Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve takt time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

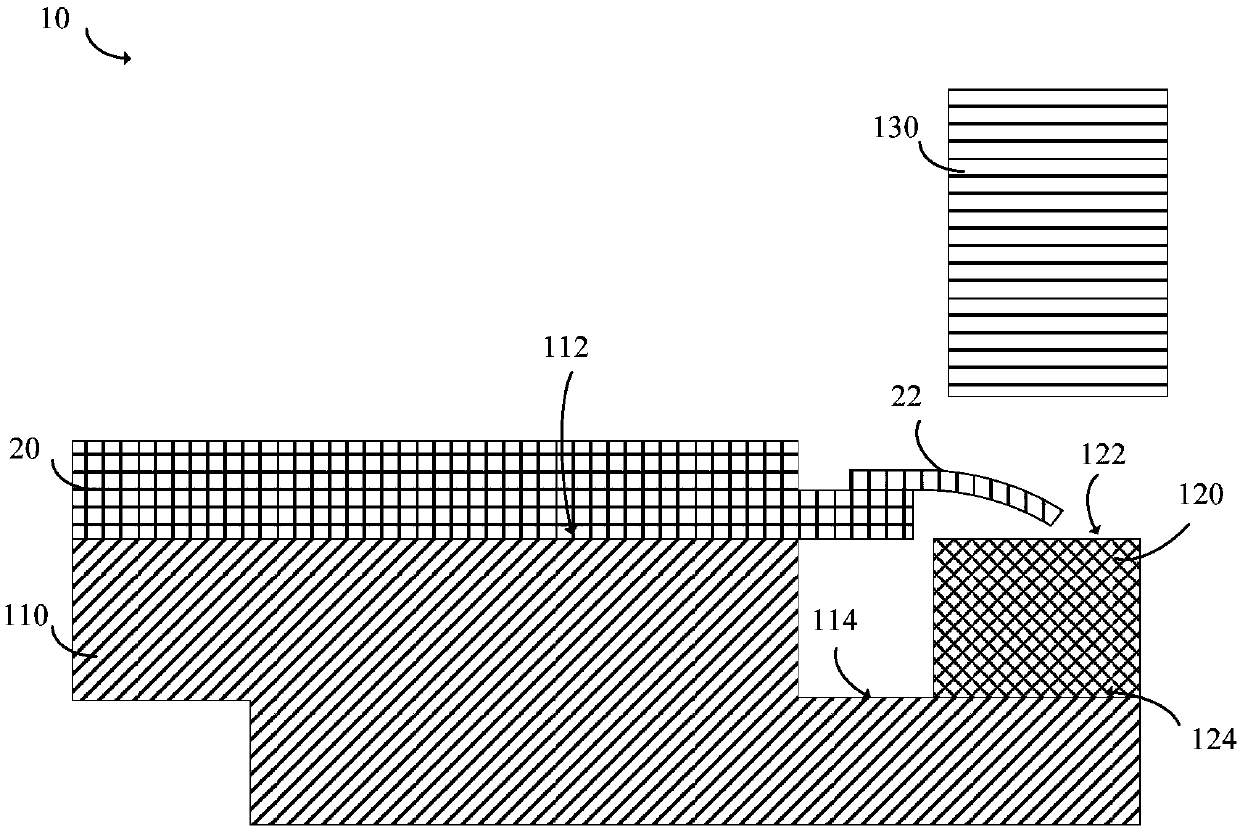

Liquid crystal display device, method of manufacturing the same, and electronic apparatus

InactiveUS20050231674A1Manufacture is easy and shortWide viewing angleSolid-state devicesNon-linear opticsVertical alignmentEngineering

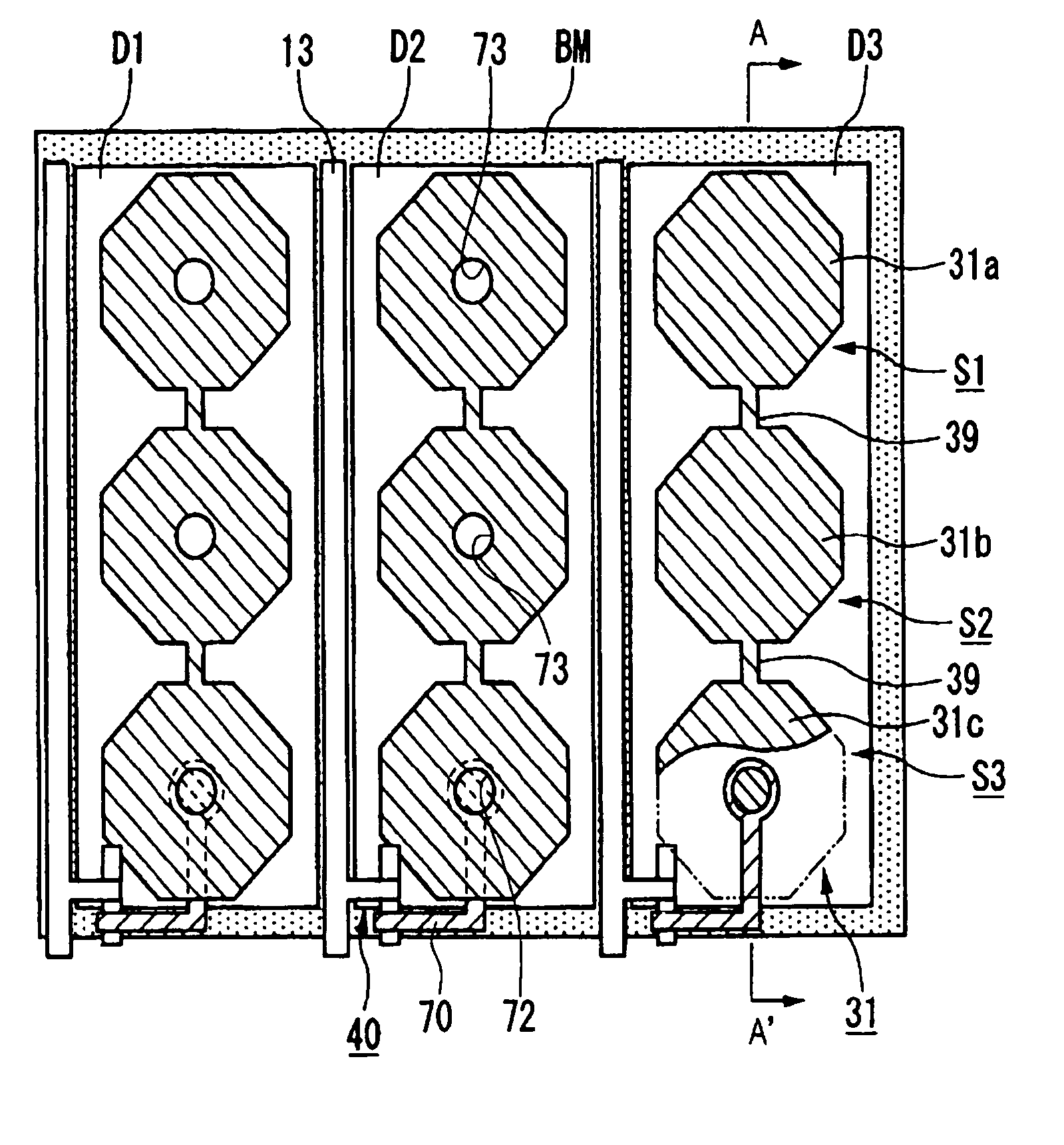

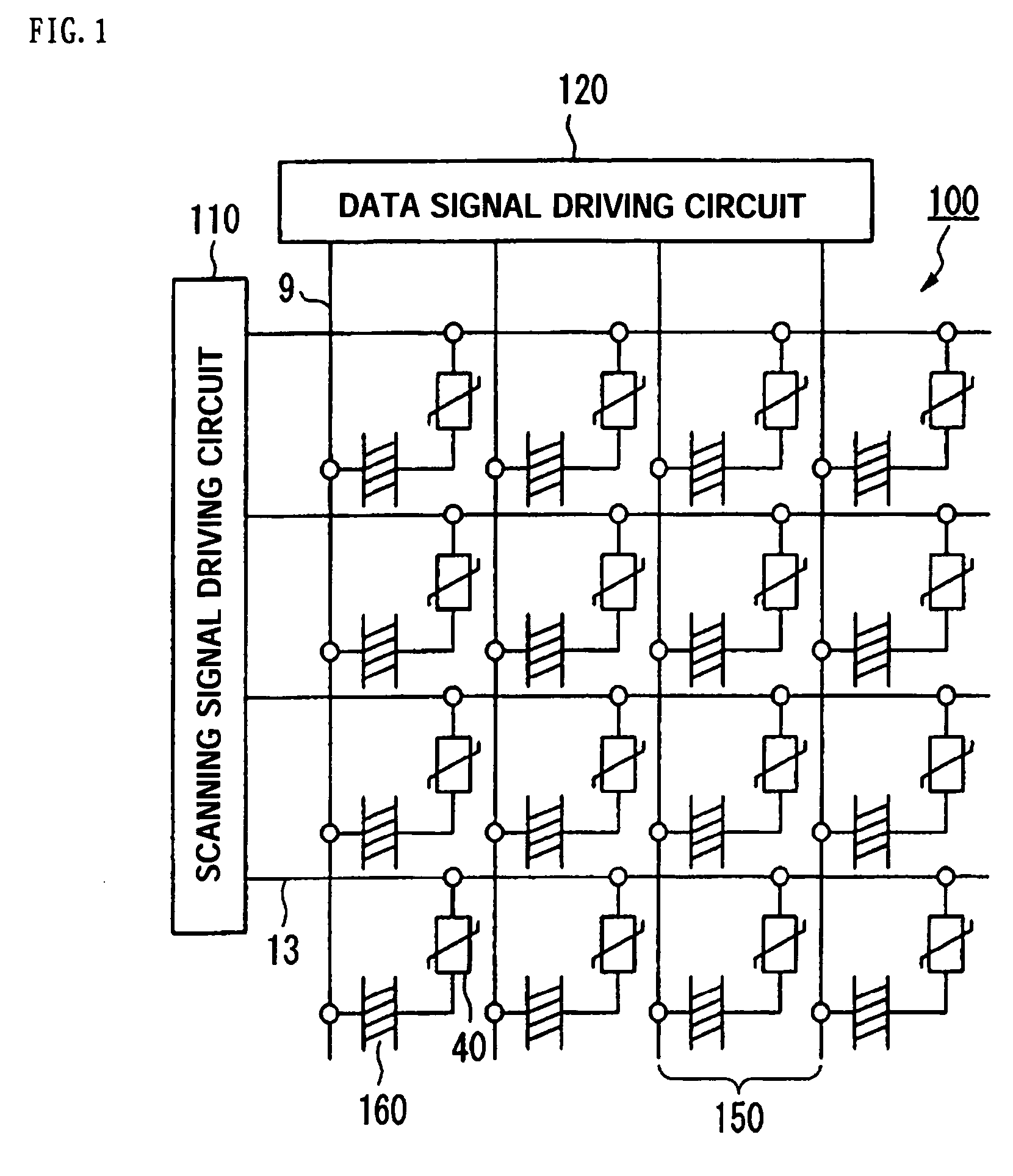

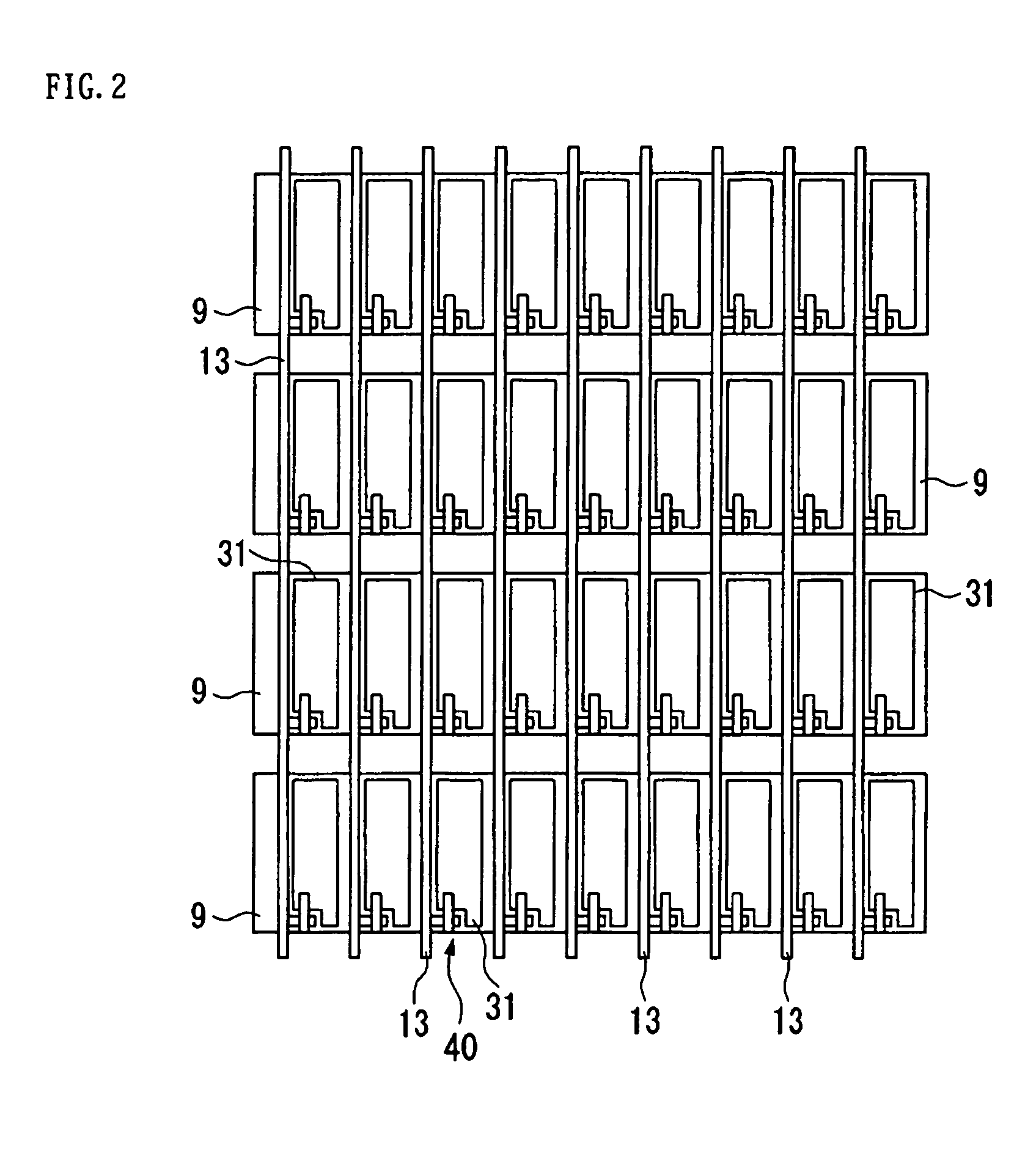

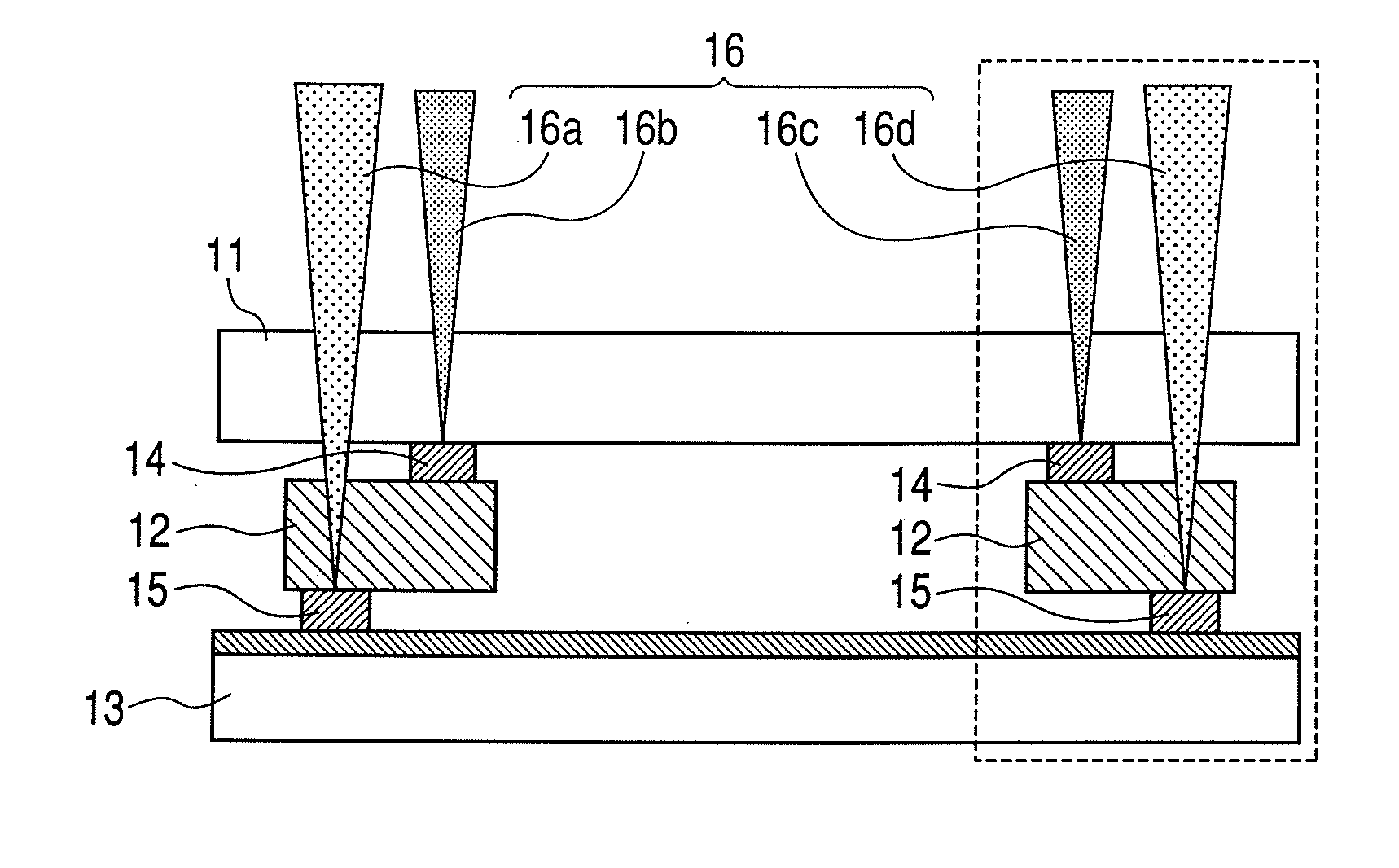

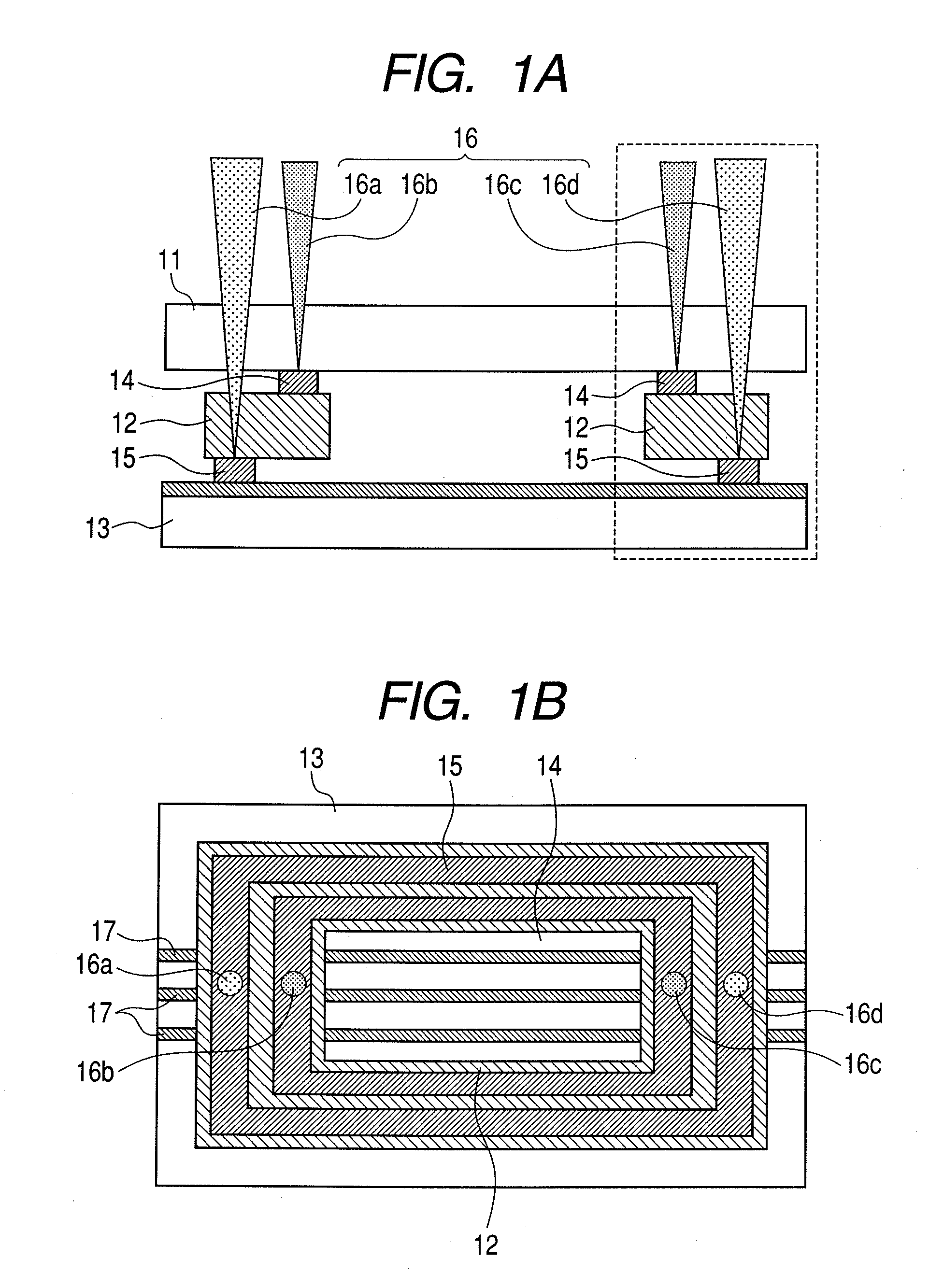

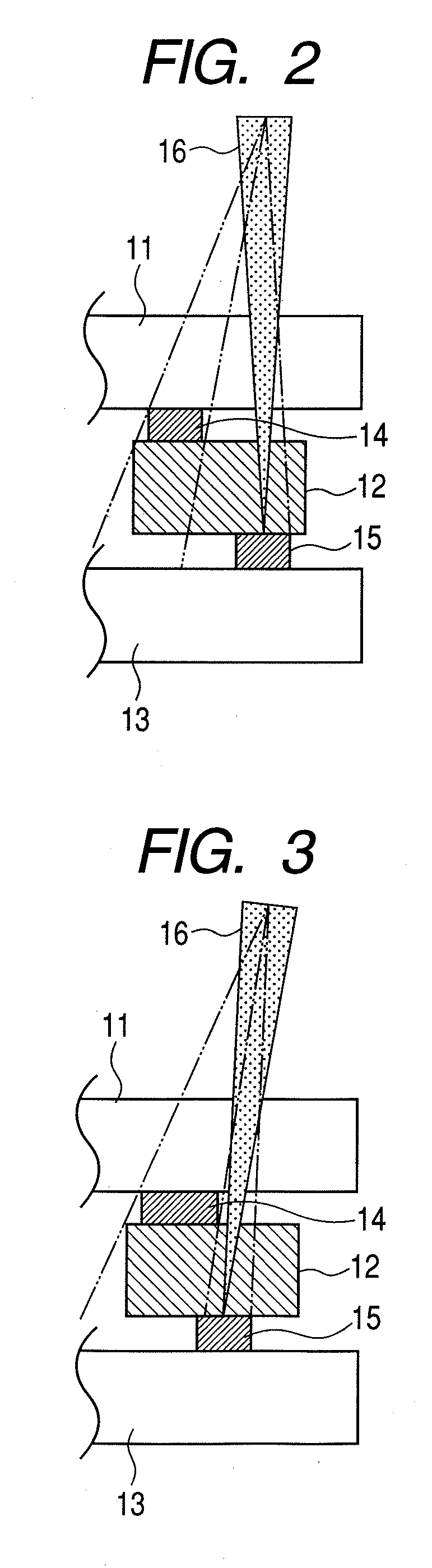

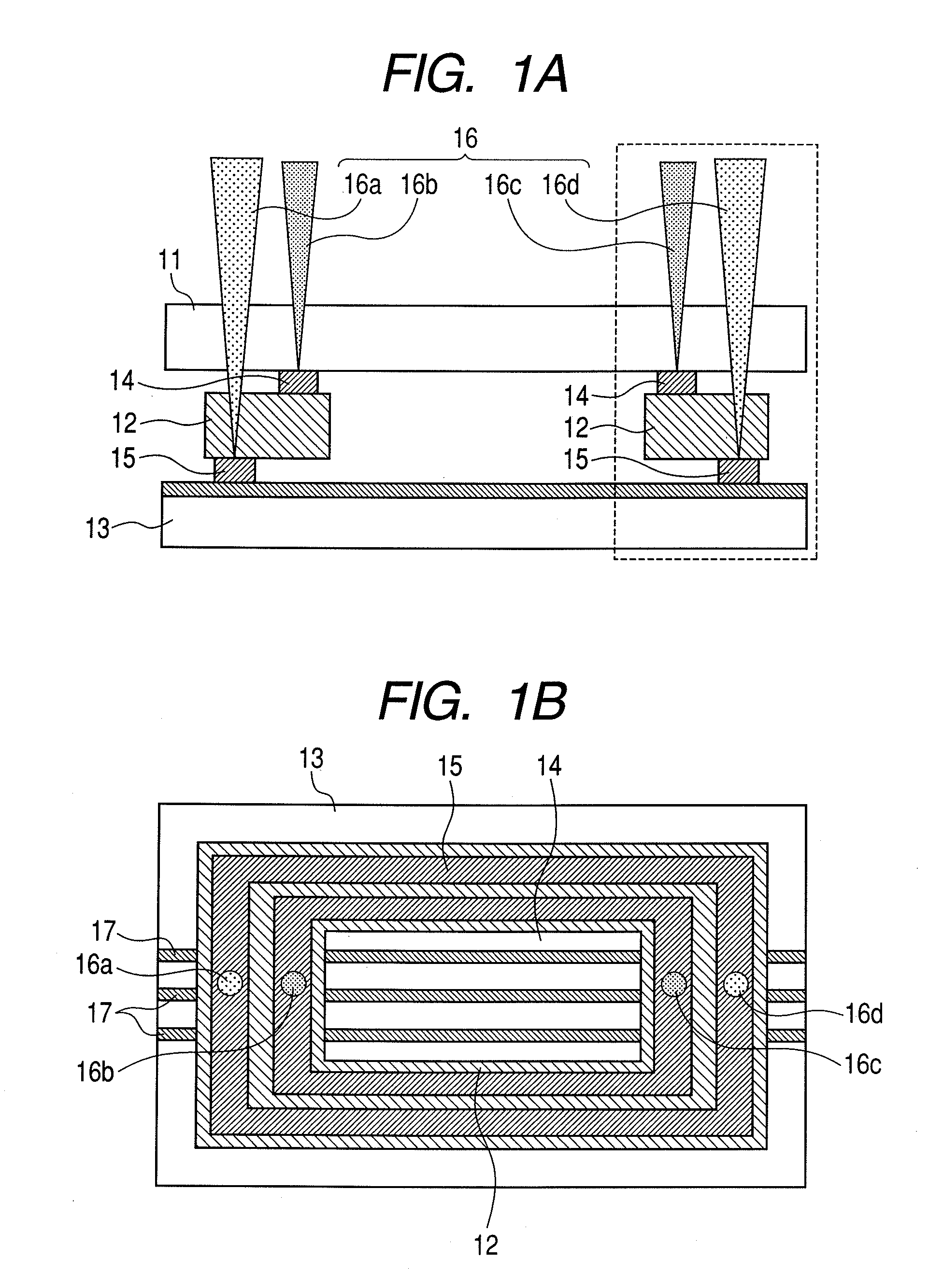

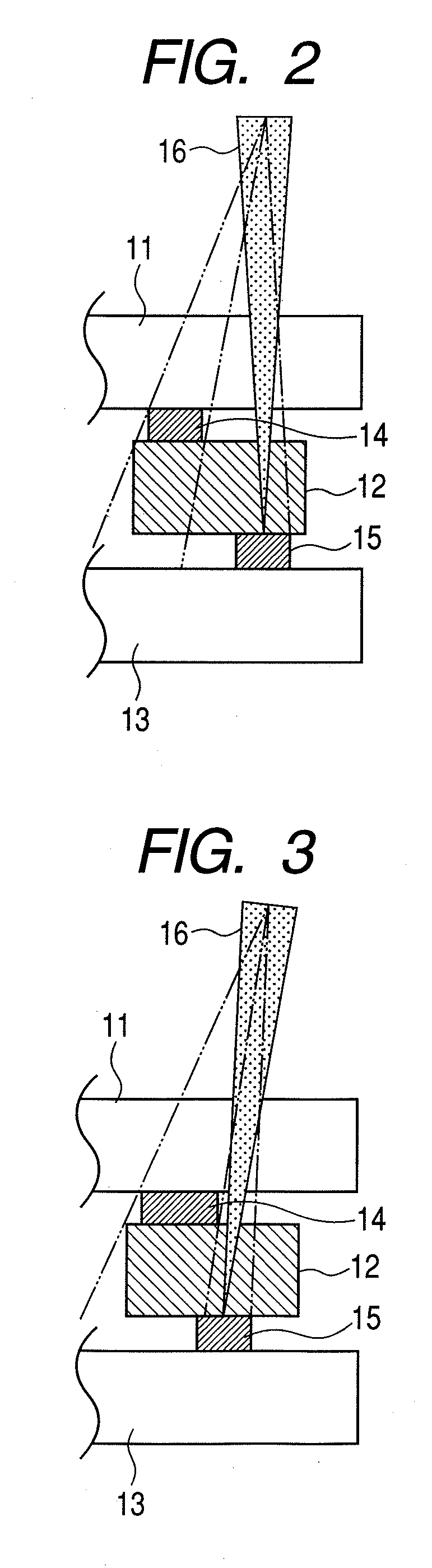

A liquid crystal display device with liquid crystal in a vertical alignment mode. A pixel electrode 31 has a plurality of island-shaped portions 31a, 31b, and 31c and connecting portions 39 for connecting the plurality of island-shaped portions in each dot region. At the centers of sub-dot regions S1, S2, and S3 respectively composed of the island-shaped portions, concave portions are formed in an interlayer insulating film on a lower substrate, and the pixel electrodes are provided along inner surfaces of the concave portions in the interlayer insulating film, thereby forming concave portions 73 for alignment control. One of the plurality of concave portions 73 also serves as a contact hole 72 in each dot region.

Owner:SEIKO EPSON CORP

Airtight container manufacturing method, and image displaying apparatus manufacturing method using airtight container manufacturing method

InactiveUS20090199963A1Efficient use ofImprove takt timeLamination ancillary operationsLaminationBonding processEngineering

Owner:CANON KK

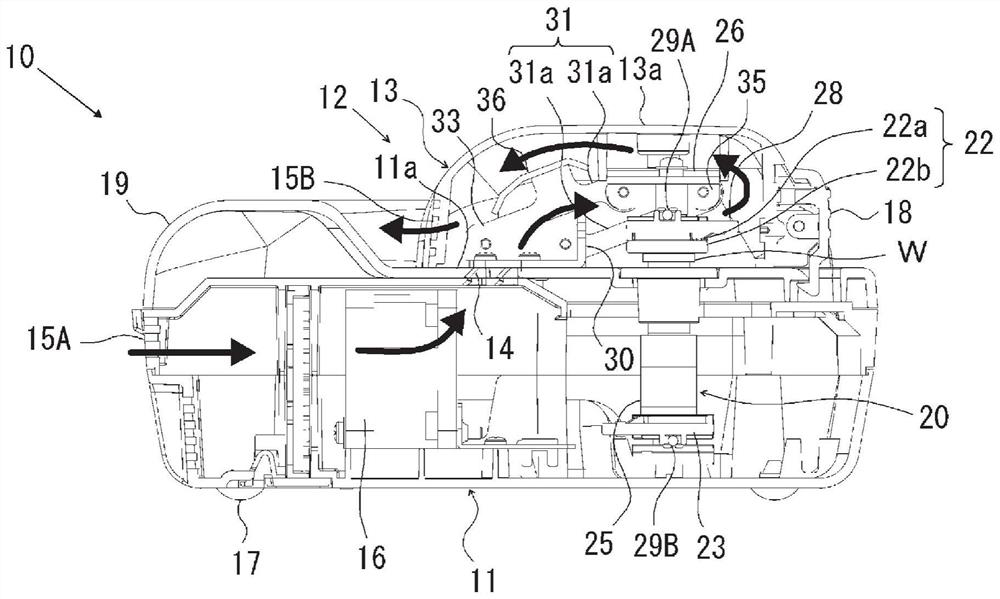

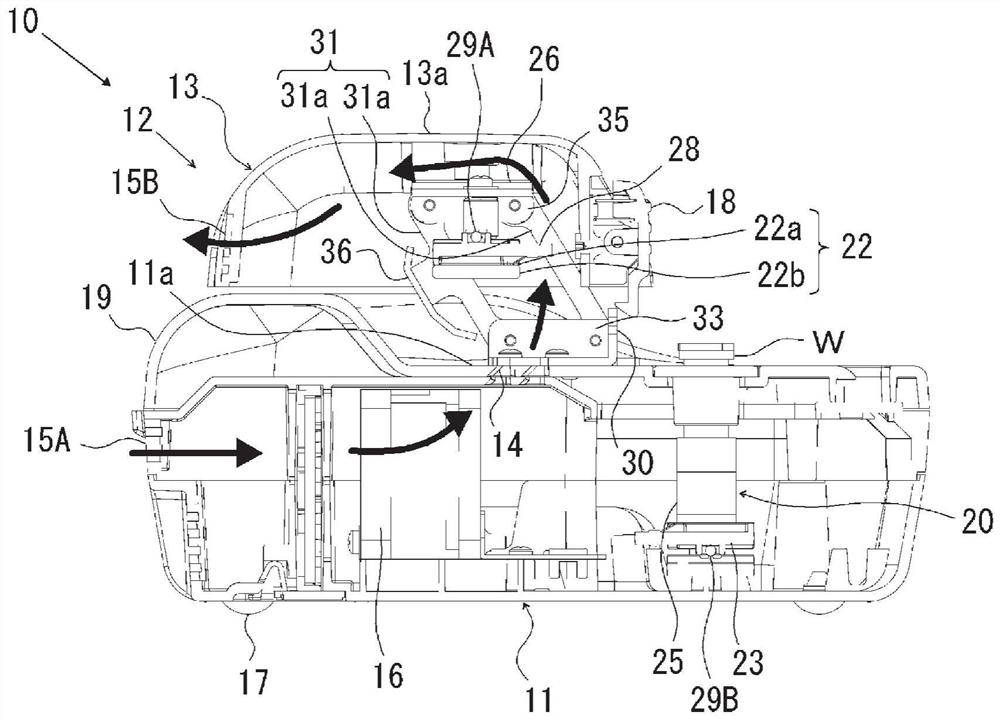

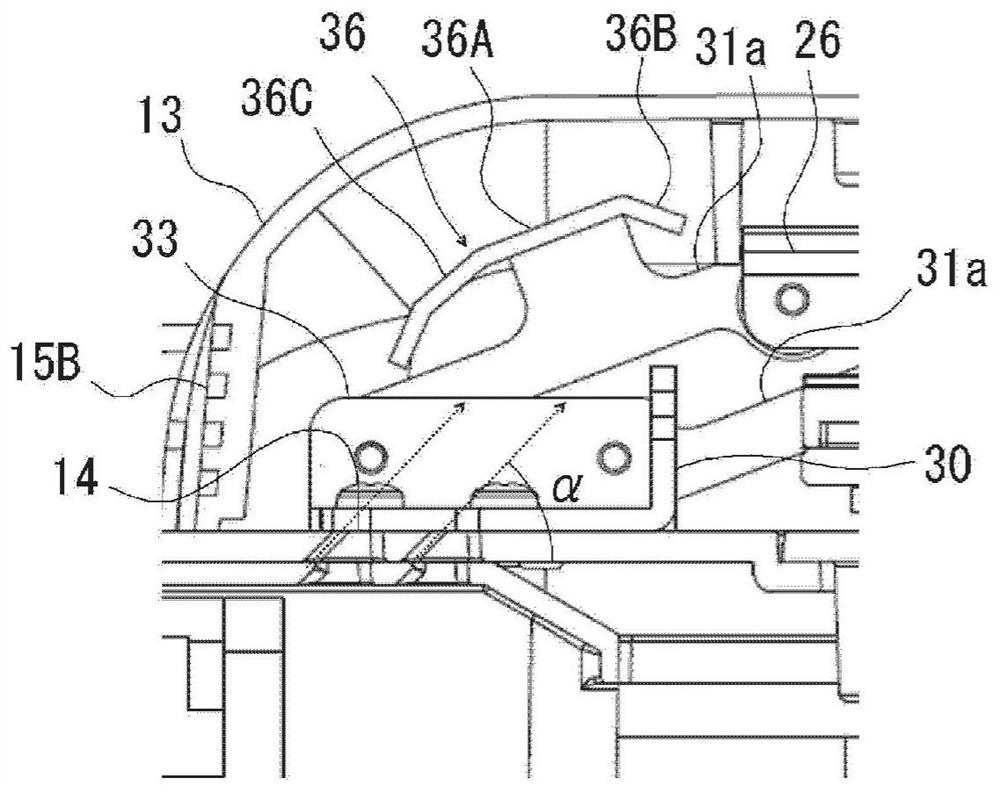

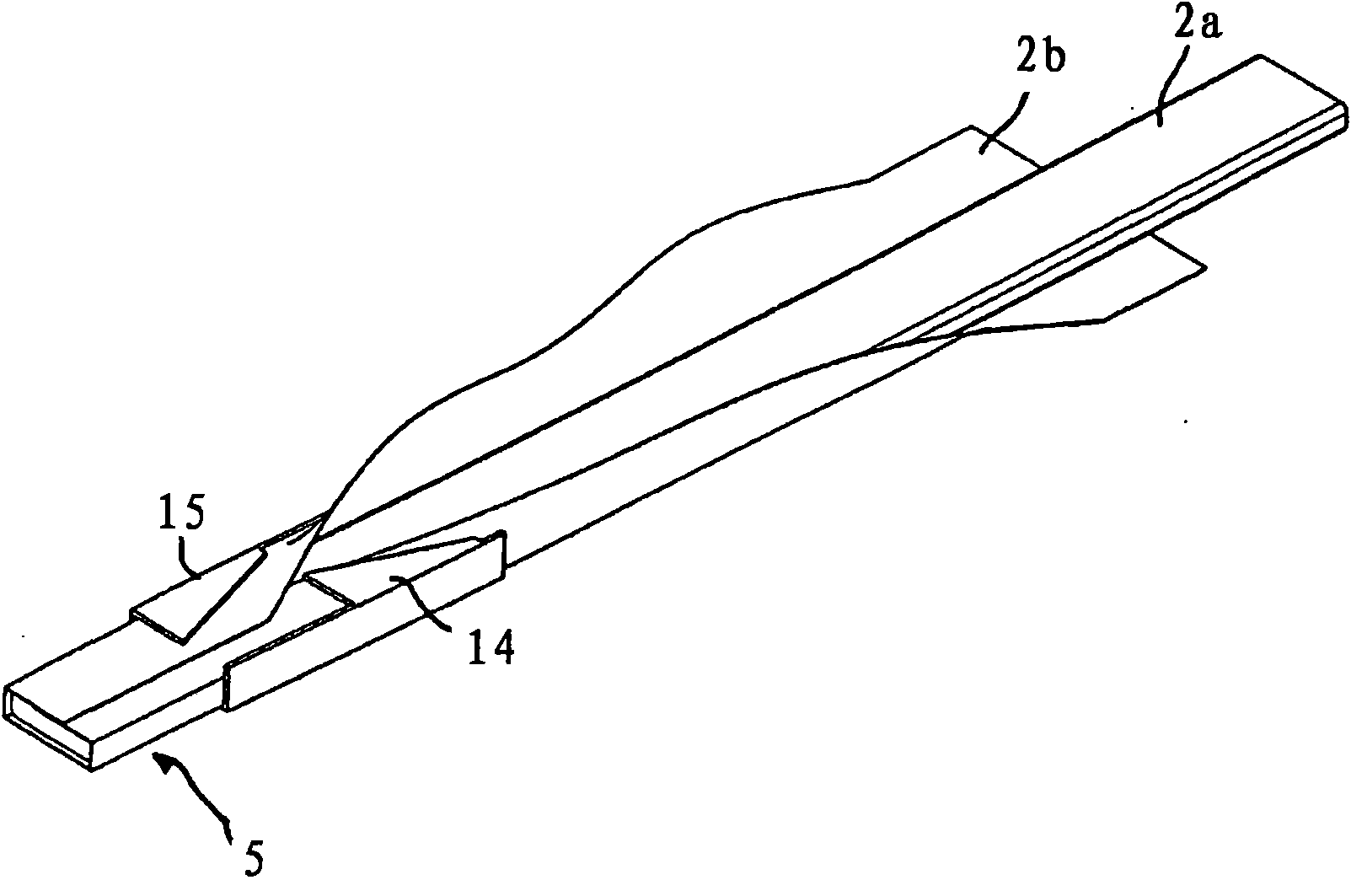

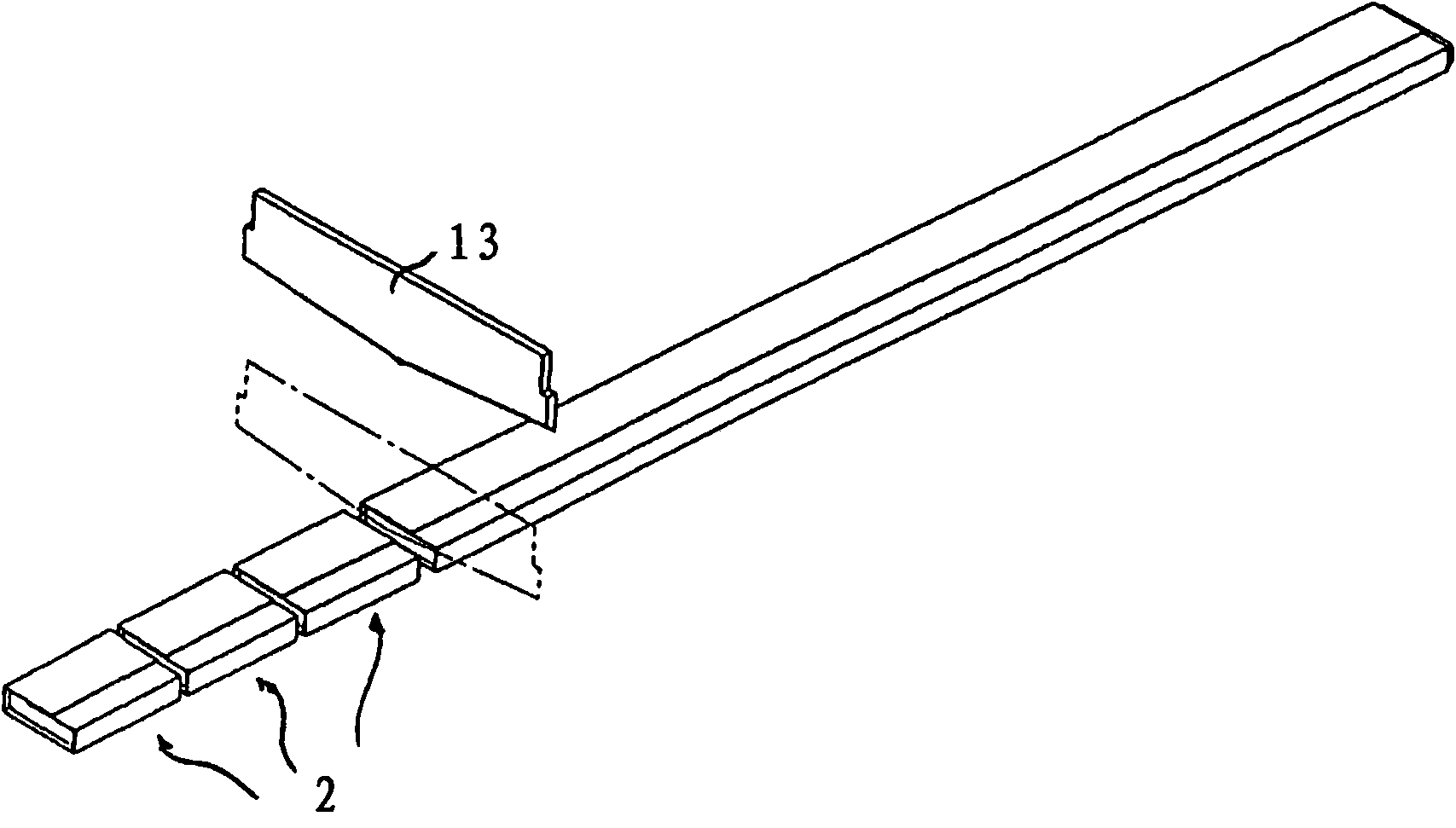

Substrate surface sealing device and organic el panel fabrication method

ActiveCN102326449AImprove pasting accuracyImprove qualityLamination ancillary operationsLayered product treatmentEngineeringSubstrate surface

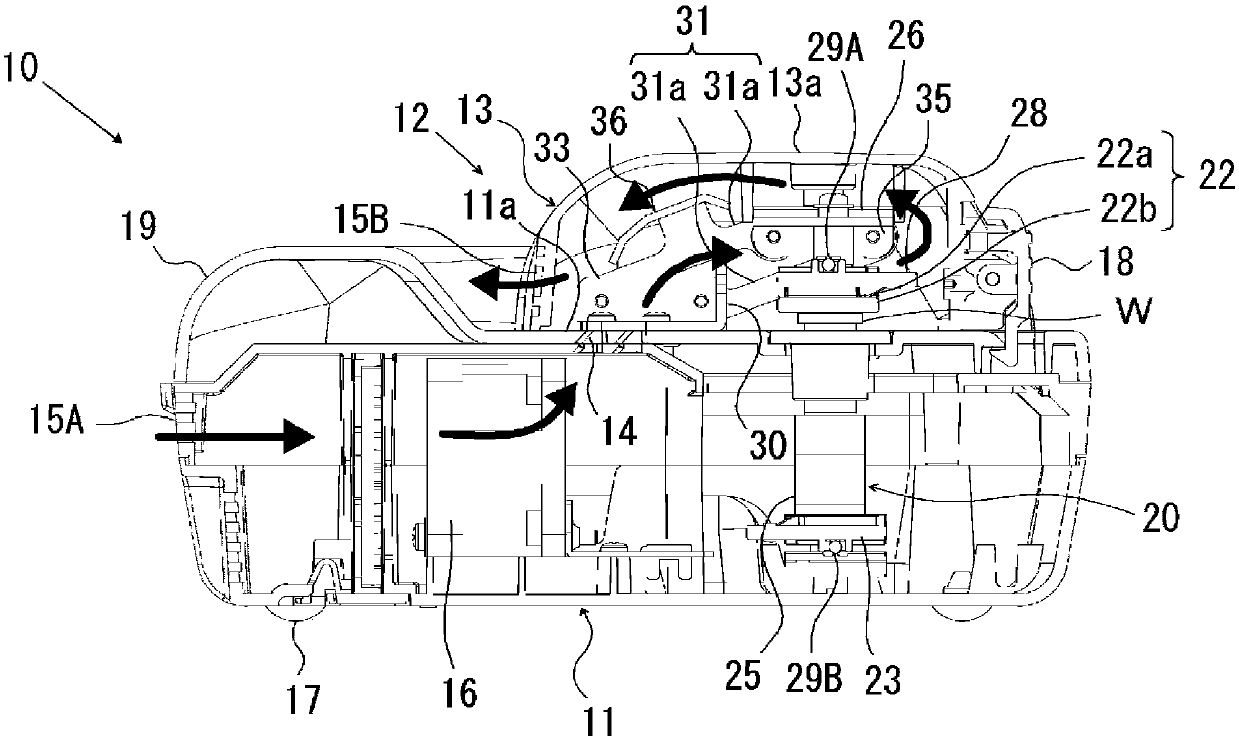

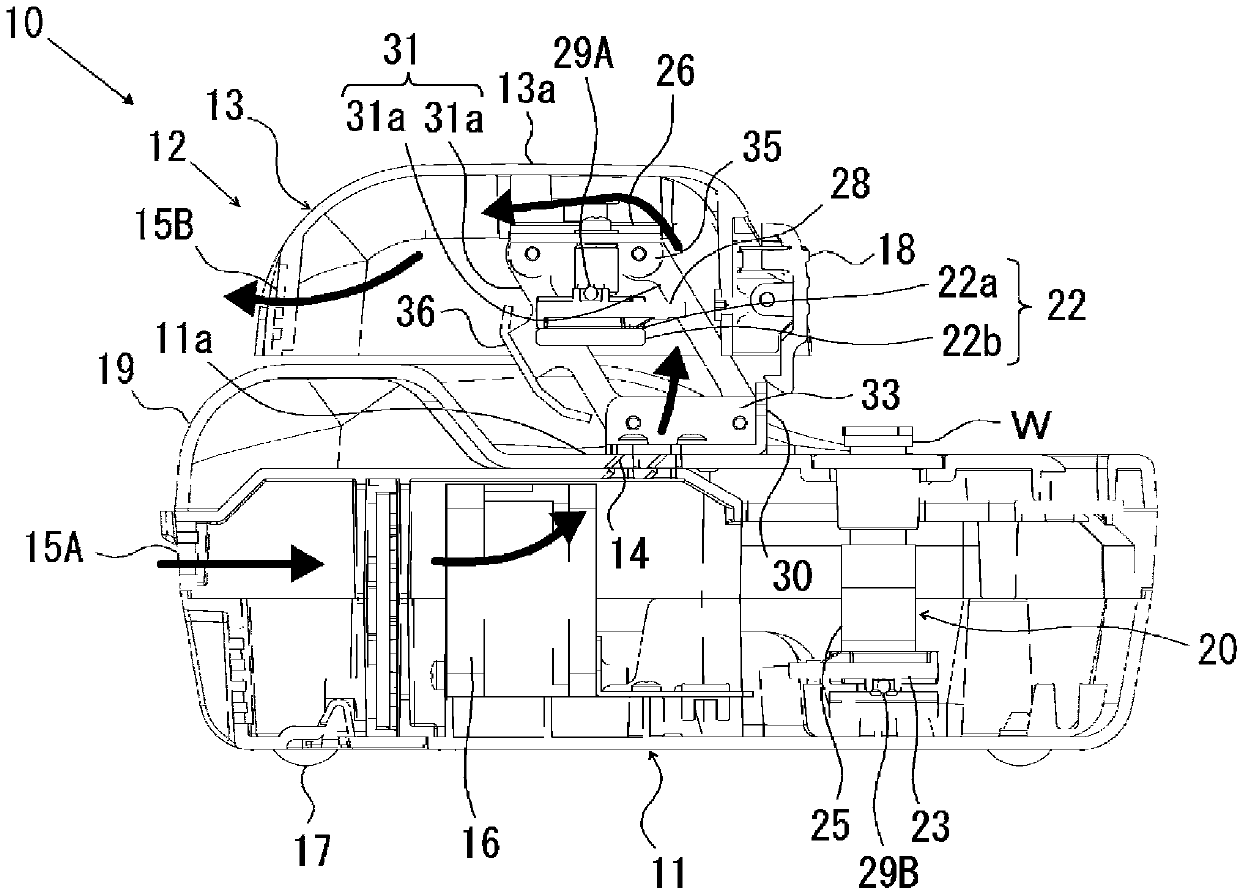

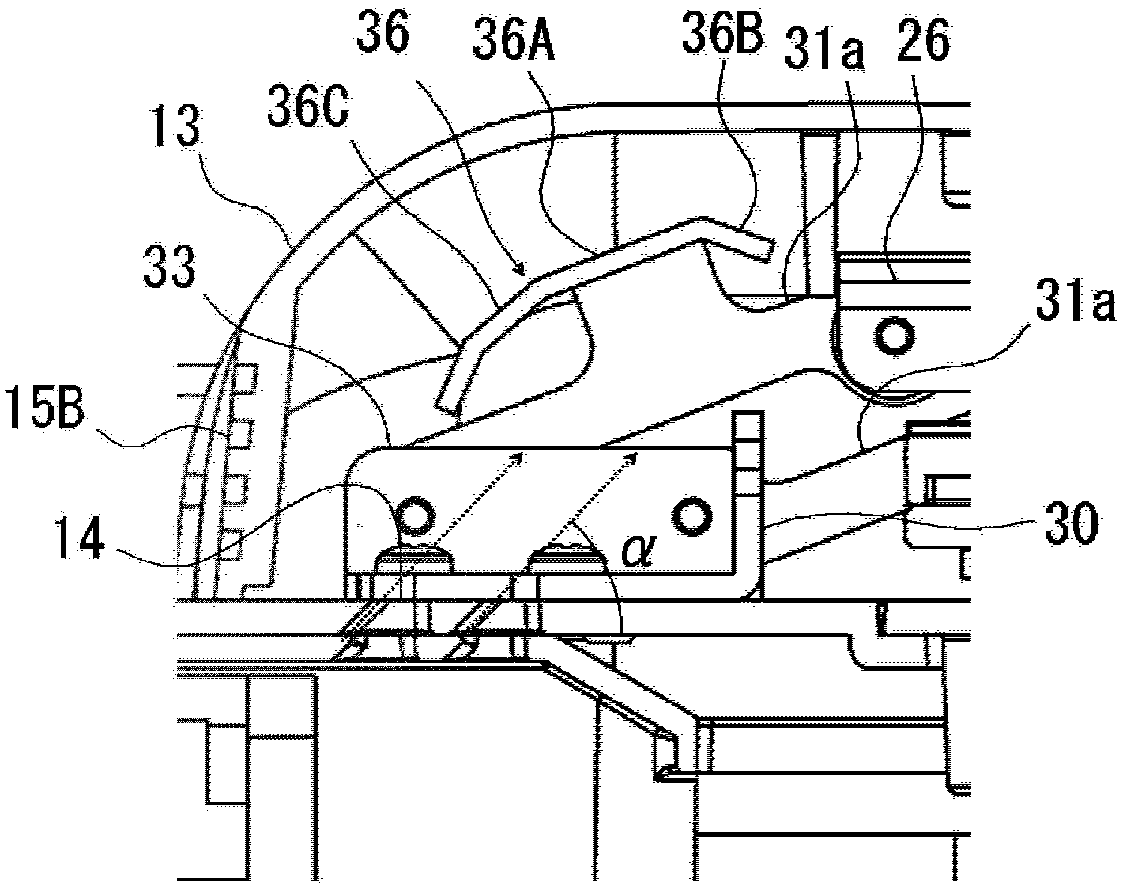

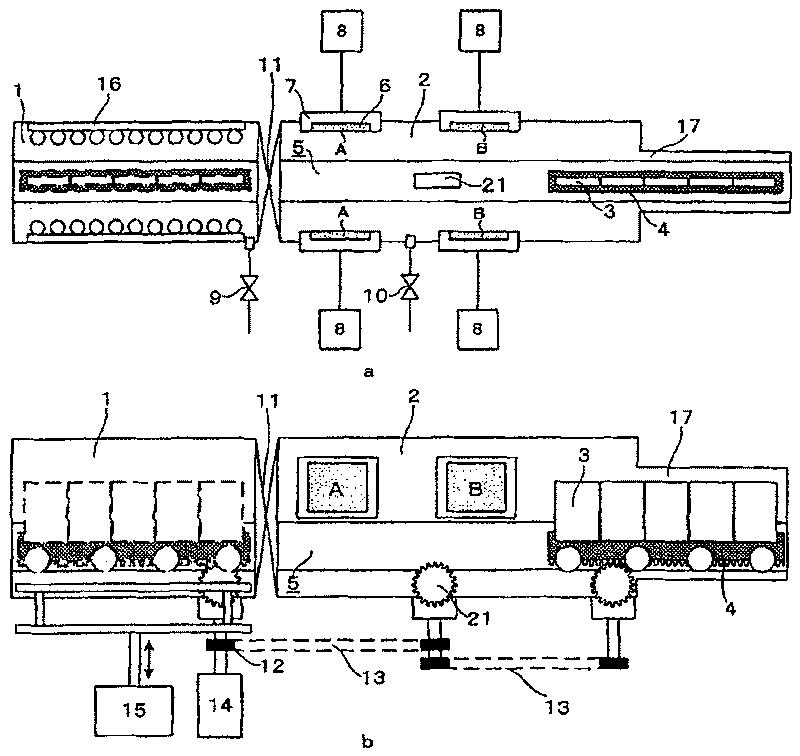

Operating labor is diminished to improve takt time, and lamination that prevents deterioration of the performance of the finished product can be realized. The cover films (13a) are peeled by a cover film uptake mechanism (15) (figure 4) from films (13) from film rolls (24a-24d) (figure 6) of a film out-feed mechanism (14), and then fed to an inter-substrate processing mechanism (16). In the inter-substrate processing mechanism (16), sheet sealing materials (5) (figure 3) are formed, in which specified lengths of the sealing material films (5') of the films (13) (figure 4) are peeled off at specified intervals, as shown in figure 9, by means of half-cut members (34) and a peel-off tape (36) (figure 7). The films (13), treated in this way, are fed into a lamination mechanism (19), where the sheet sealing materials (5) are heated and press-applied to a substrate (1) from the preceding chamber (10), and then cooled by a substrate cooling mechanism (30), and then the base films (13b) (figure 4) of the films (13) are peeled off by a base film uptake mechanism (21).

Owner:SHARP KK

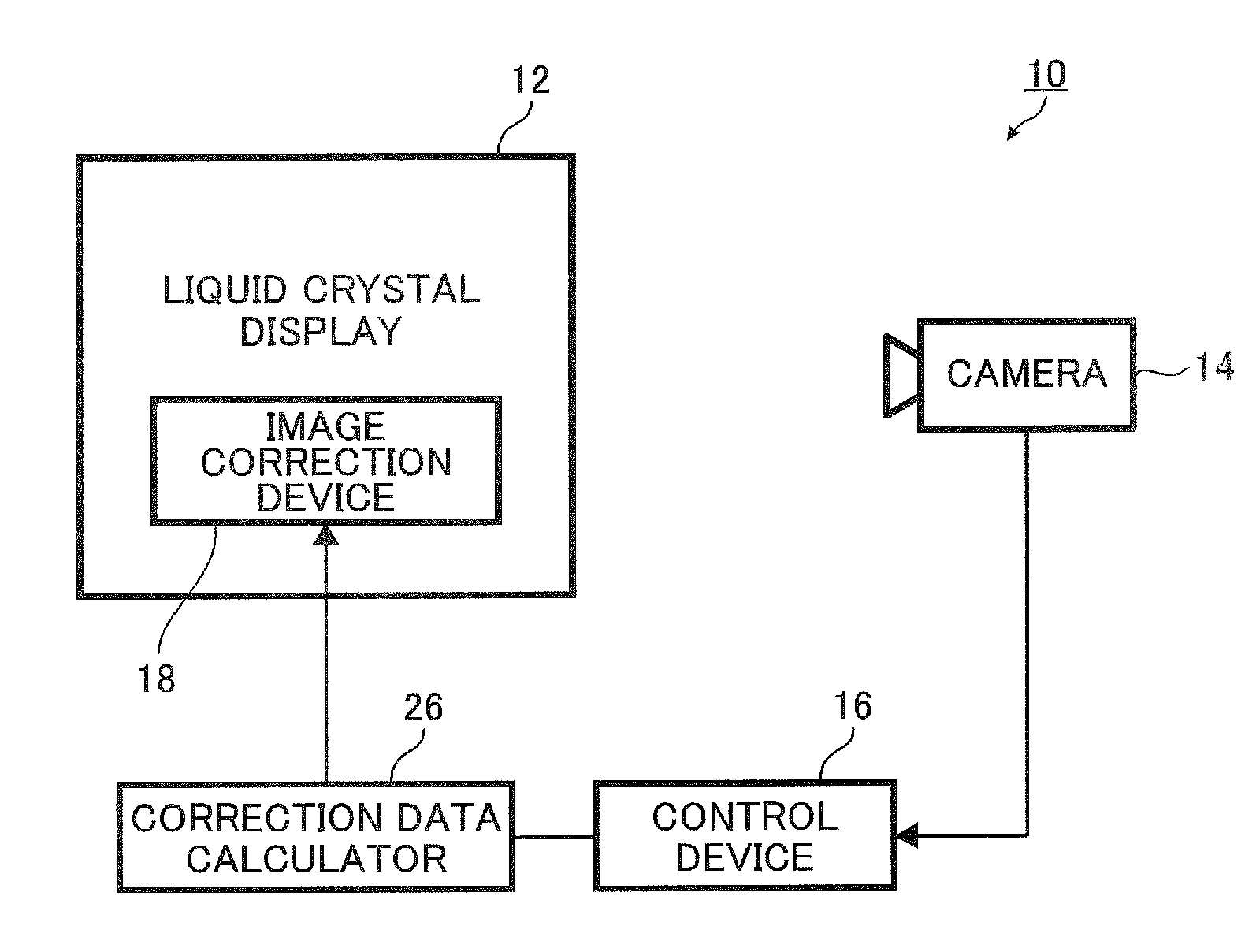

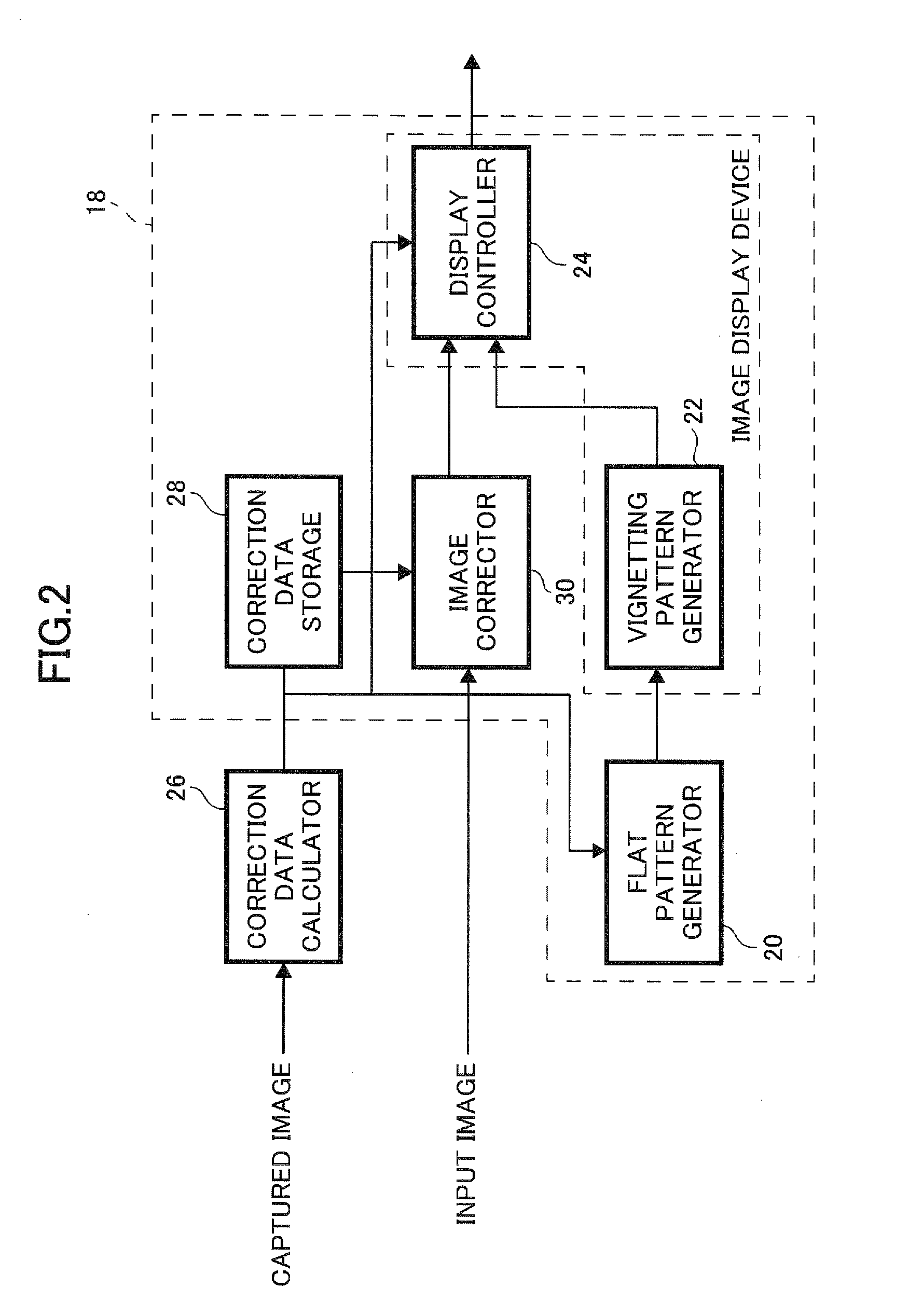

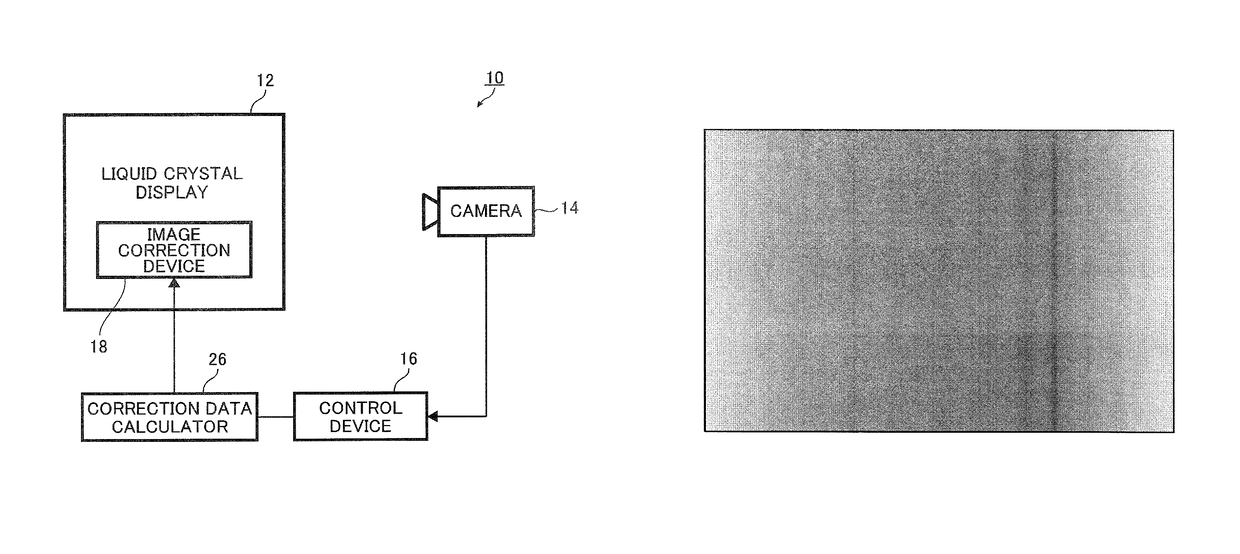

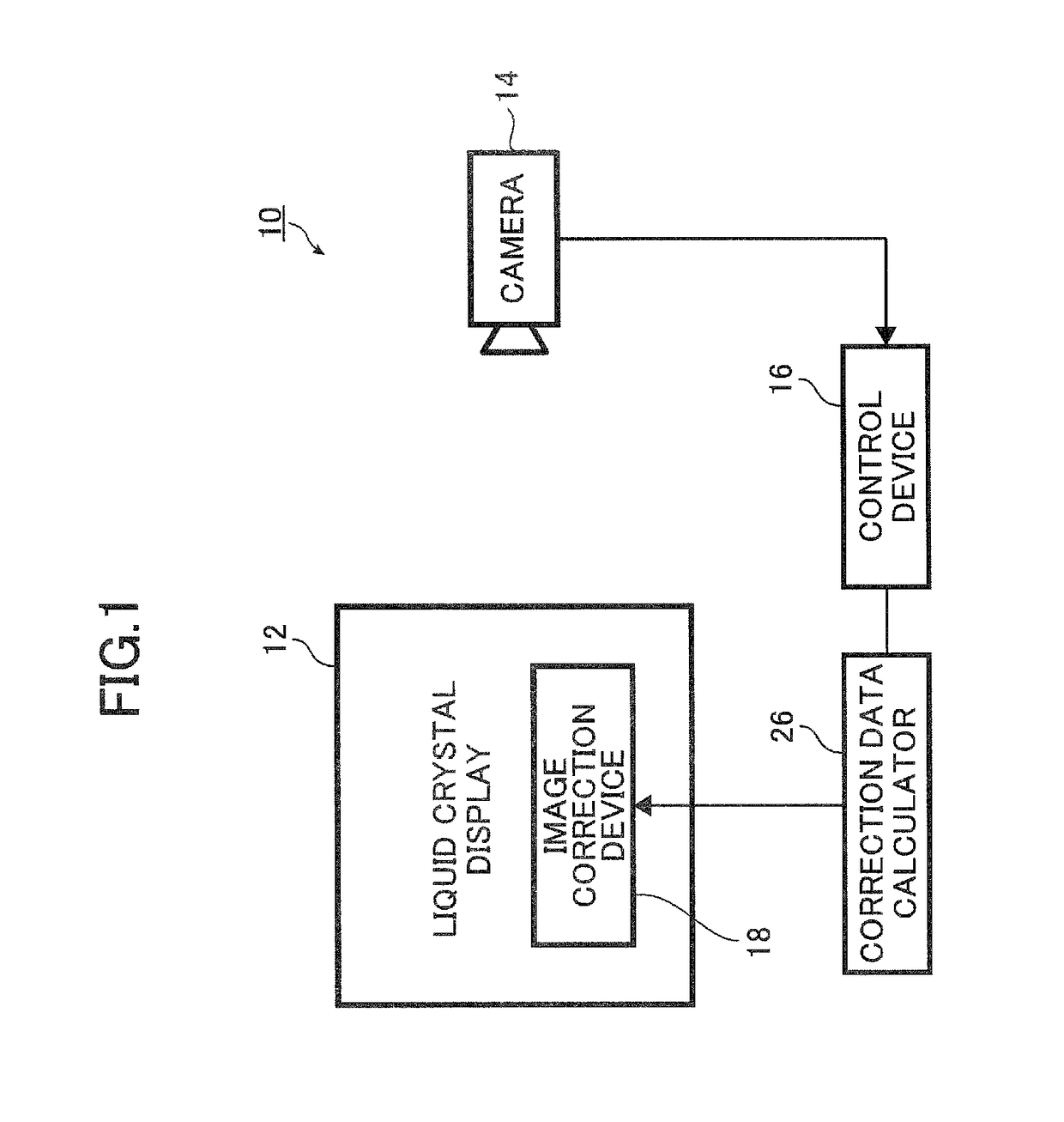

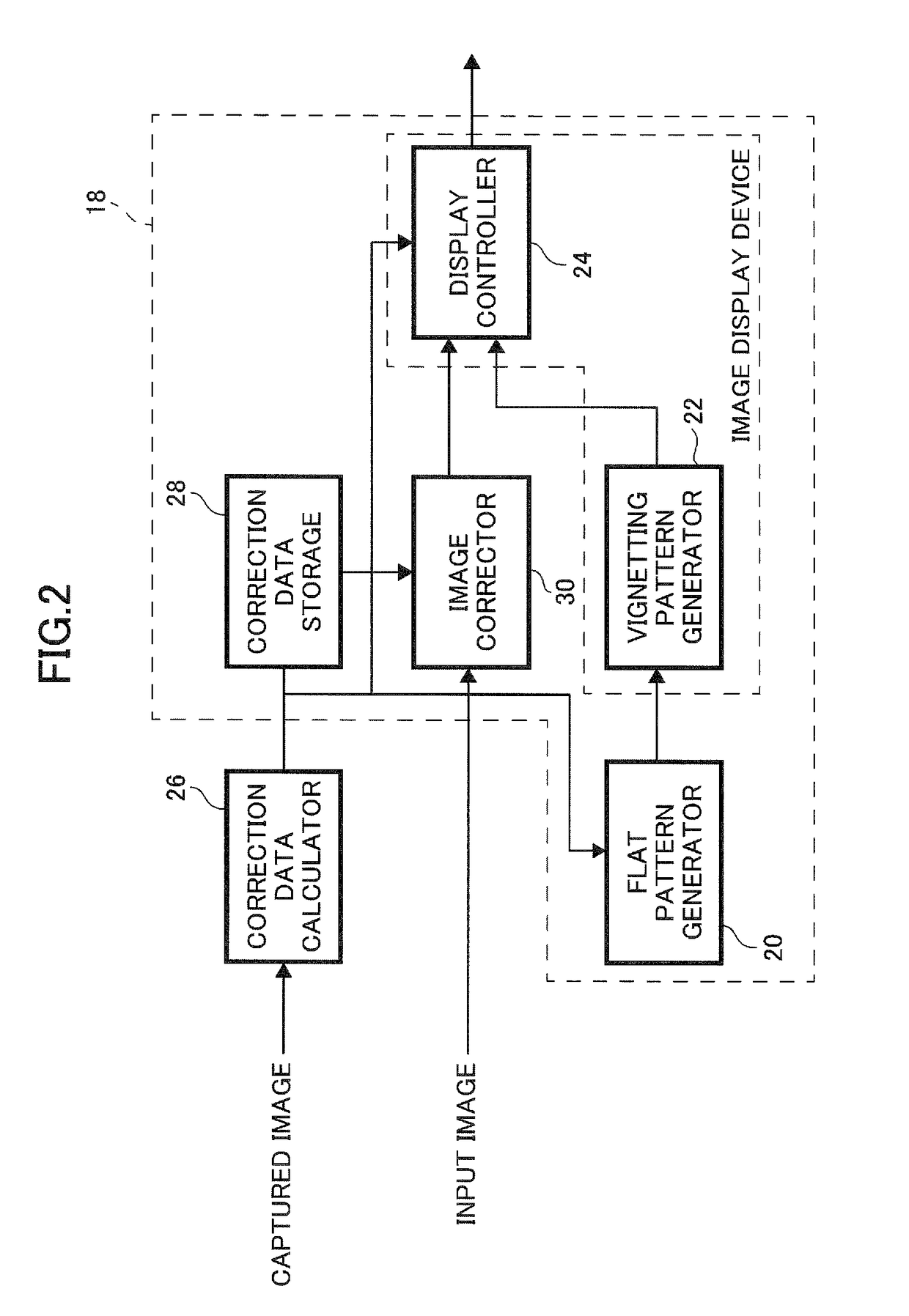

Image display device, correction data generation method, and image correction device and method, as well as image correction system

InactiveUS20160163252A1Short takt timeImprove production efficiencyCathode-ray tube indicatorsLiquid-crystal displayImage based

In the image display device, the vignetting pattern generator generates a vignetting pattern image composed of image data having inverted brightness characteristics obtained by inverting brightness characteristics of a panel of the liquid crystal display. The display controller carries out control to cause a pattern image obtained by combining a flat pattern image in gray composed of image data having a uniform grayscale level and the vignetting pattern image to be displayed on the liquid crystal display. And the correction data calculator calculates correction data for correcting brightness unevenness of an input image based on brightness values of image data of captured images obtained by imaging, by the camera, the pattern images displayed on the liquid crystal display.

Owner:MEGACHIPS

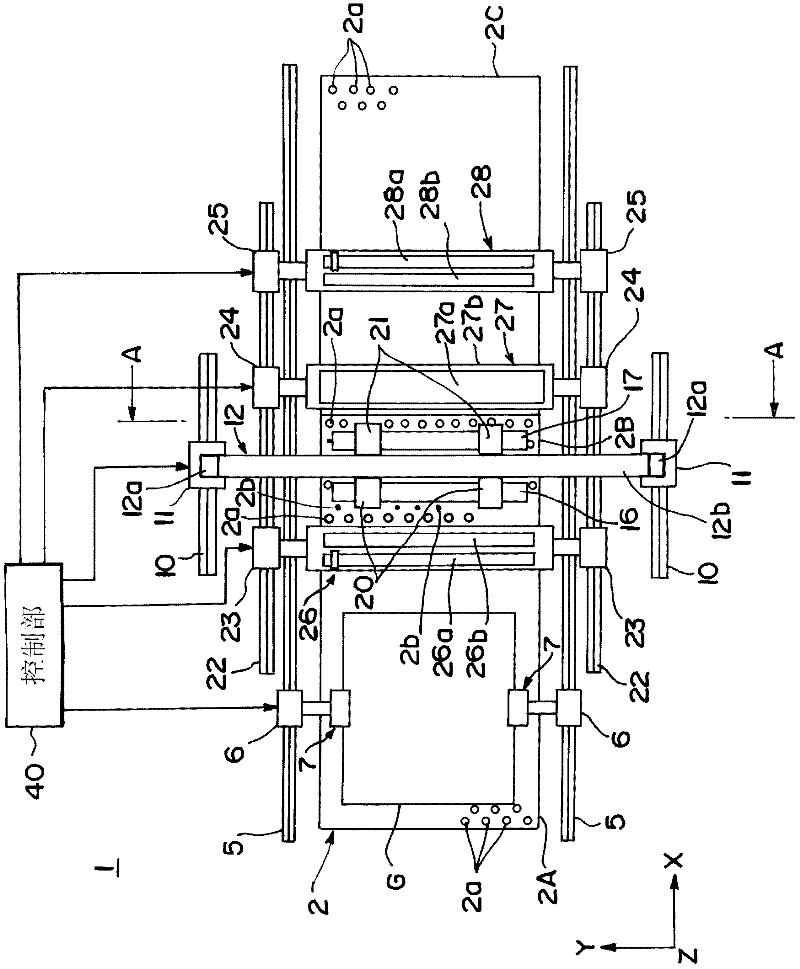

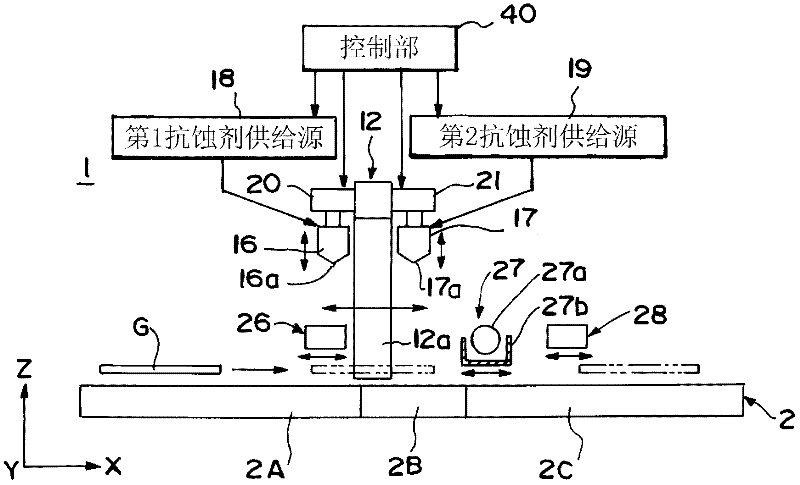

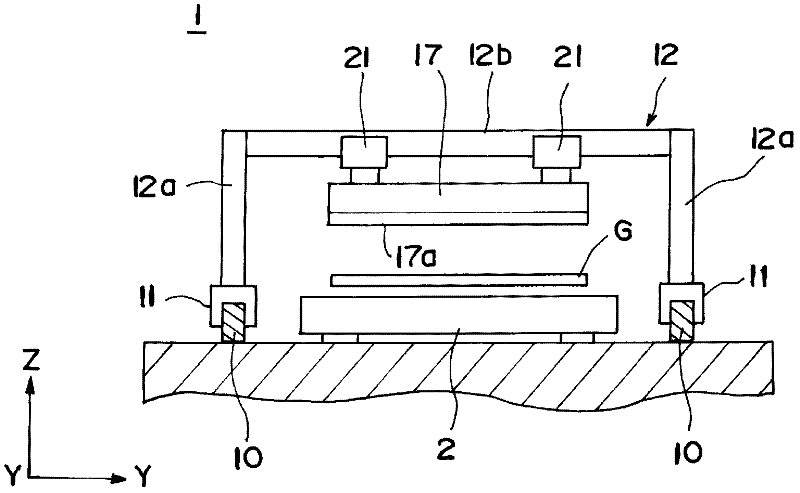

Coating film forming apparatus and coating film forming method

ActiveCN102693901AImprove takt timeCost containmentLiquid surface applicatorsSemiconductor/solid-state device manufacturingSpray nozzleMechanical engineering

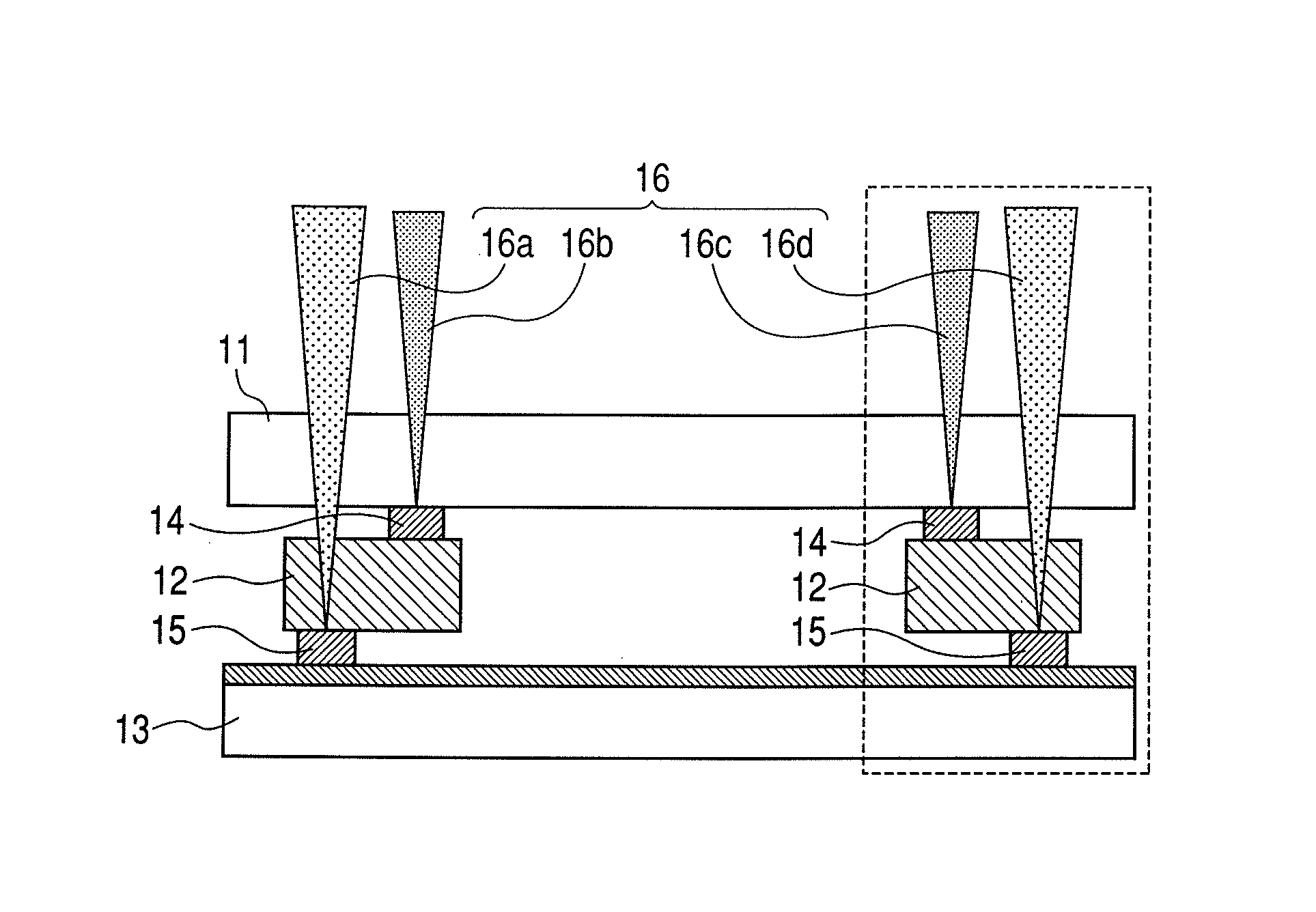

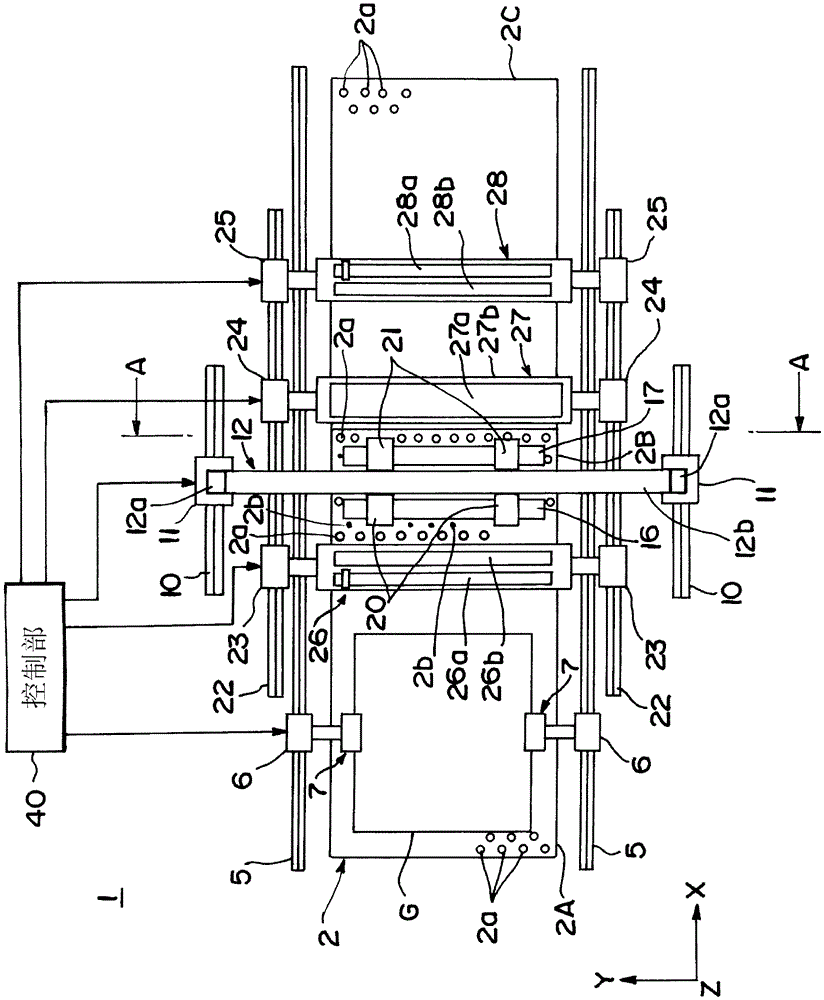

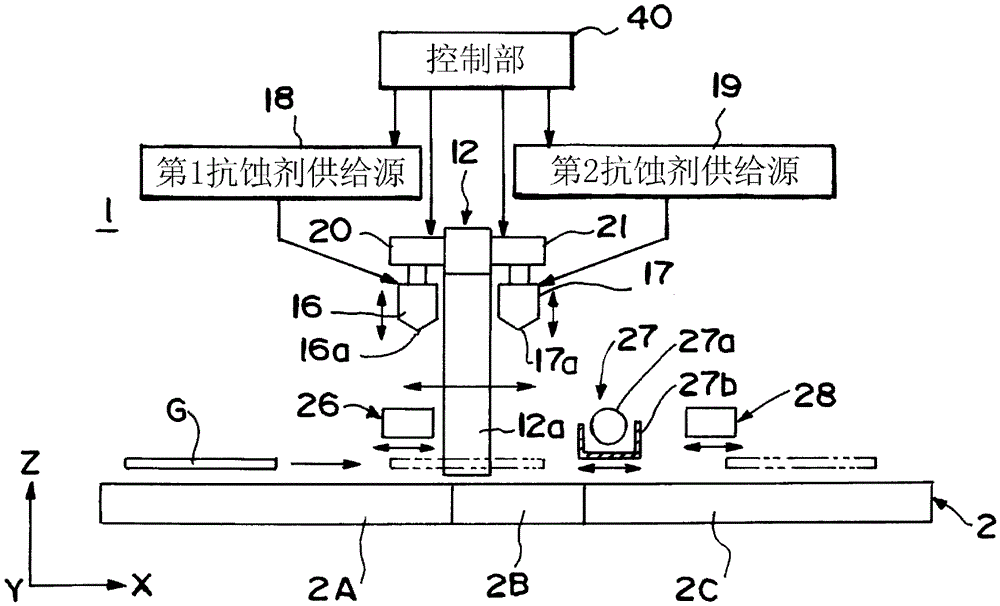

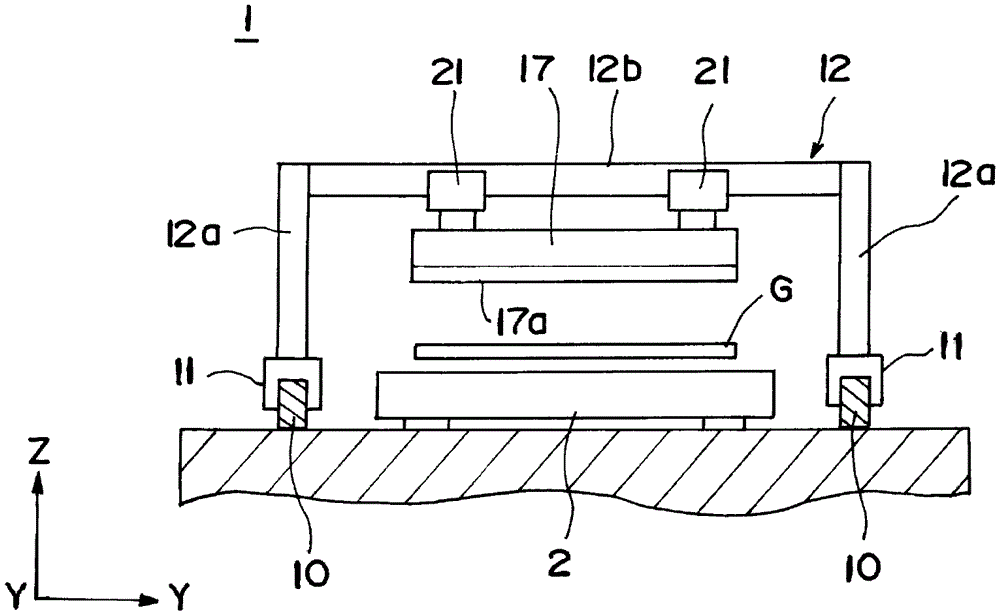

The invention provides a coating film forming apparatus and a coating film forming method. Through the application of two nozzles, the production time of a coating process is reduced, and cost is minimized. The coating film forming apparatus comprises the components as following: a nozzle mataining member (12) which maintaining a first nozzle (16) and a second nozzle (17) which arranged at the conveying direction of the substrate back and forth; a nozzle moving member (11), which enables the nozzle maintaining member to move along the conveying direction of the substrate; a control member (40), which controls the first and the second nozzles, the nozzle moving member is controlled to arrange the first and second nozzles at the same coating position on the conveying direction of the substrate, and the nozzle maintaining member is moved by the control on the nozzle moving member, and any one of the first and second nozzles is used for ejecting process liquid to the substrate.

Owner:TOKYO ELECTRON LTD

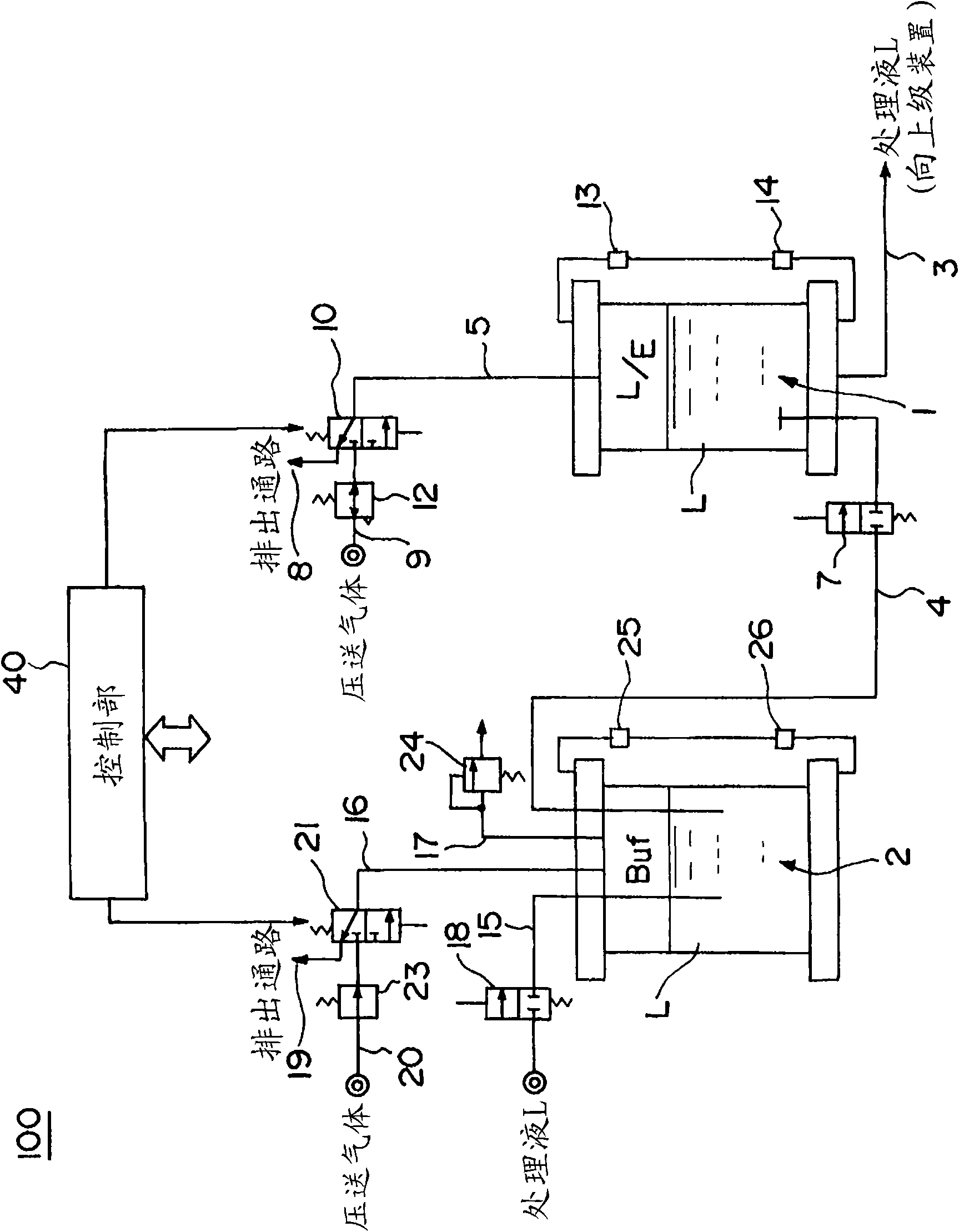

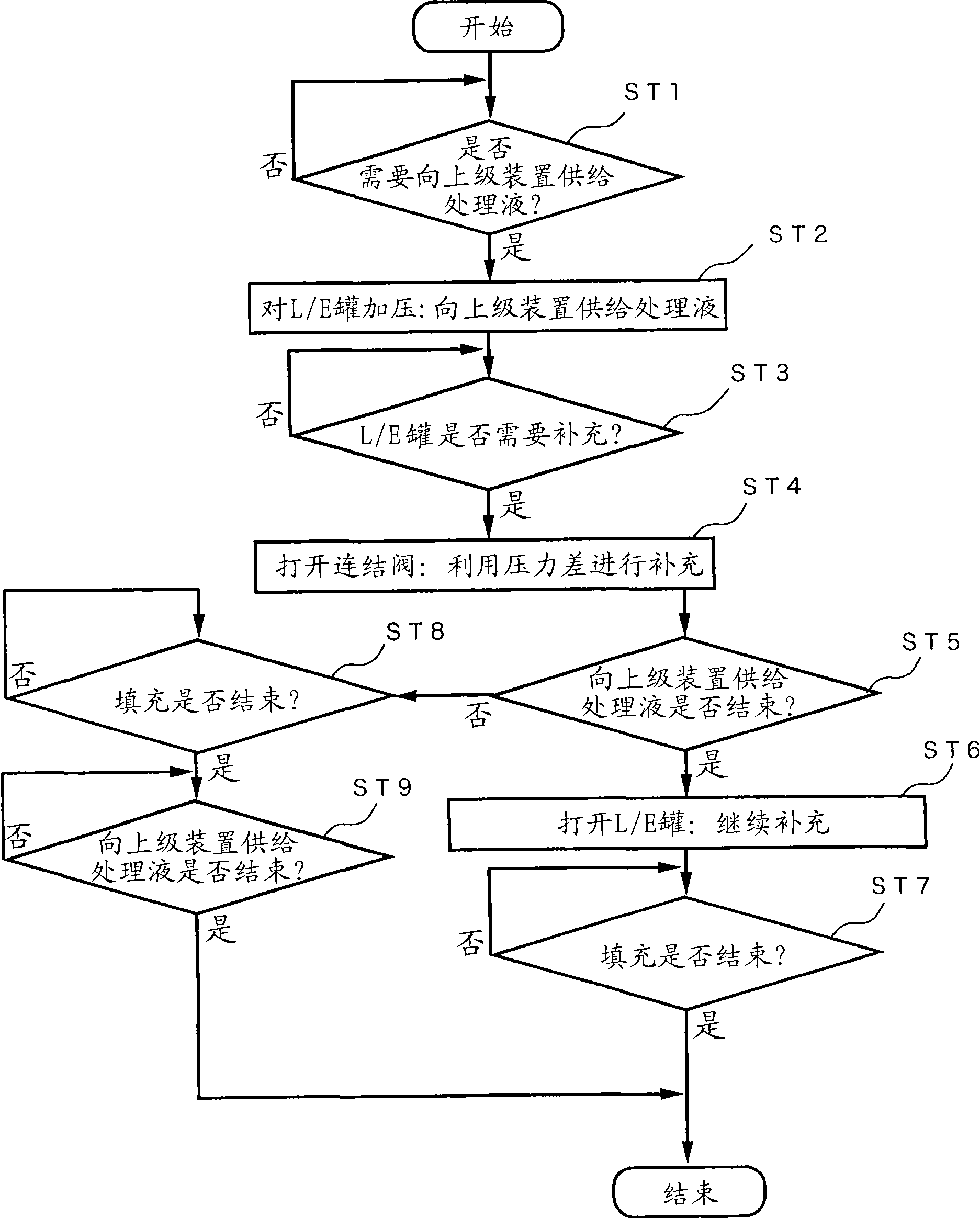

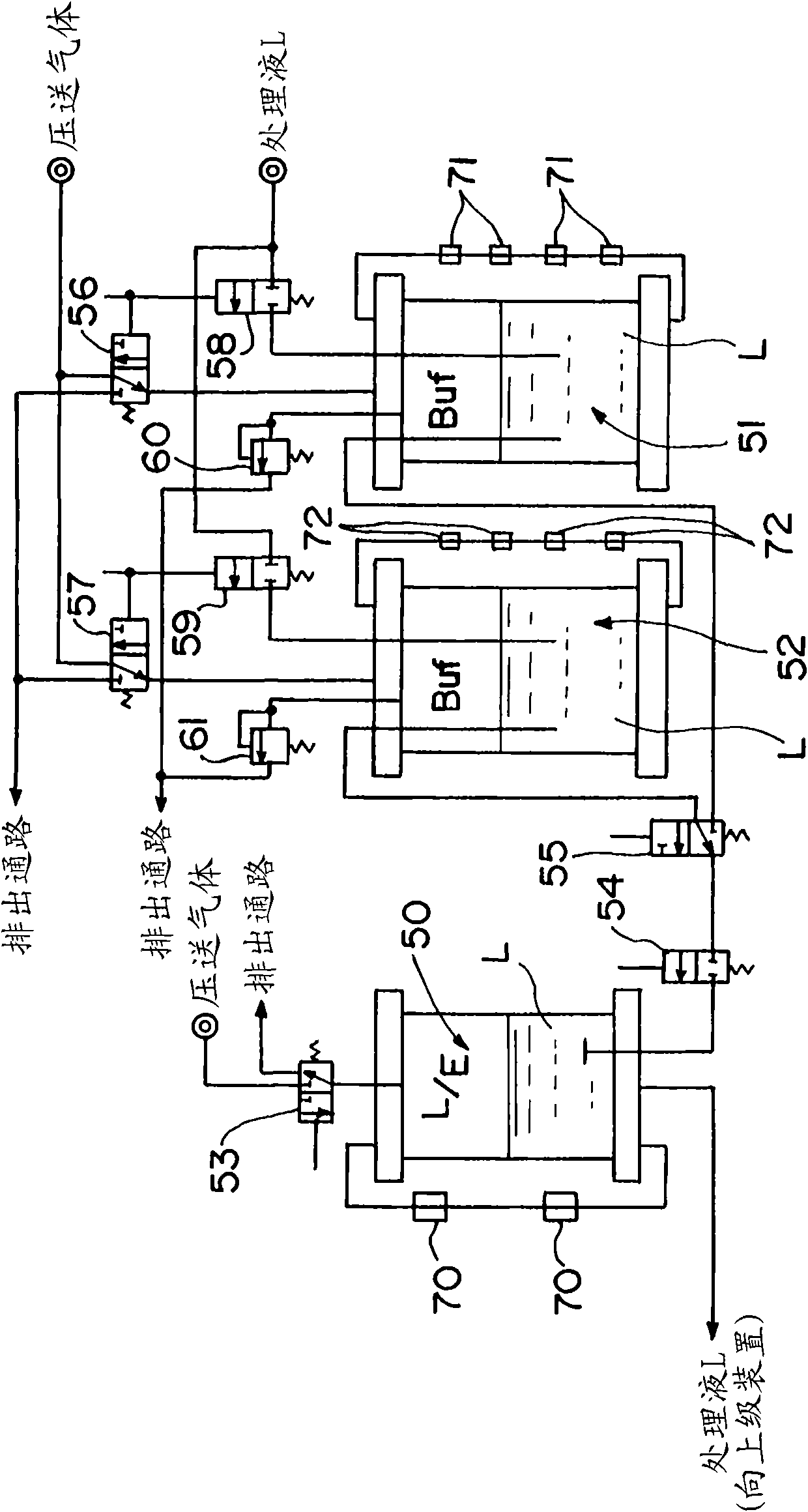

Processing liquid supply system and processing liquid supply method

InactiveCN101807005AImprove takt timeLiquid surface applicatorsSemiconductor/solid-state device manufacturingLiquid storage tankEngineering

The invention provides a processing liquid supply system and processing liquid supply method. The processing liquid supply system for supplying the processing liquid stored in a tank for a device using the specified processing liquid can supply the processing liquid for the device and adding the processing liquid into the tank simultaneously, thus the production beat time is prevented to be prolonged. The processing liquid supply system comprises a processing liquid storage tank for outputting the processing liquid, a processing liquid adding part for supplying the processing liquid for the processing liquid storage tank into the processing liquid storage tank by an adding pipeline, a valve for opening and closing the adding pipeline, a first pressure adjusting part for adjusting the pressure in the processing liquid storage tank into a first pressure value, and a second pressure adjusting part for adjusting the pressure nearer the processing liquid adding part side than the valve into a second pressure value higher than the first pressure value, after the valve is opened, the processing liquid is supplied for the device from the processing liquid storage tank, and the processing liquid is supplied for the processing liquid storage tank from the rocessing liquid adding part.

Owner:TOKYO ELECTRON LTD

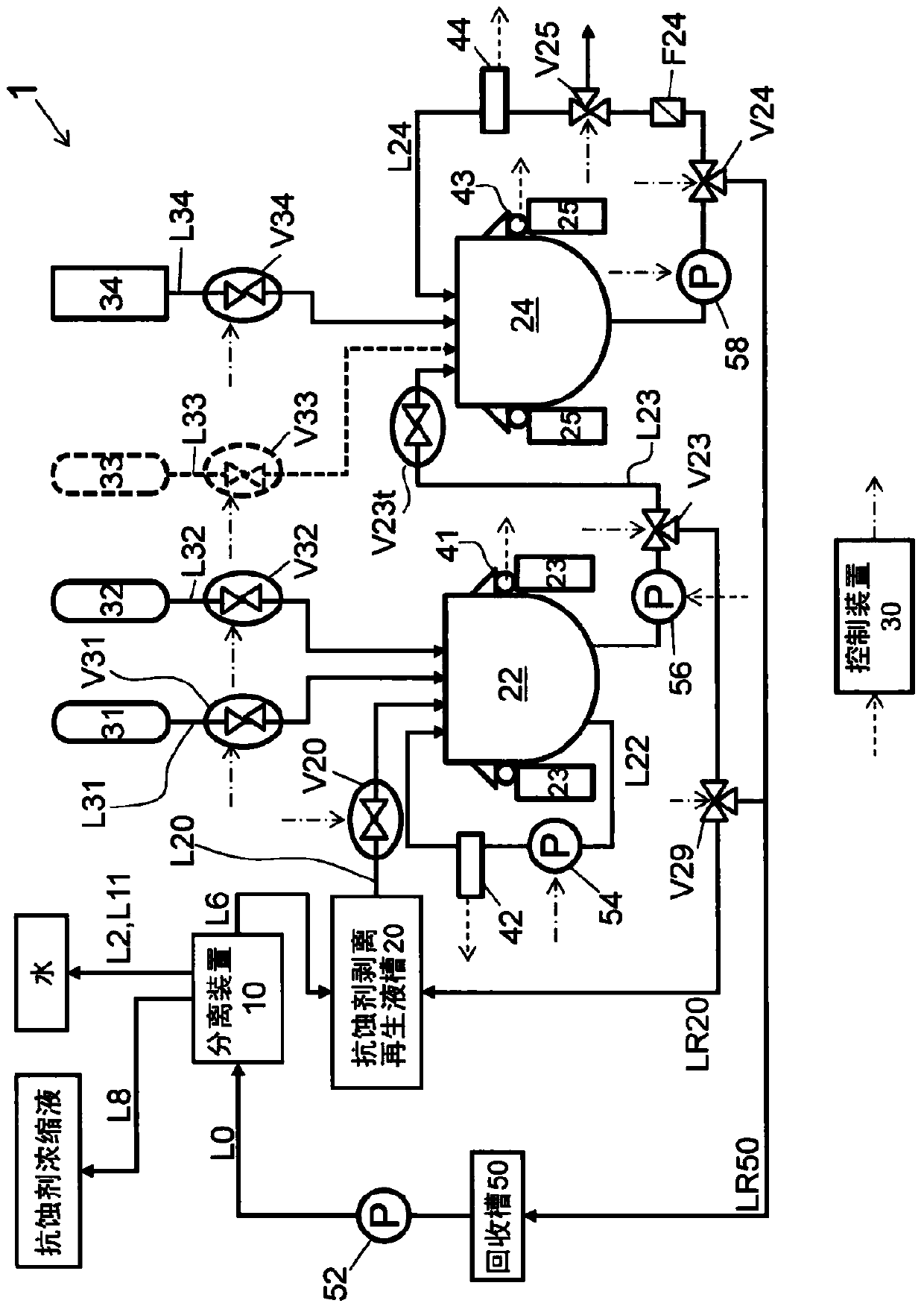

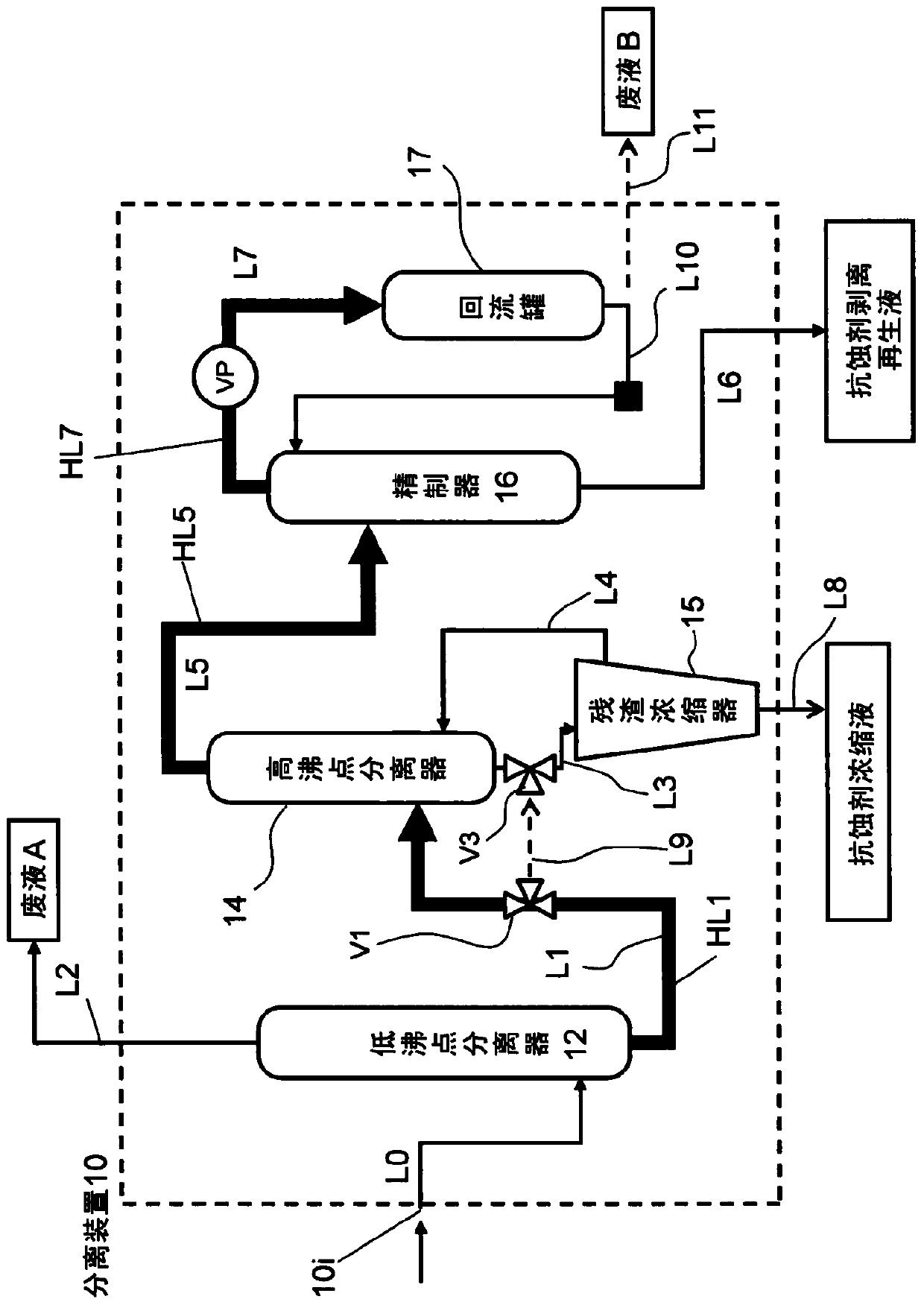

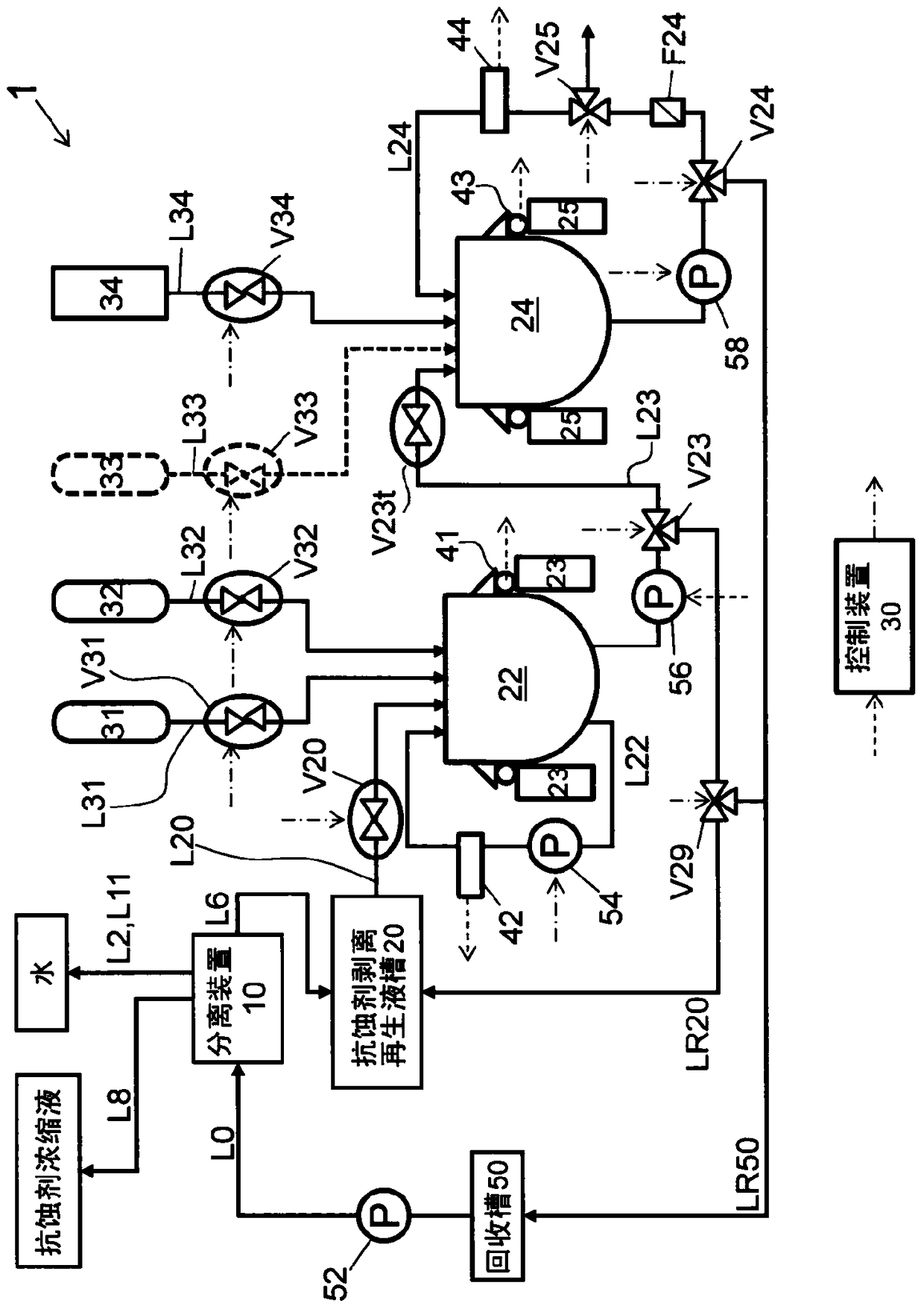

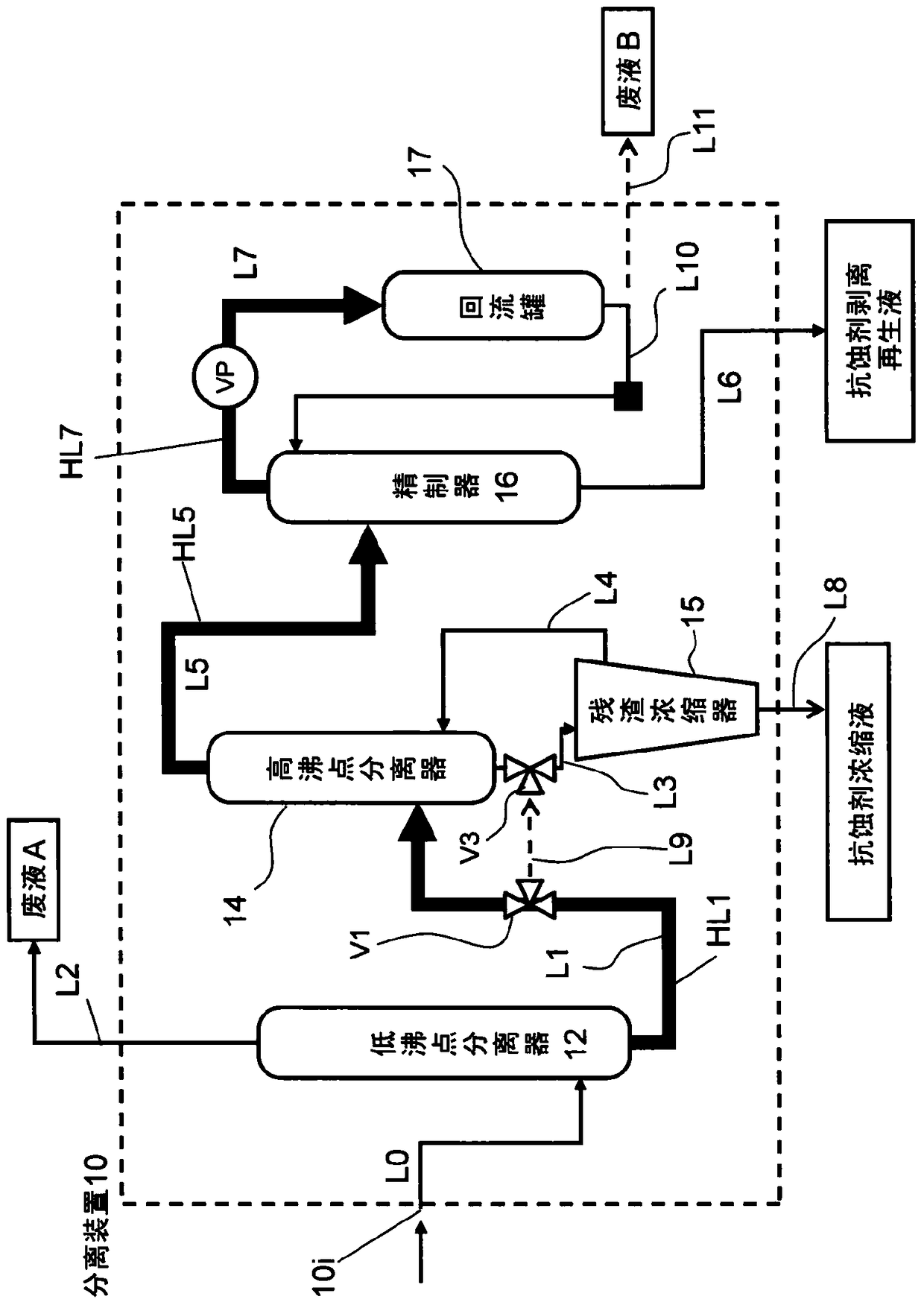

Anti-corrosion agent stripping liquid mixing method and device

ActiveCN103728847AShorten takt timeWell coordinatedPhotosensitive material processingResistSolvent based

The invention provides an anti-corrosion agent stripping liquid mixing method and device. The mixing method includes the steps of: weighing the anti-corrosion agent stripping regenerated liquid of a regenerated liquid input quantity in a solvent trough; measuring the concentration of a first solvent in the solvent trough; calculating the concentration of a second solvent; calculating the additional input of the first solvent based on a specified amount, the regenerated liquid input quantity and the concentration of the first solvent; calculating the additional input of the second solvent based on a specified amount, the regenerated liquid input quantity and the concentration of the second solvent; inputting the first solvent of the first solvent additional input and the second solvent of the second solvent additional input into the solvent trough so as to obtain a mixing solvent; supplying pure water of a reserved quantity to a mixing trough and meanwhile weighing the pure water; and conveying the mixing solvent to the mixing trough from the solvent trough so as to obtain an anti-corrosion agent stripping liquid.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

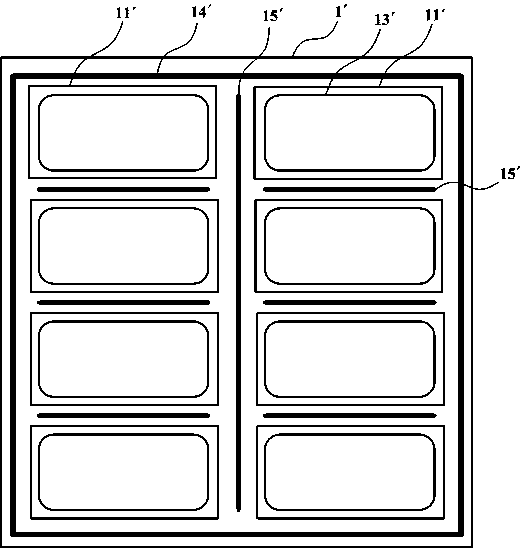

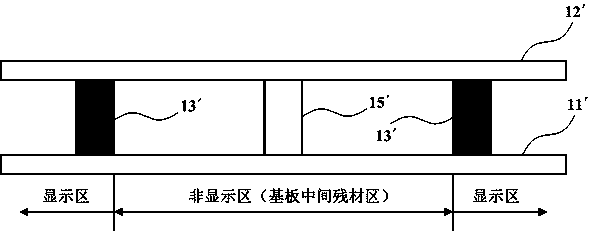

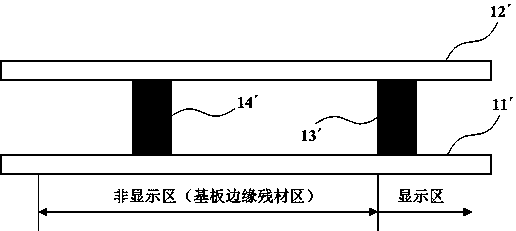

Liquid crystal display mother board and manufacturing method thereof

InactiveCN108037621AReduce process requirementsImprove takt timeNon-linear opticsLiquid-crystal displayAdhesive

The invention provides a liquid crystal display mother board and a manufacturing method thereof. The liquid crystal display mother board comprises an array substrate and a color film substrate which are oppositely arranged, a clamping structure which is arranged between the array substrate, the color film substrate and is made of a photoresist and a residual material supporting the non-display region of the liquid crystal display mother board and connecting the array substrate and the color film substrate, wherein the array substrate is provided with a plurality of TFT substrates arranged in an arrayed mode; the clamping structure is used for replacing a virtual sealing frame adhesive and an annular sealing frame adhesive. The clamping structure made of the photoresist replaces the commonvirtual sealing frame adhesive and the annular sealing frame adhesive to achieve the same effect, and due to the fact that the clamping structure can be manufactured through a common exposure technology in the manufacturing process of the array substrate or the color film substrate, the requirement for the manufacturing process of coating the virtual sealing frame adhesive and the annular sealingframe adhesive is lowered, and the product pitch time is shortened; the clamping structure is manufactured in an exposure mode, the precision is higher, the floor area is small, and therefore the product cost is lowered.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

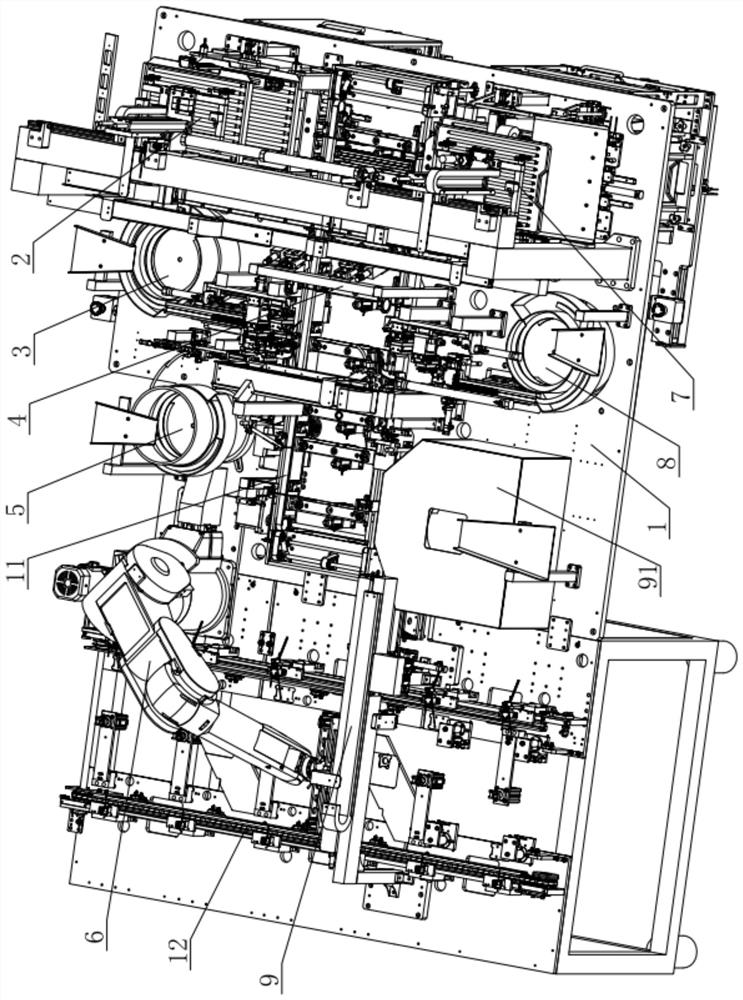

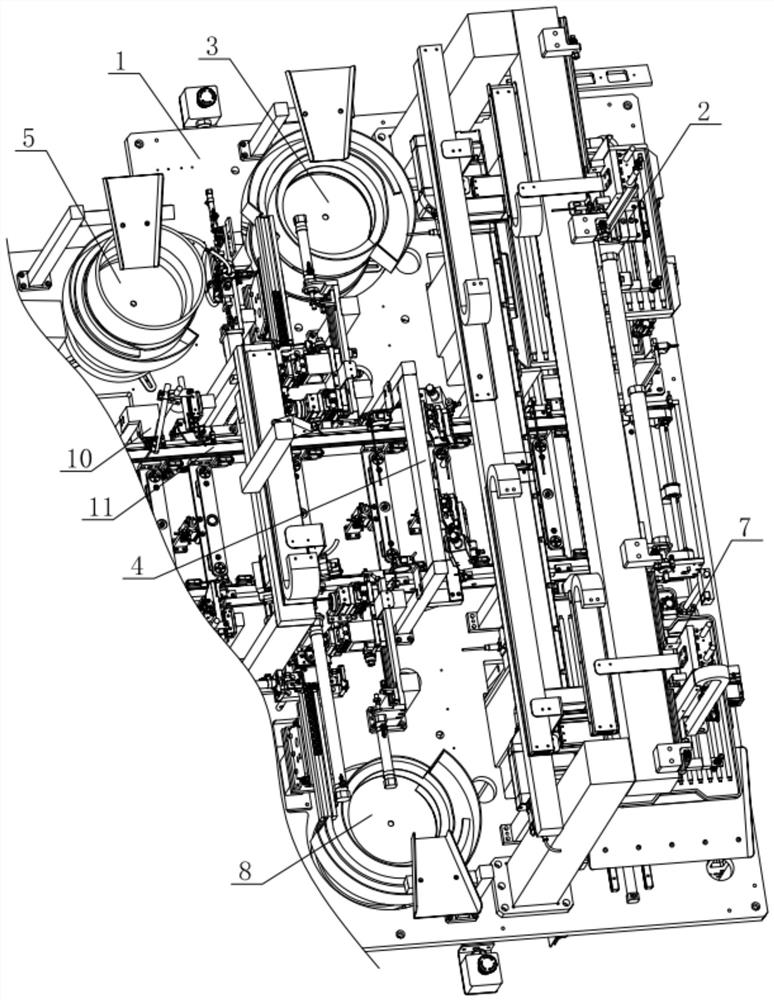

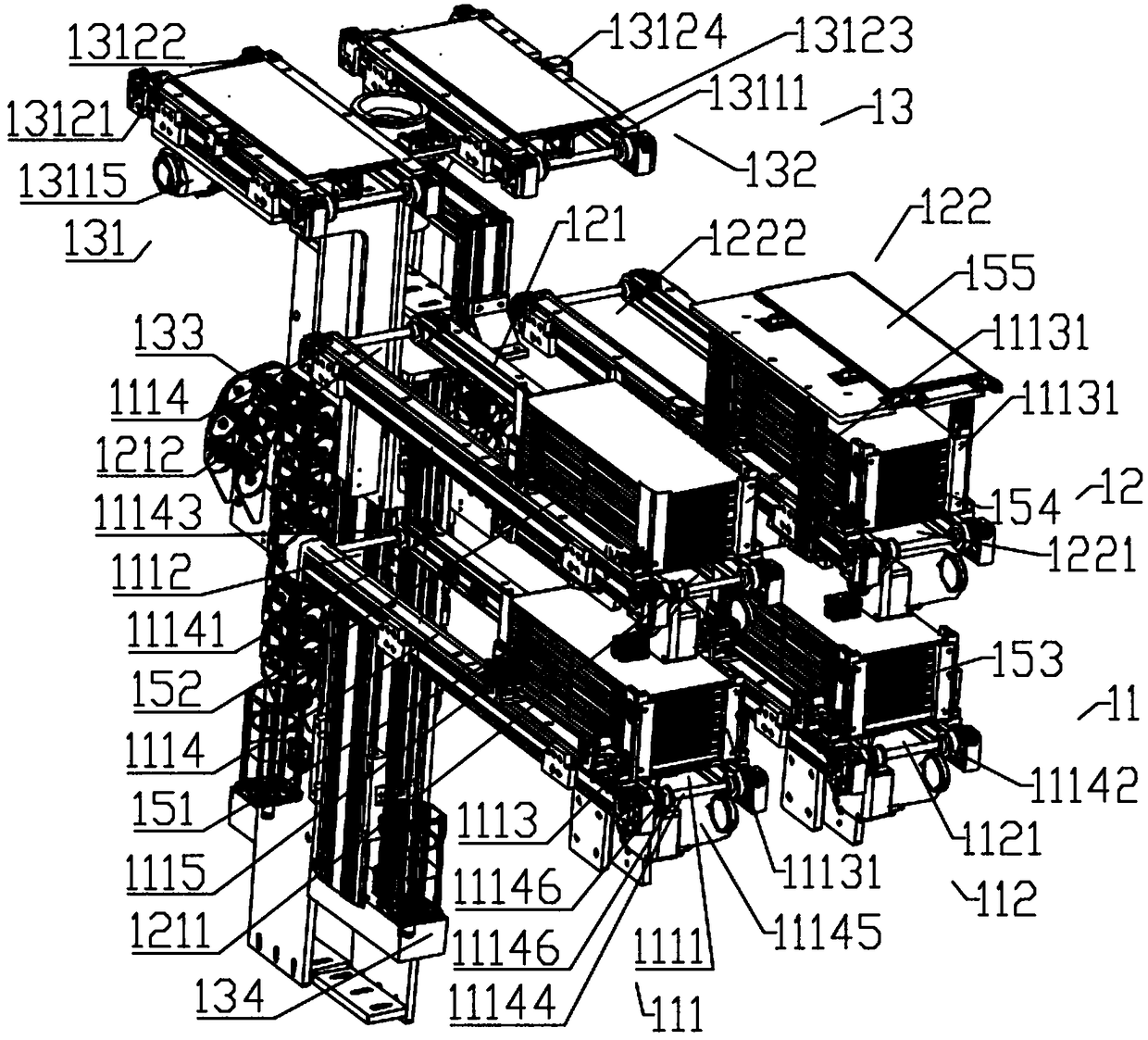

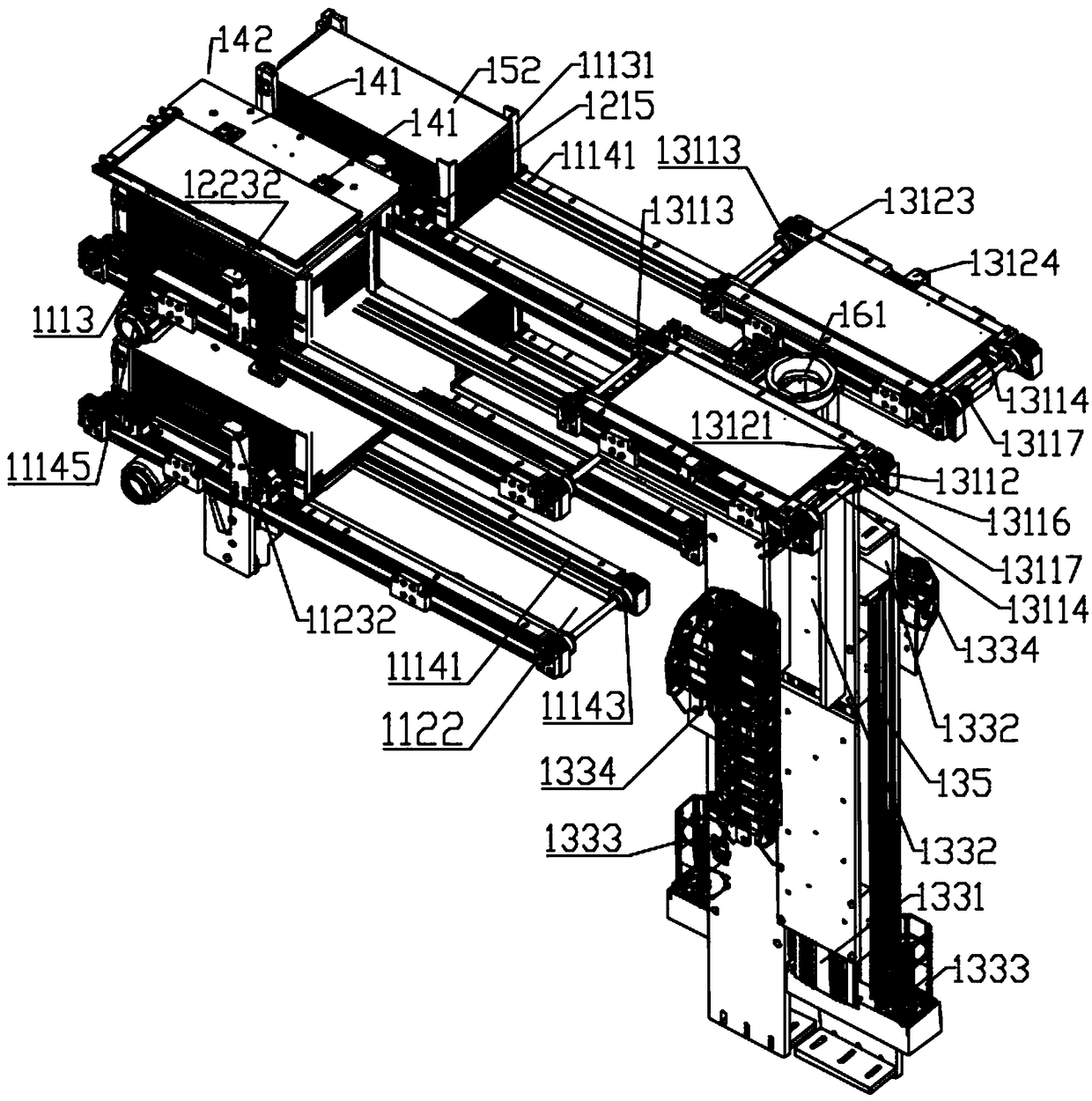

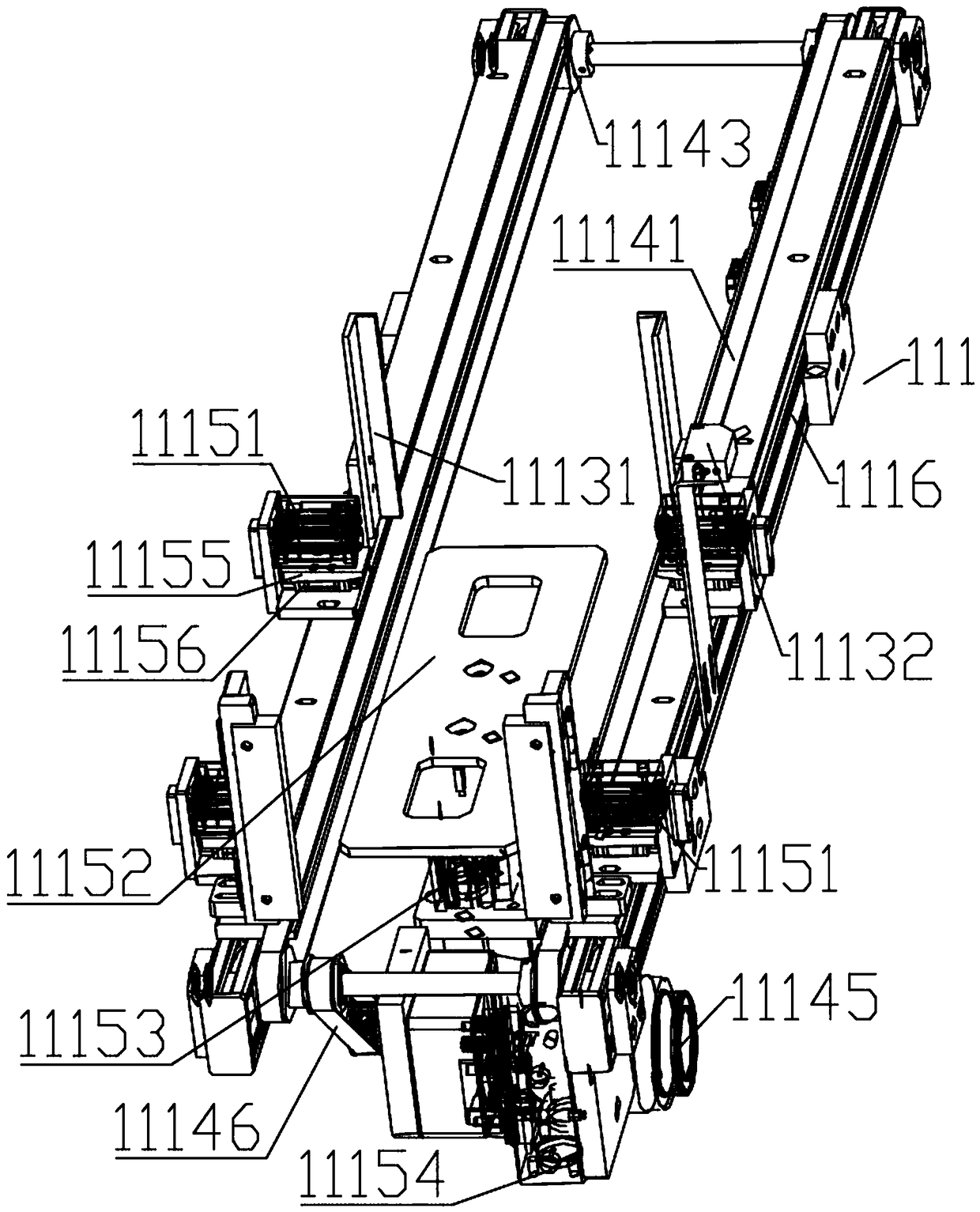

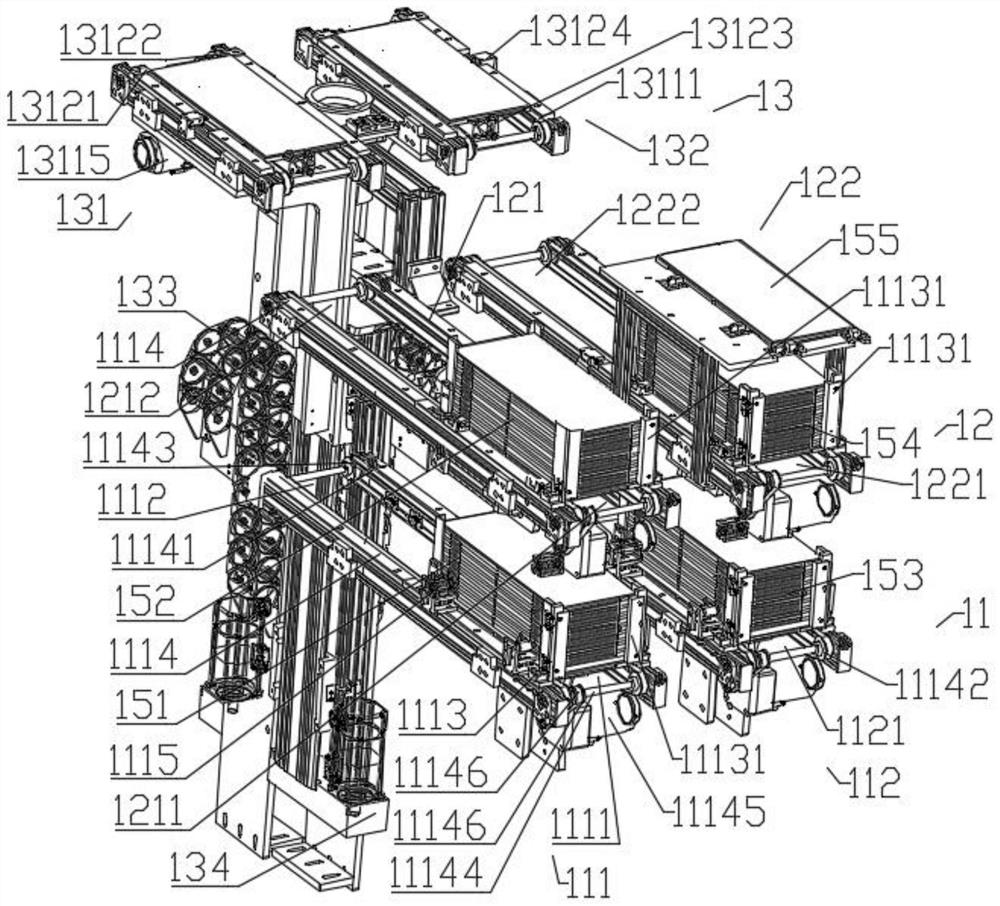

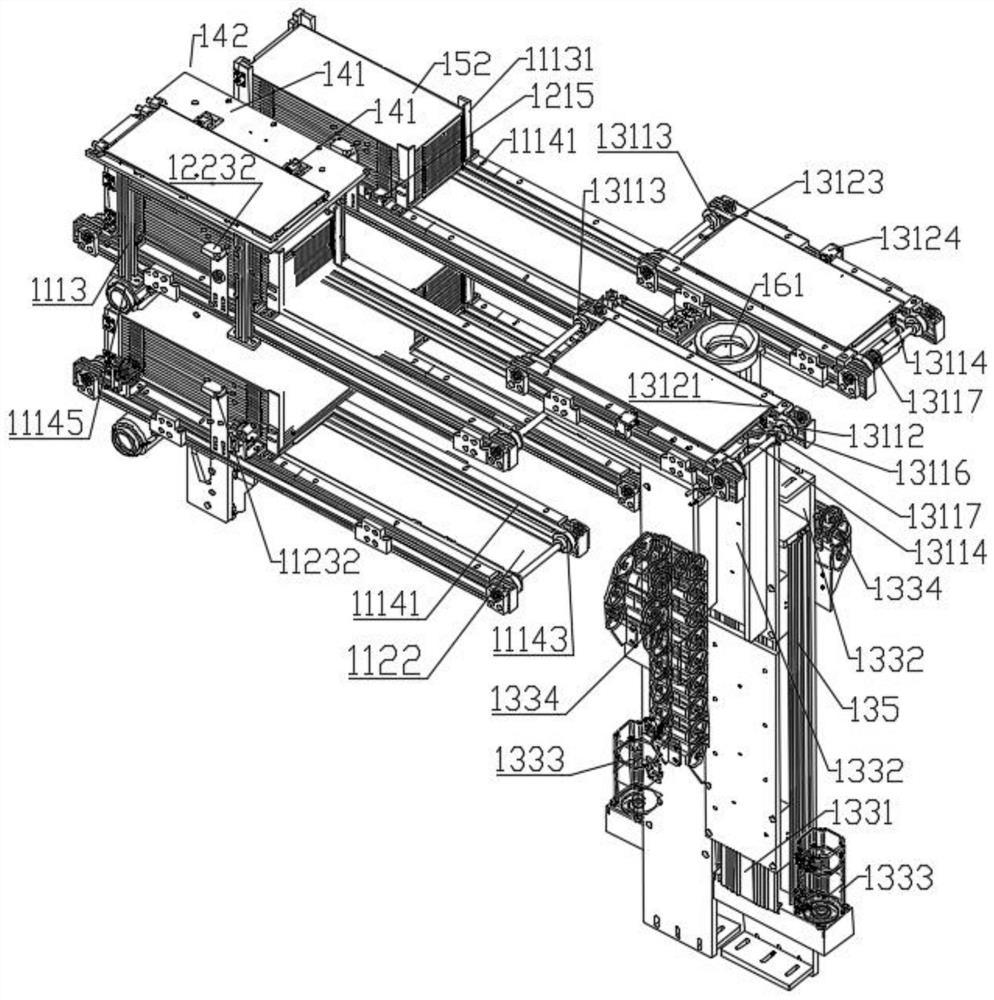

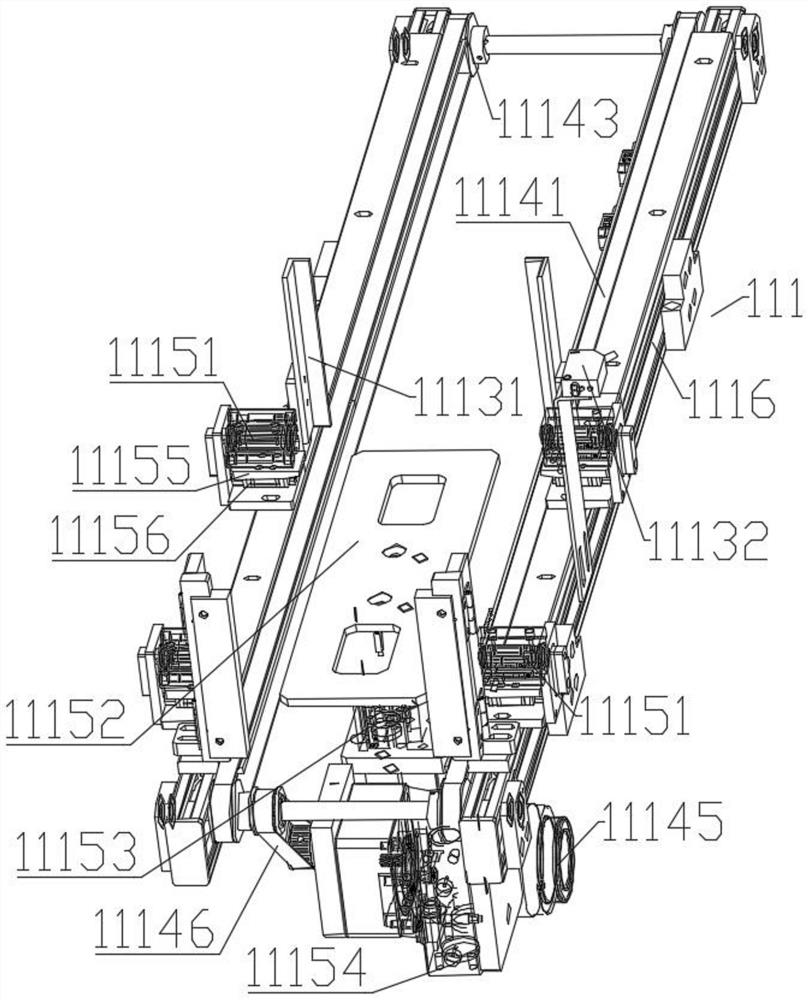

Automatic assembling equipment for electric roller assembly and assembling mode of automatic assembling equipment

ActiveCN113263323ACompact structureReasonable structureAssembly machinesMetal working apparatusMechanical engineeringFully automated

The invention relates to automatic assembling equipment for an electric roller assembly and an assembling mode of the automatic assembling equipment. An assembly conveying line and a final assembly conveying line which are arranged in a T-shaped structure in the same horizontal plane are mounted on a working platform; an oil coating detection station is arranged across the assembly conveying line, an electric roller assembly station and a cleaning roller assembly station are arranged on the working platform in front of the oil coating detection station and on the two sides of the assembly conveying line respectively, and shaft bearing assembly stations are symmetrically arranged on the working platform behind the oil coating detection station and on the two sides of the assembly conveying line; a spring assembly station and a six-axis robot are sequentially arranged on the working platform behind one shaft assembly station, and a separation jig assembly station is arranged behind the other shaft assembly station and stretches across the final assembly conveying line; the six-axis robot takes the electric roller assembly from the assembly conveying line and assembles the electric roller assembly on an assembly piece on the assembly conveying line, so that full-automatic assembly of the electric roller assembly is achieved, the electric roller assembly is relatively fixed to the assembly piece through a separation jig, the assembly efficiency and the assembly effect are greatly improved, and the labor is saved.

Owner:无锡铭方科技有限公司

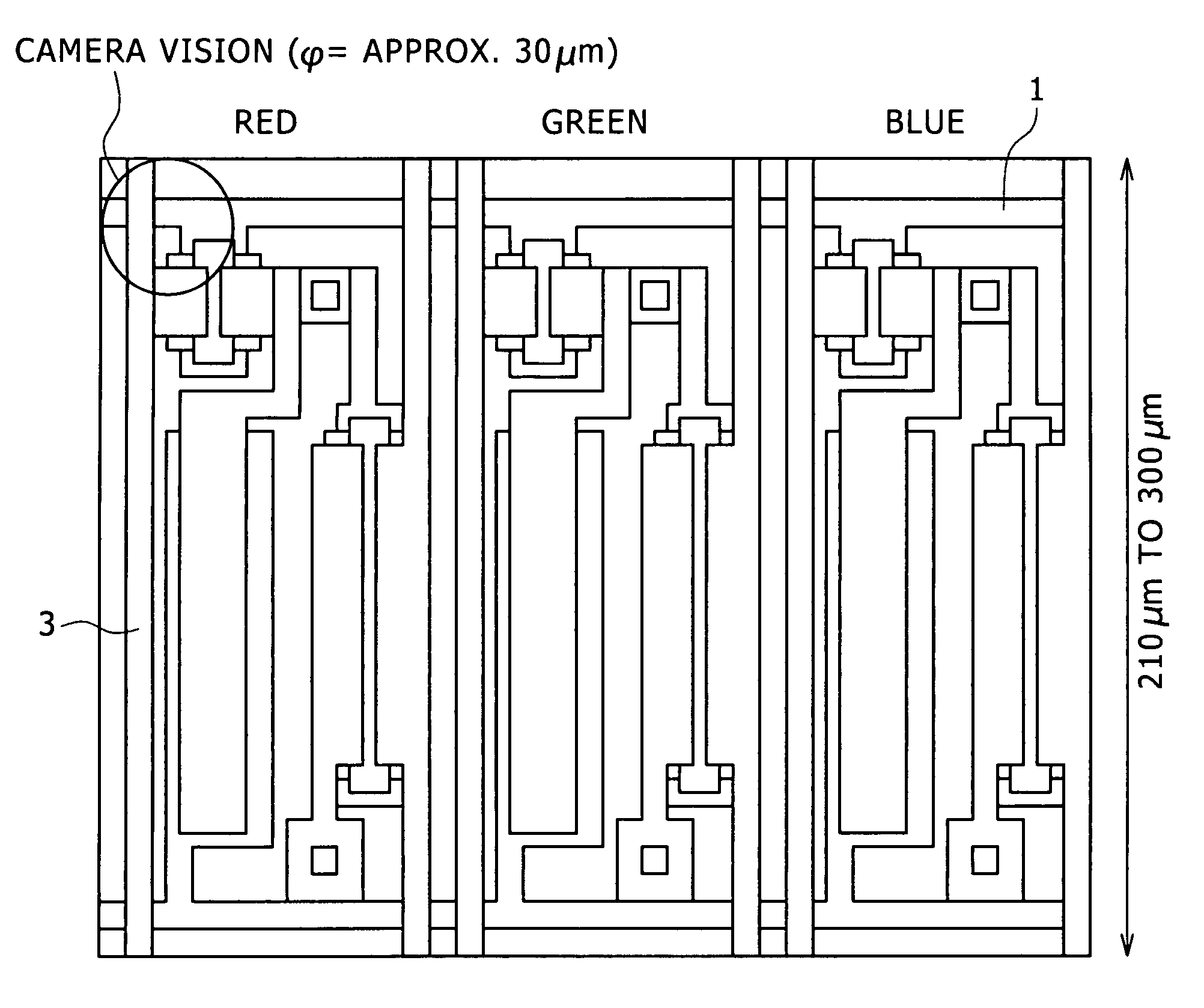

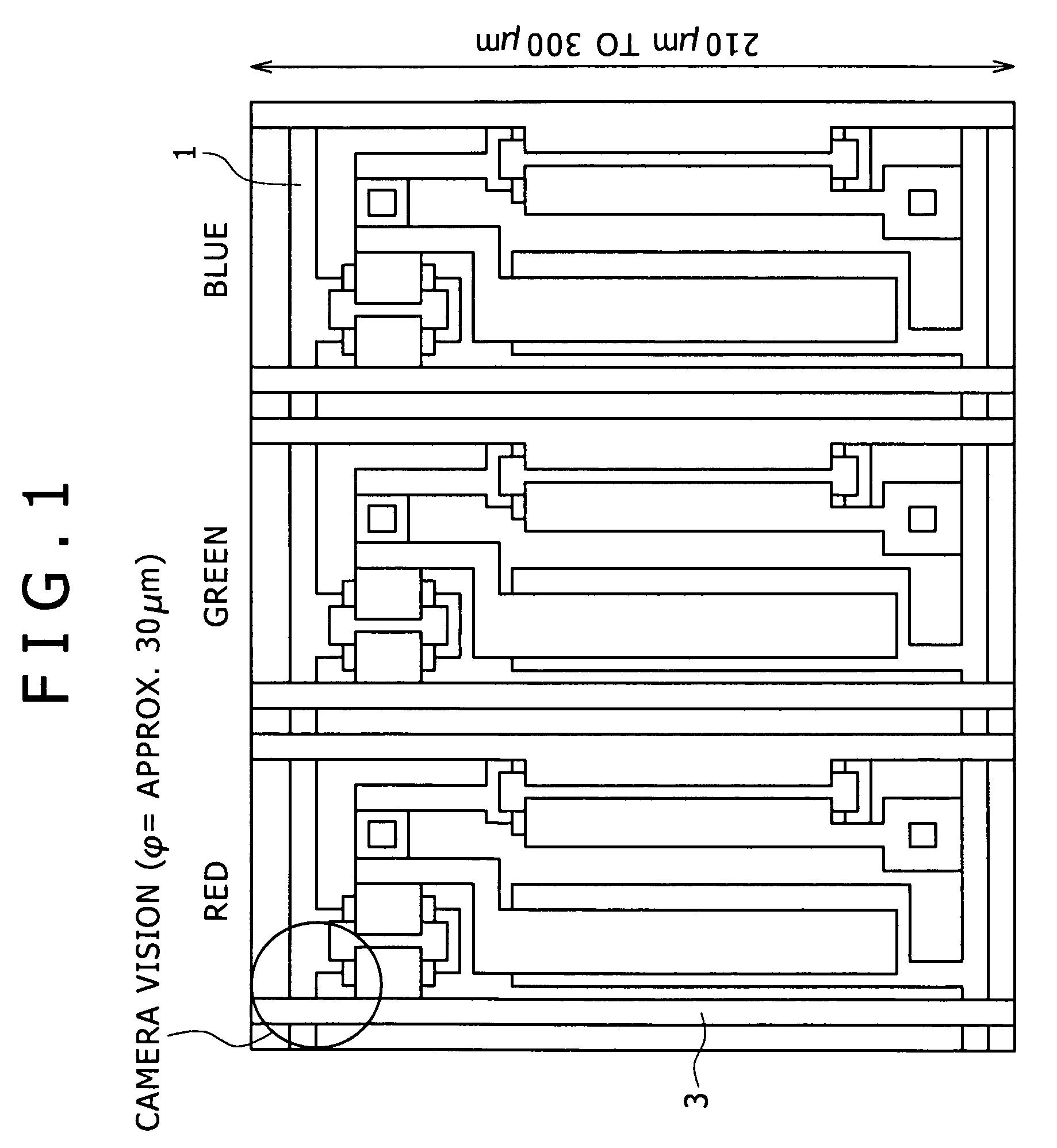

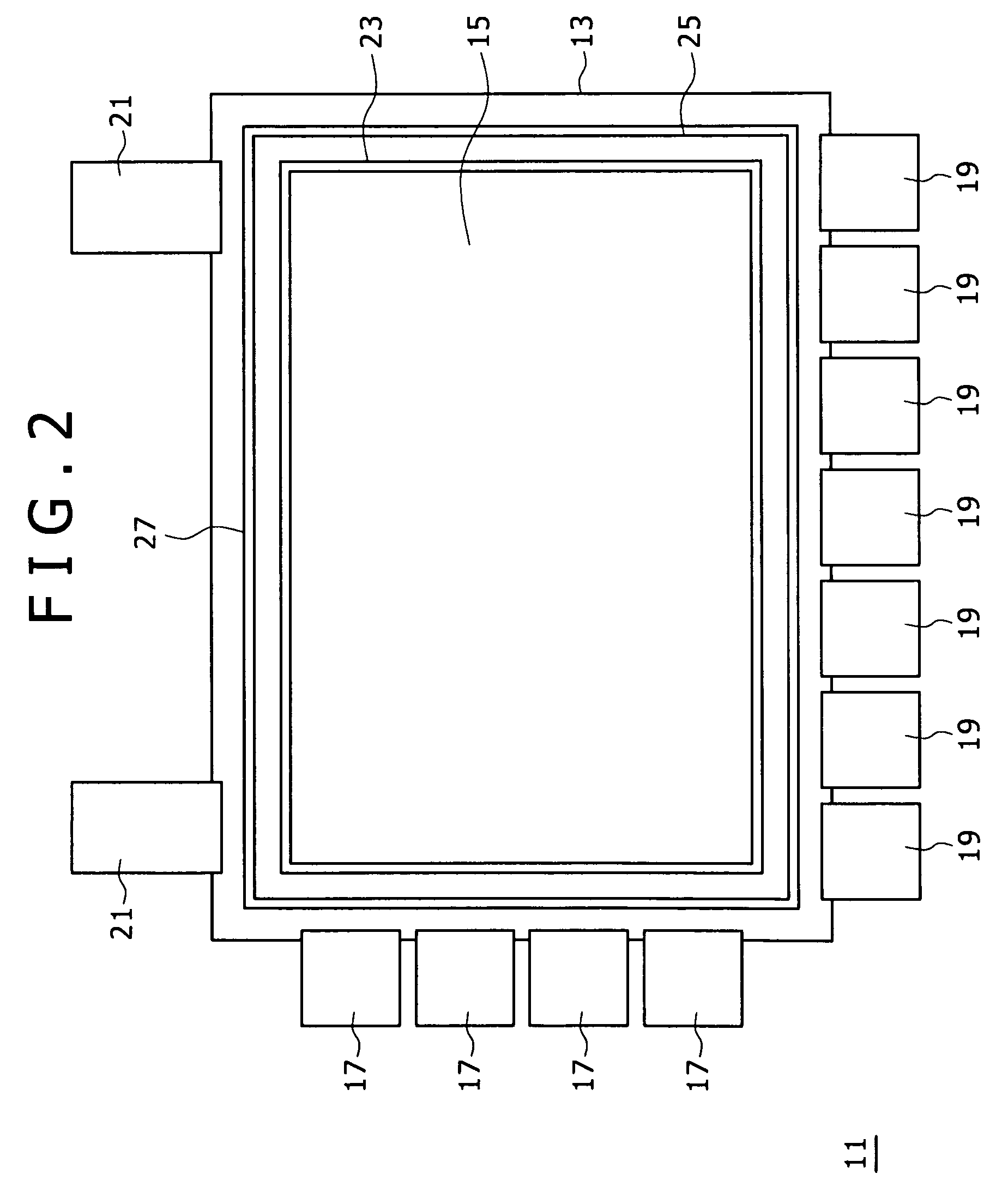

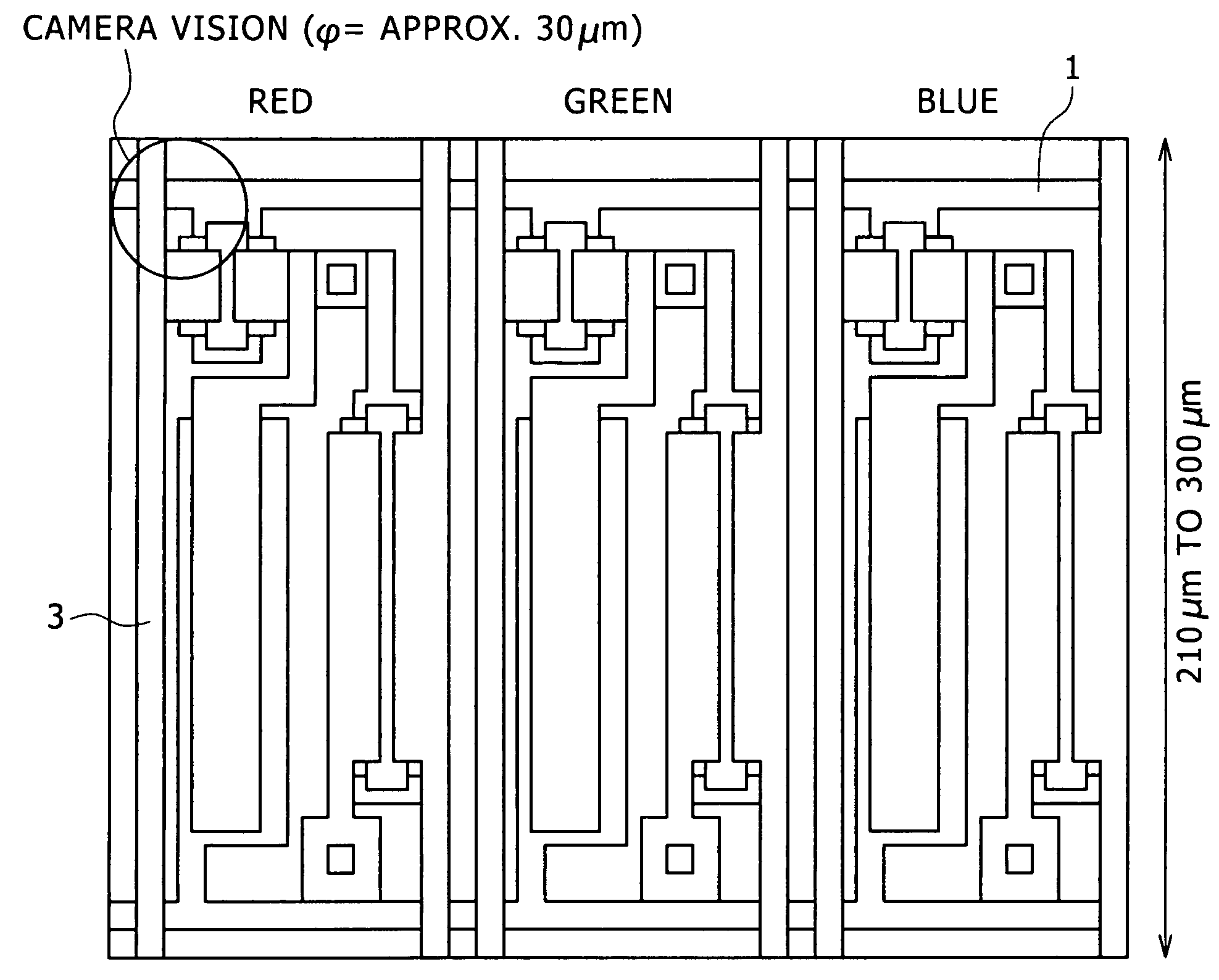

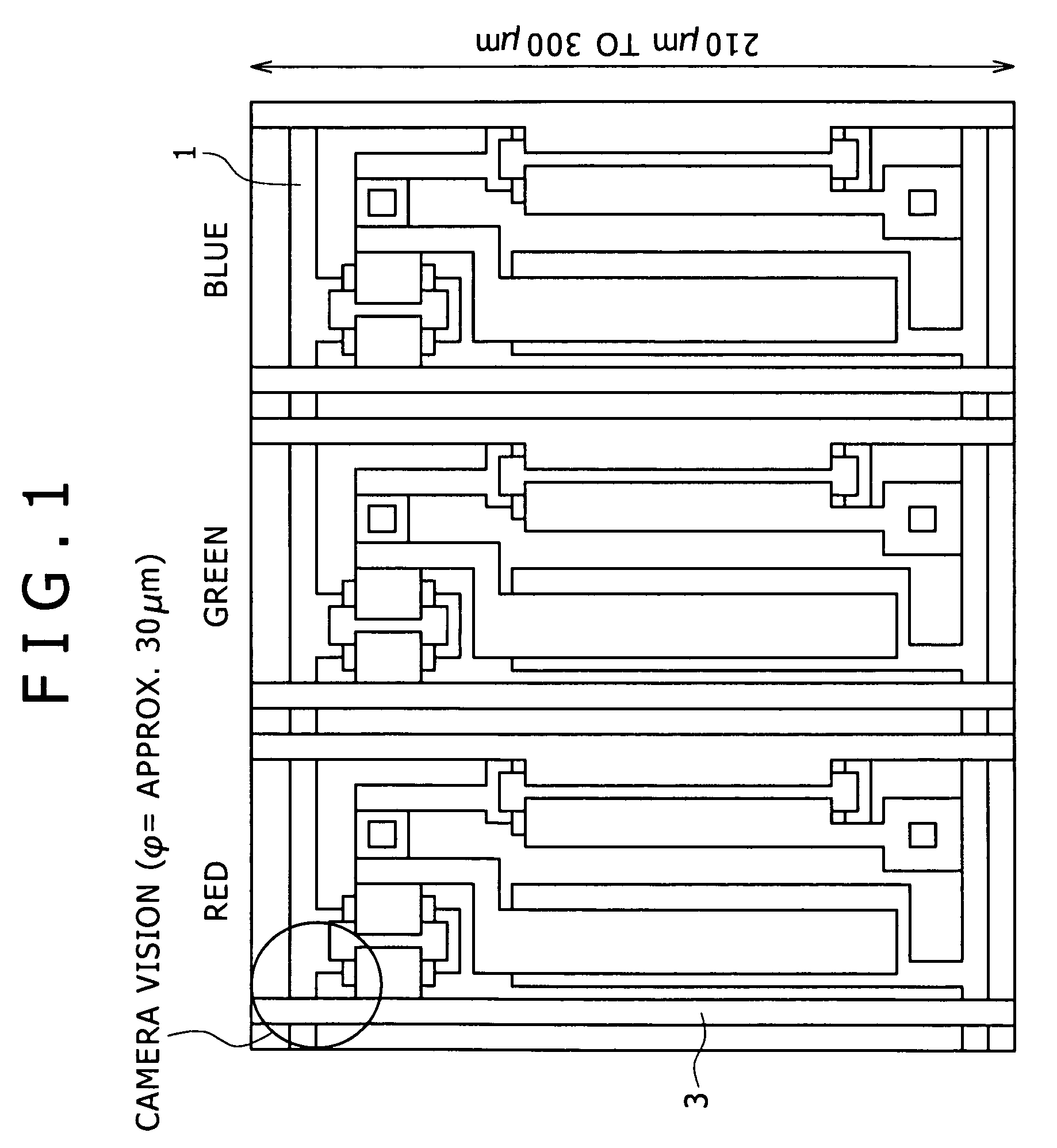

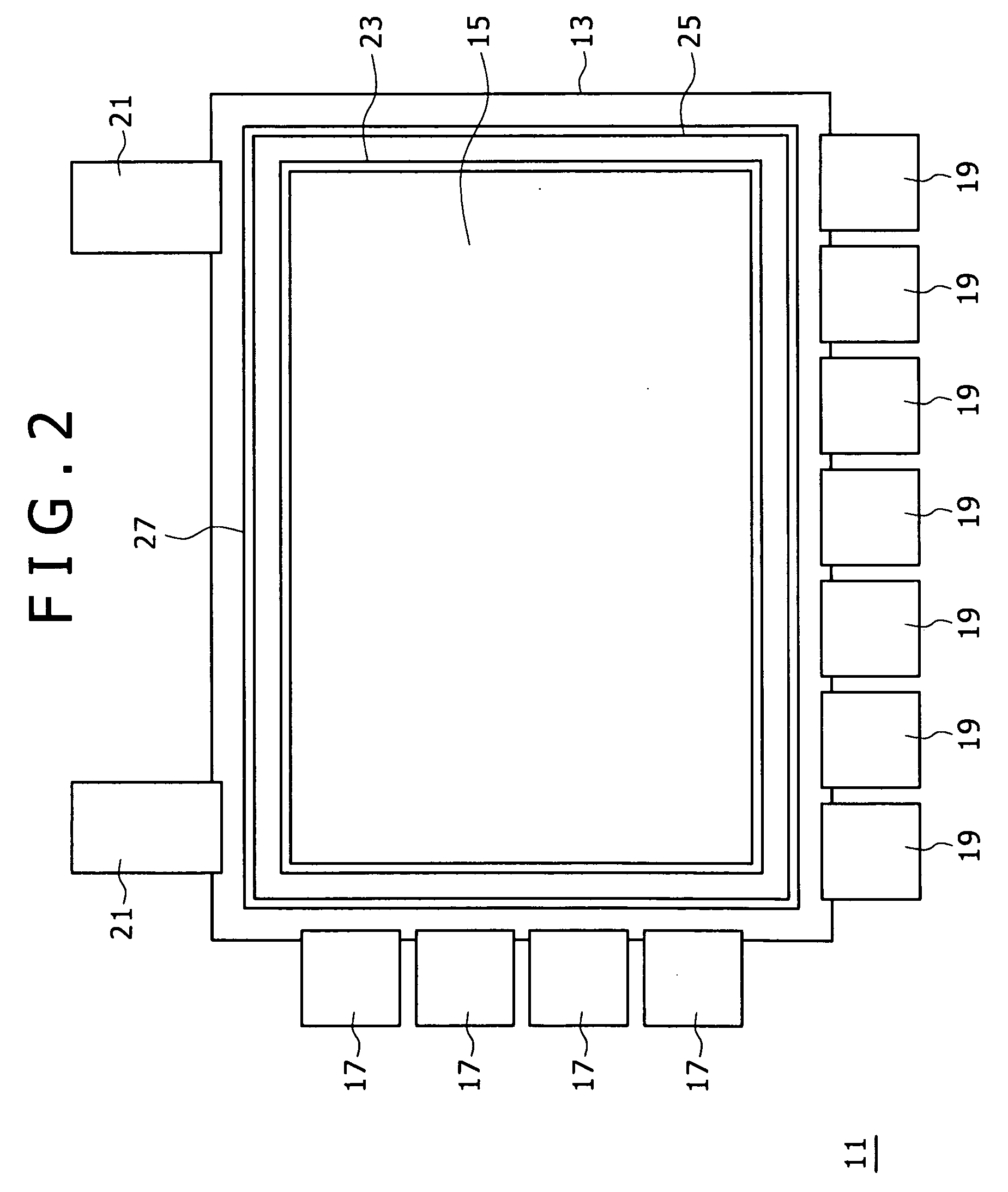

Display panel and panel inspection apparatus

InactiveUS8508123B2Shorten the timeImprove takt timeDischarge tube luminescnet screensStatic indicating devicesActive matrixControl line

Disclosed herein is a display panel based on active matrix driving having a display area made up of N pixel control lines, M video signal lines orthogonally intersecting the N pixel control lines, and pixel circuits arranged at intersections between the N pixel control lines and M video signal lines, wherein positional identification patterns are arranged on every k (k being a natural number) pixel control lines inside each of the pixel circuits.

Owner:SONY GRP CORP

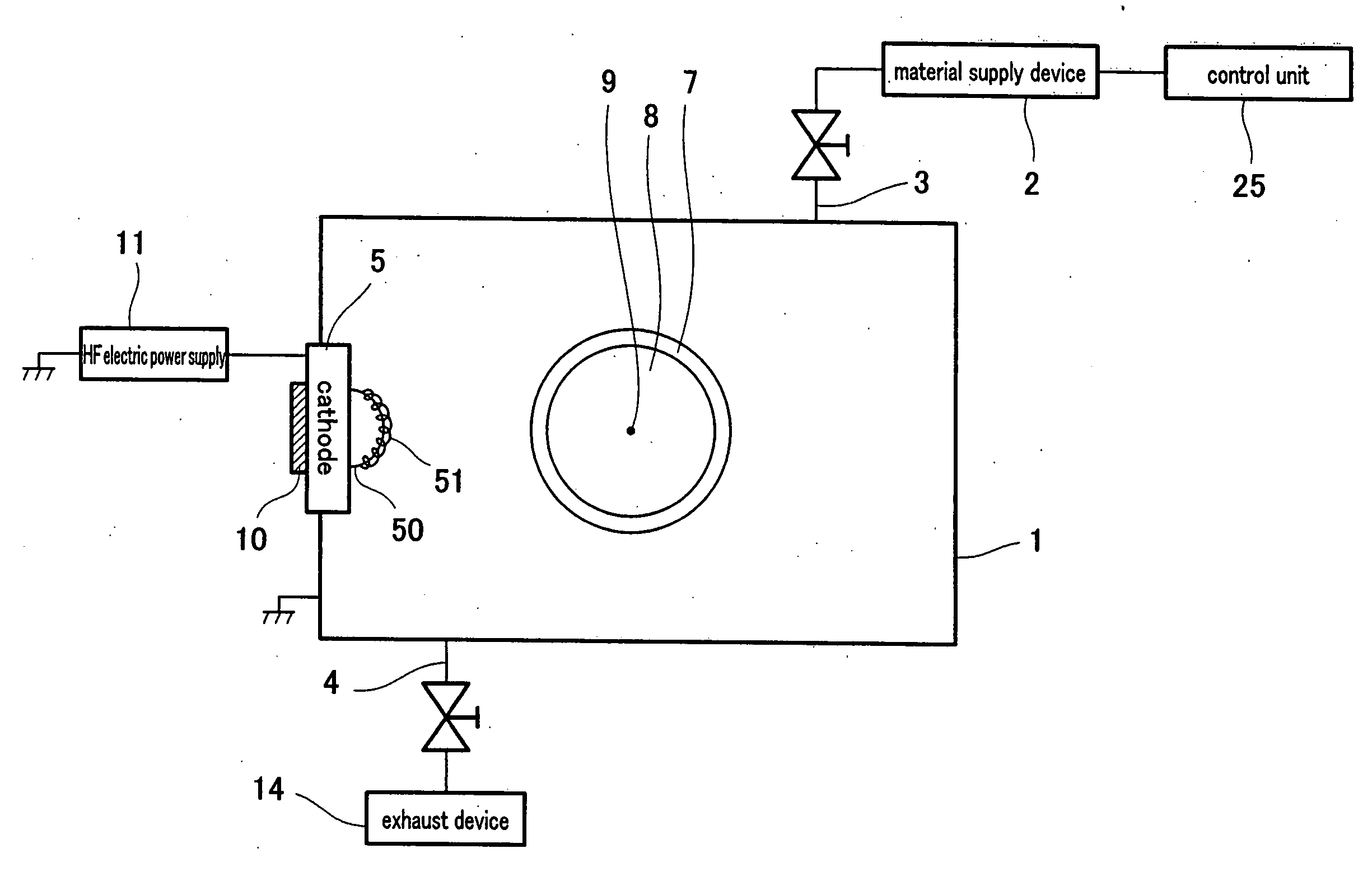

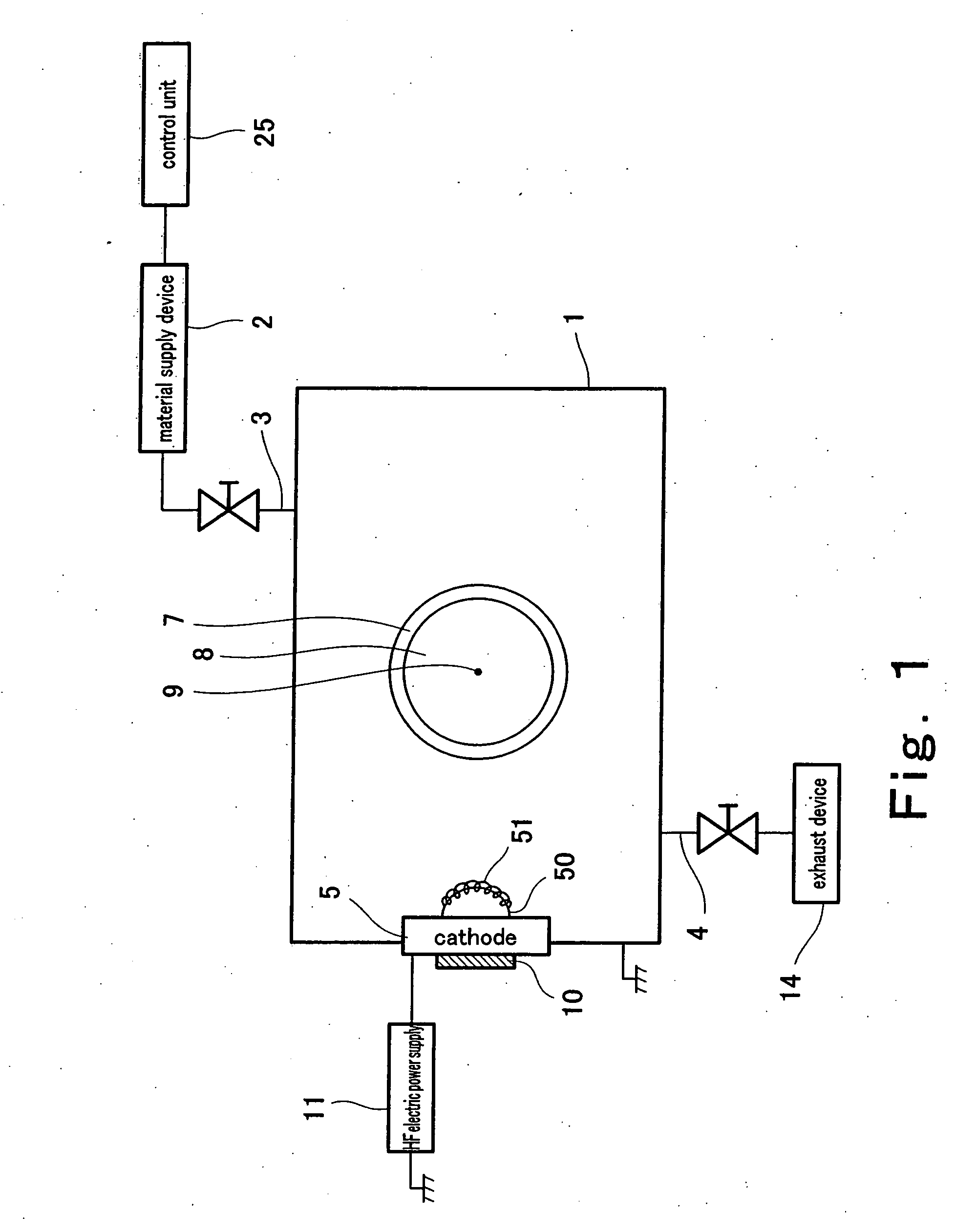

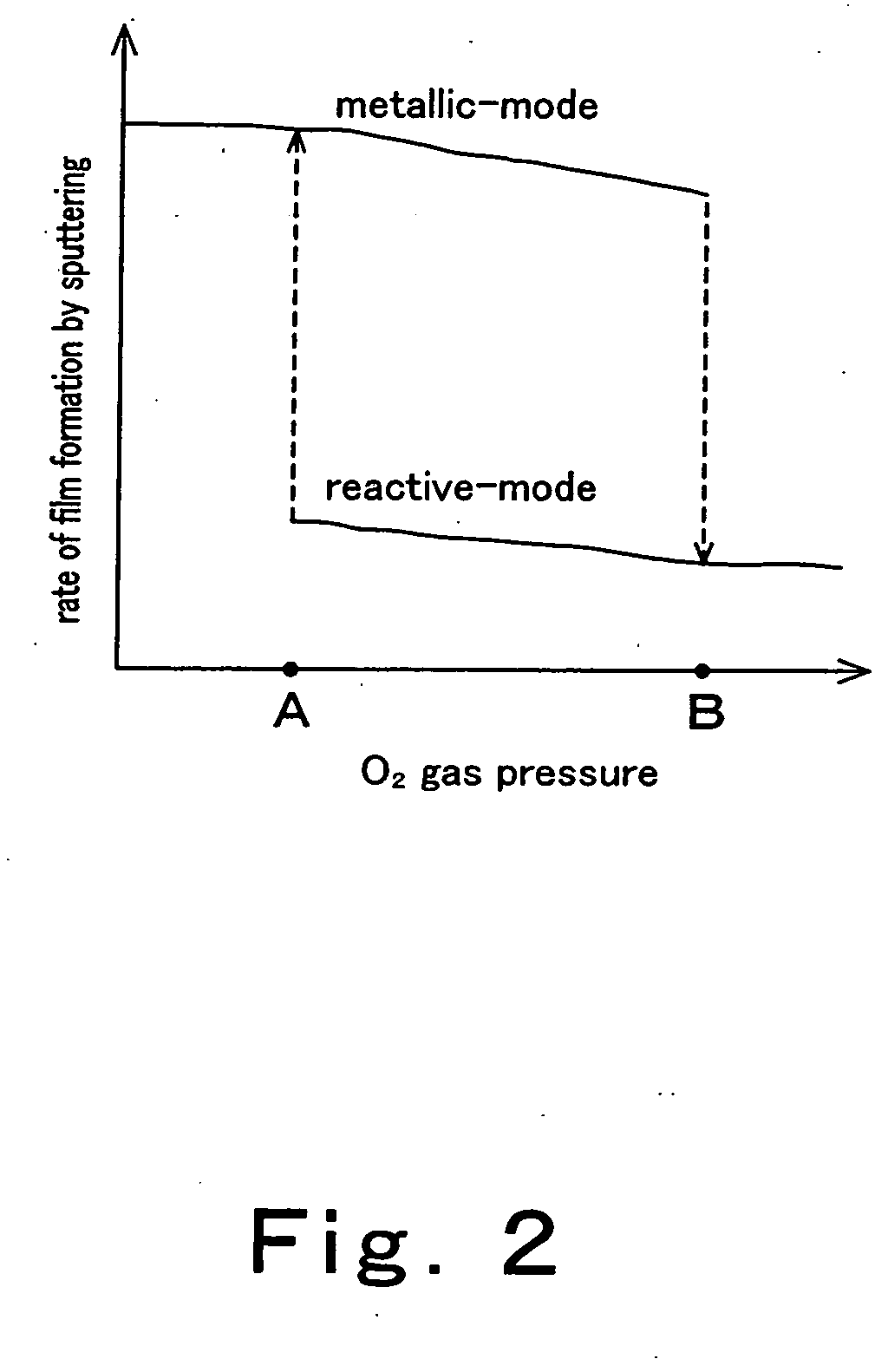

System and method for film formation

InactiveUS20070039545A1Increase ratingsHigh film forming rateVacuum evaporation coatingSputtering coatingSputteringVacuum chamber

The present invention provides film formation systems and film formation methods. A high frequency (HF) electric power supply (11) applies a high frequency voltage to a cathode (5) which is provided, at its rear surface, with a permanent magnet (10), thereby to generate a reactive-mode plasma, and film formation by plasma polymerization is performed by the use of the generated reactive-mode plasma. The pressure of a plasma source gas in a vacuum chamber (1) is regulated, thereby to generate not a reactive-mode plasma but a metallic-mode plasma. The cathode (5) as a target is subjected to sputtering by the generated metallic-mode plasma, and film formation by magnetron sputtering is carried out.

Owner:SHIN MEIWA IND CO LTD

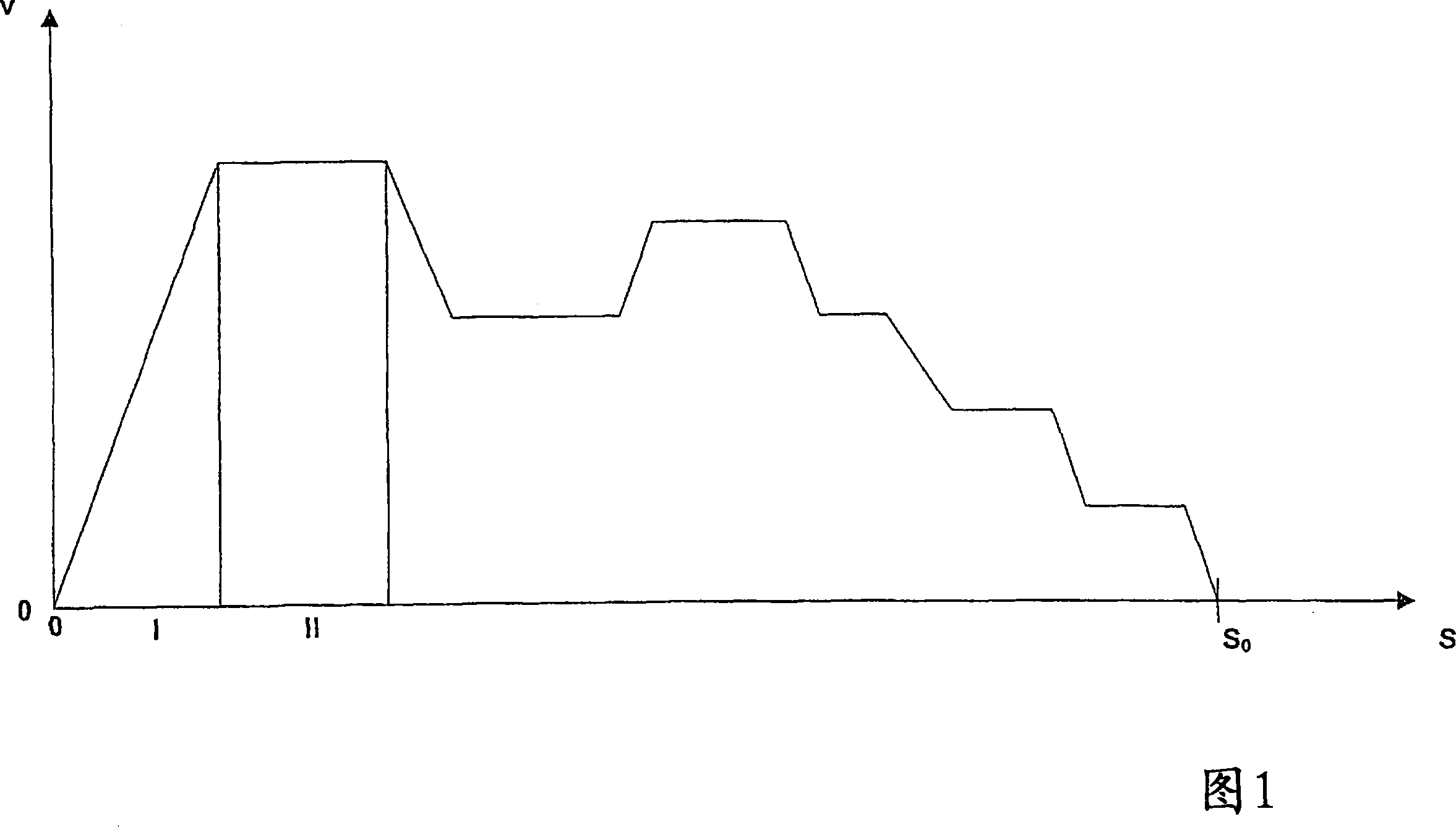

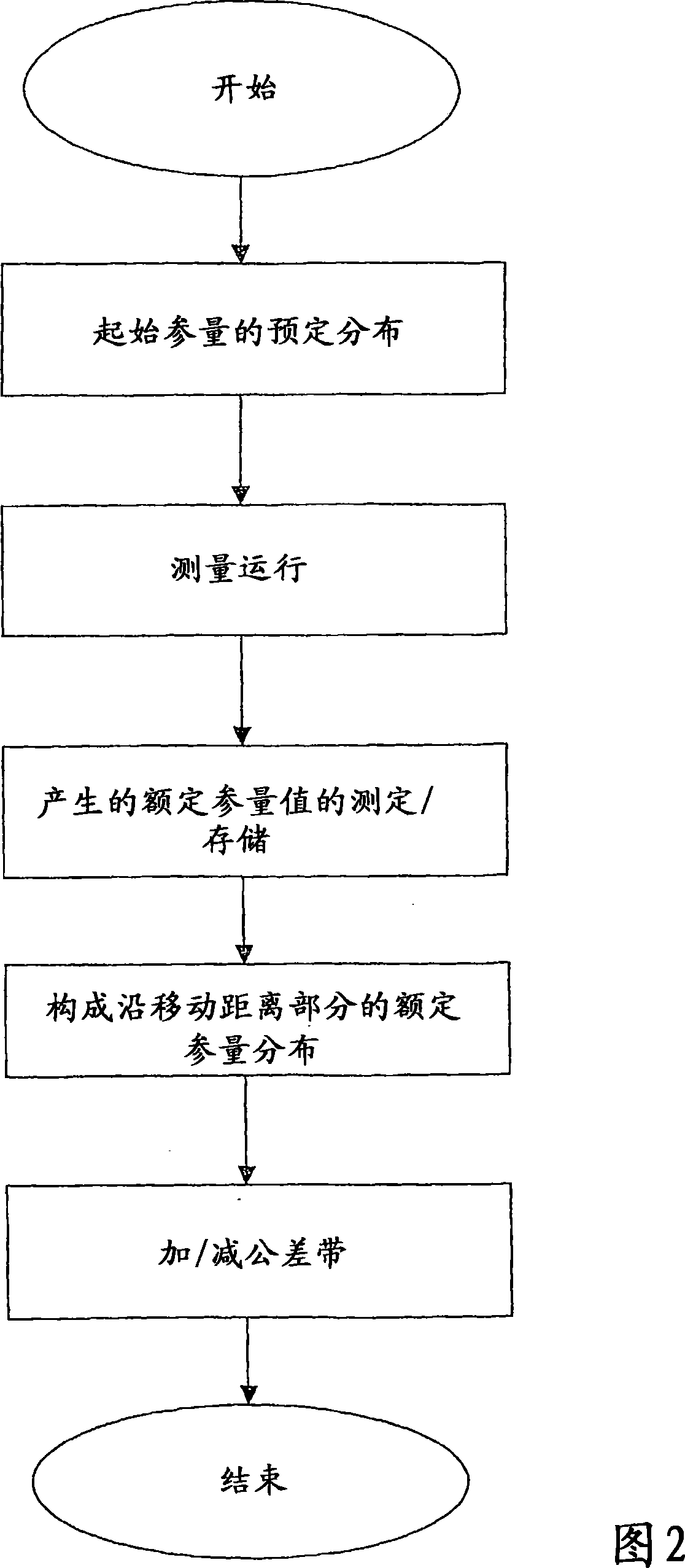

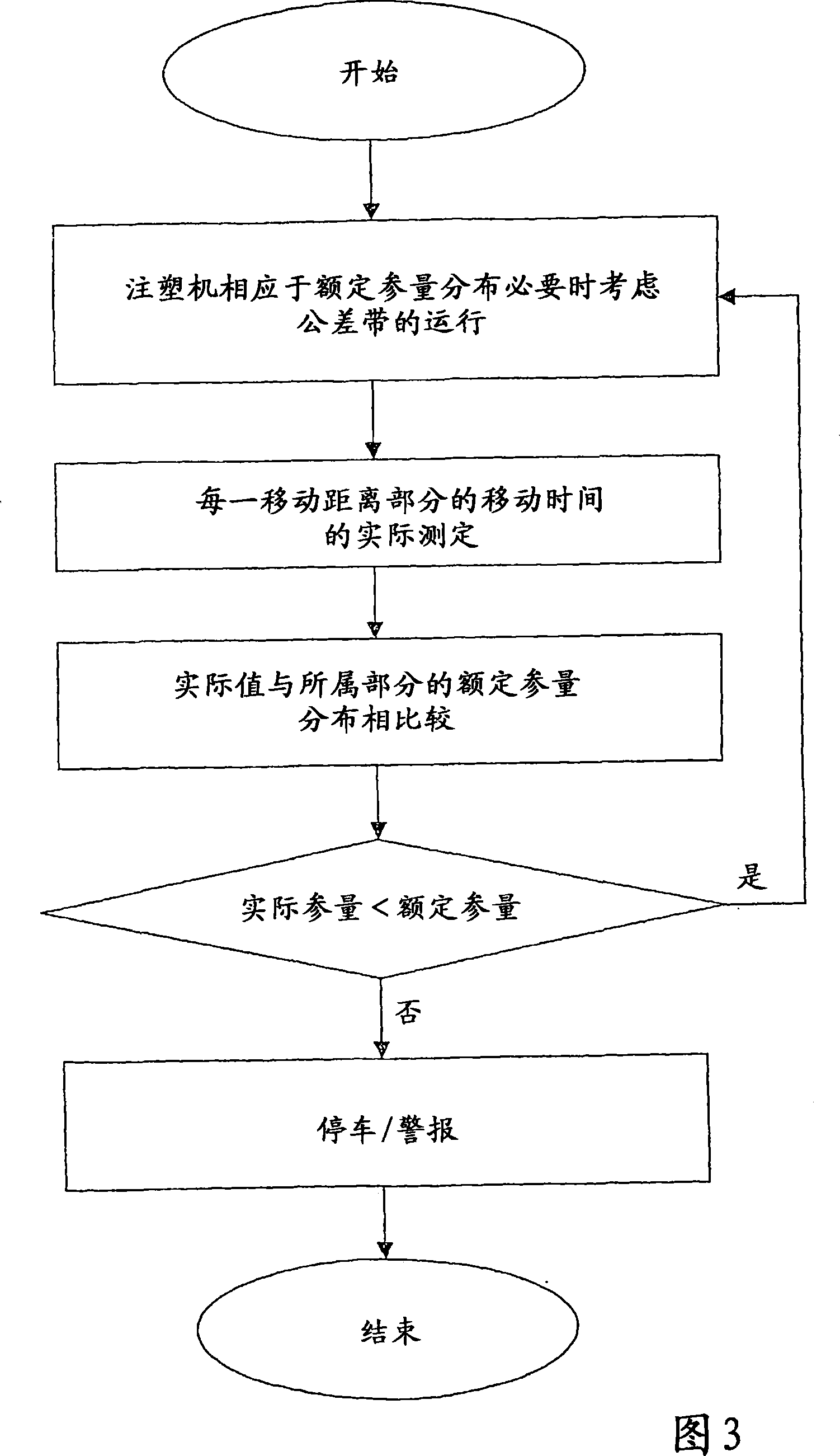

Method for operating an injection molding machine

The invention relates to a method for operating an injection molding machine, particularly a method for securing tools of an injection molding machine. According to said method, a setpoint variable curve is determined along at least one section of a displacement path of a molding tool in a setpoint variable determination phase, and the injection molding machine is operated according to the determined setpoint variable curve in a subsequent operational phase. A preset curve of at least one initial variable is predefined, the molding tool is driven in accordance with the preset curve of the initial variable in a test run, at least one resulting value of the setpoint variable is measured and stored during the test run, and a setpoint variable curve is formed along the section of the displacement path from the measured values of the setpoint variable.

Owner:KRAUSSMAFFEI TECH GMBH

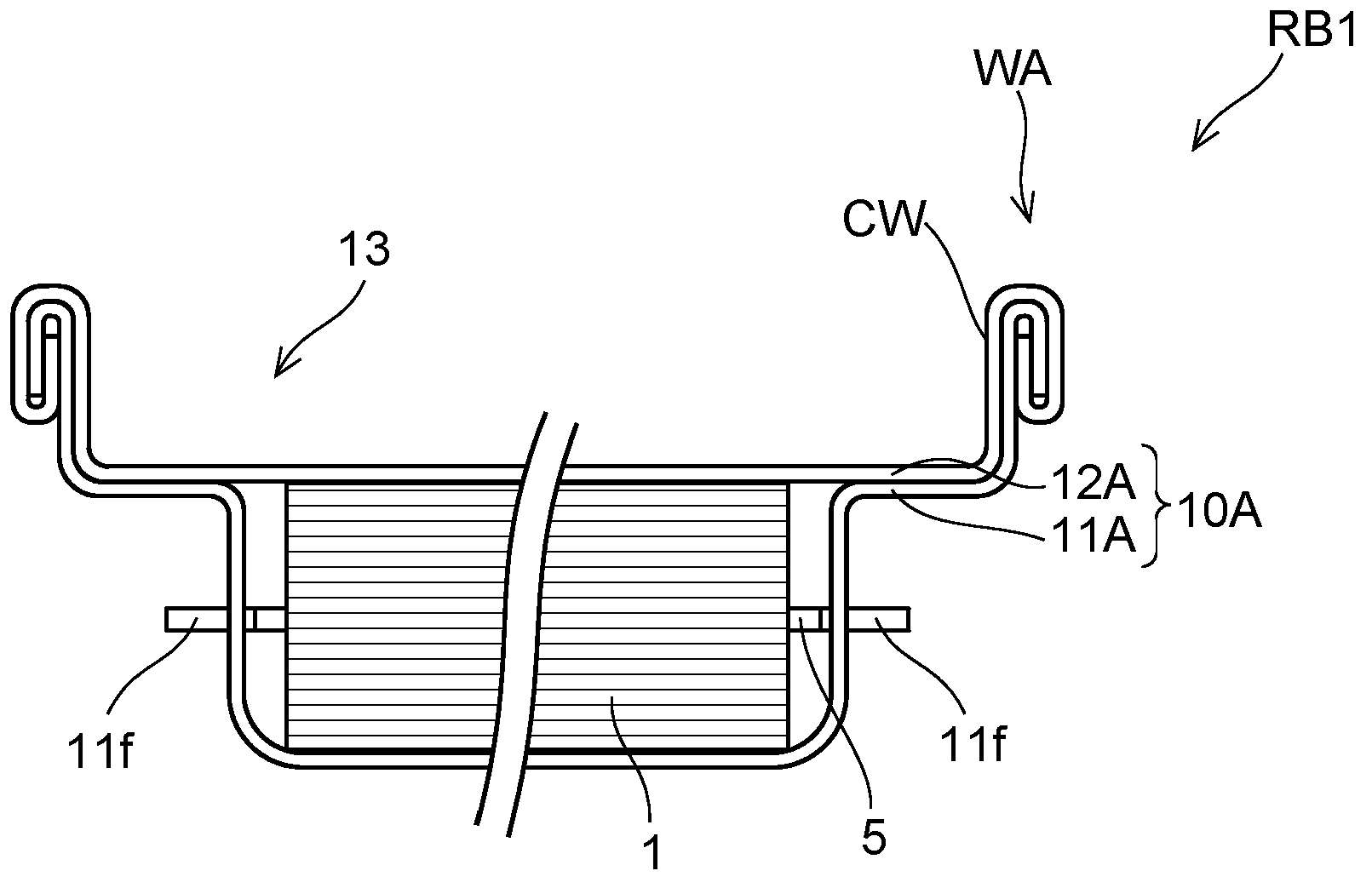

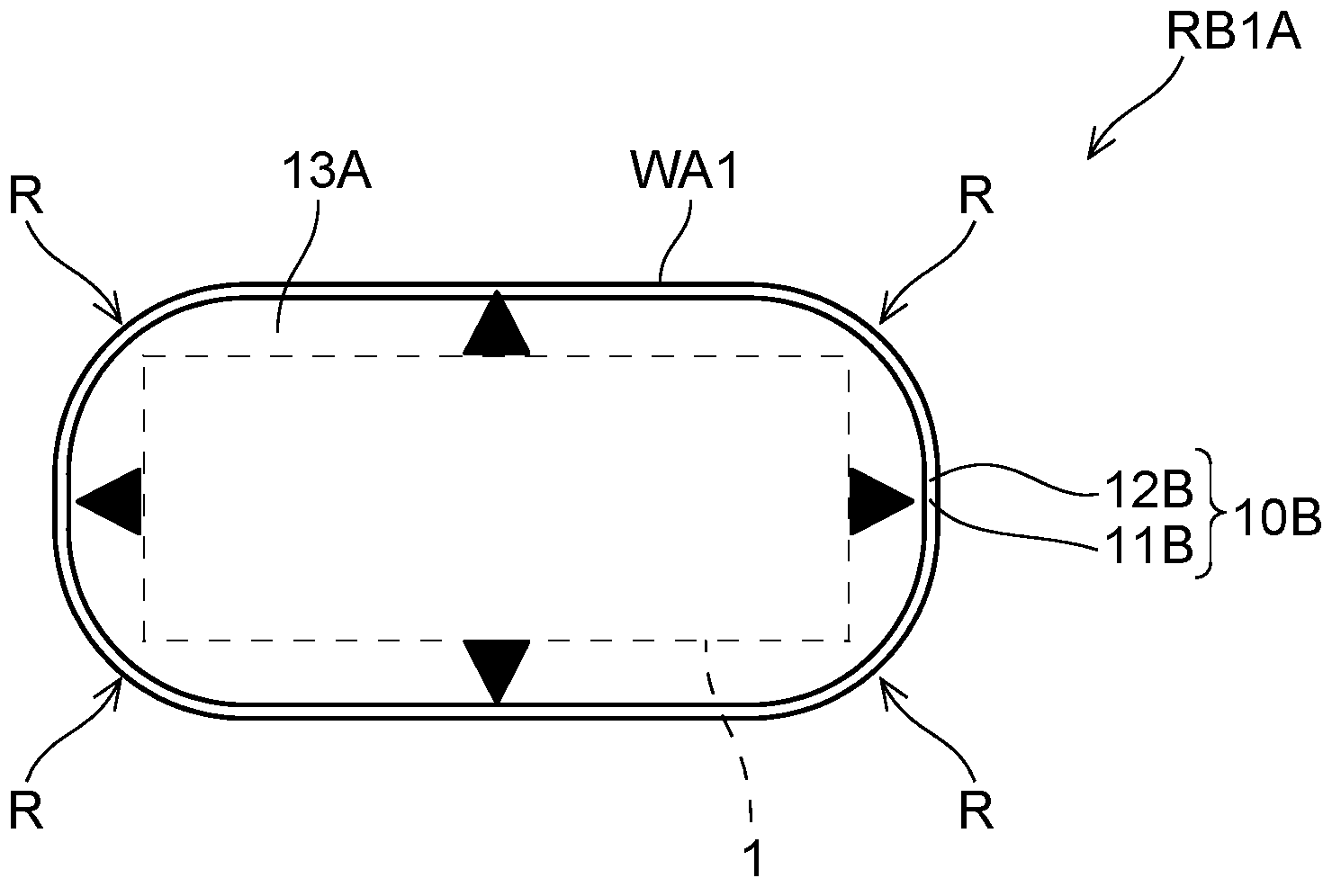

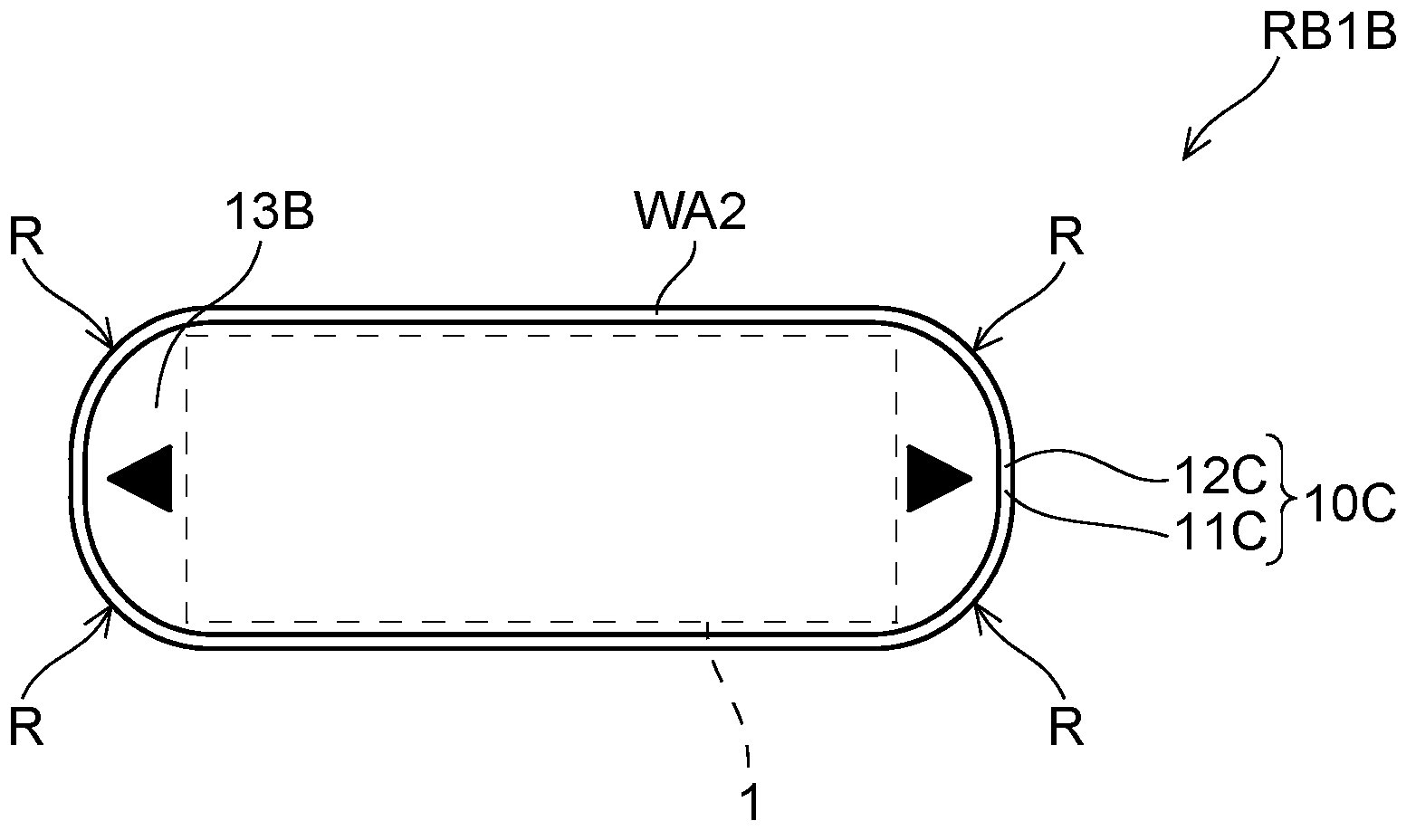

Secondary cell

InactiveCN102916140AImprove air tightnessIncrease capacityFinal product manufactureSmall-sized cells cases/jacketsEngineeringAir tightness

Provided is a secondary cell in which the production takt time can be improved, airtightness of a cell canister is exhibited, cell capacity can be increased, and excellent handling properties can be obtained. A secondary cell comprising an electrode group (1); an exterior case (11); and a cell canister (10) comprising the exterior case (11) and a lid member (12), the interior of which canister being filled with an electrolyte, and airtightness being achieved; the secondary cell being constituted such that the cell canister (10) comprises a electrode group accommodating part and a peripheral edge section in which the exterior case (11) and the lid member (12) are double-seamed and sealed; and the peripheral edge section is provided so as to bulge outward from the electrode group accommodating part, and has an appropriately sized corner R corresponding to the plate thickness of plates to be double-seamed and exhibiting airtightness.

Owner:SHARP KK

Automatic feeding and discharge system applicable to function testing equipment

ActiveCN108974825AOptimize walking pathIncrease production capacityControl devices for conveyorsStacking articlesTesting equipmentSmall footprint

The invention discloses an automatic feeding and discharge system applicable to function testing equipment. The automatic feeding and discharge system comprises a first conveying mechanism unit, a second conveying mechanism unit and a third conveying mechanism unit, wherein the first conveying mechanism unit moves along a first direction; the second conveying mechanism unit moves along the first direction; the first conveying mechanism unit and the second conveying mechanism unit are sequentially arranged along a second direction; the third conveying mechanism unit moves along the second direction, and when the third conveying mechanism unit moves to a first position, the third conveying mechanism unit is in butt joint with a first butt joint end; when the third conveying mechanism unit moves to a second position, the third conveying mechanism unit is in butt joint with a second butt joint end. The automatic feeding and discharge system is small in floor space, high in space utilization rate, capable of achieving feeding and discharge without shutdown, capable of achieving an around-the-clock working mode, capable of avoiding interference with a mechanical arm, capable of optimizing the traveling path of the mechanical arm and capable of greatly increasing the productivity and output of the function testing equipment.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Display panel and panel inspection apparatus

InactiveUS20090066608A1Reduce repairImprove takt timeStatic indicating devicesTelevision systemsActive matrixControl line

Disclosed herein is a display panel based on active matrix driving having a display area made up of N pixel control lines, M video signal lines orthogonally intersecting the N pixel control lines, and pixel circuits arranged at intersections between the N pixel control lines and M video signal lines, wherein positional identification patterns are arranged on every k (k being a natural number) pixel control lines inside each of the pixel circuits.

Owner:SONY CORP

An automatic loading and unloading system suitable for functional testing equipment

ActiveCN108974825BOptimize walking pathIncrease production capacityControl devices for conveyorsStacking articlesFunctional testingRobotic arm

The invention discloses an automatic loading and unloading system suitable for functional testing equipment, comprising: a first conveying mechanism group, a second conveying mechanism group and a third conveying mechanism group; the first conveying mechanism group moves along the first direction; the second conveying mechanism group The mechanism group moves along the first direction; the first conveying mechanism group and the second conveying mechanism are arranged in sequence along the second direction; the third conveying mechanism group moves along the second direction, when the third conveying mechanism group moves to the first position, The third conveying mechanism group docks with the first docking end; when the third conveying mechanism group moves to the second position, the third conveying mechanism group docks with the second docking end. The invention occupies a small area and has a high space utilization rate; it does not need to stop loading and unloading, and can realize a 24-hour uninterrupted working mode; it does not interfere with the mechanical arm, and optimizes the walking path of the mechanical arm; it greatly improves the productivity and performance of the functional testing equipment. output.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Optical measuring device

ActiveCN107796759BReduce the temperatureImprove cooling effectColor/spectral properties measurementsMeasuring instrumentEngineering

The present invention provides an optical measuring device capable of cooling a heater in advance and lowering the temperature of a sample container in advance. The optical measurement device is characterized in that it includes: a housing provided with an optical measurement unit, and the optical measurement unit is provided with a sample container for accommodating a measurement sample; In the closed state, a heater for heating the measurement sample is provided at the position abutting against the upper surface of the sample container, and opens downward. A cooling air supply port for supplying cooling air to the inside of the cover is provided on the surface opposite to the cover in the closed state, and the opening and closing mechanism of the cover has a combination of the cover and the housing. The link arms are provided with a rectifying plate between the pair of link arms to direct the cooling air from the cooling air supply port toward the heater.

Owner:USHIO DENKI KK

Blending method and blending device for resist stripping solution

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Optical measurement device

ActiveCN107796759AReduce the temperatureImprove cooling effectColor/spectral properties measurementsEngineeringOptical measurements

The present invention provides an optical measurement device capable of cooling a heater in advance and lowering the temperature of a sample container in advance. The optical measurement device includes a casing provided with an optical measurement section in which a sample container accommodating a measurement specimen is placed; and a cup-shaped lid body which is attached to the casing so as tobe freely opened and closed, wherein a heater for heating the measurement specimen is provided at a position opposite to the upper surface of the sample container in a closed state and opened downwards, a cooling air suppy port for supplying cooling air to the interior of the lid body is provided on a surface opposite to the lid body in a closed state in the casing, an opening and closing gmechanism of the lid body has a pair of link arms connecting the lid body and the casing, and between the pair of link arms is provided with a straightening vane for bringing the cooling air from the coolingair supply port toward the heater.

Owner:USHIO DENKI KK

Airtight container manufacturing method, and image displaying apparatus manufacturing method using airtight container manufacturing method

InactiveUS8641858B2Efficient use ofImprove takt timeLamination ancillary operationsLaminationEngineeringImage display

Owner:CANON KK

Apparatus for forming coating film and method for forming coating film

ActiveCN102693901BImprove takt timeCost containmentLiquid surface applicatorsSemiconductor/solid-state device manufacturingSpray nozzleEngineering

The invention provides a coating film forming apparatus and a coating film forming method. Through the application of two nozzles, the production time of a coating process is reduced, and cost is minimized. The coating film forming apparatus comprises the components as following: a nozzle mataining member (12) which maintaining a first nozzle (16) and a second nozzle (17) which arranged at the conveying direction of the substrate back and forth; a nozzle moving member (11), which enables the nozzle maintaining member to move along the conveying direction of the substrate; a control member (40), which controls the first and the second nozzles, the nozzle moving member is controlled to arrange the first and second nozzles at the same coating position on the conveying direction of the substrate, and the nozzle maintaining member is moved by the control on the nozzle moving member, and any one of the first and second nozzles is used for ejecting process liquid to the substrate.

Owner:TOKYO ELECTRON LTD

Thin film forming apparatus and method thereof

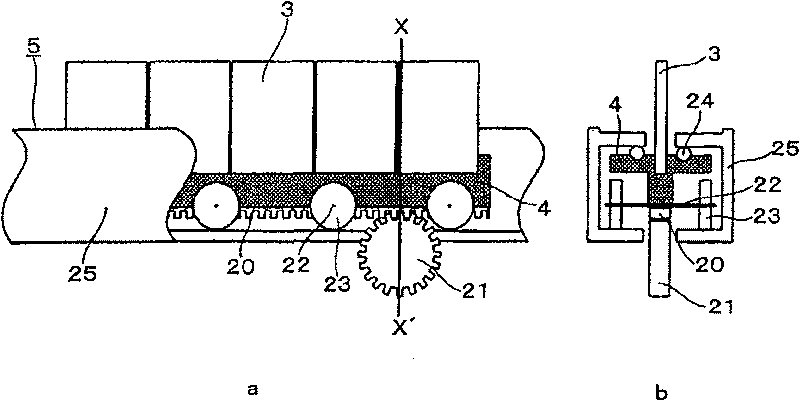

InactiveCN101044260BImprove handling partsIncrease profitPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringMechanical engineering

A utilization ratio of a target material, a tact time, maintenance easiness and film forming accuracy are improved by a thin film forming apparatus. The thin film forming apparatus is provided with avacuum chamber, a sputter cathode for holding the target material, a placing means for placing a substrate to be deposited with the sputtered target material and a carrying mechanism for the placing means. In the carrying mechanism, a carrying path is provided so as to permit the substrate pass through the front side of the target material, and the placing means is composed of a substrate tray which can hold a plurality of substrates in juncture.

Owner:SHOWA SHINKUKK

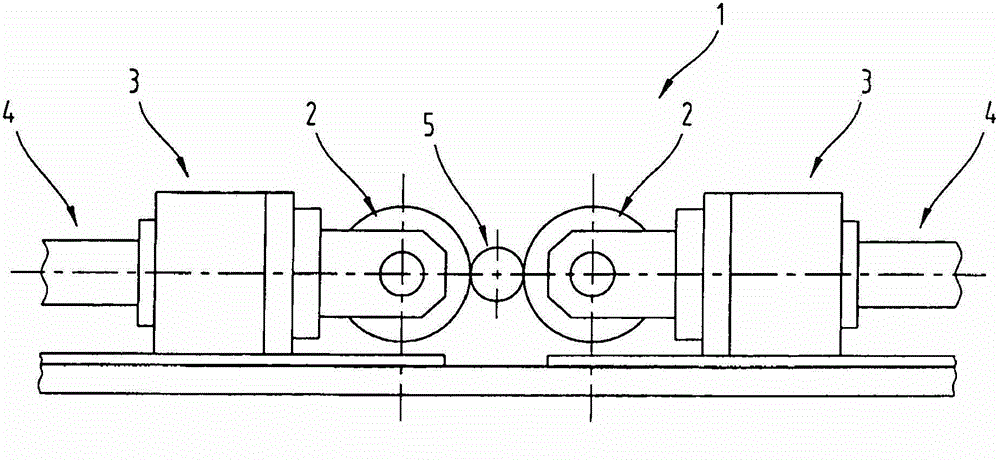

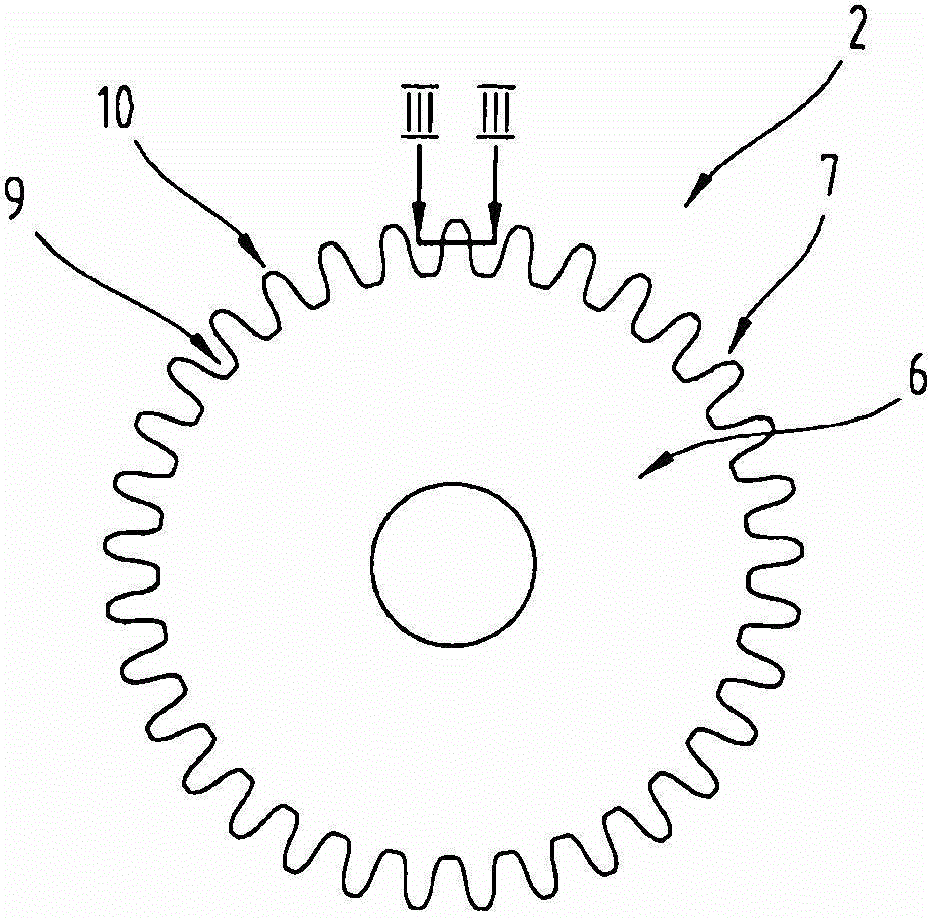

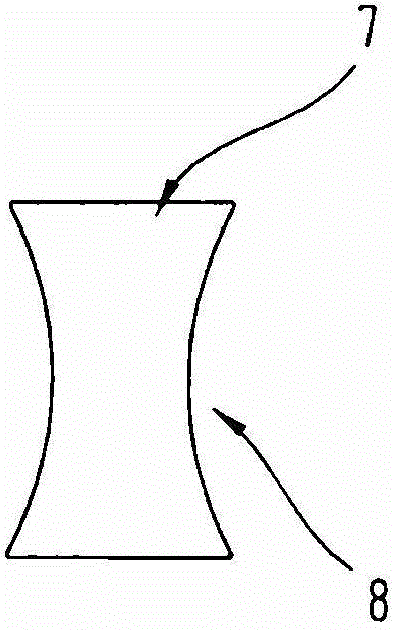

Rolling tool,apparatus,method,and gear for producing convex teeth

ActiveCN102753282AConsistent surface qualityImprove running characteristicsPortable liftingGear wheelsMechanical engineeringGear wheel

Owner:MIBA SINTER AUSTRIA

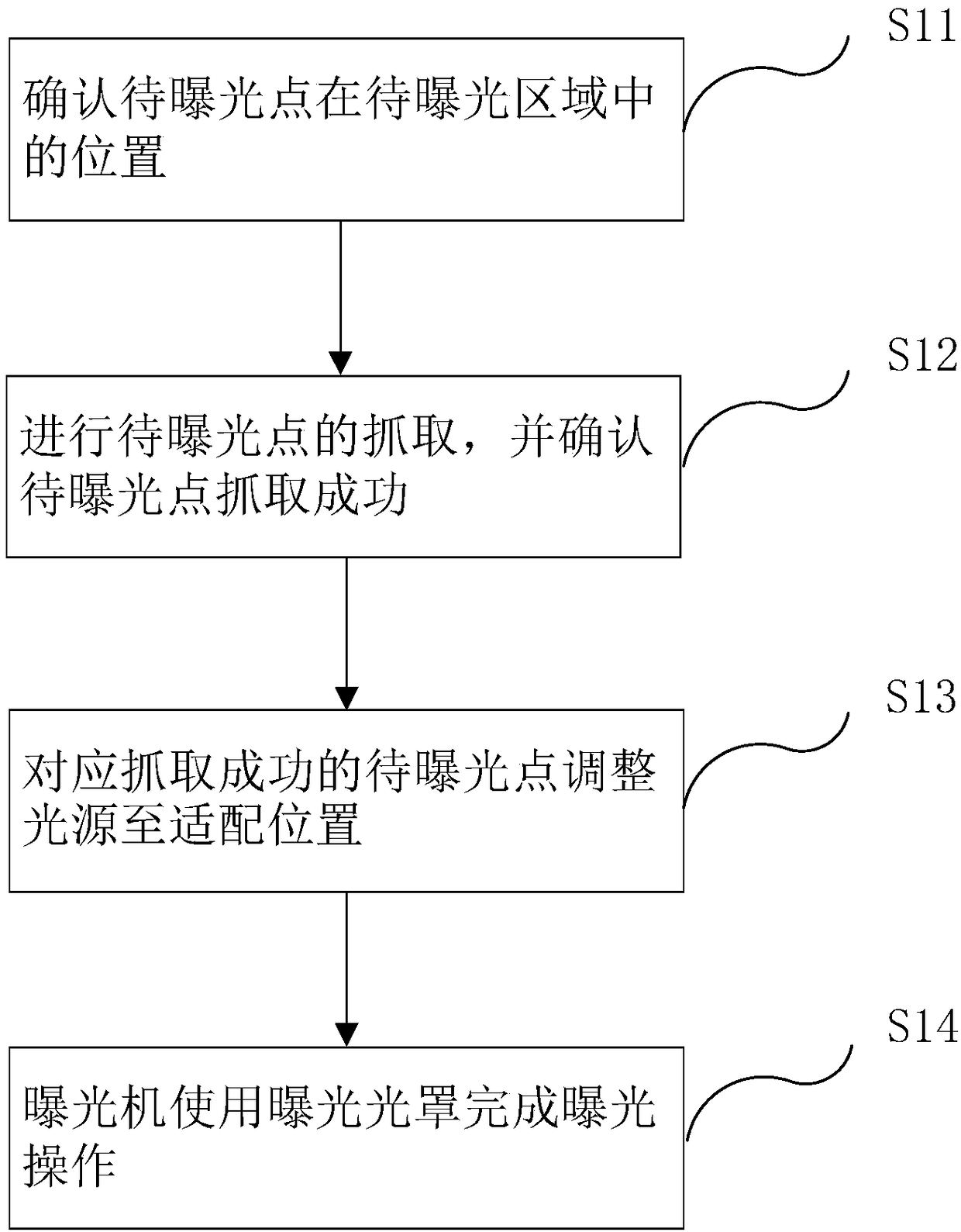

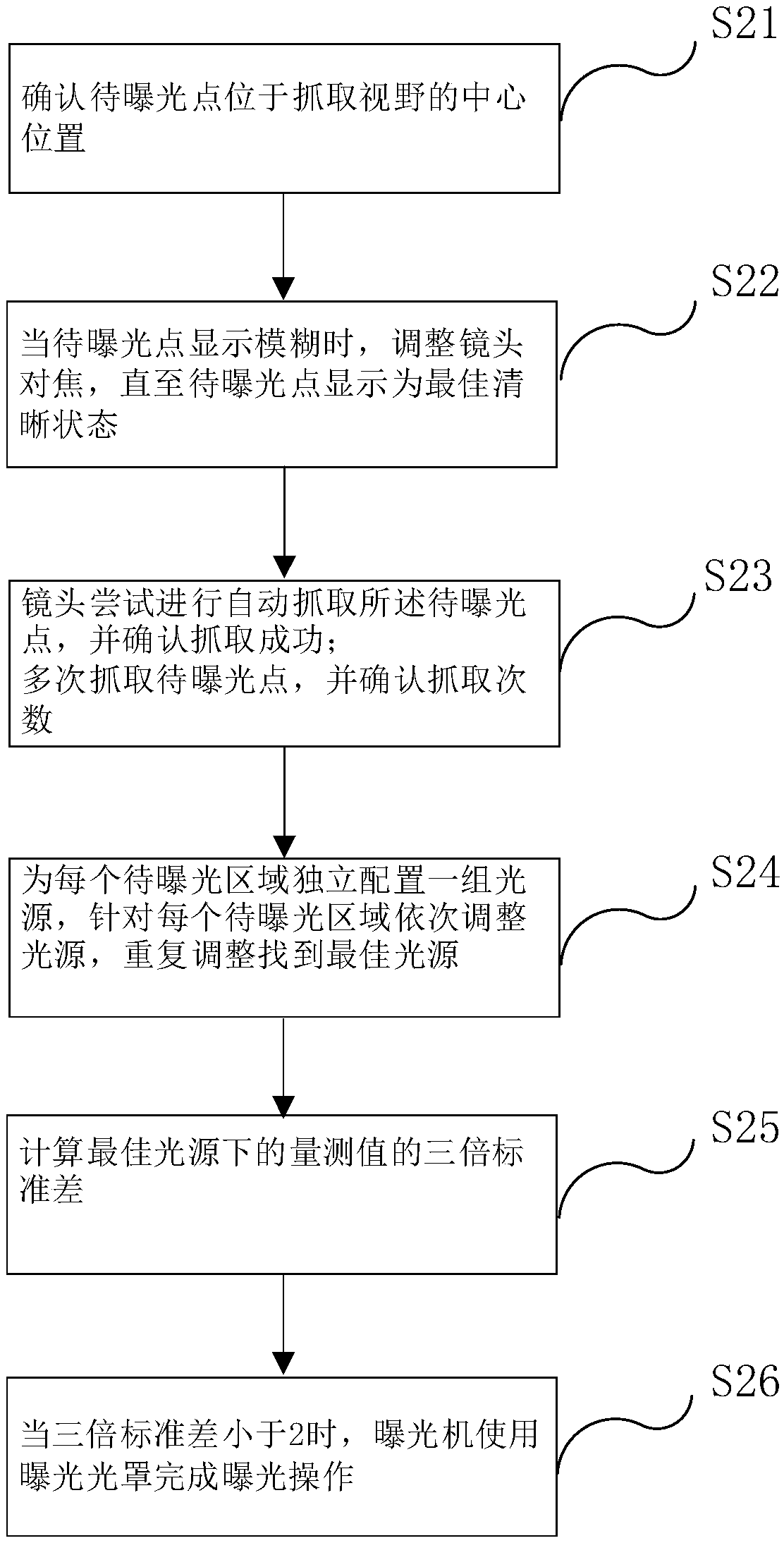

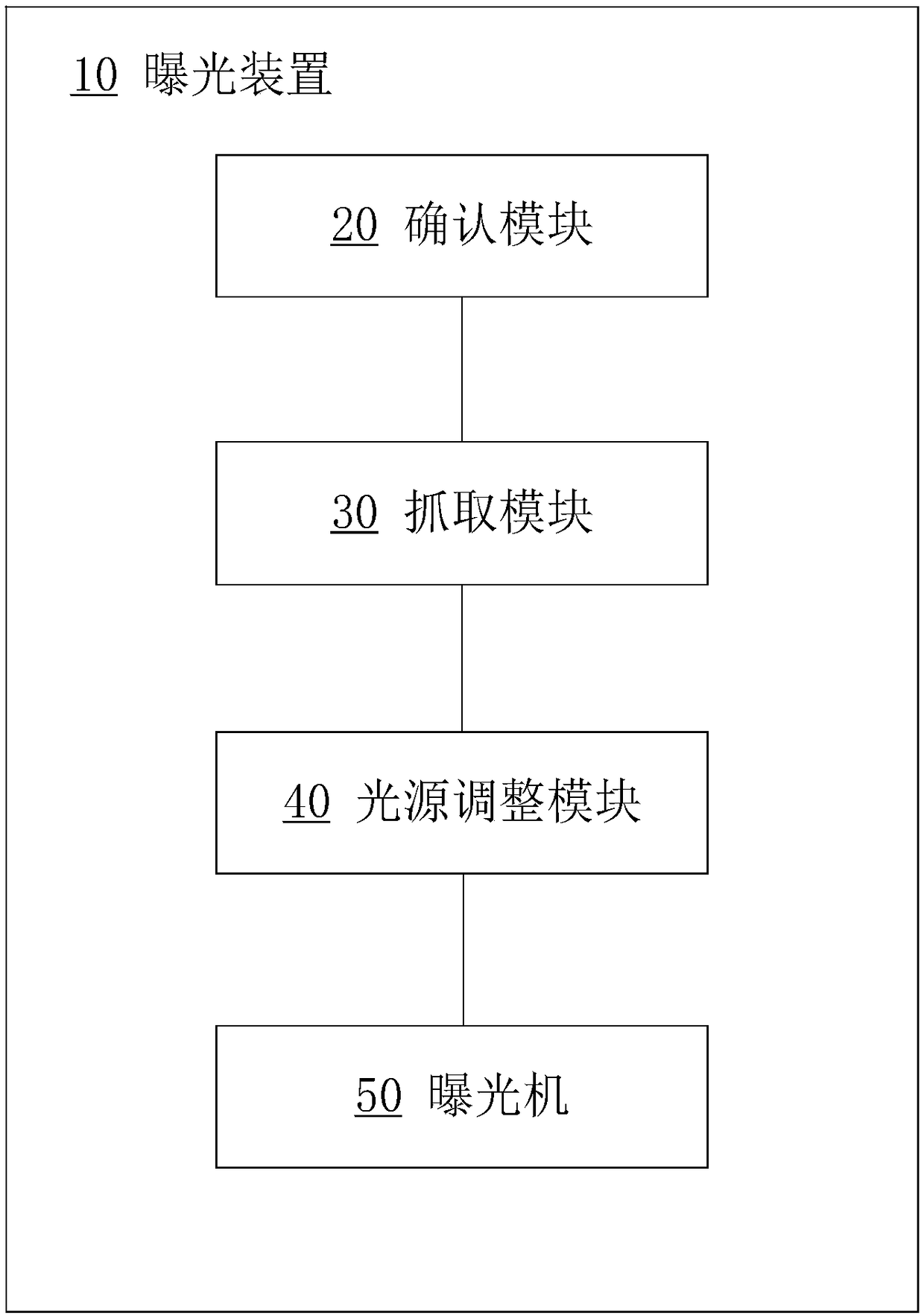

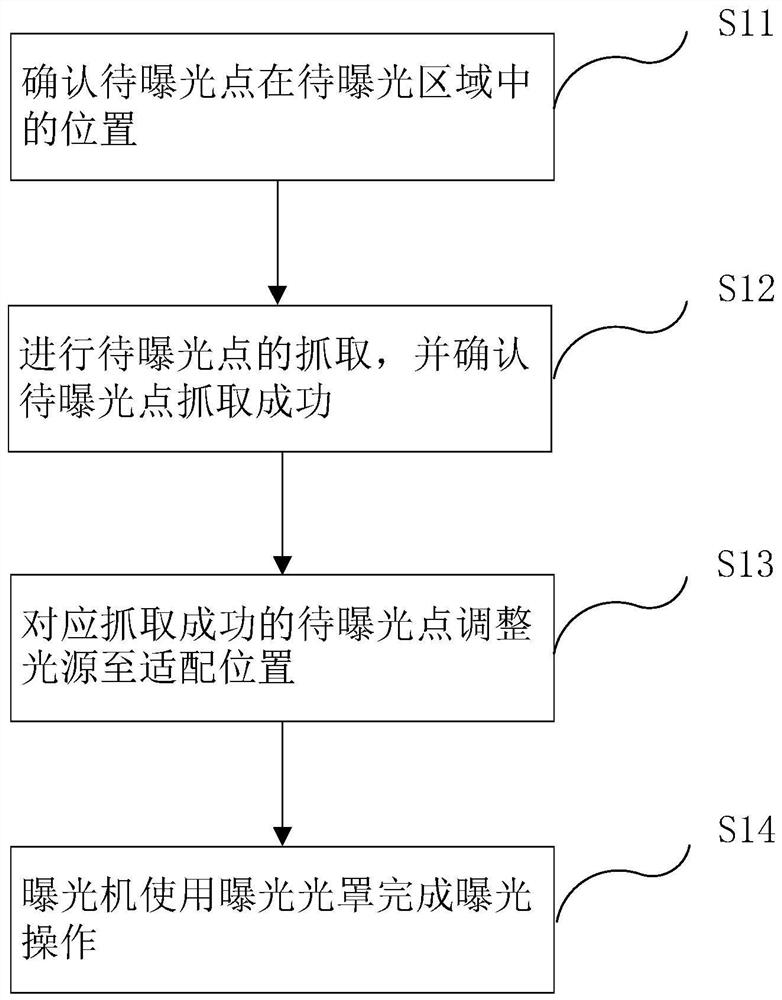

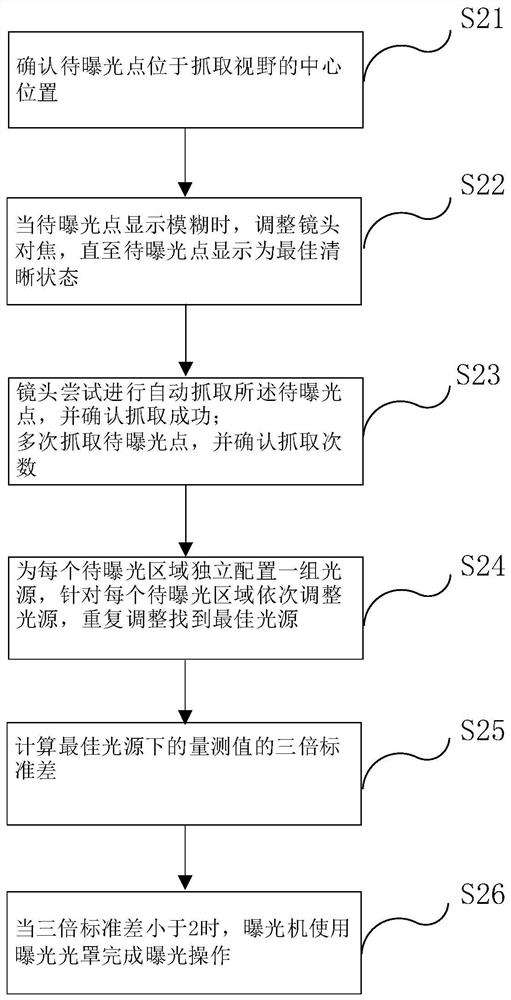

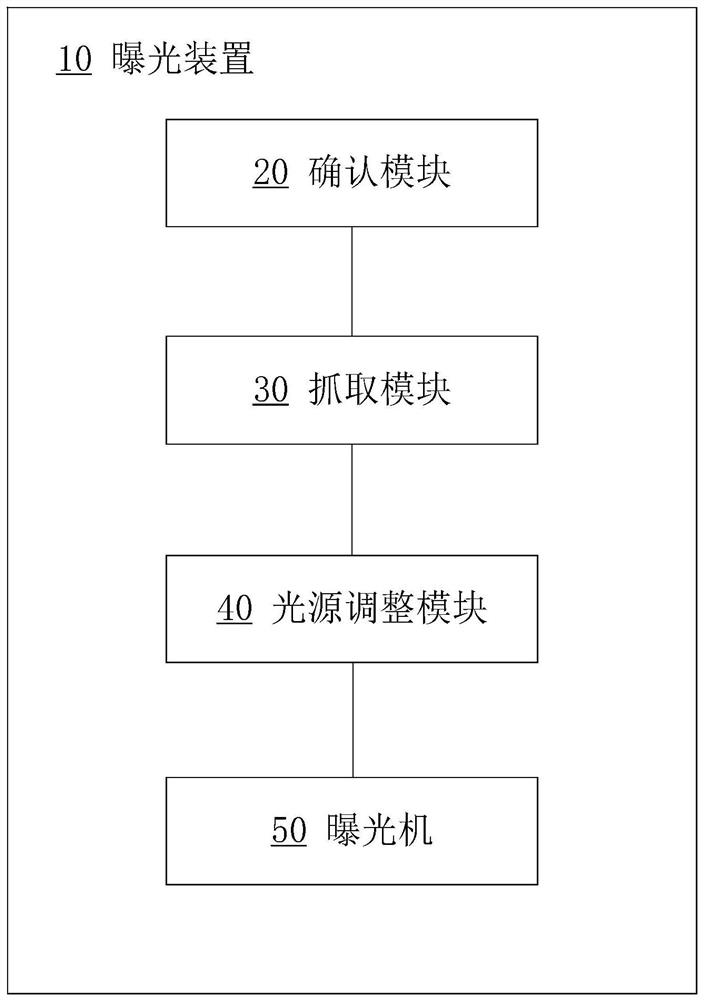

An exposure method and an exposure device thereof

ActiveCN109116685AImprove takt timeShorten takt timePhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsLight source

The invention discloses an exposure method and an exposure device thereof. The exposure method comprises the following steps: confirming the position of a point to be exposed in an area to be exposed;capturing the point to be exposed and confirming that the exposure point to be exposed is successfully captured; adjusting a light source to an appropriate position corresponding to the successfullycaptured point to be exposed; and completing the exposure operation by an exposure machine. The invention can reduce the pitch time of working of the exposure machine and improve the alignment accuracy of output products.

Owner:CHONGQING HKC OPTOELECTRONICS TECH CO LTD +1

A kind of exposure method and exposure device thereof

ActiveCN109116685BImprove takt timeShorten takt timePhotomechanical exposure apparatusMicrolithography exposure apparatusExposureBiomedical engineering

The invention discloses an exposure method and an exposure device thereof. The exposure method comprises the steps of: confirming the position of the point to be exposed in the area to be exposed; capturing the point to be exposed, and confirming that the point to be exposed is successfully captured; Adjust the light source to the appropriate position at the point to be exposed successfully; the exposure machine completes the exposure operation. The invention can reduce the takt time of the exposure machine and improve the alignment accuracy of the output products.

Owner:CHONGQING HKC OPTOELECTRONICS TECH CO LTD +1

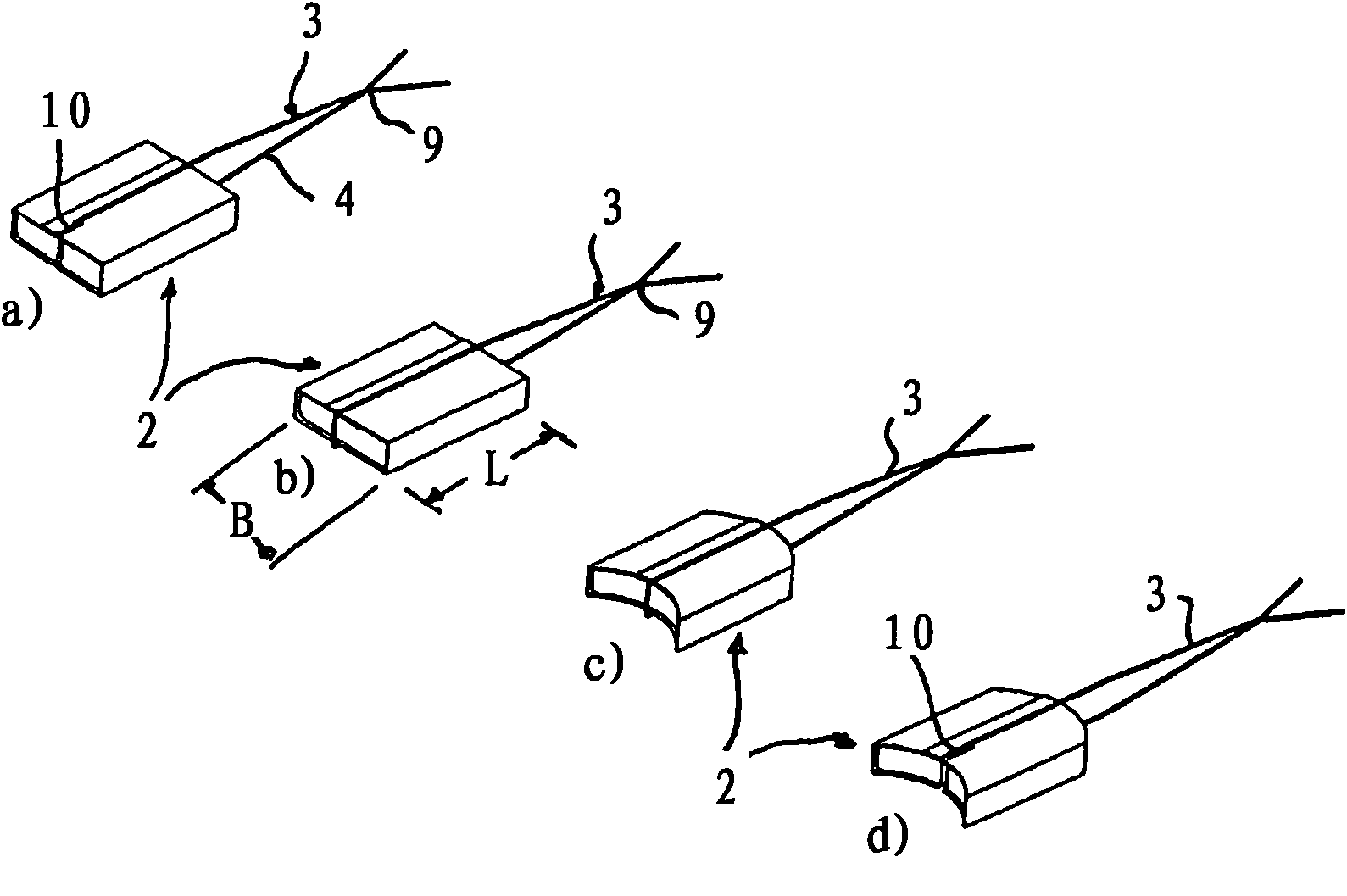

Tampon, and method for the production of a tampon

Disclosed is a tampon comprising an insertion end and a rear end, a pressed absorbent strip (2), and a withdrawal string (3) that is guided out of the rear end. In order to obtain short tampon production times, the withdrawal string (3) is guided around the strip (2) in the form of a loop (4), the strip (2) being provided with a fold (16, 17) on each side of the loop (4). Also disclosed is a method that is suitable for producing a tampon and encompasses the following steps: a) the absorbent strip (2) is cut to size; b) a withdrawal string (3) is placed in the form of a loop (4) that is put around the strip (2); c) the strip (2) is pressed between jaws (7) that can be moved towards each other such that a fold (16, 17) is formed in the strip (2) on each side of the loop (4).

Owner:RUGGLI PROJECTS AG

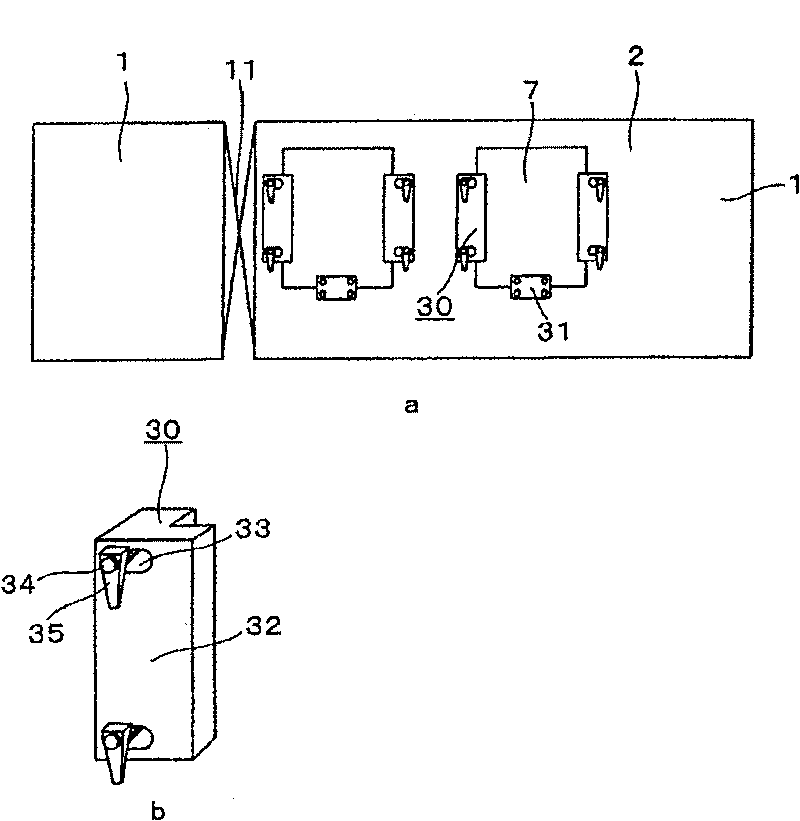

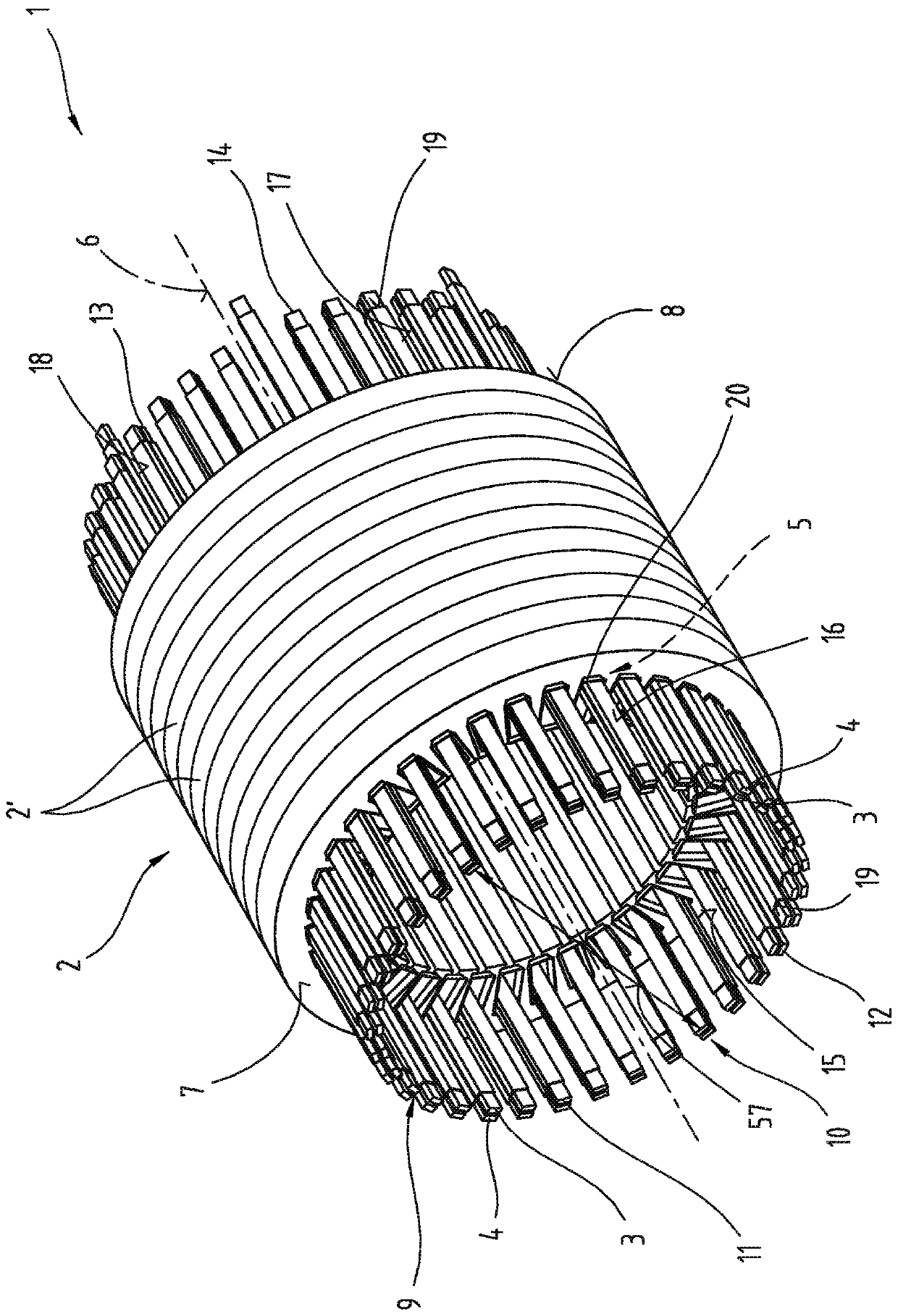

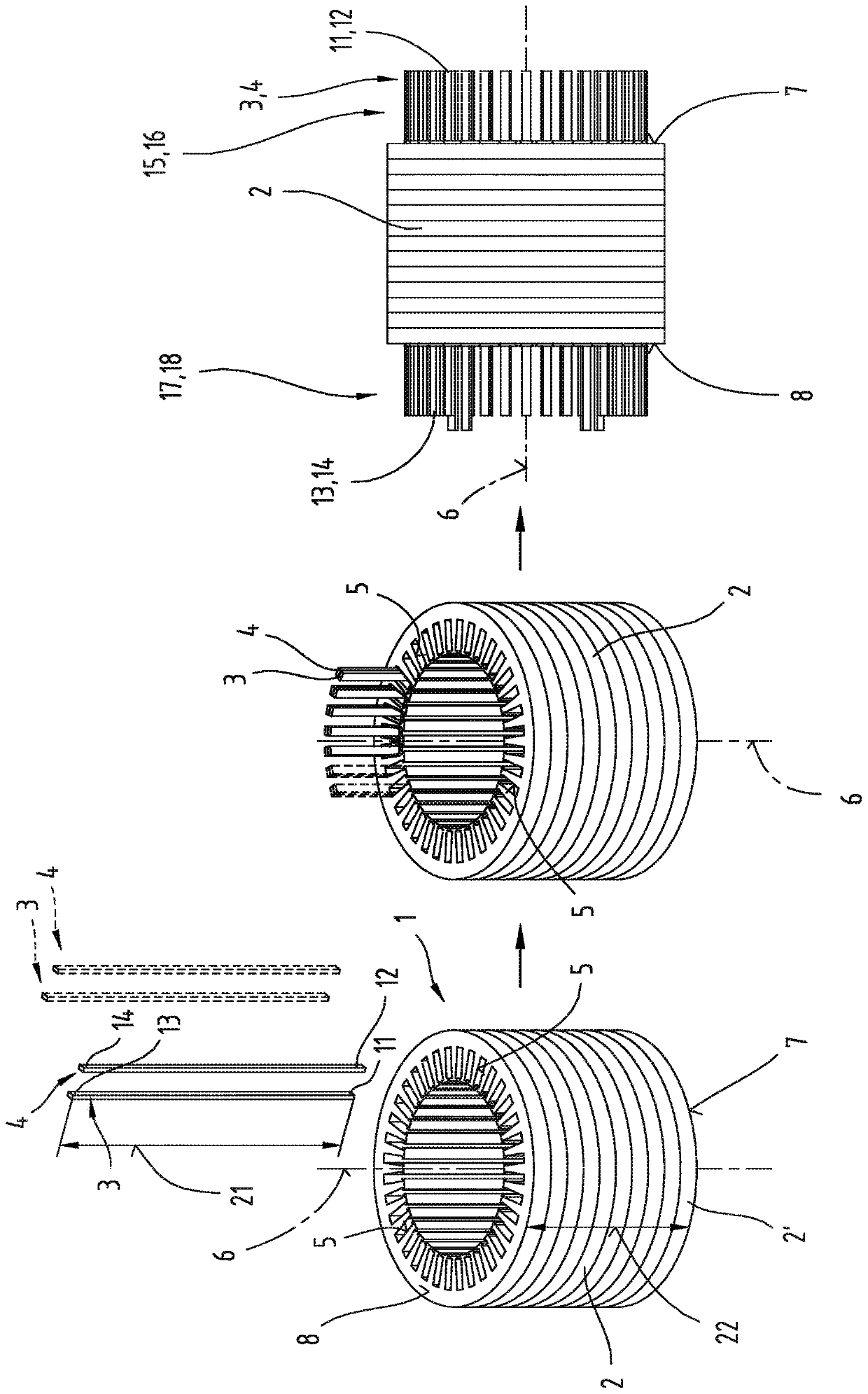

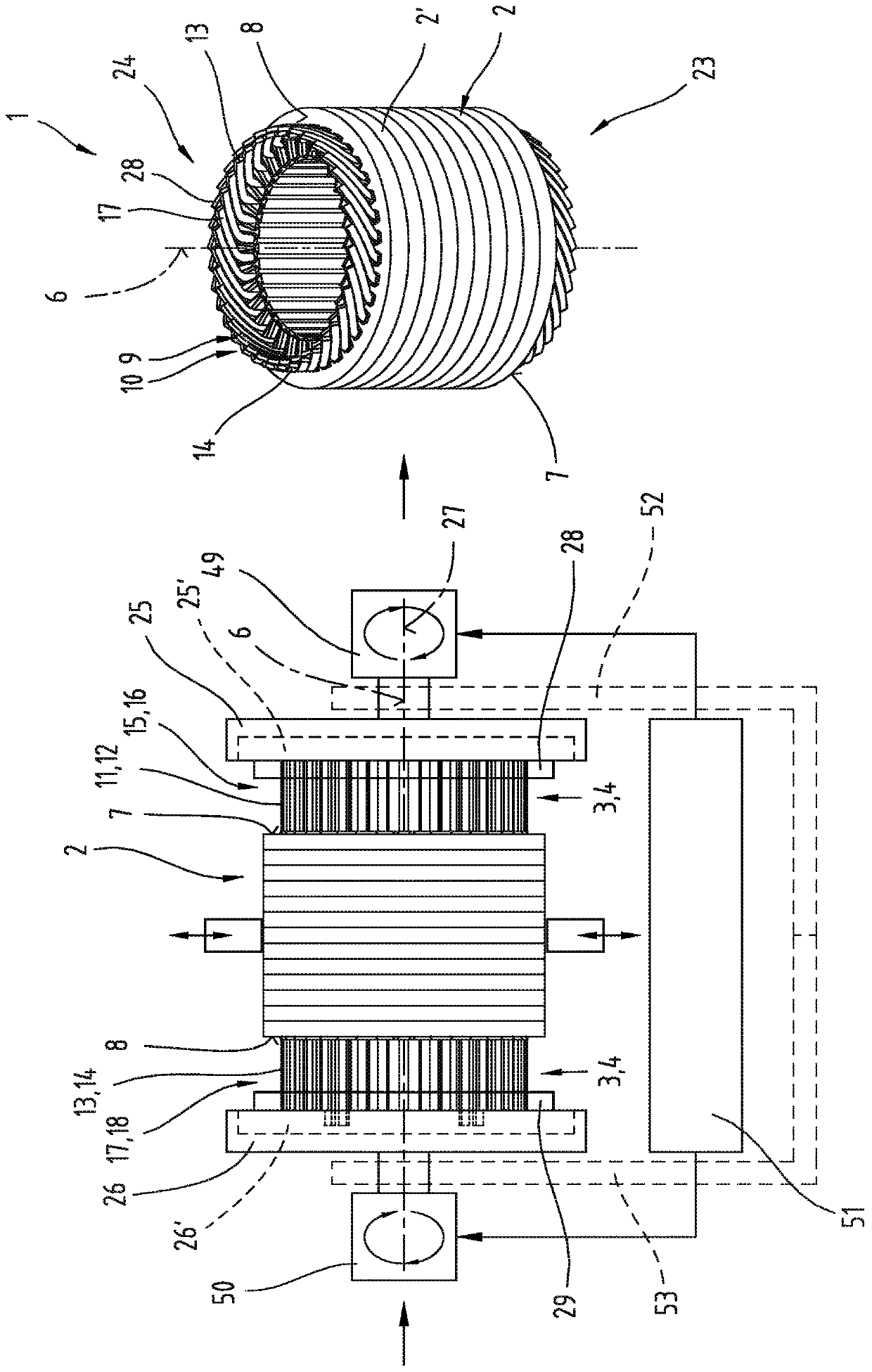

Method and device for automatically producing a stator of an electric machine

InactiveCN111434014APrecise positioningSimple structureManufacturing dynamo-electric machinesRotational axisElectrical conductor

The invention relates to a method and a device for automatically producing a semi-finished stator (1) of an electric machine. A substantially hollow cylindrical laminated core (2) is provided with a plurality of stacked sheet-metal laminates (2') which define a main axis (6). At least one of the longitudinal ends (11, 12; 13, 14) of rod-shaped conductor elements (3, 4) for producing an electric winding protrude relative to the first and / or second end faces (7, 8) of the laminated core (2) such that the conductor elements form lines (15, 16; 17, 18) that protrude from the laminated core (2) atat least one of the end faces (7, 8) of the laminated core (2). The protruding lines (15, 16; 17, 18) of the conductor elements (3, 4) are bent in the direction of the circular circumferential direction of the hollow cylindrical laminated core (2) by means of at least one bending tool (25, 25'; 26, 26') mounted so as to be rotatable about a rotational axis (27). Additionally, the longitudinal ends(11, 12, 13, 14) of the conductor elements (3, 4) are brought into a specified radial target position with respect to the laminated core (2) by means of calibrating forces which act radially in the direction of the rotational axis (27) and which are exerted by at least one calibrating device (28, 29) with calibrating fingers (30, 31) that can be adjusted in a controlled manner and are oriented radially towards the rotational axis (27) of the at least one bending tool (25, 25', 26, 26').

Owner:MIBA AUTOMATION SYST GES

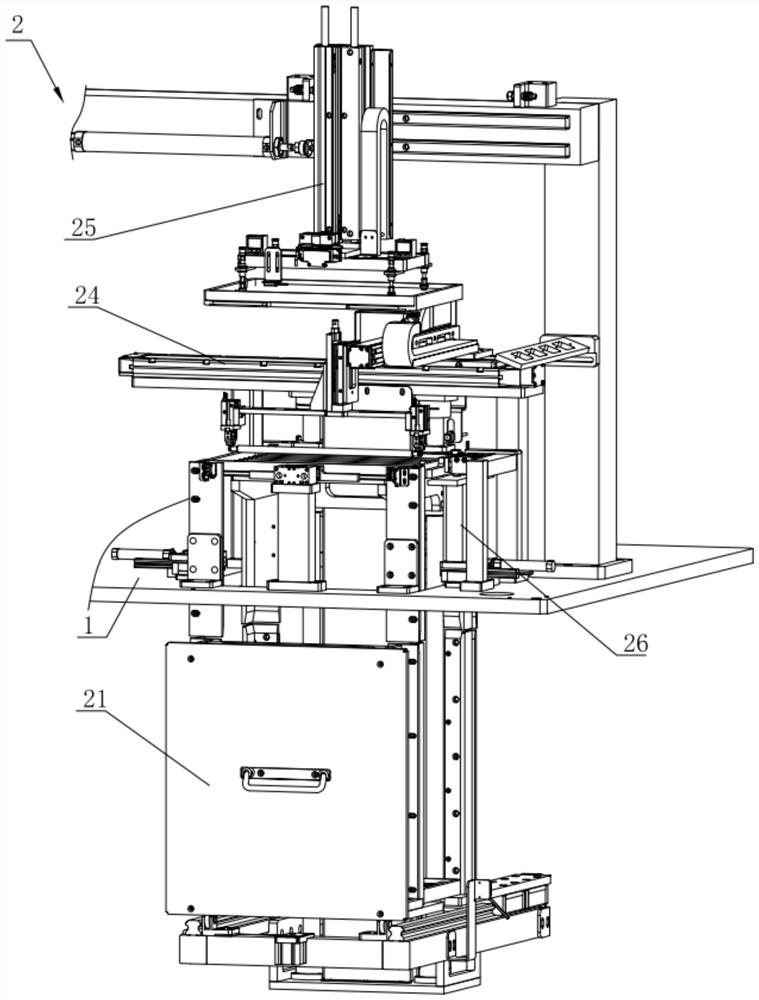

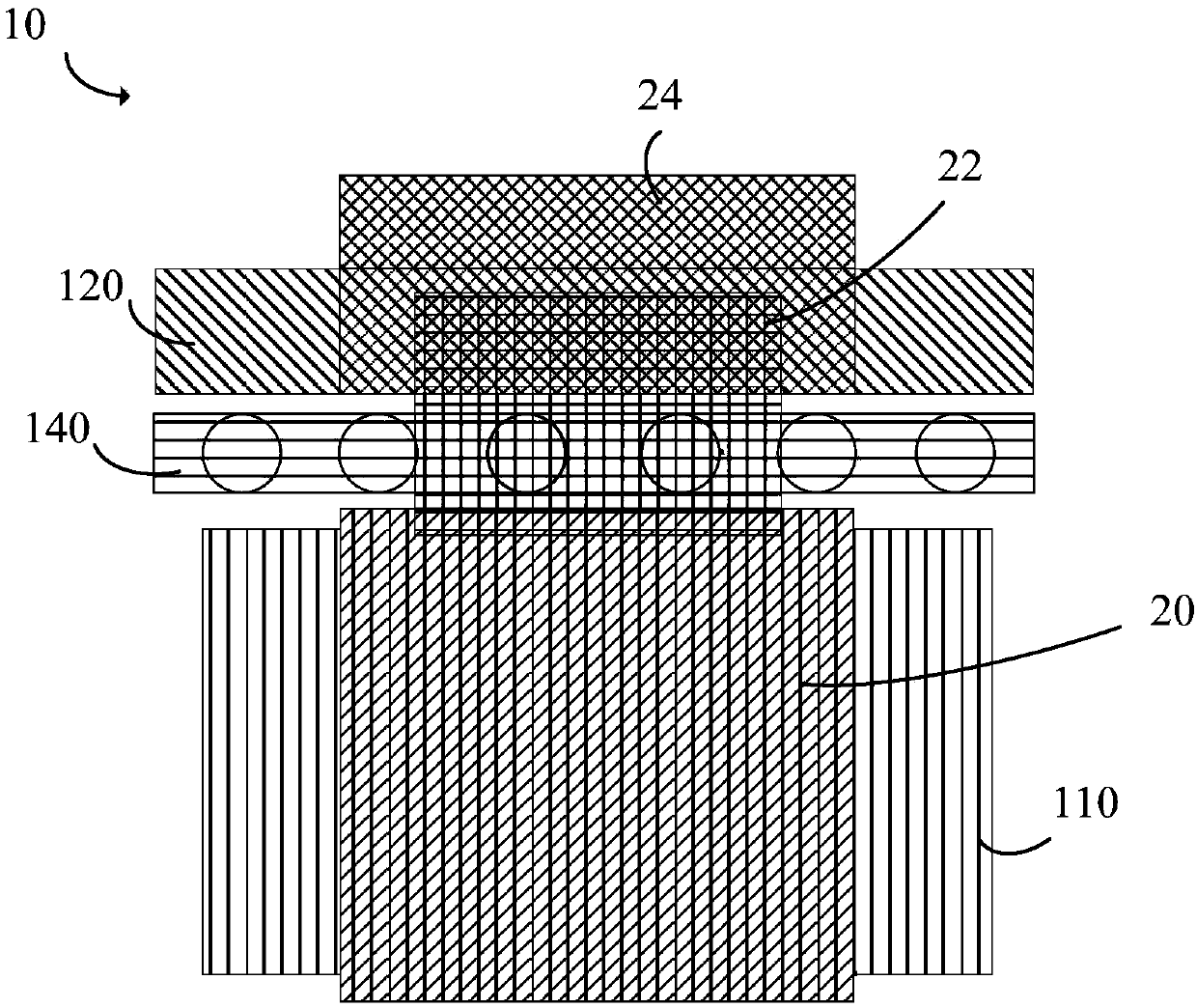

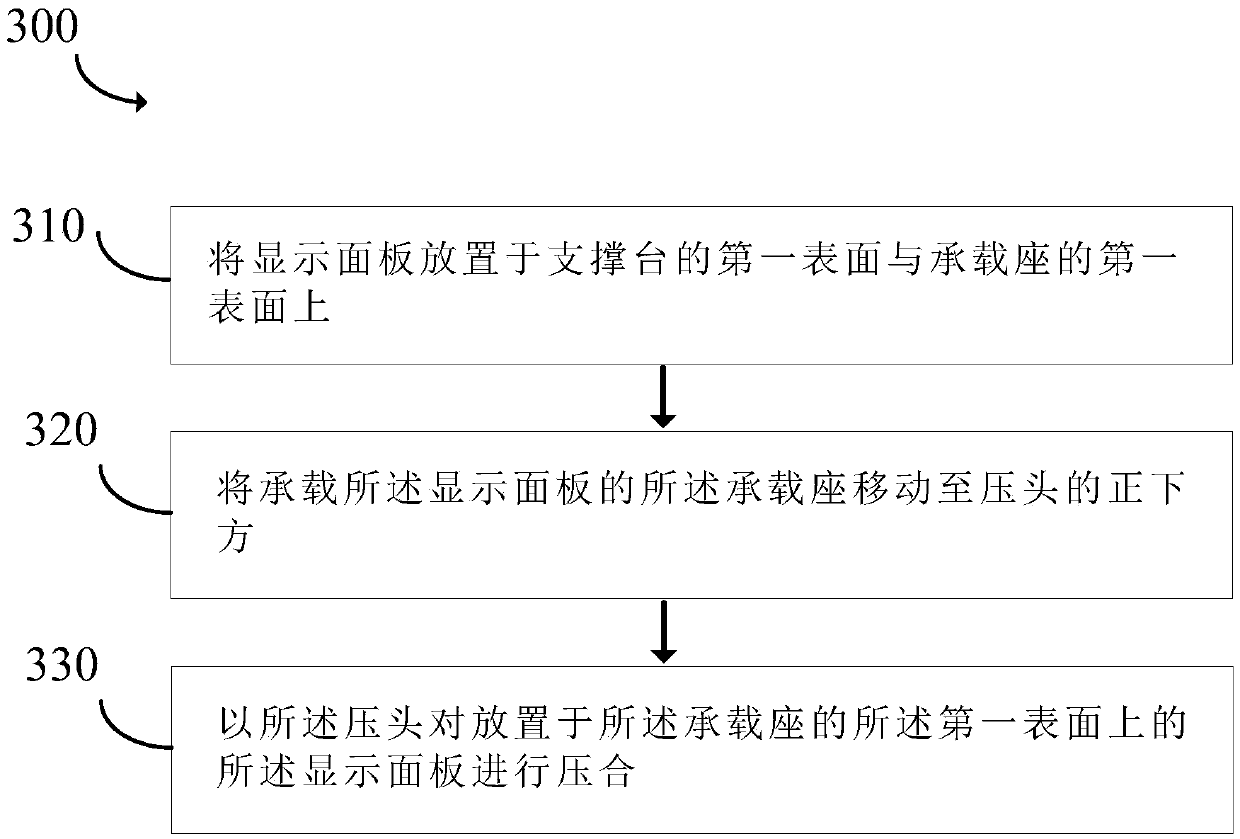

Bonding device and bonding method for display panel

InactiveCN109616589ASimplify engagementImprove takt timeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Image display device, correction data generation method, and image correction device and method, as well as image correction system

InactiveUS10089910B2A large amountImprove correction accuracyStatic indicating devicesLiquid-crystal displayImage correction

Owner:MEGACHIPS

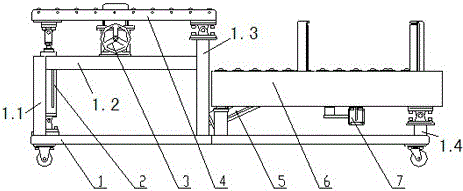

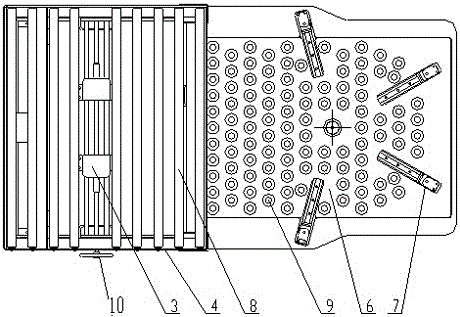

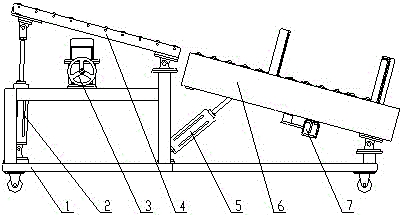

Tire vulcanizer local equipment

InactiveCN106239791AIncrease the amount of stored tire blanksIncrease profitTyresAgricultural engineeringUtilization rate

The invention relates to tire vulcanizer local equipment. According to the invention, a front roller way realizes the turnover through a front turnover cylinder; the left end of a back roller way is connected to the middle part of a frame through a back turnover cylinder; the right end of the back roller way is movably connected with the top of a third longitudinal rod; the back roller way realizes the turnover through a back turnover cylinder; smooth slide of a tire blank on the front roller way onto the back roller way is realized; multiple sets of long rollers are arranged on the front roller way; and universal rollers are arranged on the back roller way. The tire vulcanizer local equipment has the beneficial effects of increasing the tire blank storage quantity, improving the utilization rate, prolonging the tire blank supply beat time, guaranteeing the automatic operation reliability of the vulcanizer and improving the equipment production efficiency.

Owner:郭淑华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com