Flaw detecting method for stainless steel/carbon steel composite material

A technology for composite materials and flaw detection, which is applied in the preparation of test samples, optical testing of flaws/defects, etc., can solve problems such as high cost, inability to accurately identify damaged parts of stainless steel/carbon steel composite materials, and limited sample size , to speed up the corrosion process, improve the effect of flaw detection and shorten the time of flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

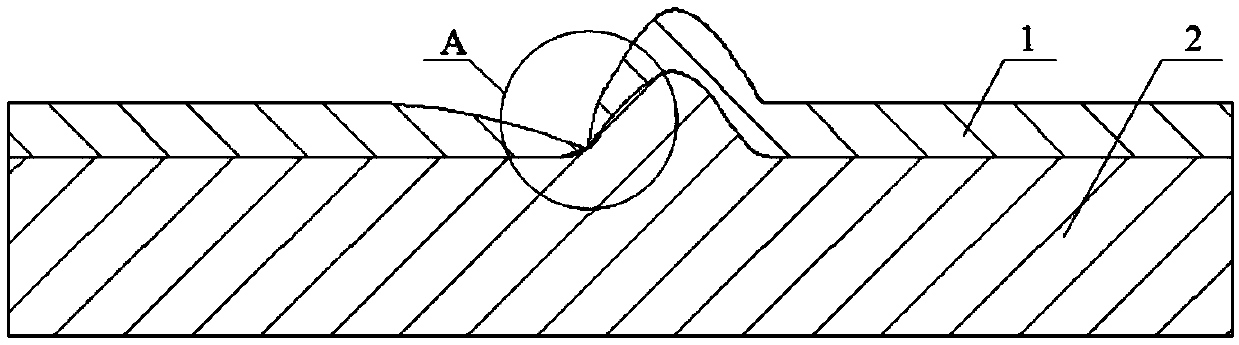

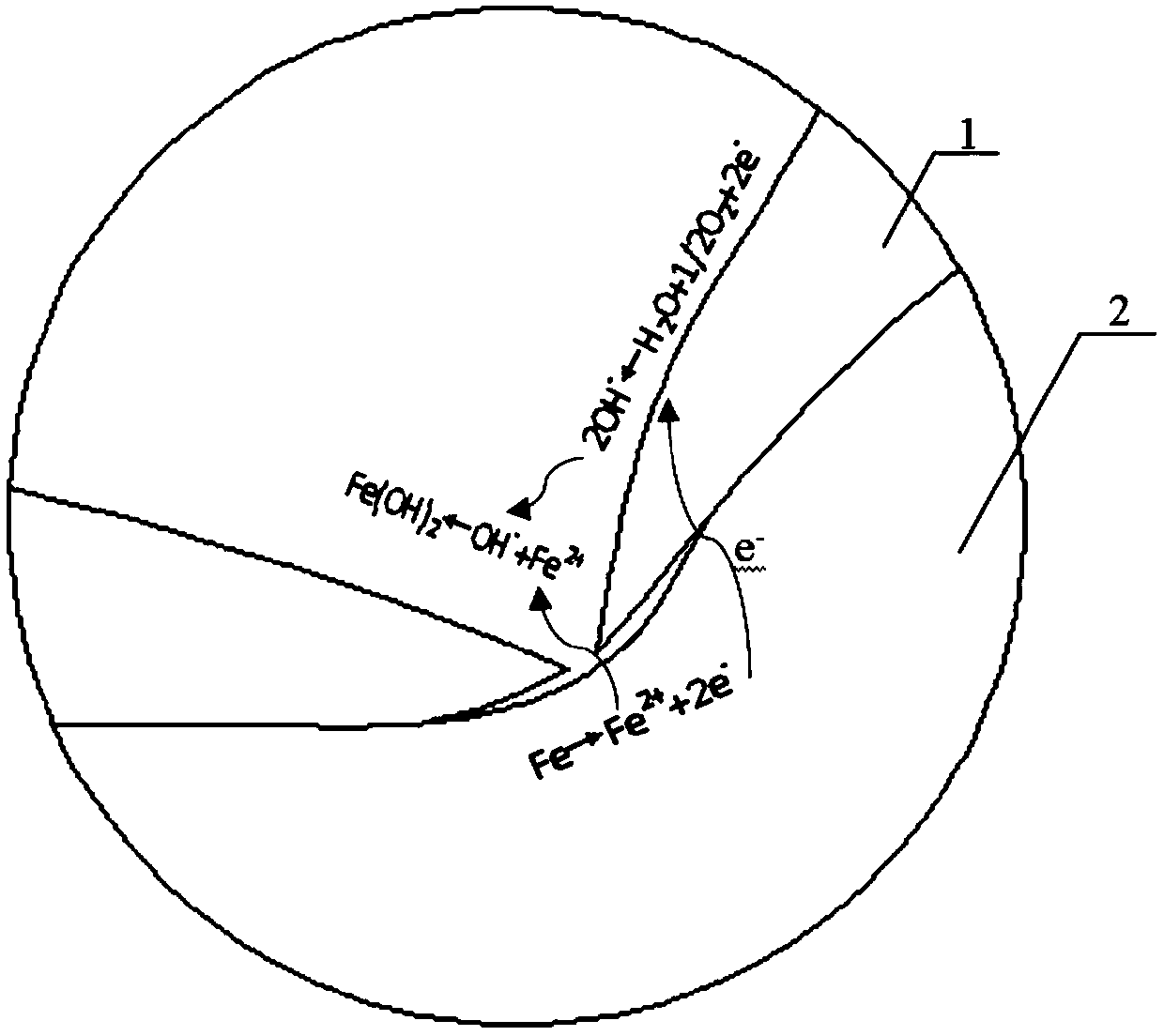

Embodiment 1

[0026] Prepare a sodium chloride solution with a concentration of 5%, pour it into the water tank, place a 2m long stainless steel / carbon steel bimetallic composite rebar in the sodium chloride solution in the water tank, and take out the stainless steel / carbon steel bimetallic composite after 24 hours For rebar, if dark green rust spots are detected, the position of the dark green rust spots is the cracking site. During the immersion process, galvanic corrosion and crevice corrosion of dissimilar metals will occur on the exposed carbon steel at the cracked part, and the corrosion product is dark green rust spots, while the surface of the uncracked stainless steel does not change significantly.

Embodiment 2

[0028] Prepare a sodium chloride solution with a concentration of 0.1%, pour it into the water tank, place a 2m-long stainless steel / carbon steel bimetallic composite rebar in the sodium chloride solution in the water tank, and take out the stainless steel / carbon steel bimetallic composite after 48 hours For rebar, if dark green rust spots are detected, the position of the dark green rust spots is the cracking site. During the immersion process, galvanic corrosion and crevice corrosion of dissimilar metals will occur on the exposed carbon steel at the cracked part, and the corrosion product is dark green rust spots, while the surface of the uncracked stainless steel does not change significantly.

Embodiment 3

[0030] Prepare a sodium chloride solution with a concentration of 10%, pour it into the water tank, place a 2m long stainless steel / carbon steel bimetallic composite rebar in the sodium chloride solution in the water tank, and take out the stainless steel / carbon steel bimetallic composite after 48 hours For rebar, if dark green rust spots are detected, the position of the dark green rust spots is the cracking site. During the immersion process, galvanic corrosion and crevice corrosion of dissimilar metals will occur on the exposed carbon steel at the cracked part, and the corrosion product is dark green rust spots, while the surface of the uncracked stainless steel does not change significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com