Warship hull descaling and flaw detecting system

A technology for ships and hulls, applied in the field of automation systems, can solve the problems of lack of ship hull detection function, insufficient removal effect, corrosion of facilities and ships, etc., to achieve thorough and effective removal effect, good descaling effect, and operational efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, present embodiment is further described:

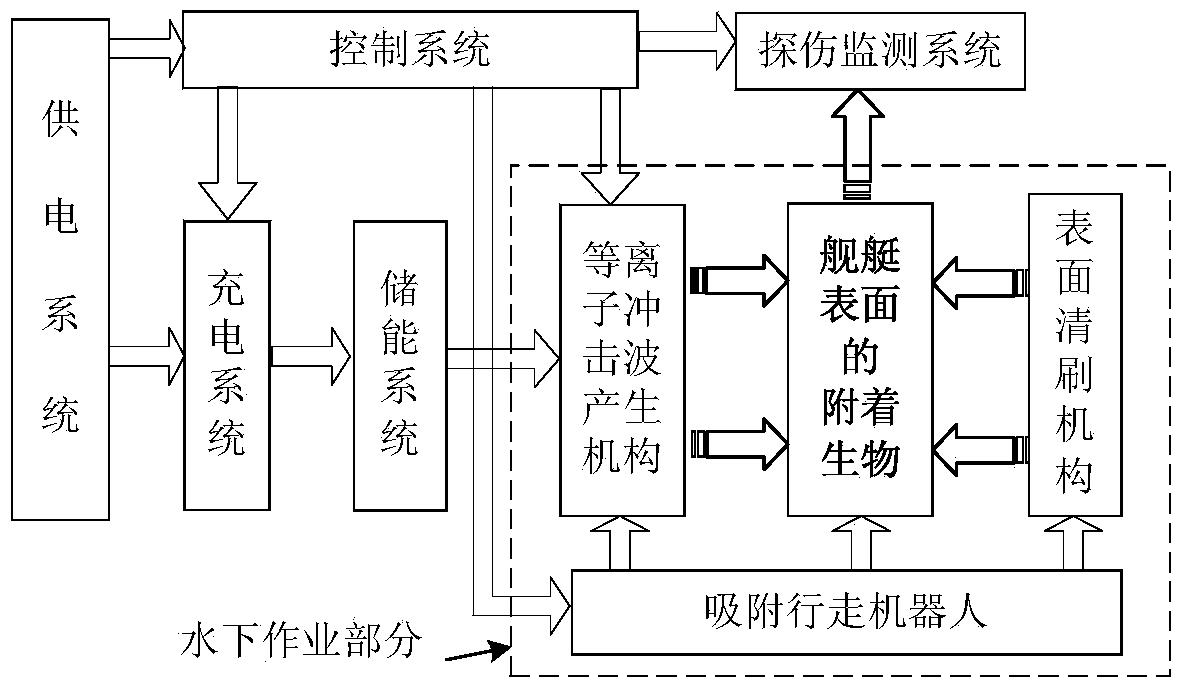

[0039] like figure 1 As shown, the ship shell descaling and flaw detection system in this embodiment includes a power supply system, a control system, a charging system, an energy storage system, a plasma shock wave generating mechanism, a flaw detection monitoring system, a surface cleaning mechanism, and an adsorption walking robot. In the system, the power supply system is connected to the control system and the charging system to provide energy for it. The whole system can be powered by the ship's own power system, or by the power supply on land, or an additional generator can be installed to supply power for the system alone. The power supply system is 220V / 50Hz.

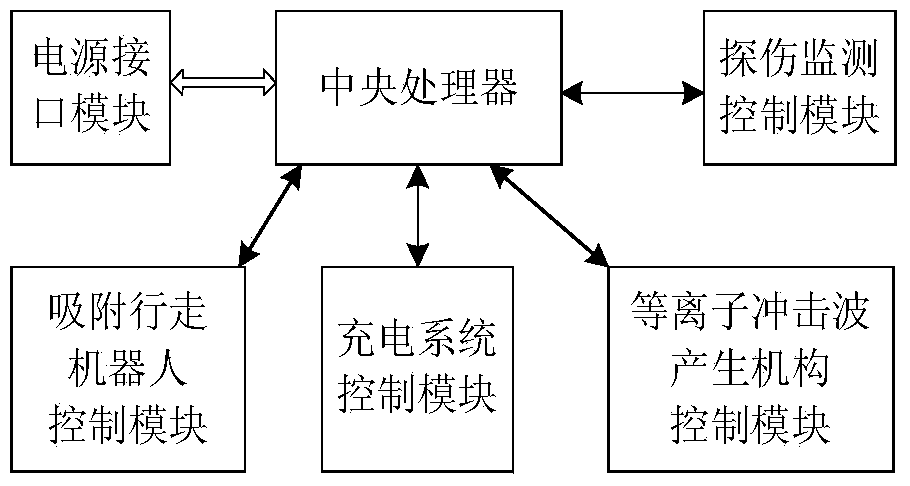

[0040] The control system is composed of a central processing unit, a charging system control module, a plasma shock wave generating mechanism control module, an adsorption walking robot control module, a flaw de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com