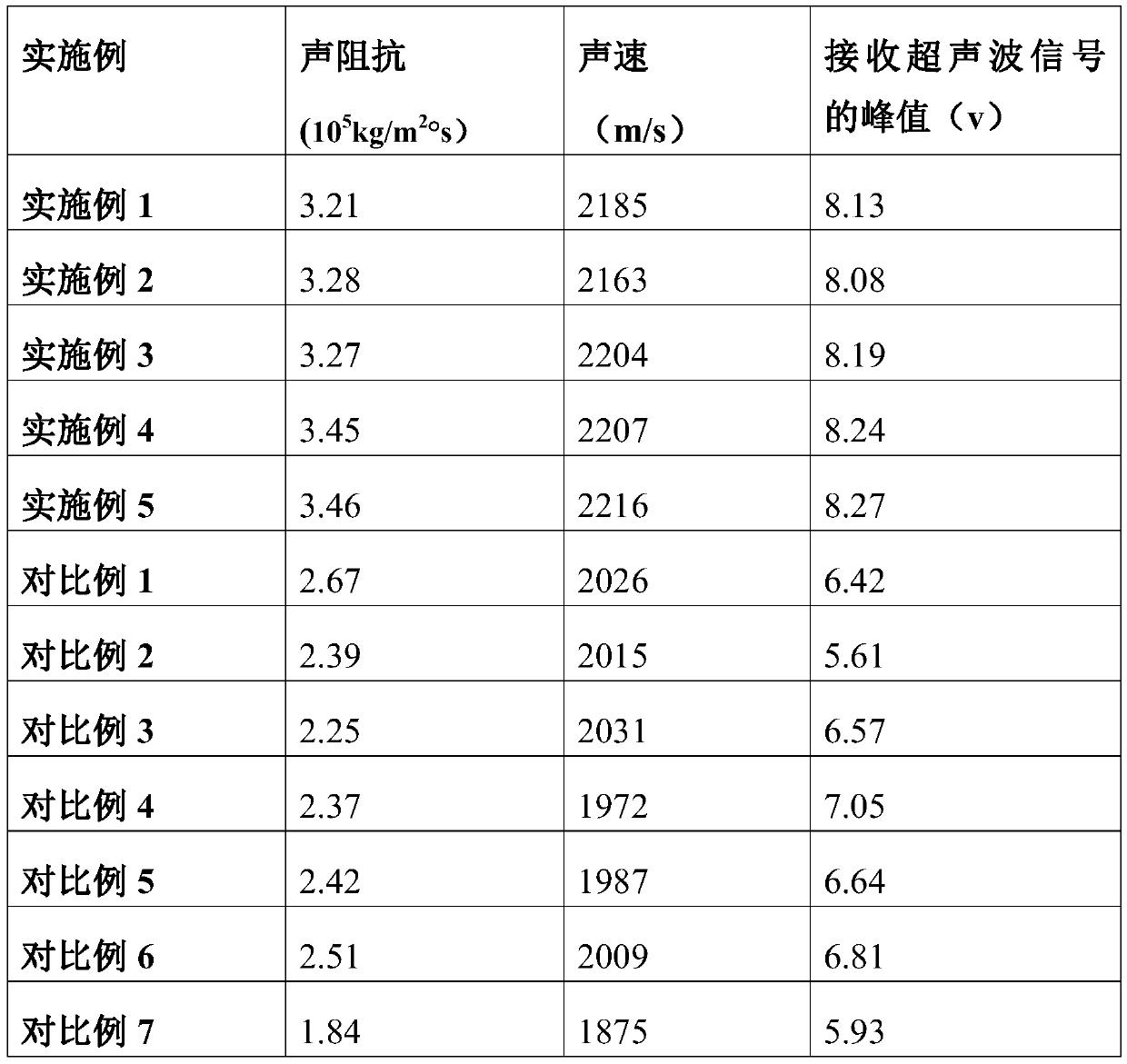

A method for ultrasonic flaw detection of steel structure welds

ActiveCN110501426BHigh viscosityImprove liquidityAnalysing solids using sonic/ultrasonic/infrasonic wavesEpoxyPolyamide

The invention provides a method for ultrasonic flaw detection of a welding line of a steel structure. The method comprises the steps that (1) a flaw detection coupling agent A which comprises, by weight, 40 to 55 parts of ethylene glycol, 25 to 35 parts of glycerin, 10 to 15 parts of epoxy resin, 1 to 3 parts of versamid with molecular weight of 200 to 300, 0.5 to 2 parts of trimethylolpropane and50 to 65 parts of water is prepared; (2) a flaw detection coupling agent B which comprises, by weight, 25 to 30 parts of xanthan gum, 0.5 to 2 parts of sodium alginate and 40 to 60 parts of water isprepared; (3) a layer of flaw detection coupling agent A is sprayed on the surface of the welding line of the steel structural member, wherein the spraying thickness is 1 to 2mm; standing for 60 to 90s is carried out to acquire the steel structural member containing a precoated layer; and (4) the surface of the welding line of the steel structural member containing the precoated layer is sprayed with a layer of flaw detection coupling agent B, wherein the spraying thickness is 1 to 3 mm; a welding line ultrasonic flaw detector is used to carry out ultrasonic flaw detection on the surface of the welding line of the steel structural member; the position information of the flaw of the welding line is recorded in real time. The method for ultrasonic flaw detection of the welding line of the steel structure, which is provided by the invention, can effectively optimize flaw detection at a contact surface with low flatness and in low temperature environment.

Owner:海南方能测试技术有限公司

A pipeline radiographic flaw detection device and flaw detection method

ActiveCN109975328BImprove the effect of flaw detectionMaterial analysis using wave/particle radiationStructural engineeringMechanical engineering

The invention discloses a pipeline ray flaw detection device and a flaw detection method. The pipeline ray flaw detection device comprises a ray flaw detector, a positioning ring and at least two fixing rings; multiple positioning rods are arranged on the positioning ring, the positioning rod and the positioning ring are movably connected to fix a welding line in the middle of the positioning ring; an annular sliding rail is arranged in the positioning ring, a sliding block is arranged on the annular sliding rail, the sliding block is fixedly connected with the ray flaw detector through a telescopic lever; the fixing rings are located at two sides of the positioning ring and connected with the positioning ring through a connecting rod mechanism; and fixing modules for fixing the fixing rings on the pipeline are arranged on the fixing rings. In the process of ensuring the flow detection process of the bend, the detector and the welding line are maintained at the fixed angle and distance, and the flaw detection effect is improved.

Owner:海南民生公用管道检验有限公司

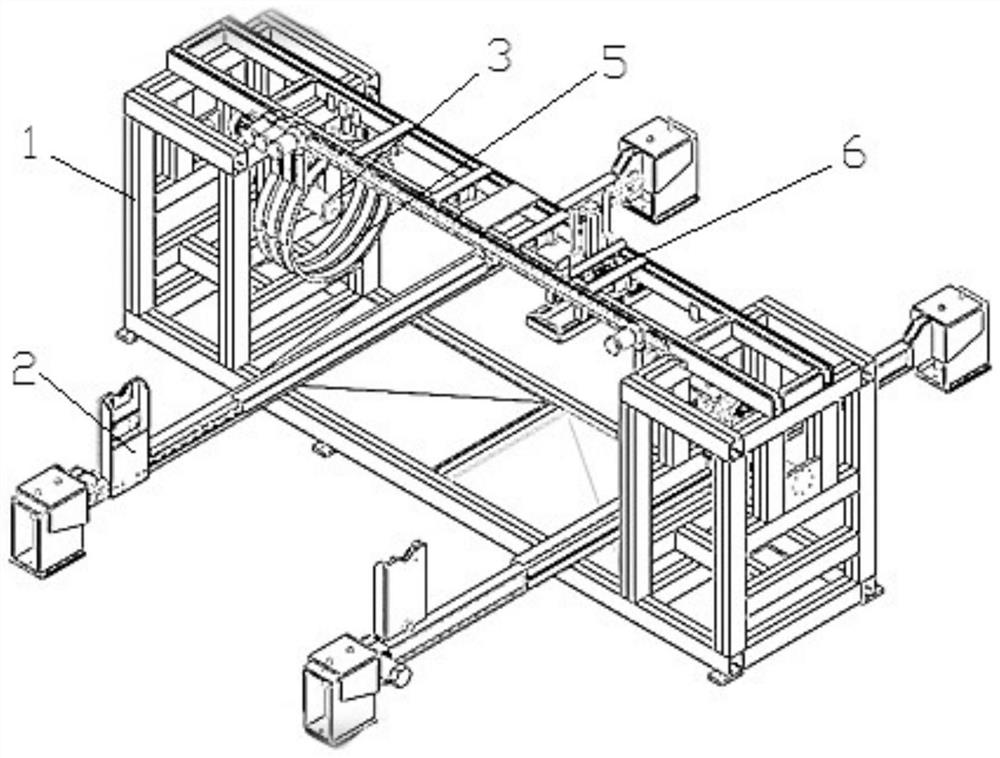

Hearth welding flaw detection device and method for soot blower

ActiveCN113566218AImpact flaw detectionImprove the effect of flaw detectionSolid removalVehiclesStructural engineeringSoot blower

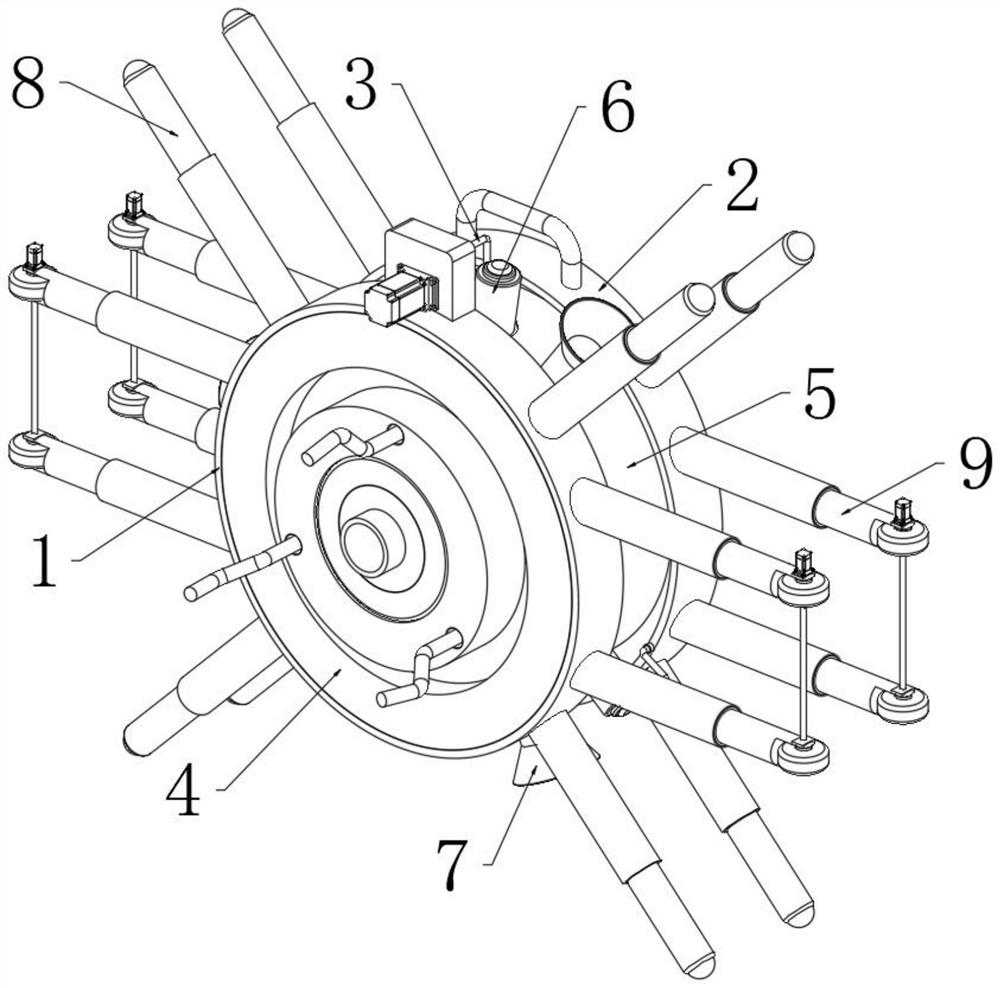

The invention discloses a hearth welding flaw detection device and method for a soot blower, and belongs to the technical field of hearth welding. The hearth welding flaw detection device comprises a first sleeve frame and a second sleeve frame, wherein the first sleeve frame and the second sleeve frame have the same structure and are horizontally and correspondingly distributed, a connecting assembly is fixedly mounted between the first sleeve frame and the second sleeve frame, clamping frames are fixedly arranged at the opposite ends of the first sleeve frame and the second sleeve frame in a clamped mode, a driving mechanism is arranged between the two clamping frames, a flaw detector and a cleaning assembly are arranged in the driving mechanism, guiding assemblies are fixedly installed on the outer walls of the first sleeve frame and the second sleeve frame, and moving assemblies are fixedly mounted on the outer walls of the first sleeve frame and the second sleeve frame. According to the flaw detection device, a cleaning assembly is arranged at the position adjacent to the flaw detector, debris cleaning can be carried out on a welding part before flaw detection is carried out on the welding part, therefore the debris is prevented from influencing flaw detection on the welding part, and the flaw detection effect of the whole device is improved.

Owner:浙江莱梦德电力设备有限公司

A progressive feed fine straightening method for metal pipes

ActiveCN109425655BSimple structureLow costAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesEngineeringMetal

The invention discloses a progressive feeding fine straightening method for a metal pipe, which includes the step of realizing the straightening of the metal pipe by means of paired straightening rollers when the metal pipe advances in the axial direction. Multiple pairs of straightening rollers are arranged horizontally so that the pressing and straightening force of each pair of straightening rollers is adjusted to increase sequentially along the moving direction of the metal pipe to achieve straightening. The invention can realize the progressive straightening of the metal pipe during flaw detection and improve the flaw detection effect, and has the advantages of simple implementation and good straightening effect.

Owner:宝武特冶航研科技有限公司

Metal pipe helical line contact feeding straightening method

ActiveCN109425658BAchieve straighteningImprove the effect of flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesMetal working apparatusStructural engineeringPipe

The invention discloses a helical line contact feeding straightening method for a metal pipe, which includes the step of realizing the straightening of the metal pipe by means of paired straightening rollers when the metal pipe advances in the axial direction, and is characterized in that The circumferential surface of the straightening rollers is set in a concave arc shape, so that each of the straightening rollers forms two symmetrical helical contact with the surface of the metal pipe to achieve straightening. The invention can realize the straightening of the metal pipe during flaw detection and improve the flaw detection effect, and has the advantages of simple implementation and good straightening effect.

Owner:宝武特冶航研科技有限公司

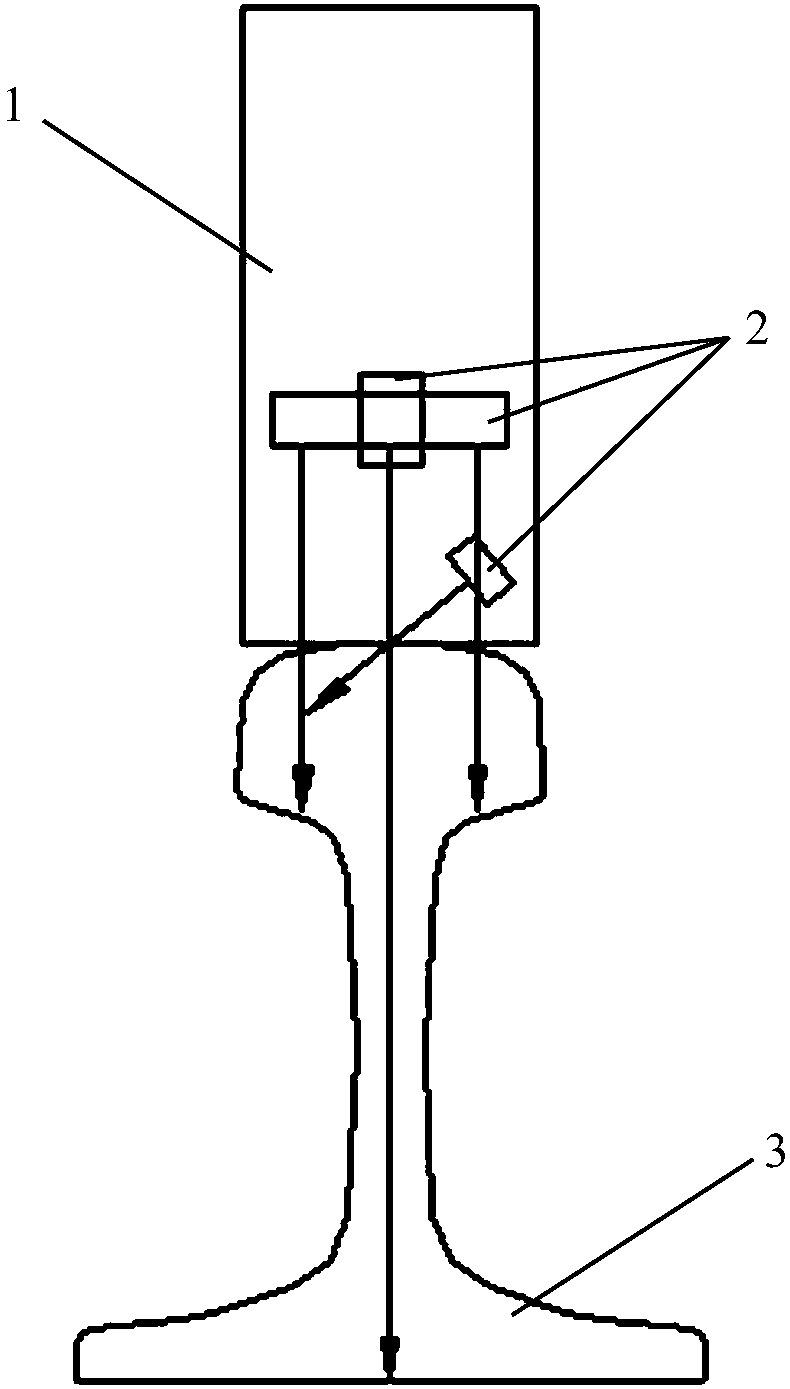

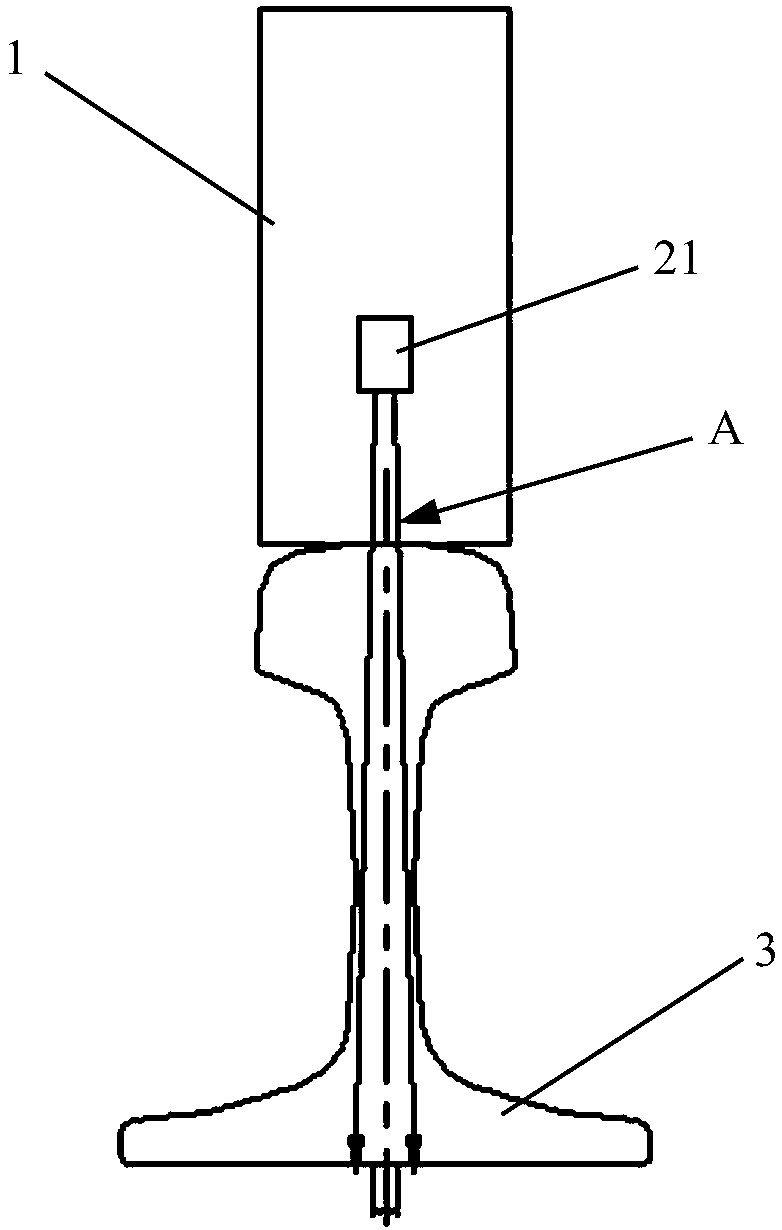

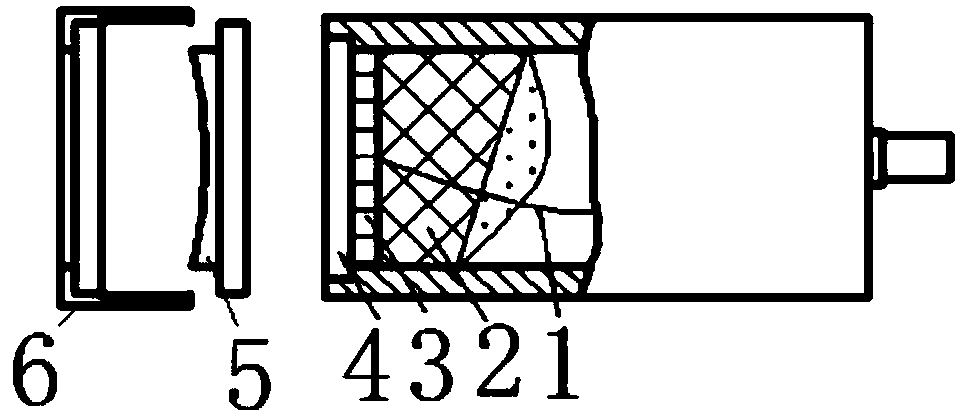

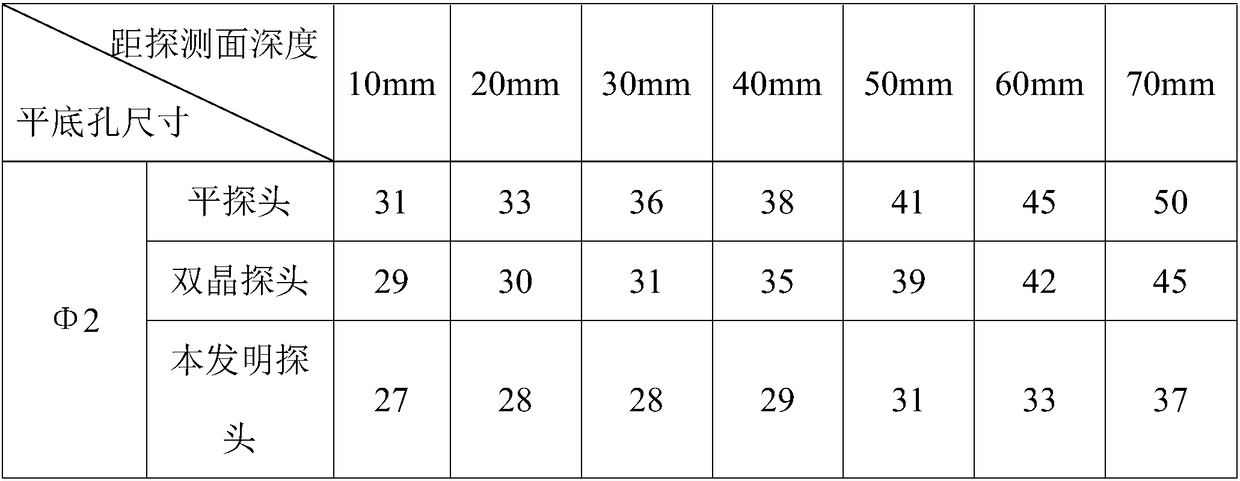

Ultrasonic probe for wheel hub

InactiveCN108061758AImprove the effect of flaw detectionSimple structureMaterial analysis using sonic/ultrasonic/infrasonic wavesAcousticsTread

The invention discloses an ultrasonic probe for a wheel hub. The ultrasonic probe comprises a probe shell and a piezoelectric wafer, wherein the piezoelectric wafer is arranged at the end part of theprobe shell; the ultrasonic probe further comprises an elastically deformable sound beam convergent lens; the sound beam convergent lens is detachably located on the outer side of the piezoelectric wafer and arranged at the end part of the probe shell. The ultrasonic probe for the wheel hub is a detachable portable focused ultrasonic probe; the sound beam convergent lens can be fitted to the curved surface of a tread to improve the ultrasonic flaw detection capacity of the tread; the sound beam convergent lens detachably detects flaws on inner and outer rim surfaces, so that various types of multiple probes are not required to be carried; furthermore, the ultrasonic probe is simple in structure and low in manufacturing cost.

Owner:MAANSHAN IRON & STEEL CO LTD

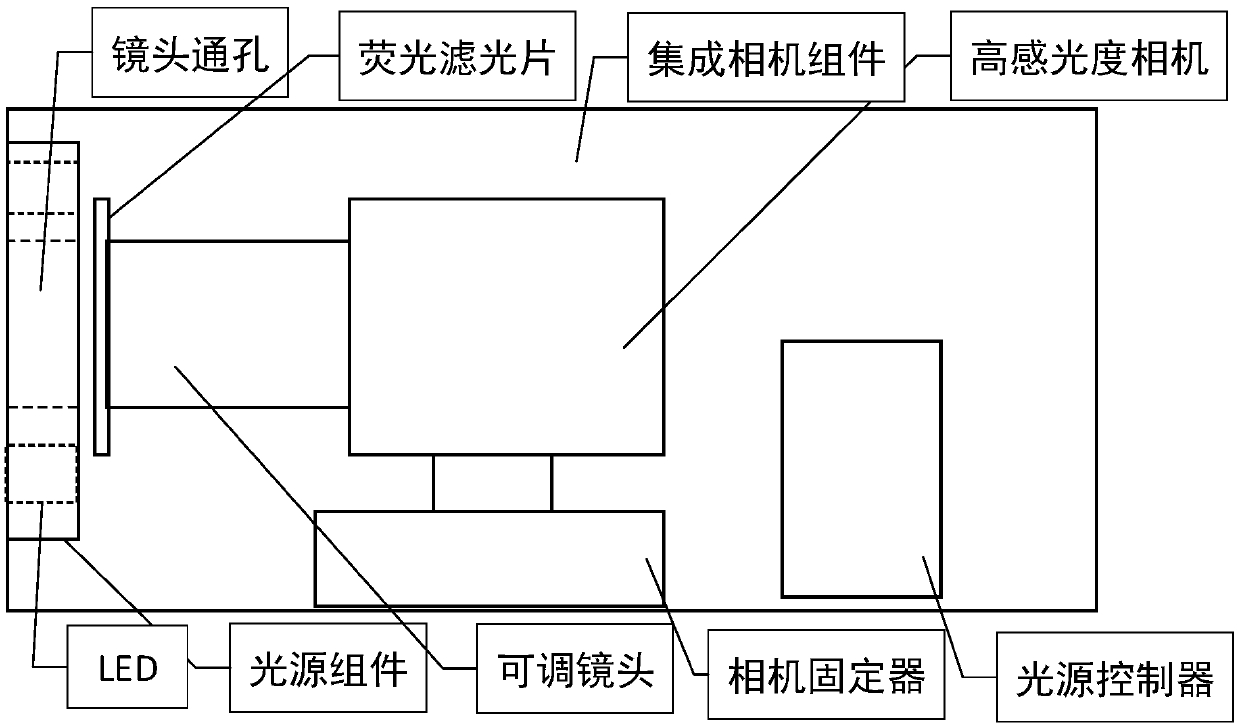

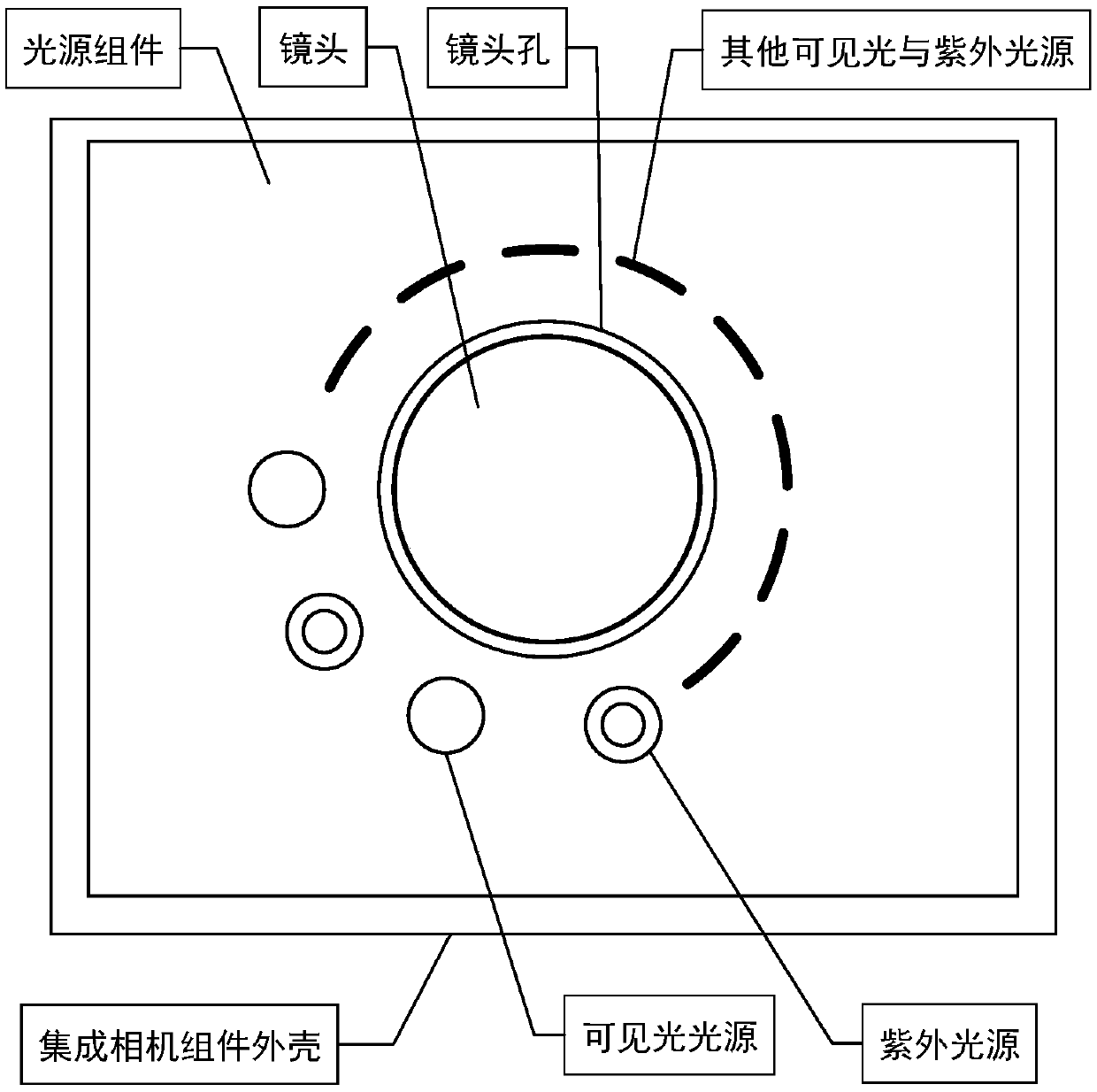

Integrated camera assembly for magnetic powder inspection fluorescence imaging of small special-shaped part

PendingCN110554085ASafety Magnetic Particle Inspection Fluorescence Imaging InspectionEfficient Magnetic Particle Inspection Fluorescence Imaging InspectionFluorescence/phosphorescenceMaterial magnetic variablesCamera lensFluorescence

The invention discloses a magnetic powder inspection fluorescence imaging device for detecting a small special-shaped part. The magnetic powder inspection fluorescence imaging device comprises an integrated camera assembly, and the integrated camera assembly comprises a camera, a lens arranged in front of the camera, a fluorescence filter arranged in front of an electric lens and a light source assembly arranged on a shell of the integrated camera assembly. The light source assembly comprises a lens through hole formed in the center of the shell and a plurality of LED light sources arranged around the lens through hole, and the plurality of LED light sources includes a plurality of ultraviolet LEDs and a plurality of visible light LEDs. The magnetic powder inspection fluorescence imaging device for detecting the small steel special-shaped part further comprises an external high-power ultraviolet light source, and the ultraviolet light is transmitted to the integrated camera assembly through an optical fiber. The integrated device provided by the invention can realize the safe and efficient magnetic powder inspection fluorescence imaging device detection. By utilizing a small LED light source or the miniaturization of a large light source optical fiber, the inconsistency of the observation positions of the ultraviolet illumination light source and the camera during detection isavoided, a detection blind area is avoided, and the magnetic powder inspection detection effect is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

A Design Method Using Multiple Frequency Simultaneous Excitation to Improve Magnetic Particle Flaw Detection Capability

ActiveCN103743812BImprove the effect of flaw detectionImprove detection accuracyMaterial magnetic variablesPower flowExcitation current

The invention discloses a design method for improving the magnetic powder inspection capacity through the simultaneous excitation at a plurality of frequencies. Magnet yoke coils are simultaneously excited by using excitation currents with a plurality of different frequencies based on the principle that induced magnetic fields generated by the excitation currents with the different frequencies have different magnetization deeps for an inspected workpiece, so that the inspected workpiece is comprehensively and uniformly magnetized, defective leakage magnetic fields on the surface and the inner part of the inspected workpiece are favorably escaped, magnetic powder is easy to gather, and therefore, the defect checkout capacity of the magnetic powder is greatly improved.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

Progressive feeding and precise straightening method for metal pipe

ActiveCN109425655ASimple structureLow costAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesEngineeringMechanical engineering

A progressive feeding and precise straightening method for a metal pipe is disclosed. The method includes a step of achieving metal pipe feeding and straightening by straightening rollers arranged inpairs in an axial forward movement process of the metal pipe. The method is characterized in that a plurality of pairs of the straightening rollers arranged horizontally are adopted to achieve straightening in a manner that straightening force of each pair of the straightening rollers increases in order in the movement direction of the metal pipe. The method can achieve progressive straightening during feeding before metal pipe flaw detection so as to improve flaw detection effects and has advantages of simple implementation and good straightening effects.

Owner:宝武特冶航研科技有限公司

A kind of metal tube rotary feeding straightening method

ActiveCN109420691BAchieve straighteningImprove the effect of flaw detectionMetal-working feeding devicesPositioning devicesStructural engineeringPipe

The invention discloses a method for performing rotary feed straightening on metal pipes. The method comprises the step of realizing feed straightening on the metal pipes by means of straightening rollers arranged in pairs in the process that the metal pipes move forwards in the axial direction, and is characterized in that the metal pipes rotate while moving forwards, and thus, the metal pipes spirally move forwards, and the metal pipes are straightened in the process that the metal pipes spirally move forwards. According to the method disclosed by the invention, the metal pipes can be straightened when being fed before flaw detection so as to improve the flaw detection effect, and the method has the advantages of being simple to implement and having a good straightening effect.

Owner:宝武特冶航研科技有限公司

Movable magnetic powder inspection device

PendingCN106248784AReduce labor intensityExpand the scope of detectionMaterial magnetic variablesDisplay deviceEngineering

The invention discloses a movable magnetic powder inspection device which comprises an inspection box, an electric control box, castors and a display. The lower end of the inspection box is open, the electric control box is positioned behind the inspection box and higher than the same, the castors are mounted at the lower end of the inspection box, and the display is mounted on the upper portion of the electric control box. A support is arranged in the inspection box, a magnetizing component and a photographic scanning component are arranged on the support, the magnetizing component comprises a closed circuit iron core and a magnetizing coil winded on the closed circuit iron core, the photographic scanning component comprises an industrial camera and an illuminating lamp for assisting the industrial camera in shooting, a processor and a storage are arranged in the electric control box and connected with the industrial camera, the processor is connected with the storage, and a handle is arranged on the upper portion of the electric control box. Inspection efficiency is effectively improved, inspection precision is also improved, labor cost is reduced, and the movable magnetic powder inspection device has humanized design.

Owner:SHEYANG SAIFU NDT EQUIP MFG

Underwater non-destructive flaw detection equipment and processing method based on the combination of vision and magnetic particles

ActiveCN112924466BRealize integrated operation processImprove the effect of flaw detectionImage enhancementImage analysisImaging processingCamera module

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com