Hearth welding flaw detection device and method for soot blower

A flaw detection device and soot blower technology, applied in combustion methods, measuring devices, instruments, etc., can solve problems such as troublesome operation and affect the effect of flaw detection, so as to improve the stability, improve the effect of flaw detection, and facilitate segmented Detecting the effect of information collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

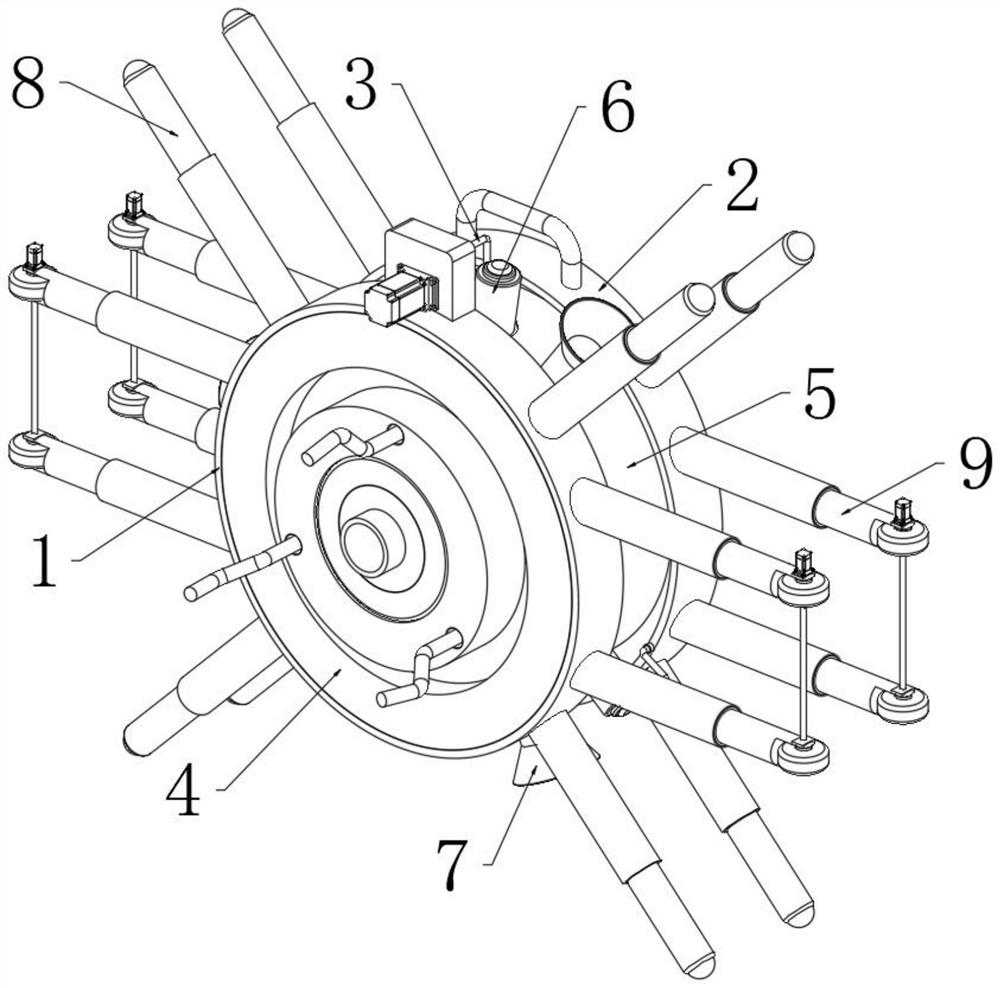

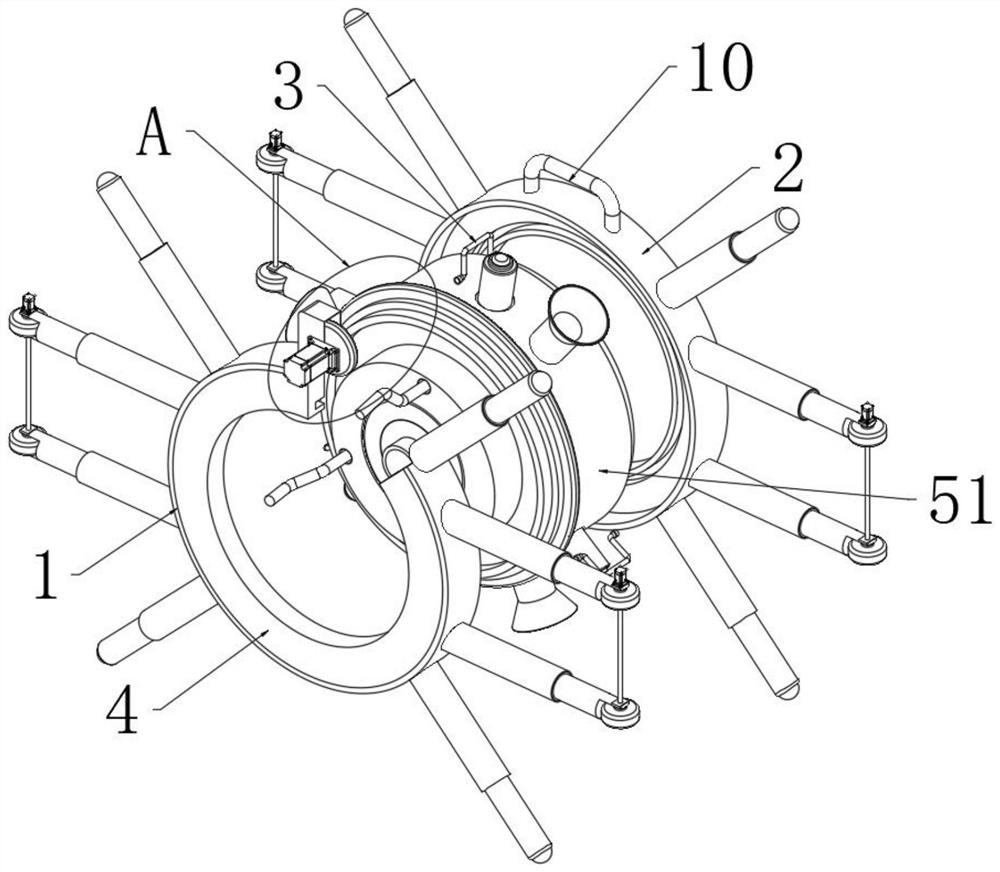

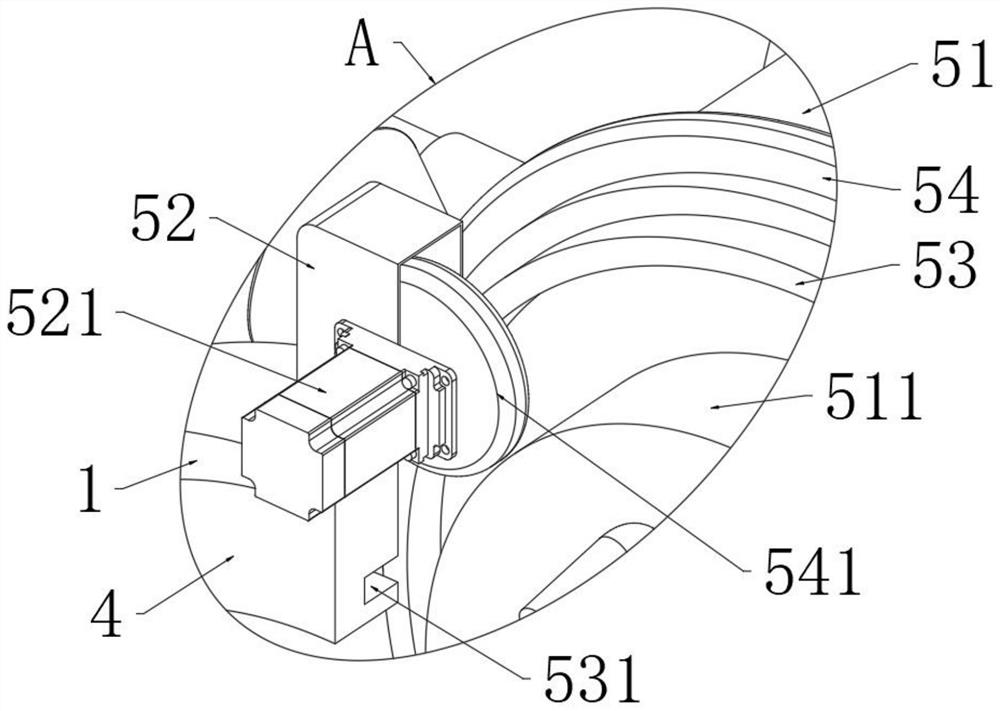

[0039] Example: such as Figure 1-9 As shown, the present invention provides a technical solution: a furnace welding flaw detection device for a soot blower, comprising a first frame 1 and a second frame 2, the first frame 1 and the second frame 2 have the same structure And the horizontal corresponding distribution, between the first frame 1 and the second frame 2 is fixedly installed with the connection assembly 3, the connection assembly 3 is provided with multiple groups distributed in a circular array; the first frame 1 and the second frame 2 The opposite ends are fixed with a card frame 4, and a drive mechanism 5 is provided between the two sets of card frames 4. The drive mechanism 5 is equipped with a flaw detector 6 and a cleaning component 7. The first set of frames 1 and the second set of frames 2 The outer walls of the outer walls are fixedly equipped with guide assemblies 8, and the guide assemblies 8 are provided with four groups distributed in a circular array; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com