Ultrasonic probe for wheel hub

A technology of ultrasonic probes and wheel rims, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves. The structure is simple, the production cost is low, and the effect of improving the ultrasonic flaw detection ability of the tread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

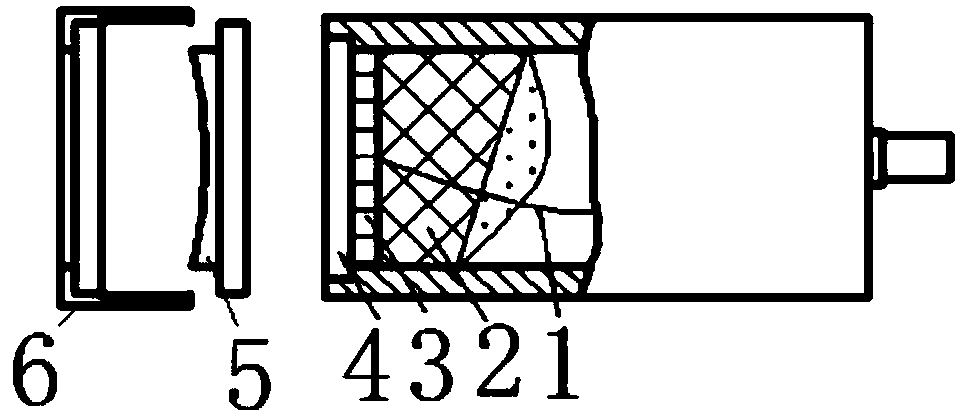

[0021] Such as figure 1 As shown, the wheel rim ultrasonic probe includes a probe housing, an electric wire 1, a damping block 2, a piezoelectric wafer 3, a protective film 4, a card frame 6 and an elastically deformable sound beam focusing lens 5; wherein the probe housing It is a cylindrical structure, the piezoelectric chip 3 is arranged at the end of the probe shell, and the sound beam converging lens 5 is detachably located outside the piezoelectric chip and set at the end of the probe shell.

[0022] The sound beam converging lens 5 can be pressed against the curved surface of the tread to improve the ultrasonic flaw detection capability of the tread; the sound beam converging lens is detachable for inner and outer rim surface flaw detection without carrying multiple and various types of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com